Muddy water bypass device for miniature pipe jacking machine

A technology of pipe jacking machine and mud water, which is applied in the direction of valve operation/release device, valve device, multi-way valve, etc., can solve the problem that does not conform to the concept of green environmental protection and sustainable development, and the washing ability of mud and face cuttings is weak. , reduce product circulation and adaptability and other issues, to achieve the effect of reducing manual labor, simple and feasible combination structure, and improving versatility and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

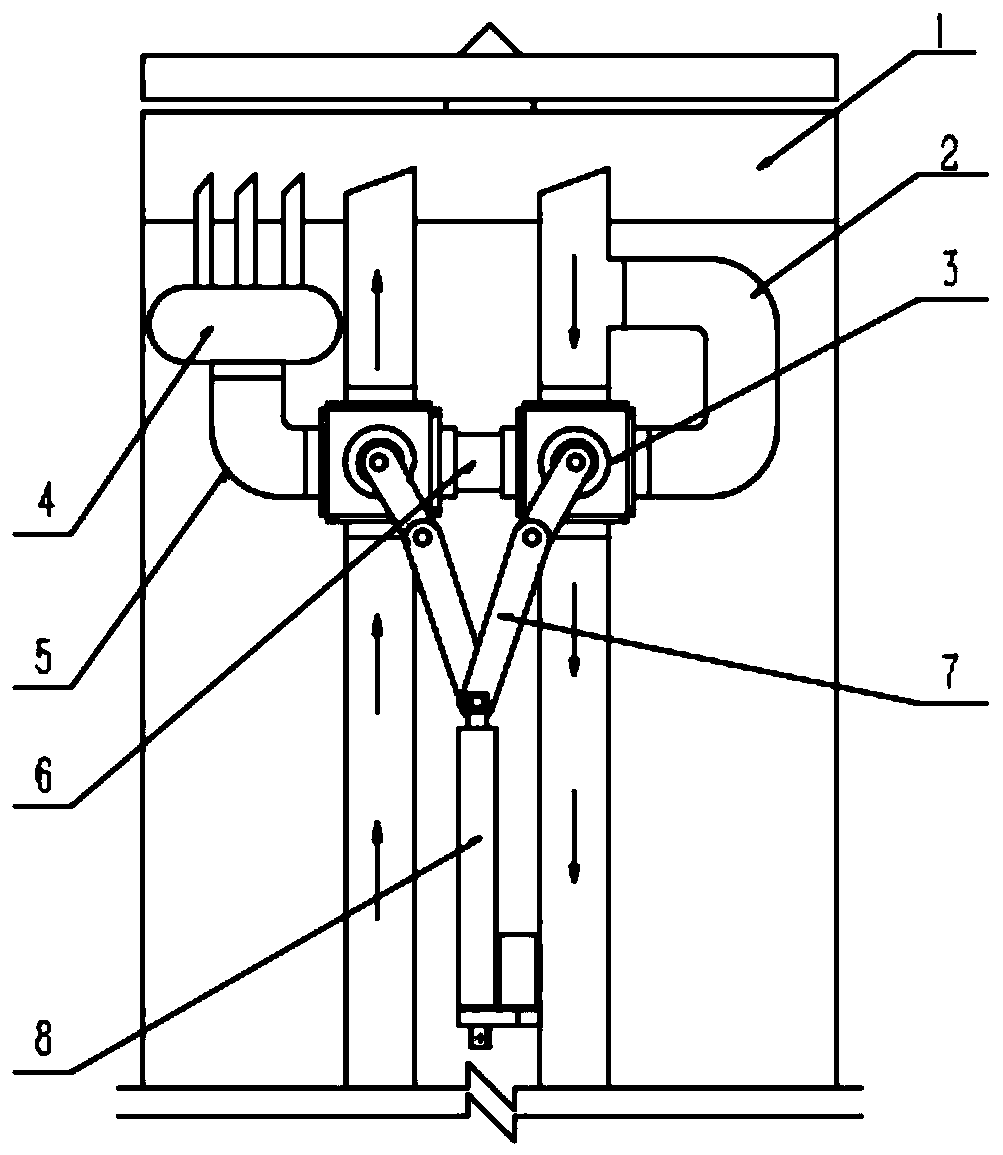

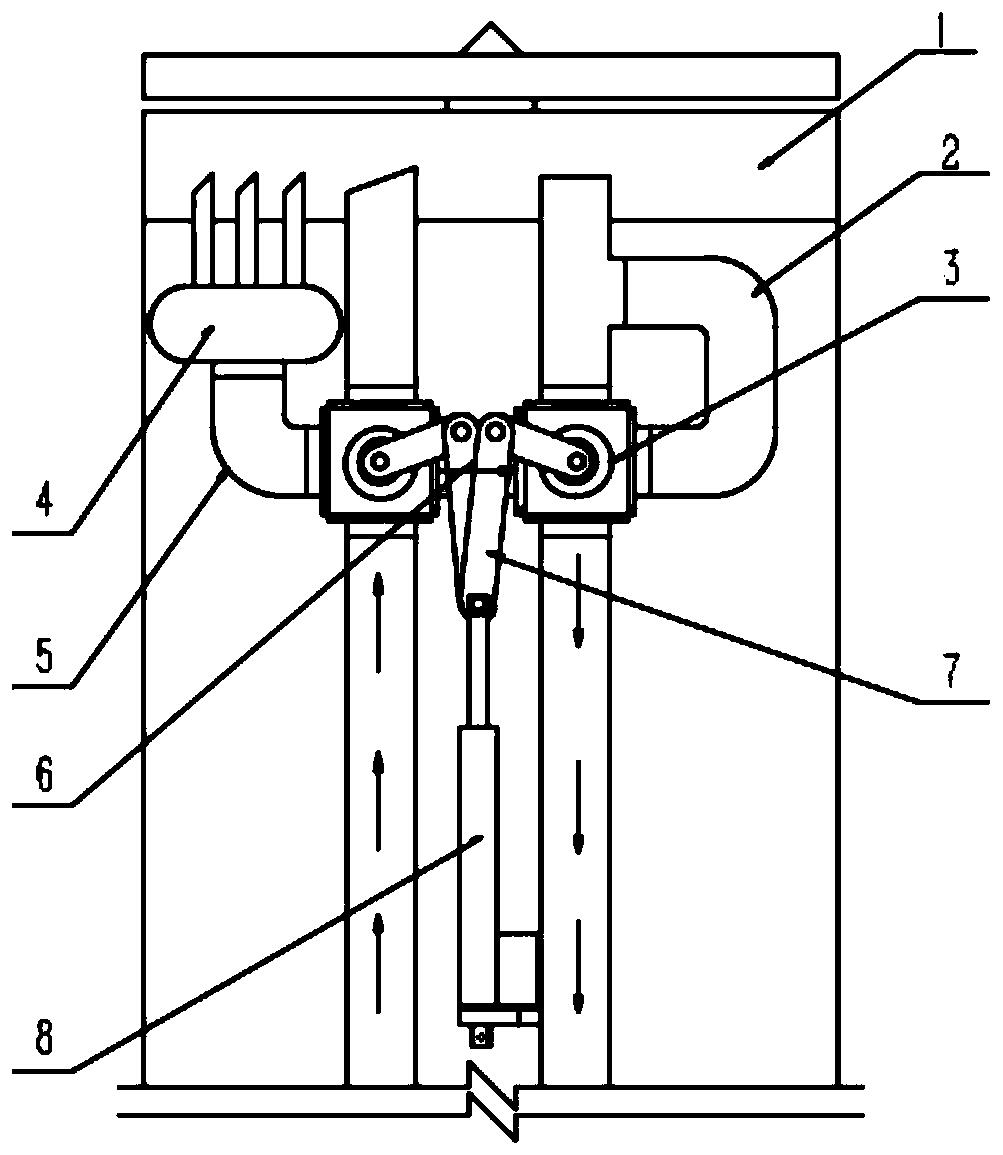

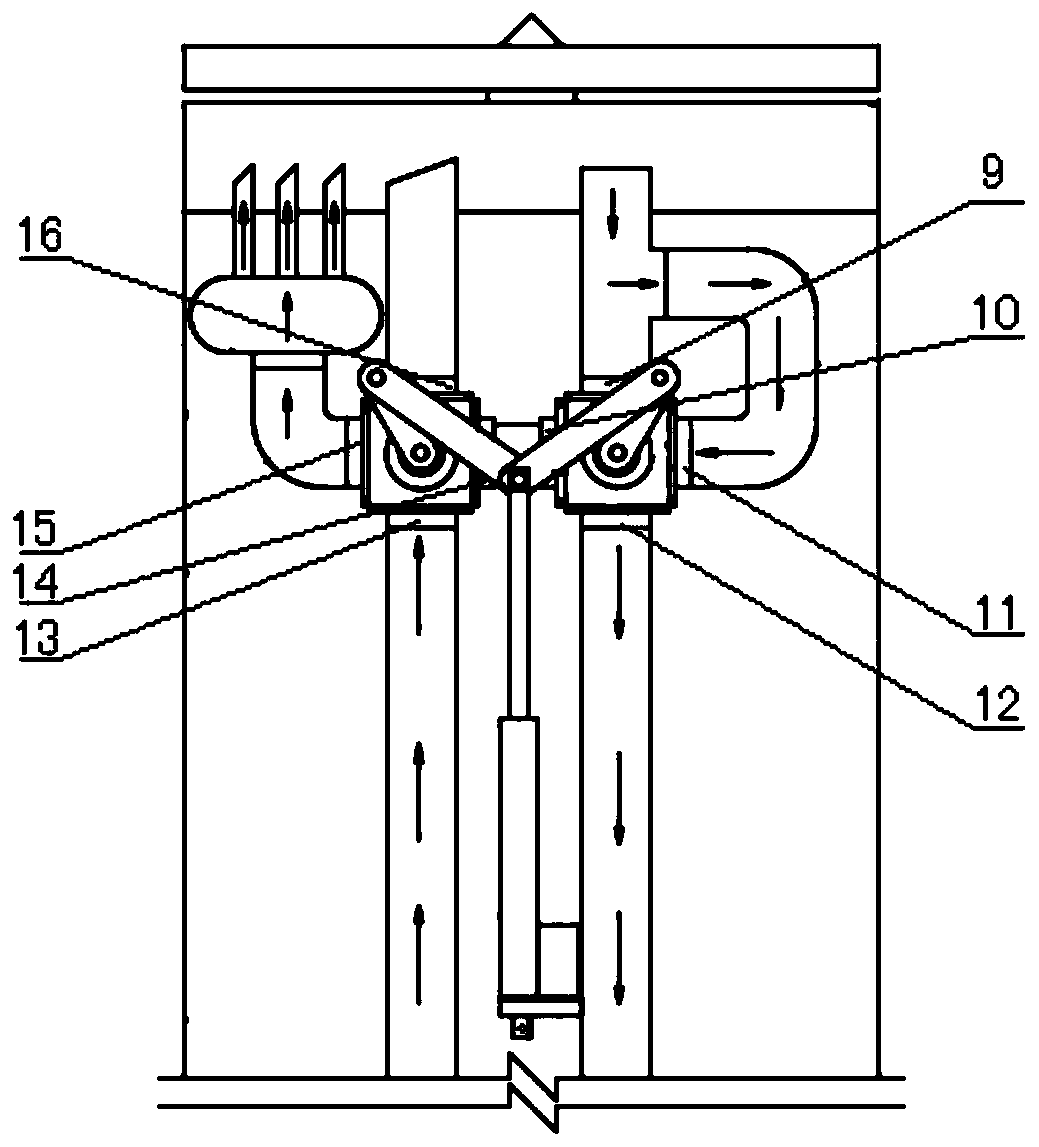

[0033] The muddy water bypass device used in the miniature pipe jacking machine in this embodiment mainly includes two four-way ball valves, a special short wire, a double-link mechanism, a booster valve and a power push rod. The handle of the through ball valve is turned to realize the switching of the three modes of four-way ball valve mud inlet and discharge, bypass circulation and high-pressure flushing. The booster valve can be a pneumatic booster valve or a hydraulic booster valve.

[0034] Among them, the four-way ball valve preferably adopts a full-flow four-way ball valve, and the interface of the full-flow four-way ball valve adopts a threaded connection instead of a traditional flange connection or a Harvard connection. The requirements for the space size of the jacking pipe; at the same time, compared with the non-detachability of welding, it also has the characteristics of convenient installation and disassembly.

[0035]The special short wire is used as the conne...

Embodiment 2

[0040] The construction method of the bypass device is as follows:

[0041] 1. Construction preparation.

[0042] 2. Test run the combined bypass device.

[0043] 3. Before the cutter head is started, the combined bypass device is in the bypass mode to perform muddy water bypass circulation.

[0044] 4. After the slurry circulation is normal, switch the bypass to the mud inlet and discharge mode, the bypass channel is closed, the mud inlet and discharge pipeline is connected to the slurry tank, and the cutter head is started for normal slurry excavation construction.

[0045] 5. When encountering complex strata such as hard clay layers, switch to the high-pressure flushing mode, and the incoming water flows through the pressurized air bag to perform high-pressure flushing on the cutterhead to realize the muddy water circulation in this mode.

[0046] 6. At the end of the excavation work, after the cutter head stops, the bypass device switches to the bypass mode to perform by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com