A piezoelectric inkjet print head

An inkjet print head, piezoelectric technology, applied in printing and other directions, can solve problems such as insufficient ink supply, uneven ink supply, poor printing quality, etc., to reduce pressure loss, reduce pressure crosstalk, and increase nozzle density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

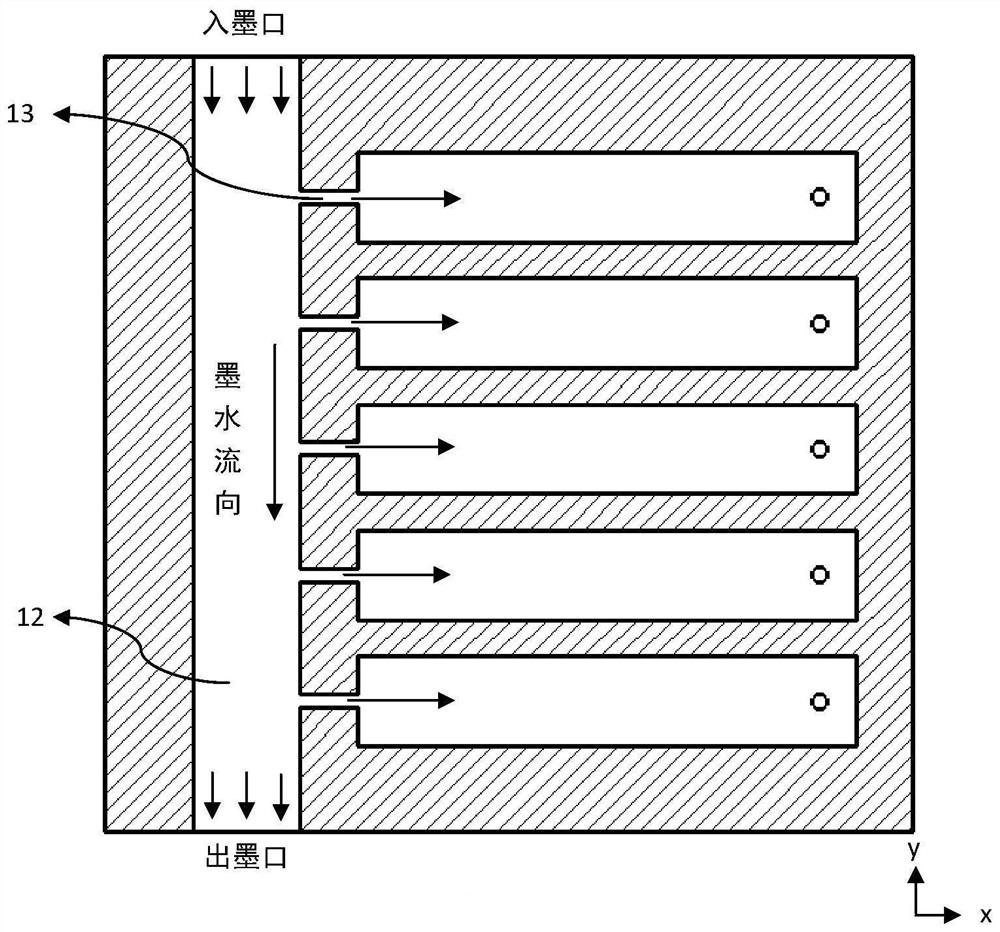

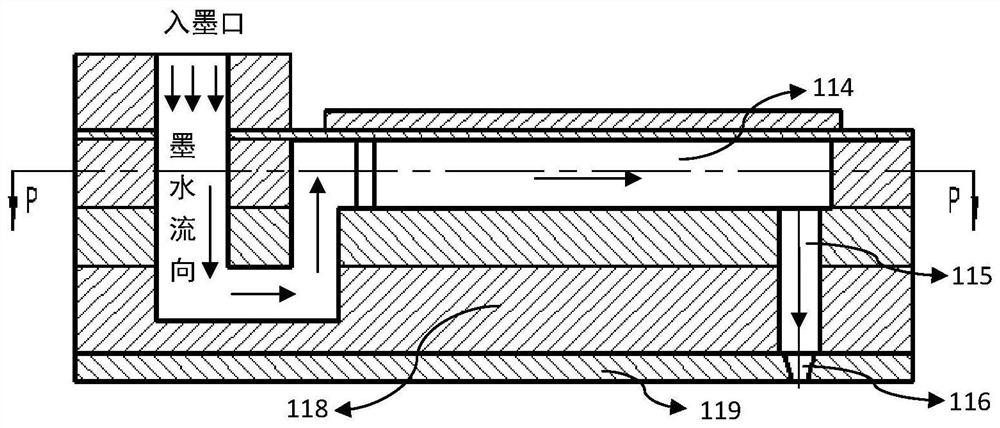

[0060] from figure 2 and image 3 It can be seen that the piezoelectric inkjet printhead in this embodiment includes a main ink channel 112 , a differential pressure channel 117 , a flow limiting channel 113 , a pressure chamber 114 , a transition channel plate 118 , a transition channel 115 , a nozzle plate 119 and nozzles 116 . Ink enters the pressure chamber 114 from the main ink channel 112 through the differential pressure channel 117 and the flow limiting channel 113 , then flows into the nozzle 116 through the transition channel 115 , and then the ink is ejected out. In this embodiment, five differential pressure channels 117 , flow limiting channels 113 and pressure chambers 114 are used for illustration, and the number is not limited in other embodiments.

[0061] The main ink channel 112 is used to provide the flow channel for ink to flow into the pressure chamber, and communicates with each pressure chamber 114 through each pressure difference channel 117 and flow...

Embodiment 2

[0066] from Figure 4a and Figure 4b It can be seen that this embodiment includes two sets of piezoelectric inkjet printing heads symmetrically arranged in Embodiment 1, the nozzles in the two groups of piezoelectric inkjet printing heads are located on the same straight line, and the pressure chambers are evenly distributed between the two nozzles. side, and the pressure chambers on both sides are aligned, which is beneficial to increase the nozzle density of the print head.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com