Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

159results about How to "Reduce flux density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

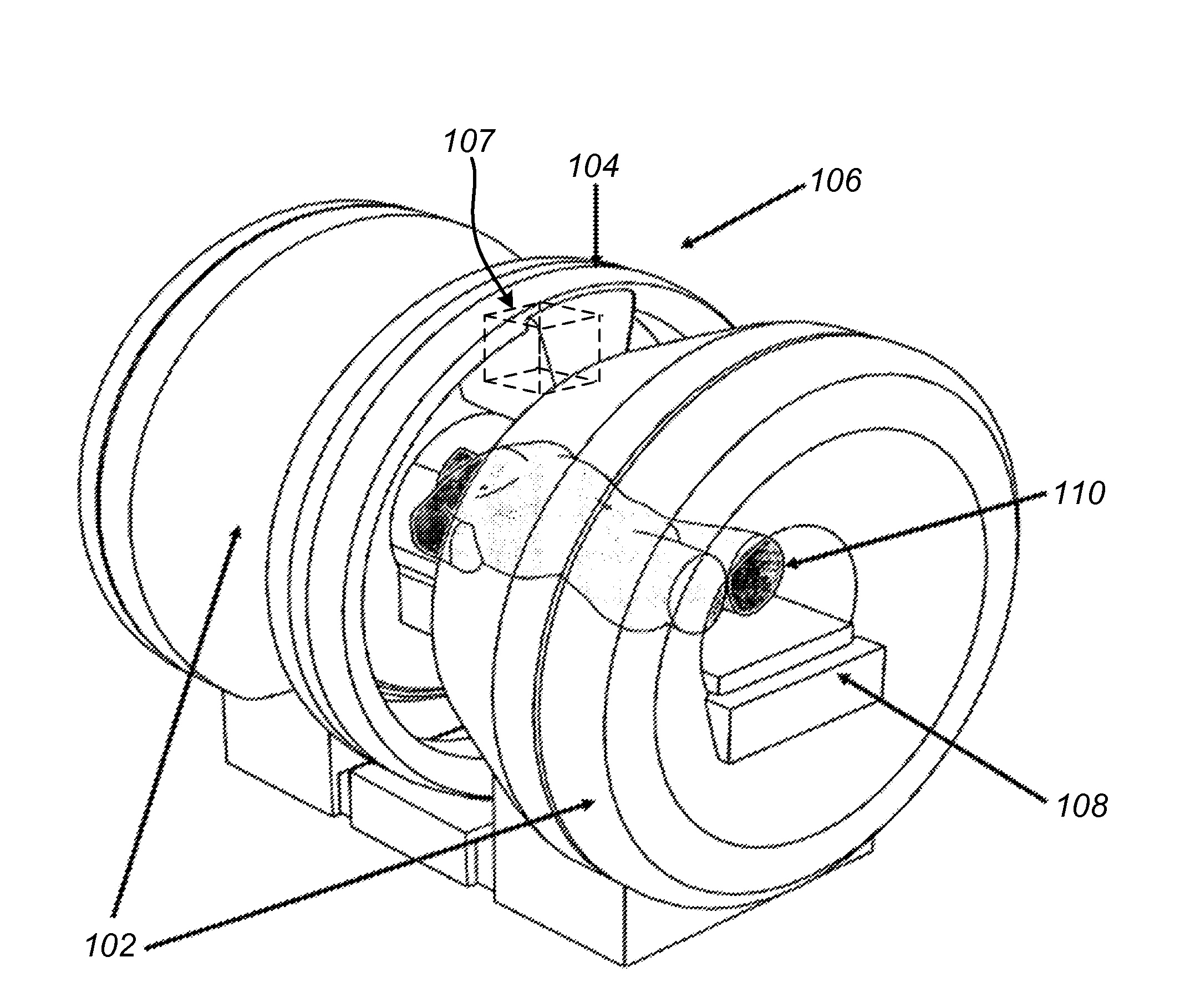

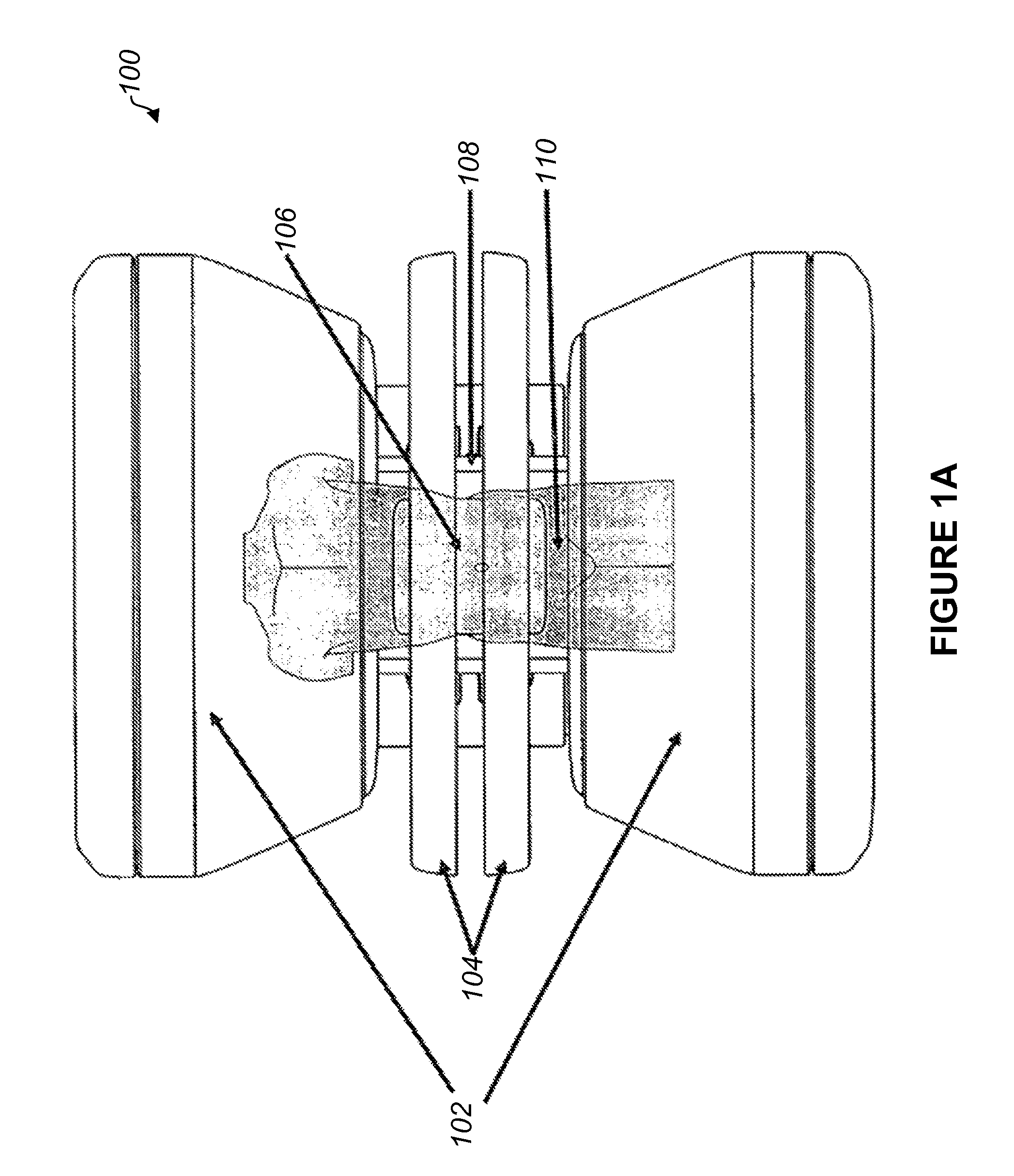

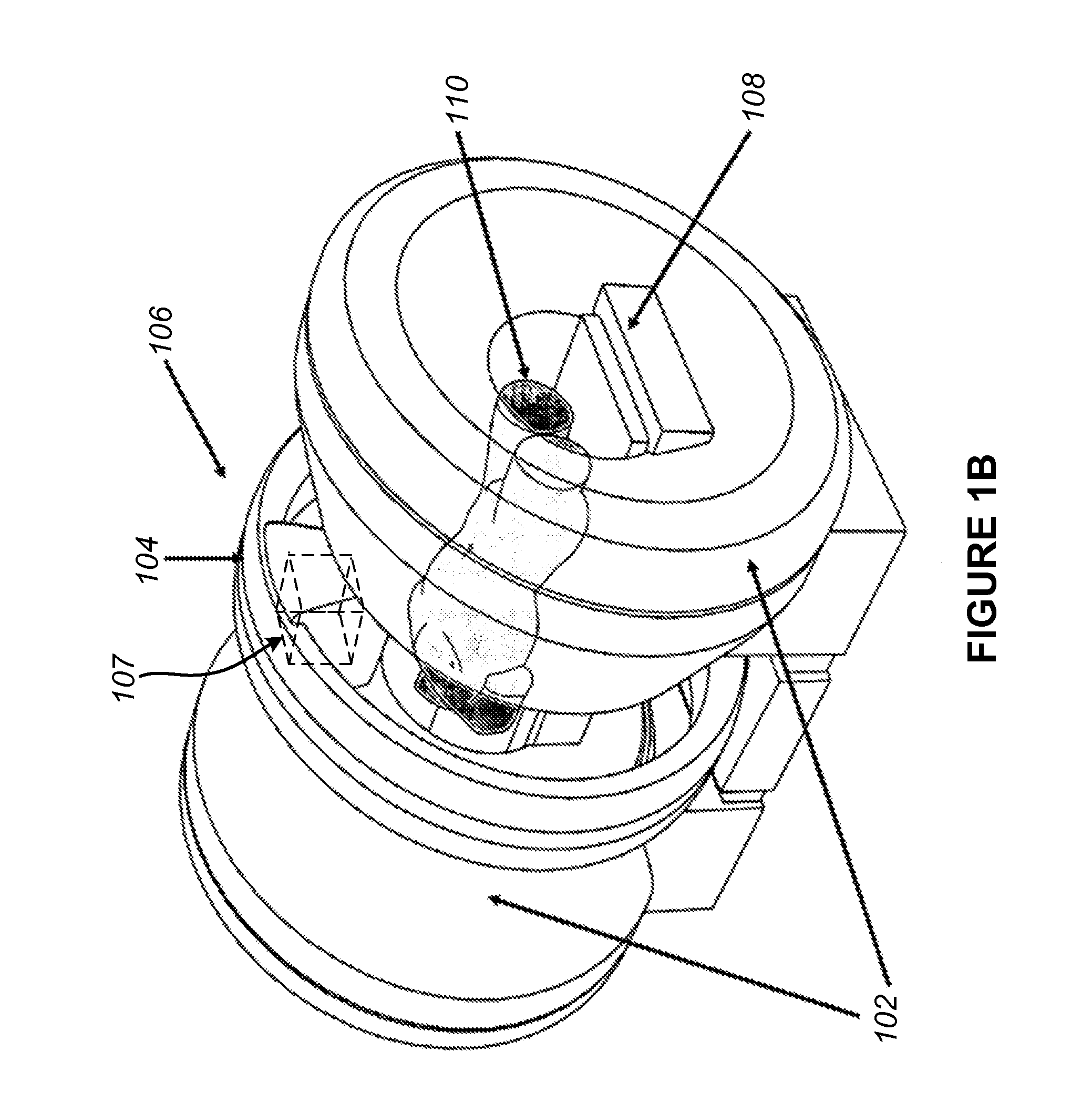

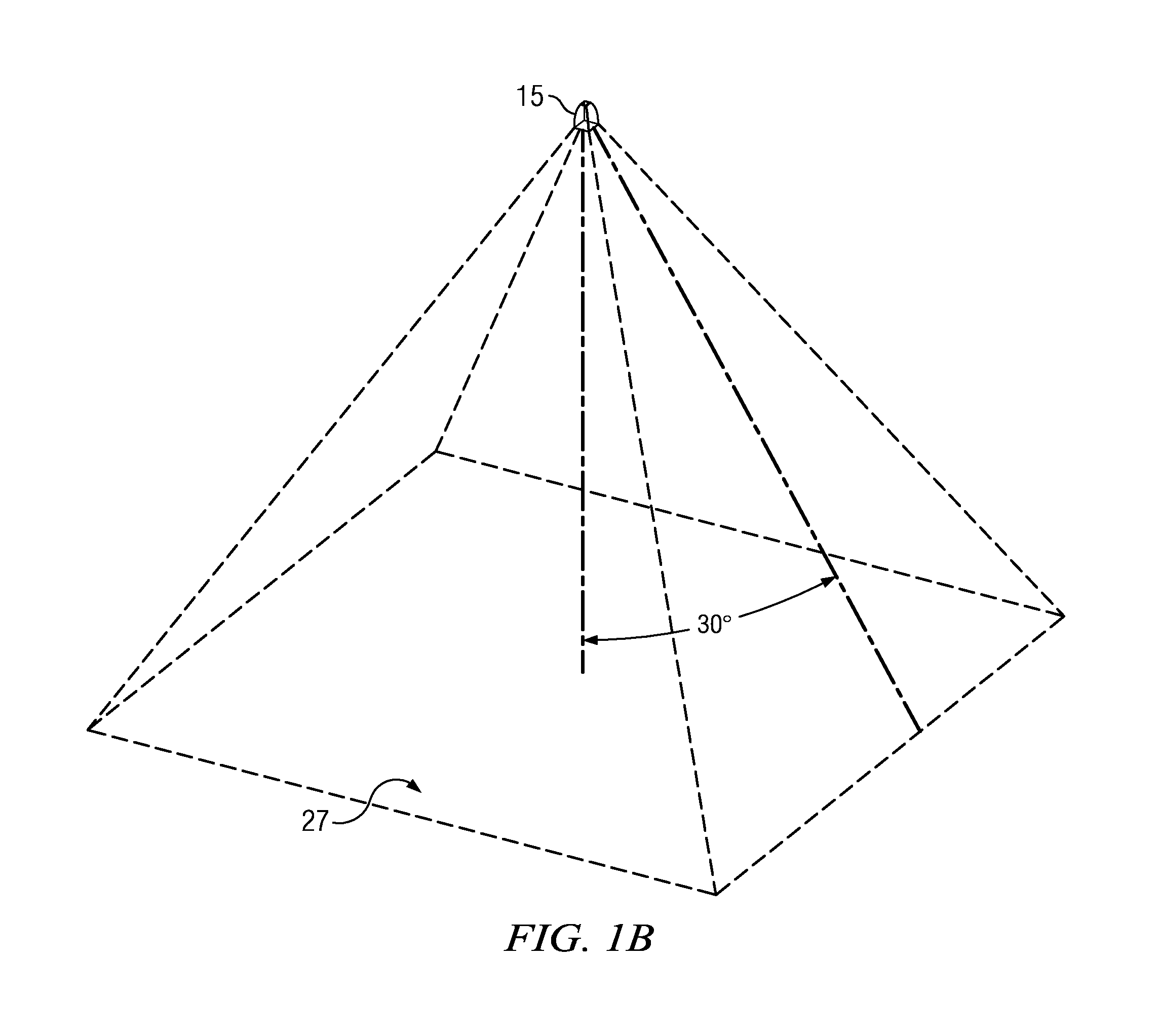

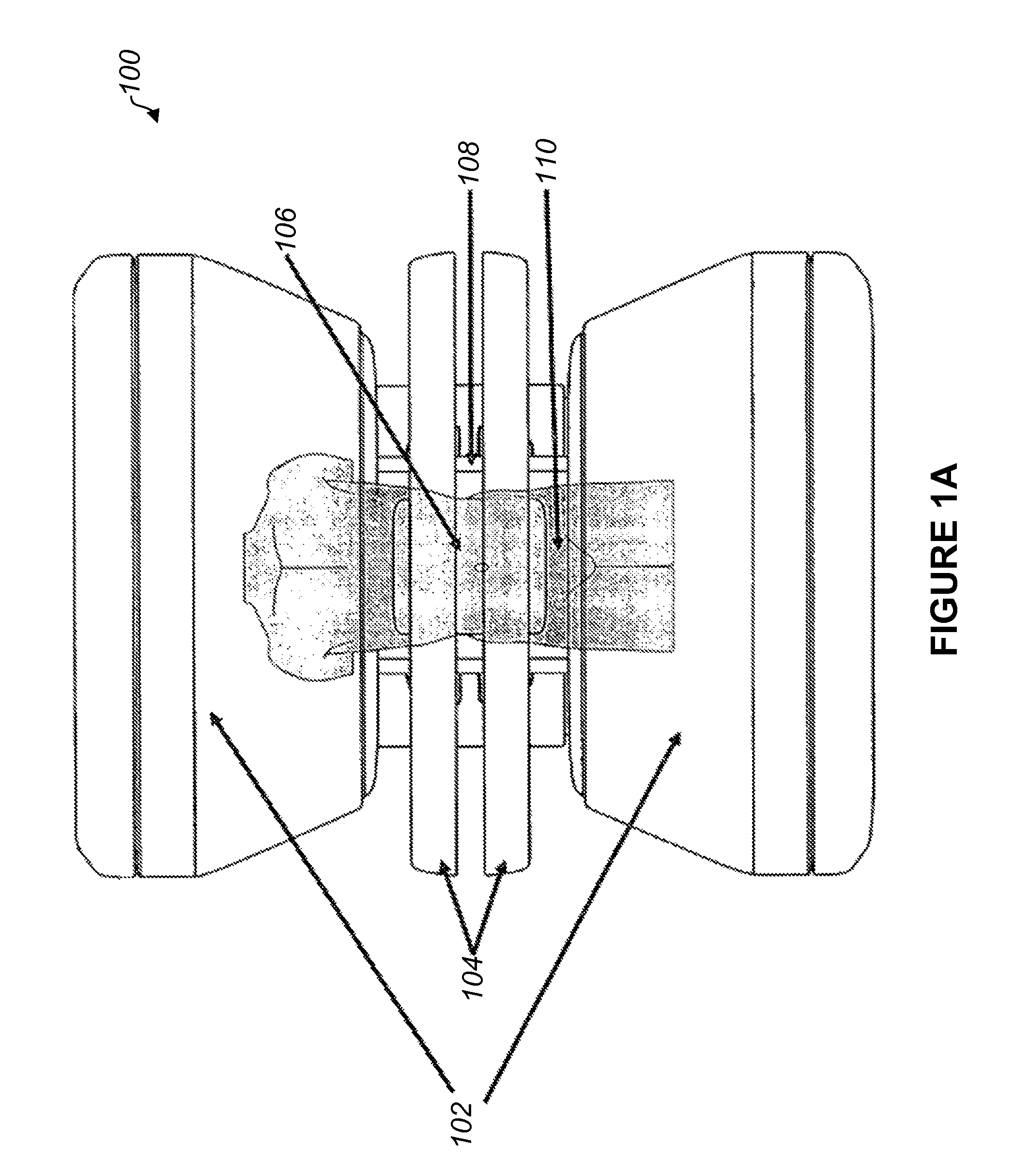

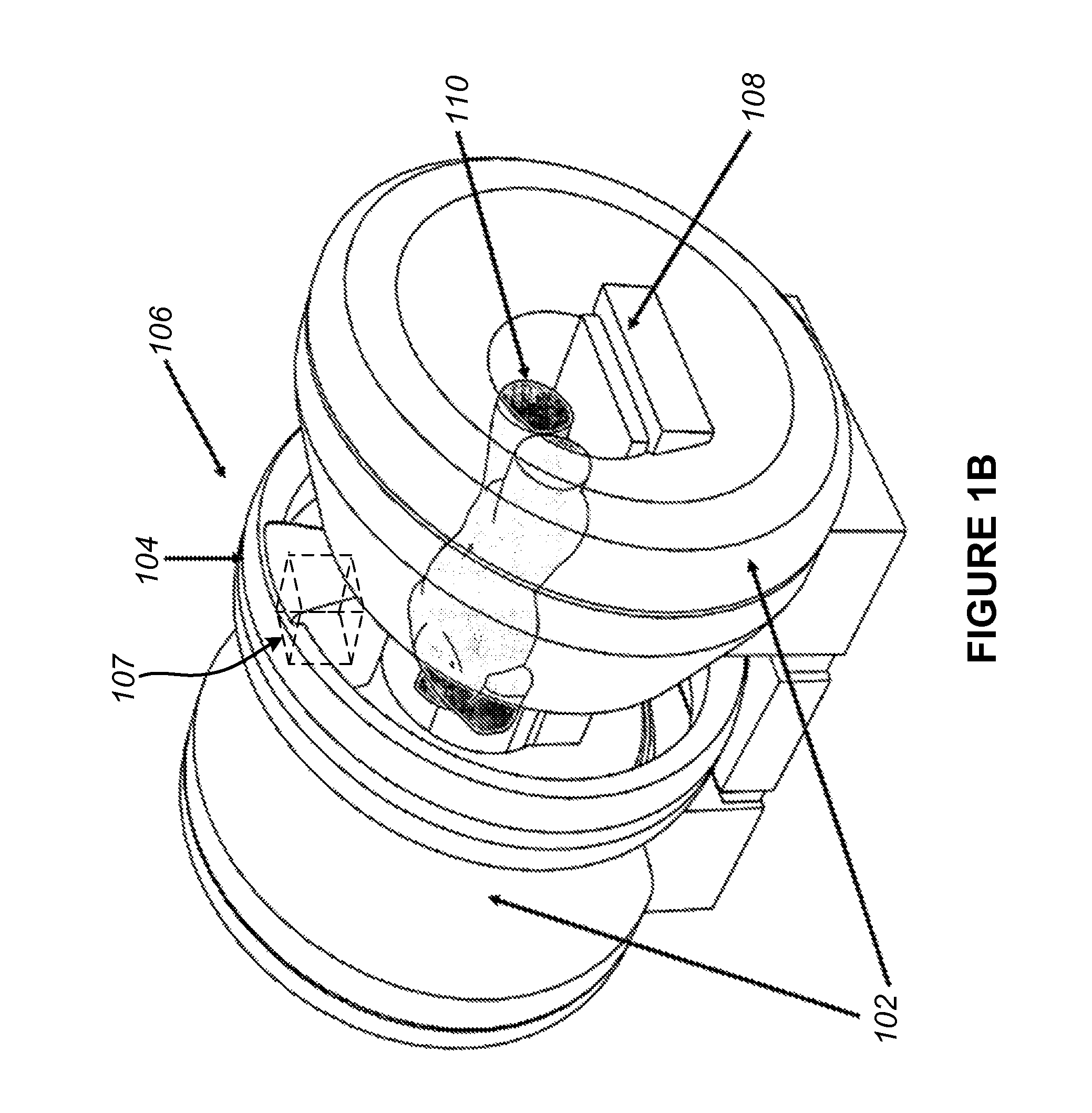

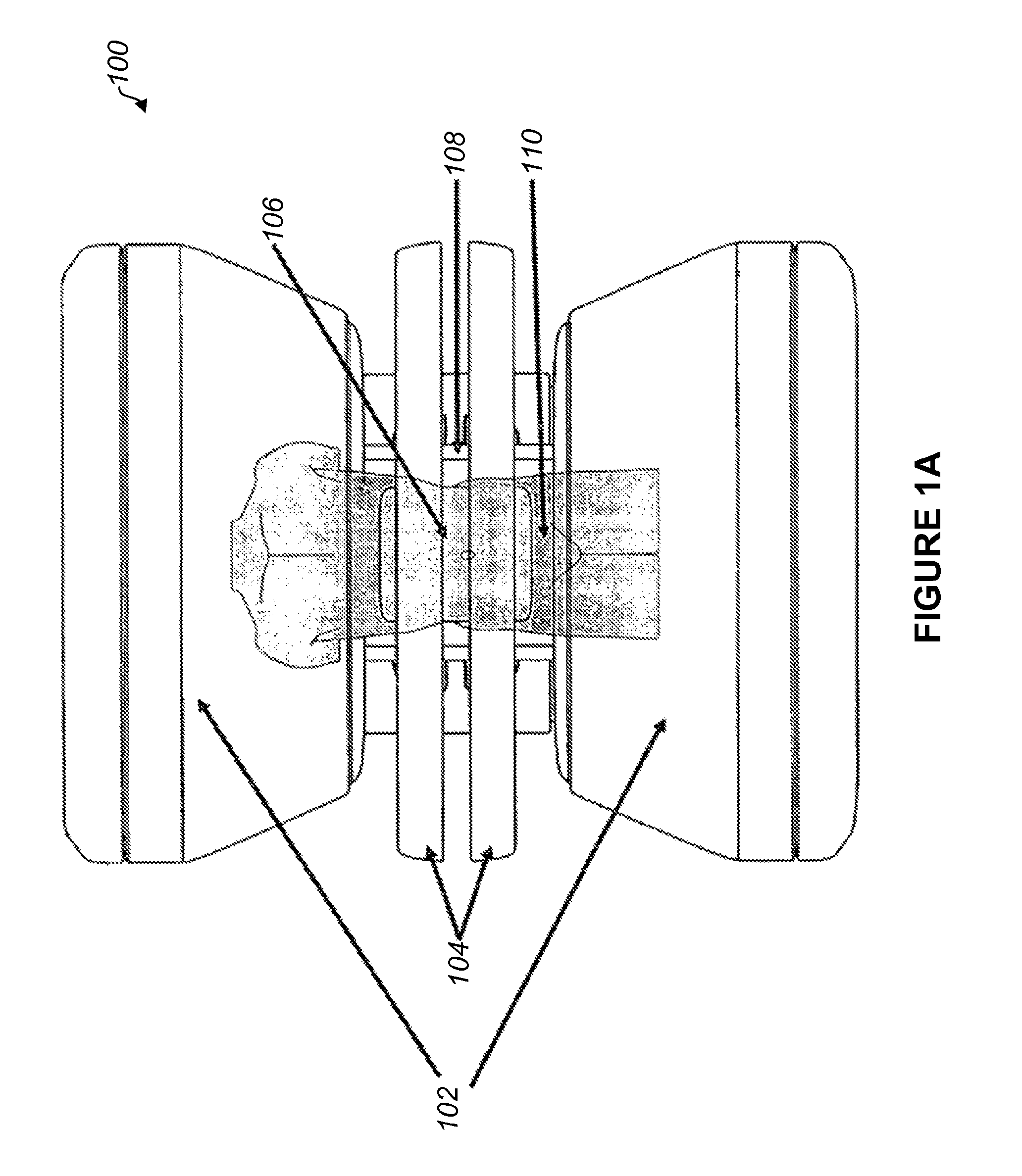

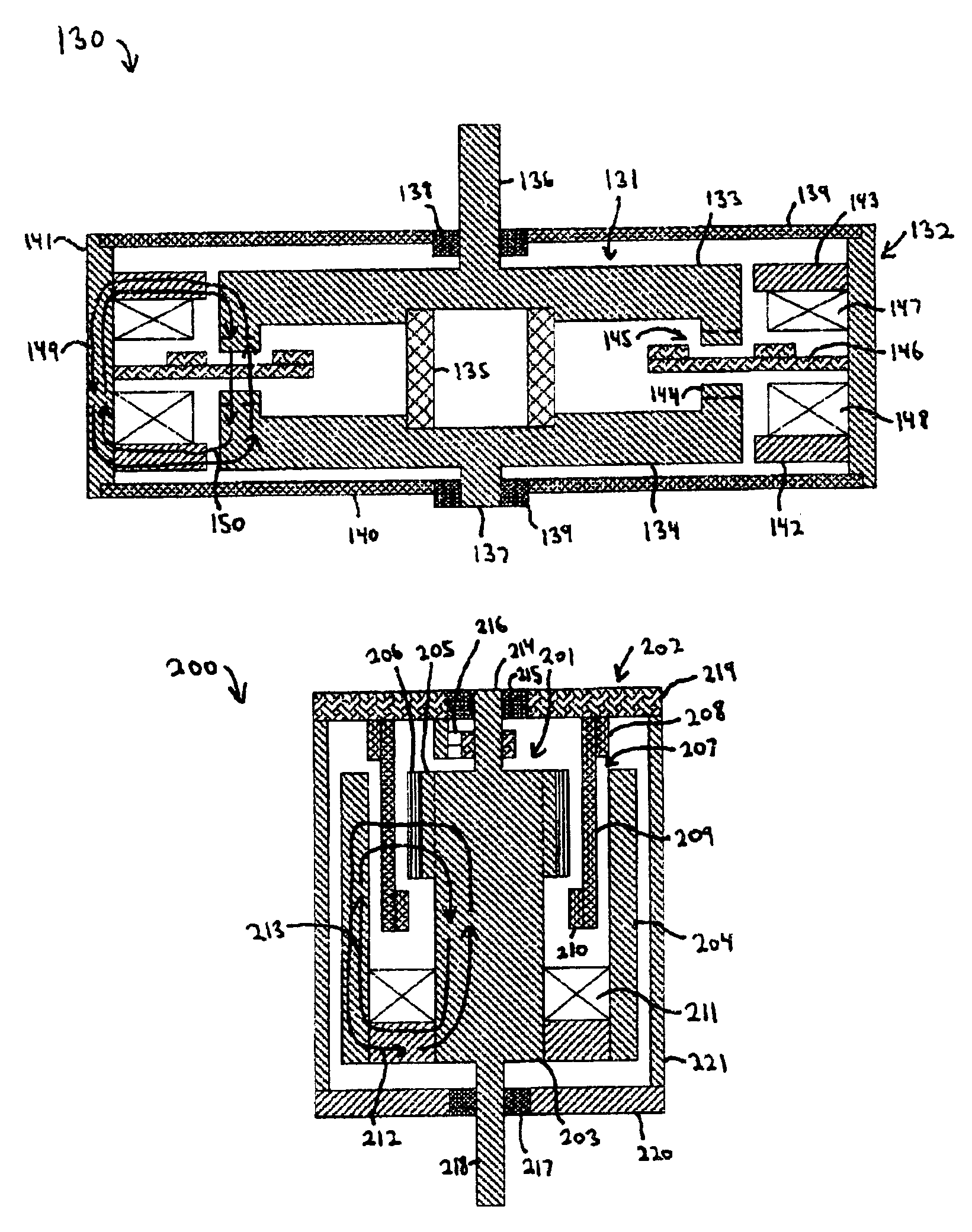

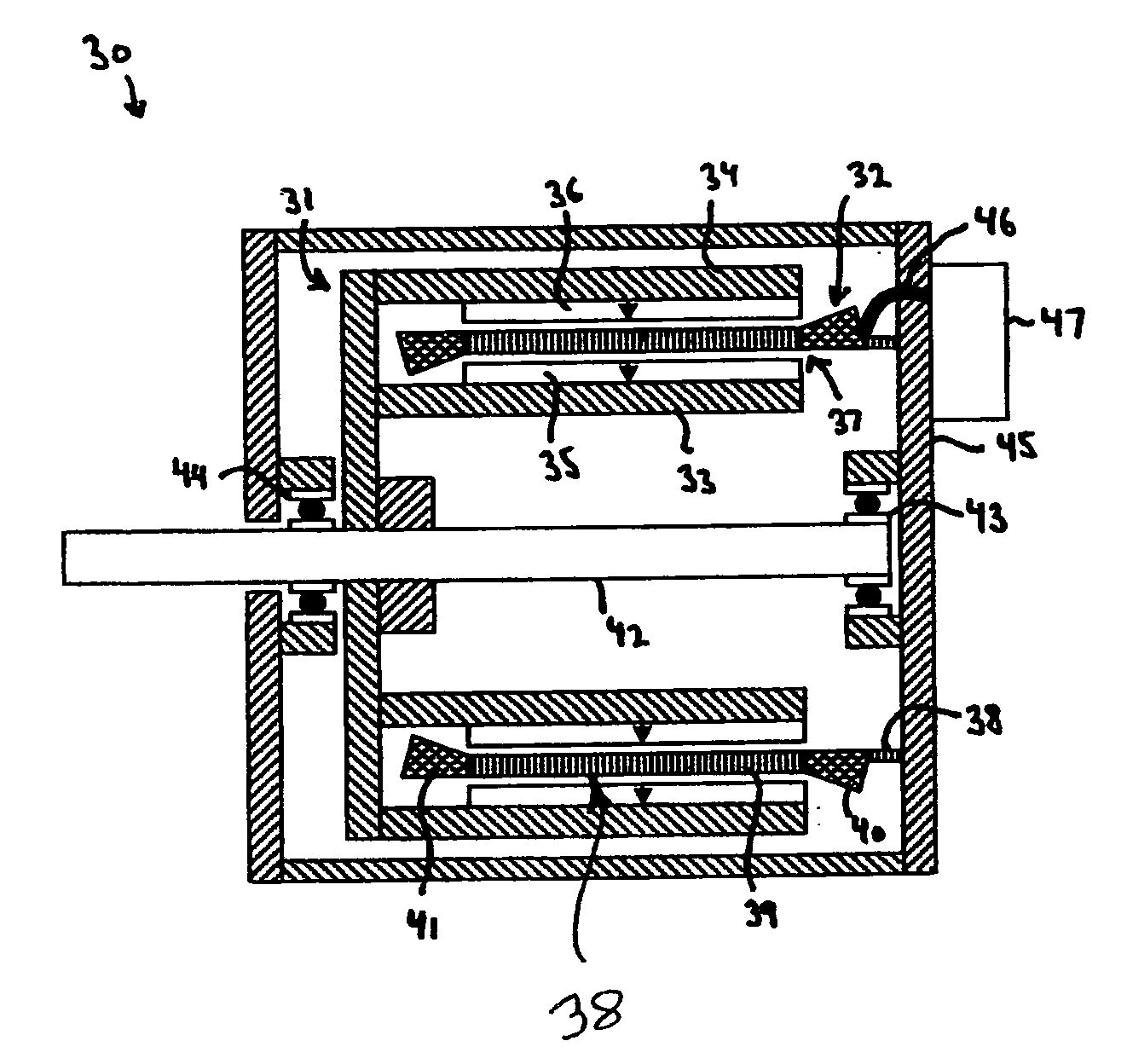

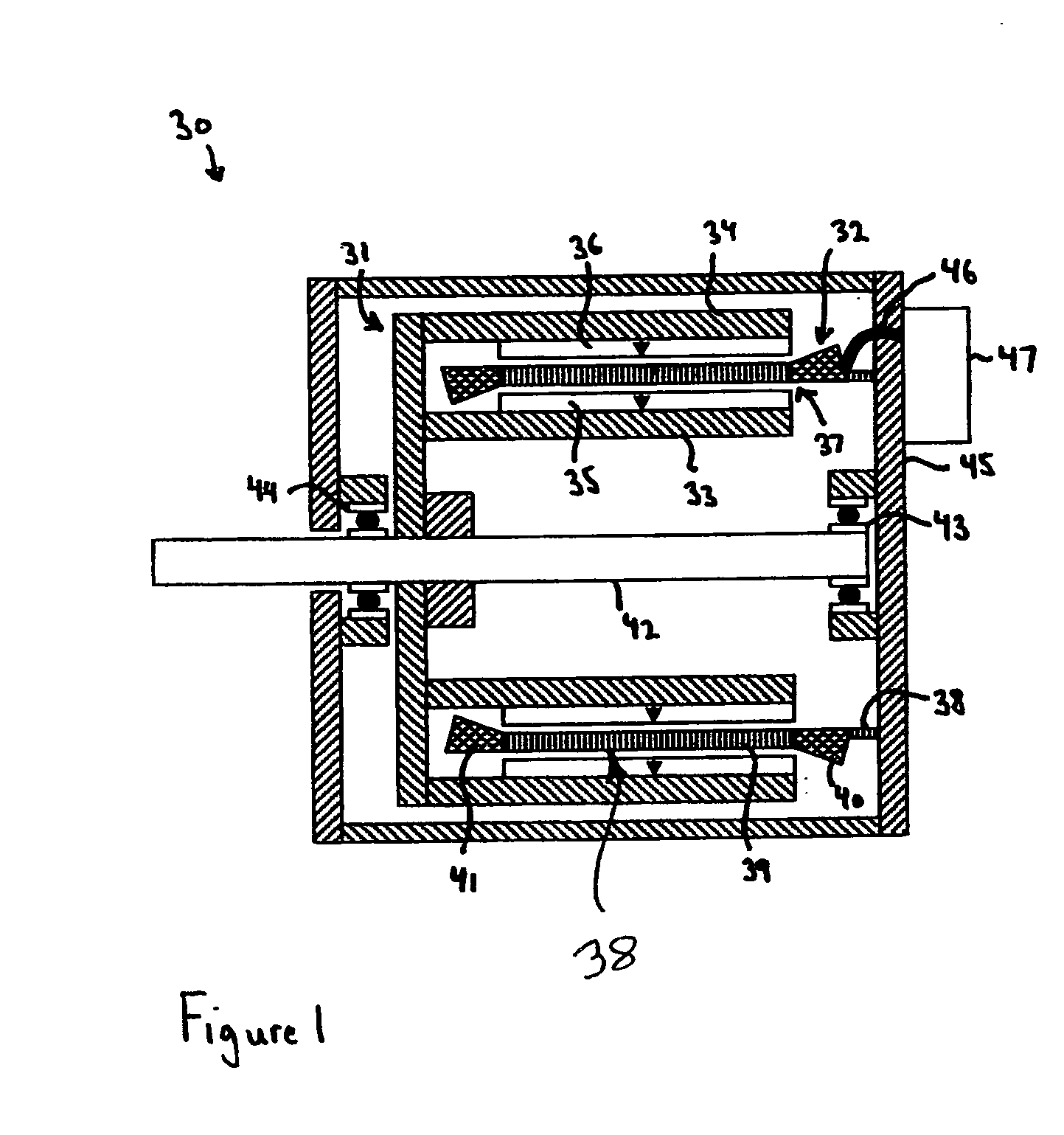

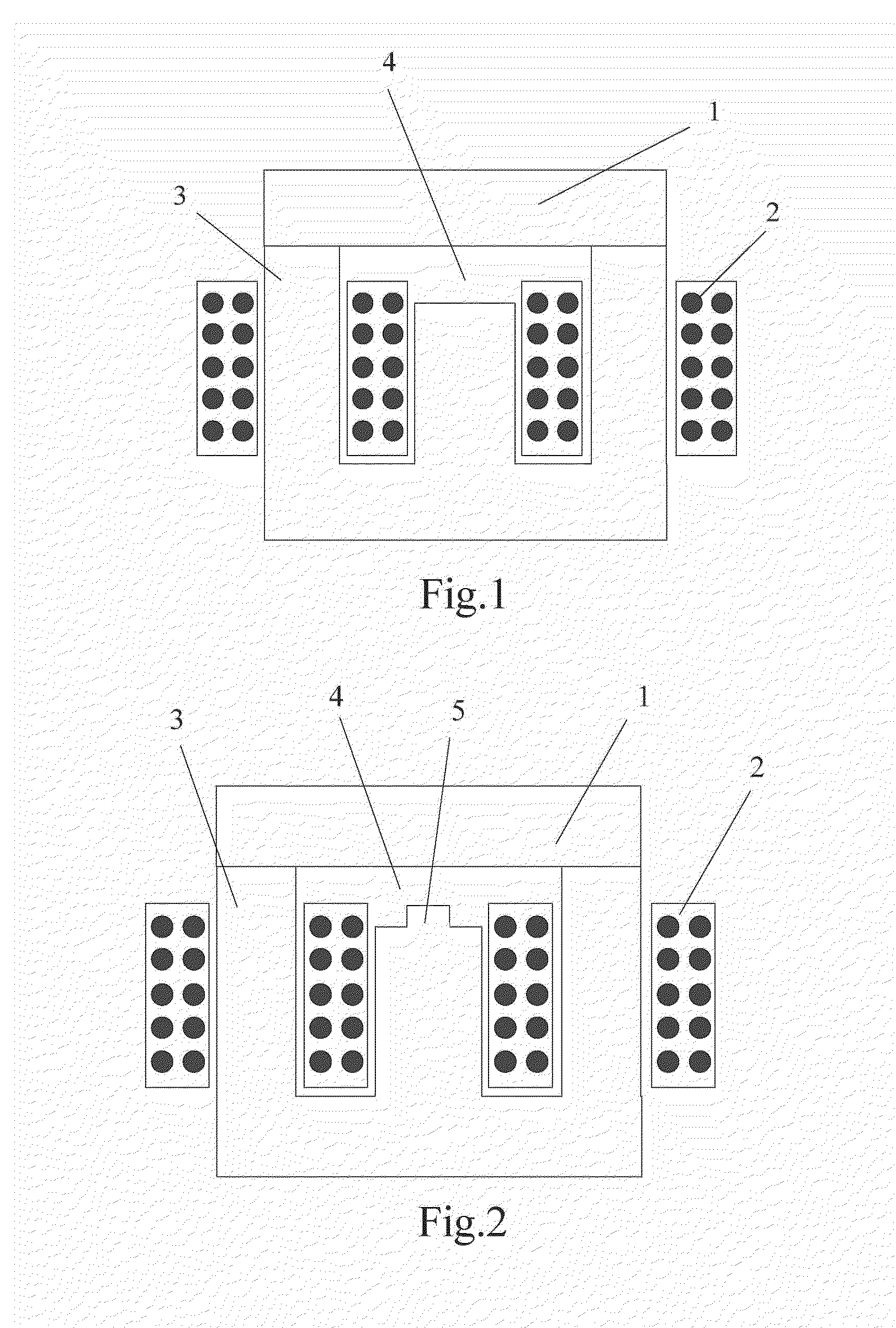

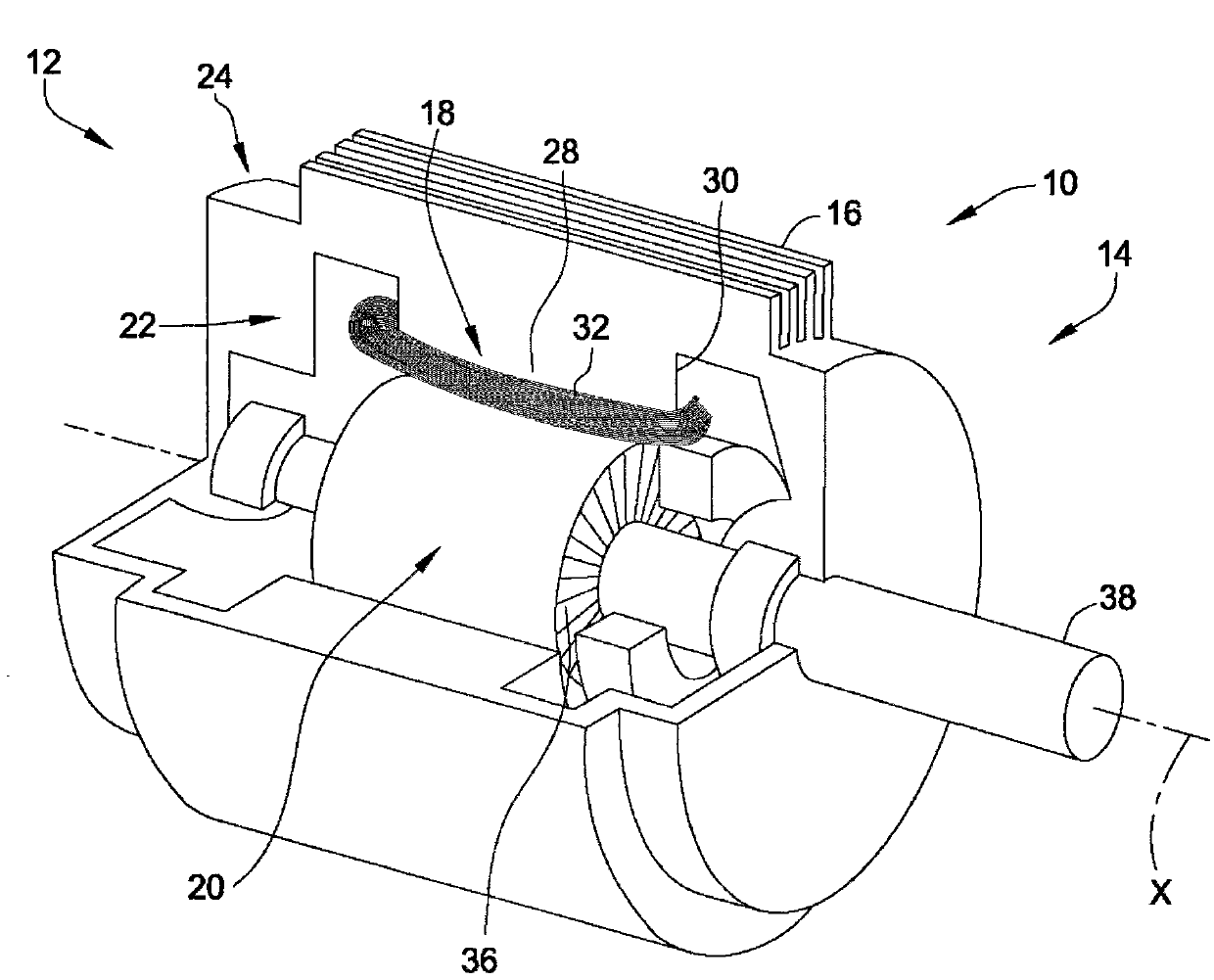

Method and apparatus for shielding a linear accelerator and a magnetic resonance imaging device from each other

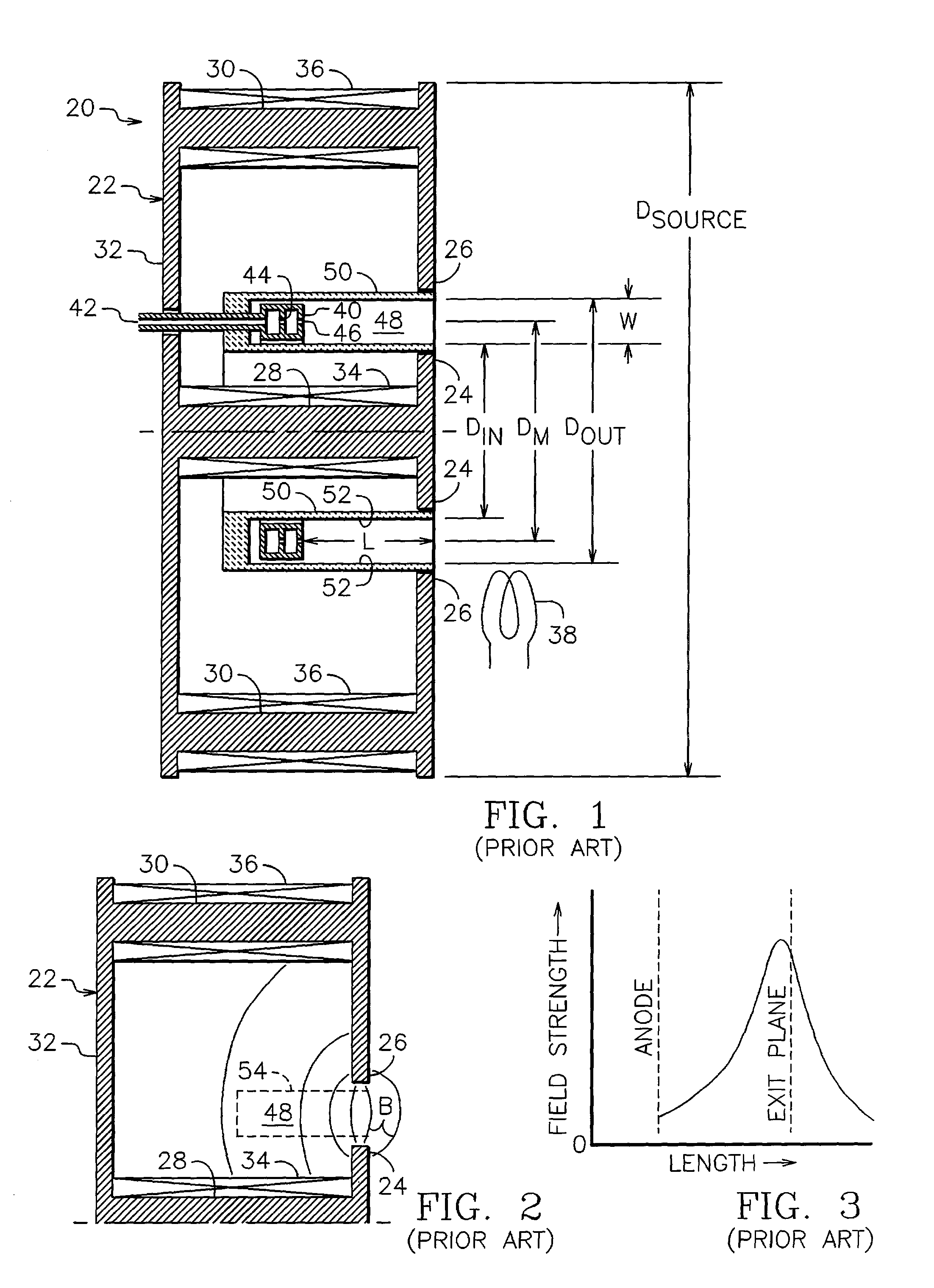

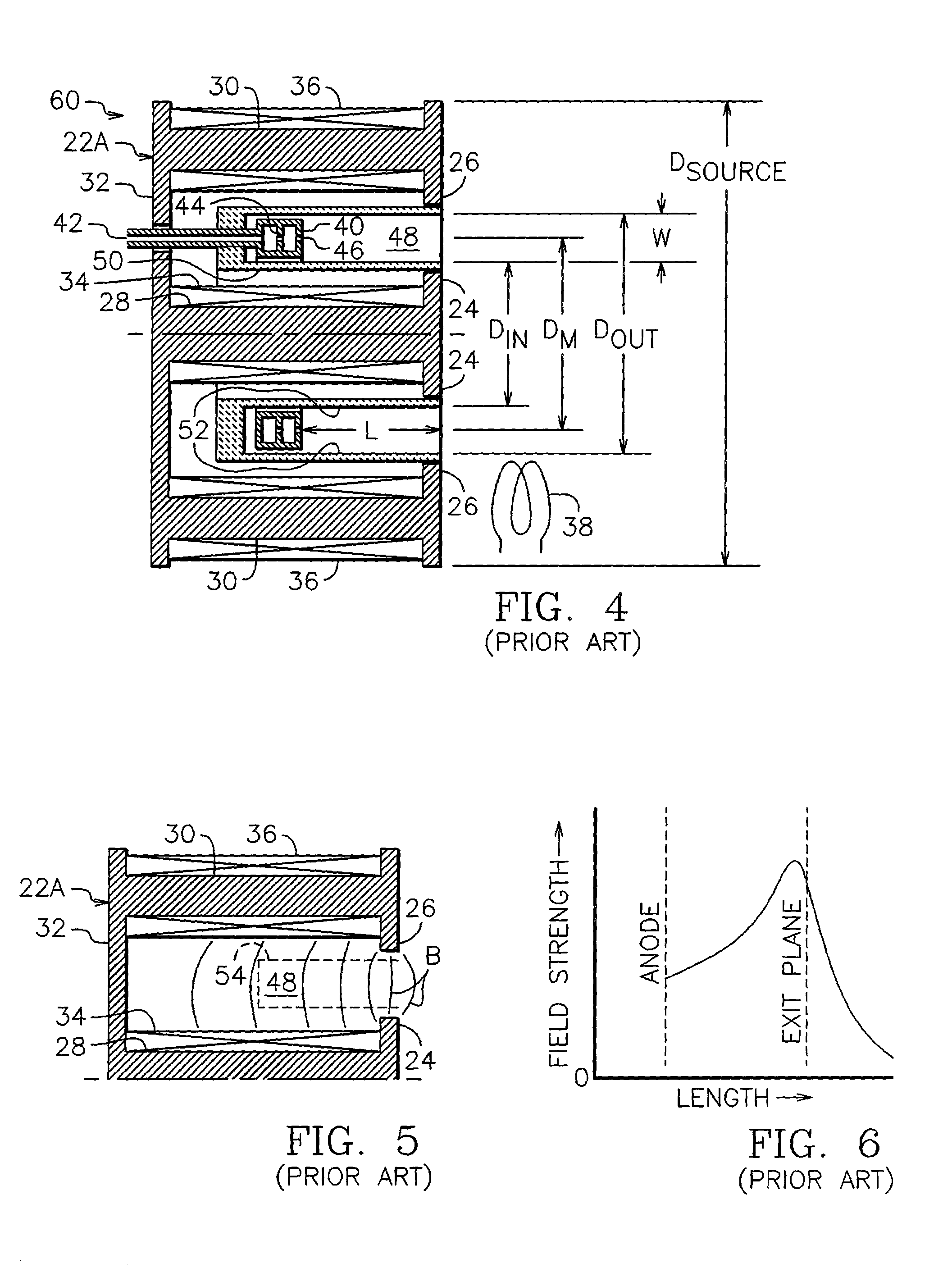

InactiveUS20110012593A1Improve permeabilityReduce flux densityDiagnostic recording/measuringSensorsSplit magnetResonance

A radiation therapy system comprises a magnetic resonance imaging (MRI) system combined with an irradiation system, which can include one or more linear accelerators (linacs) that can emit respective radiation beams suitable for radiation therapy. The MRI system includes a split magnet system, comprising first and second main magnets separated by gap. A gantry is positioned in the gap between the main MRI magnets and supports the linac(s) of the irradiation system. The gantry is rotatable independently of the MRI system and can angularly reposition the linac(s). Shielding can also be provided in the form of magnetic and / or RF shielding. Magnetic shielding can be provided for shielding the linac(s) from the magnetic field generated by the MRI magnets. RF shielding can be provided for shielding the MRI system from RF radiation from the linac.

Owner:VIEWRAY TECH

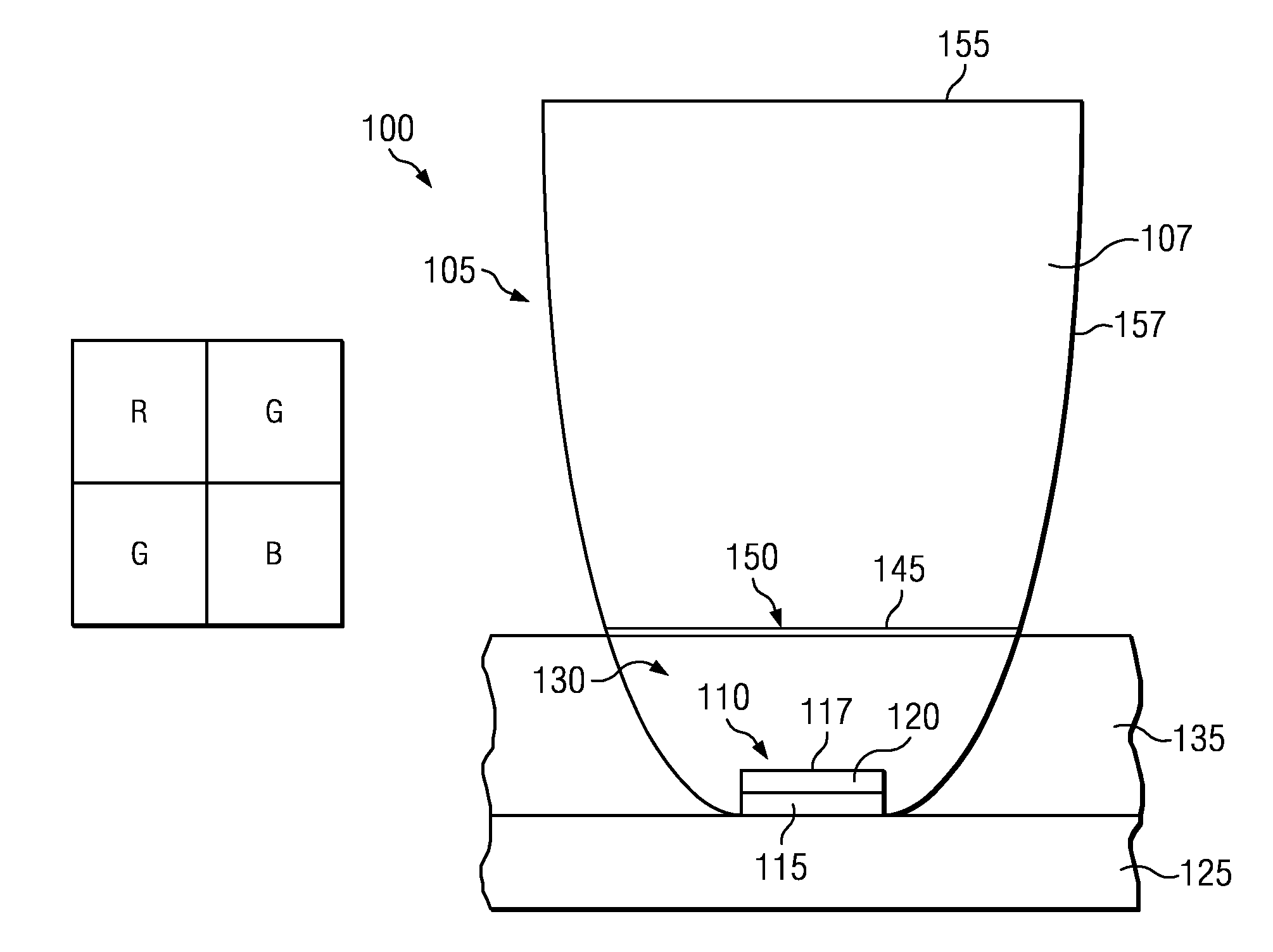

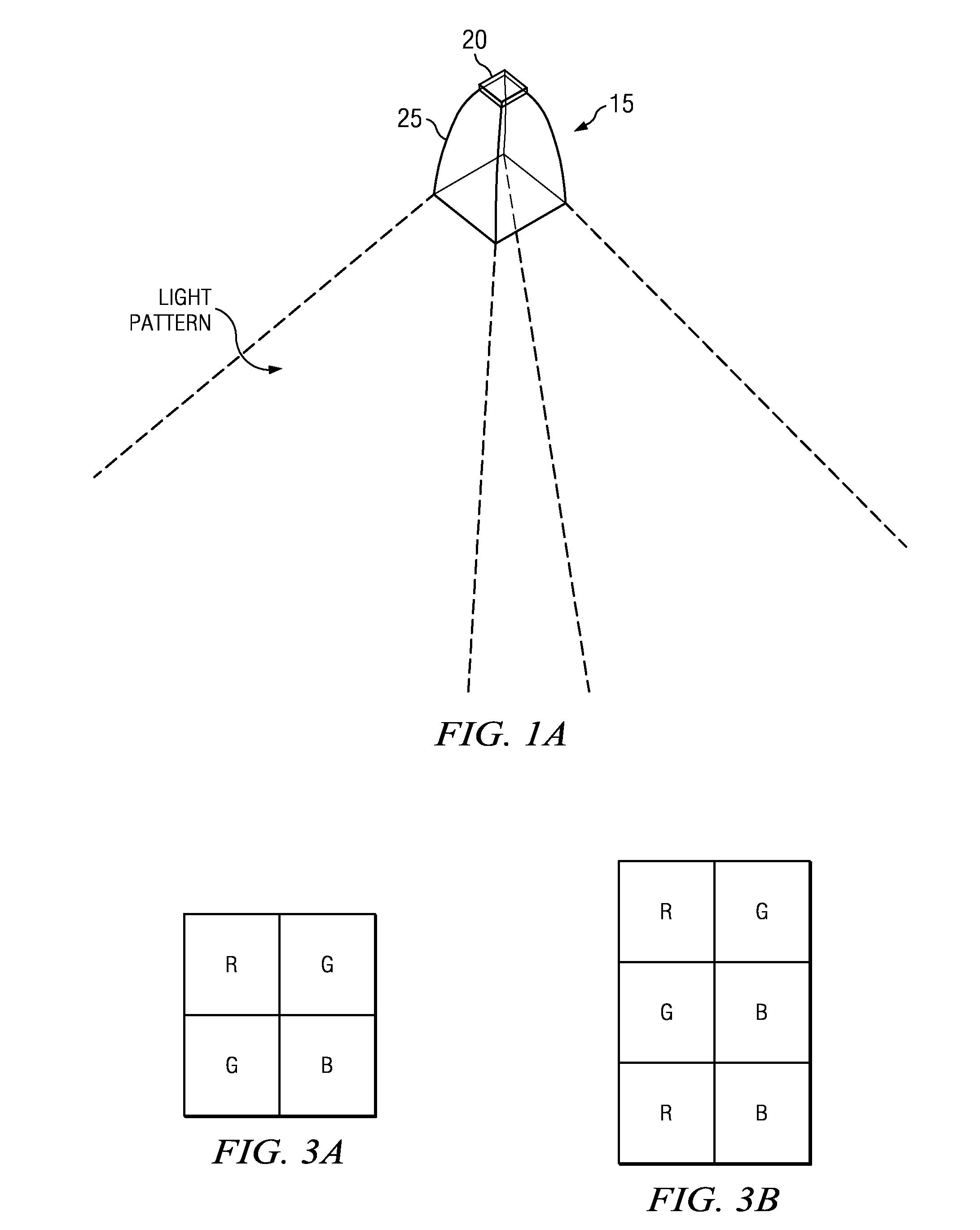

System and method for color mixing lens array

InactiveUS8585253B2Heating is therefore reduced and preventedImprove conversion efficiencyPlanar light sourcesLight source combinationsLight beamUltimate tensile strength

Owner:ILLUMITEX INC

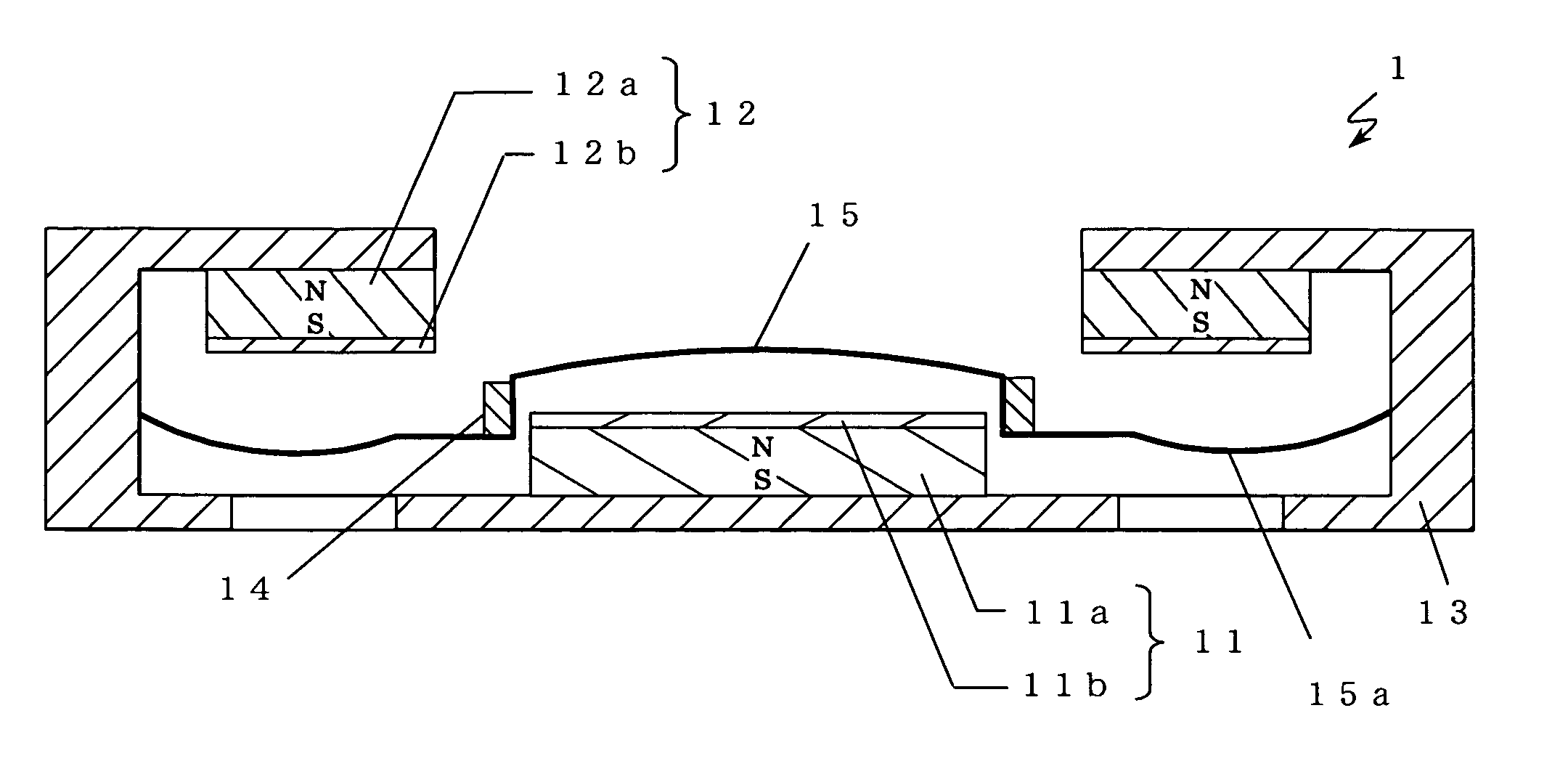

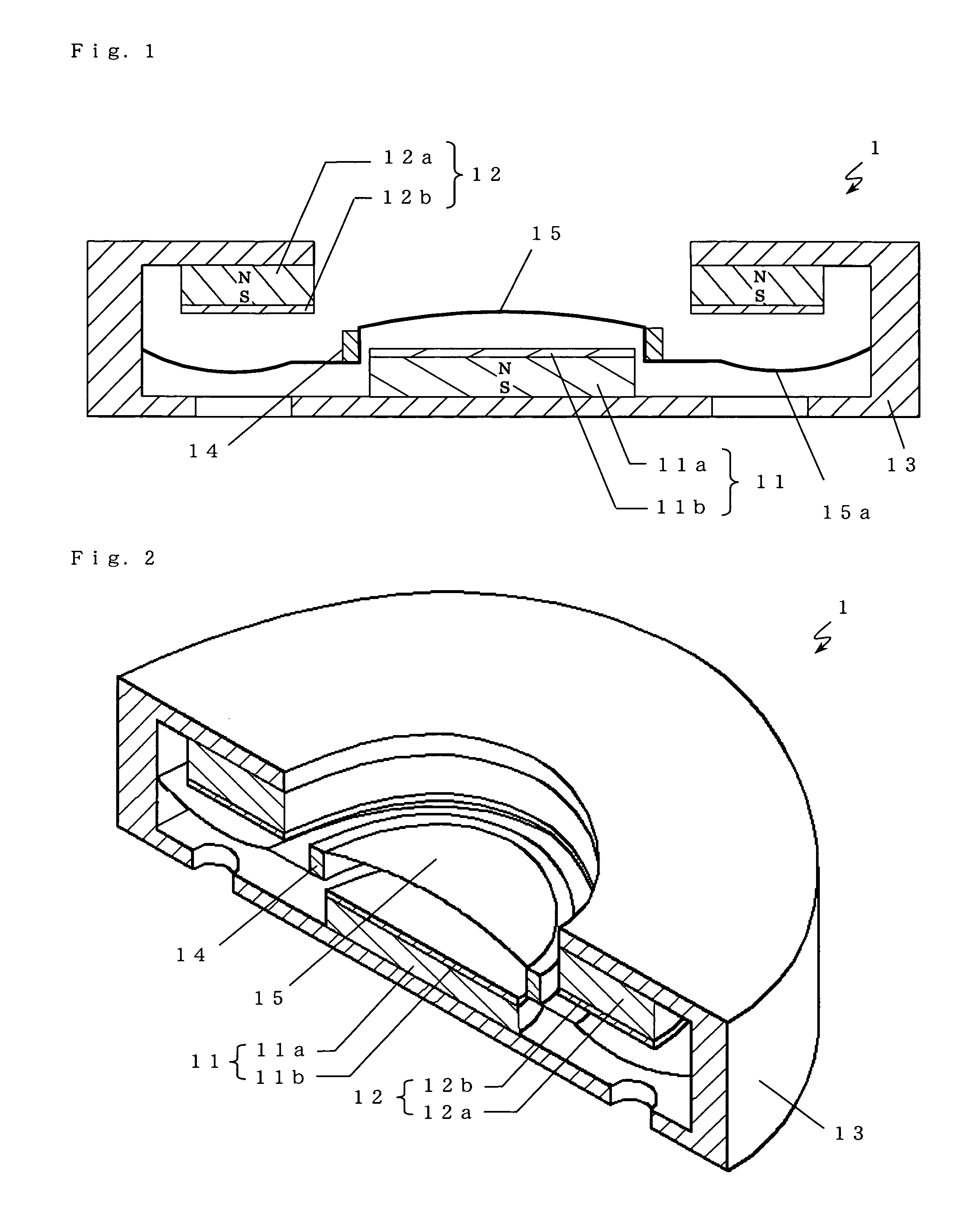

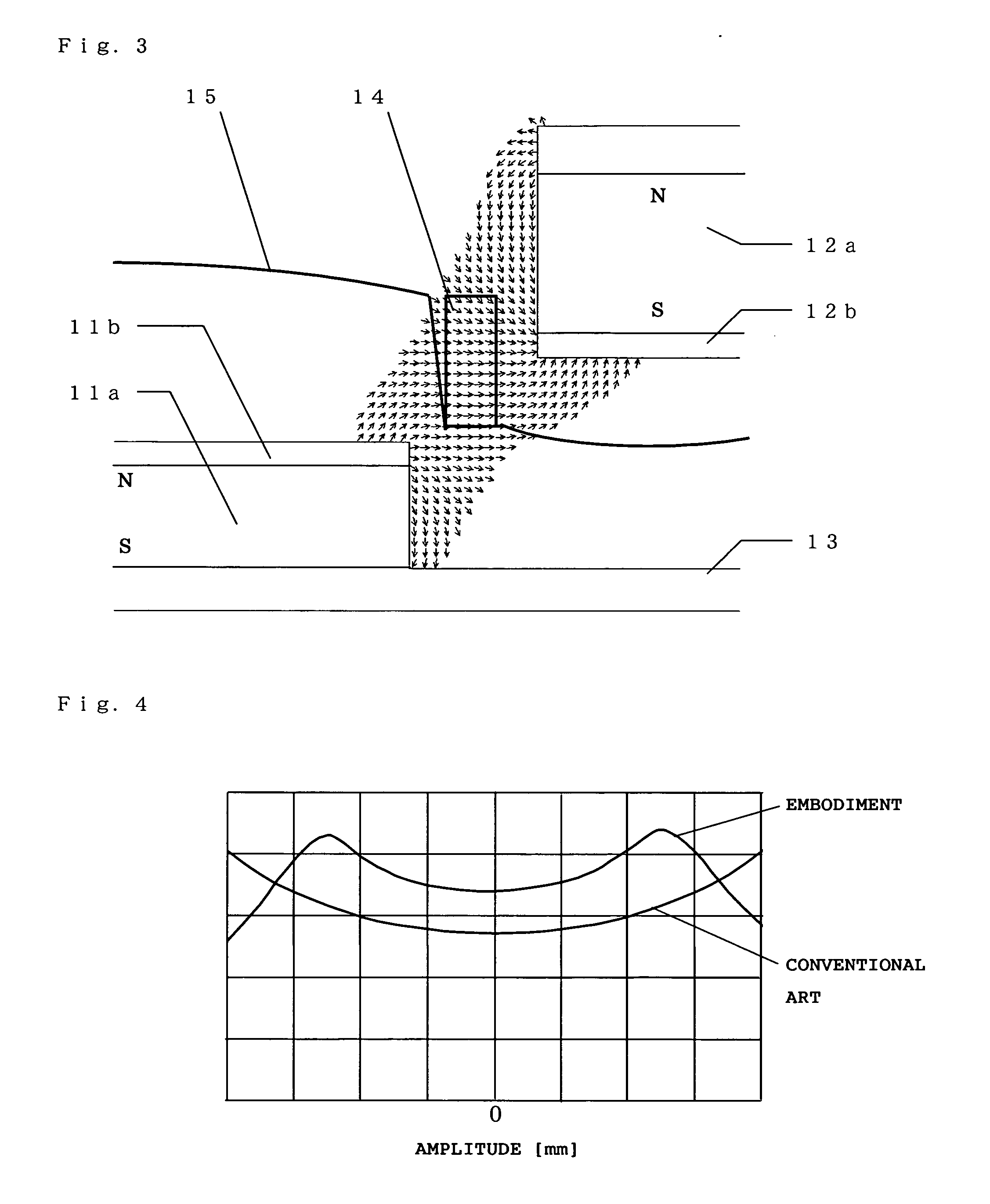

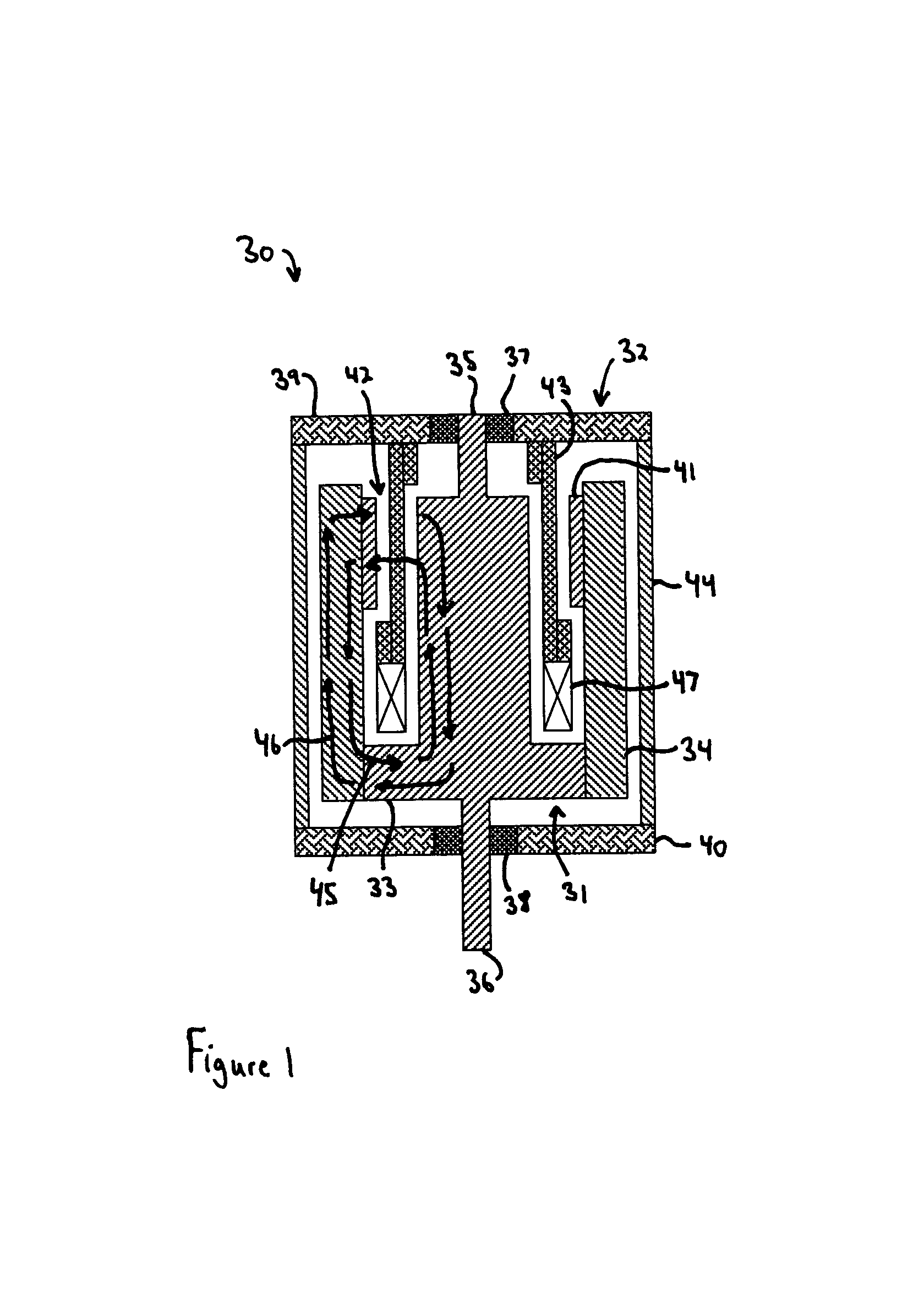

Electrodynamic electroacoustic transducer and electronic device

ActiveUS20070165902A1High magnetic flux densityImprove performanceTransducer detailsTransducerMagnetic poles

An electrodynamic electroacoustic transducer comprises: a first magnetic pole; a second magnetic pole that forms a magnetic gap between itself and the first magnetic pole and is arranged in a space excluding spaces in upper and lower face directions of the first magnetic pole; a yoke; a diaphragm; and a voice coil. The yoke magnetically couples one magnetic pole face of the first magnetic pole with one magnetic pole face of the second magnetic pole so as to support them. The diaphragm is arranged in a space in an upper face direction of the first magnetic pole and in a space in a lower face direction of the second magnetic pole, while its outer periphery is supported by the yoke. The voice coil is arranged in the magnetic gap and adhered to the diaphragm. At least one of the first magnetic pole part and the second magnetic pole part includes a magnet.

Owner:PANASONIC CORP

Method and apparatus for shielding a linear accelerator and a magnetic resonance imaging device from each other

InactiveUS8836332B2Improve permeabilityReduce flux densityDiagnostic recording/measuringMeasurements using NMR imaging systemsSplit magnetResonance

A radiation therapy system comprises a magnetic resonance imaging (MRI) system combined with an irradiation system, which can include one or more linear accelerators (linacs) that can emit respective radiation beams suitable for radiation therapy. The MRI system includes a split magnet system, comprising first and second main magnets separated by gap. A gantry is positioned in the gap between the main MRI magnets and supports the linac(s) of the irradiation system. The gantry is rotatable independently of the MRI system and can angularly reposition the linac(s). Shielding can also be provided in the form of magnetic and / or RF shielding. Magnetic shielding can be provided for shielding the linac(s) from the magnetic field generated by the MRI magnets. RF shielding can be provided for shielding the MRI system from RF radiation from the linac.

Owner:VIEWRAY TECH

Method And Apparatus For Shielding A Linear Accelerator And A Magnetic Resonance Imaging Device From Each Other

ActiveUS20150065860A1Improve permeabilityReduce flux densityDiagnostic recording/measuringSensorsSplit magnetResonance

A radiation therapy system comprises a magnetic resonance imaging (MRI) system combined with an irradiation system, which can include one or more linear accelerators (linacs) that can emit respective radiation beams suitable for radiation therapy. The MRI system includes a split magnet system, comprising first and second main magnets separated by gap. A gantry is positioned in the gap between the main MRI magnets and supports the linac(s) of the irradiation system. The gantry is rotatable independently of the MRI system and can angularly reposition the linac(s). Shielding can also be provided in the form of magnetic and / or RF shielding. Magnetic shielding can be provided for shielding the linac(s) from the magnetic field generated by the MRI magnets. RF shielding can be provided for shielding the MRI system from RF radiation from the linac.

Owner:VIEWRAY TECH

Magnetic field for small closed-drift ion source

InactiveUS20020145389A1Easy to useCompact and efficient and economicalElectric arc lampsMachines/enginesElectron currentElectron flow

Owner:KAUFMAN & ROBINSON

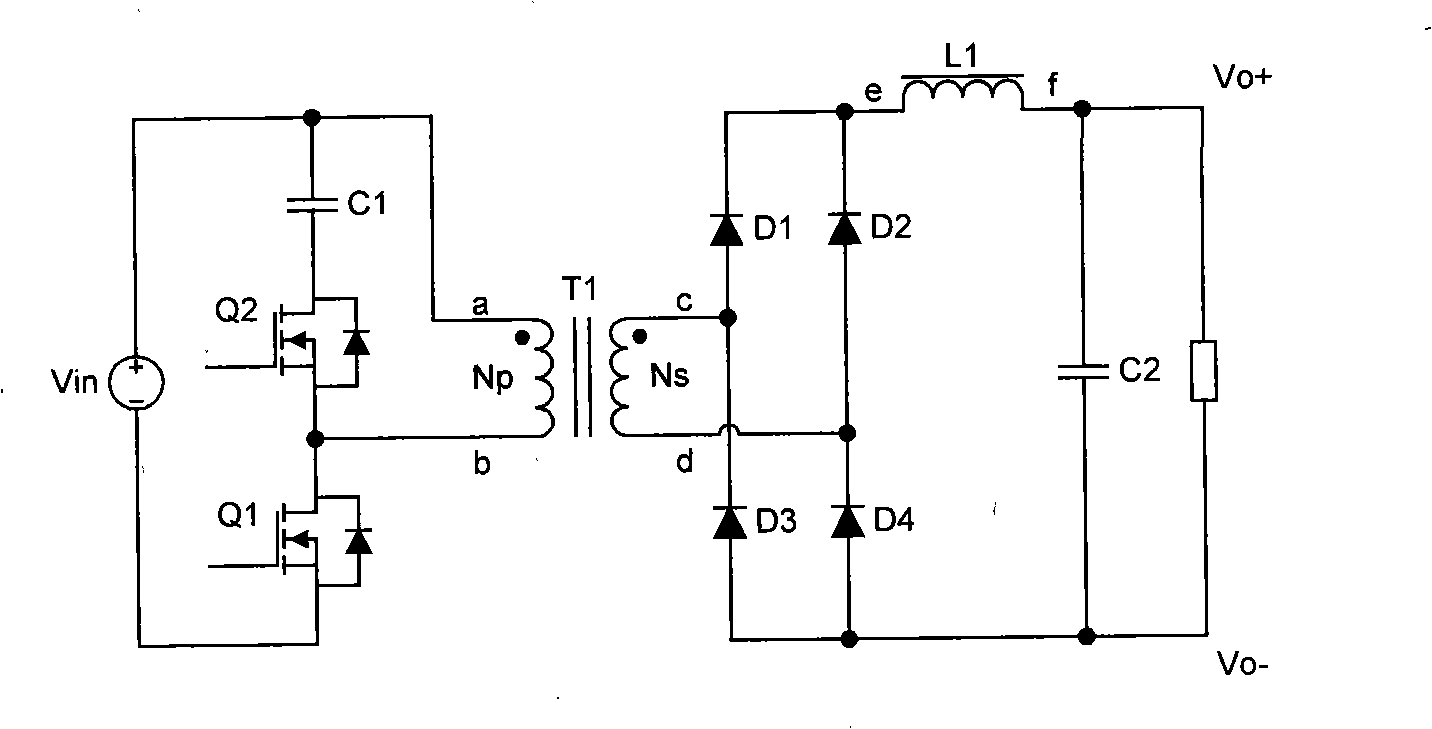

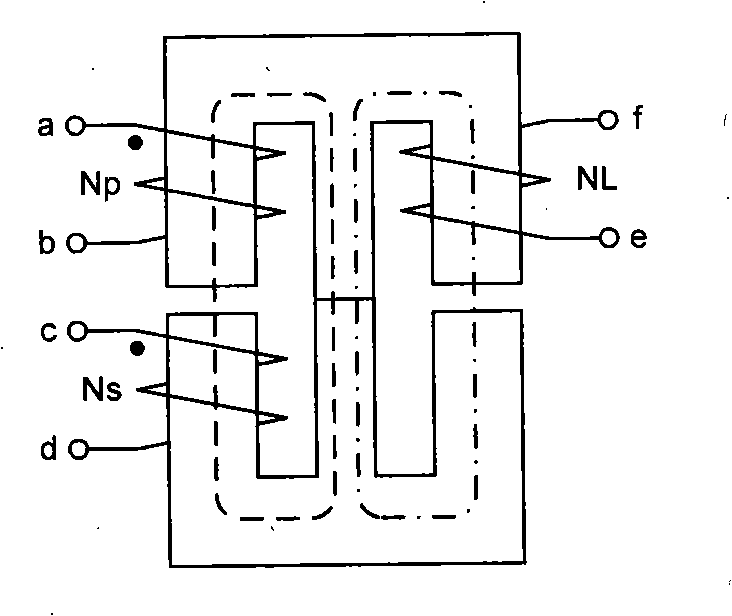

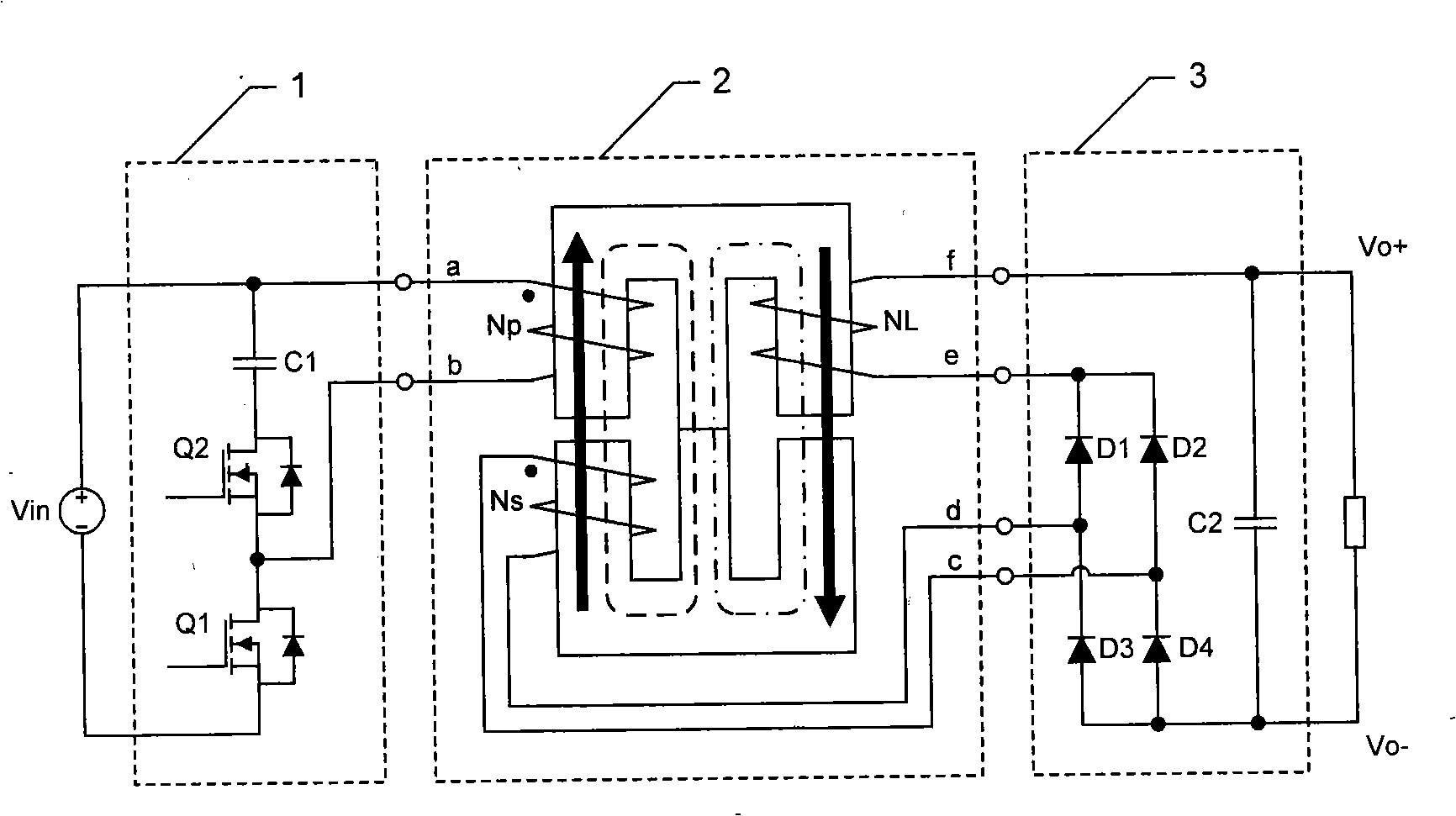

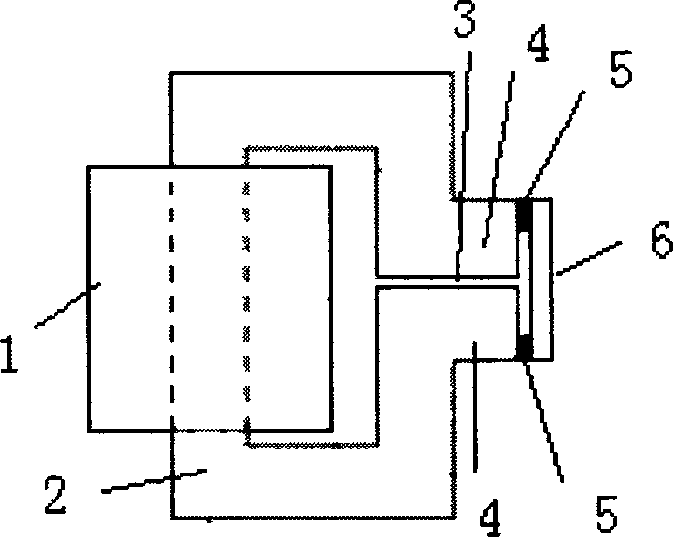

Magnetic component integrated active clamp positive and negative laser converter

InactiveCN101404454AReduce flux densityReduce volumeTransformersApparatus with intermediate ac conversionCapacitanceTransformer magnetic circuits

An actively clamped forward-flyback converter of an integrated magnetic element comprises a primary circuit (1), a secondary rectification and capacitance filter circuit (3) which consists of a filter circuit and a rectification circuit as well as an integrated magnetic circuit (2) which is connected with the primary circuit (1) and the secondary rectification and capacitance filter circuit (3); wherein, the integrated magnetic circuit (2) is composed of iron cores of at least three magnetic pillars; one of the magnetic pillars is respectively wound with a primary winding (Np) and a secondary winding, thus forming a transformer magnetic circuit; the other one of the magnetic pillars is wound with an inductive winding (NL) to form an inductive magnetic circuit; and at least another one of the magnetic pillars forms a common magnetic circuit of the transformer magnetic circuit and the inductive magnetic circuit; the magnetic pillars of the transformer magnetic circuit and the inductive magnetic circuit are respectively provided with an air gap; the primary winding (Np) is connected with the primary circuit (1) of the converter, the secondary winding is connected with the rectification circuit of the secondary rectification and capacitance filter circuit (3); the inductive winding (NL) is connected with the filter circuit of the secondary rectification and capacitance filter circuit (3); and the rectification circuit and the filter circuit are connected with the output terminal. The invention is small in volume and light in weight.

Owner:北京新雷能有限责任公司 +1

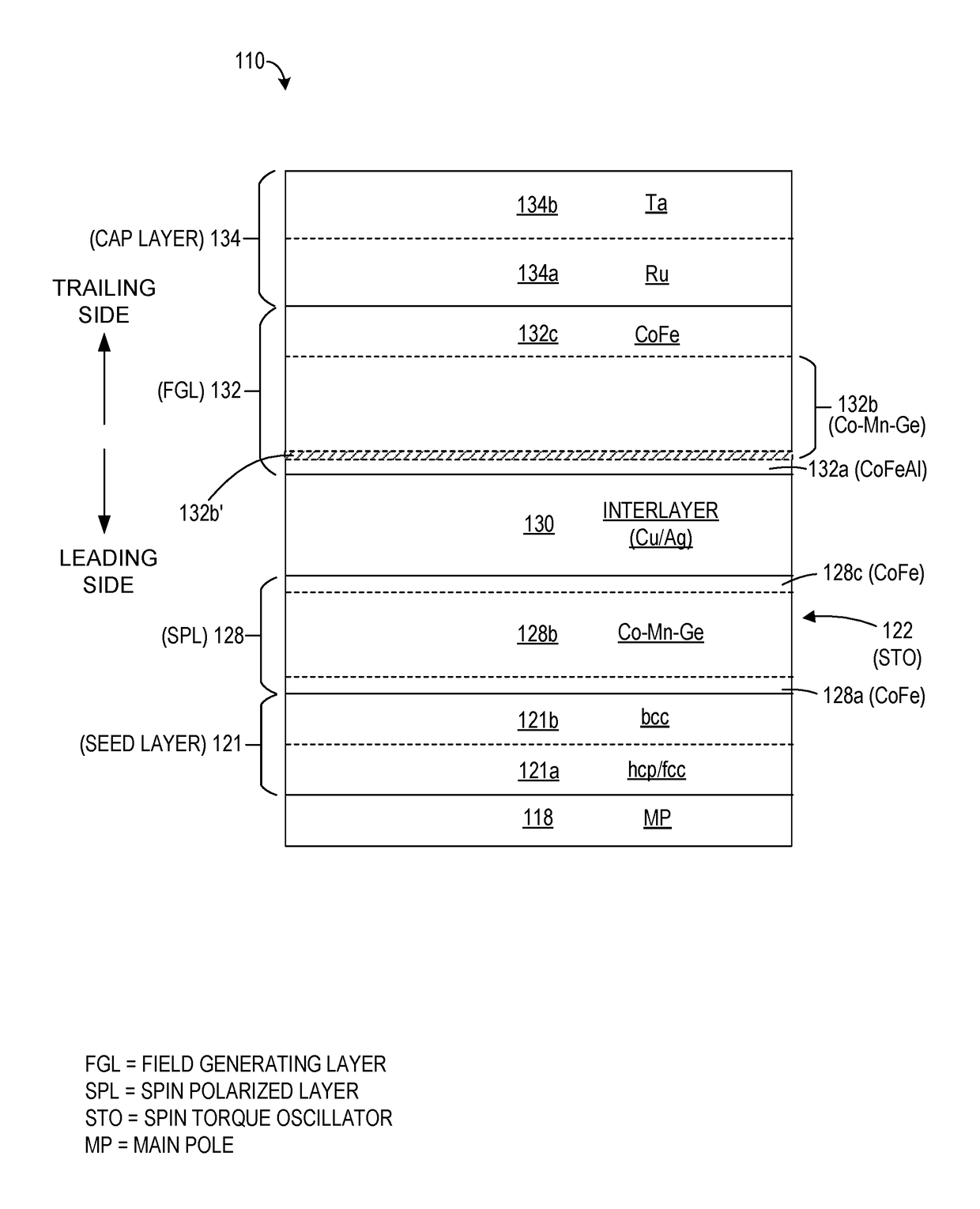

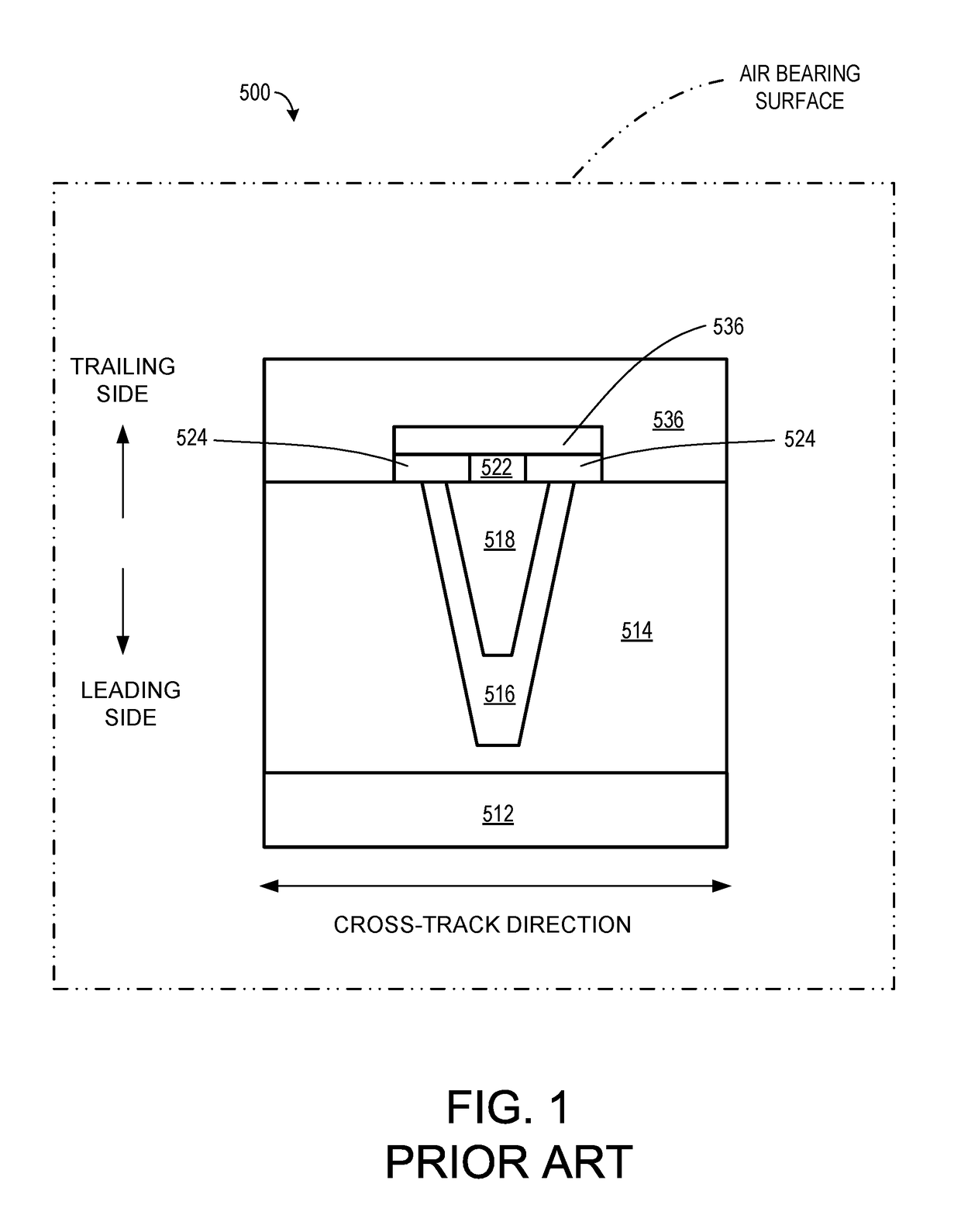

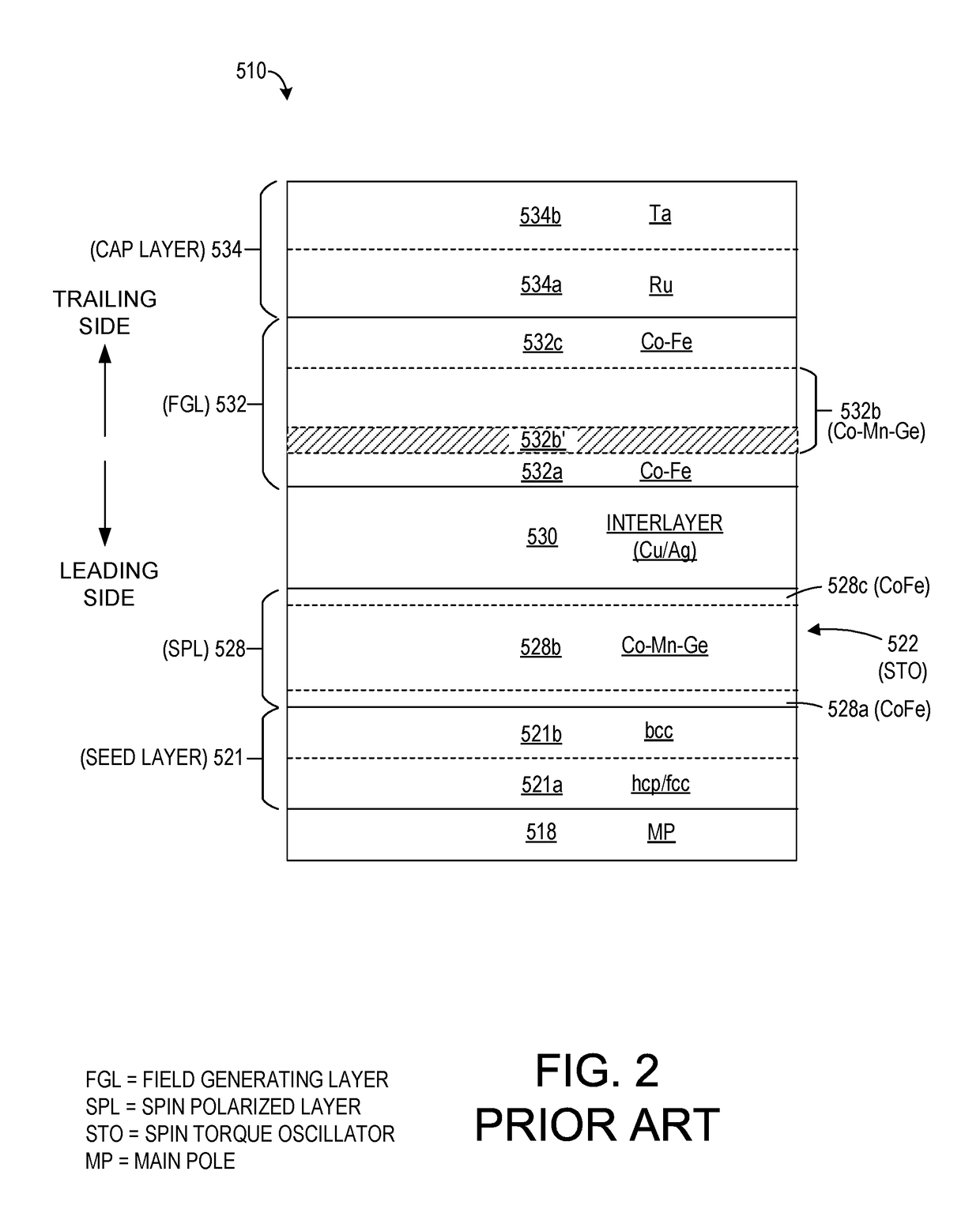

Low magnetic flux density interface layer for spin torque oscillator

ActiveUS10037772B2Reduce flux densityWell formedHeads using thin filmsRecord information storageInter layerSpin torque oscillators

A magnetic field-assisted magnetic recording (MAMR) head is provided, which includes a recording main pole, a seed layer, and a spin torque oscillator (STO) positioned over the main pole, in this order, in a stacking direction from a leading side to a trailing side of the recording head. The STO comprises a spin polarized layer (SPL), an interlayer with fcc structure, and a field generating layer (FGL), in this order in the stacking direction. The FGL comprises a low magnetic flux density interface (LMFDI) layer with bcc structure that directly contacts the interlayer.

Owner:WESTERN DIGITAL TECH INC

Magnetic core of low conductive magnet, manufacturing method and application thereof

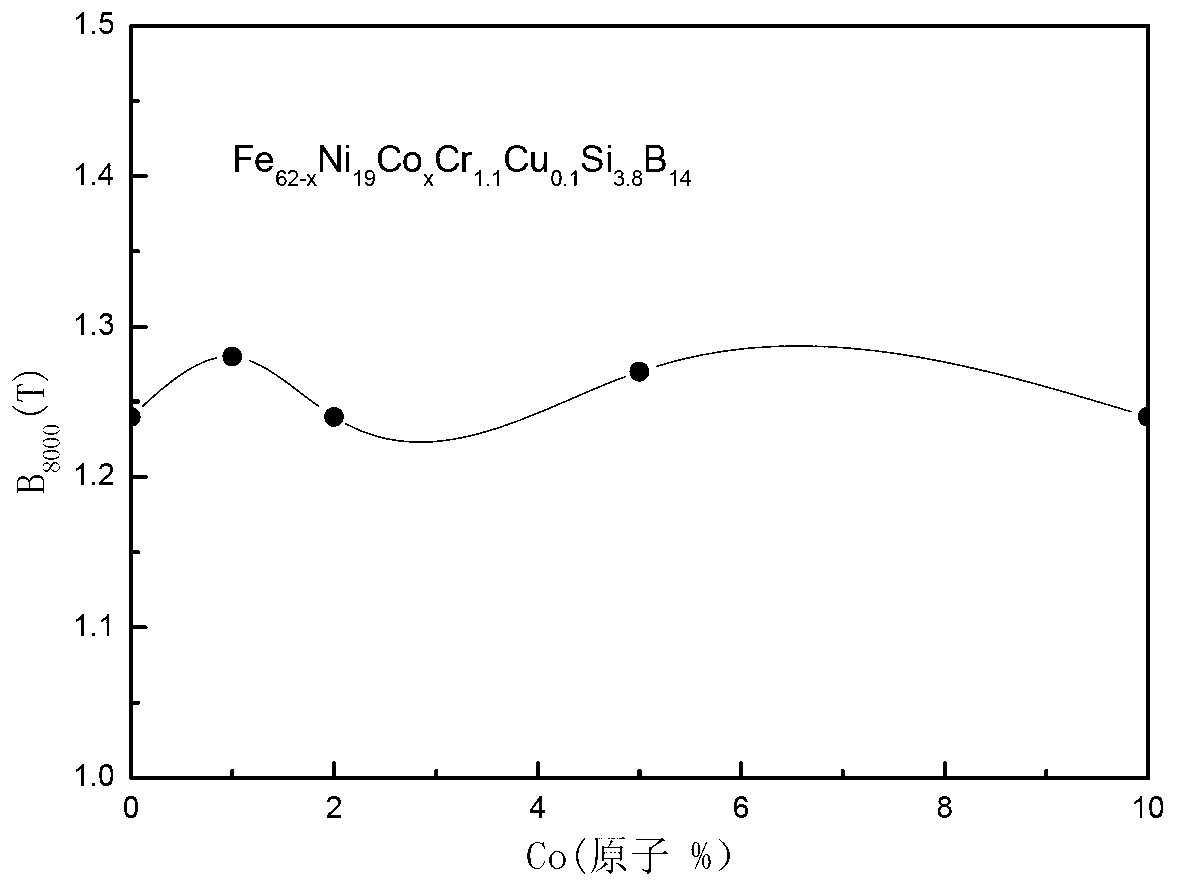

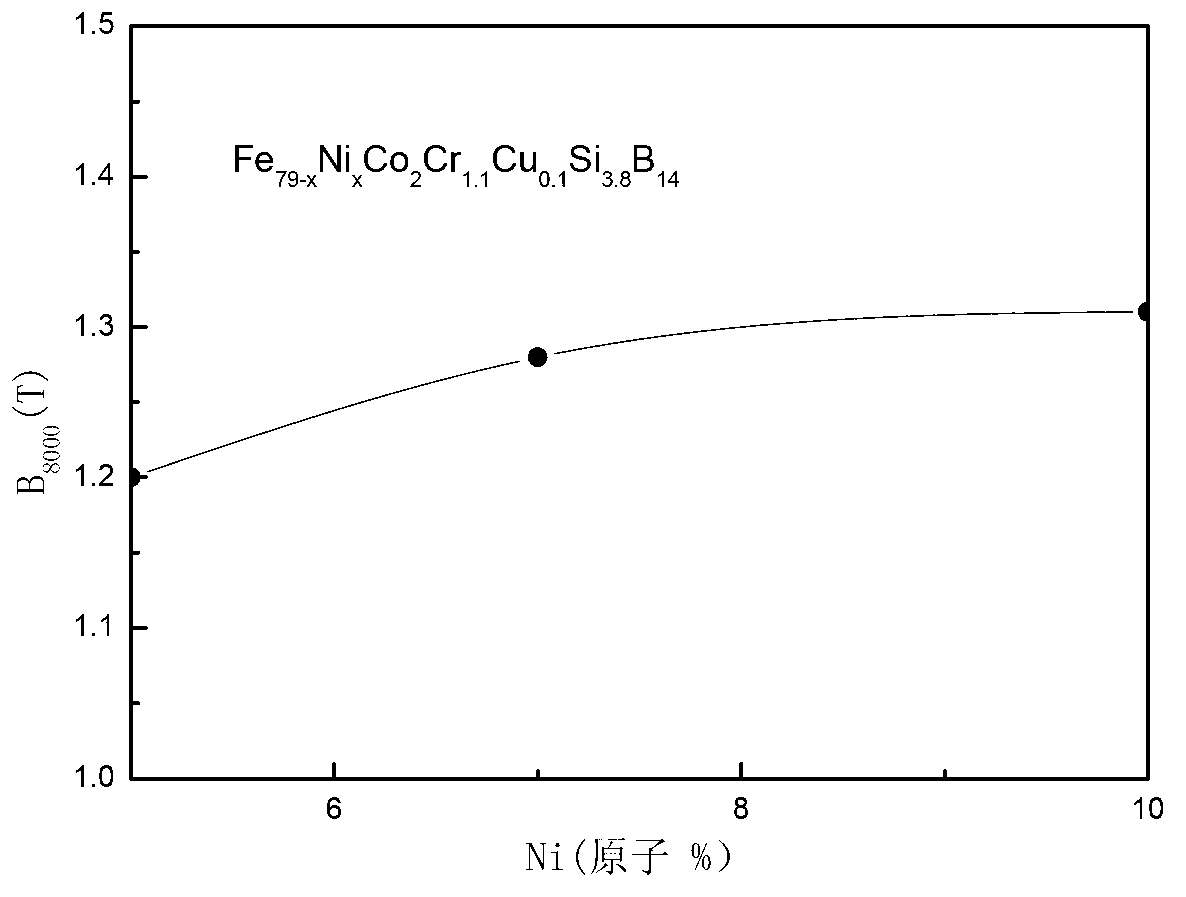

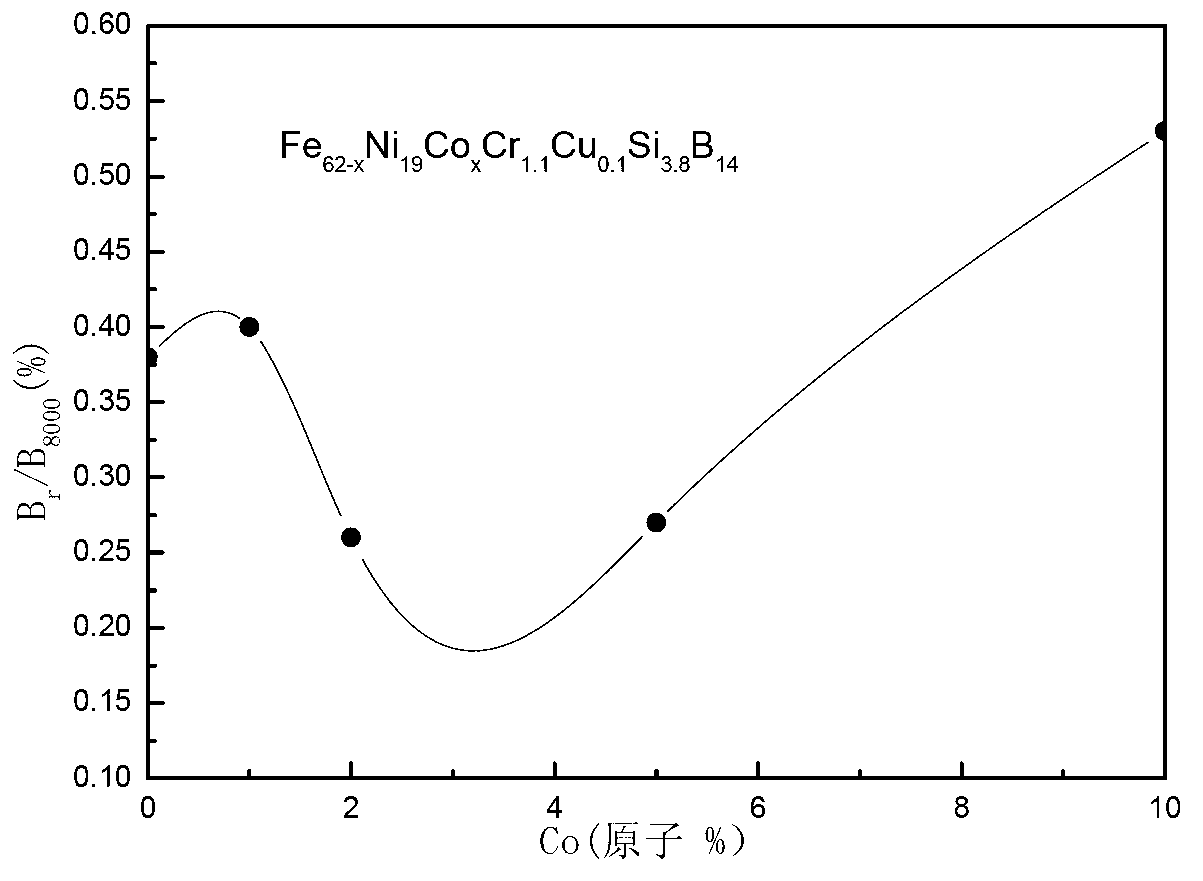

ActiveCN103258612ALow coercivityStrong corrosion resistanceTransformers/inductances magnetic coresInductances/transformers/magnets manufactureAlloyAlternating current

The invention relates to a magnetic core of a low conductive magnet, a manufacturing method and and application thereof. The magnetic core of the low conductive magnet is made of ferromagnetic magnetically soft alloy, the molecular formula of the alloy is FeaMbCucSidBeM'fXg, wherein M represents Ni and / or Co, M' represents at least one element among V, Ti, Nb, Mo, Cr, Hf, Ta and W, and X represents P, Ge, C and impurities. With atomic percent as the unit, a, b, c, d, e, f and g meet the following conditions: b is larger than or equal to 5 and is smaller than or equal to 40, c is larger than or equal to 0.05 and is smaller than or equal to 1, d is larger than or equal to 1 and is smaller than or equal to 8, e is larger than or equal to 10 and is smaller than or equal to 20, f is larger than or equal to 0.5 and is smaller than or equal to 5, g is larger than or equal to 0 and is smaller than or equal to 0.5, d and e are larger than or equal to 10 and are smaller than or equal to 25, and a is equal to 100 minus b minus c minus d minus e minus f minus g. The microstructure of the using state of the alloy is an amorphous state. The magnetic core is low in magnetic conductivity, high in anti-saturation performance and high in modulation property to alternating current and direct current components. Further, a B-H loop line is of a linear shape, and the magnetic conductivity of the linear B-H loop line is high in modulation property in the alternating current and the direct current.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

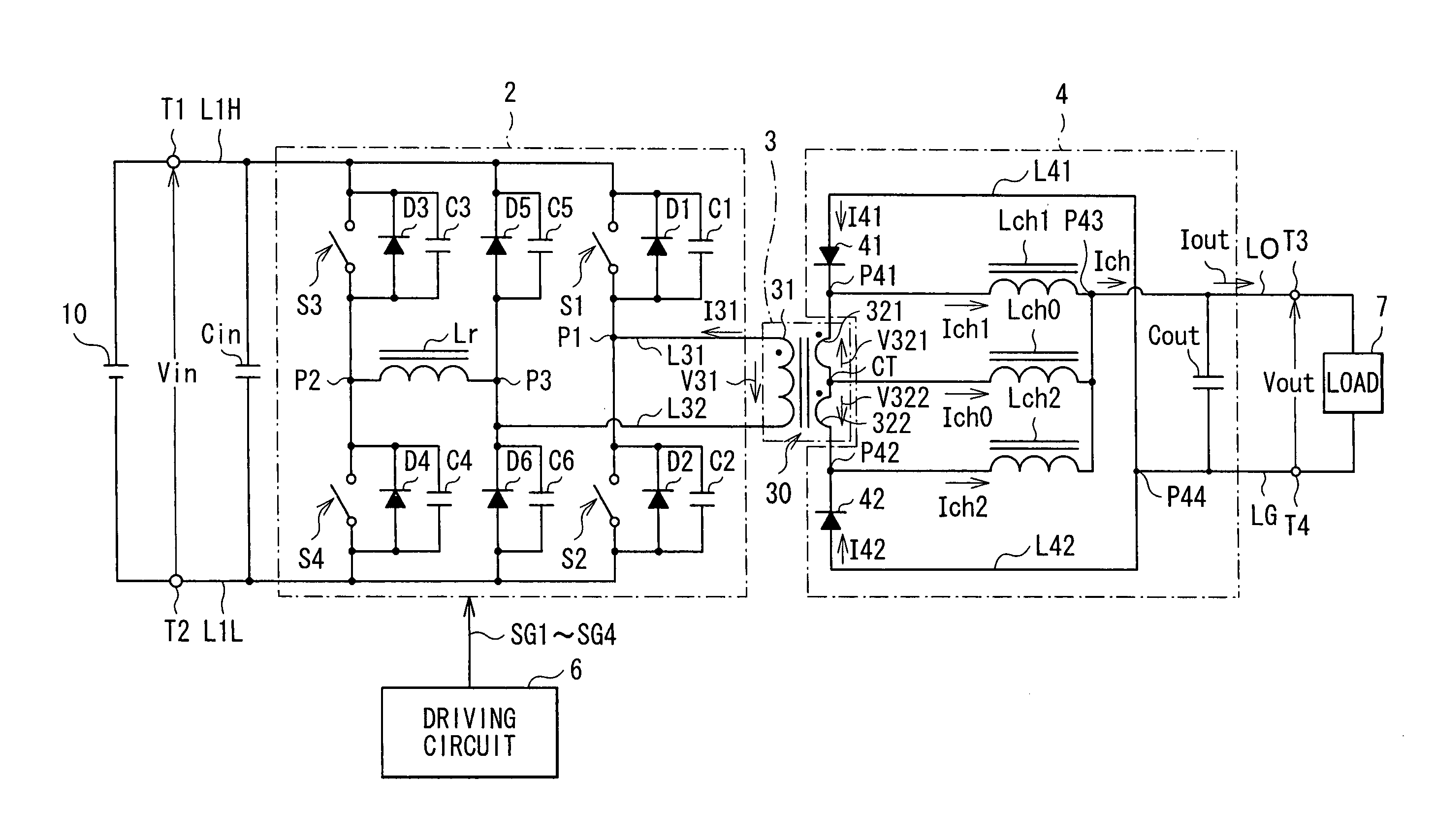

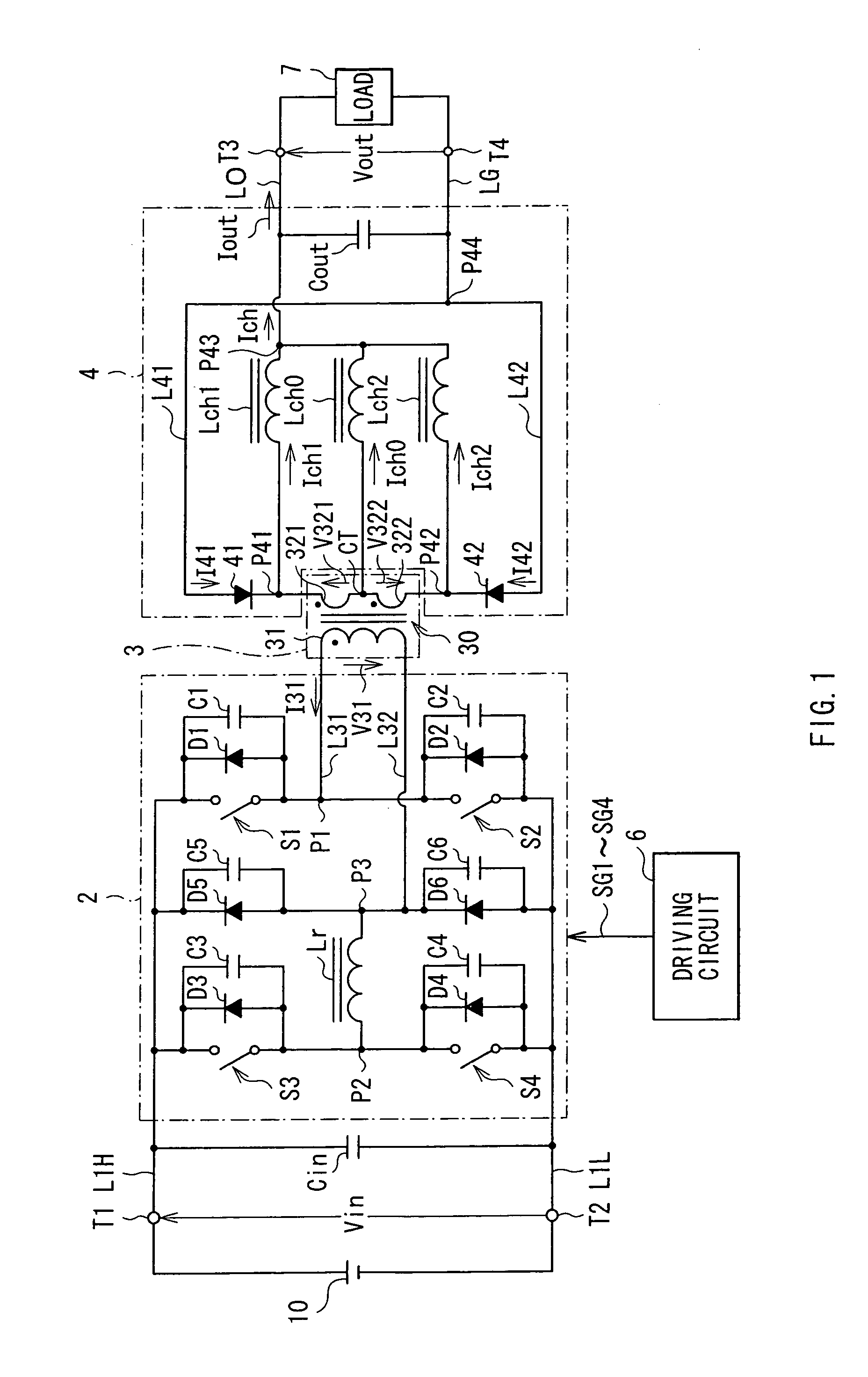

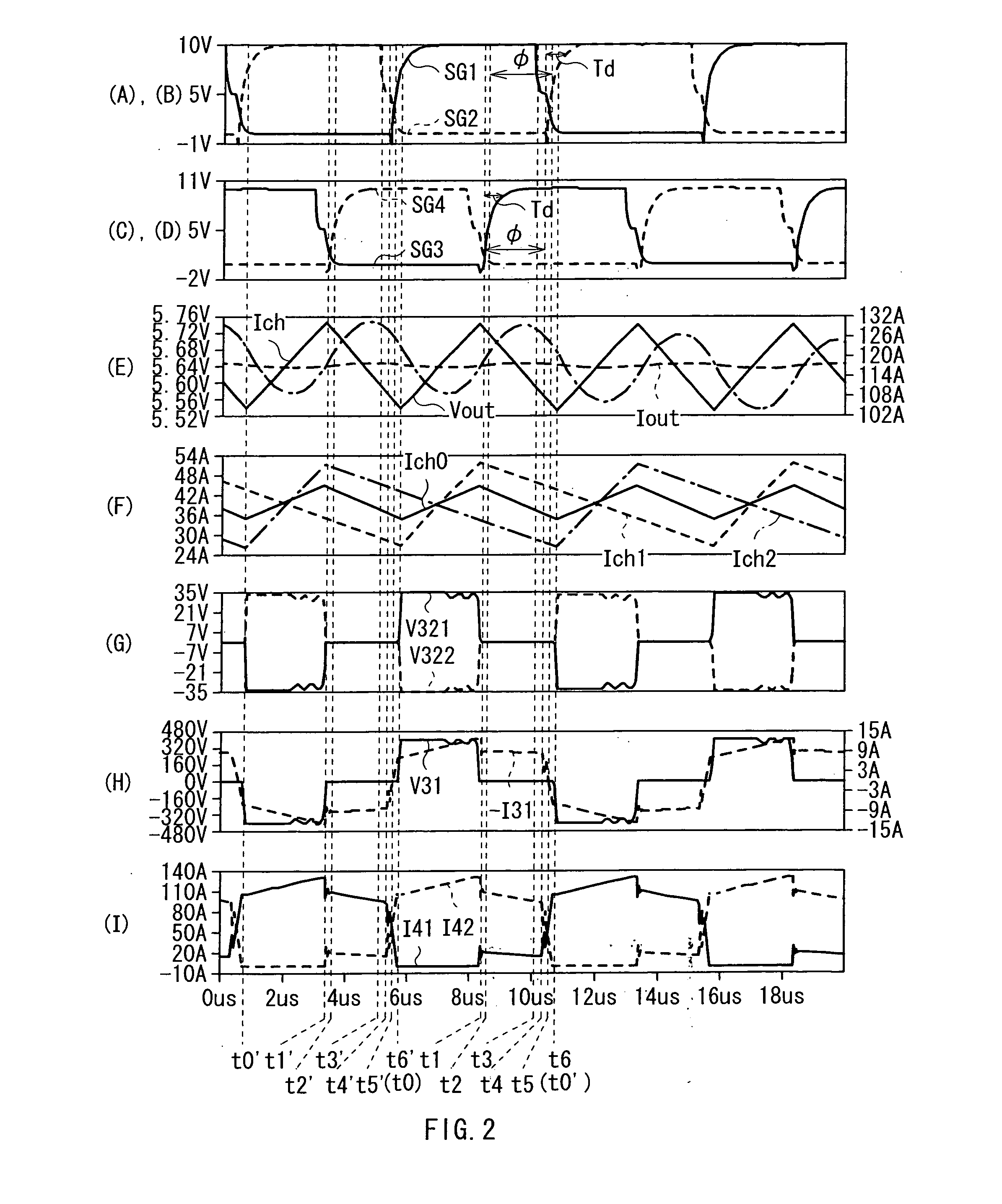

Switching power supply unit

InactiveUS20100321960A1Reduce the amount requiredTotal current dropDc-dc conversionTransformers/inductances detailsCapacitanceEngineering

The switching power supply unit includes: a transformer having a primary winding and two secondary windings; and a rectifying-smoothing circuit having two rectifying elements, three choke coils and a capacitive element. A first rectifying element is between a junction of ends of the first secondary winding and the second choke coil, and one end of the capacitive element. A second rectifying element is between a junction of ends of the second secondary winding and the third choke coil, and the one end of the capacitive element. The other end of the first secondary winding and the other end of second secondary winding are connected to the one end of the first choke coil. The other end of the first choke coil, the other end of the second choke coil, and the other end of the third choke coil are connected to the other end of the capacitive element.

Owner:TDK CORPARATION

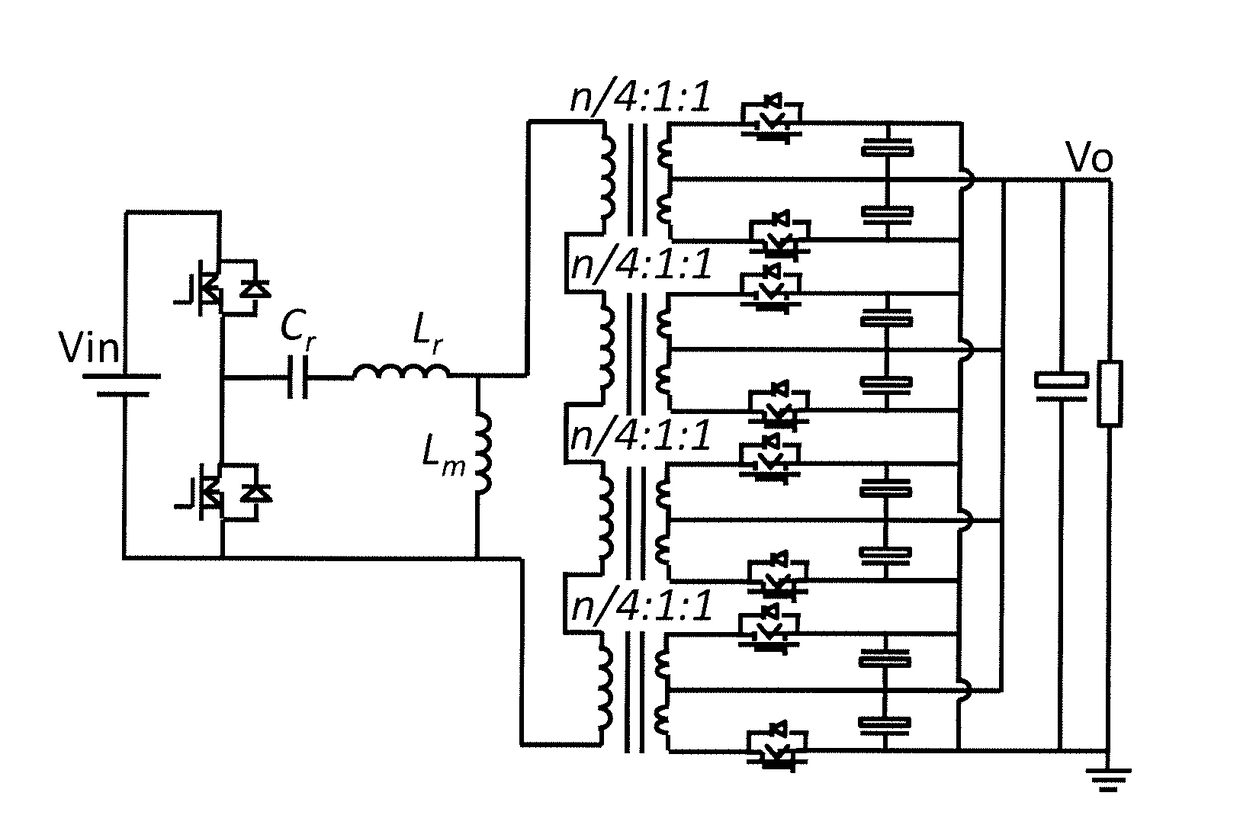

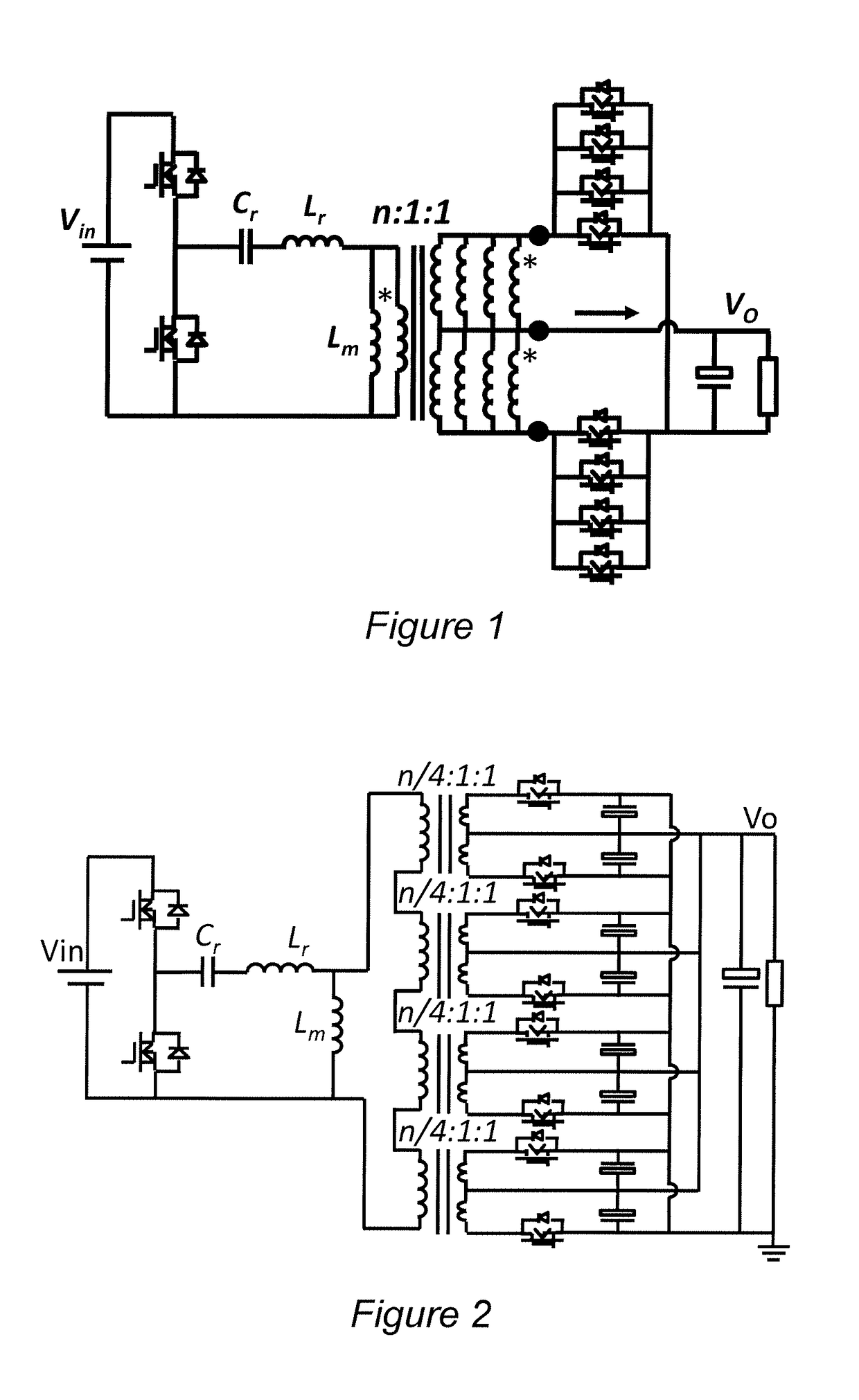

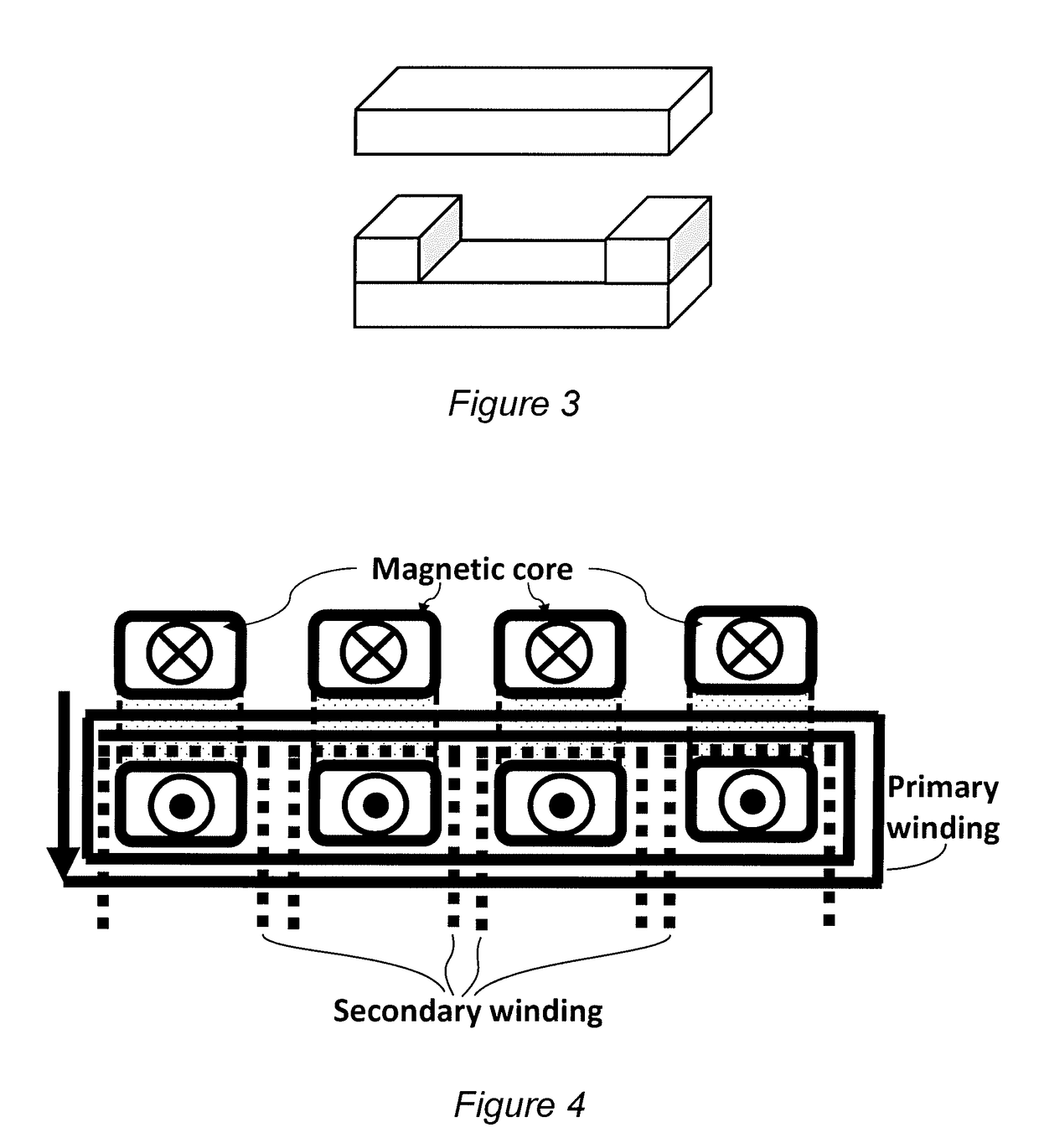

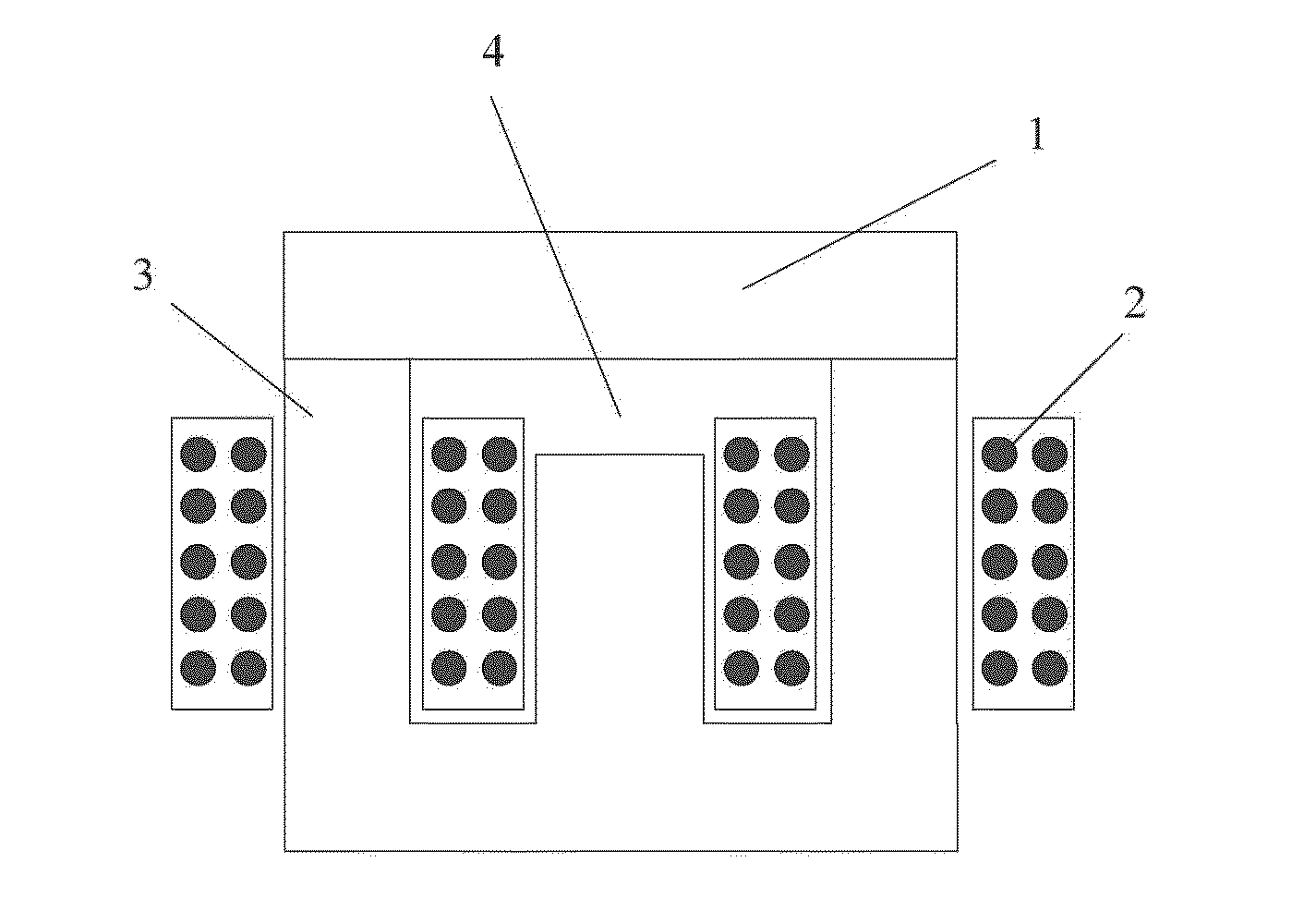

Matrix Transformer and Winding Structure

ActiveUS20180226182A1Simple structureImproved flux distributionTransformersEfficient power electronics conversionConductor CoilPrinted circuit board

A matrix transformer particularly suited to large voltage step-down, high current applications achieves increased good current sharing uniformity or air gap and electrical characteristics and reduced or eliminating termination losses, core losses and winding losses with a unitary magnetic core structure featuring sheets of magnetic material and a two-dimensional array of pillars on which windings, oriented in opposite directions on pillars that are adjacent in orthogonal directions, can be formed or placed comprising metallization on or embedded in a printed circuit board (PCB) structure. Magnetic flux density is reduced by at least one-half by dividing the magnetic flux in each pillar into two paths of increased width in the sheets of magnetic material. Magnetic flux density may be further decreased and flux uniformity improved by extending the sheets of magnetic material beyond a periphery defined by the pillar array.

Owner:VIRGINIA TECH INTPROP INC

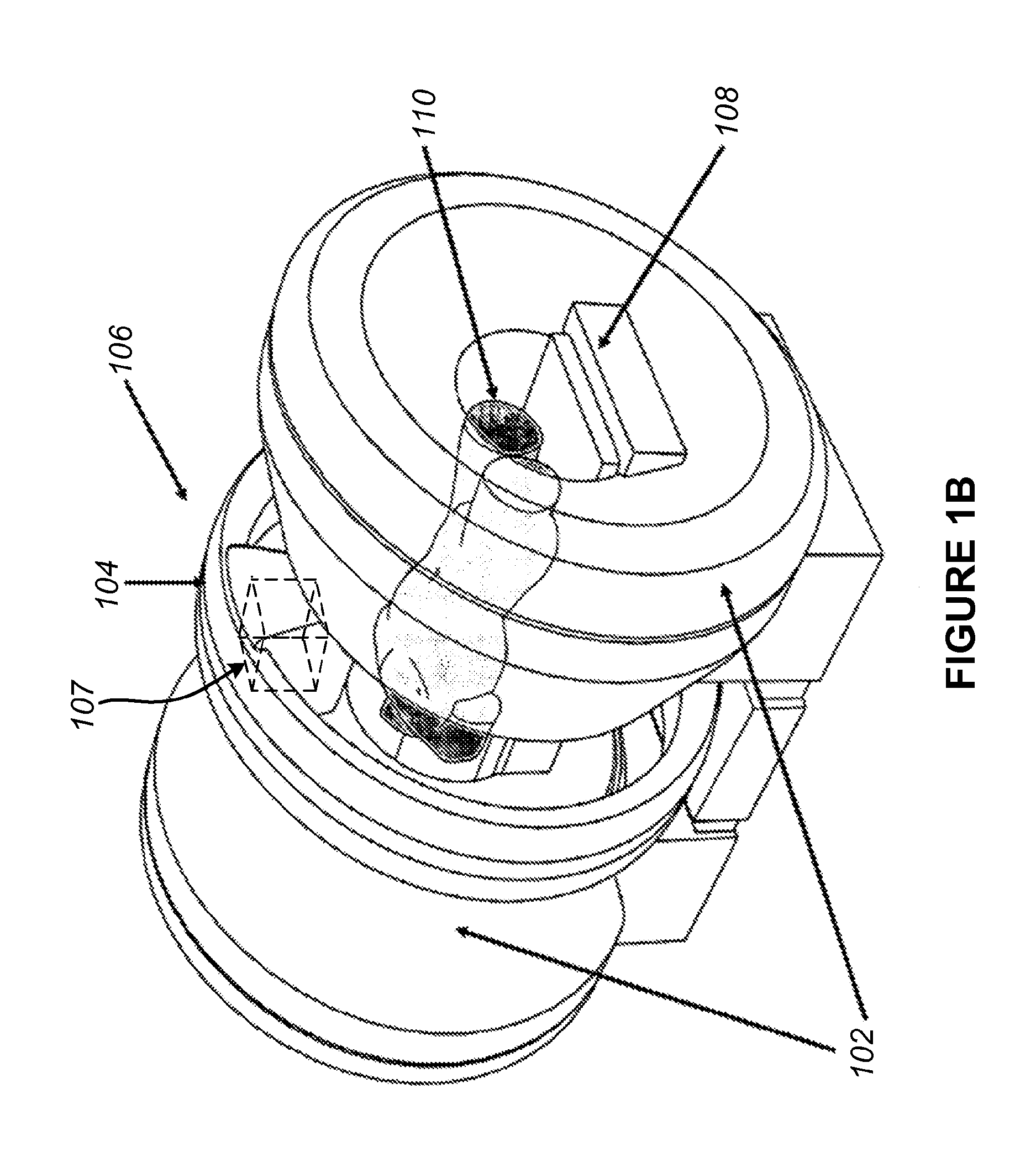

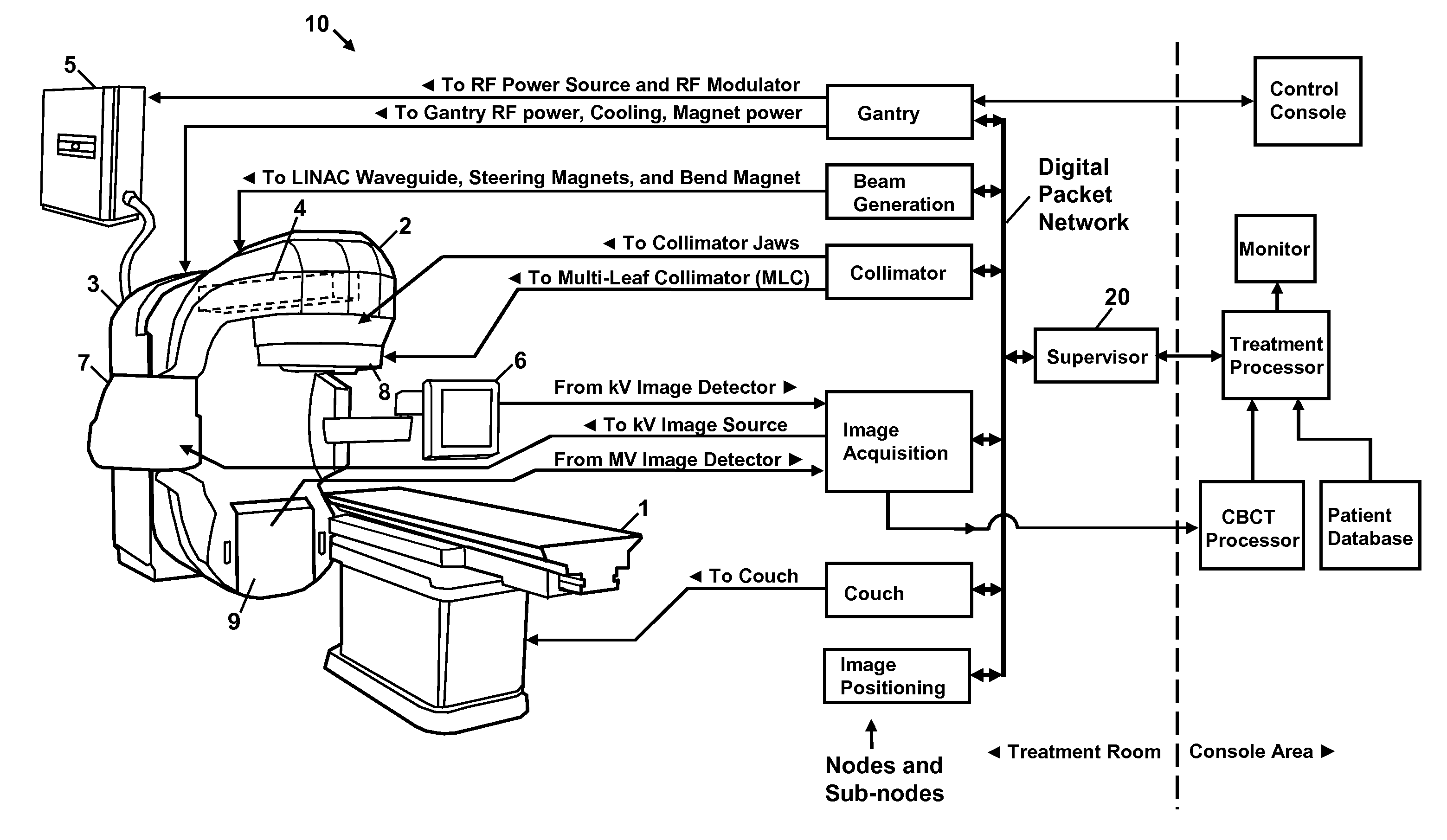

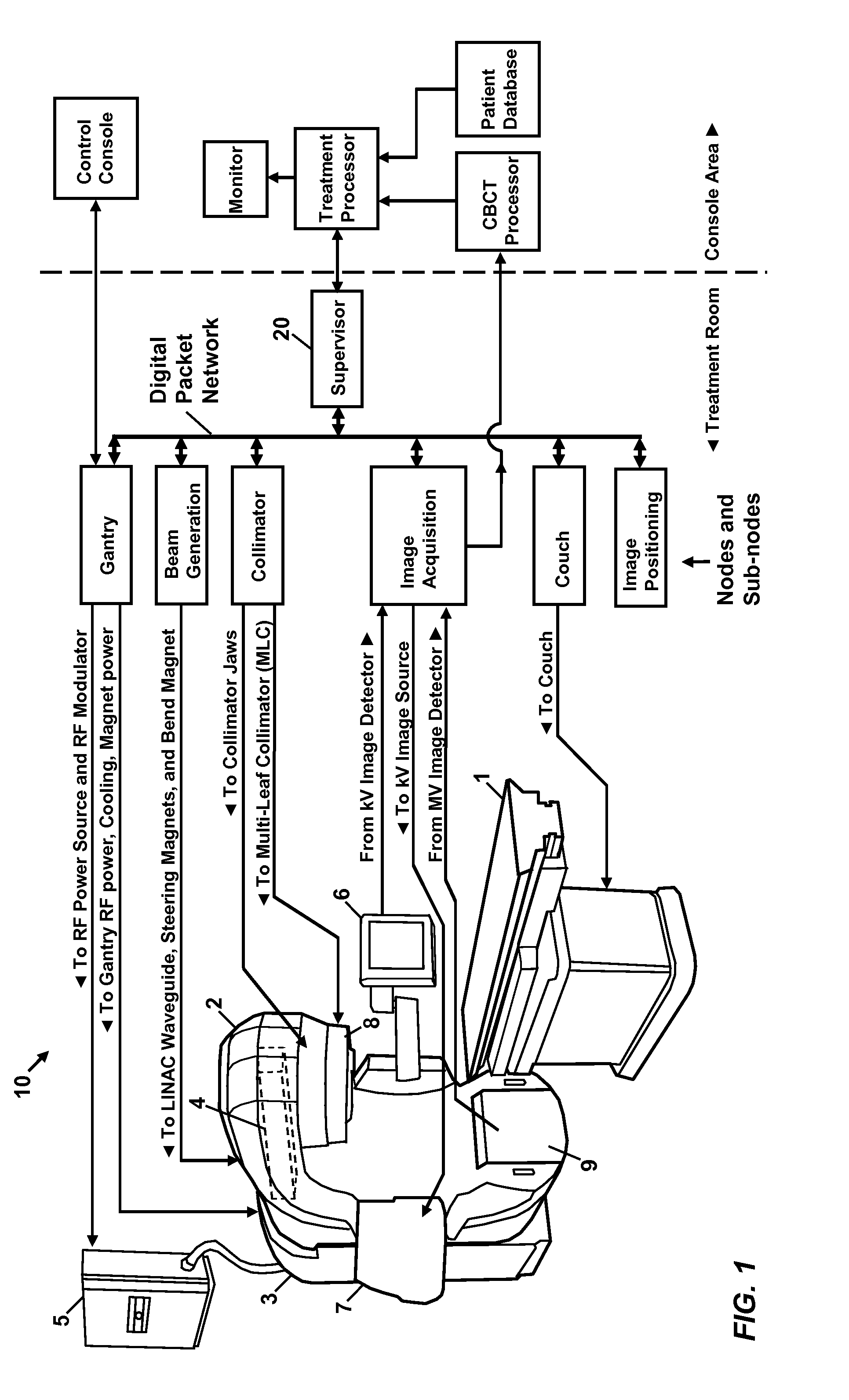

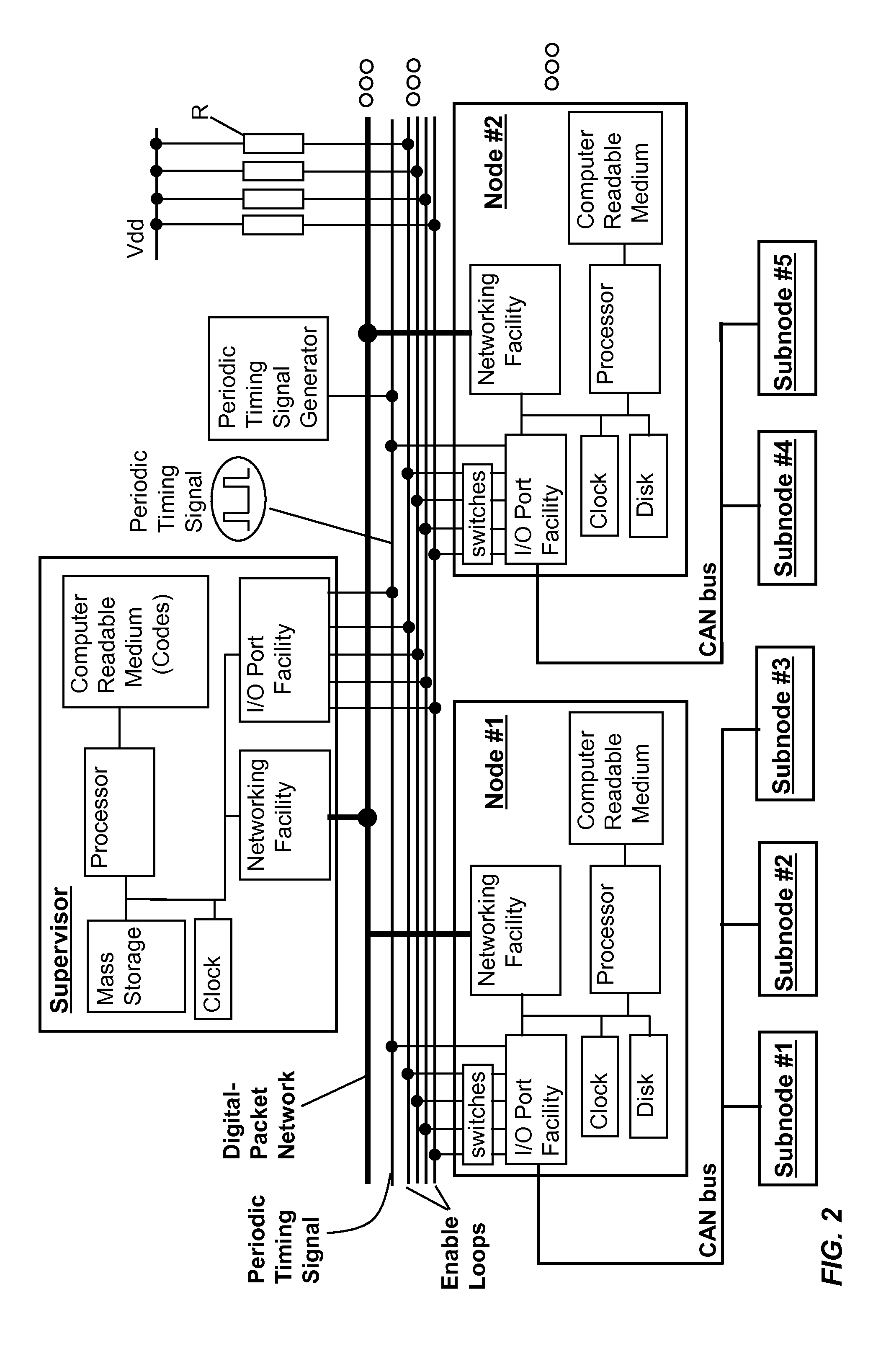

Radiation treatment systems

ActiveUS8992404B2Increased ability to withstand interfering effectReduce flux densityRadiation/particle handlingElectrode and associated part arrangementsElectricityComputer science

Owner:VARIAN MEDICAL SYSTEMS +1

Compact heteropolar hybrid alternator-motor

InactiveUS7105979B1Good heat transferSpeed capability be reduceWindingsMagnetic circuit rotating partsDynamoEngineering

A brushless hybrid electrical machine for converting between electrical and mechanical energy has a rotor supported for rotation about an axis of rotation relative to a juxtaposed stator that is stationary and magnetically interacts with the rotor. The rotor includes a ferromagnetic rotor structure having two portions spaced apart, but rotating together, and defining therebetween an armature air gap. Magnetic poles are arranged in a circumferentially alternating array of ferromagnetic and permanent magnet poles, bordering the air gap. A stationary air core armature having multiple phase windings is located in the armature air gap, and a field coil is also positioned between the two portions of the rotor for generating field coil flux that flows in a flux path through the ferromagnetic poles, the armature air gap and through the ferromagnetic rotor structure. The permanent magnet poles generate permanent magnet flux that also flows in a flux path through the armature air gap and through the ferromagnetic rotor structure. The field coil flux and the permanent magnet flux induces an AC voltage in the multiple phase windings of the air core armature as said rotor rotates.

Owner:REVOLUTION ELECTRIC MOTOR +1

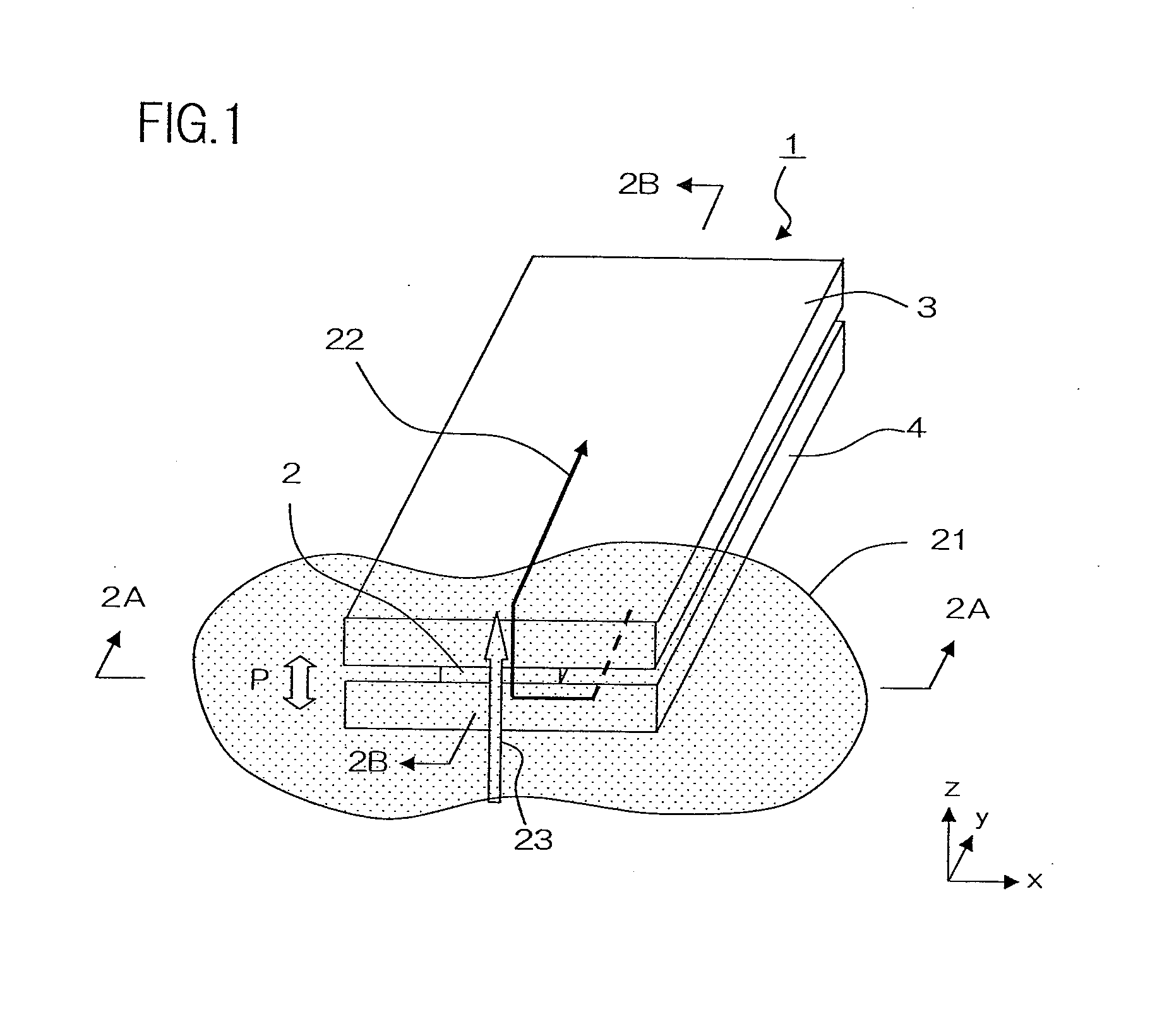

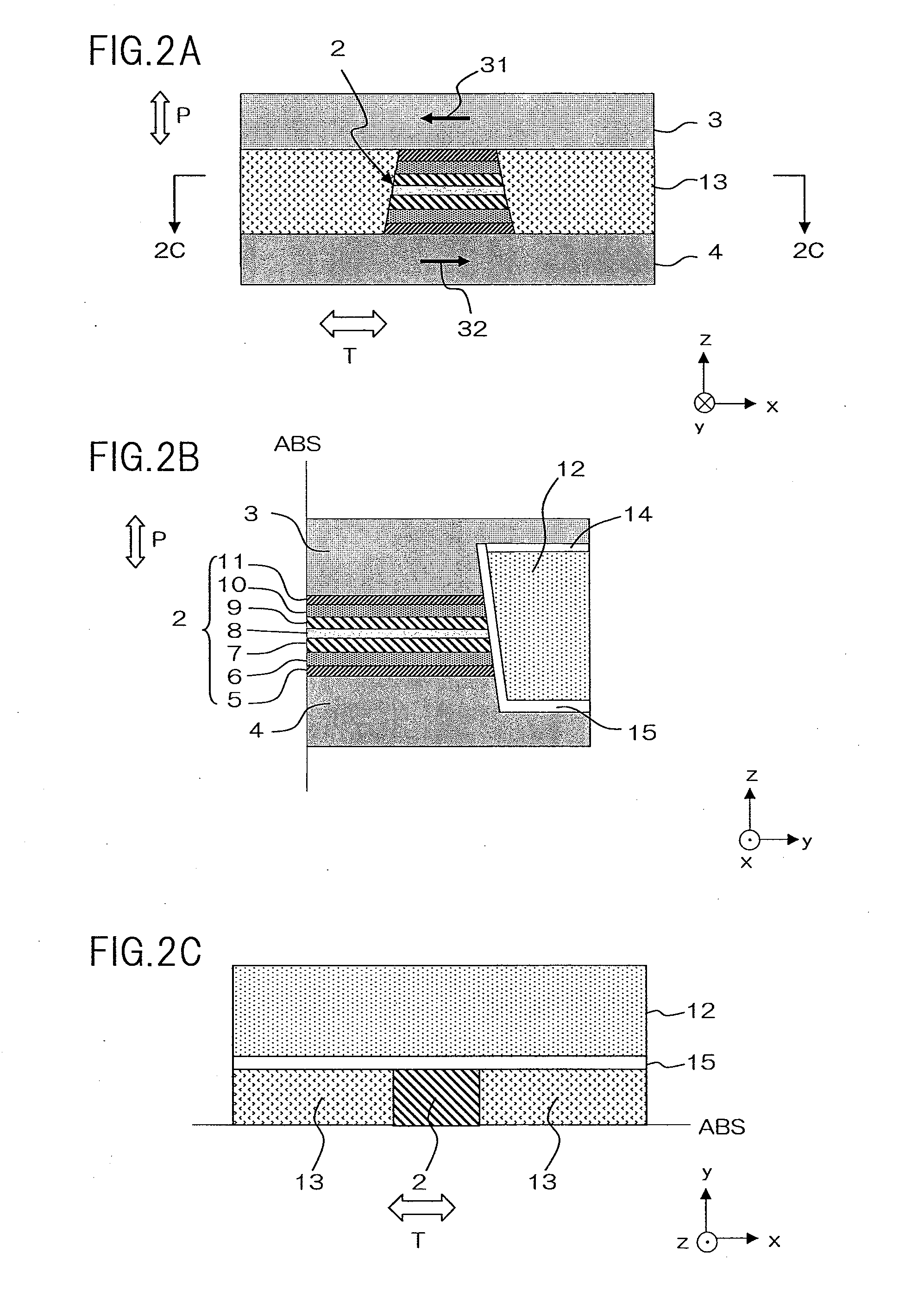

Magneto-resistance effect element including stack with dual free layer and magnetized shield electrode layers

InactiveUS20090207534A1Easy to detectImprove shielding effectNanomagnetismMagnetic measurementsInter layerCoupling

A magneto-resistance effect element comprises; a magneto-resistance effect stack including an upper magnetic layer and a lower magnetic layer in which respective magnetization directions change in accordance with an external magnetic field, a non-magnetic intermediate layer sandwiched between the upper and lower magnetic layers, an upper gap adjustment layer and a lower gap adjustment layer provided at respective ends in the direction of stacking the magneto-resistance effect stack, an upper exchange coupling transmission layer configured to generate exchange coupling between the upper magnetic layer and the upper gap adjustment layer, and a lower exchange coupling transmission layer configured to generate exchange coupling between the lower magnetic layer and the lower gap adjustment layer; an upper shield electrode layer and a lower shield electrode layer which are provided to sandwich the magneto-resistance effect stack therebetween in the direction of stacking the magneto-resistance effect stack, wherein the upper shield electrode layer and the lower shield electrode layer supply sense current in the direction of stacking, and magnetically shield the magneto-resistance effect stack; and a bias magnetic layer which is provided on a surface of the magneto-resistance effect stack opposite to an air bearing surface, and wherein the bias magnetic layer applies a bias magnetic field to the upper and lower magnetic layers in a direction perpendicular to the air bearing surface, wherein the upper and lower shield electrode layers are each magnetized in a track width direction by a magnetization controller, and the upper and lower gap adjustment layers are composed of a material having a higher magnetic permeability and a lower saturation magnetic flux density than the upper and lower shield electrode layers respectively.

Owner:TDK CORPARATION

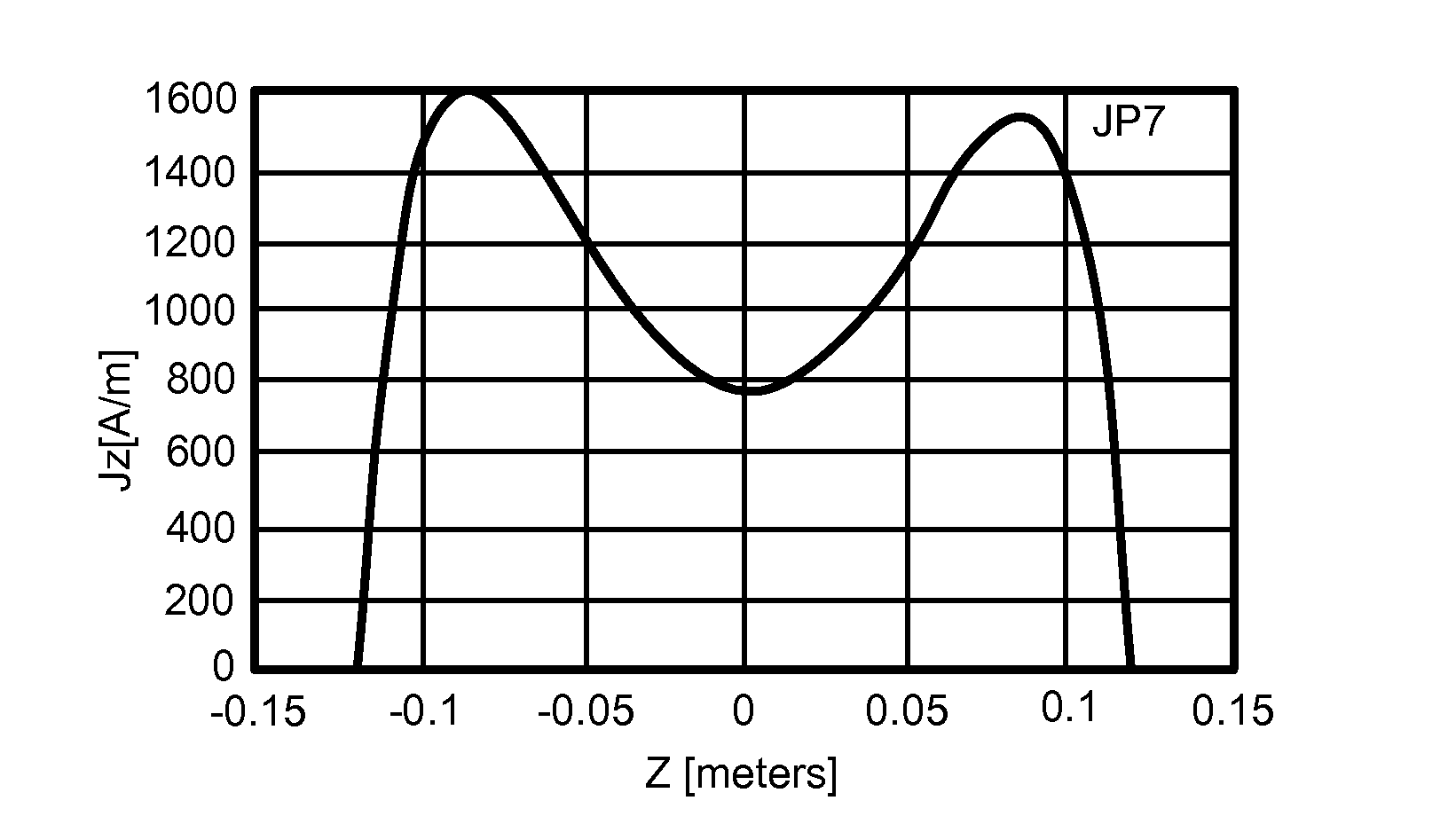

Optimized air core armature

InactiveUS20060038461A1Improve efficiencyStrong power capabilityWindingsMagnetic circuit rotating partsMagnetic polesAir core

An air core motor-generator has a rotor that is journalled to rotate about an axis of rotation, and a stator that is stationary and magnetically applies torque to the rotor. The rotor has magnetic poles that drive magnetic flux across an armature airgap, and the stator has an air core armature located in the armature airgap. Windings on the armature cause AC voltage to be induced in the windings as the rotor rotates. The windings include active length portions that are located in the armature airgap to receive the magnetic flux and induce the AC voltage, and end turn portions that traverse circumferentially and connect together the active length portions. The magnetic poles have a circumferential pole pitch, Y, and the active length portions of the windings having an active length circumferential width of a single phase, X, such that 0.5 Y<X<Y.

Owner:REVOLUTION ELECTRIC MOTOR

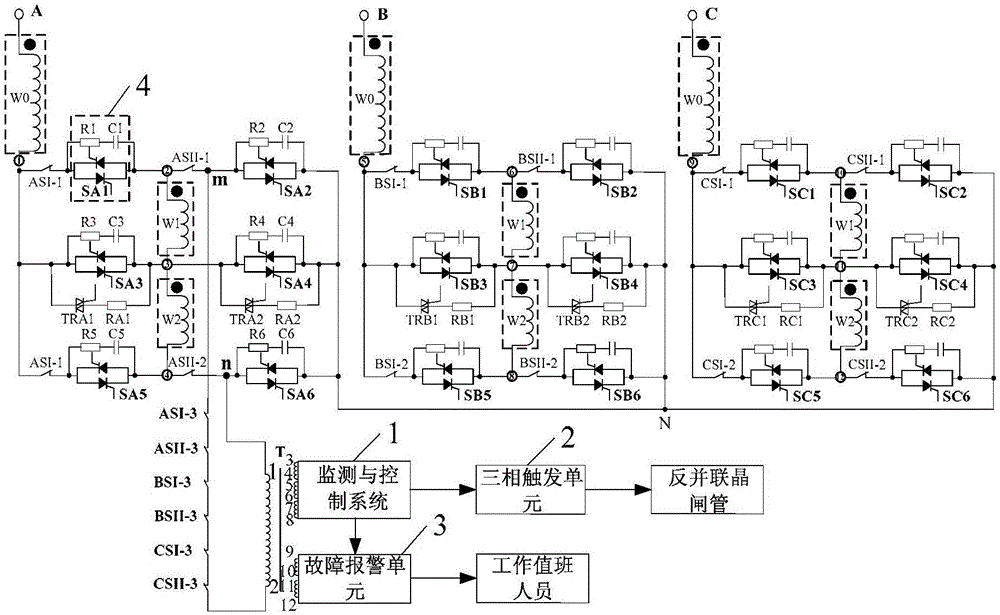

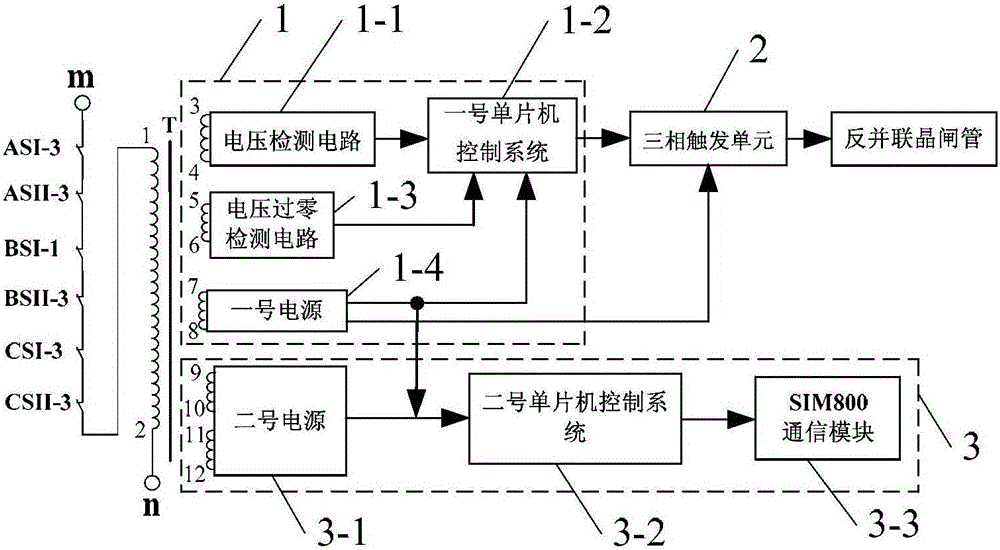

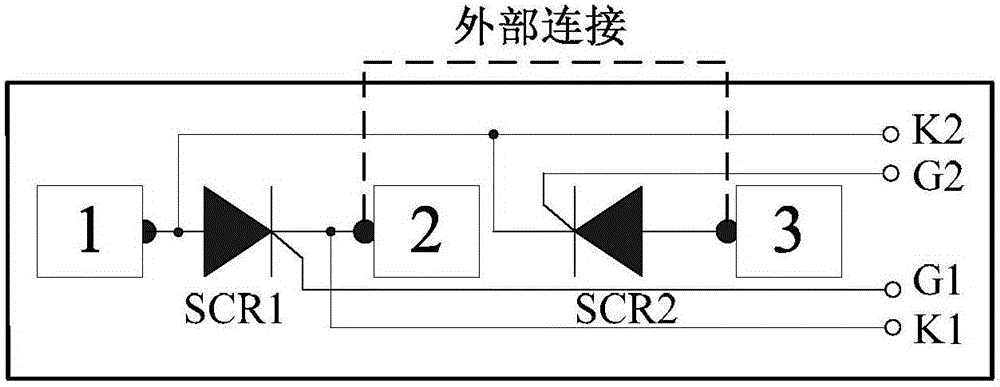

Contactless on-load automatic positive and negative voltage regulating tap switch device for three-phase distribution transformer

ActiveCN105826063AReduce withstand voltageTo achieve the purpose of on-load voltage regulationVariable inductancesElectronic switchingLow voltageDistribution power system

The invention discloses a contactless on-load automatic positive and negative voltage regulating tap switch device for a three-phase distribution transformer and relates to the technical field of electric engineering. The problems that the contactless on-load voltage regulating range is small and power supply reliability is poor due to the fact that an existing power electronic element is low in voltage resistance can be solved. An antiparallel thyristor is used as a switching tap switch device, on-load voltage regulation is carried out in a positive and negative voltage regulation mode, a low-voltage air switch is used as a circulating current protecting device, and on-off of the tap switch is controlled through a monitoring and control system and a trigger unit. When the tap switch breaks down, an air switch trips out, a fault current is cut off, meanwhile, a power source of an isolation transformer is cut off, the on-load voltage regulating function exits, and the distribution transformer is automatically recovered to a rated tap to continue to supply power to a user; meanwhile, a fault alarm unit automatically sends a short message to a transformer manager through a mobile communication network to inform the transformer manager that the on-load automatic positive and negative voltage regulating tap switch is in the abnormal operation stage, and therefore fault removal is carried out at the right moment. The contactless on-load automatic positive and negative voltage regulating tap switch device is used for a power distribution system.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

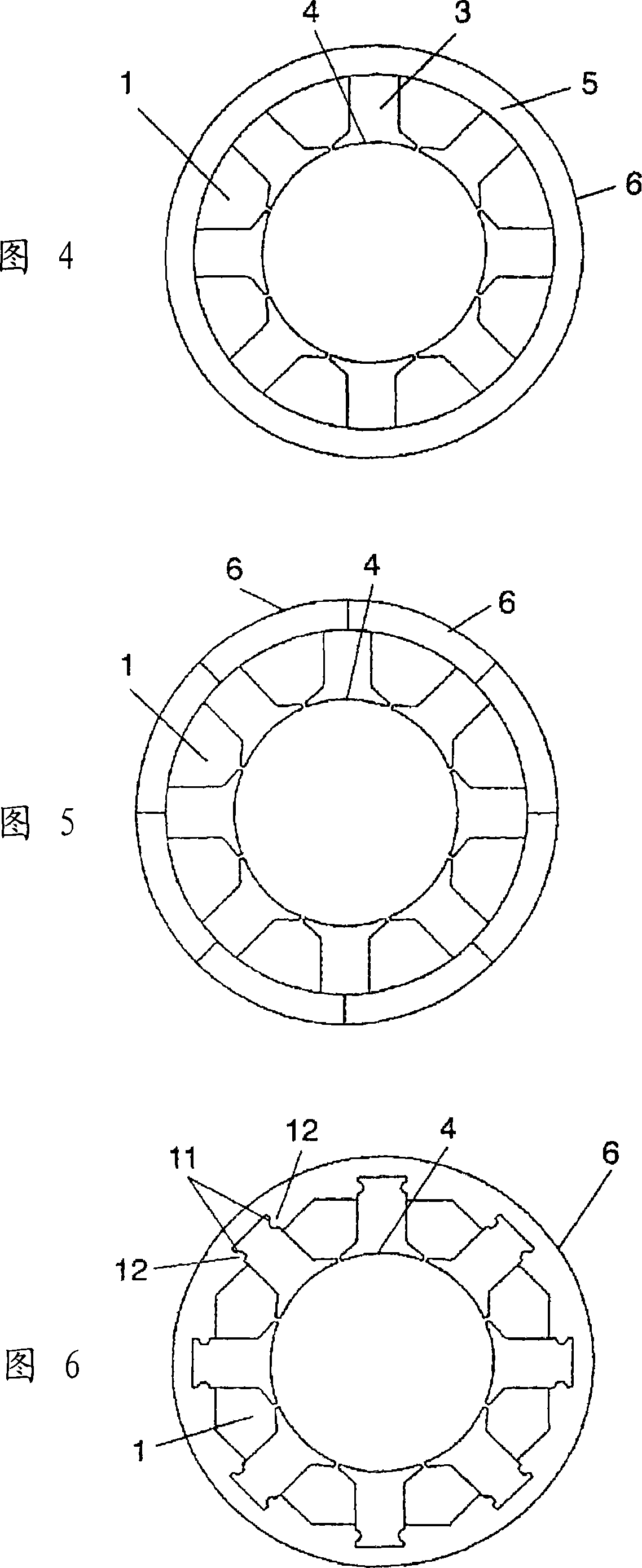

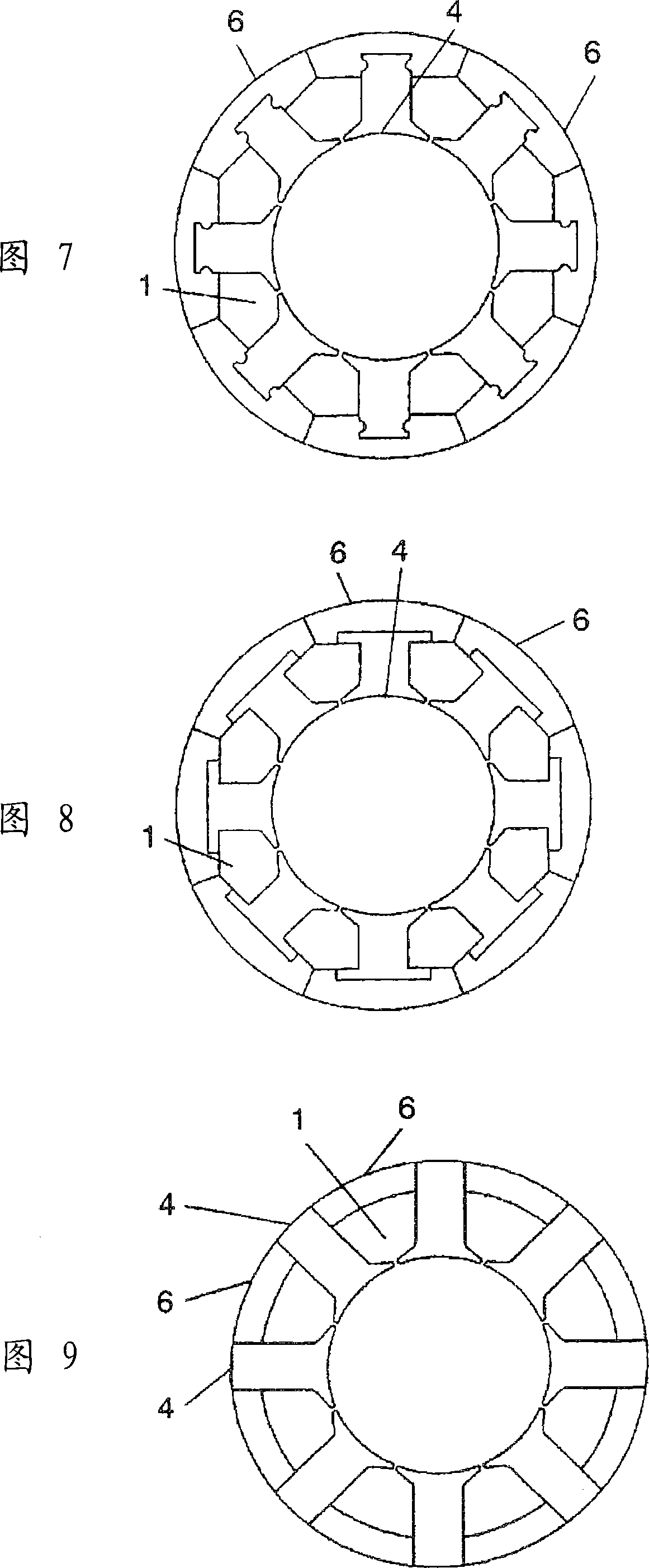

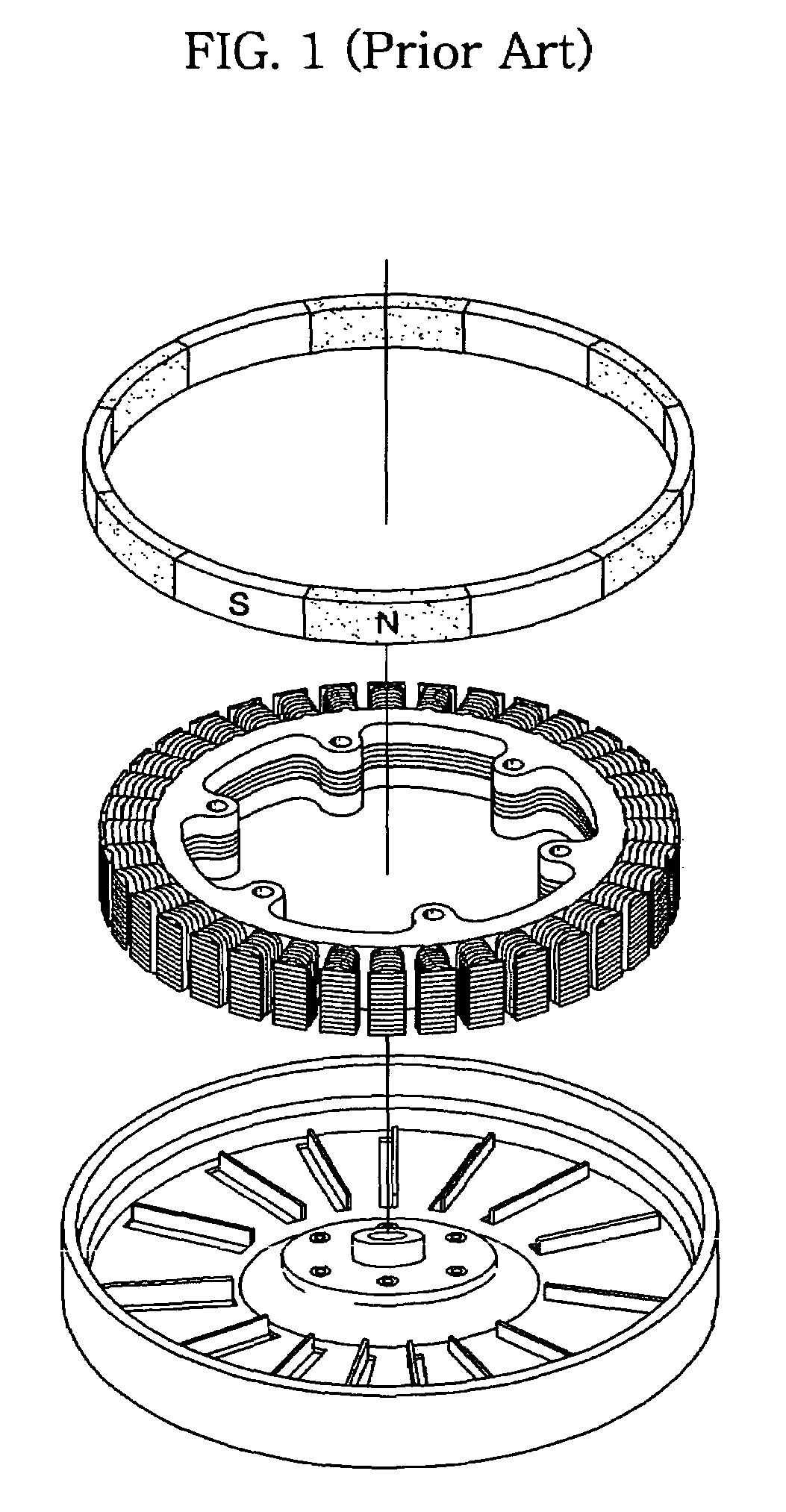

Capacitor motor and process for producing the same

InactiveCN101243594AImprove efficiencyIncrease the cross-sectional areaMagnetic circuit stationary partsMagnetic circuit characterised by magnetic materialsPunchingConductor Coil

A capacitor motor which comprises a stator having stator iron cores and winding wires and a rotor having rotor iron cores, wherein the stator iron cores are composed of first divided iron cores having teeth and second divided iron cores forming magnetic paths for these first divided iron cores, and the winding wires are fitted to the teeth and housed in slots formed by the first divided iron cores and second divided iron cores. The first divided iron cores each is formed by superposing electromagnetic steel sheets formed by punching, while the second divided iron cores each is formed by molding magnetic particles into a given shape. The first divided iron cores are bonded to the second divided iron cores by a given means so that the teeth are radially formed along the outer periphery of the rotor iron cores.

Owner:PANASONIC CORP

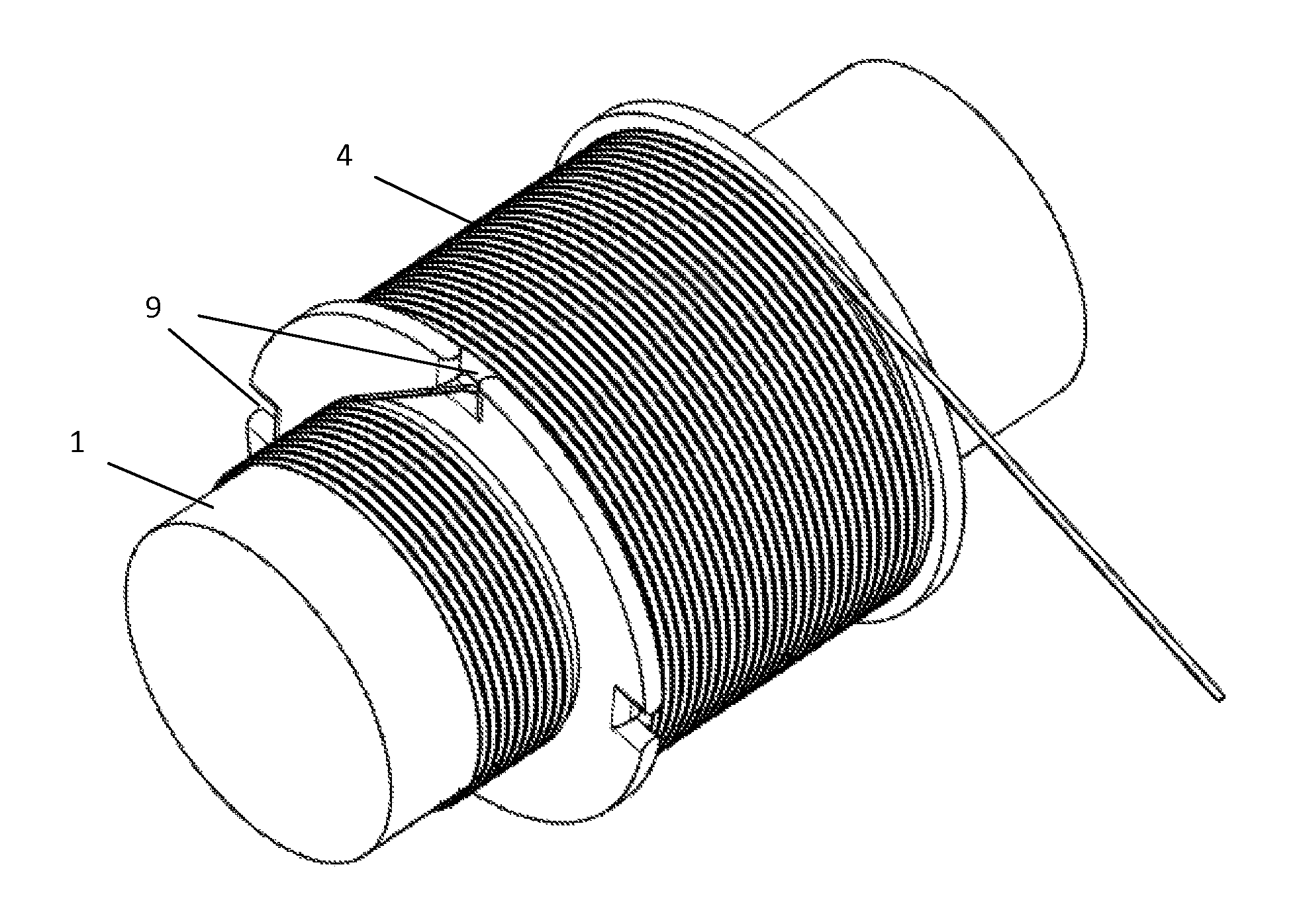

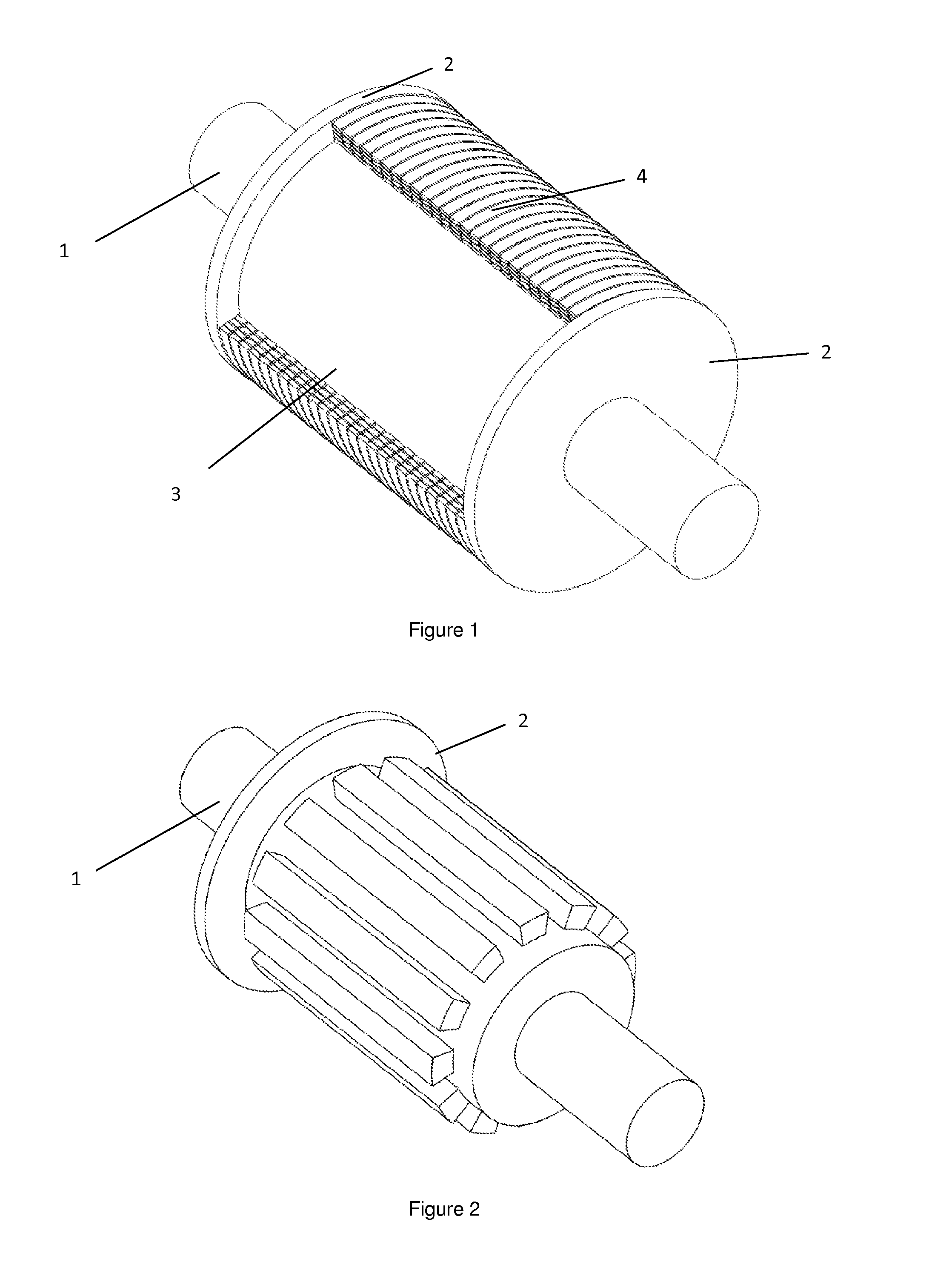

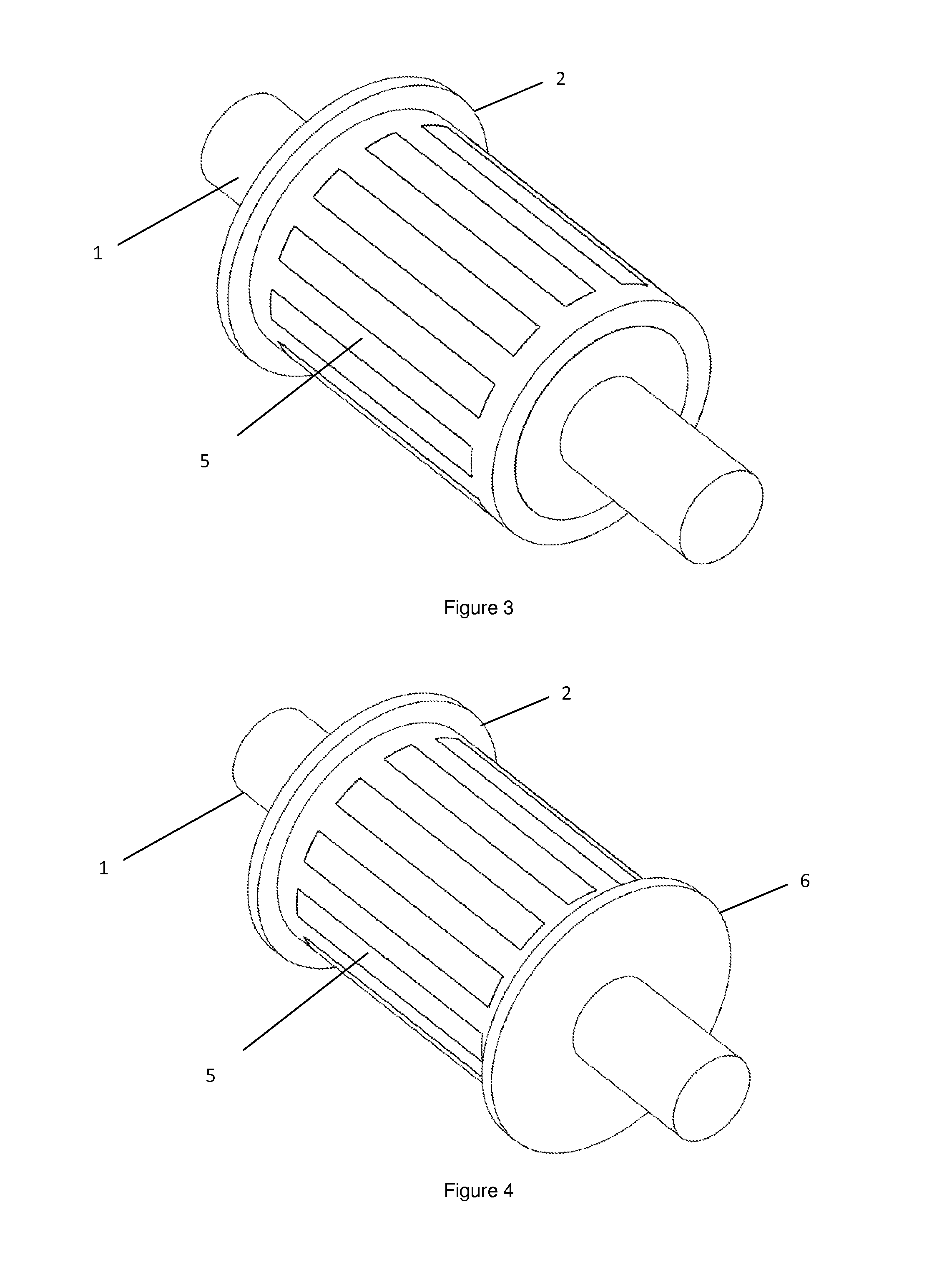

Method of manufacturing multilayer metal wire or ribbon bandage over operational zone of rotor

ActiveUS9130437B1High pulsationReduce effectWindingsMagnetic circuit rotating partsMagnetic coreBandage

A manufacturing method for permeable bandages and magnetic cores for rotors of electrical machines is proposed. The proposed method relies on winding with insulated metal preferably permeable wire or ribbon with high pretension and maintaining pretension in the wire or ribbon during manufacturing steps. The proposed method could be especially useful for high-speed electrical machines.

Owner:PULNIKOV SERGEY

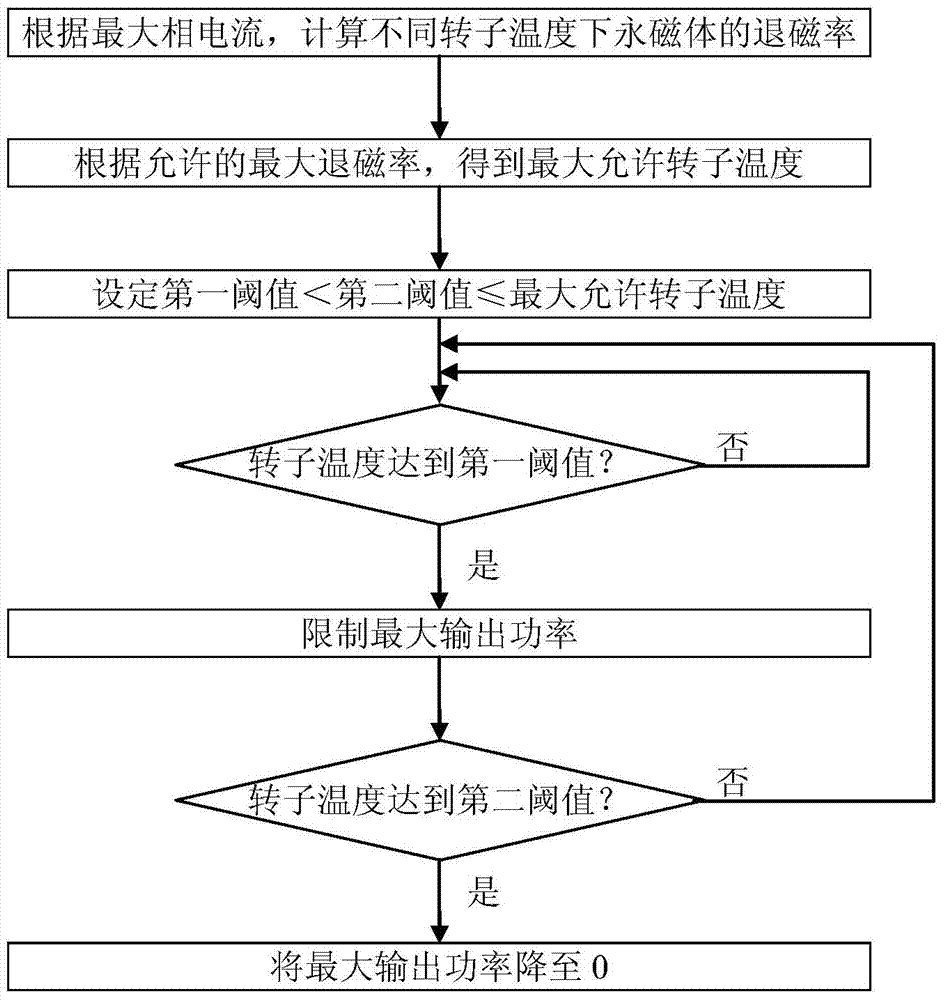

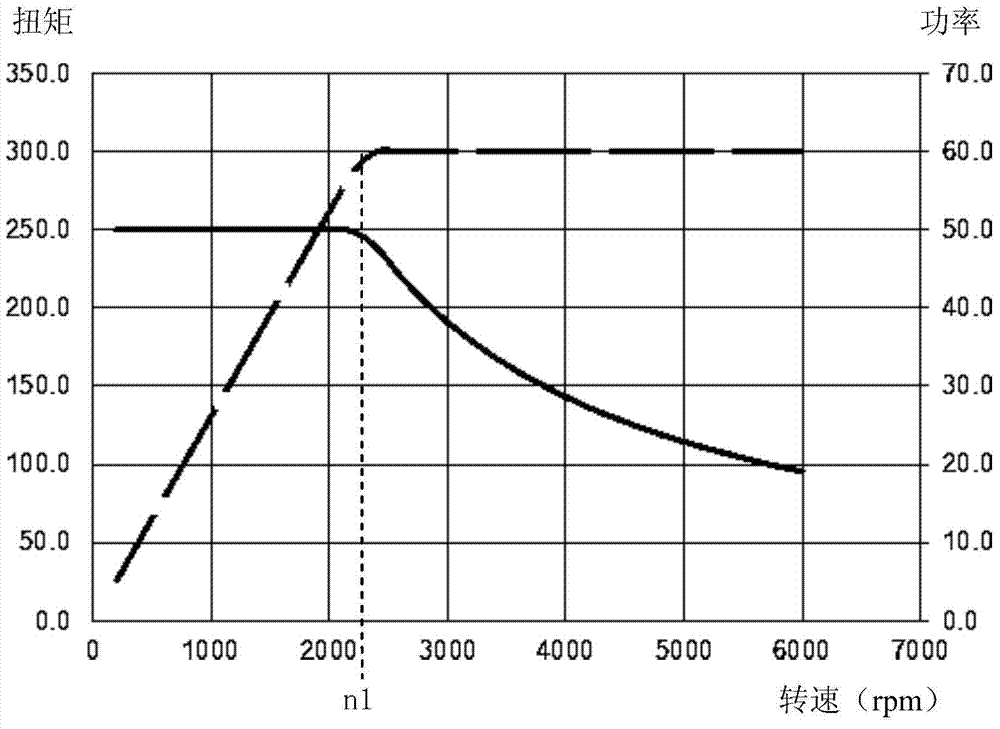

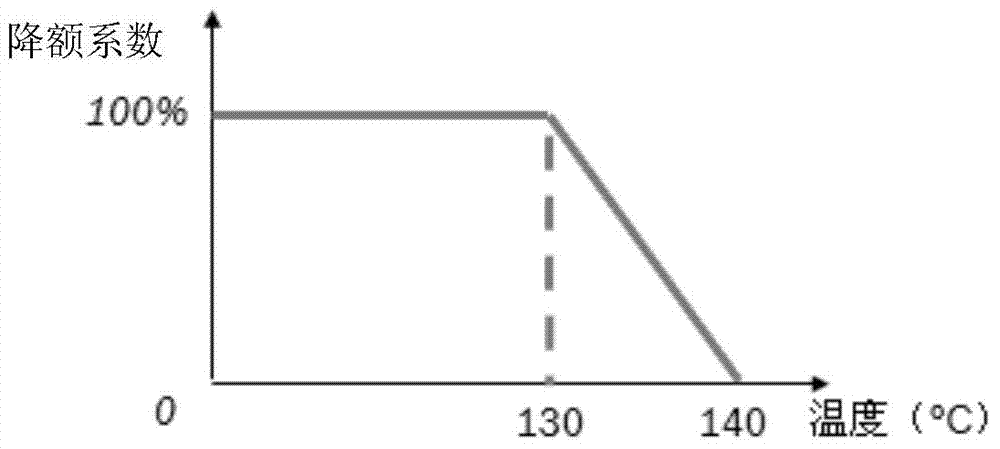

Derating control method for permanent magnet synchronous motor

ActiveCN103762911AReduce flux densityReduce performanceSingle motor speed/torque controlMaximum torqueOvertaking

The invention discloses a derating control method for a permanent magnet synchronous motor. The method includes the first step of recording the instantaneous peak current of the permanent magnet synchronous motor from a normal working mode to an invalid response mode under the conditions of different rotation speeds and constant maximum torque, the second step of recording degaussing rates at different rotor temperatures according to the instantaneous peak current at each rotation speed, the third step of obtaining the maximum allowable rotor temperature at each rotation speed according to the maximum allowable degaussing rate, the fourth step of setting derating coefficients for each rotation speed and each rotor temperature, and the fifth step of limiting the maximum output torque and the maximum output power according to the derating coefficients set at the fourth step and the current rotation speed and rotor temperature. The derating control method is especially suitable for the permanent magnet synchronous motors on new energy automobiles, can ensure that the residual magnetic flux density of permanent magnets does not exceed a certain scope and can meet the requirements for climbing at low speed and overtaking at high speed.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

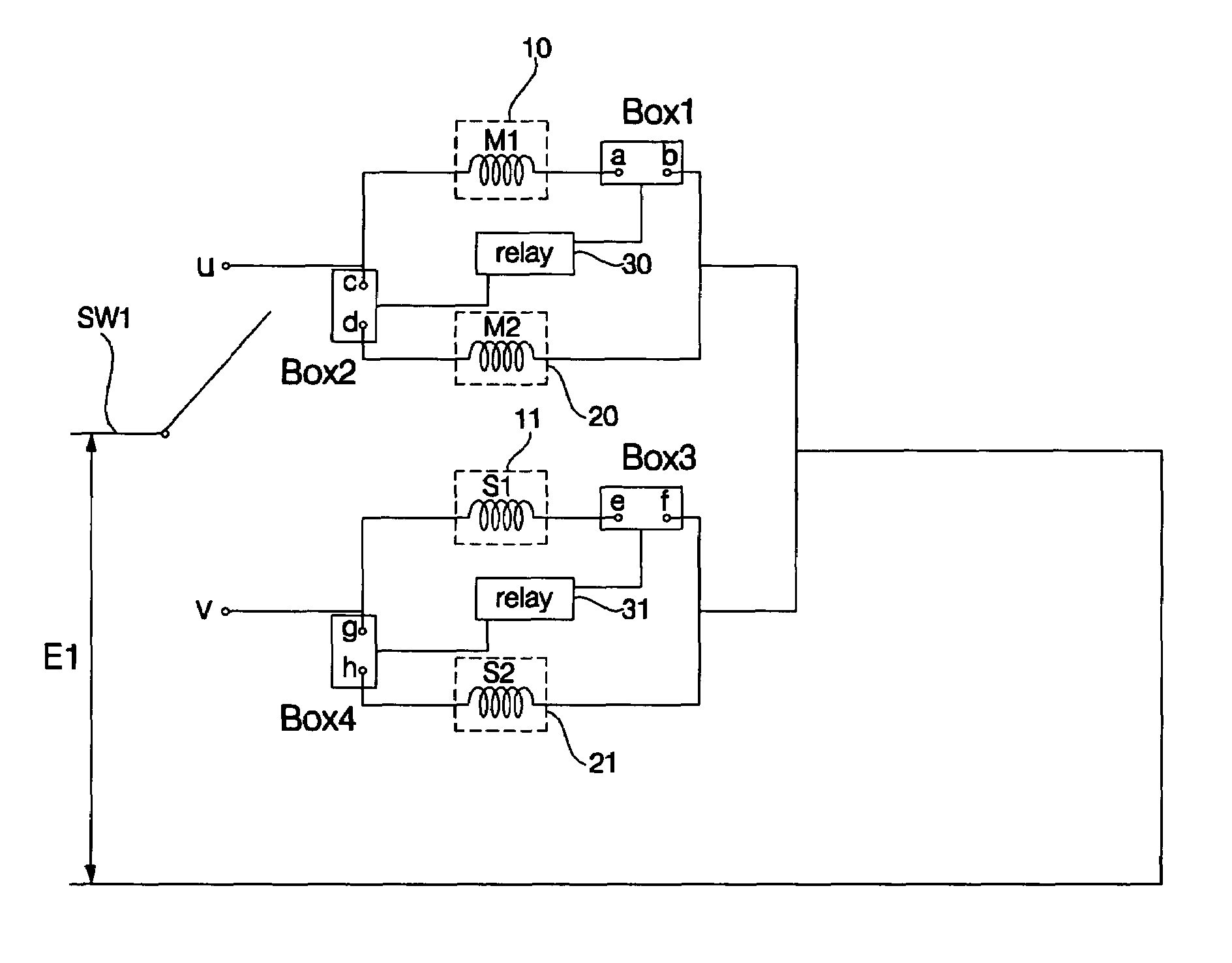

Variable speed motor

ActiveUS7196490B2Low production costReduce electromagnetic vibration noiseSingle-phase induction motor startersMotor/generator/converter stoppersMotor speedEngineering

A variable speed motor includes first and second main windings wound on a stator, and a relay for performing a switching operation between serial / parallel connections of the first and second main windings to control motor speed. The variable speed motor further includes a tap winding connected in series to the main windings, or an additional capacitor, such that it can greatly extend the range of a variable speed without using a drive unit capable of changing the motor speed at an external location, resulting in reduced production costs of the motor, reduced electromagnetic vibration noise, and reduced power consumption.

Owner:LG ELECTRONICS INC

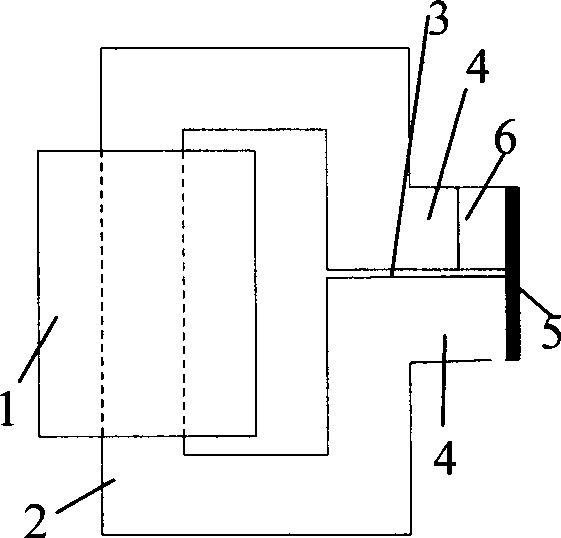

Electrodynamic electroacoustic transducer and electronic device

ActiveUS7885425B2Improve performanceReduce flux densityTransducer detailsDeaf-aid setsTransducerMagnetic poles

An electrodynamic electroacoustic transducer comprises: a first magnetic pole; a second magnetic pole that forms a magnetic gap between itself and the first magnetic pole and is arranged in a space excluding spaces in upper and lower face directions of the first magnetic pole; a yoke; a diaphragm; and a voice coil. The yoke magnetically couples one magnetic pole face of the first magnetic pole with one magnetic pole face of the second magnetic pole so as to support them. The diaphragm is arranged in a space in an upper face direction of the first magnetic pole and in a space in a lower face direction of the second magnetic pole, while its outer periphery is supported by the yoke. The voice coil is arranged in the magnetic gap and adhered to the diaphragm. At least one of the first magnetic pole part and the second magnetic pole part includes a magnet.

Owner:PANASONIC CORP

Inductor and switching circuit including the same

InactiveUS20150069853A1Reduce eddy-current lossImprove non-linear inductance graphsTransformersTransformers/inductances magnetic coresInductorConductor Coil

The present disclosure provides an inductor and a switching circuit including the inductor. The inductor at least includes a winding, and a magnetic core which includes one or more limbs and further includes one or more yokes adapted to form a closed magnetic path, the winding being wounded on the limbs. A gap is provided between at least one end of at least one of the limbs and at least one of the yokes, a flat magnetic core unit is provided in the gap, the flat magnetic core unit is formed of a material having a high permeability and a low saturation magnetic flux density, the limbs and yokes are formed of a material having high permeability and high saturation magnetic flux density, and the saturation magnetic flux density of the material of the flat magnetic core unit is lower than that of the material of the limbs and yokes.

Owner:DELTA ELECTRONICS (SHANGHAI) CO LTD

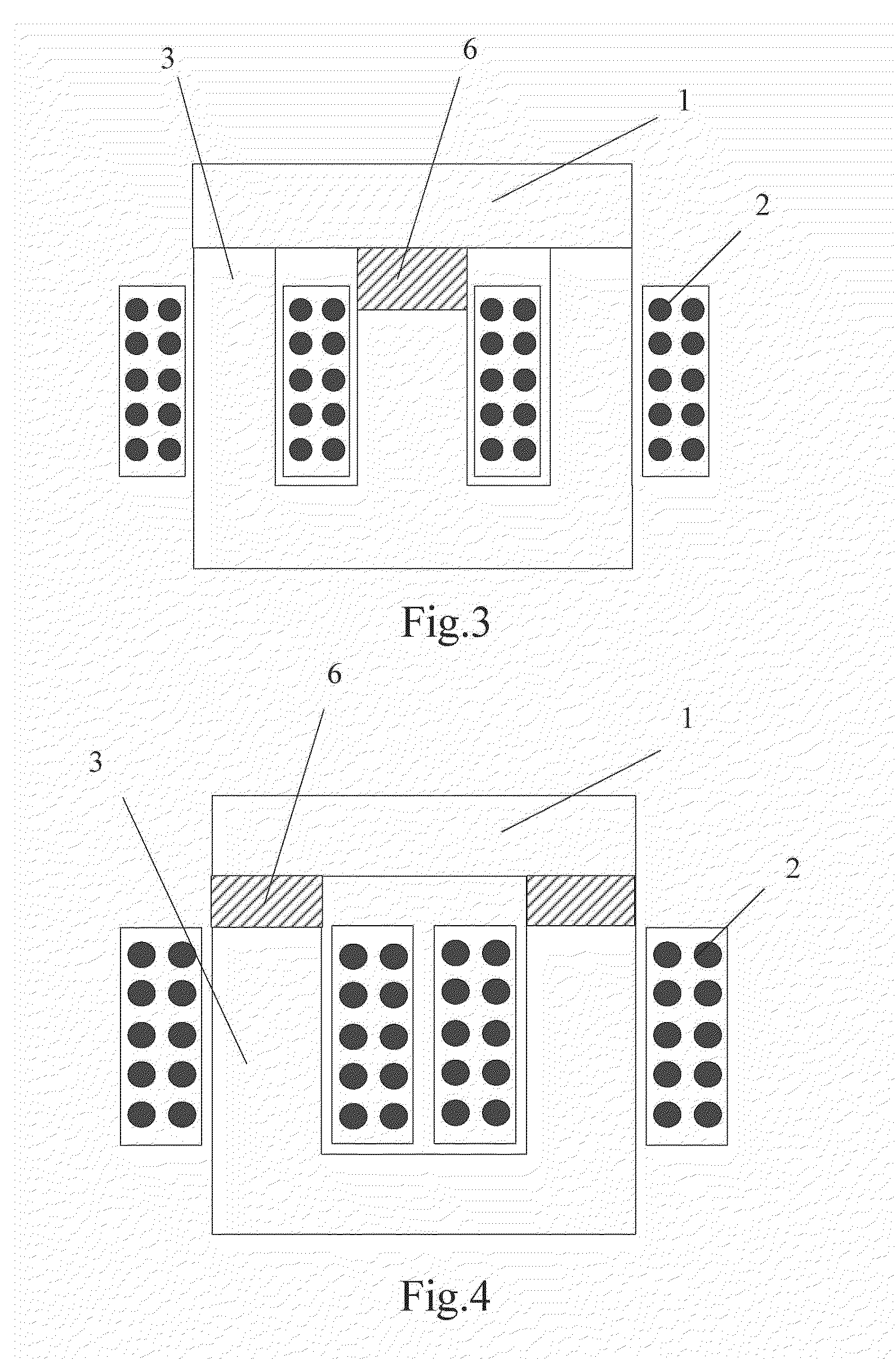

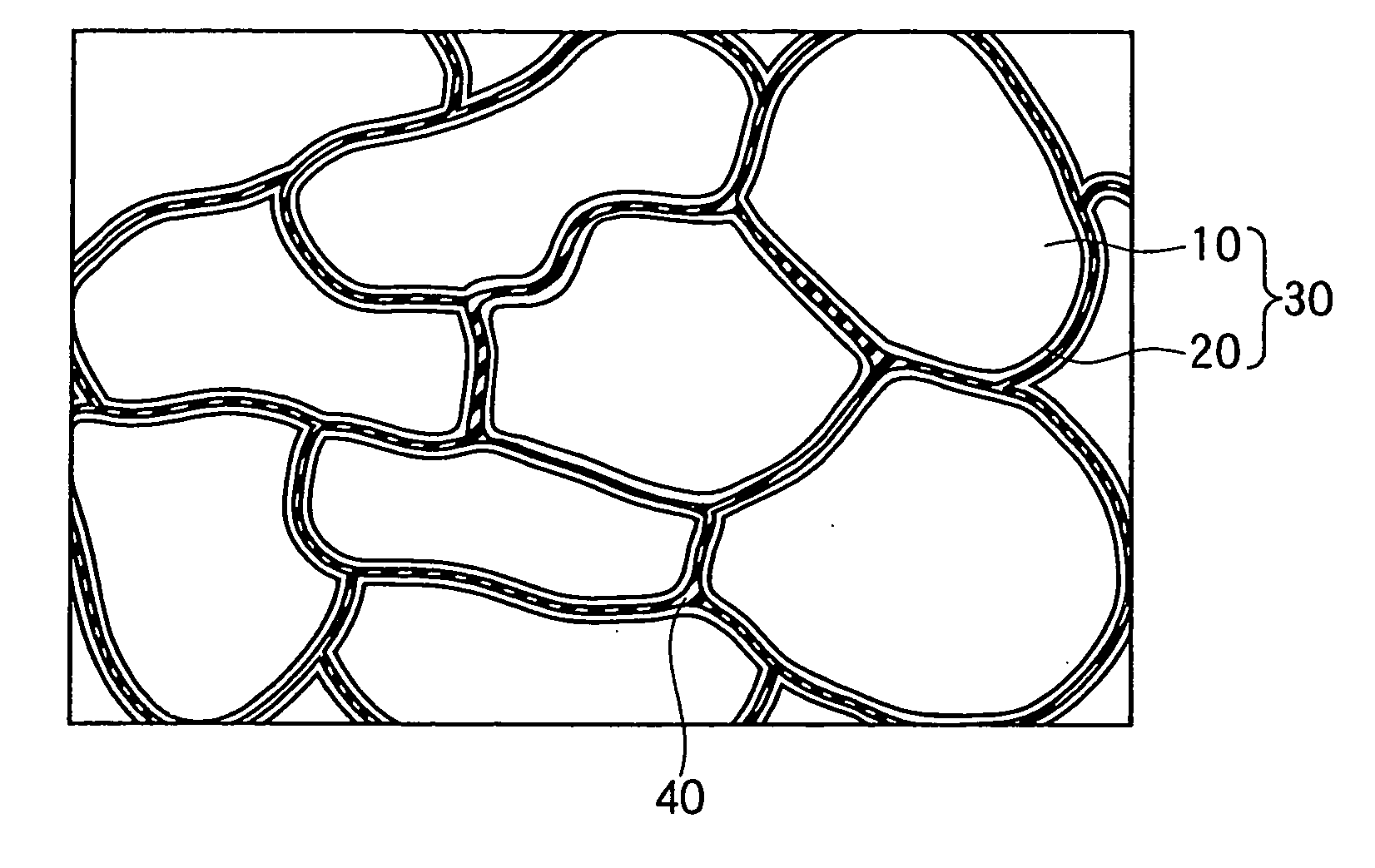

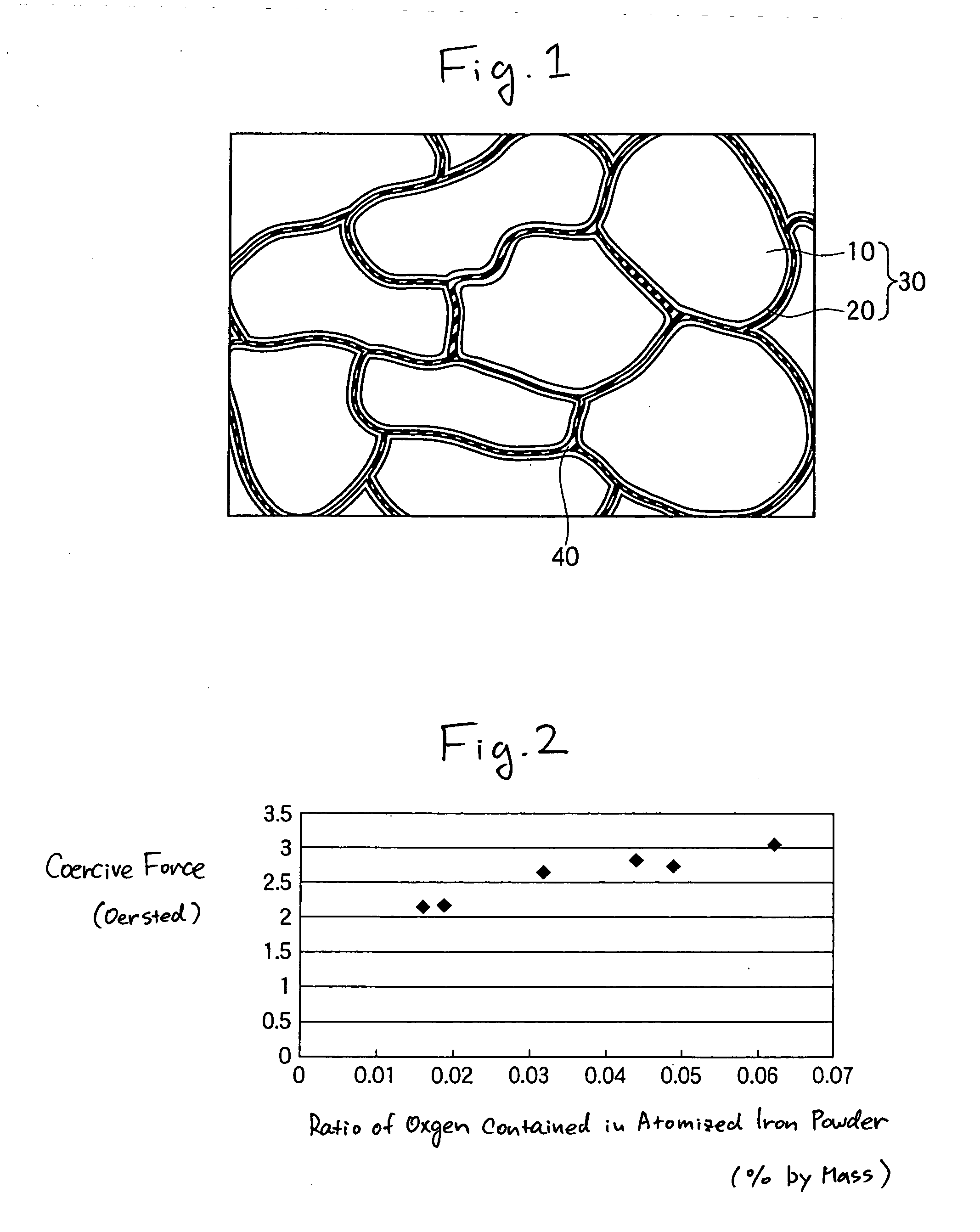

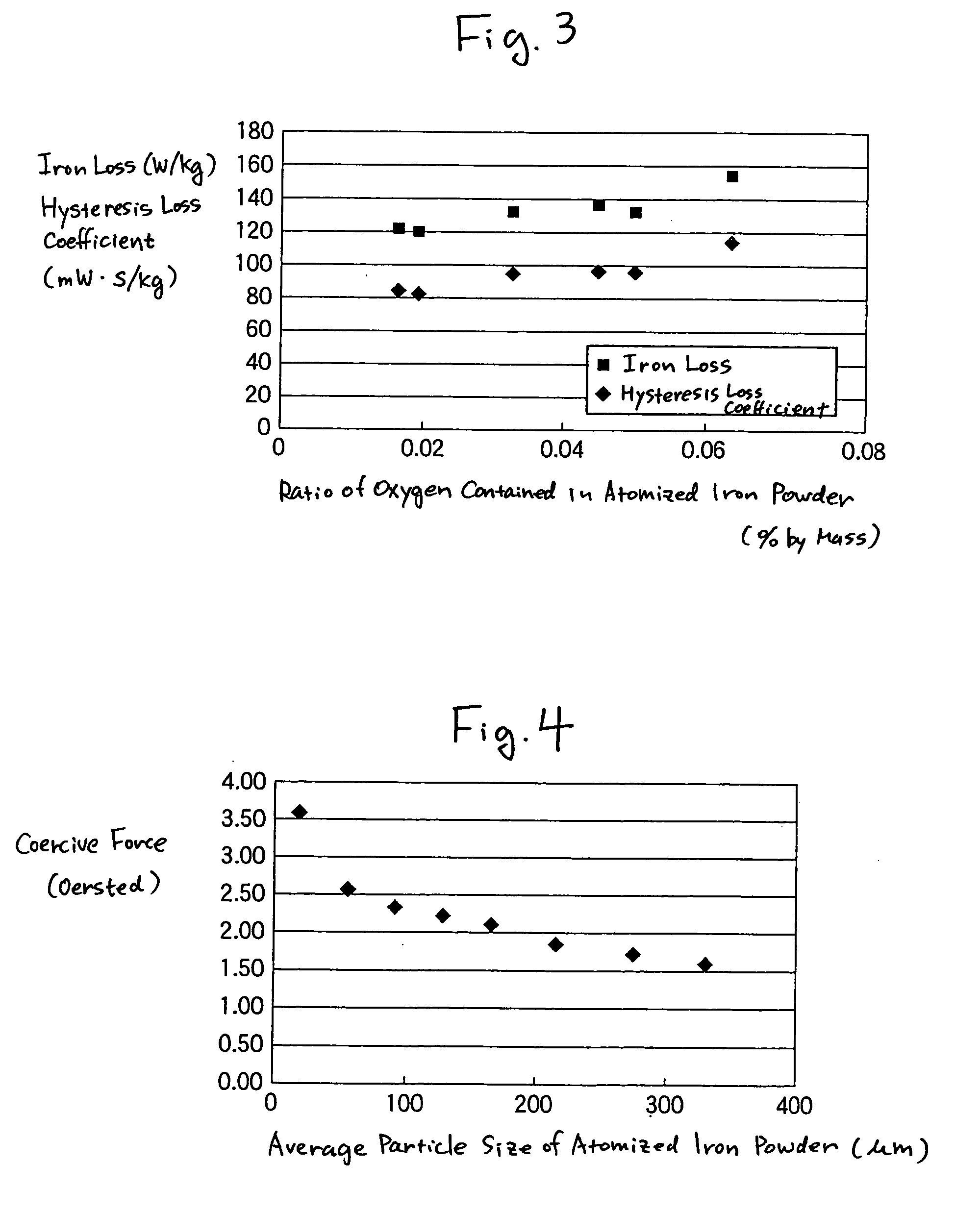

Soft magnetic material and dust core

InactiveUS20070169851A1Low densityReduce flux densityTransportation and packagingMetal-working apparatusMagnetic characteristicOxygen

An object of the present invention is to provide a soft magnetic material exhibiting excellent magnetic characteristics regardless of the frequency to be applied and a dust core produced from the soft magnetic material. The means for solving the invention is a soft magnetic material that comprises metal magnetic particles 10 containing iron and oxygen. The ratio of oxygen contained in metal magnetic particles 10 is more than 0 and less than 0.05% by mass. A dust core produced using such a soft magnetic material has a coercive force of 2.0×102 A / m or less.

Owner:SUMITOMO ELECTRIC IND LTD

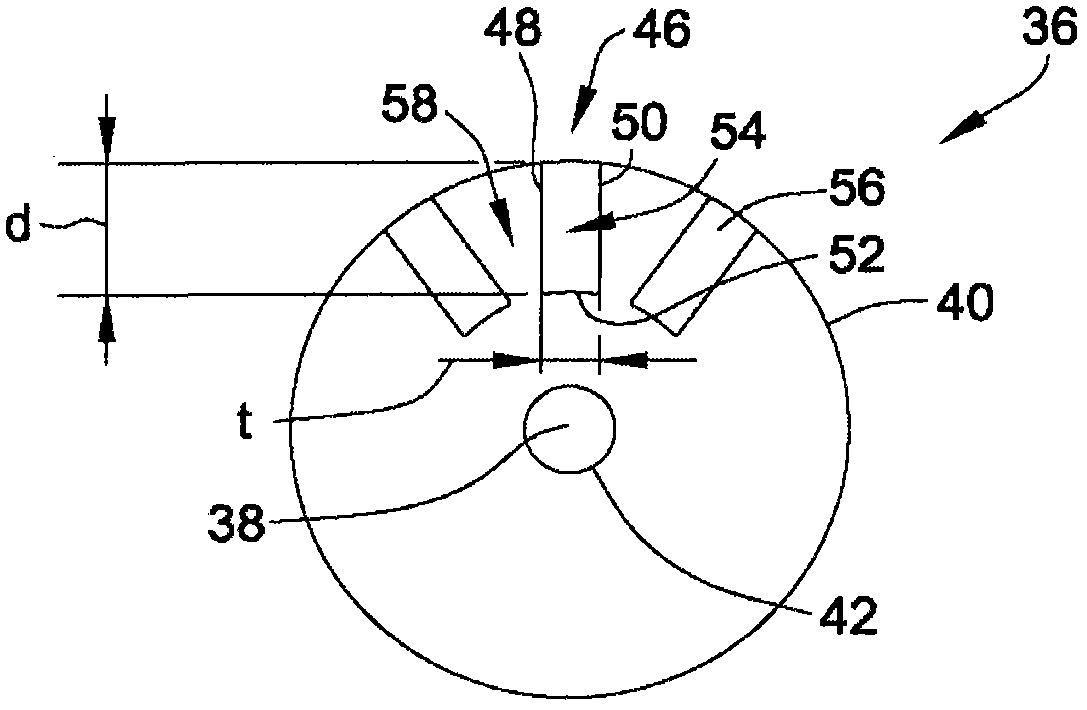

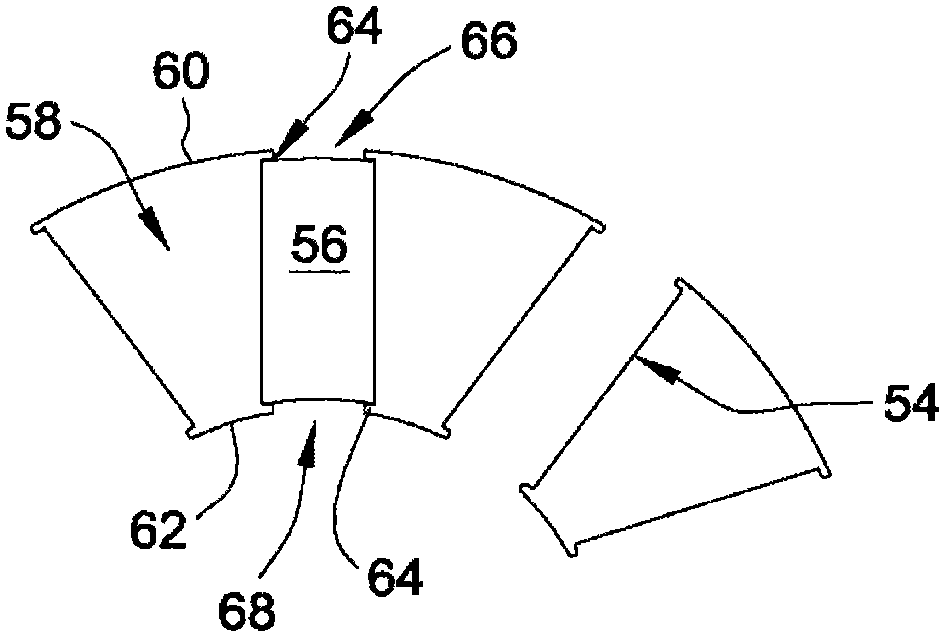

Permanent magnet rotor and method thereof

ActiveCN103795168AReduce flux densityReduced flux outputMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet rotorElectric machine

In one embodiment, an electric machine is provided. The electric machine includes a machine housing and a stator disposed at least partially within the housing. The stator comprises a plurality of teeth and an aluminum winding wound around at least one tooth of the plurality of teeth. The electric machine further includes a radially embedded permanent magnet rotor disposed at least partially within the housing; and the rotor comprises at least one radially embedded permanent magnet and configured to provide increased flux to reduce motor efficiency loss compared to a copper winding.

Owner:REGAL BELOIT AMERICA

Inductance element provided with permanent magnet bias magnet and bypass magnetic core

InactiveCN103578688AReduce core saturationIncrease inductanceTransformers/inductances magnetic coresInductance with magnetic corePhysicsMagnetic core

An inductance element having a permanent magnet bias magnet and a bypass magnetic core comprises a coil, a magnetic core provided with at least one air gap inside the coil, partial bypass soft magnets which are form into the air gap together and a permanent magnet which is in series connection on lateral side of the air gap. According to the inductance element, the coil wraps the magnetic core; at least one air gap is formed in the magnetic core; magnetic core portions, which are close to the air gap, are in series connection with partial bypass soft magnet portions which are provided with the air gap; the permanent magnet is in series connection with an air gap opening, so that the coil magnetic branched circuit, the air gap magnetic branched circuit and the permanent magnet magnetic branched circuit are formed; the permanent magnet for the inductance element performs reverse pre-magnetic-biasing on the coil magnetic branch circuit and the output magnetic energy product of the permanent magnet is adjusted according to the size of the air gap; the direct current component of the coil current and magnetic flux density superposed through synclastic pre-magnetic-biasing of the permanent magnet are reduced, the disadvantages that in a traditional permanent magnet bias magnetic inductance element, magnetic flux density of a synthetic pre-magnetic-biasing branch is increased and inductance value is decreased, the inductance value and power density of the inductance element under certain direct current bias current are improved due to the fact that the length of partial bypass soft magnets is one fifth of the length of a main magnetic circuit.

Owner:NANCHANG HANGKONG UNIVERSITY

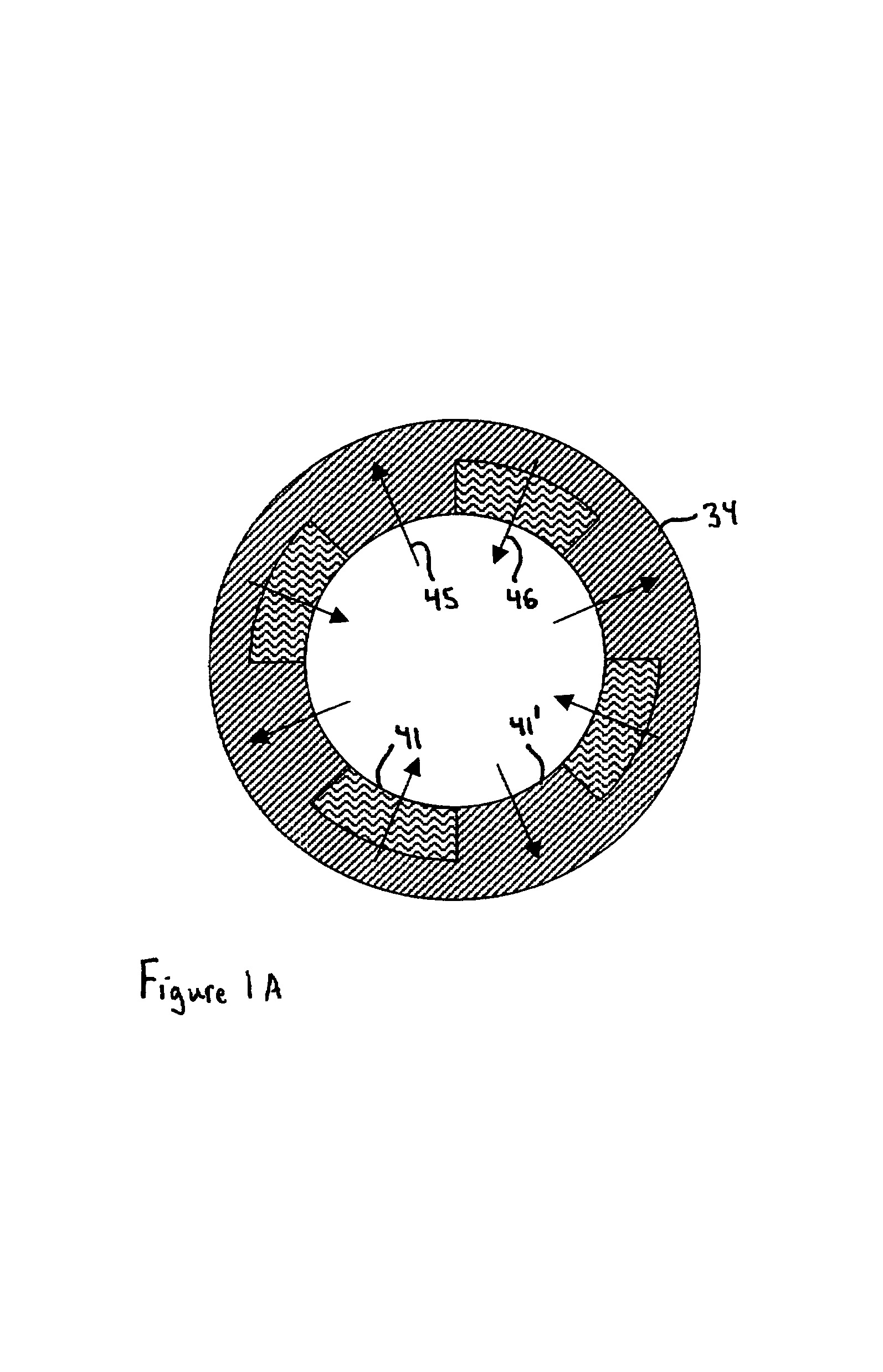

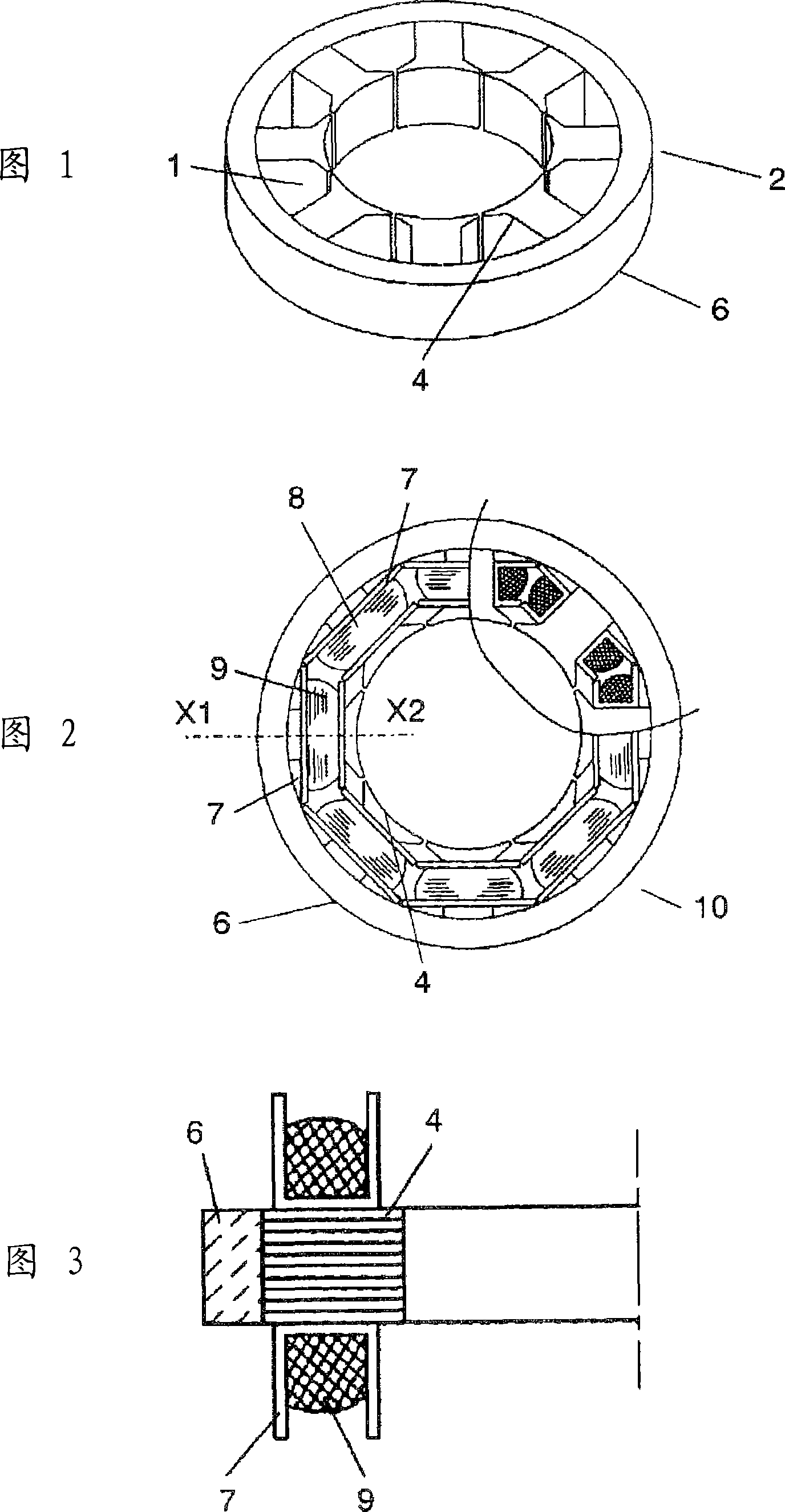

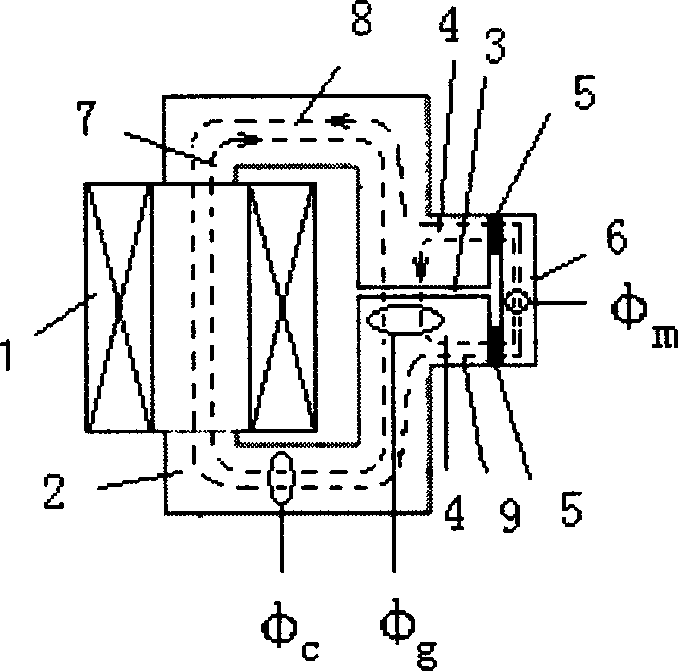

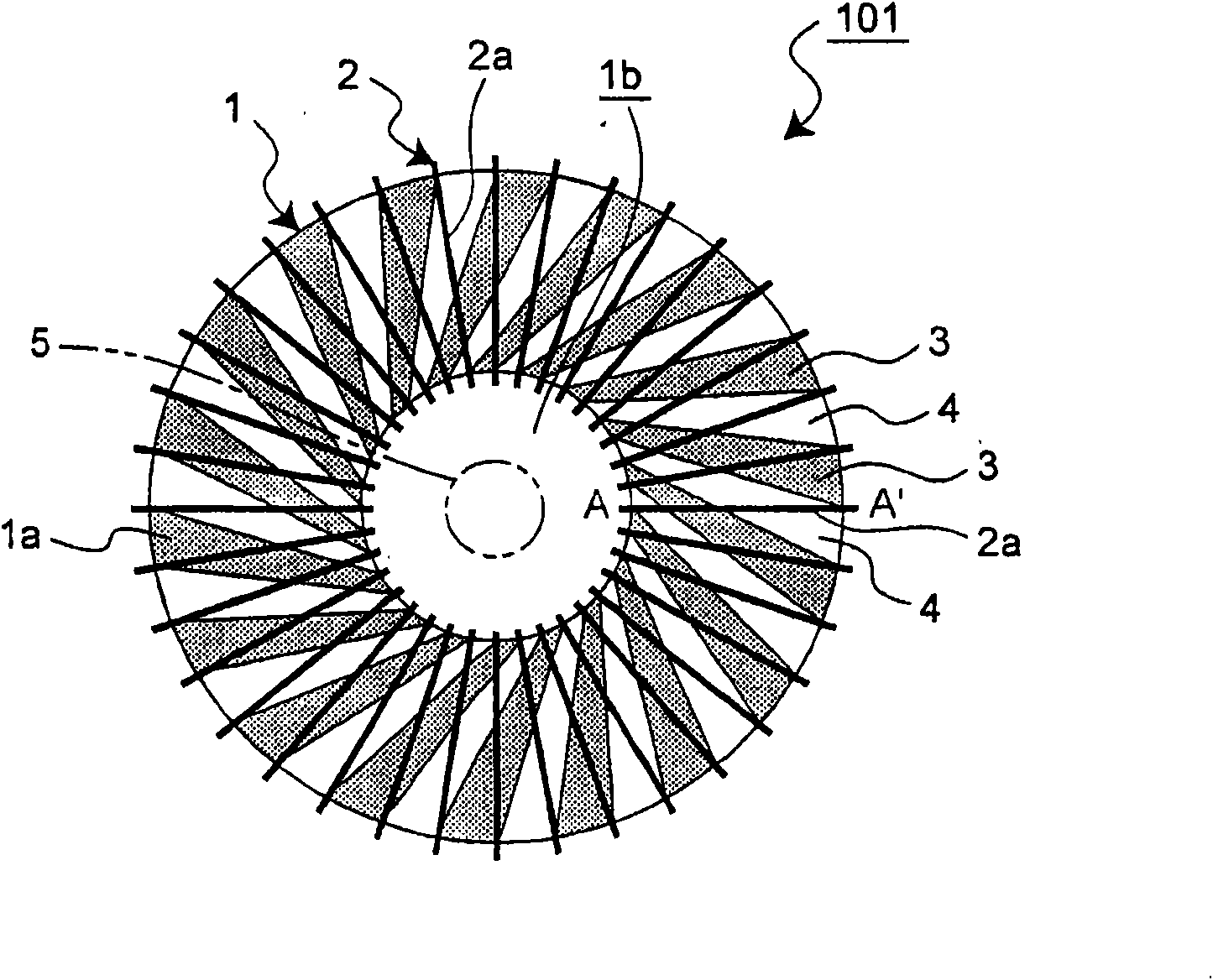

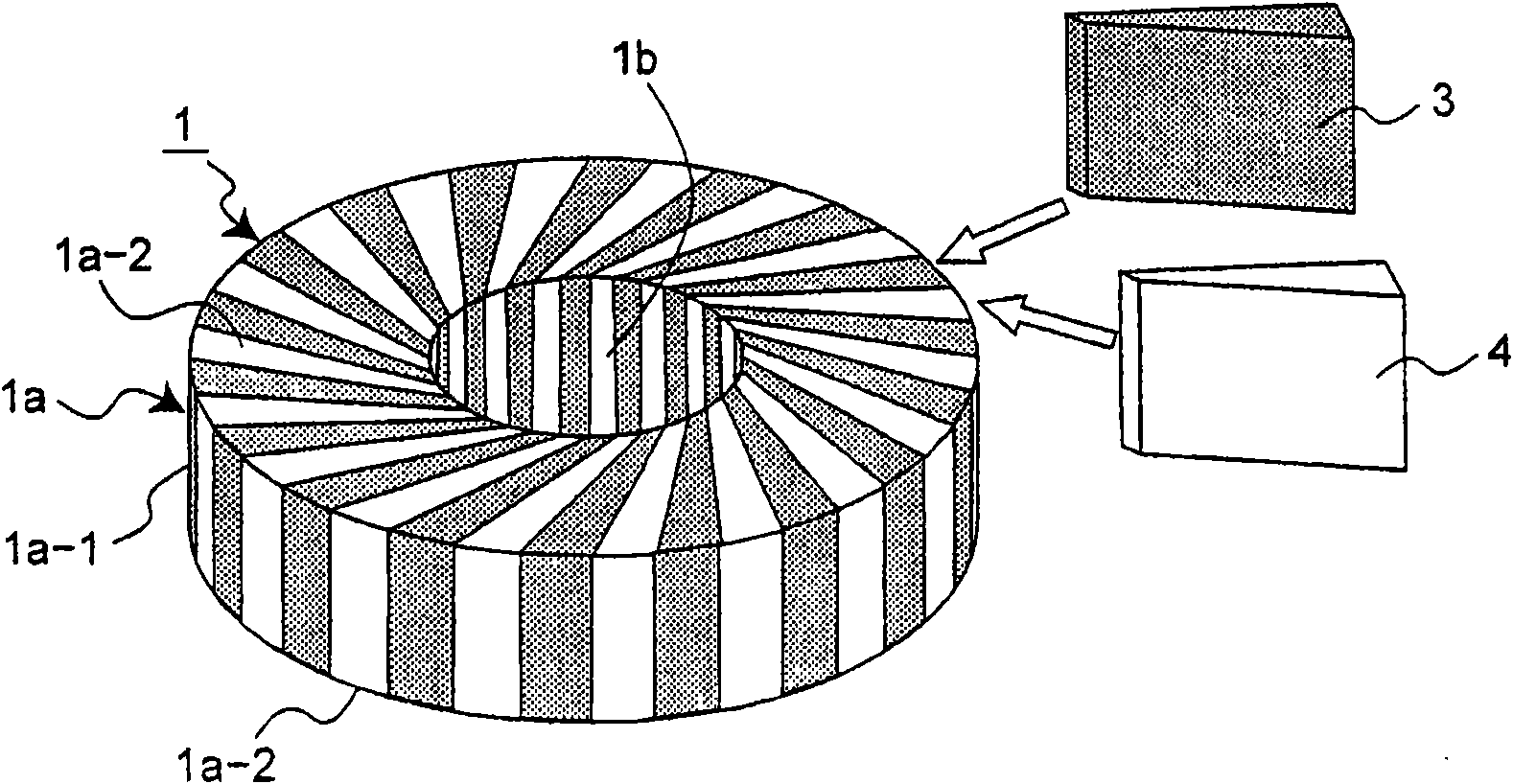

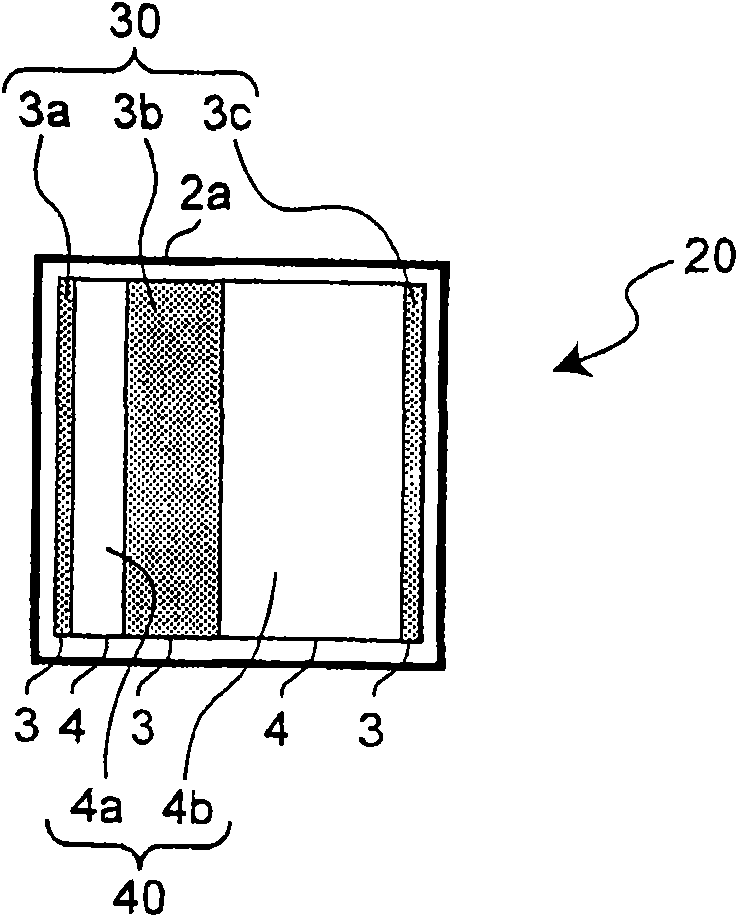

Current sensor

ActiveCN101562073AReduce flux densityReduced current measurement accuracyTransformers/inductances detailsInductances/transformers/magnets manufactureElectrical conductorCurrent sensor

The invention provides a current sensor, which is indicated that a core (1) is divided by alternately arranging plural magnetic material portions (3) and plural non-magnetic material portions (4) in a circumferential direction of the core through which a primary conductor penetrates (5), a conductor is wound around the core under conditions in which each core cross section of the core (1) intersects the magnetic material portion and the non-magnetic material portion, each core cross section including a cut end surface of each conductor (2a) of a secondary winding wound (2) around the core (1), and a ratio of a magnetic material portion cross-sectional area of the magnetic material portion to a non-magnetic material portion cross-sectional area of the non-magnetic material portion at the core cross section is kept constant at each core cross section. Then, the core (1) has a plurality of cutting cores, in which the ratio of a magnetic material portion cross-sectional area to a non-magnetic material portion cross-sectional area is defferent.

Owner:MITSUBISHI ELECTRIC CORP

MnZn ferrite material of low loss and high saturation magnetic flux density and preparation method of MnZn ferrite material

The invention discloses a MnZn ferrite material of low loss and high saturation magnetic flux density and a preparation method of the MnZn ferrite material. The ferrite material is composed of major ingredients and accessory ingredients. The contents of the major ingredients calculated by oxides are as follows: 53 to 55 mol % of Fe2O3, 6 to 8 mol % of ZnO, 35 to 37 mol % of MnO and 1 to 4 mol % of NiO; the accessory ingredients calculated by the total weight of the major ingredients are as follows: 100 to 250 ppm of SiO2, 150 to 1,600 ppm of CaCO3, 50 to 500 ppm of Nb2O5, 50 to 300 ppm of ZrO2, 200 to 6,000 ppm of SnO2 and 500 to 2,000 ppm of Co2O3. The MnZn ferrite material and the preparation method thereof have the advantages that the design is reasonable, the low loss of magnetic cores and the improvement of saturation magnetic flux density can be realized by utilizing the conventional manufacturing equipment, and the dc superposition characteristic and energy storage property are favorable.

Owner:苏州天源磁业股份有限公司

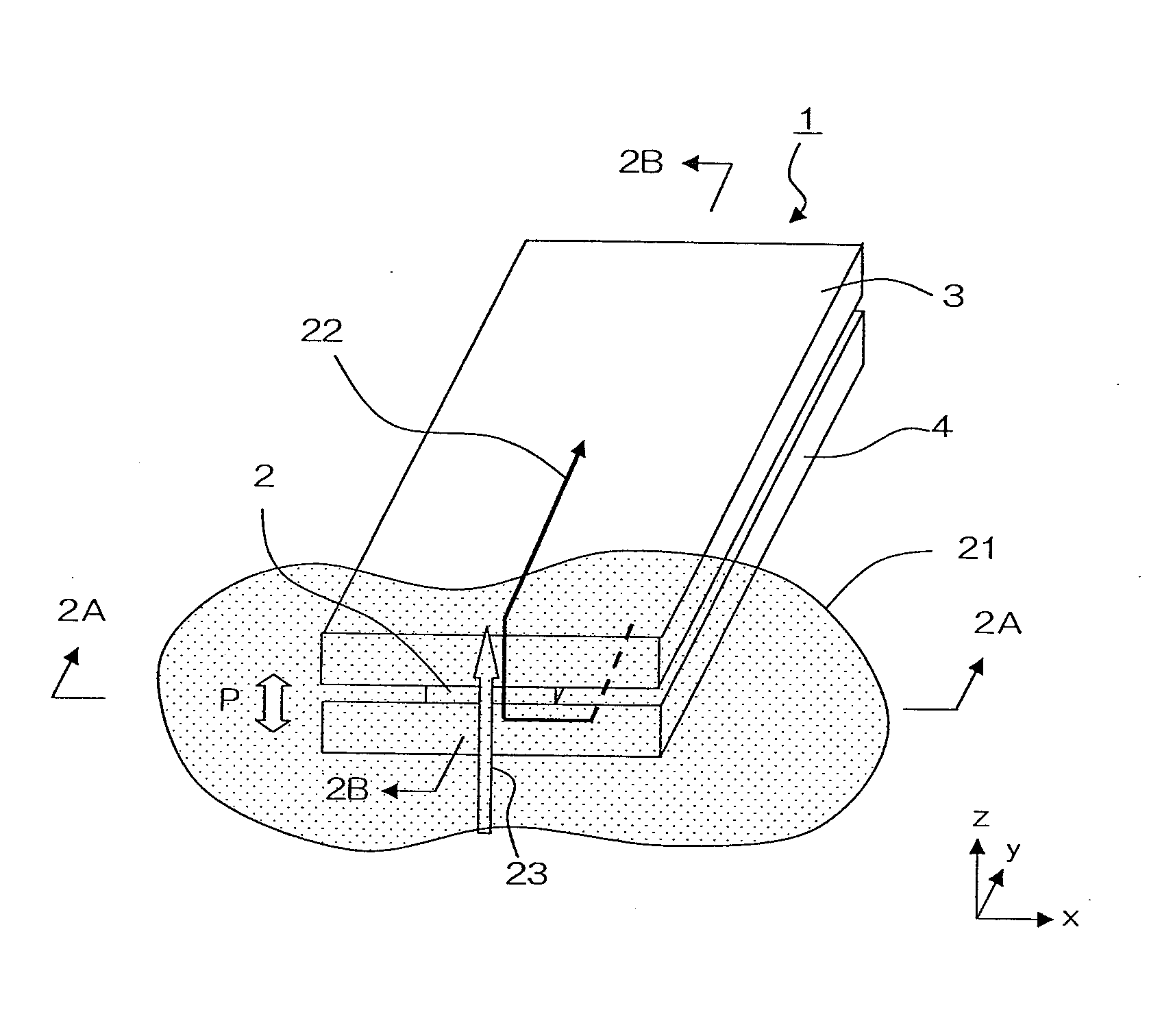

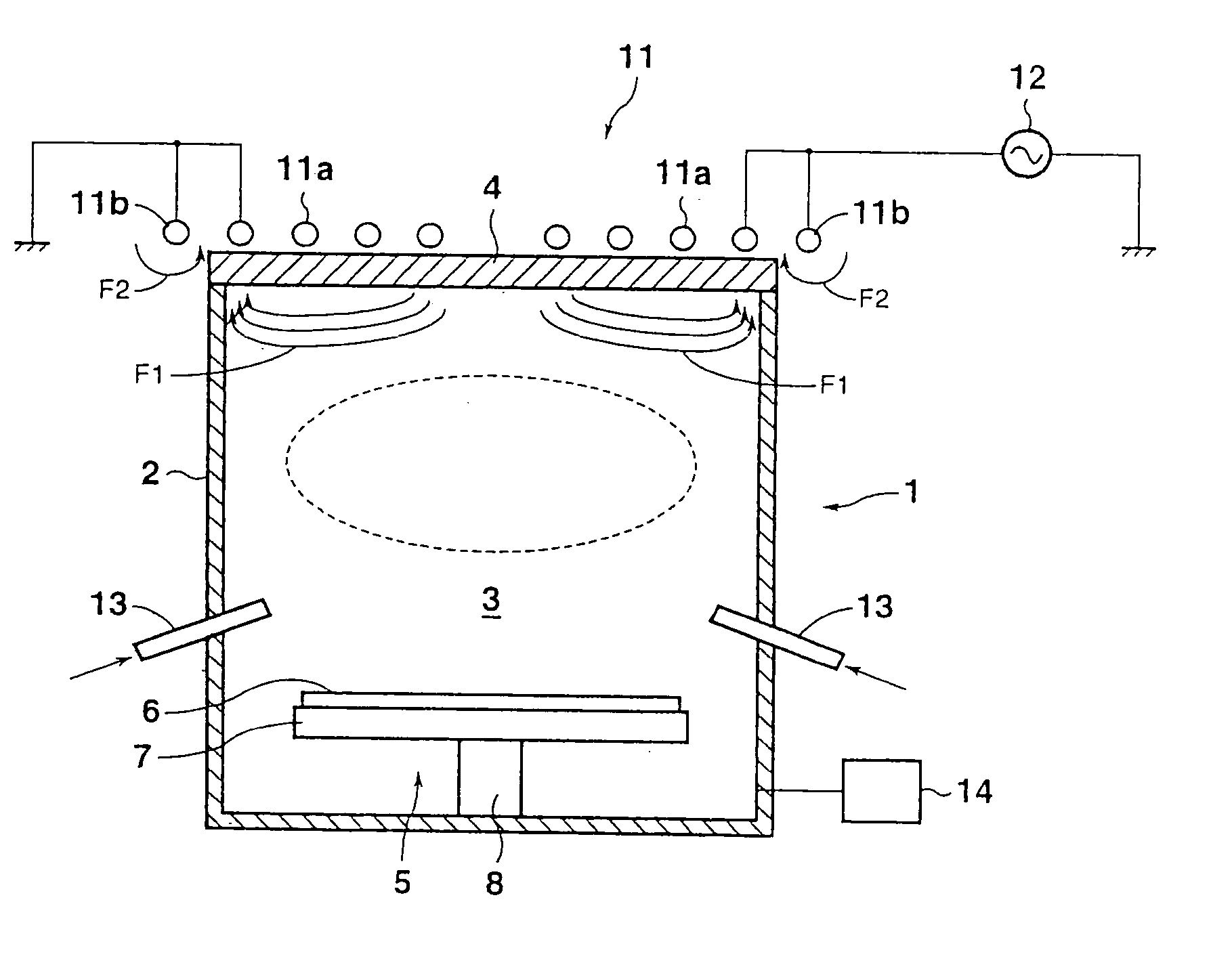

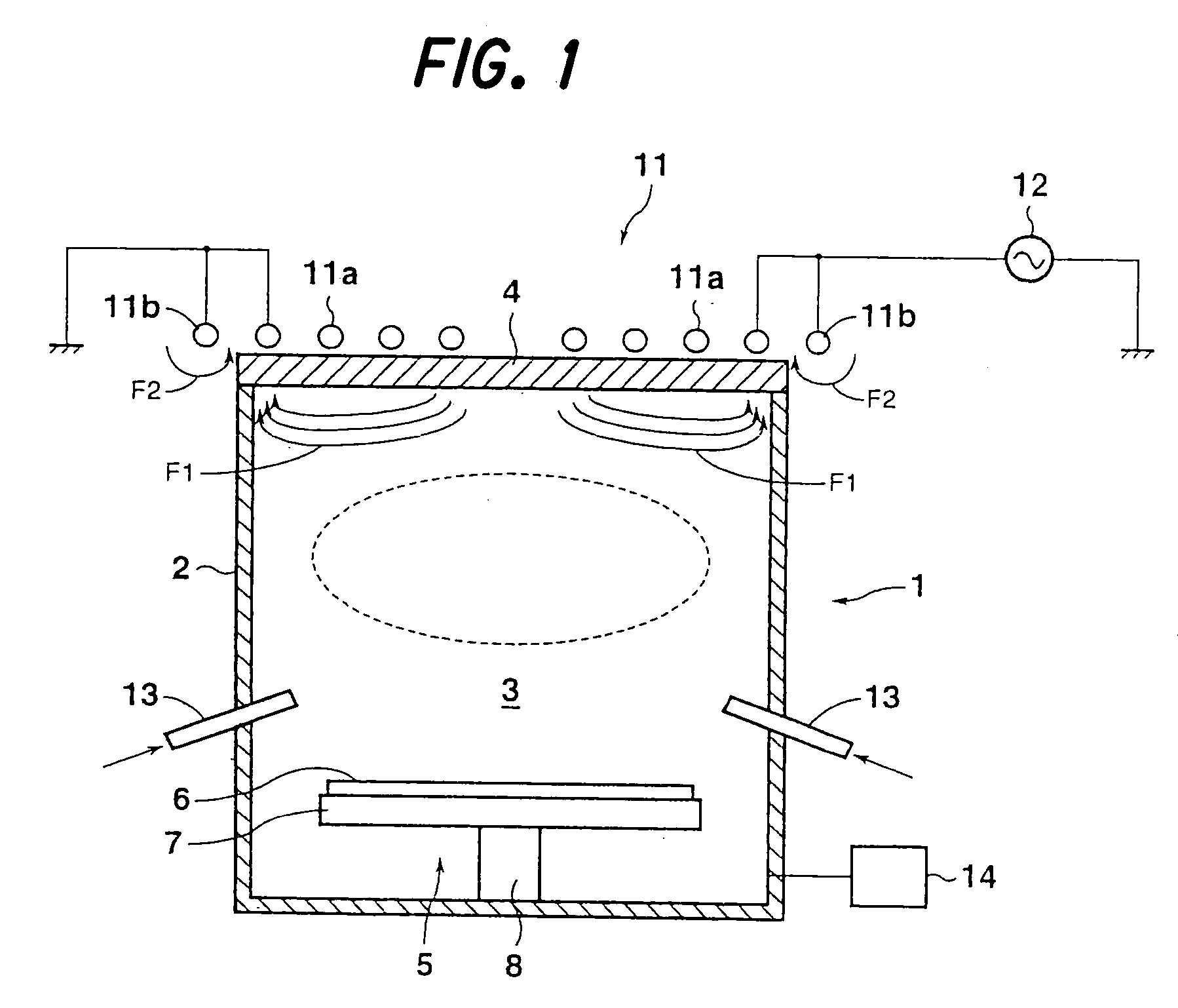

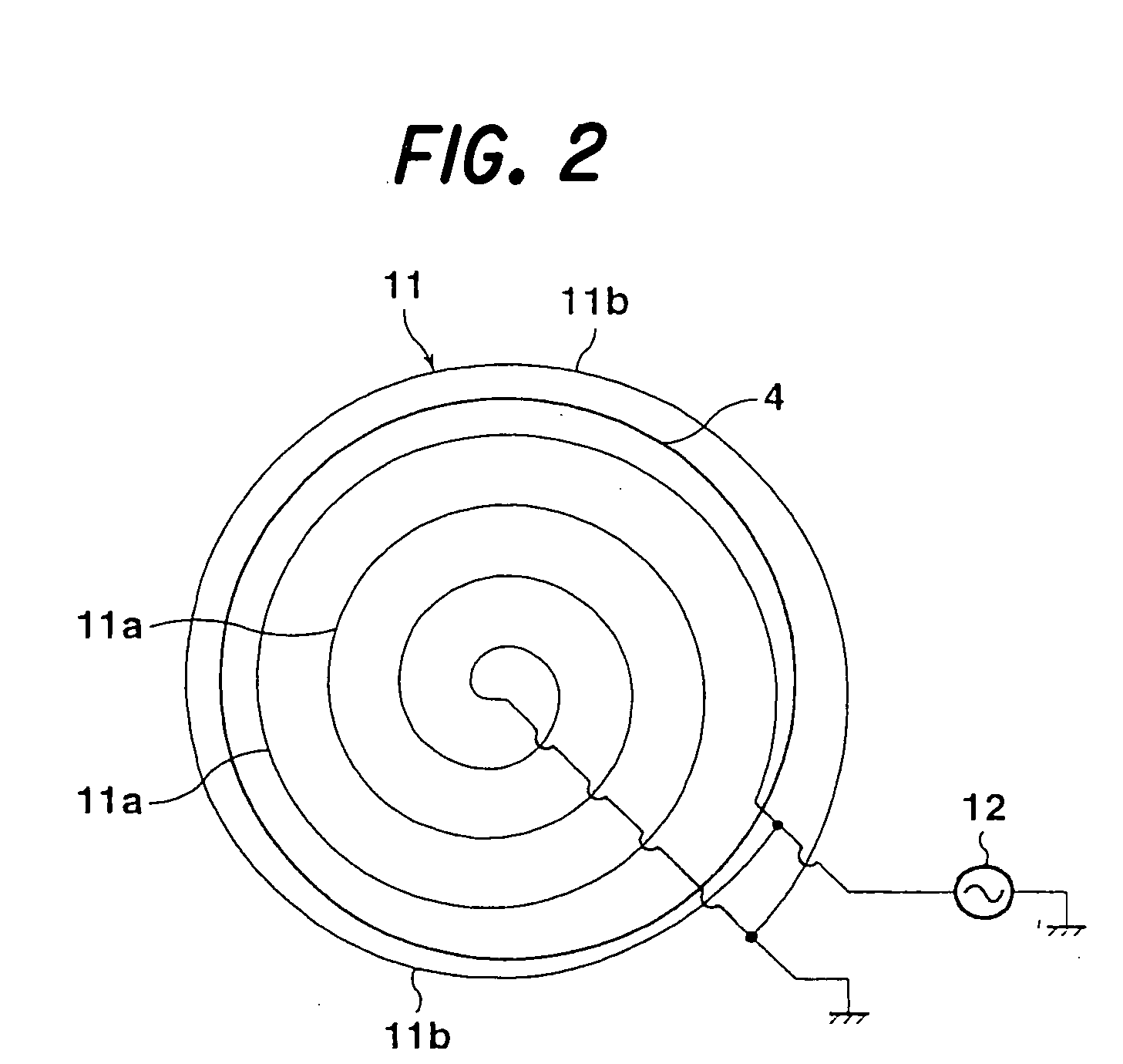

Plasma processing system, plasma processing method, plasma film deposition system, and plasma film deposition method

InactiveUS20050202183A1Low electron temperatureReduce flux densityElectric discharge tubesDecorative surface effectsElectric current flowMagnetic flux

A plasma film deposition apparatus (plasma processing apparatus) is disclosed, which includes a second antenna 11b disposed around an antenna 11a and located outwardly of a ceiling surface, and which supplies the second antenna 11b with an electric current flowing in a direction opposite to the direction of an electric current supplied to the antenna 11a by power supply means, whereby lines of magnetic force, F2, heading in a direction opposite to the direction of lines of magnetic force, F1, appearing at the site of the antenna 11a are generated at the site of the second antenna 11b. Thus, the magnetic flux density in the direction of the wall surface is lowered, even when a uniform plasma is generated in a wide range within a tubular container 2.

Owner:MITSUBISHI HEAVY IND LTD

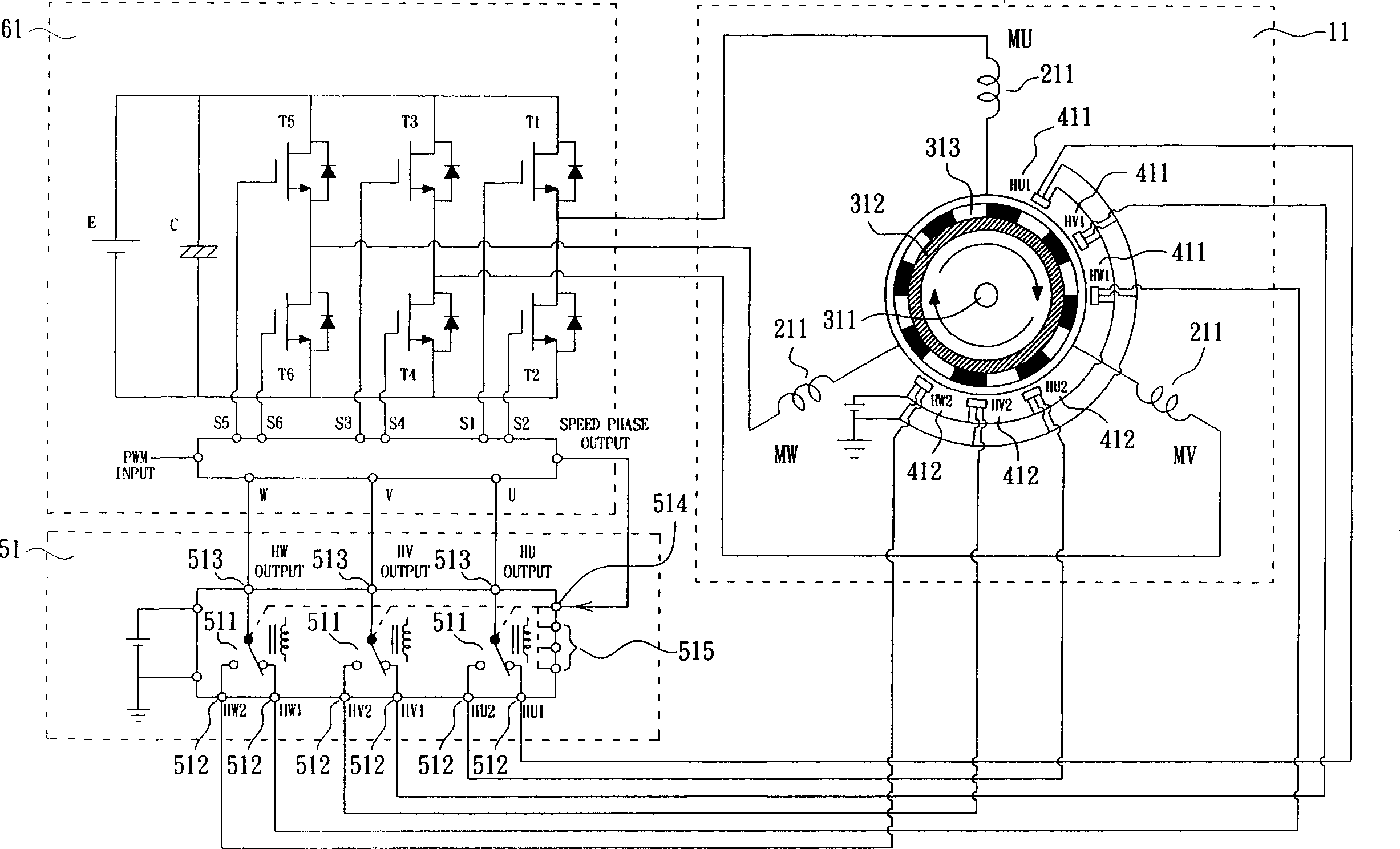

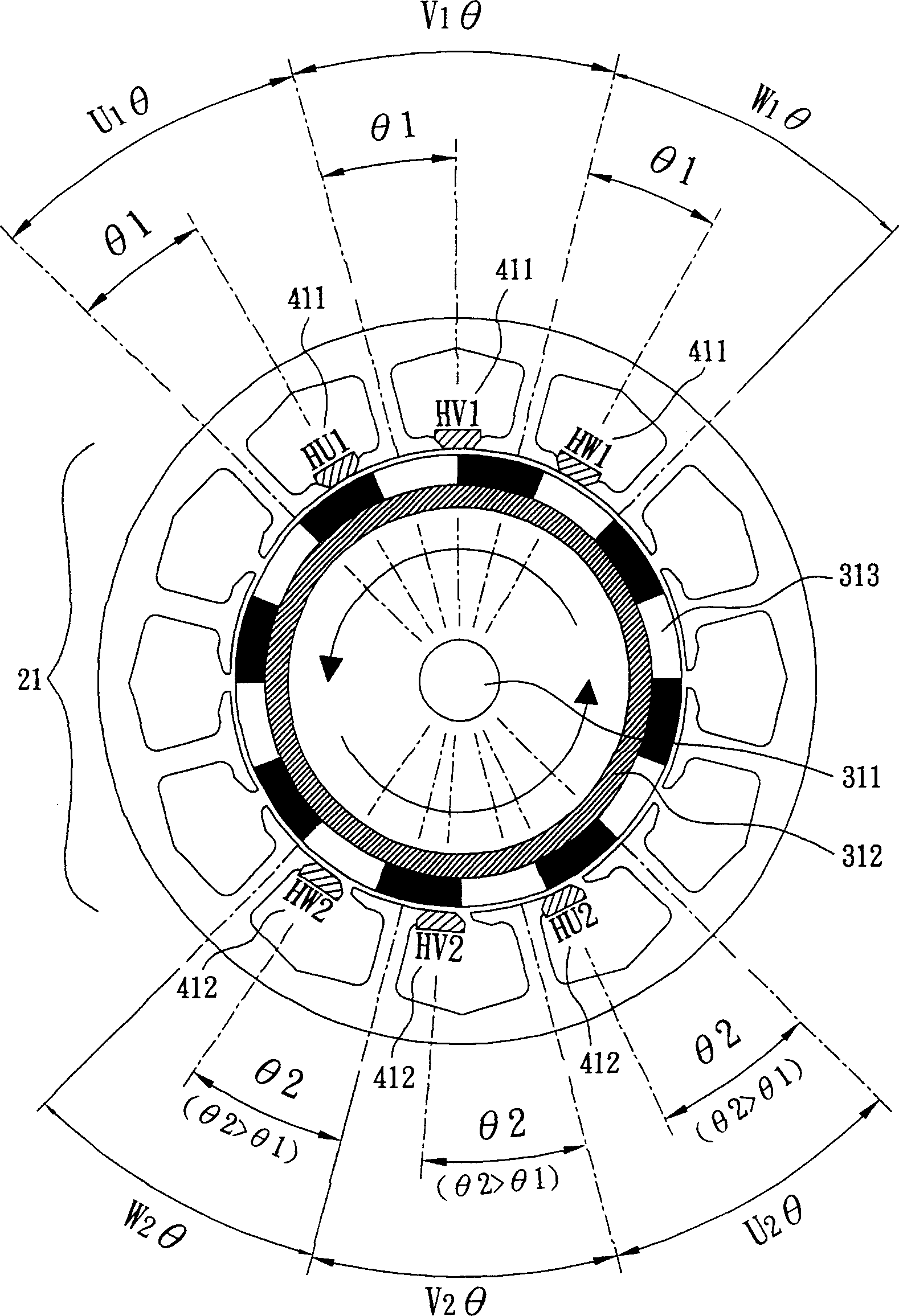

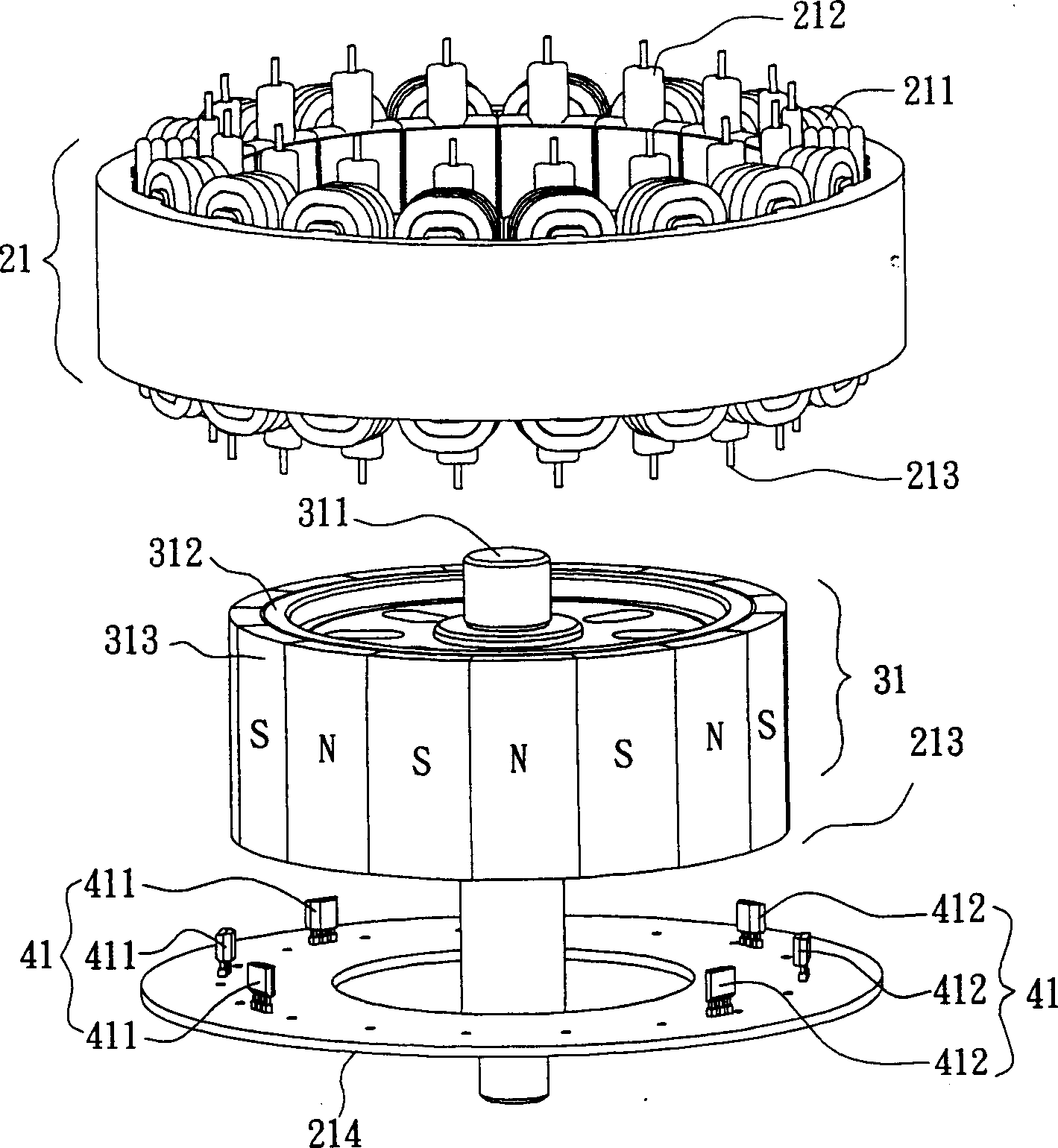

Rotation speed raising device for permanent magnetic motor

InactiveCN1437314AImprove operational efficiencyLarge torque constant KT valueSingle motor speed/torque controlElectronic commutatorsNuclear magnetic resonanceMagnetic flux

The rotation speed raising device for permanent magnetic motor includes several magnetic sensors set inside the permanent magnetic motor to sense the magnetic pole conversion of the permanent magnetsin the rotor. One of the magnetic sensors makes the stator and the permanent magnetic rotor produce armature reaction with relatively strong armature air gap magnetic flux density, while the others make the motor controlled in the effect similar to weak magnetic control resulting in weak armature air gap magnetic flux density, lowered torque constant KT of the motor and increased rotation speed of the rotor. The said device makes it possible to design motor in relatively high torque constant Kt and when high rotation speed is required, the magnetic sensing selection circuit is made to output signal to produce effect similar to weak magnetic control.

Owner:许俊甫

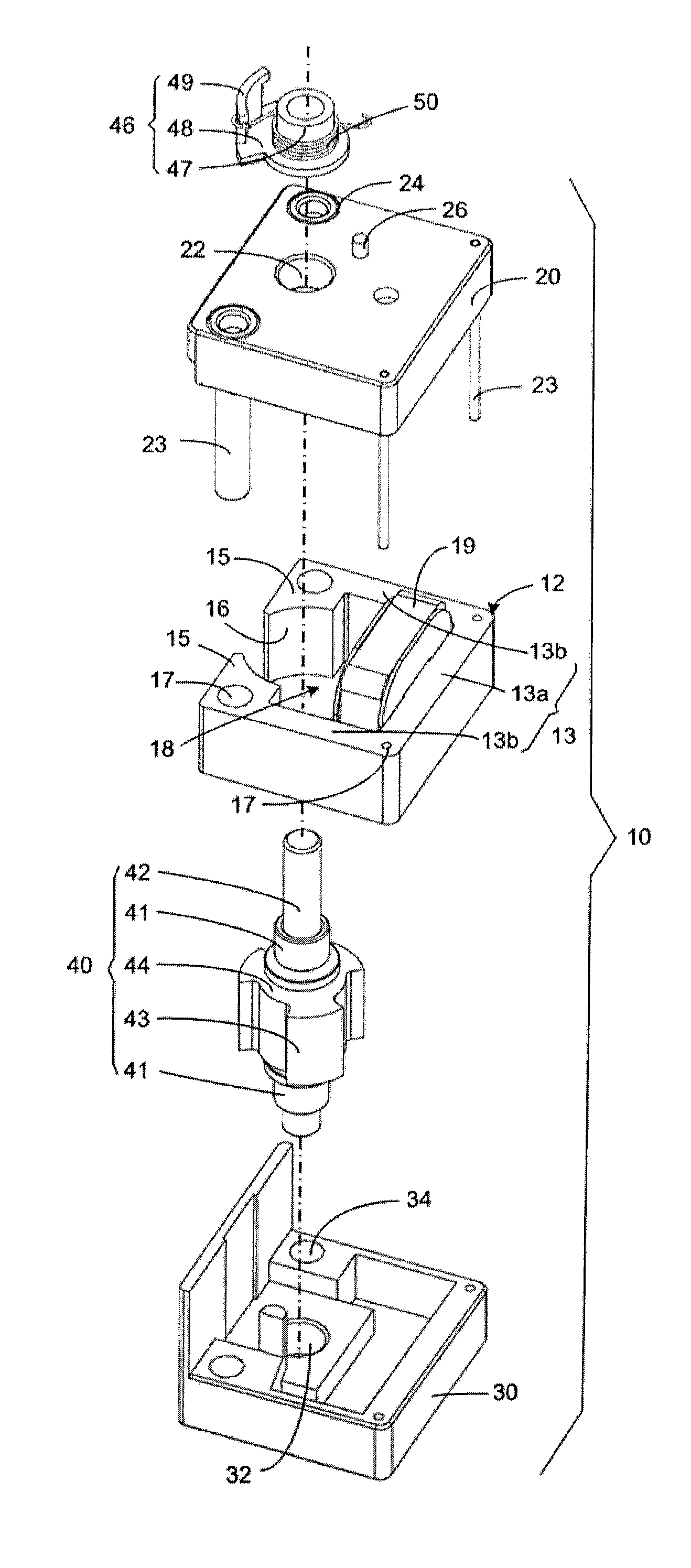

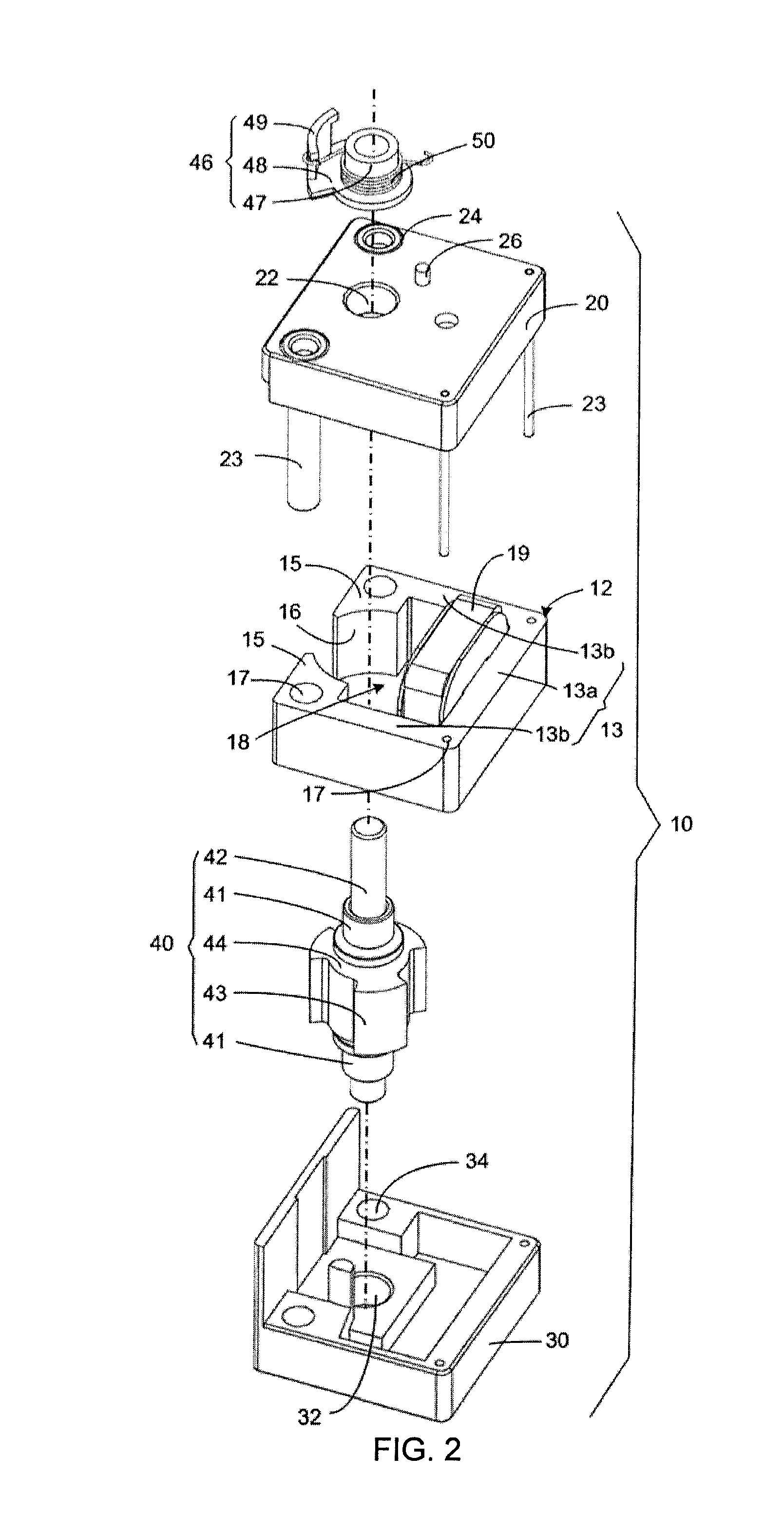

Rotary solenoid

ActiveUS20130342296A1Reduce flux densityLow densityDynamo-electric machinesElectromagnets with armaturesTorsion springStator poles

A rotary solenoid (1) includes a stator (10), a rotor (40), and a torsion spring (50) connected between the stator (10) and the rotor (40). The stator (10) includes an armature (13) having three stator poles (14, 15) cooperatively defining a substantially cylindrical space (18) and a coil (19) wound about one of the stator poles (14). The rotor (40) includes a shaft (42) rotatably assembled to the stator (10) and a rotor core (44) fixed to the shaft (42) and received in the cylindrical space (18). The rotor core (44) has three rotor poles (43) corresponding to the stator poles (14, 15). The rotor (40) stays at a first position under the force of the torsion spring (50) and rotates to a second position under the force of the torsion spring (50) and the magnetic force of stator (10) when the coil (19) is powered.

Owner:JOHNSON ELECTRIC SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com