Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "Realize automatic flow operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

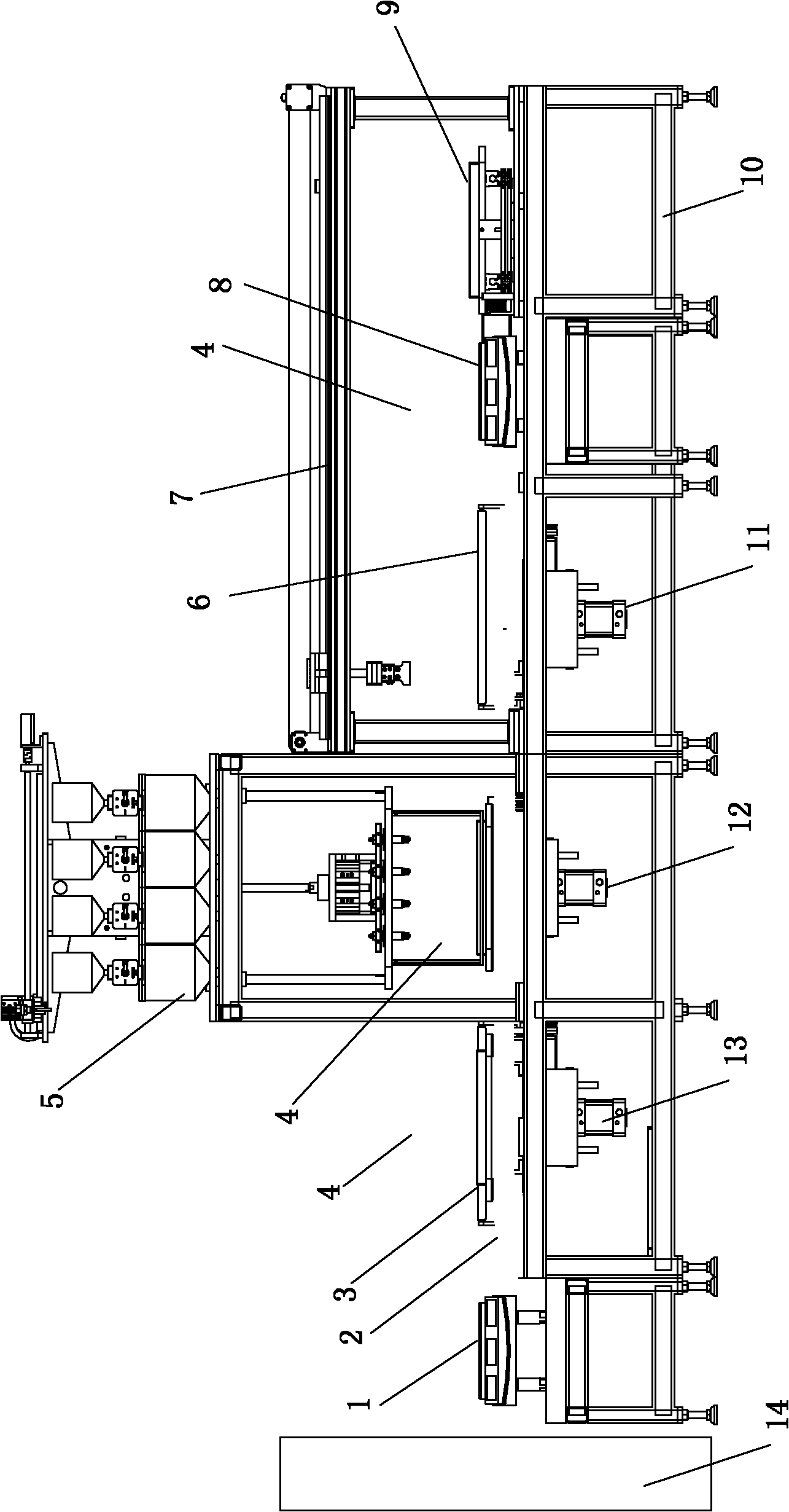

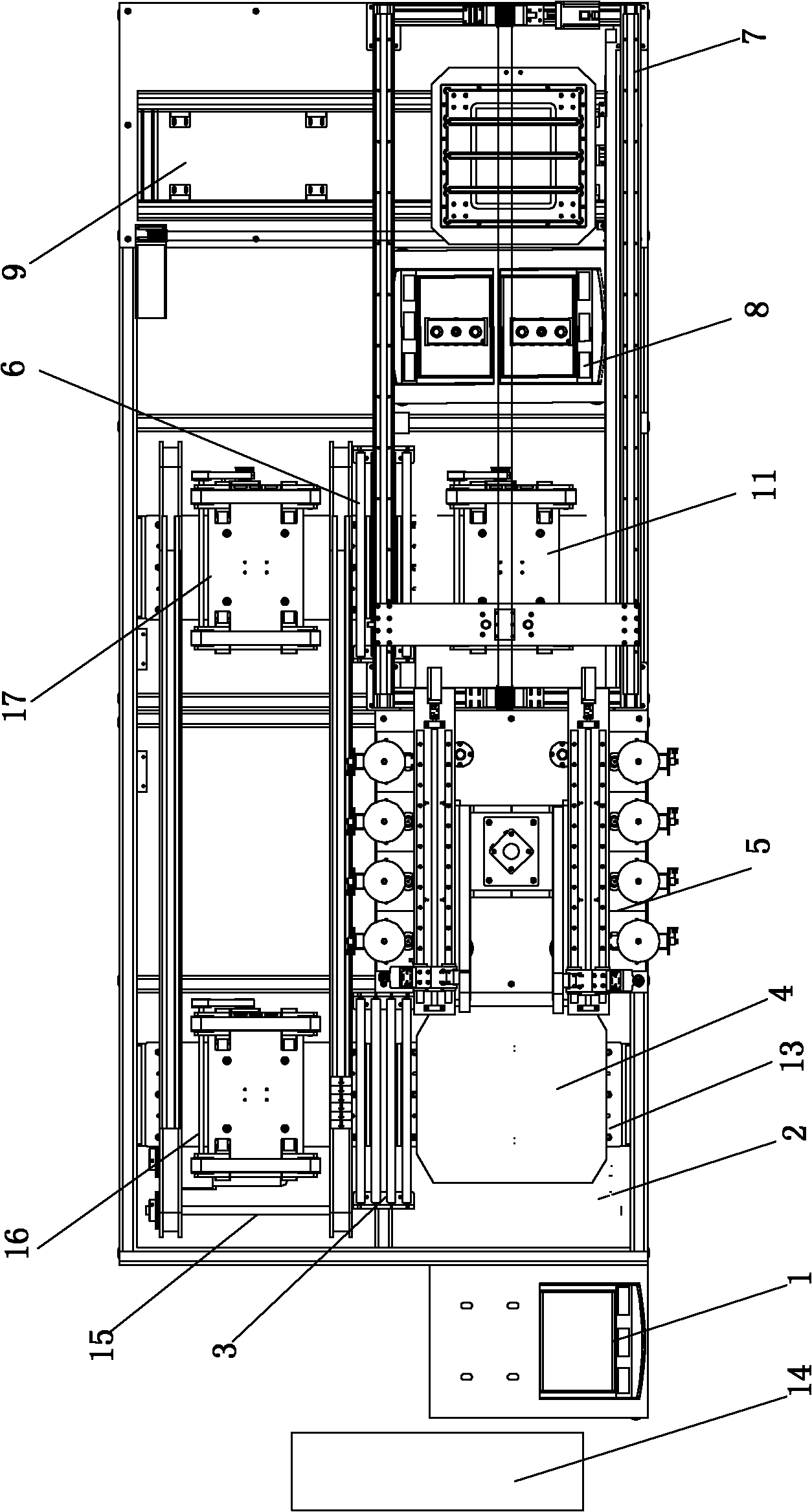

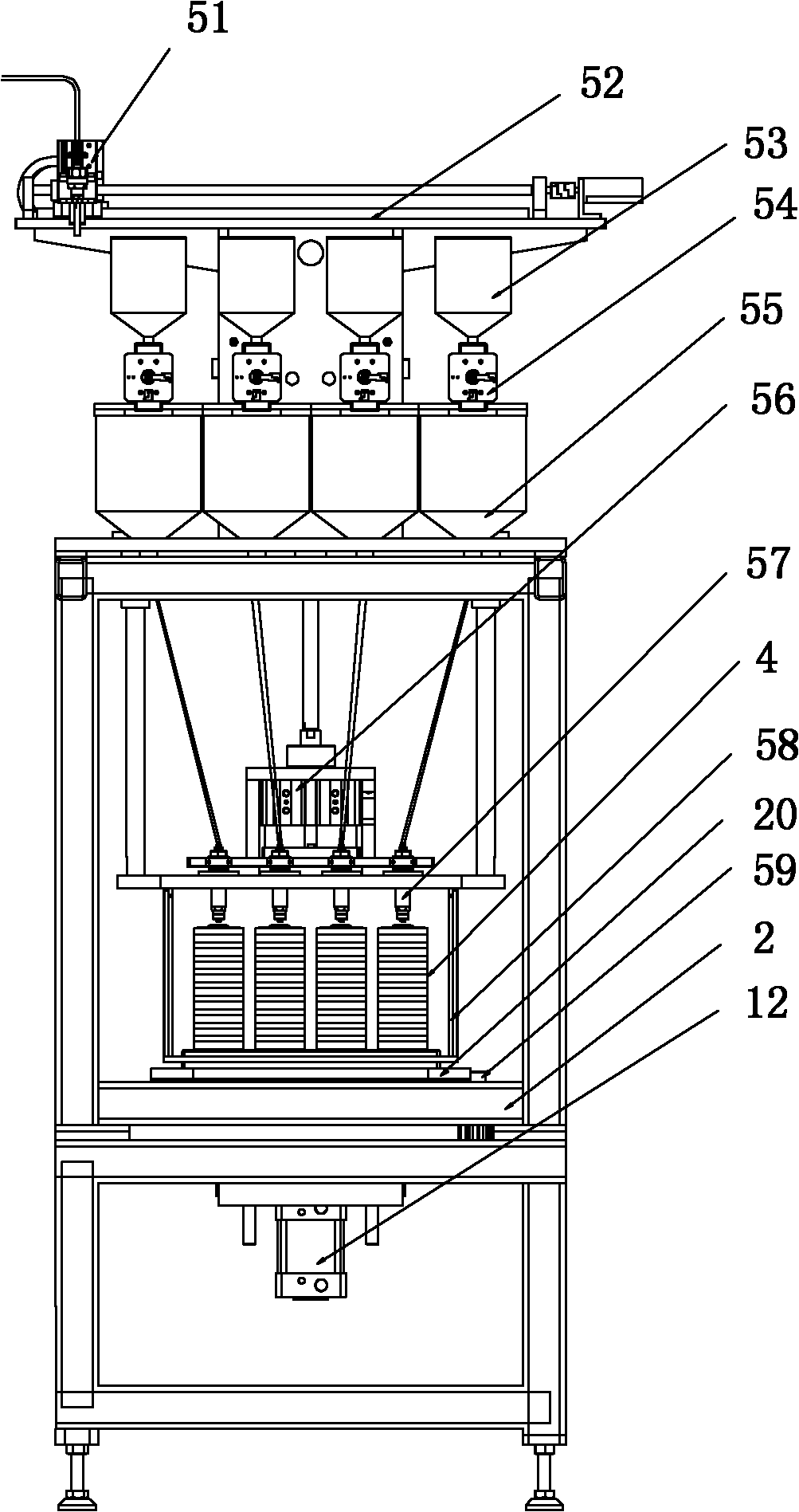

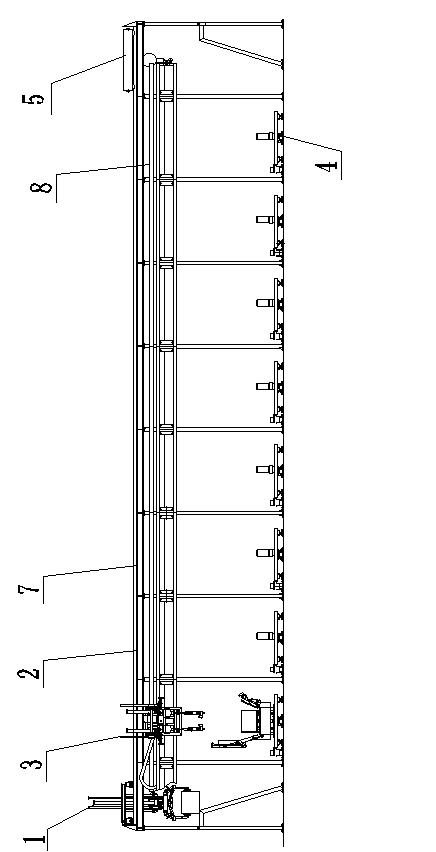

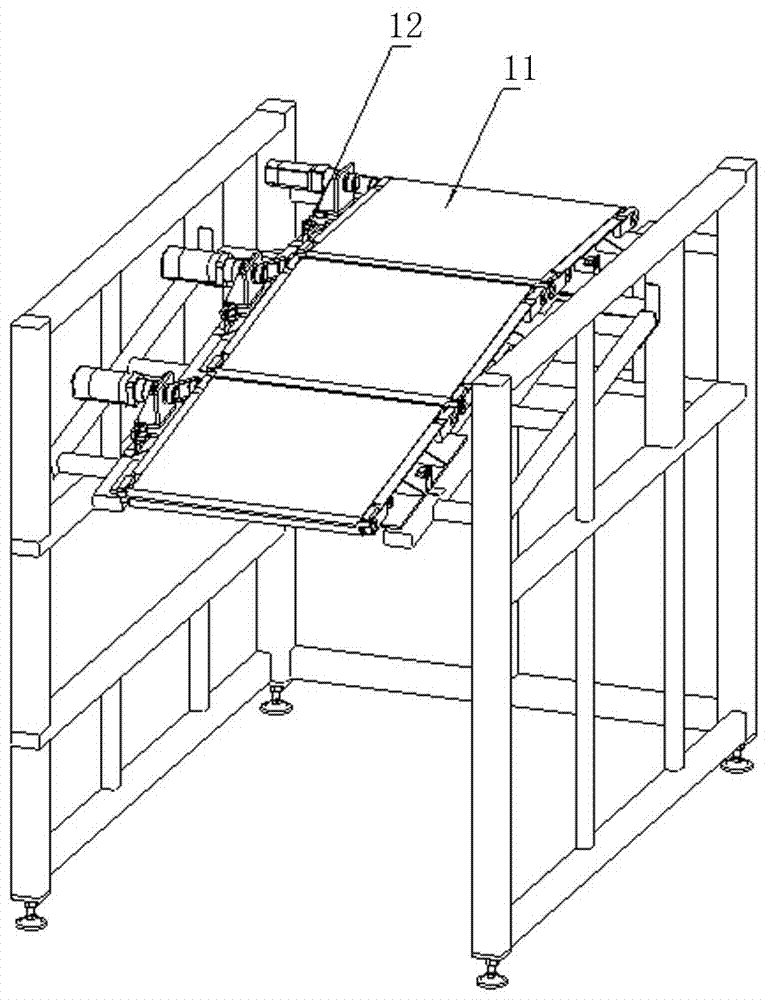

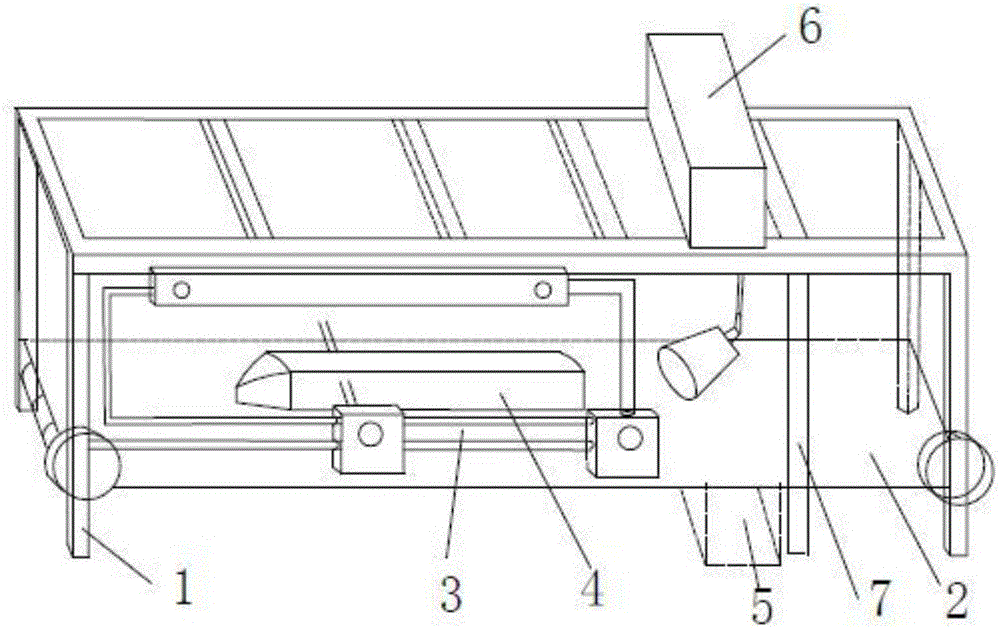

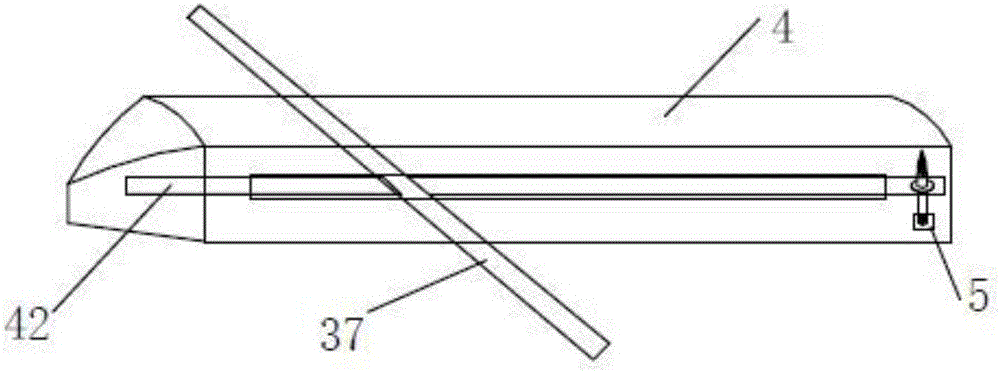

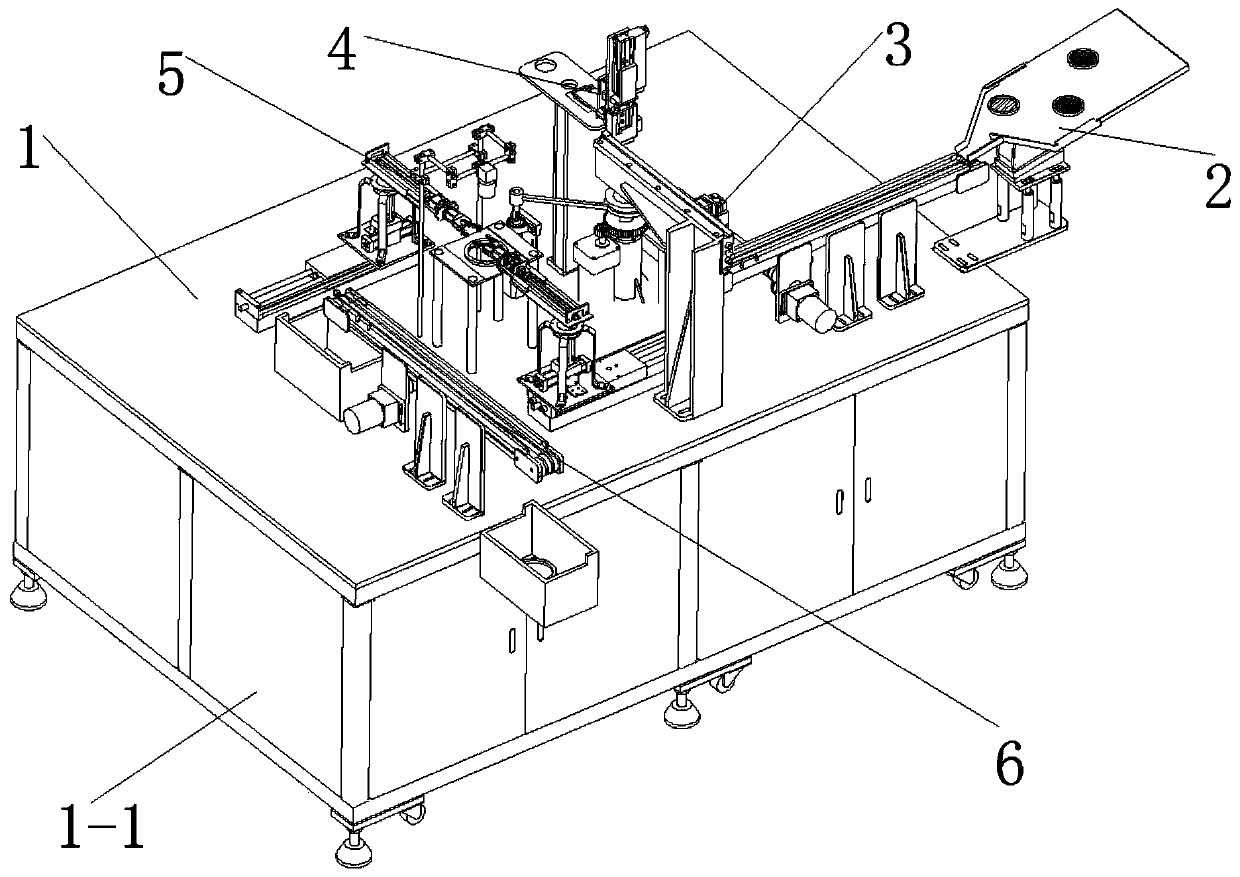

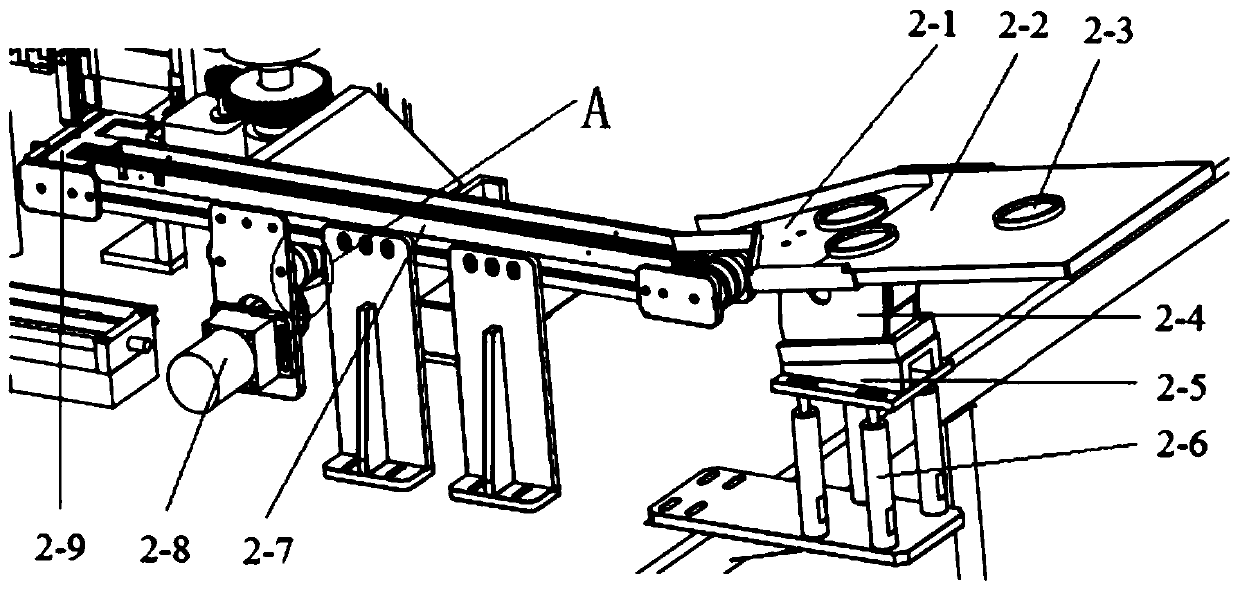

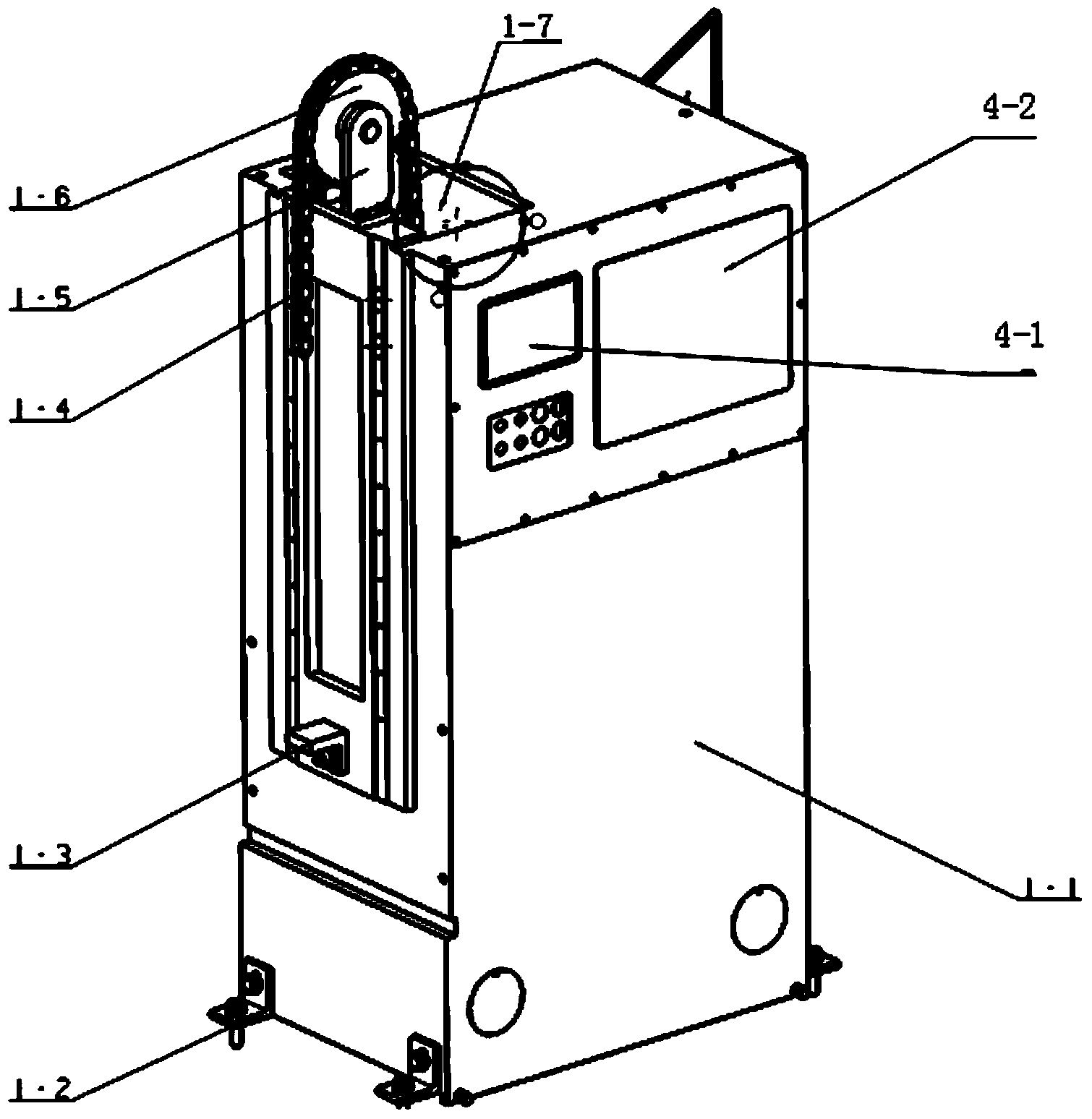

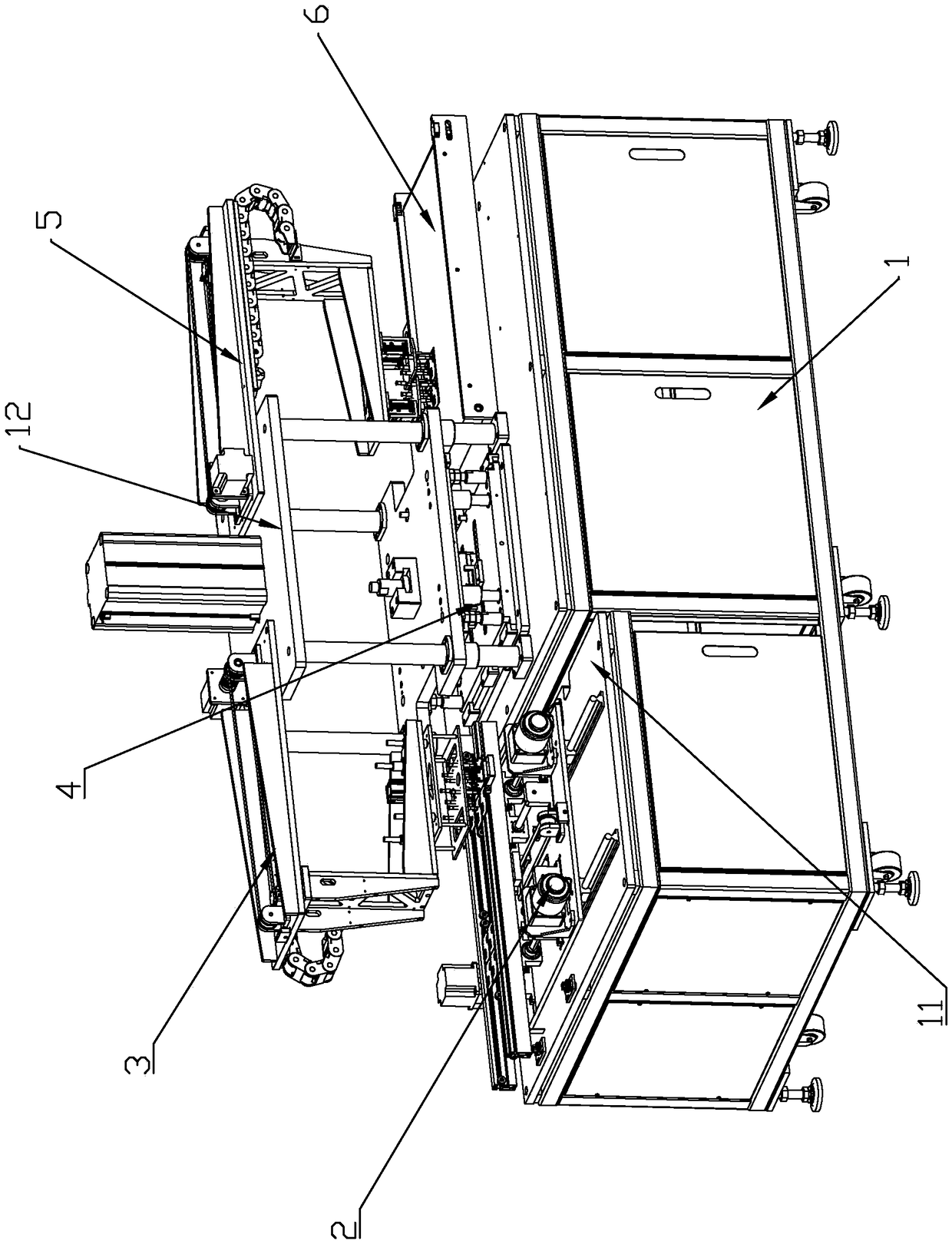

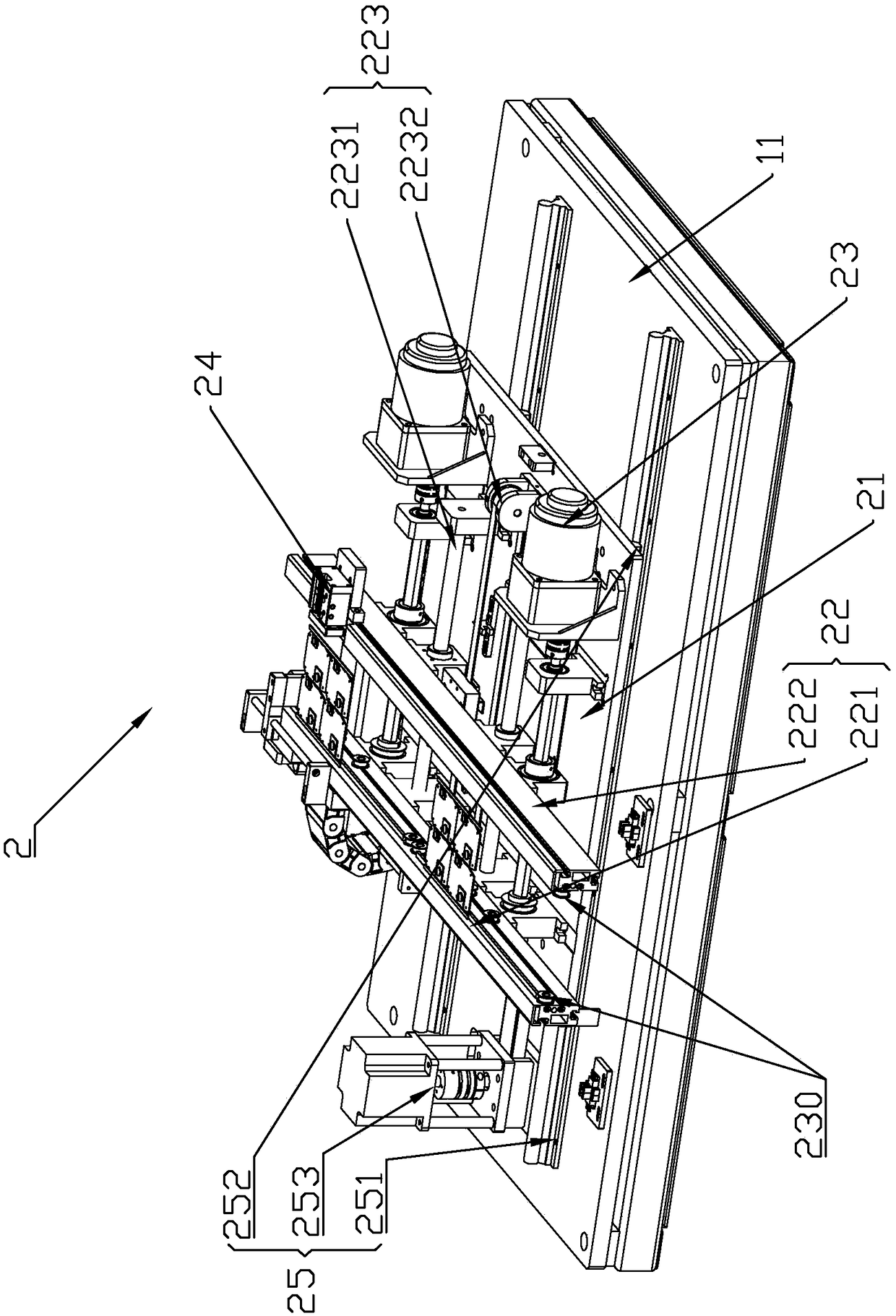

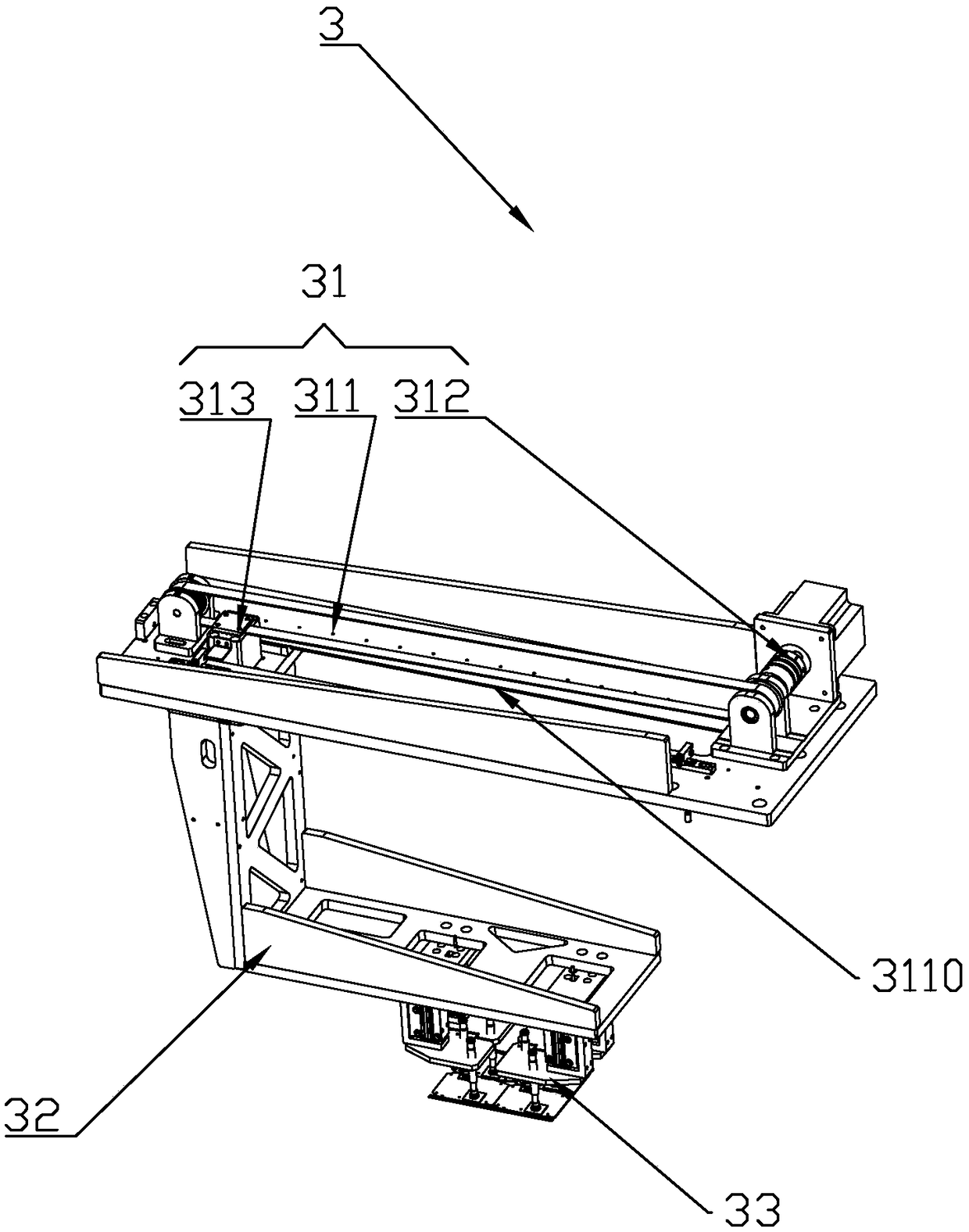

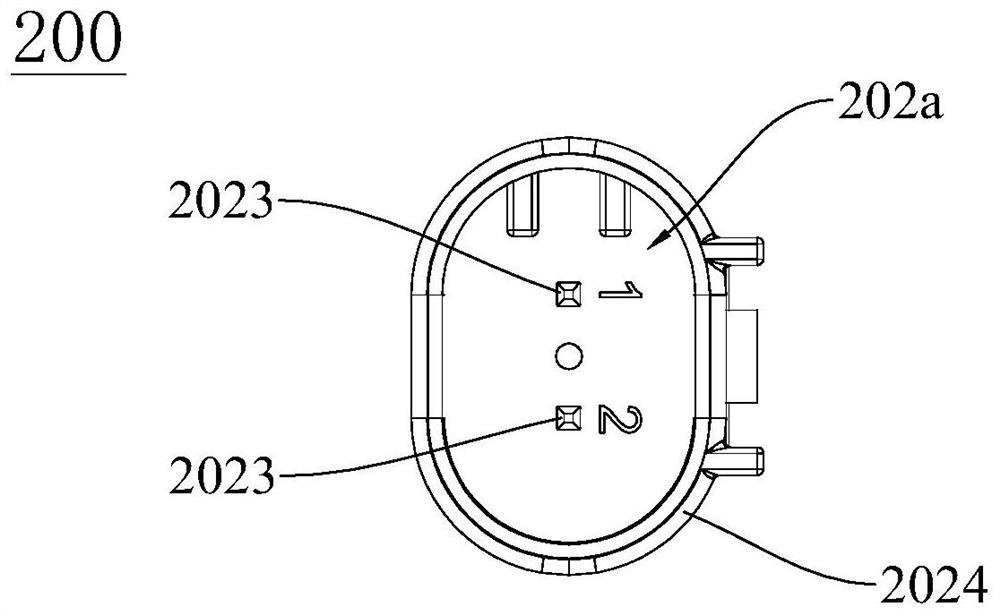

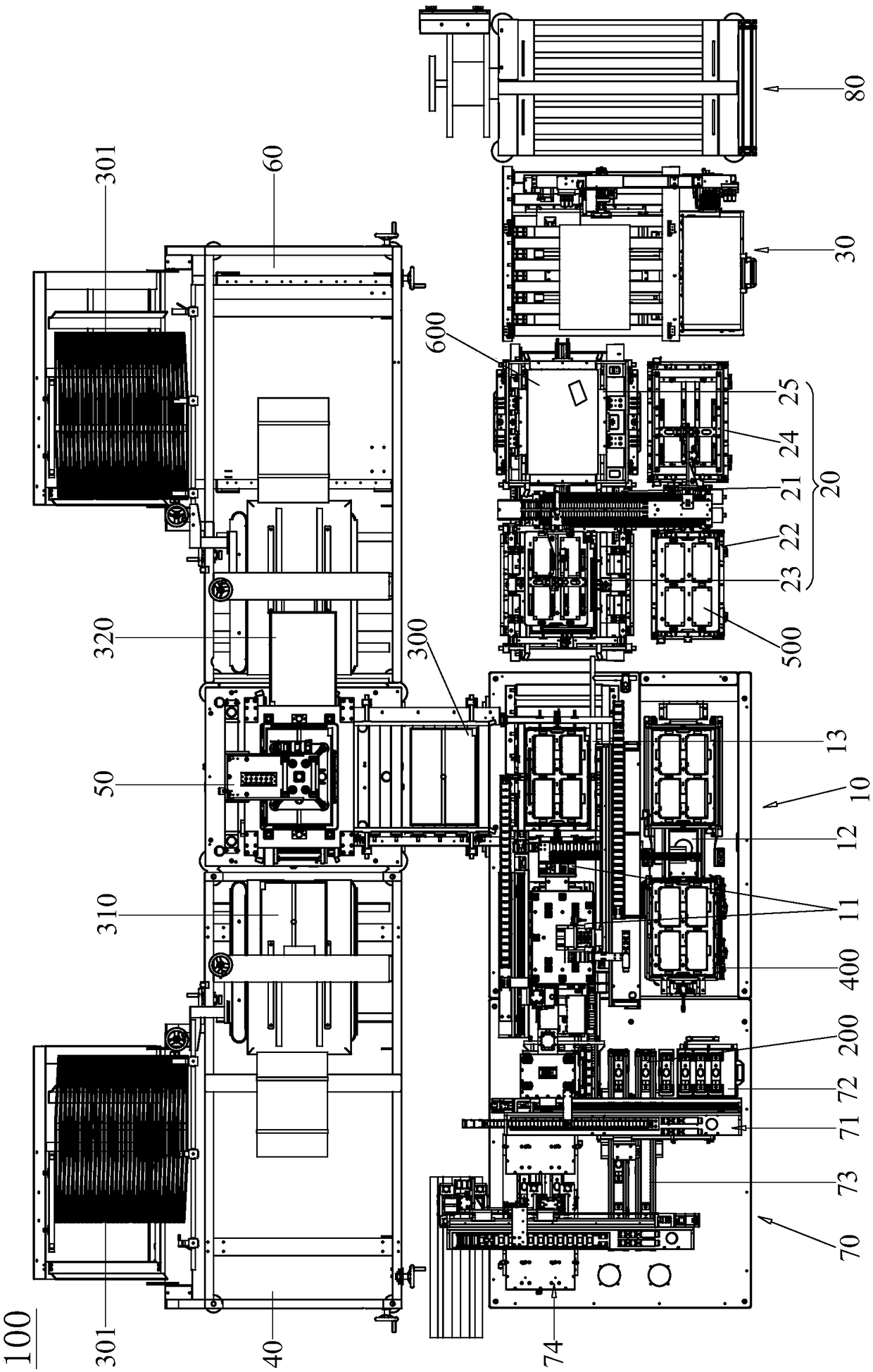

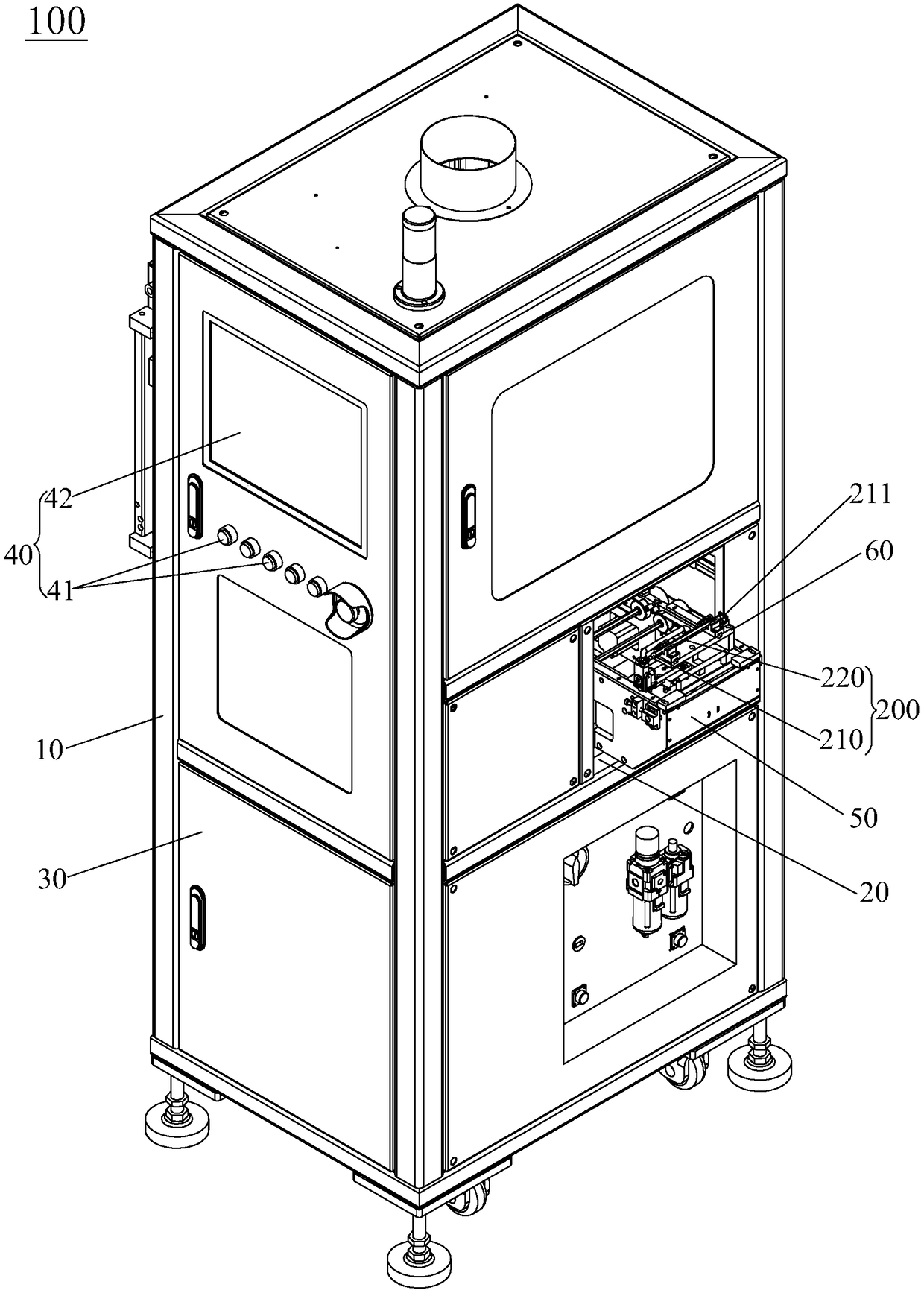

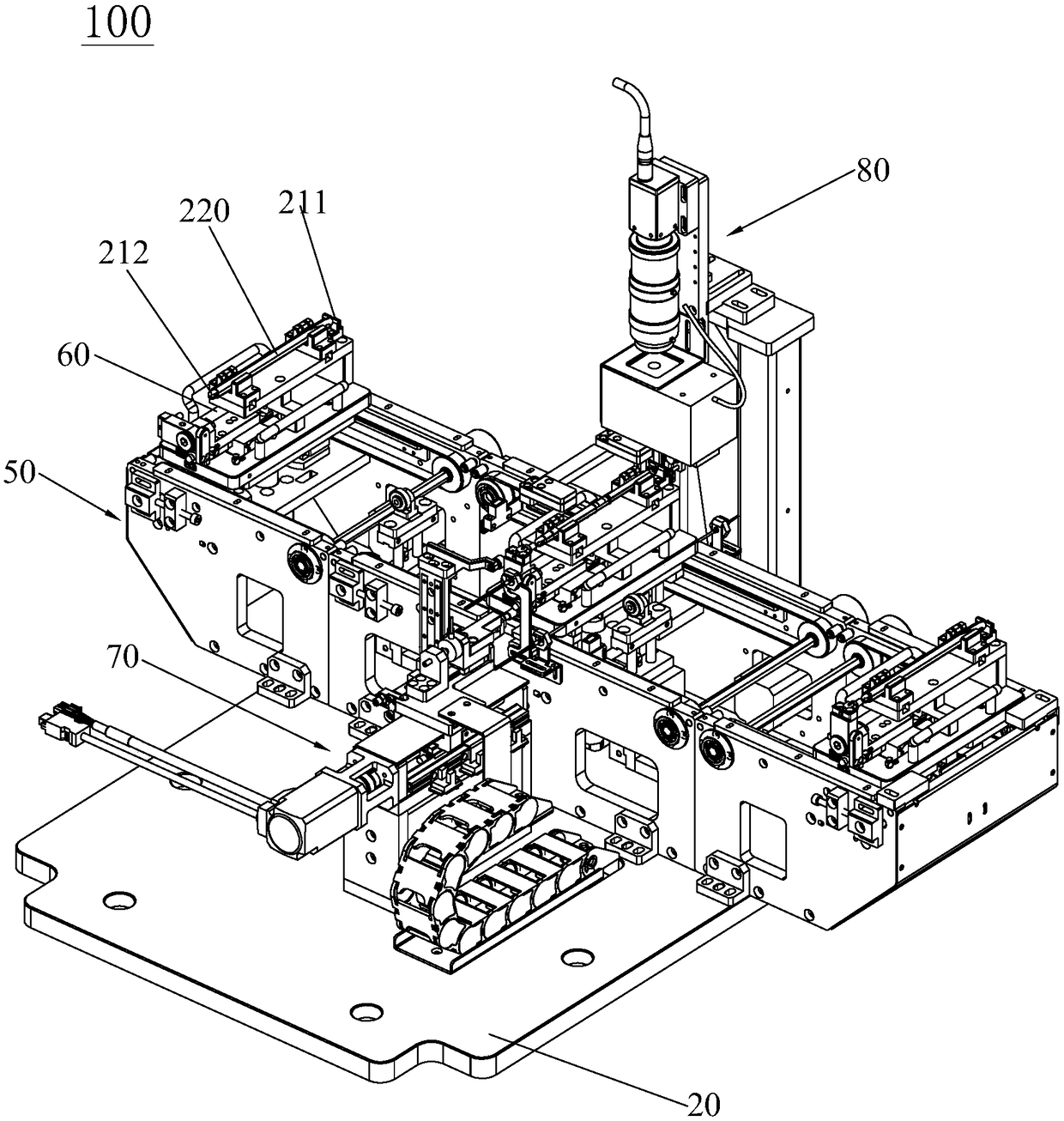

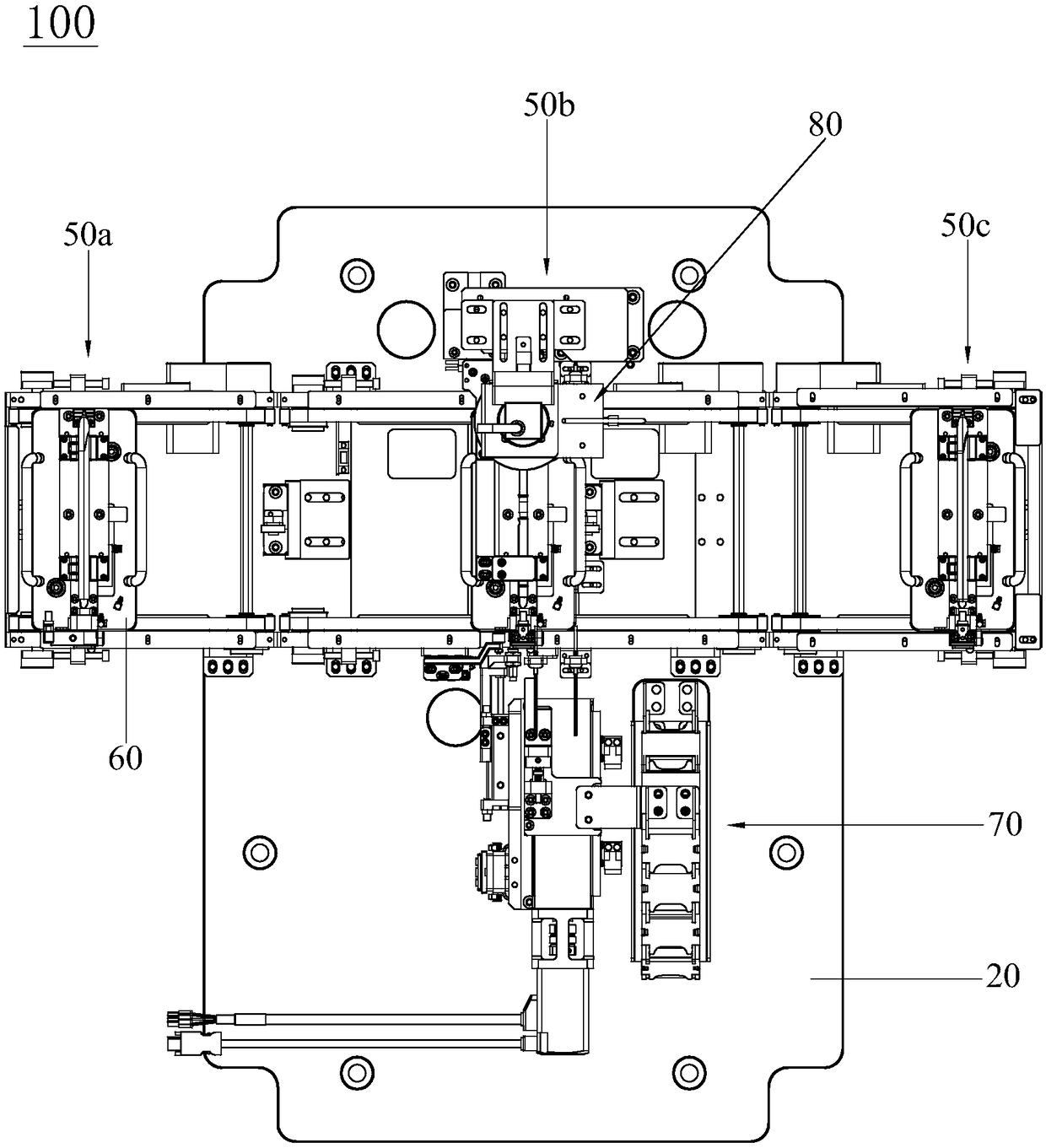

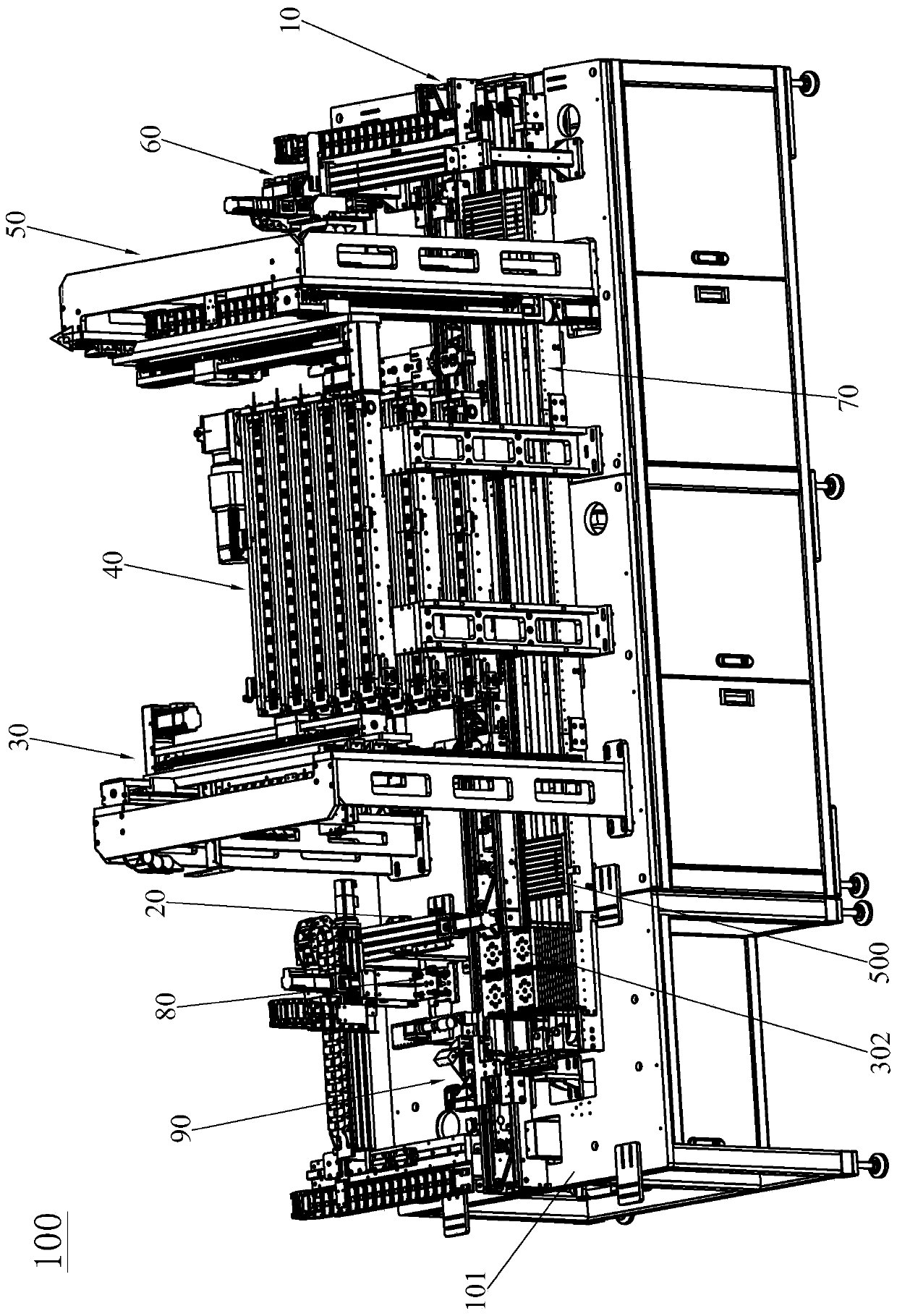

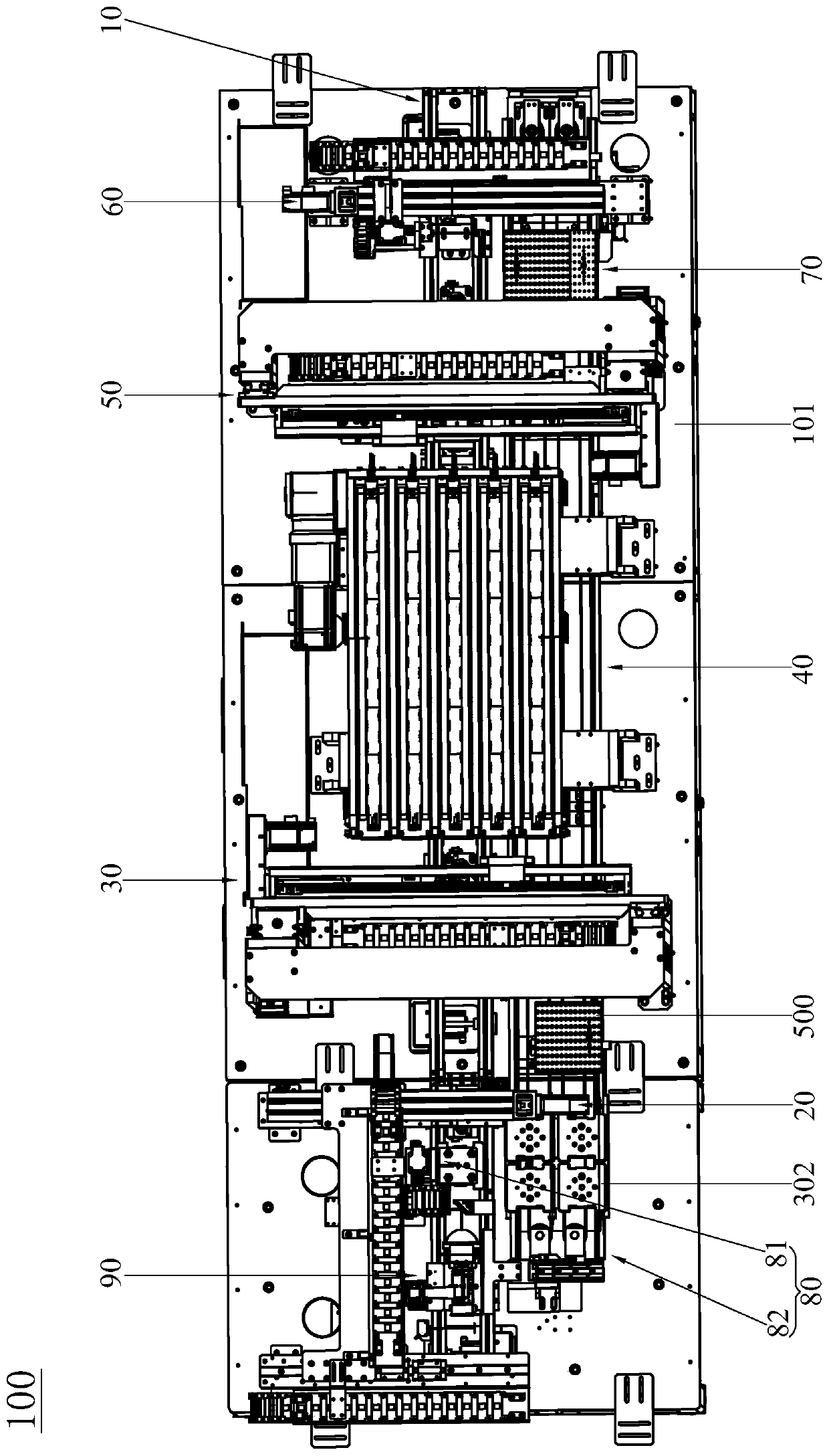

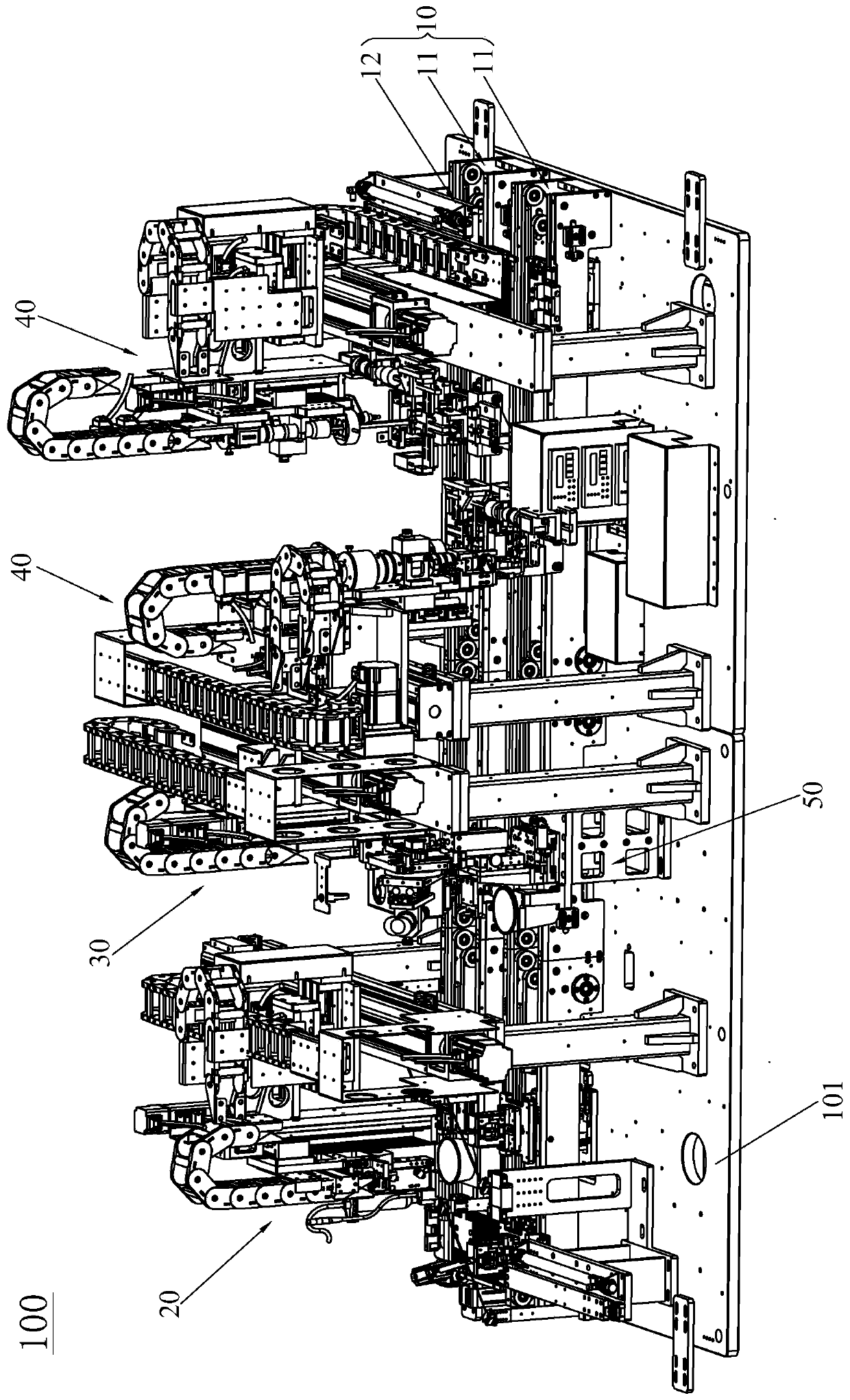

Automatic filling machine for battery and battery filling method

InactiveCN102148349ARealize automatic flow operationCompact machine designCell component detailsBuffer tankEngineering

The invention discloses an automatic filling machine for a battery and a battery filling method. The filling machine comprises a rack, a front weighing device arranged on the rack, a filling conveying line, an evacuation filling device, a discharging device, a rear weighing device and a control module. The filling machine also comprises a carrier backflow mechanism which comprises a carrier conveying line parallel to the filling conveying line and carrier transfer devices arranged at two ends of the filling conveying line and the carrier conveying line; and the evacuation filling device comprises a filling nozzle, a driving part for driving the filling nozzle to move, a filling cup communicated with the filling nozzle, a filling buffer tank communicated with the filling cup and a sealing cylinder for sealing the filling nozzle and the battery in the sealing cylinder. In the invention, automatic operations of battery conveying, filling, evacuation and discharging are ensured, the machine design and process layout are compact, the vacuum and high-pressure circulating alternate filling method is adopted, and the full absorption and filling precision of electrolyte of the battery are ensured.

Owner:GEESUN AUTOMATION TECH

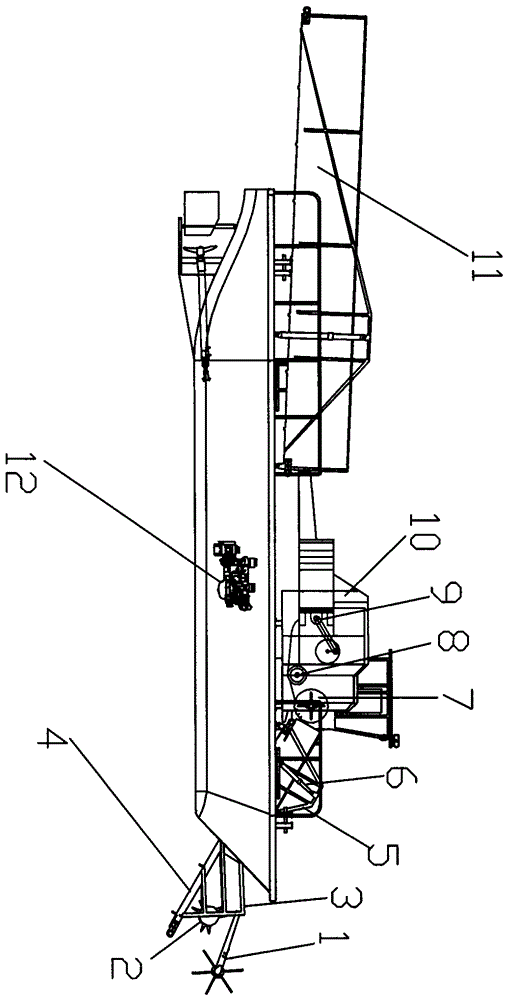

Full-automatic float-garbage clearing and packaging vessel

ActiveCN104097751AReduce volumeIncrease loading capacityWaterborne vesselsSpecial purpose vesselsMarine engineeringAquatic plant

The invention discloses a full-automatic float-garbage clearing and packaging vessel. A vessel body is of a double-head single-hull type. The vessel comprises the vessel body, a collecting device, a smashing device, a screw conveying device, a compressing and bundling device and a storing and discharging device. The collecting device, the smashing device, the screw conveying device, the compressing and bundling device and the storing and discharging device are sequentially mounted from a vessel bow to a vessel stern in the vessel body. The collecting device is arranged between two heads of the vessel bow. The vessel is adaptable to cleaning riverway rubbish and aquatic plants and capable of compressing collected and smashed rubbish and aquatic plants, thus improving load of the vessel, shortening discharging time of round trip, facilitating discharging, increasing production efficiency and saving production cost.

Owner:ZHANGJIAGANG HAIFENG WATER SURFACE ENVIRONMENTAL PROTECTION MACHINERY

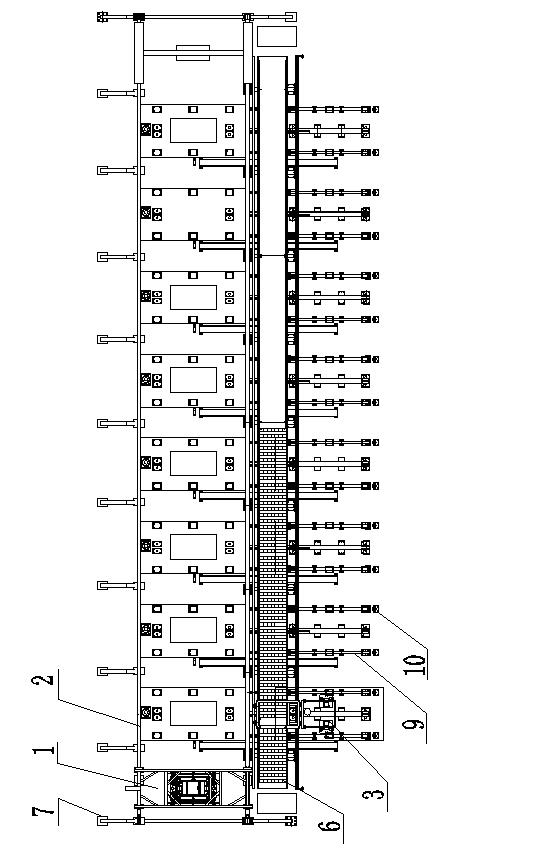

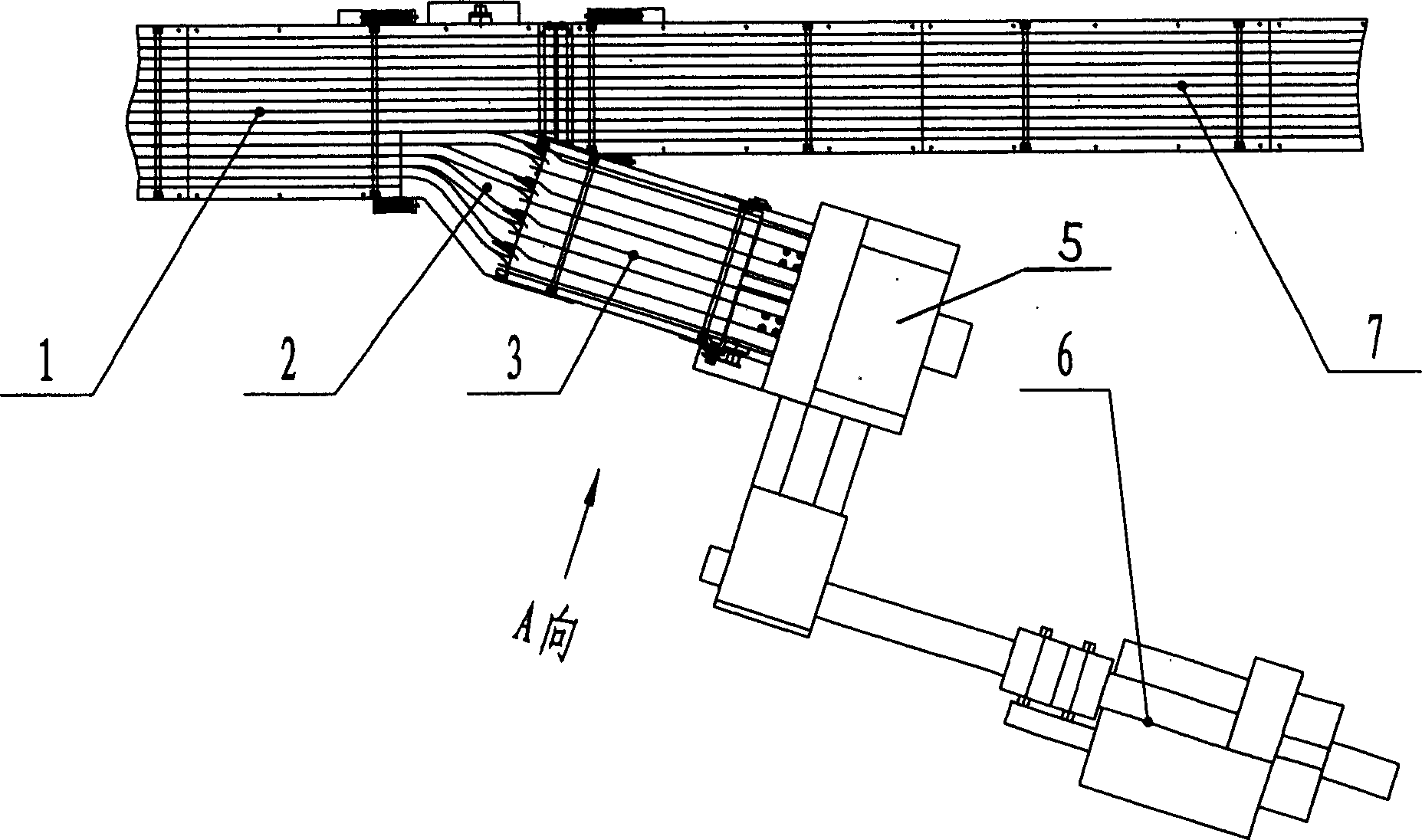

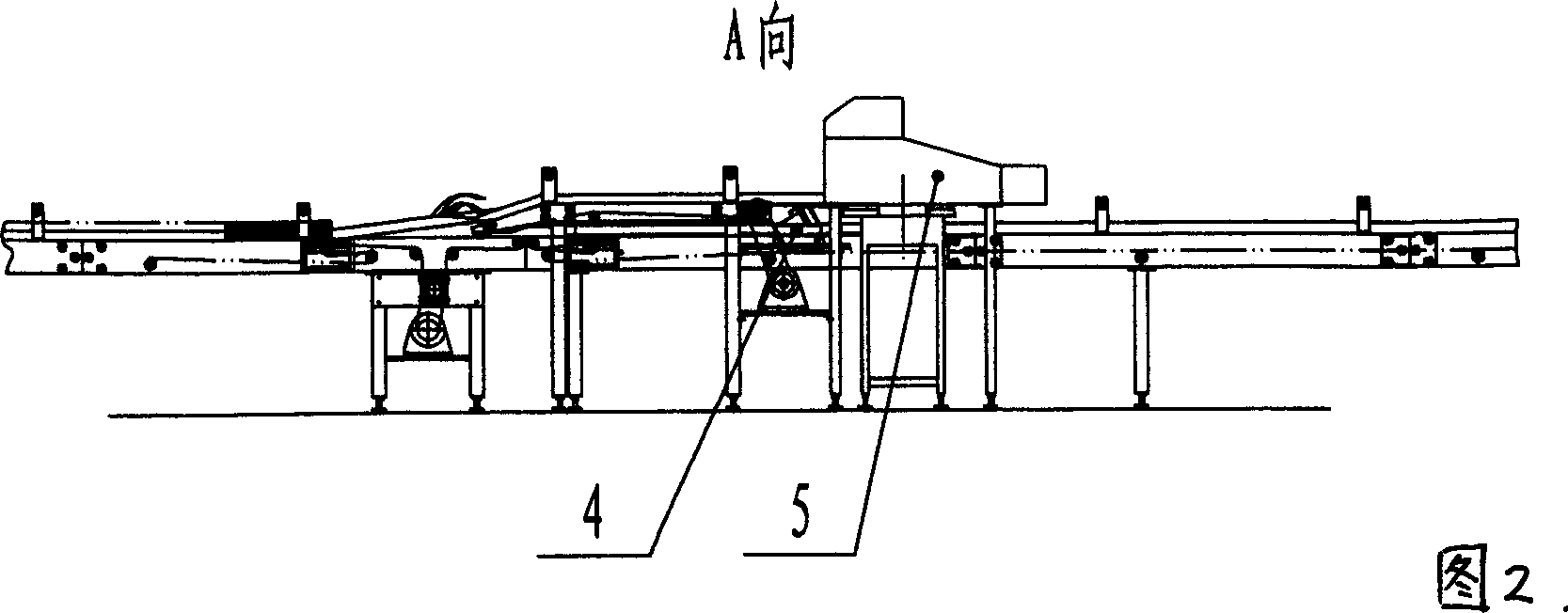

Multi-station refrigerator body foaming production line equipment

The invention discloses multi-station refrigerator body foaming production line equipment. A track and a trolley track are arranged on a rack, a die trolley rail is arranged on a foundation, a die trolley conveys a foaming die to a foaming station by gear rack transmission, a foaming manipulator runs to the foaming station on the trolley track, and a foaming mixing head is driven to lift by the lifting of a cylinder so that the foaming mixing head generates foam for the refrigerator body on the foaming station; and meanwhile, a taking manipulator runs on the track, the taking manipulator drives a vacuum sucking disc to work by stretching of the lifting cylinder and a link mechanism to lift up the foaming refrigerator body in a foaming die so as to realize the scheme that the foaming mixing head continuously generates foam for the refrigerator body on a plurality of foaming stations. The equipment overcomes the defects of high cost and complex control of the fixed refrigerator body production line and single type of the produced refrigerator products. The equipment is suitable for batch production of foaming products of various industries.

Owner:HUNAN JINGZHENG EQUIP MFG

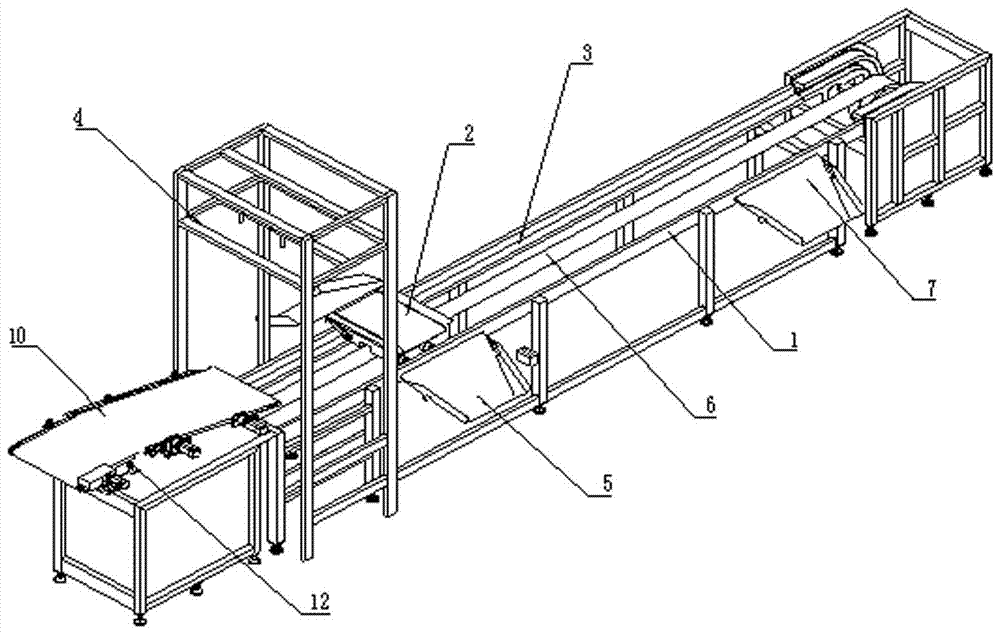

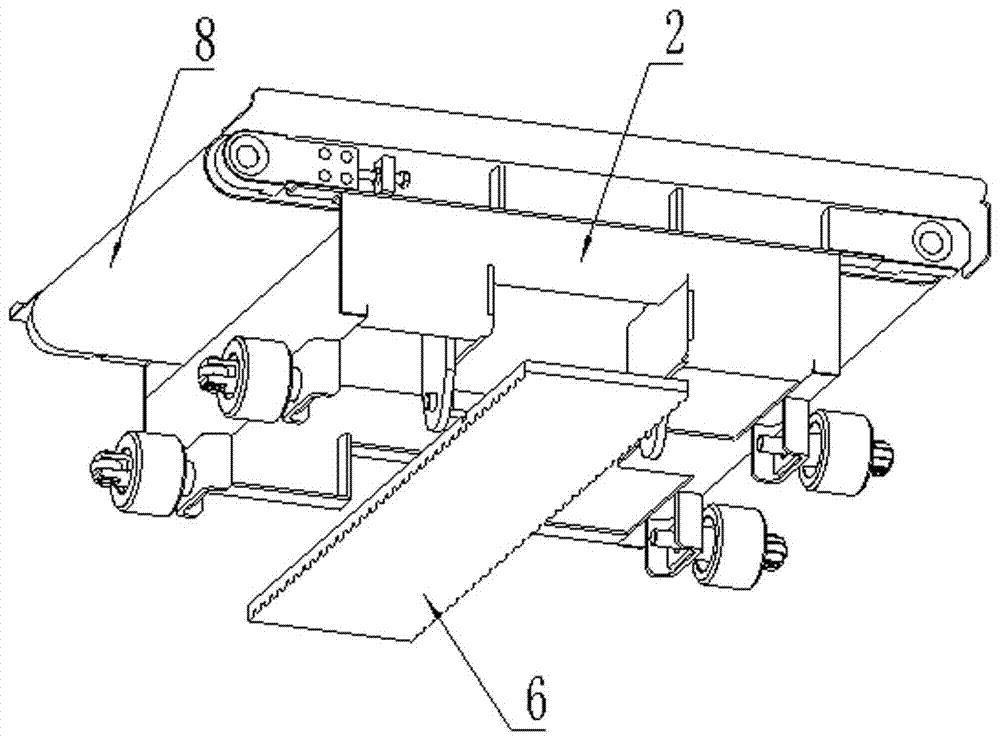

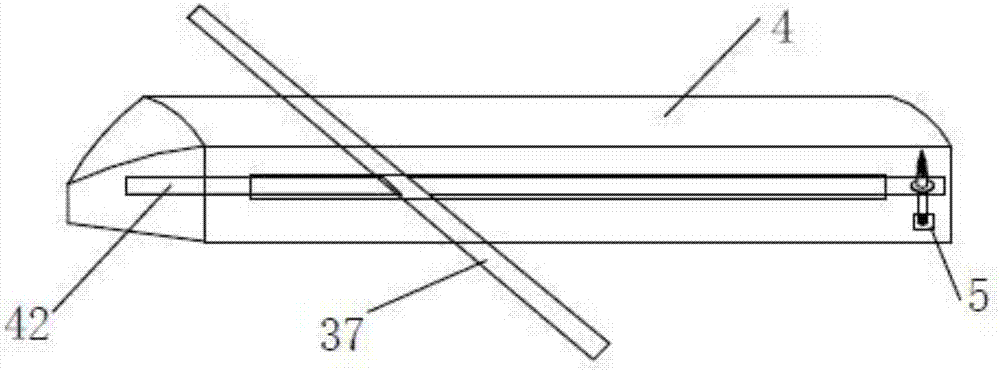

Straight line vertical type intersected belt sorting machine, and control system and control method thereof

The invention relates to a straight line vertical type intersected belt sorting machine. A main transmission conveying belt is arranged on the middle part of a frame body along the length direction; the main transmission conveying belt is connected with a plurality of sorting trolleys; material output devices are arranged on the sorting trolleys; a circular operation rail is arranged on the side surface of the frame body; a rolling wheel at the bottom of each sorting trolley rolls on the circular operation rail; a plurality of sorting feeding ports are formed in the two sides of the frame body; and a vision mechanism is arranged above the input end of the main transmission conveying belt. The sorting machine is simple in structure, low in cost and small in occupied space and is a high-efficiency sorting machine capable of preparing to sort single object; meanwhile, through the control system and the control method of the sorting machine, fully-automatic flow work is realized and a large amount of labor force is saved.

Owner:沈阳瑞晟智能装备有限公司

Automatic double-end sawing machine for processing chopping board

PendingCN109822677AReduce irregularitiesIncrease productivityFeeding devicesGripping devicesEngineeringMechanical engineering

An automatic double-end sawing machine for processing a chopping board comprises a frame, a conveying mechanism, a chopping-board horizontal-position adjustment system, a sawing device and a clampingconveying system, wherein the conveying mechanism is arranged on the frame and used for conveying the chopping board to a chopping-board horizontal-position adjustment station; the chopping-board horizontal-position adjustment system is used for adjusting the horizontal position of the chopping board so that two ends of each of an upper board layer and a lower board layer of the chopping board canbe cut; the sawing device is arranged at a sawing station and used for sawing the ends of the chopping board passing through; and the clamping conveying system is used for clamping the chopping boardof which the horizontal position is adjusted and for conveying the chopping board through the sawing station. The automatic double-end sawing machine for the chopping board is achieved; the choppingboard produced is more in line with the requirements; the problem of irregularity of the chopping board in manual sawing is solved; the risk during the processing is reduced; and more importantly, theautomatic double-end sawing machine can cooperate with other processing machines for the chopping board to realize full-automatic flow-line operation for processing the chopping board, thereby improving the production efficiencies of enterprises.

Owner:浙江千束家居用品有限公司

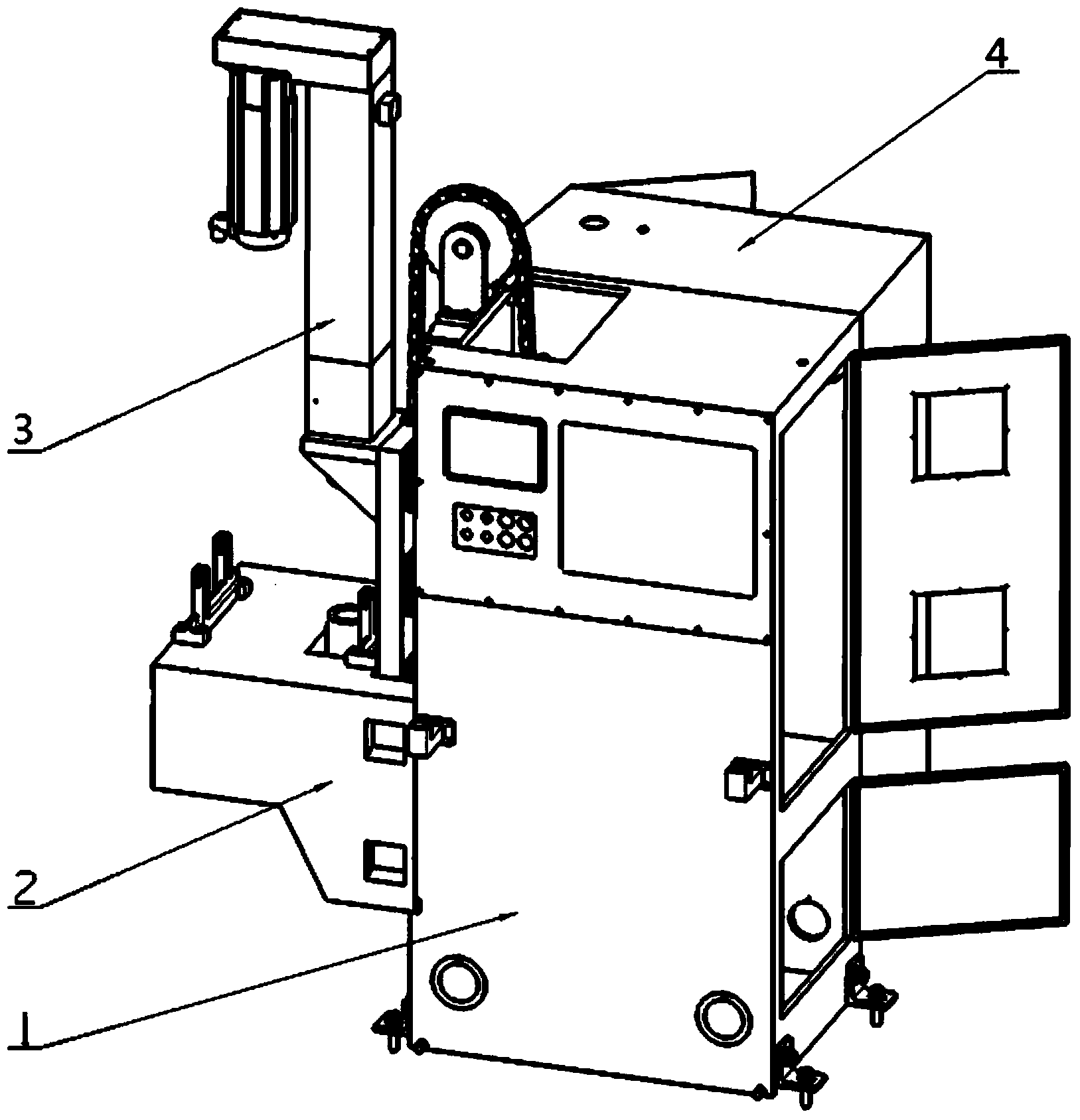

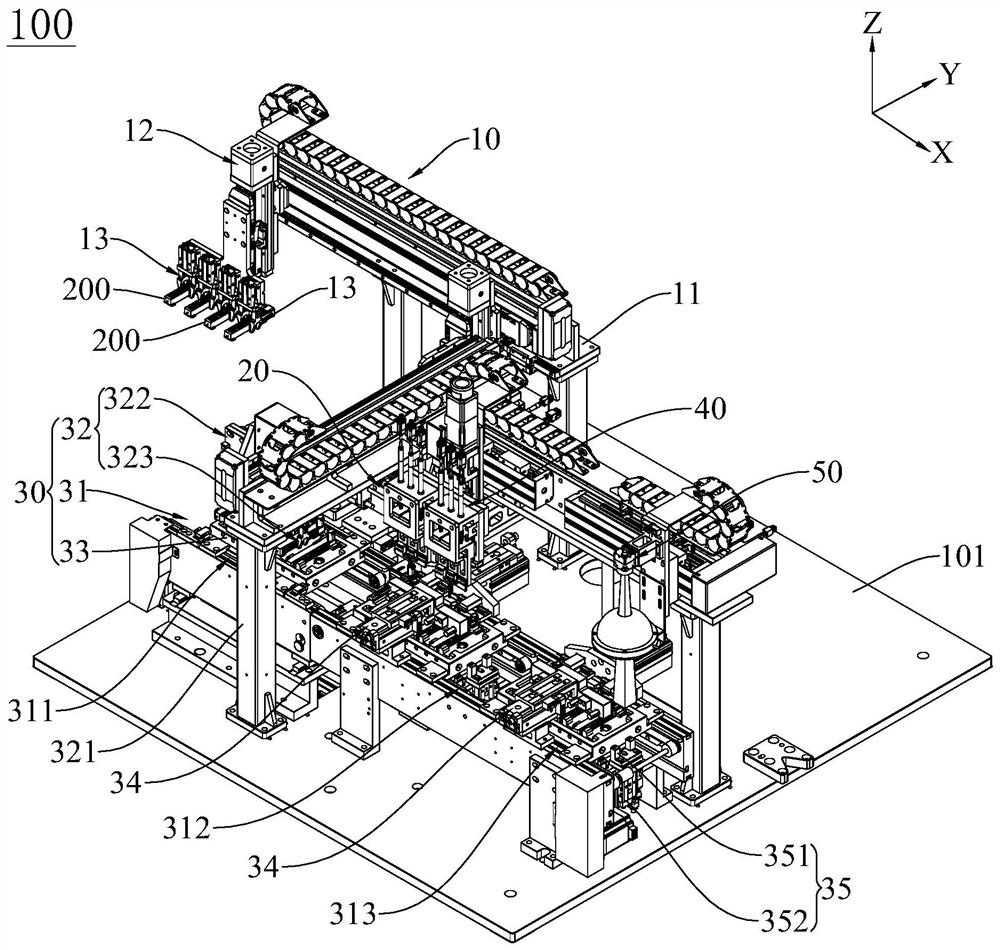

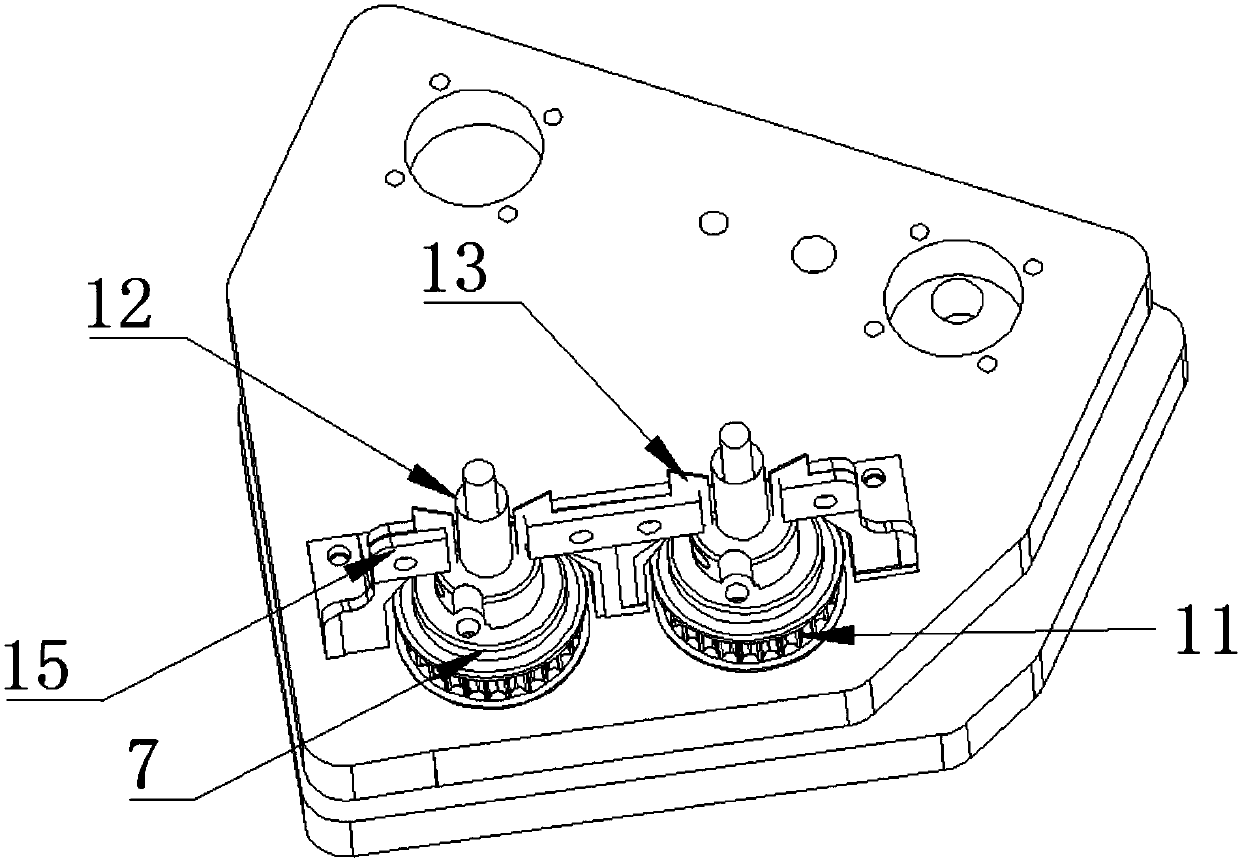

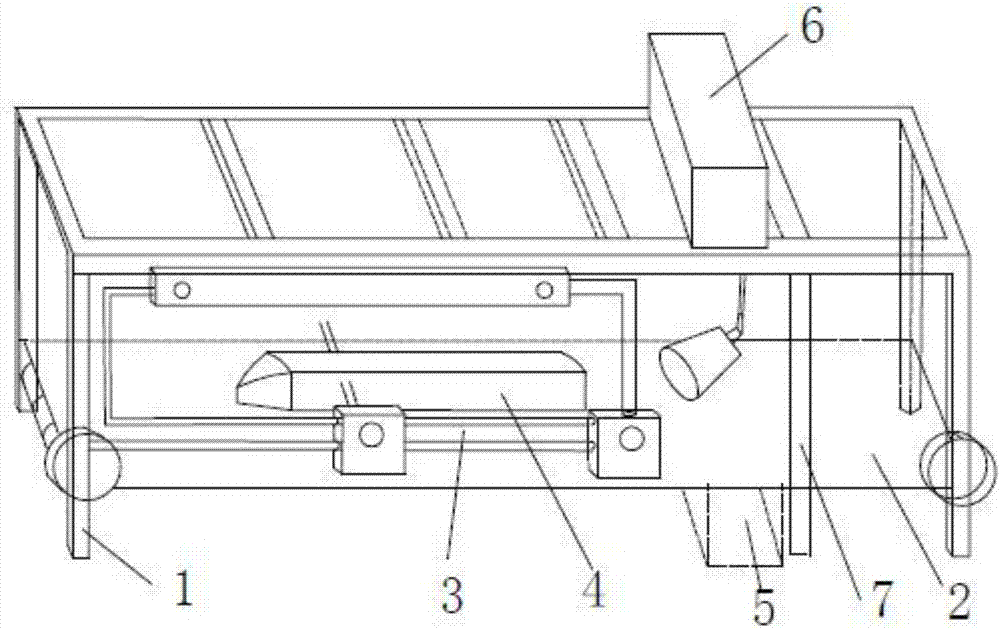

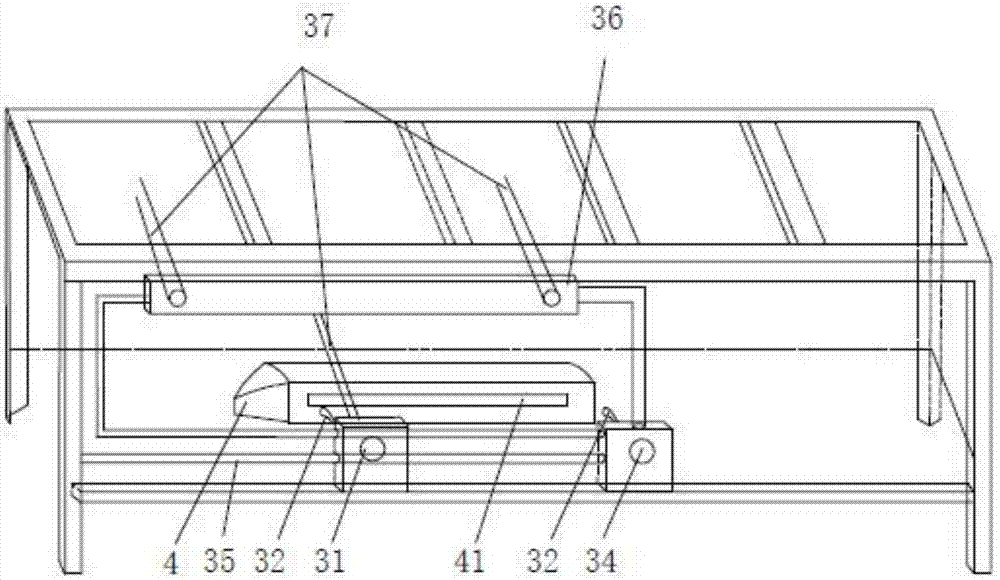

Linear glue dispensing quality detection device for loudspeaker diaphragm

ActiveCN106101976ARealize automatic flow operationHigh degree of automationElectrical transducersLoudspeakerMechanical engineering

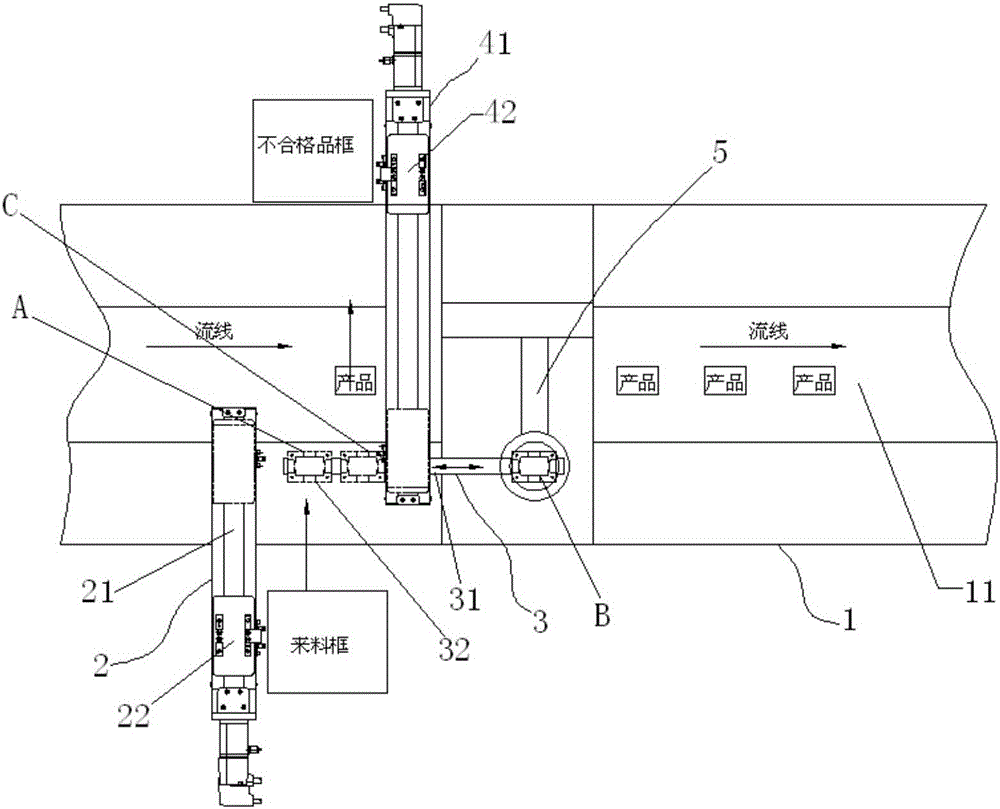

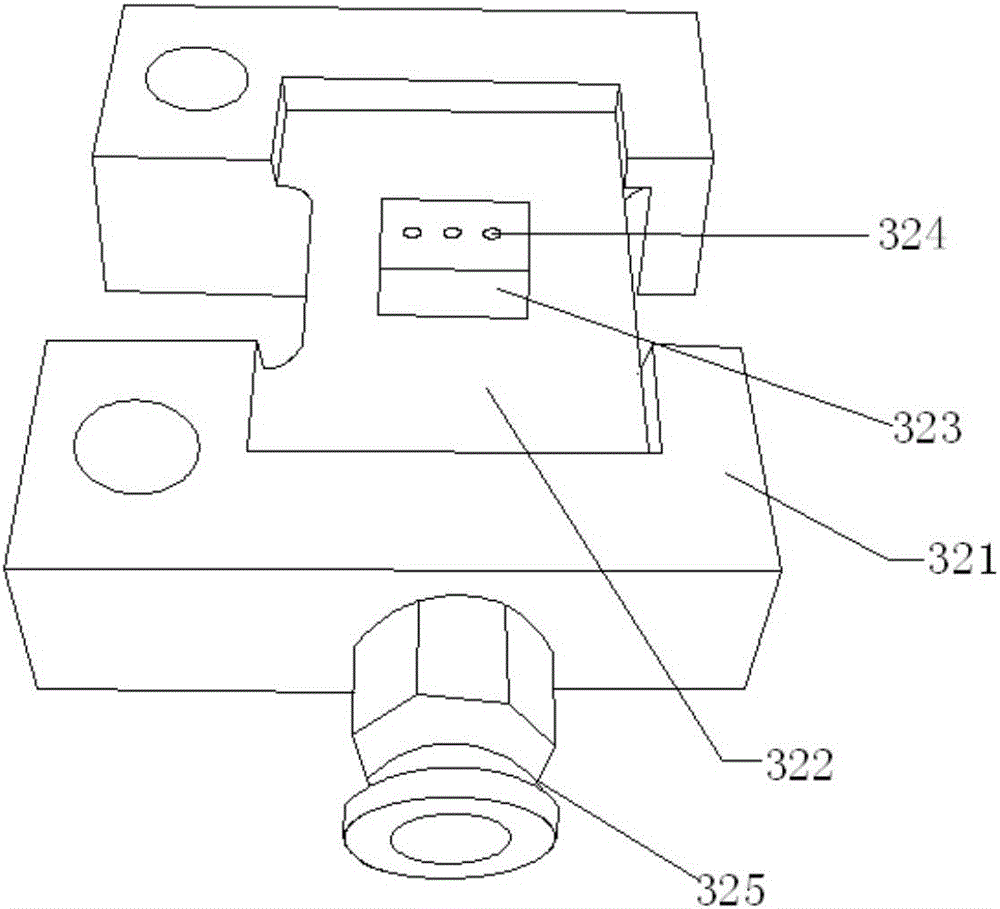

The present invention discloses a linear glue dispensing quality detection device for a loudspeaker diaphragm. The linear glue dispensing quality detection device comprises a transport pipeline mechanism, an automatic feeding mechanism, a to-be-fed and discharged material carrying mechanism, a linear station transport mechanism, an automatic discharging mechanism, and a glue dispensing and quality detecting mechanism. The transport pipeline mechanism transports a material out. The automatic feeding mechanism pushes the material to a feeding station, and the automatic discharging mechanism pushes unqualified material out from a discharging station. The to-be-fed and discharged material carrying mechanism carries the material to the feeding station and carries the material down from the discharging station. The material is automatically transported and located among the feeding station, a glue dispensing and quality detecting station and the discharging station by using the linear station transport mechanism. Through adoption of the device, the loudspeaker diaphragm material is fed and discharged automatically, the glue is automatically dispensed on the loudspeaker diaphragm material on the pipeline, glue dispensing quality is determined automatically, and the automated flow process is realized, so that the production efficiency is greatly improved, and labor cost is lowered.

Owner:KUNSHAN IND TECH RES INST INTELLIGENT MFG TECH CO LTD

Live pig slaughtering equipment

InactiveCN105981795AImprove slaughter efficiencyReasonable designSlaughtering/stunning masksBlood collection/stirring apparatusProduction lineBlood collection

The invention discloses live pig slaughtering equipment. The live pig slaughtering equipment comprises a rack and a live pig conveyor belt and is characterized in that pig body limiting devices capable of being automatically adaptive to the width of a pig body are arranged at the parts, located on the two sides of the live pig conveyor belt, of the rack; a lug boss capable of separating left and right legs of a live pig is arranged at the part, located in the middle of the live pig conveyor belt, of the rack; a nitrous oxide conveying system for automatically releasing nitrous oxide toward a pig nose is arranged at the part, located above the rear end of the lug boss, of the rack; a pig head limiting device for positioning a pig head is arranged at the part, located at the rear end of the lug boss, of the rack; a vacuum blood collection device for bleeding the live pig is arranged at the part, located on the rear side of the lug boss, of the rack; and a sharp corner inclined plane is arranged at the front end part of the lug boss. The live pig slaughtering equipment has the advantages of reasonable design and easiness of manufacturing; silent anaesthesia and slaughtering is realized and blood is completely released so as to ensure that no residual blood exists in pork; pollution-free vacuum blood collection is carried out so that the equipment is safe, reliable and sanitary; and automatic production line work can be realized and the live pig slaughtering efficiency is improved.

Owner:FOSHAN UNIVERSITY

Ultrasonic surface cleaning process for forged workpiece

The invention discloses an ultrasonic surface cleaning process for a forged workpiece. The process flow is as follows: feeding; entering an ultrasonic coarse cleaning tank; draining; spraying and rinsing under a high pressure; draining; entering an ultrasonic rinsing tank; wind shearing; cold air drying; and discharging. Technological parameters in the coarse cleaning tank and the rinsing tank are as follows: the concentration of an acidic cleaner is 3%-15% (pH=4-5.5), and the concentration of an alkaline cleaner is 3%-15% (pH=8-11); ultrasonic cleaning is performed at the temperature of 35-70 DEG C for 5-20 minutes under the conditions of ultrasonic power of 20-60kW and ultrasonic frequency of 20-45kHz; and ultrasonic rinsing is performed at the temperature of 25-45 DEG C for 5-15 minutes under the conditions of ultrasonic power of 20-60kW and ultrasonic frequency of 20-45kHz.

Owner:CITIC DICASTAL

Automobile oil seal online cutting and size detecting platform

ActiveCN110465991ARealize automatic flow operationModerate accuracySortingMetal working apparatusEngineeringWaste material

The invention discloses an automobile oil seal online cutting and size detecting platform comprising a platform, a control cabinet and an online cutting and size detecting system. The platform is installed on the top of the control cabinet. The online cutting and size detecting system is installed on the platform. The online cutting and size detecting system comprises a feeding module, a cutting module, a size detecting module and a sorting module. The feeding module comprises a feeding mechanism and a clamping mechanism. The cutting module comprises a cutting mechanism and a waste material collection mechanism. The size detecting module comprises a size detecting grabbing mechanism and a detecting mechanism. The sorting module comprises a sorting grabbing mechanism and a sorting mechanism. The invention provides the automobile oil seal online cutting and size detecting platform, the cutting, size detecting and sorting automated line production can be achieved for an oil seal through the oil seal online cutting and size detecting platform, the automobile oil seal online cutting and size detecting platform is appropriate in precision and high in efficiency, and the automated line production can be achieved.

Owner:CHANGCHUN UNIV OF SCI & TECH

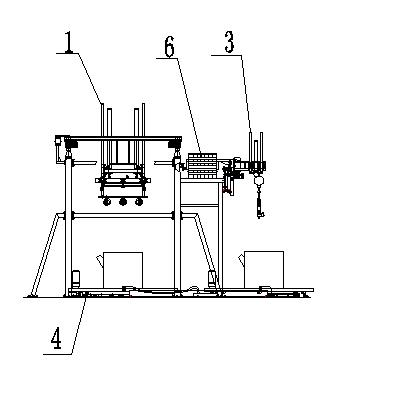

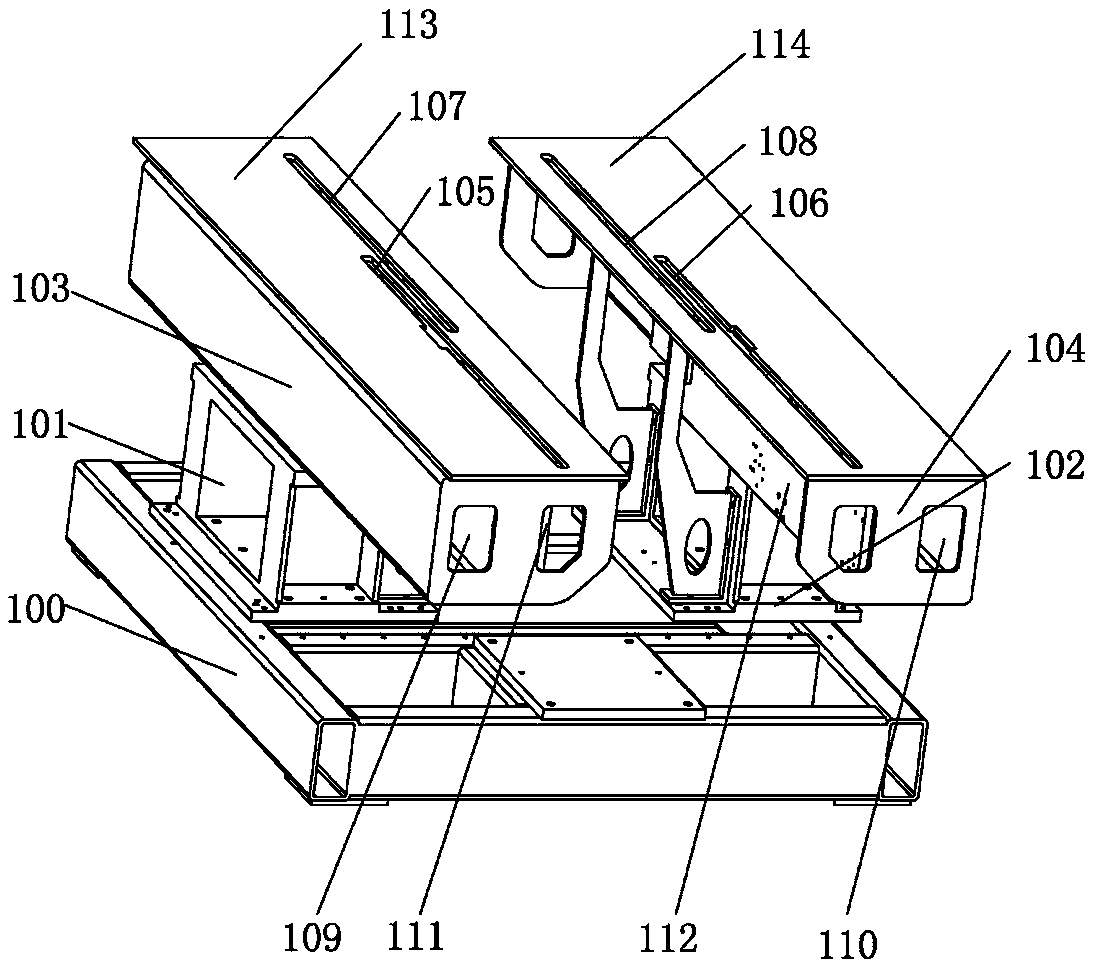

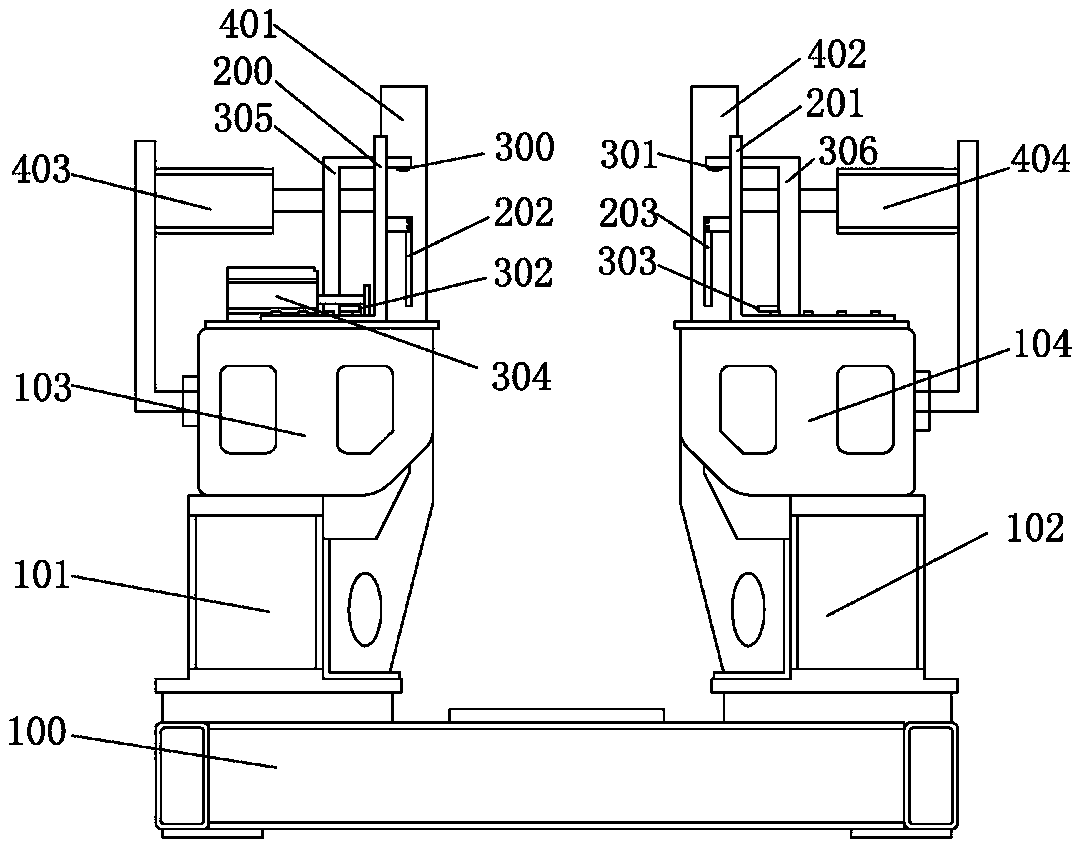

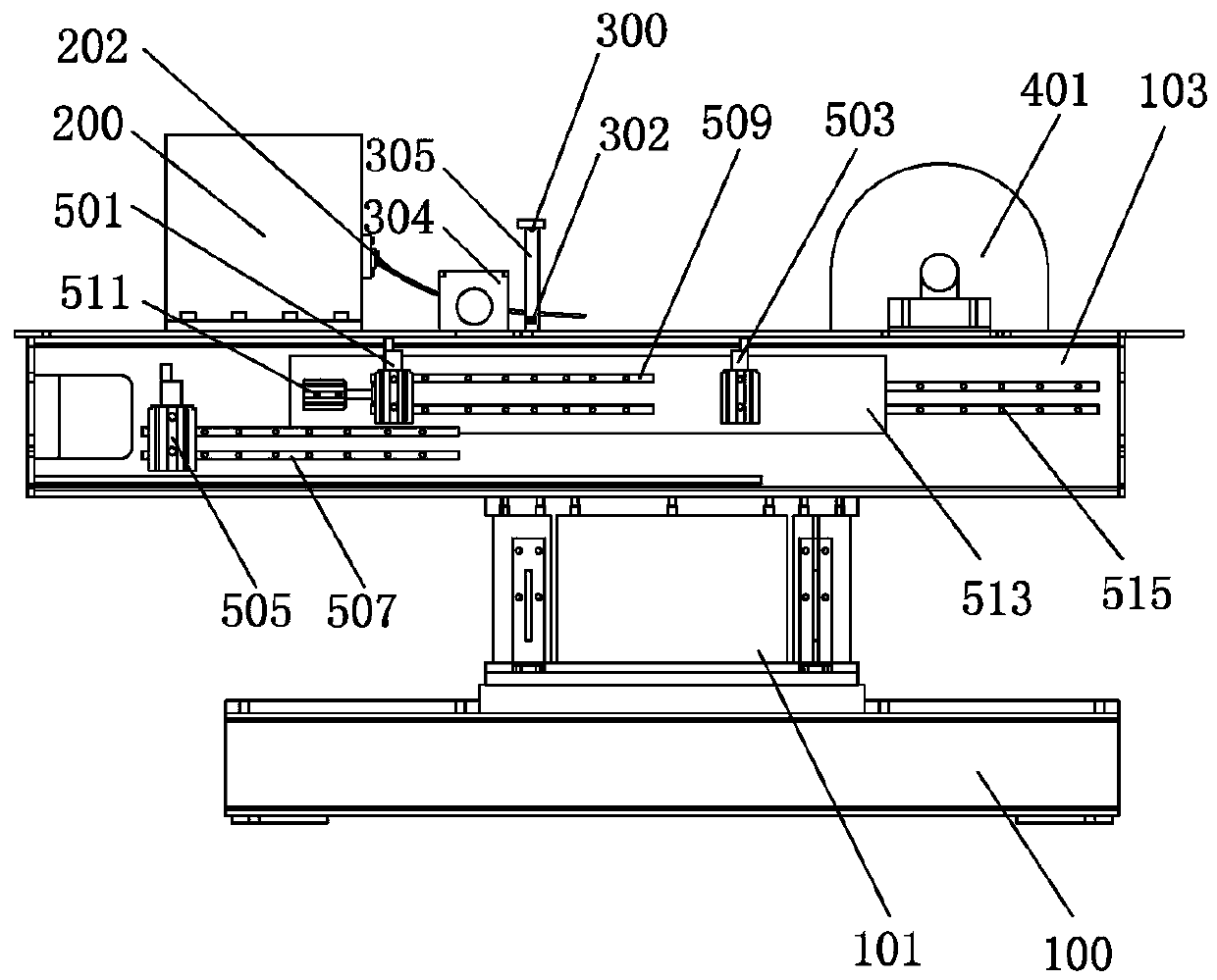

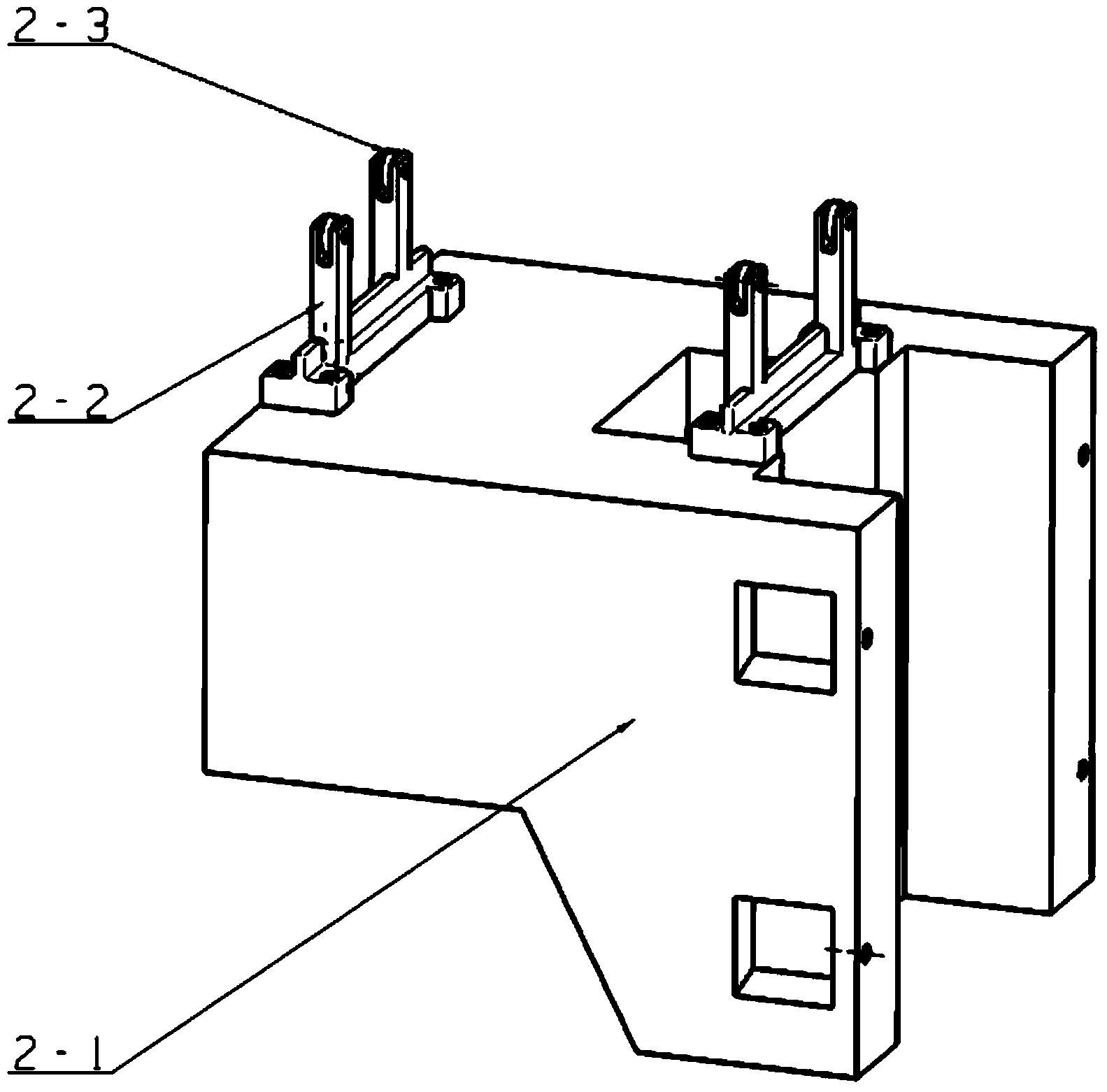

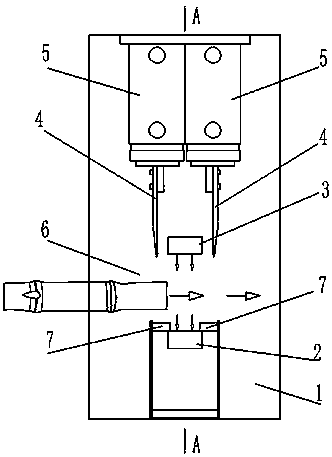

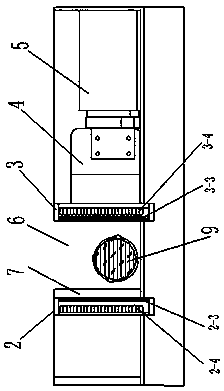

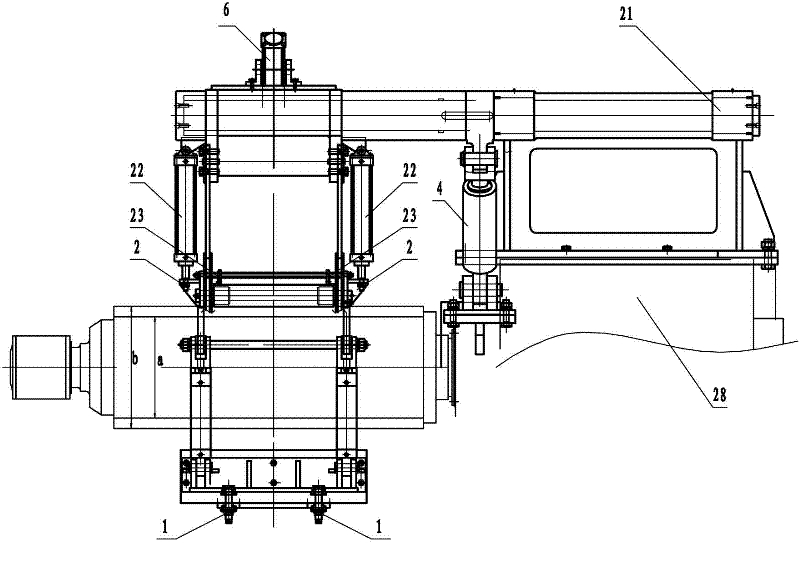

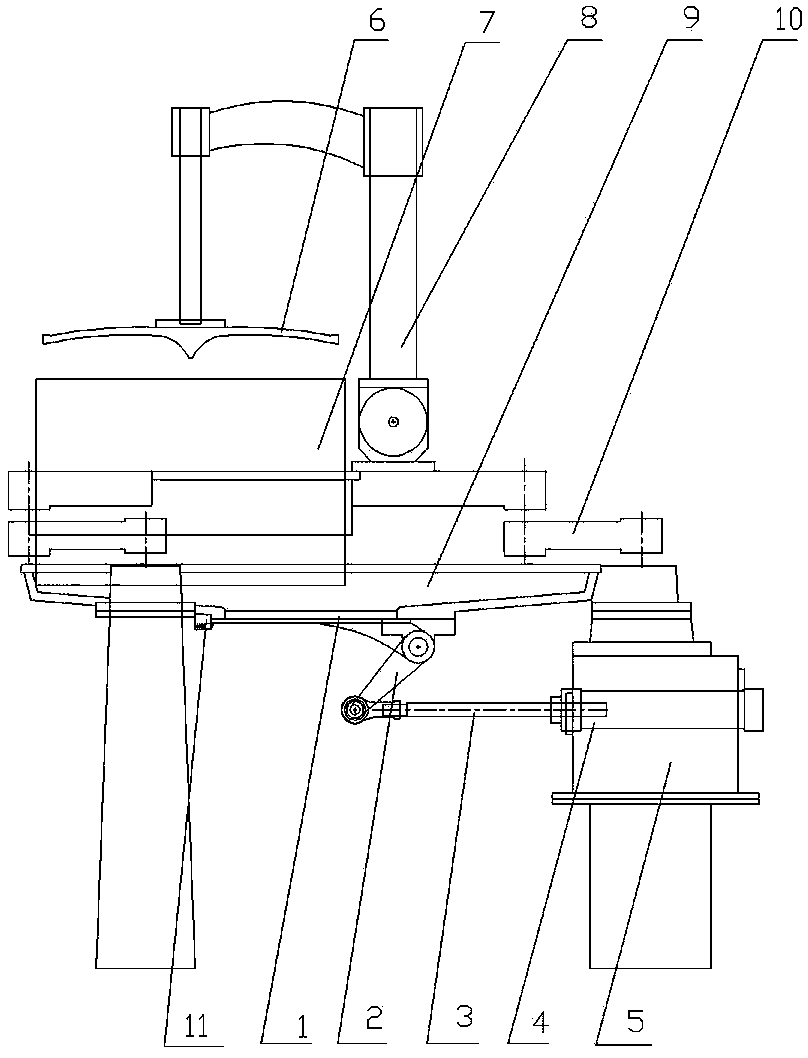

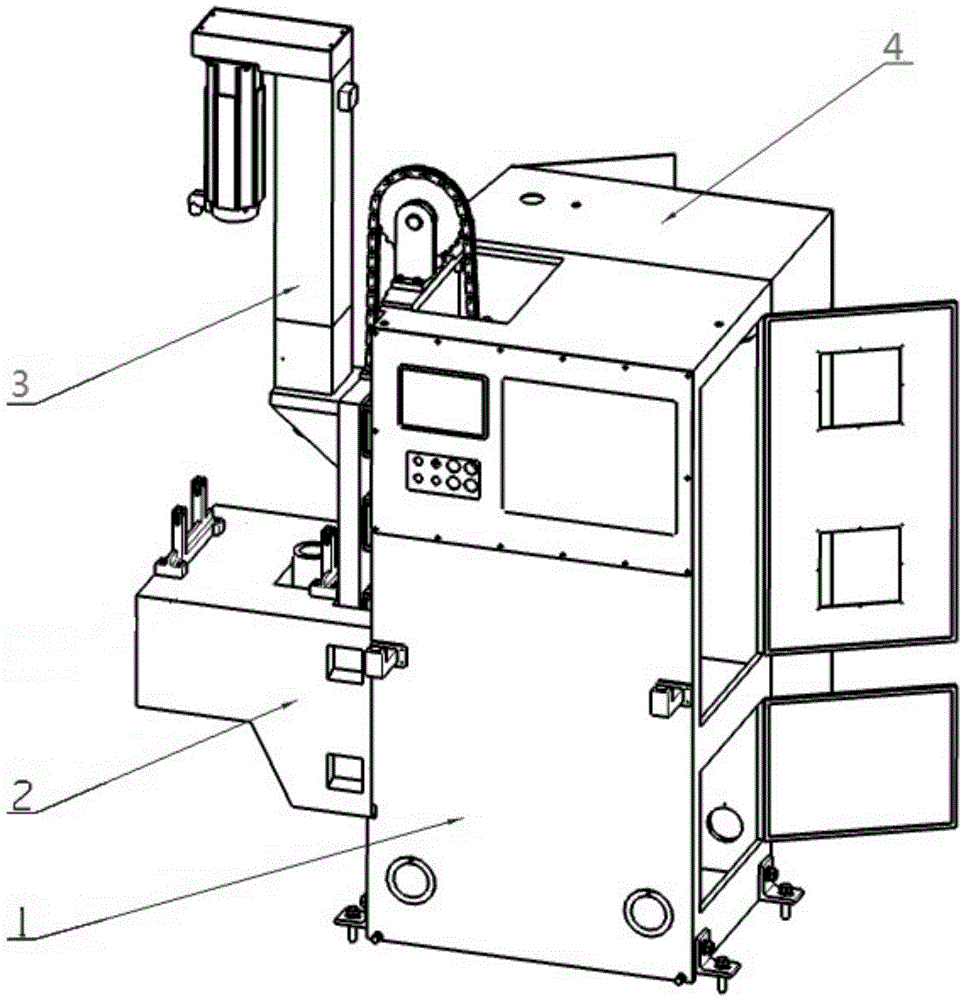

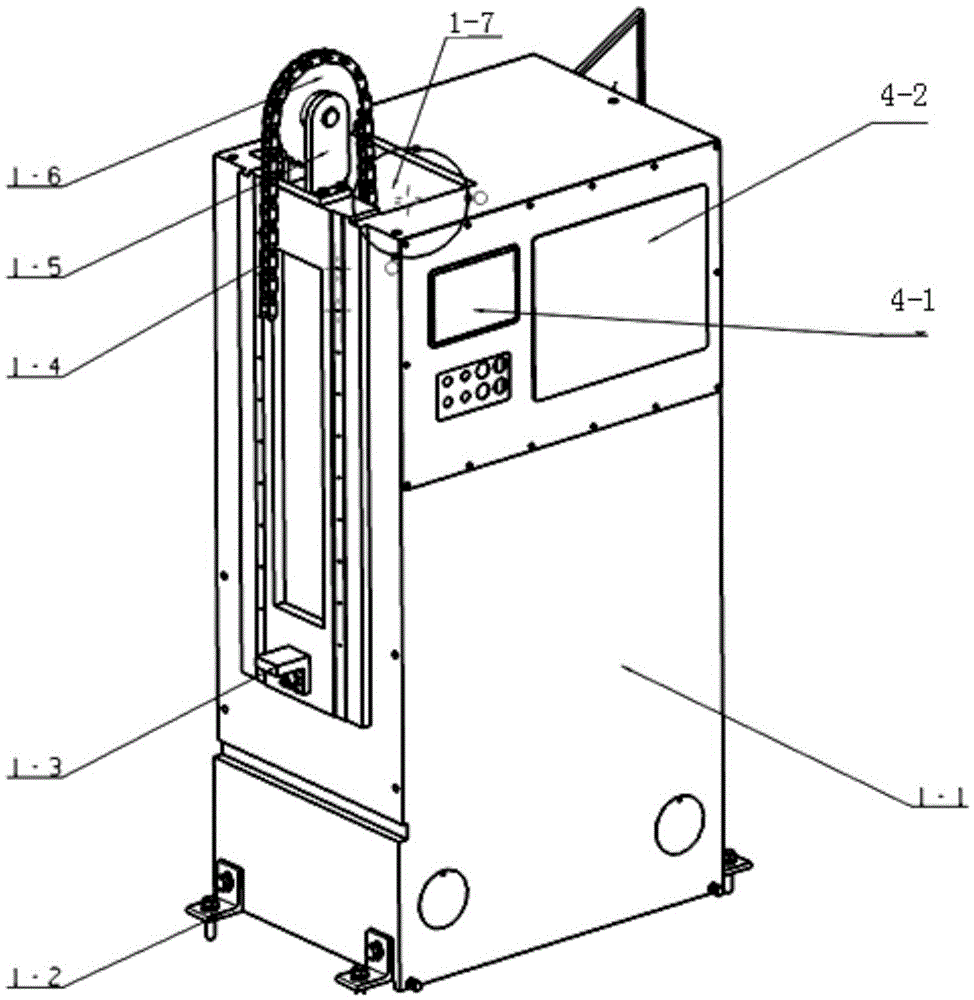

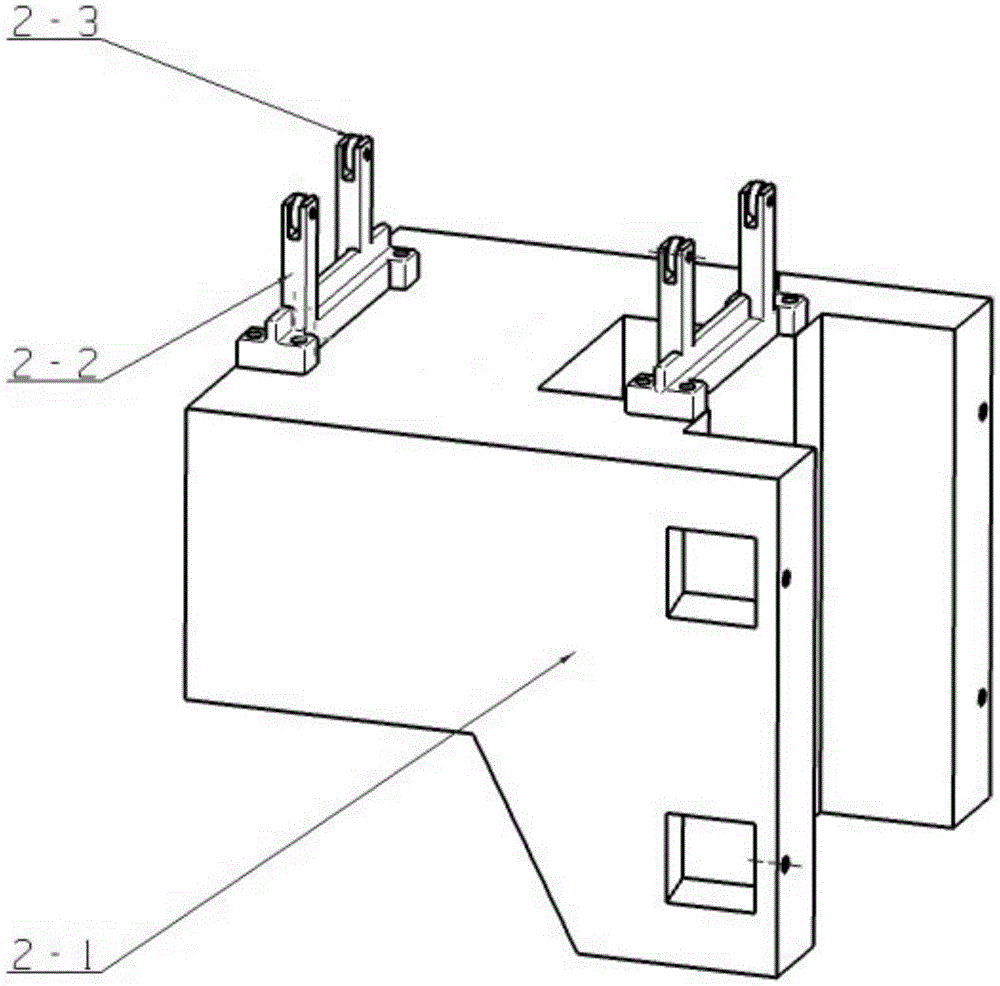

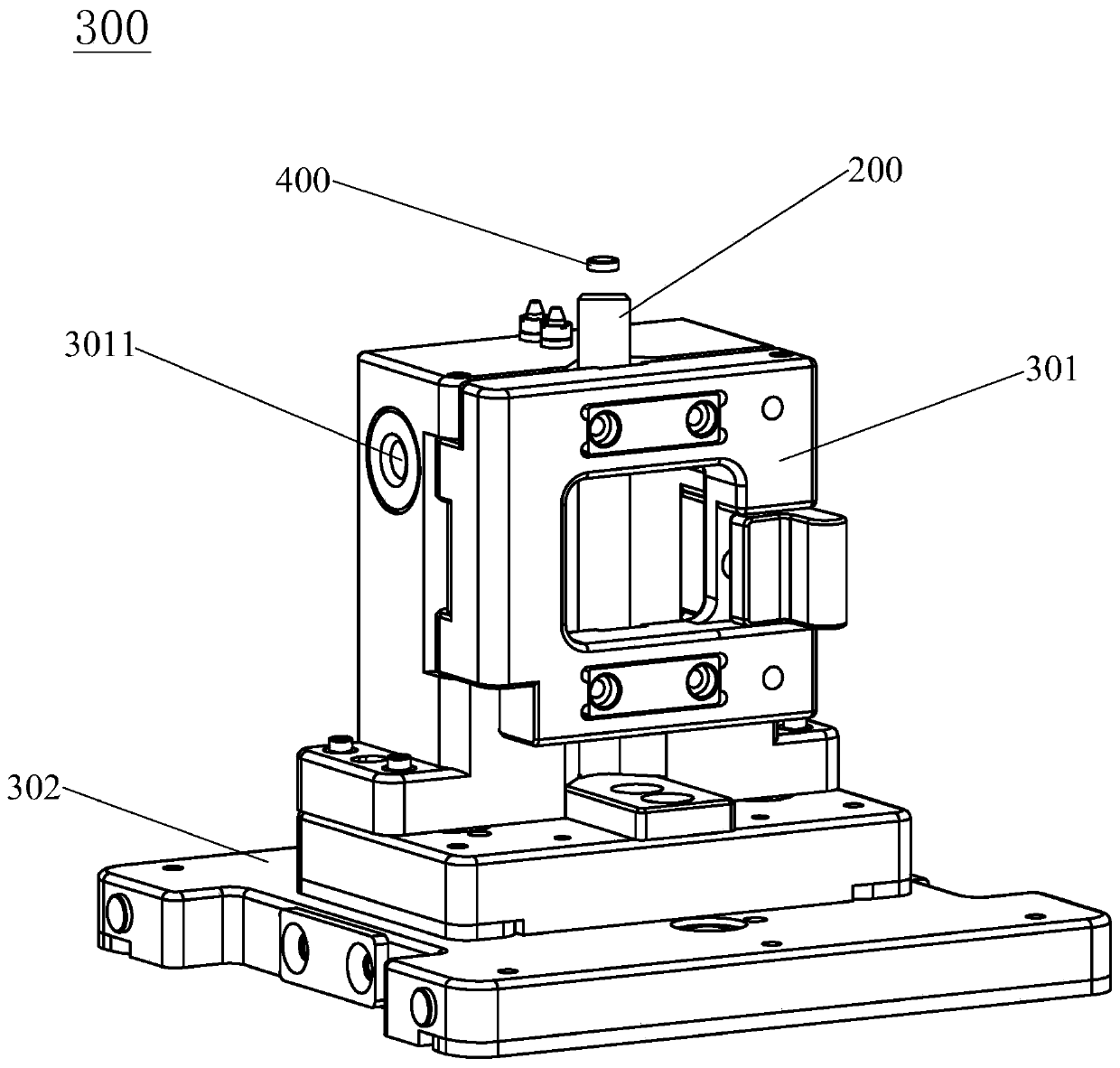

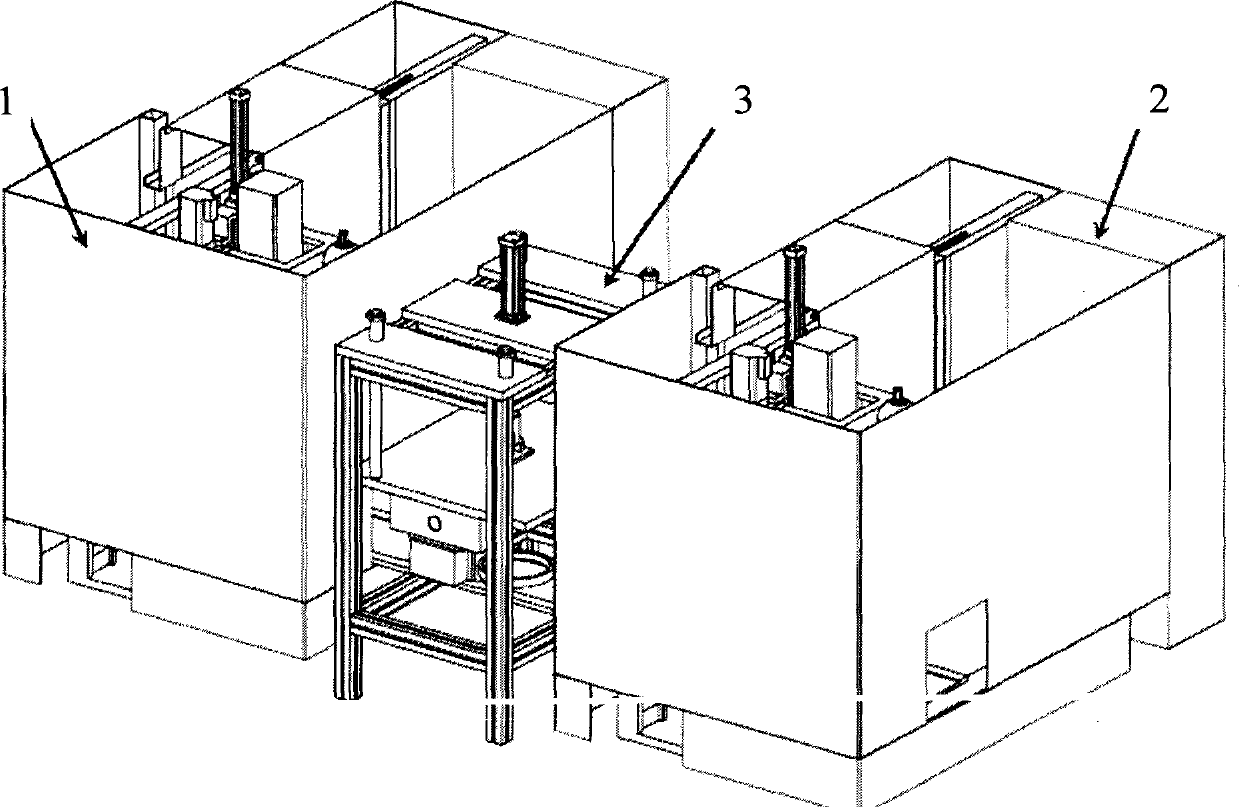

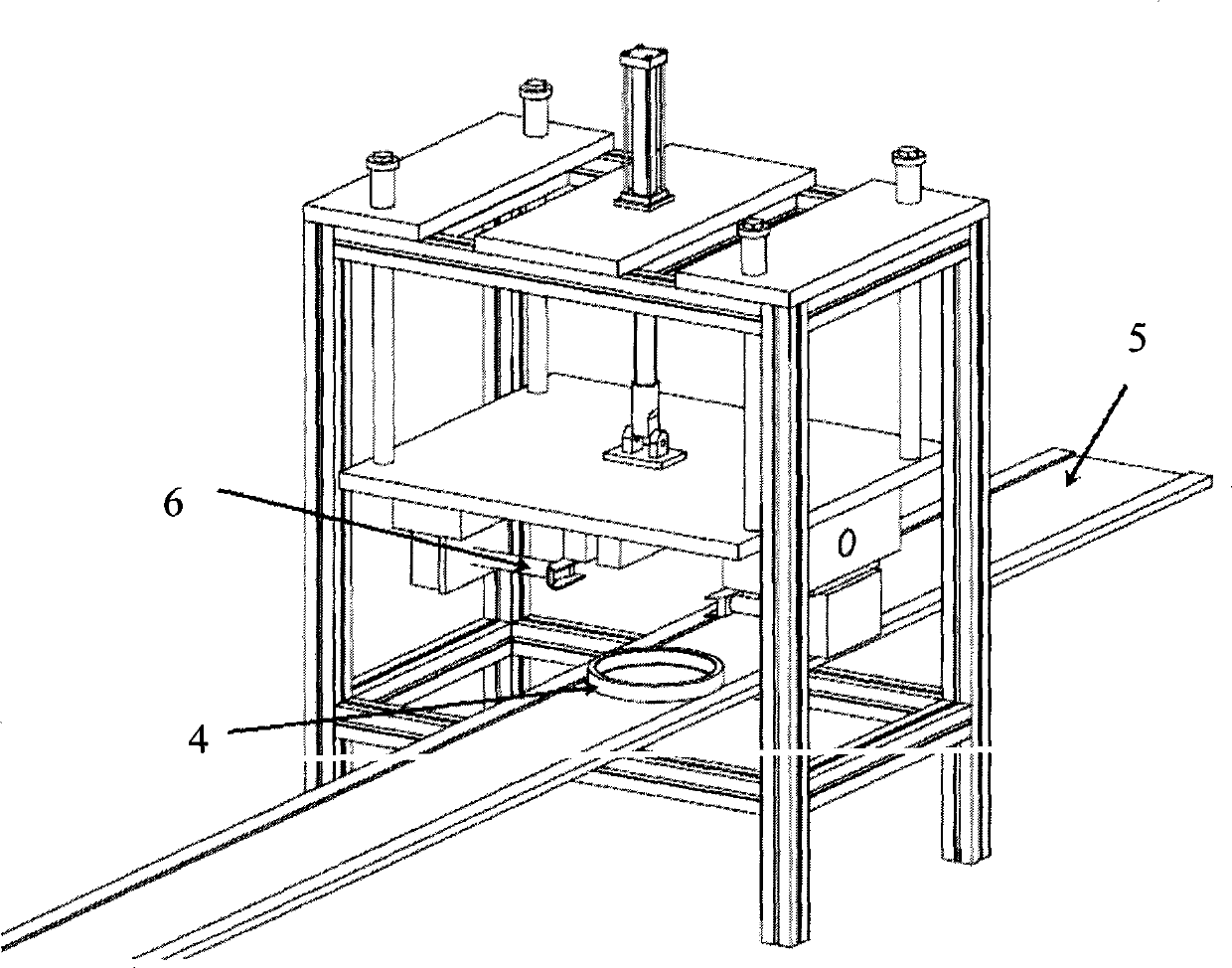

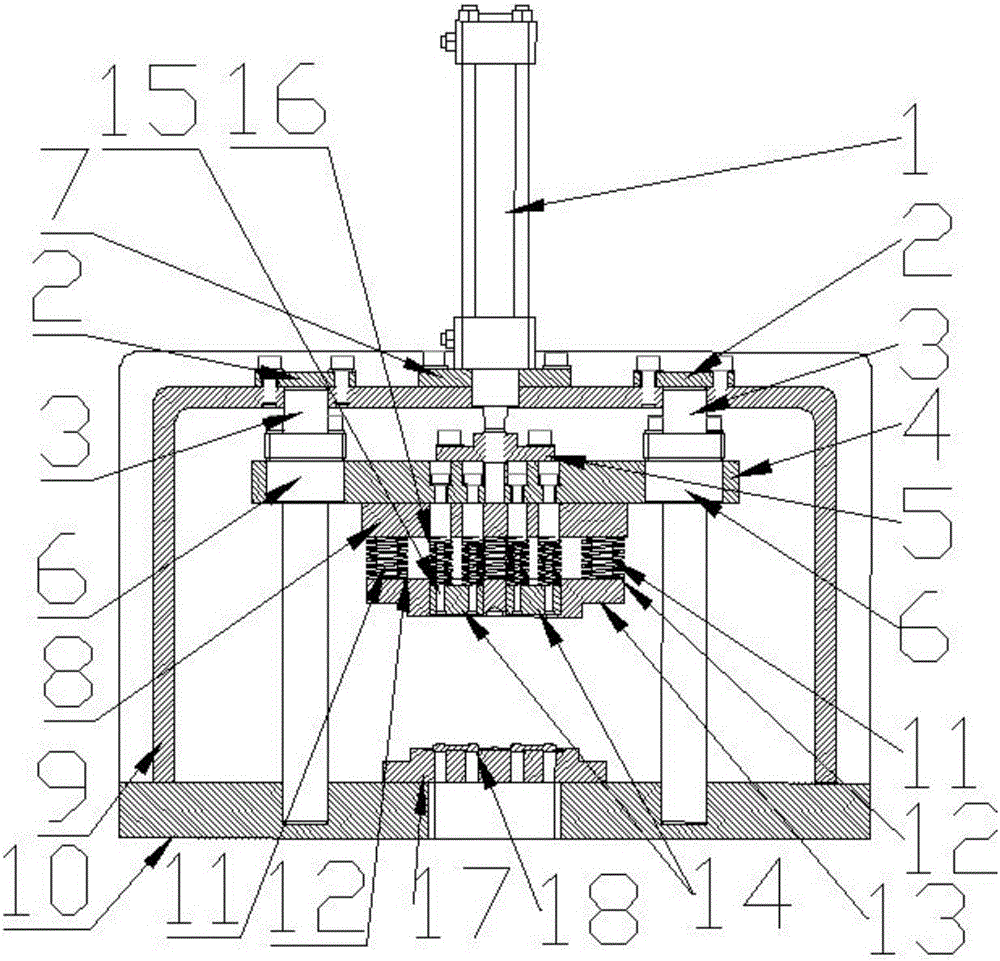

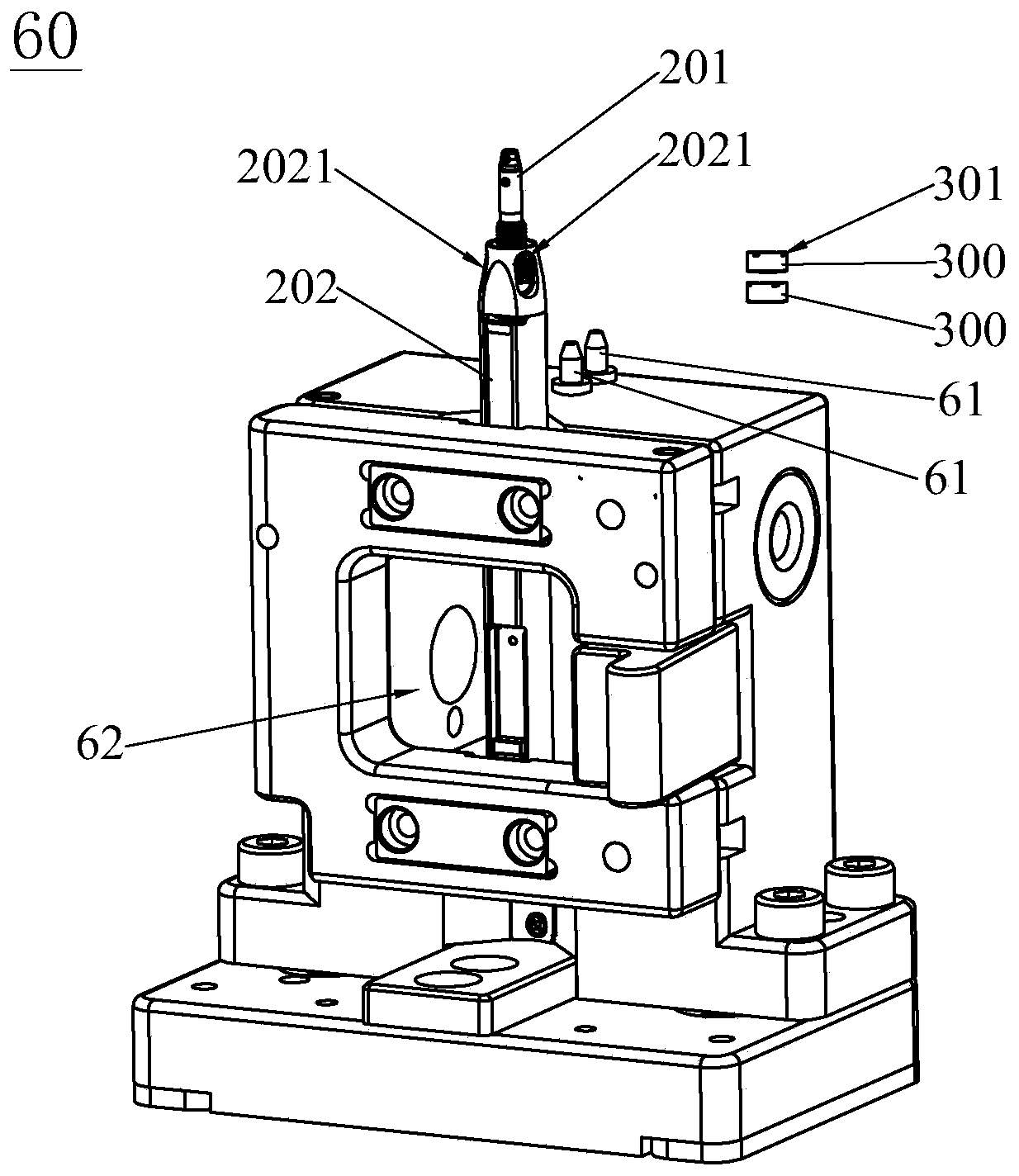

Rear bush automatic press mounting equipment for automotive suspension control arm

ActiveCN103949871AImprove reliabilityRealize automatic flow operationMetal working apparatusProduction lineControl arm

The invention provides a rear bush automatic press mounting equipment for an automotive suspension control arm. The press mounting equipment comprises an engine base component, a control arm supporting table component, an electric cylinder, a guide rail component and a control cabinet component, wherein the control arm supporting table component is fastened to the lower part of one side of the engine base component; the electric cylinder and the guide rail component are fastened to the upper part of the engine base component on the same side surface as the control arm supporting table component; the control cabinet component is fixed to the back of the engine base component through a bolt. The press mounting equipment provided by the invention can be operated on different occasions, can be mounted in a rear bush press mounting position of a production line to be cooperated with the production line so as to realize an automation line production, and can also be operated in a uniprocessor manner. The equipment has the advantages of high reliability, security and stability. The press mounting equipment provided by the invention uses a differential operating principle to convert the pressure of the press mounting rear bush into the internal force of a press machine to effectively remove the pressure acted on a tooling fixture in the press mounting process and ensure the accuracy and the stability of the press mounting.

Owner:SHANGHAI JIAO TONG UNIV

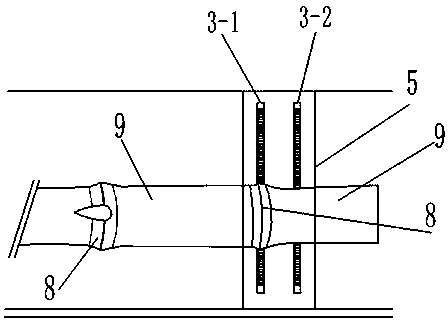

Seed bud recognition sensor of sugarcane cutting machine

InactiveCN111457849AIncrease nutrient supplyCalculate movement speedUsing optical meansMetal working apparatusAgricultural engineeringEngineering

The invention discloses a seed bud recognition sensor of a sugarcane cutting machine. The seed bud recognition sensor comprises an emitting mechanism and a receiving mechanism, the emitting mechanismis provided with a light source emitting unit A and a light source emitting unit B which are arranged in parallel; the receiving mechanism is provided with a signal receiving unit A and a signal receiving unit B which are installed in parallel, the seed bud recognition sensor can intelligently detect and judge sugarcane sections containing sugarcane buds and the accurate positions of the sugarcanesections, and when sugarcane passes through the cutting channel of the sugarcane section cutting machine, automatic cutting is conducted, and the sugarcane sections are located in the middles of thesugarcane sections.

Owner:广西孚农科技有限公司

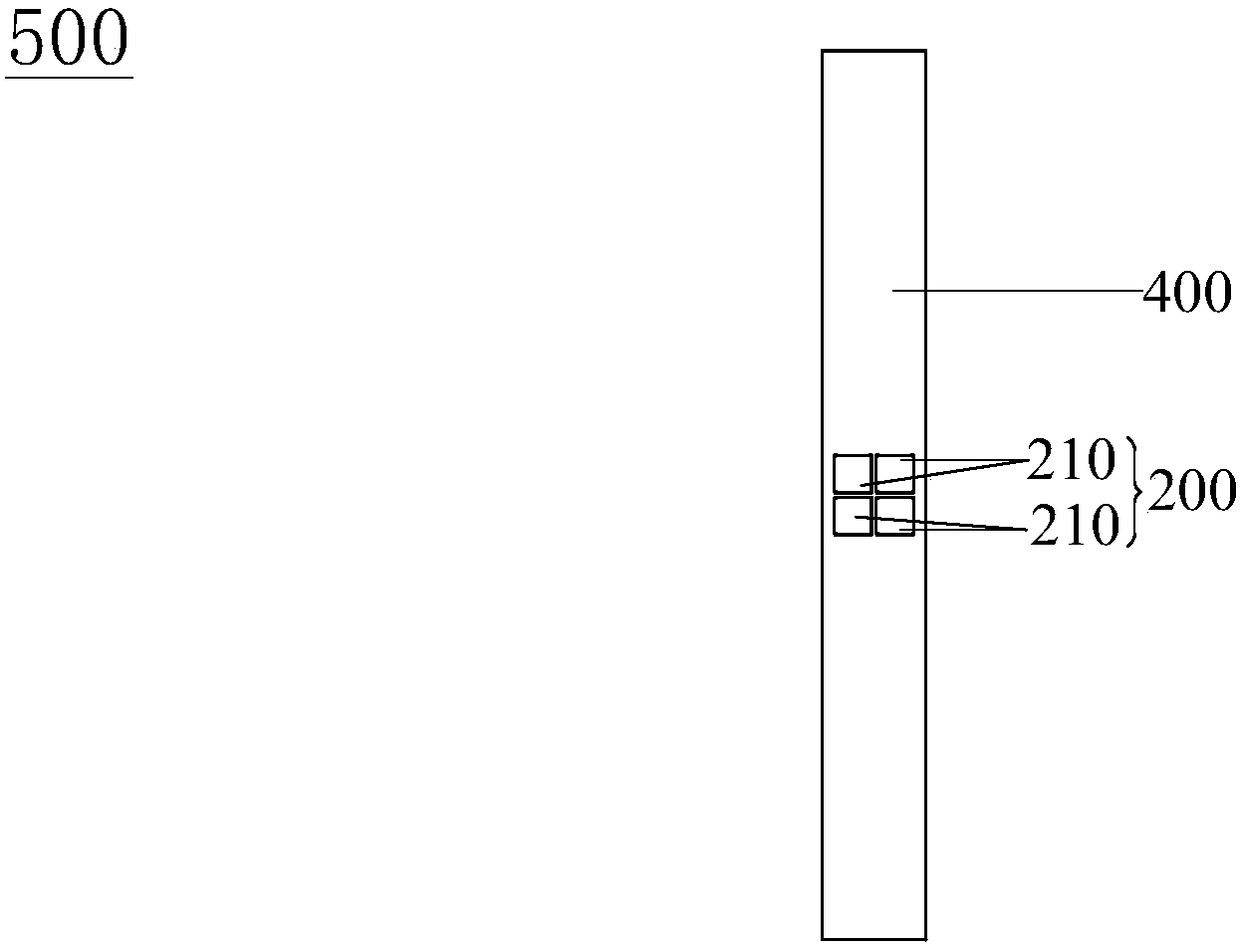

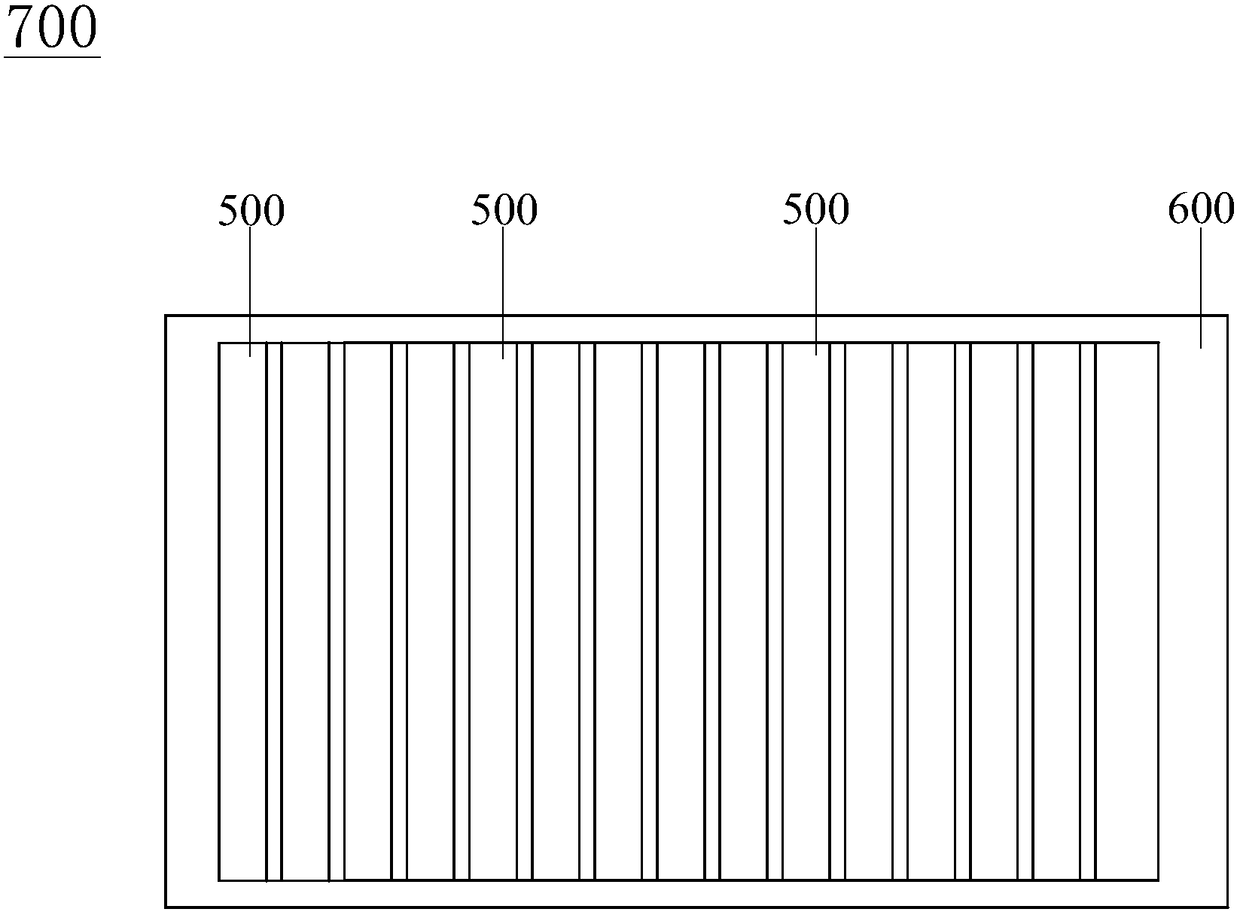

Full-automatic PCB board splitting machine

PendingCN108834316ARealize automatic flow operationImprove work efficiencyInsulating layers/substrates workingMetal working apparatusDepanelingEngineering

The invention discloses a full-automatic PCB board splitting machine, which relates to the technical field of PCB board splitting equipment. The full-automatic PCB board splitting machine adopts a feeding and conveying mechanism, a feeding mechanism, a board splitting mechanism, a discharging mechanism and a discharging and conveying mechanism which are arranged on a machine frame and operate cooperatively, wherein the feeding and conveying mechanism is used for inputting a PCB at a preorder station to a feeding station, the feeding mechanism is used for moving the PCB from the feeding stationto a board splitting station, the discharging mechanism is used for moving the PCB from the board splitting station to a discharging station, and the discharging and conveying mechanism is used for outputting the processed PCB. The full-automatic PCB board splitting machine realize the fully automatic assembly line operation of the PCB in the process from aligned transmission to feeding, board splitting, discharging and output, and has the advantages of high working efficiency, good board splitting quality, high yield, high automation degree and low labor cost.

Owner:江门市蓬江区科技中心

Automatic-feeding metered-packing biscuit production process

ActiveCN1803536ACan't solveSolve the problem of automatic docking of packaging machineSolid materialConveyor partsButt jointEngineering

The invention discloses an improvement craft of biscuit batch package in the food package technique domain, which is characterized by the following: steering the biscuit; shocking to feed the material; transmitting material with speed difference; gauging batch length; solving the problem that the array of biscuit can't butt-joint the packer; reducing the labor strength and biscuit pollution; realizing automatic streamline working; fitting for packing the rectangle shaped biscuit.

Owner:青岛食品股份有限公司

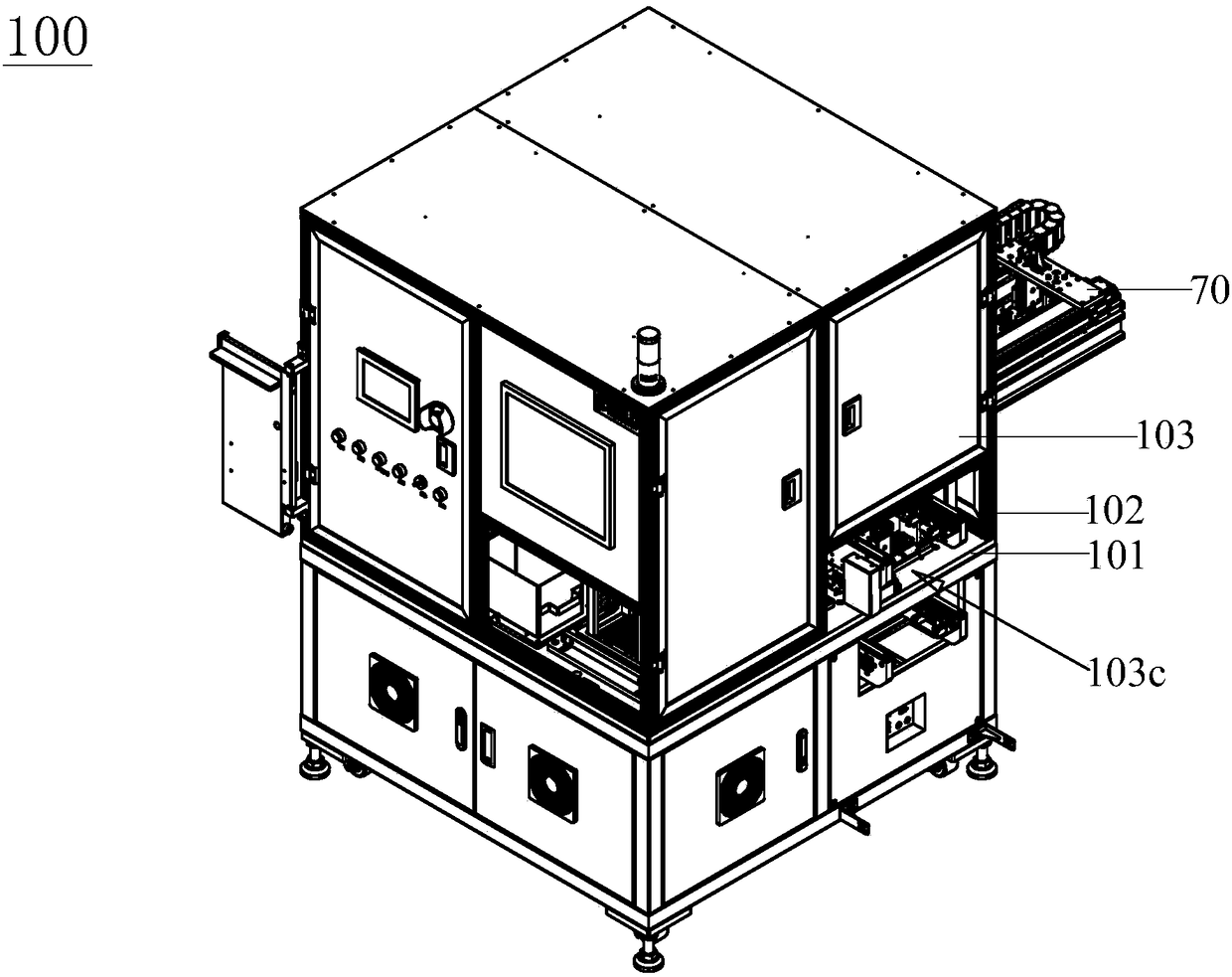

Detection machine

PendingCN112284315AImprove detection efficiencyHigh degree of automationUsing optical meansConveyor partsComputer hardwareEngineering

The invention discloses a detection machine. The detection machine comprises a feeding device, a conveying device, a steering device, a height detection device and a visual detection device, wherein the feeding device and the conveying device are arranged in parallel at intervals, the steering device is arranged between the feeding device and the conveying device, and the height detection device and the visual detection device are erected above the conveying device and sequentially arranged in the conveying direction of the conveying device. The feeding device is used for transferring a filterto the steering device, the steering device can clamp the filter and rotate the filter by a certain angle, so that the end, provided with a PIN, of the filter is rotated to be placed upwards, and theconveying device is used for conveying the filter with the PIN facing upwards at the steering device. The height detection device is used for detecting the assembling height of the PIN of the warp-passing filter, and the visual detection device is used for detecting the assembling position of the PIN of the warp-passing filter. The machine is high in automation degree, and can realize automatic line production for detecting the assembly of the PIN of the magnetic core in the filter.

Owner:DONGGUAN WORLD PRECISION MACHINERY

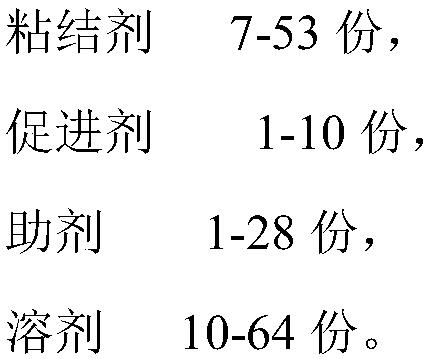

Method for hotly plating zinc and aluminum on surface of steel product

InactiveCN108395806APerformance is easy to controlSimple processAnti-corrosive paintsEpoxy resin coatingsPipe fittingFree cooling

The invention discloses a method for hotly plating zinc and aluminum on the surface of a steel product. The method comprises the following steps: (1) pre-treating: carrying out oil removal and rust removal treatment on the surface of the steel product and wiping and cleaning; (2) immersing: putting a workpiece treated by step (1) into a zinc and aluminum plating solution; after immersing for 5 to10 seconds, draining; (3) baking: transferring the workpiece treated by step (2) into a baking device and baking; (4) naturally cooling to room temperature and packaging to obtain a finished product.The method disclosed by the invention has a simple technology and no emission of VOC (Volatile Organic Compounds); automatic line production can be realized and the performance of a plated layer is controllable in real time; a finished product has stable quality and high yield; parts which are difficultly electroplated with zinc, such as deep holes, slits and pipe fitting inner walls, also can beuniformly coated and plated; the method is especially applicable to surface protection of abnormal-shape members including lamp rods, steel pipes, parts and the like.

Owner:中山市普利斯顿化工科技有限公司

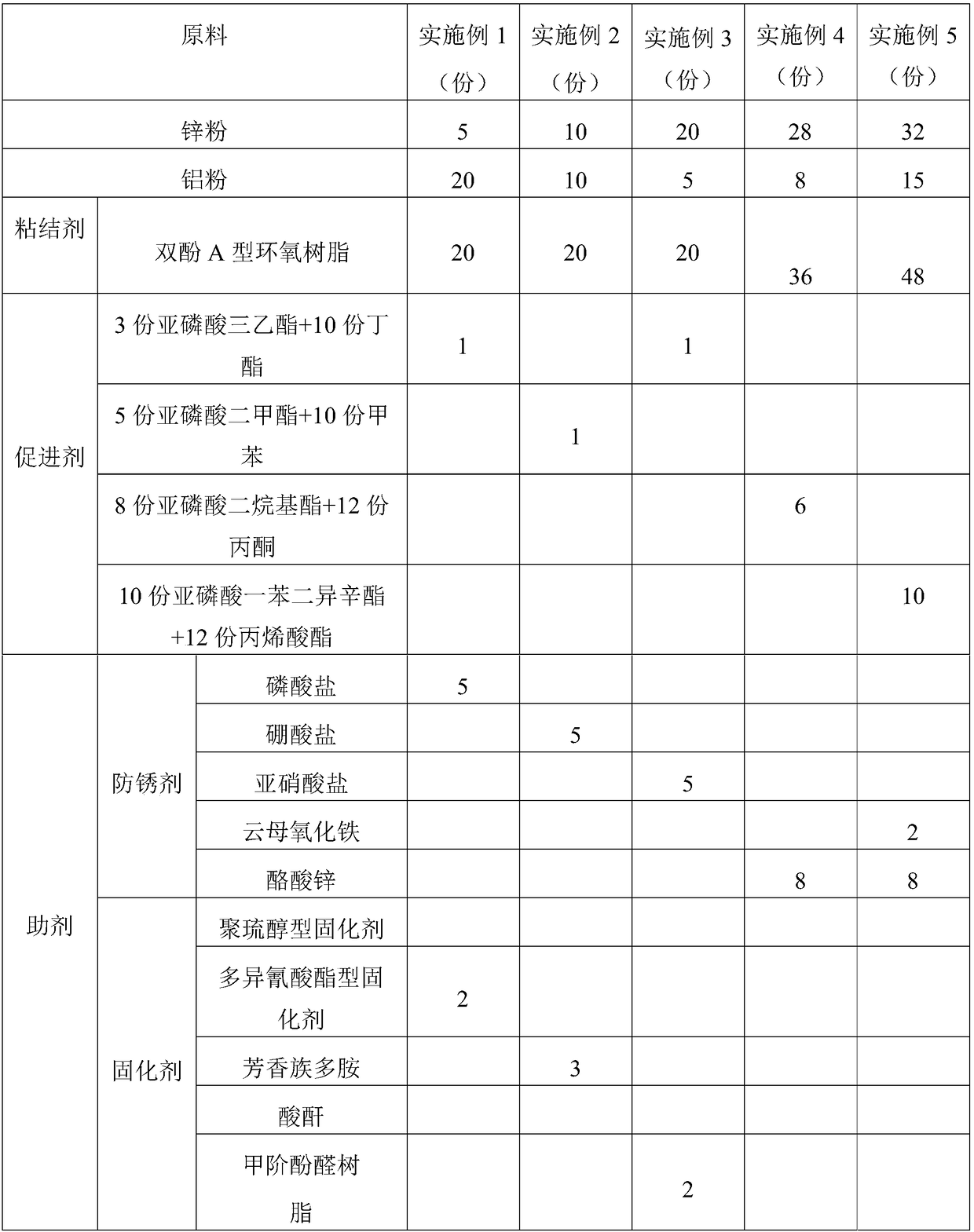

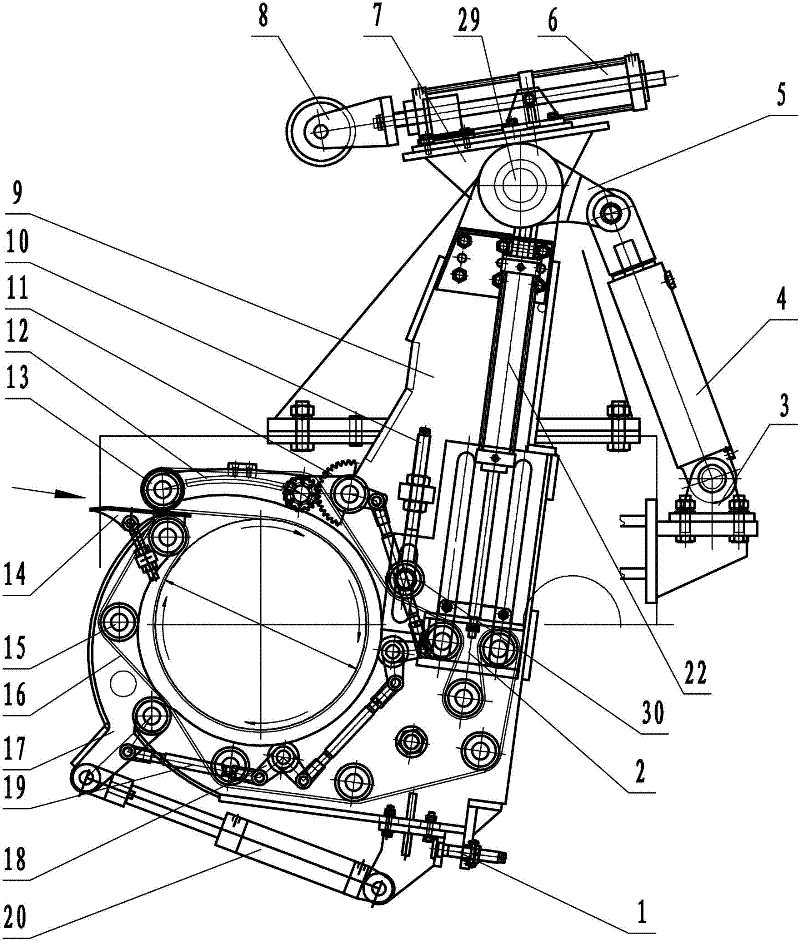

Closed multifunctional reducing wrapper

The invention provides a closed multifunctional reducing wrapper. The closed multifunctional reducing wrapper comprises a supporting base, wherein a large bent hook is connected with the supporting base through a rotating shaft; the large bent hook is provided with an upper pressing arm and a lower pressing arm; the lower pressing arm is connected with a pressing cylinder; the lower pressing arm is connected with the upper pressing arm through an amplification mechanism; wrapping adhesive tape devices are arranged in the large bent hook, the upper pressing arm and the lower pressing arm and two-wheel tension mechanisms and adhesive tape error correction mechanisms are arranged in the wrapping adhesive tape devices; one end of a beam position cylinder is connected with the rotating shaft through a crank, and the other end of the beam position cylinder is connected with a beam position cylinder support; and the pressing cylinder, the amplification mechanism, the tension adjustment cylinders in the two-wheel tension mechanisms and the adhesive tape error correction mechanisms are in a double-side symmetric distribution. The closed multifunctional reducing wrapper can be conveniently applicable for working situations of different winding drum diameters after being adjusted simply; due to the stacking of the upper pressing arm and the lower pressing arm, a 360-degree wrap angle of a wrapping adhesive tape on a winding drum can be realized, so the wrapping forces of the winding drums having different diameters cannot be influenced; therefore, slipping of the closed multifunctional reducing wrapper due to an undersized wrap angle during wrapping of the wrapping drums having smaller diameters can be avoided; and the appearance of a tape volume can be guaranteed.

Owner:OUDA YICHANG ELECTROMECHANICAL EQUIP

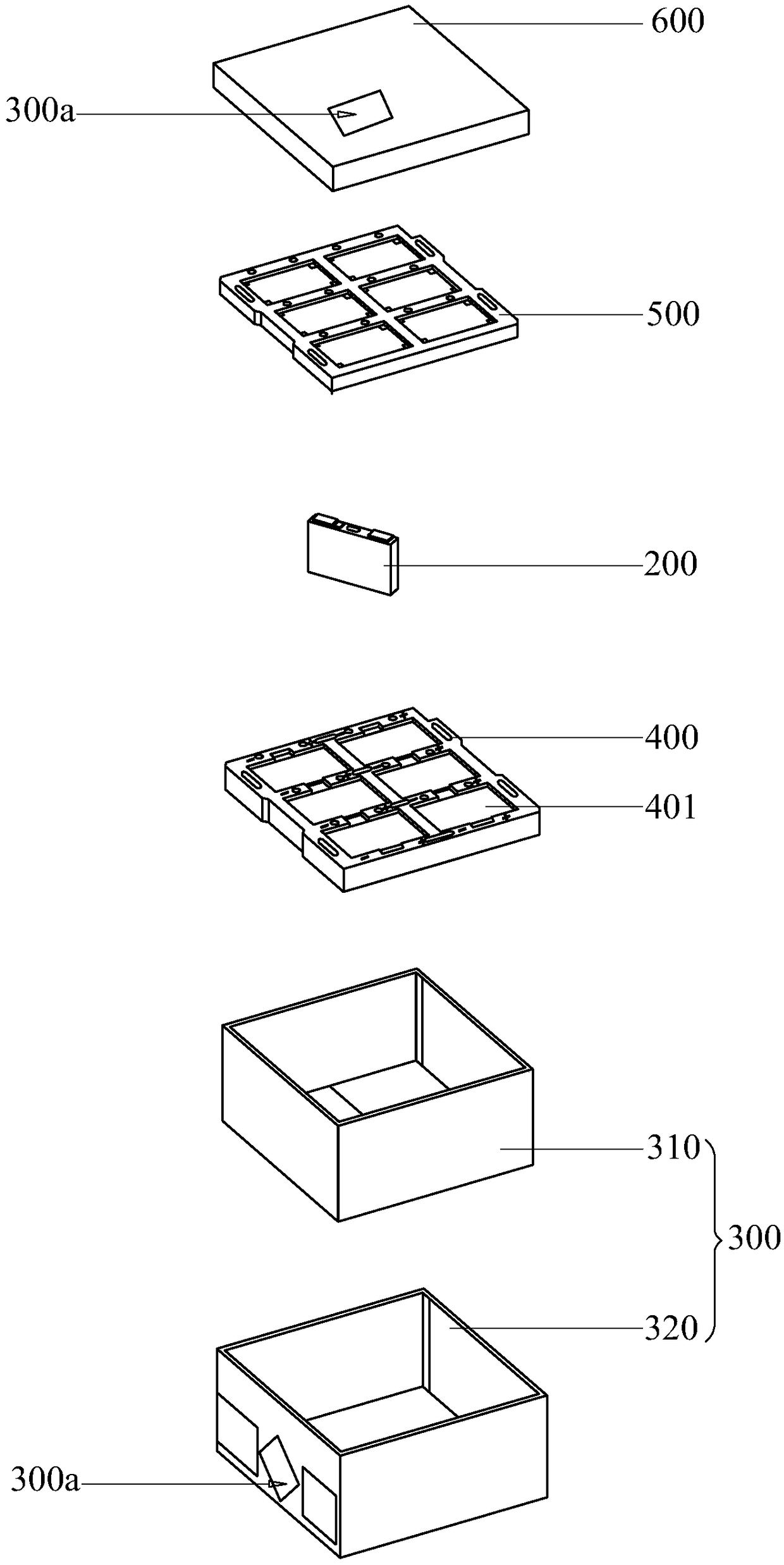

Battery packaging line

PendingCN108860853AHigh precisionSmall footprintLabelling flat rigid surfacesPackaging machinesCartoning machineButt joint

The invention discloses a battery packaging line. The battery packaging line comprises a boxing machine, a capping machine and a labeling machine which are sequentially connected to form a main conveying line. An inner box unpacking machine, a box sleeving machine and an outer box unpacking machine which are sequentially connected to form an auxiliary conveying line is arranged beside the main conveying line. The box sleeving machine and the boxing machine are laterally arranged in a butt-joint mode. The inner box unpacking machine and the outer box unpacking machine are used for unpacking andforming of an inner box and an outer box and conveying the inner box and the outer box to the box sleeving machine oppositely. The inner box and the outer box are received by the box sleeving machineand mounted into a packaging box in a sleeved mode, and the box sleeving machine conveys the packaging box to the boxing machine. The boxing machine receives the packaging box, moves a plastic plateinto the packaging box after a battery is put into the plastic plate and conveys the packaging box to the capping machine. The capping machine is used for feeding a rubber cover and an outer box coverand fastening the rubber cover and the outer box cover to the plastic plate and the packaging box in sequence. The labeling machine is used for printing labels and attaching the labels to the outer box cover or / and the packaging box. The battery packaging line is high in automation degree, efficiency and packaging precision.

Owner:DONGGUAN WORLD PRECISION MACHINERY

Automatic discharging device of rolling machine

InactiveCN104186718ASimple structureLight structurePre-extraction tea treatmentAssembly lineEngineering

The invention relates to an automatic discharging device of a rolling machine, which is matched with a tea rolling machine. The automatic discharging device is characterized in that a discharging door is provided with a discharging door lifting connecting rod, a pneumatic component is arranged on a rolling disc base of the rolling machine, and a pneumatic component expansion link is connected with the discharging door lifting connecting rod and the pneumatic component, so that the automatic discharging device of the rolling machine is formed. According to the invention, by replacing manual operation with an automatic pneumatic device, the automatic discharging device has the characteristics of reliability in operation, reasonable structure, light weight, easiness for installation and maintenance, low pressure level, safety in use, and the like, and can realize the automated assembly-line operation of tea production, therefore, the automatic discharging device disclosed by the invention creates conditions for the automated assembly-line operation of tea production.

Owner:NANNING CHUANGYU TEA MACHINERY

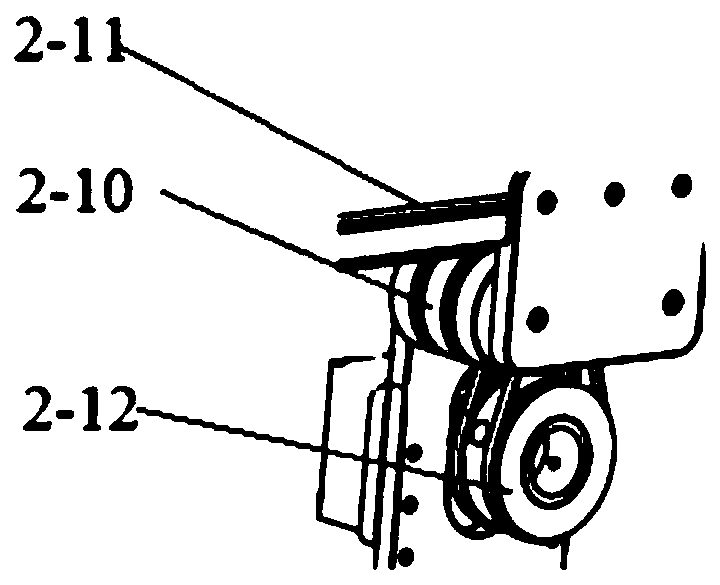

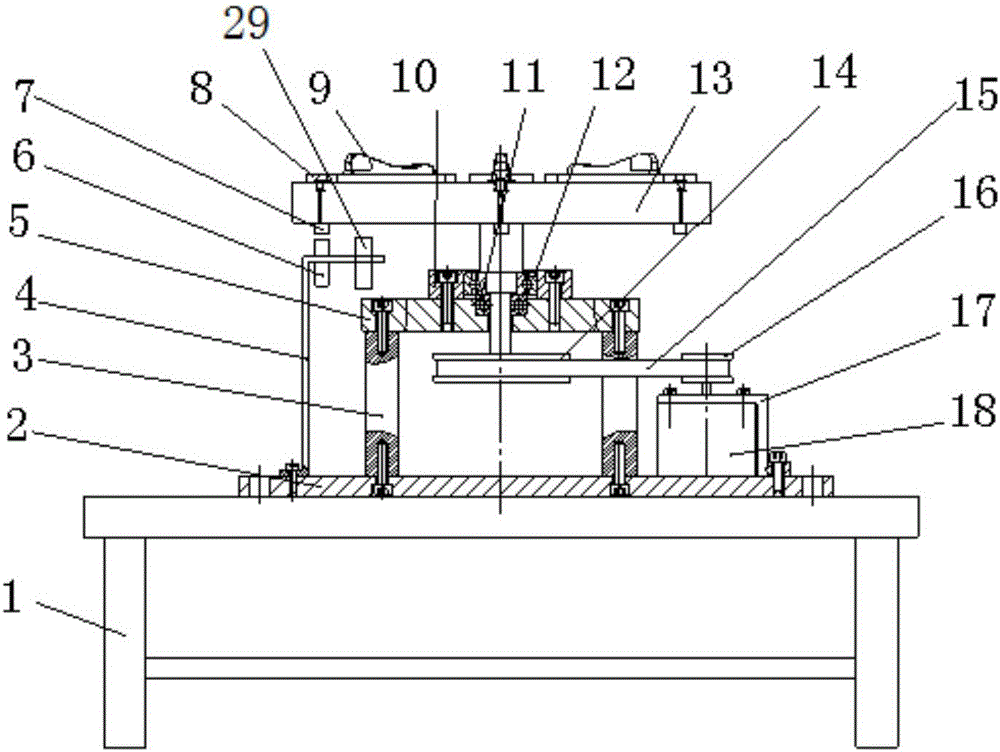

Automatic press-fitting equipment for rear bushing of automobile suspension control arm

ActiveCN103949871BImprove reliabilityRealize automatic flow operationMetal working apparatusProduction lineControl arm

The invention provides a rear bush automatic press mounting equipment for an automotive suspension control arm. The press mounting equipment comprises an engine base component, a control arm supporting table component, an electric cylinder, a guide rail component and a control cabinet component, wherein the control arm supporting table component is fastened to the lower part of one side of the engine base component; the electric cylinder and the guide rail component are fastened to the upper part of the engine base component on the same side surface as the control arm supporting table component; the control cabinet component is fixed to the back of the engine base component through a bolt. The press mounting equipment provided by the invention can be operated on different occasions, can be mounted in a rear bush press mounting position of a production line to be cooperated with the production line so as to realize an automation line production, and can also be operated in a uniprocessor manner. The equipment has the advantages of high reliability, security and stability. The press mounting equipment provided by the invention uses a differential operating principle to convert the pressure of the press mounting rear bush into the internal force of a press machine to effectively remove the pressure acted on a tooling fixture in the press mounting process and ensure the accuracy and the stability of the press mounting.

Owner:SHANGHAI JIAOTONG UNIV

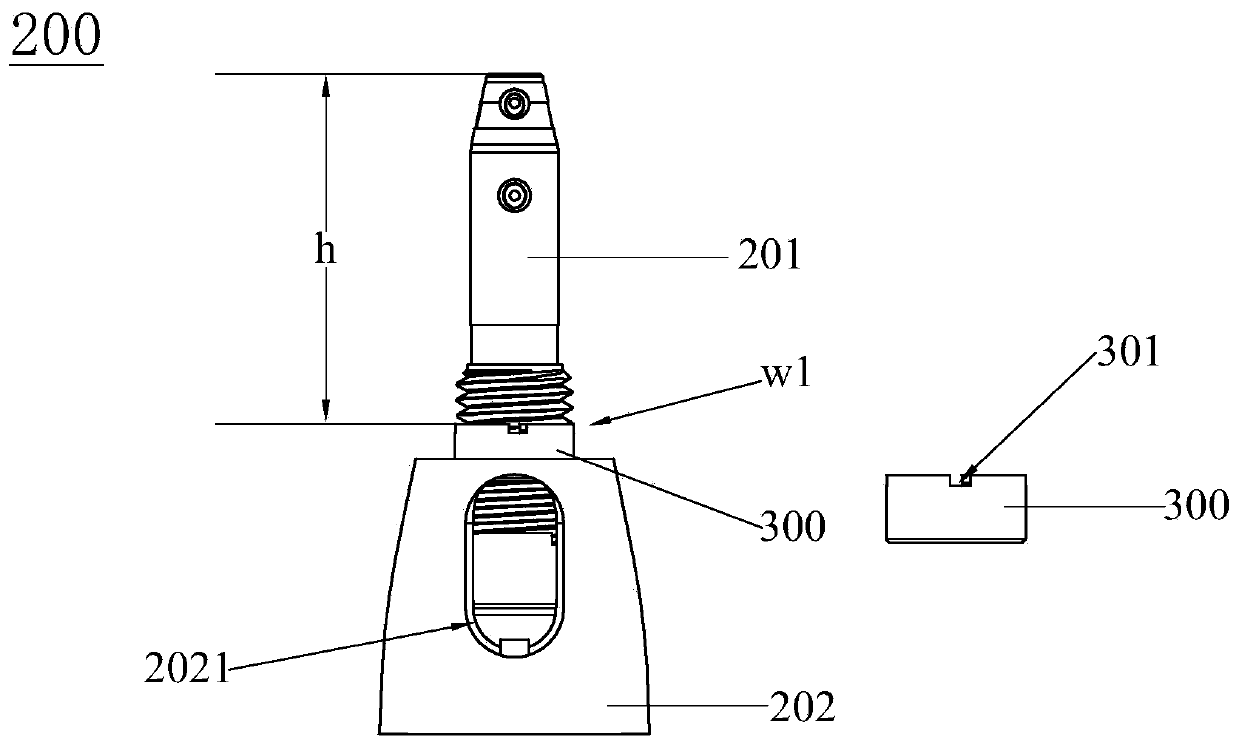

Automatic alignment equipment

ActiveCN108817937ASimple structureReasonable layoutMetal working apparatusAutomatic test equipmentControl system

The invention discloses automatic alignment equipment, which is suitable for accurately aligning a core and a tube of a primarily aligned stylus. The automatic alignment equipment comprises a conveying device, a positioning jig, an alignment device and a recognition device which are arranged on a working platform and electrically connected with a control system, wherein the conveying device is arranged along the longitudinal direction of the working platform, the stylus is arranged on the positioning jig and is conveyed on the conveying device along with the positioning jig, the alignment device is arranged on at least one side of the conveying device, the recognition device is arranged at the alignment device, the recognition device recognizes coordinates of the length, protruding from the tube, of a contact portion and / or a positioning portion of the core and feeds back the recognition information to the control system, and the alignment device cooperates with the positioning jig topush the core or the tube so as to adjust the length, protruding from the tube, of the contact portion of the core. The automatic alignment equipment has the advantages of simple structure, reasonablelayout and high alignment precision, can realize automatic flow operation, and effectively guarantees product quality while improving production efficiency.

Owner:DONGGUAN WORLD PRECISION MACHINERY

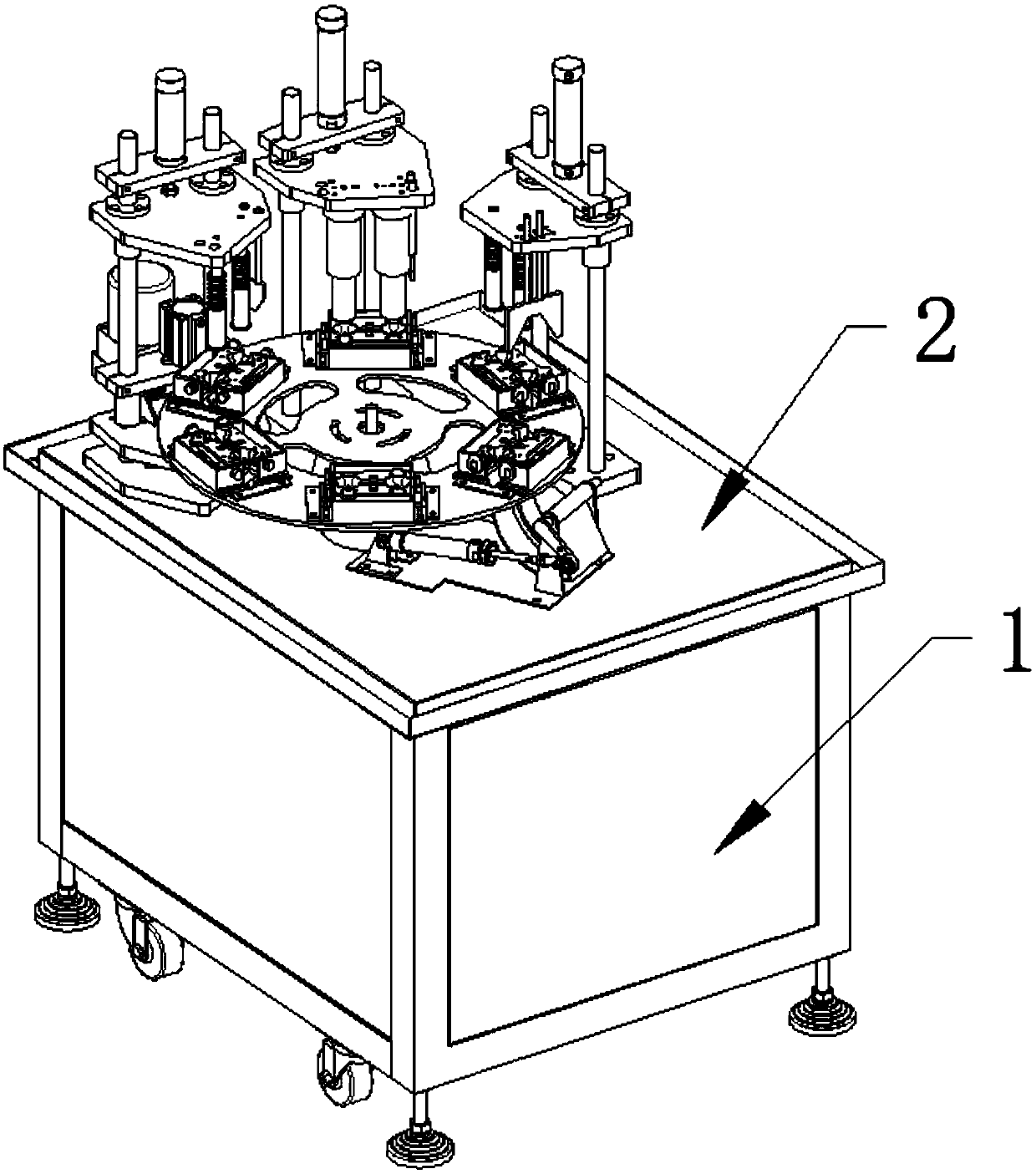

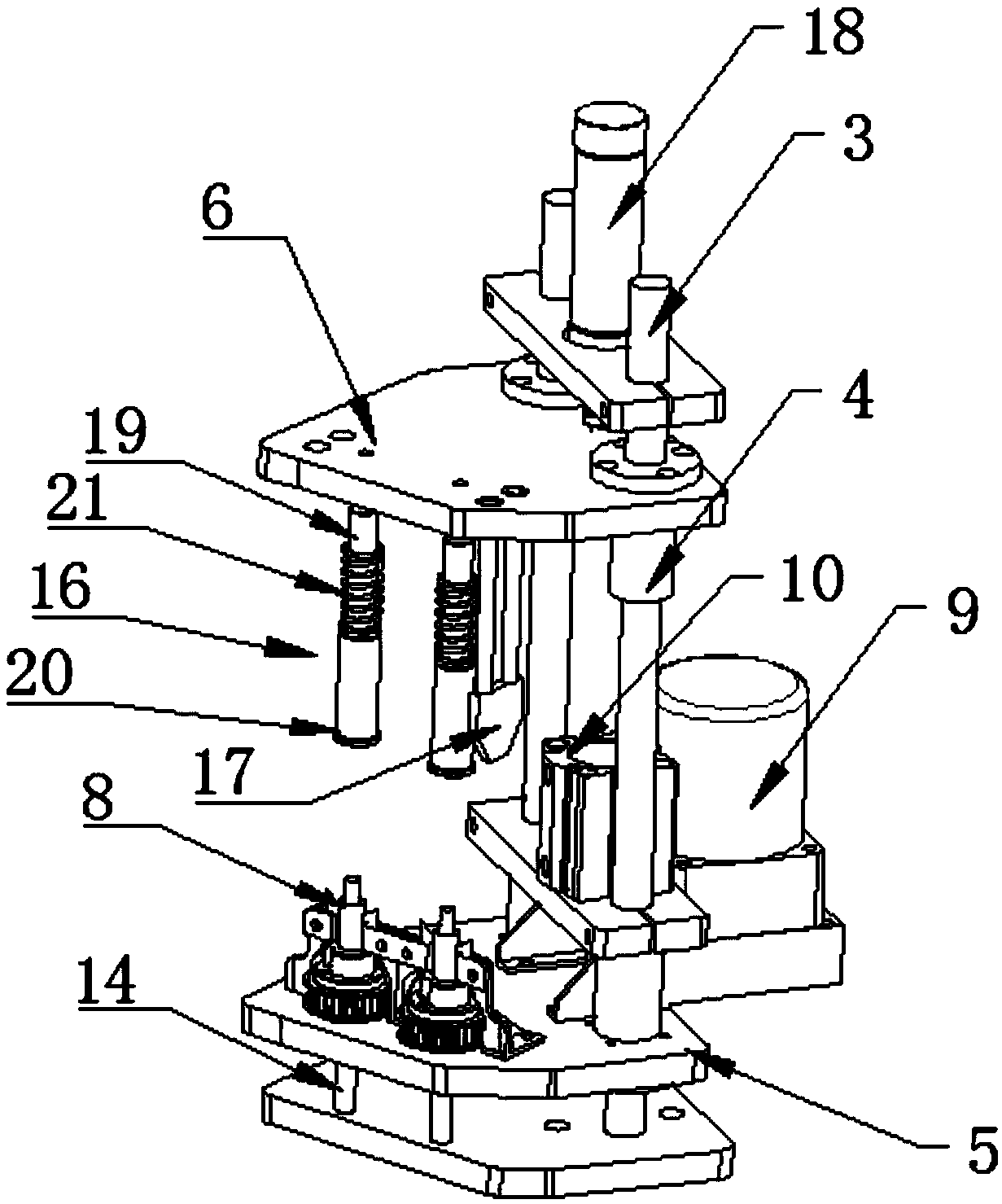

High-pressure copper finger touch fixture and clamping finger touch method thereof

InactiveCN106064316AHigh degree of automationRealize automatic flow operationPrecision positioning equipmentMeasurement/indication equipmentsEngineeringCopper

The invention discloses a high-pressure copper finger touch fixture. The high-pressure copper finger touch fixture comprises a base; the base is connected with a detecting mechanism and an indexing mechanism; and the indexing mechanism is connected with a finger touch clamping mechanism. The high-pressure copper finger touch fixture can realize three functions: (1) the finger touch clamping is realized by dint of the finger touch clamping mechanism; (2) the indexing function is realized by dint of the indexing mechanism; and (3) the detecting function is finished by dint of the detecting mechanism. The invention further discloses a finger touch clamping method; the finger touch clamping adopts forward and reverse clamping; the finger touch clamping method conveniently and quickly performs the finger touch clamping; and the method is high in finger touch burr removing efficiency and excellent in removing quality.

Owner:XIAN UNIV OF TECH

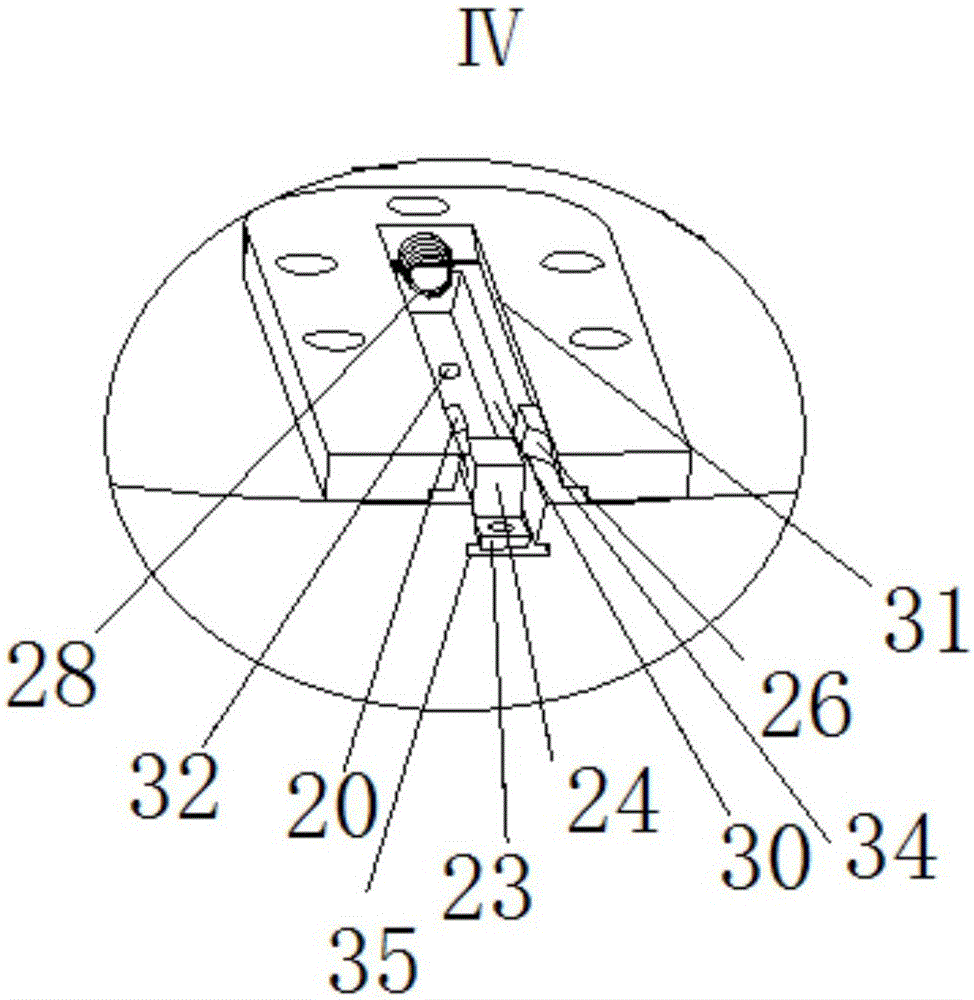

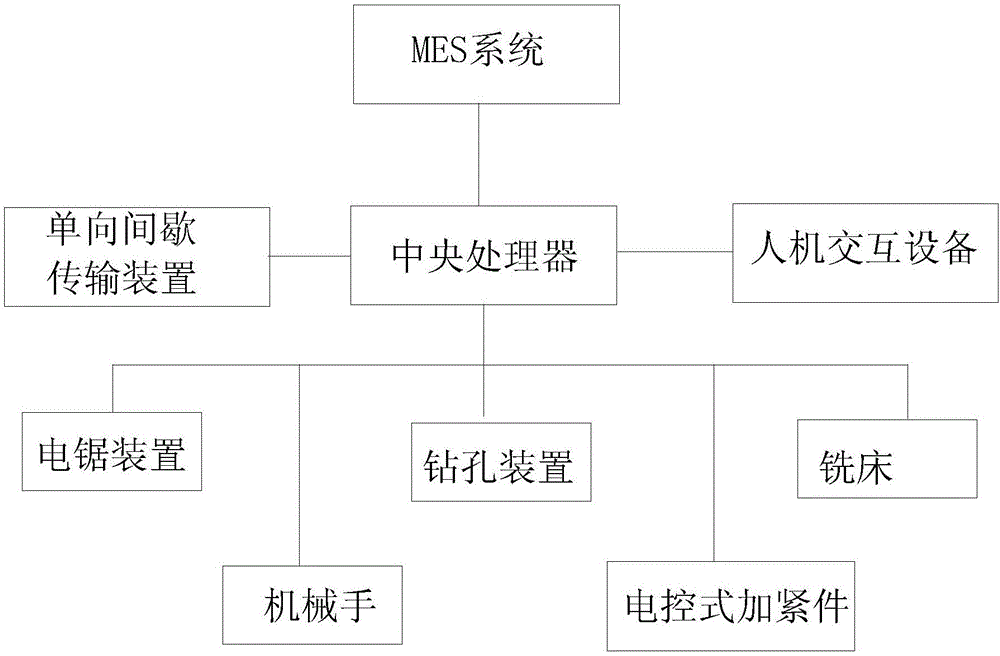

Control system of sawing, drilling and milling machining production line

InactiveCN106182210ASave manpower and materialsImprove securityMulti-purpose machinesEngineeringData lines

The invention discloses a control system of a sawing, drilling and milling machining production line. The sawing, drilling and milling machining production line comprises a one-way intermittent transmission device for driving a strip-shaped plate to move, an electric saw device for sawing the strip-shaped plate, a drilling device for drilling the strip-shaped plate, and a milling machine for milling the strip-shaped plate. The one-way intermittent transmission device comprises two conveyor belts arranged in parallel, and a stepping motor for driving the two conveyor belts to move synchronously. Electric control clamping pieces for clamping the strip-shaped plate are arranged on the conveyor belts at equal intervals. The control system at least comprises a field controller and an MES for carrying out remote data interaction with the field controller. The field controller is used for controlling the working state of the stepping motor, the working state of the electric saw device, the working state of the drilling device, the working state of the milling machine and the working state of the electric control clamping pieces. The field controller comprises a central processor and man-computer interaction equipment. The central processor and the man-computer interaction equipment are connected through a data line.

Owner:美克国际家私(天津)制造有限公司

Longan husking and pitting machine

ActiveCN109674071AEasy to separateReduce churnClimate change adaptationFruit stoningEngineeringClockwise

The invention discloses a longan husking and pitting machine. The longan husking and pitting machine comprises a machine case; the upper end of the machine case is provided with an installing panel; the installing panel is clockwise successively provided with a core-chopping device, a core-beating device, a pulp-beating device and a peel-taking device; the middle of the installing panel is provided with a feeding device; the feeding device is capable of respectively feeding for the core-chopping device, the core-beating device, the pulp-beating device and the peel-taking device in clearance fit through rotation; a core-chopping cutter fixing plate is provided with a core-chopping cutter fixing base, a core-chopping cutter and a core-chopping cutter rotating motor; the core-chopping cutterfixing plate is further connected with a core-chopping cutter cylinder; the bottom of the core-chopping cutter fixing base is provided with a core-chopping cutter turntable; the core-chopping cutterturntable is in transmission connection with the core-chopping cutter rotating motor through a belt. The longan husking and pitting machine is simple to operate, and convenient and reliable to maintain, realizes complete shell-pulp separation, less juice loss, automatic flow line production and high single-machine yield, and is capable of keeping integrity of pulp in the greatest degree in an pitting process.

Owner:广州市冠浩机械设备有限公司

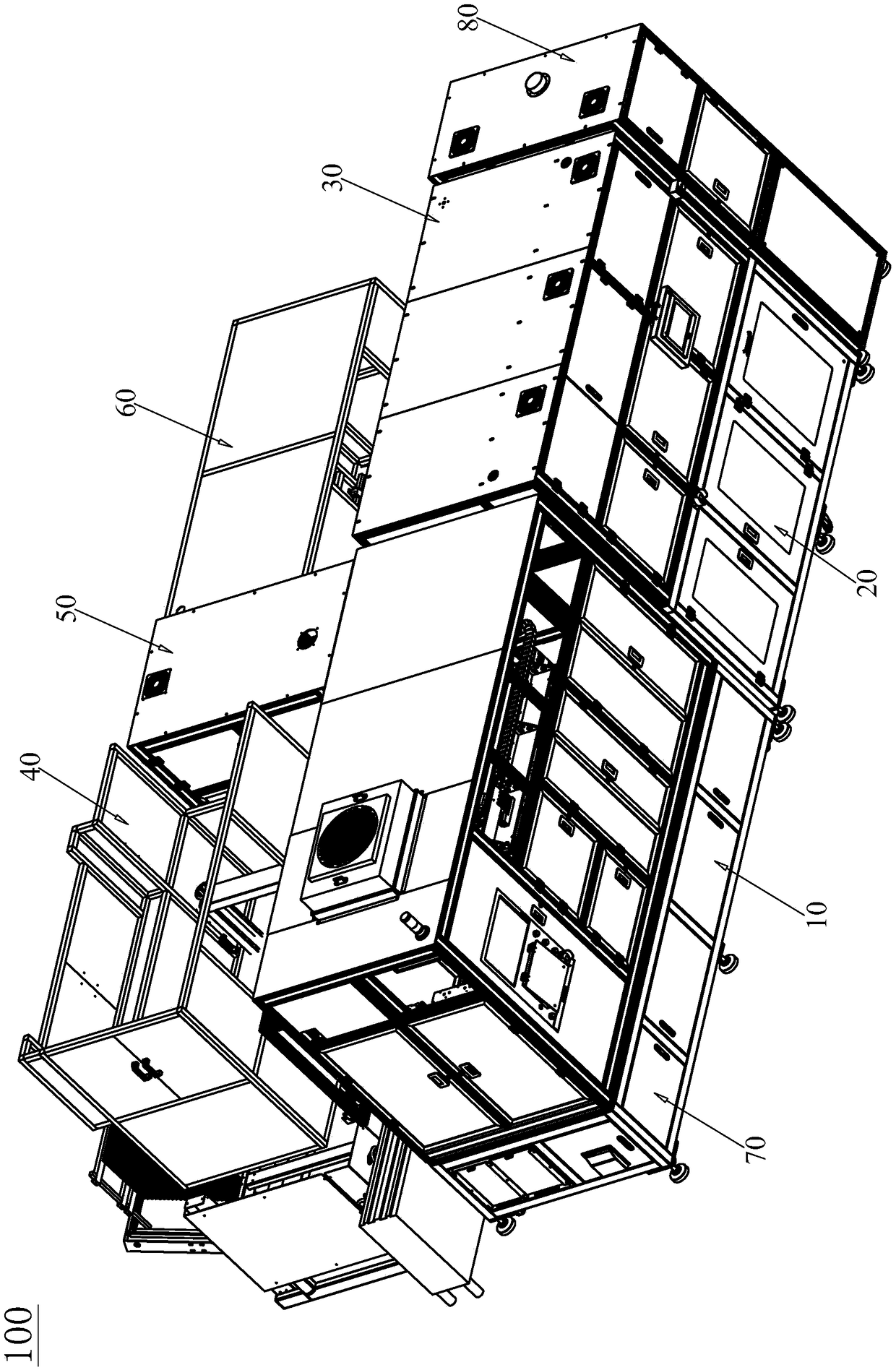

Standing curing equipment

PendingCN111306160ASimple structureReasonable layoutConveyorsMaterial gluingElectrical and Electronics engineeringManufacturing engineering

The invention discloses standing curing equipment which comprises a conveying device, a loading device, a feeding device, a standing device, a discharging device and a dismounting device. The conveying device is used for conveying a product fixed in a positioning jig, the loading device is used for assembling a gasket for preventing glue overflow on the product, the conveying device is matched with the feeding device, upper carriers of the positioning jig are separated from lower carriers, after the upper carriers are rotated by a certain angle, the upper carriers are moved into the standing device through the feeding device, the multiple upper carriers can be placed on the standing device, the placed upper carriers can be transferred to the discharging device according to the placing sequence, the conveying device is further matched with the discharging device, the upper carriers taken out from the standing device are rotated reversely by the certain angle and then are loaded into thelower carriers, and the dismounting device is used for dismounting the gasket from the product. The equipment is simple in structure, high in efficiency, capable of effectively preventing glue overflow, and capable of effectively ensuring product quality while improving production efficiency.

Owner:DONGGUAN WORLD PRECISION MACHINERY

Automatic labeling machine

Owner:DONGGUAN WORLD PRECISION MACHINERY

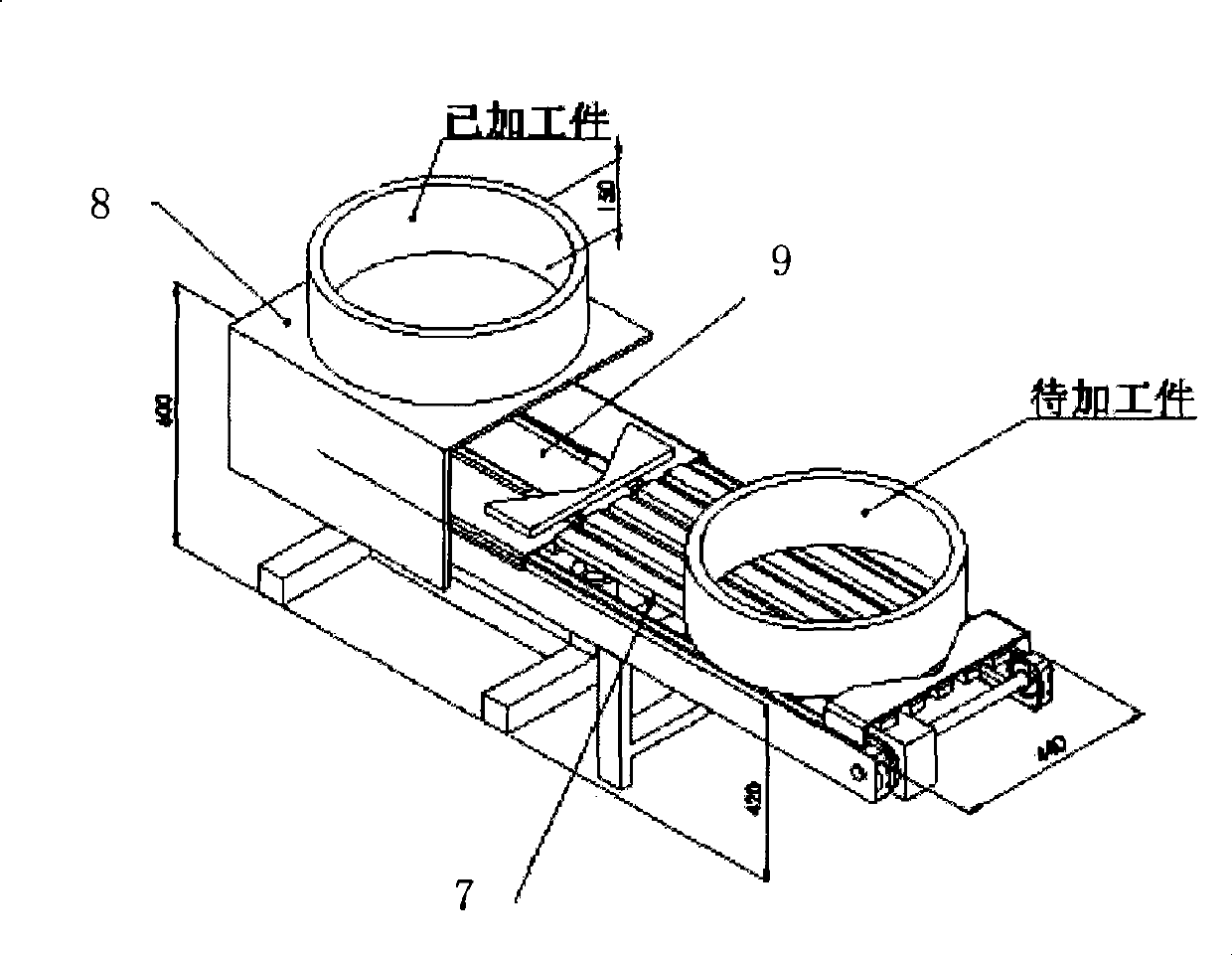

Automatic charging and discharging and transmitting device for handstand type numerical controlled lathe

ActiveCN101417345BRealize automatic flow operationRealize automated productionAutomatic conveying/guiding stockNumerical controlReciprocating motion

The invention discloses an automatic feeding and discharging and transmission device used for an inverted numerically controlled lathe, comprising a feeding and discharging platform, a conveying guide rail and a workpiece turnover mechanism. The feeding and discharging platform is arranged at one side of the lathe bed of the lathe, the back of the lathe bed is provided with a feed hole, the conveying guide rail is distributed and arranged on the feeding and discharging platform from the feed hole and is connected with the subsequent inverted numerically controlled lathes mutually, and the workpiece turnover mechanism is arranged on the conveying guide rail among the lathes, wherein, the feeding and discharging platform comprises a conveying table, a discharging platform and an automatic aligning mechanism; the conveying table has fixed structure which is driven by a chain and connected with the conveying guide rail, the discharging platform is driven by the chain at the bottom to carry out reciprocating motion, and the automatic aligning mechanism is arranged between the conveying table and the discharging platform. In the invention, the workpiece feeding and discharging is realized by the automatic feeding and discharging and transmission device, thus effectively reducing the labor intensity of workers; and the workpiece machining process and the workpiece feeding and discharging can be finished on one machine, thus realizing the factory automated production.

Owner:CSC BEARING

pig slaughtering equipment

InactiveCN105981795BImprove slaughter efficiencyReasonable designSlaughtering/stunning masksBlood collection/stirring apparatusBlood collectionProduction line

The invention discloses live pig slaughtering equipment. The live pig slaughtering equipment comprises a rack and a live pig conveyor belt and is characterized in that pig body limiting devices capable of being automatically adaptive to the width of a pig body are arranged at the parts, located on the two sides of the live pig conveyor belt, of the rack; a lug boss capable of separating left and right legs of a live pig is arranged at the part, located in the middle of the live pig conveyor belt, of the rack; a nitrous oxide conveying system for automatically releasing nitrous oxide toward a pig nose is arranged at the part, located above the rear end of the lug boss, of the rack; a pig head limiting device for positioning a pig head is arranged at the part, located at the rear end of the lug boss, of the rack; a vacuum blood collection device for bleeding the live pig is arranged at the part, located on the rear side of the lug boss, of the rack; and a sharp corner inclined plane is arranged at the front end part of the lug boss. The live pig slaughtering equipment has the advantages of reasonable design and easiness of manufacturing; silent anaesthesia and slaughtering is realized and blood is completely released so as to ensure that no residual blood exists in pork; pollution-free vacuum blood collection is carried out so that the equipment is safe, reliable and sanitary; and automatic production line work can be realized and the live pig slaughtering efficiency is improved.

Owner:FOSHAN UNIVERSITY

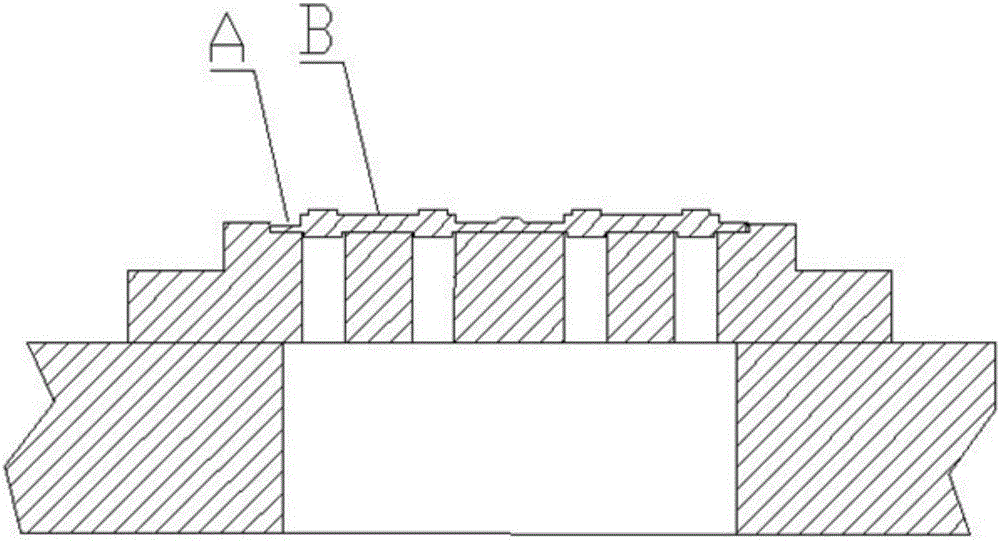

Pole removing device and method for recycling waste power battery cover plates

ActiveCN106159370ARealize automatic flow operationImprove efficiencyWaste accumulators reclaimingBattery recyclingPower batteryHydraulic cylinder

The invention discloses a pole removing device and method for recycling waste power battery cover plates. The pole removing device comprises a hydraulic cylinder, wherein the hydraulic cylinder is further connected with an upper mold mounting plate; the upper mold mounting plate is connected with a guide sleeve; the guide sleeve is matched with a guide shaft; the hydraulic cylinder can push the upper mold mounting plate to move vertically in a reciprocating manner along the guide shaft; an upper mold base is arranged under the upper mold mounting plate and is connected with a stamping pin; and a workpiece pressing block can axially move along the stamping pin, and can move axially in a slot of an upper mold. The pole removing device is simple in structure, small in size, convenient to use, continuous in disassembling process, high in disassembling speed and high in efficiency; potential safety hazards do not exist; and recycling of poles and follow-up recycling of cover plates are facilitated.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Automatic assembly alignment equipment

PendingCN111266257ARealize automatic flow operationSimple structureLiquid surface applicatorsMaterial gluingFastenerEngineering

The invention discloses automatic assembly alignment equipment. The automatic assembly alignment equipment comprises a conveying device, a dispensing device, a connecting device, a screwing device anda spraying device. The conveying device is used for conveying a fastener borne on a positioning jig and a stylus fixed into the positioning jig. The dispensing device is used for dispensing thread adhesive to an outer thread of a refill located at the position of an opening of a pen container. The connecting device reciprocates between the conveying device and the spraying device, is used for moving the fastener on the positioning jig to the position of the spraying device, cooperates with the spraying device to spray a catalyst to the inner wall of the fastener, and is further used for enabling the sprayed fastener to be arranged on the dispensed refill in a sleeving manner. The screwing device is used for screwing the fastener arranged on the refill in the sleeving manner, the fasteneris adjusted and pasted at the assembly position, one end of the fastener located at the assembly position is screwed into the pen container, and the other end of the fastener is located outside the pen container. The equipment can achieve automatic assembly line operation and is simple in structure, high in assembly precision and efficient.

Owner:DONGGUAN WORLD PRECISION MACHINERY

A fully automatic cleaning, drifting and packing integrated ship

ActiveCN104097751BReduce volumeIncrease loading capacityWaterborne vesselsSpecial purpose vesselsMarine engineeringFully automatic

The invention discloses a full-automatic clearing, drifting and packing integrated ship. The hull is a double-headed single type, including a hull, a collection device, a crushing device, a screw conveying device, a compression and bundling device, and a storage and unloading device; on the hull, from the ship The collection device, crushing device, screw conveying device, compression and bundling device, and storage and unloading device are installed in sequence from the bow to the stern, and the collection device is located in the middle of the double heads of the bow. The invention is used for cleaning river garbage and aquatic plants, can compress the collected and pulverized garbage and aquatic plants, increases the loading capacity of ships, reduces round-trip unloading time and is convenient for unloading, improves production efficiency, and saves production costs .

Owner:ZHANGJIAGANG HAIFENG WATER SURFACE ENVIRONMENTAL PROTECTION MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com