Longan husking and pitting machine

A longan and chassis technology, which is applied in the field of longan peeling and denucleating machines, can solve the problems of low production efficiency, non-compliance with hygienic requirements, etc., and achieve the effects of simple structure, good prospects for economic and social benefits, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

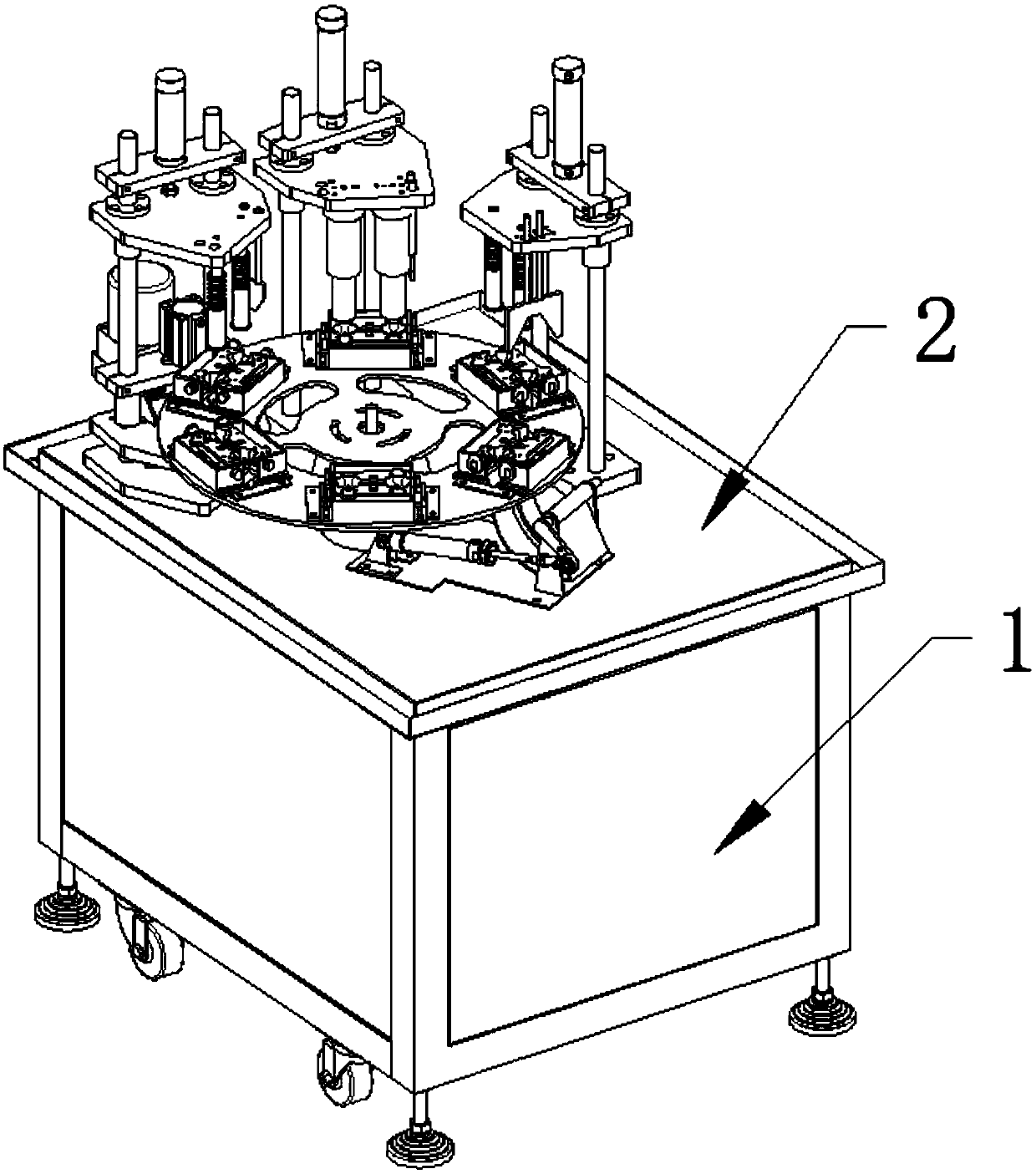

[0037] Such as Figure 1 to Figure 9 As shown, the solution of this embodiment provides a longan shelling and core removing machine, which includes a chassis 1, and a mounting panel 2 is provided on the upper end of the chassis 1;

[0038] The installation panel 2 is provided with a nucleation device, a nucleation device, a meat device, and a skin removal device in a clockwise direction; the middle of the installation panel 2 is provided with a feeding device; the feeding device is respectively fed by rotation The nucleation device, the nucleation device, the meat beating device and the skin removing device are movably matched with the feeding.

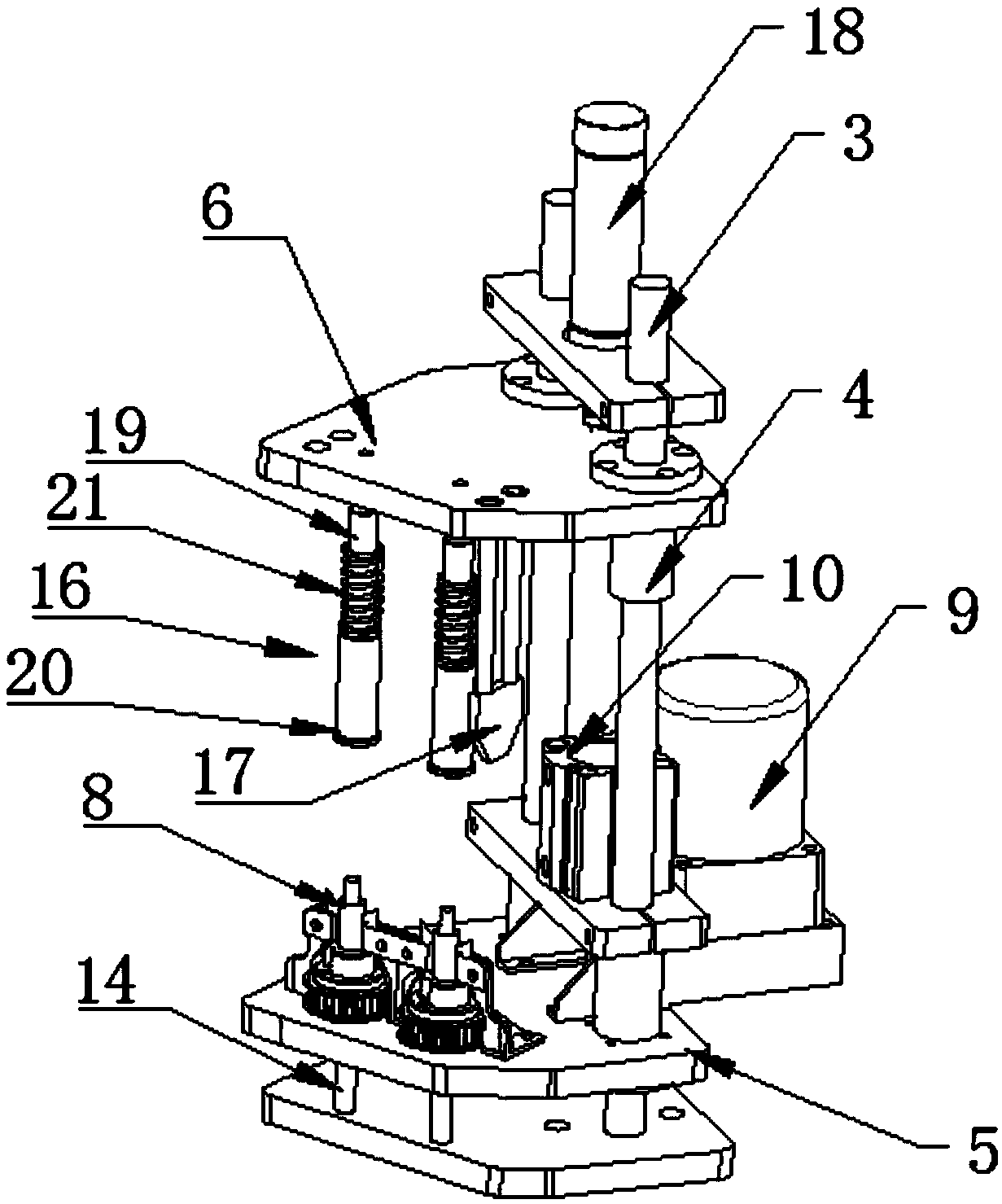

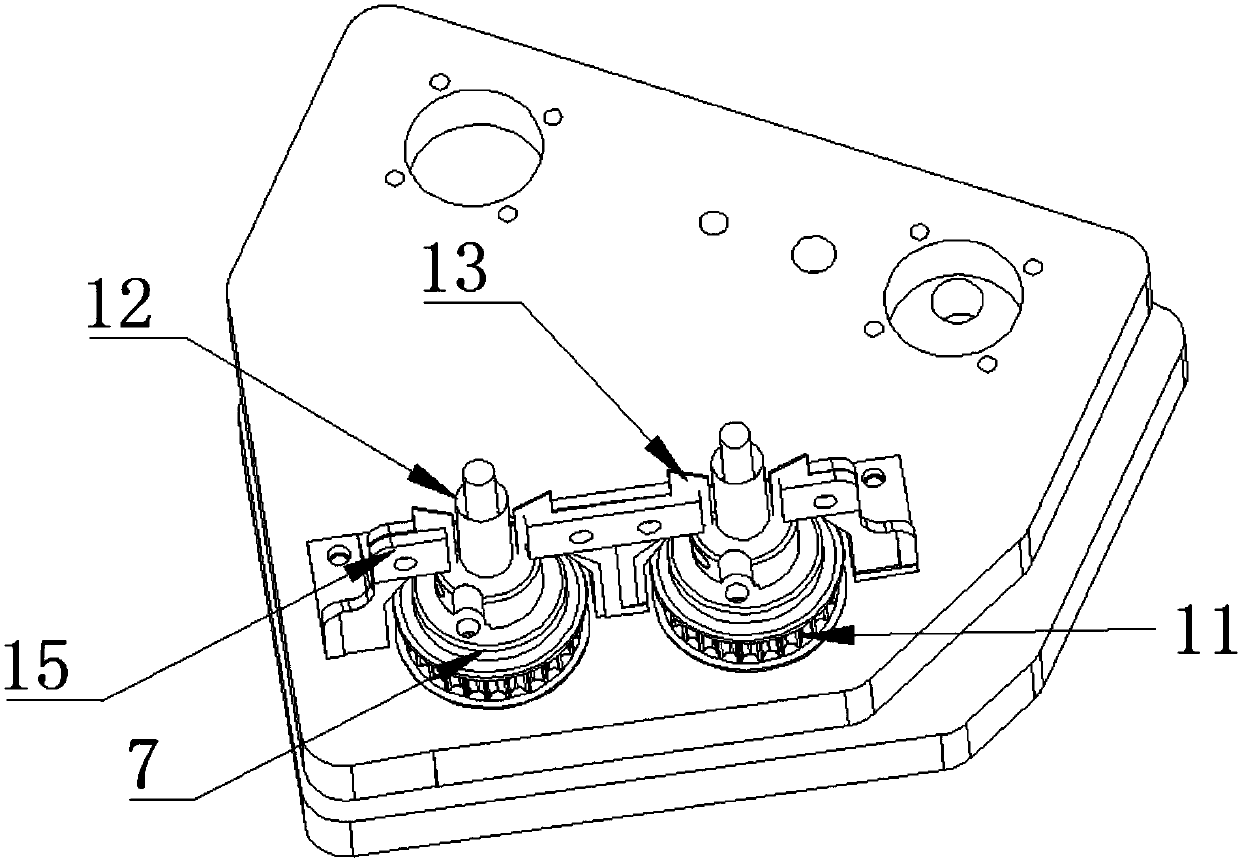

[0039] Specifically, in the solution of this embodiment, the nucleation device includes a nucleation guide 3; the nucleation guide 3 is respectively mounted with a nucleation knife fixing plate 5 and a nucleation head mounting plate from bottom to top through a sliding bearing 4 6; The nuclear cutting knife fixing plate 5 is respectively i...

Embodiment 2

[0054] Such as Figure 10 to Figure 12 As shown, the solution of this embodiment provides a longan peeling and nucleating machine. Based on the original implementation of Example 1, the cylindrical nucleating knife 12 is replaced with a cylindrical tooth-shaped nucleating knife 59. The upper end of the nucleation knife 59 is a toothed blade. The nucleation guide pressure head 20 fixes the longan through the constant elastic force of the nucleation return spring 21 without crushing the longan flesh. The nucleation knife turntable 11 passes the nucleation Driven by the knife rotating motor 9 and the belt, the rotation is realized to realize the rotation of the nucleation knife 8 to cut the nucleus; after the top skin fixing rod 14 fixes the longan, the cylindrical tooth nucleation knife 59 is first inserted into the pedicle structure of the longan core In the process, the core and pulp of the longan are cut by rotation, and the sheet-shaped core cutter 13 cuts two notches in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com