Control system of sawing, drilling and milling machining production line

A control system and milling technology, applied in the direction of wood processing appliances, manufacturing tools, multi-purpose machinery, etc., can solve the problems of low degree of automation, unsafe accidents, labor and material consumption, etc., to save labor and materials, high safety factor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

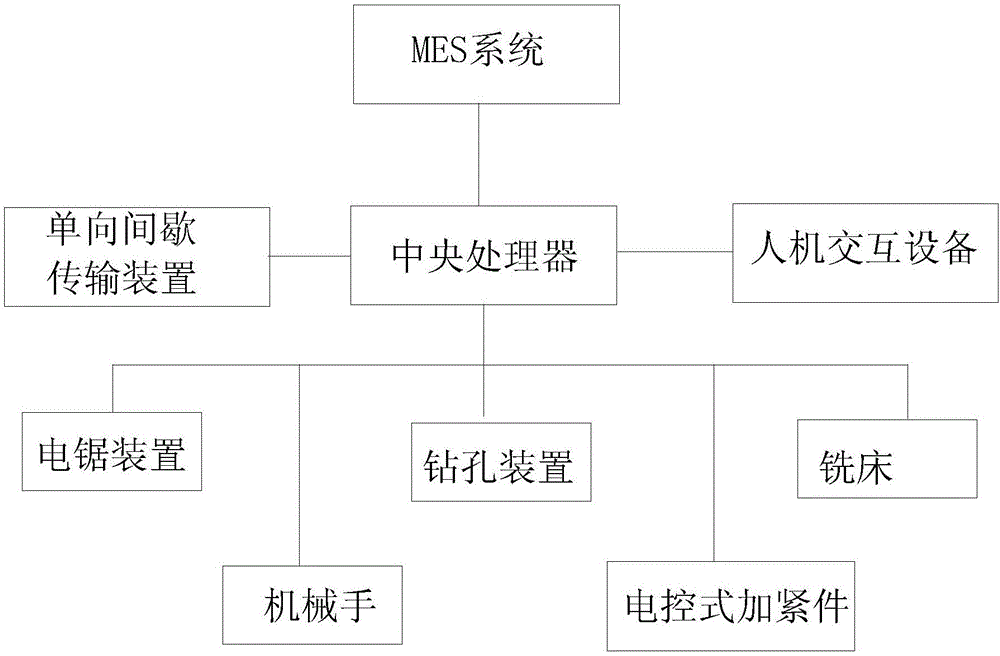

[0016] see figure 1 , a control system for a sawing, drilling and milling production line, the sawing, drilling and milling production line includes a one-way intermittent transmission device for driving a strip-shaped plate to run, an electric saw device for sawing a strip-shaped plate, and an electric saw device for sawing a strip-shaped plate A drilling device for drilling holes in strip-shaped plates, a milling machine for milling strip-shaped plates; wherein: the one-way intermittent transmission device includes two parallel transmission belts, and a belt that drives the two transmission belts to move synchronously A stepper motor, with electronically controlled tightening parts for clamping strip-shaped plates at equal intervals on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com