Linear glue dispensing quality detection device for loudspeaker diaphragm

A detection equipment, speaker technology, applied in the direction of sensors, electrical components, etc., can solve the problems of inability to accurately know the dispensing position and dispensing quality, reduce production efficiency, increase labor costs, etc., to reduce labor costs and labor intensity, high Economic and social benefits, and the effect of improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to understand the technical content of the present invention more clearly, the following examples are given in detail, the purpose of which is only to better understand the content of the present invention but not to limit the protection scope of the present invention.

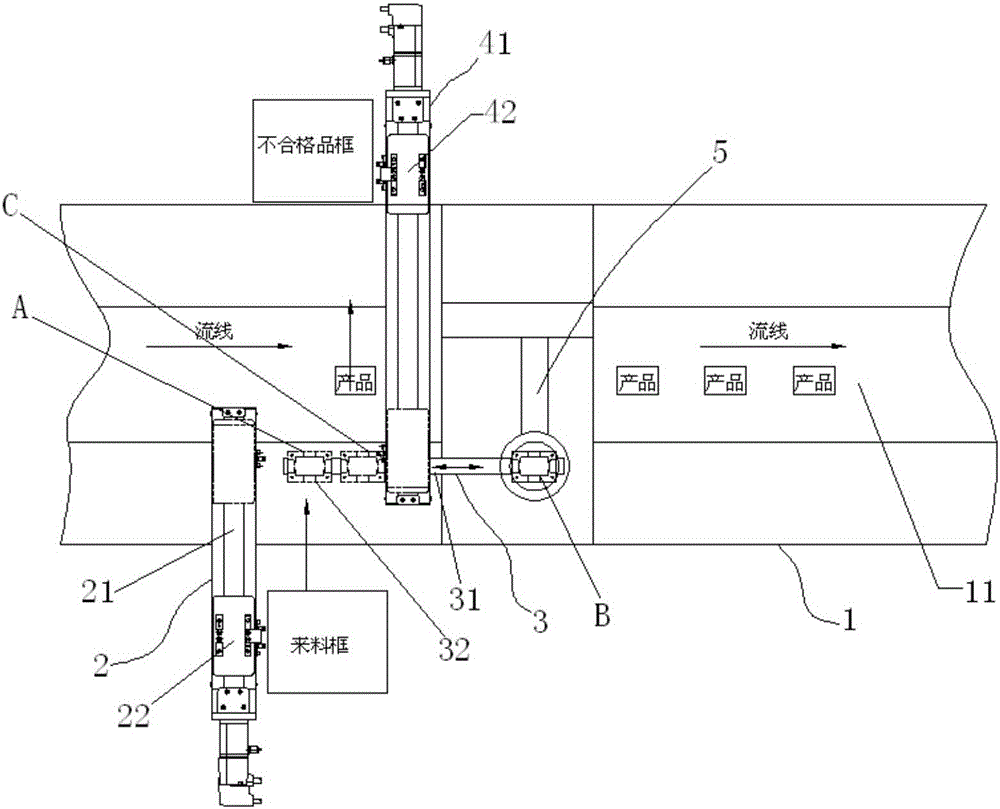

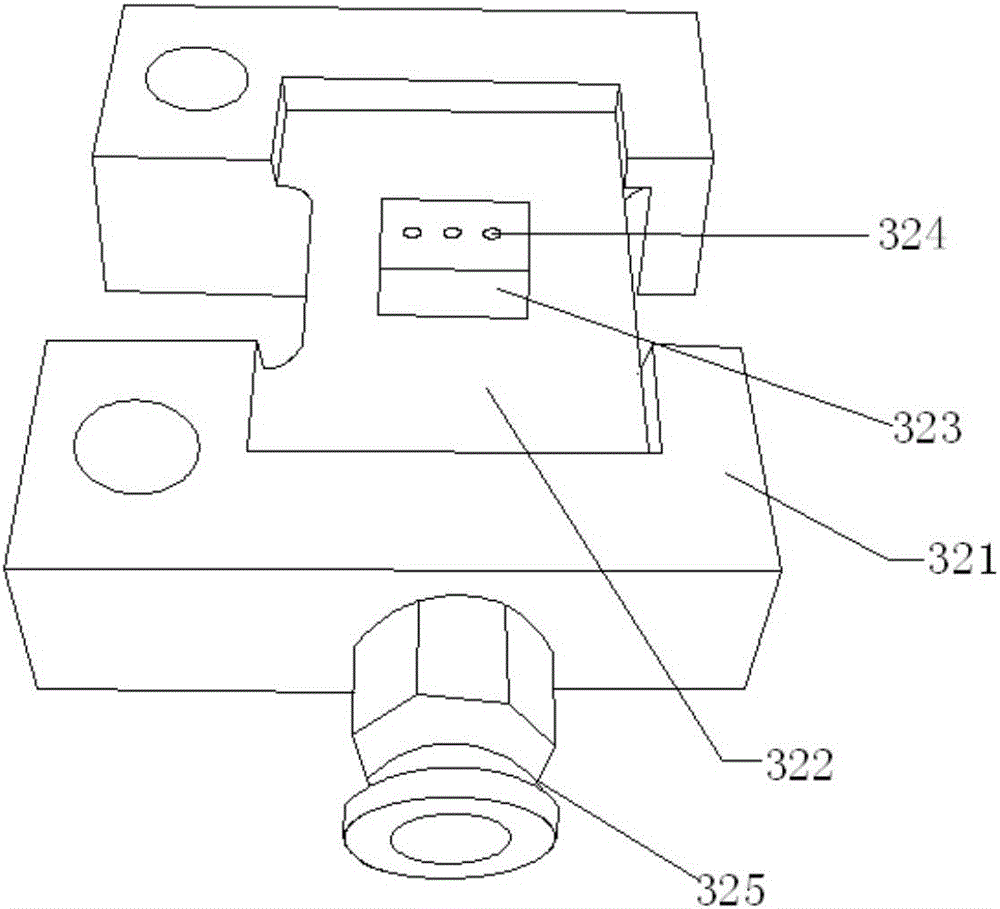

[0021] Such as figure 1 As shown, a loudspeaker diaphragm linear dispensing quality inspection equipment, including a conveyor line mechanism 1, an automatic feeding mechanism 2, a loading and unloading mechanism, a linear station conveying mechanism 3, an automatic unloading mechanism 4, and dispensing and quality Detection mechanism 5; the linear station transport mechanism includes a station linear slide 31 installed on the conveying line mechanism and a positioning jig 32 fixedly connected to the slide seat of the station linear slide, along the station In the sliding direction of the linear slide table, there are loading station A, unloading station C, and dispensing and quality inspection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com