Method for hotly plating zinc and aluminum on surface of steel product

A technology of hot-dip galvanizing and products, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problem of poor heat resistance, corrosion resistance, adhesion and film-forming properties of coatings, environmental pollution, waste water, waste gas and Problems such as waste residue and inability to form zinc oxide layer, to achieve the effects of stable product quality, good bonding force, and real-time controllable coating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

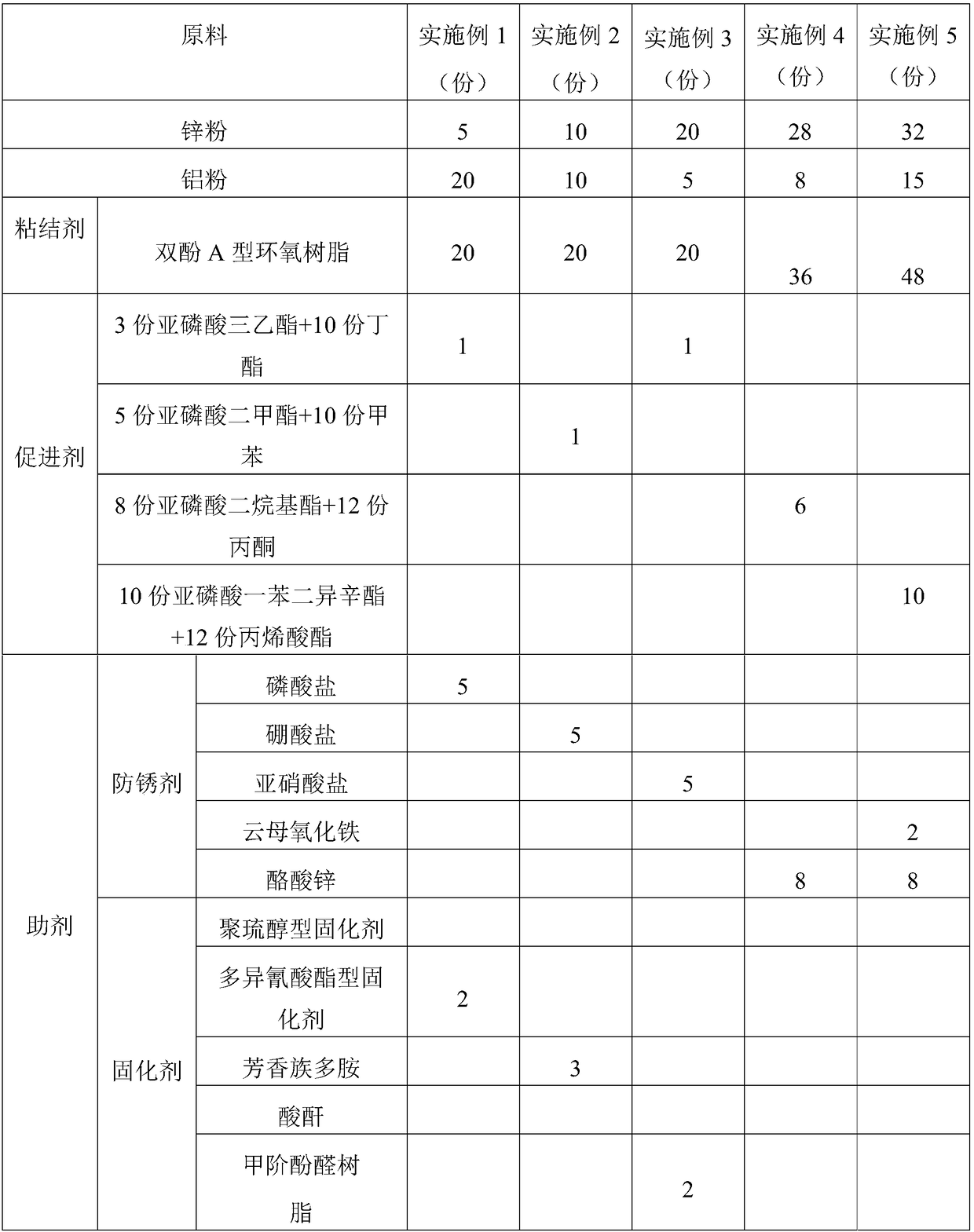

[0046] The formula of table 1 embodiment 1-5 environment-friendly type zinc-aluminum plating solution

[0047]

[0048]

Embodiment 6

[0050] A method for hot-dip galvanized aluminum on the surface of steel products, comprising the following steps:

[0051] (1) Pre-treatment: Carry out degreasing and derusting treatment on steel products, specifically: first spray neutral treatment agent (thina water) to degrease, then mechanical sandblasting and derusting to Sa2.5 level, and finally manually polish and derust To St3 level, the derusting level is determined according to the provisions of the national standard GB / T 8923, wipe clean after treatment, and obtain pre-treated parts;

[0052] (2) Soaking: the workpiece after step (1) is placed in the plating solution tank that the zinc-aluminum plating solution of embodiment 1 is housed, after soaking for 5-10 seconds, drain unnecessary plating solution;

[0053] The plating solution tank is equipped with a stirring device, a viscosity monitoring device and a filtering device. The stirring device regularly stirs the plating solution to prevent precipitation; the vis...

Embodiment 7

[0057]Example 7 uses the zinc-aluminum plating solution of Example 2 to treat the surface of steel products, and the process of hot-dip galvanized aluminum is the same as that of Example 6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com