Three-dimensional chitosan hydrogel and preparation method thereof

A three-dimensional chitosan water, chitosan technology, applied in pharmaceutical formulations, medical preparations with inactive ingredients, prostheses, etc., can solve the problems of increasing the preparation process time and cost, long operation time, etc., and achieve a good biological phase. Capacitive and biodegradable, short reaction time, easy molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Preparation of Chitosan Porous Hydrogel I

[0050] Put 1.5 g of chitosan into 90 ml of deionized water, and magnetically stir at room temperature to make the chitosan evenly dispersed in the water. Slowly add 10 ml of acetic acid-phosphate buffer solution dropwise to the dispersion, adjust the pH to 6.5, and completely dissolve the chitosan, pour it into a mold, put it into a high-temperature incubator, and carry out high-temperature cross-linking at 80 °C for 30 minutes to obtain Porous chitosan hydrogel crude product.

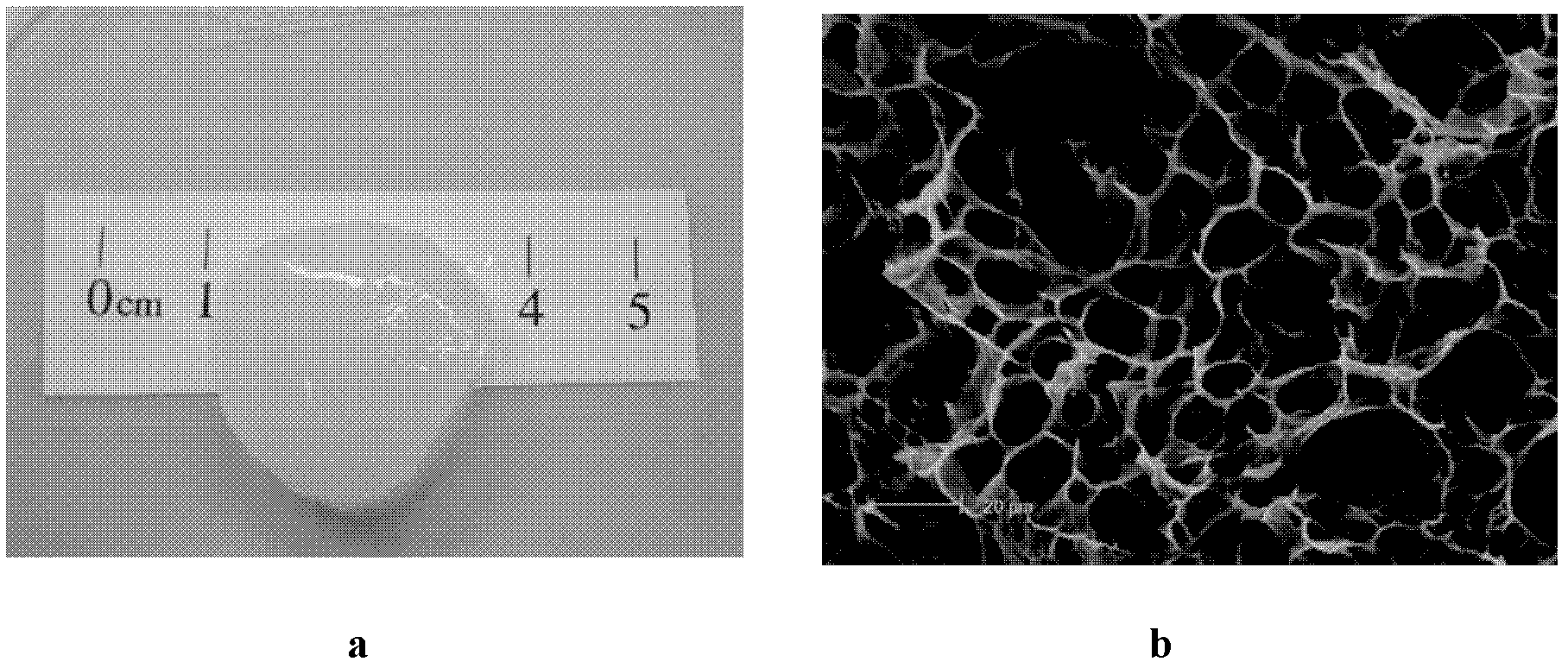

[0051] The chitosan hydrogel was soaked and rinsed with deionized water to remove the acid residue, and a three-dimensional porous chitosan hydrogel scaffold material I was obtained. see attached figure 1 a.

[0052] The prepared three-dimensional chitosan hydrogel I is disc-shaped with an average pore size of 30 μm, see attached figure 1 b.

Embodiment 2

[0054] Preparation of Chitosan Porous Hydrogel II

[0055] Put 0.2 g of chitosan into 9 ml of deionized water, and magnetically stir at room temperature to make the chitosan evenly dispersed in the water. Slowly add 1 ml of hydrochloric acid-phosphate buffer solution dropwise to the dispersion, adjust the pH to 7, and completely dissolve the chitosan, pour it into a mold, put it into a high-temperature incubator, and carry out high-temperature cross-linking at 121 ° C for 30 minutes to obtain Porous chitosan hydrogel crude product.

[0056] The chitosan hydrogel was soaked and rinsed with deionized water to remove the acid residue, and a three-dimensional porous chitosan hydrogel scaffold material I was obtained.

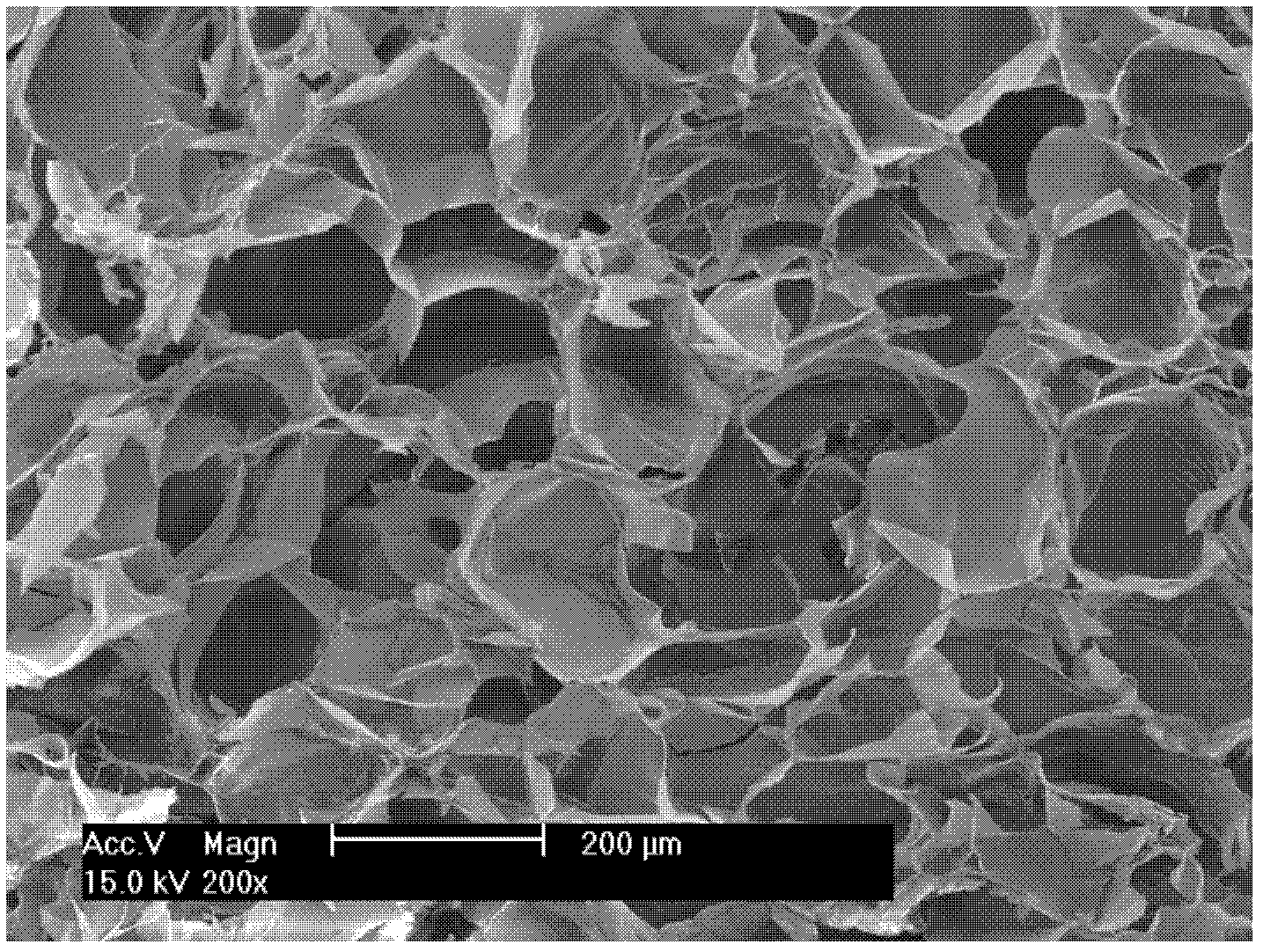

[0057] The obtained three-dimensional chitosan hydrogel II is disc-shaped with an average pore diameter of 100 μm, see attached figure 2 .

Embodiment 3

[0059] Preparation of Chitosan Porous Hydrogel III

[0060] Put 0.2 g of chitosan into 9 ml of deionized water, and magnetically stir at room temperature to make the chitosan evenly dispersed in the water. Slowly add 1 ml of acetate-phosphate buffer solution dropwise to the dispersion, adjust the pH to 6.3, and pour the chitosan into the mold after completely dissolving it. A crude product of porous chitosan hydrogel was obtained.

[0061] The chitosan hydrogel was soaked and rinsed with deionized water to remove the acid residue to obtain a three-dimensional porous chitosan hydrogel scaffold III with an average pore size of 20 μm. image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com