Automatic labeling machine

A labeling machine, fully automatic technology, applied in the direction of labeling machines, labels, packaging, etc., can solve the problem that it is difficult to ensure whether the bonding distance meets the bonding requirements, the flatness of the patchwork part is difficult to ensure, and the bonding accuracy is difficult to control and other problems, to achieve the effect of streamlined operation, simple structure, and improved lamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

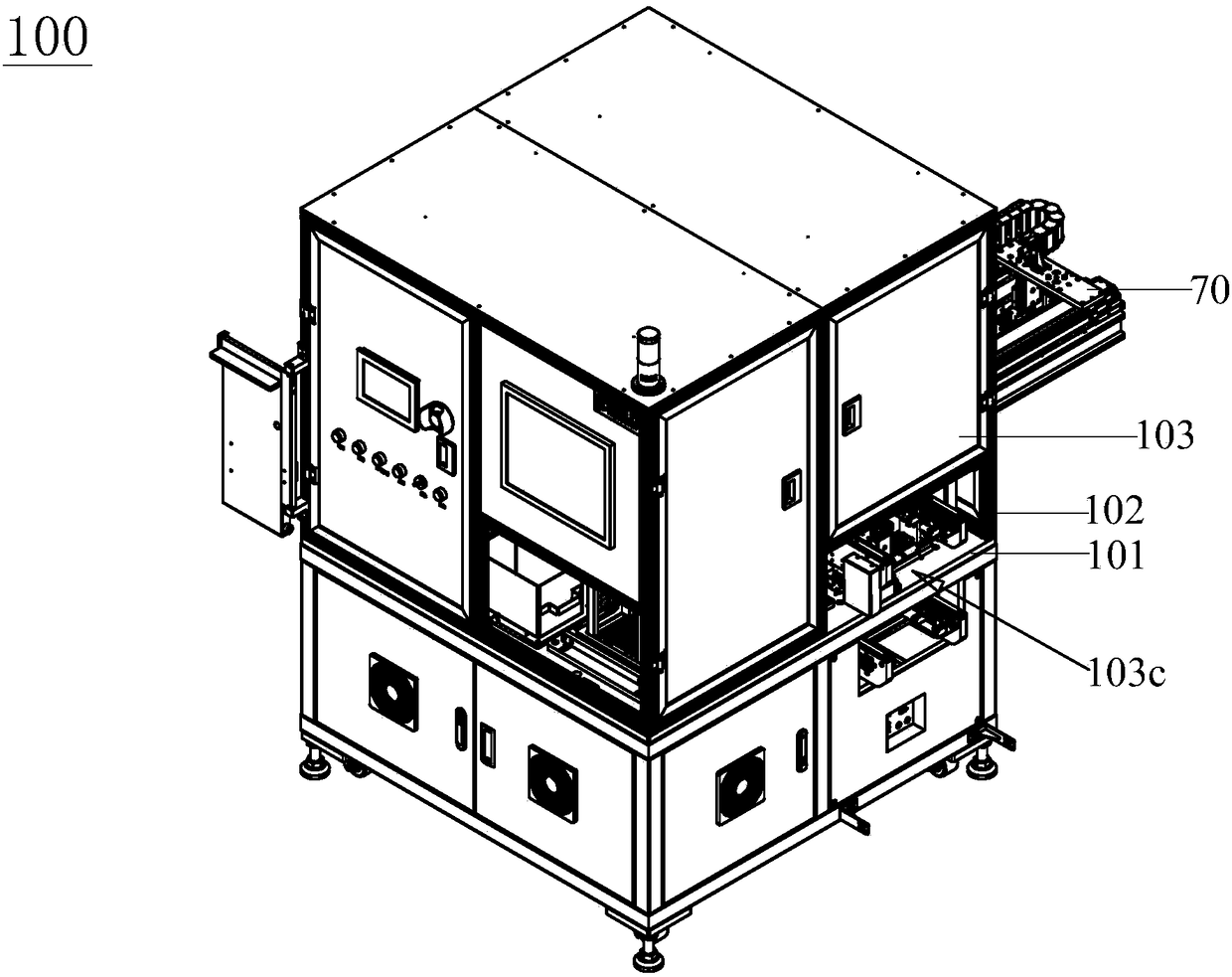

[0030] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

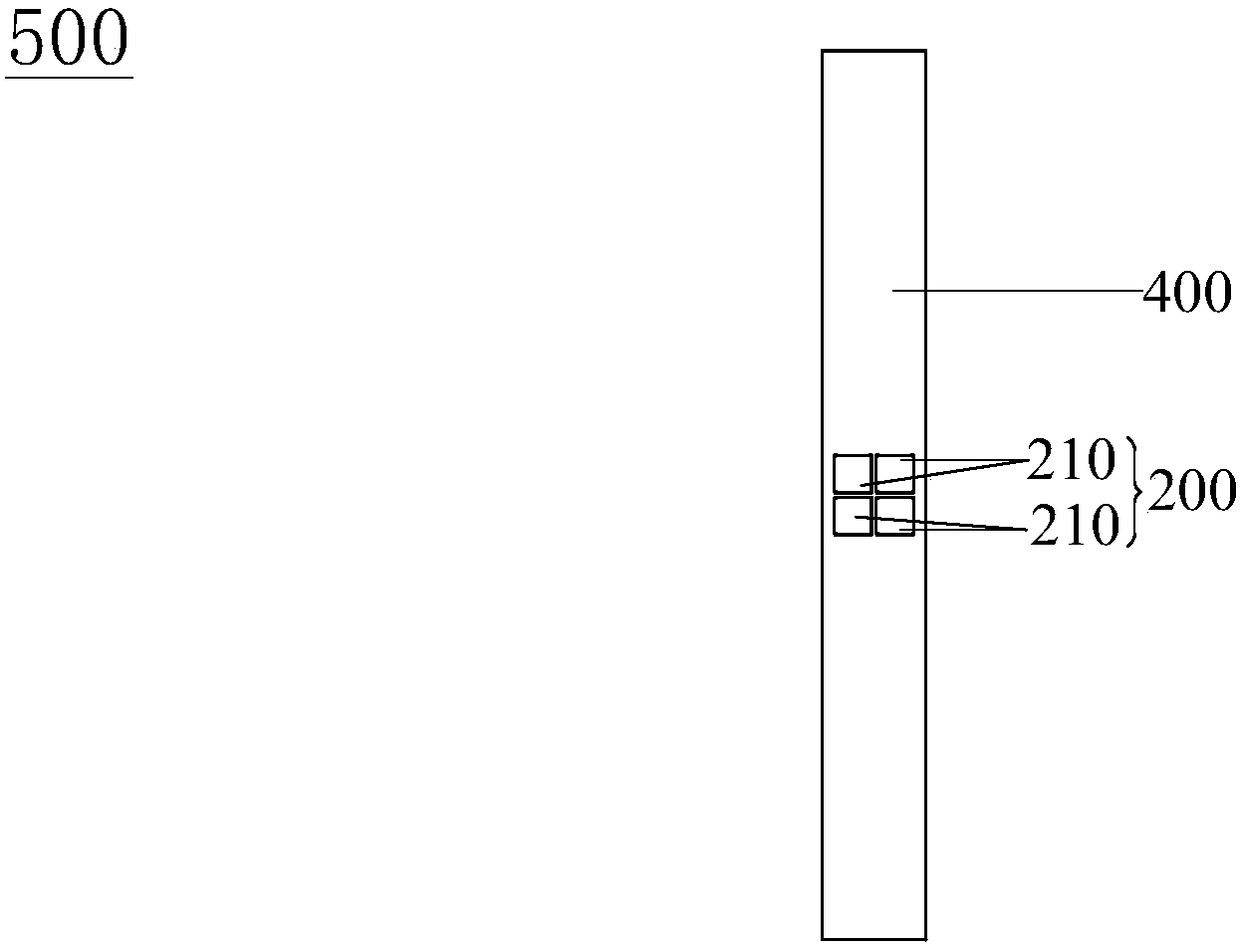

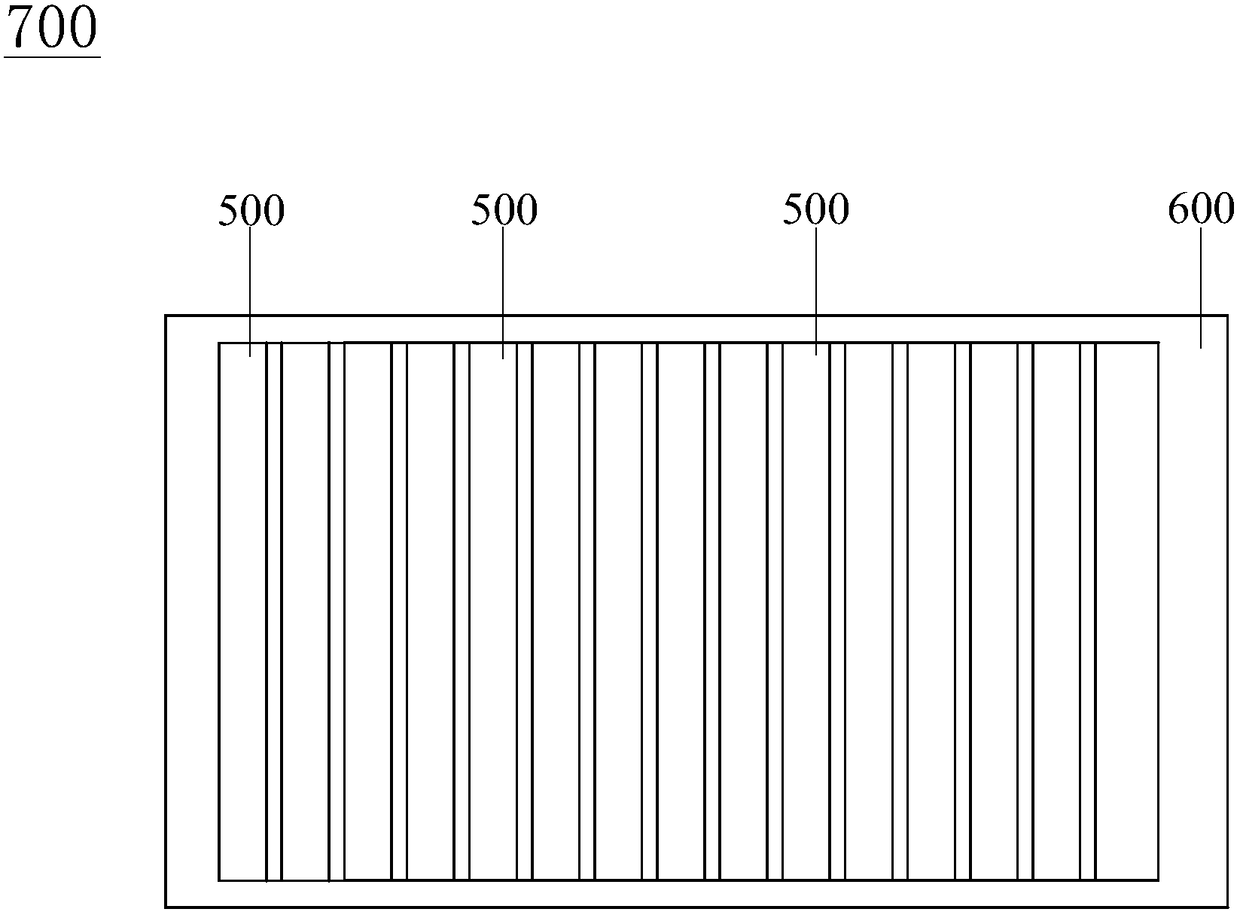

[0031] see Figure 1 to Figure 20 , the present invention discloses a fully automatic labeling machine 100, which is suitable for electrical connection with a controller (not shown in the figure), and is used for sticking the label 200 on the mobile phone case 300. The fully automatic labeling machine 100 of the present invention is controlled by the controller to further improve the degree of automation of the fully automatic labeling machine 100, wherein the controller is an existing controller, and its structure and control principles are well known in the art. Therefore, it will not be described in detail here. The mobile phone case 300 is provided with a bonding area 300a that matches the shape of the sticker 200. The sticker 200 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com