Multi-station refrigerator body foaming production line equipment

A production line equipment and multi-station technology, which is applied in the field of multi-station refrigerator box foaming production line equipment, can solve the problems of not being suitable for the production of various types of refrigerator boxes, the single model of refrigerator products produced, and the high price and cost of the production line. , to achieve the effect of streamline operation, shorten production cycle and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

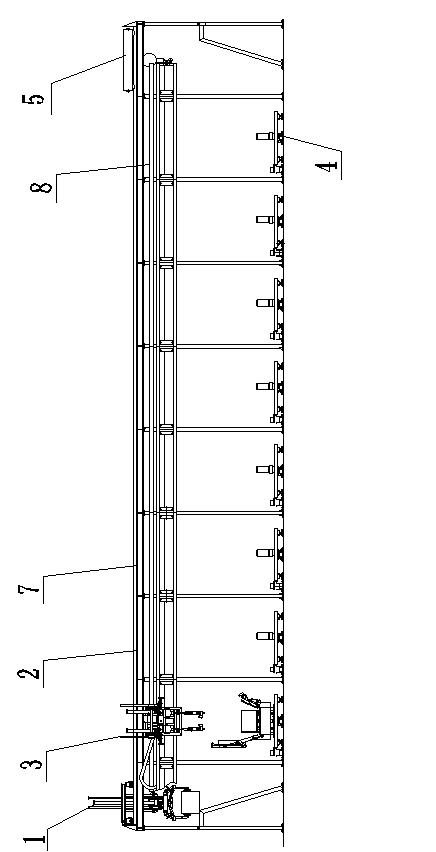

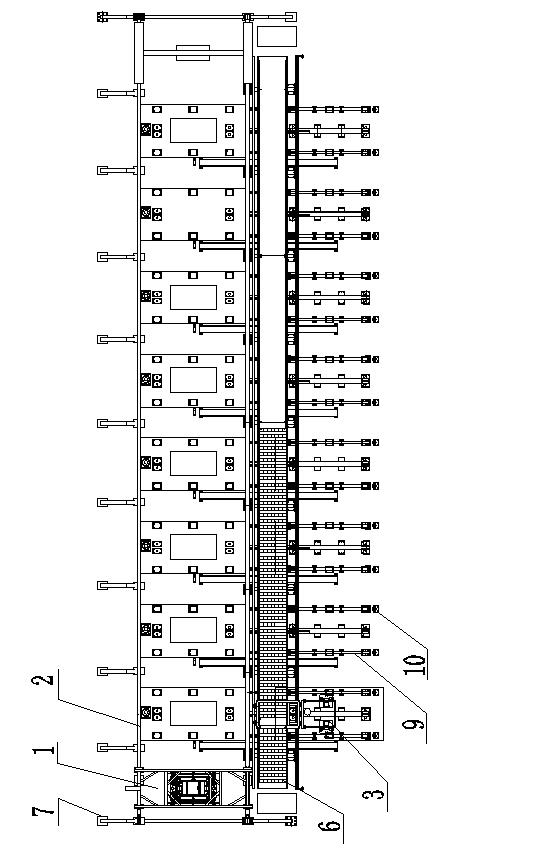

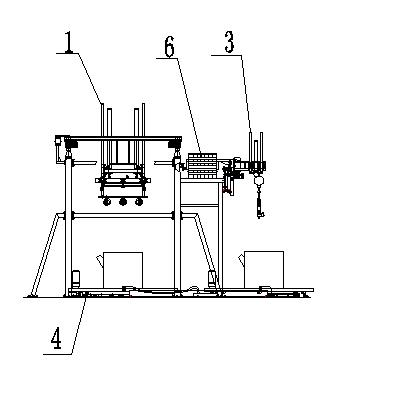

[0033] by attached Figure 1 to Figure 12 As shown, a multi-station refrigerator box foaming production line equipment includes: a frame 7 is provided with a track 2, and a pick-up manipulator 1 is arranged on the track 2; a trolley track 8 is provided on the frame 7, and a trolley track 8 The foaming manipulator 3 is movably connected, and multiple sets of rails 9 and frame 10 are laid on the foundation corresponding to the frame 7, and a mold trolley 4 is arranged on each set of rails 9; the pick-up manipulator 1 is included on the track 2 Moving car body 12, at least one lifting cylinder 15 is fixed on the car body 12, and the lifting cylinder 15 is connected to the manipulator base 16. Movably connected, linkage mechanism 18 is set on the manipulator seat 16, clamping cylinder 17 is connected between the two main arms of linkage mechanism 18, vacuum suction cup 19 is set on the support arm of linkage mechanism 18, and motor is installed on both sides of car body 12. 13; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com