Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Realize assembly construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Green assembly type digital construction platform and working method thereof

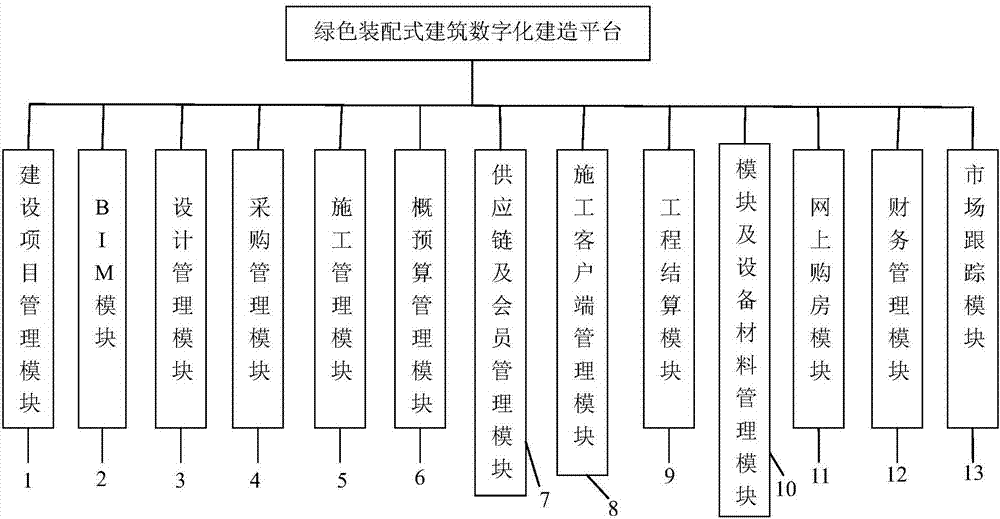

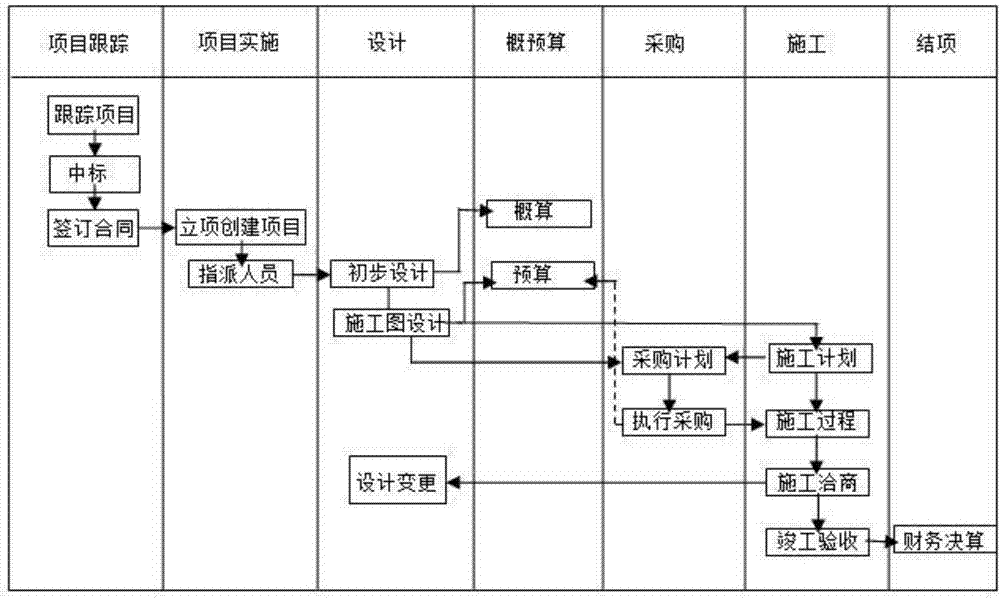

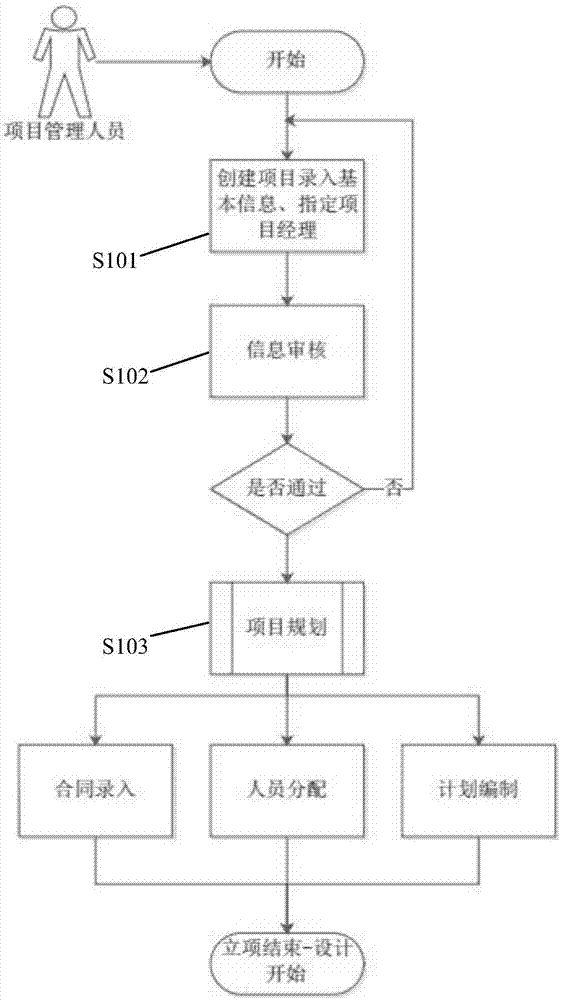

InactiveCN107958328ALive UpdateDigitization hasGeometric CADResourcesInformation sharingModular design

The invention discloses a green assembly type digital construction platform and a working method thereof and belong to the assembly building field. The platform includes a construction project management module, a BIM module, a design management module, a procurement management module and a construction management module; the information data of each module are stored in an BIM (digital information model); and with the digital information model adopted as the basis of each construction project, relevant work is carried out, information can be updated in real time, and information sharing can be realized. According to the green assembly type digital construction platform of the invention, construction projects are planed and designed in a unified manner; building components and general equipment materials manufactured in factories are transported to construction sites on time according to constructional engineering requirements; and the whole process of the construction of more than a dozen of construction sites can be simultaneously monitored, controlled and managed remotely; and modular design, industrial production, assembly-based construction, and intelligent management are completely realized.

Owner:北京善筑科技股份有限公司

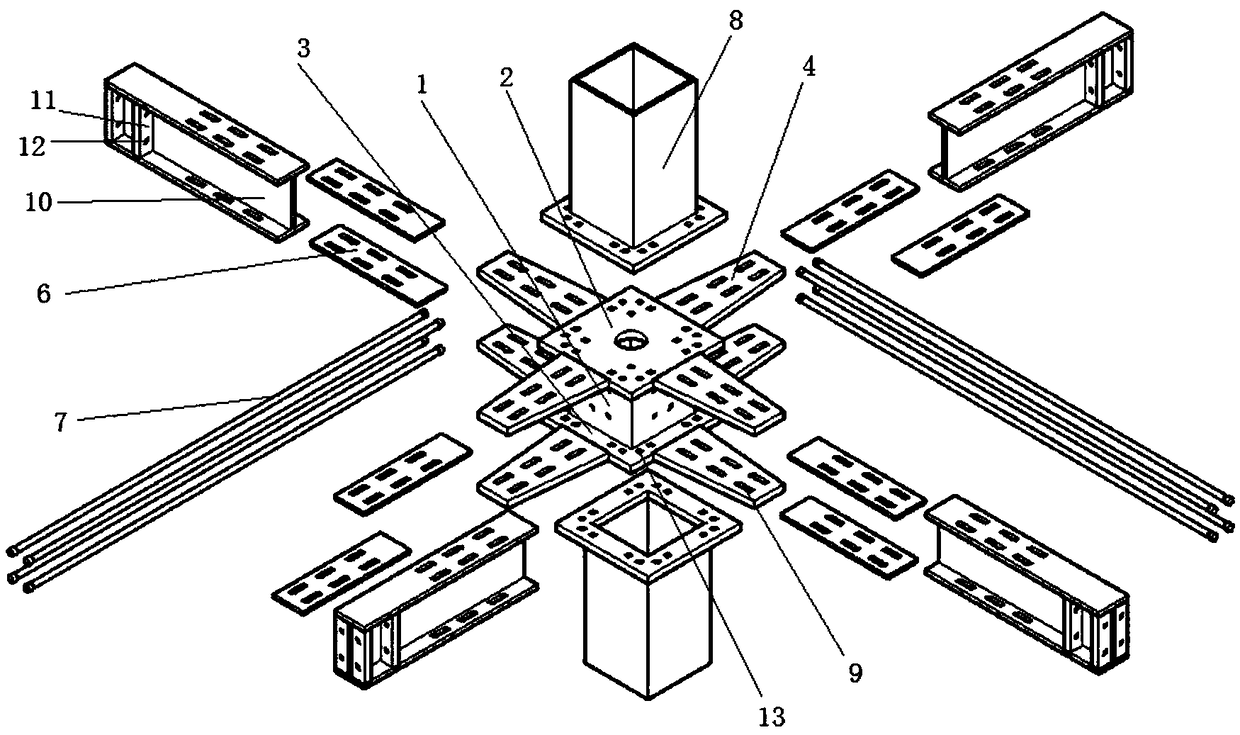

Prefabricated friction-energy-consuming self-resetting baffle communication node

InactiveCN109138179AIncrease frictional energy dissipation functionAvoid damageProtective buildings/sheltersBuilding reinforcementsPre stressInstallation Error

Provided in the invention is a prefabricated friction-energy-consuming self-resetting baffle communication node comprising node-domain rectangular steel tube concrete columns. A first baffle plate anda second baffle plate are arranged at the upper ends and the lower ends of the node-domain rectangular steel tube concrete columns respectively; and extending arms are arranged around the first baffle plate and the second baffle plate; H-shaped steel beams are arranged between the extending arms arranged in parallel between the first baffle plate and the second baffle plate; rubber gaskets are arranged between upper and lower flanges of the H-shaped steel beams and the extending arms; and the H-shaped steel beams and the node-domain rectangular steel tube concrete columns that are arranged inopposite are connected by high-strength prestressed steel strands with cables. The flange-included node-domain rectangular steel tube concrete columns are arranged at the top of the first baffle plate and the bottom of the second baffle plate. According to the prefabricated friction-energy-consuming self-resetting baffle communication node, the installation error is reduced; the prefabrication ofthe factory is realized; the node quality is improved; the node has the self-resetting function; the post-earthquake maintenance costs are lowered; and the anti-seismic capacity is enhanced.

Owner:LIAONING TECHNICAL UNIVERSITY

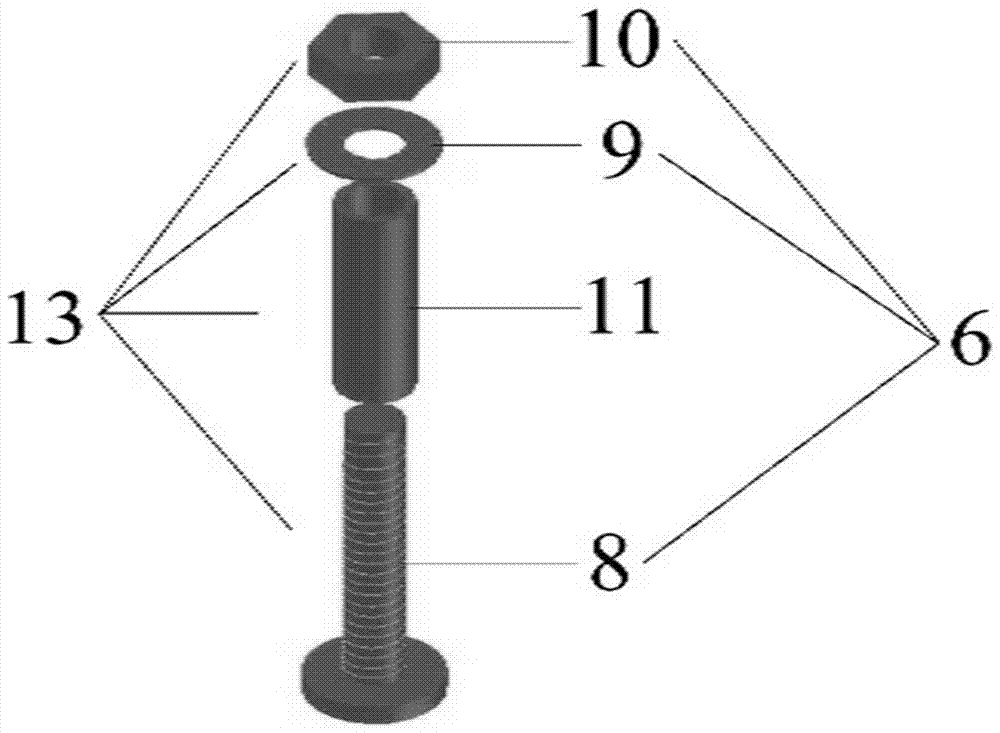

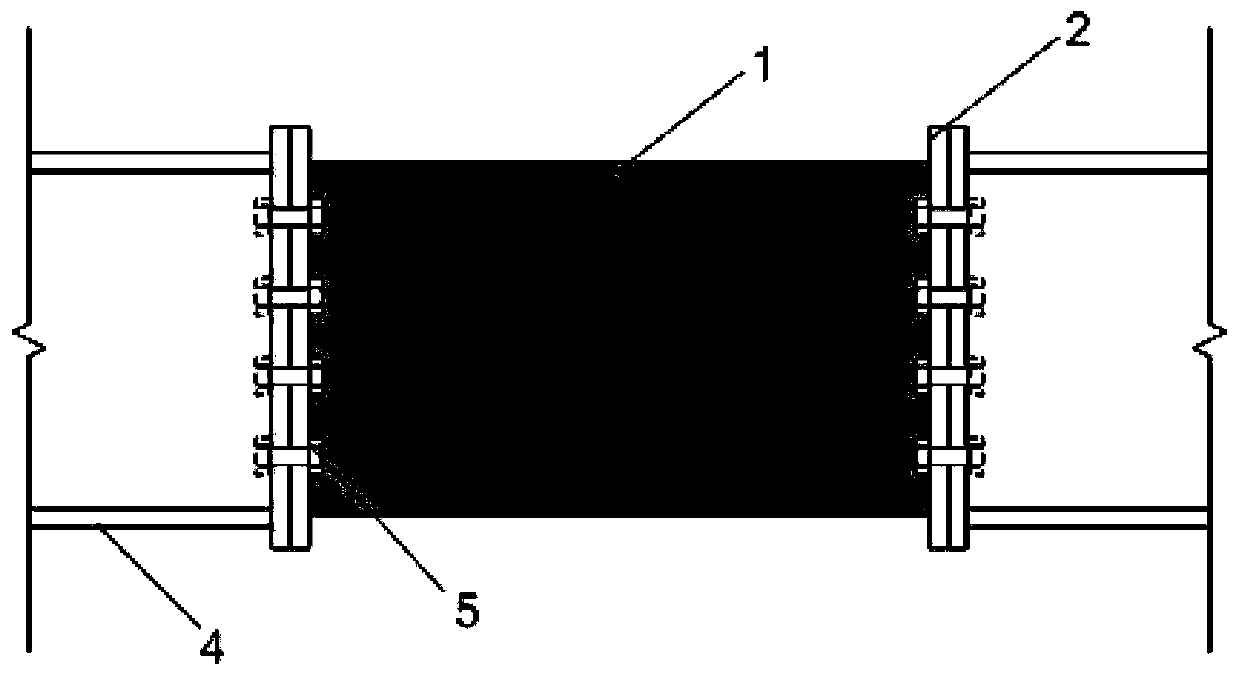

Fireproof and buckling-restrained fabricated composite beam and construction method

ActiveCN107313540AImprove local stabilityImprove bearing capacityFloorsFire proofingRebarTreatment costs

The invention discloses a fireproof and buckling-restrained fabricated composite beam, and belongs to the field of house construction. The fireproof and buckling-restrained fabricated composite beam mainly comprises a prefabricated reinforced concrete slab, a wrapped concrete steel beam, a friction-type high-strength bolt connect set and a rubber sleeve; the prefabricated reinforced concrete slab and the wrapped concrete steel beam are connected into a whole through the friction-type high-strength bolt connect set and the rubber sleeve. According to the fireproof and buckling-restrained fabricated composite beam, through combination of the design philosophy of a recoverable structure, the prefabricated reinforced concrete slab, the wrapped concrete steel beam, the friction-type high-strength bolt connect set and the rubber sleeve are combined mutually, the bearing capacity of steel components is improved, the anti-corrosion and fireproof treatment cost of the steel components is saved, the suitable range of the composite beam is enlarged, fabricated construction of the composite beam is achieved, the time spent on in-situ reinforced assembling, concrete pouring and concrete maintenance is saved, the construction period is shortened to a large extent, the construction efficiency is improved, and the fireproof and buckling-restrained fabricated composite beam has wide application prospects in building structures with steel structures.

Owner:TAIYUAN UNIV OF TECH

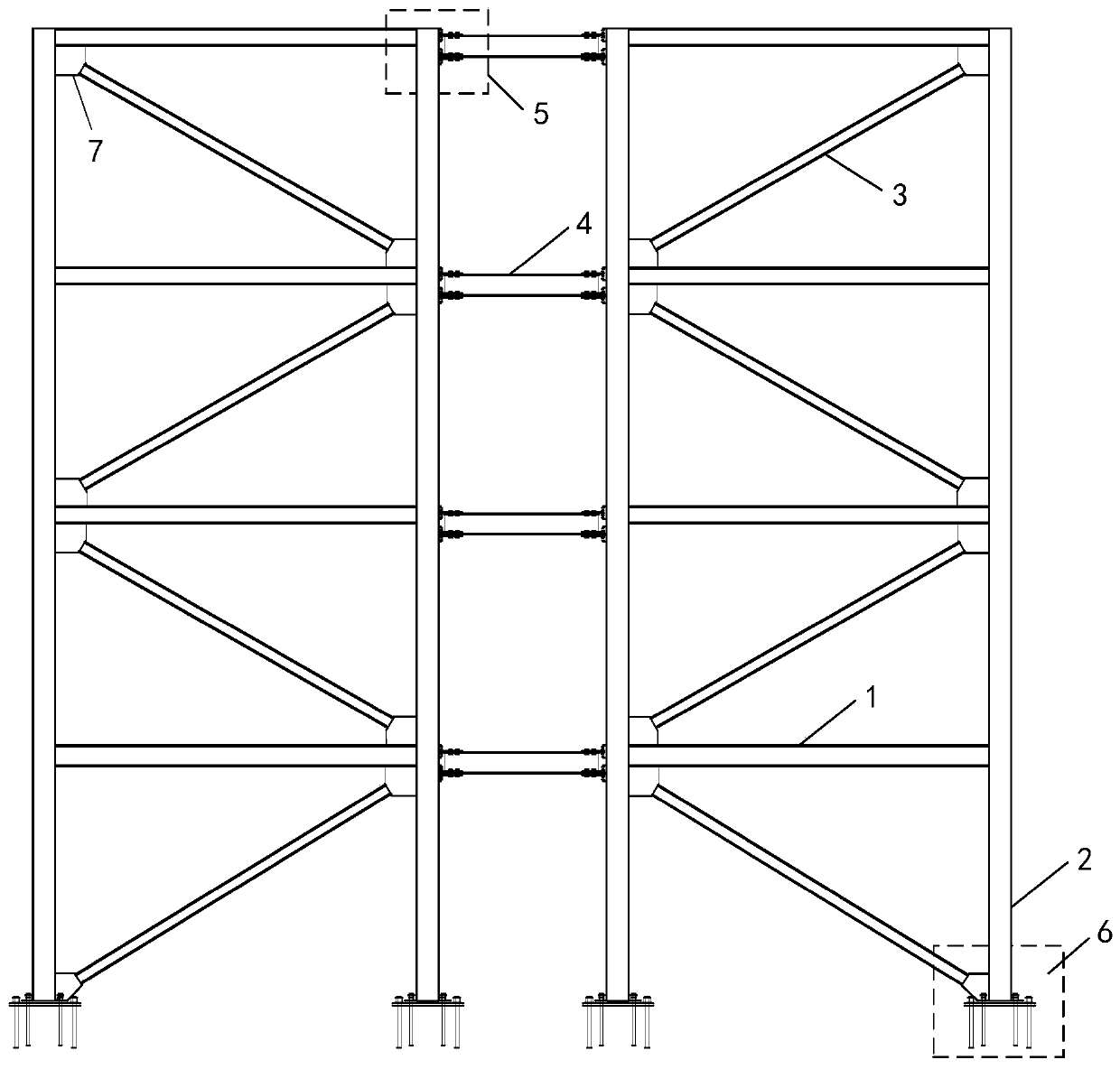

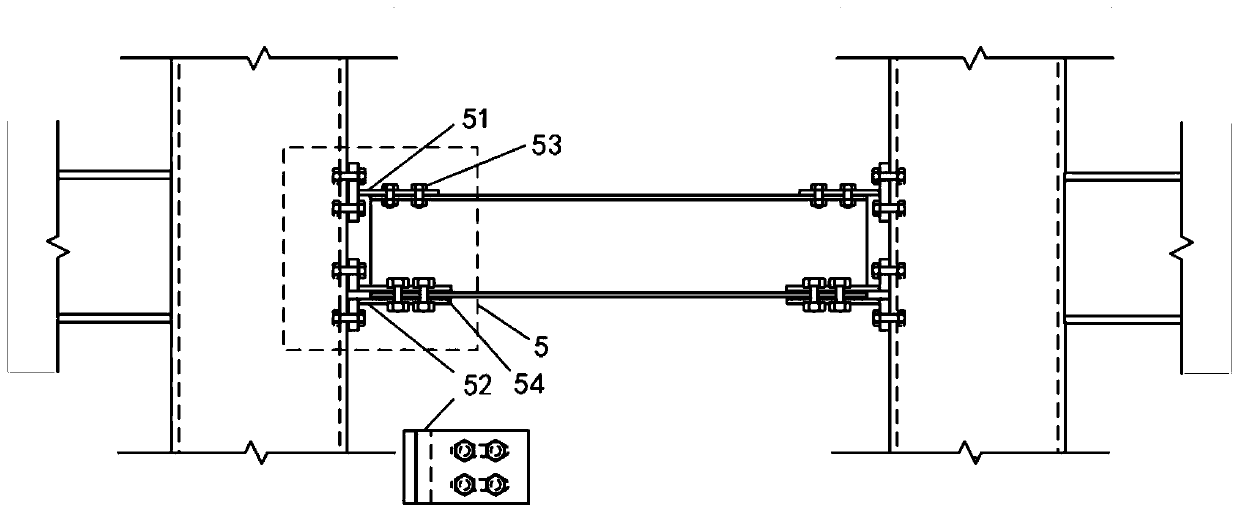

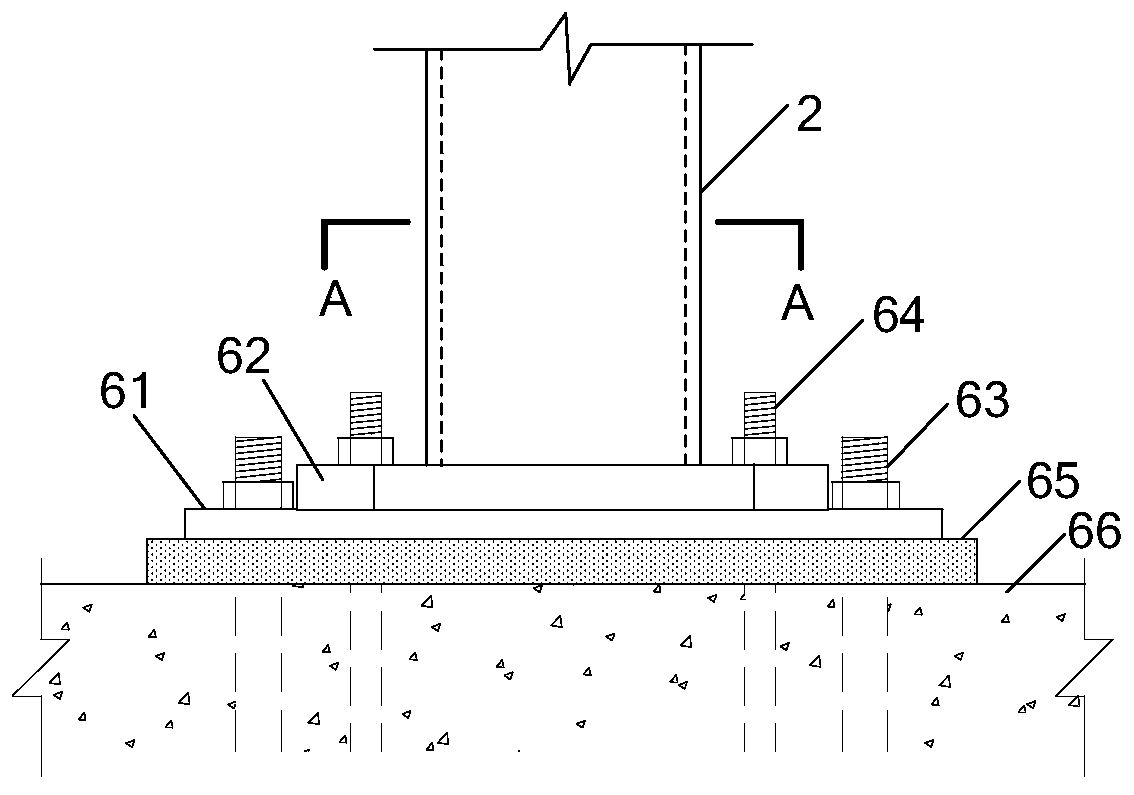

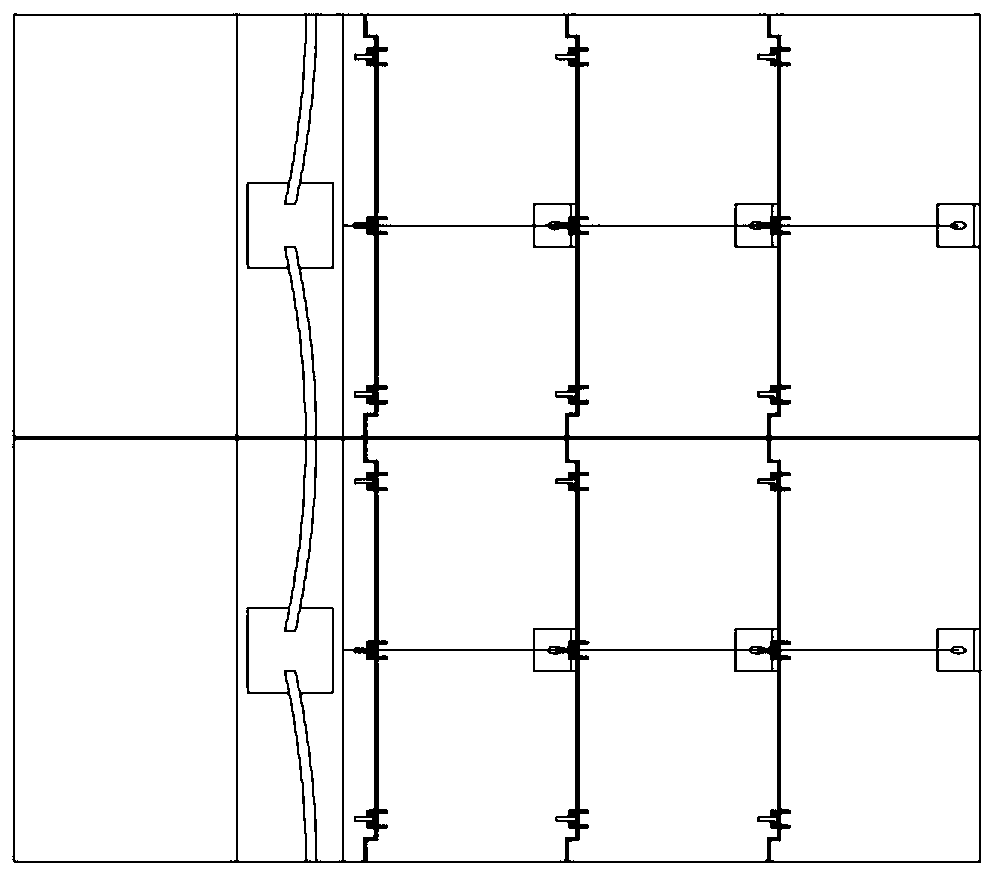

Ductile coupling beam swinging steel frame system

ActiveCN109837988ASimple structureThe mechanism of action is clearFoundation engineeringProtective buildings/sheltersBraced frameEarthquake resistant structures

The invention belongs to the technical field of civil engineering aseismic structural systems, and provides a ductile coupling beam swinging steel frame system. According to the ductile coupling beamswinging steel frame system, steel supporting frames composed of frame beams, frame columns and steel supports bear the vertical load, the lateral rigidity and resilience are provided, and the elasticity is maintained all the time by allowing the bottoms of the steel columns to rise under the action of an earthquake; seismic energy is dissipated through replaceable connecting beams and swinging type column feet, wherein the steel supporting frames on the left side and right side are connected through the replaceable connecting beams, and the bottoms of the frame columns adopt the swinging typecolumn feet; when a structural system is subjected to the seismic action, the seismic energy is dissipated by the replaceable connecting beams and the swinging type column feet, and the steel supporting frames on the two sides are prevented from being damaged; and the concept of the structural system is clear, design is simple, the action mechanism is clear, the replaceable connecting beams and the swinging type column feet are used as energy dissipation elements and connected with steel columns through bolts, input energy is dissipated in the earthquake, and after the earthquake, the purposeof quick recovery of the use function of the structure system can be achieved by replacing an energy dissipator.

Owner:DALIAN UNIV OF TECH

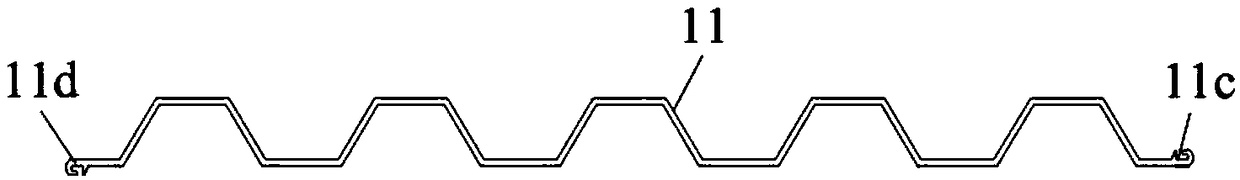

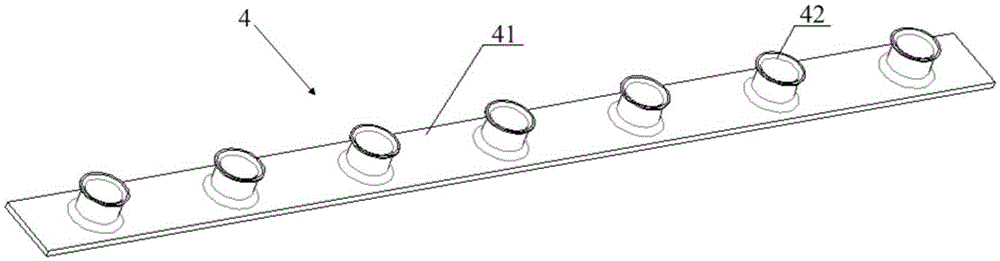

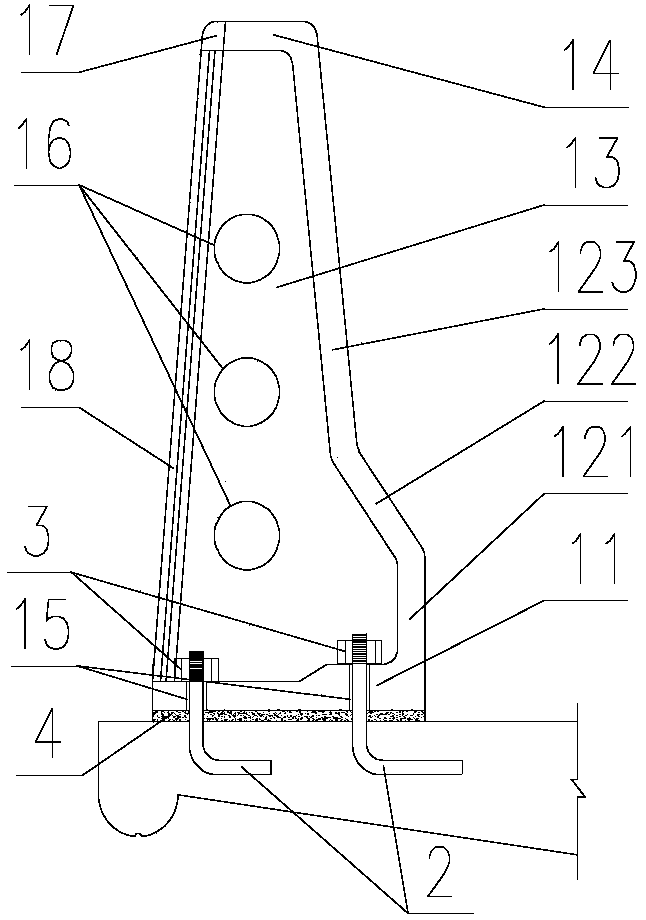

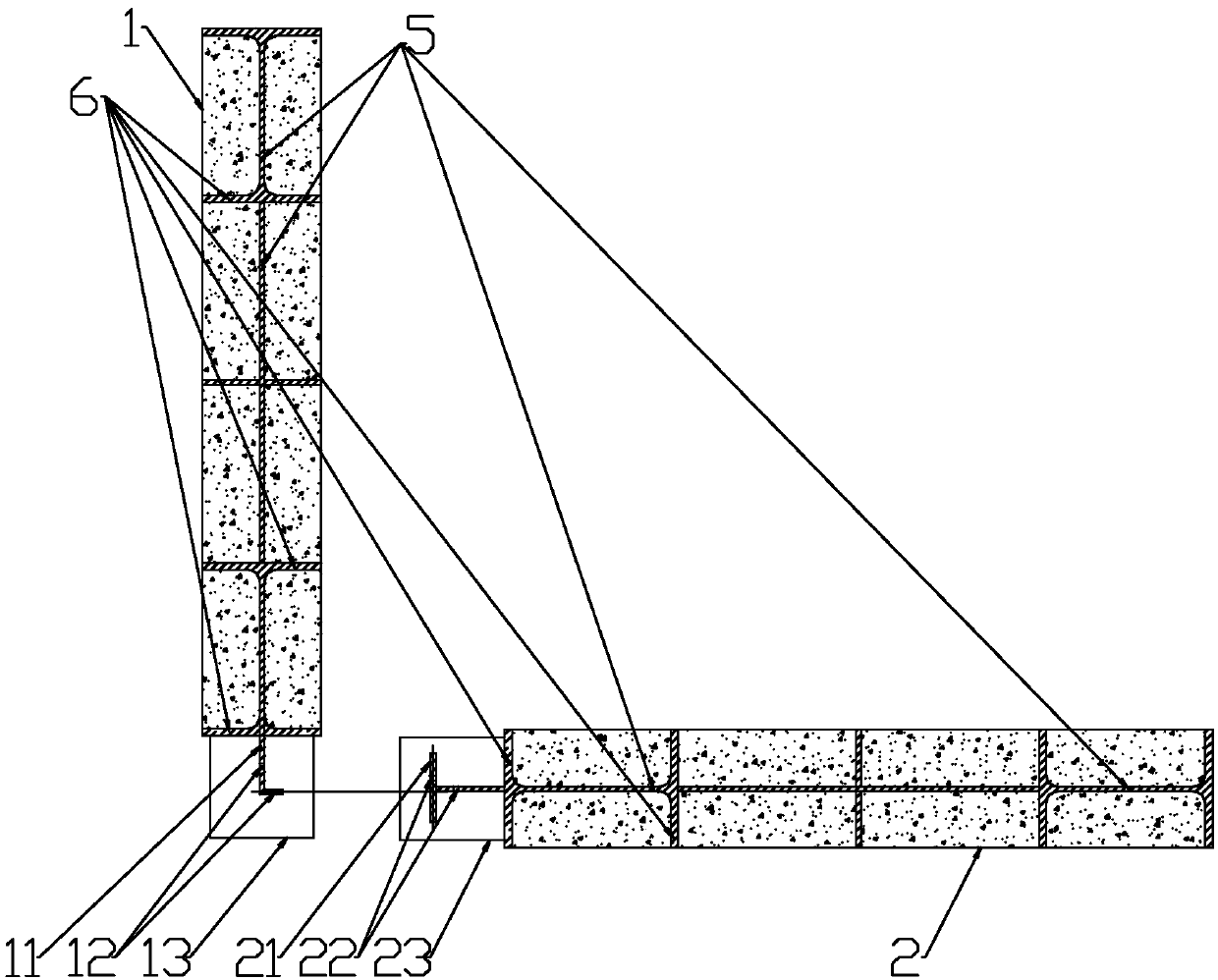

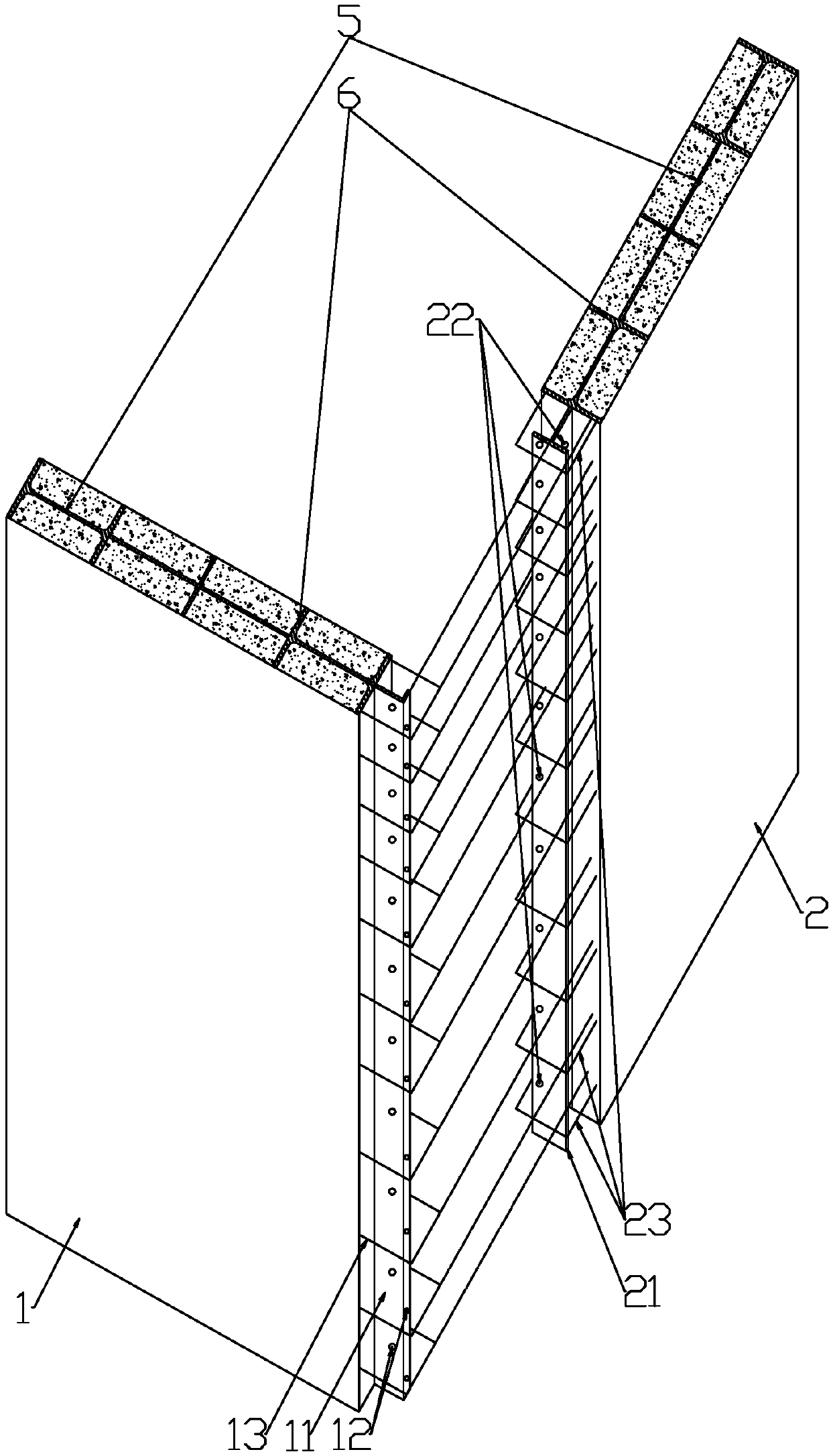

Assembly type anti-seismic anti-freezing-thawing deformation corrugated plate rigid-flexible retaining wall

PendingCN111305258ASmall sizeRealize assembly constructionArtificial islandsProtective foundationFreezing thawingCyclic deformation

The invention relates to an assembly type anti-seismic anti-freeze-thaw deformation self-adaptive corrugated plate rigid-flexible retaining wall. The retaining wall comprises a bottom plate and a retaining plate above the bottom plate, and the cross section of the retaining wall is in an inverted T shape; the bottom plate transversely comprises a plurality of rows of unit plates which are sequentially a front end bottom plate, a middle connecting bottom plate and a foundation bottom plate from inside to outside and are assembled and connected through inserting grooves and inserting strips in the end faces; the retaining plate comprises a plurality of stand columns and an arched steel corrugated retaining plate among the stand columns, strip-shaped grooves are formed in the two longitudinalside faces of each stand column, and the ends of the arched steel corrugated retaining plate are inserted into the strip-shaped grooves of the stand columns; and the longitudinal inserting grooves are formed in the surface of the foundation bottom plate, and the bottoms of the stand columns and the arched steel corrugated retaining plate are inserted into the inserting grooves of the foundation bottom plate. According to the retaining well, a prefabricated assembly type construction method is adopted, foundation deformation caused by huge horizontal seismic force and frost heaving force and vertical frost heaving force can be adapted, and the cyclic deformation adaptive capacity is achieved.

Owner:CCCC FIRST HIGHWAY CONSULTANTS +2

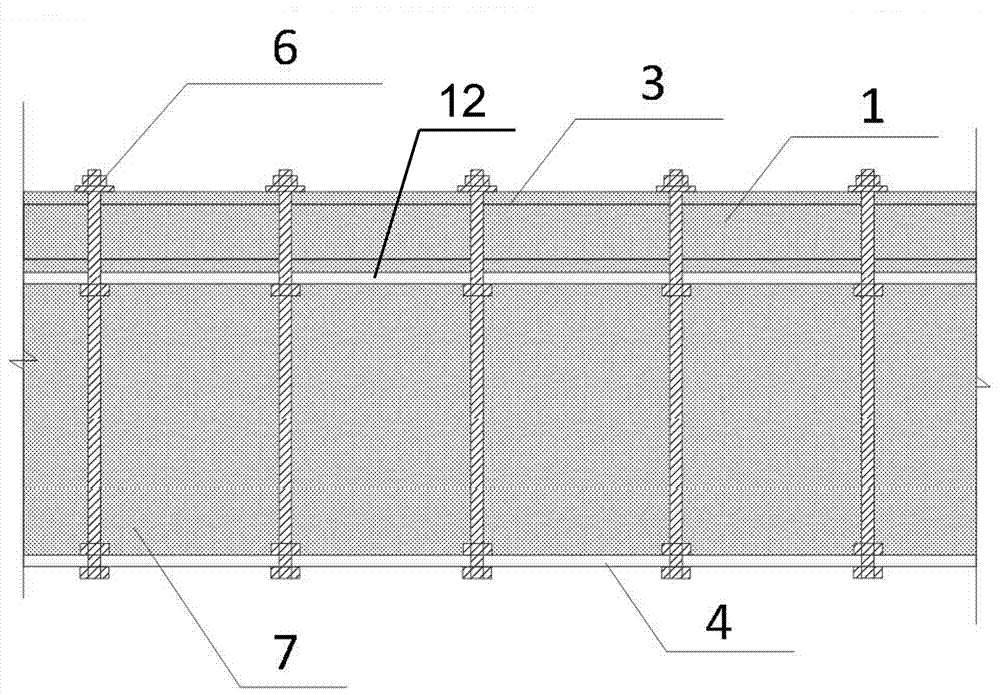

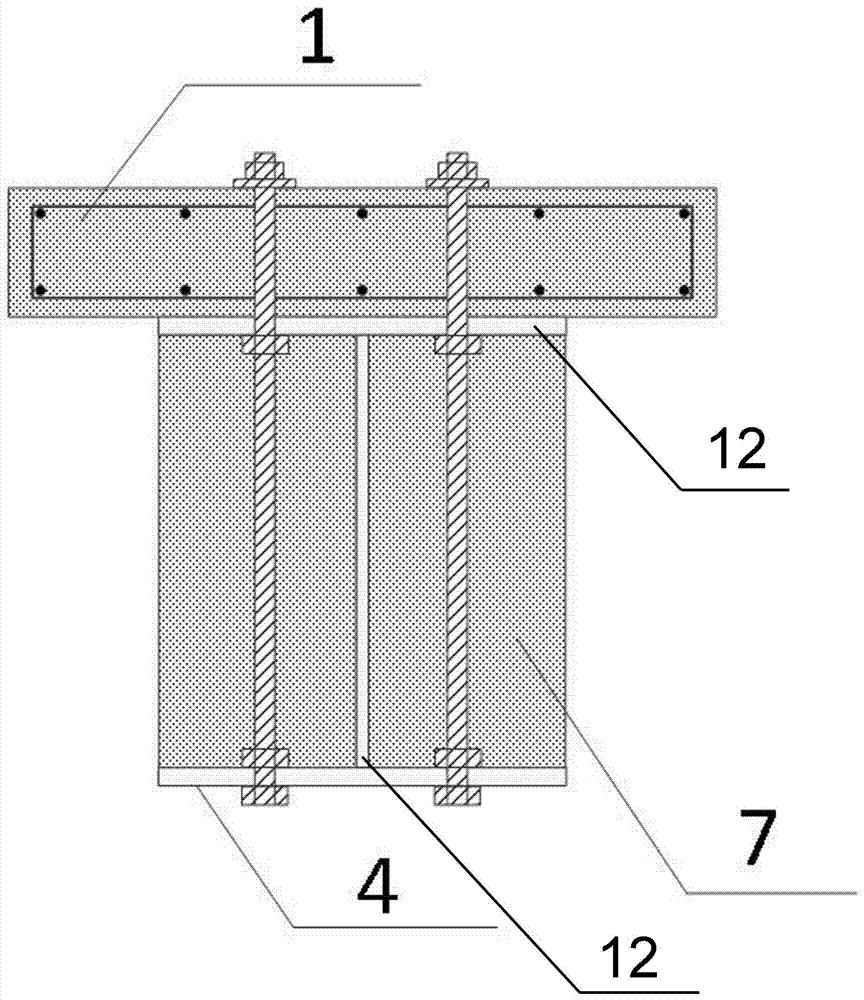

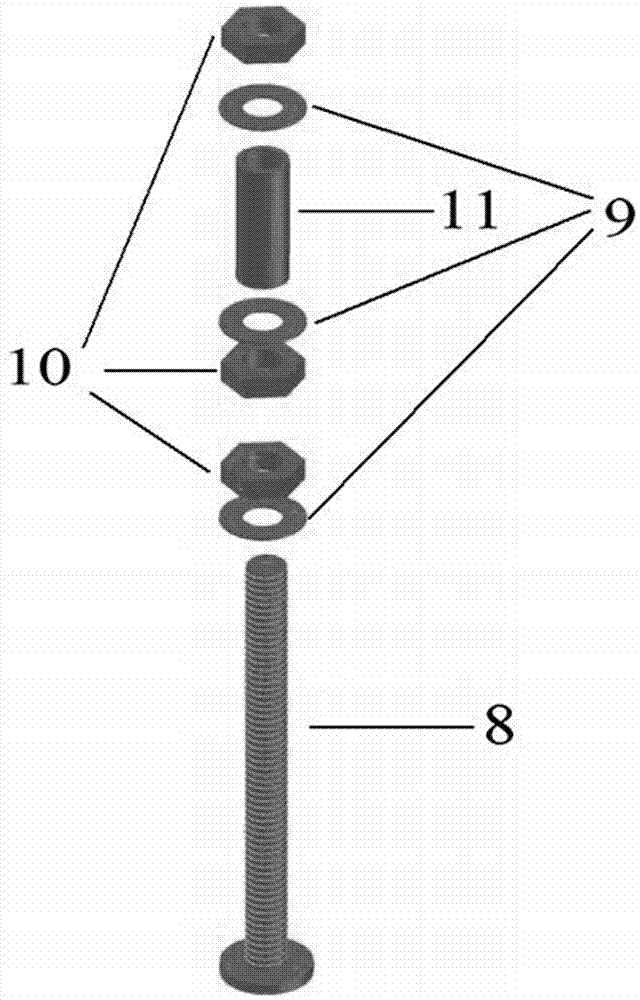

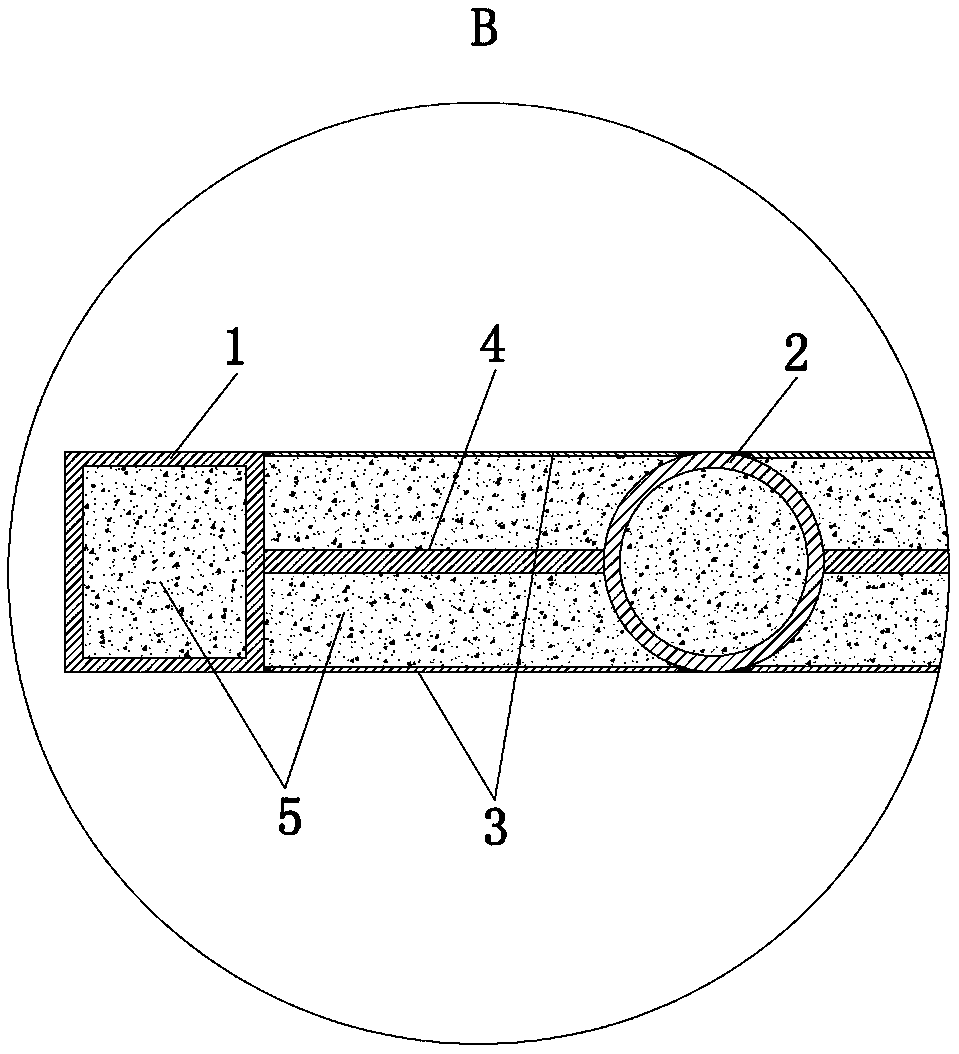

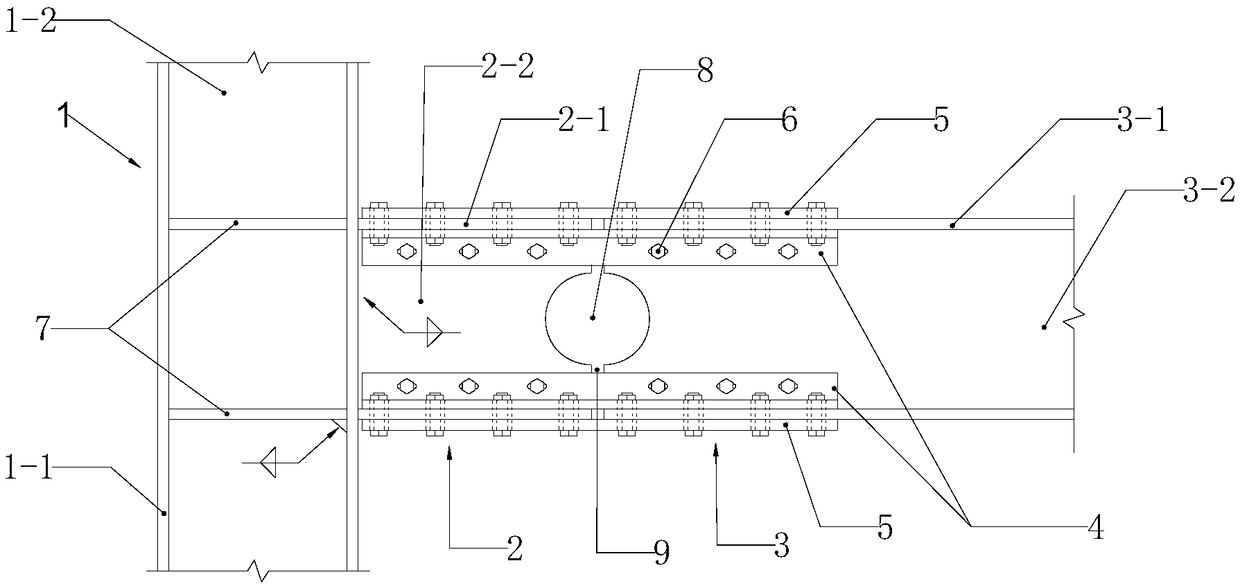

Anti-fatigue damage element-replaceable assembled composite beam and construction method

InactiveCN107313347ARealize assembly constructionReduce maintenance costsBridge structural detailsBridge erection/assemblyFatigue damageFatigue loading

The invention discloses an anti-fatigue damage element-replaceable assembled composite beam and belongs to the field of bridge and road building. The composite beam mainly comprises a main structure, anti-fatigue damage elements and bridge deck pavement, wherein the main structure mainly comprises prefabricated high performance concrete bridge decks, high-strength steel beams and concrete post-poured belts; the anti-fatigue damage elements mainly comprise friction type high-strength bolt pairs and rubber sleeves and are used for connecting the prefabricated high performance concrete bridge decks and the high-strength steel beams; and the rubber sleeves are arranged outside the friction type high-strength bolt pairs to ensure that under the action of fatigue loading, the deformation constraint on the friction type high-strength bolt pairs is reduced. The composite beam disclosed by the invention has the advantages that the application range of the composite beam is expanded; the assembly type construction of the composite beam is realized; the performance of the composite beam is increased; the construction time is shortened to a great extent; the construction efficiency is increased; the problems of economy and maintenance convenience in the composite beam operating process are solved; and the maintenance cost of the composite beam and the risk in the using process of the composite beam are reduced.

Owner:TAIYUAN UNIV OF TECH

Corrugated single steel plate wall system and construction method thereof

InactiveCN107514075ASave steelImprove out-of-plane stability bearing capacityWallsHeat proofingEngineeringSteel plate shear wall

The invention discloses a corrugated single steel plate wall system and a construction method thereof. The system includes a structural part, an interior part and a fireproof part. The structural part includes a corrugated steel plate and a side column. The part includes the pipeline and the switch box, and the pipeline is connected with the switch box; the fireproof part includes the first fireproof board and the second fireproof board, the first fireproof board is fixedly connected with the stiffener, the side of the side column is welded with a square tube, the first fireproof board and the The second fire prevention boards are respectively fixedly connected with the square pipes. The construction method includes: (a) on-site fabrication of the structural part in the workshop; (b) installation of the interior part; (c) installation of the fire protection part; (d) on-site docking installation of the corrugated single steel plate shear wall system as a hoisting joint. The invention can improve the bearing capacity, has the characteristics of good anti-seismic performance, light weight of the structure, and fast construction speed, and can arrange pipelines and fire prevention measures at the same time, realizing the harmony and unity of the structure and the building.

Owner:浙江中南绿建科技集团有限公司 +1

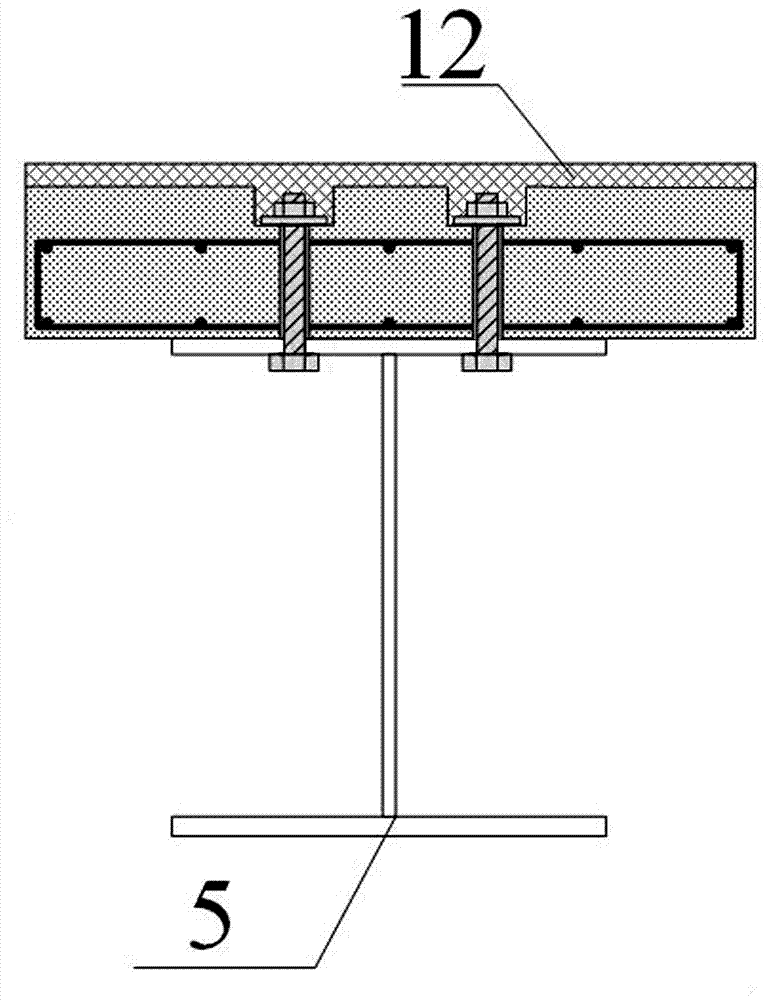

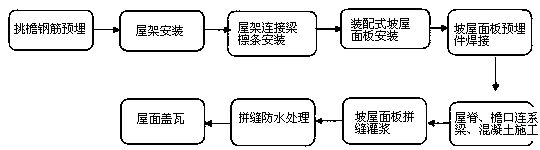

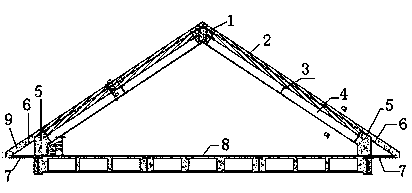

Building slope roof fabricated construction process

InactiveCN109577539ALow costLose weightRoof covering using slabs/sheetsBuilding roofsSurface layerEngineering

The invention relates to a building slope roof fabricated construction process which is mainly characterized in that a concrete slope roof panel is changed from on-site formwork casting into factory production to form a slope roof panel component, the slope roof panel component is transported to an installation site and lifted and installed by a crane, a small quantity of concrete is poured at anchor points to fixedly embed the slope roof panel, abutted seams of the slope roof panel are treated as required, waterproof treatment is performed on a roof, and then the roof is covered with a roof decoration tile surface layer. The building slope roof fabricated construction process has the advantages that the problem of difficulty in fabricated construction of a slope roof is solved, the building construction period of the slope roof is shortened, slope roof construction procedures are simplified, roof building material categories are simplified, construction cost is saved, resources and energy are saved, steel consumption is reduced by 40%, concrete consumption is reduced by 30%, and the dead weight of the component is reduced by 30%.

Owner:仇国辉

Ladder waveform steel plate and steel truss combined assembled envelop enclosure structure and construction method thereof

ActiveCN108239984AReduce deformation effectsIncrease stiffnessExcavationsBulkheads/pilesEngineeringStructural engineering

The invention discloses a ladder waveform steel plate and steel truss combined assembled envelop enclosure structure and a construction method thereof, relates to the technical field of foundation pitengineering, and solves the problems of low rigidity, high environmental influence, difficult quality control and incapability of recycling in a traditional foundation pit envelop enclosure structure. The assembled envelop enclosure structure is formed by continuously assembling multiple envelop enclosure structure units arranged along the edge lengths of a foundation pit; each envelop enclosurestructure unit comprises two ladder waveform steel plates, multiple steel trusses connected between the two ladder waveform steel plates n the height directions, and multiple connecting rods connectedbetween the ladder waveform steel plates and the steel trusses; the ends of the two adjacent ladder waveform steel plates are joined or engaged; and the steel trusses are of plane truss structures consisting of two parallel chord rods and multiple web rods connected between the two chord rods. The envelop enclosure structure units are inserted in a unit overall manner or a component insertion manner; and the adjacent envelop enclosure structure units are in joined or engaged connection to form the continuously complete assembled envelop enclosure structure capable of retaining soil and stopping water at the same time.

Owner:SHANGHAI CONSTRUCTION GROUP

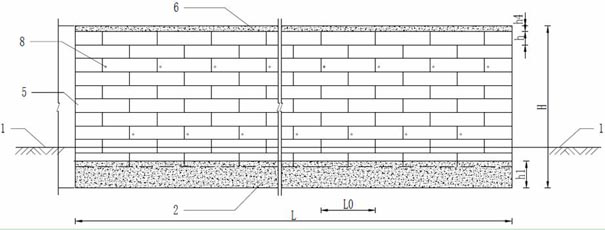

Retaining wall and construction method thereof

PendingCN114263211AImprove performanceReduced bearing capacity requirementsGeometric CADArtificial islandsReinforced concretePre stress

The invention discloses a retaining wall and a construction method thereof, belongs to the technical field of retaining engineering, and particularly relates to a retaining wall and a construction method thereof. According to the retaining wall and the construction method thereof, the defects of existing reinforced soil, anchoring plates and other fabricated retaining wall small modules are overcome, and the standard module assembly of the retaining wall is achieved. The retaining wall is composed of a cast-in-place reinforced concrete foundation, a prefabricated wall body box-shaped module and a prefabricated unloading plate solid plate module. Vertical steel anchor rods, vertical prestressed steel strands and longitudinal connecting bolts are connected with prefabricated parts to be assembled to form the retaining wall. The module is made of reinforced concrete prefabricated parts and is manufactured in a factory-like mode. The construction method of the retaining wall comprises four steps. According to the invention, the module assembly construction of the retaining wall is realized, and the adaptability to application conditions is high; the prestressed technology is adopted, the scattered modules are assembled into the eccentric and pressed complete cantilever type wall body through the prestress applied by the vertical connection steel anchor rods and the vertical steel strands and the longitudinal connection high-strength bolts, and the cantilever type wall body has the advantages of being high in adaptability, simple in design, easy to construct and control quality safety, high in construction speed and low in manufacturing cost.

Owner:王开明

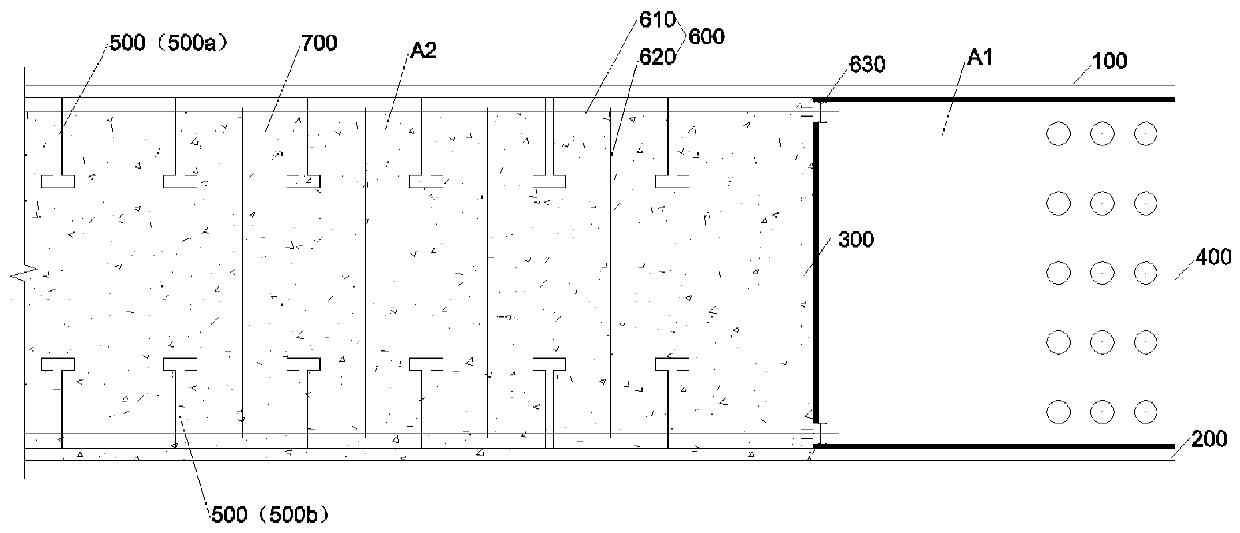

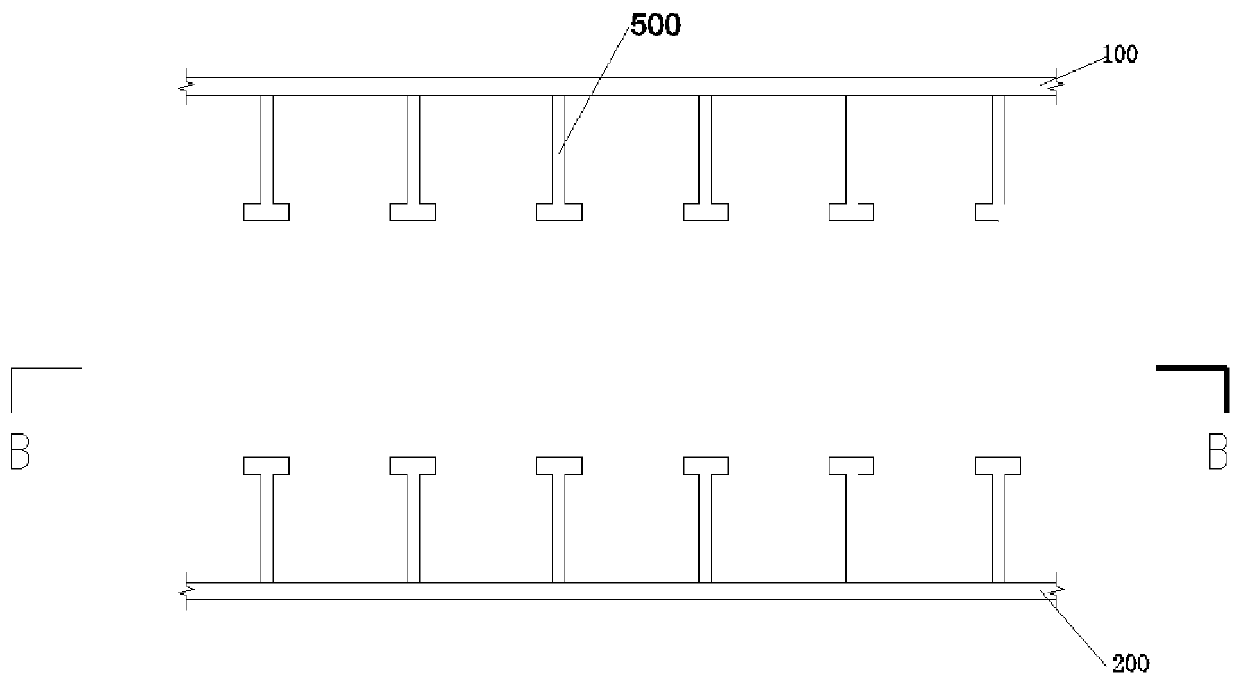

Prefabricated light steel concrete plate column structure and construction method thereof

ActiveCN105275120ASufficient horizontal stiffnessPlay the role of energy dissipation and shock absorptionFloorsShock proofingPlate columnVertical load

The present invention provides a prefabricated light steel concrete plate column structure and a construction method thereof. The prefabricated light steel concrete floor of each storey is divided into a plurality of floor sections according to the column spaces of prefabricated light steel concrete columns and are connected to form a main body structure, and at the same time a prefabricated light steel concrete wall type support is arranged between two prefabricated light steel concrete columns in each storey. In an overall structure, the prefabricated light steel concrete plate bears a vertical load, at the same time sufficient horizontal stiffness is provided, the prefabricated light steel concrete columns bear the vertical load transmitted by the prefabricated light steel concrete floor, and the prefabricated light steel concrete wall type support only bears a lateral load. Structure resistant-lateral rigidity is provided in a normal use state, and the effect of energy consumption shock reduction is achieved under an earthquake effect. The prefabricated light steel concrete plate column structure and the construction method have the advantages of high prefabricated assembly rate, low construction cost, few field wet operation, and high architectural adaptability.

Owner:SHANGHAI MECHANIZED CONSTR GRP

Prefabricated lightweight high-strength bridge crash barrier

InactiveCN108532458ASimple designConducive to lightweightBridge structural detailsToughnessWaste management

The invention discloses a prefabricated lightweight high-strength bridge crash barrier applied to the technical field of bridges. The prefabricated lightweight high-strength bridge crash barrier comprises a barrier precast by ultra-high performance concrete (UHPC), wherein the barrier is arranged on the bridge by virtue of an embedded part arranged on the bridge; the barrier comprises a side panel, a bottom plate and ribbed plates arranged on the outer side of the side panel; a mounting position matched with the embedded part is arranged on the bottom plate. The crash barrier disclosed by theinvention is divided into the panel and the ribbed plates, so that the weight of the crash barrier is effectively reduced. Meanwhile, due to super-toughness of the UHPC, after an automobile collides with the UHPC crash barrier, the barrier does not cause brittle failure, and the automobile is prevented from dropping from the bridge. Moreover, the UHPC crash barrier can realize industrialized production and field prefabricated construction, and the environmental pollution is greatly alleviated.

Owner:GUANGZHOU MUNICIPAL ENG DESIGN & RES INST CO LTD +1

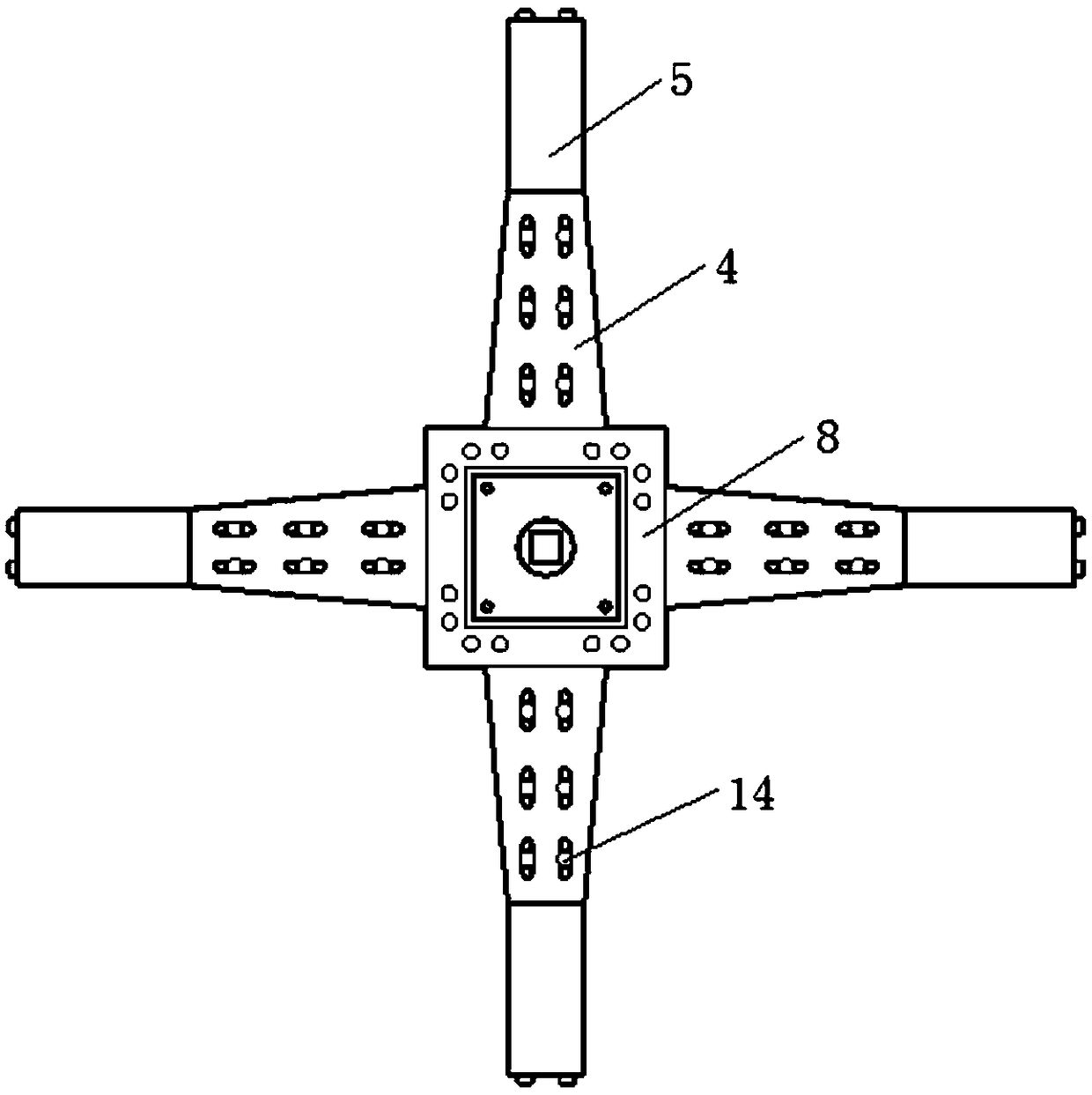

Assembly type joint of round-inside and square-outside compound steel structure type column, connection and generation method thereof

PendingCN112282212ARealize assembly constructionReduce on-site weldingStrutsProtective buildings/sheltersSteel tubeManufacturing engineering

The invention discloses a assembly type joint of a round-inside and square-outside compound steel structure type column. The assembly type joint comprise a first joint connector and a second joint connector, the first joint connector comprises a first cross-shaped connecting panel which is connected with the lower end part of an upper side inner round steel pipe and a first sleeve connector whichis connected with the inner wall of the lower end part of an upper side outer square steel pipe, the second joint connector is consistent with the first joint connector in structure, and a first channel steel connector and a second channel steel connector are further included. Through reasonable arrangement of part structures, field welding and concrete operation are reduced, the construction quality is guaranteed, the construction speed is increased, and meanwhile the construction cost is saved; by the adoption of the assembly type splicing joint for the round-inside and square-outside hollowinterlayer type compound concrete-filled steel tubular column and the connecting method, assembly construction of a compound concrete-filled steel tubular structure can be achieved, and the buildingindustrialization process is accelerated; and meanwhile, a user does not need to manually carry out position selection and parameter setting on a connecting part, and then the column splicing joint required in design software can be automatically generated.

Owner:CHANGAN UNIV

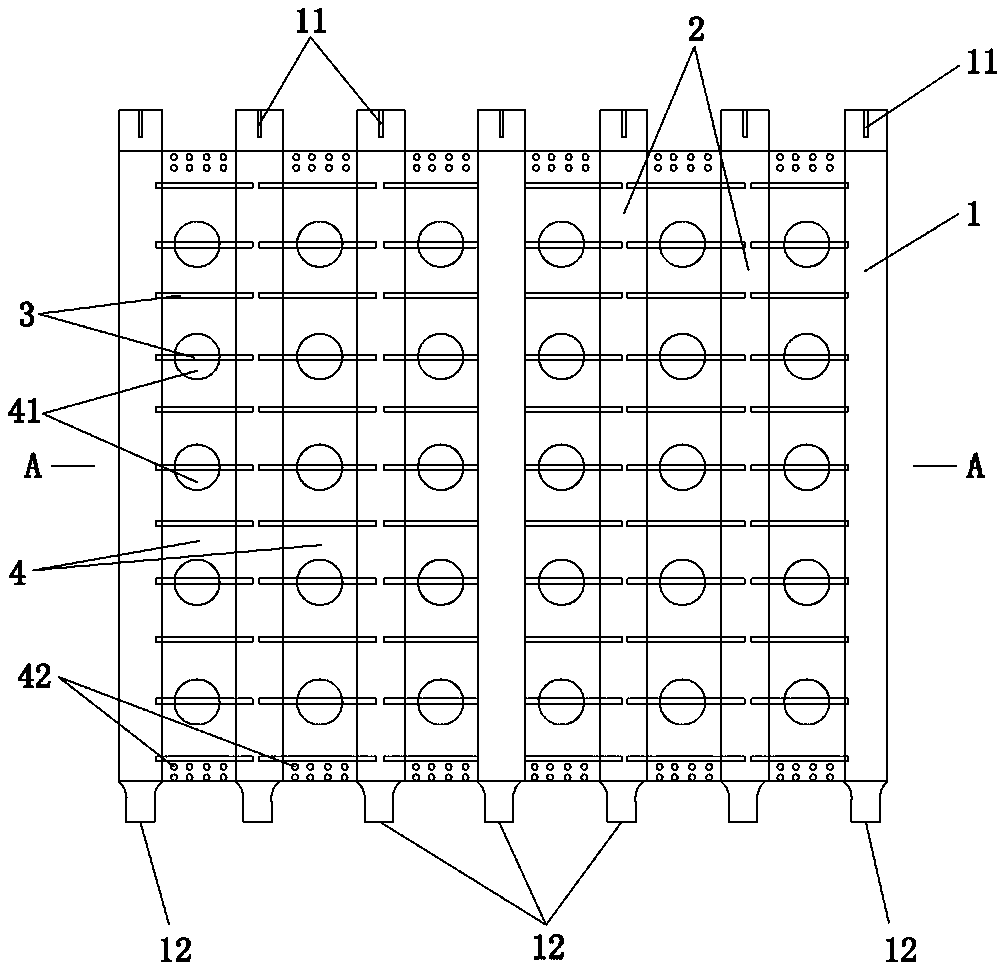

L-shaped assembled core column steel plate shear wall and assembly construction method thereof

PendingCN107989230AImprove connection strengthStructural safety and reliabilityStrutsWallsUltimate tensile strengthSteel plate shear wall

The invention mainly relates to an L-shaped assembled core column steel plate shear wall. The shear wall comprises square edge stiffening columns, a plurality of circular core columns, a plurality offlat steel tie rods, webs and concrete; the circular core columns are evenly arranged in an L shape to form an L-shaped core column wall body, the corners and top of the wall body are provided with the square edge stiffening columns, and the square edge stiffening columns and the circular core columns are welded to one another through the webs by means of groove penetration welding; the flat steeltie rods are evenly arranged at the two outer side surfaces of the wall body, the two ends of each flat steel tie rod are welded to the two corresponding adjacent core columns respectively, and the outer side portions of the circular core columns and the square edge stiffening columns are filled with the concrete; the upper end of each circular core column is symmetrically provided with four notches, the upper end of each square edge stiffening column is symmetrically provided with four notches, and the lower ends of the circular core columns and the lower ends of the square edge stiffening columns are all provided with horn-shaped necking ports getting smaller downwards. The L-shaped assembled core column steel plate shear wall is good in overall performance, easy to manufacture and convenient to splice, and the working efficiency is improved; meanwhile, the connection strength among the components is high, the structural safety performance is good, and the seismic performance is good.

Owner:ZHEJIANG GREEN BUILDING INTEGRATION TECH CO LTD

Partially cladding steel-concrete composite member and composite structure building thereof

PendingCN111173195AImprove insulation effectImprove the effective anti-corrosion periodLoad-supporting elementsHeat proofingEarthquake resistanceArchitectural engineering

The invention provides a partially cladding steel-concrete composite member and a composite structure building thereof. The composite member includes a first side steel plate, a second side steel plate, studs, a repair welding steel plate, stiffening steel plates, a reinforcement framework and concrete; the two stiffening steel plates, the first side steel plate and the second side steel plate enclose a prefabricated web cavity in a prefabricated area; concrete is poured into the prefabricated web cavity; and the reinforcement framework is embedded in the concrete. According to the partially cladding steel-concrete composite member and the composite structure building thereof, the advantages of convenient connection and good anti-seismic performance of a steel structure are developed, andmeanwhile the advantages of high rigidity, good anti-corrosion and fire-proof performance and low cost of a concrete structure are integrated; and by using the combined action of steel-concrete, the defects of poor anti-corrosion and fire-proof performance, low rigidity and high cost of a steel member are overcome, and many advantages of the standardized production, assembly construction, long-term durability, economic applicability and the like of the member are achieved, the competitive advantage of the steel structure is greatly enhanced, and the application prospect in prefabricated buildings is broad.

Owner:SHENZHEN YJY BUILDING TECH +2

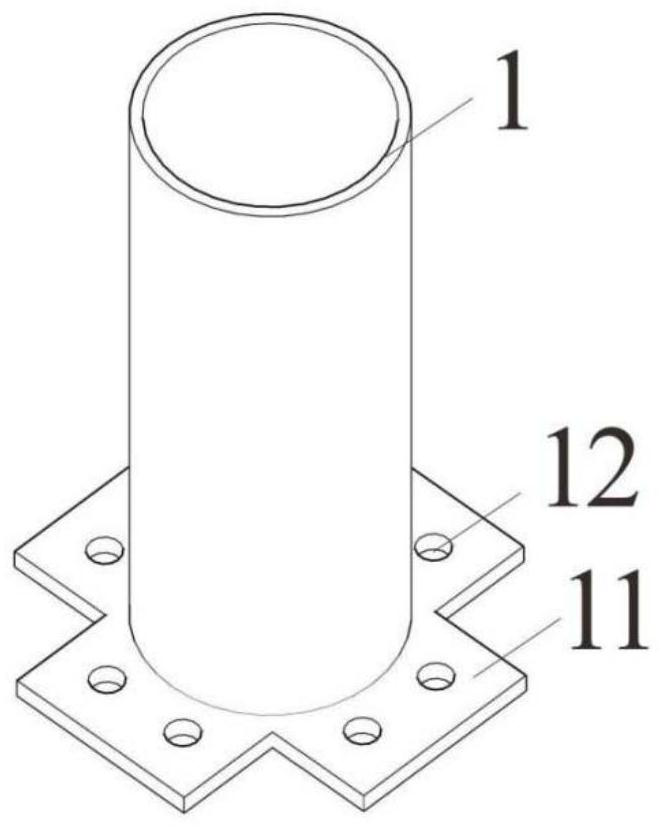

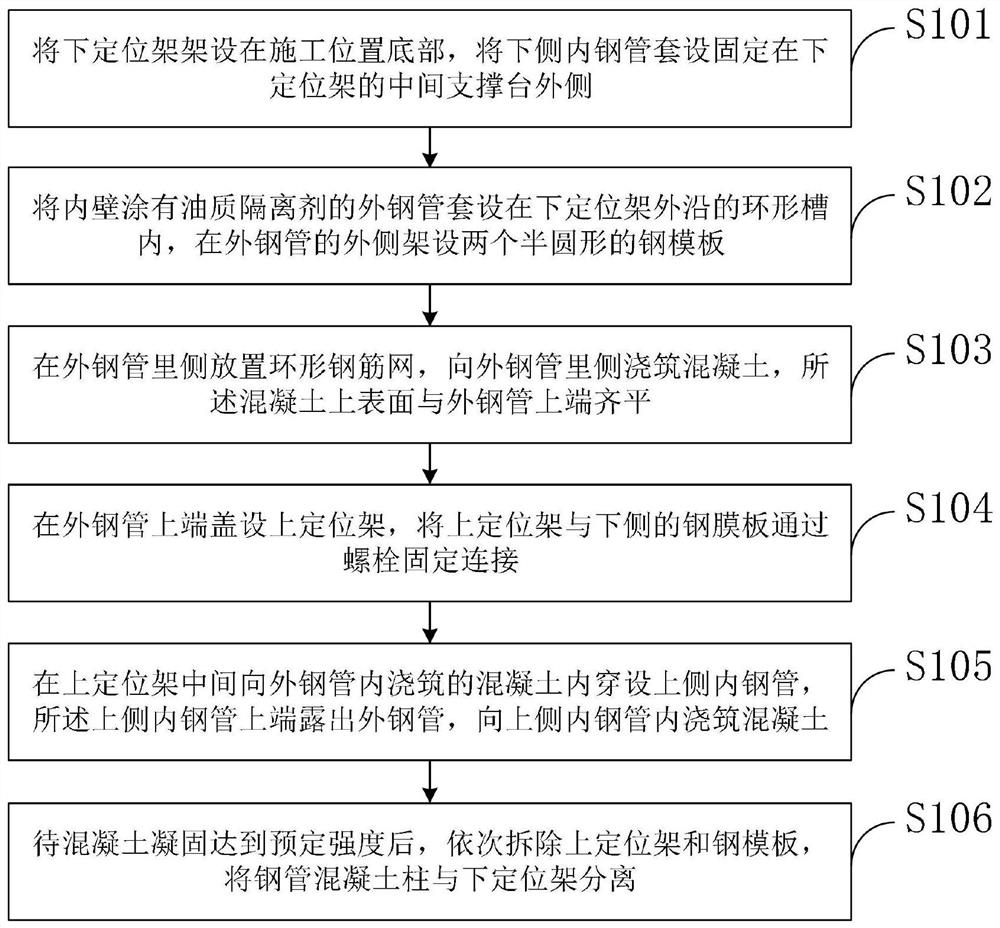

Prefabricated prestressed concrete filled steel tubular column and construction method

PendingCN113700221AHigh compressive strengthSolve constraint problemsStrutsBuilding material handlingPre stressArchitectural engineering

The invention belongs to the technical field of building construction, and discloses a prefabricated prestressed concrete filled steel tubular column and a construction method. The prefabricated prestressed concrete filled steel tubular column is mainly composed of steel pipes, an oil separant, positioning frames, concrete, steel formworks, bolts, column top connecting pieces and column foot connecting pieces, wherein the steel formworks are located outside the whole device, the inner wall of the outer steel pipe is coated with the oil separant, and the concrete is poured, so that the steel pipe and the concrete are kept in an isolated state; the column top connecting pieces and the column foot connecting pieces are located on the whole column top and the whole column foot respectively and play a role of a support, and the positioning frames are divided into an upper positioning frame and a lower positioning frame. The prestressed concrete filled steel tubular column manufactured through the construction method of the prefabricated prestressed concrete filled steel tubular column is simple in structure, compressive pre-stress is applied to internal concrete in advance, and therefore, the compressive strength of the concrete is improved, the restraining effect of the steel pipe can be achieved at the initial loading stage, and the stress performance is good.

Owner:河北省建筑工程质量检测中心有限公司

Z-shaped fabricated core column steel plate shear wall and assembly construction method thereof

InactiveCN108118804AImprove connection strengthStructural safety and reliabilityWallsThroatSteel plate shear wall

The invention relates to a Z-shaped fabricated core column steel plate shear wall. The shear wall comprises square edge stiffening columns, circular core columns, flat steel tie rods, webs and concretes, a plurality of circular core columns are uniformly distributed in a Z shape to form a Z-shaped core column wall body, square edge stiffening columns are arranged at the corner and the top of the wall body, the square edge stiffening columns are welded with the circular core columns through the webs by groove penetration welding, two outer side surfaces of the wall body are evenly provided witha plurality of flat steel tie rods, two ends of the flat steel tie rods are respectively welded on the adjacent two core columns, and the outer portions of the circular core columns and the square edge stiffening columns are filled with concretes; four gaps are symmetrically formed in upper ends of the circular core columns and the square edge stiffening columns, and downward shrinking trumpet-shaped throats are formed in the lower ends of the circular core columns and the square edge stiffening columns. The shear wall has good overall performance, simple manufacture and convenient splicing,work efficiency is improved, simultaneously the connection strength between components is high, structure safety performance is high, and anti-seismic performance is good.

Owner:ZHEJIANG GREEN BUILDING INTEGRATION TECH CO LTD

Functionally recoverable assembled beam-column connection joint and construction method

PendingCN109457804AGuaranteed StrengthGuaranteed carrying capacityBuilding constructionsArchitectural engineeringPlastic hinge

The invention provides a functionally recoverable assembled beam-column connection joint. The end of an H-shaped short beam is fixedly connected to the flange of an H-shaped column, the H-shaped shortbeam and an H-shaped long beam are coaxially arranged and both provided with a splicing segment, and the splicing segment of the H-shaped short beam is connected to the splicing segment of the H-shaped long beam through a fastening device; the fastening device comprises angle steel, joint plates and bolts; the joint plates closely fit the outer sides of the flanges of the splicing segments of theH-shaped short beam and H-shaped long beam; the angle steel is arranged at the junction between of the flange and web plate of the H-shaped short beam and the junction between the flange and web plate of the H-shaped long beam; the flanges of the H-shaped short beam and H-shaped long beam are connected to the angle steel and the joint plates through bolts respectively, and the web plates of the H-shaped short beam and H-shaped long beam are connected to the angle steel on both sides through bolts respectively. The connection joint is simple in structure and convenient in construction, and thepurposes of external displacement of plastic hinges, reduction of energy consumption and a replaceable 'three in one' effect can be realized.

Owner:CHANGAN UNIV

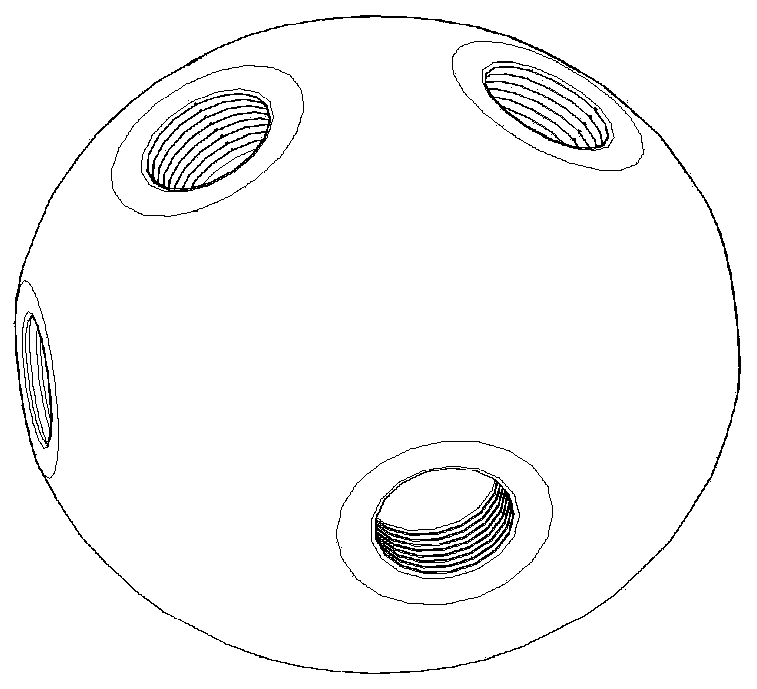

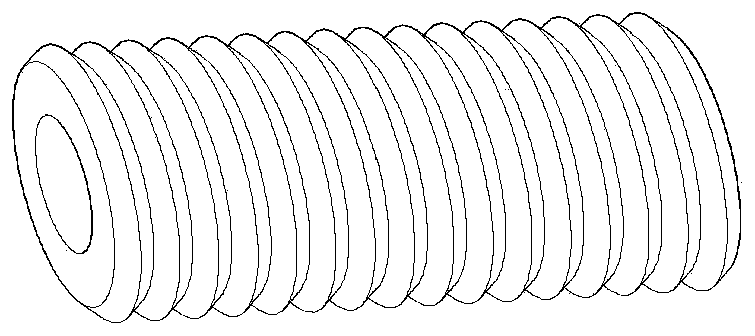

Solid ball sleeve pitch point

The invention discloses a solid ball sleeve pitch point. The solid ball sleeve pitch point specifically comprises a multi-screw-hole solid ball, sleeves with inner threads, screw rods with outer threads, and connectors with outer threads. The solid ball is provided with multiple screw holes with the inner threads, the contacting areas of the end surfaces of the screw holes and the sleeves with theinner threads are rubbed flatly, the solid ball can be connected with the screw rods with the outer threads in multiple positions through the inner threads, the screw rod with the outer threads and the connectors with the outer threads can be hollow and can also be solid, the sleeves with the inner threads is connected with the connectors with the outer threads through the threads, and the sleeves sleeves the outside of the screw rod with the outer threads and the connectors with the outer threads. According to the solid ball sleeve pitch point, all kinds of metal materials such as a steel material and an aluminum alloy can be adopted to be applied to all kinds of metal space structures, the pitch point can be manufactured in a factory standardization mode, the sleeves are only needed tobe rotated in field construction to complete rod part connection, field welding is avoided, the operation difficulty is reduced, and the mounting processes of net racks and net shells are more convenient and fast through the pitch point.

Owner:BEIJING UNIV OF TECH

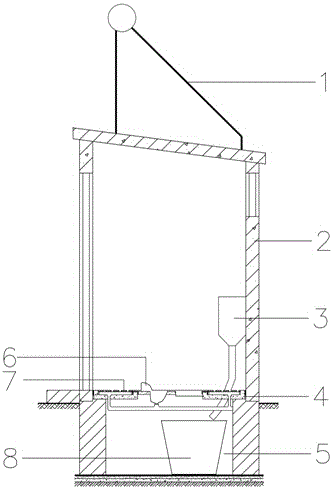

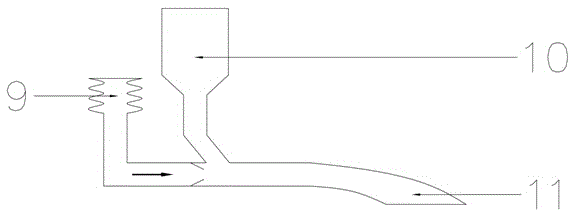

Assembly type rural pit toilet having bathing function

InactiveCN104563544ARealize assembly constructionEasy to buildBathroom accessoriesSpecial buildingDraining tubeBathing water

The invention belongs to the field of toilets, and relates to an assembly type rural pit toilet having a bathing function. The assembly type rural pit toilet is partitioned into an upper part and a lower part, wherein the lower part is an excrement pond; urine is connected with a urine storage bucket through a urine discharge pipe; excrement is collected through an excrement collecting bucket; the upper part is a small house which is constructed in an assembly way; in the small house, a cover plate of a partially-opened embedded separate collecting excrement and urine collector is arranged on a cover plate of the excrement pond; the excrement collecting bucket can be taken out by opening the cover plate of the embedded separate collecting excrement and urine collector. When a bathing function is needed, a bathing floor is laid down, and bathing water drains to floor drain holes in the four corners of the cover plate of the excrement pond, flows into a water drain pipe through the floor drain holes, and is discharged outside. The upper part main body is a prefabricated member, so that assembly type construction is realized, construction becomes easy and convenient, and the manufacturing cost is low; an excrement taking port is formed in the upper part of the excrement pond, so that the floor area is reduced on the basis of realizing separate collection of excrement and urine, and arrangement becomes easy. The pit toilet has a bathing function, has a plurality of functions, and is convenient and sanitary, and a bathing room does not need to be built additionally.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

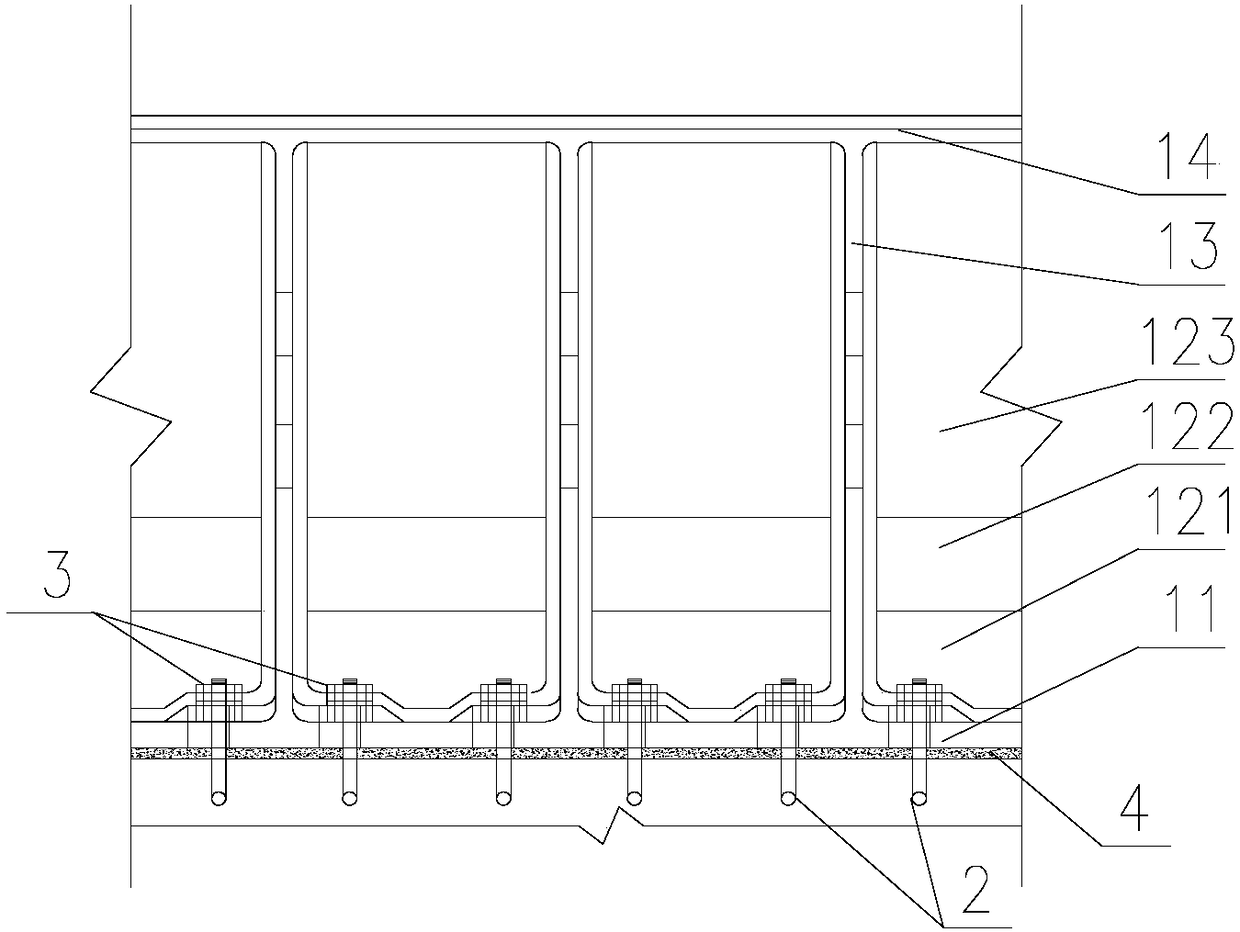

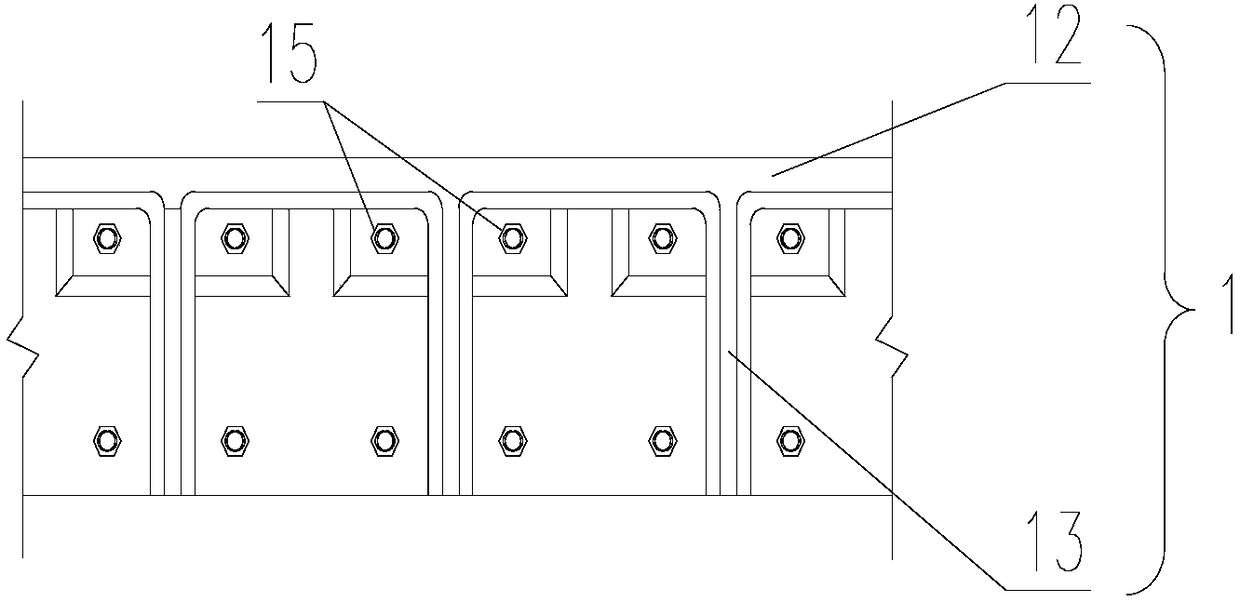

Connection structure of prefabricated corrugated steel web composite box girder roof and construction method

PendingCN110644348AFirmly connectedIntermittent shear connection reinforcementBridge erection/assemblyArchitectural engineeringRebar

The invention relates to a connection structure of a prefabricated corrugated steel web composite box girder roof. The connection structure includes a roof, corrugated steel webs and shear connectingpieces connected between the roof and the corrugated steel webs. The corrugated steel webs include upper flange steel plates, and are characterized in that the roof is provided with at least two mortises at intervals, and at least two embedded through steel bars perpendicular to the corrugated steel webs are further arranged at the lower edge of each mortise. The shear connecting pieces include first steel plates connected to the upper flange steel plates, and each first steel plate is provided with at least two clamp-in parts at intervals for the corresponding embedded through steel bars to clamp in the length direction of the first steel plate. The invention further provides a construction method. Compared with the prior art, the connection structure and construction method have the advantages that the prefabricated concrete roof reserved with the discontinuous mortises is directly hoisted to the upper flange steel plates of the corrugated steel webs, and the assembly can be completed only by connecting the discontinuous shear connecting pieces.

Owner:NINGBO COMM PLANNING INST CO LTD

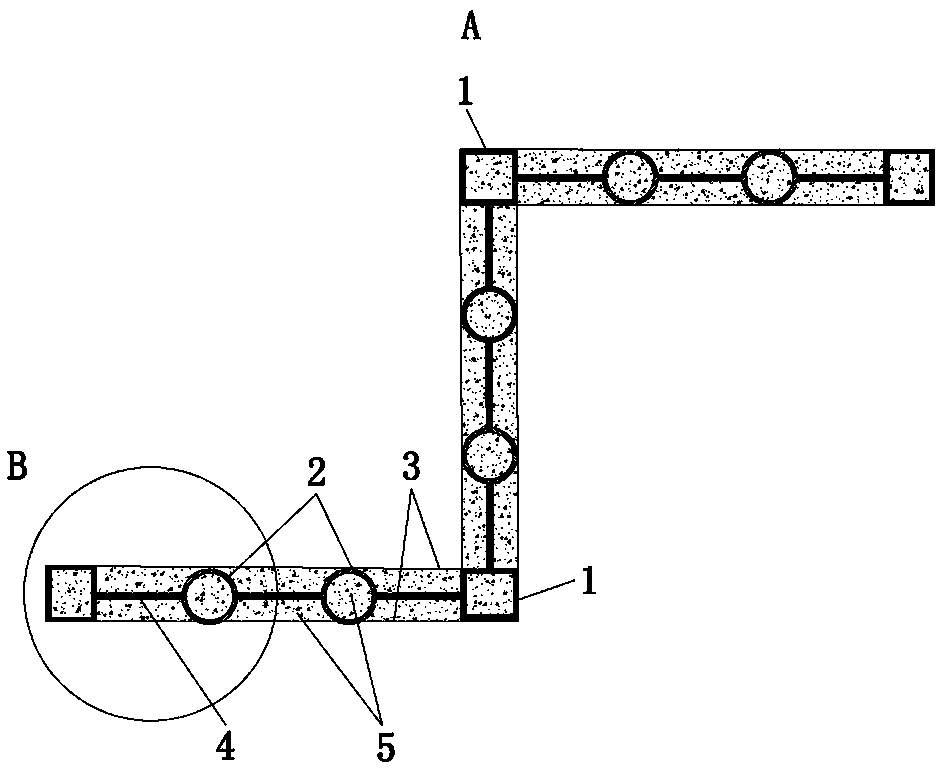

Fabricated composite wall connecting method

PendingCN108049504ARealize assemblyAchieve standardized designBuilding constructionsFloor slabUltimate tensile strength

The invention relates to a fabricated composite wall connecting method and belongs to the technical field of specially-designed floor slab structures of general building construction. A composite wallcomprises a first wall board, a second wall board and a transition wall. The connecting end of the first wall board is provided with a first connecting piece, and the connecting end of the second wall board is provided with a second connecting piece. The first connecting piece and the second connecting piece are in buckling-fit with each other and fixed, and thus connecting of the first wall board and the second wall board is achieved. Concrete is poured on the connecting position of the first wall board and the second wall board to form the transition wall. The fabricated composite wall connecting method is applied to processing and fabricating of a shearing wall and has the advantages that the structural strength is high, the anti-shearing, torsion-resistant and anti-bending propertiesare good, and meanwhile the good anti-shocking property is further achieved.

Owner:ZHEJIANG GREEN BUILDING INTEGRATION TECH CO LTD

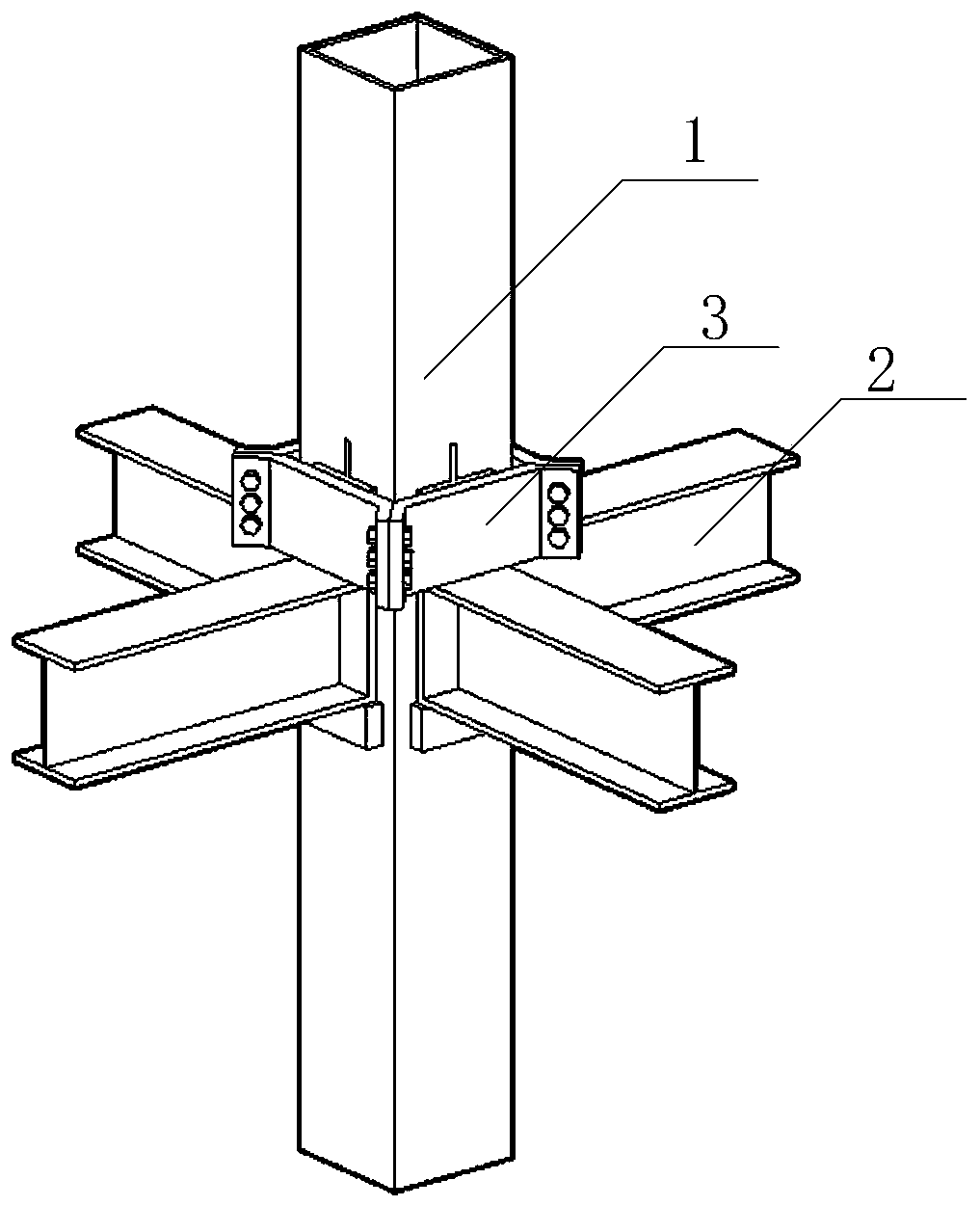

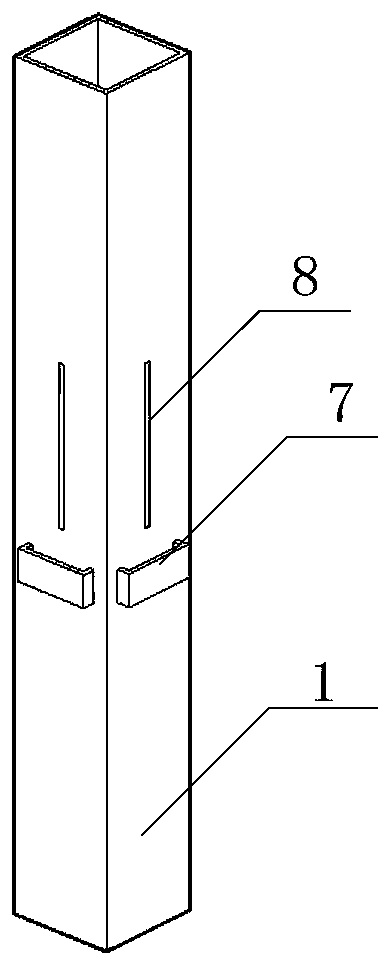

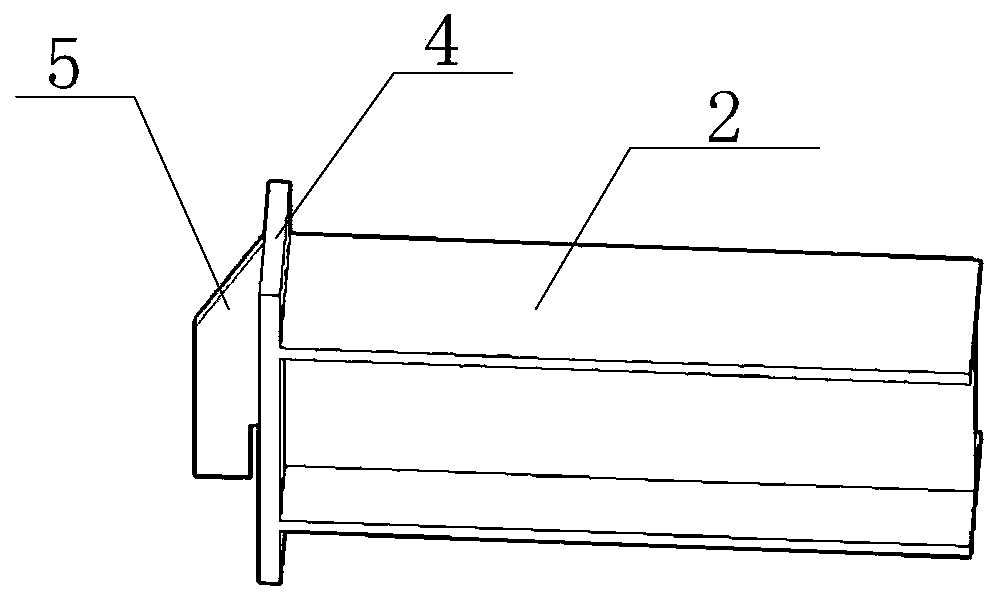

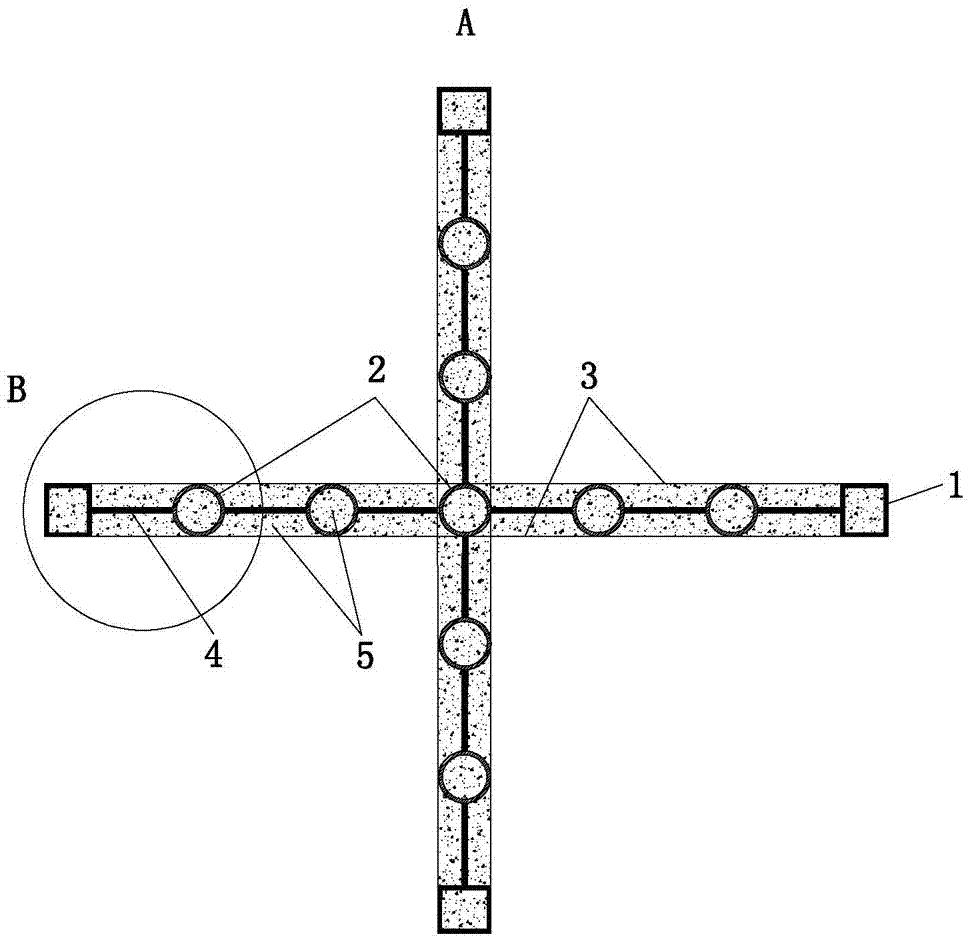

An assembled connection node between a plug-in buckle beam and a column

ActiveCN109629681BRealize assembly constructionPrevent axial displacementBuilding constructionsClassical mechanicsEngineering

The invention discloses an assembly type connecting node of an plug-in type buckling beam and a column, which comprises a steel pipe column, a plurality of embedded steel plates and a plurality of steel beams, wherein the end part of each steel beam is provided with a fixing plate, and the side surface of the steel pipe column is provided with a plurality of slotted holes, a slotted hole corresponds to an embedded steel plate and a fixed plate, the upper side of each embedded steel plate is fixedly connected with the corresponding fixed plate, a gap is formed between the lower side of each embedded steel plate and the corresponding fixed plate, each embedded steel plate is inserted into the corresponding slotted hole, and the side wall of the steel pipe column is inserted into the gap; thetop of each steel beam is provided with a first limiting steel plate; each first limiting steel plate is sequentially connected to form an annular sleeve; each fixing plate is positioned in the annular sleeve; and the node can effectively avoid various problems caused by on-site welding.

Owner:西安建筑科大工程技术有限公司

Fabricated composite wallboard T-shaped constructional column and independent foundation connecting structure and construction method

PendingCN114658141ARealize assembly constructionAll-in-one connectionWallsFoundation engineeringEarthquake resistanceArchitectural engineering

The invention discloses a fabricated composite wallboard T-shaped constructional column and independent foundation connecting structure and a construction method, and relates to the technical field of fabricated constructional engineering. A T-shaped steel plate is welded to the bottom of a T-shaped constructional column reinforcement cage, a T-shaped notch is reserved in an independent foundation, steel plates are laid on the periphery of the notch, the whole steel plates are wedge-shaped, and the wedge-shaped steel plate laid on the inner side of the notch of the independent foundation in advance, the T-shaped steel plate at the bottom of the T-shaped constructional column and cast-in-place concrete interact. The T-shaped constructional column and the independent foundation form a whole, the pulling resistance of the constructional column is enhanced, the integrality is higher, more stable and firmer, a wall plate and a foundation beam are connected firstly, then the connecting part of the T-shaped constructional column and the independent foundation is poured through concrete, and connection of the T-shaped constructional column and the independent foundation is completed. The method is suitable for a large-quantity and wide-area low multi-layer fabricated (regenerated) concrete structure, and is excellent in anti-seismic property, ecological, environment-friendly, convenient to construct, economical and applicable.

Owner:BEIJING UNIV OF TECH

Cross-shaped assembly type core column steel plate shear wall and assembly construction method thereof

InactiveCN108005262AImprove connection strengthStructural safety and reliabilityWallsProtective buildings/sheltersSteel platesSteel plate shear wall

The invention mainly relates to a cross-shaped assembly type core column steel plate shear wall. The cross-shaped assembly type core column steel plate shear wall comprises square edge stiffening columns, a plurality of round core columns, a plurality of flat steel tying rods, webs and concrete. The multiple round core columns are evenly arranged to be in a cross shape to form a cross-shaped corecolumn wall, the four top ends of the cross-shaped core column wall are provided with the square edge stiffing columns correspondingly, the square edge stiffening columns and the round core columns are welded mutually through the webs by adopting slope penetration weld, the multiple flat steel tying rods are evenly arranged on the two outer side faces of the wall, the two ends of each flat steel tying rod are welded to every two adjacent core columns, and the outer sides of the round core columns and the square edge stiffening columns are filled with concrete. The upper ends of the round corecolumns and the square edge stiffening columns are each symmetrically provided with four notches, and the lower ends of the round core columns and the square edge stiffening columns are each providedwith a horn-shaped contraction port contracting downwards. The cross-shaped assembly type core column steel plate wall is good in integrity, easy to manufacture and convenient to splice, and the working efficiency is improved. Meanwhile, the connection strength among the components is high, the structural safety is high, and the anti-seismic property is good.

Owner:ZHEJIANG GREEN BUILDING INTEGRATION TECH CO LTD

Corrugated type replaceable energy dissipation device with controllable performance

PendingCN111119364AEasy to manufactureEasy to install on siteProtective buildings/sheltersShock proofingManufacturing technologyClassical mechanics

The invention belongs to the technical field of constructional engineering seismic energy dissipation, and provides a corrugated type replaceable energy dissipation device with the controllable performance. The device is mainly composed of a corrugated steel plate and two connecting plates. The corrugated steel plate is of an integrated structure, and the two ends of the corrugated steel plate arewelded to the connecting plates respectively, so that an I-shaped structure is formed. Out-plane buckling can be effectively avoided due to corrugations of the corrugated steel plate, the out-plane rigidity is improved, then, in-plane bearing capacity and rigidity degeneration are remarkably lowered, a hysteresis curve is full, and the energy dissipation capacity is improved. By changing the included angle between the connecting plates and the directions of corrugated lines, the bearing capacity and the rigidity of the corrugated steel plate can be adjusted, steel plate alignment is enhancedor weakened, and then the actual requirements of different projects for dampers can be precisely matched. Compared with the prior art, the manufacturing technology is simple, the steel plate performance is stable, installation is convenient, the device has the advantages that the energy dissipation capacity is high, the bearing capacity and rigidity are controllable, after an earthquake, the device can be replaced, and therefore the using function of the structure can be rapidly recovered, and the device can be used for improving the structure post-earthquake function restorability.

Owner:DALIAN UNIV OF TECH

Assembly type residential steel structure system

InactiveCN107090938AAchieve standardized designRealize factory manufacturingConstruction materialFloorsFloor slabSteel bar

The invention relates to an assembly type residential steel structure system. The system comprises steel plate shear walls, superimposed steel composite beams and superimposed floor stabs; stiffened plates are welded to the steel plate sheer walls; the end portions of the superimposed steel composite beams are connected with the steel plate shear walls; an out-wrapped concrete layer is wrapped on the outer surface of each superimposed steel composite beam, and stressed steel bars are laid in the out-wrapped concrete layer; the stressed bars are connected to the stiffened plates; the superimposed floor stabs are connected to the superimposed steel composite beams. The fabricated steel structural system of the house has the advantages of high industrialization and modularization, controllable quality and short investment payback period and can be applied and popularized in the field of architecture structures.

Owner:ZHEJIANG GREEN BUILDING INTEGRATION TECH CO LTD

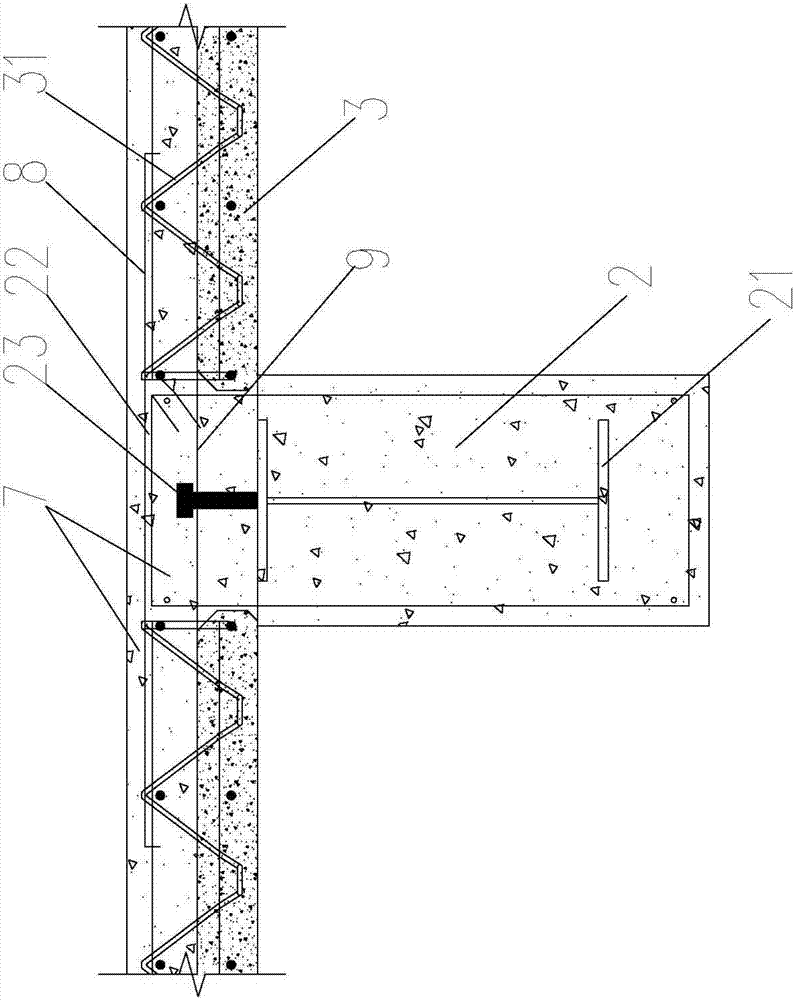

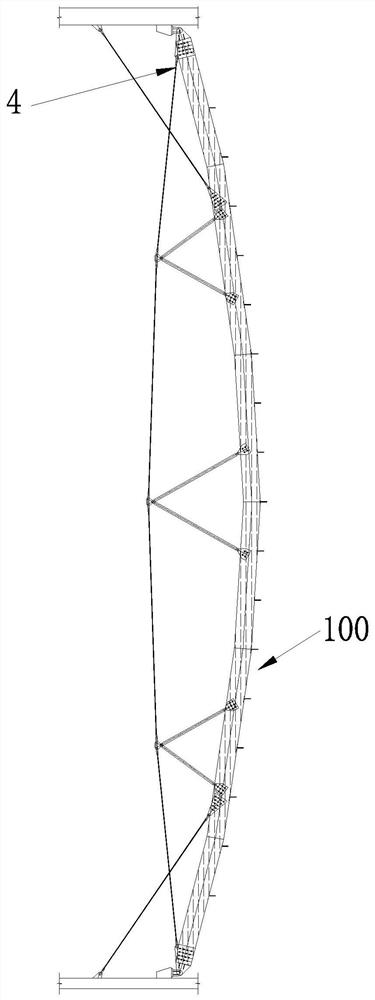

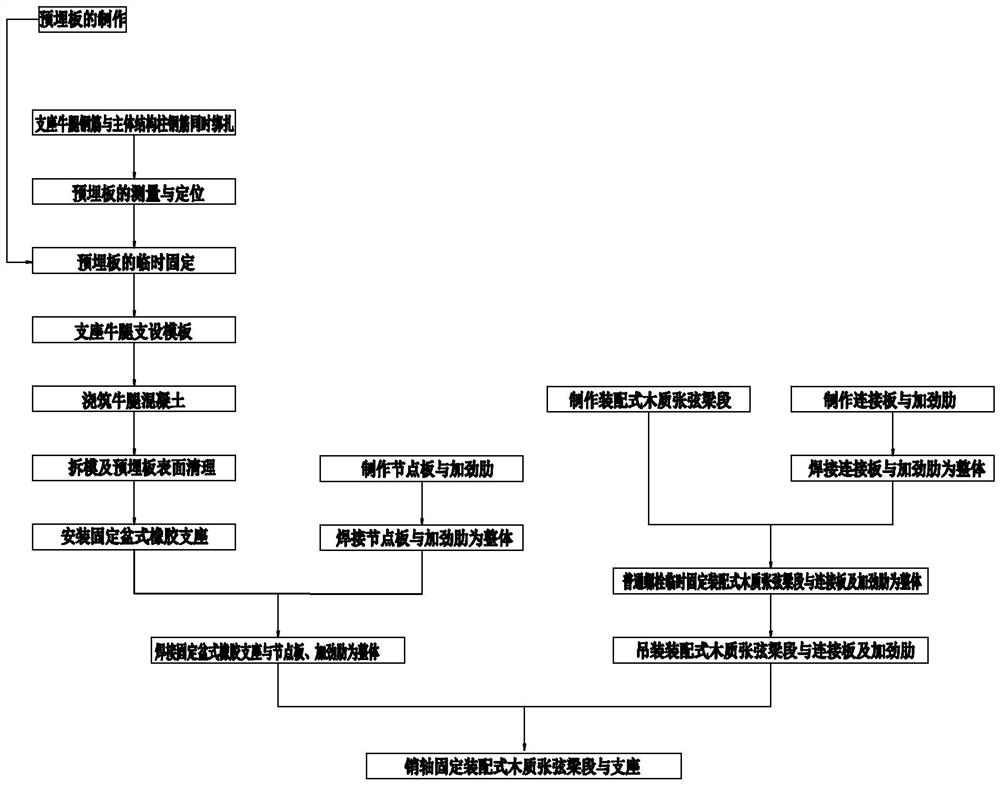

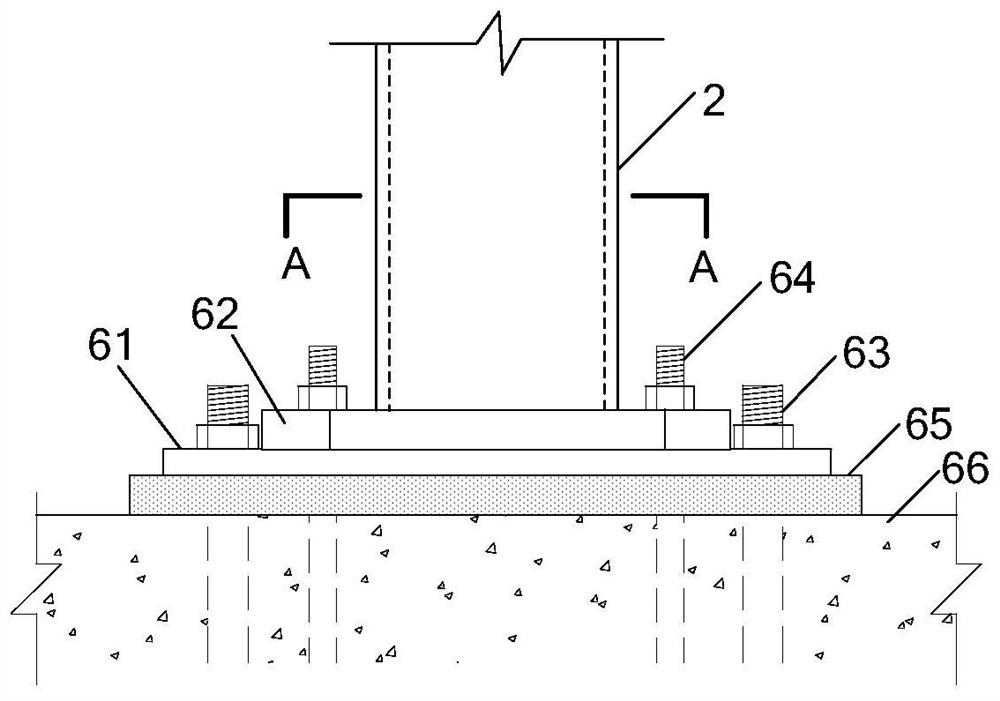

A construction method for fixing pot-type rubber bearing nodes of an assembled large-span wooden string beam structure

ActiveCN110387970BGuarantee the construction qualityImprove construction efficiencyBuilding constructionsGusset plateBobbin

The invention relates to a construction method for fixing pot-type rubber bearing nodes of an assembled large-span wooden string beam structure. Measurement and positioning, fabrication of pre-embedded slabs, temporary fixation of pre-embedded slabs; step 3: setting up formwork for support corbels; pouring corbel concrete; demoulding and surface cleaning of pre-embedded slabs; step 4: installing and fixing basin rubber Bearings; making gusset plates and stiffeners; welding the gusset plates and stiffeners as a whole; Step 5: Welding and fixing the basin-type rubber bearings to the gusset plates and stiffeners as a whole; this construction method can effectively ensure that the assembled large-span wooden The tension beam structure fixes the construction quality of the basin rubber bearing node, and multiple steps can be carried out simultaneously and interspersed, effectively saving the construction period, improving the construction efficiency of the construction enterprise, realizing the assembly construction, and having a strong engineering practice application prospect and economic benefits.

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

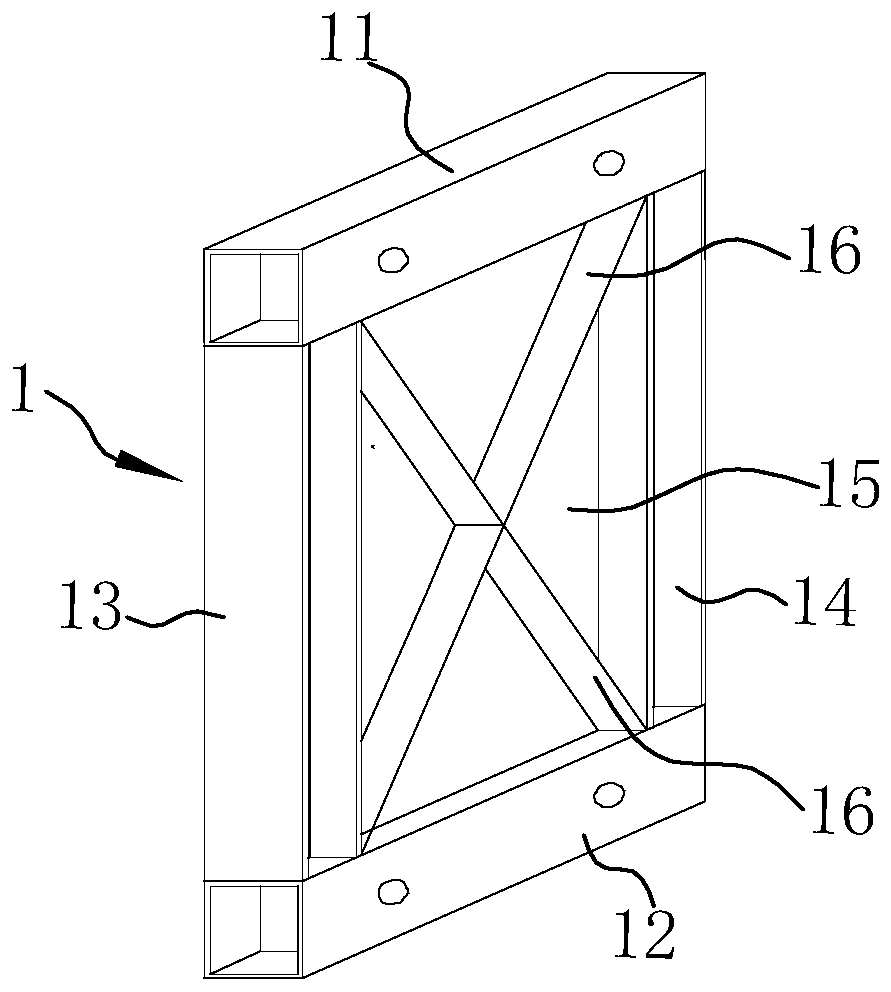

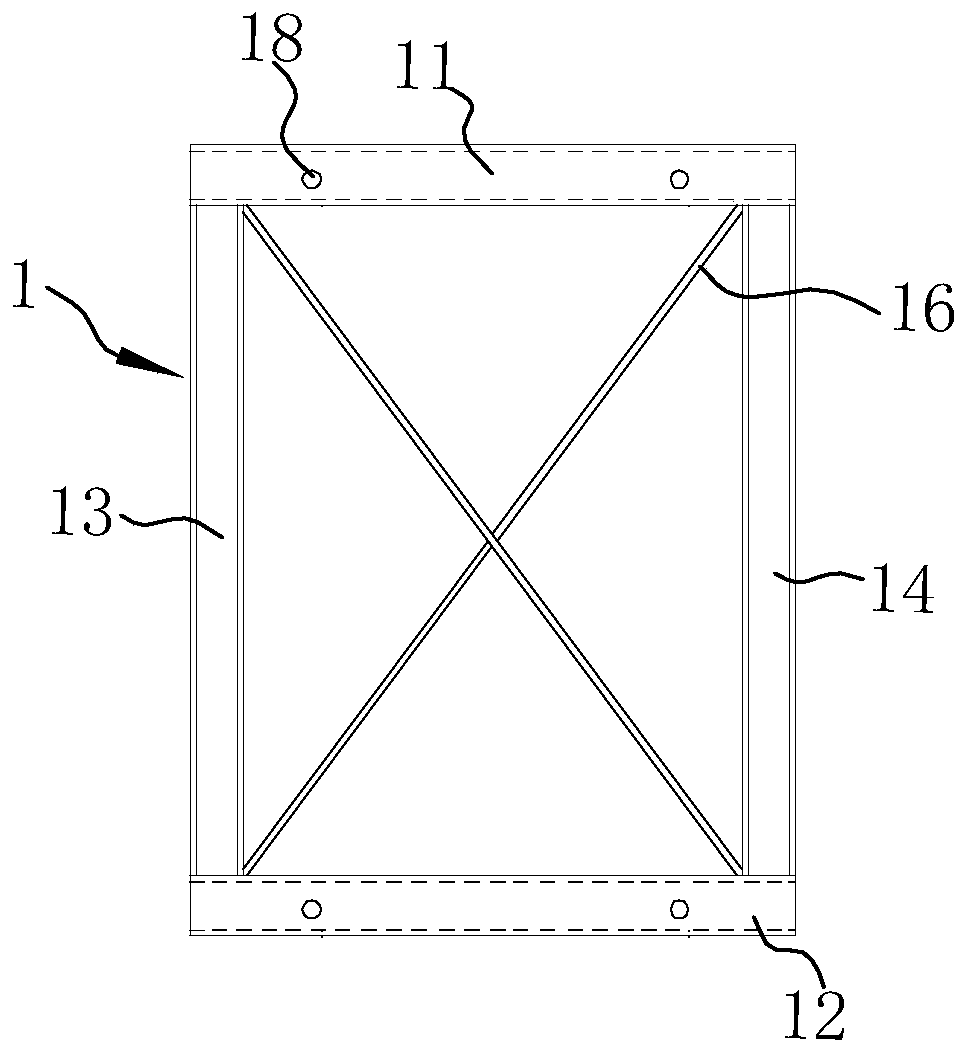

Fabricated shear resisting unit and wall fabricated through shear resisting unit

PendingCN110886410AImprove shear resistanceIncreased load-bearing capacityWallsHeat proofingBolt connection

The invention relates to a fabricated shear resisting unit. The fabricated shear resisting unit is characterized by comprising an I-type shear resisting unit body and an II-type shear resisting unit body; the I-type shear resisting unit body comprises a first frame and two stiffeners, the hollowed-out first frame is defined by fixedly connecting a first upper frame part, a first lower frame part,a first left frame part and a first right frame part, and the two stiffeners are arranged in a crossed manner about the diagonal of the first frame; the II-type shear resisting unit body comprises a second frame, two steel channels and a reinforced steel channel, the hollowed-out second frame is defined by fixedly connecting a second upper frame part, a second lower frame part, a second left framepart and a second right frame part, the two steel channels are arranged in a crossed manner about the diagonal of the second frame, and the reinforced steel channel is arranged between two arbitrarysteel channels. The invention further discloses a wall. The shear resisting unit bodies both have good shear resisting capacity and bearing capacity and are all connected through bolts, welding construction is not needed on site, construction is easy, and the fabricated shear resisting unit can be flexibly assembled according to actual construction needs.

Owner:COLLEGE OF SCI & TECH NINGBO UNIV

A Ductile Coupling Beam Swing Steel Frame System

ActiveCN109837988BSimple structureThe mechanism of action is clearFoundation engineeringProtective buildings/sheltersBraced frameEarthquake resistant structures

The invention belongs to the technical field of civil engineering aseismic structural systems, and provides a ductile coupling beam swinging steel frame system. According to the ductile coupling beamswinging steel frame system, steel supporting frames composed of frame beams, frame columns and steel supports bear the vertical load, the lateral rigidity and resilience are provided, and the elasticity is maintained all the time by allowing the bottoms of the steel columns to rise under the action of an earthquake; seismic energy is dissipated through replaceable connecting beams and swinging type column feet, wherein the steel supporting frames on the left side and right side are connected through the replaceable connecting beams, and the bottoms of the frame columns adopt the swinging typecolumn feet; when a structural system is subjected to the seismic action, the seismic energy is dissipated by the replaceable connecting beams and the swinging type column feet, and the steel supporting frames on the two sides are prevented from being damaged; and the concept of the structural system is clear, design is simple, the action mechanism is clear, the replaceable connecting beams and the swinging type column feet are used as energy dissipation elements and connected with steel columns through bolts, input energy is dissipated in the earthquake, and after the earthquake, the purposeof quick recovery of the use function of the structure system can be achieved by replacing an energy dissipator.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com