Fabricated composite wall connecting method

A connection method and combined wall technology, which is applied in the direction of architecture and building construction, can solve the problems of difficult control of precision, poor quality assurance, and low construction efficiency, and achieve the effects of convenient structure processing, low cost, and improved construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

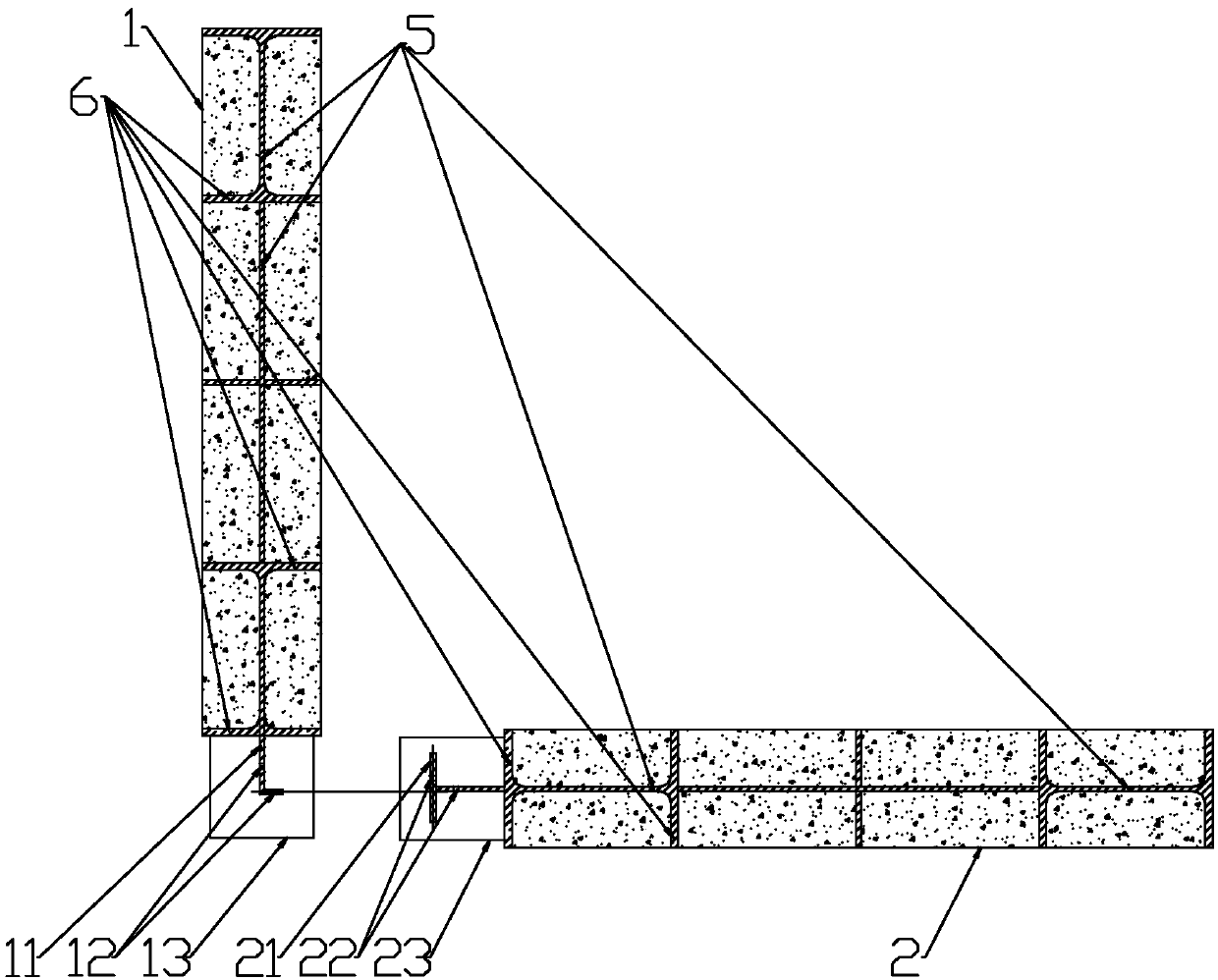

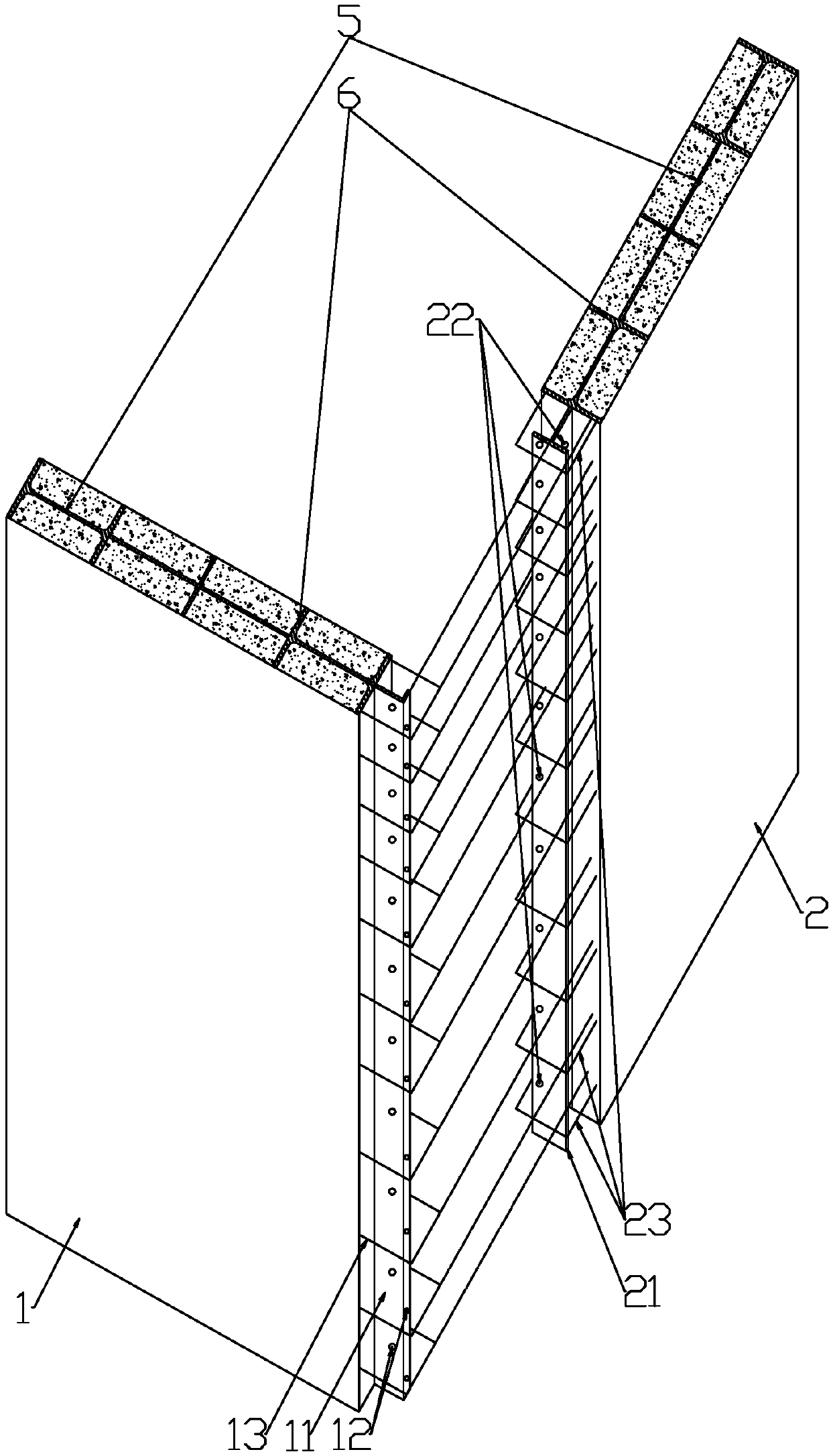

[0025] In this embodiment, a method for connecting a prefabricated composite wall combines figure 1 , the composite wall includes a wall panel 1, a wall panel 2 and a transition wall 4, the connection ends of the wall panel 1 and the wall panel 2 are respectively provided with a connector 11 and a connector 21, and the connector 11 is connected to the Part two 21 are interlocked and fixed, that is, to realize the connection of wallboard one 1 and wallboard two 2, and the cast-in-place concrete at the junction of wallboard one 1 and wallboard two 2 forms a transition wall 4.

[0026] In order to achieve more effects, the above scheme can also be added in the following way:

[0027] combine figure 2 and image 3 , the connector one 11 is L-shaped formed by the horizontal extension of the wallboard one 1 and then bent (such as figure 2 , image 3 shown) or L-like structure, the connector 2 21 is a T-shape formed by the horizontal extension of the wall panel 2 and then bifur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com