Assembly type joint of round-inside and square-outside compound steel structure type column, connection and generation method thereof

A steel structure, prefabricated technology, applied in columns, piers, pillars, etc., can solve problems such as high requirements for construction equipment, inability to guarantee welding quality, delaying construction progress, etc., to reduce welding and concrete operations, and accelerate the process of building industrialization. , the effect of speeding up the construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

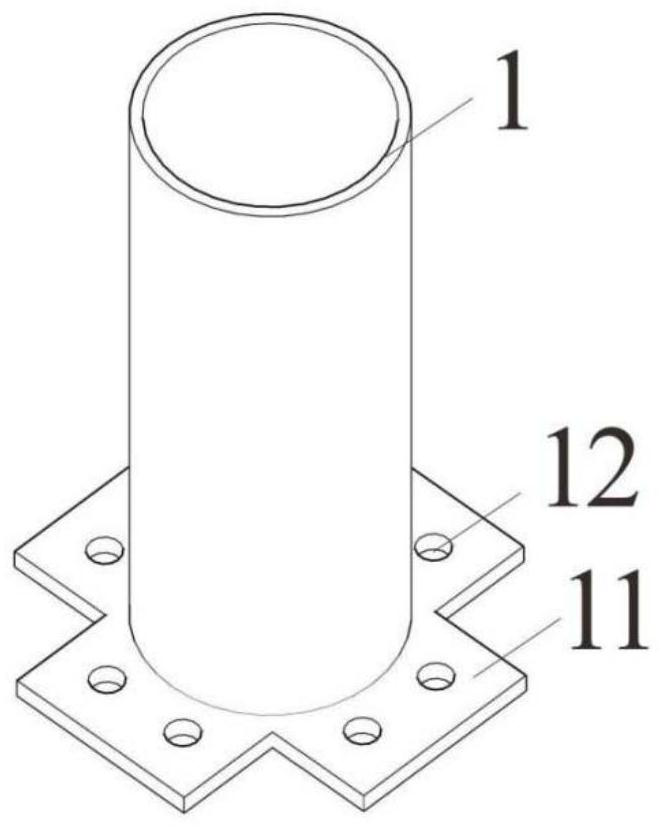

[0045] Embodiment 1 discloses a column-assembled node of an inner-circle-external-square compound steel structure. The column of the inner-circle-external compound steel structure refers to the inner-circle steel pipe 1 set inside the outer-square steel pipe 2, and the outer-square steel pipe 2 and the inner It is obtained by pouring concrete between the interlayers of round steel pipes 1; the nodes include a first node joint 6 and a second node joint 7, and the first node joint 6 includes a first cross-shaped connection panel 11 connected to the lower end of the inner round steel pipe 1 on the upper side. A node joint 6 also includes a first sleeve joint 5 connected to the inner wall of the lower end of the upper outer steel pipe 2;

[0046] The second node joint 7 includes a second cross-shaped connecting panel 15 connected to the upper end of the lower inner round steel pipe 1, and the second node joint 7 also includes a second sleeve joint 10 connected to the inner wall of ...

Embodiment 2

[0064] Embodiment 2 discloses a column-assembled node connection method of an inner-circle-external-square compound steel structure, and the column-assembled node of the inner-circle-external-square compound steel structure is the column assembly of the inner-circle-external-square compound steel structure disclosed in Embodiment 1 node, including:

[0065] S61: Connect the first sleeve joint 5 and the second sleeve joint 10 to the inner wall of the outer steel pipe 2 respectively, and place the inner round steel pipe 1 in the center of the outer steel pipe 2;

[0066] S62: Concrete 3 is poured in the interlayer between the inner round steel pipe 1 and the outer square steel pipe 2 to be flush with the cross section of the outer square steel pipe 2, and the first cross-shaped connecting panel 11 and the second cross-shaped connecting panel 15 are respectively connected to the two inner round steel pipes. 1 end welding;

[0067] S63: Through the first through hole 12 of the fi...

Embodiment 3

[0075] A method for generating a column-assembled node of an inner-circle-external-square compound steel structure, the column-assembled node of an inner-circle-external-square compound steel structure disclosed in Embodiment 1 and Example 2 . can be applied as Figure 8 shown in the application environment. Wherein, the terminal 100 may be, but not limited to, various personal computers, notebook computers, smart phones, and tablet computers. The terminal 100 includes a memory, a processor and a display screen. The processor can run architectural design software, which can be stored in the memory in the form of a computer program. The memory also provides an operating environment for the architectural design software, and the memory can store operating information of the architectural design software. Specifically, the display screen can display the design interface of the architectural design software, and the user can input information through the design interface to ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com