Retaining wall and construction method thereof

A technology for retaining walls and retaining walls, applied to buildings, sheet pile walls, underwater structures, etc., to achieve the effects of improving efficiency, reducing material consumption, and saving foundation treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

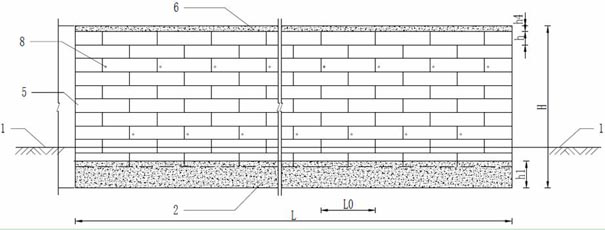

[0146] refer to Figure 10 to Figure 14 , the height of the retaining wall is 6 meters, the slope line at the top of the wall is horizontal, the load width of the first-class roadway of the highway is 7.5 meters, the backfill of the wall is powder clay, and the bulk densityγ 0 =18.5KN / m³, internal friction angle φ=26°, internal cohesion C=15KPa, foundation strength 250KPa, foundation level, foundation soil bulk densityγ 1 =19KN / m³, the friction coefficient of the base is 0.35, and the retaining wall is designed in a modular manner.

[0147] The design method steps are as follows:

[0148] (1) A modular cantilever retaining wall with a height of H=6m is adopted, and the foundation is a soil foundation. In non-water-soaked areas, the buried depth of the foundation is determined to be 1.5m, and the foundation overhang of the wall heel is determined to be b 3 =1.7m, the foundation of the wall toe is overhanging b 4 =1.0m, the wall and the foundation are set with cast-in-place c...

Embodiment 2

[0192] refer to Figure 15 to Figure 17 , the height of the retaining wall is 12 meters, the slope line at the top of the wall is horizontal, the load width of the first-class roadway of the highway is 7.5 meters, the backfill of the wall is powder clay, and the bulk densityγ 0 =18.5KN / m³, internal friction angle 26°, internal cohesion C=15KPa, foundation level, foundation soil bulk densityγ 1 =20KN / m³, the friction coefficient of the base is 0.4, try to adopt the modular design of the retaining wall.

[0193] The method steps are as follows:

[0194] (1) The total height of the retaining wall is H=12m, the soil foundation, the non-soaked area, the buried depth of the foundation is determined to be 2.5m, and the foundation of the wall is suspended b 4 =2.5m, the heel foundation hangs out b 3 =1.0m, the wall and the foundation set up a cast-in-place chamfer u=0.5m, v=0.5m; at a distance from the base h 5 = 7.3m to set prefabricated unloading plate;

[0195] (2) A modular u...

Embodiment 3

[0255] refer to Figure 18 to Figure 20 , the height of the retaining wall is 18 meters, the slope line at the top of the wall is horizontal, the load width of the first-class roadway of the highway is 7.5 meters, the backfill of the wall is powder clay, and the bulk densityγ 0 =18.5KN / m³, internal friction angle 26°, internal cohesion C=15KPa, foundation level, foundation soil bulk densityγ 1 =19KN / m³, the friction coefficient of the base is 0.35, and the retaining wall is designed in a modular manner.

[0256] The method steps are as follows:

[0257] (1) The total height of the retaining wall is H=18m, the soil foundation, the non-immersion area, the design foundation buried depth is 3.0m, and the wall heel foundation is overhanging b 3 =3.0m, the toe of the wall is overhanging b 4 =1.5m, chamfer u=0.5m×v=0.5m for wall foundation; set prestressed anchor cable at 11.6m from base,

[0258] (2) Using anchor cables + modular cantilever retaining wall, the total height of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Carrying capacity | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com