Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Optimizing the packaging process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

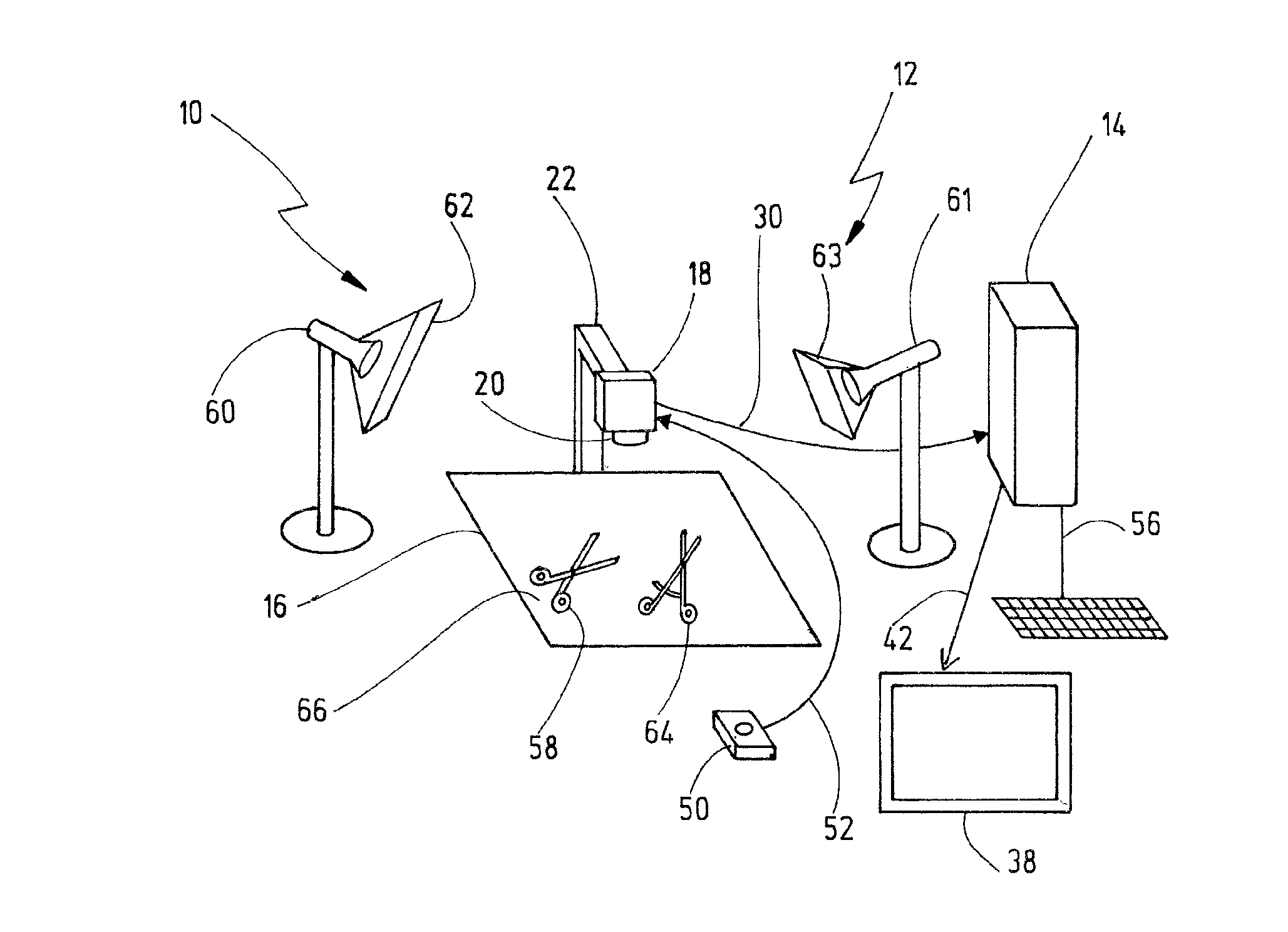

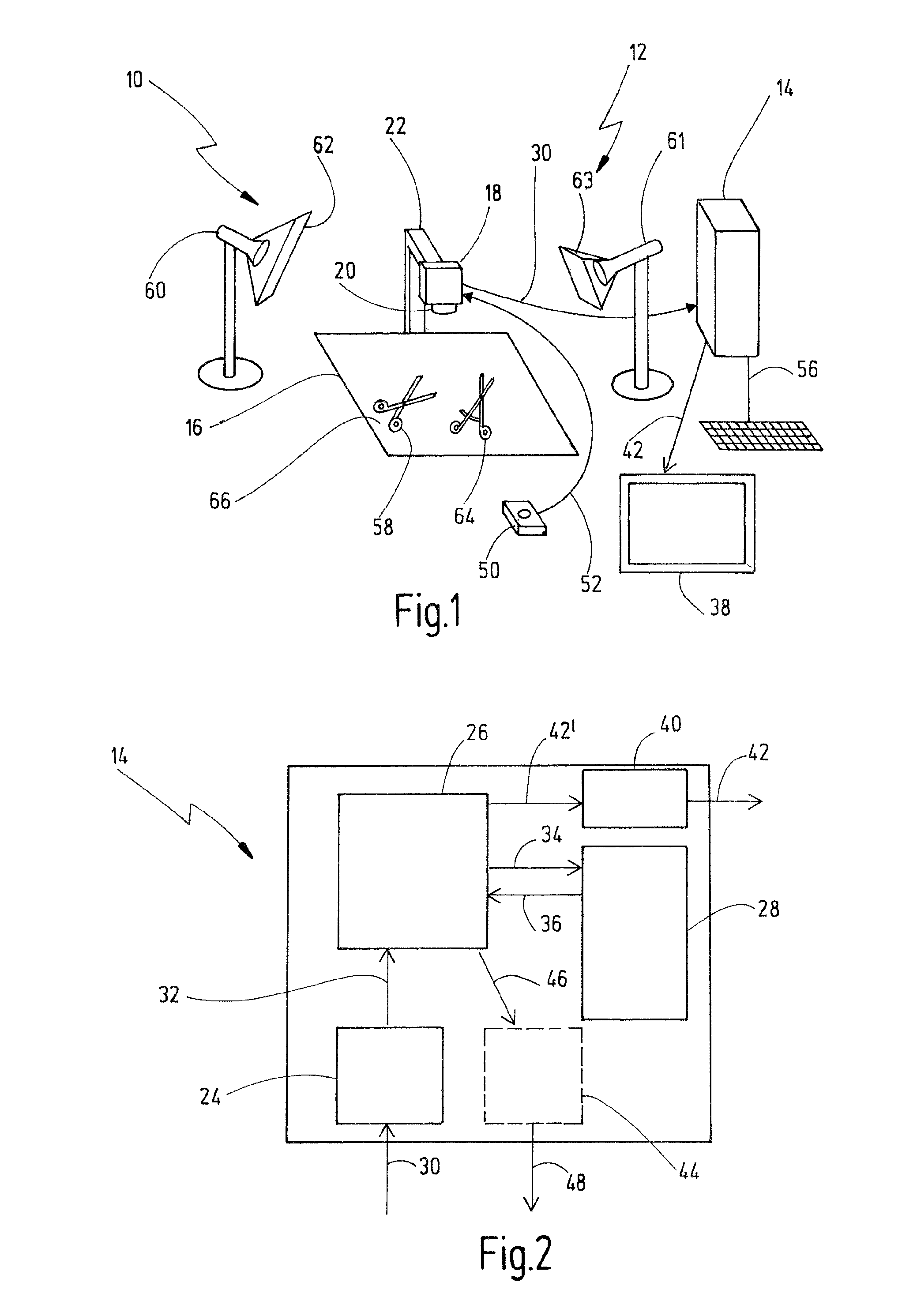

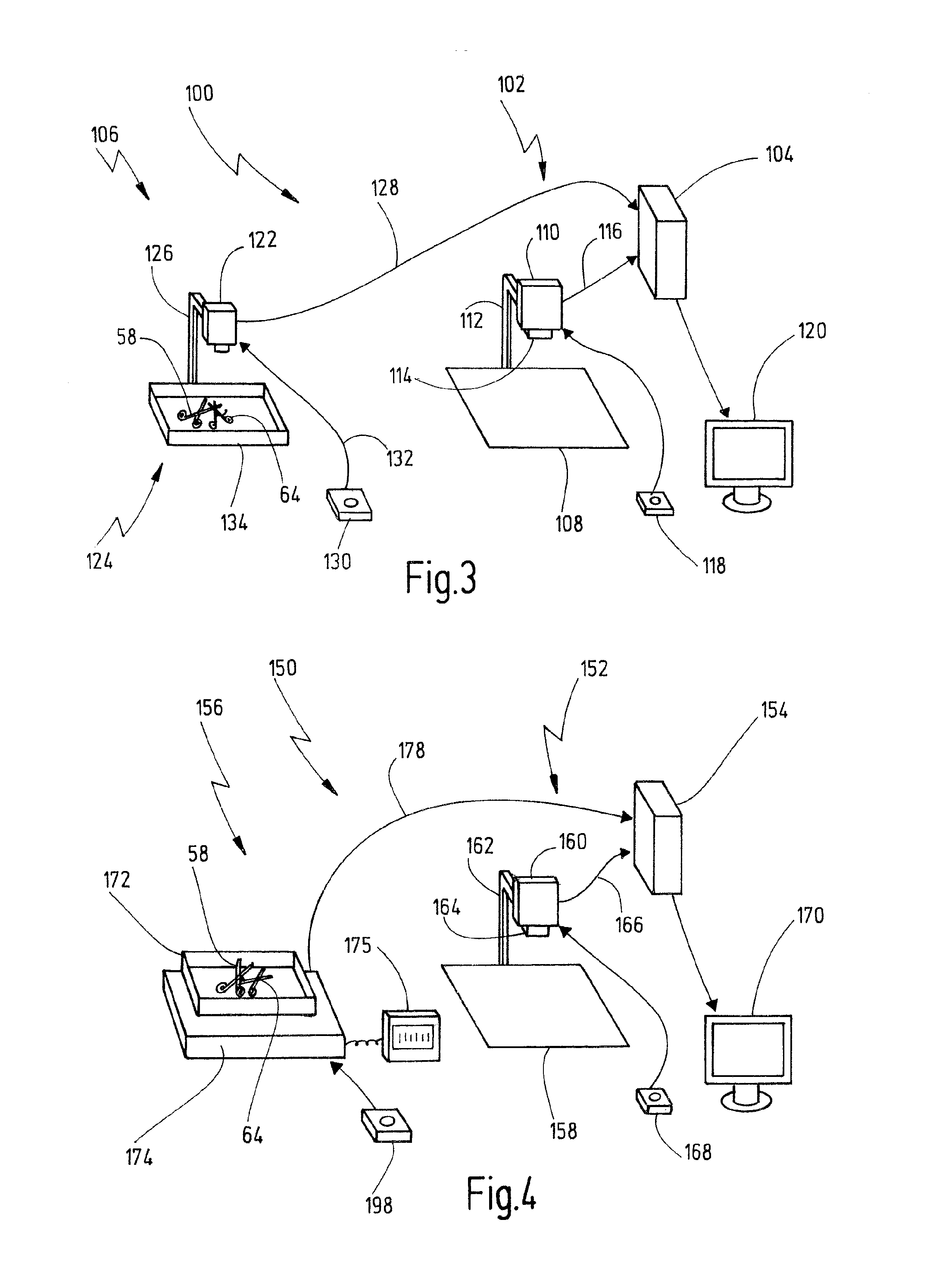

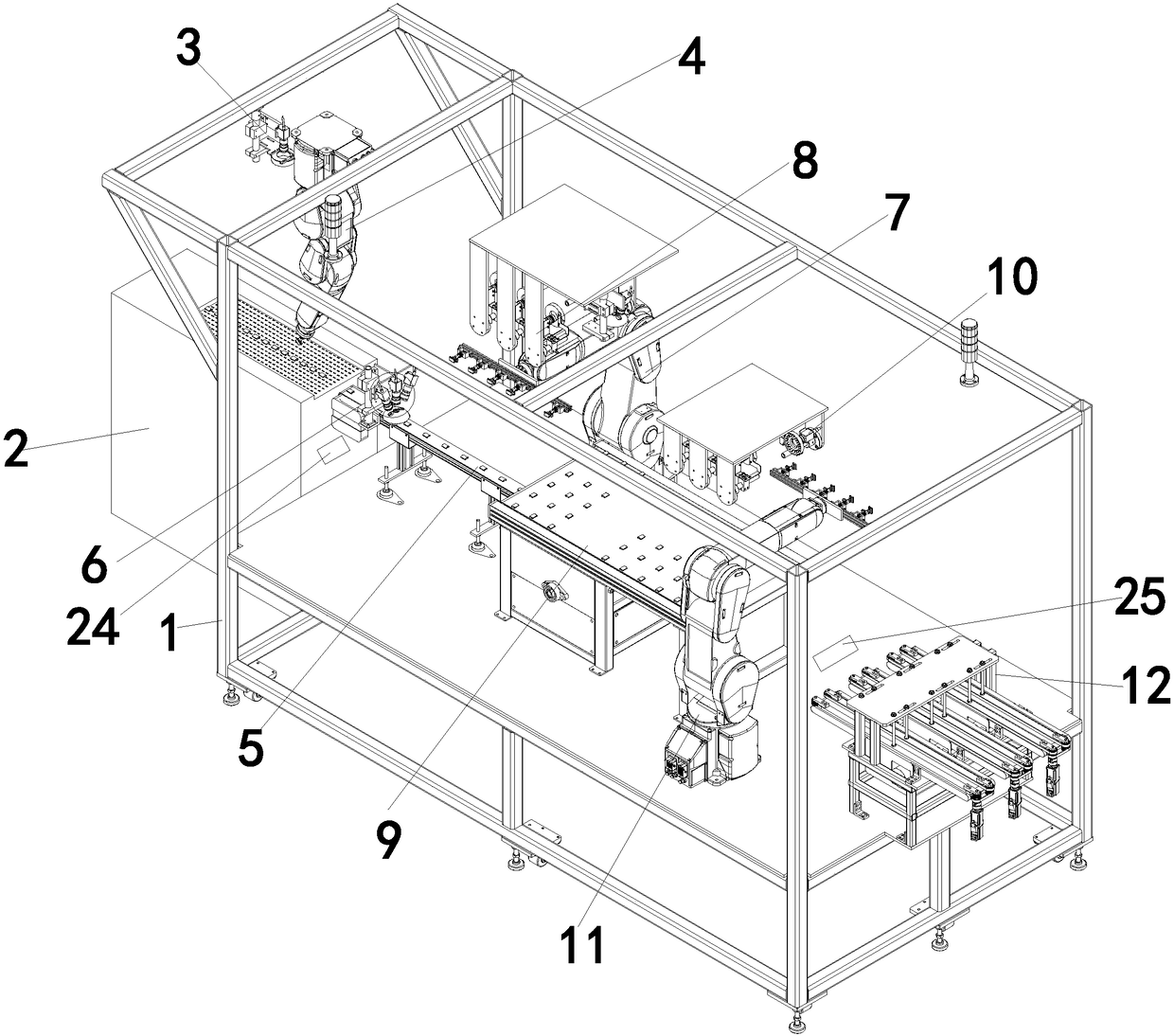

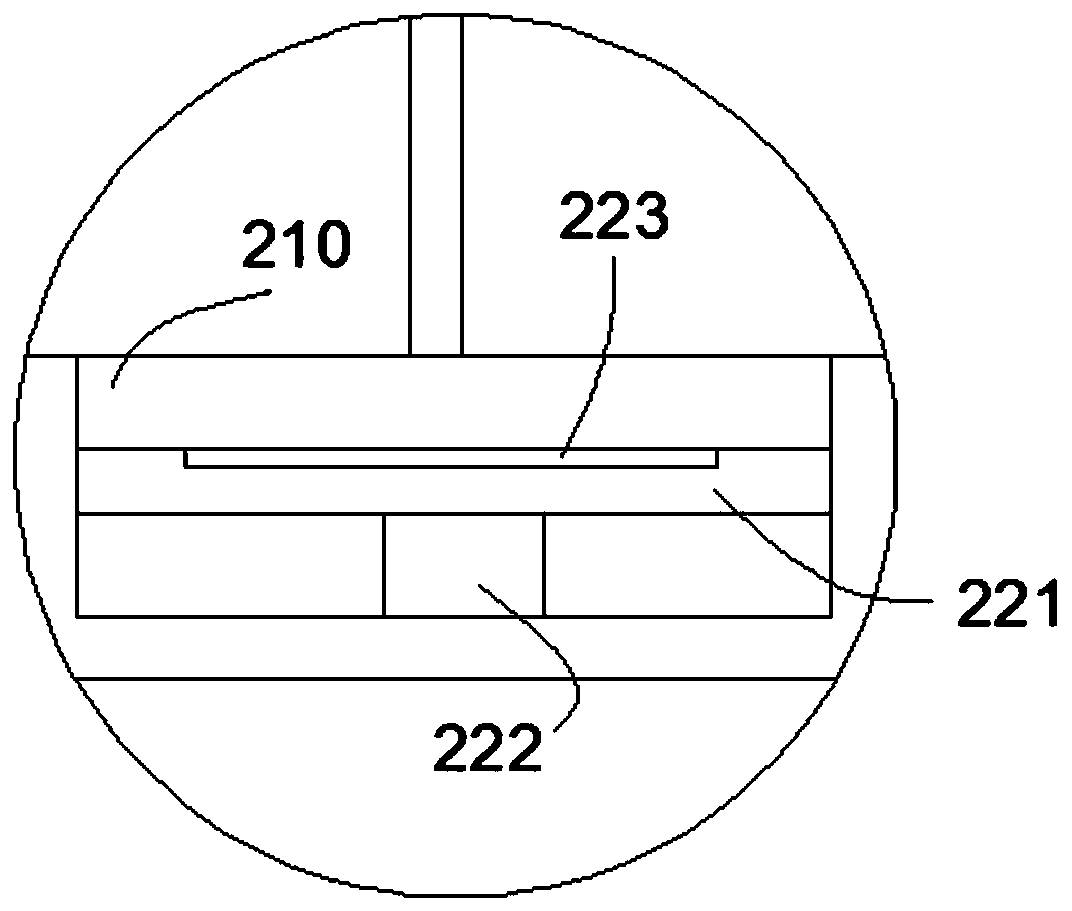

Device And Method For Assembling Sets Of Instruments

InactiveUS20130091679A1Optimizing the packaging processKeep down time and cost involvementAutomatic control devicesData processing applicationsVisual perceptionComputer science

The invention relates to a device for assembling sets of instruments, having a data processing installation and a fine identification unit. The data processing installation has a display unit, a database, a first interface and an evaluation unit. The fine identification unit has a first support for placing the instruments of a set of instruments thereon and a first camera. The first camera is arranged and oriented such that it can capture image data from instruments to be identified and arranged on the first support from at least one perspective, and the data processing installation is designed such that it uses the first interface to receive image data from the first camera and can store the received image data in the database. It can further visually identify a respective instrument by use of the evaluation unit. The invention also relates to an according method for assembling sets of instruments.

Owner:HOW TO ORGANIZE H2O

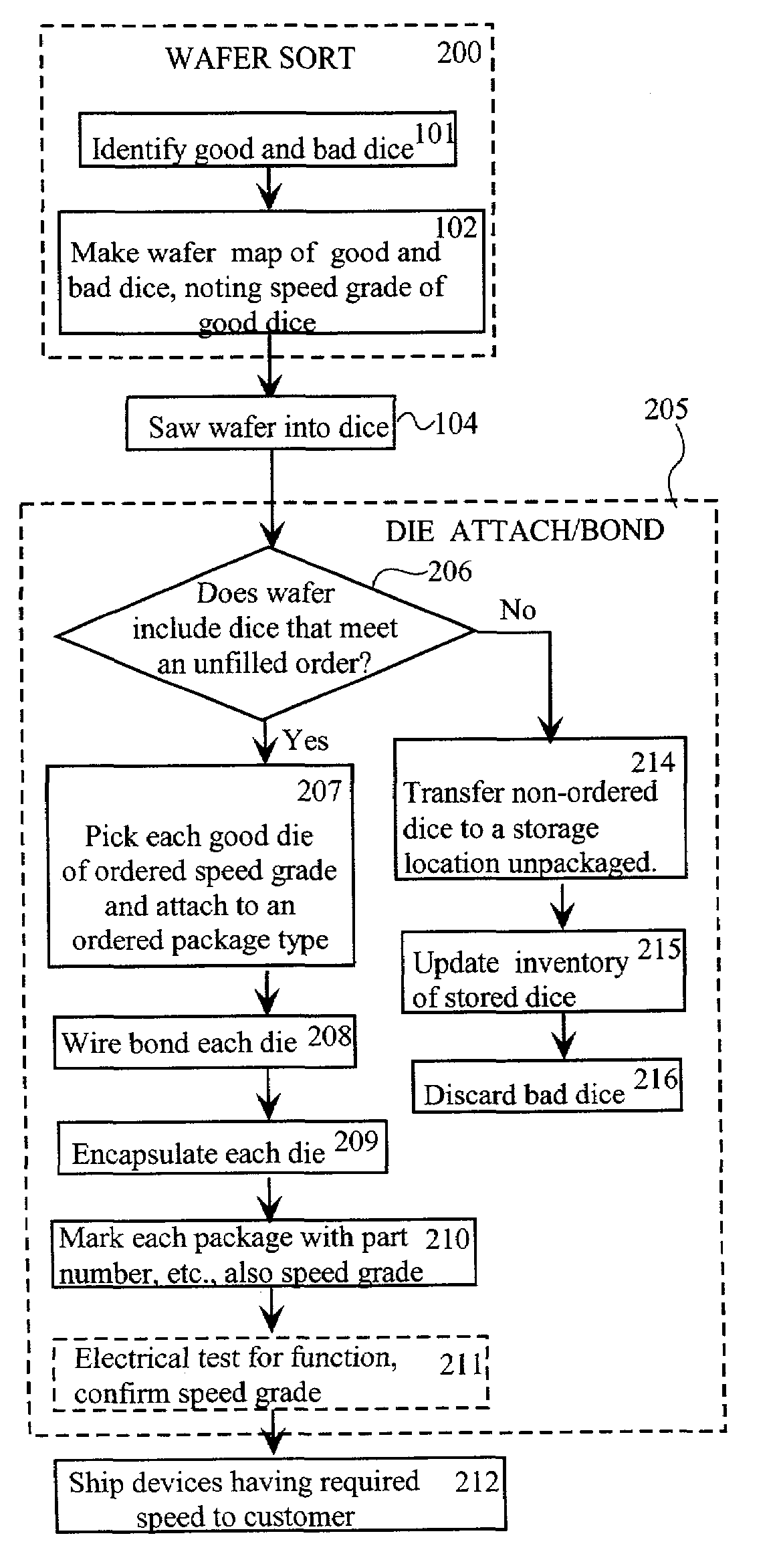

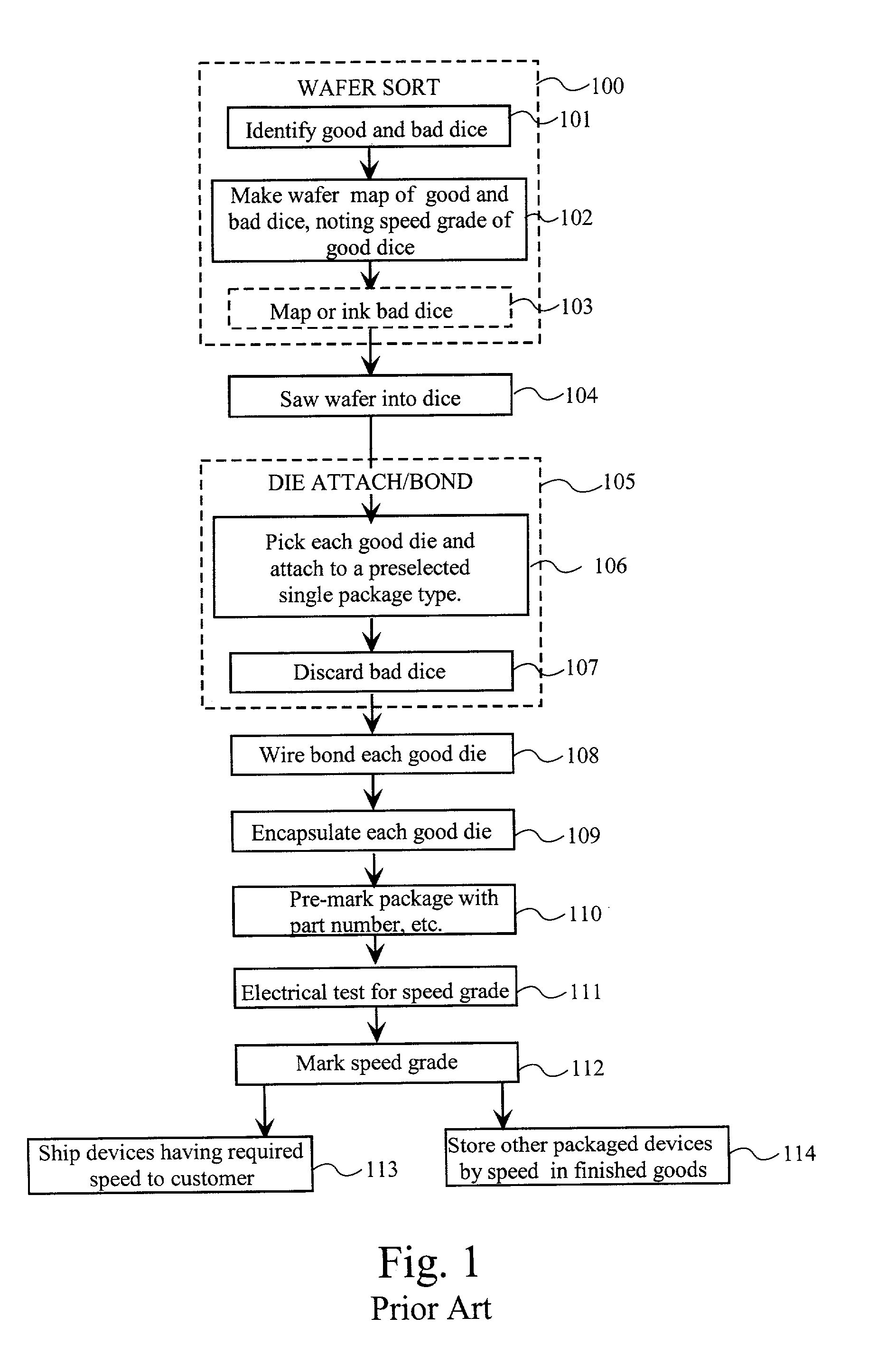

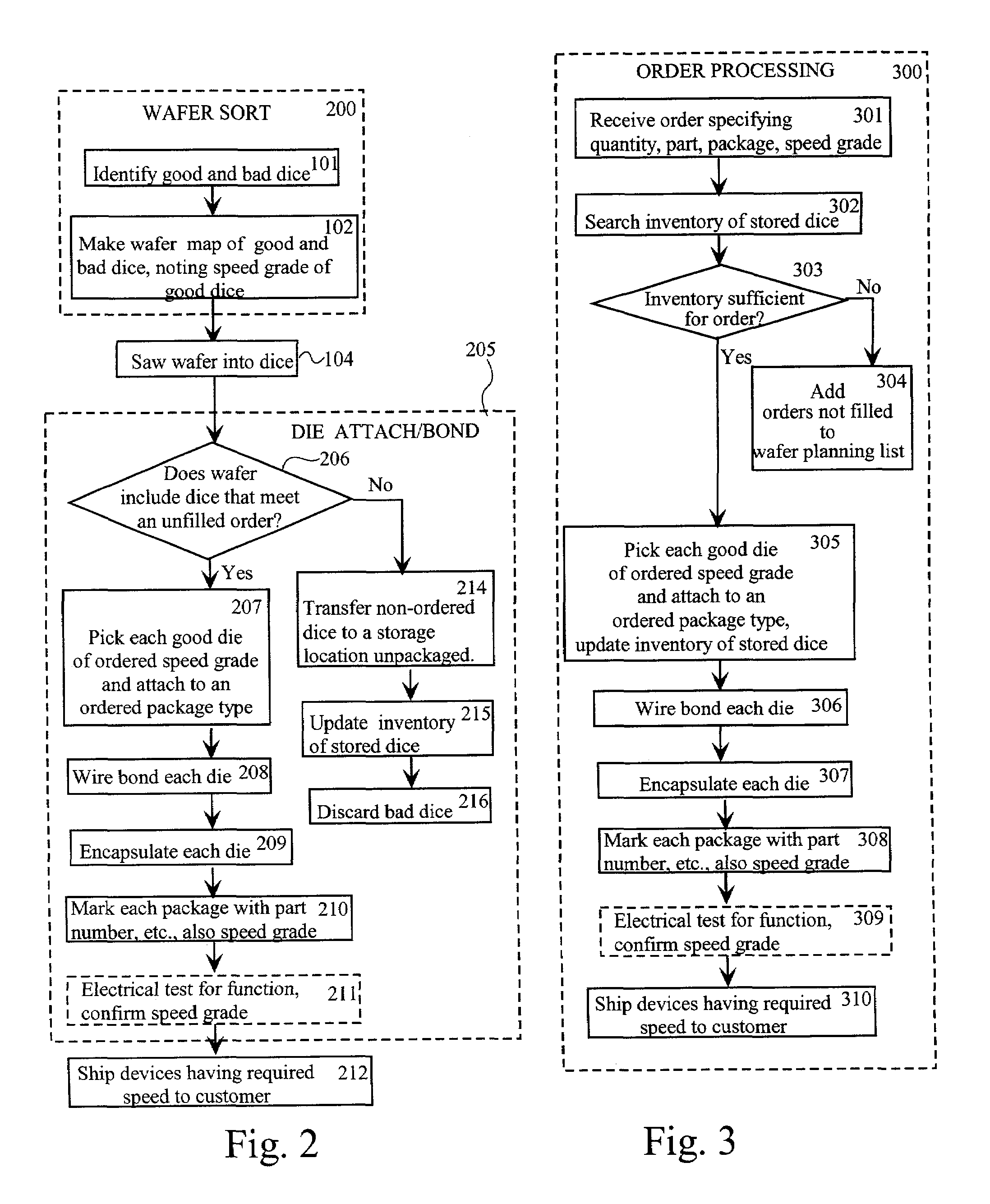

Method of sorting dice by speed during die bond assembly and packaging to customer order

ActiveUS6984533B1Improvement in packaging flowShort amount of timeSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsIntegrated circuitEngineering

When integrated circuit dice are tested as part of a completely manufactured wafer, the individual die is tested both for proper function and for speed grade. A wafer map is formed in a computer to keep up with which dice on the wafer are good and to record the speed grade of each good die. This wafer map is then used during the step of dicing and packaging the wafer to fill existing orders by placing a die that meets a speed grade of an order into the package that has been ordered. More than one kind of order can be filled from dice in a single wafer. The method allows integrated circuit devices to be packaged to order and eliminates the need to keep an inventory of packaged dice.

Owner:XILINX INC

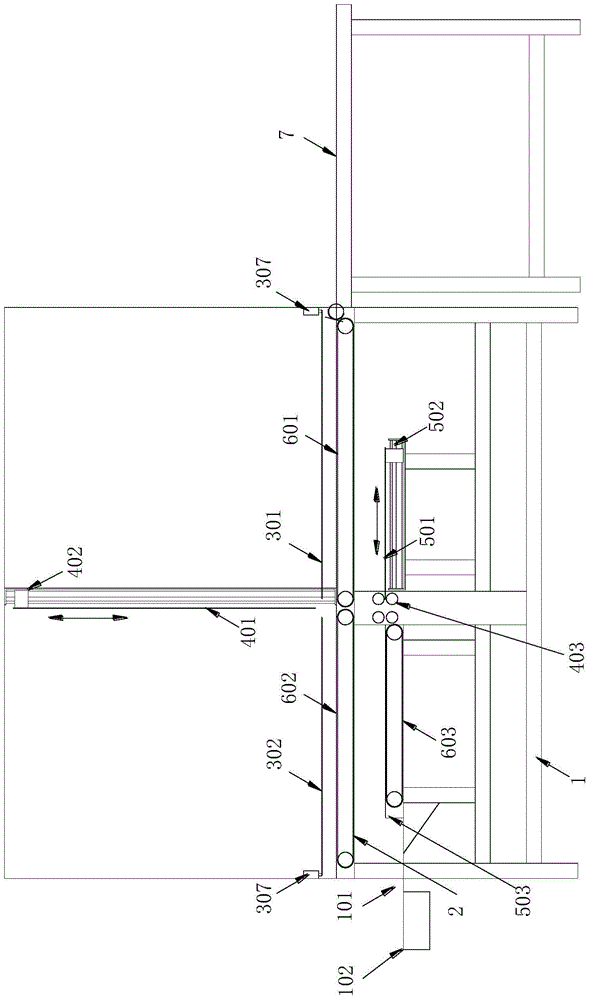

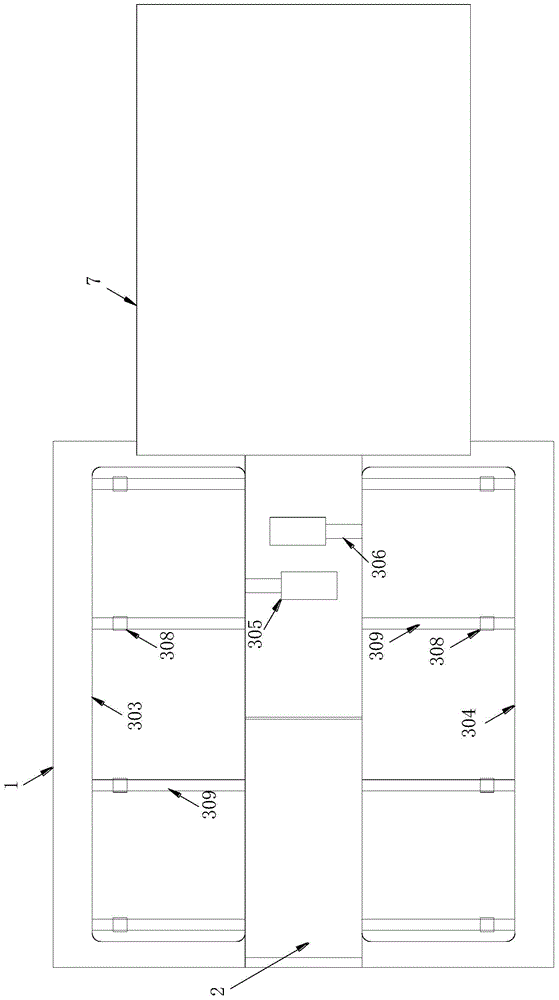

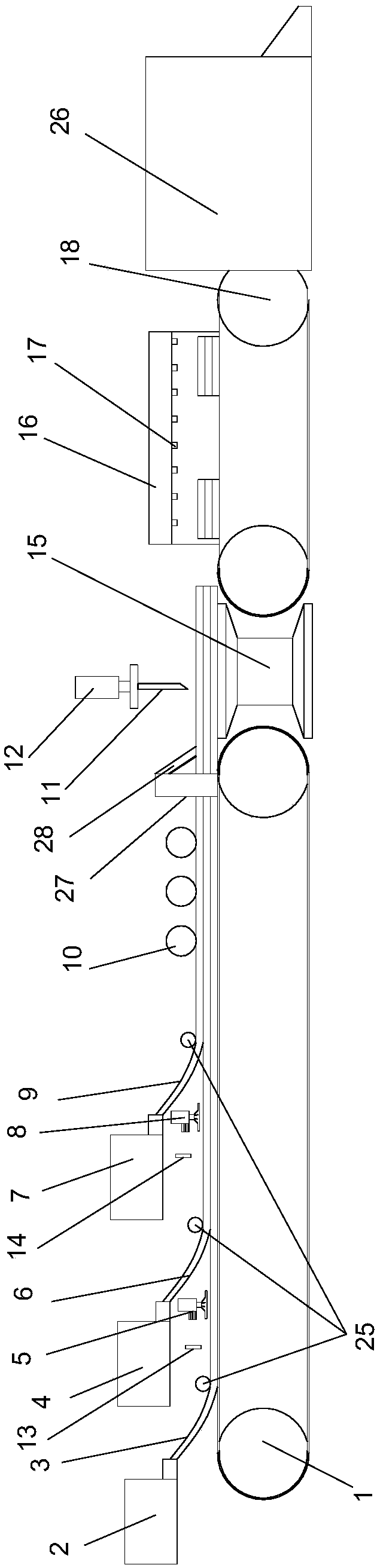

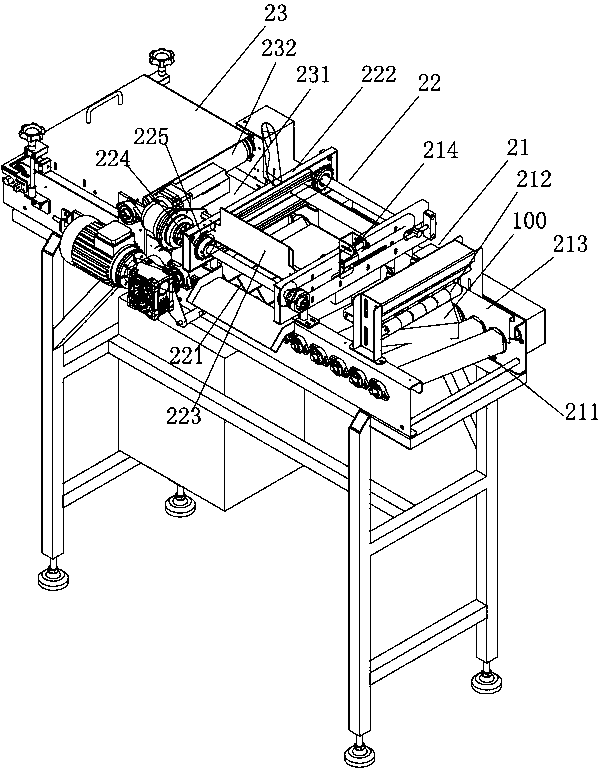

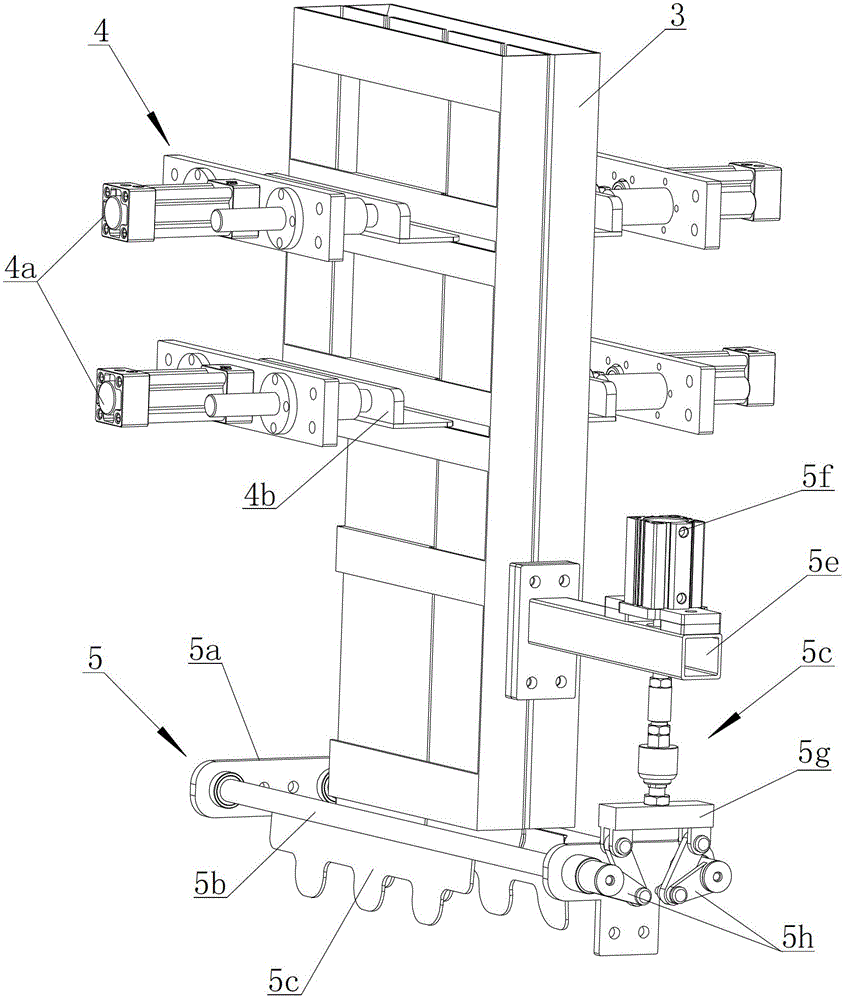

Automatic dress material folding machine

InactiveCN104444554AFold applicableUnified specificationsFolding thin materialsControl systemAgricultural engineering

The invention provides an automatic dress material folding machine. The automatic dress material folding machine comprises a panel, a position sensor, horizontal folding mechanisms, a vertical folding mechanism and a control system; a vertical folding groove is formed in the panel, and the horizontal folding mechanisms are fixed to the two sides of the panel; the vertical folding mechanism comprises a vertical insertion plate and a guide roller set, the vertical insertion plate is correspondingly arranged at the position, above the vertical folding groove, of the panel, and the guide roller set is fixed to the position, below the vertical folding groove, of the panel; the input end of the control system is connected with the output end of a position sensor, the output end of the control system is connected with the control ends of the horizontal folding mechanisms and the control end of the vertical folding mechanism, and the control system receives signals of the position sensor, starts to control the horizontal folding mechanisms to complete longitudinal folding of dress materials, and then controls the vertical folding mechanism to complete transverse folding of the dress materials. The automatic dress material folding machine is simple and rapid in folding movement, folding of the dress materials can be automatically and rapidly completed, and the time spent in the overall folding process is shorter than or equal to 8 minutes per piece. The labor cost is reduced. The automatic dress material folding machine is particularly suitable for folding the light, thin and soft dress materials.

Owner:WUHAN HENGFEI ELECTRICAL TECH CO LTD

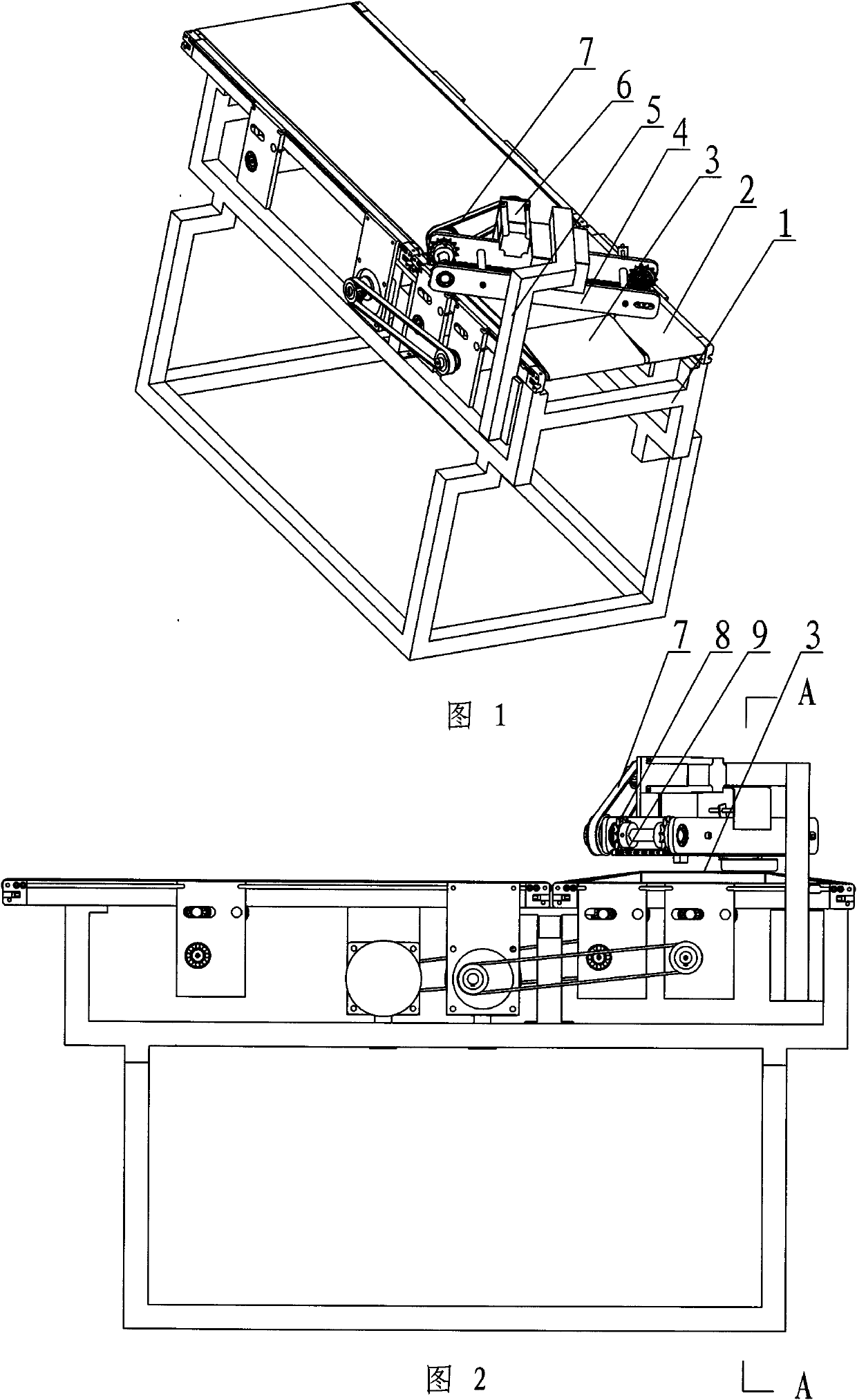

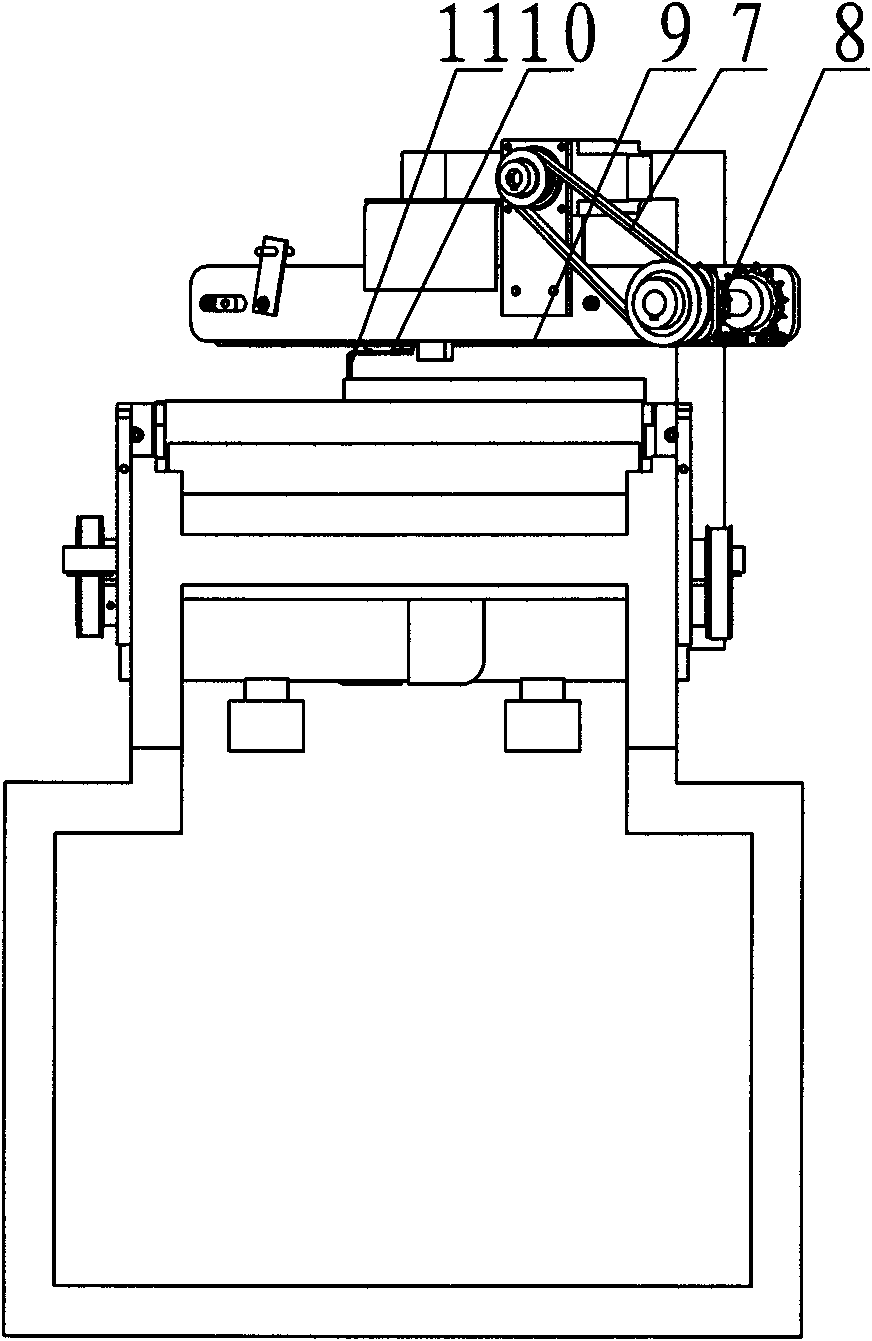

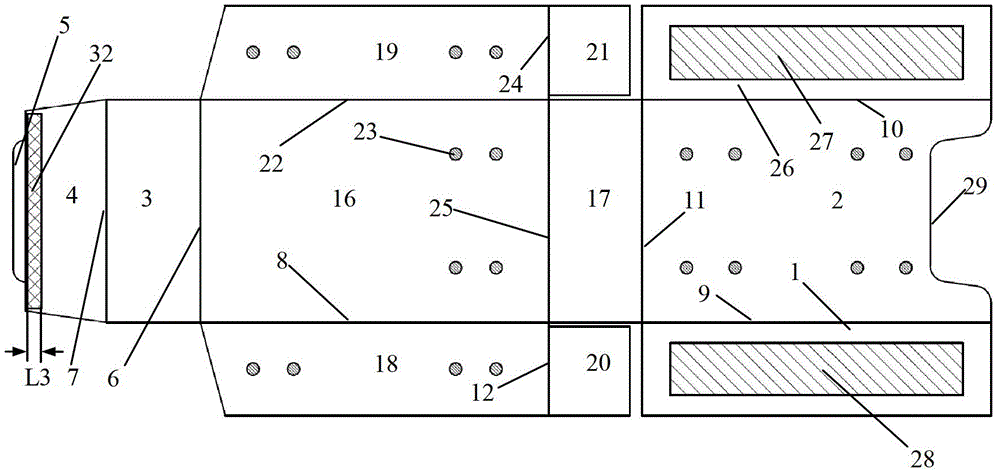

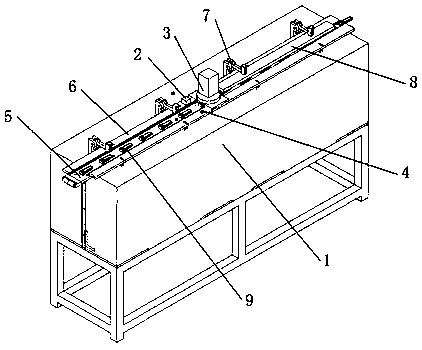

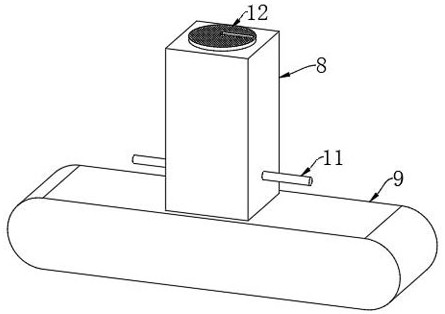

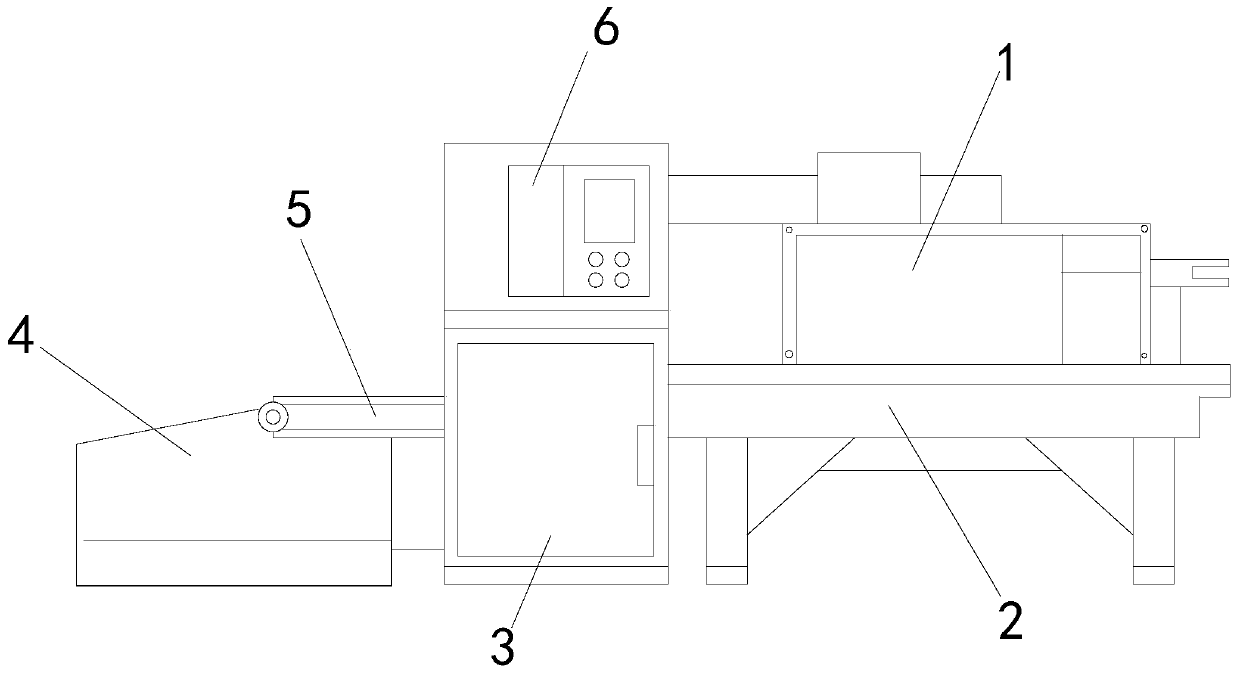

Material distributor for packing machine

The invention discloses a material distributor for a packing machine. The material distributor comprises a machine body (1), a conveyer belt and an installation frame (4), wherein the conveyer belt is arranged on the machine body; and the installation frame is arranged on the machine body. The material distributor is characterized in that: a motor (6) and a chain (9) are arranged on the installation frame; the motor is in transmission connection with the chain; a material pushing plate (14) is arranged on the chain; an included angle is formed between the axial center line of the installation frame and the axis of the conveyer belt; a photoelectric eye (15) and a proximity switch (12) are also arranged on the installation frame (4) and electrically connected with a programmable controller; and the programmable controller is connected with the motor. The material distributor with the structure can distribute a row of fed food into arrays according to a packing quantity in the moving process, and is not required to be stopped, and the distributed arrays are tidily arranged and are convenient to pack in subsequent procedures.

Owner:钟锦唐

Packaging paper for forming straight packaging of cigarette packaging box, forming method and using method

InactiveCN103332353ASimple structureEasy to take outContainers for flexible articlesPackaging cigaretteEngineeringMechanical engineering

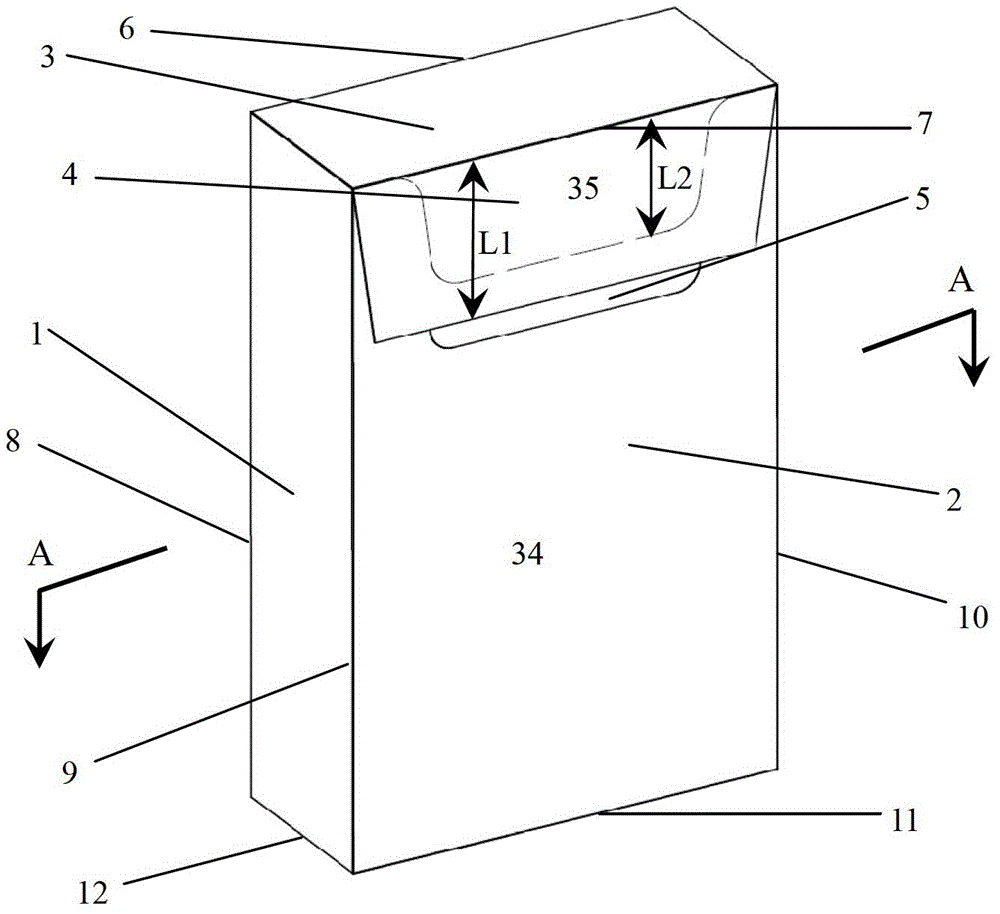

The invention discloses packaging paper for forming straight packaging of a cigarette packaging box. The packaging paper comprises a box front wall, a box bottom wall, a box rear wall, a covering piece top wall, a covering piece front wall and a covering piece drawing bolt which are sequentially and longitudinally connected, wherein an inverted-trapezoid-shaped notch is formed in the top end of the box front wall, the two sides of the box front wall are connected with a box left outer side wall and a box right outer side wall respectively, and the two sides of the box rear wall are connected with a box left inner side wall and a box right inner side wall respectively. The covering piece top wall, the covering piece front wall and the covering piece drawing bolt serve as a covering piece which rotates around a rear top connection line to complete opening and closing actions of the covering piece relative to the box. The packaging paper is simple in structure and can simplify package process procedures; the cigarette packaging box formed by the packaging paper can facilitate taking out and carrying of cigarettes; the box does not deform easily, can be opened and closed repeatedly, facilitates cigarette taking, can well seals the cigarettes, and protects the cigarettes. The invention further discloses a forming method and a using method for forming straight packaging of the cigarette packaging box.

Owner:CHINA TOBACCO MACHINERY TECH CENT

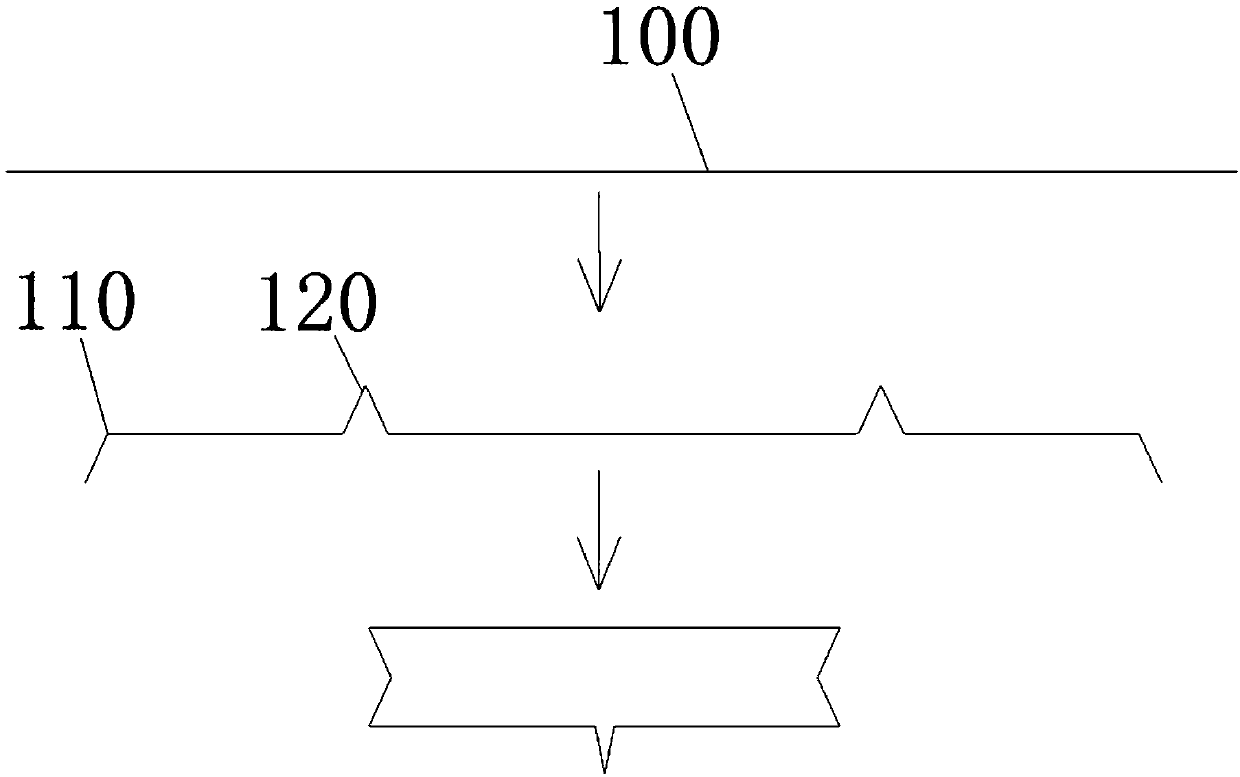

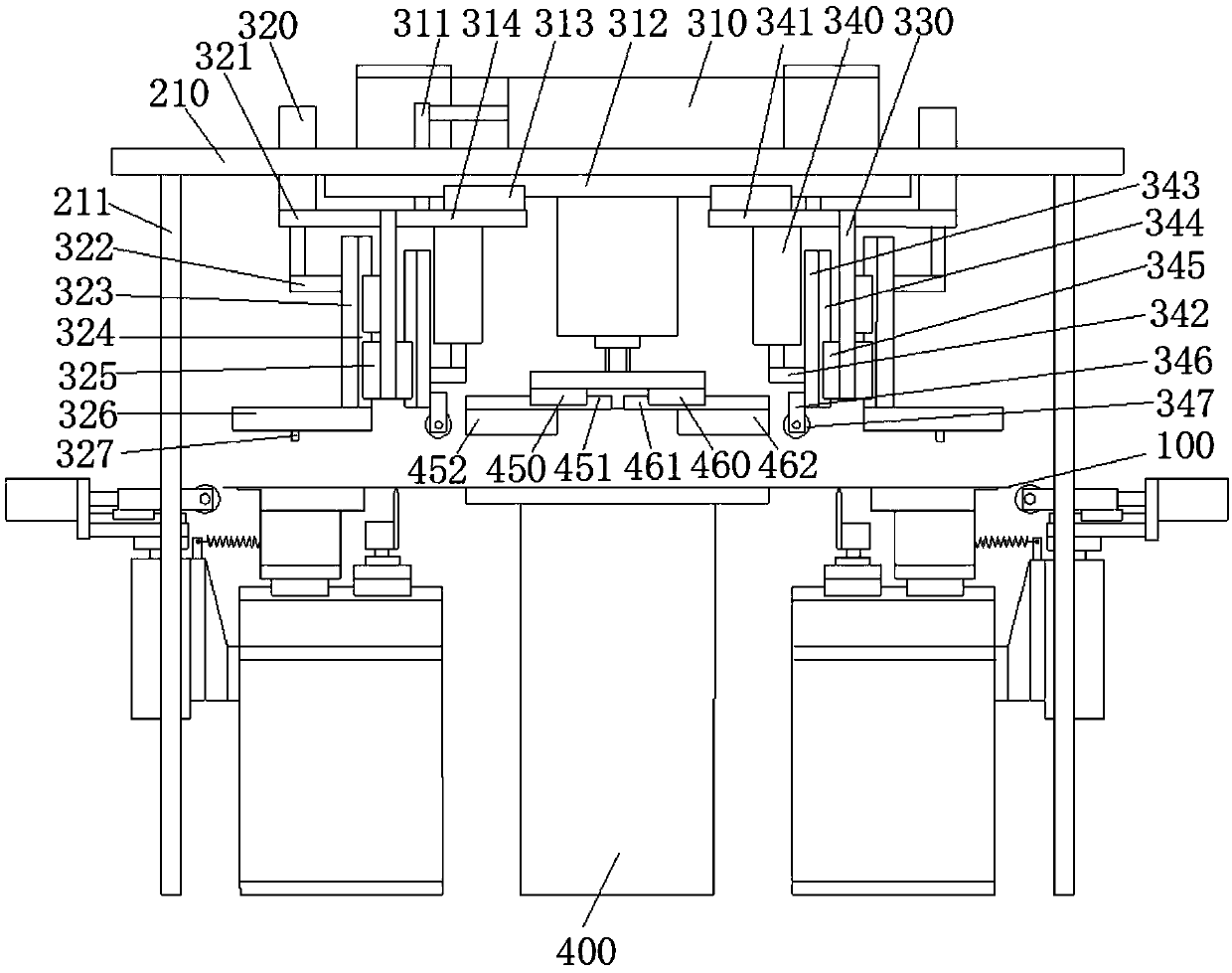

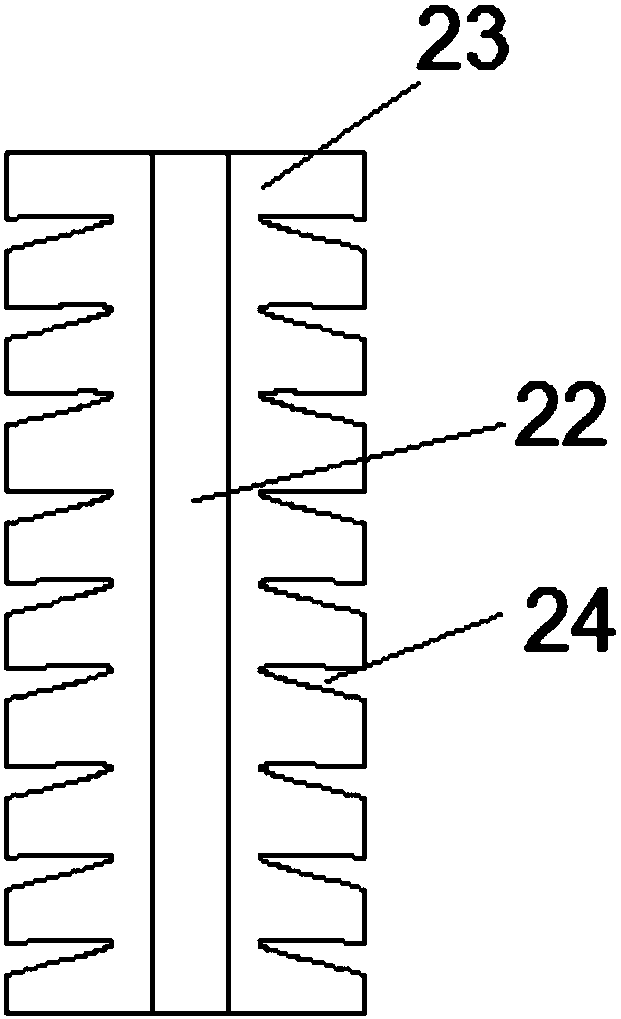

Edge-folding assembly, bending device and bending method

PendingCN107716675AReduce gapOptimizing the packaging processAssembling battery machinesFinal product manufactureSet distanceLinear drive

The invention relates to an edge-folding assembly, a bending device and a bending method. The bending method is characterized by comprising the following steps: (1) a side pressing plate descends to an edge-folding table to press and position the side of a material plate; (2) a folding knife ascends to jack the lower surface of the material plate, and continuously moves upwards to arch the material plate, and a linear drive device drives the side pressing plate and the edge-folding table to drive the material plate to move by a set distance A towards the middle, and the folding knife simultaneously moves by a A / 2 distance towards the middle; and the folding knife withdraws the material plate, and the side pressing plate and the edge-folding table continuously drive the material plate to move towards the middle, so that the material plate forms a V-shaped second folding mark inside a first folding mark. The bending method can be used for bending the edge position and the middle positionof the material plate, so that the follow-up packaging process is convenient.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

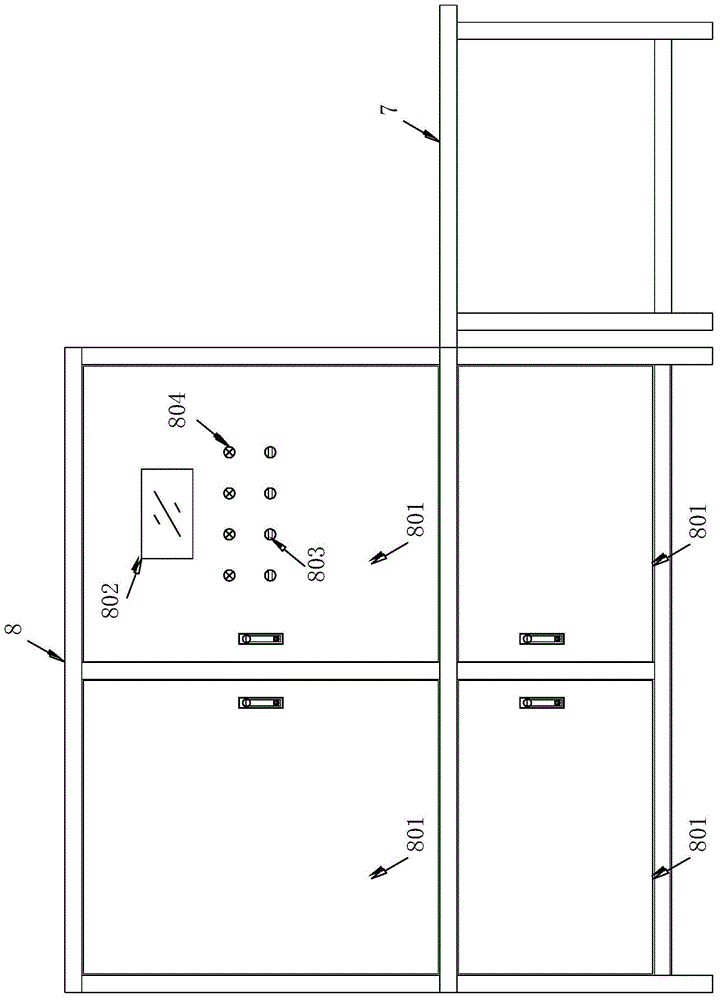

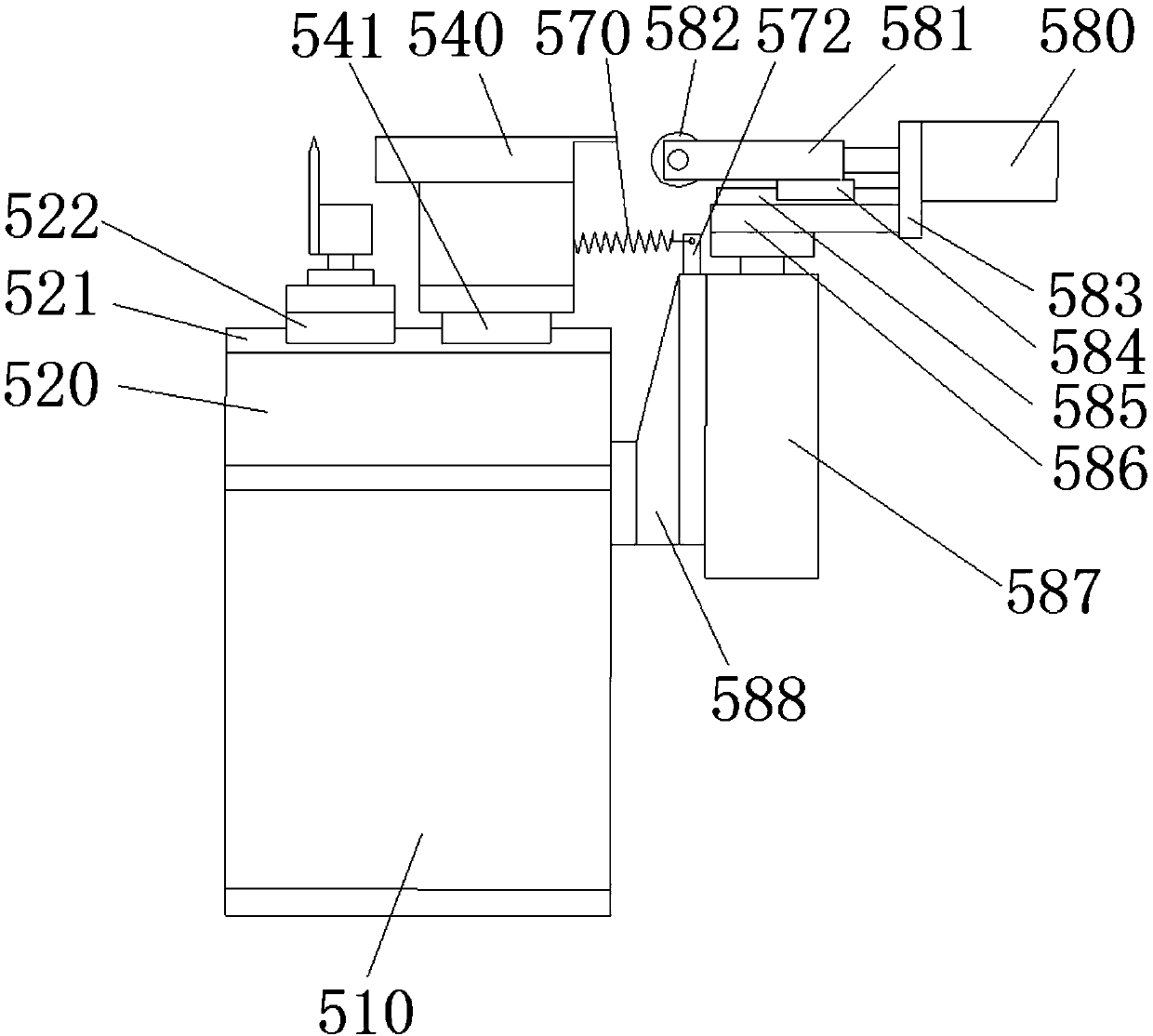

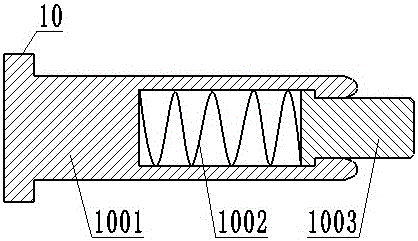

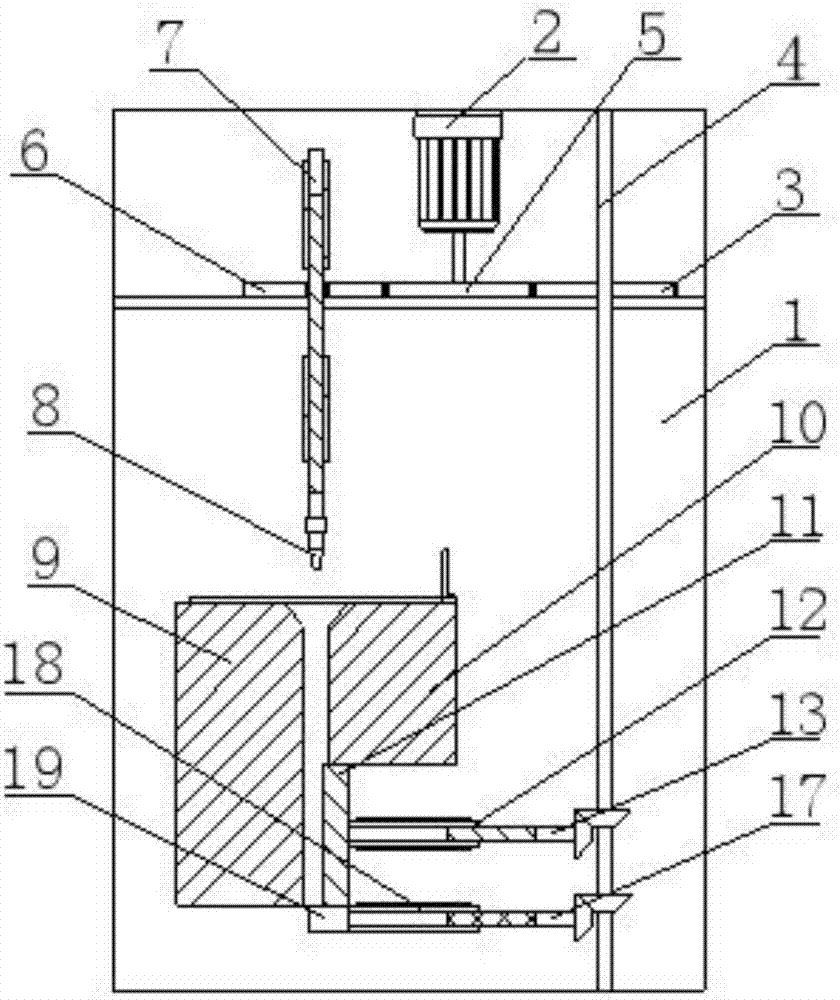

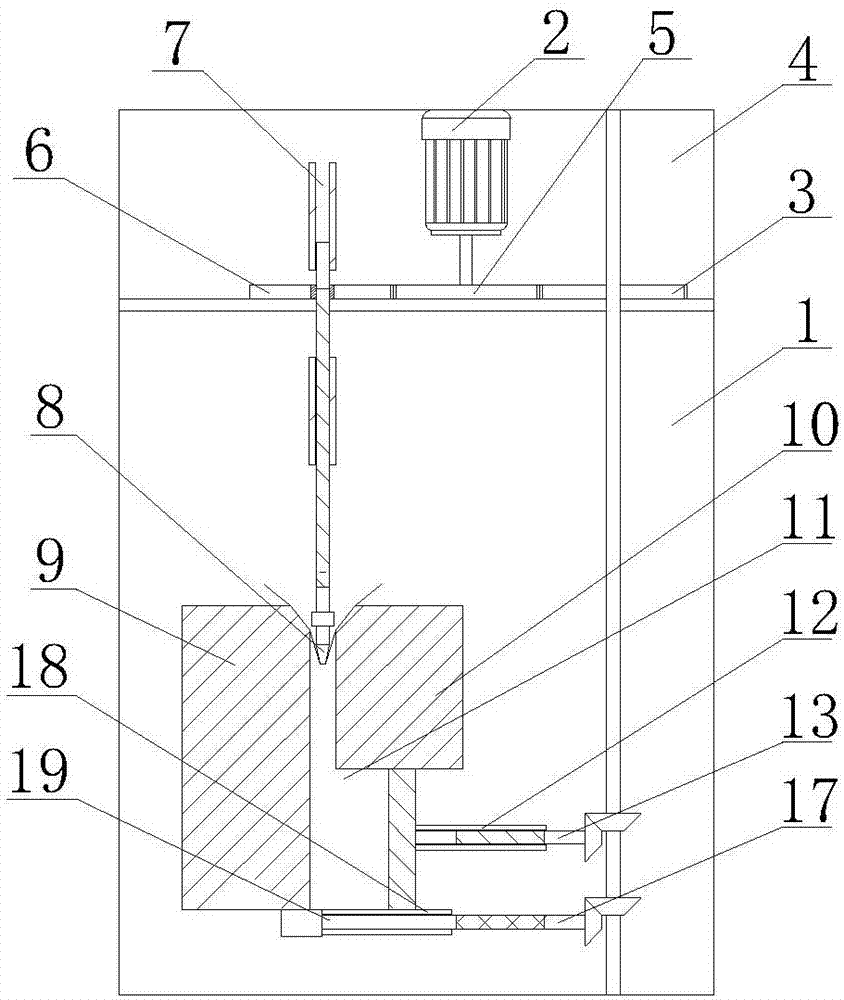

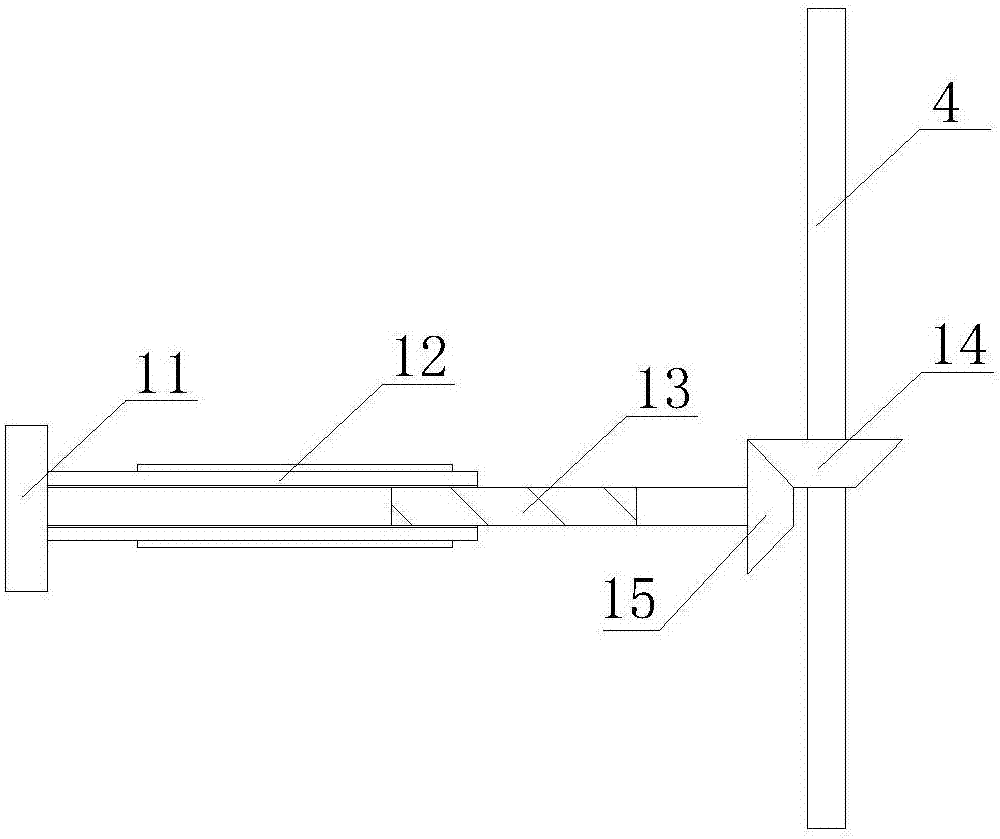

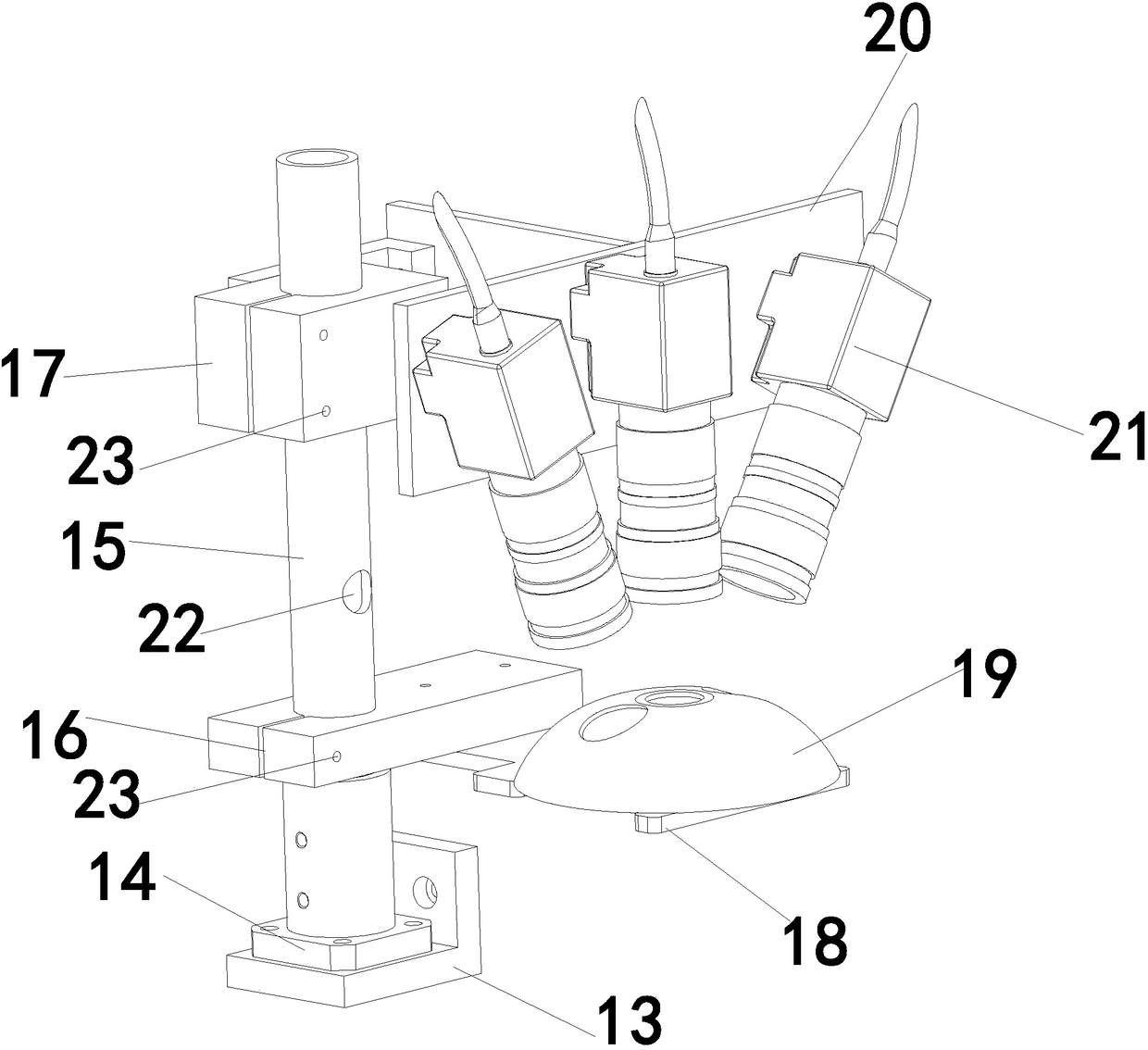

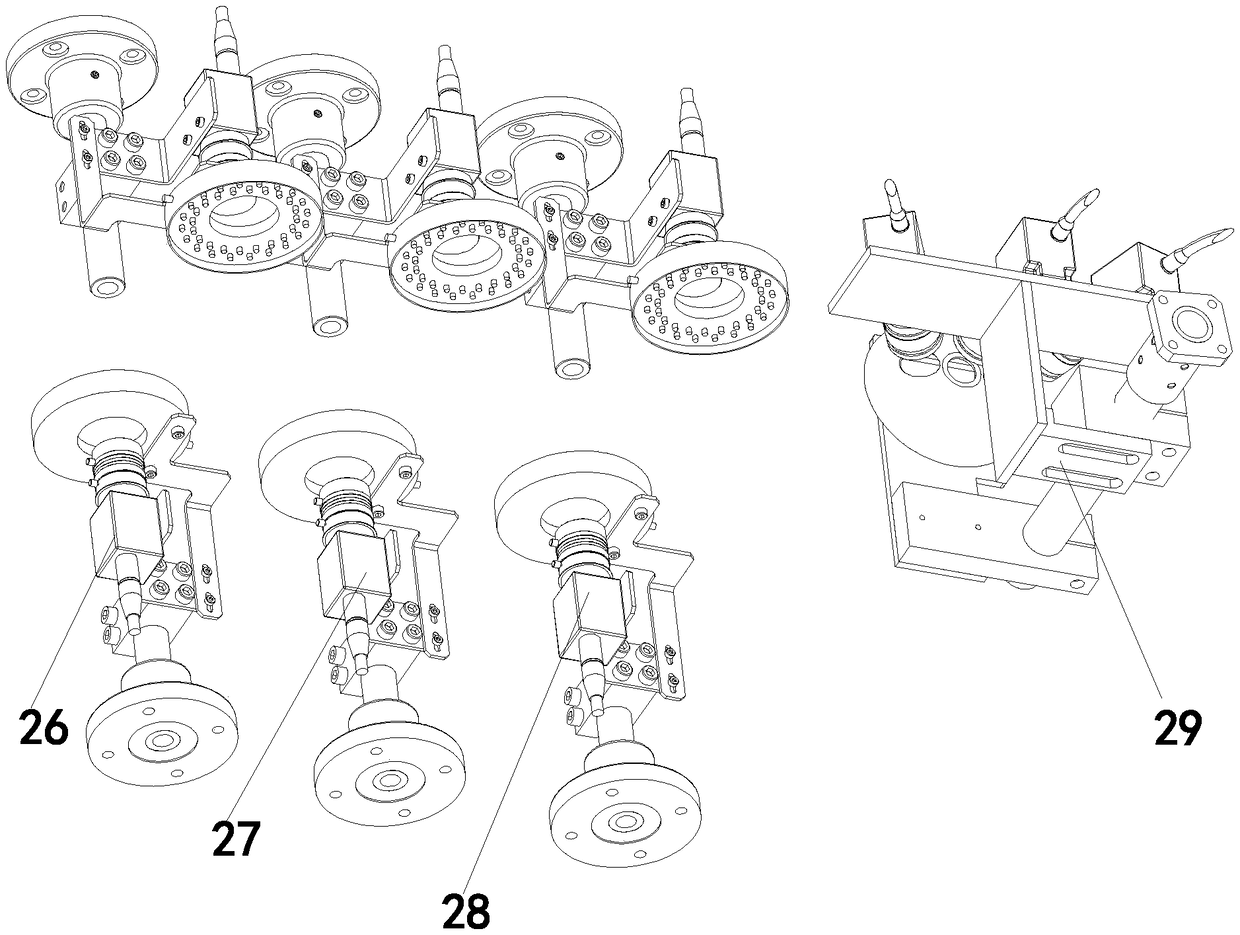

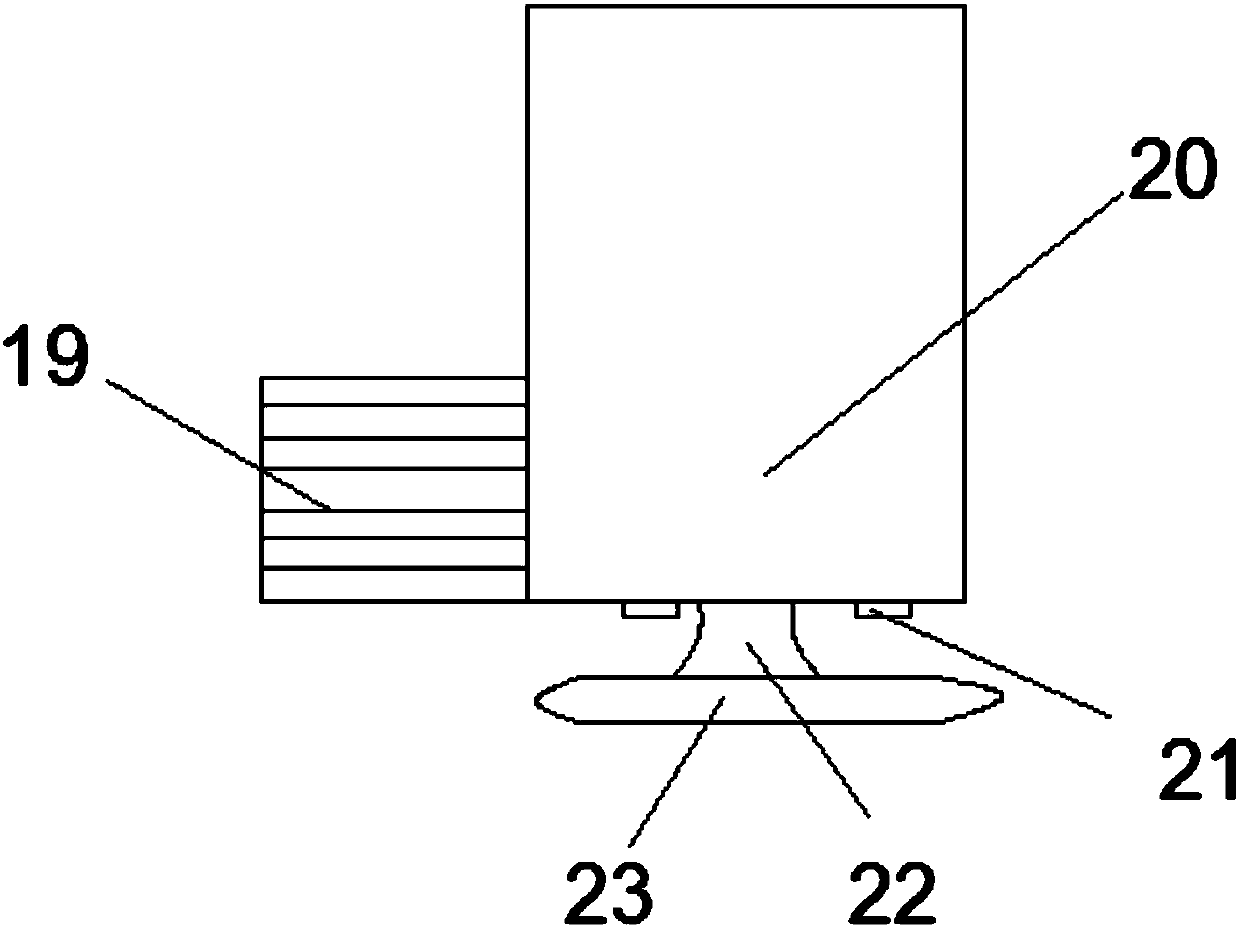

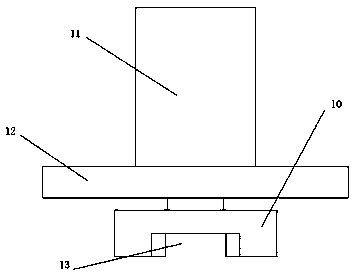

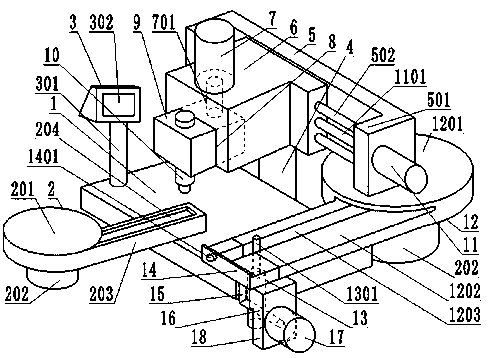

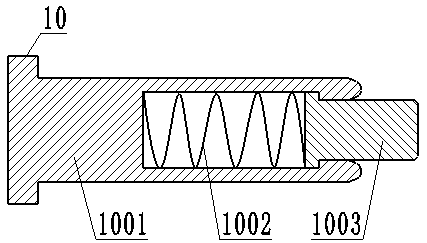

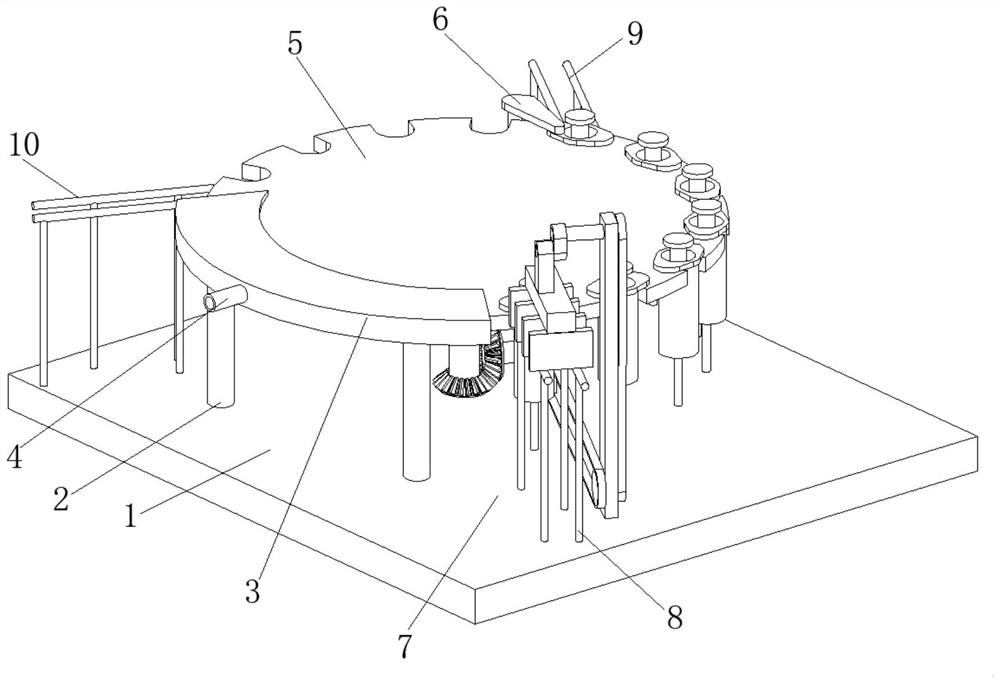

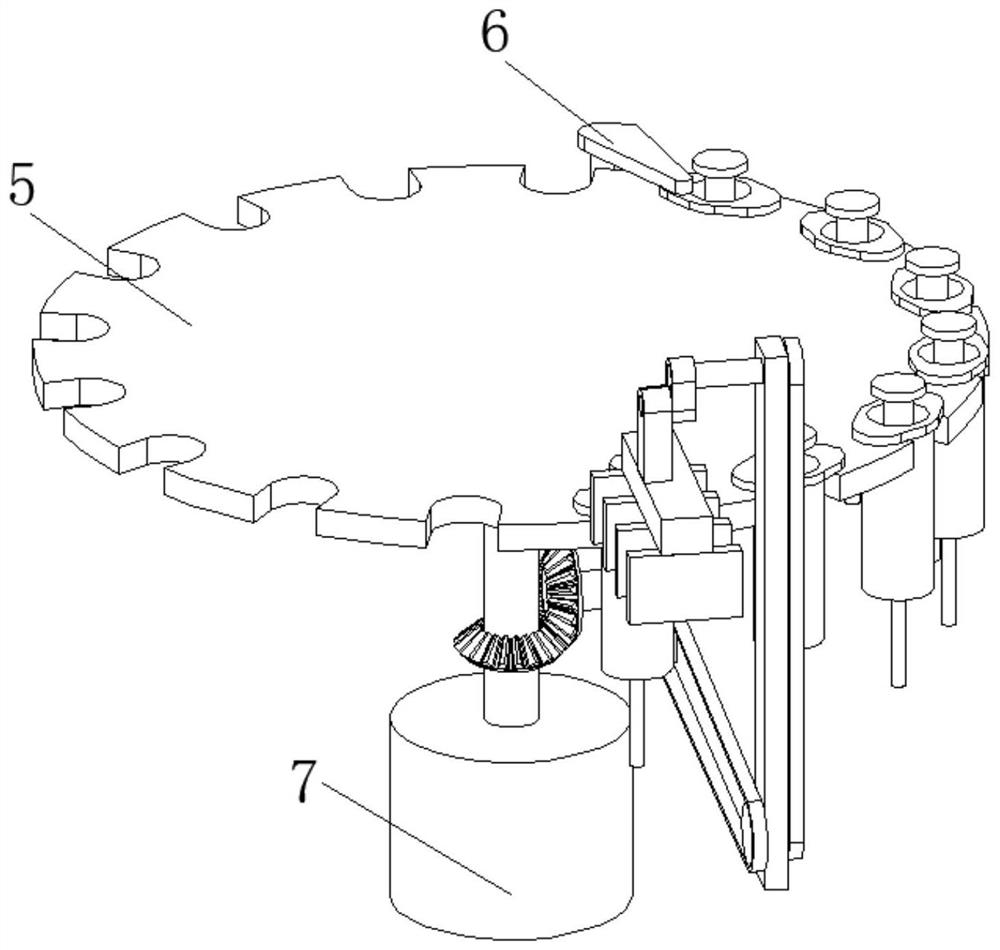

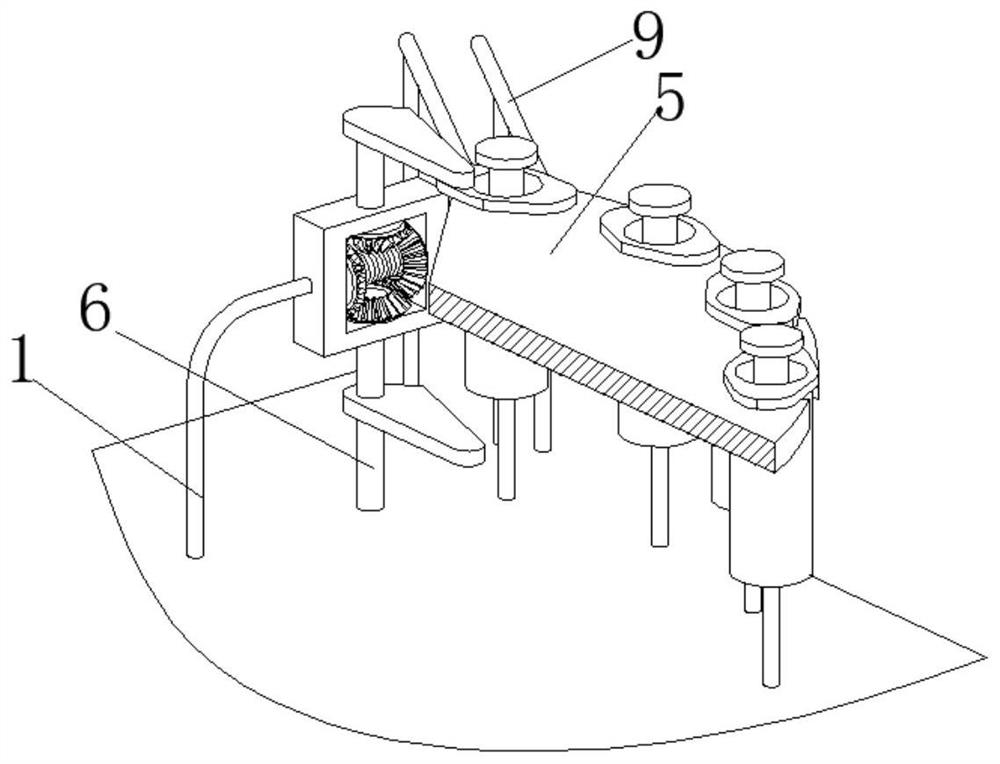

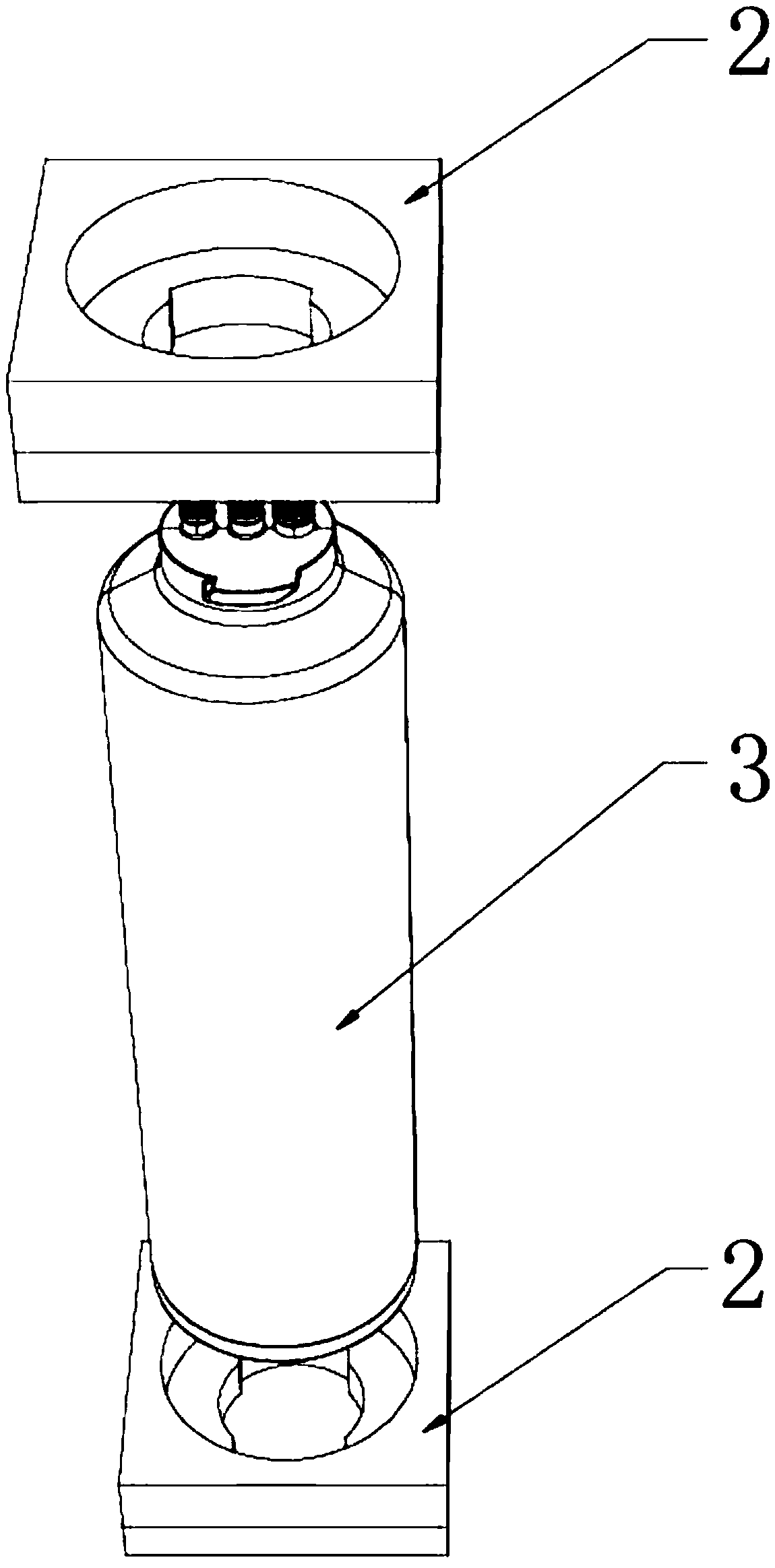

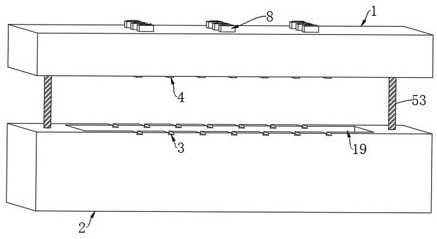

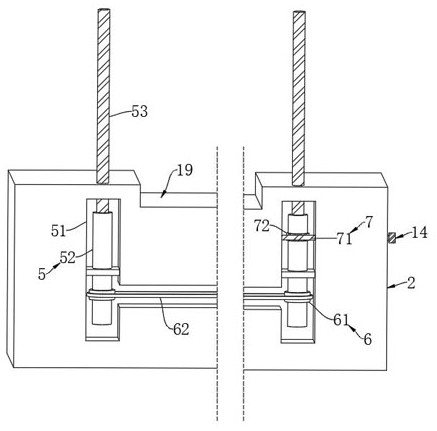

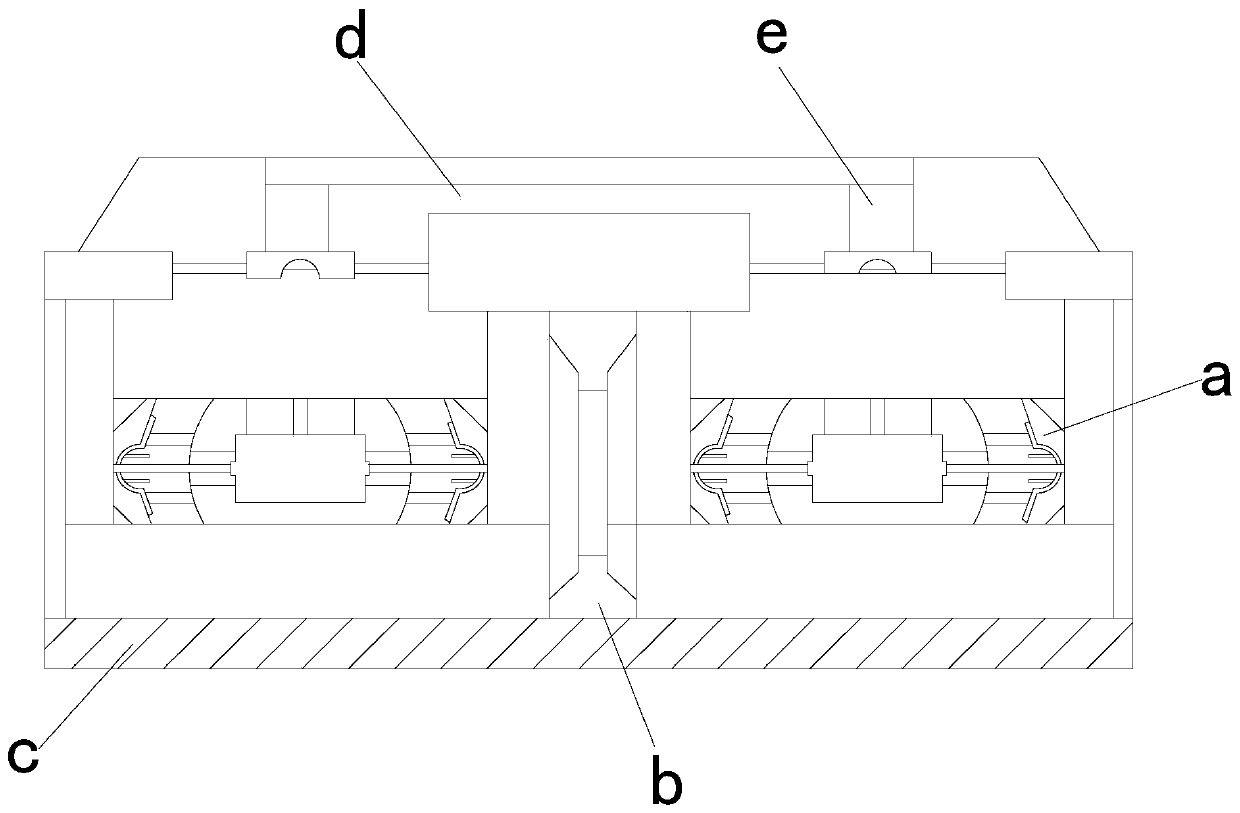

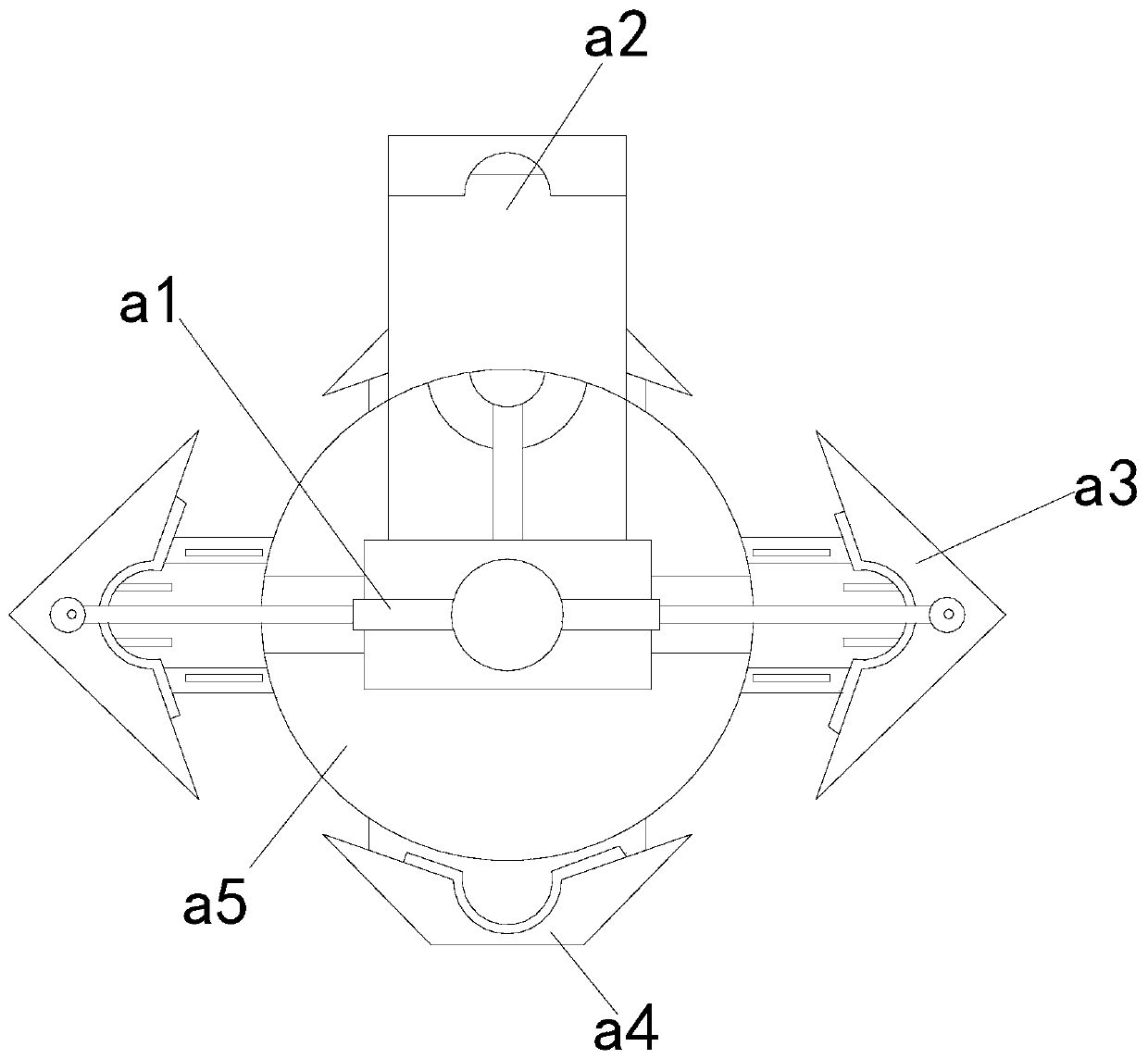

Waterproof tile cap sealing ring automatic assembling machine

InactiveCN106378619AImplement automatic assemblyReduce operating costsMetal working apparatusEngineeringTransverse beam

The invention relates to a waterproof tile cap sealing ring automatic assembling machine, in particular to the waterproof tile cap sealing ring automatic assembling machine. The waterproof tile cap sealing ring automatic assembling machine comprises an assembling machine base and an O-shaped sealing ring vibrating disk conveying assembly. The O-shaped sealing ring vibrating disk conveying assembly is arranged in the middle of the left side of the assembling machine base. A console is fixedly connected to the upper end of the assembling machine base through a supporting column, and a display screen is arranged on the vertical surface of one side of the console. A stand column is fixedly connected to the middle of the right side of the assembling machine base, a transverse beam is fixedly connected to the top end of the stand column, and vertical plates are fixedly connected to the two ends of the transverse beam respectively. Two sliding supporting rods are fixedly connected between the vertical plates, a moving base is movably installed on the sliding supporting rods, a first air cylinder is fixedly connected to the top end of the moving base, and a first telescopic shaft is movably connected to the center of the bottom end of the first air cylinder. The waterproof tile cap sealing ring automatic assembling machine is simple and reasonable in structure and high in practicability, is suitable for popularization and utilization, and greatly improves the assembling efficiency of O-shaped sealing rings of waterproof tile caps.

Owner:佛山市山金精密机械制造有限公司

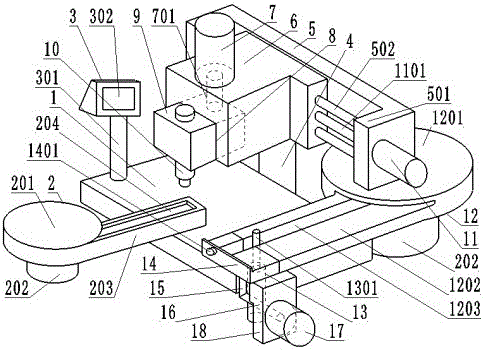

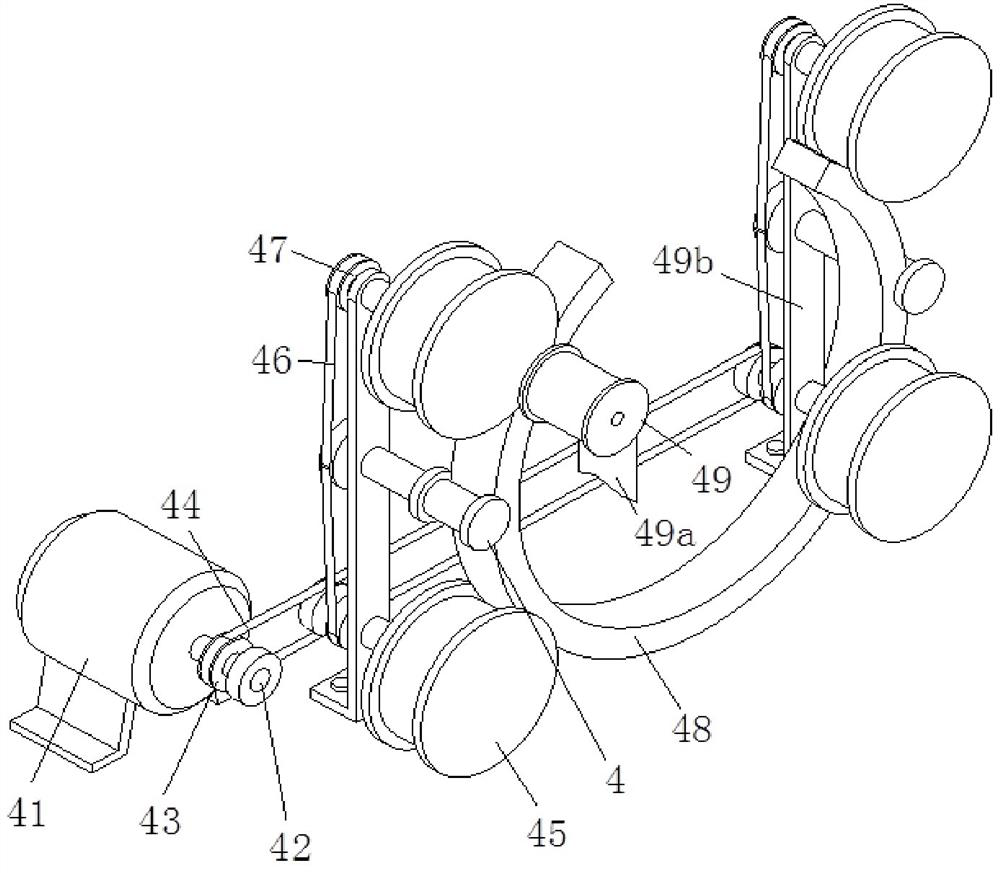

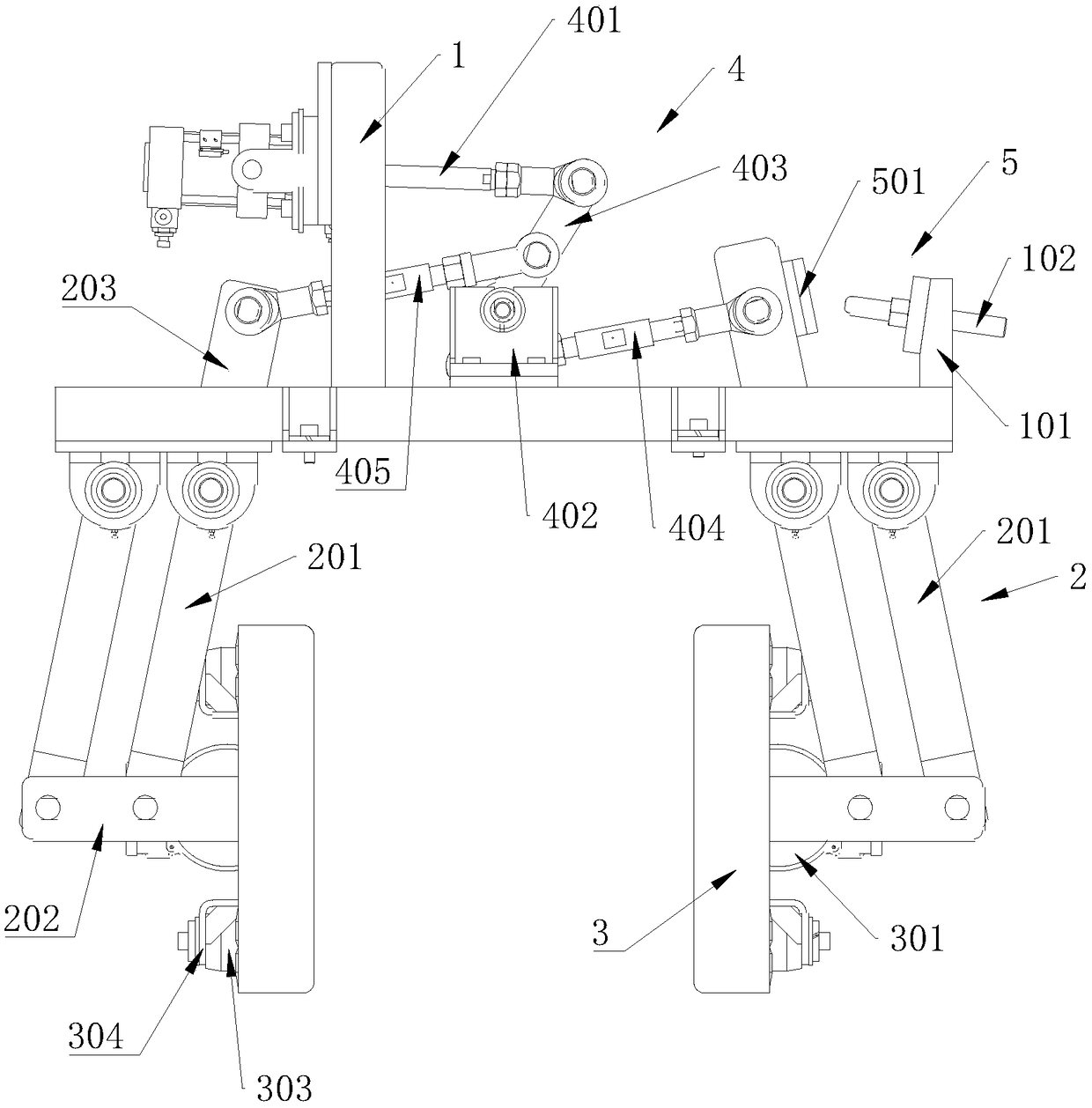

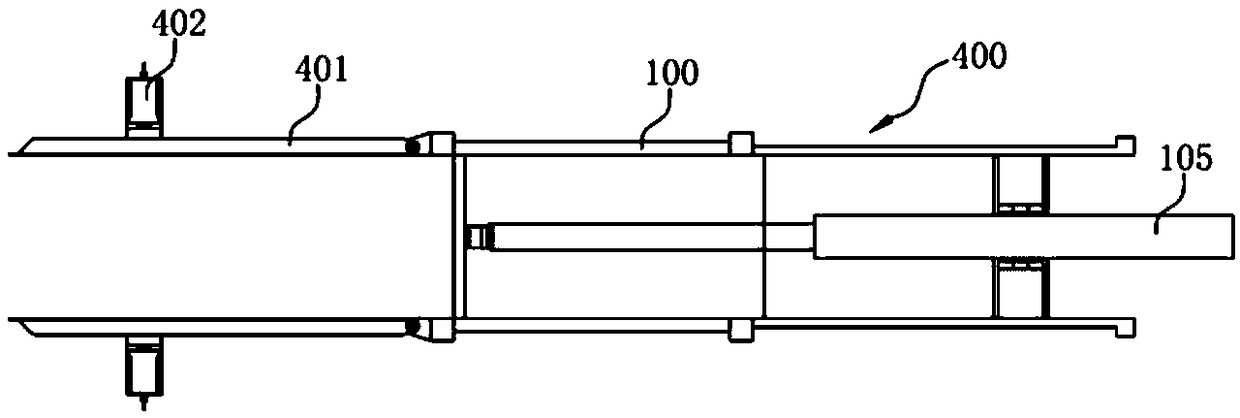

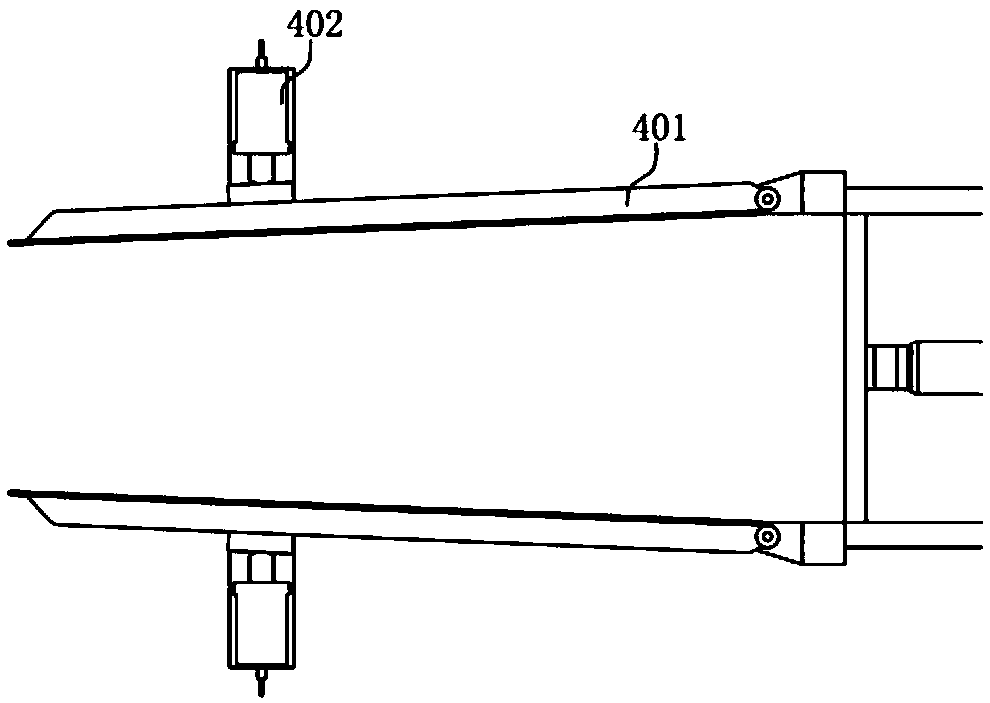

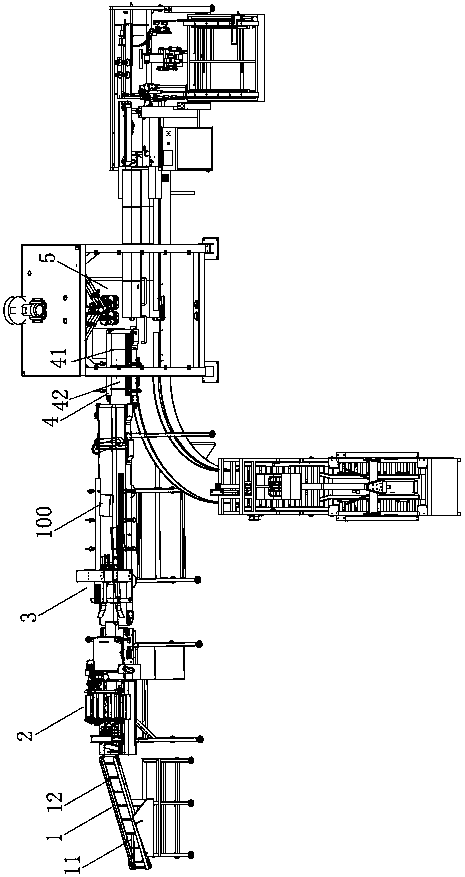

Horizontal pushing and side out type cigarette sorting machine and sorting method

PendingCN107618891ASimple sorting processSimple structureDe-stacking articlesLoading/unloadingEngineeringSmoke

The invention discloses a horizontal pushing and side out type cigarette sorting machine and sorting method. The cigarette sorting machine includes a conveying belt (1). A sorting base plate (2) is installed above the conveying belt (1). A smoke outlet (3) is formed in the sorting base plate (2). A sorting assembly (4) is installed on one side of the smoke outlet (3). A smoke storage warehouse (5)is installed above the sorting assembly (4). The sorting assembly (4) comprises a driving device (41) and the driving device (41) is connected with a connecting block (42). The connecting block (42)penetrates through a receding groove (43) formed in the sorting base plate (2) and is connected with a sliding block (44). The sliding block (44) is connected with the sorting base plate (2) through asliding rail (45). The sliding block (44) is also connected with one end of a smoke pushing rod (46). The horizontal pushing and side out type cigarette sorting machine has the characteristics of being simple in structure, low in cost, simple in working procedure and high in reliability.

Owner:GUIZHOU HUILIAN TECH LIMITED

Bending device for scrap steel plate recovery and method for recycling scrap steel plate by using device

The invention relates to a bending device for scrap steel plate recovery. A bending unit is used for bending scrap steel plates on a workbench. Under the natural condition, when a driving mechanism drives a stamping knife to move downwards, an extruding plate is driven by the driving mechanism to move to one side deviating from a left support plate, and a bearing plate is driven by the driving mechanism to move to one side close to the support plate. When the driving mechanism drives the stamping knife to move upwards, the extruding plate is driven by the driving mechanism to move to one sideclose to the left support plate, and the bearing plate is driven by the driving mechanism to move to one side deviating from the support plate. The bending device has the advantages of clever design and simple operation, effectively reduces the design cost and processing cost of the device, and is conducive to market promotion. The volume of the scrap steel plates recycled by the method is much smaller than before, and the recovery efficiency is increased by 30-40%.

Owner:江苏联航工贸有限公司

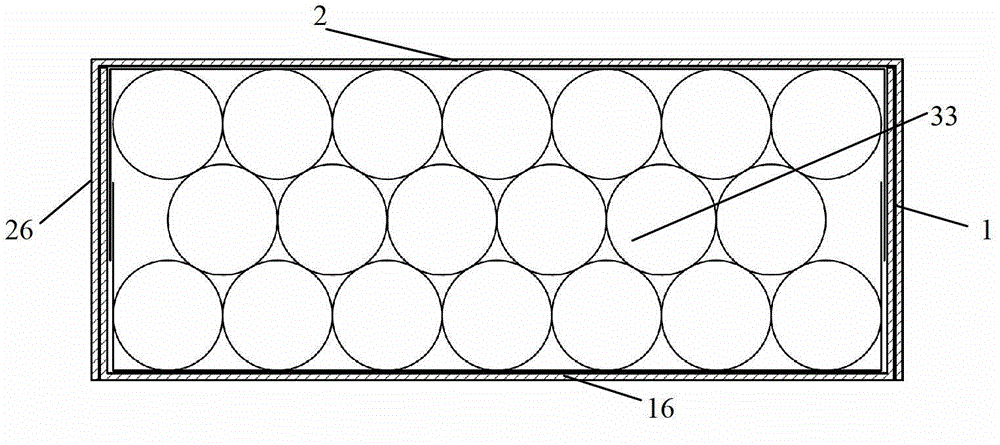

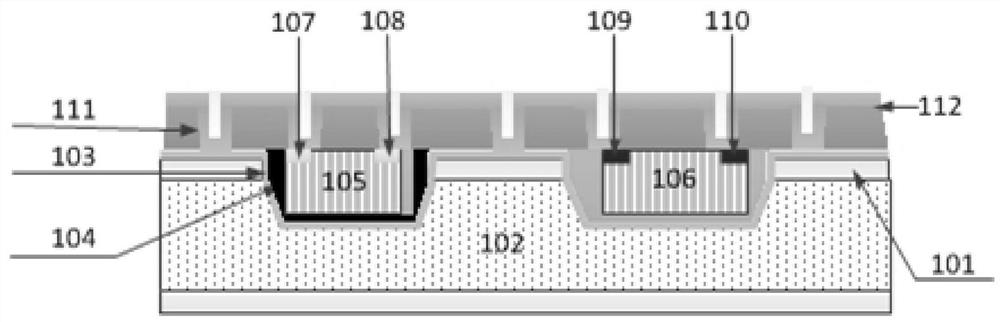

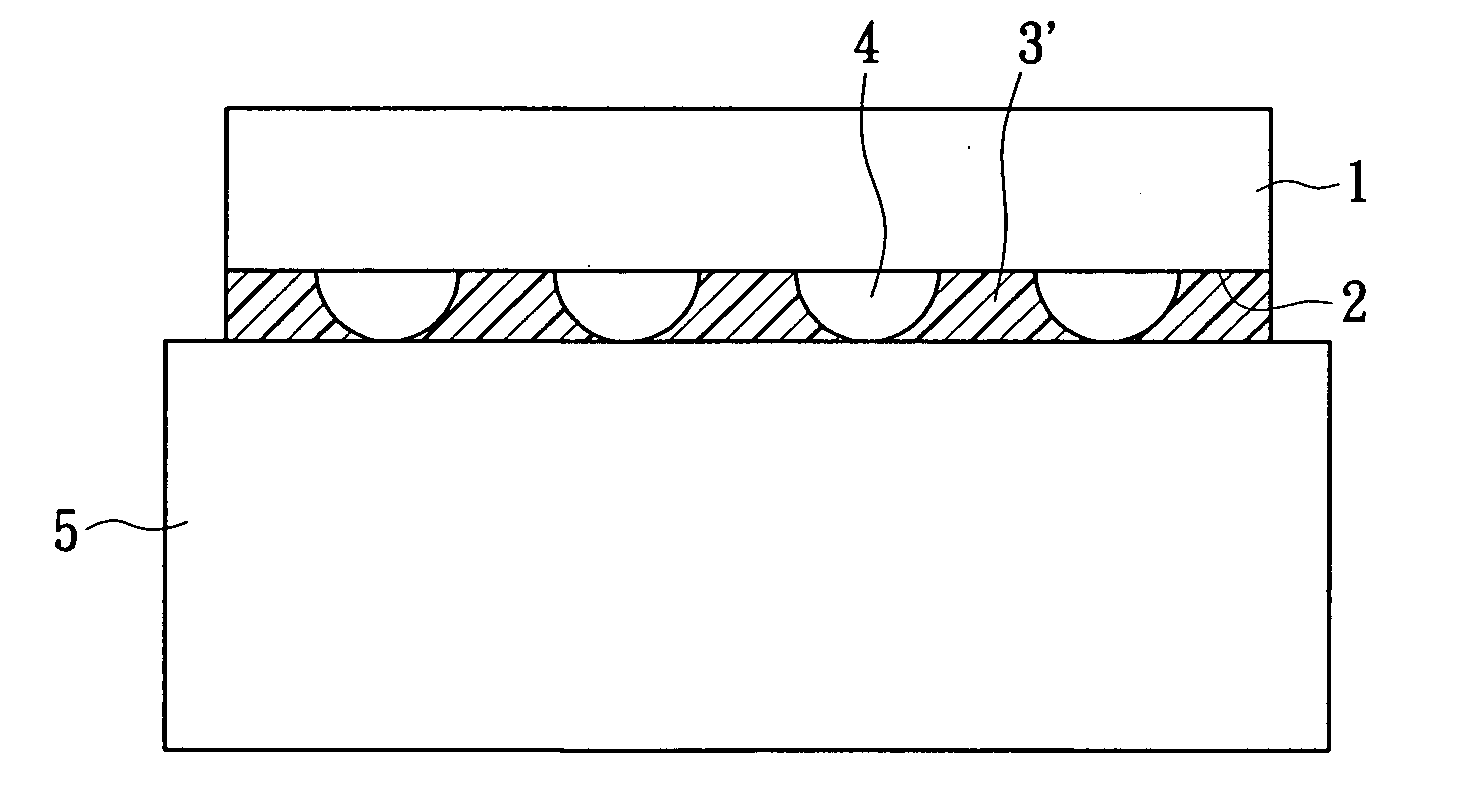

Packaging method of photovoltaic module and photovoltaic module

InactiveCN103000765AImprove photoelectric performanceOptimizing the packaging processFinal product manufacturePhotovoltaic energy generationBackplaneEngineering

The invention discloses a packaging method of a photovoltaic module. The method is used for sealing a battery piece and includes the following steps: stacking, namely tempered glass, a first bonding piece, the battery piece, a second bonding piece and rear panel glass are sequentially stacked from the bottom to the top to form a stacked piece, and the first bonding piece and the second bonding piece are both solid silica membranes; laminating, namely arranging the stacked piece in a laminating machine, vacuumizing and heating, bonding the tempered glass, the first bonding piece, the battery piece, the second bonding piece and the rear panel glass to form a laminated piece, cooling, and taking the laminated piece out; and framing the laminated piece to obtain the photovoltaic module. By means of an embodiment of the packaging method, the photoelectric property, weather fastness and reliability of the photovoltaic module can be improved, the service life of the module is prolonged, the module cost is reduced, and packaging process is optimized. In addition, the invention further discloses the photovoltaic module packaged through the packaging method.

Owner:赛维LDK太阳能高科技(南昌)有限公司

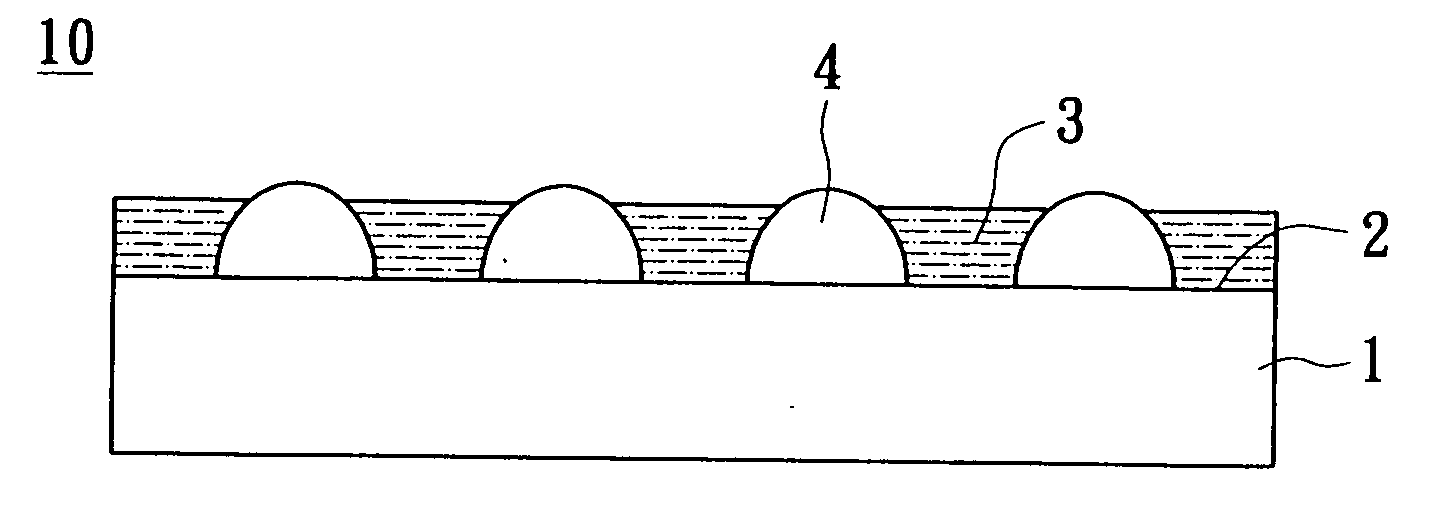

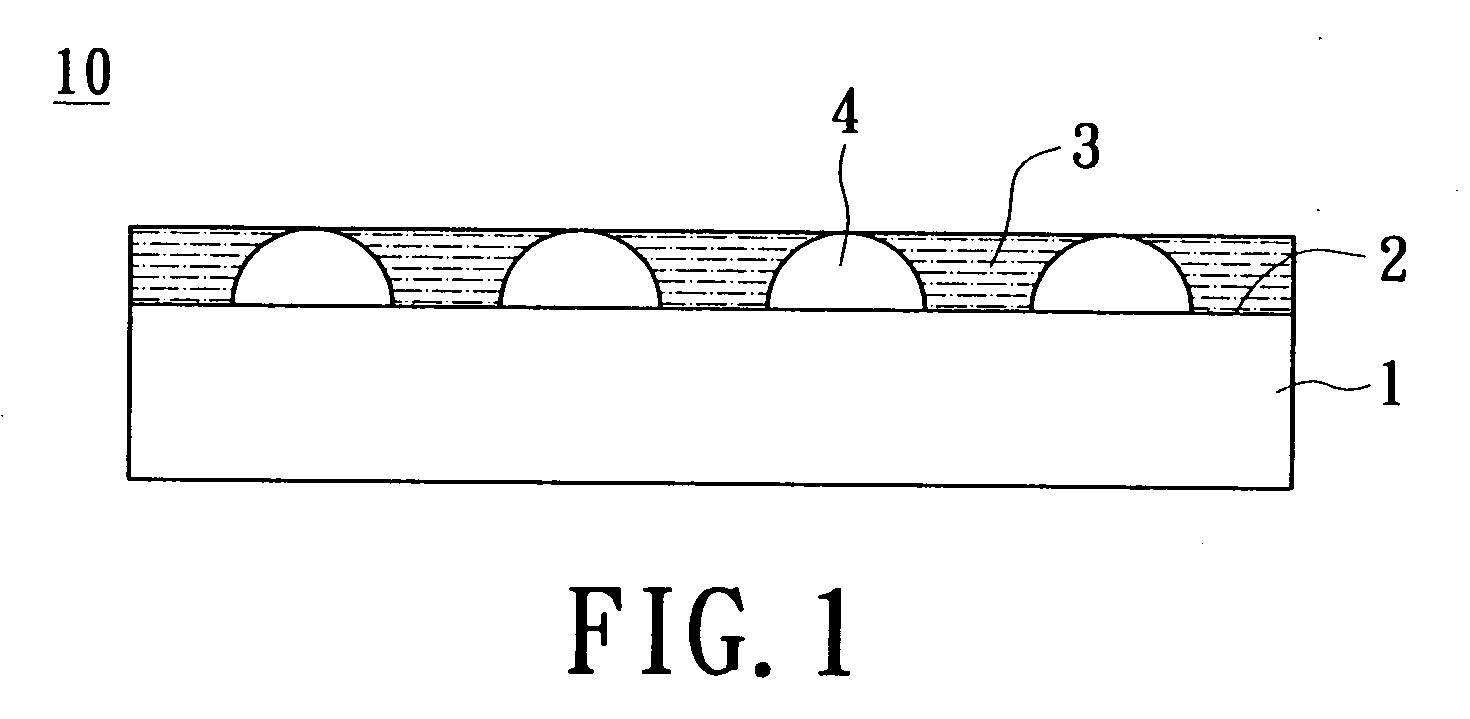

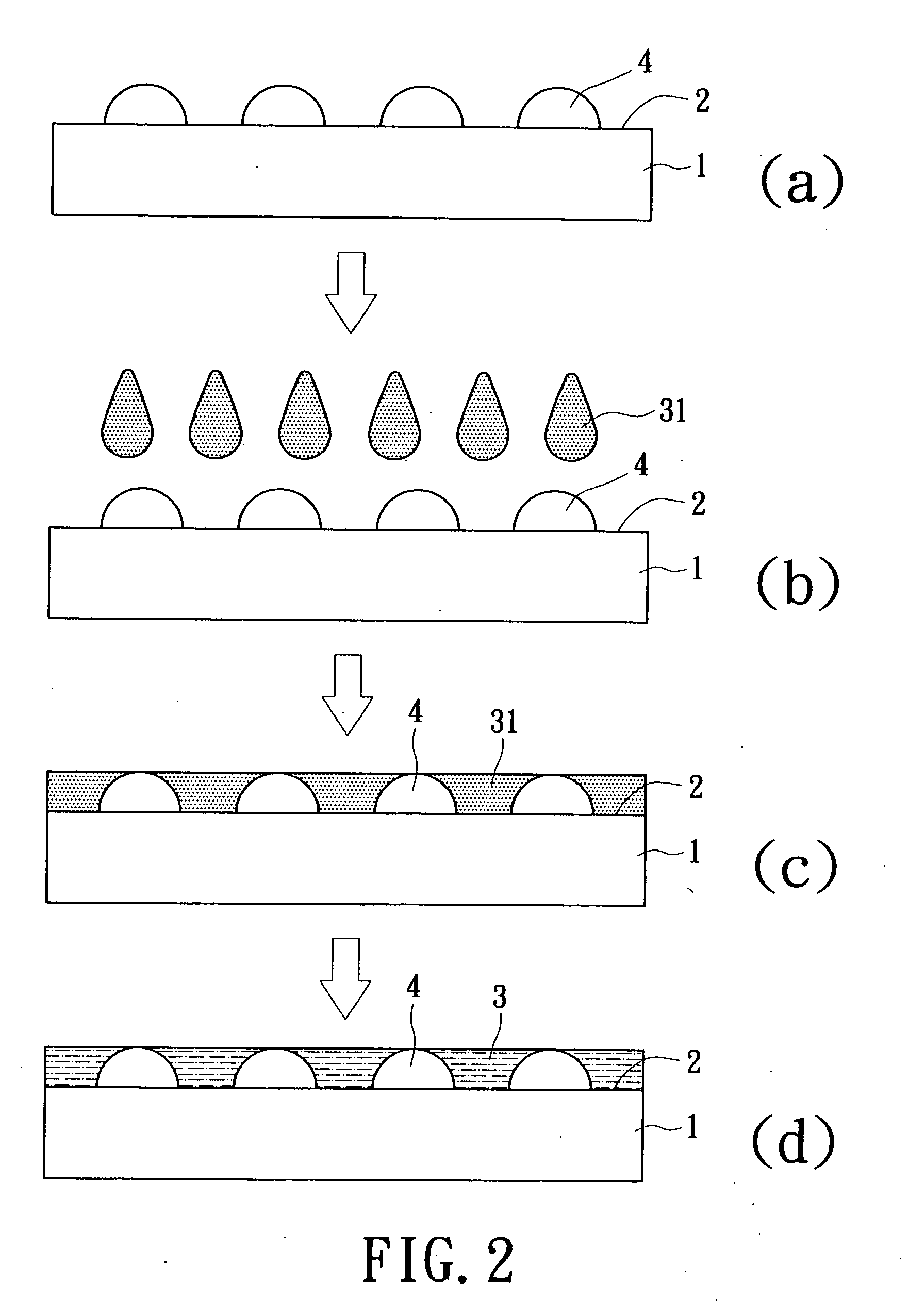

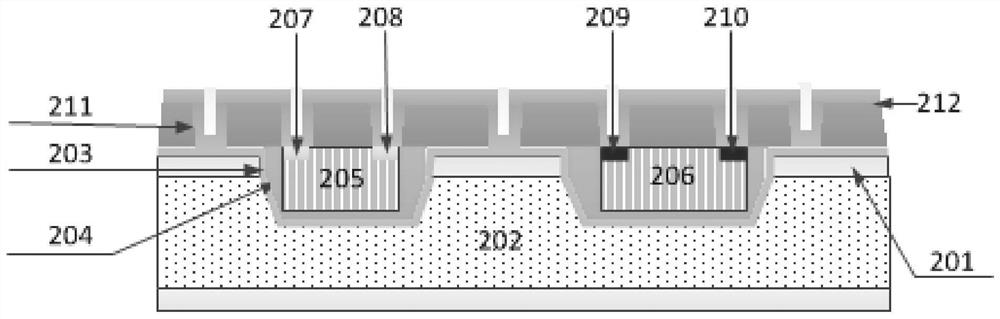

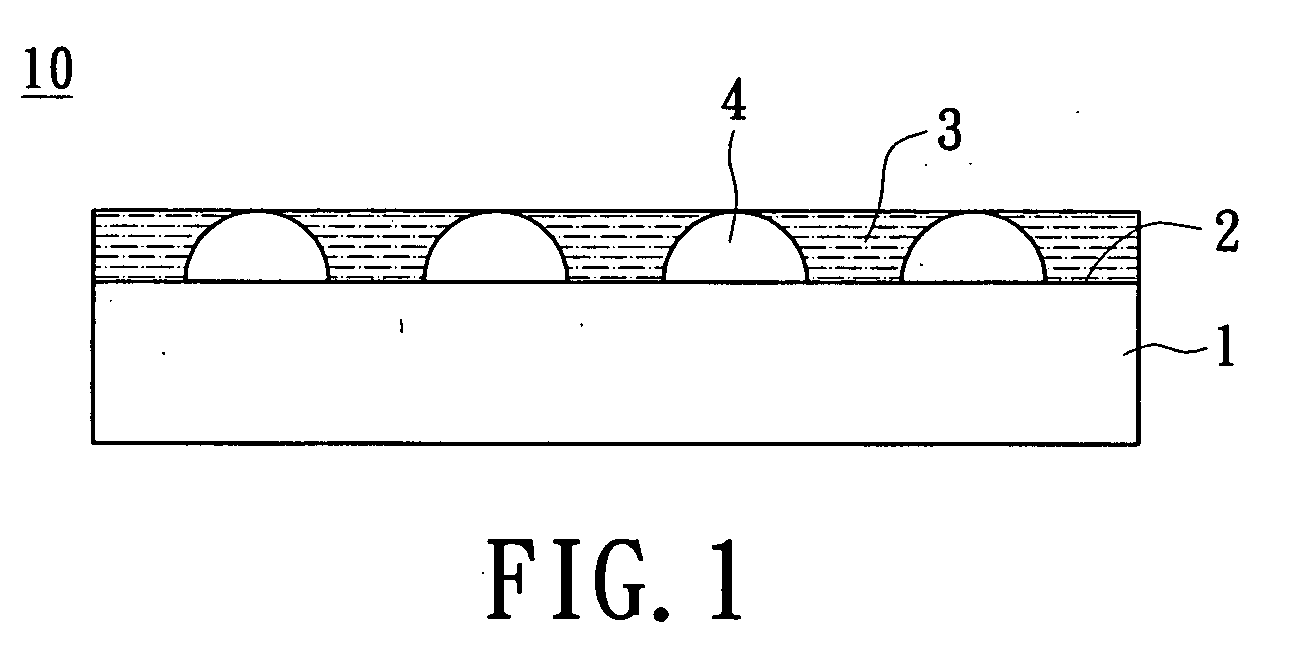

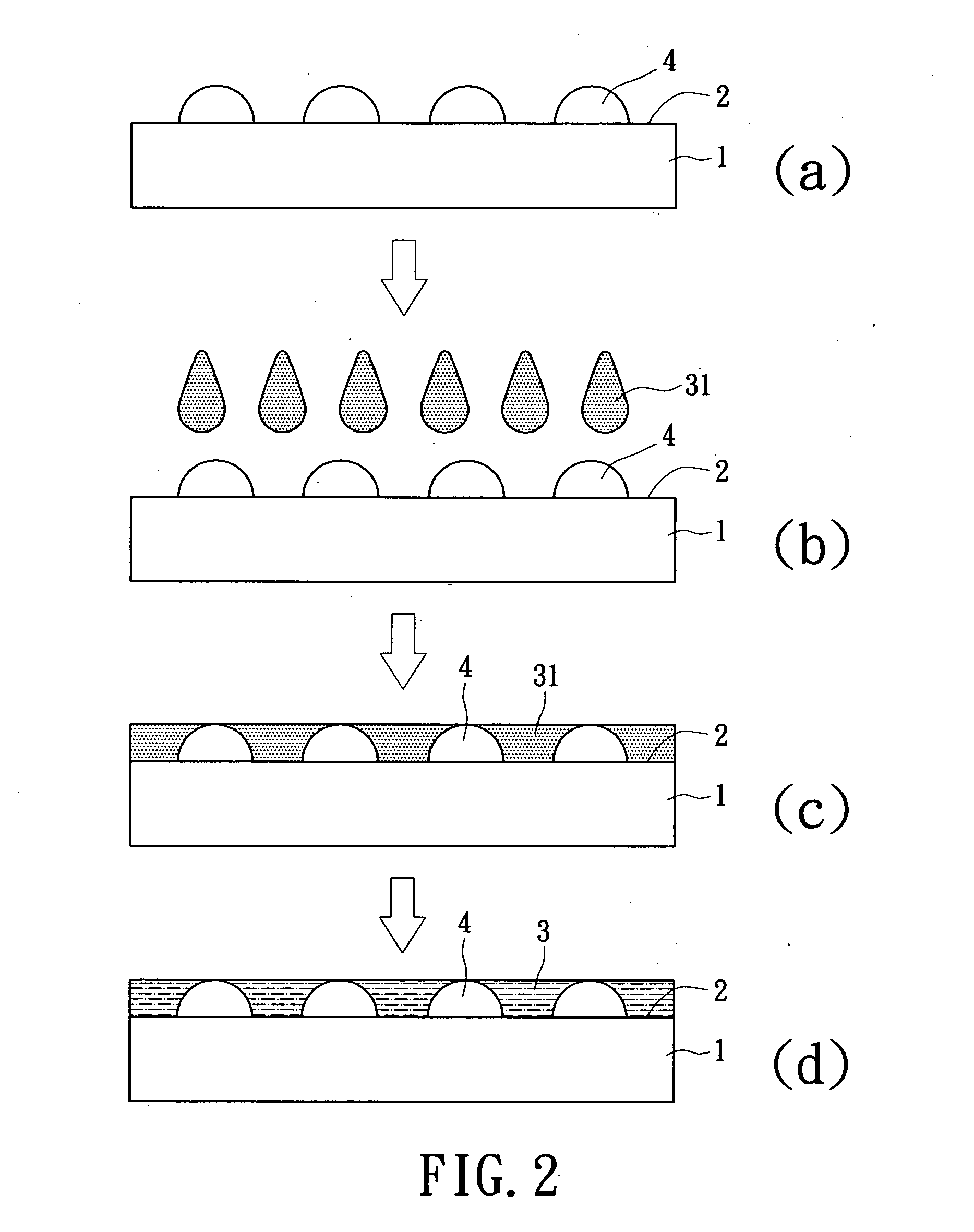

Packaging structure, method for manufacturing the same, and method for using the same

InactiveUS20090179327A1Improve packaging efficiencyImprove connection reliabilitySemiconductor/solid-state device detailsSolid-state devicesSurface mountingEngineering

A packaging structure applied for a surface mounting process, comprising: a chip module having a packaging surface; and a pre-cured layer formed on the packaging surface of the chip module. As above-mentioned, the structure is employed for protecting the external surface of the wafer. The pre-cured layer is formed on pre-curing a gluing material and the gluing material is uniformly filled with the space between the connecting protrusions on the packaging surface. The pre-cured later is post-curing in a connecting process for mounting the connecting protrusions to the substrate so that the connecting strength is improved. Moreover, the rate of the packaging process is increasing.

Owner:ANHUI HAIHUA CHEM

Magnetic shoe apparent defect detection machine and method for implementing same

The invention discloses a magnetic shoe apparent defect detection machine which comprises a framework, a dynamic identification robot and a first robot. A first belt line is arranged at an outlet endof a washing machine, an outer cambered surface detection device is fixedly connected with a side edge of the first belt line, a second robot is arranged at a side edge of the first belt line, a firstdetection unit is arranged above the first belt line, a wide belt conveyor line is arranged at an outlet end of the first belt line, a second detection unit is fixedly connected onto the framework and is positioned above the wide belt conveyor line, a third robot is arranged at a side edge of the wide belt conveyor line, and a discharge device is arranged at an outlet end of the wide belt conveyor line; a controller is in signal connection with the dynamic identification camera, the first robot, the outer cambered surface detection device, the second robot, the first detection unit, the second detection unit, the third robot and the discharge device. The invention further discloses a method for implementing the magnetic shoe apparent defect detection machine. The magnetic shoe apparent defect detection machine and the method have the advantages of simple structure, low manufacturing cost, high production efficiency, good detection quality, capability of saving labor and the like.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

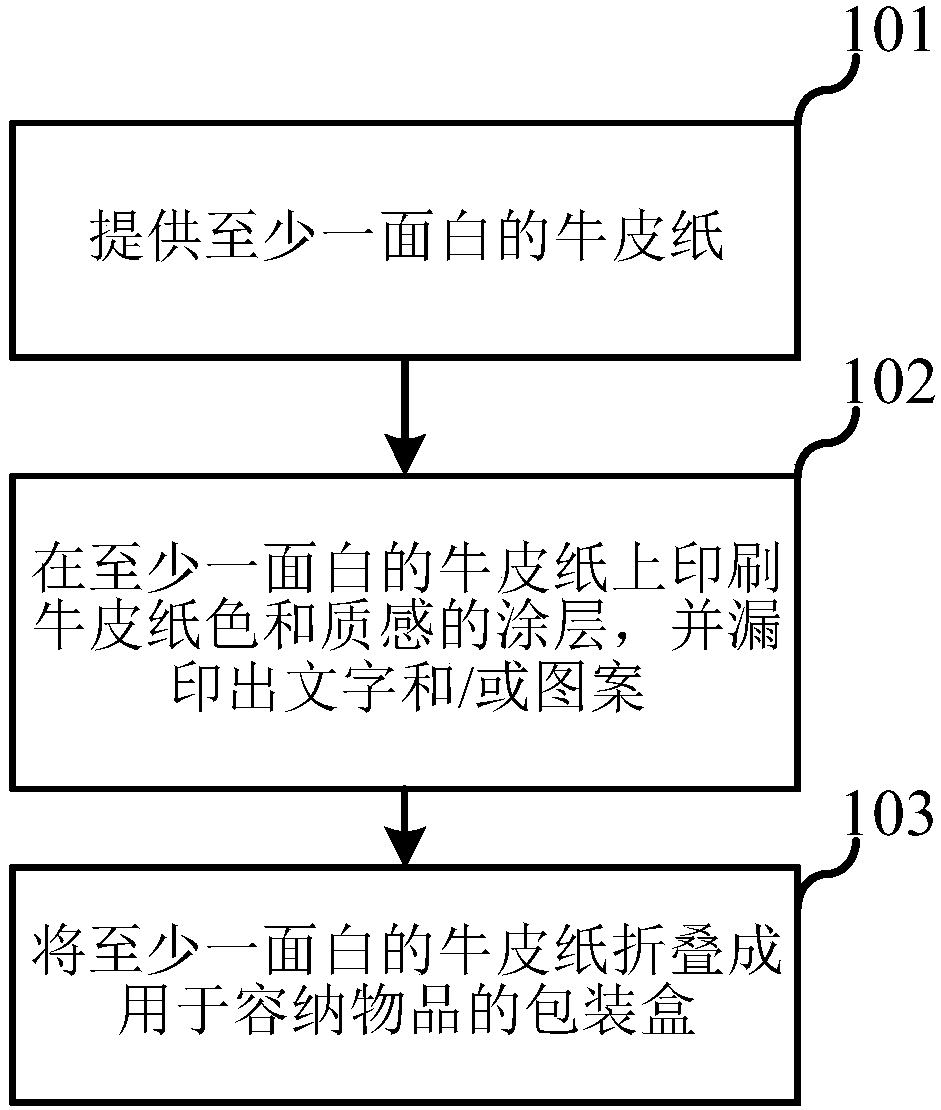

Manufacturing method of object packaging box and object packaging box

InactiveCN106144118ARealistic coating effectIncrease salesContainer decorationsLevel indicationsEnvironmentally friendlyPackaging Case

The invention discloses a manufacturing method of an object packaging box and the object packaging box. The manufacturing method of the object packaging box comprises the following steps that a piece of kraft paper with at least one white face is provided; and a coating with the kraft paper color and texture is printed on the kraft paper with at least one white face, characters and / or patterns are printed in a through printing mode, and the kraft paper with at least one white face is folded into the packaging box used for containing objects. The object packaging box is manufactured through the manufacturing method of the object packaging box. Compared with the prior art, the vivid deep-color kraft paper coating effect is achieved, the high-purity white color is represented through the natural color of the through-printed kraft paper with at least one white face, the distinct-level kraft paper bottom white character effect is achieved finally, and the problem of printing of high-purity white color on the surface of the deep-color kraft paper is solved. Due to the utilization of the material of the kraft paper, the object packaging box is more environmentally friendly, concise and high-graded, thereby promoting selling.

Owner:KOHLER CHINA INVESTMENT

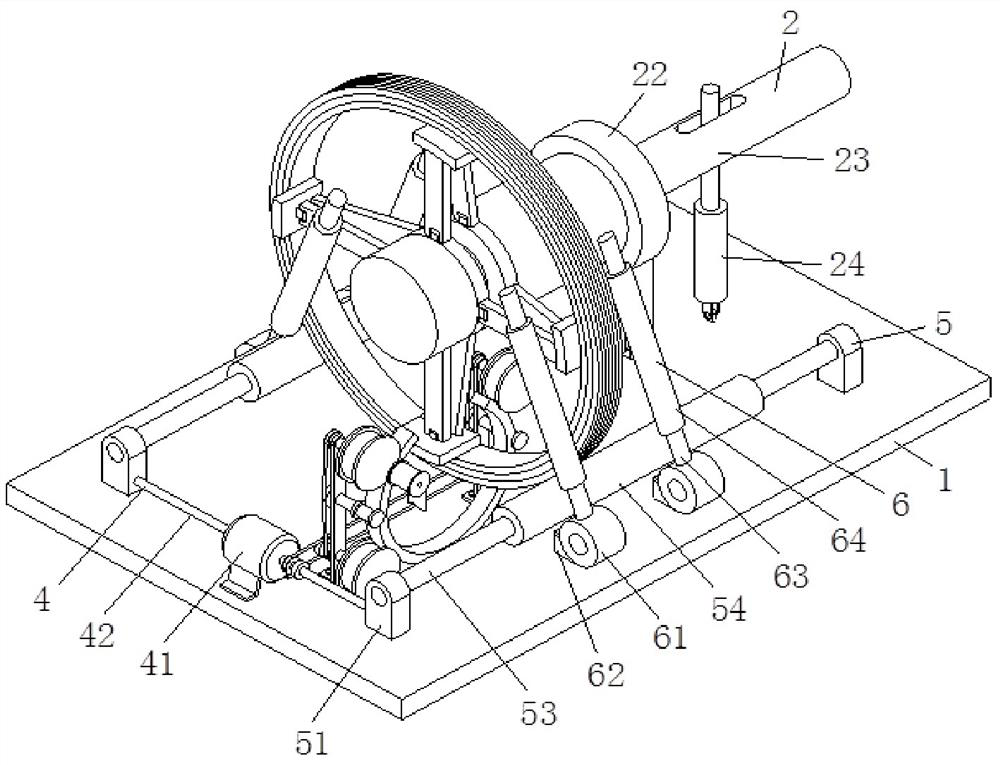

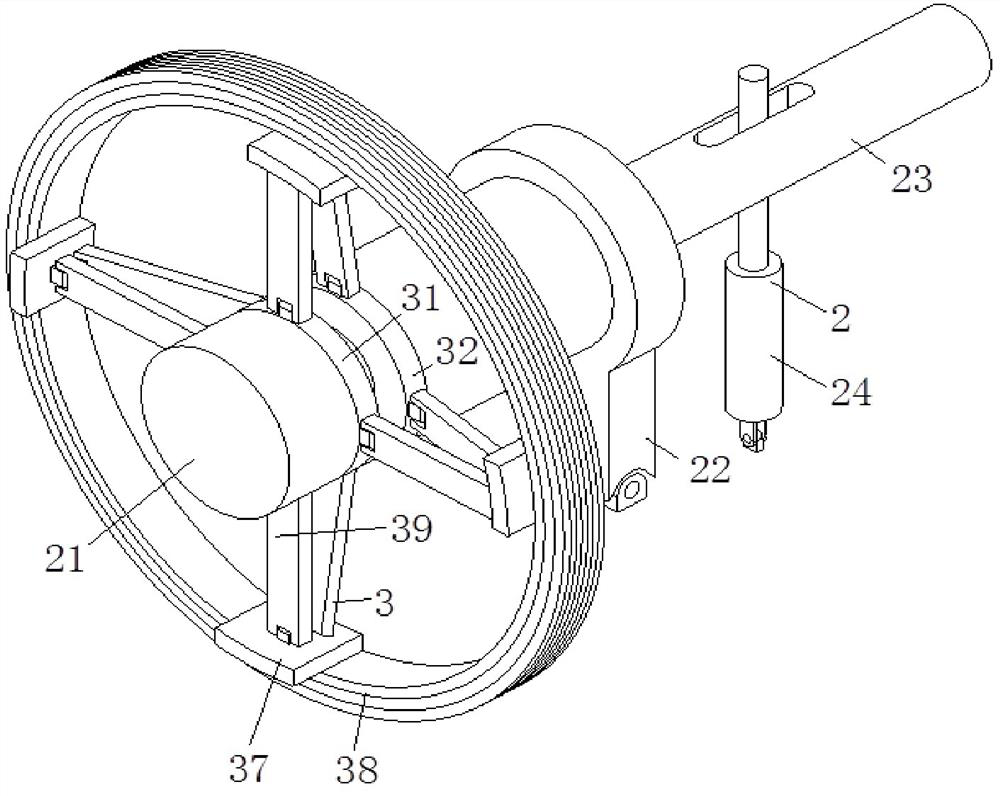

Power cable packaging equipment

InactiveCN114368502AEasy accessEasy to installWeb rotation wrappingPackaging automatic controlPower cableStructural engineering

The invention relates to the field of cable packaging equipment, in particular to power cable packaging equipment which comprises a base, a discharging mechanism is arranged on the base, a tensioning mechanism is installed on the discharging mechanism, a packaging mechanism is installed on the base, an auxiliary mechanism is connected to the packaging mechanism, and the packaging mechanism drives the auxiliary mechanism. A correction mechanism is mounted on the base; a cable roll can be conveniently wound through the packaging mechanism, winding and packaging are uniform in speed and orderly, and the attractiveness after packaging is improved; through the arrangement of the auxiliary mechanism, when the packaging mechanism is started, the cable roll is synchronously driven to rotate at a constant speed, and the cable roll is conveniently packaged in all directions by being matched with the winding packaging speed; through the arrangement of the correction mechanism, the cable roll can be prevented from being separated from the tensioning mechanism during rotation, the cable roll is prevented from toppling over and hurting people, and the safety during packaging operation is improved.

Owner:徐州华隆热电有限公司

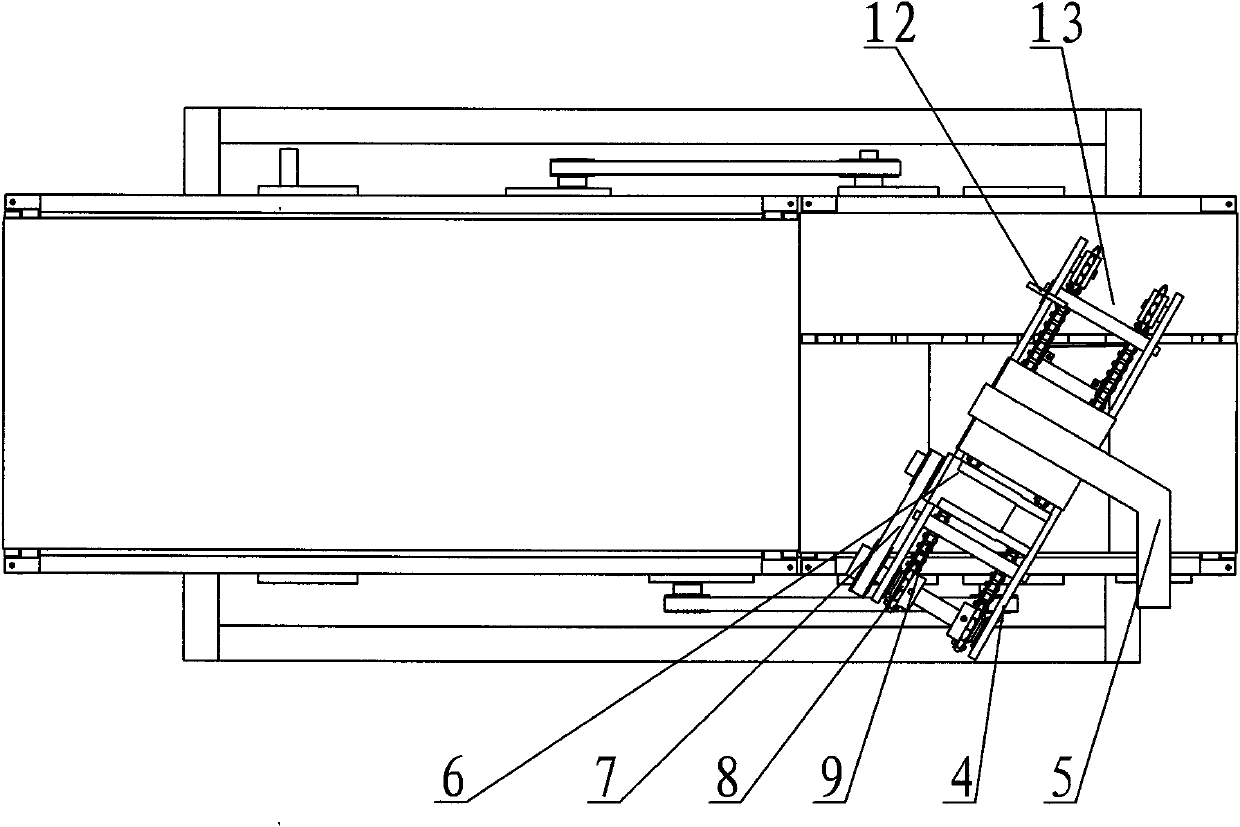

Chinese bacon slicing device capable of achieving automatic loading and unloading

ActiveCN111482993AAvoid stockpilingIncrease weightMetal working apparatusStructural engineeringConveyor belt

The invention relates to the technical field of food machinery, and discloses a Chinese bacon slicing device capable of achieving automatic loading and unloading. A pushing device is arranged at one end of a feeding platform of a slicing machine, a loading device is arranged above a side of the pushing device, a slicing device is arranged at the other end of the feeding platform of the slicing machine, and an unloading device is arranged below the slicing device. The loading device comprises a loading channel, a loading part communicating with the loading channel and a fixing support connectedwith the feeding platform, and the fixing support is connected with the loading part. The loading device comprises a loading roller and a first control mechanism capable of driving the loading rollerto rotate, and an inlet and outlet is formed in the length direction of the loading roller. The unloading device comprises a vibration channel and a conveyor belt communicating with the vibration channel. The production system has the advantages that manual continuous loading can be avoided, manual processing time can be reduced, and a slicing procedure can be continuously and stably carried out.

Owner:四川道泉老坛酸菜股份有限公司

Equipment for large-batch production of anti-cracking double-layer sandwich rice cakes

InactiveCN107319320AIncrease productivityAvoid sticking to each otherFood scienceBatch productionAgricultural engineering

The invention discloses a device for mass production of anti-cracking double-layer sandwich rice cakes, which comprises a first conveyor belt and a second conveyor belt. The first rice cake extruder for extruding the second rice cake strip, the second rice cake extruder for extruding the third rice cake strip, and the third rice cake extruder for extruding the third rice cake strip, the first rice cake strip, the second rice cake extruder The rice cake strips and the third rice cake strips are arranged sequentially from bottom to top; a first powder spreading device is arranged above the first rice cake strips on the left side of the second rice cake strips, and a first pulse powder is provided on the left side of the first powder spreading device. clean water nozzle. The invention has reasonable structural design, convenient use, and can mass-produce rice cake strips with auxiliary material sandwiches, and the auxiliary materials are spread evenly, reducing the chance of cracking, improving the quality of rice cakes, and can quickly realize the cutting, cooling and packaging of sandwich rice cake strips without difficulty. Bonding, improve production efficiency.

Owner:李一鸣

Sugar block finishing conveying device

PendingCN108639464AReasonable designSimple structurePackaging automatic controlPulp and paper industrySugar

The invention relates to a sugar block finishing conveying device. The device comprises a conveying device, wherein the conveying device comprises a conveyor belt, and the sugar block is conveyed through the conveyor belt; the device further comprises an industrial vision camera and a selection device, wherein the industrial vision camera and the selection device are arranged on the conveying device in sequence in the conveying direction of the conveyor belt, the conveying device is further provided with a trigger switch, the trigger switch corresponds to the industrial vision camera, the trigger switch detects the sugar block, the trigger switch is connected with the industrial vision camera, and the industrial vision camera is connected to the selection device. The sugar block finishingconveying device has the advantages that the design is reasonable, the structure is simple, the sugar block can be automatically examined and finished, the time and labor are reduced, the efficiency is high, the sugar block is not missed easily, and convenience is provided for the subsequent packaging process.

Owner:RUGAO PACKING FOOD MACHINERY

Shaping device for bagged power

The invention discloses a shaping device for bagged power. The shaping device comprises a support frame, the support frame is provided with two swing frames which are arranged in a mirrored mode, oneclose end of each swing frame is correspondingly provided with a plastic board; the support frame is provided with a synchronous drive mechanism, the synchronous drive mechanism is connected with bothtwo swing frames. A packing bag containing powder is transmitted to the shaping boards, then the synchronous drive mechanism drives the two swing frames arranged in mirror to do synchronization action and make the two shaping boards close up, and the two closing shaping boards squeeze the packing bag containing power to make a difference of the size of the packaging bag, and the shaping operationof the packaging bag is finished, then encasement process is conducted. The shaping device for the bagged powder is used for mechanized shaping operation of the packing bag containing the power. Notonly is operation efficiency greatly improved, but also labor intensity of operators is reduced efficiently, meanwhile, the number of employment and labor cost are greatly reduced.

Owner:JIANGSU HAGONG PHARMA MACHINE TECH CO LTD

Bag body sealing detection module, detection device and detection method

PendingCN114414172AAvoid damageMovement precisionMeasurement of fluid loss/gain rateEngineeringPressure balance

The invention discloses a bag body sealing detection module, a detection device and a detection method, a bag body is provided with a connecting pipe communicated with the bag body, the bag body sealing detection module comprises a support, a detection module and a control module, and the support is provided with a bag body placing groove for placing the bag body; the air inflation mechanism comprises a sealing air inflation connector connected with an air source and a pipe body fixing position for fixing the connecting pipe, and the sealing air inflation connector is in butt joint with the connecting pipe to inflate the connecting pipe and the bag body; the pipe pressing mechanism comprises a pipe clamp, and the pipe clamp is used for blocking communication between the connecting pipe and the bag body; and the pressing plate mechanism comprises a limiting stable pressing plate, and the limiting stable pressing plate can be pressed on the bag body and is used for carrying out expansion limiting when the medicine bag is inflated and carrying out pressure balance after the medicine bag is inflated. The device can complete the detection of the sealing performance of the bag body and the connecting pipe at the same time, is high in automation degree, reduces the labor intensity, and improves the efficiency.

Owner:珠海福尼亚医疗设备有限公司

A waterproof tile cap sealing ring automatic assembly machine

InactiveCN106378619BImplement automatic assemblyReduce operating costsMetal working apparatusEngineeringAssembly machine

Owner:佛山市山金精密机械制造有限公司

Side discharging horizontal type packer

PendingCN108820397AReasonable optimization and adjustmentEasy to adjustPackaging machinesOutput deviceEngineering

The invention belongs to the technical field of packers and provides a side discharging horizontal type packer which comprises a rack, a package output opening, a cabin door and a rear baffle. A packing cavity is formed in the rack. The front end of the packing cavity is provided with a feeding opening and a pushing disc assembly. The package output opening is formed in the side portion of the rear end of the packing cavity. The cabin door is arranged in the manner of corresponding to the package output opening. The rear baffle is arranged on the rear portion of the packing cavity and corresponds to the pushing disc assembly. The rear baffle is provided with a package output device corresponding to the package output opening. The packer is reasonable in overall structural design, by meansof side arranging of the package output opening, the structural design of the cabin door and the design of the package output device, optimization of the effective operation area of the whole machineis achieved, compared with a traditional blocking door type packer, the occupied area can be reduced by over 40%, the foundation investment of clients is reduced, optimization and adjustment of the whole operation area are more reasonable, and collaborative operation of all working procedures of a whole packing system is facilitated.

Owner:ZHENGZHOU XIELI CONSTR EQUIP

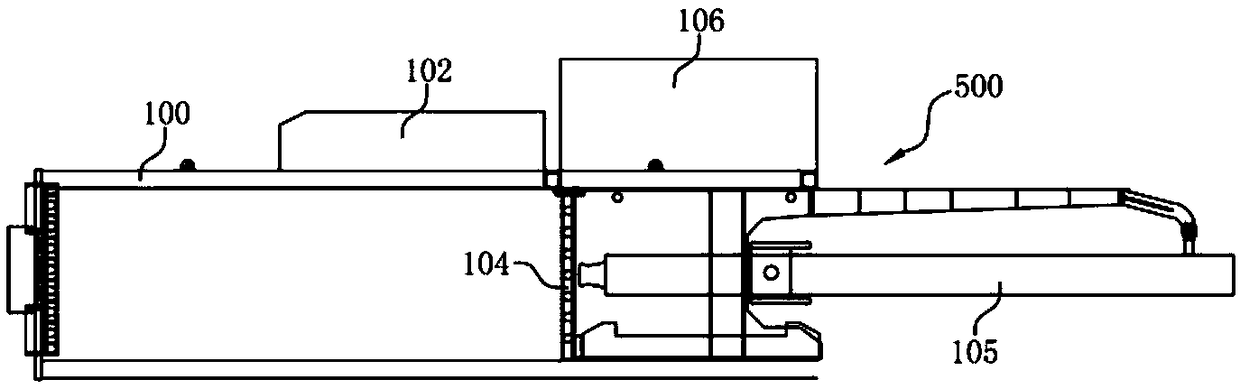

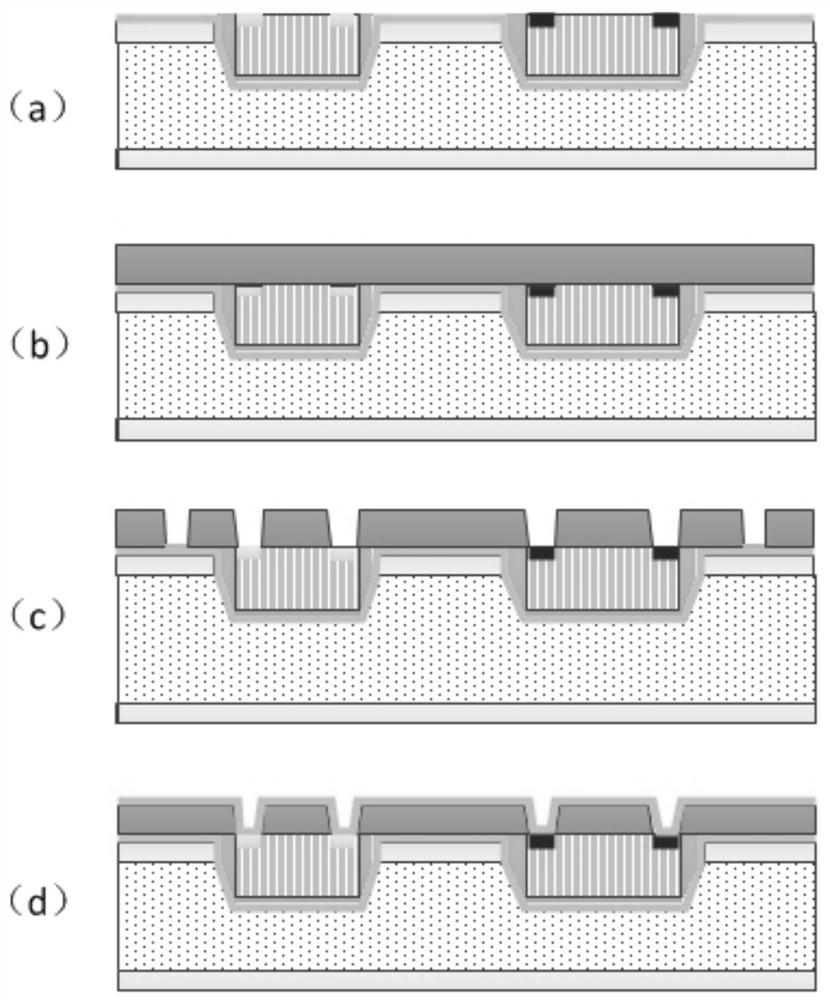

Method and device for reducing positional deviation between chip embedding and photolithographic pattern

ActiveCN110517961BThe process steps are simpleOptimizing the packaging processSemiconductor/solid-state device testing/measurementSolid-state devicesEmbedded systemPhotoresist

The method and device for reducing the positional deviation between chip embedding and photolithographic patterns of the present invention comprise the following steps: Step 1, embedding a chip on a substrate; Step 2, obtaining measurement data of the chip; Step 3, using the measurement data to draw an upper layer pattern The photolithographic mask layout; step 4, to obtain the upper layer graphics. Compared with the prior art, the present invention has the following beneficial effects: after embedding the chip, use precision observation equipment to measure the size and relative position of the chip and its pins, and then use the measured data or pictures to draw a photoresist mask , to solve the problem of short circuit or open circuit between the chip pin and the photoresist pattern on the upper layer caused by the error of chip embedding; the process steps added by the present invention are simple, and the wafer level heterogeneity is greatly improved. Integrated packaging process.

Owner:SHANGHAI JIAO TONG UNIV

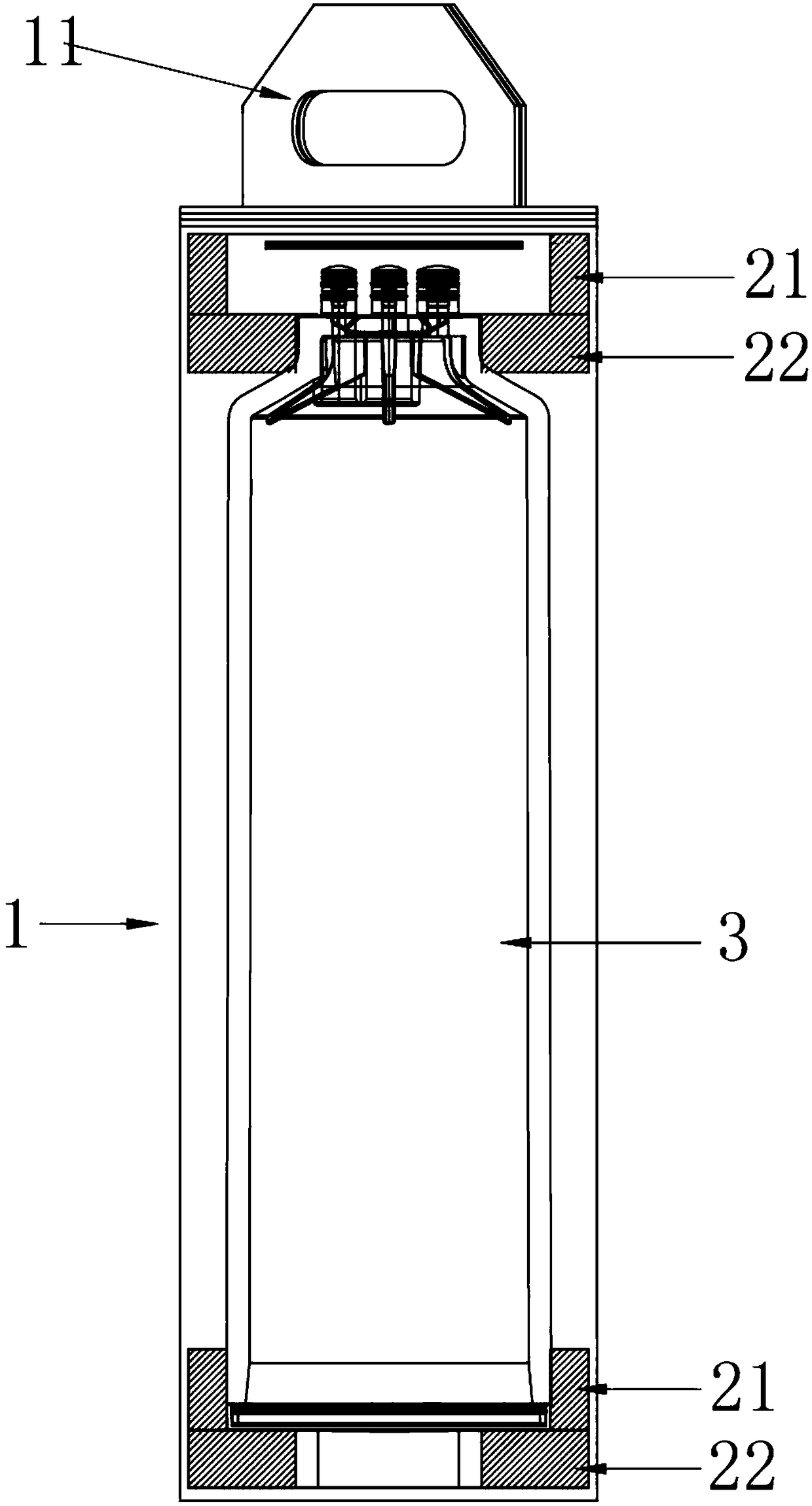

Medical detection equipment convenient for medical injectors and use method of medical detection equipment

The invention relates to the technical field of detection equipment, and discloses medical detection equipment convenient for medical injectors. A mounting plate is included, two supporting columns are welded to the top of the mounting plate, limiting blocks are welded to the tops of the supporting columns, the surfaces of the limiting blocks communicate with a feeding pipe, the inner walls of the limiting blocks are movably connected with a turntable, a detection mechanism and a transmission mechanism are arranged at the top of the mounting plate, the supporting columns are located between the detection mechanism and the transmission mechanism, and a feeding frame, a qualified product frame and a defective product frame are fixedly mounted at the top of the mounting plate. Whether piston rods or needle heads on the injectors are installed or not can be detected at the same time through the detection mechanism, so that the piston rods or the needle heads can be detected together in one working procedure, the cost investment can be reduced, meanwhile, manual detection and feeding are replaced with the detection mechanism and the transmission mechanism, the labor intensity of workers is reduced, and the labor cost is reduced.

Owner:邵欠欠

Separated boxing production method

ActiveCN110525722AAchieve flatteningRealize the effect of continuous lane separationPackaging automatic controlConveyor partsReciprocating motionFood packaging

The invention belongs to the technical field of food packaging, and particularly relates to a separated boxing production method which comprises the following steps: step 1, transversely removing bagsof bagged food and flattening and pressing the bagged food; step 2, carrying out orientation correction and separation on the bagged food through continuous swing of separation channels; step 3, preliminarily arranging the bagged food obtained after the separation; and step 4, grabbing the preliminarily arranged bagged food into a packaging box. According to the invention, bagged food can be flattened, transversely-packaged bagged food is removed, the direction of inclined bagged food is corrected, the bagged food is made to be in a vertically-packaged state as much as possible, and meanwhilethe effect that single-row bagged food is continuously divided into channels can be achieved. A separation channel is formed between the two oppositely-arranged separation side plates, the rear portions of the two separation side plates are driven by the power part to do left-right reciprocating motion, and therefore separation of bagged food is achieved.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

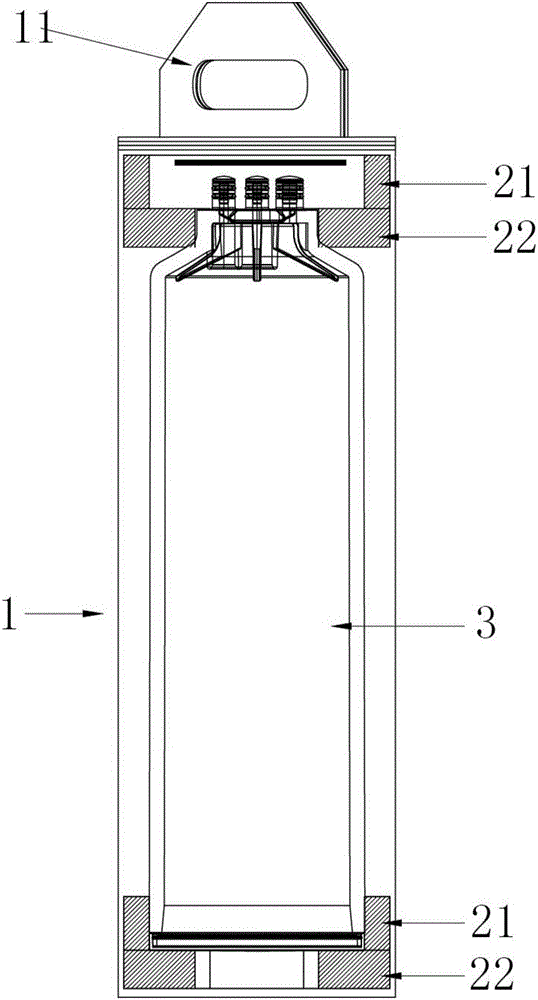

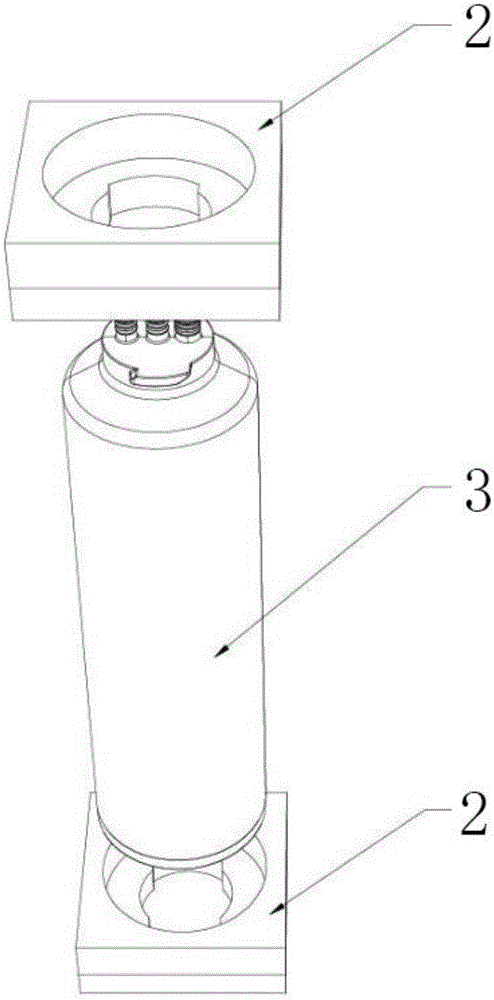

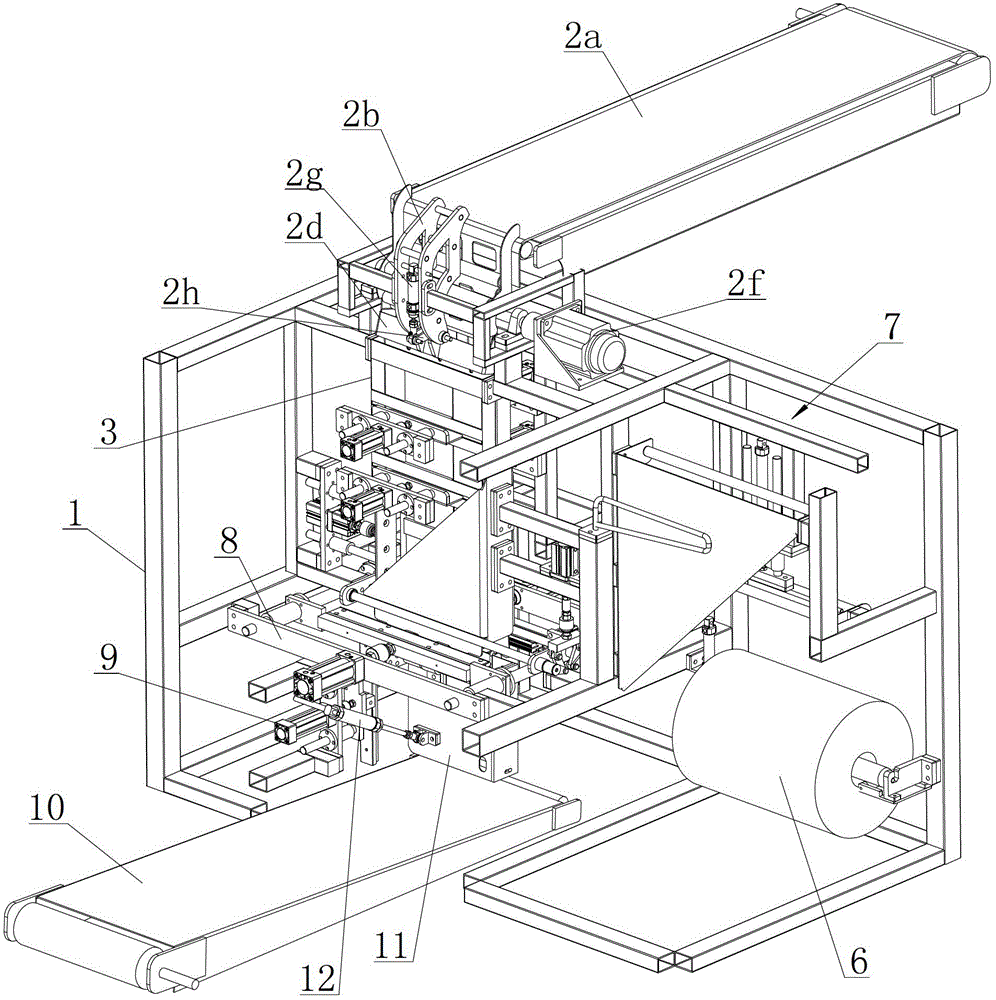

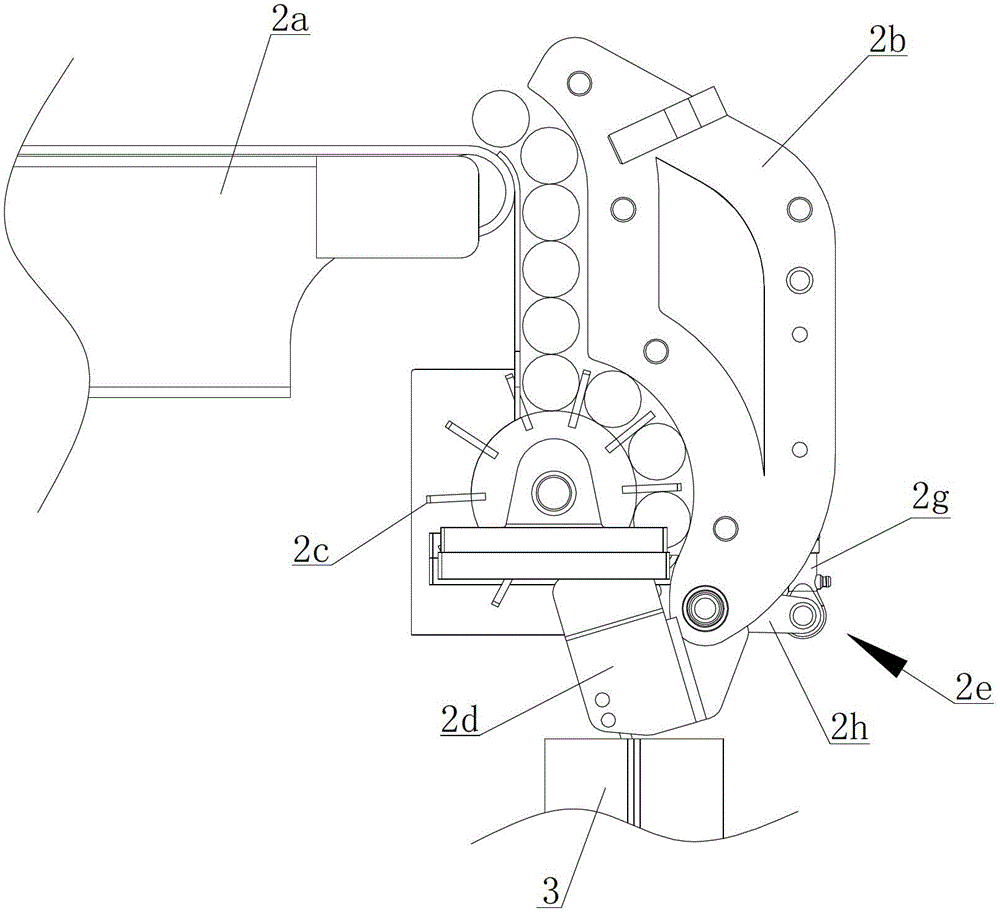

Vertical packaging machine for emulsion explosives

InactiveCN103206902BSimple structureCompact structureAmmunition storageEmulsion explosiveEngineering

The invention discloses a vertical packing machine for emulsion explosives, and belongs to the technical field of explosive packing equipment. The vertical packing machine comprises a frame, a feed mechanism is arranged at the top of the frame, the frame, on the side of the feed mechanism, is provided with at least two rows of explosive stacking bins along the vertical direction, the explosive stacking bins in each row are adaptive to to-be-stacked emulsion explosives in size, a plurality of stock stops are arranged on the side wall of each explosive stacking bin at intervals along the vertical direction, and each stock stop is connected with an external main control unit circuit. An explosive supporting mechanism is arranged at the bottom of each explosive stacking bin. A drum film roll for packing is disposed on the frame, and a drum film on the drum film roll for packing is guided to the periphery of each explosive stacking bin through a film guide mechanism and extends downwards vertically. A welding bag horizontal sealing mechanism and a welding bag vertical sealing mechanism are arranged below the explosive supporting mechanisms, and a conveying belt is arranged below the welding bag vertical sealing mechanism. The vertical packing machine for emulsion explosives is compact in structure, concise in packing processes and high in working efficiency, and is used for packing explosive cartridges.

Owner:GUANGDONG ZHENSHENG PACKAGING TECH +1

Packaging structure, method for manufacturing the same, and method for using the same

InactiveUS20100009501A1Improve connection reliabilityOptimizing the packaging processSolid-state devicesSemiconductor/solid-state device manufacturingSurface mountingUltimate tensile strength

Owner:HUANG CHUNG ER +1

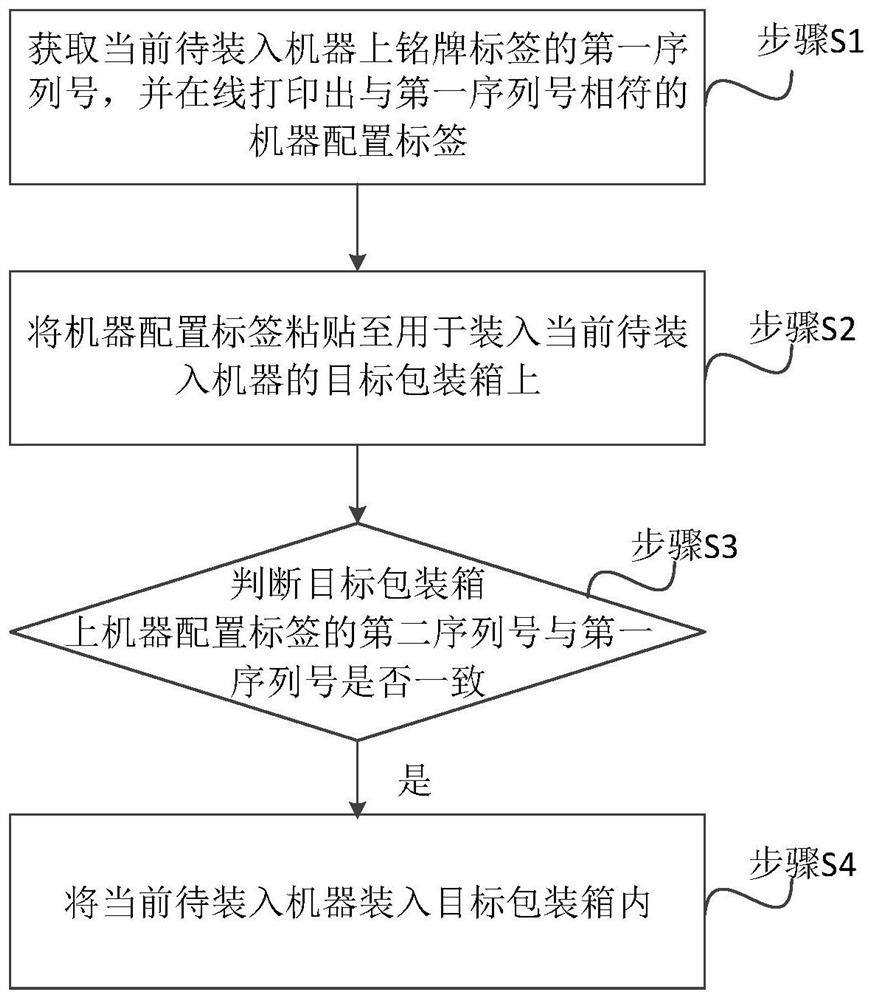

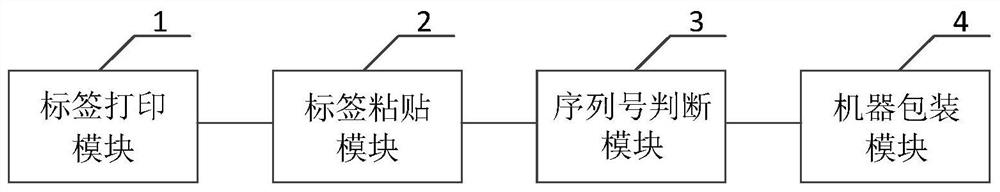

Wrong packaging preventing method, system and device

ActiveCN113071726AOptimizing the packaging processImprove packaging efficiencyPackaging automatic controlIndividual articlesNameplateEmbedded system

The invention discloses a wrong packaging preventing method, system and device. The method comprises the steps: obtaining a first serial number of a nameplate label on a current to-be-loaded machine, and printing a machine configuration label consistent with the first serial number online; pasting the machine configuration label to a target packaging box used for the current to-be-loaded machine to be put in; judging whether a second serial number of the machine configuration label on the target packaging box is consistent with the first serial number or not; and if yes, the current to-be-loaded machine is loaded into the target packaging box. Therefore, the machine packaging process is optimized by setting label online printing and label correctness verification, so that the machine packaging efficiency and correctness are improved.

Owner:SHANDONG YINGXIN COMP TECH CO LTD

A method for manufacturing an item packaging box and the item packaging box

InactiveCN106144118BSimple structureOptimizing the packaging processContainer decorationsLevel indicationsPulp and paper industryKraft paper

The invention discloses a manufacturing method of an object packaging box and the object packaging box. The manufacturing method of the object packaging box comprises the following steps that a piece of kraft paper with at least one white face is provided; and a coating with the kraft paper color and texture is printed on the kraft paper with at least one white face, characters and / or patterns are printed in a through printing mode, and the kraft paper with at least one white face is folded into the packaging box used for containing objects. The object packaging box is manufactured through the manufacturing method of the object packaging box. Compared with the prior art, the vivid deep-color kraft paper coating effect is achieved, the high-purity white color is represented through the natural color of the through-printed kraft paper with at least one white face, the distinct-level kraft paper bottom white character effect is achieved finally, and the problem of printing of high-purity white color on the surface of the deep-color kraft paper is solved. Due to the utilization of the material of the kraft paper, the object packaging box is more environmentally friendly, concise and high-graded, thereby promoting selling.

Owner:KOHLER CHINA INVESTMENT

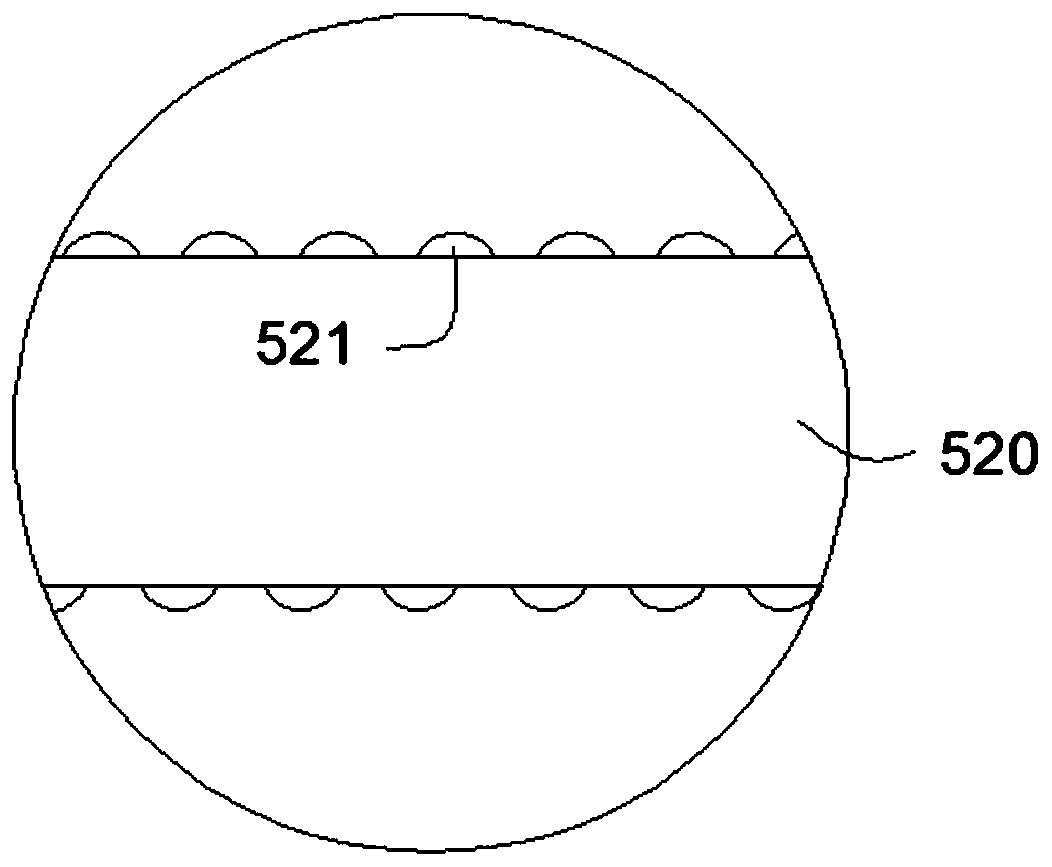

Packaging Structure and Packaging Technology of Lead Frame

ActiveCN114334750BQuick guideImplement encapsulationNon-rotating vibration suppressionSemiconductor/solid-state device manufacturingBristleStructural engineering

Owner:NINGBO DEZHOU PRECISION ELECTRONIC CO LTD

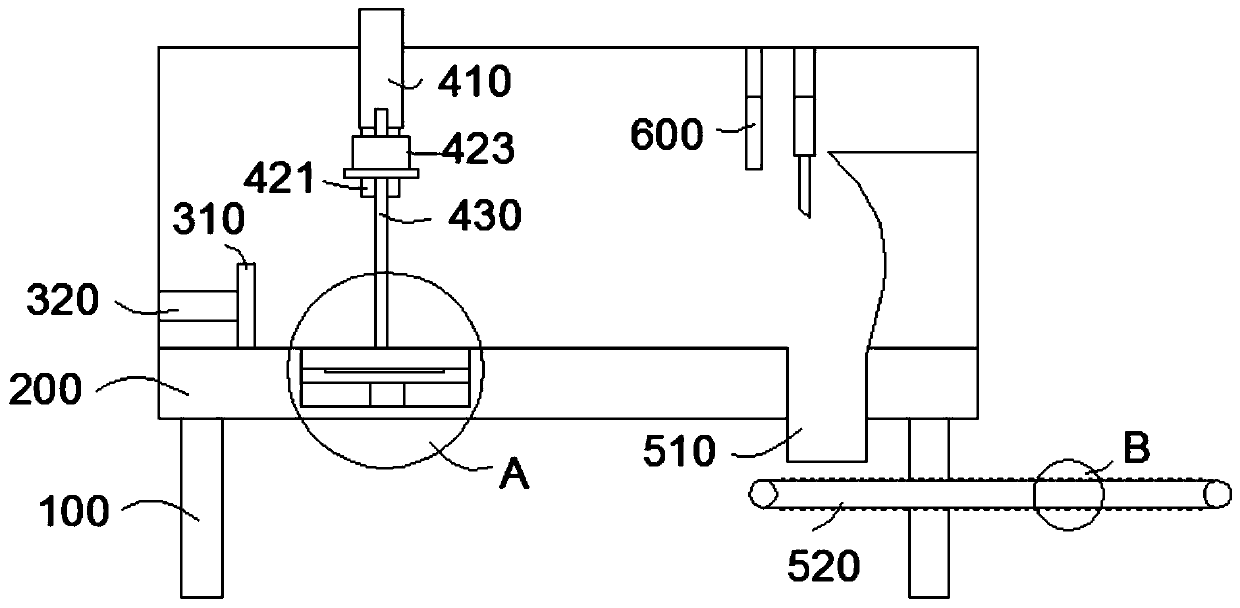

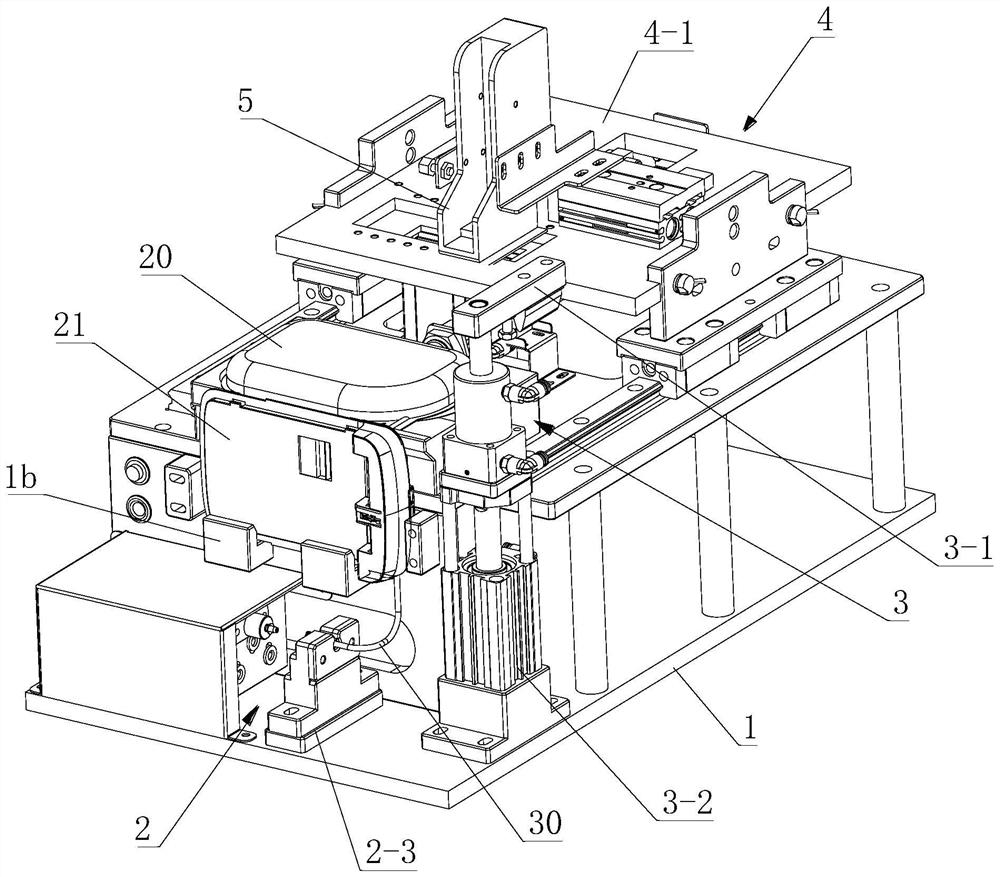

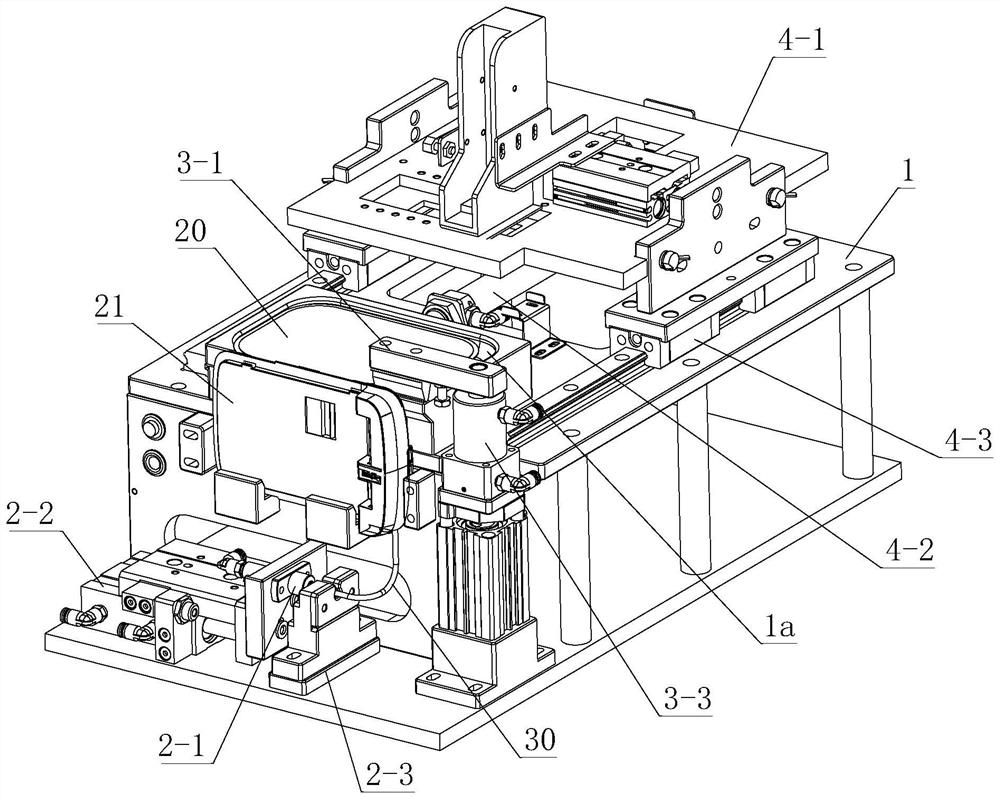

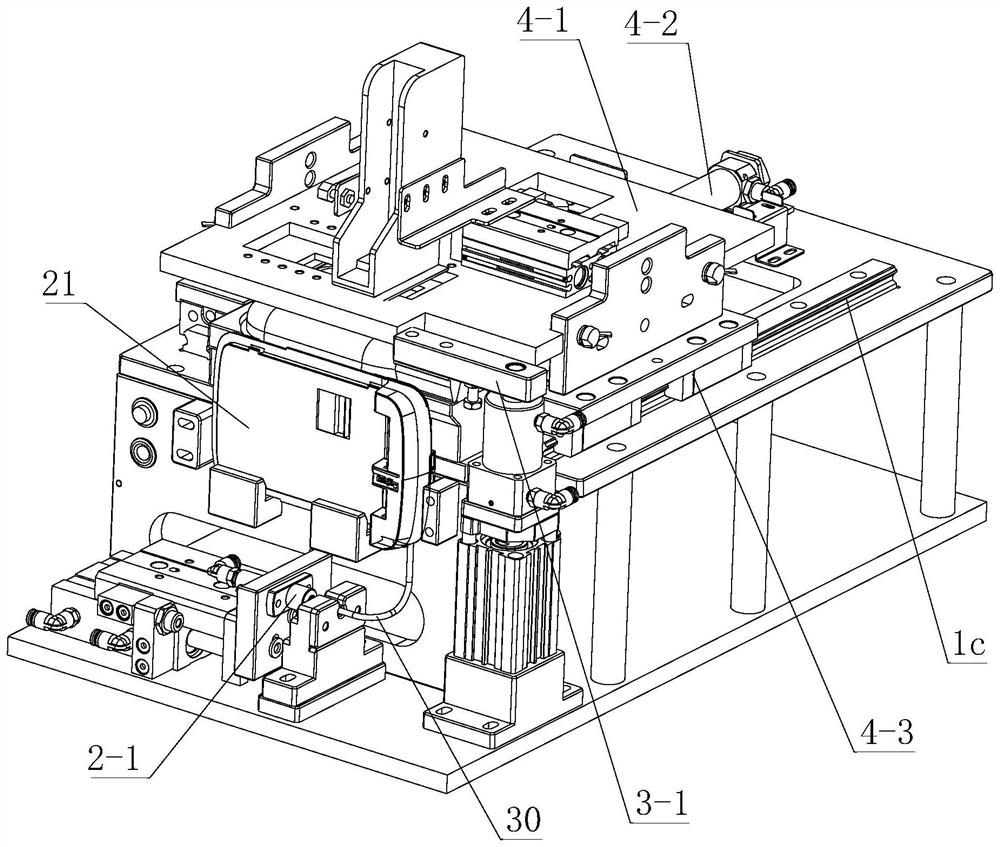

Assembling device for packaging box

ActiveCN111532504AOptimizing the packaging processReduce manual deployment stepsPackagingCartonElectric machinery

The invention discloses an assembling device for a packaging box. The assembling device for the packaging box structurally comprises a self-unfolding machine body, a base, a motor cabinet, a collecting bin, a conduction belt and a control cabinet. When equipment is used, the self-unfolding machine body is arranged, so that the problems that a paper box needs to be unfolded into a square three-dimensional state manually in the batch production process of the paper box during the loading and using process of the paper box, which is a part for wasting much labor for personnel for loading, the auxiliary unfolding process of the packaging box can not be directly carried out through the equipment, and batch work is not facilitated are solved, the equipment extrudes the periphery of the packagingbox and a fixing frame into a square through cooperation with a special plate clamping device and an adjusting device, the folded paper box is automatically unfolded to form a three-dimensional structure and is conveyed downwards, the packaging process in the next step is facilitated, the manual unfolding step is reduced, and the loading efficiency is greatly improved.

Owner:武汉艾特纸塑包装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com