Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

90results about How to "Many contacts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

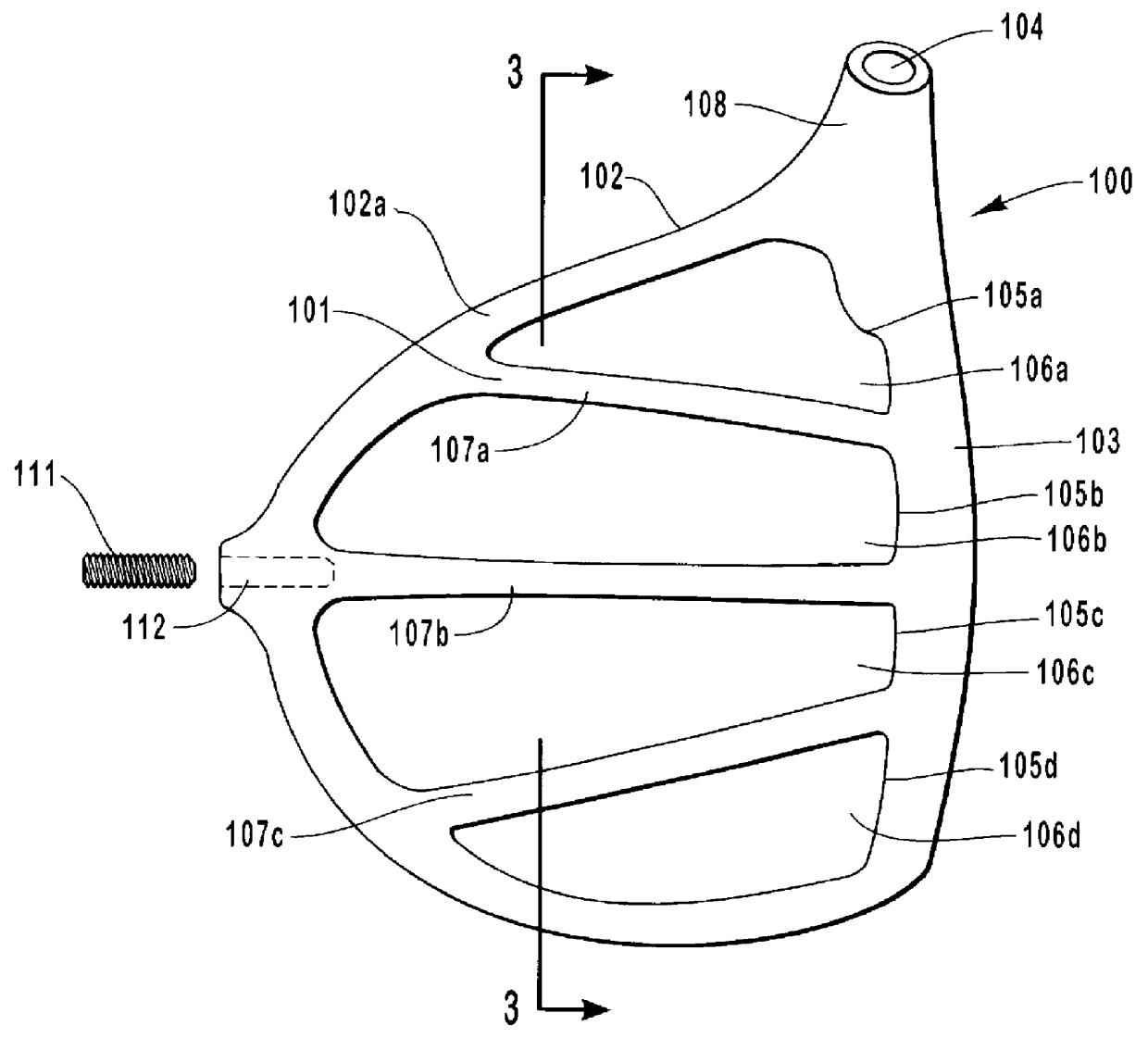

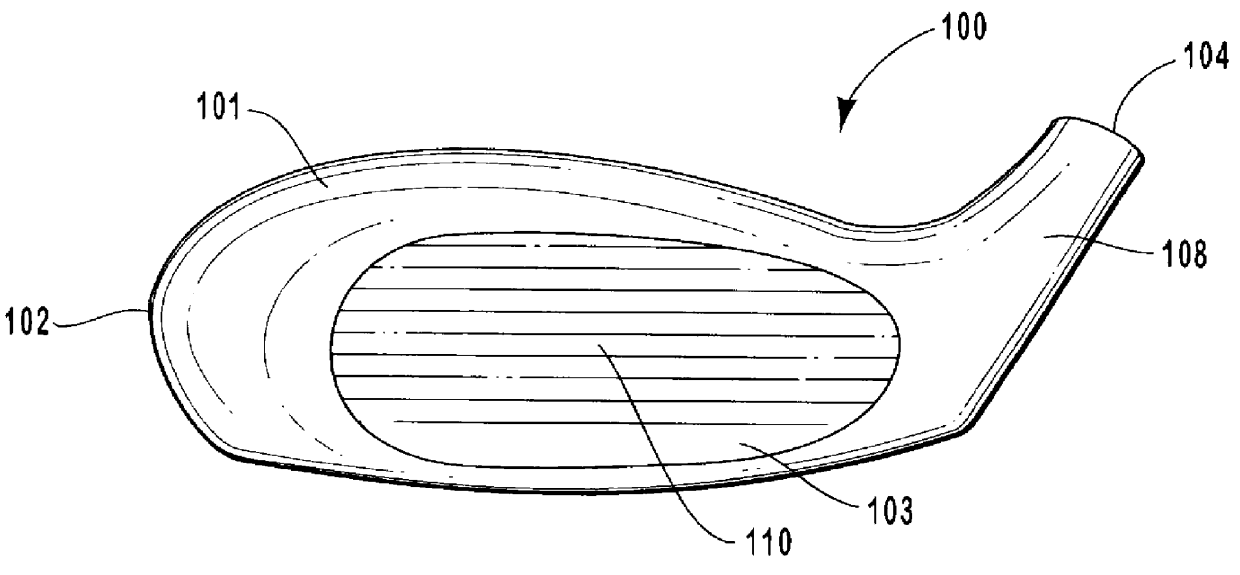

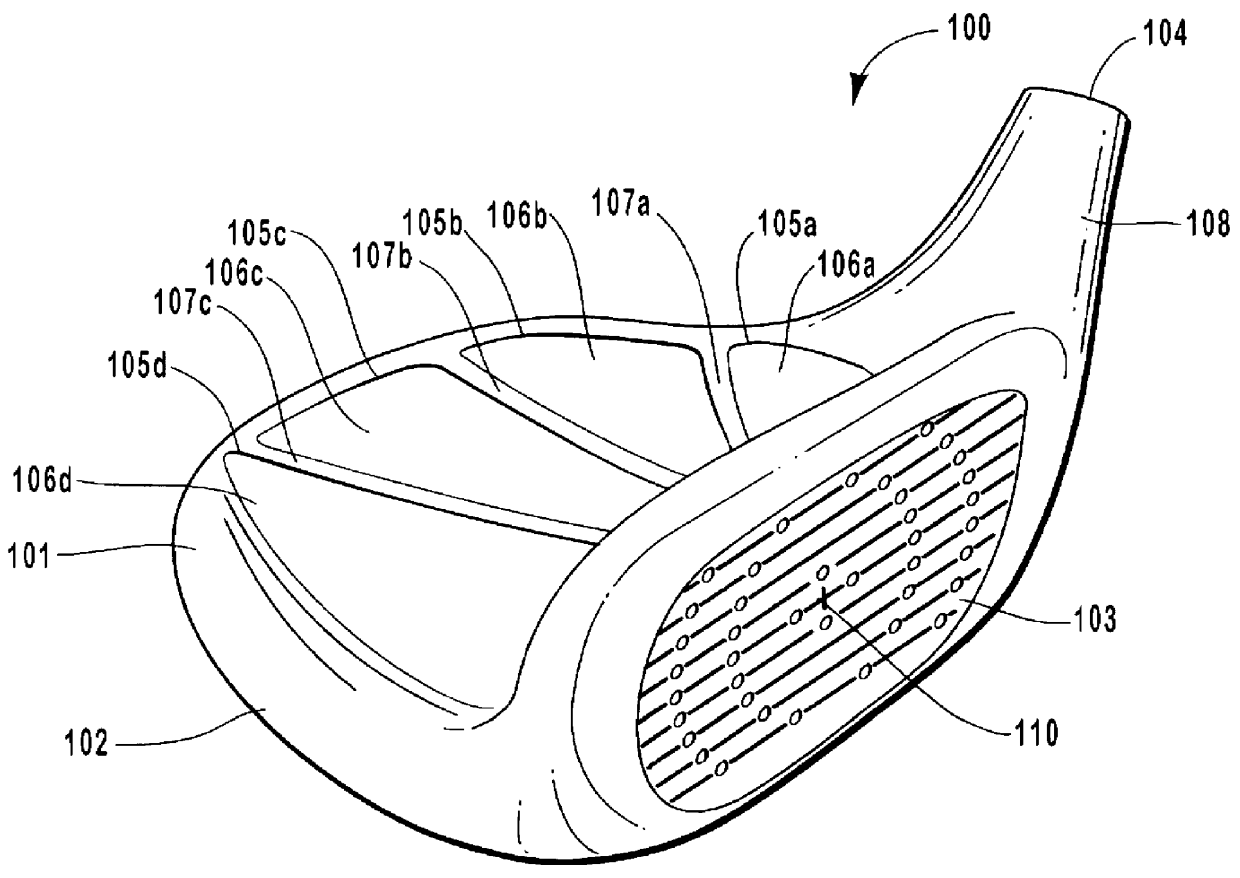

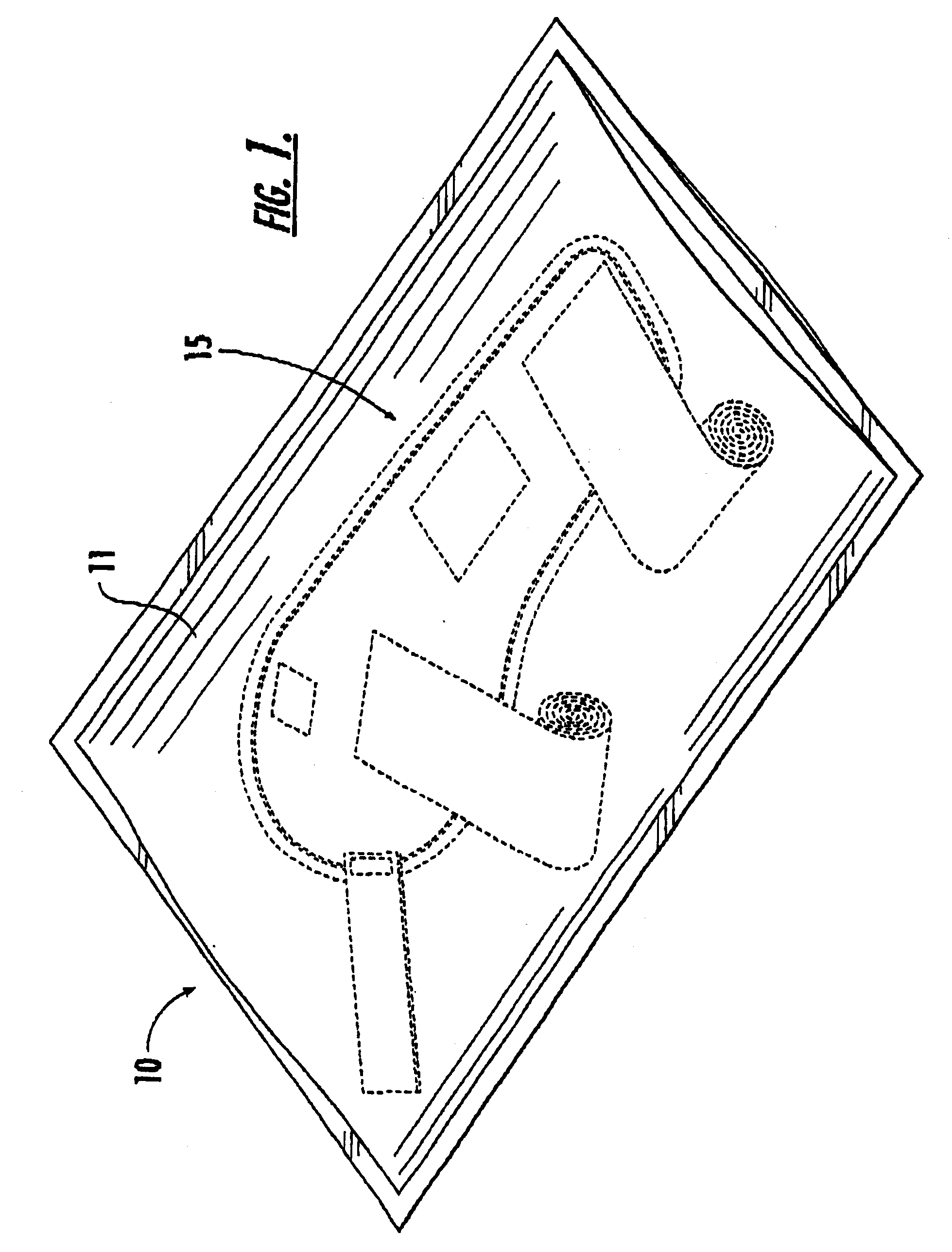

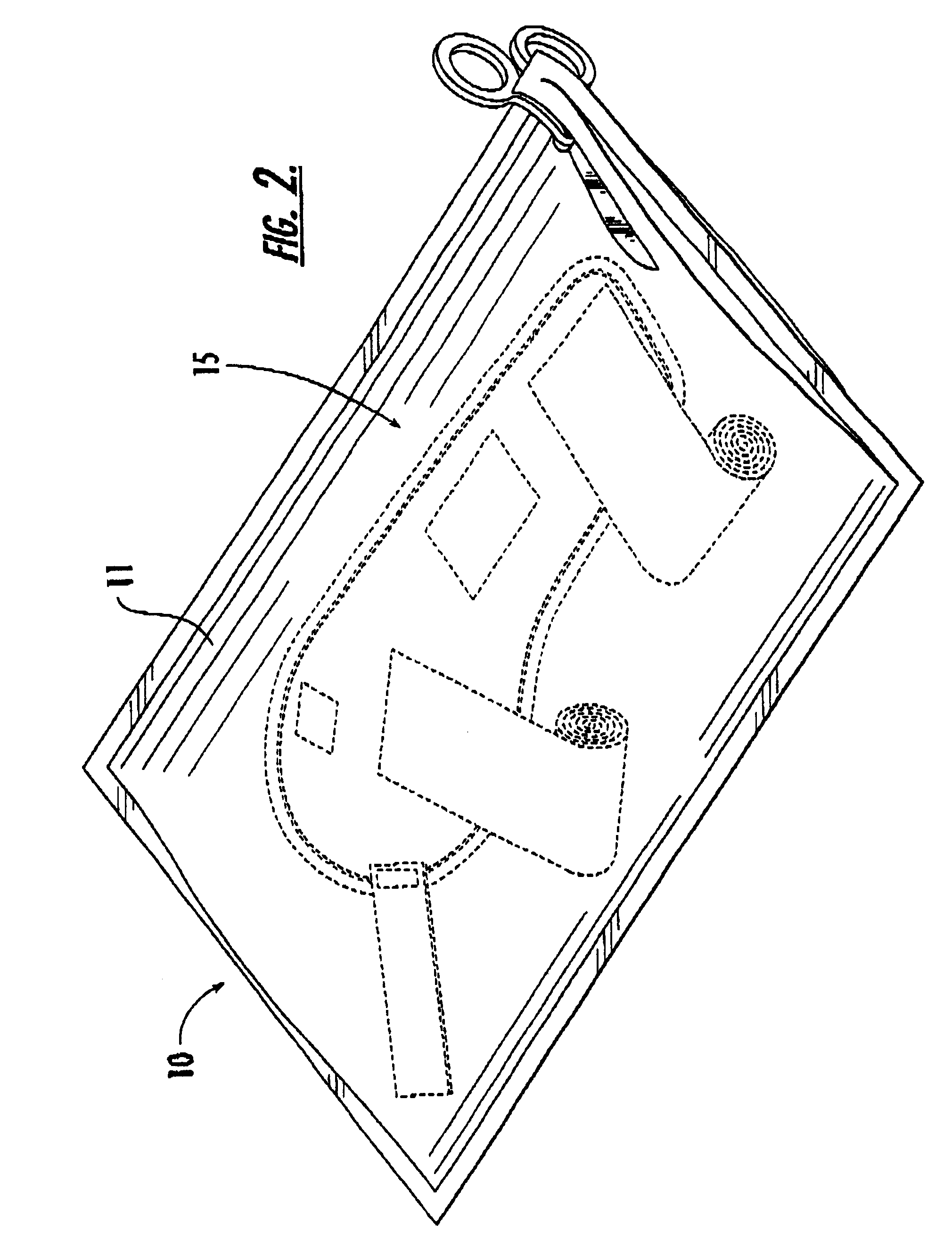

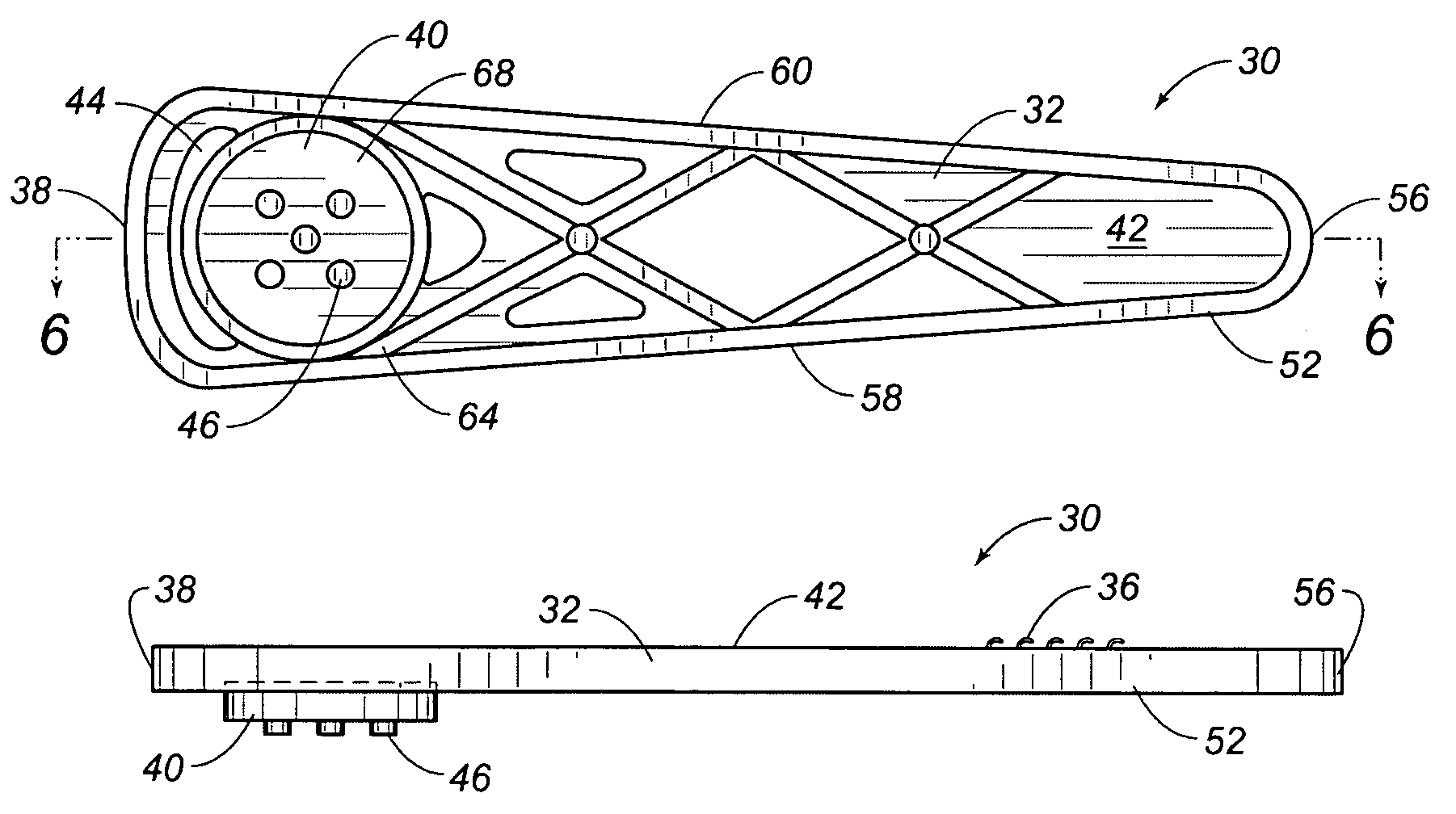

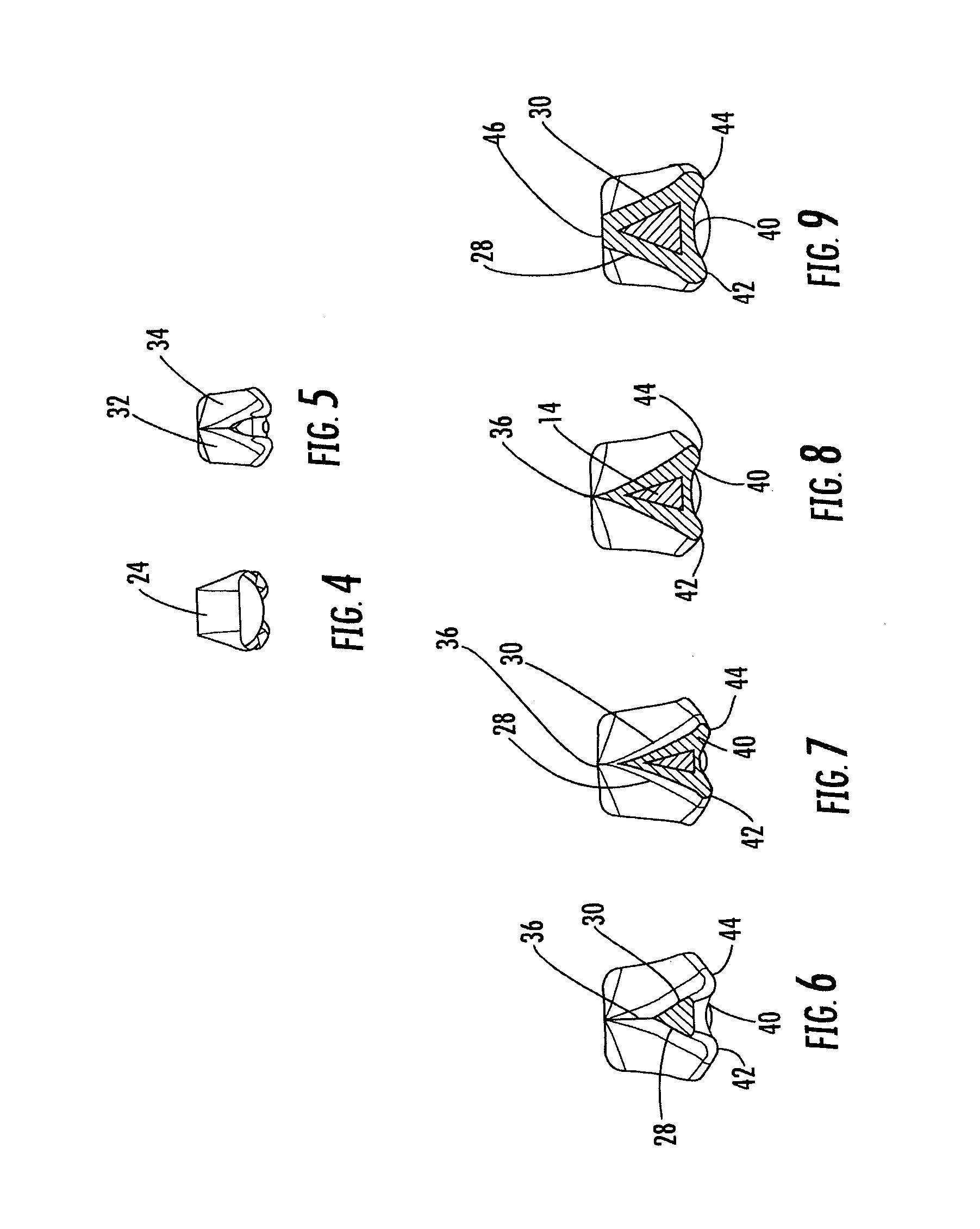

Golf club head having performance-enhancing structure

InactiveUS6059669AEconomical and labor-efficientGreat distance of ball flightGolf clubsRacket sportsFiberEngineering

A golf club that is preferably made from fiber-reinforced plastic composite by an injection molding process. The preferred golf club head includes a striking face for striking a golf ball, an outer periphery, a cavity formed between the outer periphery and the back of the striking face, a sole enclosing the bottom portion of said cavity, and at least one elongate power bar extending across the cavity from the striking face to the outer periphery. The sole is preferably integrally formed with the face plate and outer periphery. The cavity of the golf club head opens to the top of the club head. Each elongate power bar separates the cavity into receptacles. Inserts may be placed within the receptacles for aesthetic, aerodynamic, acoustic, and other purposes.

Owner:EDIZONE LC

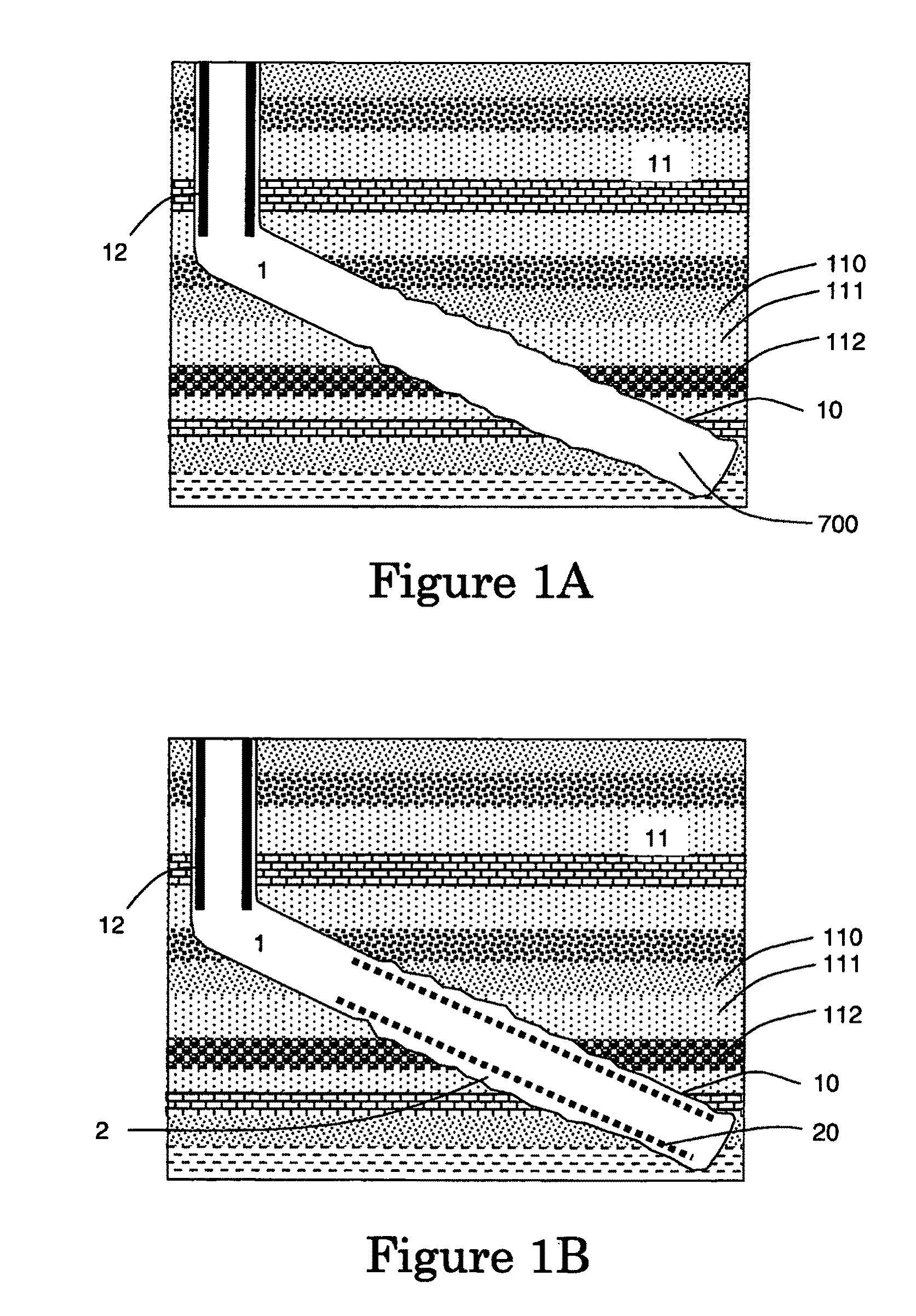

Method and Apparatus to Cement A Perforated Casing

A method of and an apparatus for treating a near zone and / or a far zone of a well is disclosed. The method comprises the following steps. (1) A tube that is permeable to a material is placed inside a wellbore, forming an annulus inside the wellbore. (2) A setting section surrounded by a sleeve is placed inside the tube. The sleeve is expandable and impermeable to the material. (3) The sleeve is inflated so that the sleeve is in contact with the tube, ensuring for a first zone of the tube is impermeable to the material, but leaving a second zone permeable to the material. (4) A treatment fluid is pumped to the zones that passes through the second zone still permeable to the material. (5) The near zone in the annulus and / or the far zone in the surrounding formation is treated with the treatment fluid.

Owner:SCHLUMBERGER TECH CORP

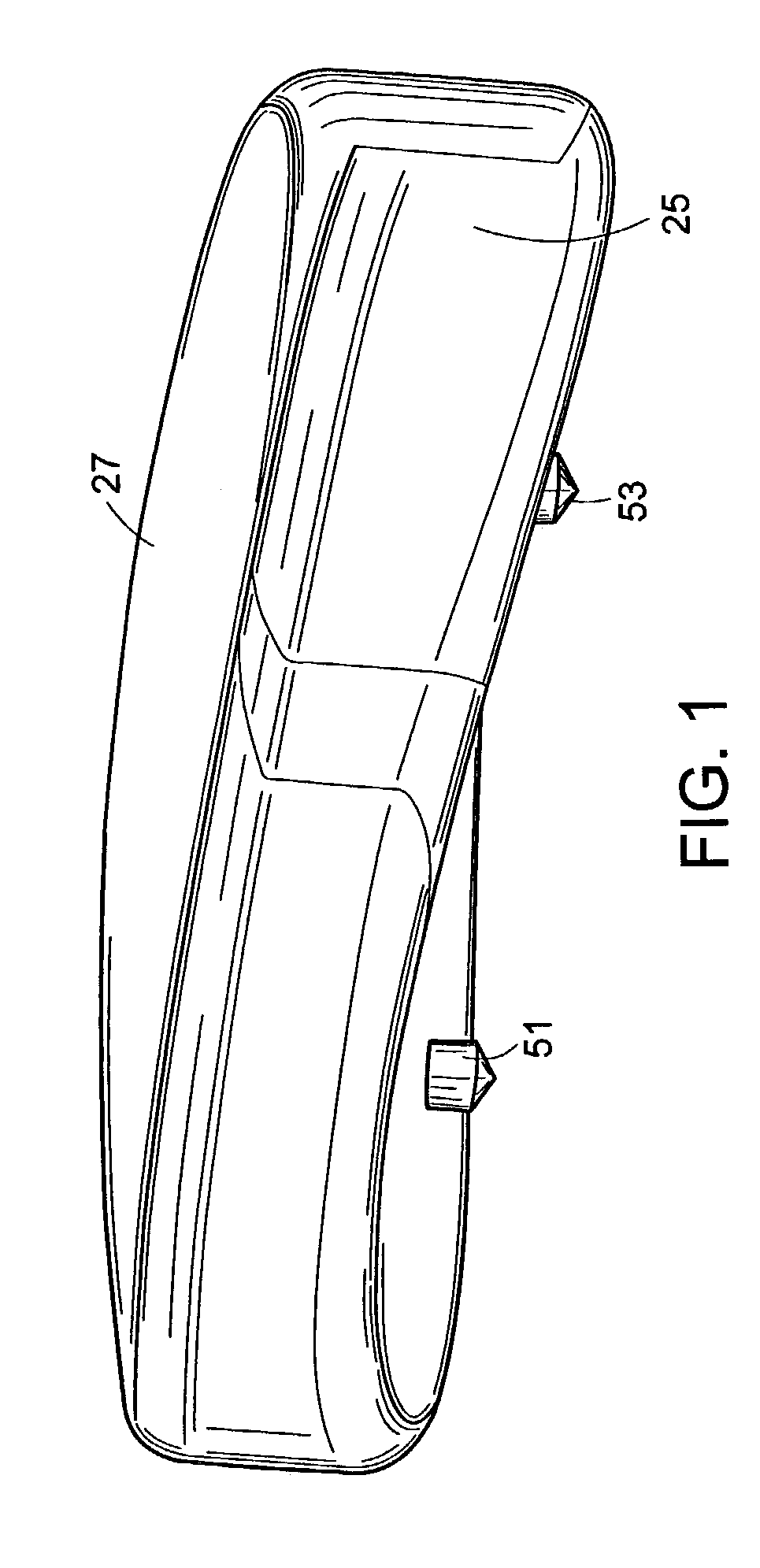

Dual durometer elastomer artificial disc

InactiveUS7008452B2Reduce chanceMany contactsJoint implantsSpinal implantsElastomerIntervertebral disc

Owner:DEPUY ACROMED INC

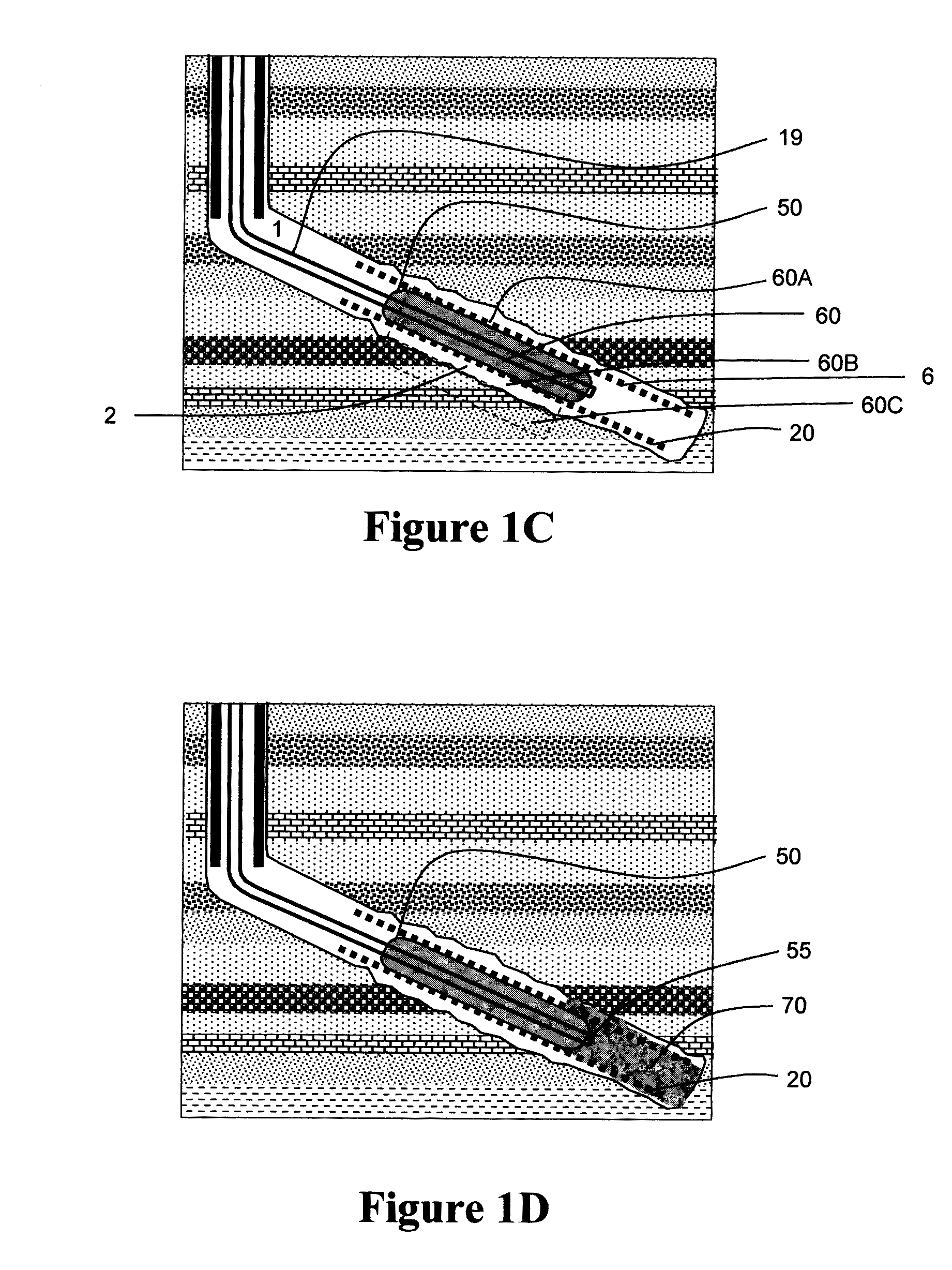

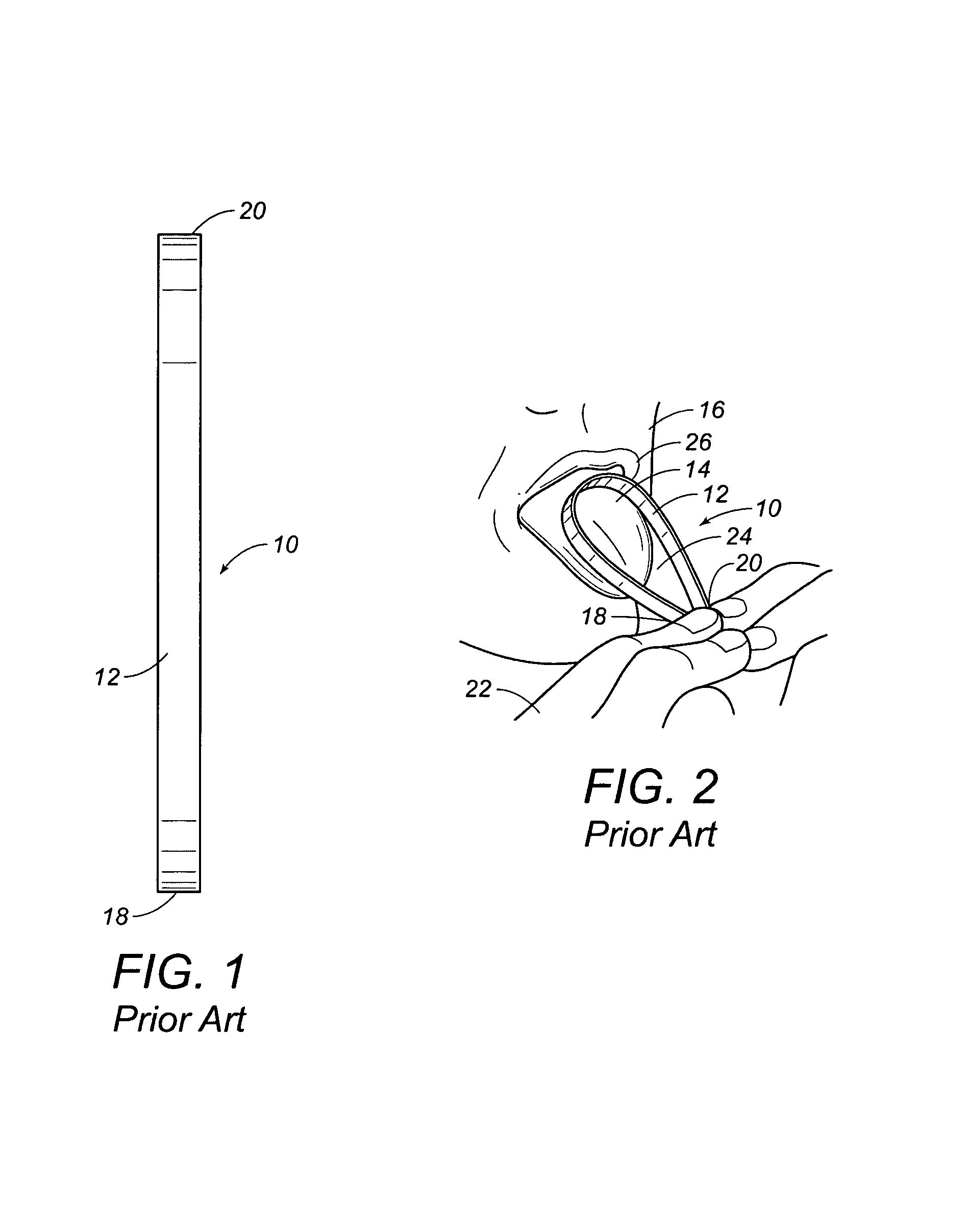

Custom-moldable universal thumb spica splint

A thumb spica splint for being custom-fitted to the thumb portion of the hand for immobilizing the thumb while permitting continued unrestricted use of the other fingers of the hand, and including an elongate, flexible inner cushion layer, an initially flexible intermediate layer overlying the inner cushion layer, the intermediate layer formed of a fabric impregnated or coated with a moisture-curable resin which hardens upon curing to form a rigid structure of the fabric which retains a shape into which it is molded during curing. A flexible protective outer layer overlies the intermediate layer and is attached to the inner cushion layer for enclosing the intermediate layer and forming the inner layer, intermediate layer and outer layer into a single, integrated splint structure. The splint is shaped to extend along and conform to the medial aspect of the lower arm and thumb to the distal joint thereof. An elongate thumb strap is fixedly attached by one end thereof to the splint structure adjacent the thumb for extending around the thumb and releasably attaching to a thumb strap attachment element fixedly attached to the splint structure for holding the splint structure in a supporting position around the thumb. Arm straps are fixedly attached by one end thereofto the splint structure adjacent the arm for extending around the arm and releasably attaching to an arm strap attachment element fixedly attached to the splint structure for holding the splint structure in a supporting position around the arm.

Owner:BSN MEDICAL INC

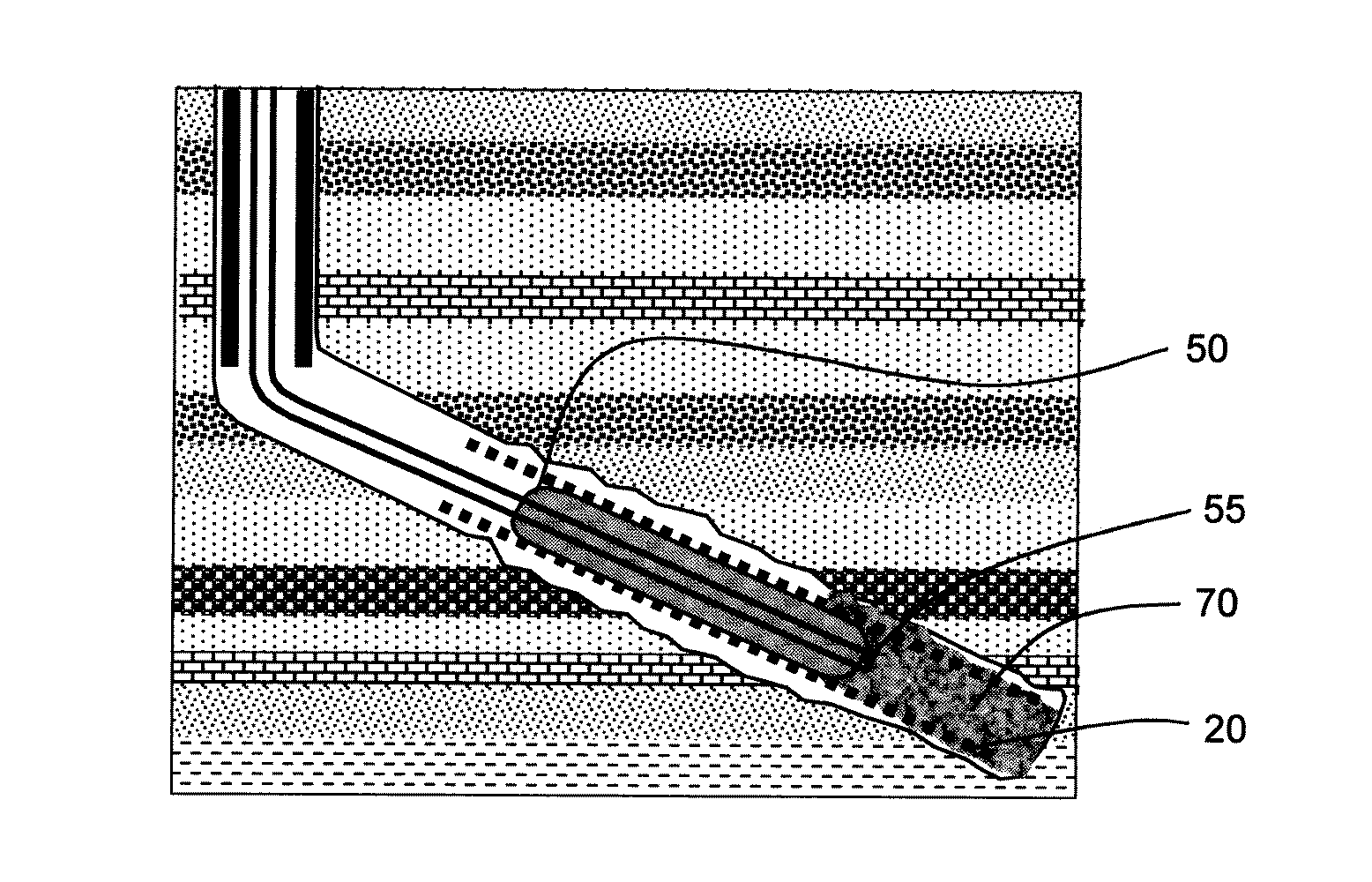

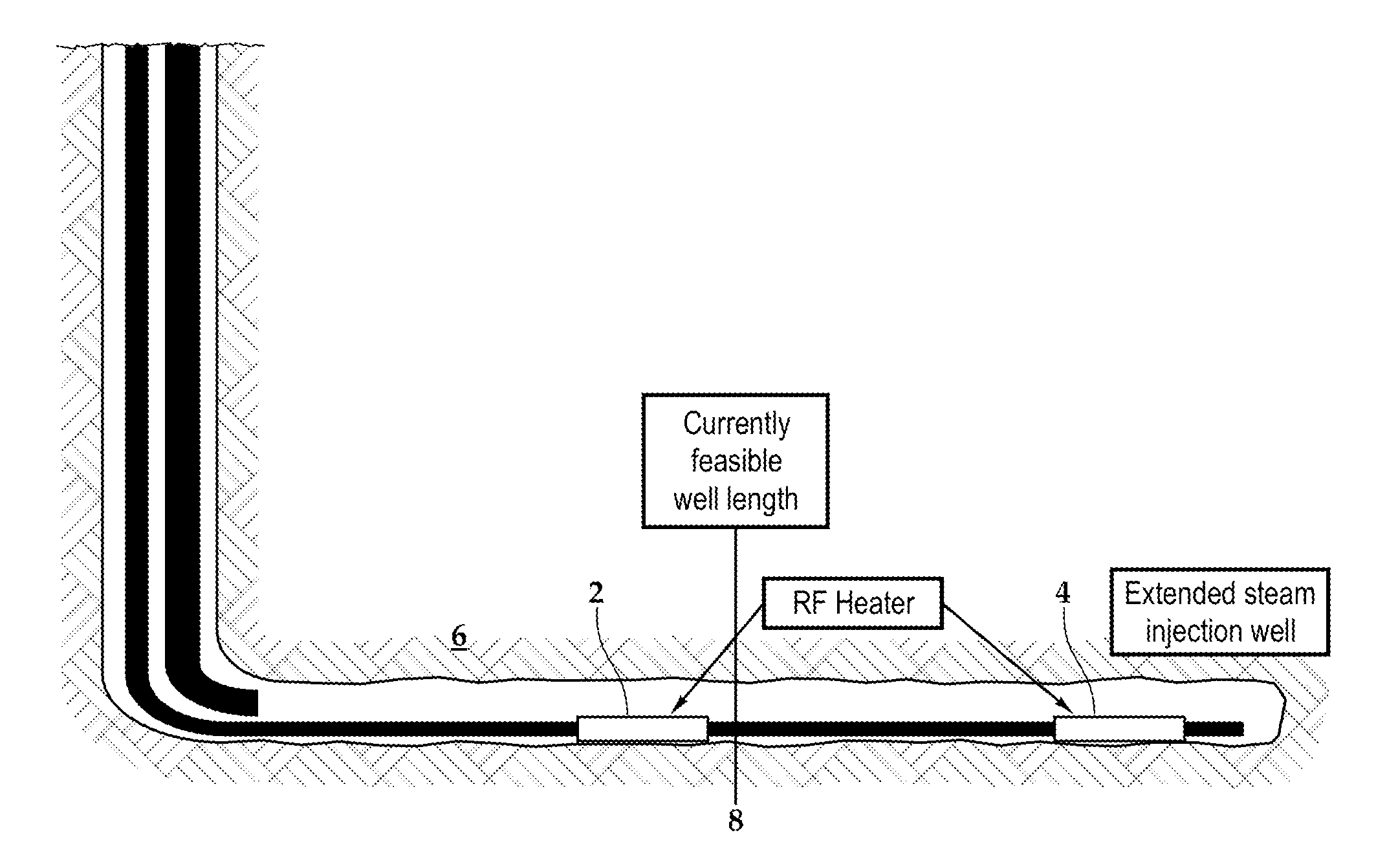

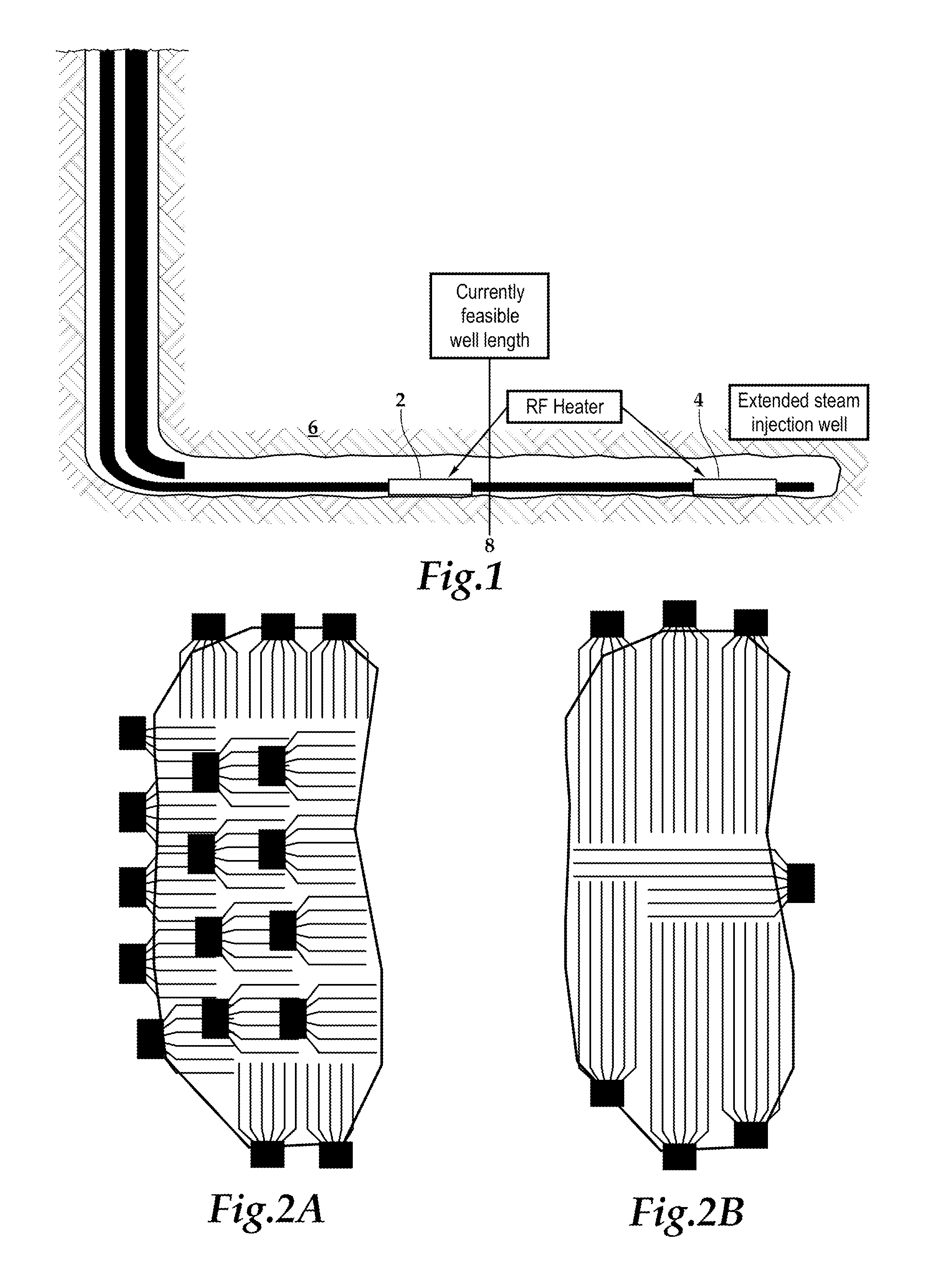

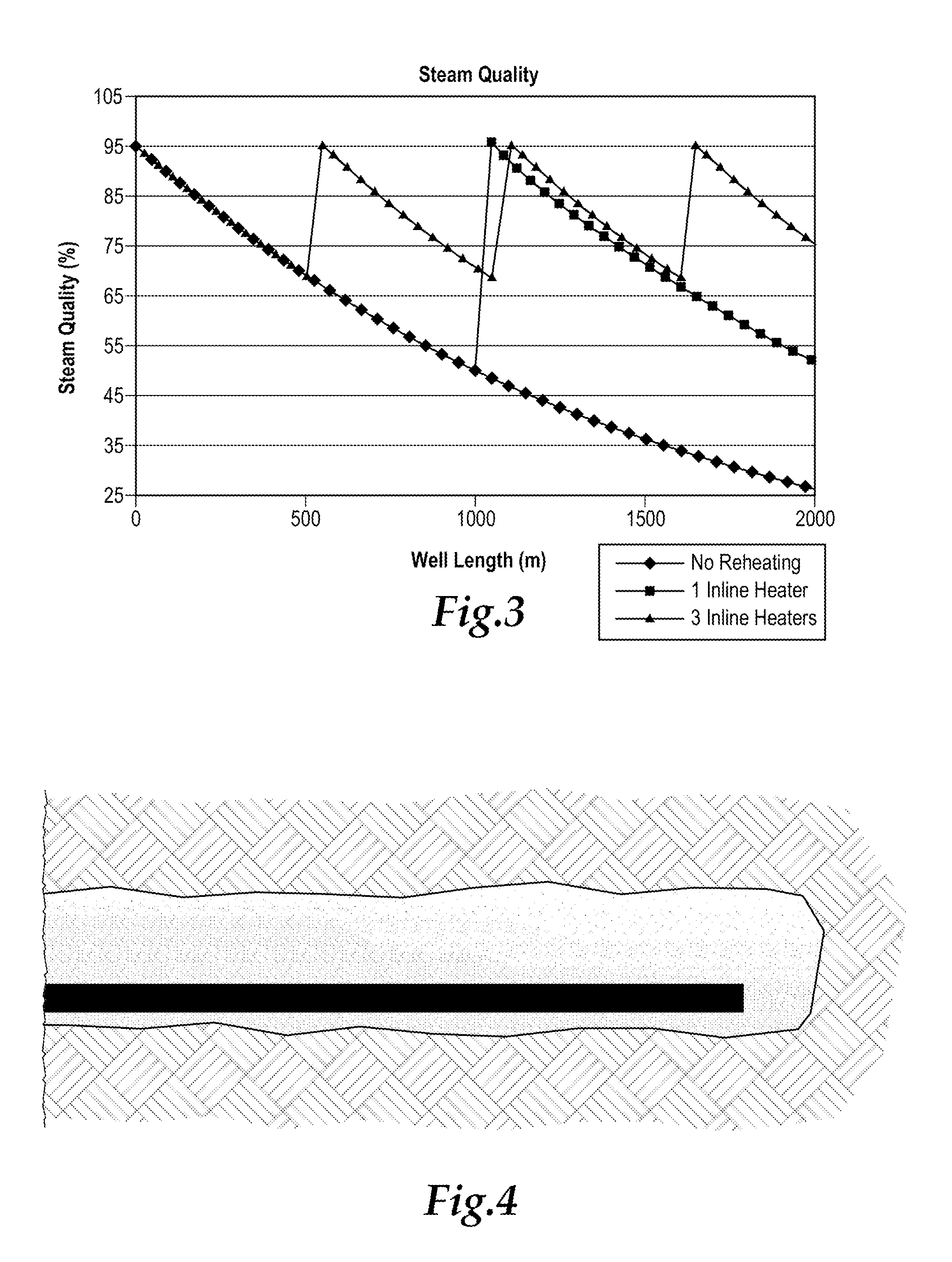

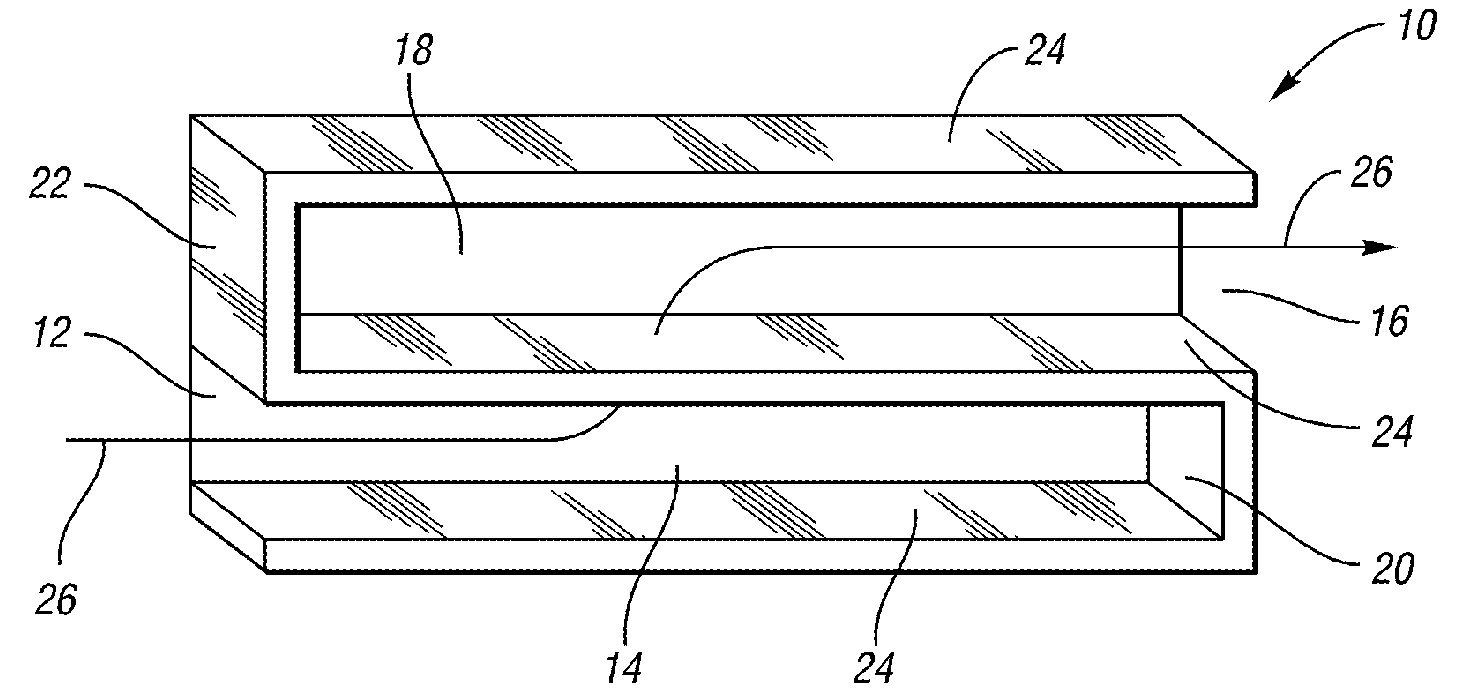

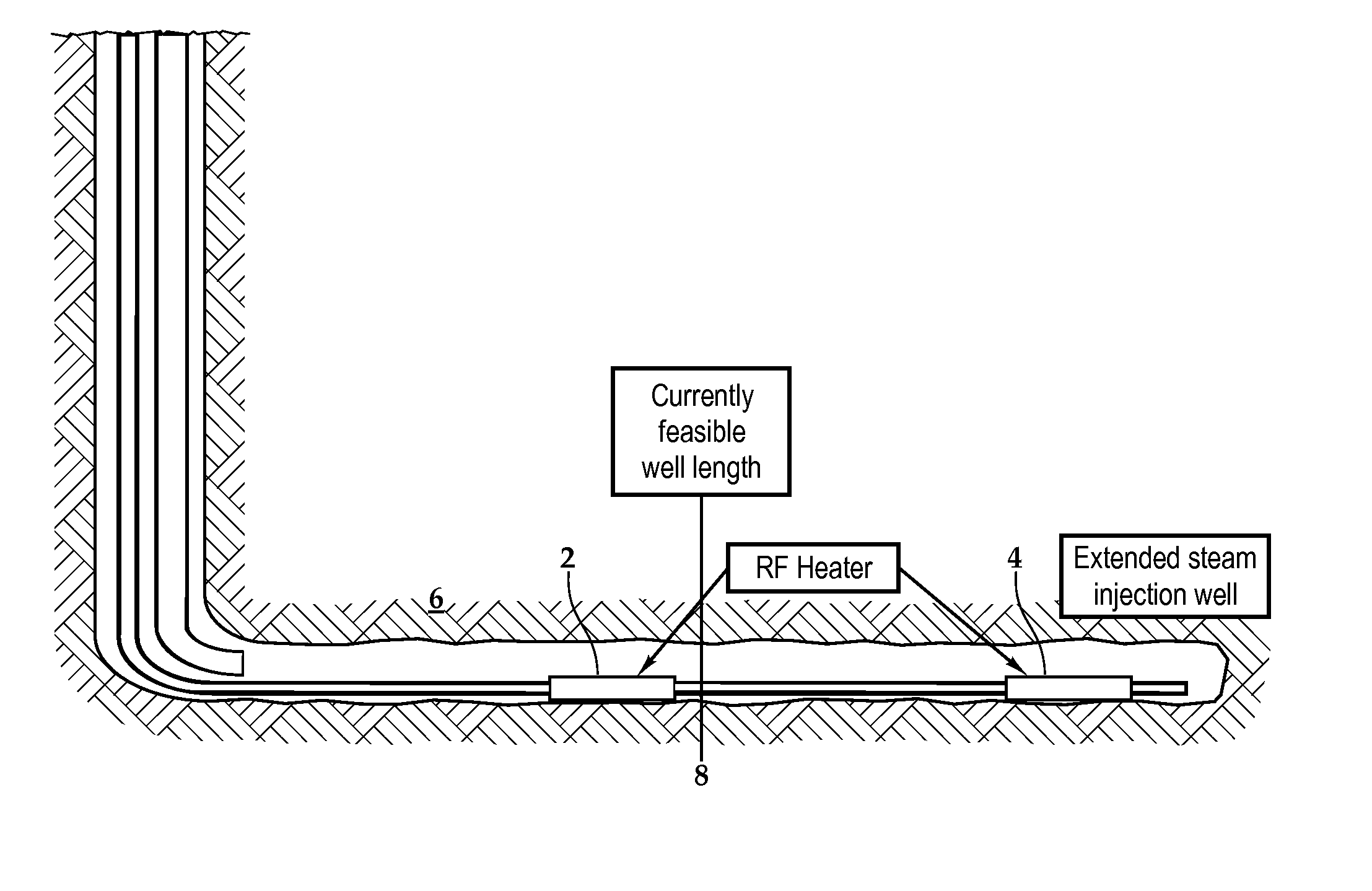

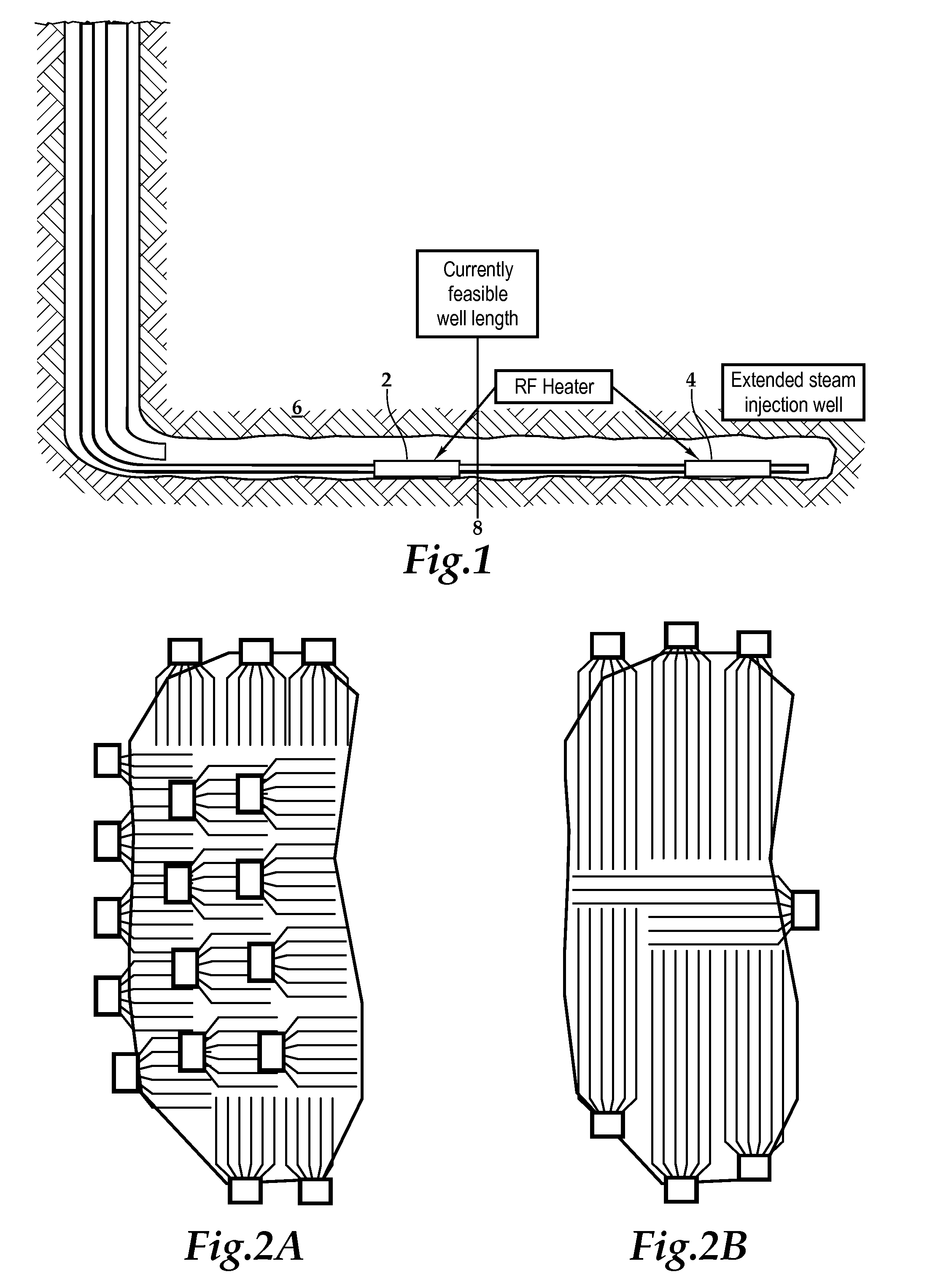

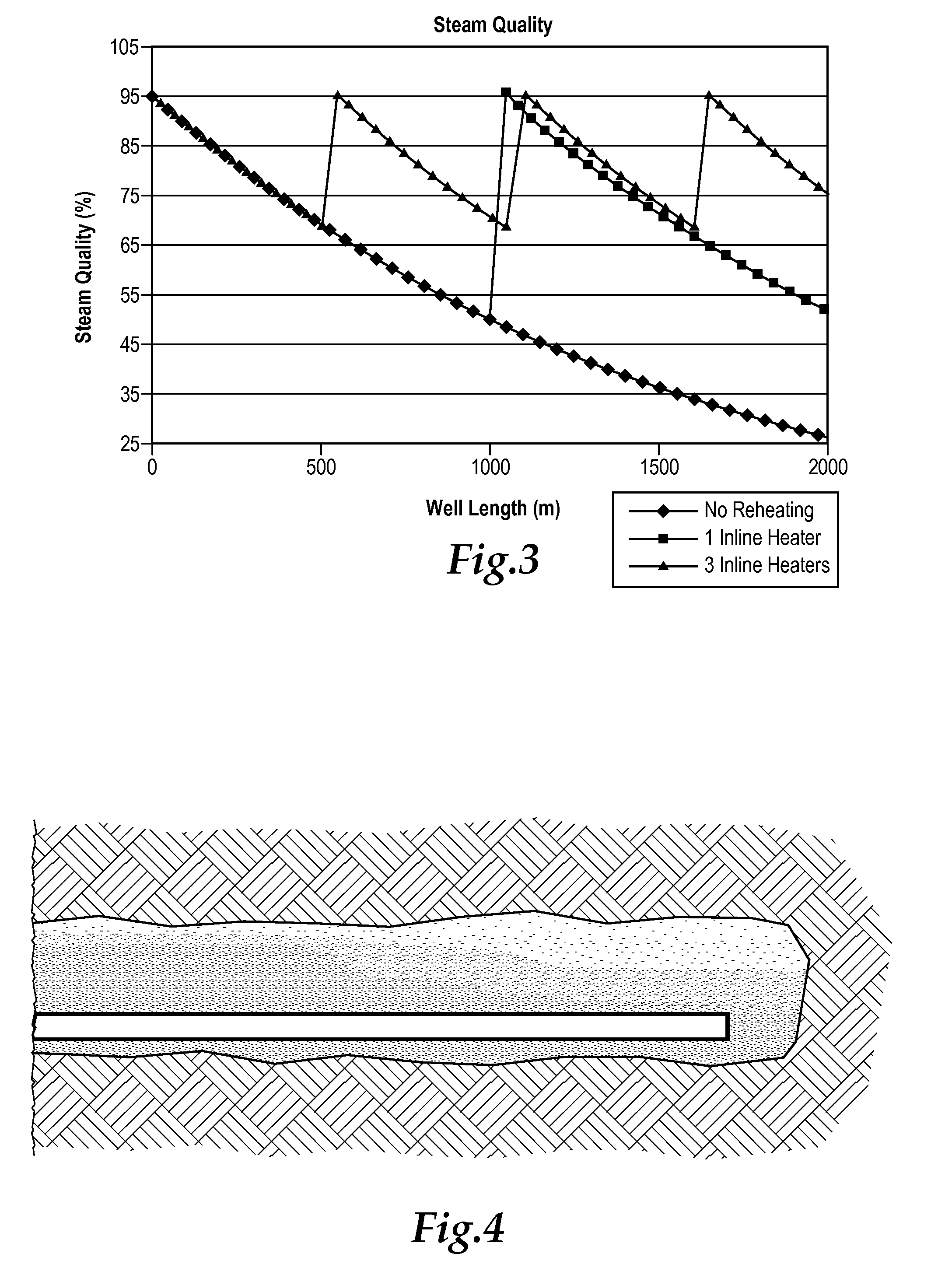

Inline RF heating for SAGD operations

ActiveUS20120061080A1Improve heat transfer efficiencyImprove consistencyInsulationFluid removalThermal energyEngineering

The present invention provides a method for accelerating start-up for SAGD-type operation by providing radio frequency heating devices inside the lateral wells that can re-heat the injected steam after losing heat energy during the initial injection. The method also extends the lateral wells such that the drilling of vertical wells can be reduced to save capital expenses.

Owner:HARRIS CORP +1

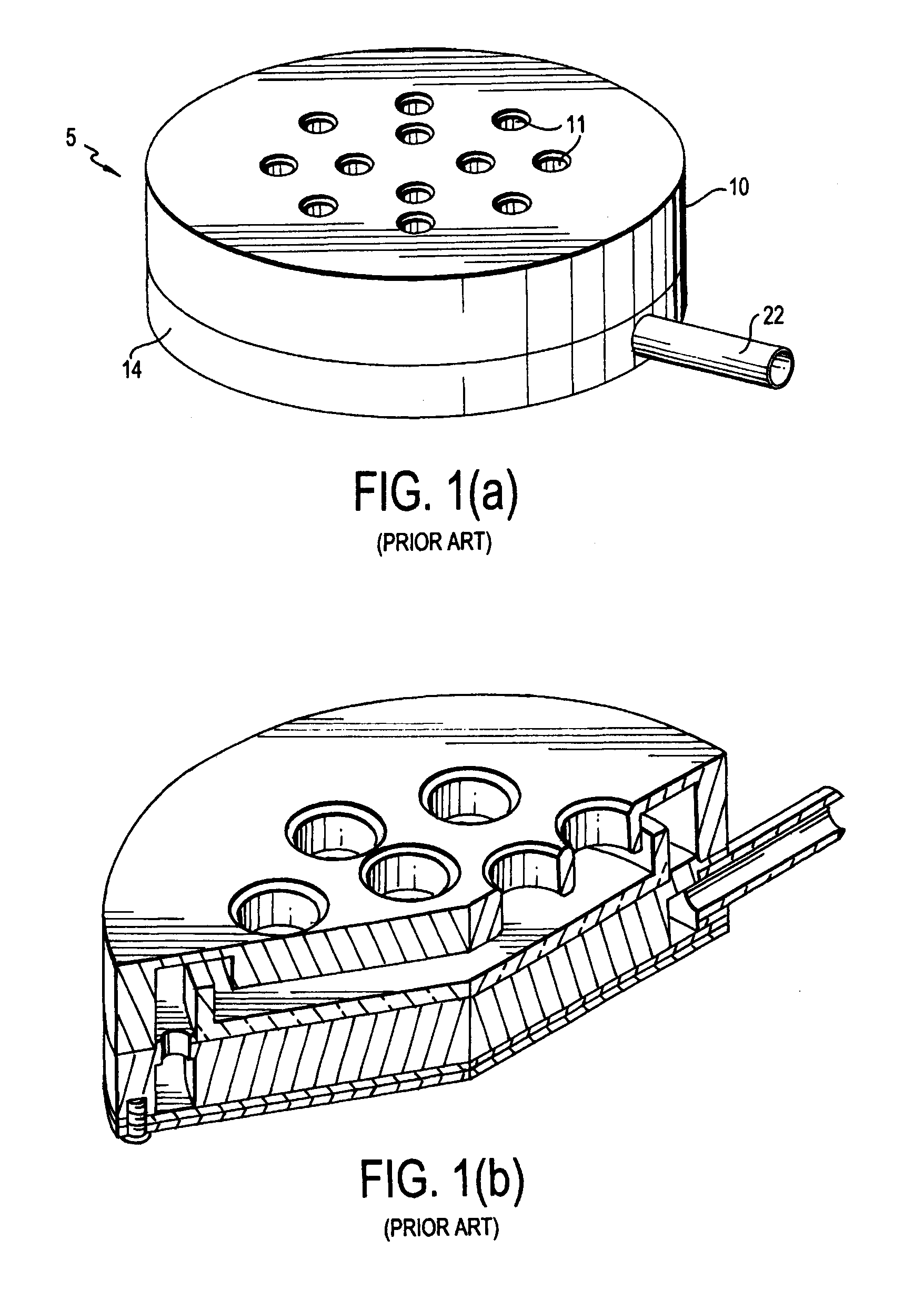

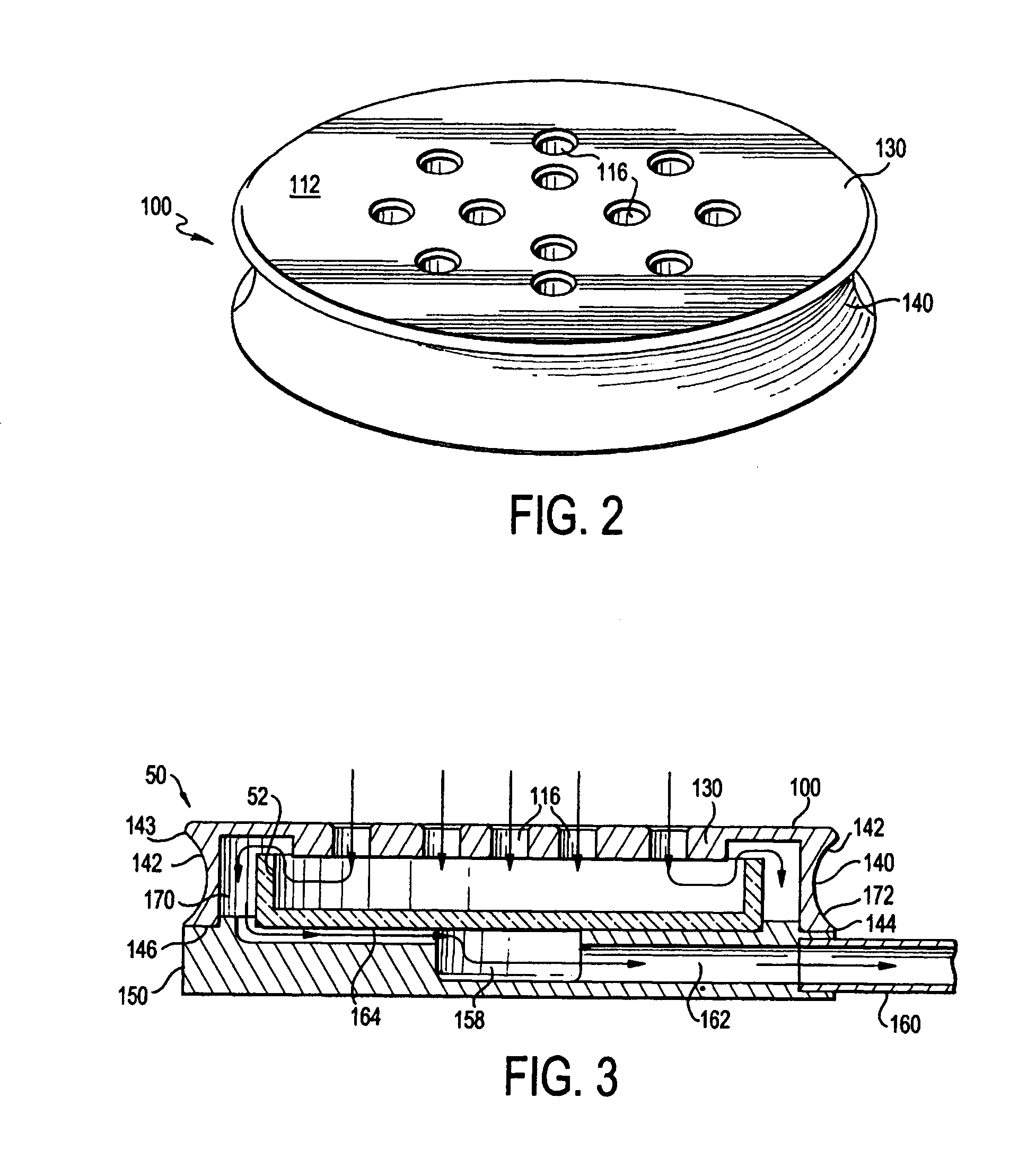

Diesel engine after treatment device for conversion of nitrogen oxide and particulate matter

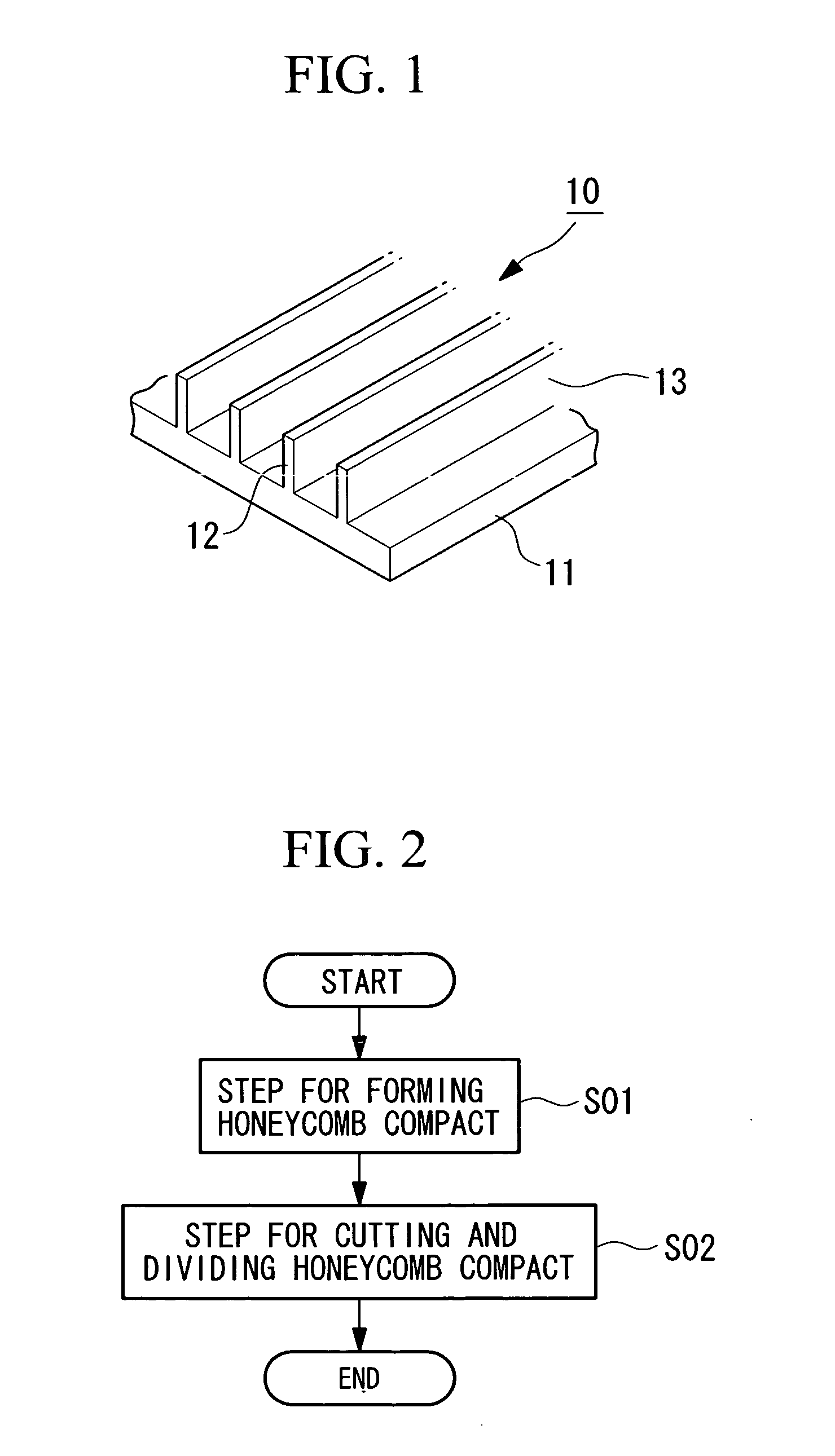

ActiveUS7225613B2Area maximizationImproved thermal managementCombination devicesInternal combustion piston enginesAfter treatmentNitrogen oxide

An automobile exhaust filter that both traps particulates while altering the concentration of one or more gaseous species is provided. This dual functionality is combined in a single device by utilizing a reactive material that simultaneously alters gaseous component concentration while filtering out particulate material. The automobile exhaust filter is suitable for inclusion in the exhaust of a diesel-powered vehicle. A method utilizing the automobile exhaust catalyst is also provided.

Owner:FORD GLOBAL TECH LLC

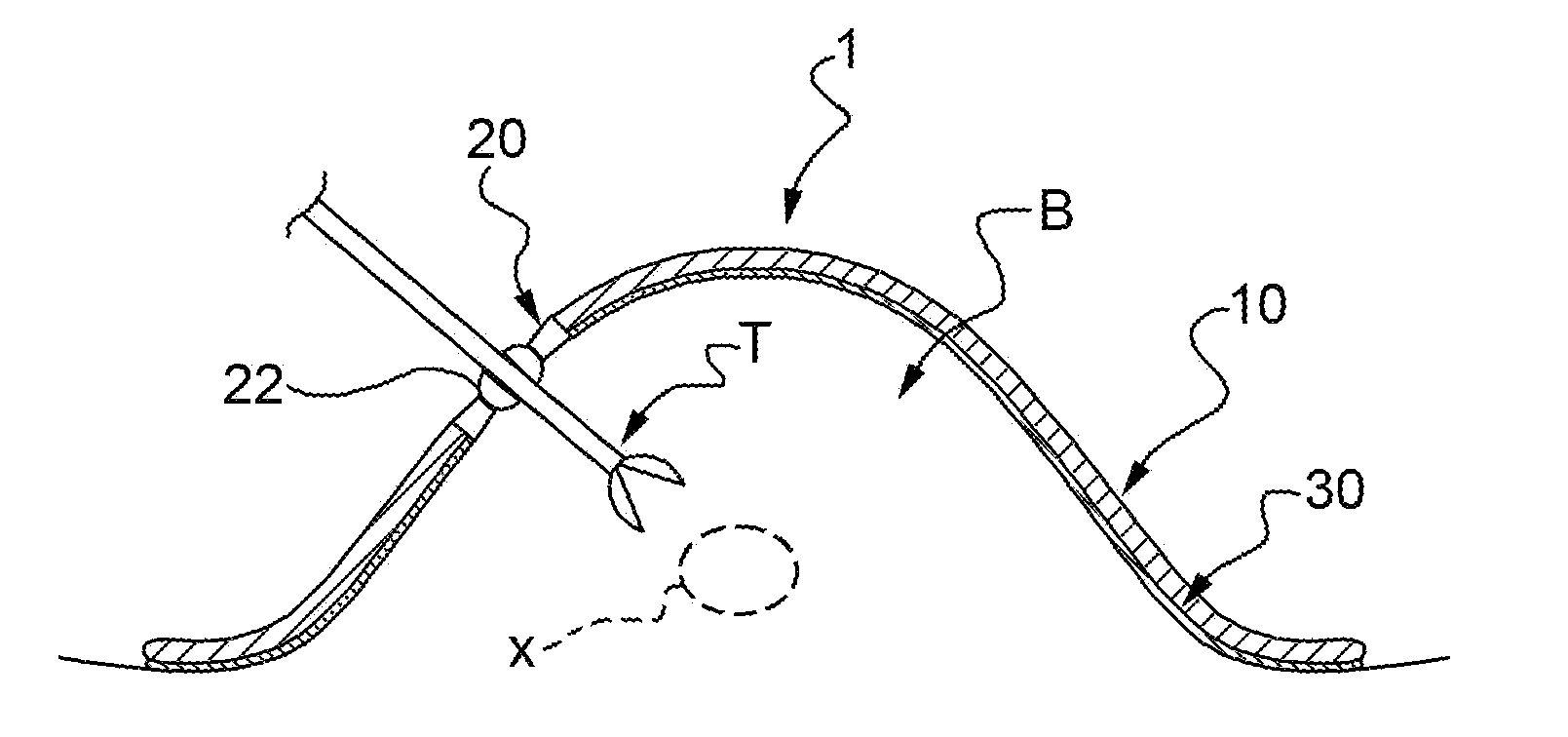

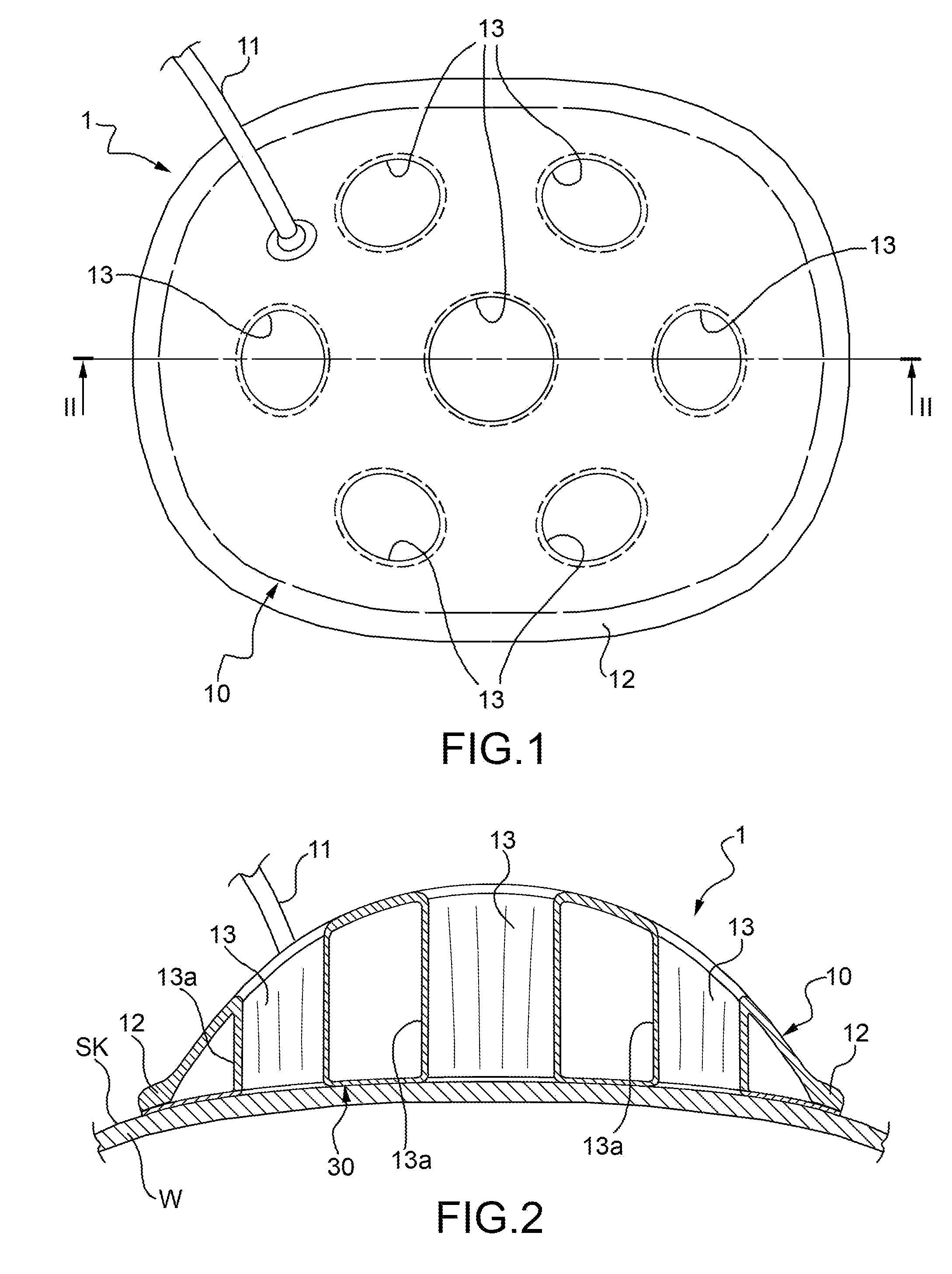

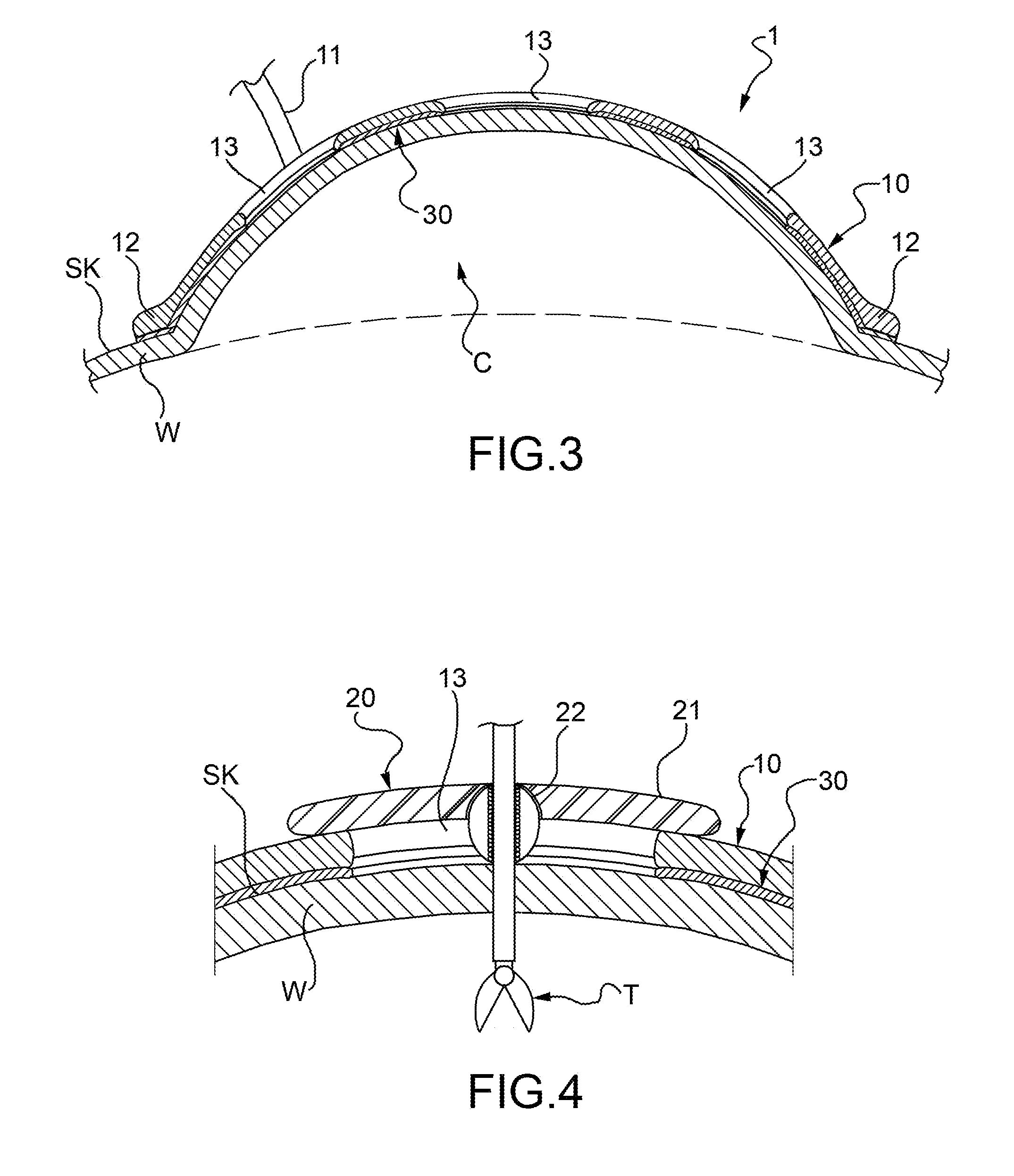

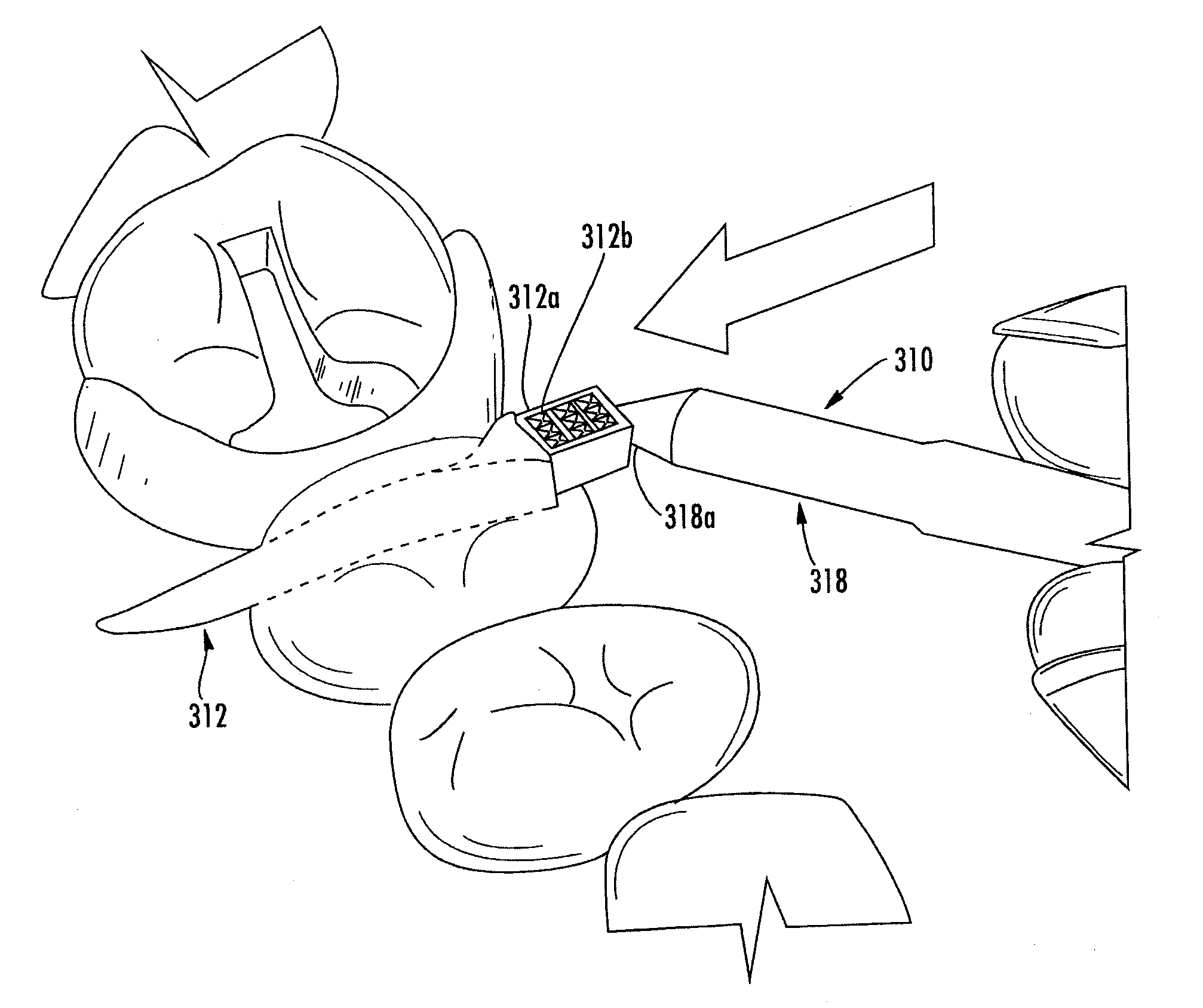

Surgical lift device to assist in surgical access through skin, tissue and organs

A surgical lift device includes a suction member for detachably contacting an external skin surface of a human body wall and holding the external skin surface by application of negative pressure between the suction member and the external skin surface. The suction member has a gripping force sufficient to permit lifting of the human body wall to an elevated position and to hold the human body wall in the elevated position. The suction member has a load-bearing domed structure which determines the lifting of the human body wall during application of negative pressure. The surgical lift device further includes a low friction entry port device arranged on the dome structure, wherein the low friction entry port device has a low friction port fixture for inserting a tool.

Owner:FOND INST ITAL DI TECH

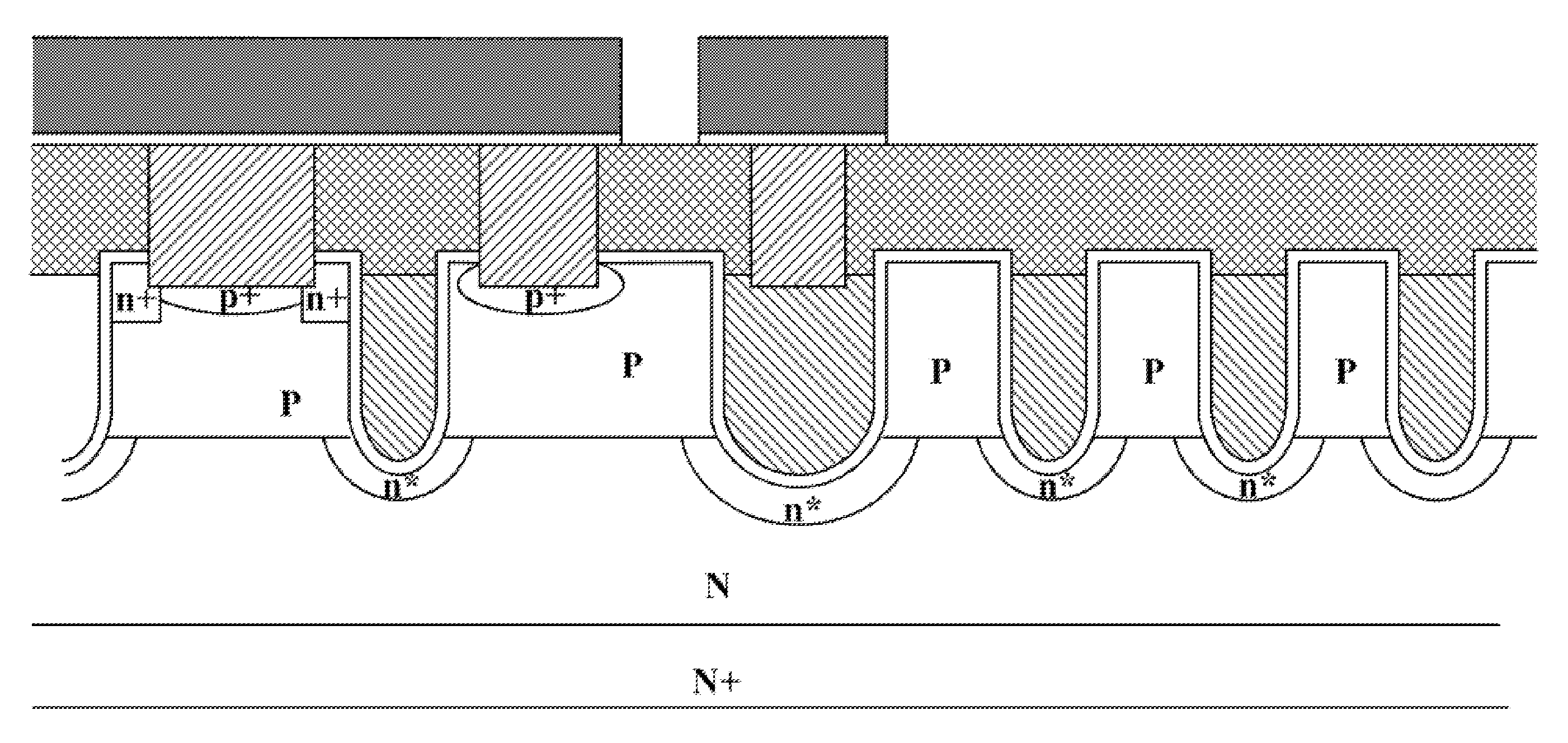

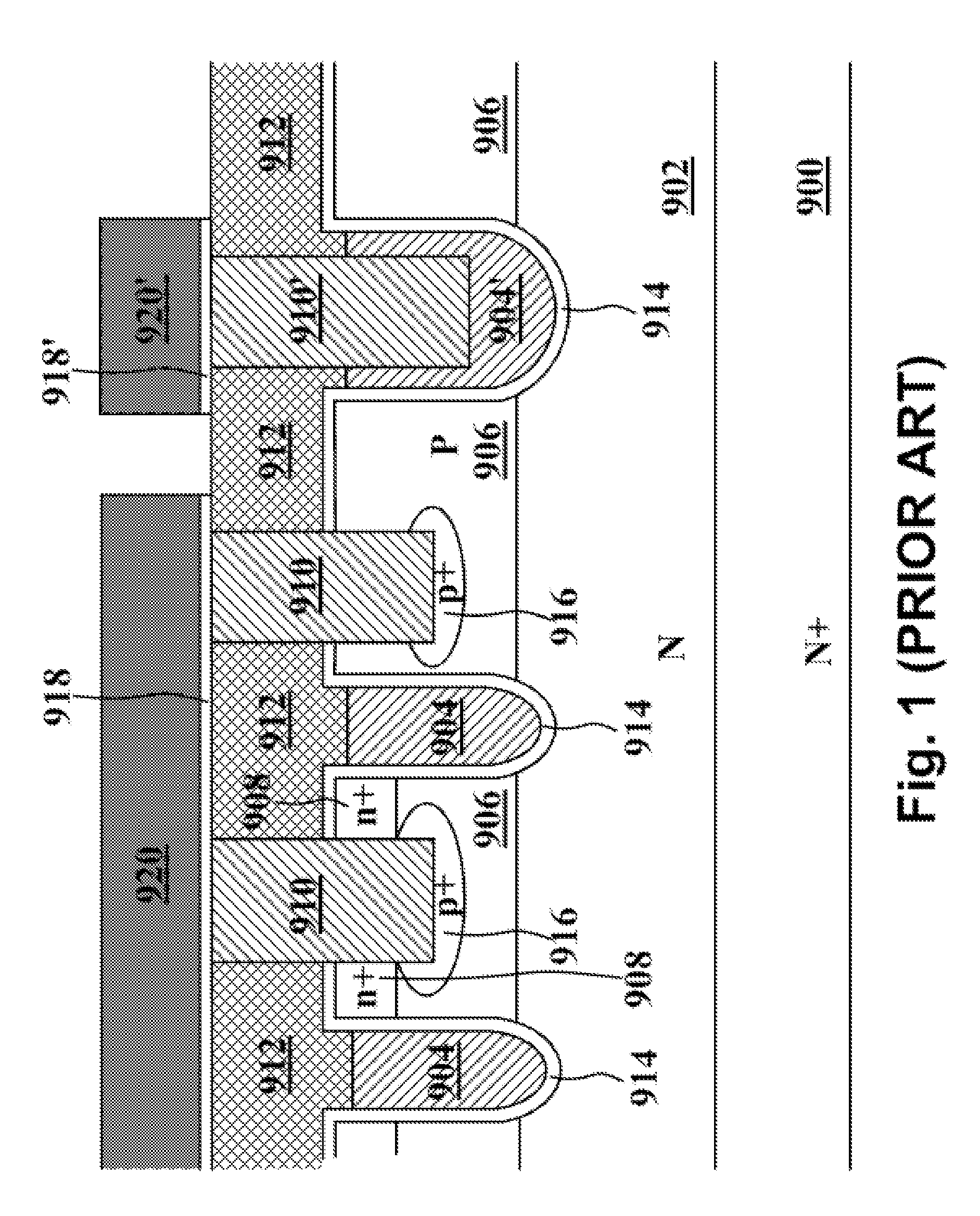

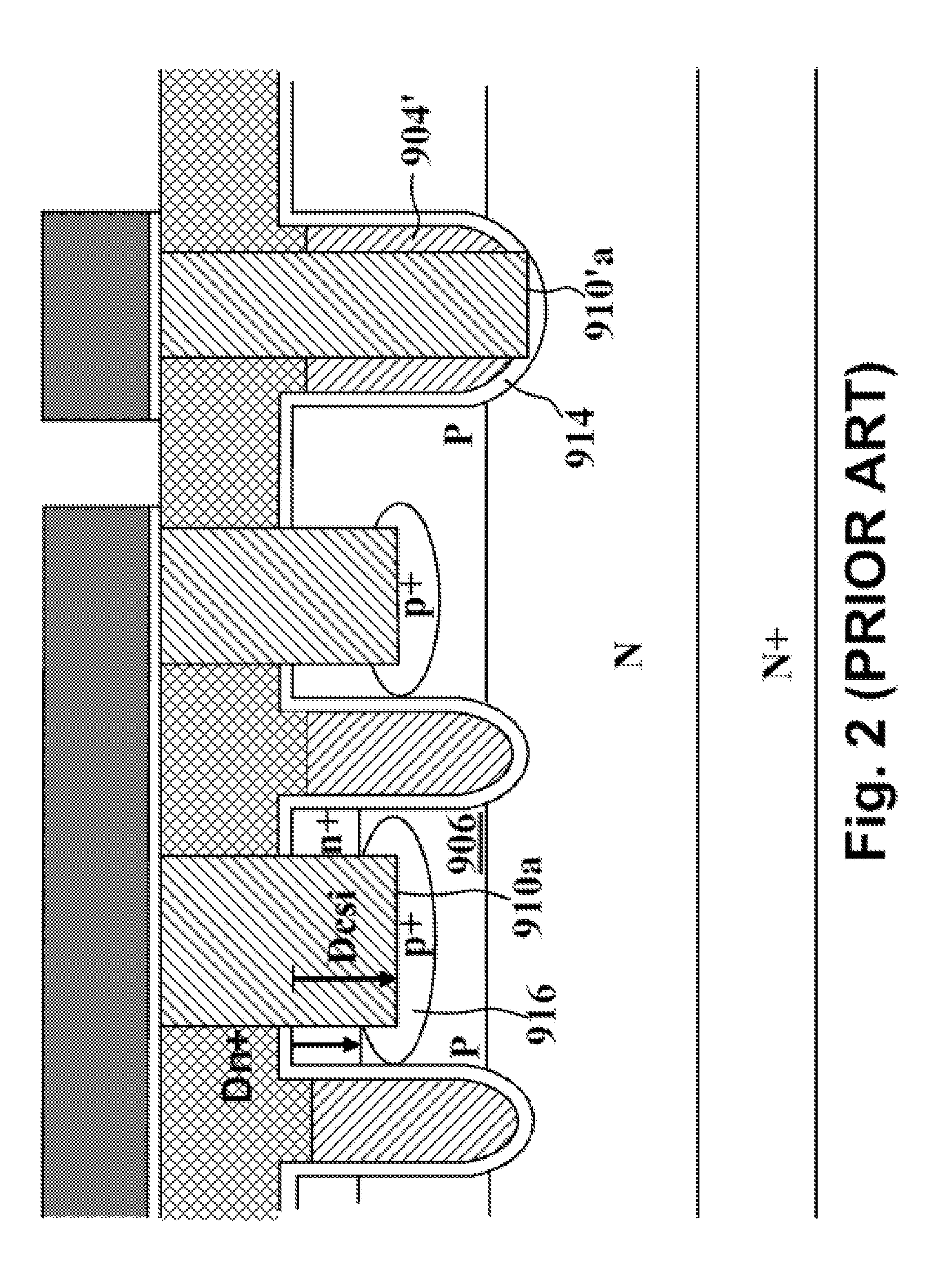

Trench mosfet with shallow trench contact

InactiveUS20100090274A1Lower costGood performanceSemiconductor/solid-state device manufacturingSemiconductor devicesLateral diffusionTrench mosfet

A trench MOSFET element with shallow trench contact is disclosed. This shallow trench contact structure has some advantages: blocking the P+ underneath trench contact from lateral diffusion to not touch to channel region when a larger trench contact CD is applied; avoiding the trench gate contact etching through poly and gate oxide when trench gate becomes shallow; making lower cost to refill the trench contact using Al alloys with good metal step coverage as the trench contact is shallower. The disclosed trench MOSFET element further includes an n* region around the bottom of gate trenches to reduce Rds. In some embodiment, the disclosed trench MOSFET provides a terrace gate to further reduce Rg and make self-aligned source contact; In some embodiment, the disclosed trench MOSFET comprises a P* area underneath said P+ region for avalanche energy improvement with lighter dose than said P+ region.

Owner:FORCE MOS TECH CO LTD

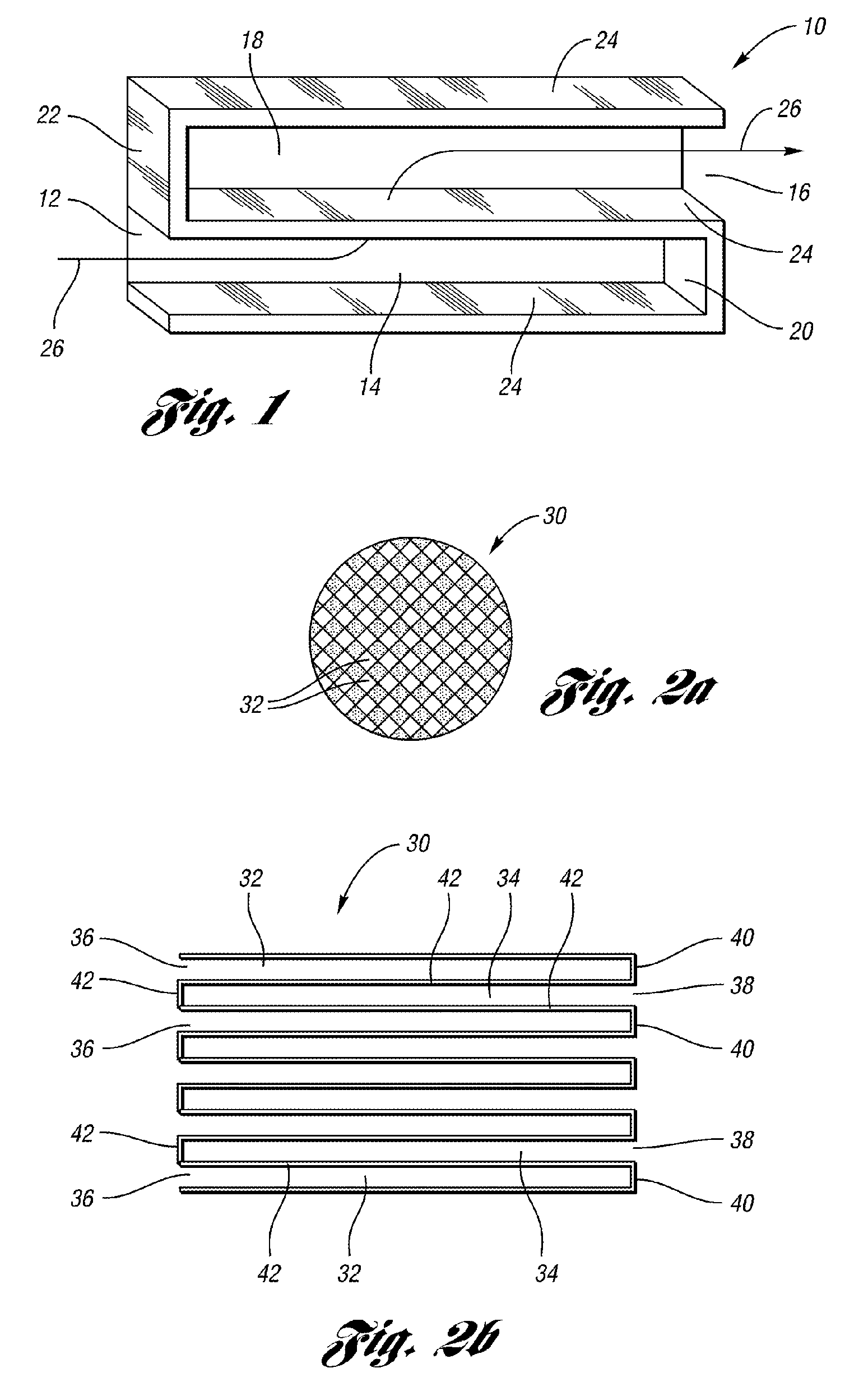

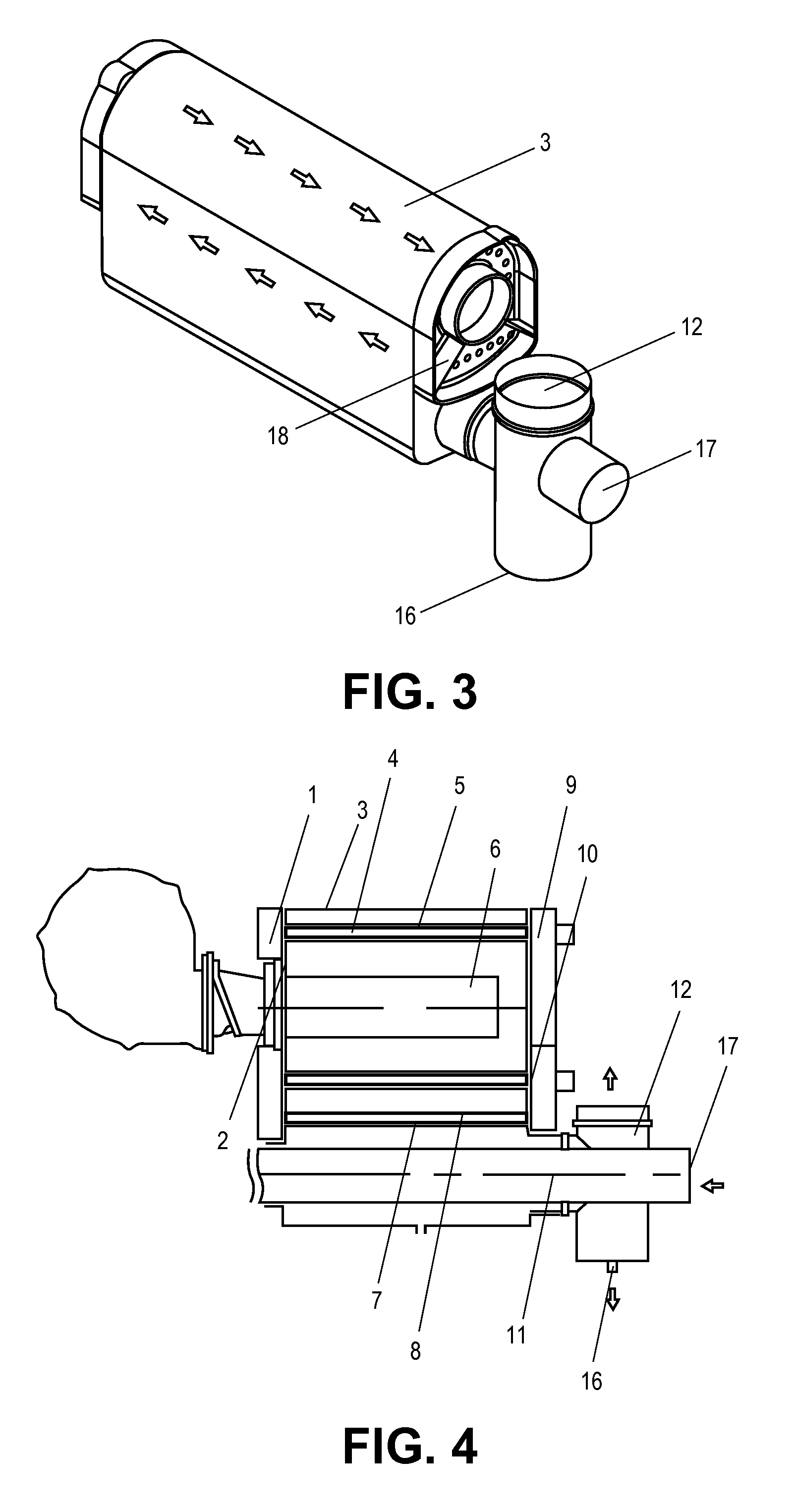

Apparatus for heating of elongate tubular article

InactiveUS20120090765A1Reduce quality problemsFast heating/coolingFurnace componentsLaminationHeat-shrinkable sleeveEngineering

The invention is directed to an apparatus for heating an elongate tubular article, comprising a frame member adapted to be disposed around said article, a heater with multiple heating zones and a controller for operating the heating device. The apparatus may be used to apply a heat shrinkable sleeve around a welded pipe joint. The heater may be infrared and also may use thin stamped sheets. If a heat shrinkable sleeve is used, the controller may activate the heating zones from the centre of the weld outward to eliminate pockets of air. The diameter of the interior of the frame may change along the length of the frame.

Owner:SHAWCOR LTD

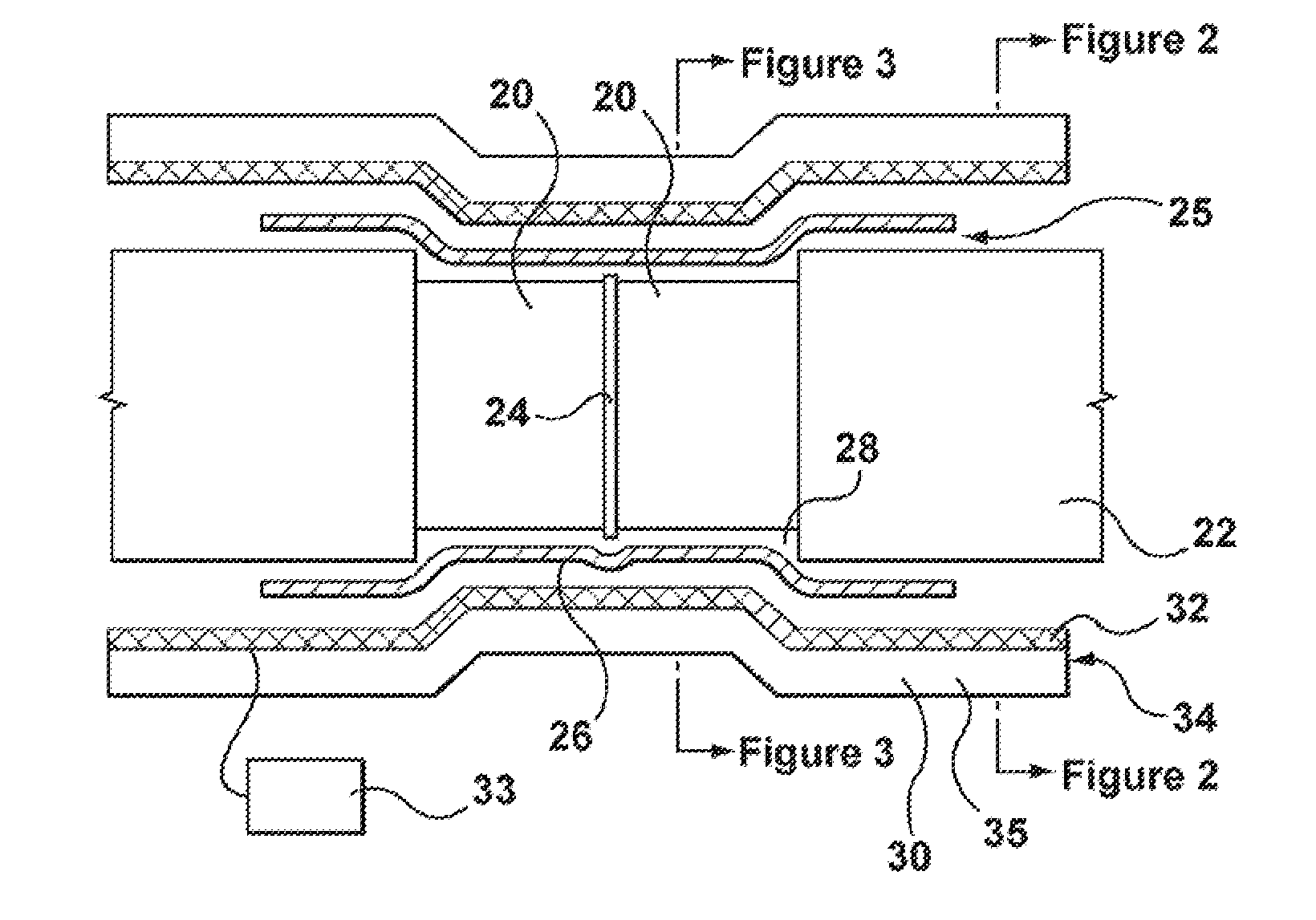

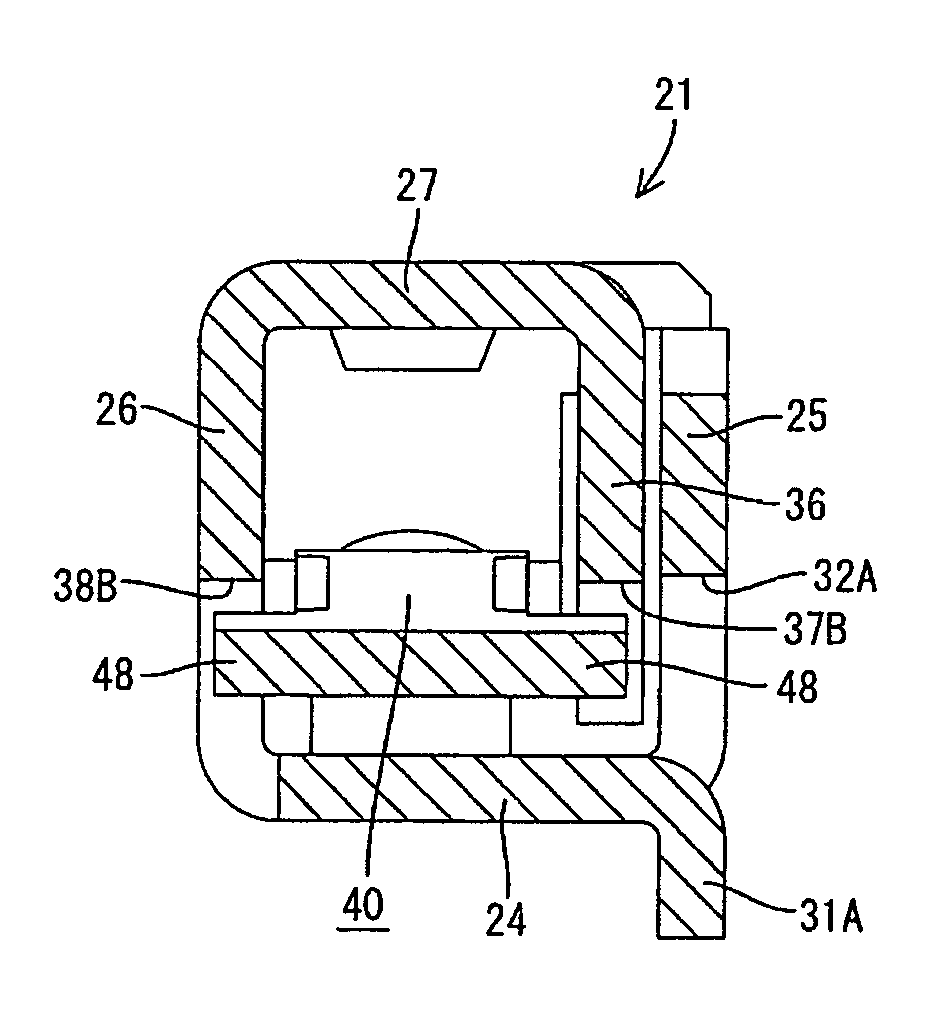

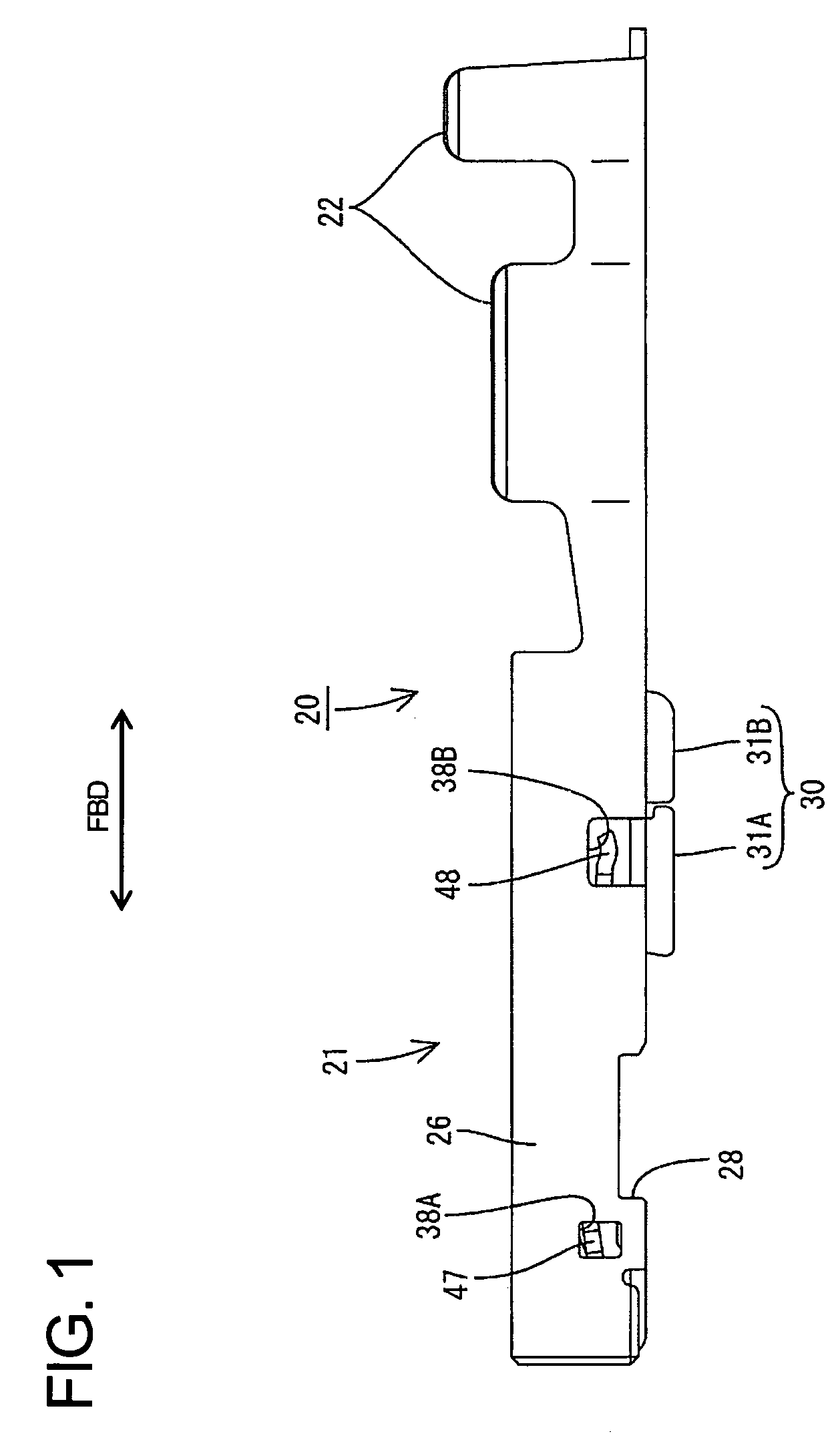

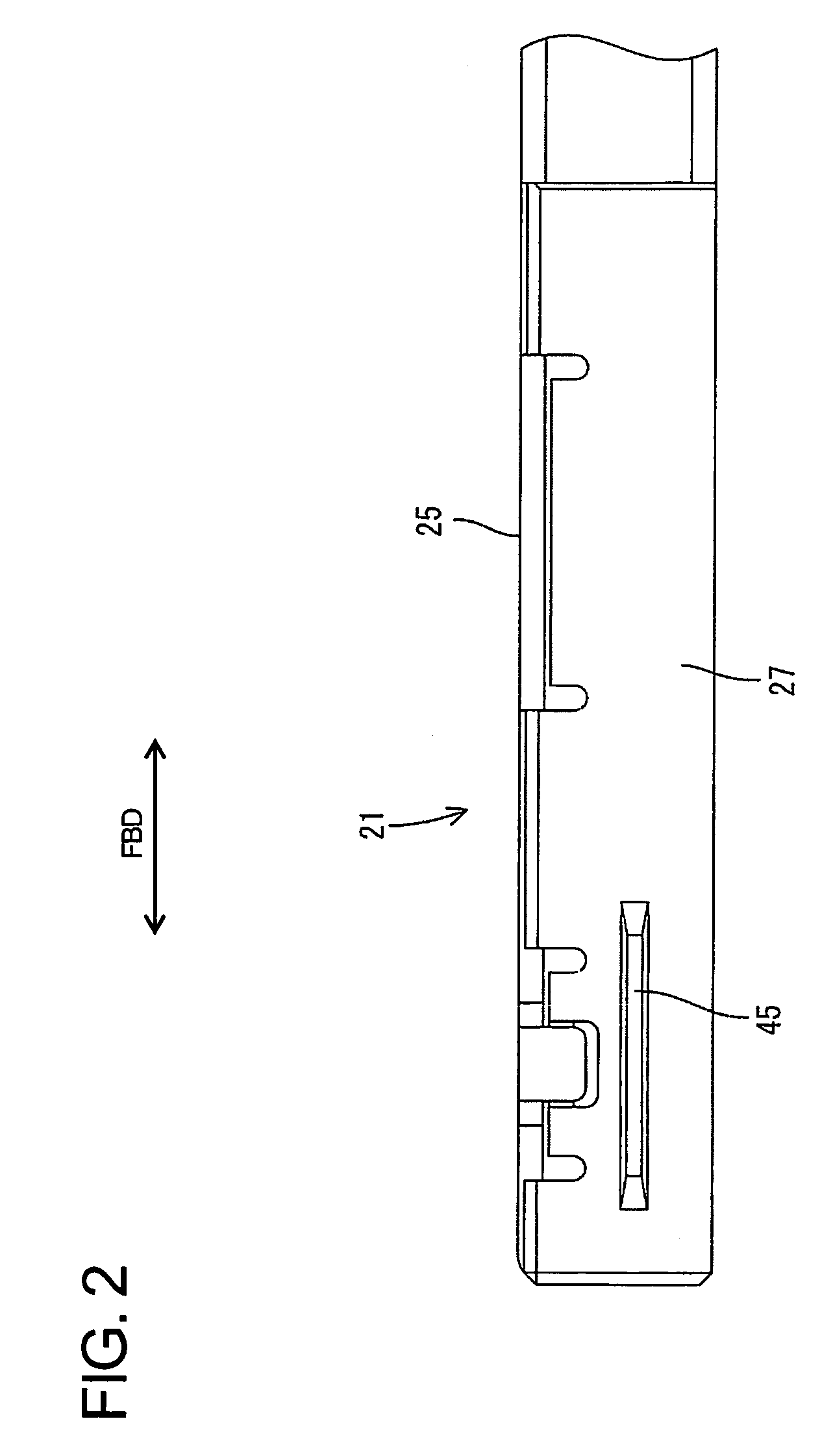

Terminal fitting and a connector provided therewith

ActiveUS7147522B2Entanglement is preventedMany contactsContact member manufacturingSecuring/insulating coupling contact membersEngineeringMechanical engineering

A stabilizer (30) is divided into a front stabilizer (31A) and a rear stabilizer (31B) with a small clearance therebetween. The front and rear stabilizers (31A, 31B) are formed from a left side plate (25) and a bottom plate (25) of a main portion (21) by cutting and bending while leaving holes (32A, 32B). The side hole (32A) is relatively larger and exposes a free end (40A) of a resilient contact (40) to the outside. Thus, a rear inner plate (36) is arranged at an inner side of the side hole (32A) to close the side hole (32A). The plastic deformation of a side of the resilient contact (40) towards the free end (40A) is prevented by preventing the intrusion of a tab (51) of a male terminal fitting (50) or other external matters through the side hole (32A).

Owner:SUMITOMO WIRING SYST LTD

Diesel engine after treatment device for conversion of nitrogen oxide and particulate matter

ActiveUS20060162323A1Maximize surface areaImproved thermal managementCombination devicesInternal combustion piston enginesAfter treatmentProduct gas

An automobile exhaust filter that both traps particulates while altering the concentration of one or more gaseous species is provided. This dual functionality is combined in a single device by utilizing a reactive material that simultaneously alters gaseous component concentration while filtering out particulate material. The automobile exhaust filter is suitable for inclusion in the exhaust of a diesel-powered vehicle. A method utilizing the automobile exhaust catalyst is also provided.

Owner:FORD GLOBAL TECH LLC

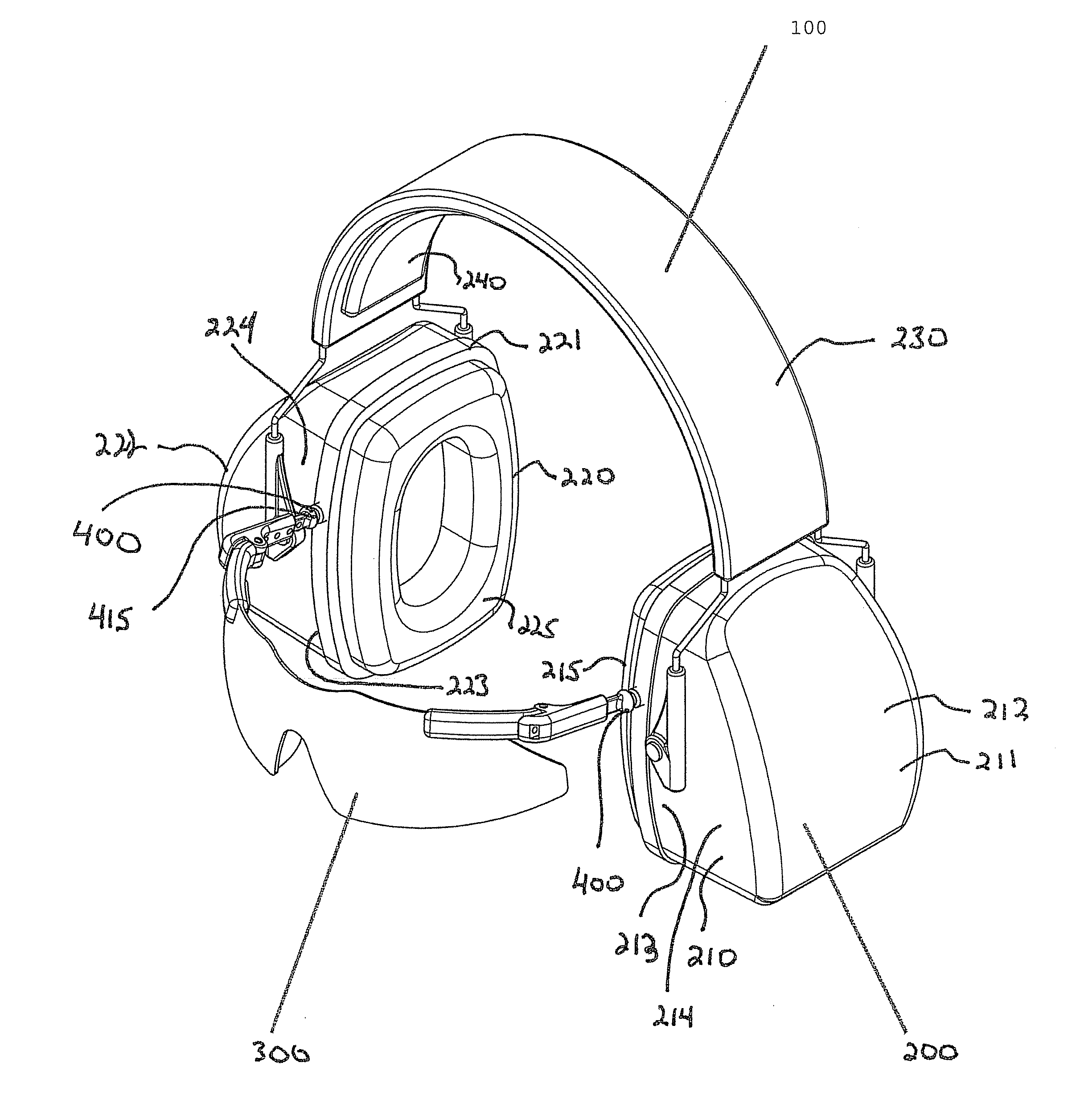

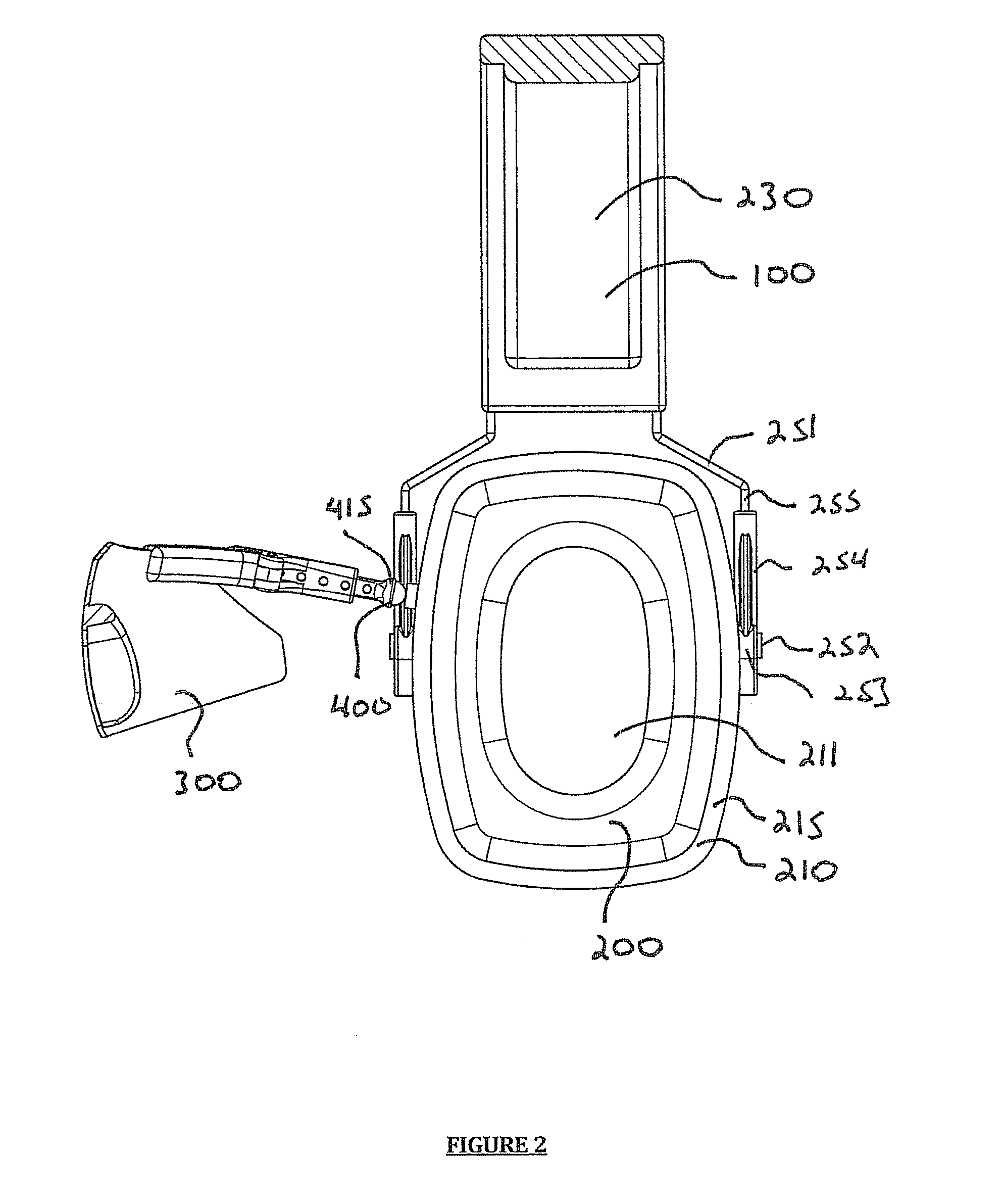

Combination headgear and eye protection system

A combination headgear assembly and protective eyewear system includes protective eyewear that attaches to a headgear assembly via magnetic connectors. The headgear assembly includes an adjustable headrest with first and second ends. The first end connects to a first spherical capsule having a first side wall, and the second end connects to a second spherical capsule having a second side wall. The protective eyewear includes a vision blade with a first end attaching via a first finger to a first telescoping member while a second end attaches via a second finger to a second telescoping member. A first magnetic connector is positioned between the first telescoping member and the first side wall of the first spherical capsule, and a second magnetic connector is positioned between the first telescoping member and the second side wall of the second spherical capsule.

Owner:GAUSS TECH LLC

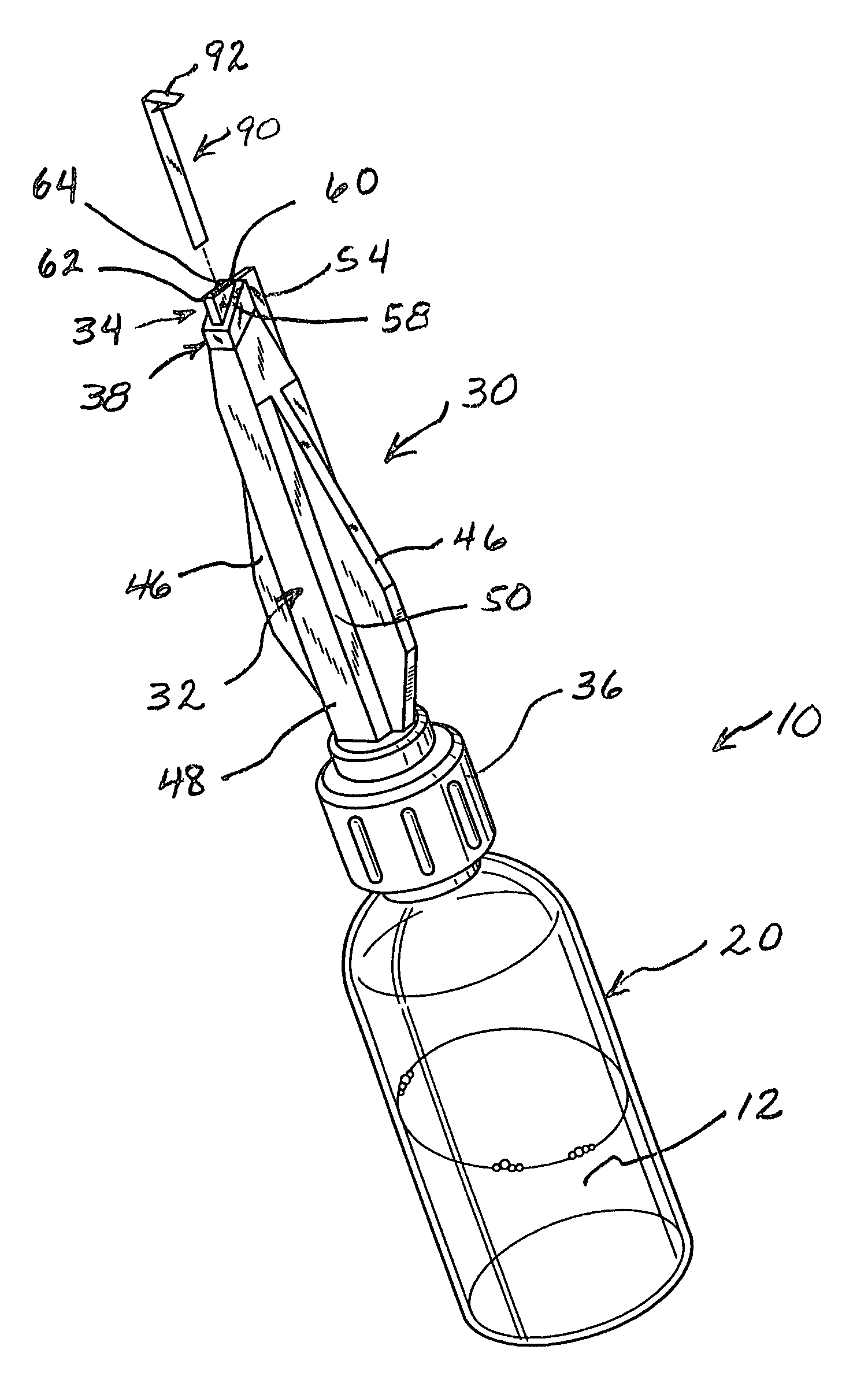

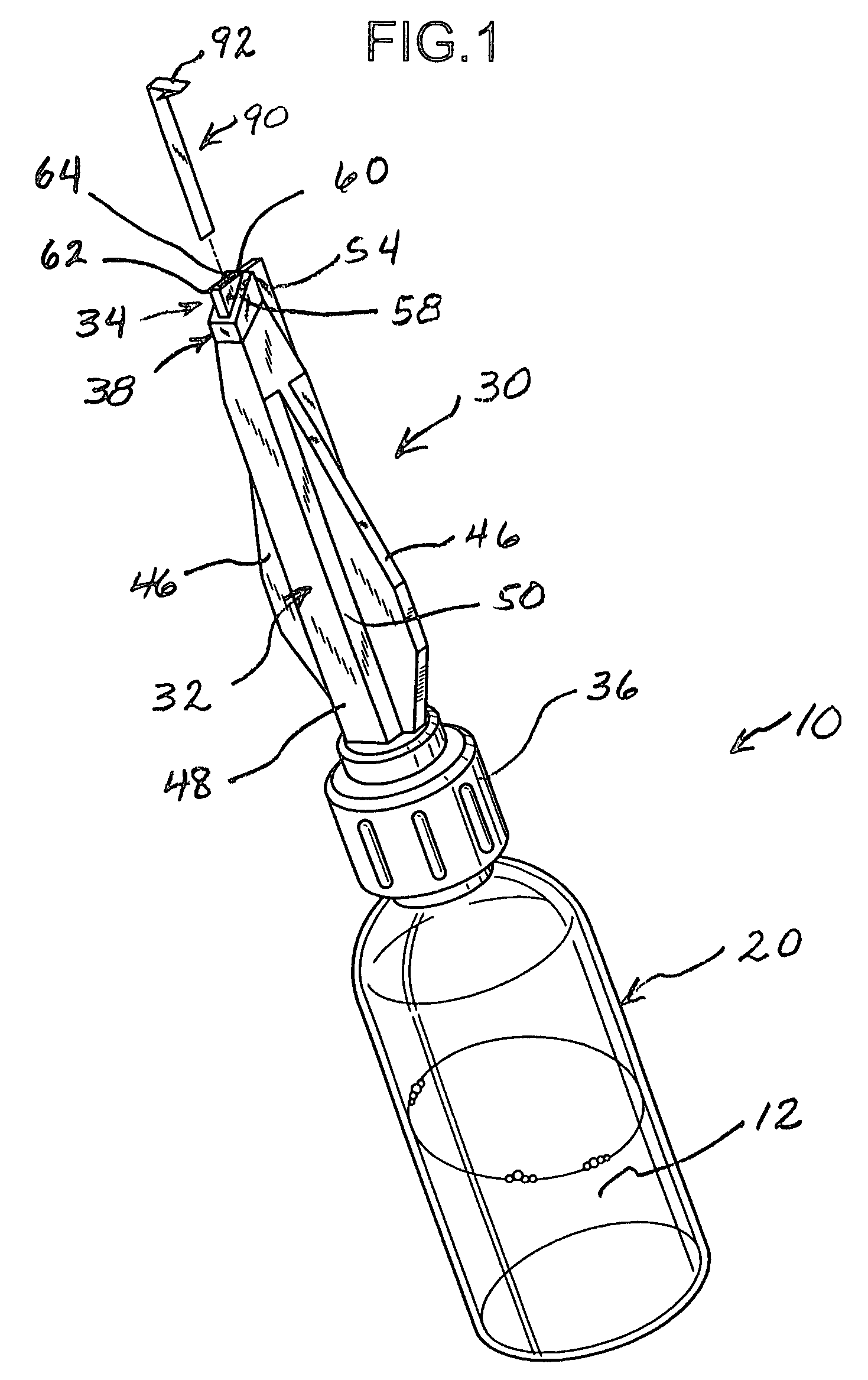

Seam sealer applicator

A seam sealing applicator for dispensing chemical sealant into seams between adjacent sheets of flooring is comprised of a sealant reservoir mounted atop an improved seam sealer applicator tip. The applicator tip of the invention has an elongated, hollow, rigid plastic body with a pair of laterally projecting wings or flanges between its proximal end which receives the sealant reservoir and its opposite, distal sealant dispensing end. The distal end of the plastic body terminates in a flat face, preferably oriented at an angle of about seventy degrees relative to the alignment of the linear sealant delivery duct formed within the body. A thin, hollow, narrow metal insert is set into the distal end of the body. A keel or fin portion of the metal insert protrudes beyond the flat face and projects into a seam between adjacent sheets of flooring. The fin portion of the metal insert defines a thin, narrow, dispensing slit through which sealant may be dispensed deep into the seam between sheets of adjacent flooring. A tracking sight ridge is preferably formed on the front of the applicator tip at the distal end thereof, directly above the flat sealant application flow face. The applicator tip body is at least three inches in length so that it can be gripped by the hand of the installer in a variety of different ways.

Owner:MARTINEZ LEO

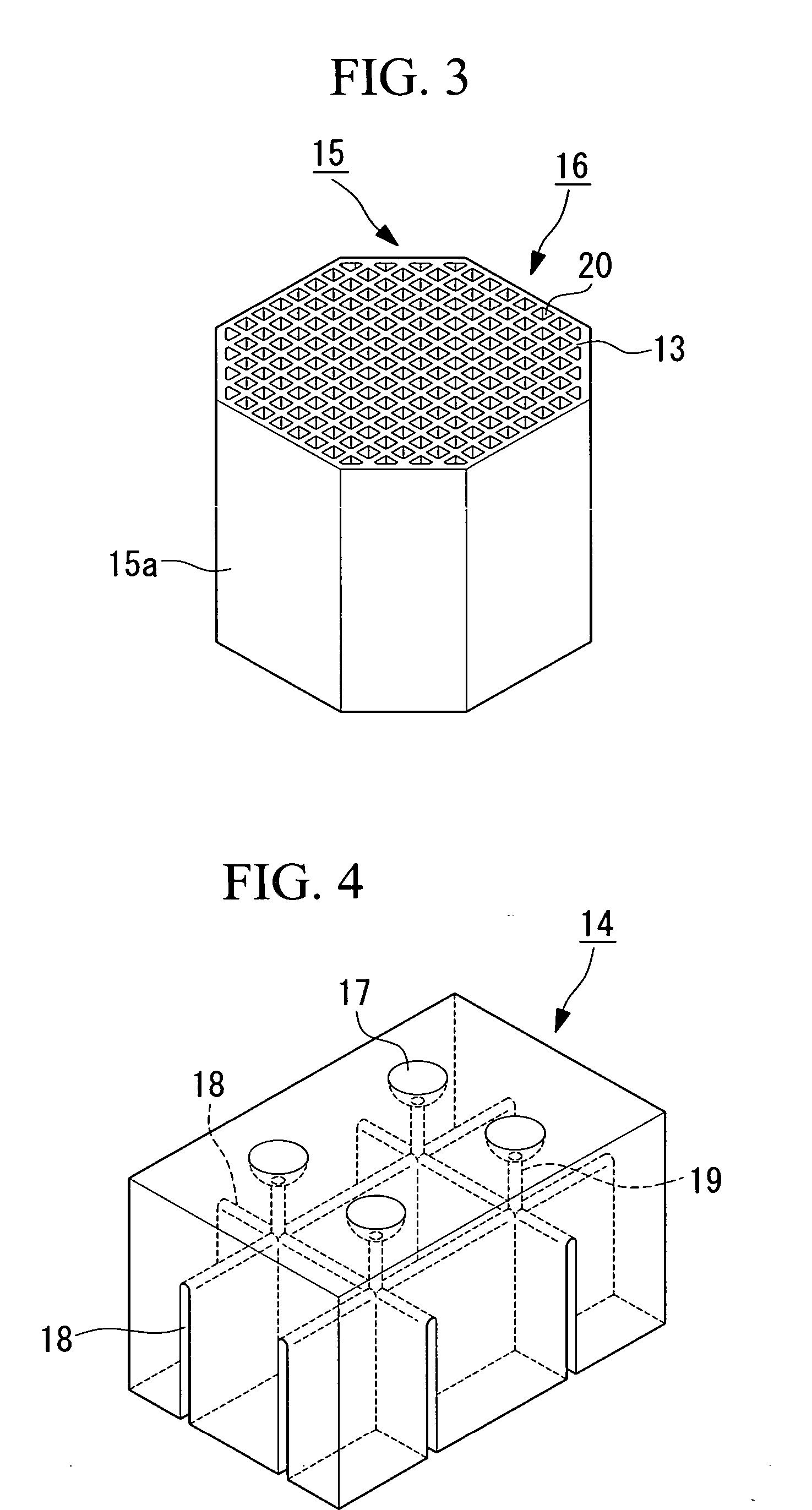

Material for repairing biological tissues and process for producing the same

InactiveUS20070112434A1Promote formationSufficient forceBone implantJoint implantsCell activityBinding force

A bone substitute (a material for repairing biological tissues) made from β-TCP as the raw material comprises a plate-type base member on the surface of which a plurality of grooves extending in a single direction are formed and separated from each other by partition wall members having an almost uniform thickness. This material sustains a sufficient binding force after application to a biological tissue and exhibits an excellent effect of forming a biological tissue. This bone substitute (material for repairing biological tissues) having a main body provided with a plurality of grooves extending in a single direction which are separated from each other by partition wall members having an almost uniform thickness, and a biodegradable viscous member which is filled into at least one of the penetrating holes of the main body, and contains an agonistic factor capable of increasing the cell activity, can provide agonistic factors of sufficient types and amounts to a biological tissue, and can control the sustained-release dose thereof.

Owner:OLYMPUS CORP

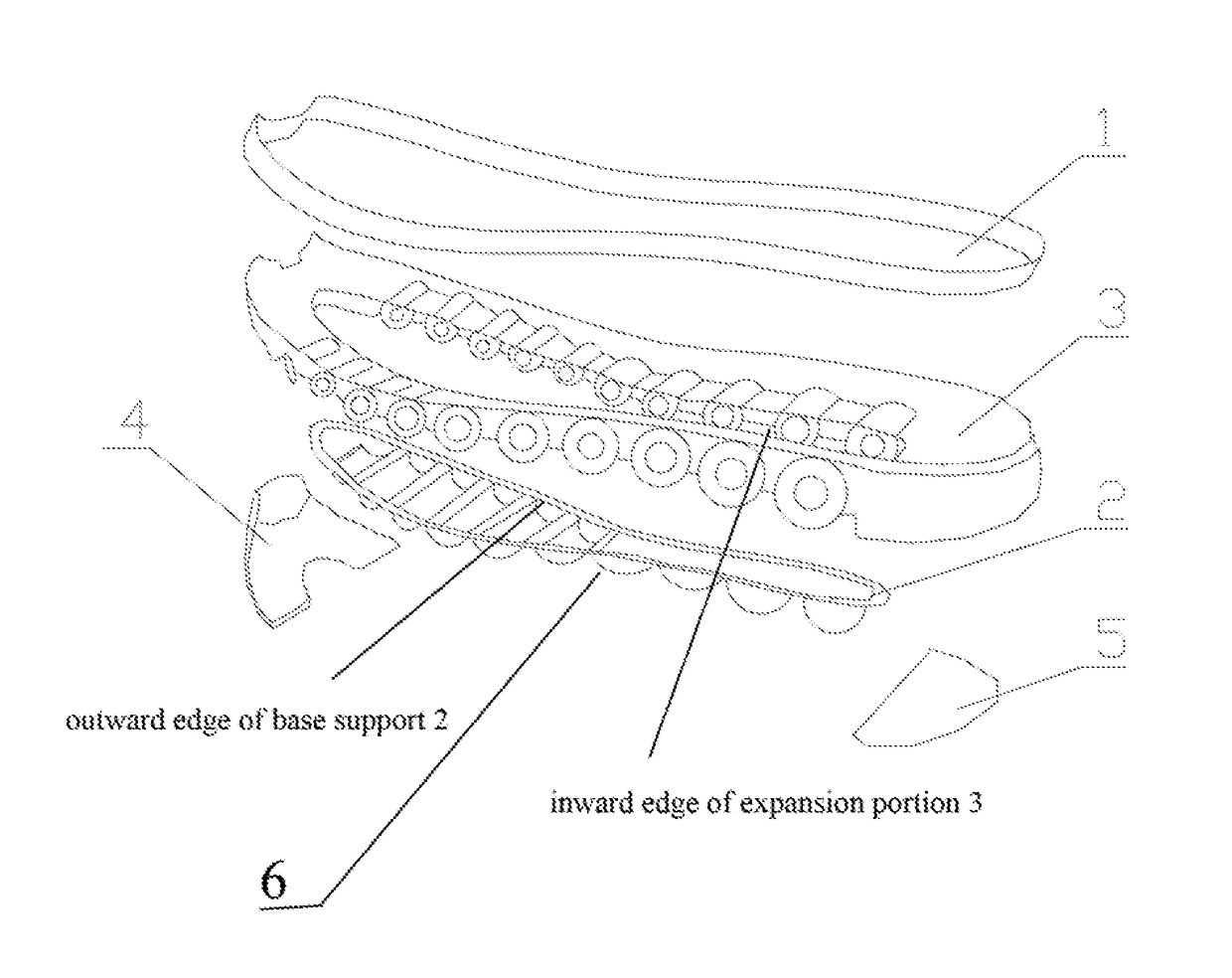

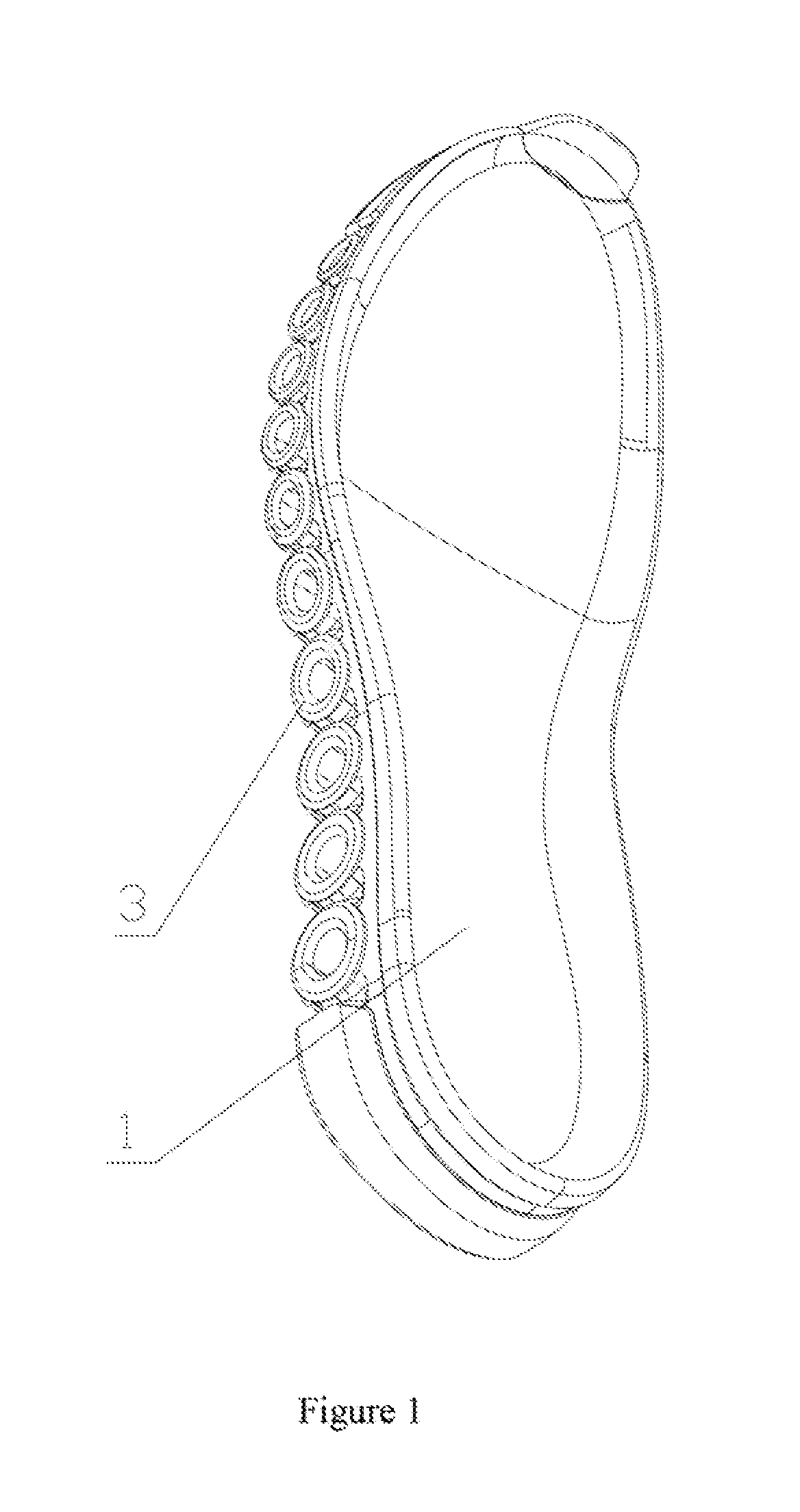

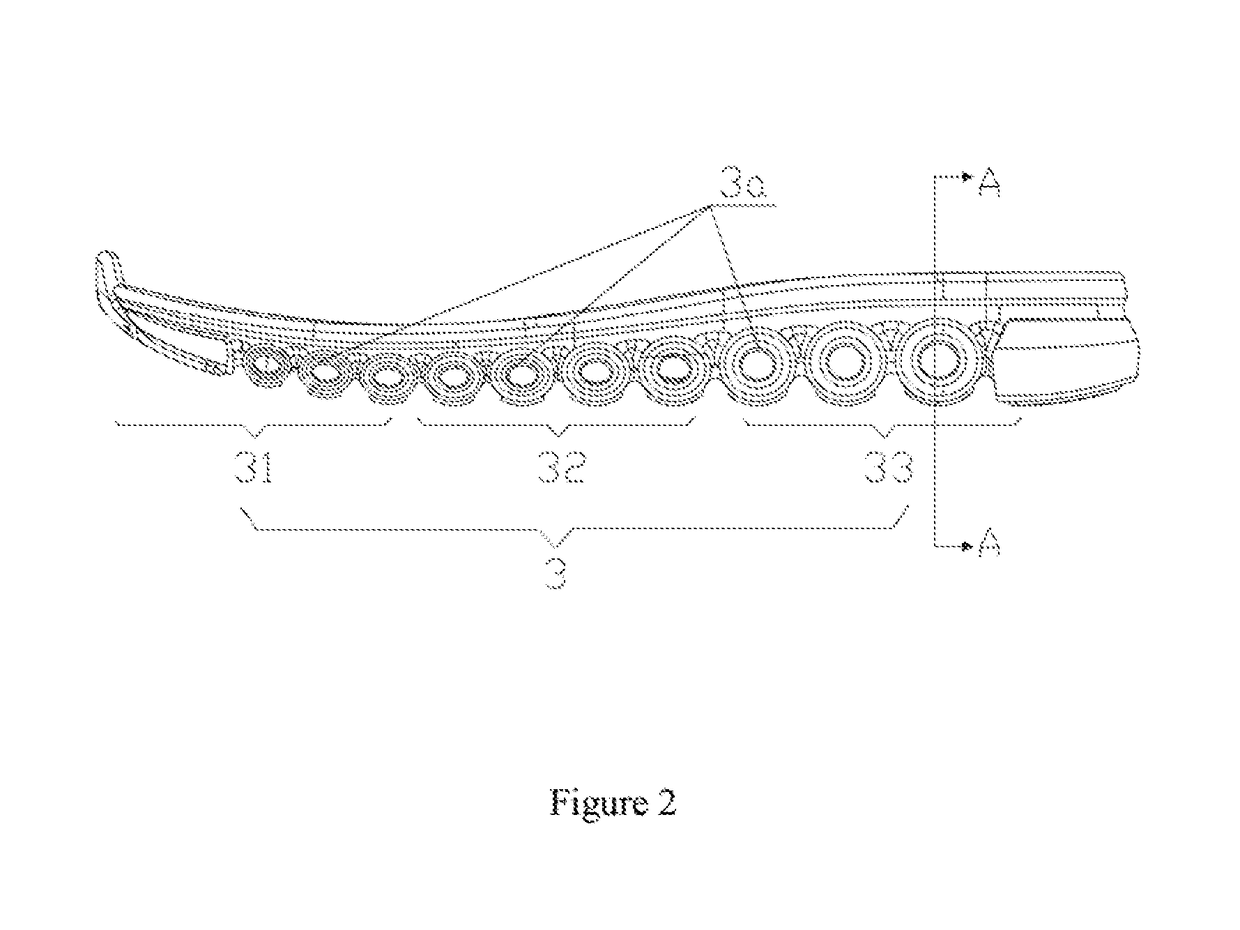

Shoe sole and footwear constituted thereof

Owner:ANTA CHINA

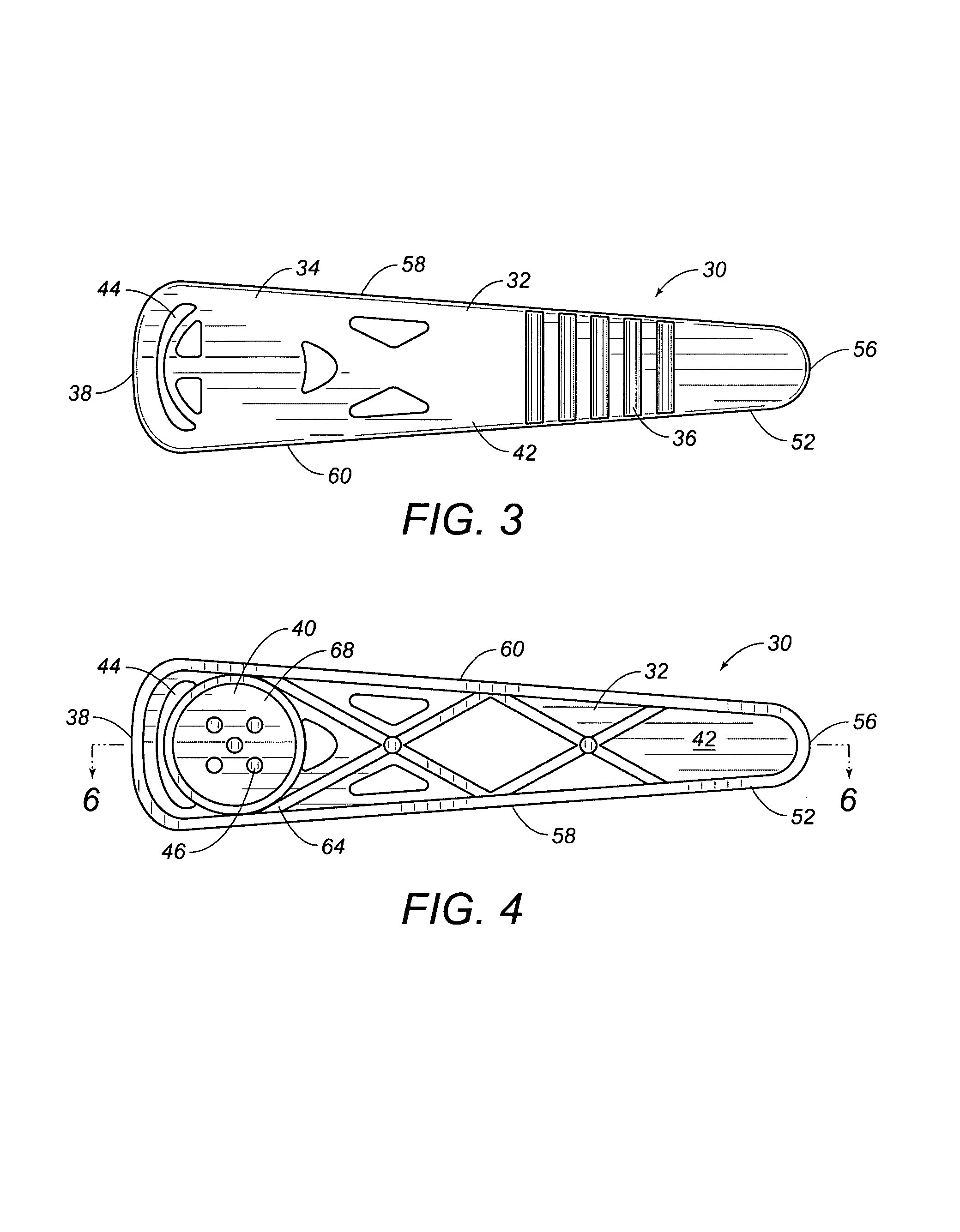

Tongue cleaner apparatus with an abrasive tablet

InactiveUS7090687B1Improves abrasive scrubbing actionSmooth connectionEar treatmentSurgeryTongue cleanerBiomedical engineering

A tongue cleaner apparatus having a elongate body with a gripping area at one end thereof and a tablet receiving area adjacent an opposite end thereof, a cleaning edge formed at the opposite end of the elongate body, and a tablet affixed within the tablet receiving area of the elongate body. The tablet has a plurality of protrusions or a plurality of indentations on a surface of the tablet. The protrusions or indentations extend from the surface of the tablet that contacts the tongue. The tablet increases the abrasiveness and surface area of contact on the tongue.

Owner:GWEN PATRICK

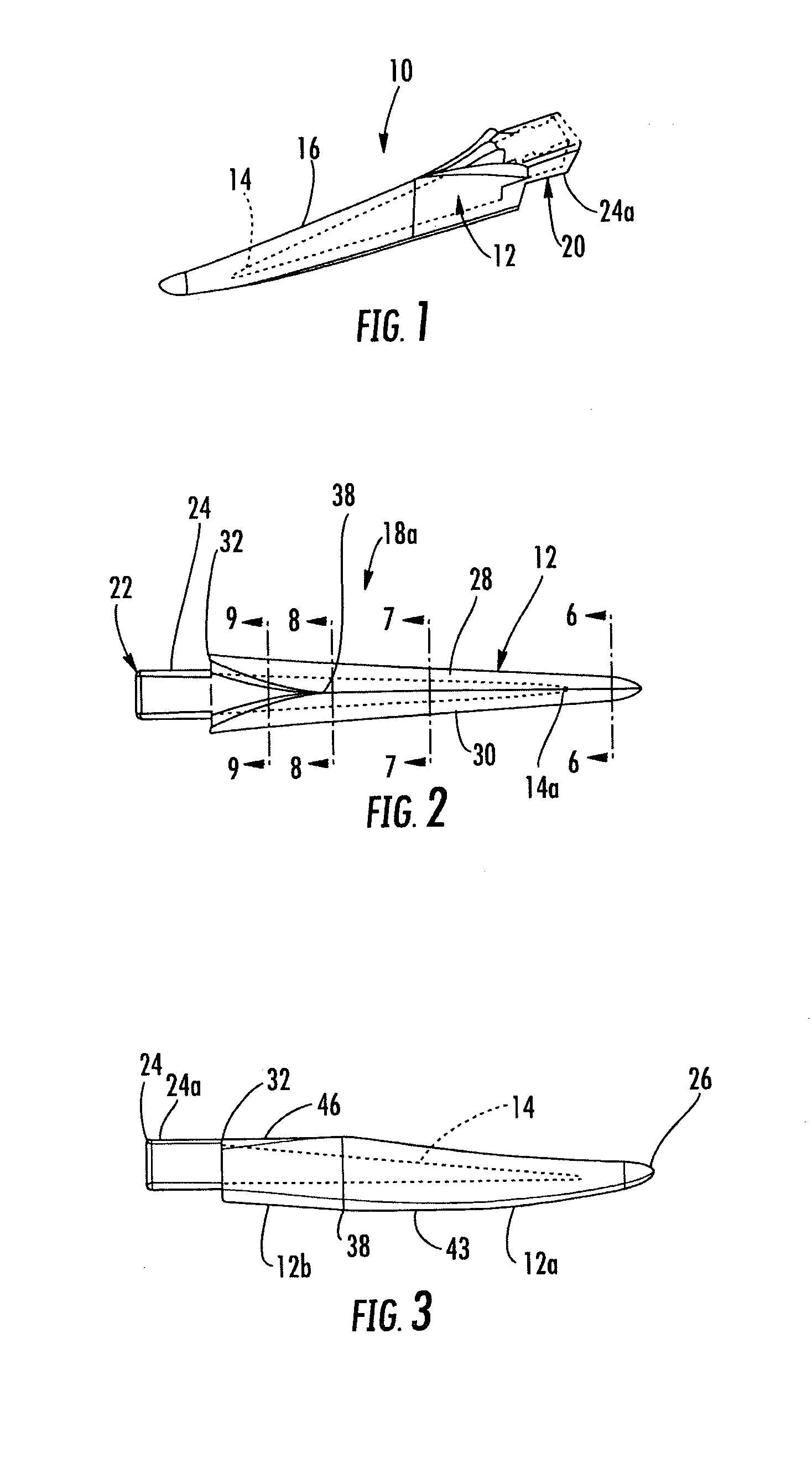

Wedge for use in dental restoration

ActiveUS7223101B2Reduces trauma to the gum tissueEliminate degradationOthrodonticsDam holdersDental restoration

A dental wedge comprises an elongated body, which includes a distal end and a proximal end which tapers to the distal end. The distal end defines an insertion end and tilts upwardly. The elongate body has a first portion starting at the distal end and has a second portion that ends at the proximal end. The first portion has a generally triangular-shaped cross-section and the second portion has a generally trapezoidal cross-section.

Owner:GARRISON TOM +1

Inline RF heating for SAGD operations

ActiveUS8936090B2Improve heat transfer efficiencyImprove consistencyInsulationFluid removalThermal energyEngineering

A method is described for accelerating start-up for SAGD-type operation by providing radio frequency heating devices inside the lateral wells that can re-heat the injected steam after losing heat energy during the initial injection. The method also extends the lateral wells such that the drilling of vertical wells can be reduced to save capital expenses.

Owner:HARRIS CORP +1

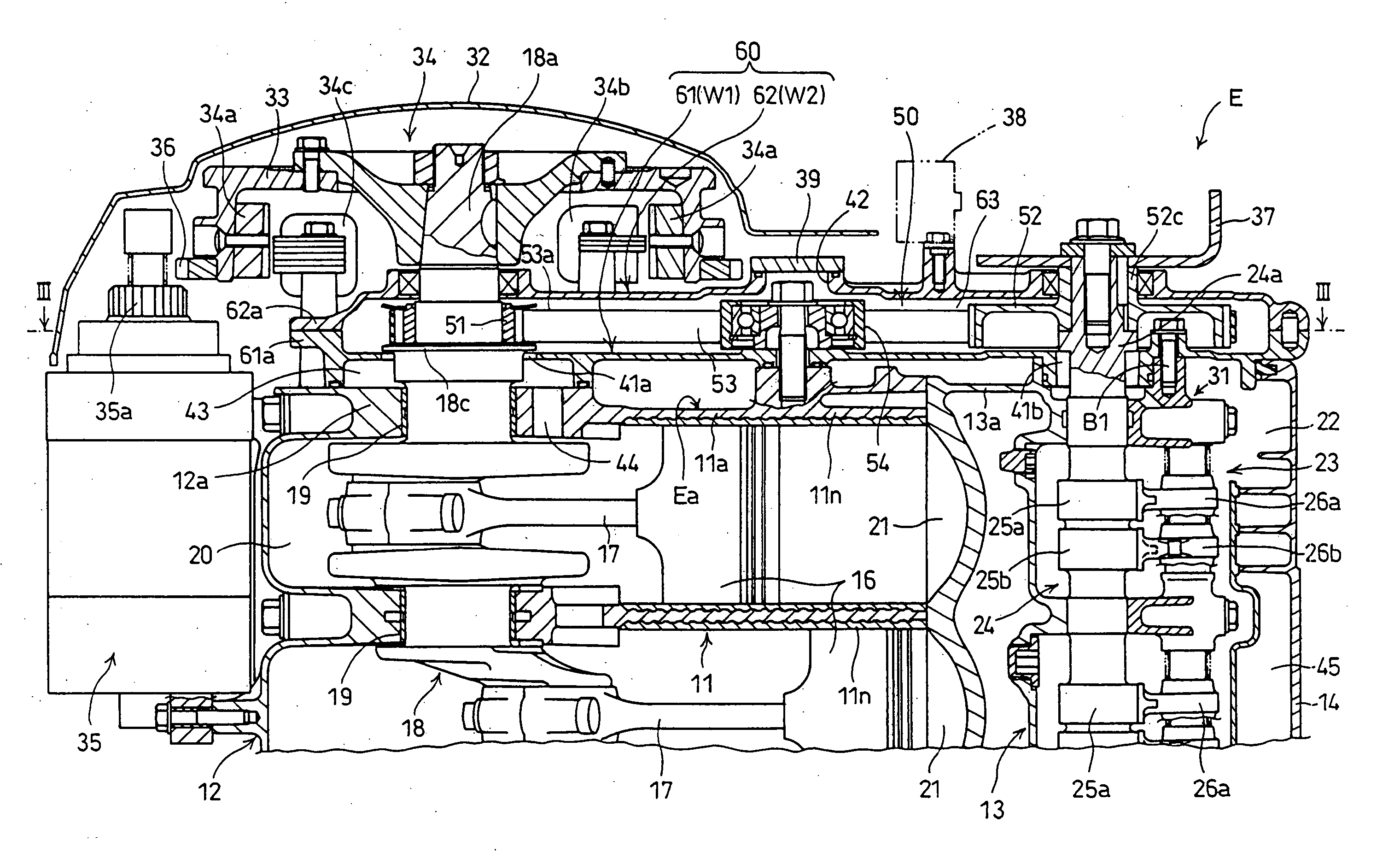

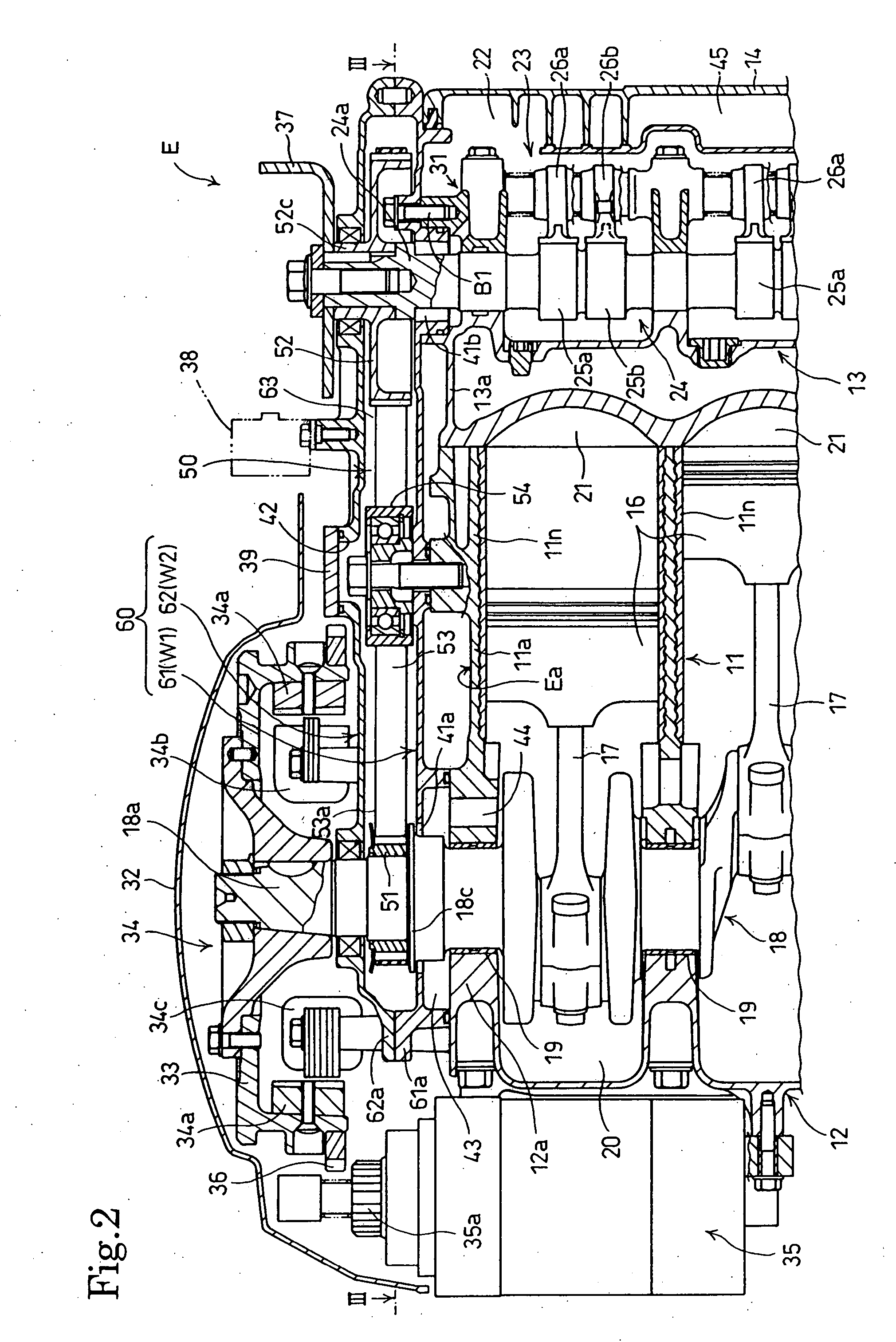

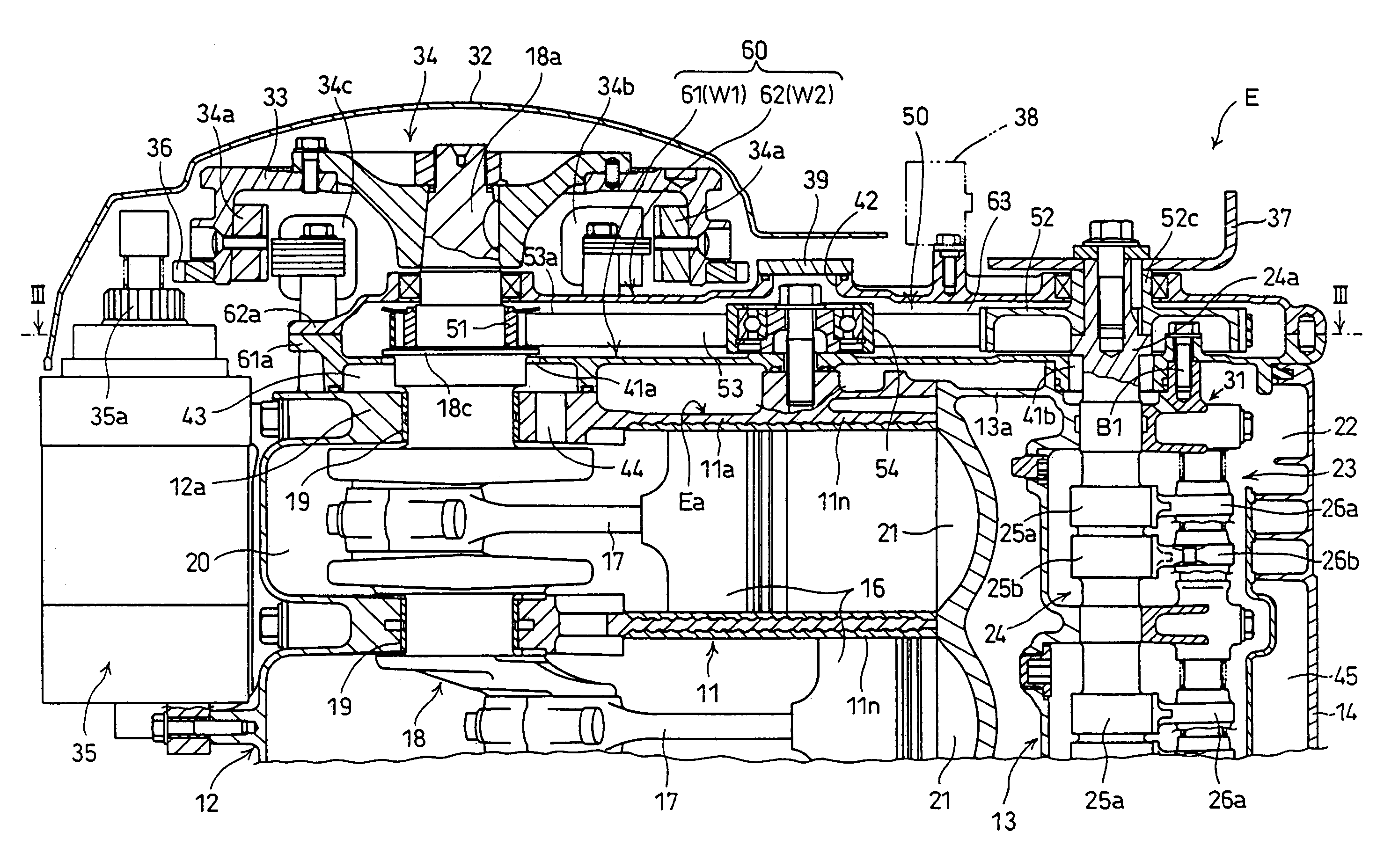

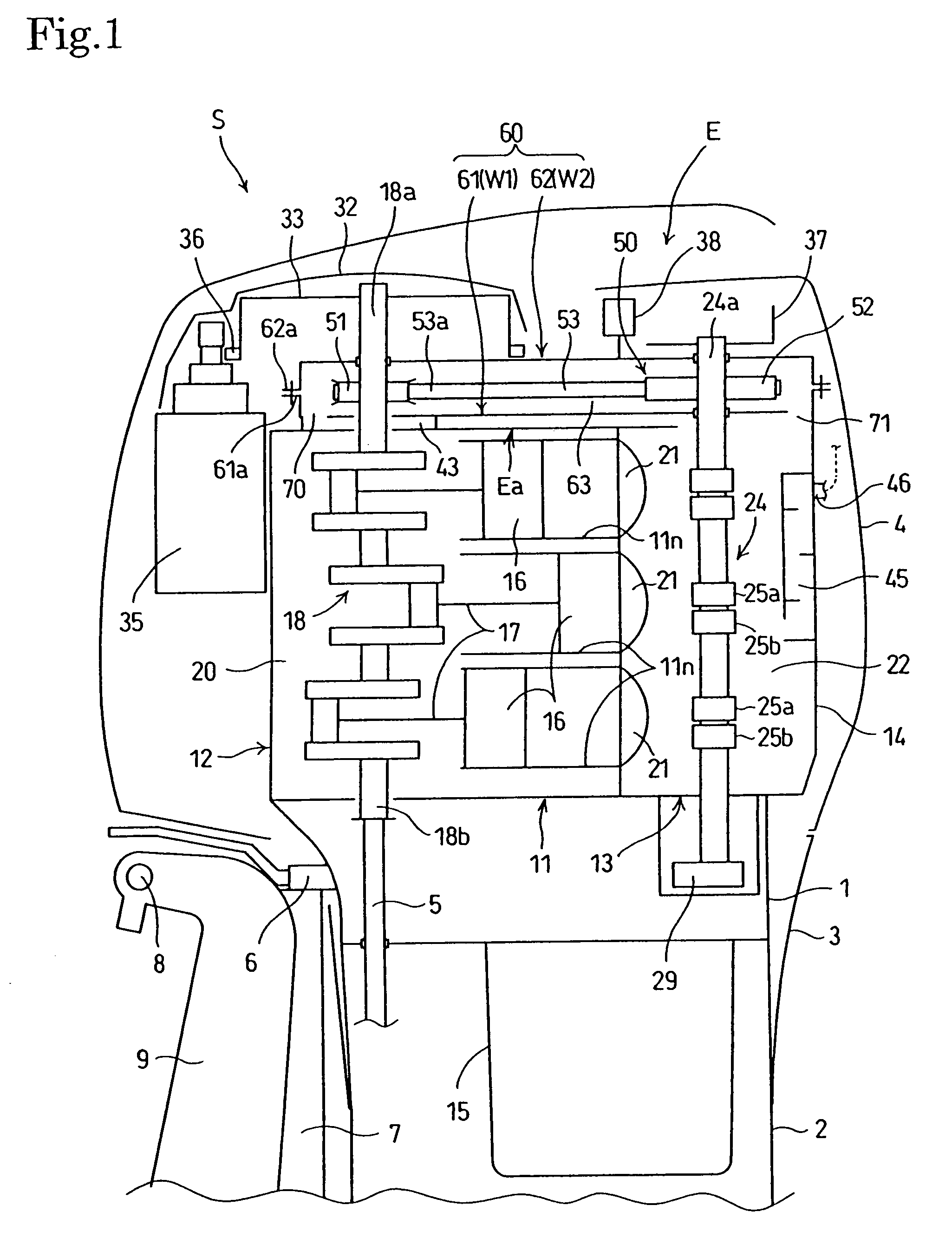

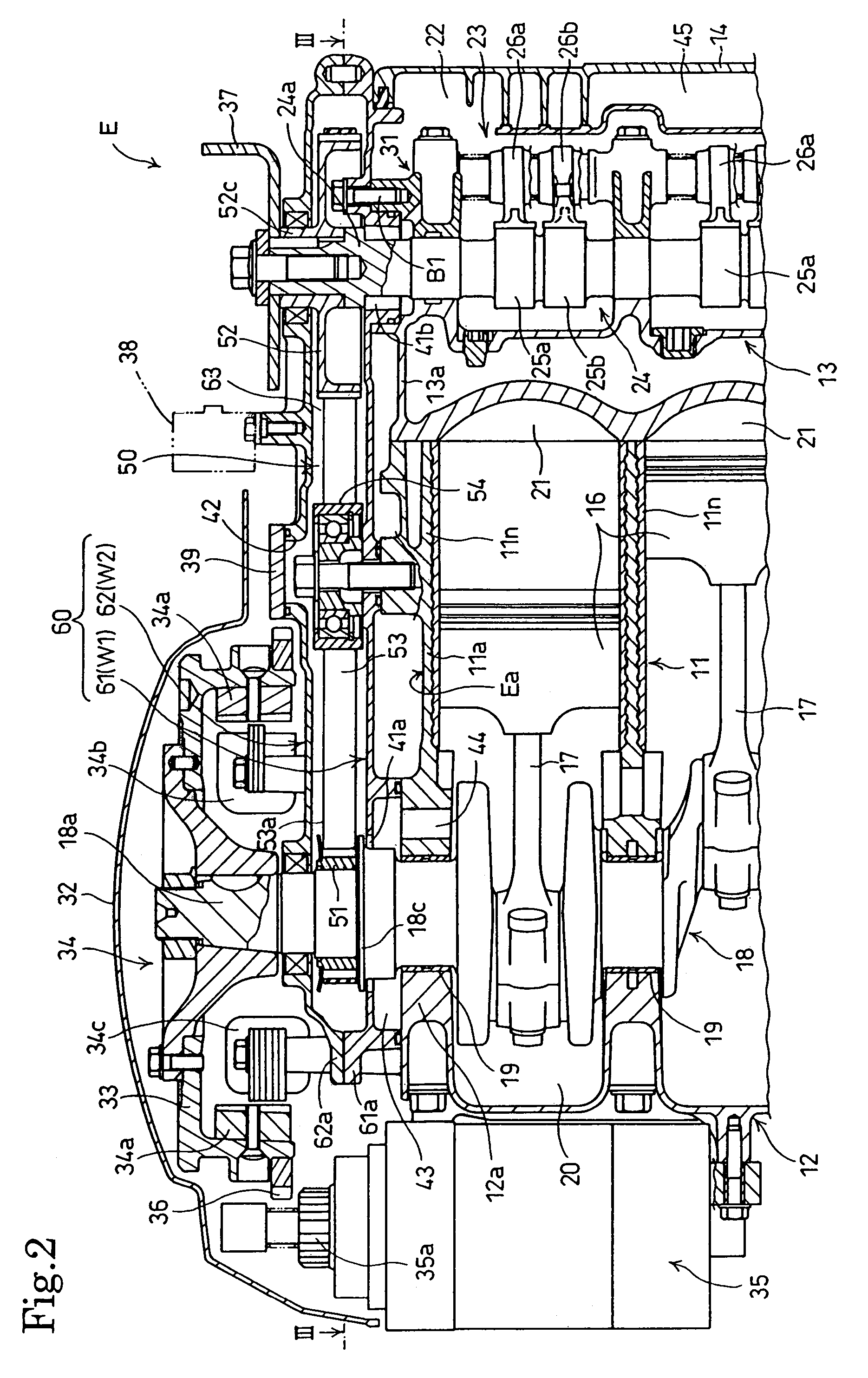

Vertical internal combustion engine provided with belt-drive transmission mechanism

InactiveUS20070251479A1Avoid contactProlong lifeLubrication of auxillariesGearboxesTransmitted powerEngineering

A vertical internal combustion engine E includes a crankshaft 18 enclosed in a crank chamber 20, a belt-drive transmission mechanism 50 held in a belt chamber 63 and including a rubber belt 53 for transmitting power of the crankshaft 18 to a camshaft 24 included in a valve train 23, and a transmission case 60 defining the belt chamber 63. The transmission case 60 has a lower case 61 between the crank chamber 20 and the belt chamber 63. The belt 53 has a part 53a extending over the crank chamber 20, and the lower case 61 is disposed to screen the part 53a of the belt 53 from the crank chamber 20. The belt 53 is lubricated by oil in oil-containing gas from the crank chamber 20. Thus the oil-containing gas is prevented from excessively contacting the rubber belt, so that the life of the belt is extended.

Owner:HONDA MOTOR CO LTD

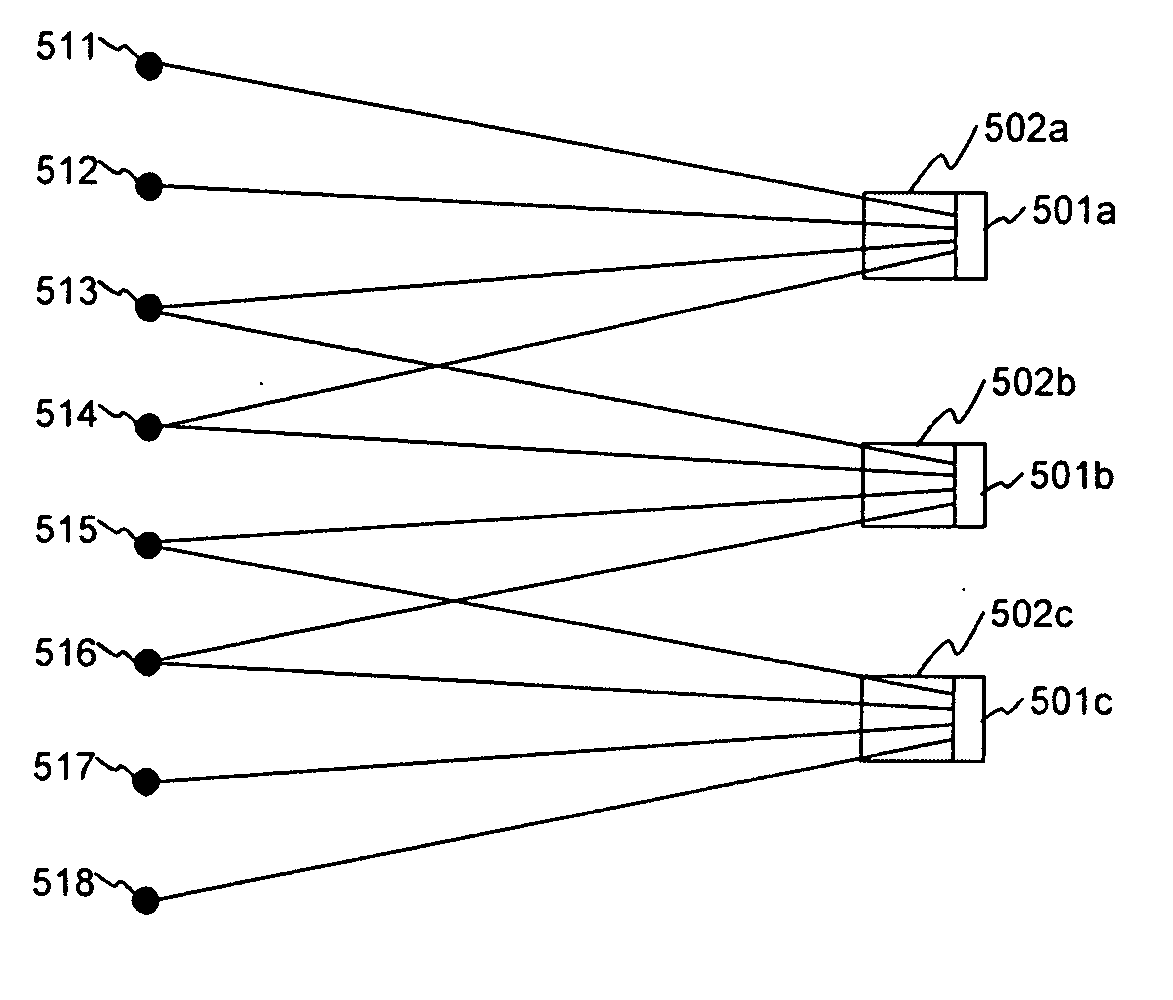

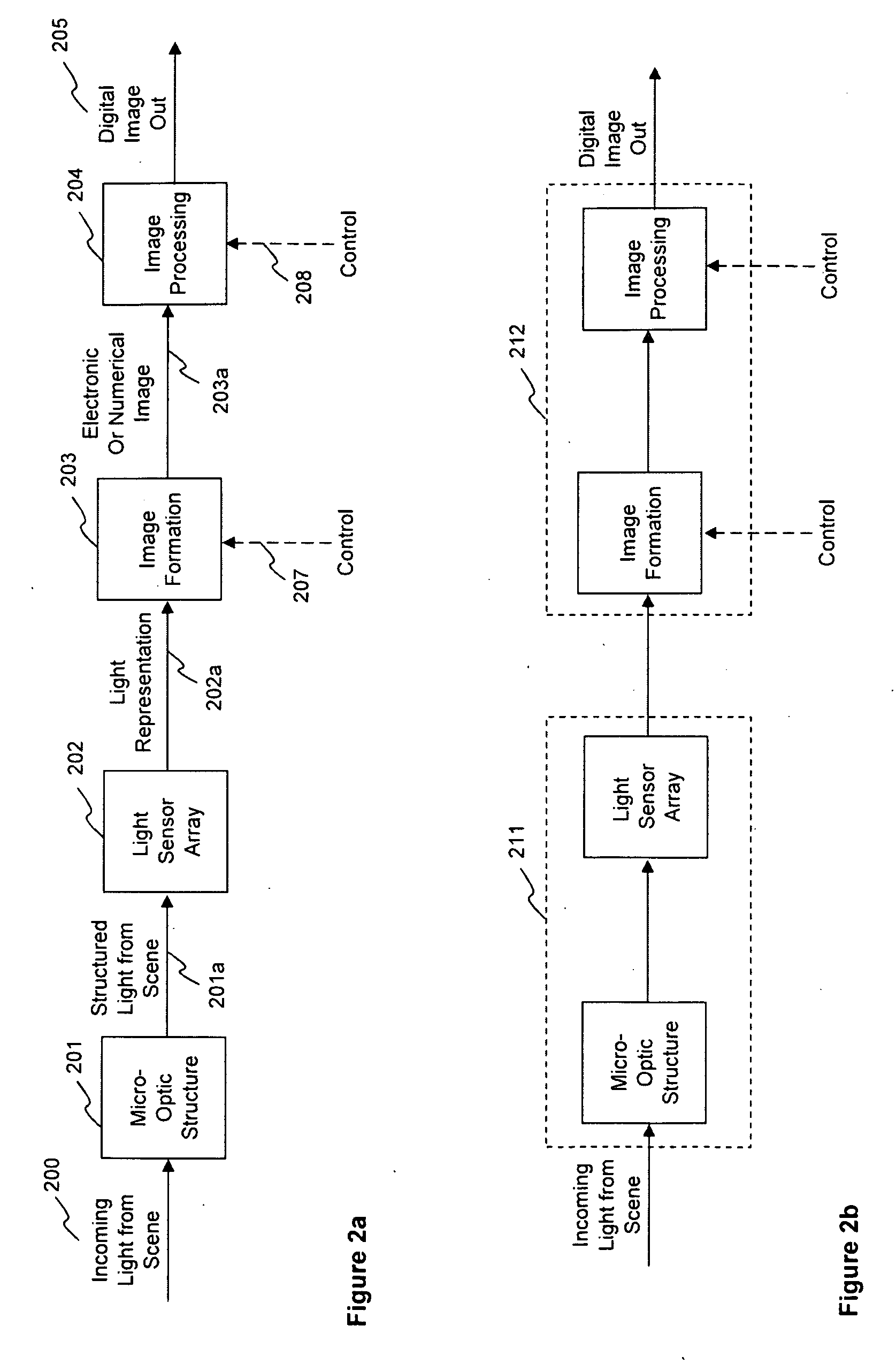

Image formation for large photosensor array surfaces

InactiveUS20090290034A1Many contactsMore experienceTelevision system detailsColor television detailsSensor arrayColor image

The invention performs electronic image formation and refinement from overlapping measurement vignettes captured by an array of image sensors and associated micro-optics. The invention is directed to an alternate image formation system that combines readily-fabricated micro-optical structures, a two-dimensional image sensor array with electronic or digital image processing to actually construct the image.Image formation is performed without a conventional large shared lens and associated separation distance between lens and image sensor, resulting in a “lensless camera.”In an embodiment, a readily fabricatable LED array is used as a light-field sensor. In an embodiment, the LED array further serves as a color “lensless camera.” In an embodiment, the LED array also serves as an image display. In an embodiment, the LED array further serves as a color image display. In an embodiment, one or more synergistic features of an integrated camera / display surface are realized.

Owner:NRI R&D PATENT LICENSING LLC

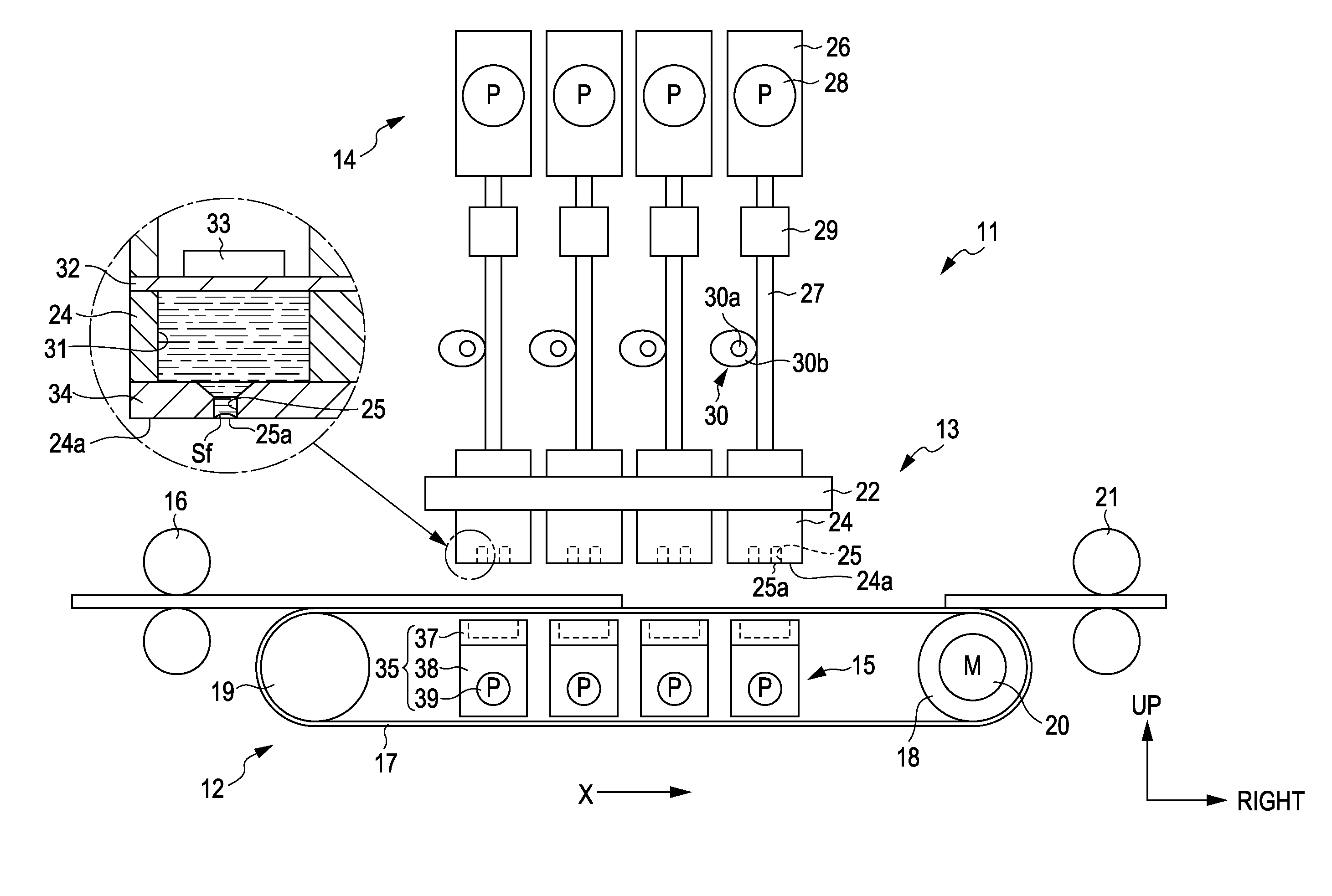

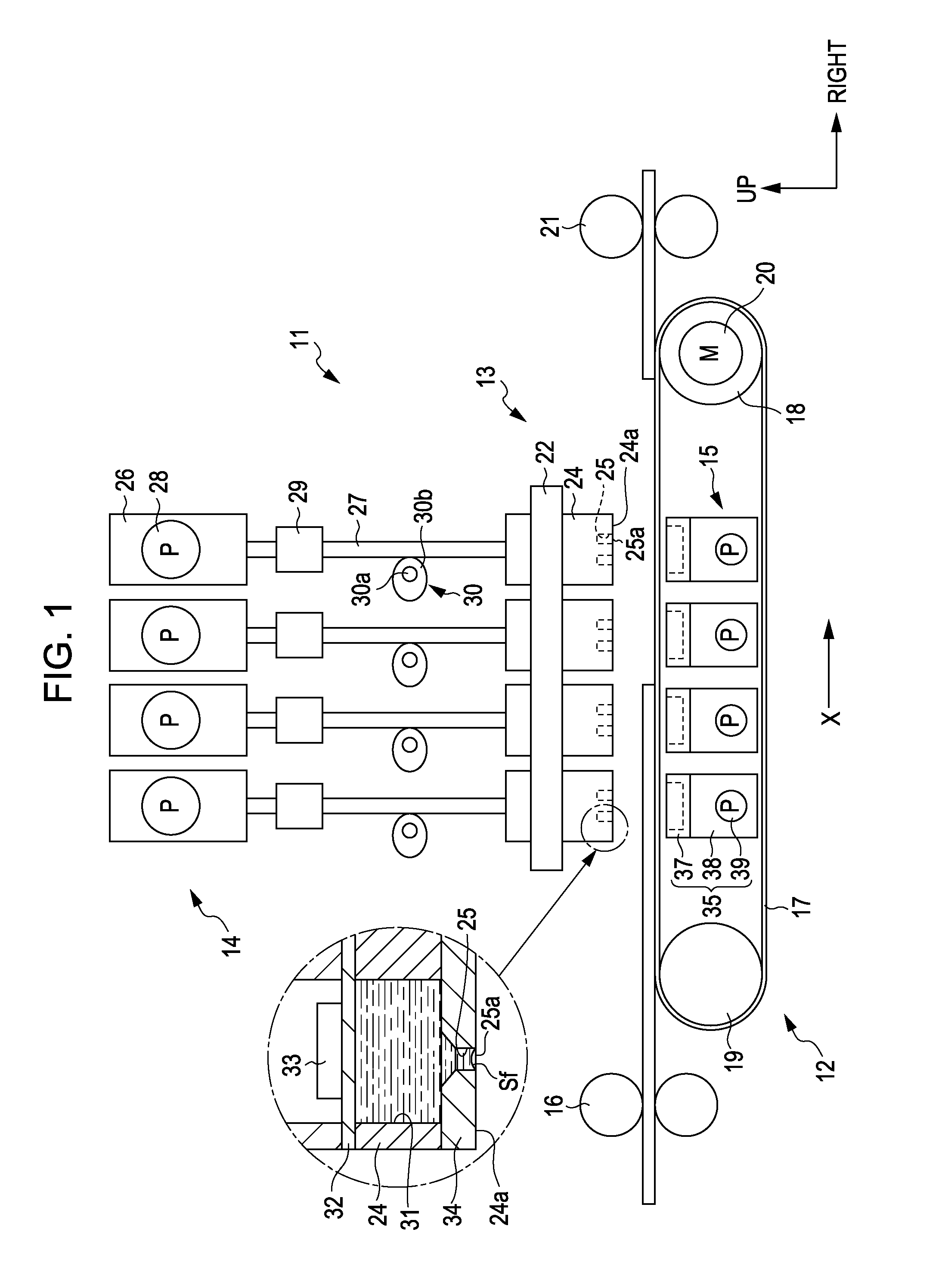

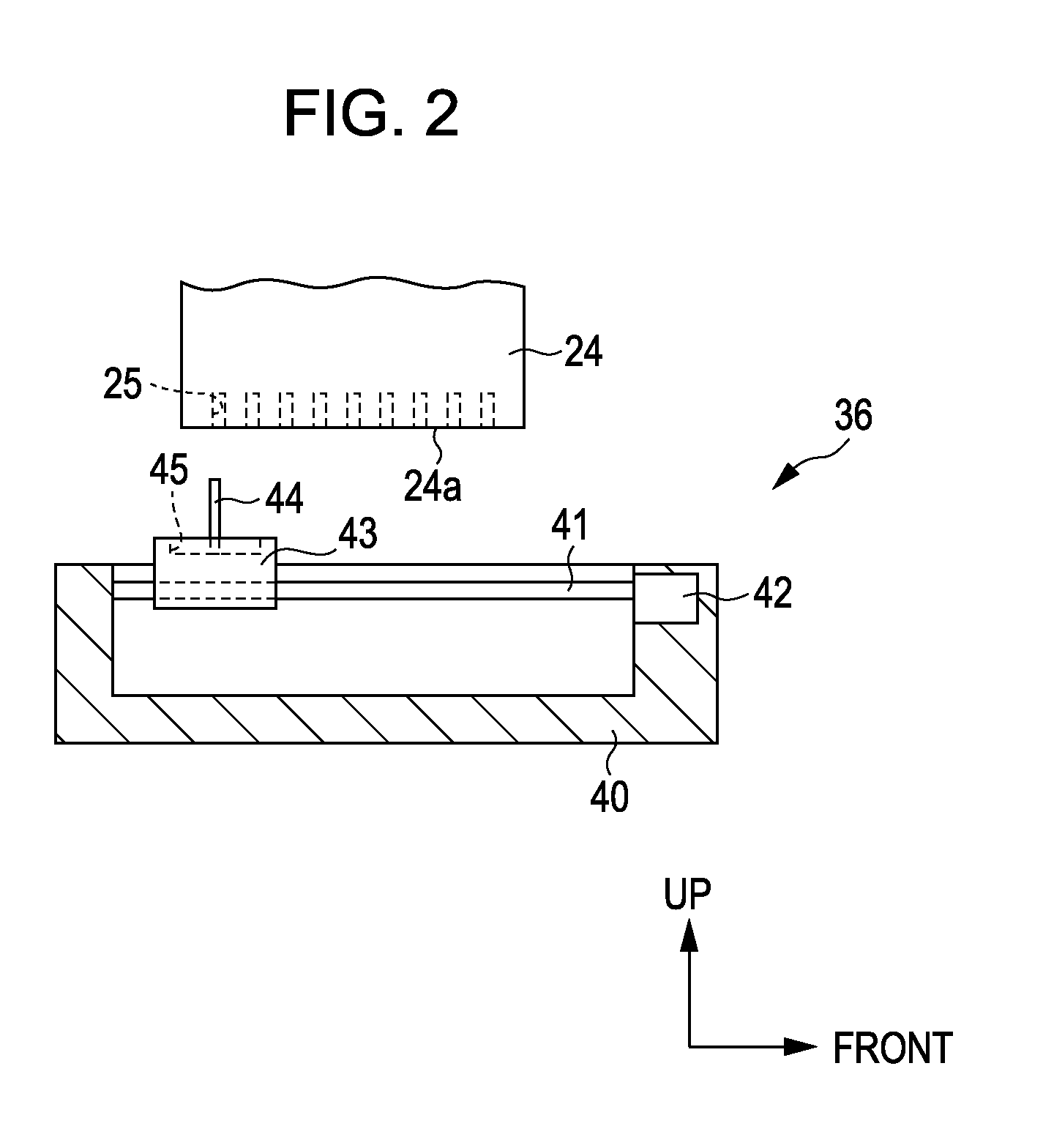

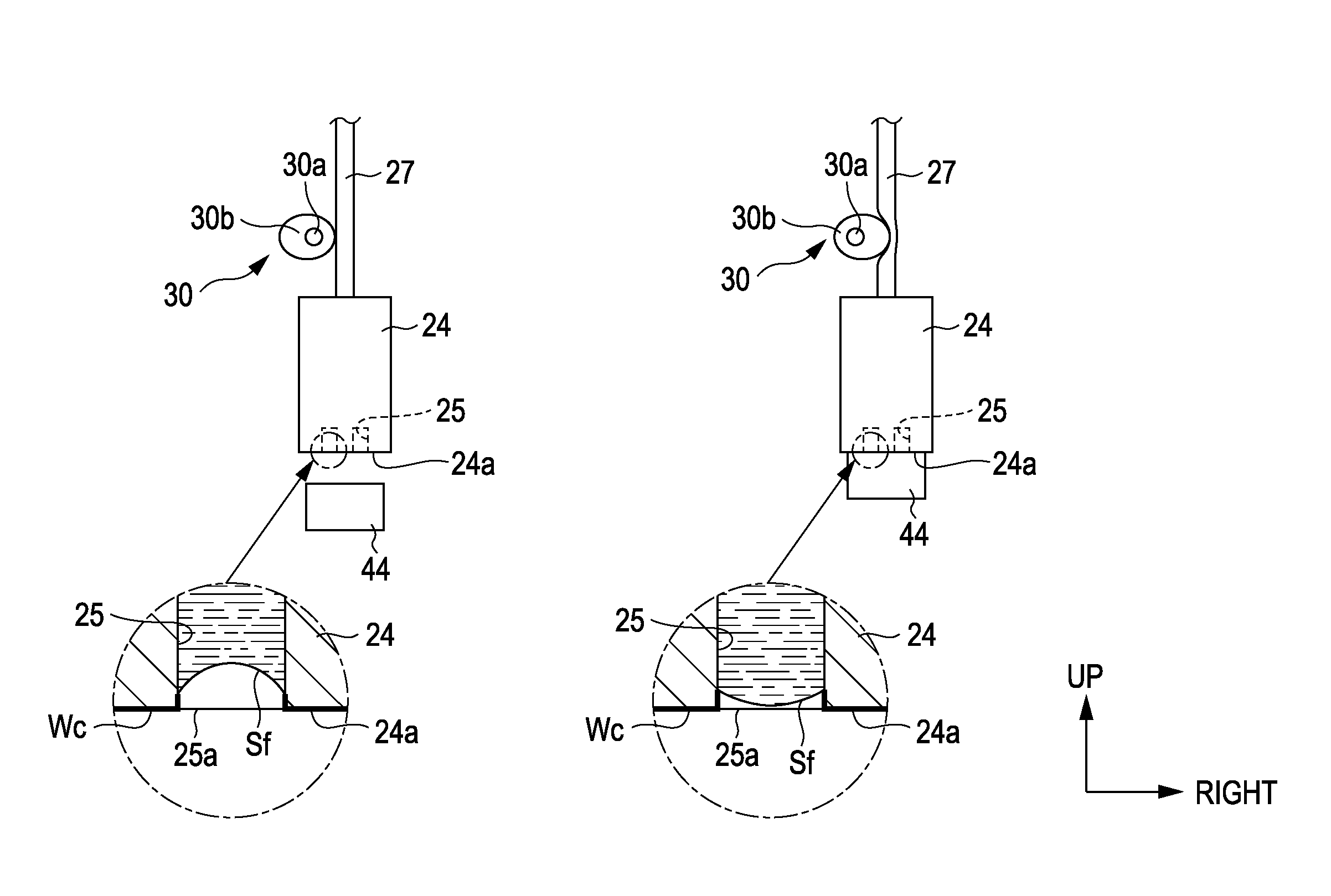

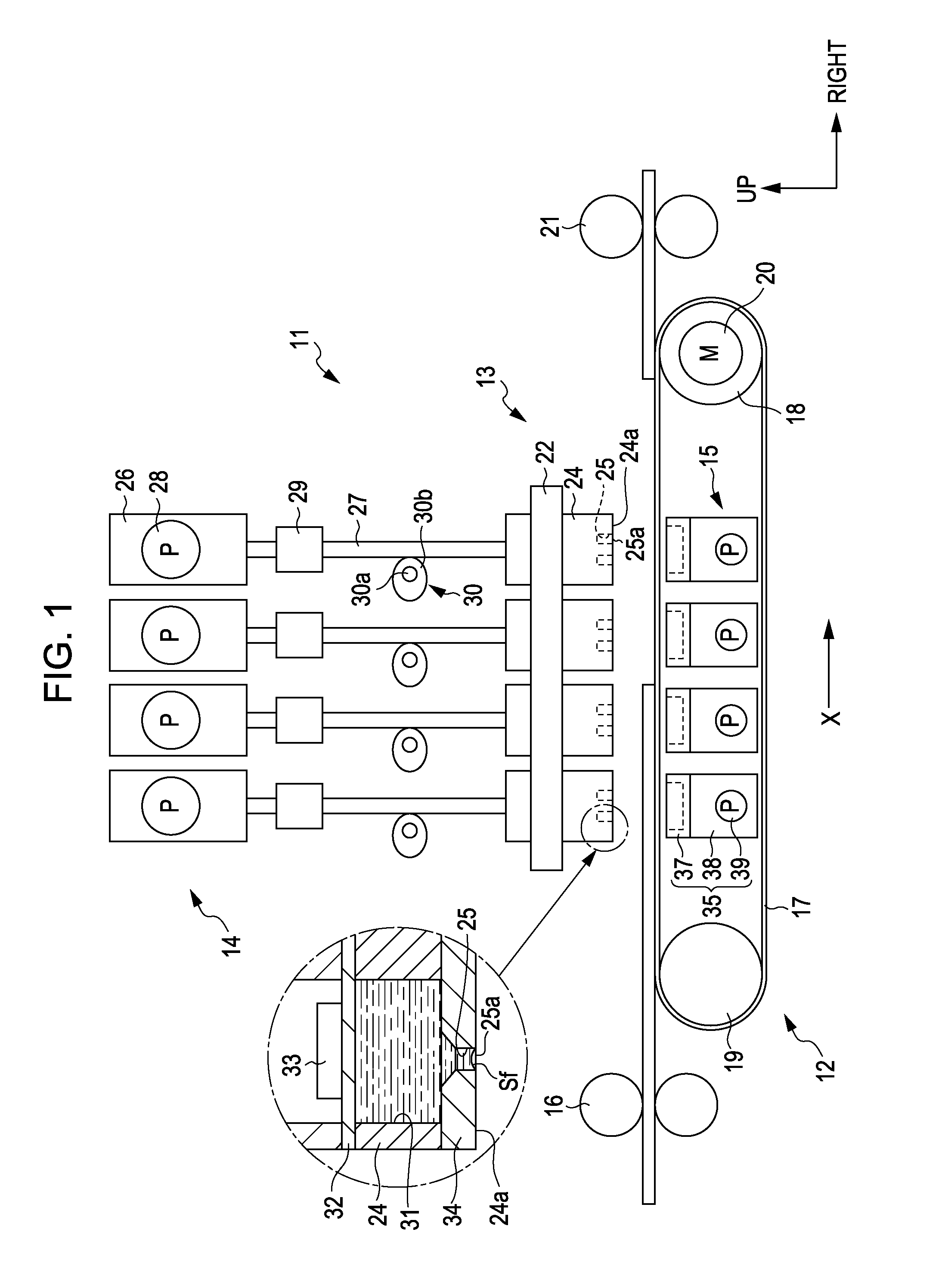

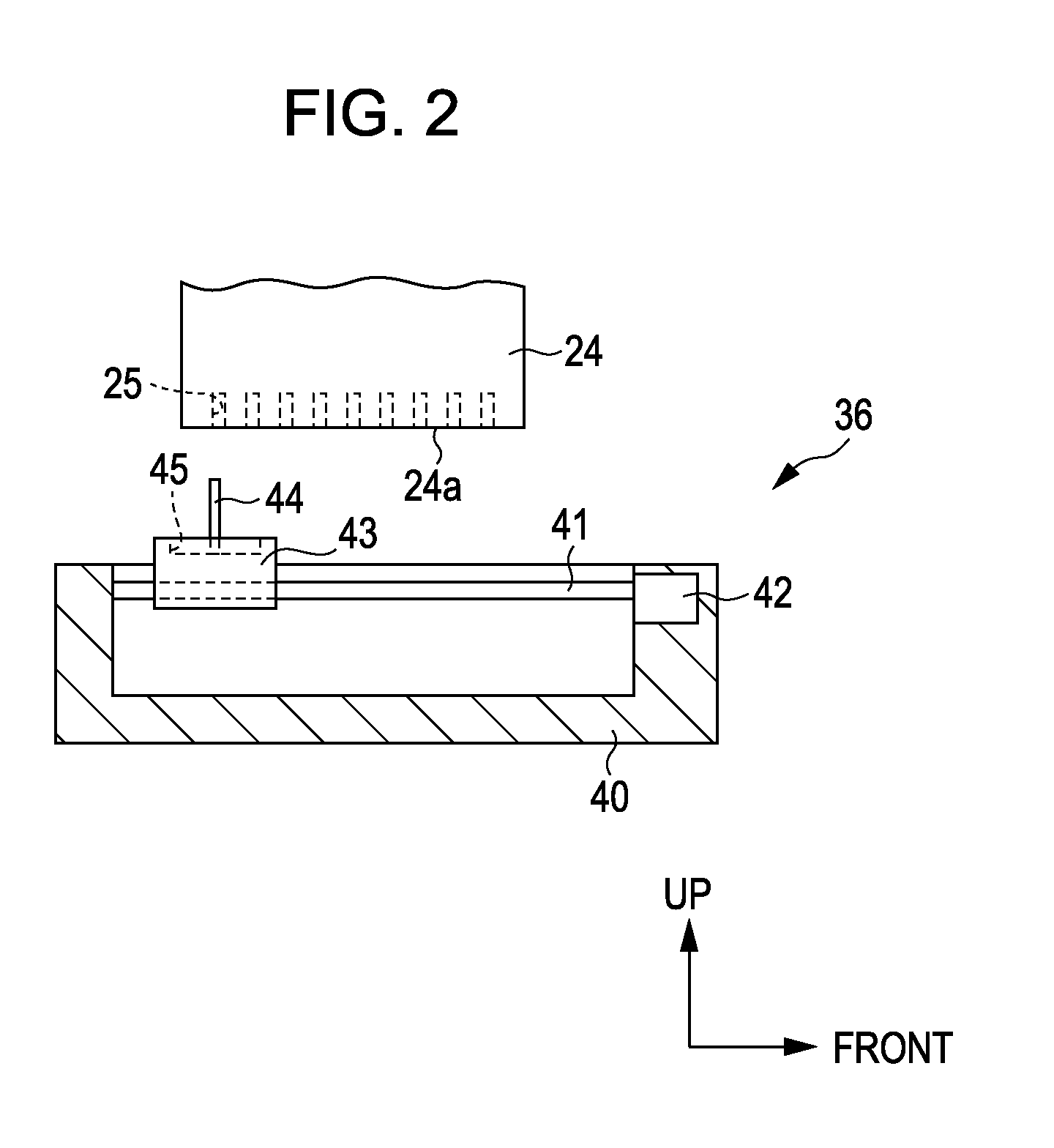

Fluid ejecting apparatus and wiping method

A fluid ejecting apparatus includes: a fluid ejecting head in which nozzles that eject fluid are provided; a wiper that wipes a nozzle formation face, in which nozzle orifices of the nozzles are formed, in the fluid ejecting head; and a pressurization mechanism which changes the curvature of a concave liquid surface formed in the nozzle, in the nozzle by performing pressurization on the fluid in the fluid ejecting head at the time of the wiping.

Owner:SEIKO EPSON CORP

Vertical internal combustion engine provided with belt-drive transmission mechanism

InactiveUS7704174B2Avoid contactProlong lifePower plants using condensersCasingsTransmitted powerInternal combustion engine

A vertical internal combustion engine includes a crankshaft enclosed in a crank chamber, a belt-drive transmission mechanism held in a belt chamber and including a rubber belt for transmitting power of the crankshaft to a camshaft included in a valve train, and a transmission case defining the belt chamber. The transmission case has a lower case between the crank chamber and the belt chamber. The belt has a part extending over the crank chamber, and the lower case is disposed to screen the part of the belt from the crank chamber. The belt is lubricated by oil in oil-containing gas from the crank chamber. Thus the oil containing gas is prevented from excessively contacting the rubber belt, so that the life of the belt is extended.

Owner:HONDA MOTOR CO LTD

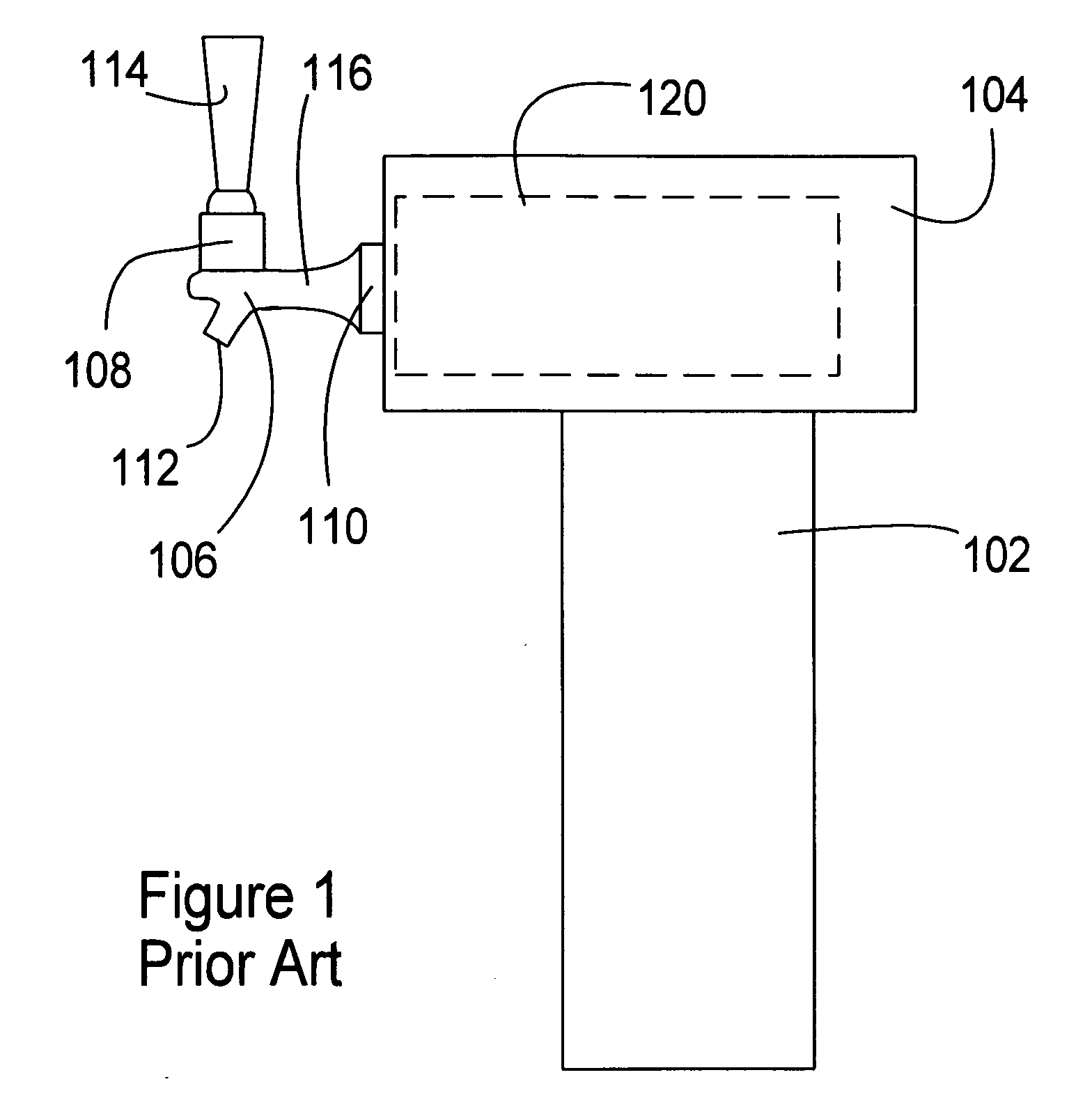

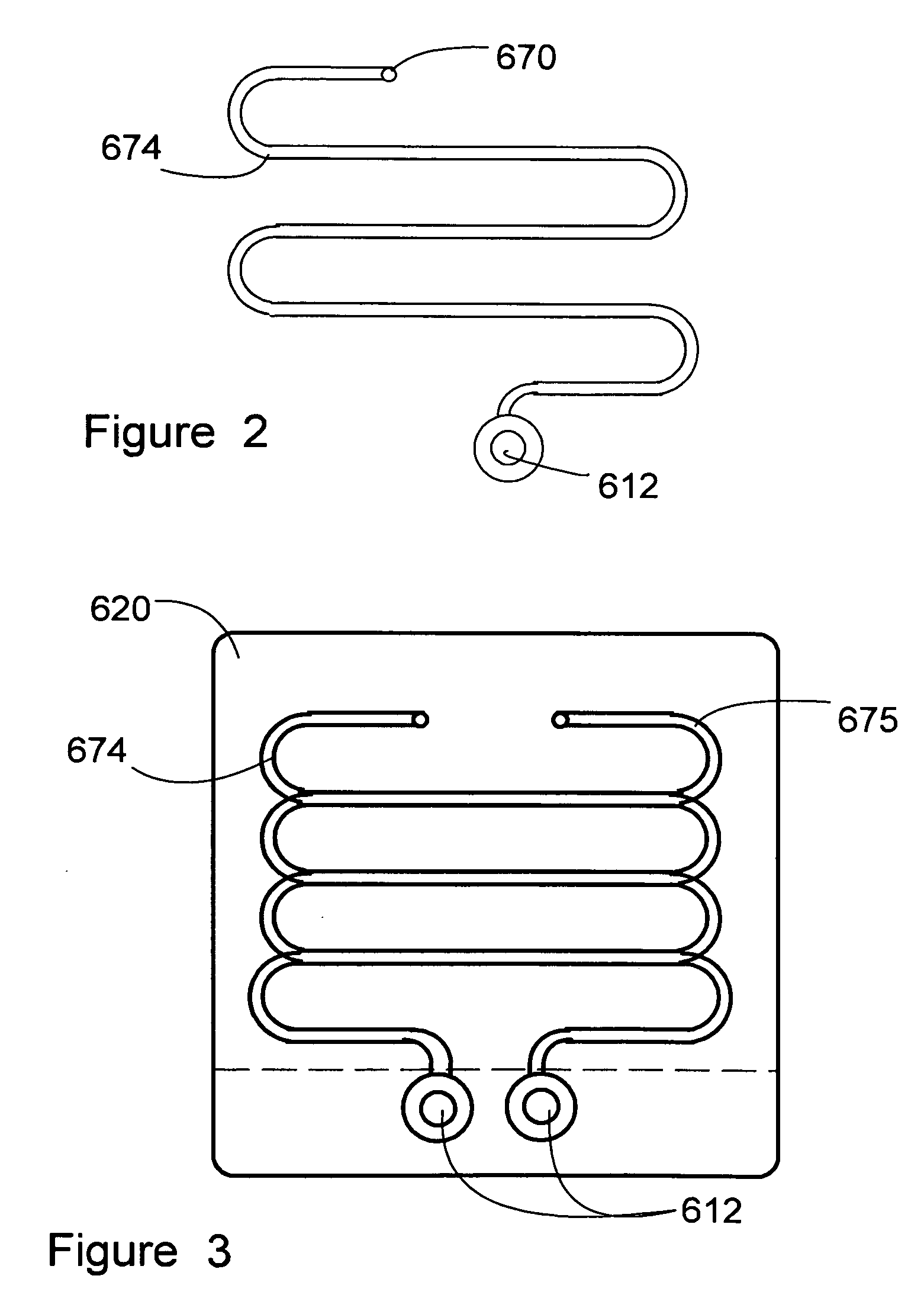

Cold block with integral beer tap

InactiveUS20100181341A1Reduce bacterial growthKeep coldLiquid transferring devicesLiquid dispensingSerpentine channelConductive materials

The present invention teaches a beverage tower of the type having a cold block with glycol recirculation, however, the traditional tap is actually built into the cold block, so as to keep the entire beer tap or other type of tap cold and maintain the beverages in a sanitary condition meeting health codes. The glycol lines within the cold block are then arranged so as to pass around the tap in the cold block, resulting in a tap which remains cooled so long as the glycol recirculation system keeps the block cold. Serpentine channels may be used so that the beverage passing through the beverage supply channels has a longer run in contact with the conductive material of the cold block and thus more opportunity to reject heat thereinto.

Owner:KIRSHBAUM BRUCE

Female terminal fitting

ActiveUS20160006143A1Reduce resilient forceMany contactsCoupling device detailsElectric connection basesEngineeringMechanical engineering

A female terminal fitting (10) is provided with a tubular main body portion (20) into which a mating male tab (90) is to be inserted, and a resilient contact piece (21) deflectably arranged in the main body portion (20). The resilient contact piece (21) is resiliently deformed toward a base wall (22) of the main body portion (20) to resiliently come into contact with the male tab (90) when the male tab (90) is inserted into the main body portion (20). An excessive deflection regulating piece (33) for regulating excessive deflection of the resilient contact piece (21) by coming into contact with the base wall (22) of the main body portion (20) is integrally provided to the resilient contact piece (21).

Owner:SUMITOMO WIRING SYST LTD

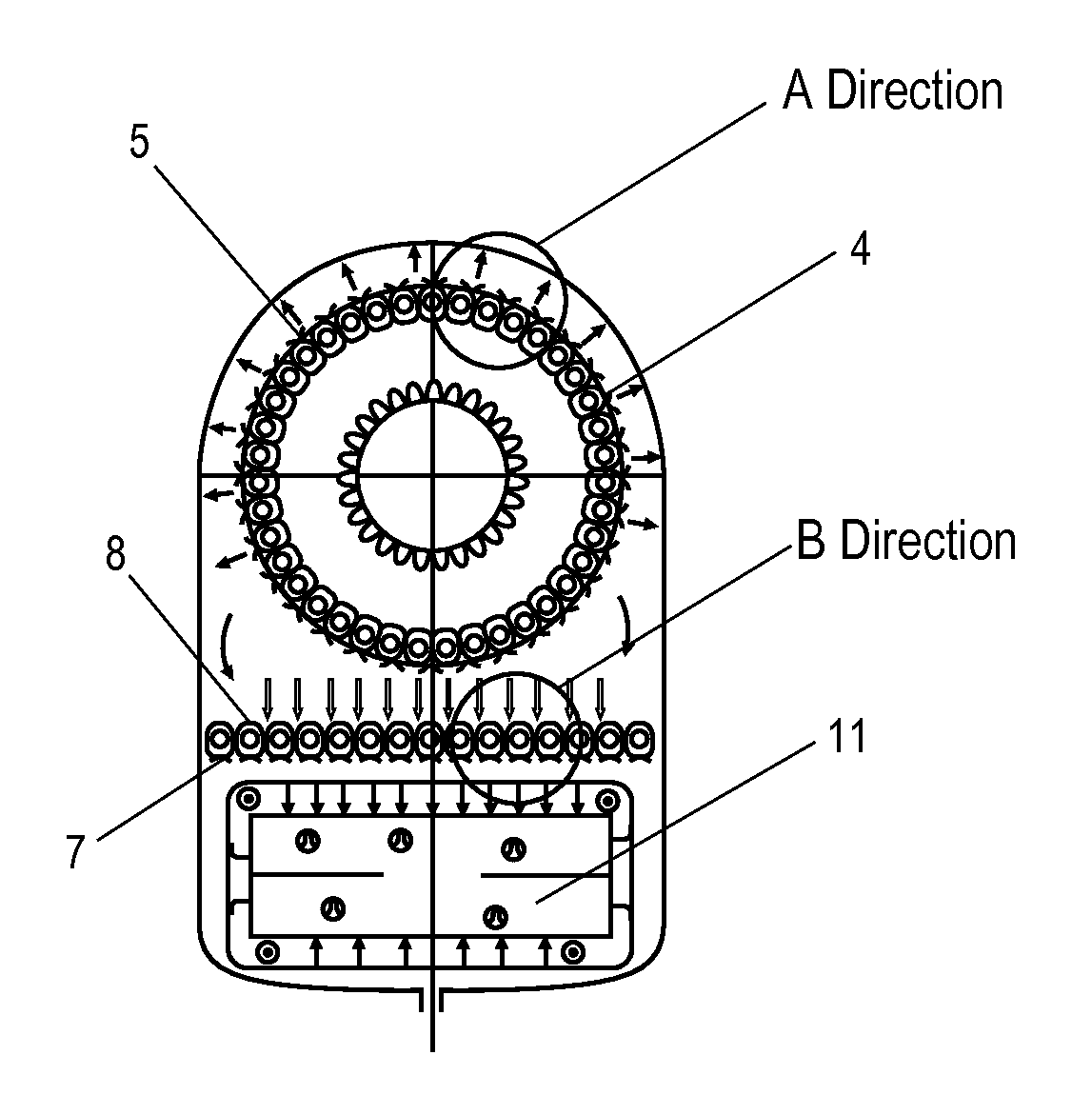

A Straight Fin Tube with Bended Fins Condensing Heat Exchanger

InactiveUS20150300687A1Small distanceMany contactsAir heatersIndirect heat exchangersCombustorEngineering

A forced convection fin tube condensing heat exchanger for supplying heat includes a shell, burner and fin tubes bundle. The burner is at the top of the shell, circular fin tubes bundle installed around the burner tightly, circularly and coaxially. The flue channel which is formed by the shell and a row of fin tubes bundle is below the burner. The flue flows along the flue channel to flue outlet. There are front and rear water manifolds at the two ends of the fin tubes. Water baffles inside the rear water manifold divide the rear water manifold into water inlet and outlet areas. The water enters the small portion of circular fin tubes bundle from water inlet area, through the front water manifold, back to the water outlet area via the main portion of the circular fin tubes bundle. The use of bended fin tube to improves efficiency.

Owner:SUZHOU CQ HEAT EXCHANGER

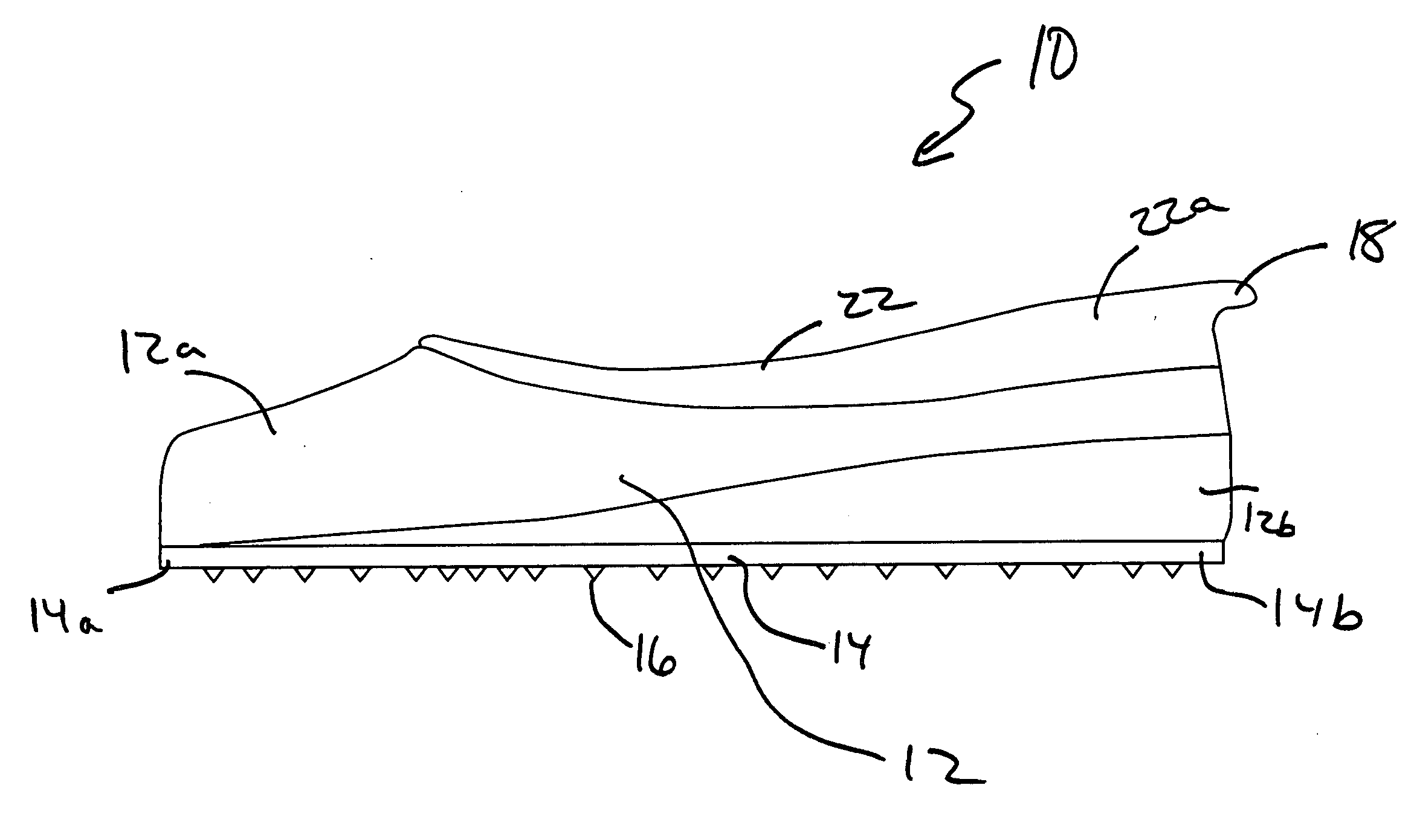

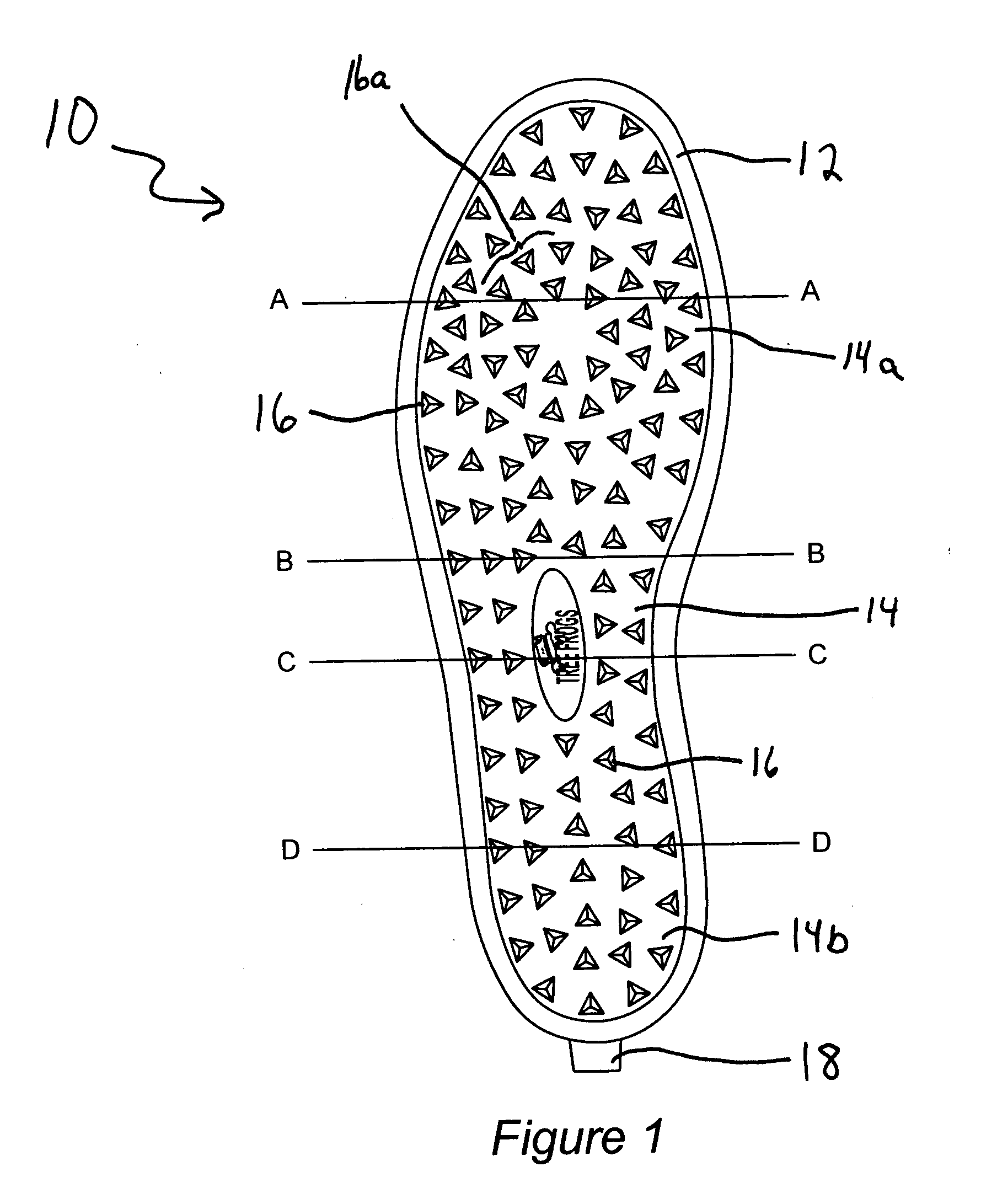

Overshoe for sports

An overshoe for sports is comprised of a flexible, stretchable, waterproof material with a plurality of spikes extending from the a base surface that is entirely flat. The plurality of spikes forms a circular design at the toe portion of the flat base and staggers outward so that the spikes uniformly cover the base. The design and placement of the spikes enhances the balance of the user while preventing large amounts of turf or earth from clinging to the base of the outsole. The flat base surface allows the overshoe to contour around a user's footwear of choice thus maintaining a flat surface with the ground while, at the same time, maintaining the user's comfort in his footwear of choice. The flat base surface also assists in maintaining balance while contemporaneously restricting sway and movement of other parts of the body.

Owner:CROMLEY RALPH W

A processing process of high-modulus low-shrinkage high-colour-fastness polyester filament yarn by direct melt spinning and real-time injection

ActiveCN104294393AImproved elongation and uniformityLow bending stiffnessMelt spinning methodsFilament-forming treatmentLow modulusMelt spinning

The invention relates to a processing process of high-modulus low-shrinkage high-colour-fastness polyester filament yarn by direct melt spinning and real-time injection. By the special design of steps including subjecting a polyester raw material to shrinkage reducing processing, performing modulus-increasing blending and melting melt processing, performing low-frequency real-time compression and injection, subjecting the melt to multi-stage direct-melting and spinning, passing through a filter screen, spinning, cooling, applying oil, stretching, and the like, and by special optimization of related parameters, the technical difficult problems of fiber in the prior art, namely low modulus, low strength and poor natural-color fasteness are overcome, and the objective of purification, high color fasteness, high modulus and low shrinkage is achieved. Under the obvious improvement on the high color fasteness, the high modulus and the low shrinkage which are good properties, stability, thermal resistance, resistance to hot water, elasticity resilience, elongation and homogeneity are largely improved.

Owner:福建百宏聚纤科技实业有限公司

Ergonomic microbial air sampler

ActiveUS20140013866A1Reduce weightMore positive contactWithdrawing sample devicesBottlesAir samplerEngineering

Owner:VALTEK ASSOC INC

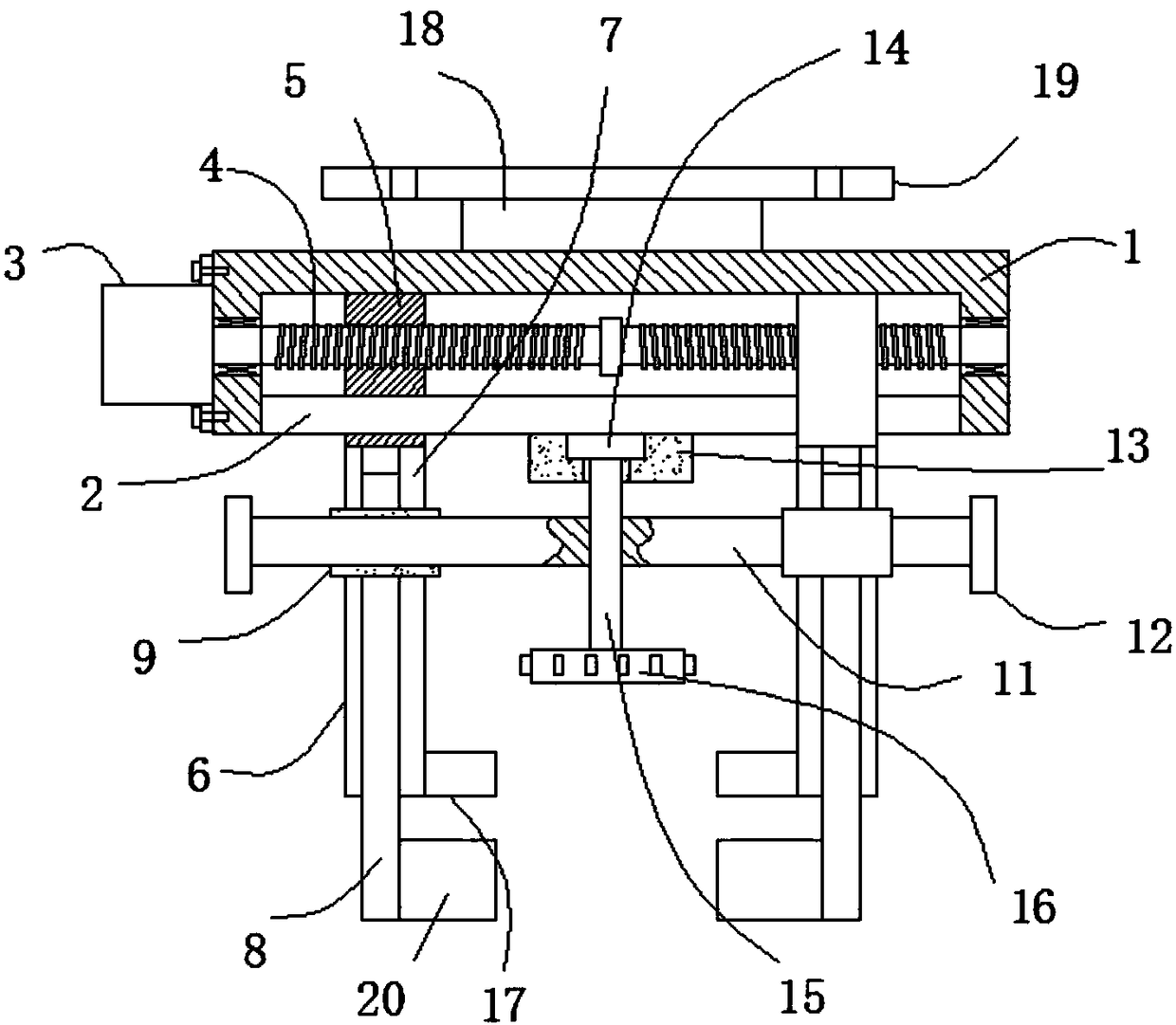

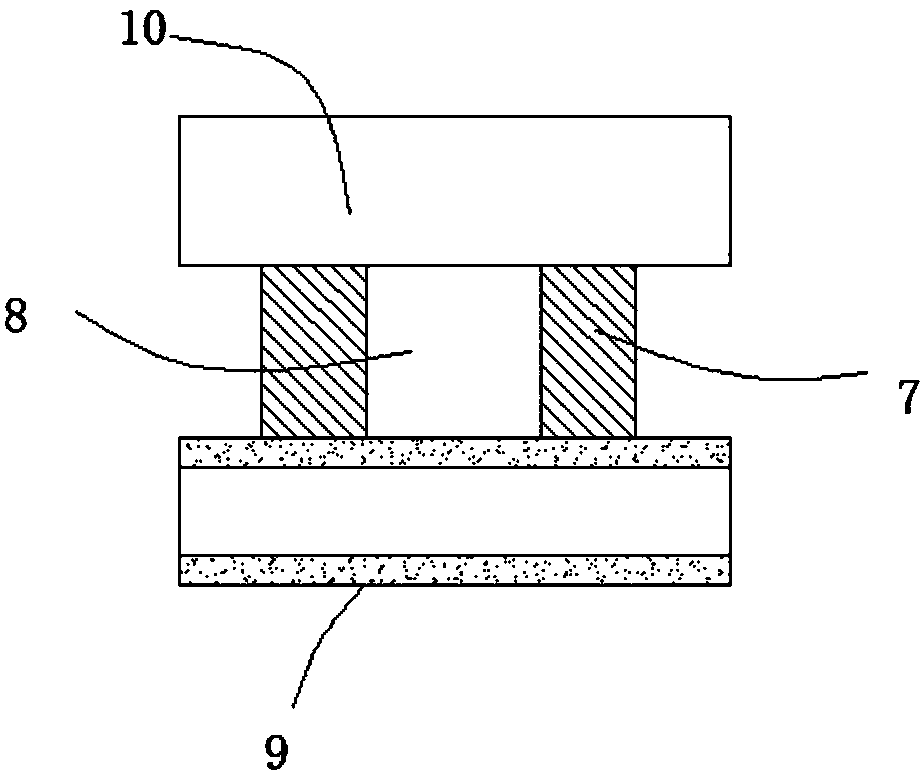

Mechanical arm convenient to adjust

The invention discloses a mechanical arm convenient to adjust. The mechanical arm comprises a hollow mounting block with an opening in the bottom, wherein a rectangular rod is vertically welded to theinner walls of the opposite sides of the opening; a driving motor is fixed to one side of the hollow mounting block through screws; a first threaded rod rotationally connected with the hollow mounting block is fixed to an output shaft of the driving motor through a shaft coupler; the first threaded rod is positioned on the inner side of the hollow mounting block; forward and reverse threads are formed in the outer side of the first threaded rod in the length direction; a group of slide blocks in threaded connection with the forward and reverse threads respectively are in threaded connection with the outer side of the first threaded rod in a sleeving manner. Through a knob, connecting sleeves, a second threaded rod, a guiding rod, first limiting plates, second limiting plates and telescopic rods, the distance between a second clamping head and a first clamping head can be adjusted as required, and then the distance between contact points when an object is clamped is changed, so that the mechanical arm convenient to adjust is strong in adjustability, thereby being capable of clamping objects with different heights and good in universality.

Owner:JINGDE COUNTY HANHAI NEBULA INTELLIGENTIZE TECH RES & DEV CO LTD

Fluid ejecting apparatus and wiping method

ActiveUS8465121B2Curb consumptionOccurrence of dot omission can be suppressedPrintingEngineeringLiquid surfaces

A fluid ejecting apparatus includes: a fluid ejecting head in which nozzles that eject fluid are provided; a wiper that wipes a nozzle formation face, in which nozzle orifices of the nozzles are formed, in the fluid ejecting head; and a pressurization mechanism which changes the curvature of a concave liquid surface formed in the nozzle, in the nozzle by performing pressurization on the fluid in the fluid ejecting head at the time of the wiping.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com