Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

125results about How to "Lay flat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

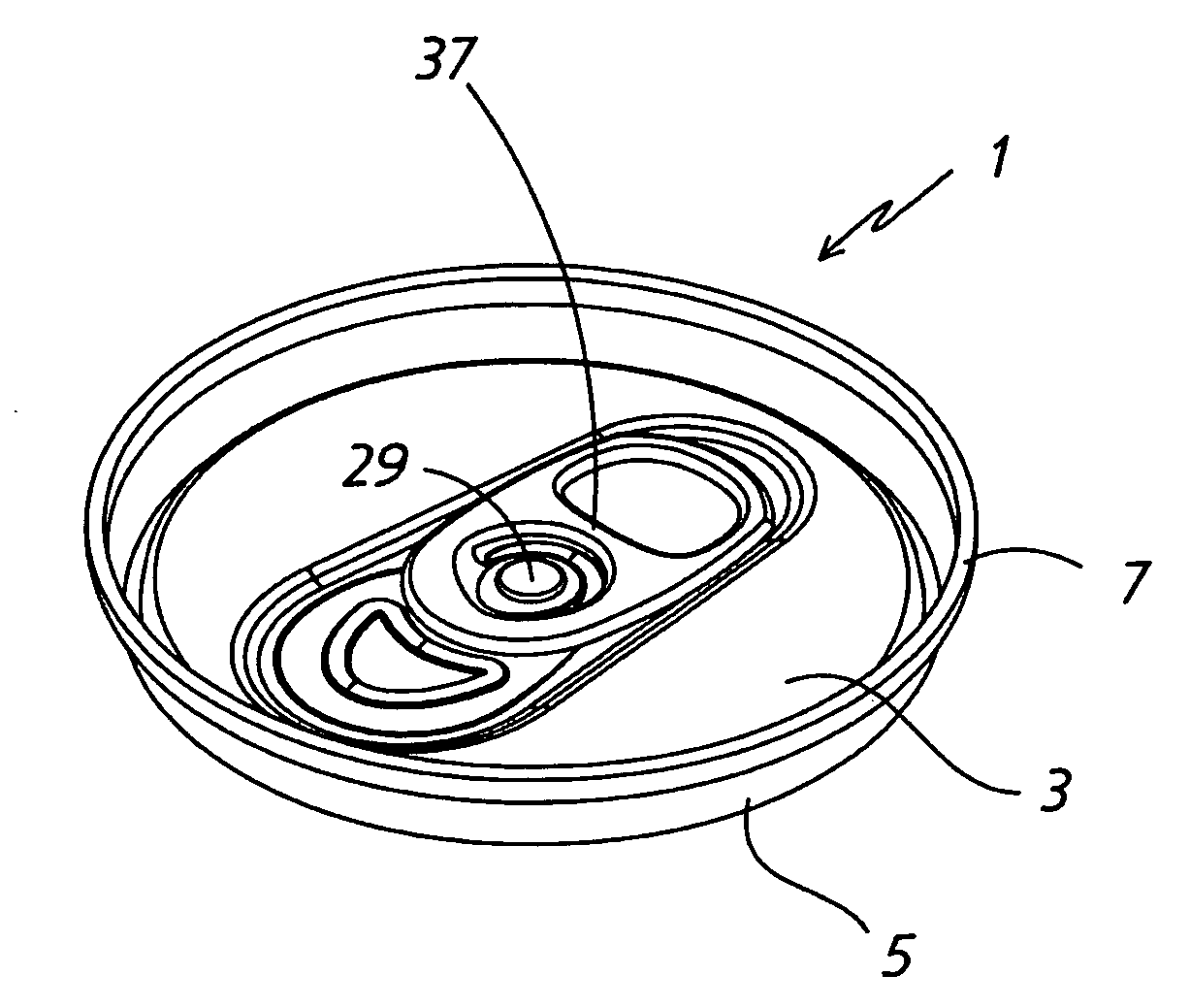

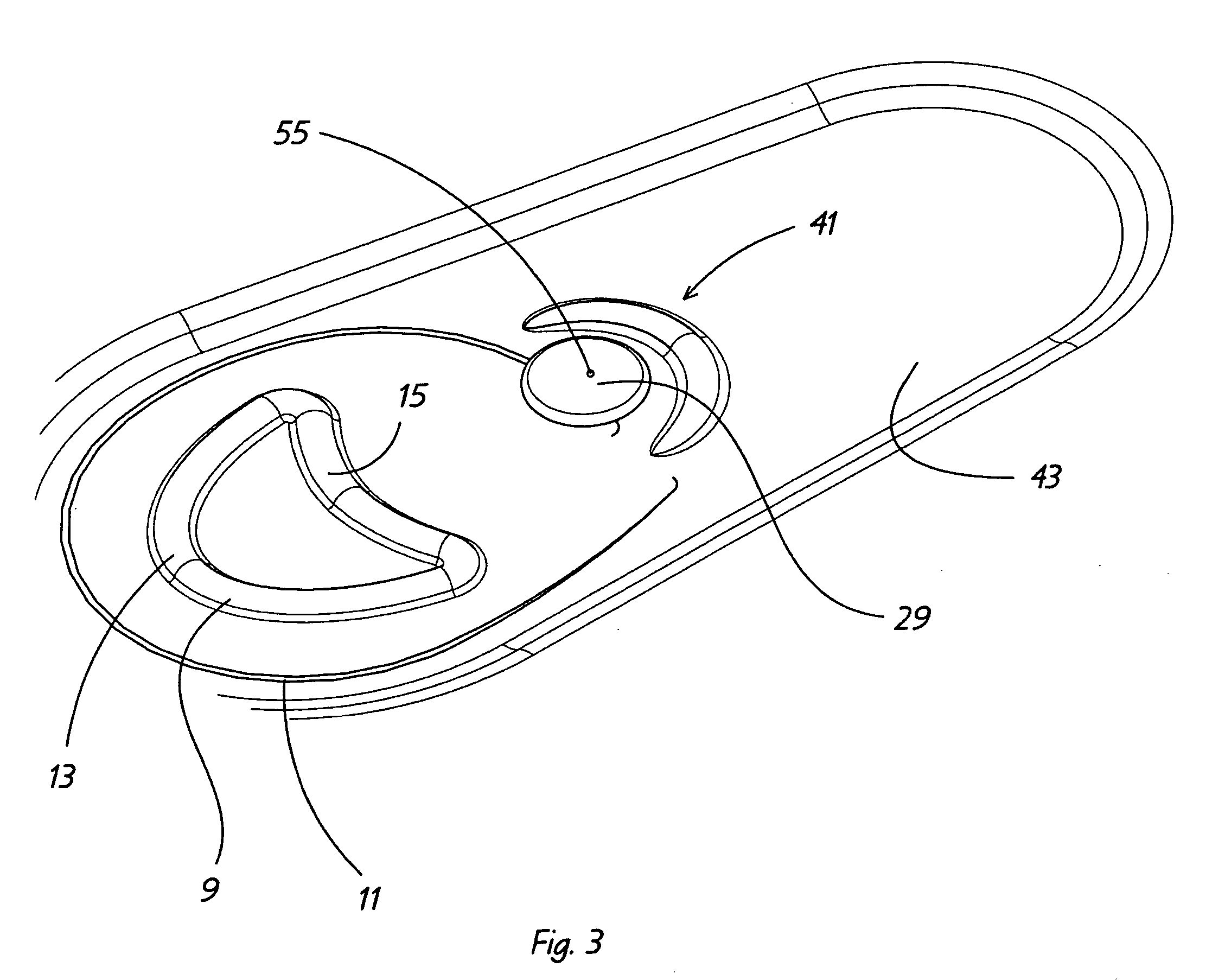

Container end closure with pull tab

InactiveUS20070108208A1Lessen free lift forceReduce lifting forceRigid containersEngineeringFace sheet

An easy opening end closure for a container has a central panel with a tear panel defined by a score line. A pull tab is attached by a rivet to the central panel and has a nose end for engaging the tear panel and an opposite lift end for pivoting the tab about the rivet to fracture the score line. One or a pair of crescent-shaped protrusions are formed on the central panel closely adjacent to and rearwardly of the rivet to reduce the lift force required to initially lift the lift end of the tab to start the fracturing of the score line. The protrusions are concentric to each other and partially circumscribe the rivet and are located beneath the pull tab or within openings of the pull tab to avoid interference with can making equipment and with the pull tab. The protrusions provide greater flexibility to the area of the central panel adjacent the rivet to enable the rivet to pull slightly upwards from the panel at the start lifting the lift end of the tab.

Owner:SPARKTAB

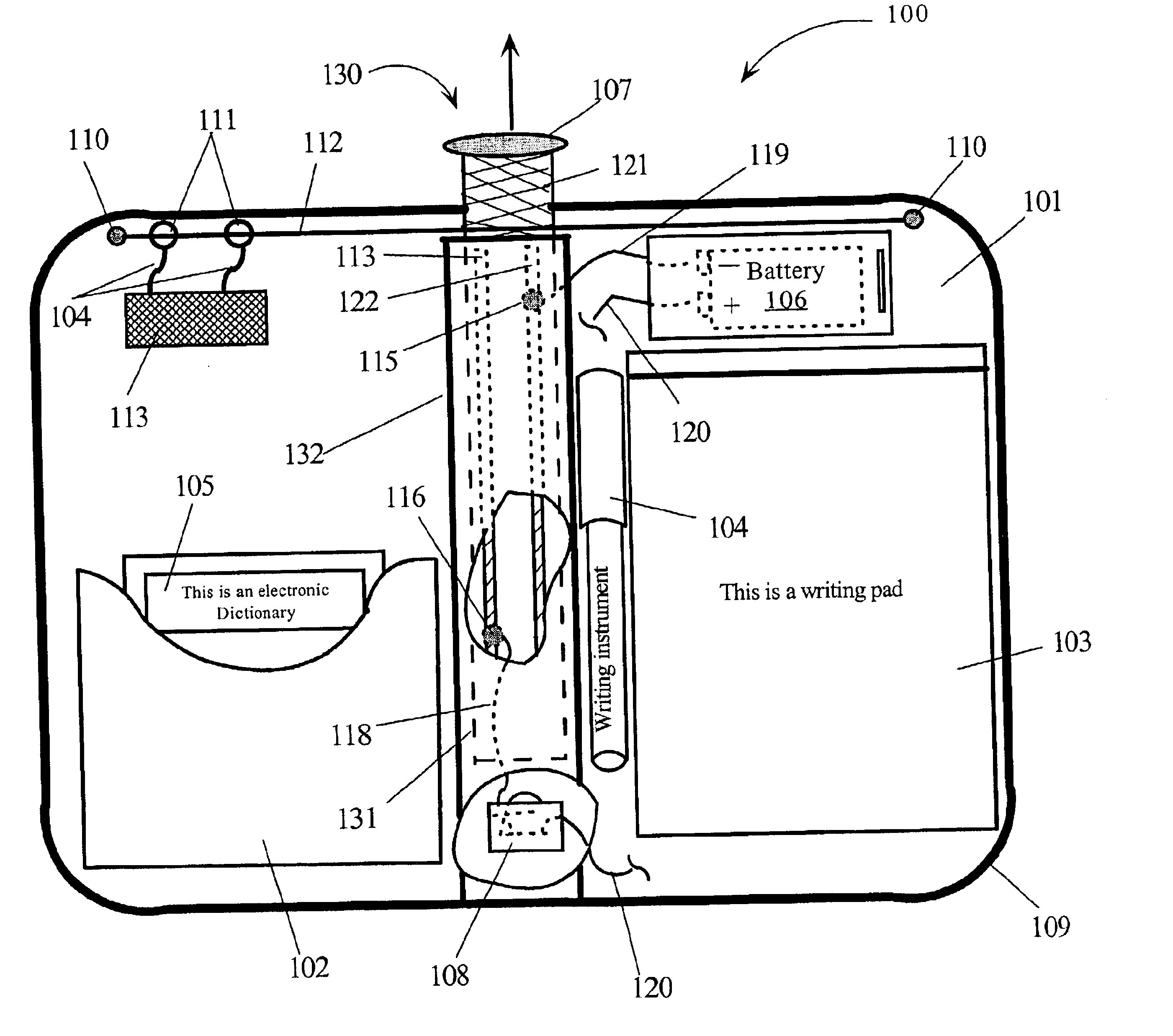

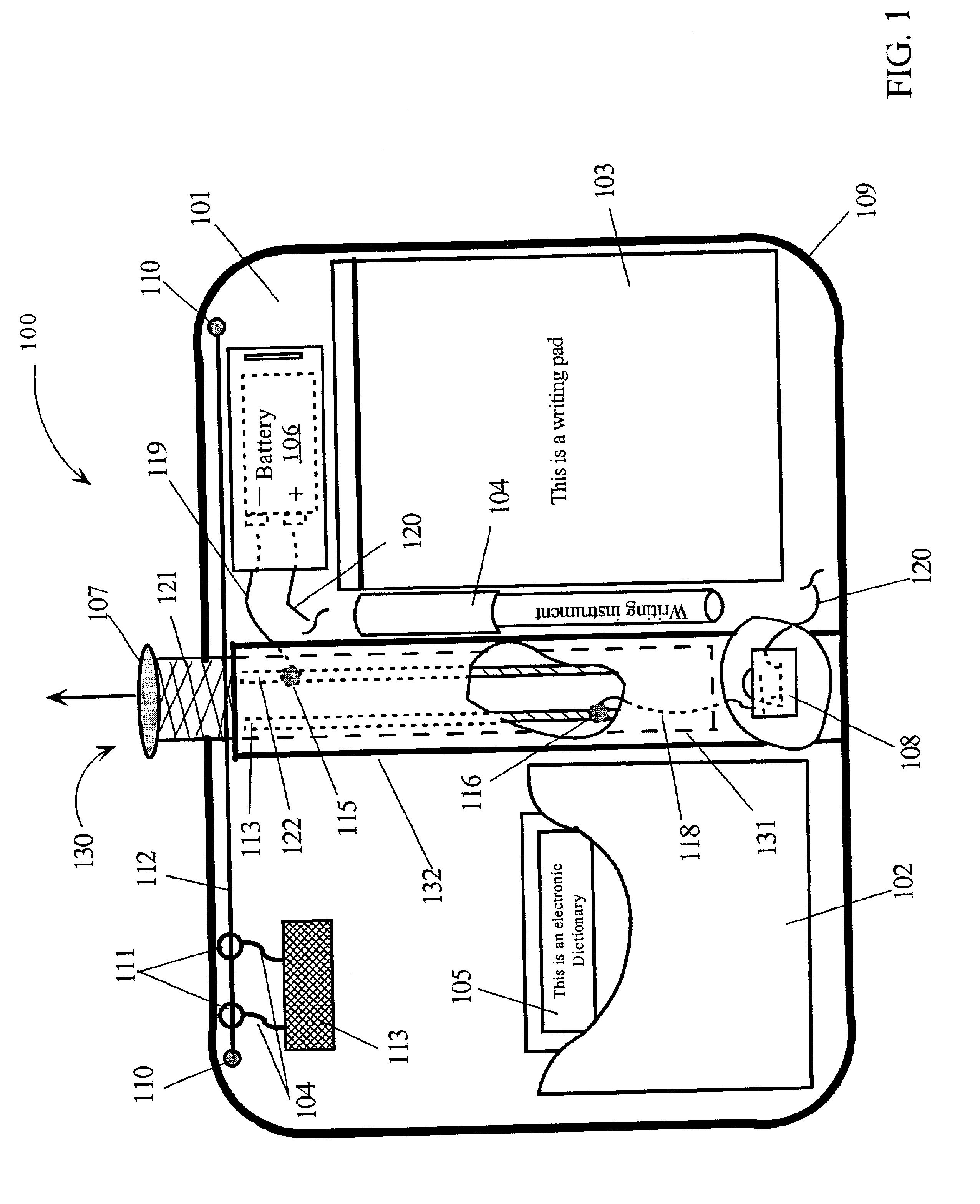

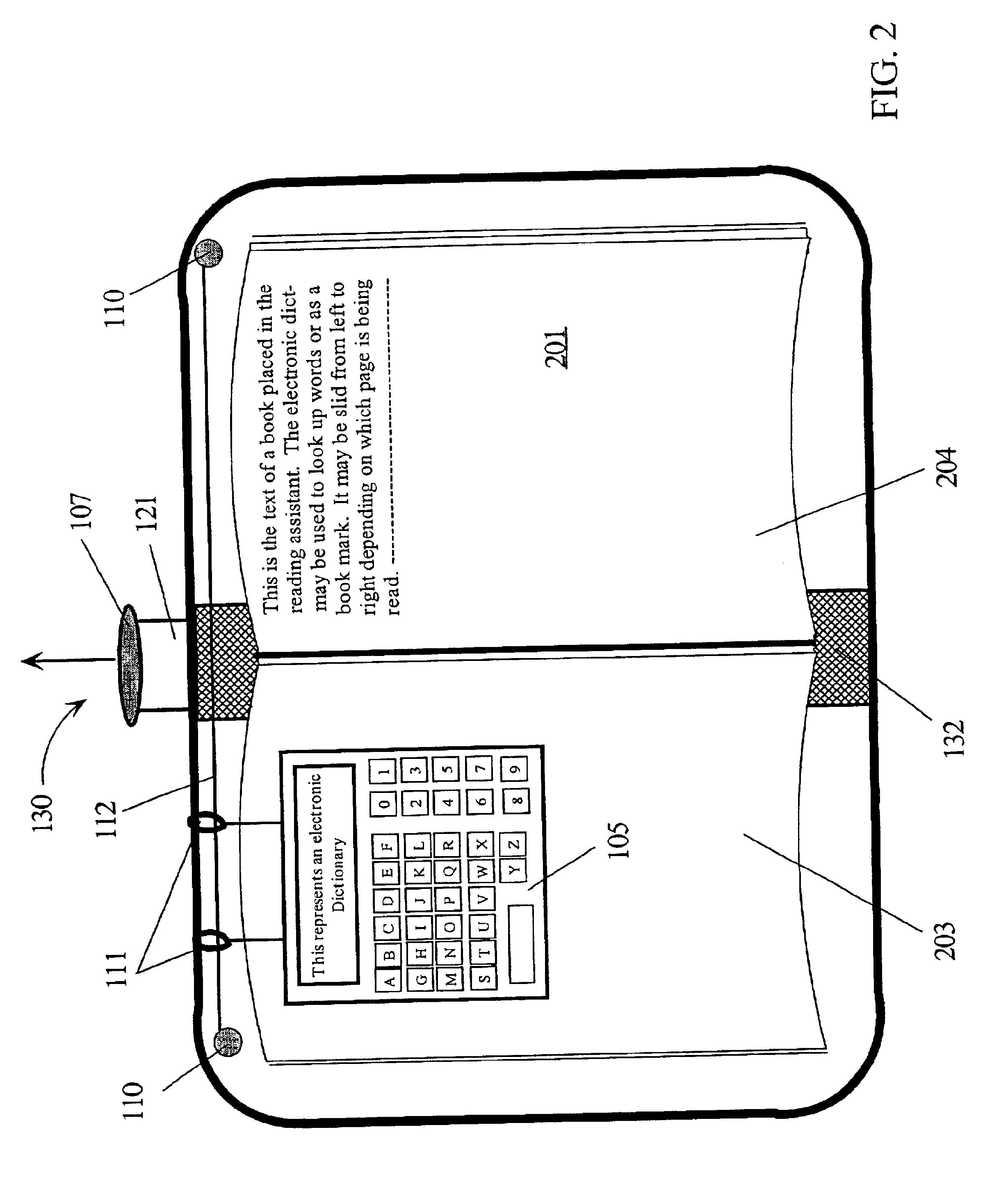

Reading and writing assistant device

InactiveUS6851822B2Convenient and available to userEasy accessHanging devicesPursesEngineeringSliding contact

A Reading and Writing Assistant (RW) device has a foldable case for placing reading material in an open and readable position. A retractable light is housed within the case and connected to a battery with sliding contacts. The battery is connected to the sliding contacts with a switch that is OFF when the light is in a stored position and ON when said light is in position to illuminate the reading material. The RW device has a pocket for holding writing material, writing instrument and an electronic dictionary. An option allows the electronic dictionary to be coupled to a slider which attaches to a flexible guide extending from one side of the case to the other parallel to the top edge of the reading material. The electronic dictionary may be moved and placed on the page not being read allowing easy user access. A strap or zipper secures the RW device when closed.

Owner:HERRERA FR T

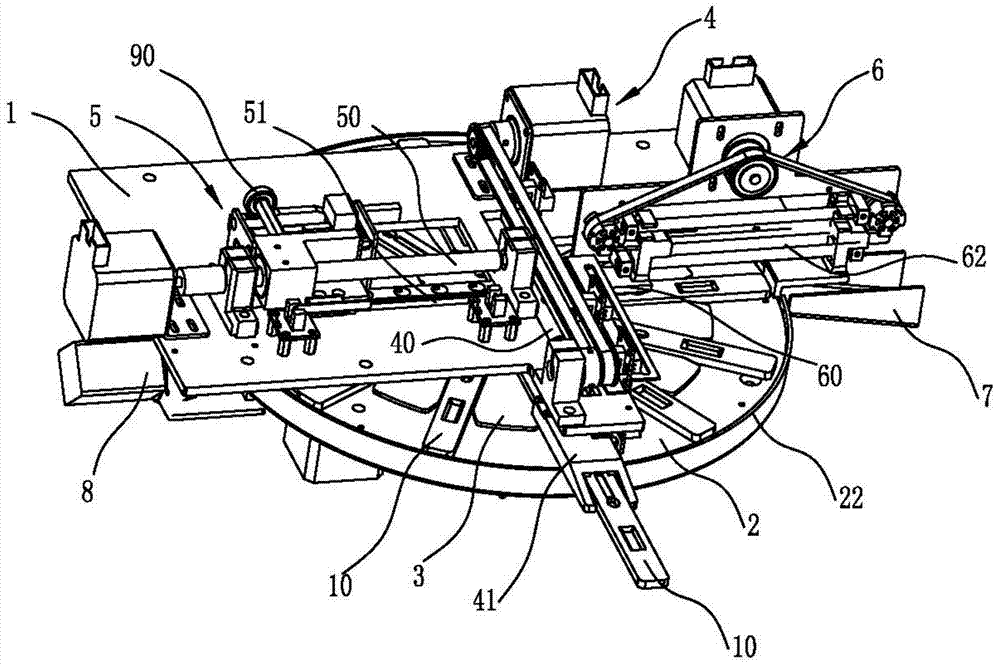

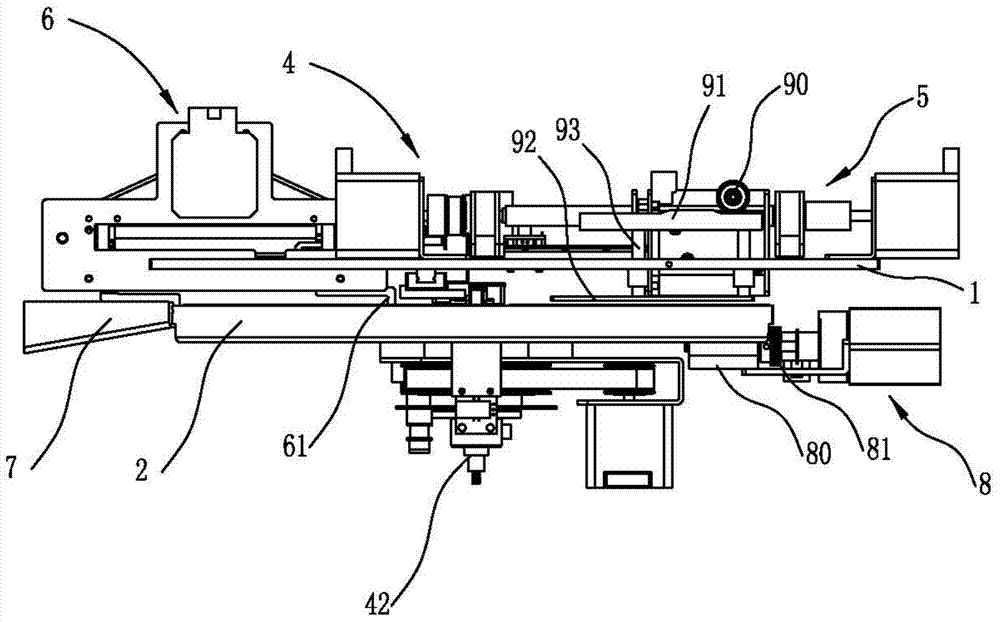

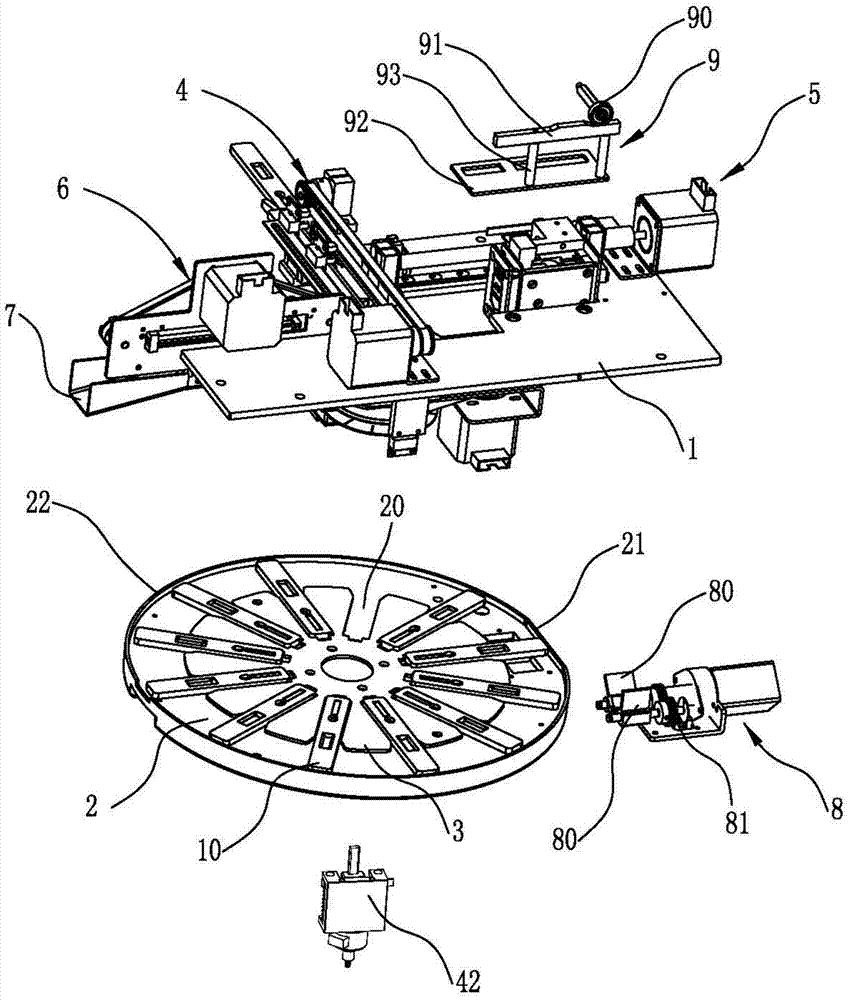

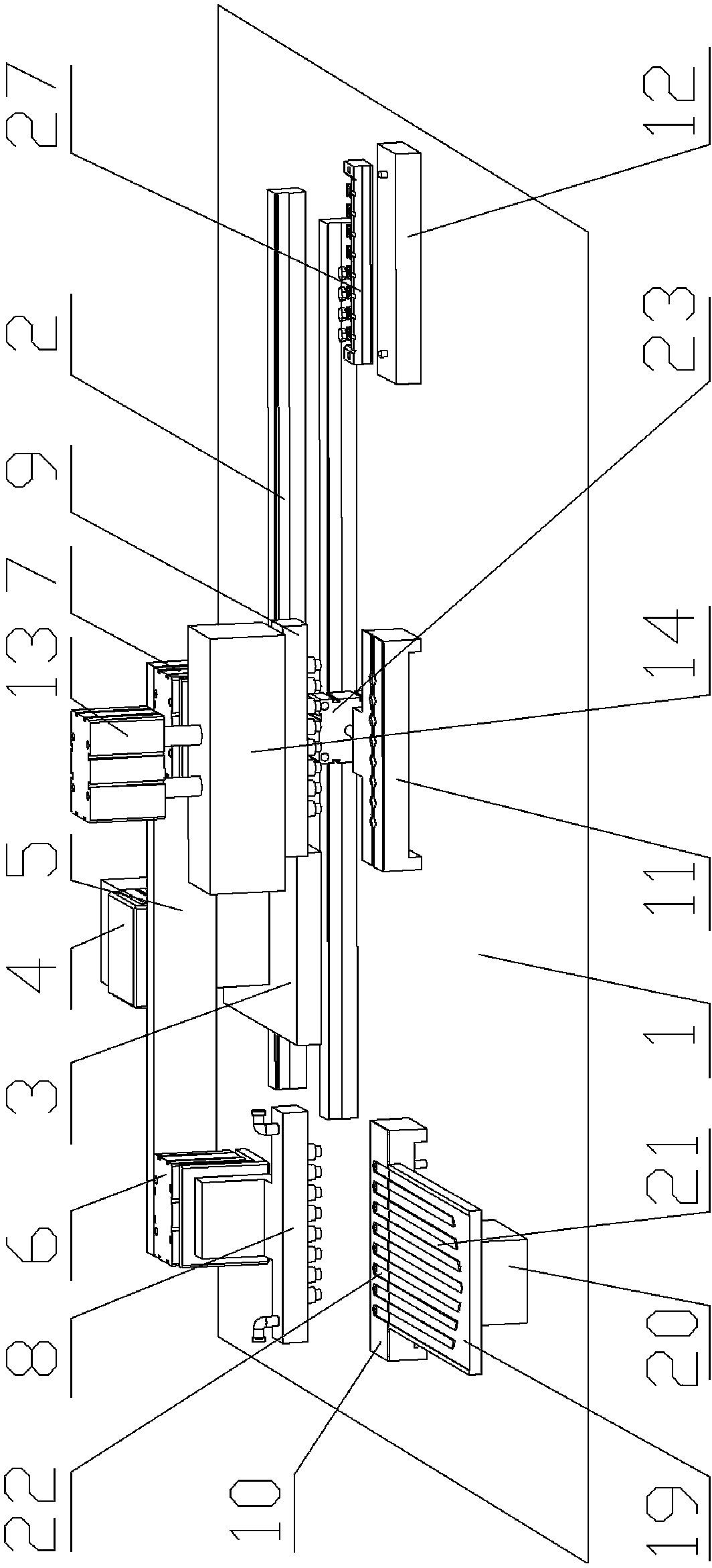

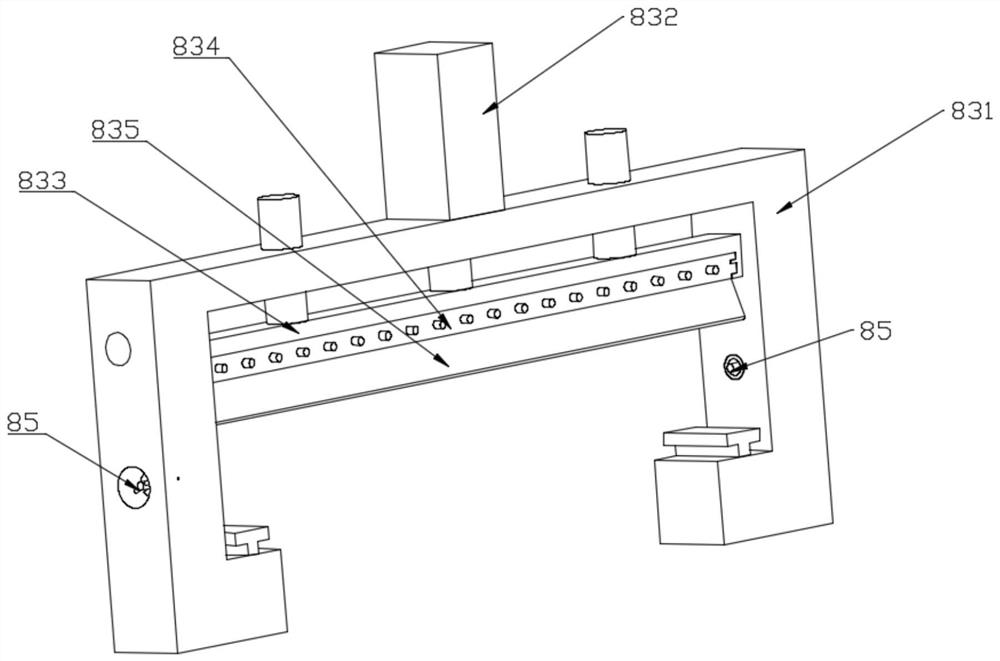

Stereotaxic localization rotating disc type multi-project dry-type fluorescence detector

ActiveCN104849445AImprove reliabilityImprove stabilityBiological testingFluorescence/phosphorescenceFluorescenceEngineering

The invention discloses a stereotaxic localization rotating disc type multi-project dry-type fluorescence detector. The stereotaxic localization rotating disc type multi-project dry-type fluorescence detector comprises a mounting plate, a testing card bearing plate, a card pulling device, a card entry device, a card reading detection device, a card exit device, a card pressing device and a card clamping device, wherein the mounting plate is fixedly arranged, the testing card bearing plate is fixedly arranged under the mounting plate, the card pulling device is rotationally overlapped on the testing card bearing plate, a card groove for preventing a testing card from sliding is formed in the testing card bearing plate, the testing card is radially conveyed to the clamping groove by the card entry device, the card reading detection device moves radially to detect the testing card, a baffle plate for preventing the testing card from sliding out of the card groove is arranged on the testing card bearing plate, the card pressing device can press the testing card when the card reading detection device performs detection, the card clamping device clamps the testing card from two sides and rights the testing card before the card reading detection device performs detection, and the testing card can be conveyed out of the card groove by the card exit device. According to the stereotaxic localization rotating disc type multi-project dry-type fluorescence detector, the detection error can be avoided, and the reliability and the stability of the detector are improved.

Owner:GUANGZHOU LABSIM BIOTECH CO LTD

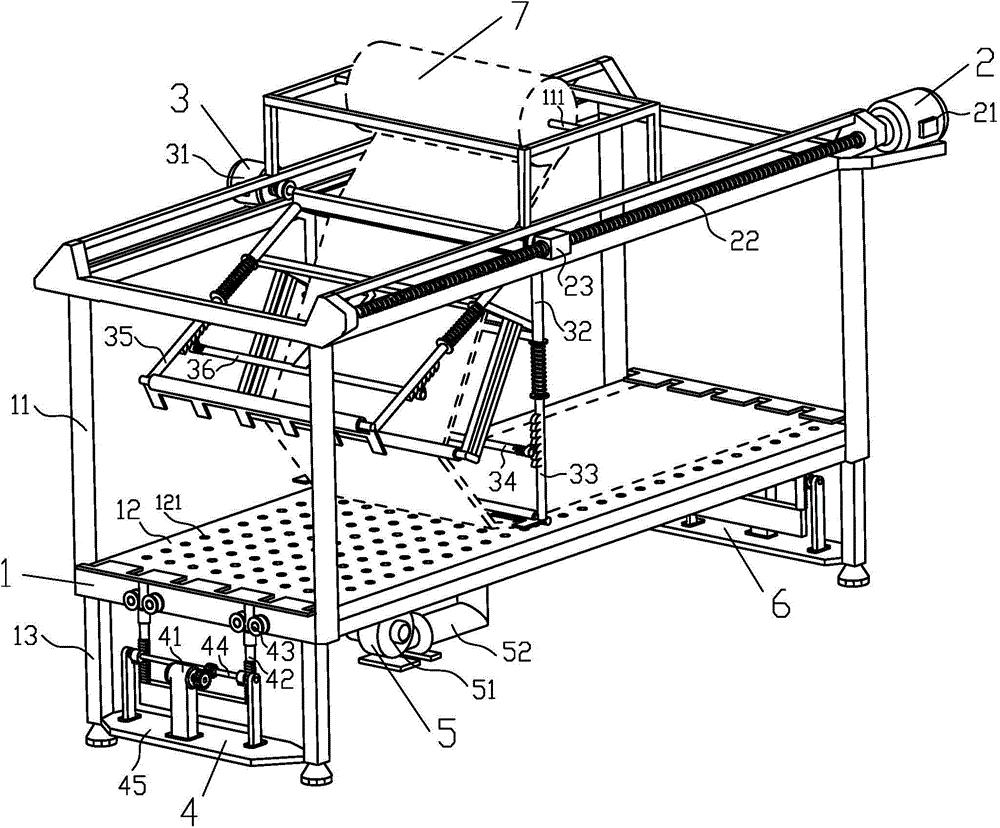

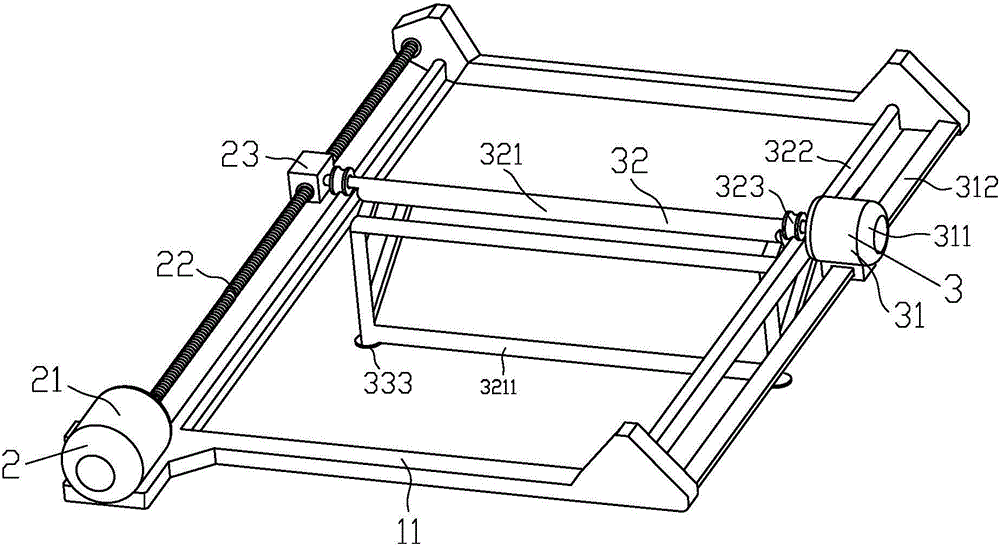

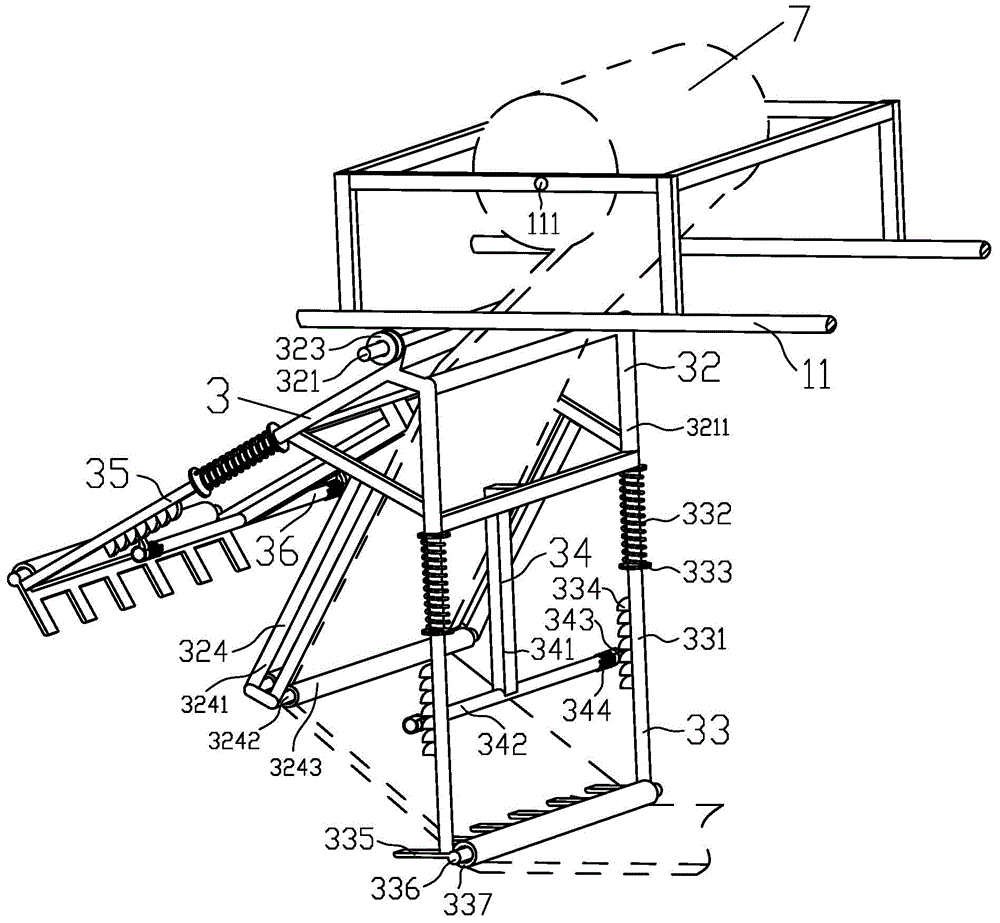

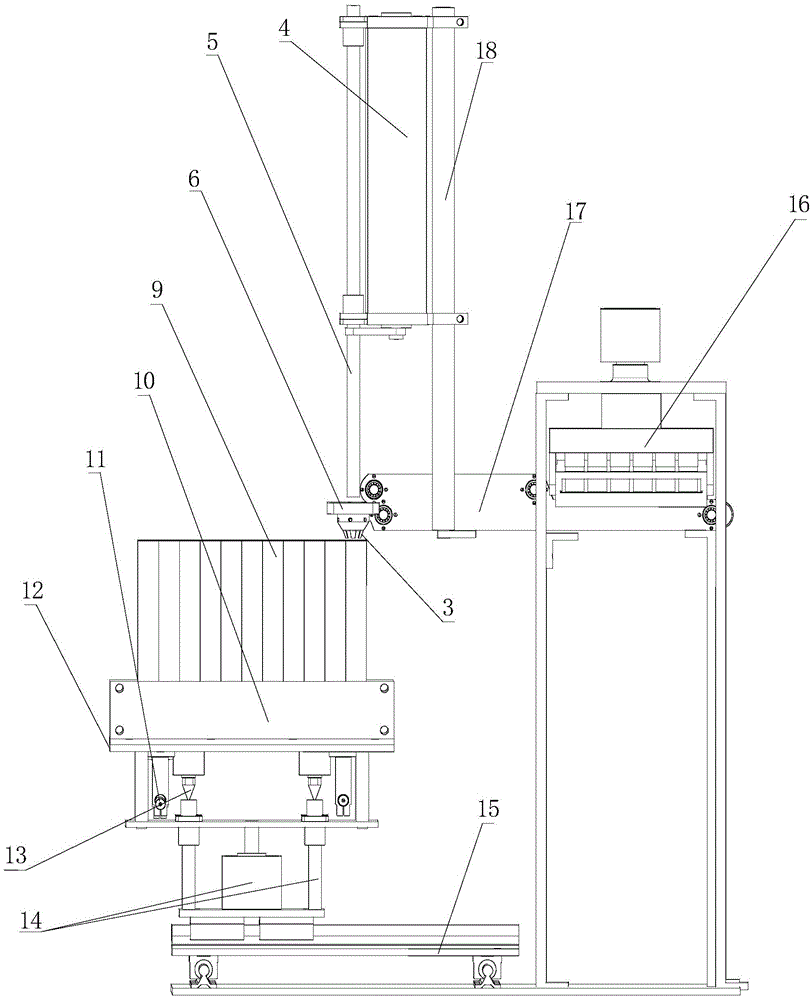

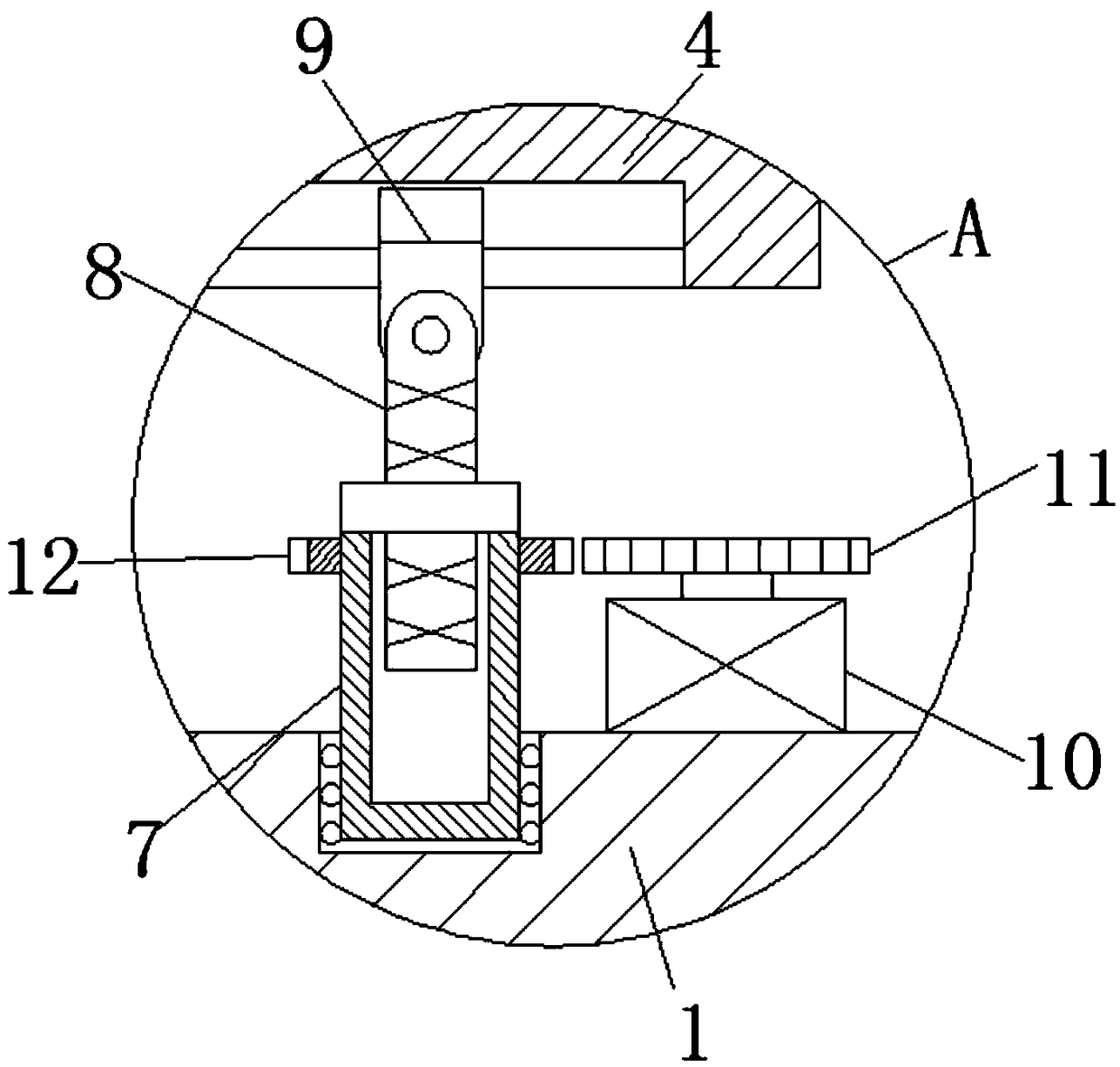

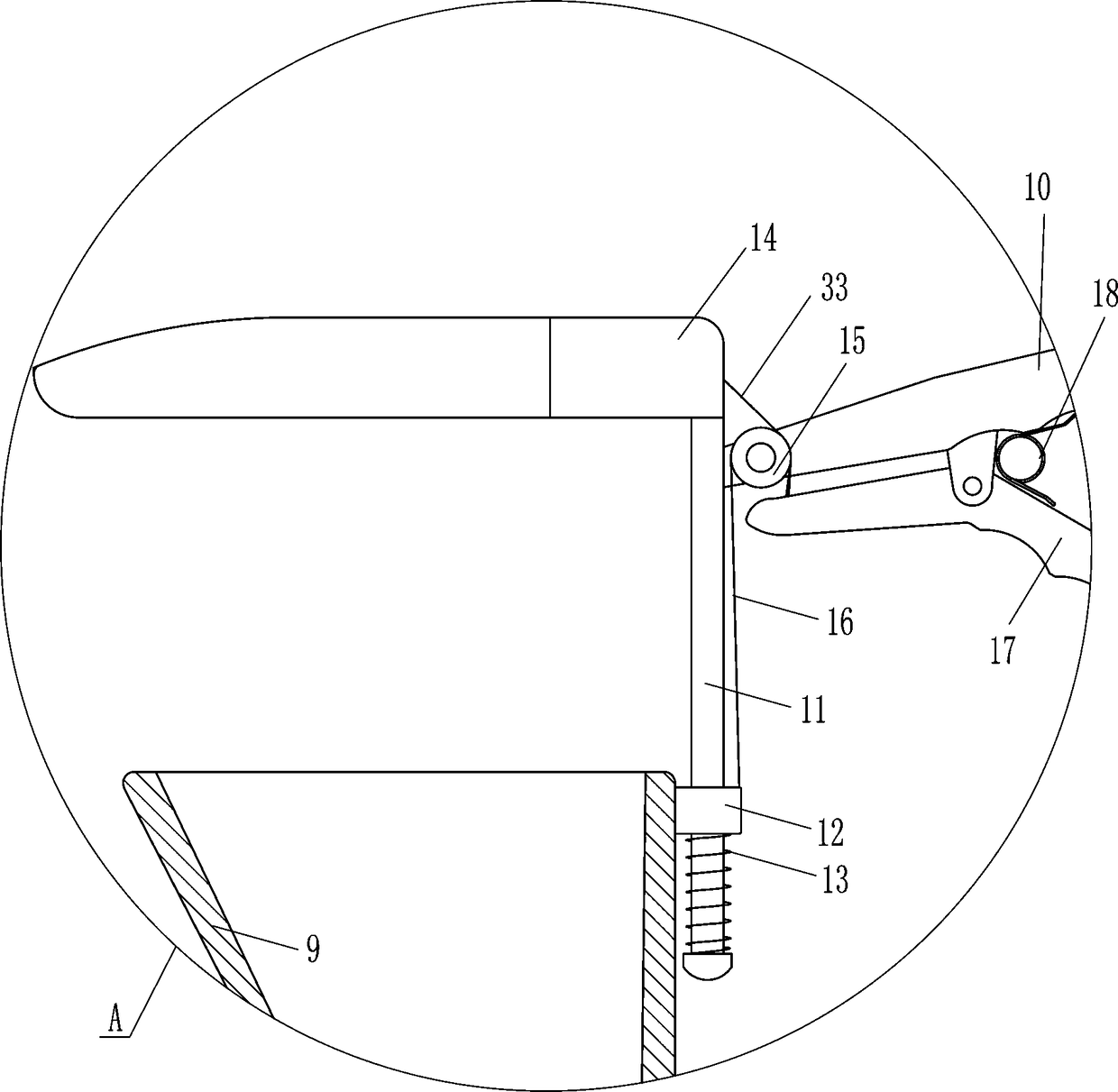

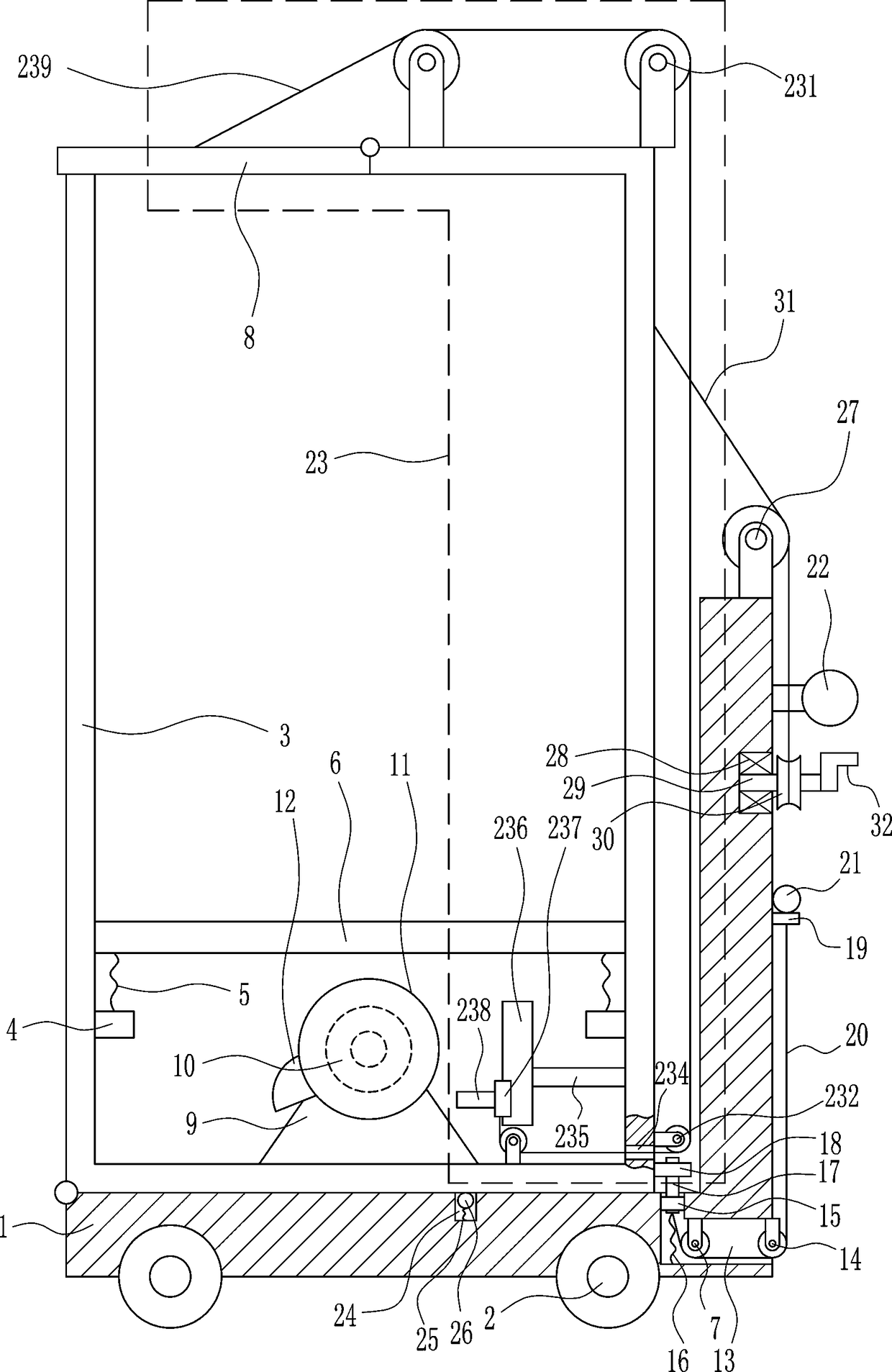

Automatic spreading machine

InactiveCN104876053AReduce the impactSave human effortUnfolding thin materialsWebs handlingSelf lockingEngineering

The invention discloses an automatic spreading machine which is composed of a workbench, a spreading device, a cloth laying device, a left cloth pressing device, an adsorption device and a right cloth pressing device. The workbench is composed of a supporting frame, a cloth laying platform and adjustable table legs. The spreading device is composed of a spreading motor, a lead screw and a movable sliding block. The cloth laying device is composed of a cloth laying driving device, a spreading connecting frame, a right cloth laying ascending mechanism, a right self-locking mechanism, a left cloth laying ascending mechanism and a left self-locking mechanism. The left cloth pressing device is composed of a cloth pressing driving device, a lifting mechanism, a pressing rod guide device, a cloth pressing transmission device and a cloth pressing supporting plate. The adsorption device is composed of an adsorption air pump and an air pipe. Cloth can be pulled out and flatly laid on the cloth laying platform with all the layers closely attached, and no wrinkle exists. Every time one layer of cloth is laid, cloth spreading and laying can be carried out in a reciprocating mode without breaking the cloth. According to the automatic spreading machine, manpower is saved, and cloth laying efficiency and quality are improved.

Owner:ANHUI UNIV OF SCI & TECH

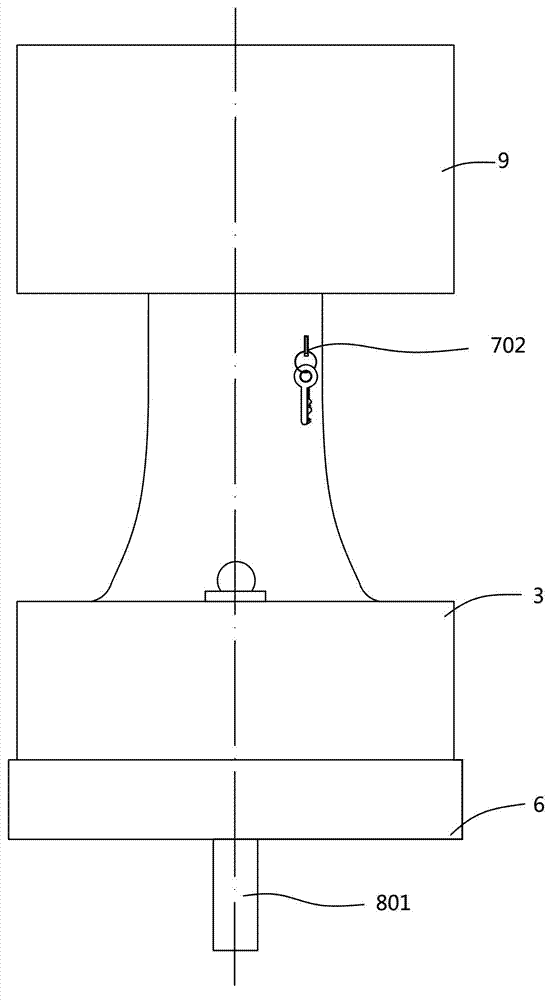

Seal cangue

The invention discloses a seal cangue. A seal is embedded and sleeved in a bracket; a jackscrew and a spring sheet are arranged on the bracket to fix the seal; the bracket is embedded and sleeved in an upper shell; a slide way groove is machined in the upper shell; the jackscrew slides in the slide way groove; a sleeve which is internally provided with a spring is fixed at the top surface of the upper shell; a push rod permeates through the sleeve and the upper shell; the lower end of the spring is fixed on the bottom surface of the sleeve while the upper end per se is fixed on the push rod; the lower end of the push rod is fixed to the top surface of the bracket; a lower shell which is internally provided with a pair of support rod supporting jackscrews is buckled to the lower end of the upper shell; a lock is fixed on the lower surface of the top surface of the upper shell; and the push rod is correspondingly provided with a lock hole. The upper end of the push rod is provided with an annular groove and is mounted with an annular lock. An outer shell is also provided with a counter and a level gauge; and an inkpad support is arranged in the lower shell. The seal cangue, disclosed by the invention, has the advantages of guaranteeing safekeeping and safe use of the seal through a locking key, guaranteeing flatness of the seal as a slide way is adopted for positioning, being convenient operate, counting use time by using the counter, showing if the seal is placed neatly through the level gauge, and preventing the seal against damage through the upper shell and the lower shell.

Owner:李育翰

Automatic putting device for round paper scrip of fireworks

ActiveCN105571407AGuarantee processing qualityGuarantee the quality of fireworksFireworksInternal cavityLinear drive

The invention discloses an automatic putting device for round paper scrips of fireworks. The automatic putting device comprises a paper scrip compression rod which is connected with an up and down reciprocating linear drive mechanism; a paper scrip guide mechanism is arranged below the paper scrip compression rod and comprises a hole duct capable of passing through the paper scrip compression rod; a plurality of elastic claw bodies are arranged around the lower end of the hole duct; roots of the elastic claw bodies are arranged in the periphery of the hole duct; the plurality of elastic claw bodies are combined in a shape with big roots and small free ends. The device is capable of eliminating interference of factors, such as irregular paper tubes, the outer diameter of the round paper scrip being larger than the inner diameter of a paper tube, etc. on automatic machine putting work, and precisely and dynamically guiding a process that the round paper scrips are put into the inner cavity of the paper tube so that the round paper scrips are put automatically and smoothly; a tube body is not damaged, the round paper scrips are placed flatly, the processing quality is guaranteed; a center hole is not needed in a top sheet and thus the fireworks quality is guaranteed.

Owner:罗词芳

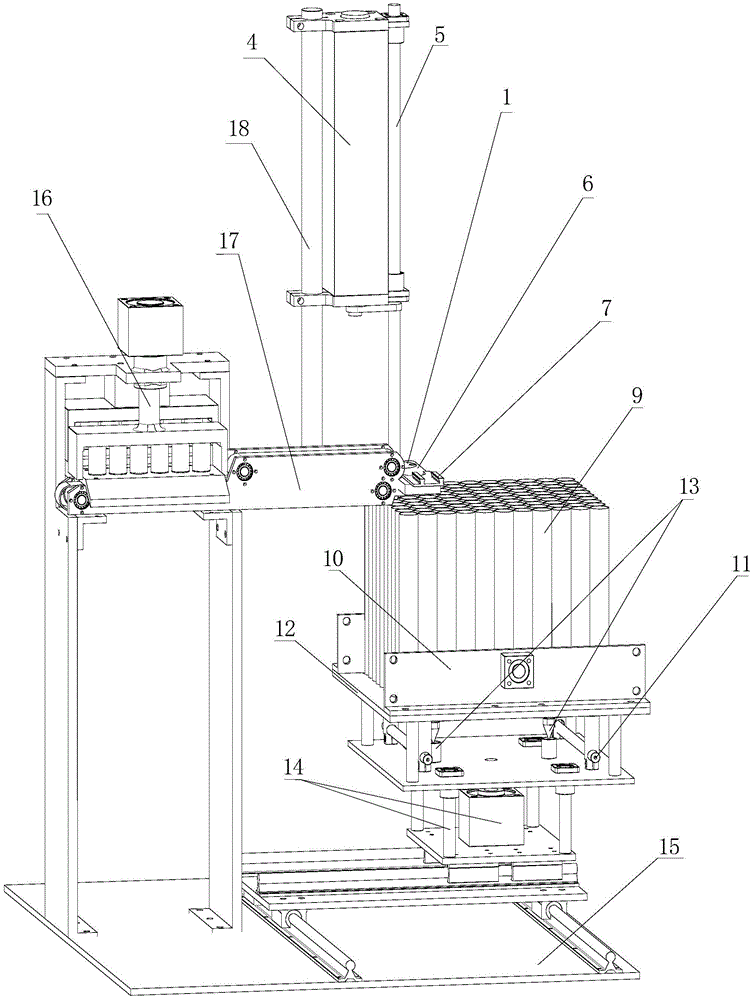

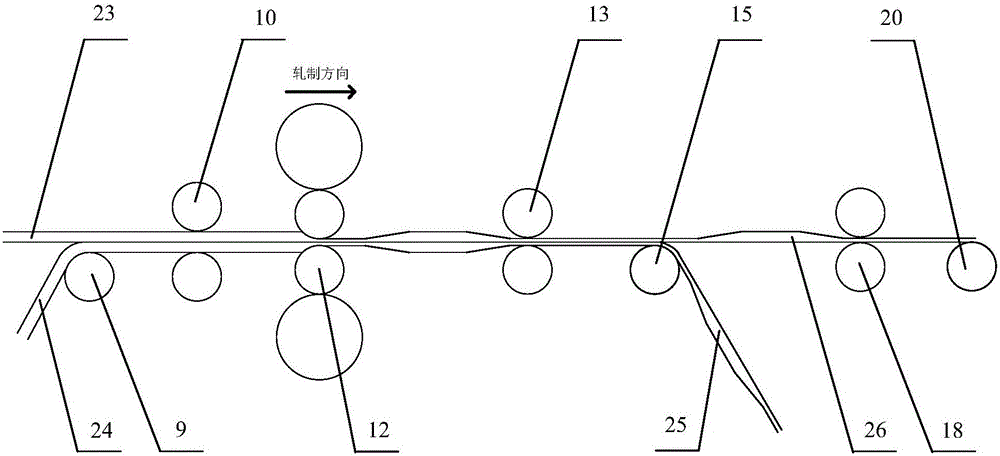

Rolling method for single-face periodically variable thickness plate strip materials

ActiveCN106513436AAchieve productionImprove rolling efficiencyTension/compression control deviceWork lubrication devicesVariable thicknessMetal

The invention disclose a rolling method for single-face periodically variable thickness plate strip materials, and belongs to the technical field of metal rolling. According to the method, double-strip synchronous variable-thickness ply rolling is conducted through two uncoilers and two coilers, that is, the two uncoilers and the two coilers are arranged on two sides of a rolling mill correspondingly. The rolling method includes the specific steps that (1) feeding is carried out, specifically, upper-layer raw plate strip materials and lower-layer raw plate strip materials are installed on the corresponding uncoilers; (2) strip penetrating is conducted, specifically, the upper-layer raw plate strip materials and the lower-layer raw plate strip materials are welded to guide strips of the corresponding coilers separately through guide strip movement and welding, so that strip penetrating is completed; (3) variable-thickness rolling is conducted, specifically, setting of rolling parameters and control over alignment, speed, thickness, tension and the like in the rolling process are included; and (4) the single-face periodically variable thickness plate strip materials are obtained and moved out. By the adoption of the method, rolling of the single-face periodically variable thickness plate strip materials and double-face periodically variable thickness plate strip materials can be realized, different production requirements are met, the rolling efficiency is greatly improved, and the production cost is lowered.

Owner:NORTHEASTERN UNIV

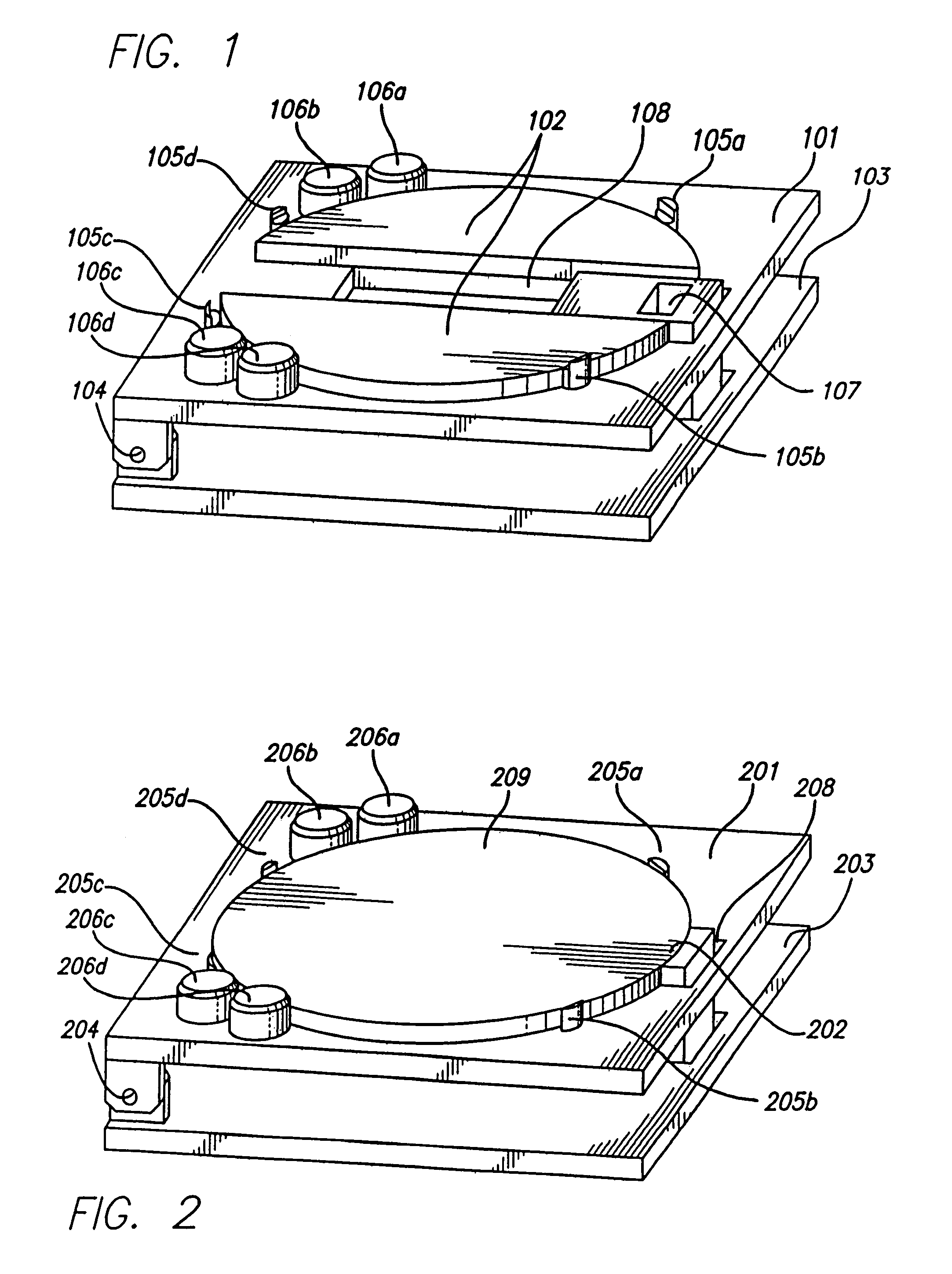

Backside contamination inspection device

InactiveUS7038771B2Effectively throughput of inspectionOpportunities decreaseSemiconductor/solid-state device manufacturingOptically investigating flaws/contaminationEngineeringContamination

A system for simultaneously inspecting the frontsides and backsides of semiconductor wafers for defects is disclosed. The system rotates the semiconductor wafer while the frontside and backside surfaces are generally simultaneously optically scanned for defects. Rotation is induced by providing contact between the beveled edges of the semiconductor wafer and roller bearings rotationally driven by a motor. The wafer is supported in a tilted or semi-upright orientation such that support is provided by gravity. This tilted supporting orientation permits both the frontside and the backside of the wafer to be viewed simultaneously by a frontside inspection device and a backside inspection device.

Owner:KLA CORP

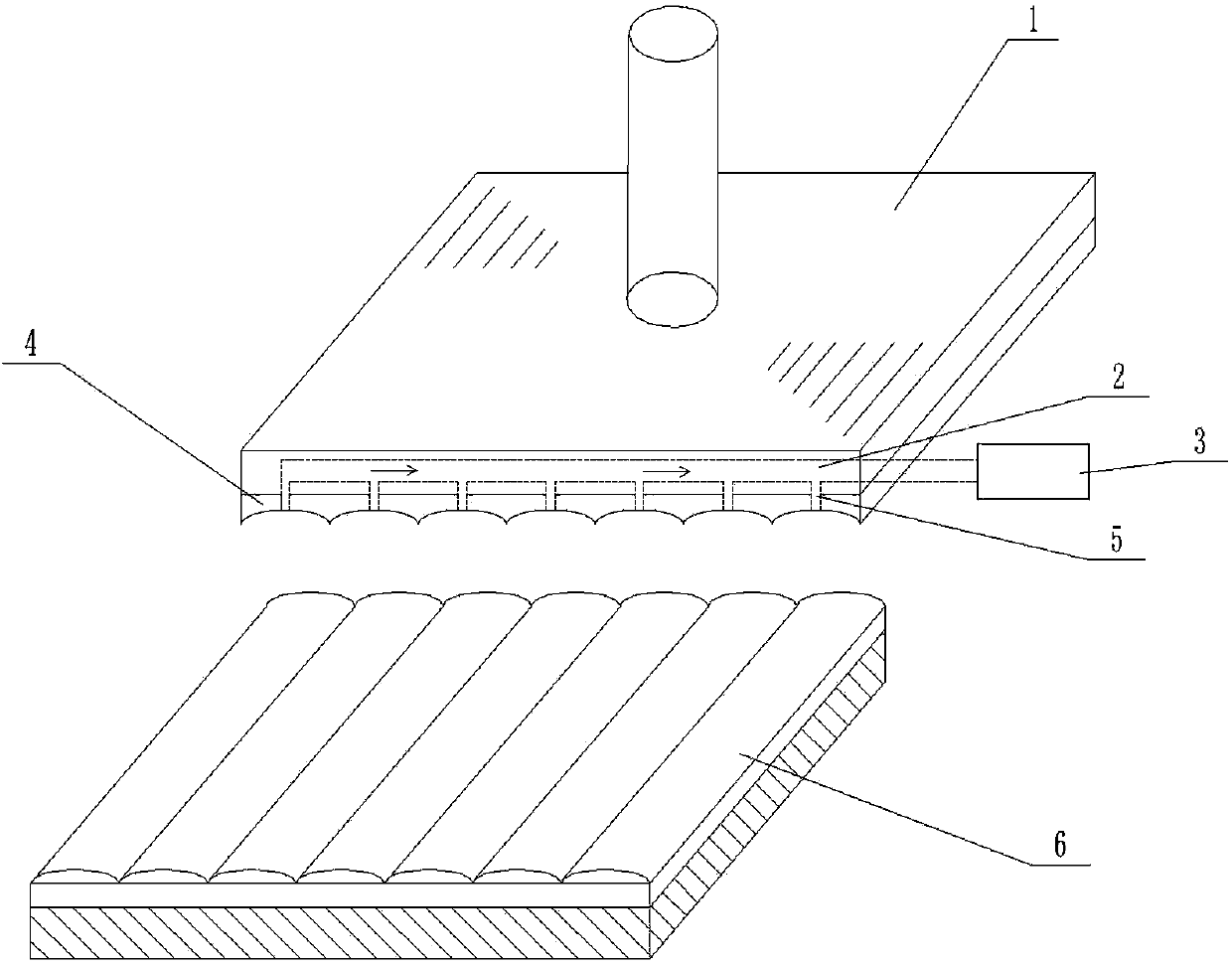

Concave-convex surface vacuum adsorption device and manufacturing method of concave-convex surface vacuum adsorption device

The invention discloses a concave-convex surface vacuum adsorption device and a manufacturing method of the concave-convex surface vacuum adsorption device. The concave-convex surface vacuum adsorption device comprises a vacuum adsorption disc (1), wherein an air flow passage (2) is arranged in the vacuum adsorption disc (1) and is connected onto a first vacuum generator (3), a concave-convex surface complementary assembly complemented with the concave-convex surface on an adsorbed device is arranged on the vacuum adsorption disc (1), and a plurality of air holes are formed in the concave-convex surface complementary assembly and are communicated with the airflow passage (2). The concave-convex surface vacuum adsorption device can adsorb and grab devices with concave-convex uneven surfaces. The manufacturing method of the concave-convex surface vacuum adsorption device has the advantages that the processing is convenient, and the precision is high.

Owner:NINGBO VISION DISPLAY TECH

Micro motor magnetic steel assembly device

ActiveCN103872860AImprove adsorption capacityIncrease productivityMagnetic bodiesManufacturing dynamo-electric machinesMicro motorUltimate tensile strength

The invention discloses a micro motor magnetic steel assembly device which comprises a working platform and two guide rails on the working platform. A movable supporting base is arranged on the two guide rails. A third air cylinder is arranged on the movable supporting base. An installation arm parallel to the two guide rails is fixed to a piston rod of the third air cylinder. The two ends of the installation arm are provided with a first air cylinder and a second air cylinder. A first magnetic steel attraction device is arranged on a piston rod of the first air cylinder. A second magnetic steel attraction device is arranged on a piston rod of the second air cylinder. A first magnetic steel positioning base, a second magnetic steel positioning base and a shell positioning base are sequentially arranged on the working platform along the straight line. The distance between every two adjacent positioning bases is equal to the distance between the first magnetic steel attraction device and the second magnetic steel attraction device. A fourth air cylinder is installed on the working platform through a support. A piston rod of the fourth air cylinder extends downwards. A magnetizing apparatus corresponding to the second magnetic steel positioning base is arranged on the piston rod of the fourth air cylinder. According to the micro motor magnetic steel assembly device, the labor intensity of workers is reduced, and production efficiency is improved.

Owner:广安市超颖电子科技有限公司

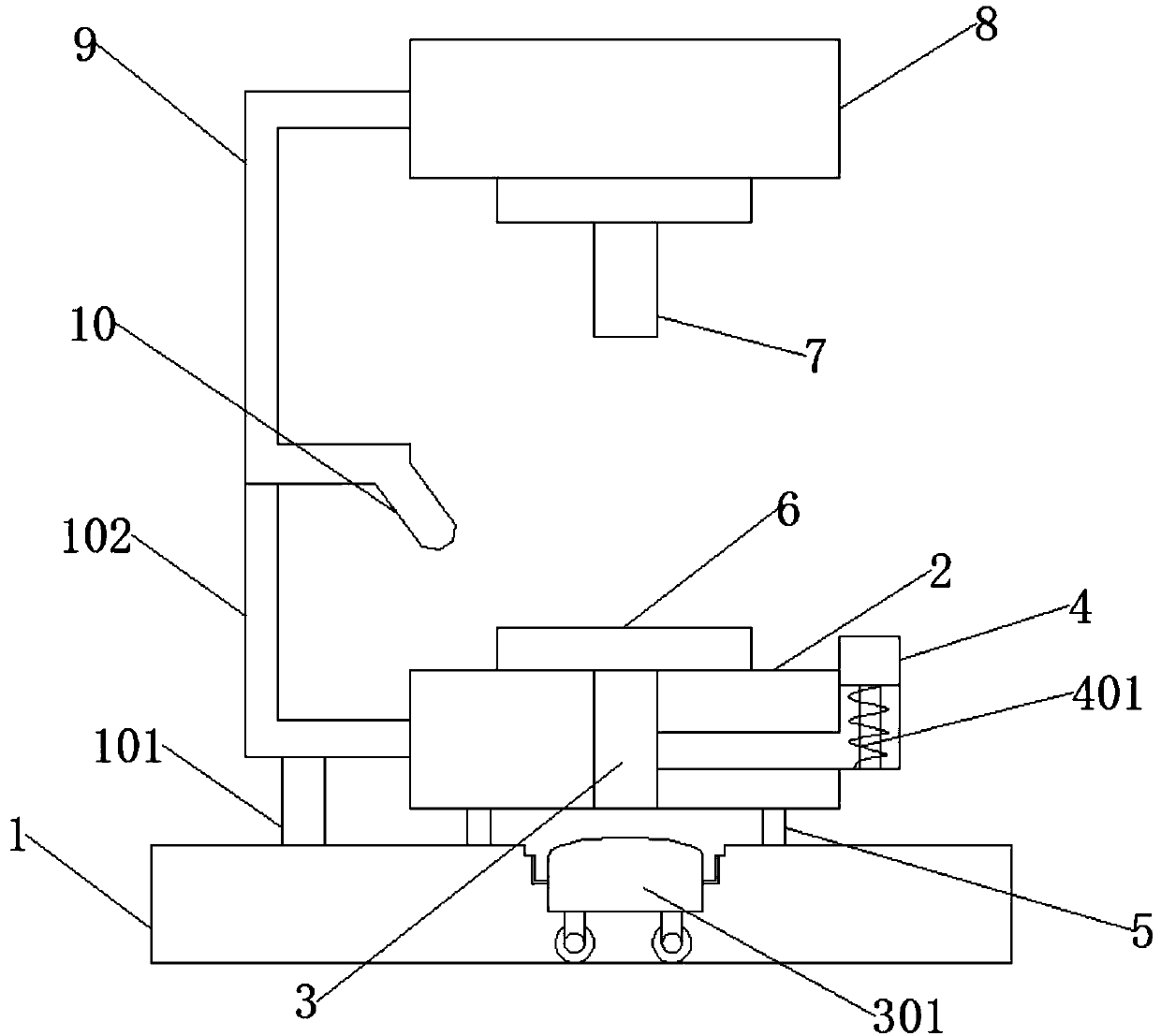

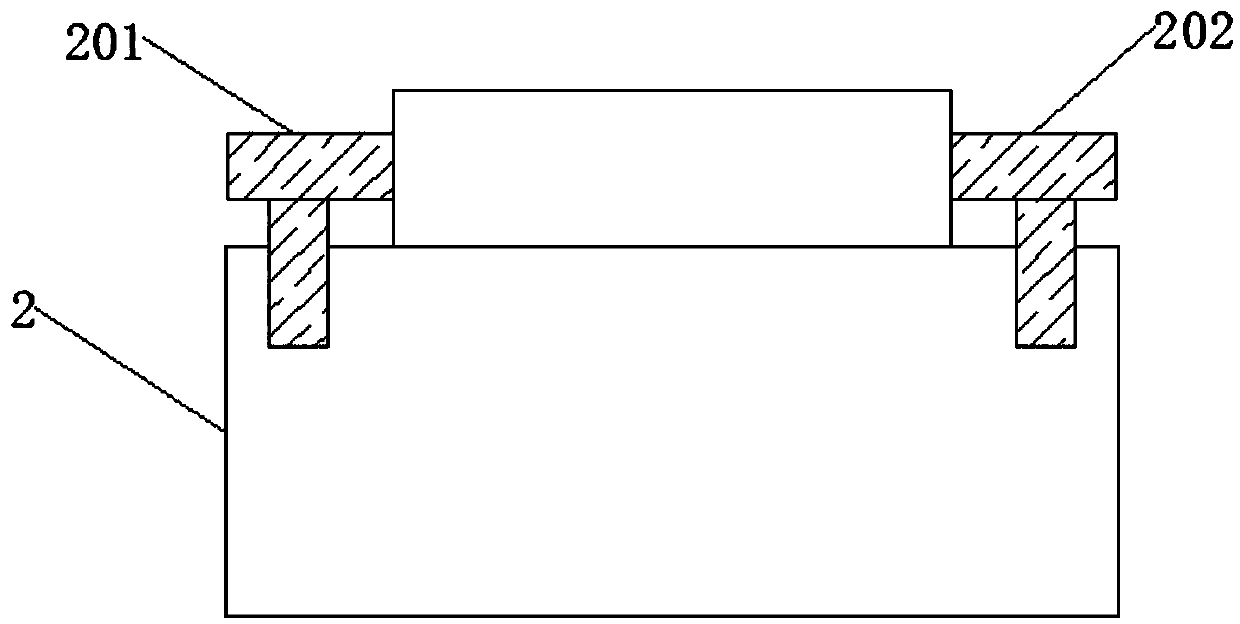

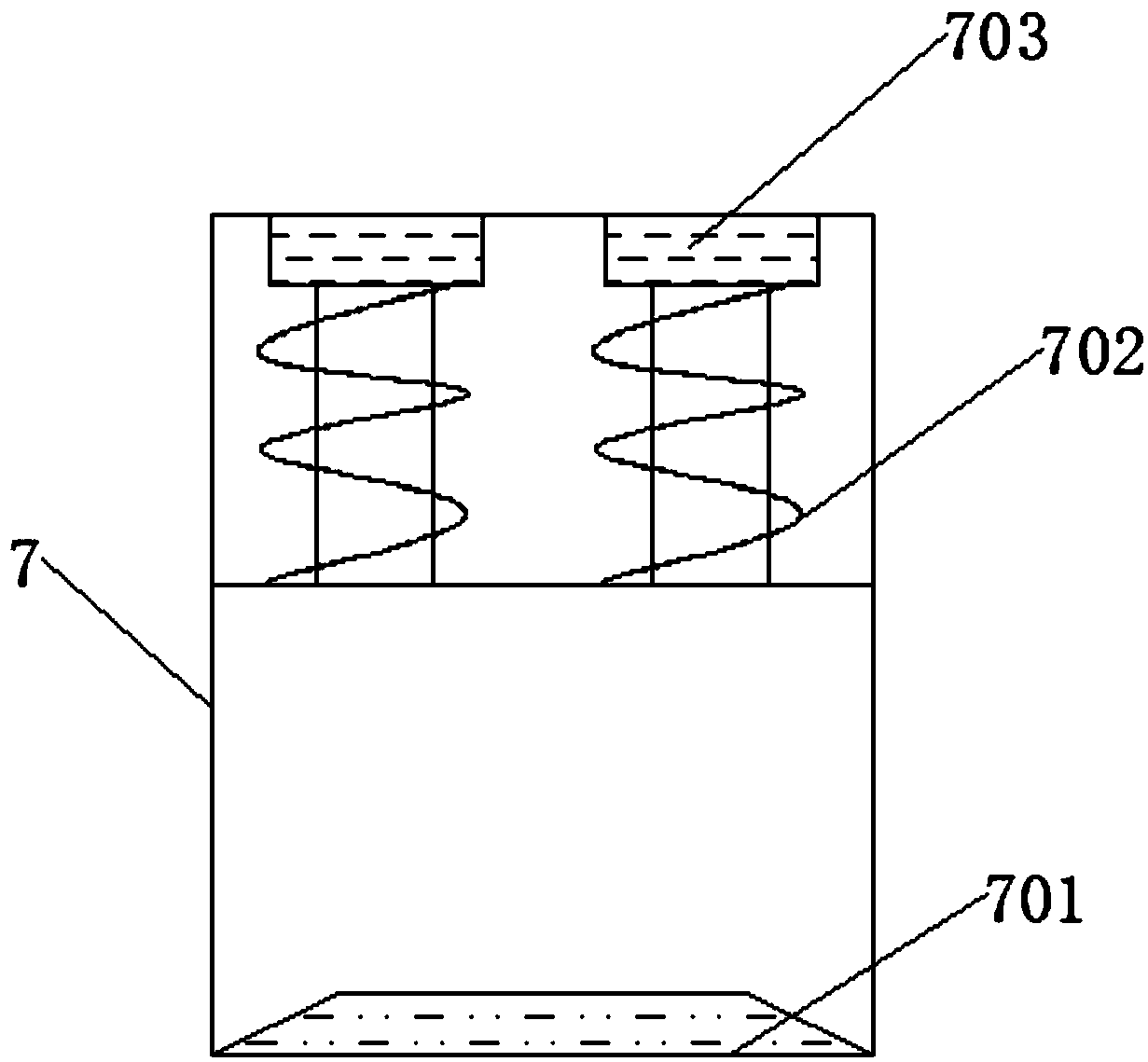

Press-fitting device of automobile pipe support

ActiveCN105414440ALay flatAvoid unevennessCleaning using gasesCleaning using liquidsPipe supportAutomotive engineering

The invention discloses a press-fitting device of an automobile pipe support. The press-fitting device comprises a work table board, a stamping head, a press sleeve and a fixing sleeve. When the stamping head stamps the automobile pipe support downwards, the automobile pipe support can be flattened in advance through the press sleeve, and the automobile pipe support is flat after being riveted and pressed.

Owner:NINGBO FUSHI AUTOMOBILE COMPONENTS

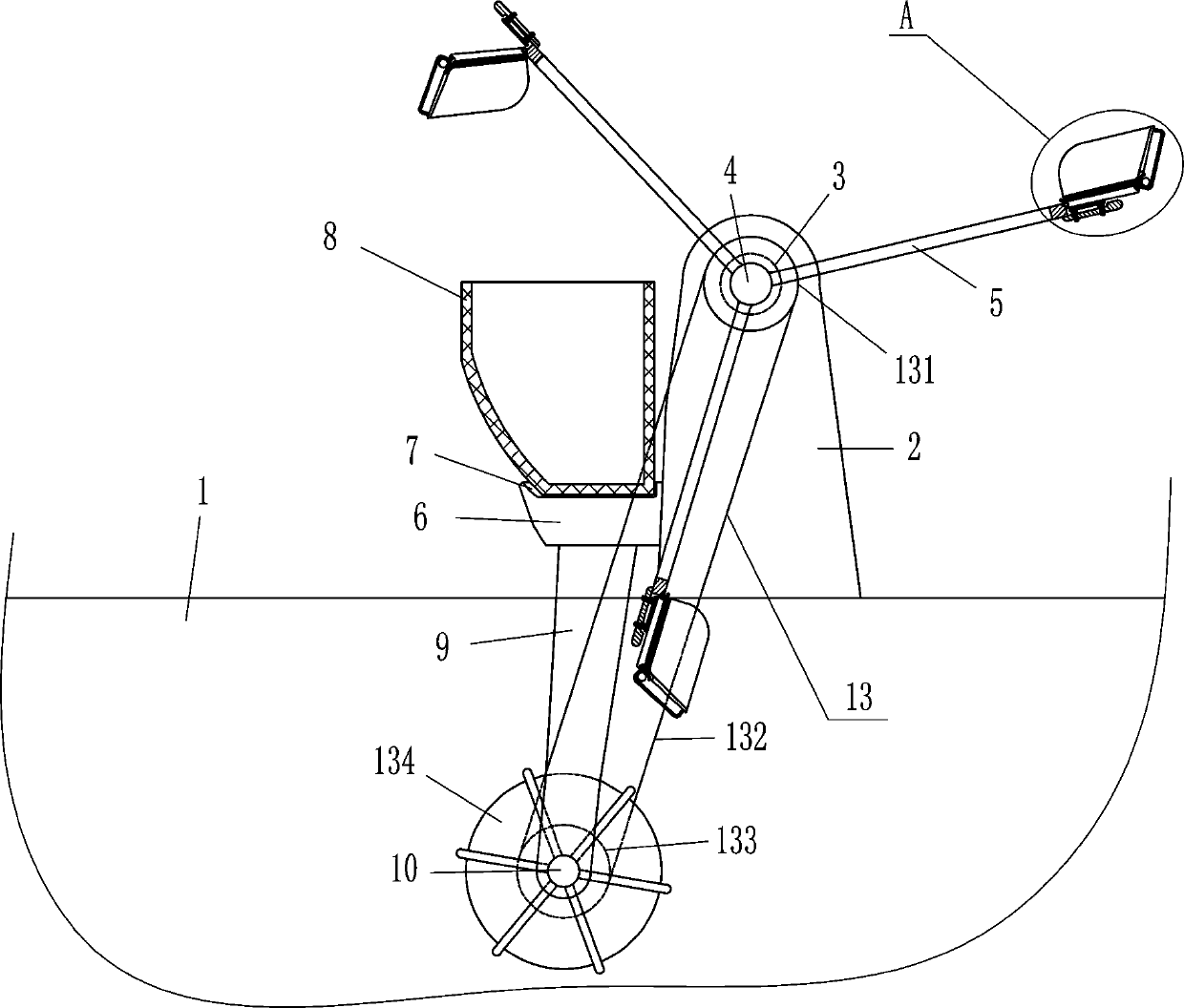

Sewage channel garbage salvage equipment

The invention relates to salvage equipment, in particular to sewage channel garbage salvage equipment. The sewage channel garbage salvage equipment can continuously salvage garbage through water driving, is low in labor intensity, does not need manual salvage through hands, and is high in working efficiency. According to the technical scheme, the sewage channel garbage salvage equipment comprisestwo supporting plates, bearing seats, a first rotating shaft, a 7-shaped connecting rod and the like; the bearing seats are fixedly connected to the upper portions of a front supporting plate and a rear supporting plate in an embedded mode, and the first rotating shaft is connected with bearings in the bearing seats on the front side and the rear side. A water wheel is driven by water in a canal body to rotate reversely, thus a salvage frame can rotate reversely to salvage floating garbage into a net frame for collecting the floating garbage, people do not need to use a net bag to salvage thegarbage, time and labor are saved, the working efficiency is higher, the garbage in the salvage frame can fall into the net frame more quickly through a vibration device, and thus next use of the salvage frame is not affected by garbage residues.

Owner:禹城市惠福新能源有限公司

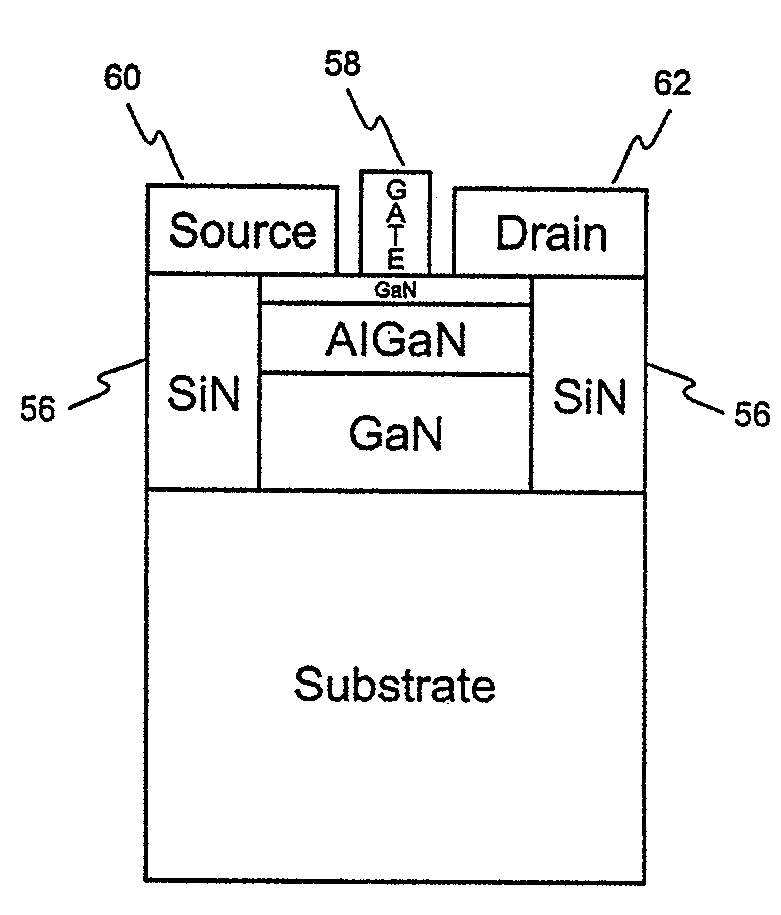

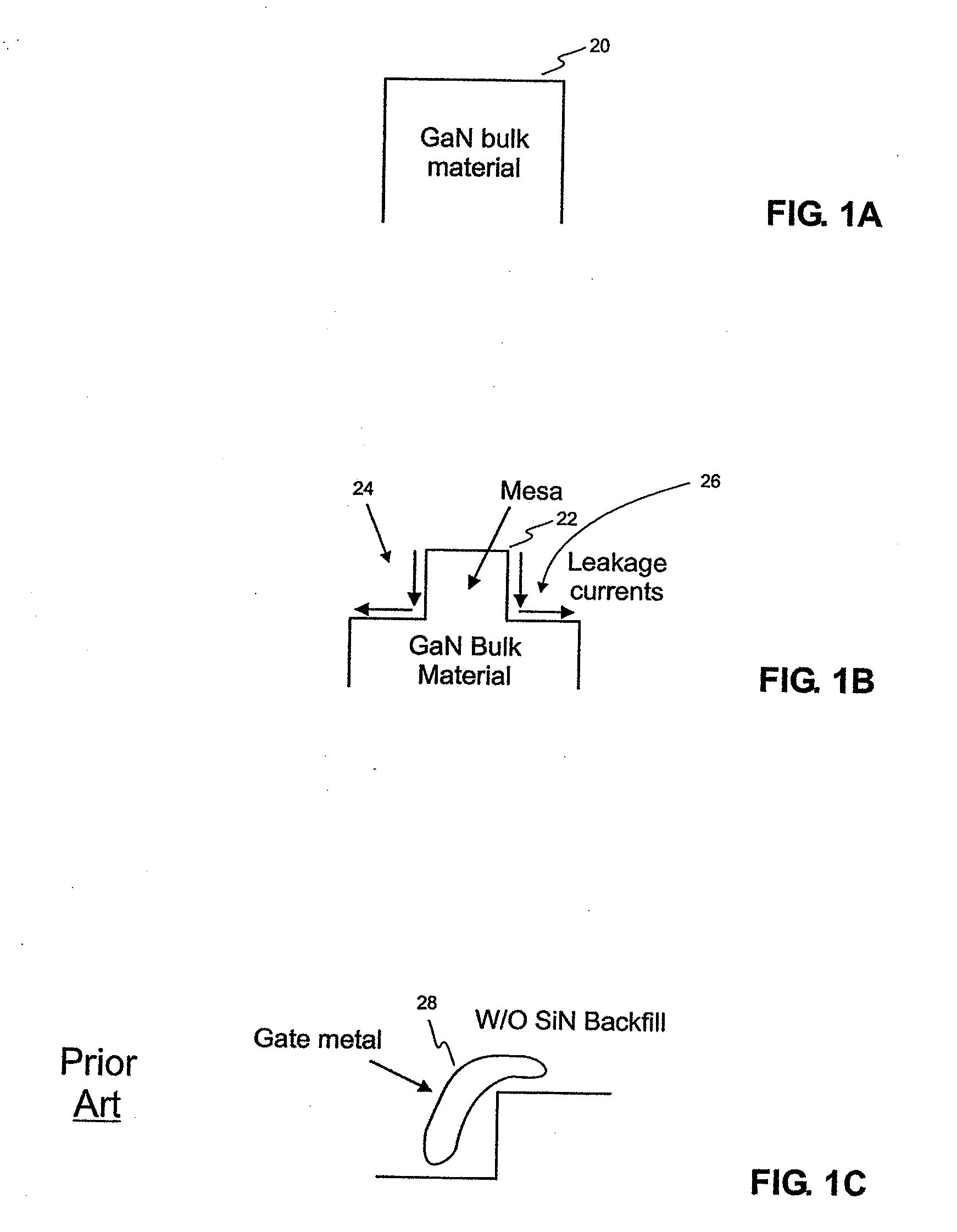

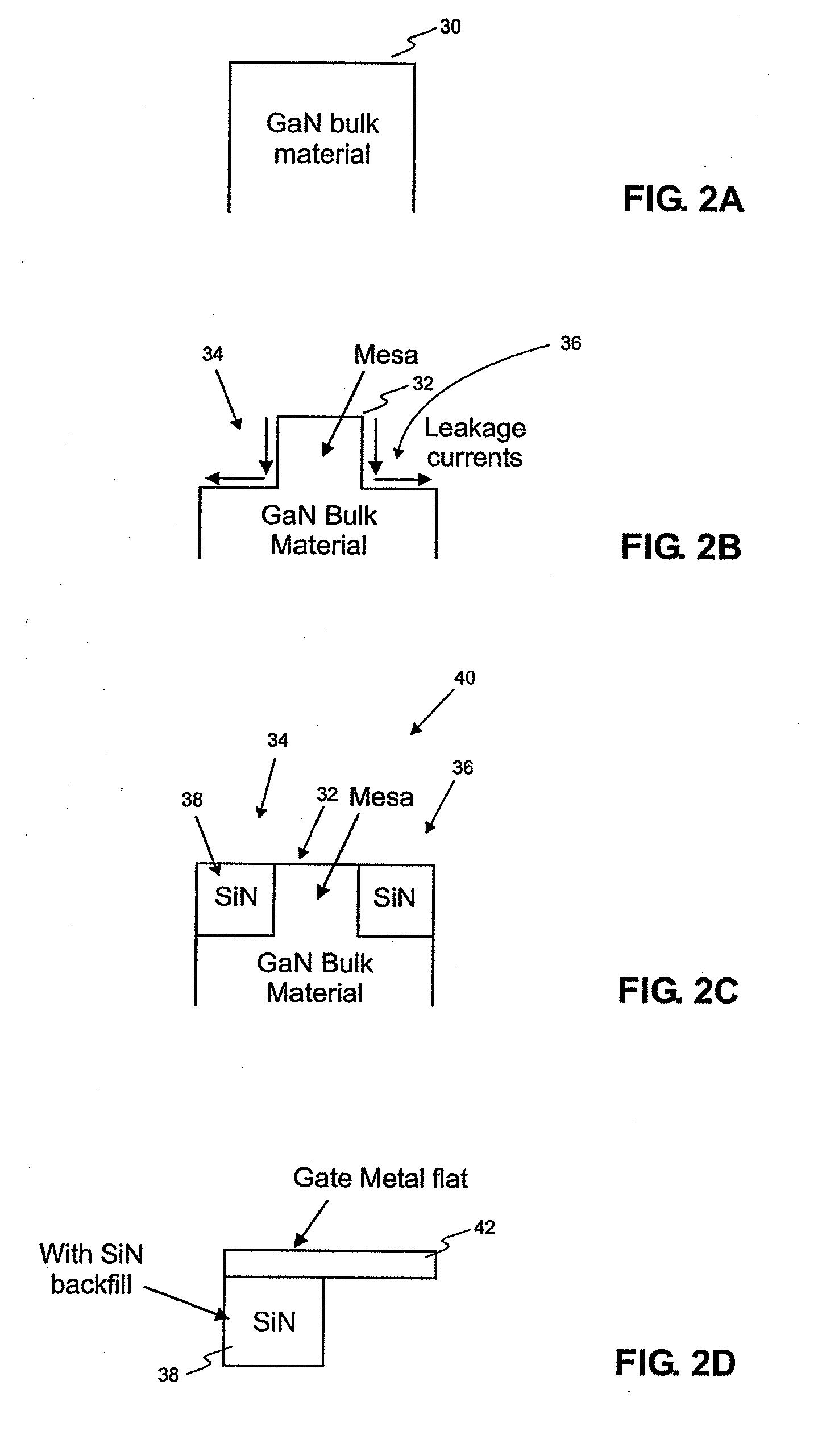

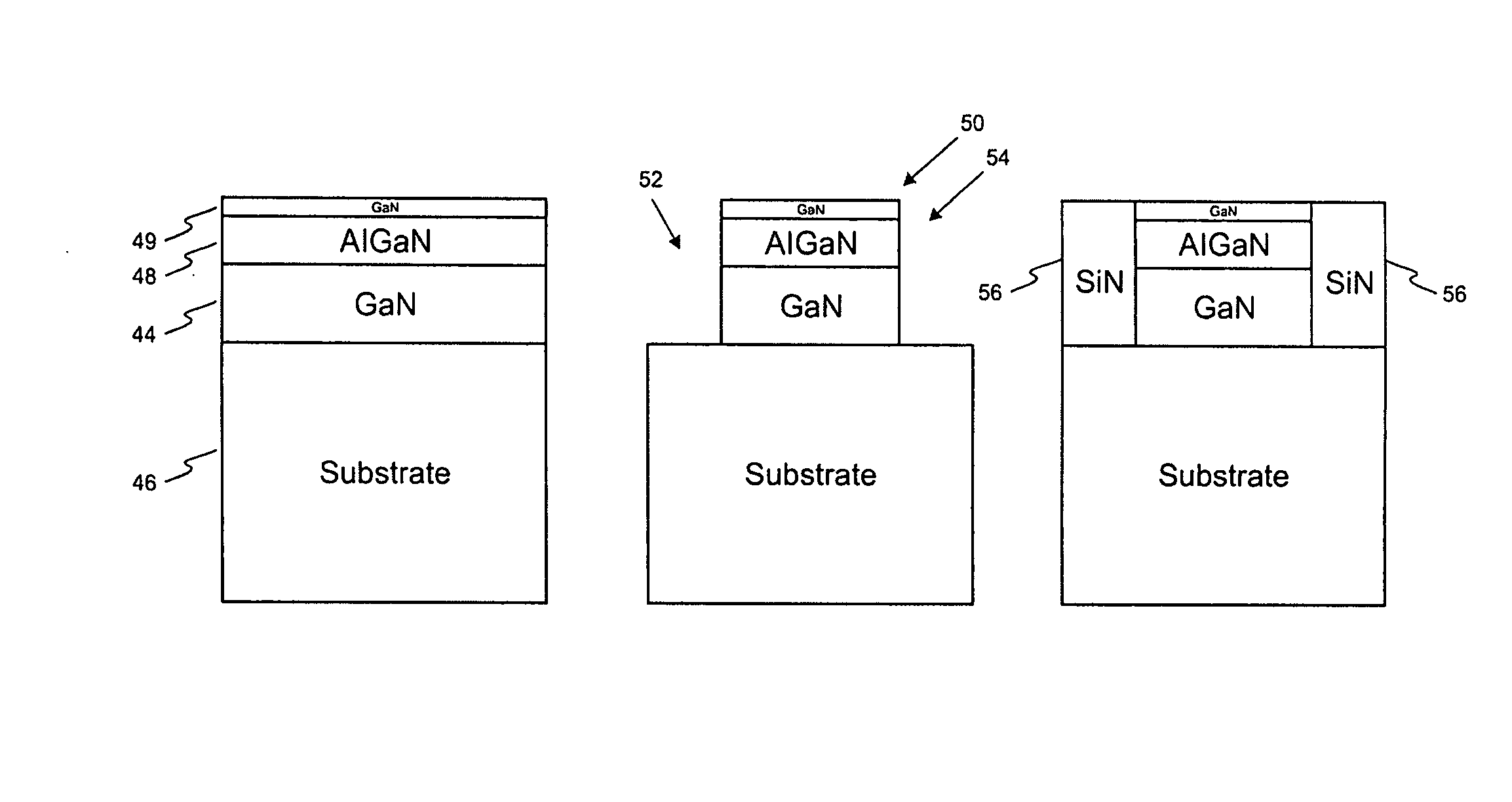

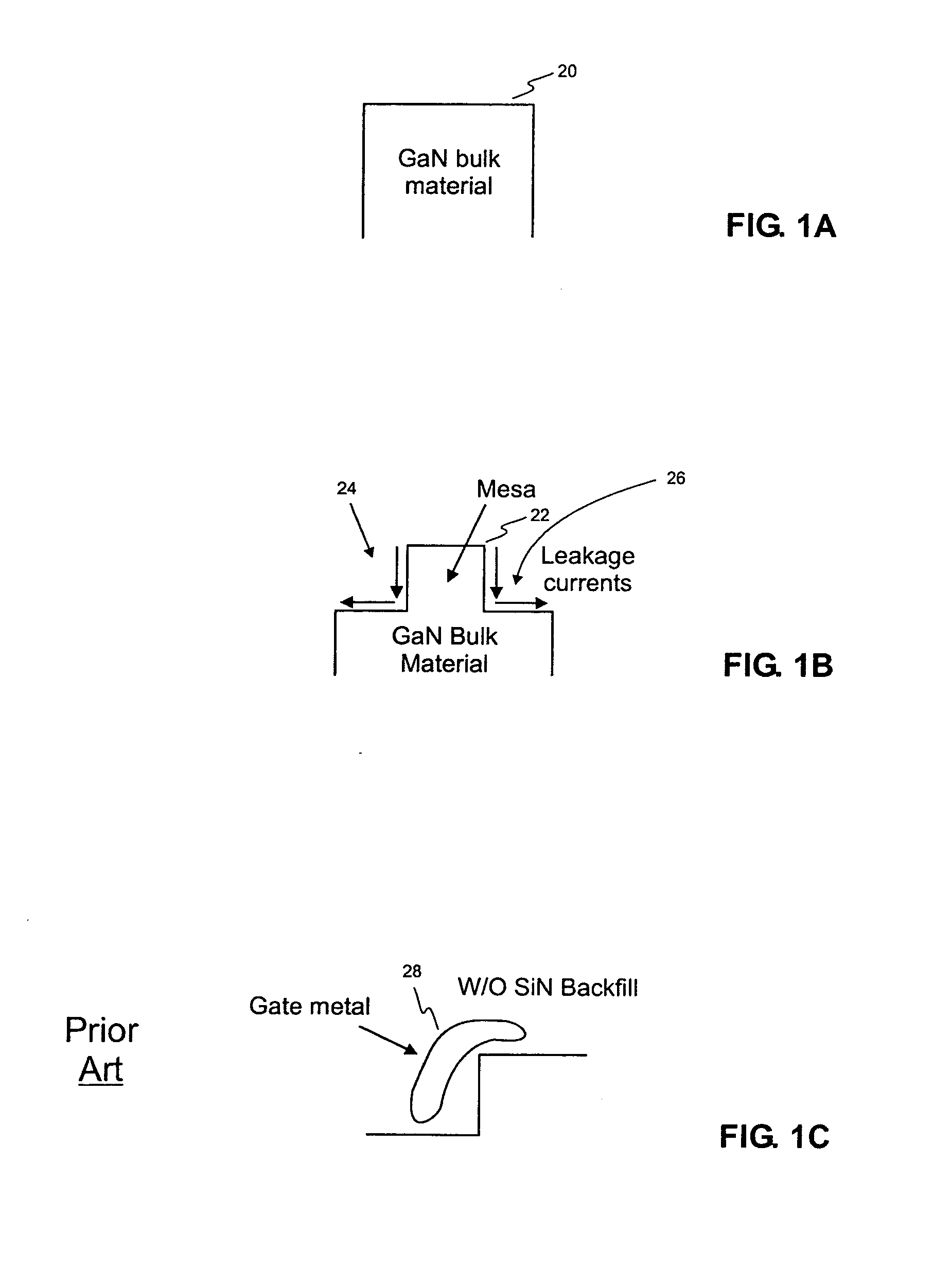

LEAKAGE BARRIER FOR GaN BASED HEMT ACTIVE DEVICE

ActiveUS20080153215A1Obviates problemReduce leakage currentSemiconductor/solid-state device manufacturingSemiconductor devicesGate leakage currentDrain current

An improved HEMT formed from a GaN material system is disclosed which has reduced gate leakage current relative to known GaN based HEMTs and eliminates the problem of current constrictions resulting from deposition of the gate metal over the step discontinuities formed over the gate mesa. The HEMT device is formed from a GaN material system. One or more GaN based materials are layered and etched to form a gate mesa with step discontinuities defining source and drain regions. In order to reduce the leakage current, the step discontinuities are back-filled with an insulating material, such as silicon nitride (SiN), forming a flat surface relative to the source and drain regions, to enable to the gate metal to lay flat. By back-filling the source and drain regions with an insulating material, leakage currents between the gate and source and the gate and drain are greatly reduced. In addition, current constrictions resulting from the deposition of the gate metal over a step discontinuity are virtually eliminated.

Owner:NORTHROP GRUMMAN SYST CORP

Dustproof cutting machine for polypropylene (PP) slices

ActiveCN109291129AImprove processing efficiencyKeep it flatMetal working apparatusEngineeringPolypropylene

The invention belongs to the field of polypropylene (PP) slice processing, in particular to a dustproof cutting machine for PP slices. The invention aims to solve the technical problem so as to provide the dustproof cutting machine for the PP slices, and the dustproof cutting machine for the PP slices can be used for carrying out dustproof treatment on the PP slices, and cutting and punching the PP slices at the same time. The dustproof cutting machine for the PP slices comprises a first installation plate, a first support seat, a first arc-shaped plate, a first electric push rod, an exhaust pipe, a cutting table, a third installation plate, a first lifting plate, a drive roller, a second electric push rod, a support frame, a dustproof cover, a feeding pipe, a first butterfly bolt, a thirdsupport seat and the like, wherein the first arc-shaped plate is fixedly connected to the top part of the first installation plate; and the cutting table is fixedly connected to the top part of the first installation plate through a second support seat. The dustproof cutting machine for the PP slices provided by the invention achieves the effects on carrying out dustproof treatment on the PP slices during the cutting process, punching the PP slices at the same time, and improving the PP slice processing efficiency.

Owner:刘宝义

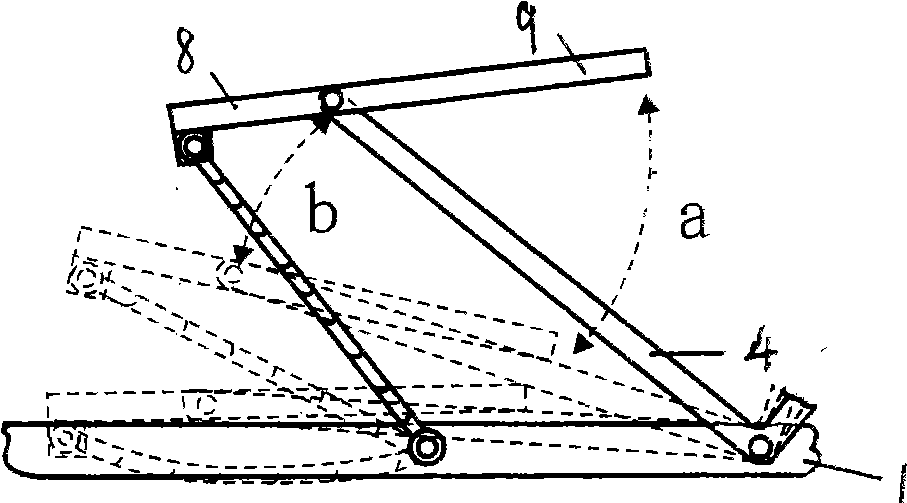

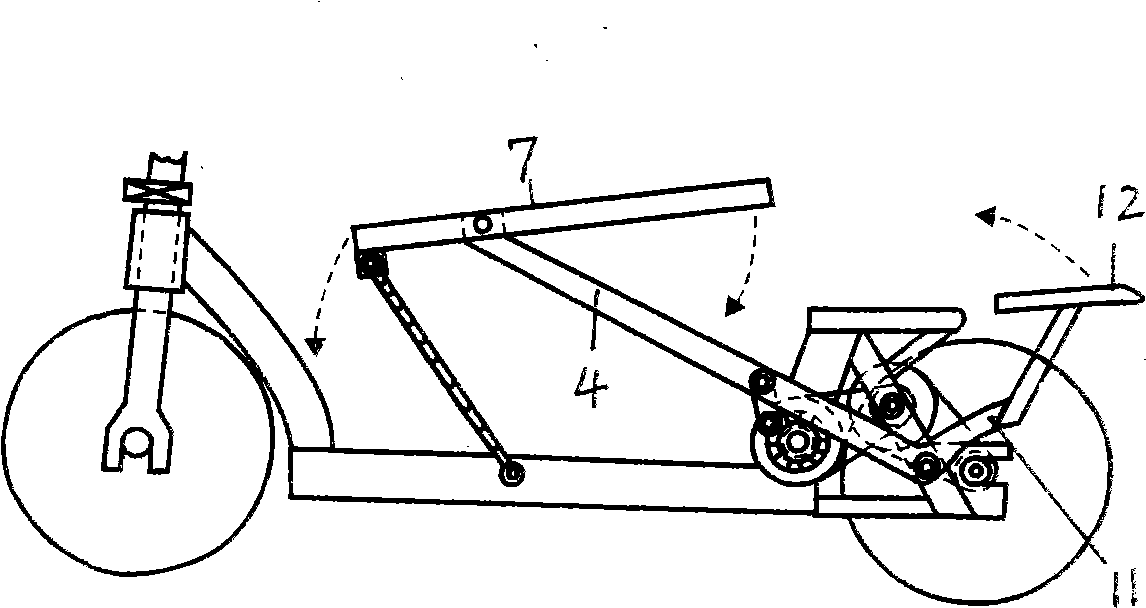

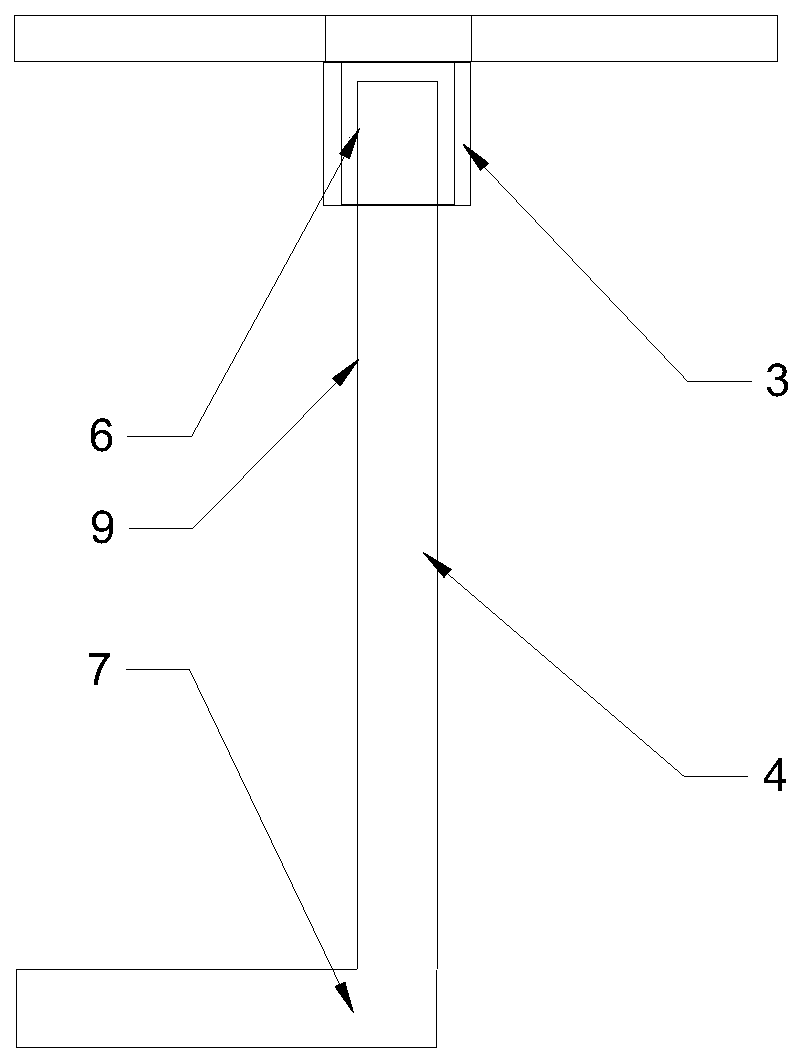

Variable speed scooter

The invention discloses a gear-shift scooter which comprises a scooter bracket (1), a front wheel (2), a rear wheel (3), a power pressure rod (4) which is movably connected above the scooter bracket, a power pressure rod returning mechanism (A), and a power driving mechanism subassembly (B) which is arranged between the power pressure rod (4) and a driving gear (13) arranged on a wheel shaft. The gear-shift scooter is mainly characterized in that the upper end of the power pressure rod (4) is movably connected with a movable pedal (7) which is divided into a position-limiting end and a labor-saving end, a movable connecting member (10) which can limit the upward motion range of the movable pedal is arranged between the front part of the limiting end of the movable pedal and the scooter bracket, and the power driving mechanism subassembly (B) adopts a connecting rod type driving ratchet wheel rotating structure and a gear-shift driving mechanism. The invention is a scooter with two to four wheels, the pedaling mode conforms to a human body standing and pedaling posture and is easy to smoothly exert force, and meanwhile, the invention has high-class, middle-class and low-class shifting effects and high output power.

Owner:林苏钦

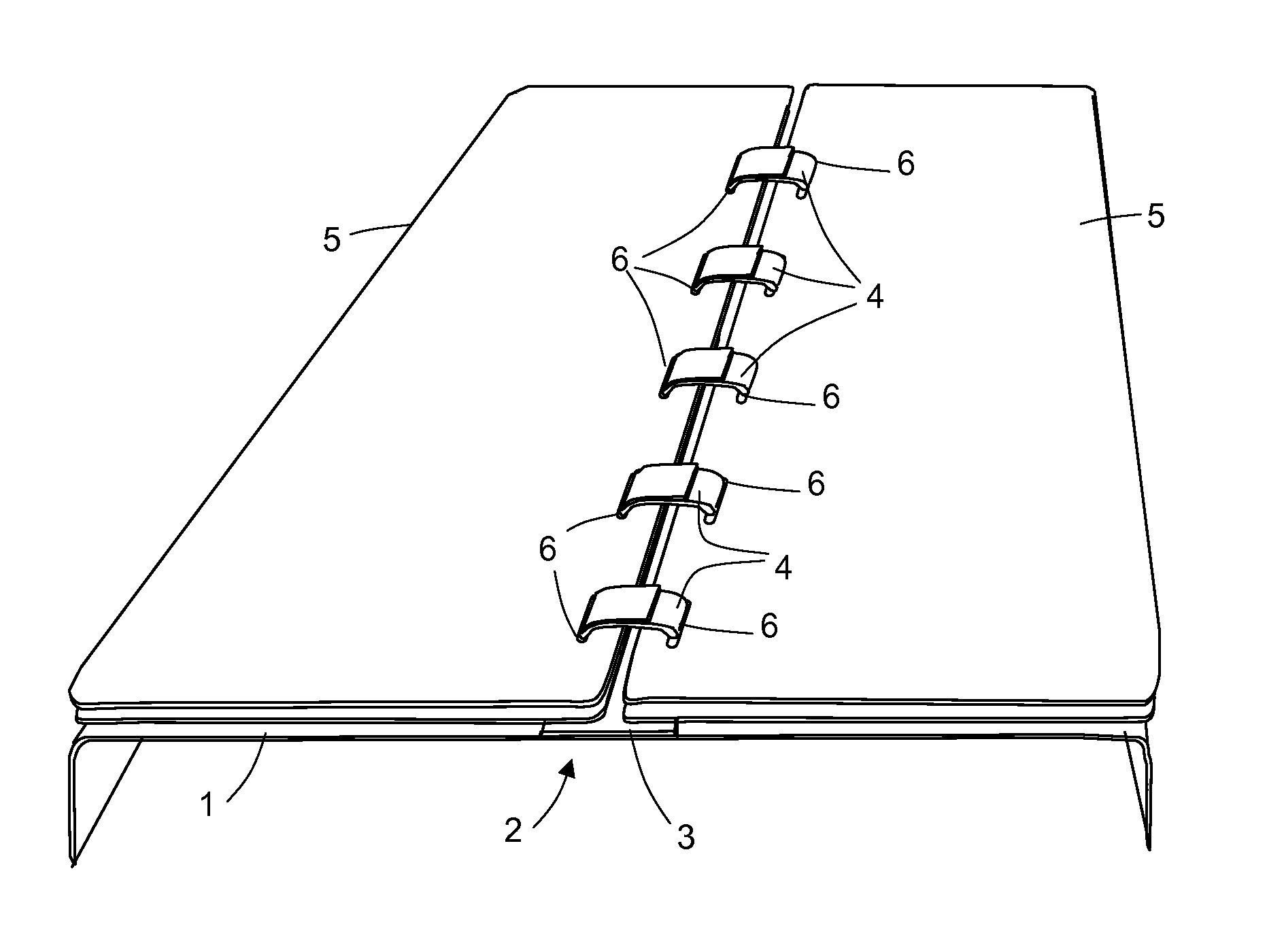

Multilayer, paging, modular bed blanket system

This invention is a modular blanket system for double beds essentially built like a ring binder where the rings, called straps, are made of a flexible material and are closed by means of detachable fasteners such as hook-and-loop, snaps or buttons. The use of straps as a binding means allows blanket leaves to be added, subtracted or paged from one side to the other depending on the sleepers' need for warmth or decorative taste.

Owner:GRADDY ROBERT F

Leakage barrier for GaN based HEMT active device

ActiveUS20070218611A1Obviates problemReduce leakage currentSemiconductor/solid-state device manufacturingSemiconductor devicesGate leakage currentCurrent limiting

An improved HEMT formed from a GaN material system is disclosed which has reduced gate leakage current relative to known GaN based HEMTs and eliminates the problem of current constrictions resulting from deposition of the gate metal over the step discontinuities formed over the gate mesa. The HEMT device is formed from a GaN material system. One or more GaN based materials are layered and etched to form a gate mesa with step discontinuities defining source and drain regions. In order to reduce the leakage current, the step discontinuities are back-filled with an insulating material, such as silicon nitride (SiN), forming a flat surface relative to the source and drain regions, to enable to the gate metal to lay flat. By back-filling the source and drain regions with an insulating material, leakage currents between the gate and source and the gate and drain are greatly reduced. In addition, current constrictions resulting from the deposition of the gate metal over a step discontinuity are virtually eliminated.

Owner:NORTHROP GRUMMAN SYST CORP

Silk-screen printing device of polymer quantum device

The invention discloses a silk-screen printing device of a polymer quantum device, and particularly relates to the technical field of silk-screen printing. The device comprises a fixed seat, wherein the top end of the fixed seat is connected with a workbench; a scale line is arranged on the front surface of the top of the workbench; a bearing plate is arranged at the position, close to the inner side of the scale line, above the workbench; limiting mechanisms are installed at the positions, at the two sides of the bearing plate, of the front edge of the top end of the workbench; fixing framesare arranged at the positions, on the two sides of the bearing plate, of the top end of the workbench; the fixing frames are fixedly connected with the workbench and located on the rear side of the limiting mechanisms; and the top ends of the fixing frames are connected with a frame. According to the device, the deviation of the printed position during printing of the to-be-printed object is avoided, a screen plate is convenient to mount, dismount and clean; and meanwhile, the scraping angle adjusting mode of a scraper blade is better, so that the scraper plate moves more stably in the horizontal direction.

Owner:青岛菲木科技有限公司

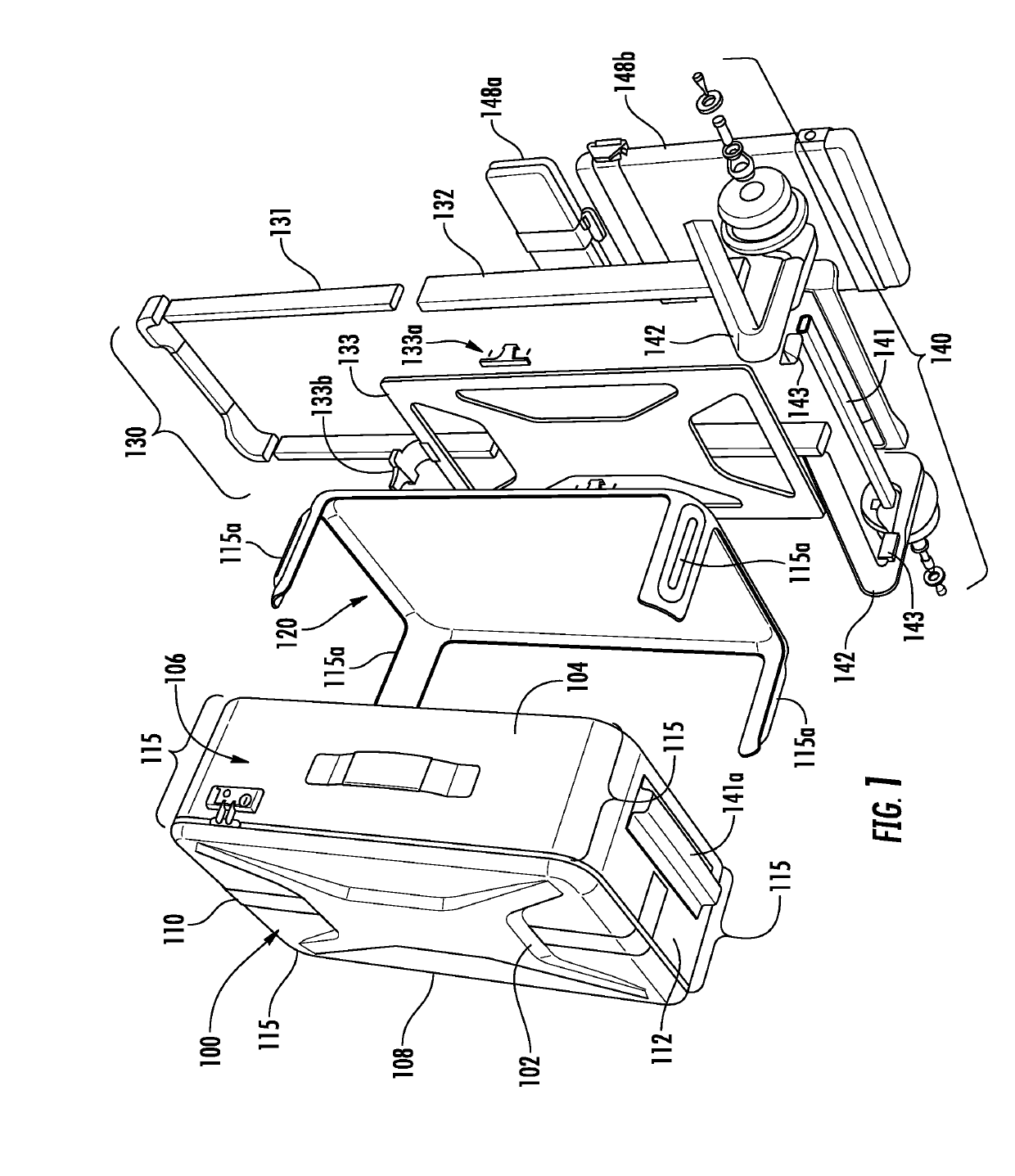

External frame luggage with fold-out computer case

InactiveUS20190142125A1Easy to disassembleEasy to replaceLuggageOther accessoriesX-rayComputer science

The present invention is a piece of luggage with an external frame with a fold-out computer case for use through an X-Ray machine.

Owner:12 GAUGE IDEAS LLC

Cardiogram paper stacking device

InactiveCN109051833AEasy to stackEasy to palletizeStacking articlesBlock matchMechanical engineering

Owner:TIANJIN GRAND PAPER IND

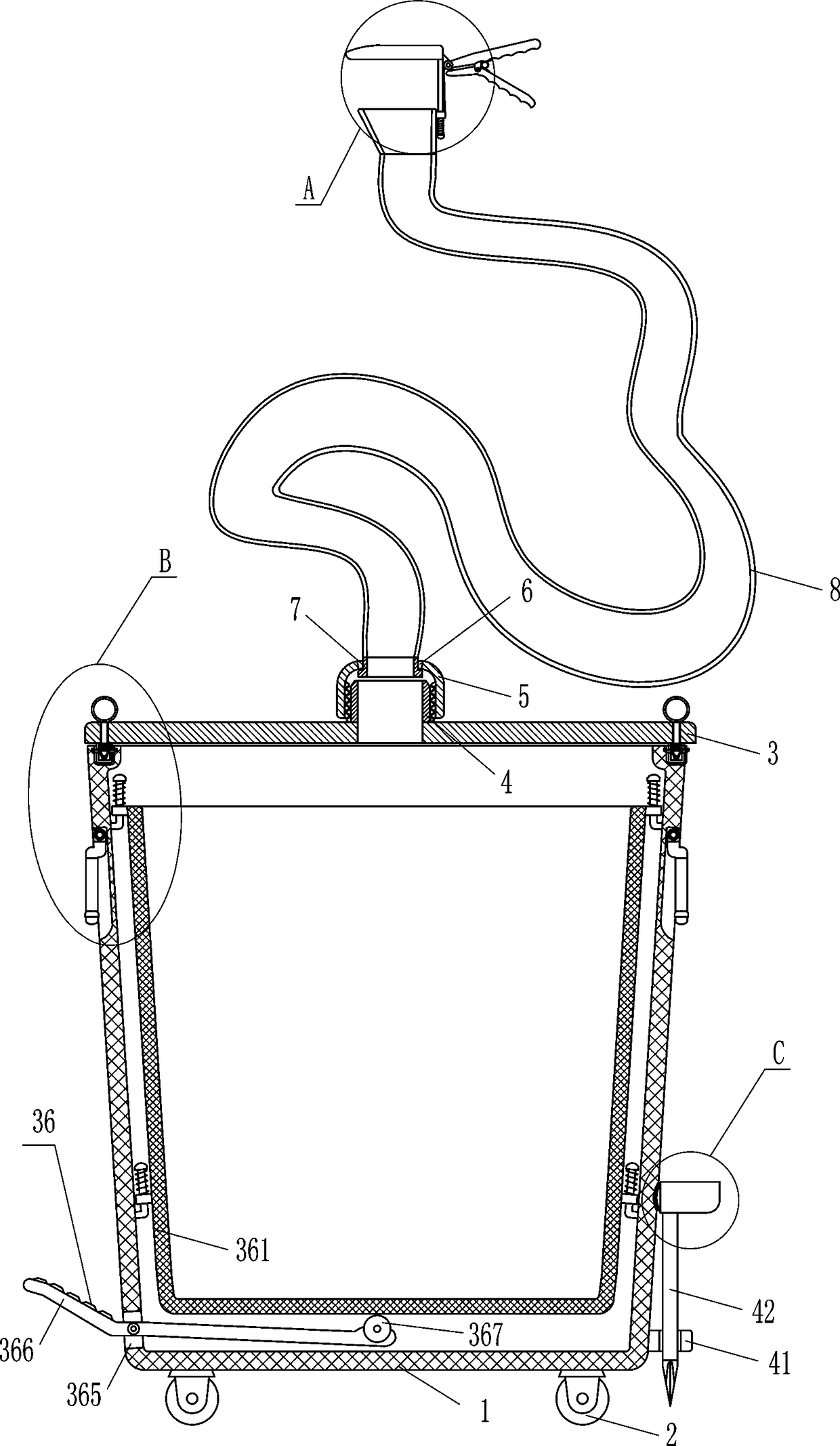

Navel-orange picking device

The invention relates to a picking device, in particular to a navel-orange picking device. By means of the navel-orange picking device, an operator can pick navel oranges with one hand, operation is convenient, and navel oranges can also be prevented from being scattered on the ground. According to the technical scheme, the navel-orange picking device comprises a screen frame, universal wheels, acover plate, an external thread cylinder, an inner thread cylinder, a clamping ring, a corrugated pipe, a discharging hopper, a handle, a first guiding rod, a first guiding sleeve, a first spring andthe like; the universal wheels are symmetrically installed on the left side and the right side of the external bottom of the screen frame, the cover plate is arranged on the screen frame, and the leftside and the right side of the tops of the cover plate and the screen frame are each provided with a fixing device. According to the navel-orange picking device, the discharging hopper sleeves the navel oranges, a grip is pulled, a cutter can move inwards to cut off navel-orange peduncles, the navel oranges can fall into the screen frame, a person does not need to hold a navel orange with one hand and cut off the navel-orange peduncles through scissors with the other hand, operation is convenient, and through a waggling device, the navel oranges can be smoothly put into a movable frame, and more navel oranges can be put into the movable frame.

Owner:陈伟明

Vibration type garbage recovery processing equipment

The invention discloses vibration type garbage recovery processing equipment. The vibration type garbage recovery processing equipment comprises a machine body. An opening is formed in the top of the machine body. A cover body is connected with the top of the opening in a clamped mode. The top of the cover body is fixedly connected with a U-shaped handle. A groove is formed in the bottom of the cover body. A limiting plate is fixedly connected with the bottom of the inner wall of the machine body. The top of the limiting plate is in clamped connection with the inner wall of the groove. Because the vibration type garbage recovery processing equipment is affected by the weight of garbage, the garbage is located on a first connecting plate and a second connecting plate, a first moving rod is made to rotate, the first connecting plate is made to skew downwards, a second moving rod rotates, the second connecting plate is made to skew downwards, the garbage is made to slide downwards, through first leaking holes and second leaking holes, some small garbage can be made to directly fall down from the first leaking holes and the second leaking holes, the garbage in the machine body is conveniently managed, and the garbage can be well recovered.

Owner:平潭诚信智创科技有限公司

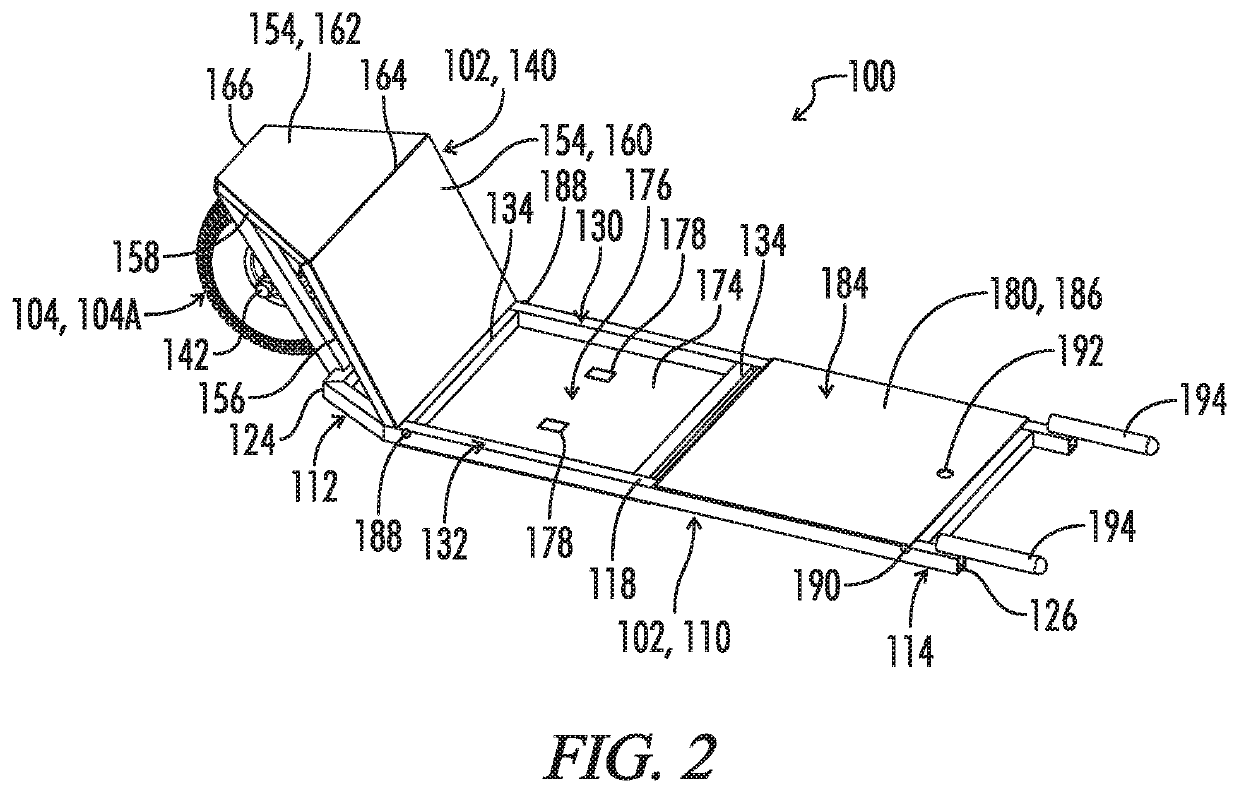

Multifunctional flat cart

ActiveUS10836415B1Stable loading surfaceMany optionsSledge wheelsSupporting partsBraced frameClassical mechanics

A multipurpose cart is provided herein. The multipurpose cart includes a substantially flat main support frame, a wheel support frame, at least one wheel, and a tarp selectively connectable to the main support frame. The wheel support frame extends from an end of the main support frame and is inclined upwardly relative to a topside of the main support frame. The wheel support frame includes an axle that is spaced apart from an underside of the main support frame by an offset distance. The at least one wheel is rotatably connected to the axle and has a radius substantially equal to the offset distance. The tarp is configurable in an open position to rest on a majority of the cart. The tarp includes reinforcement straps connected to a lower surface of the tarp and further includes at least one retainer for selectively connected the tarp to the cart.

Owner:MORROW ERICK

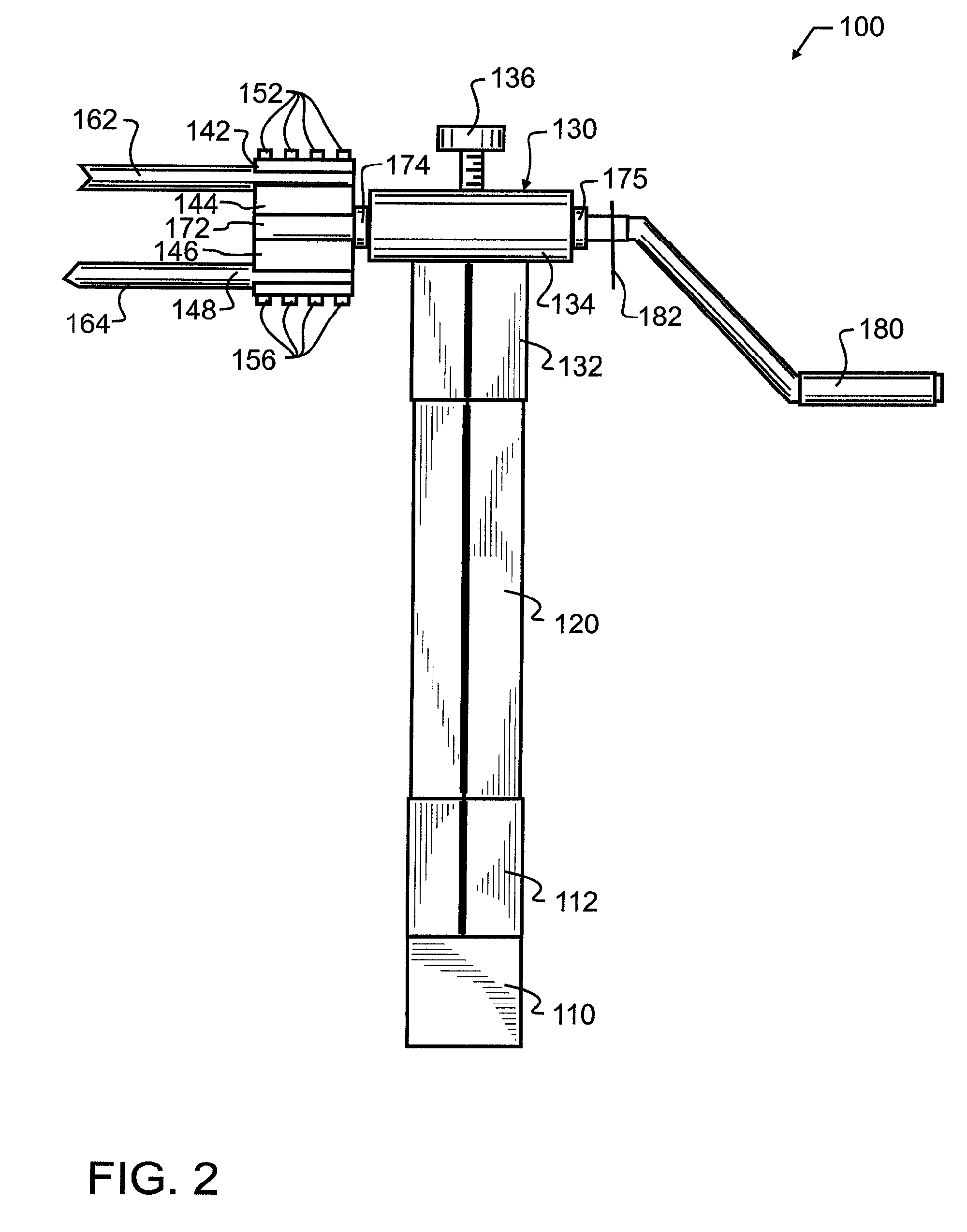

Transportable blanket roller

InactiveUS7766270B2Easy to assemble and disassembleMinimal shop fabricationFilament handlingWebs handlingCouplingBlanket

A transportable insulated blanket roller has a support, and a riser coupled to and extending vertically from the support. A bearing support is coupled to the riser, and has an insulated blanket retaining rod passing through the bearing support. The rod has a bifurcation defining first and second insulated blanket holding rods that are operative to receive an insulated blanket therebetween. A crank produces a rotary motion in the retaining rod, in turn winding the blanket onto the blanket holding rods. The transportable insulated blanket roller is combined with a land vehicle having a trailer hitch receiver or comparable coupling or support, and an insulated blanket. A method of efficiently using the transportable insulated blanket roller at a construction site is also presented, including using the bifurcated roller to roll an unrolled insulated blanket, and then sliding the insulated blanket off of the bifurcated roller.

Owner:PIEPGRAS DOUGLAS D

Edible bird nest disinfection process

The invention provides an edible bird nest disinfection process, and belongs to the technical field of food processing. In the prior art, the edible bird nest is not easily treated in the home. A purpose of the present invention is to solve the problem in the prior art. The edible bird nest disinfection process comprises: a, ultraviolet ray sterilization and disinfection, wherein edible bird nestin a disinfection cabinet is sterilized and disinfected for 1-2 h through an ultraviolet ray lamp; b, microwave sterilization and disinfection, wherein the edible bird nest in the disinfection cabinetis sterilized and disinfected for 30-60 min through a microwave generator; c, ozone disinfection and cooling, wherein the edible bird nest in the disinfection cabinet is disinfected for 5-10 min through an ozone generator; and d, refrigerating, wherein the disinfected edible bird nest is placed in a refrigerating cabined, and is refrigerated. According to the present invention, the combination treatment is performed through ultraviolet ray sterilization and disinfection, microwave sterilization and disinfection and ozone sterilization and disinfection, such that the disinfection and sterilization effect is extremely strong.

Owner:海宁杜氏进出口有限公司

Scribing equipment for cloth

Owner:TAICANG FANSHENG ELECTRONICS TECH CO LTD

Anti-rebound hardware punching die

InactiveCN108672548ALay flatReduce frequent bouncePerforating toolsMetal-working feeding devicesPunchingEngineering

The invention discloses an anti-rebound hardware punching die. The punching die comprises a fixed bottom plate, a supporting rod, a supporting frame, a lower die base, a hardware part, a punching headand an upper die base. The supporting rod is fixedly connected to the upper portion of the left side of the fixed bottom plate. The upper portion of the supporting rod is fixedly connected with the supporting frame. The lower die base is fixedly connected to the middle portion of the upper portion of the fixed bottom plate. The hardware part is fixedly connected to the middle portion of the upperportion of the lower die base. The punching head is electrically connected above the fixed bottom plate. The top end of the fixed bottom plate is fixedly connected with the upper die base. The upperdie base is electrically connected with the punching head. Moreover, the fixed bottom plate, the lower die base, the hardware part, the punching head and the upper die base are located on the same perpendicular line. The anti-rebound hardware punching die is stable in structure, has the stable placement effect, can relieve punching jittering, is fast and convenient to clean, capable of reducing waste material rebound and good in cleaning effect and has high promotional value, and the problem that the hardware part is placed unevenly is solved.

Owner:肖涵

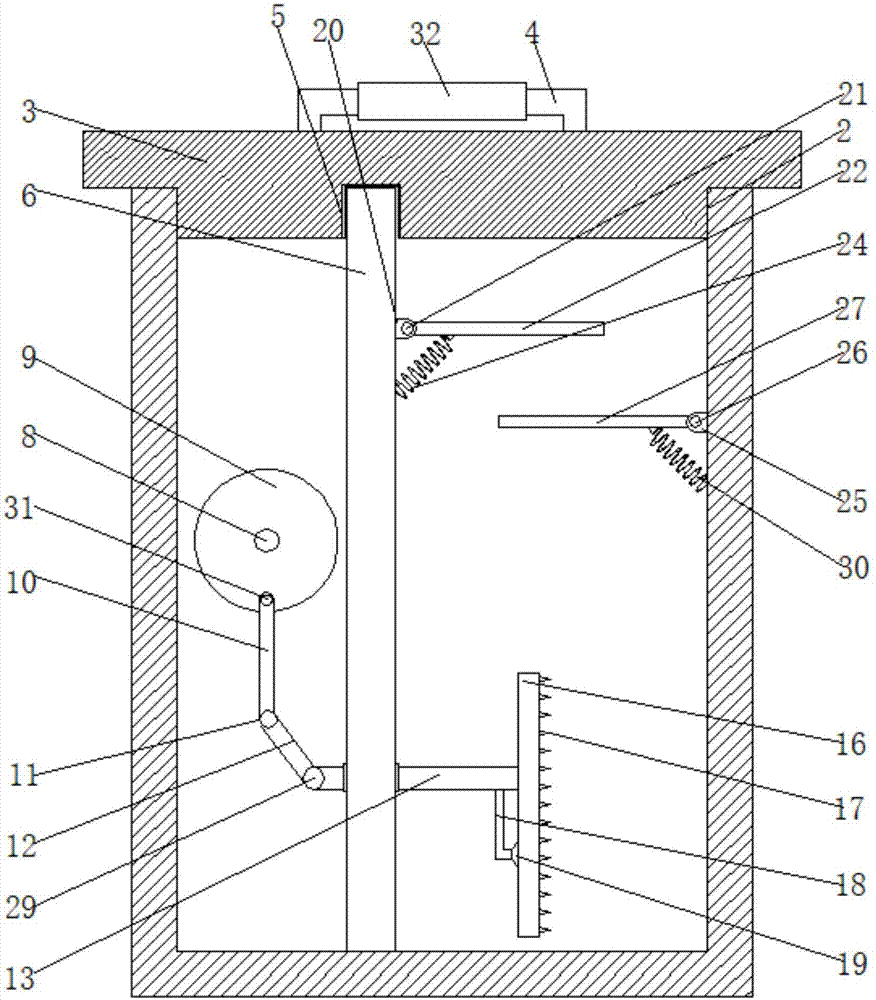

Medical dustbin

The invention relates to a dustbin, in particular to a medical dustbin. According to the medical dustbin, rubbish can be placed flat and can be poured out conveniently. The medical dustbin provided bythe invention comprises a vehicle body, wheels, a box, connecting blocks, first springs, a cover plate, an installing seat, a motor, a disc, a lug, a second fixed pulley and the like. The wheels areinstalled at the bottom of the vehicle body. The box is rotationally connected to the left side of the bottom in the vehicle body. The lower portions of the inner sides of the left wall and the rightwall of the box are each provided with one connecting block. The tops of the connecting blocks are each connected with one first spring. A holding plate is connected to the top ends of the first springs. Through the medical dustbin, the effects that the rubbish is placed flat and can be poured out conveniently are achieved, the lug drives the rubbish on the holding plate to shake, thus the rubbishon the holding plate is placed flatter, the box is placed down slowly, and the conditions that the box falls with too large force, thereby being damaged can be prevented.

Owner:曾敏

Blunt trailing edge fan blade and method for fixing vertical face core material of trailing edge of blunt trailing edge fan blade

ActiveCN103850889AReduce usageHigh bonding strengthWind energy generationWind motor componentsAdhesiveEngineering

The invention provides a blunt trailing edge fan blade. A blunt trailing edge comprises a trailing edge outer skin, a trailing edge inner skin and a vertical face core material between the trailing edge outer skin and the trailing edge inner skin; a region, which corresponds to the vertical face core material, on the trailing edge outer skin is provided with an outer skin through hole; the outer skin through hole is filled with an adhesive; the adhesive is adhered to the core material. The invention also provides a method for fixing the vertical face core material of the trailing edge of the blunt trailing edge fan blade. According to the blunt trailing edge fan blade provided by the embodiment of the invention, the core material is laid neatly, so that a resin-rich region caused by shifting of the core material is avoided on the corner of the blunt trailing edge; the core material is laid neatly, so that the spacing from the edge of the core material to the edge of a die is easy to control and cannot be excessive due to slippage of the core material to cause super poor quality of the core material.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

Building floor elevation control and adjustment tool

PendingCN110700593ASimple structureReduce weightFoundation engineeringBuilding material handlingArchitectural engineeringStructural engineering

The invention discloses a building floor elevation control and adjustment tool. A main body comprises an adjustment top plate device body, an adjustment iron plate sleeve and an adjustment J-shaped supporting rod, wherein the adjustment iron plate is arranged at the top of the adjustment top plate device body; the adjustment iron plate sleeve is arranged at the bottom end of the middle of the adjustment iron plate; and the lower part of the adjustment iron plate sleeve is connected with the adjustment J-shaped supporting rod. The building floor elevation control and adjustment tool is used forpouring building floor concrete and a carborundum building floor formed on the floor concrete at a time. The building floor elevation control and adjustment tool can be adjusted to the designed height for use according to the actual use condition and is suitable for serving as an elevation and supporting top beam in the building industry, height fine adjustment can be conducted by rotating the adjustment J-shaped supporting rod when deviation occurs, and the control and adjustment tool is invested at a time, convenient to mount and dismount and capable of being repeatedly used in a turnover mode.

Owner:江苏通平建设工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com