Automatic putting device for round paper scrip of fireworks

A round paper and paper technology, applied in the field of automatic working devices, can solve the problems of large labor load, unguaranteed fireworks quality, low production efficiency, etc., and achieve the effect of ensuring processing quality and ensuring fireworks quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

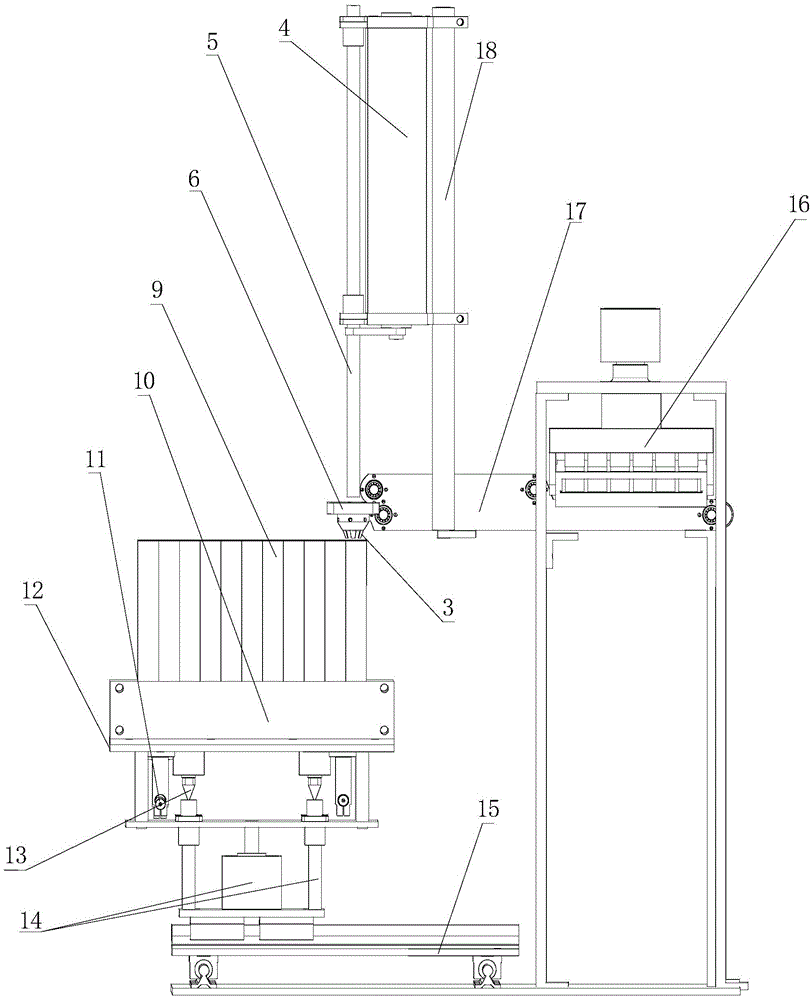

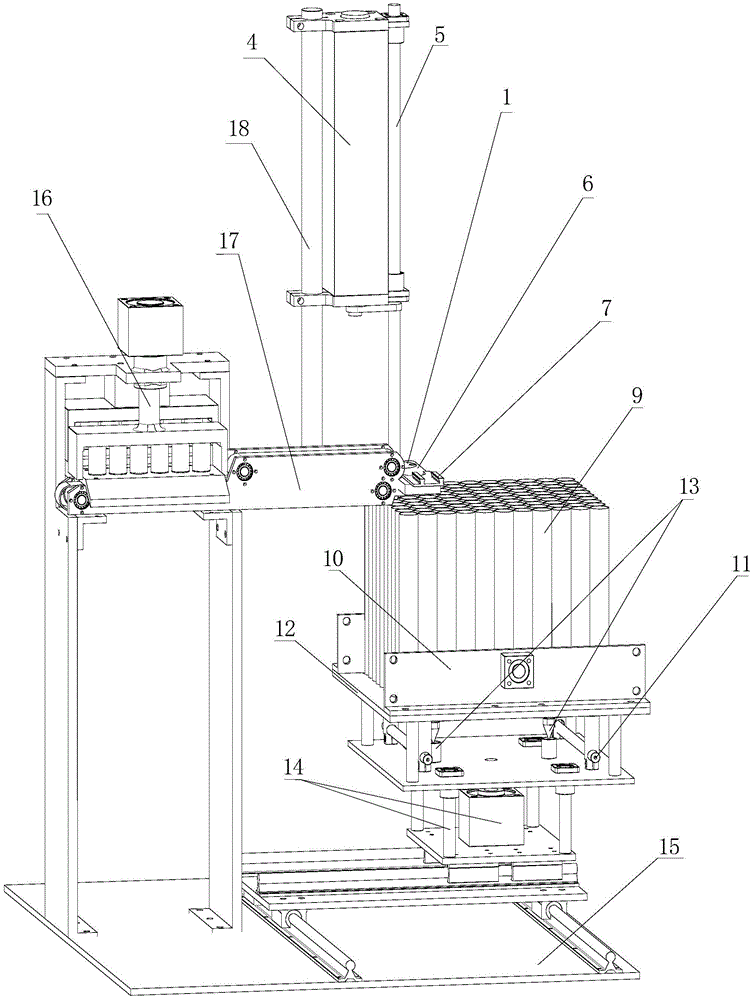

[0023] Referring to the accompanying drawings, reflecting a specific structure of the present invention, the automatic inserting device for fireworks discs includes a paper pressing rod 5 connected to an up and down reciprocating linear drive mechanism, and the up and down reciprocating linear drive mechanism includes a pressing rod cylinder 4 and a mounting column 18. A paper guiding mechanism is arranged below the paper pressing rod 5, and the described paper guiding mechanism comprises a base 1, and the base 1 is provided with a tunnel 101 which can pass through the paper pressing rod 5, and the lower end of the tunnel 101 surrounding the base 1 is provided with a There are six elastic claws 3, and the elastic claws 3 adopt elastic steel sheets. The root of each elastic claw body 3 is fixed on the circumference of the truncated cone-shaped mounting platform of the hole 101 by the annular sleeve 2 . The free ends of each elastic claw body 3 move closer to the center of circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com