Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Large pitch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

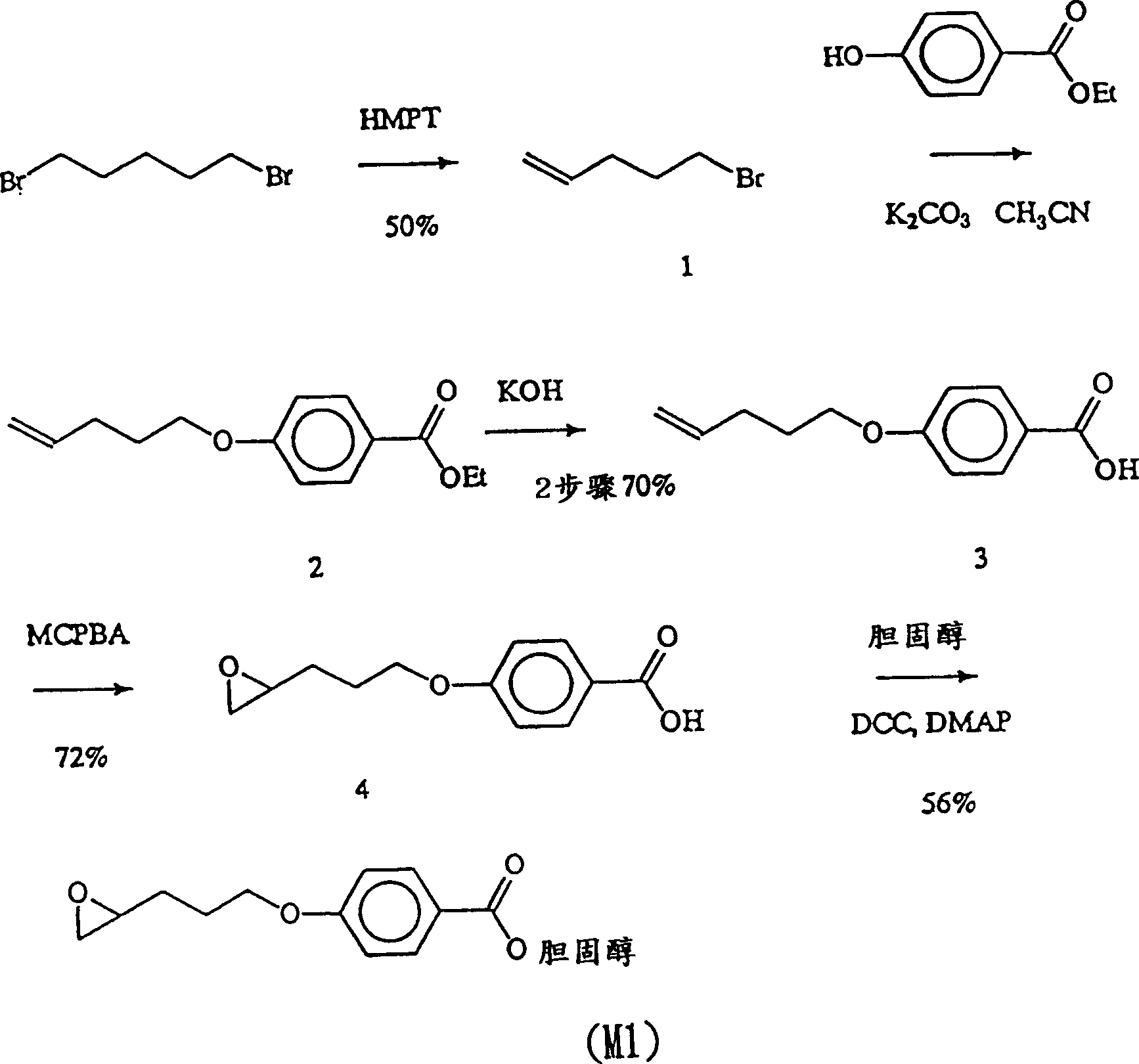

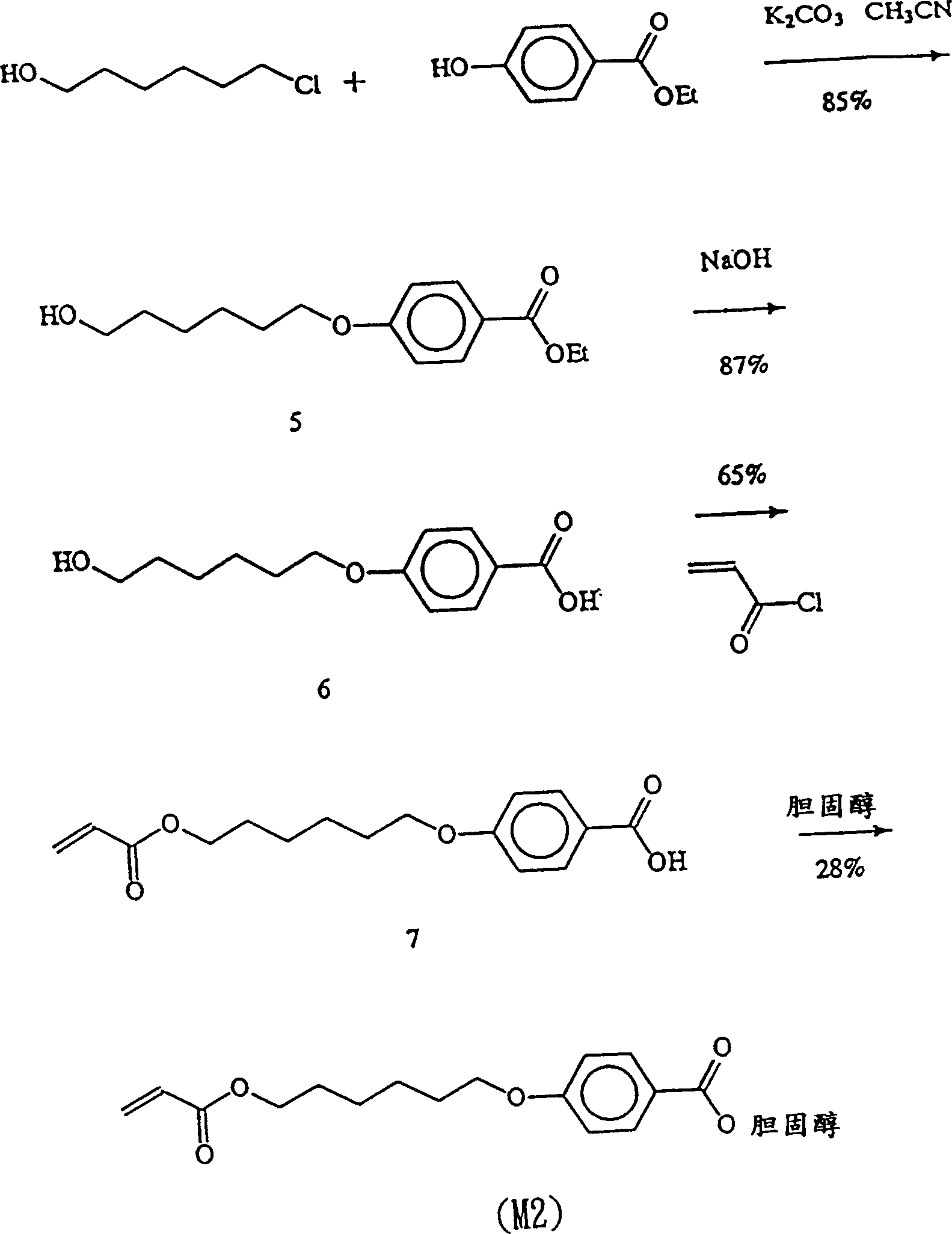

Triphenyl diacetylene compound with reaction and liquid crystal polymer containing the compound

InactiveCN1413969AHigh optical anisotropyLarge pitchLiquid crystal compositionsOrganic chemistryHalogenLiquid-crystal display

The present invention relates to a reactive triphenyl diethyne compound, which can take part in the copolymerization reaction with cholesterol-type liquid crystal to prepare cholesterol-type reflecting polaring plate.

Owner:IND TECH RES INST

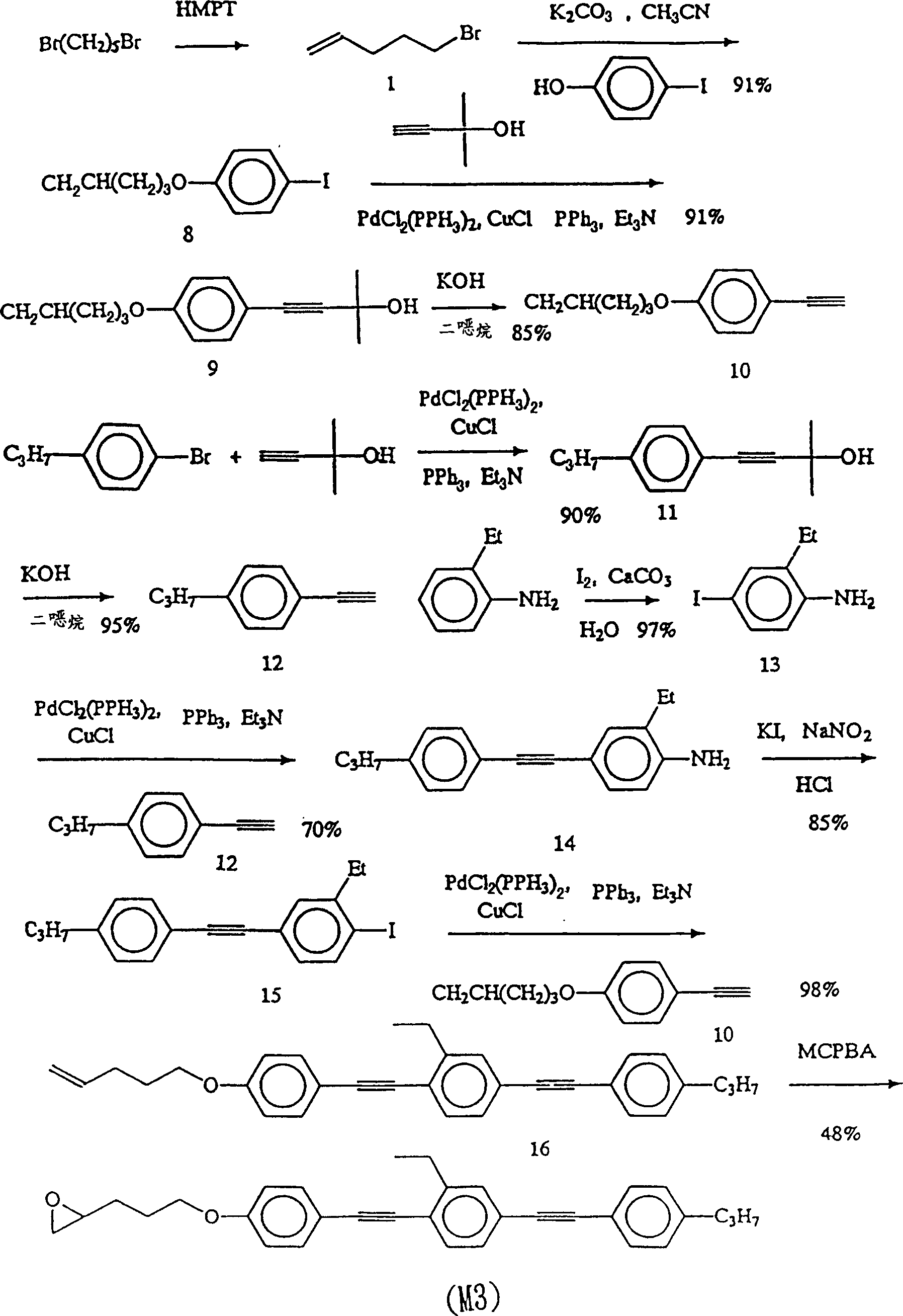

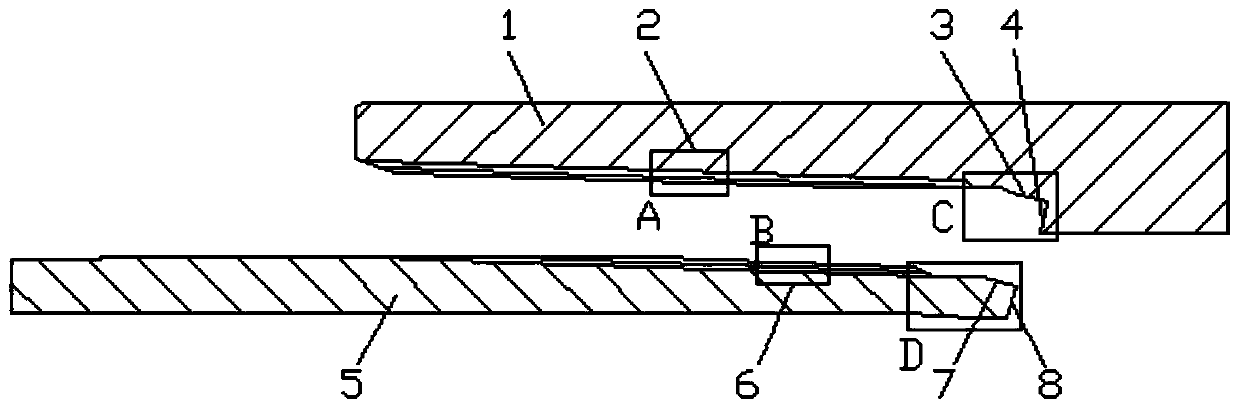

Coal-based direct reduced iron shaft furnace

The invention discloses a coal-based direct reduced iron shaft furnace and belongs to the technical field of coal-based direct reduced iron process equipment. The furnace body of the coal-based direct reduced iron shaft furnace is erected at a support steel structure, and the furnace body comprises a reduction cavity, burning cavities, and a discharge device; the reduction cavity is a rectangular structure cavity body composed of two parallel heat-conduction walls and the upper and lower parts of the reduction cavity are respectively provided with a sealed feed port and a sealed discharge port; the burning cavities provided with multiple layers of horizontal fire gas baffling channels are positioned at the both sides of the reduction cavity; and the discharge device is a spiral conveyer, the cylindrical shell of the spiral conveyer is of a jacket water cooling structure, and a spiral rotating shaft is a hollow water cooling structure. Compared with the tradition tubular reduction cavity body, the coal-based direct reduced iron shaft furnace provided by the invention has the advantages of high efficiency of heat transmission, and uniform heating of the inner and outer layers of a pelletized material in the furnace. The coal-based direct reduced iron shaft furnace can be used for effectively reducing the energy consumption of reduced iron and improving the merchantable quality and the production efficiency of a single furnace.

Owner:ZHENGZHOU ANLIANKAI IND CO LTD

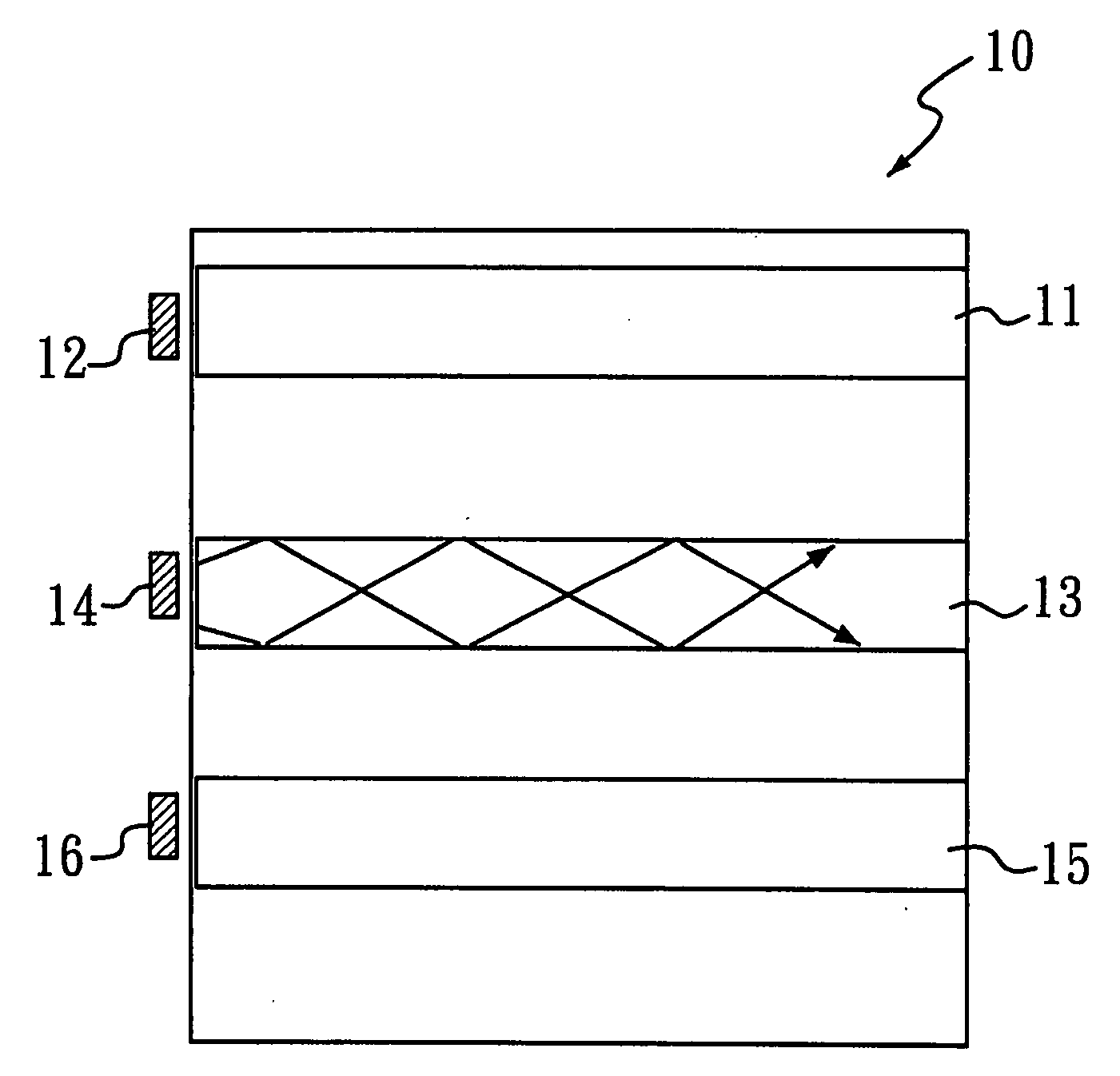

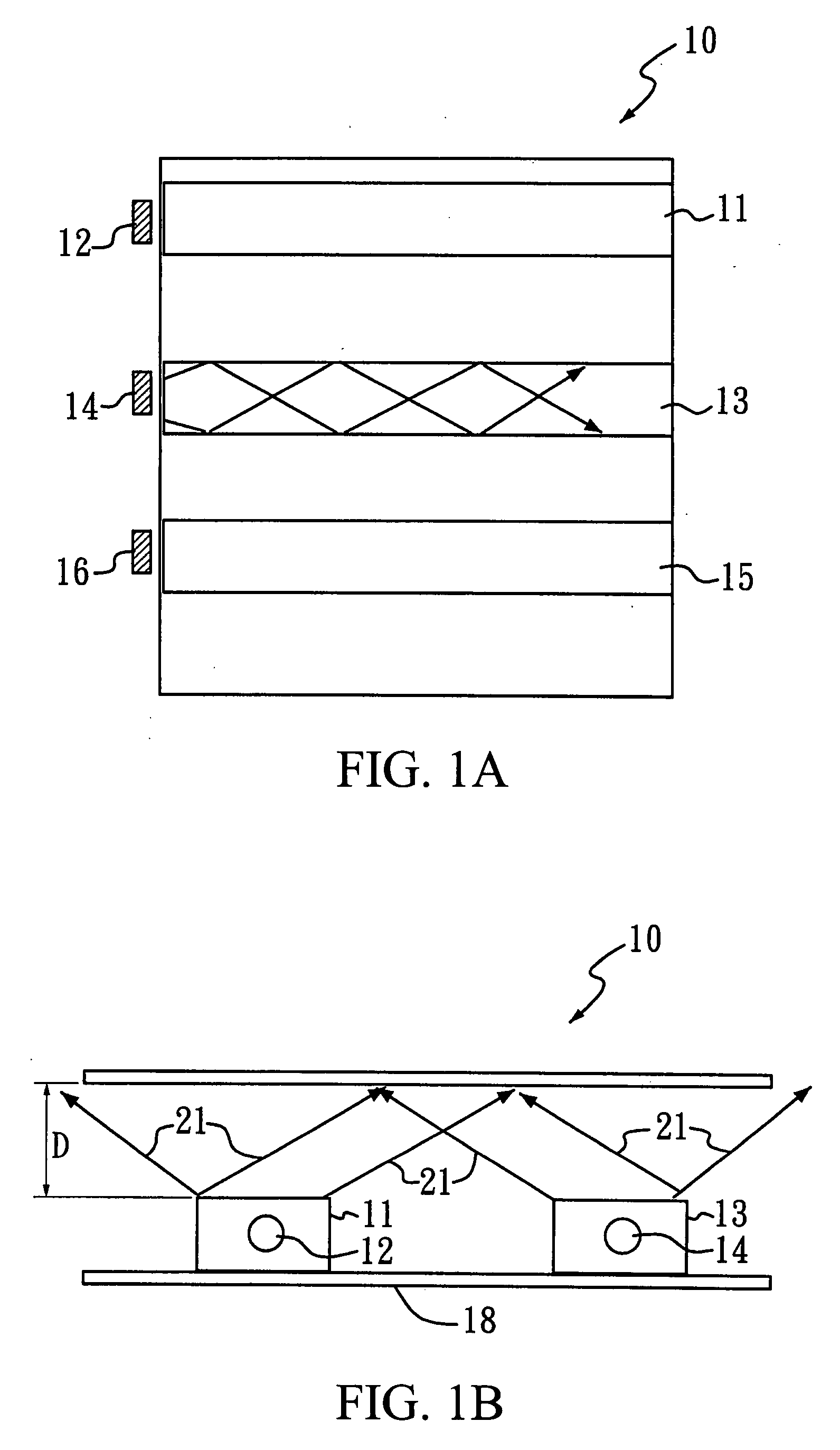

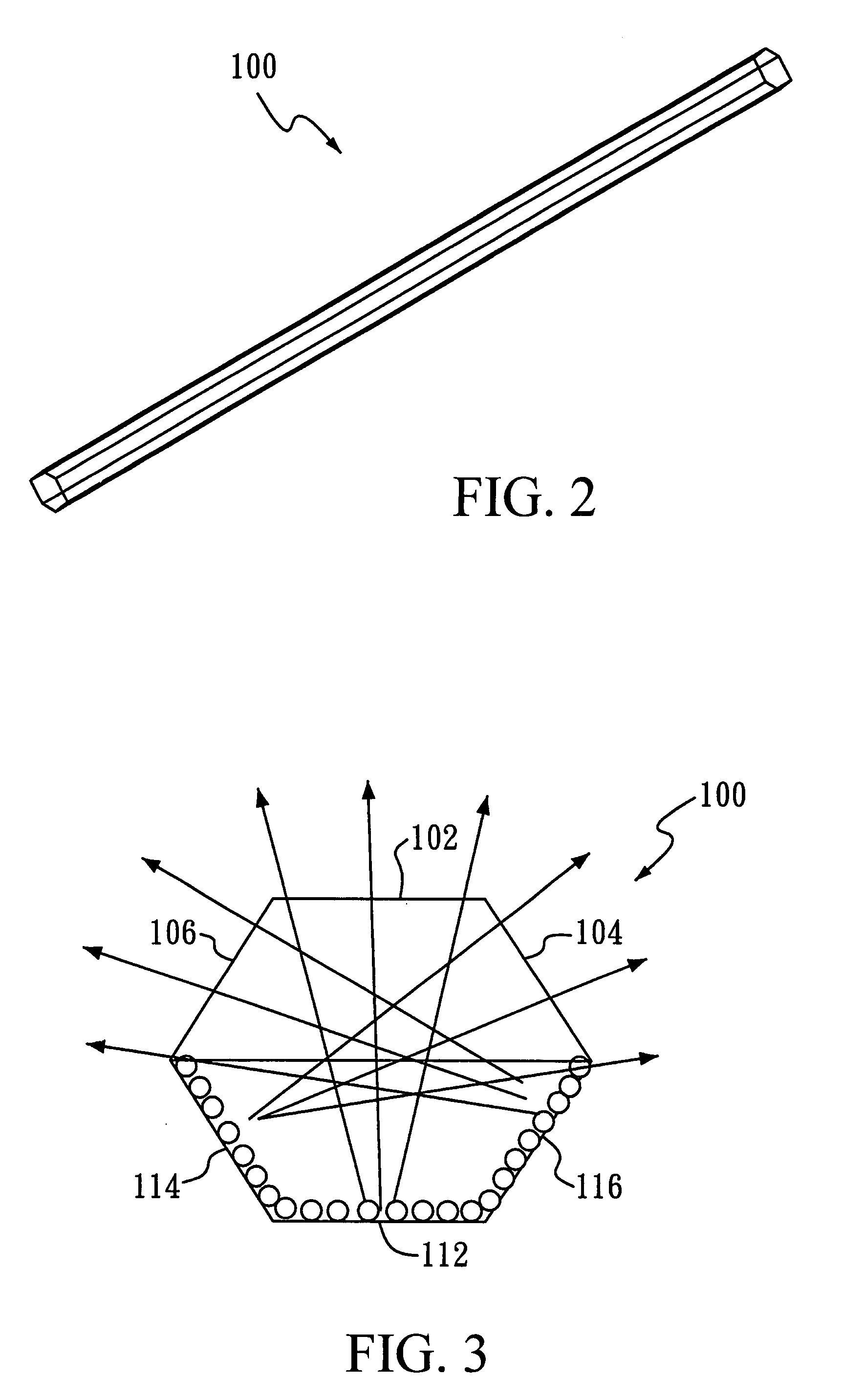

Light guiding strip and backlight module and display using the same

ActiveUS20080130314A1Low costLarge pitchMechanical apparatusElectric discharge tubesDiffusionLight guide

A light guiding strip and a backlight module and display using the same are provided. The light guiding strip of the present invention includes a plurality of light reflecting surfaces and a plurality of light emergent surfaces. Each of the light reflecting surfaces has a light diffusion pattern. The light guiding strip of the present invention has the advantages of light weight, wide LED pitch, low cost, thickness and so on.

Owner:HONG KONG APPLIED SCI & TECH RES INST

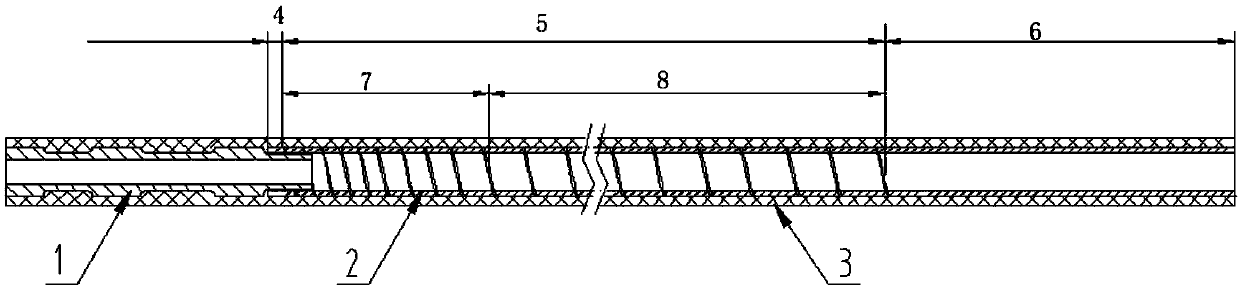

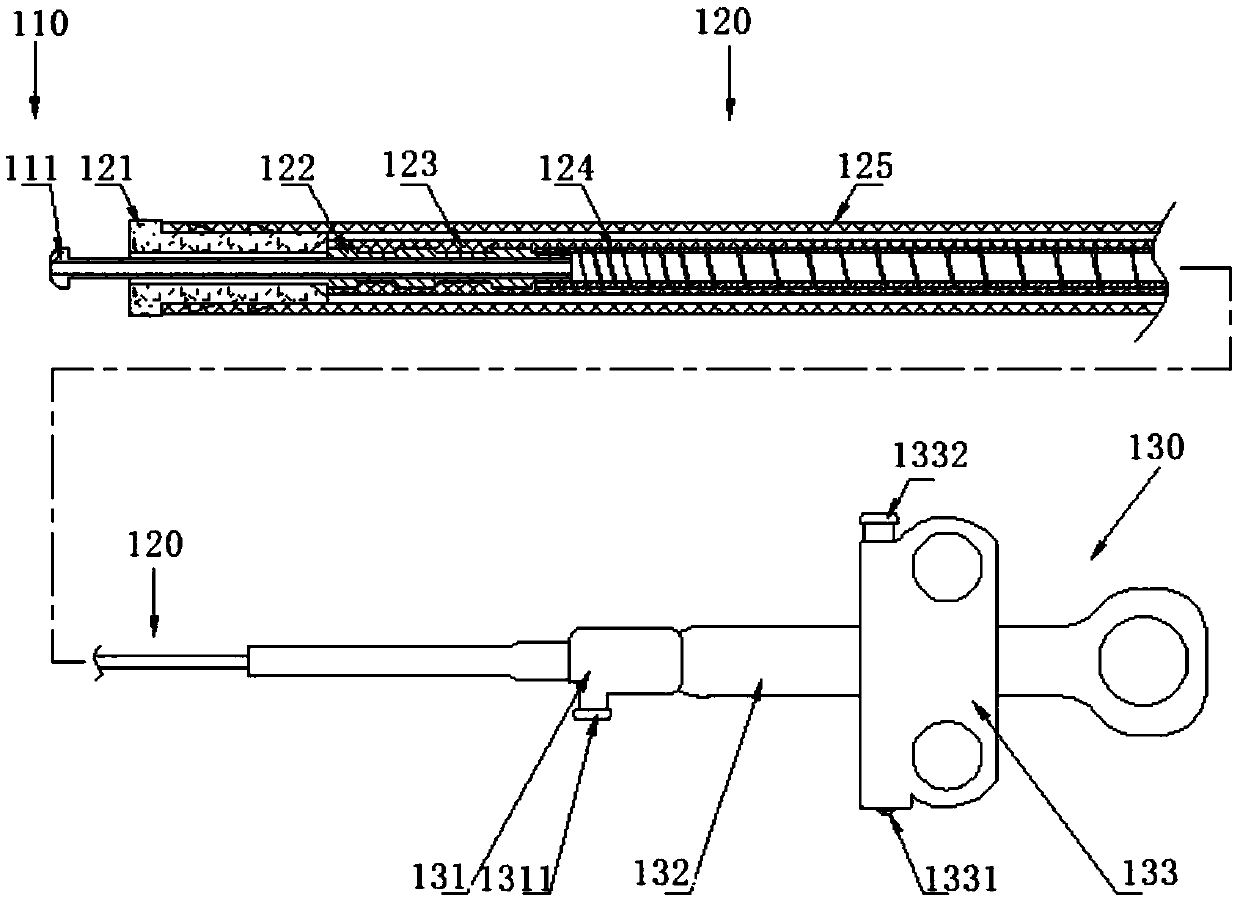

Medical connecting device

PendingCN111202485ASmall pitchLarge pitchSurgical needlesVaccination/ovulation diagnosticsMechanical engineeringPowder Spray

The invention discloses a medical connecting device. The medical connecting device has a near end and a far end and comprises an insulating layer and a spiral tube, wherein the insulating layer coversthe outermost layer of the whole device; the spiral tube is of a conductive hollow tubular structure and has a spiral structure; and the spiral structure has a screw pitch gradually changing from thenear end to the far end. According to the medical connecting device, the functions of electric conduction, liquid passing, powder spraying, negative pressure suction, sealing, insulation, supportingand the like can be integrated.

Owner:MICRO TECH (NANJING) CO LTD

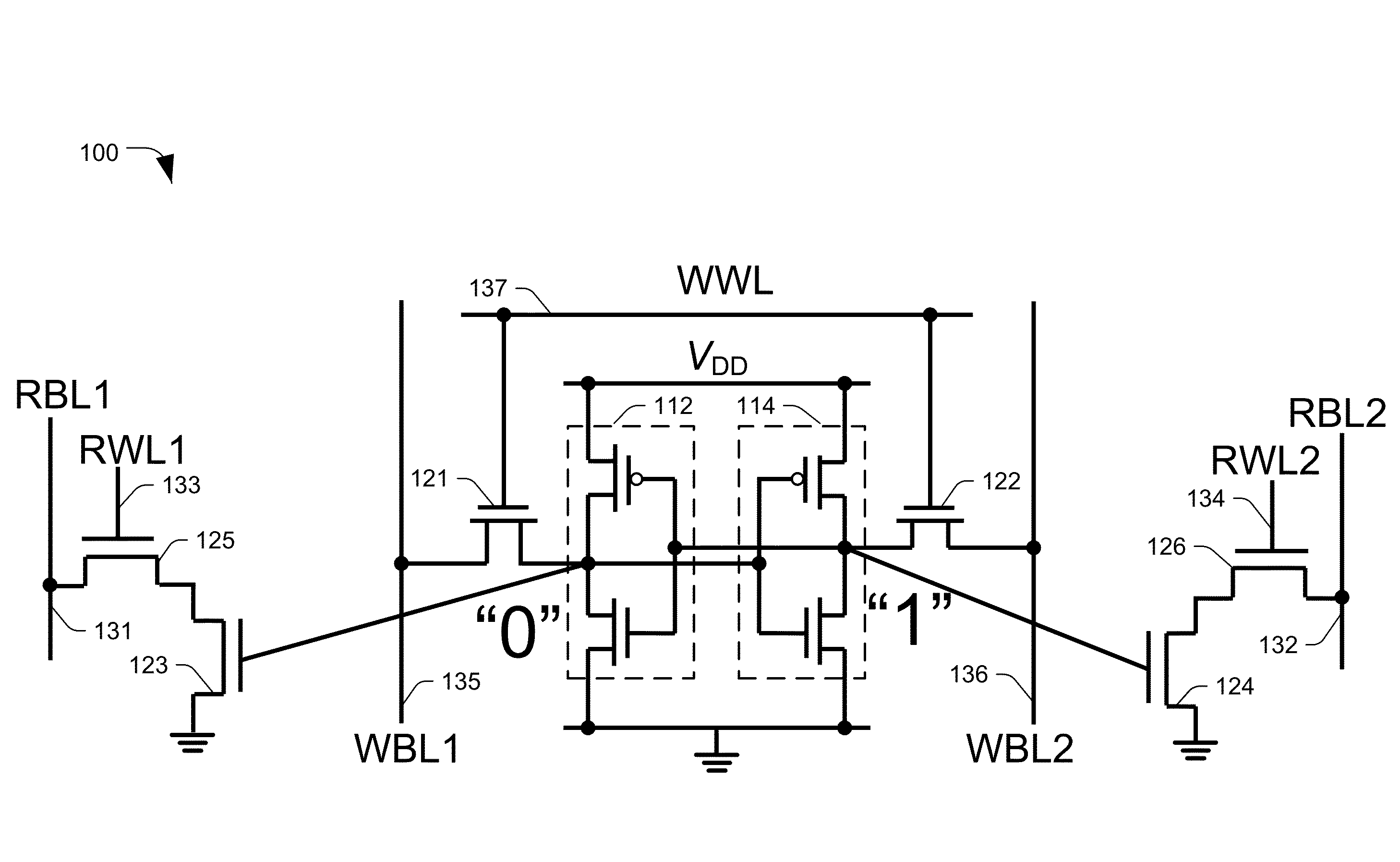

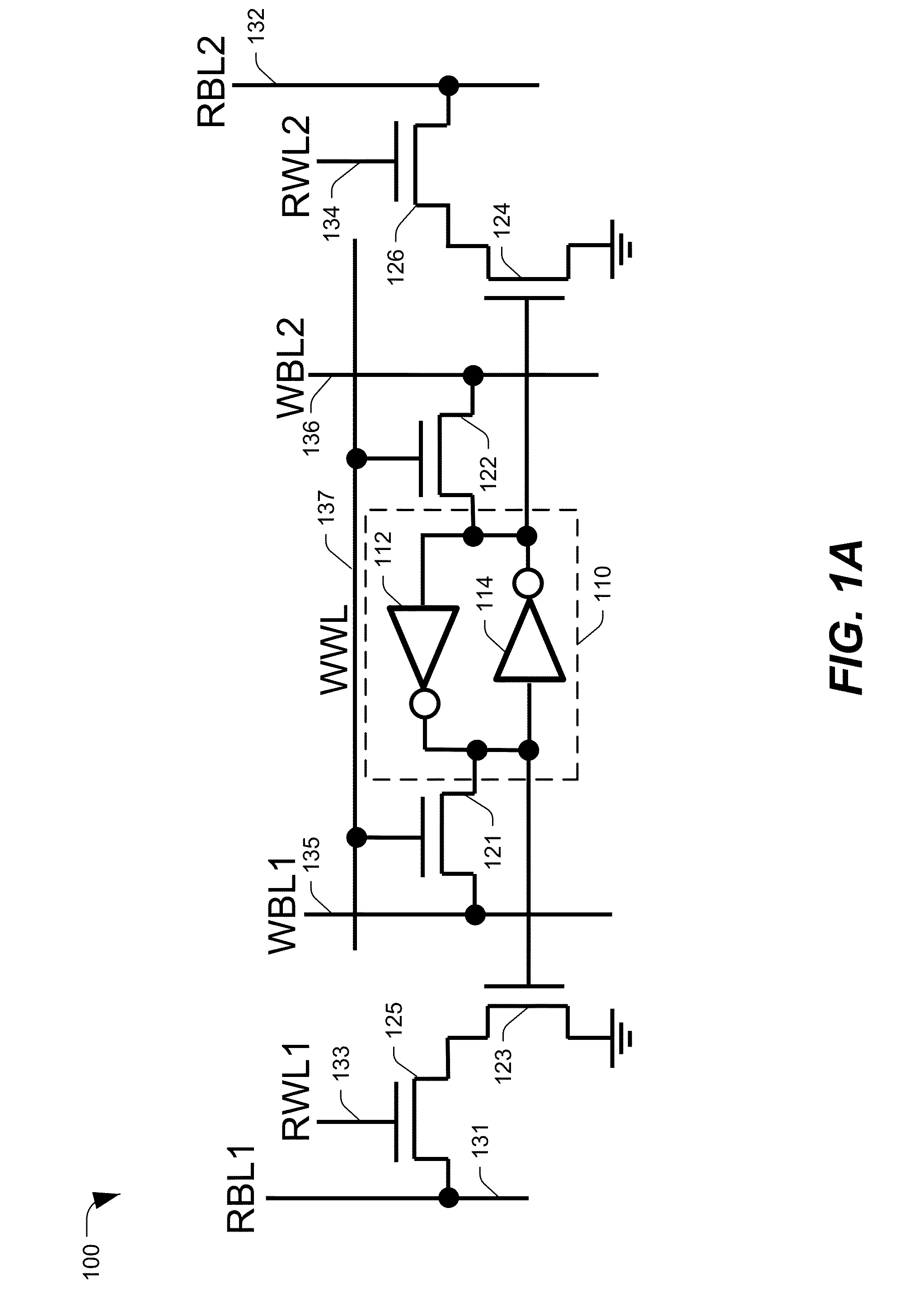

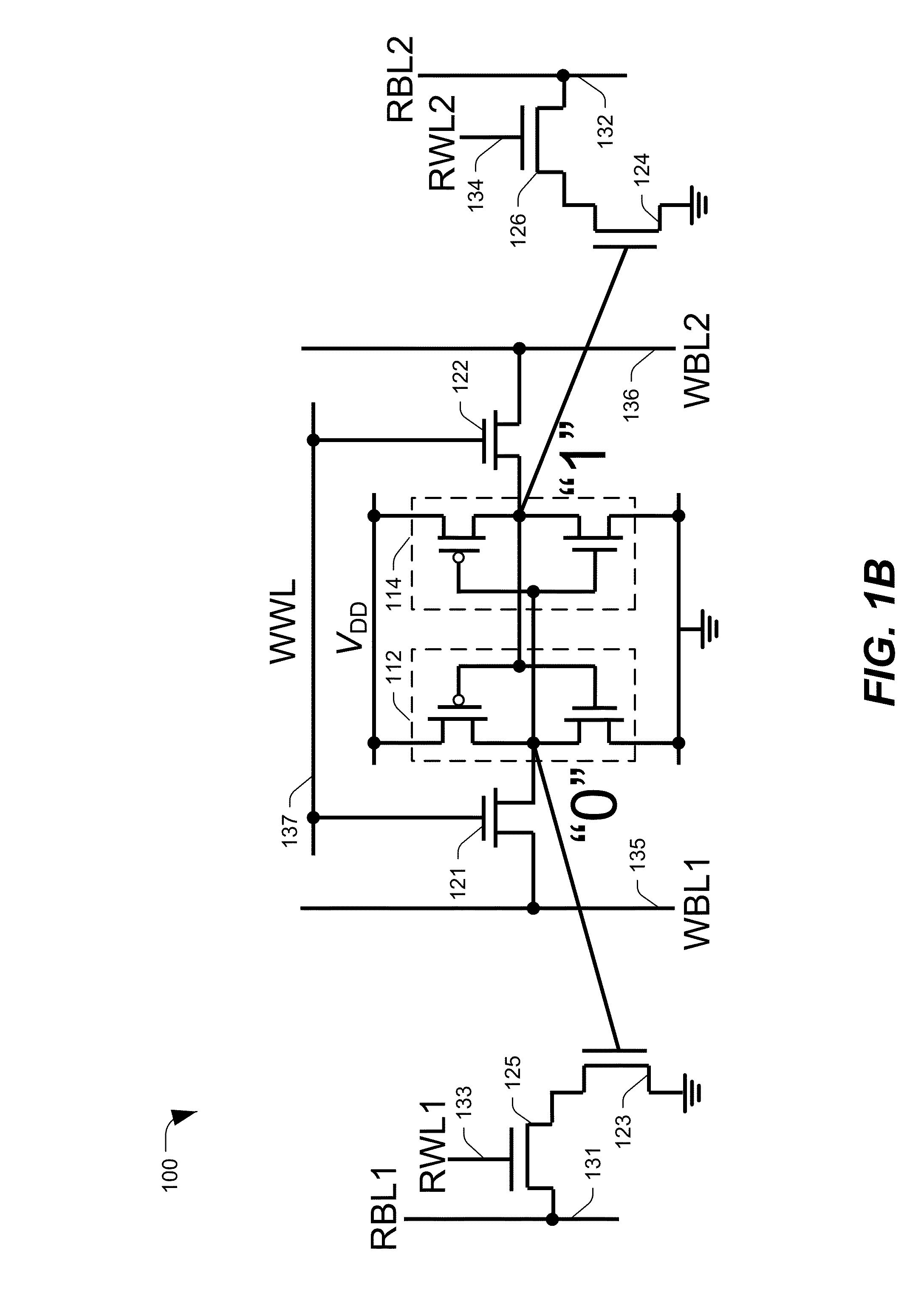

Shared global read and write word lines

An apparatus includes an array of bit cells that include a first row of bit cells and a second row of bit cells. The apparatus also includes a first global read word line configured to be selectively coupled to the first row of bit cells and to the second row of bit cells. The apparatus further includes a second global read word line configured to be selectively coupled to the first row of bit cells and to the second row of bit cells. The apparatus also includes a global write word line configured to be selectively coupled to the first row of bit cells and to the second row of bit cells. The first global read word line, the second global read word line, and the global write word line are located in a common metal layer.

Owner:QUALCOMM INC

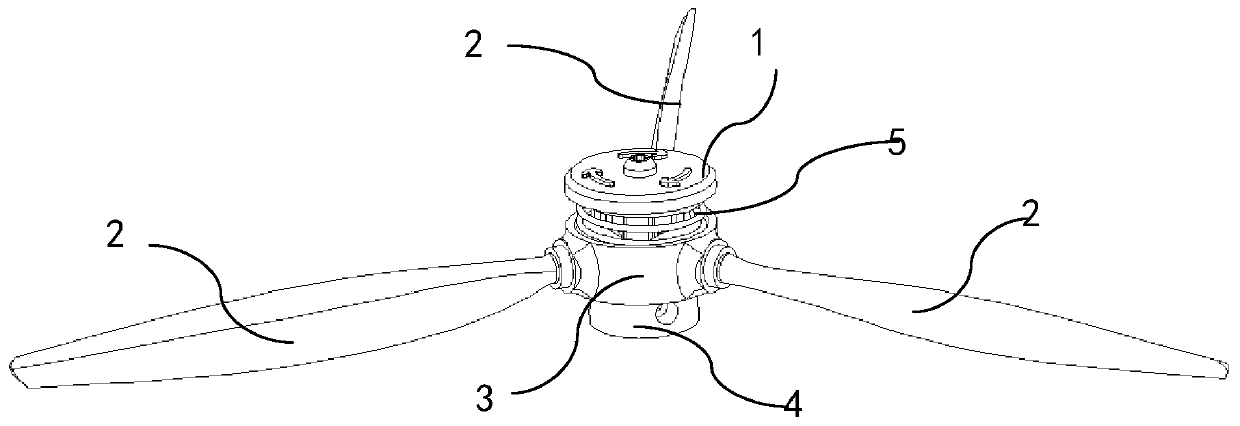

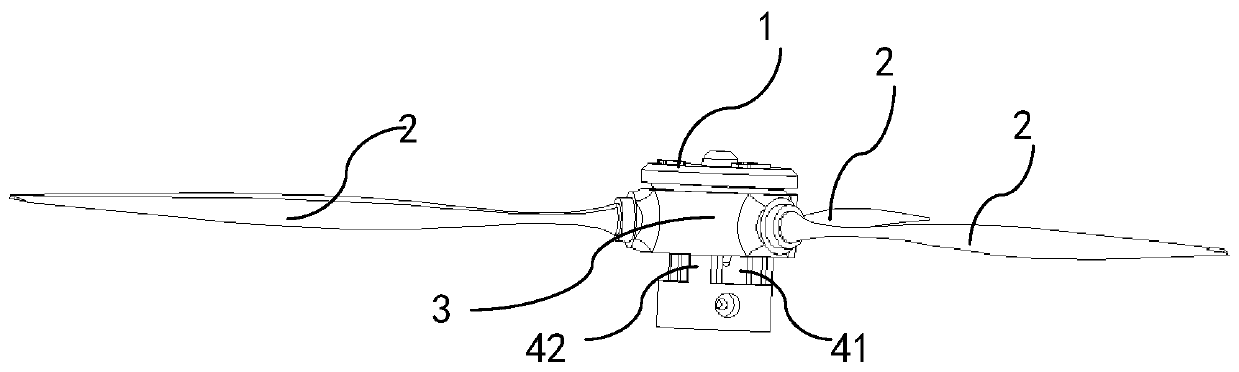

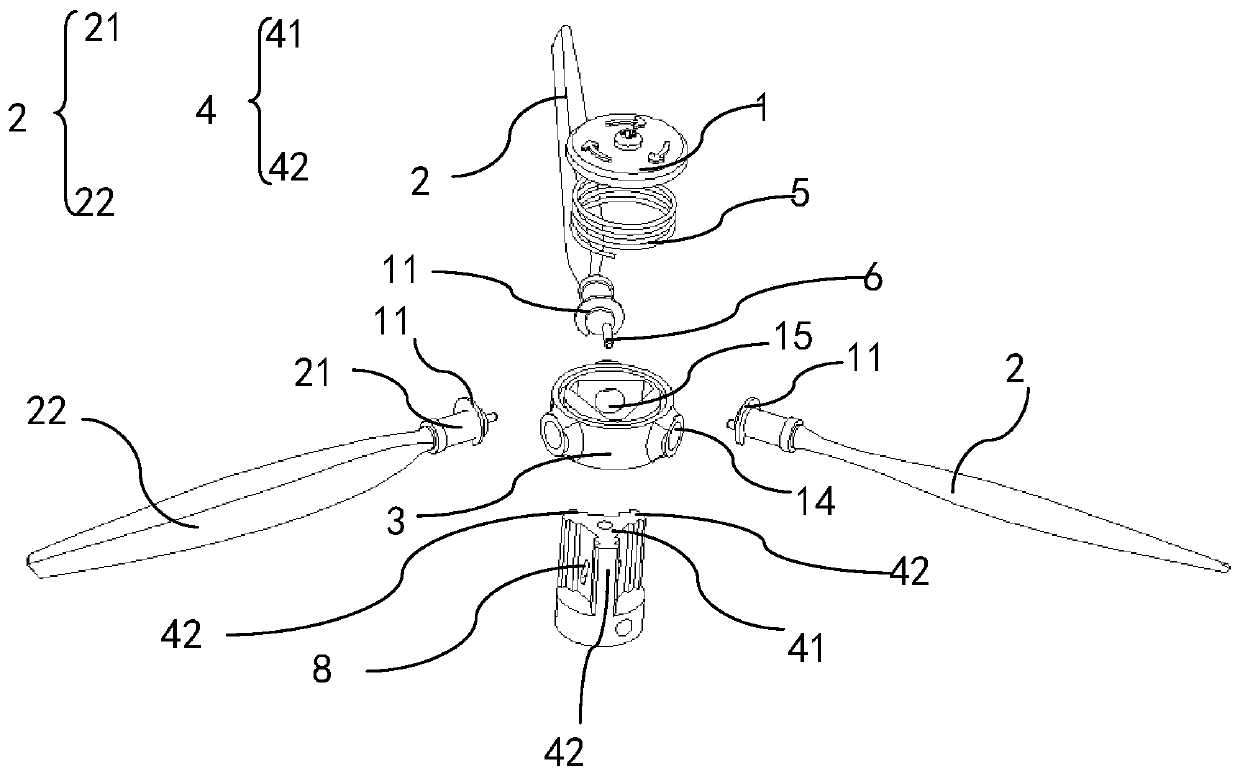

Automatic propeller torque changing mechanism

The invention provides an automatic propeller torque changing mechanism. The automatic propeller torque changing mechanism comprises at least one paddle, a flow guiding cover, a propeller base, a propeller hub and a drive device driving the propeller hub to rotate. The two ends of the propeller hub are connected with the flow guiding cover and the drive device correspondingly. Each paddle is provided with a paddle root and a paddle tip. An installing cavity is formed in the propeller base, the propeller base is provided with installing holes corresponding to the paddle roots, the paddle roots penetrate through the installing holes, the paddle roots are connected with the propeller hub through rotation devices, the propeller hub is inserted in the installing cavity, and an elastic piece is connected between the top end of the propeller base and the bottom end of the flow guiding cover. The automatic propeller torque changing mechanism can solve the problems that an unmanned aerial vehicle in the prior art cannot achieve automatic torque changing, and consequently the pneumatic efficiency is reduced.

Owner:埃游科技(深圳)有限公司

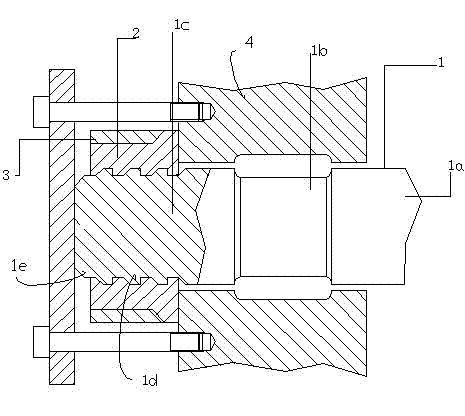

Tension rod structure of injection molding machine

The invention relates to a tension rod structure of an injection molding machine in the field of injection molding machines. Aiming at the defect of the breakage and failure of the tension rod of the conventional injection molding machine, the tension rod structure is designed. The tension rod structure comprises a tension rod and a tension rod mold adjusting nut, wherein the tension rod comprises a mold adjusting thread section; a coarse pitch tooth body is formed on the mold adjusting thread section; and the tension rod mold adjusting nut is in screw-thread fit with the mold adjusting thread section by the coarse pitch tooth body and is subjected to transition by using a large round corner at a step or a tool retracting groove. According to the design key point, a thread tooth body of the mold adjusting thread section is coarse pitch sawteeth; the outer diameter of a mold adjusting thread section body is slightly greater than that of a stress groove; the mold adjusting thread section body is in a cylindrical shape; an outer ring is matched outside the tension rod mold adjusting nut; and a mold adjusting screw cap is held tightly by the outer ring. By the improvement of the structure, the aims of running a mold closing mechanism reliably and prolonging the service life of the tension rod are fulfilled. The tension rod structure is simple and convenient to machine, and the technical content of the injection molding machine is improved.

Owner:NINGBO HAIXING MACHINERY MFG

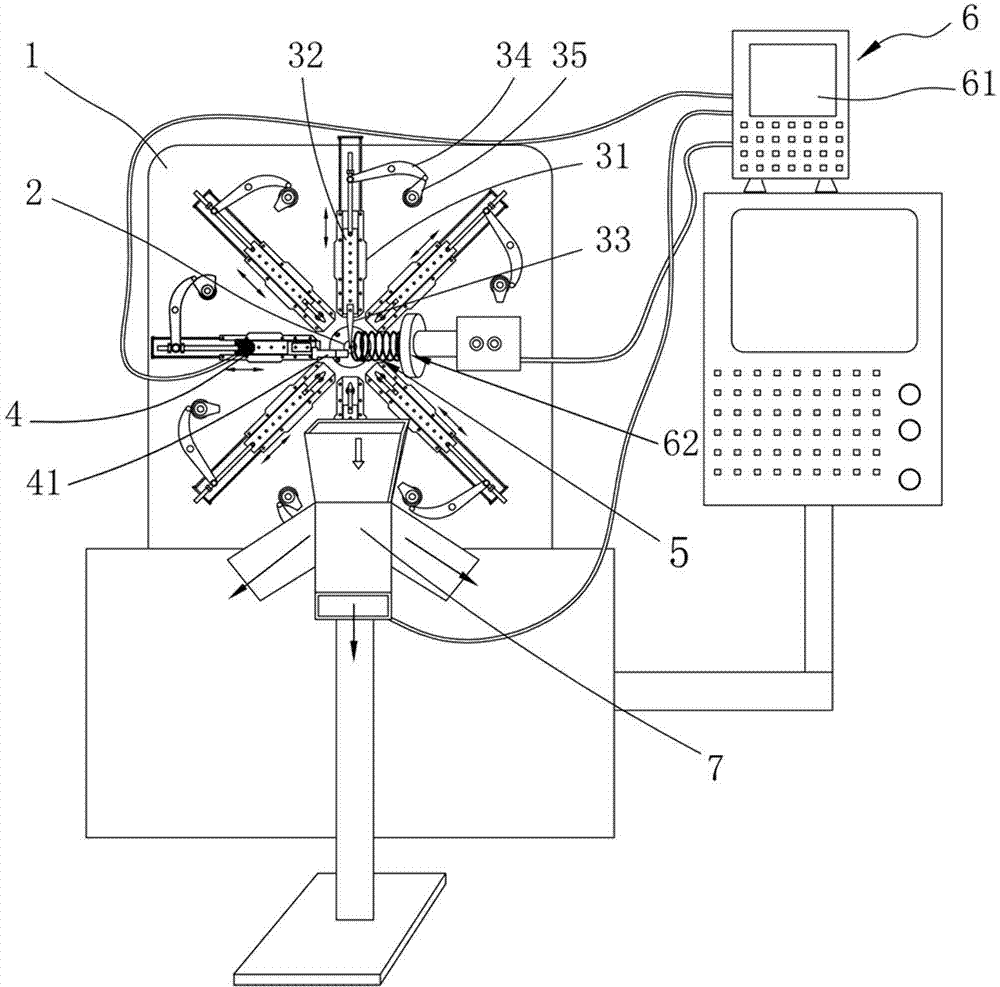

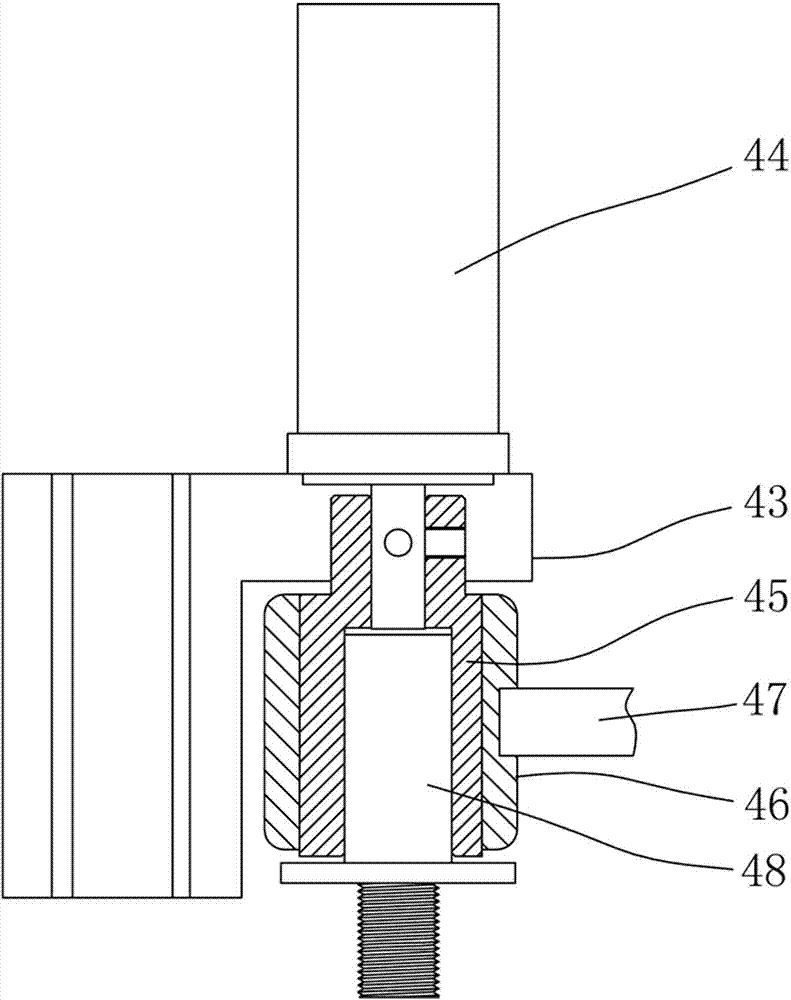

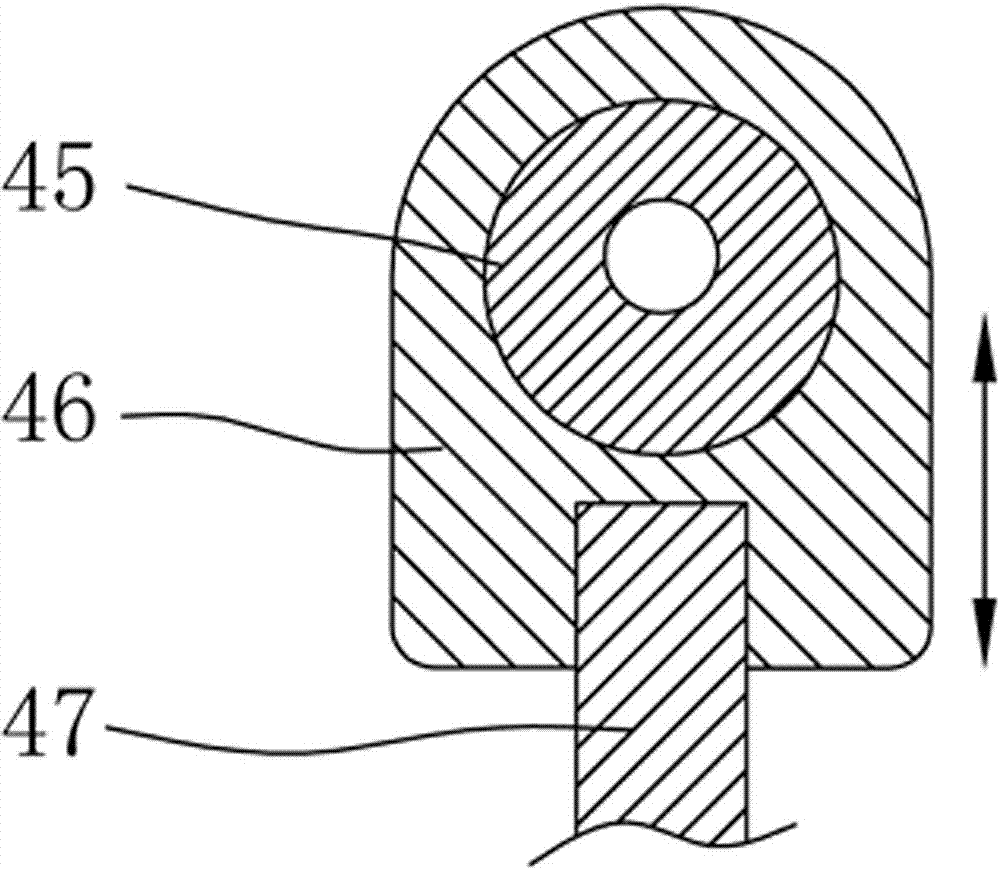

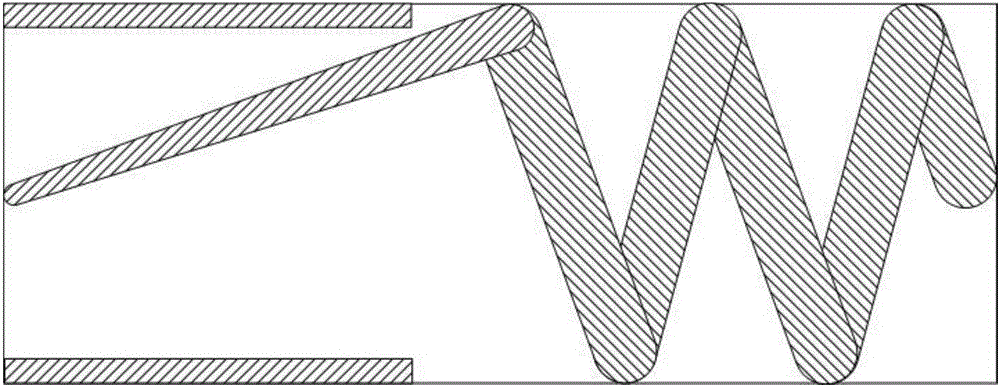

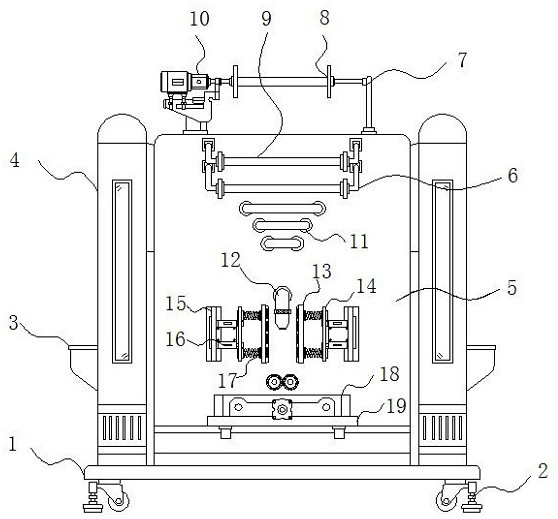

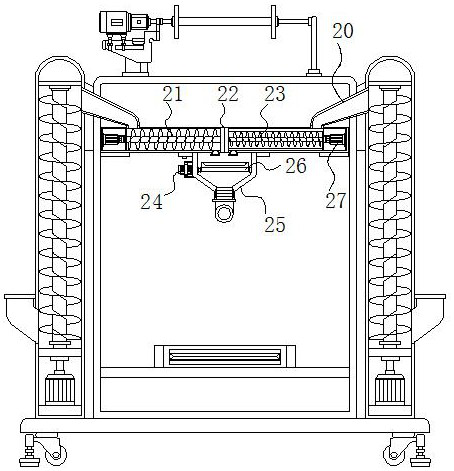

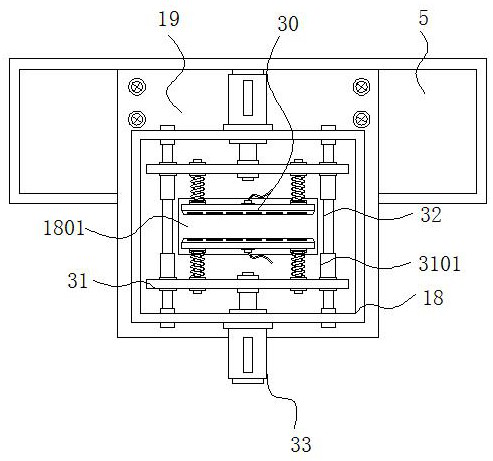

Spring machine with spring length adjusting device

The invention discloses a spring machine with a spring length adjusting device, and belongs to the technical field of precise efficient processing and forming equipment. The spring machine is provided with a push broach which is propped against the external surface of a spring. According to the spring machine, when the pitch of the spring excesses a specified value, a control system drives a driving motor so that an eccentric sleeve rotates, and the push broach is moved back, thus, the pressure on the spring can be released, as a result, the pitch of the spring is reduced; conversely, when the pitch of the spring is less than the specified value, the pressure on the spring is increased through the push broach under the driving of the driving motor and the eccentric sleeve, thus the pitch of the spring is raised. The spring machine has simple structure, and is convenient to operate, and can effectively improve the percent of pass of the product and reduce the cost of production; and the spring machine removes the conventional mode of manually adjusting the processing cutter, and therefore the precision of the product can be greatly improved.

Owner:ZHUHAI LONGXIN TECH

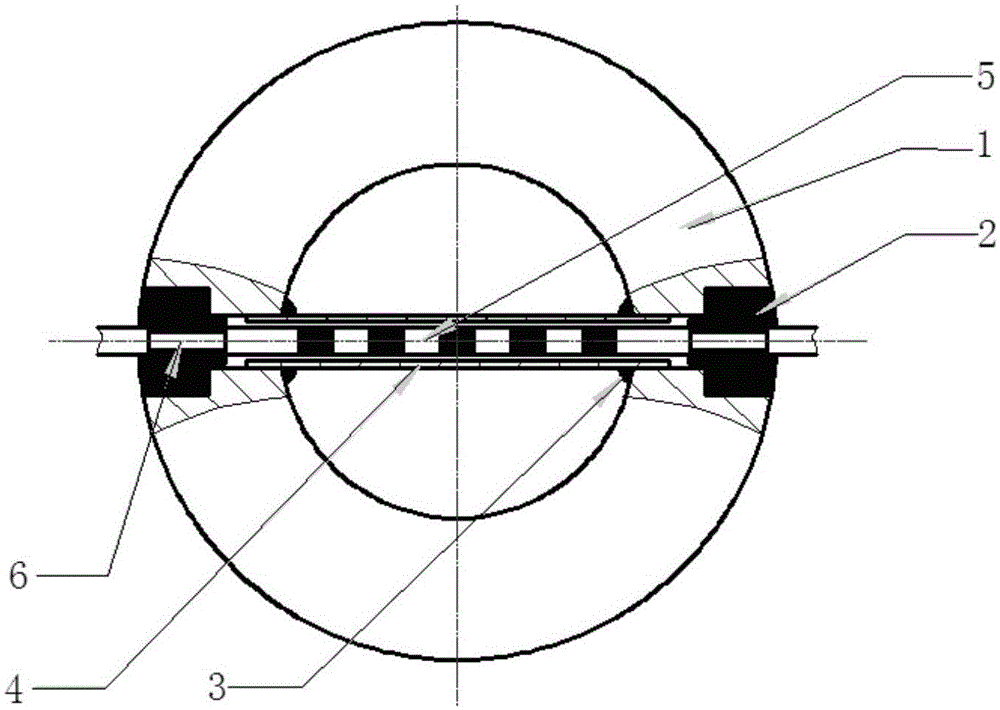

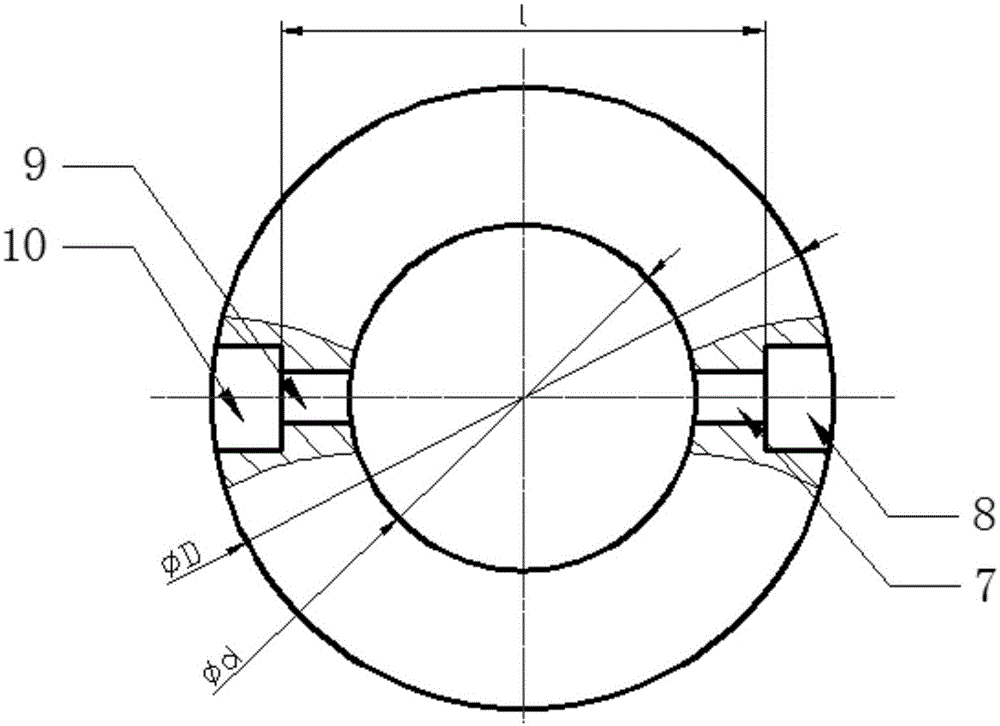

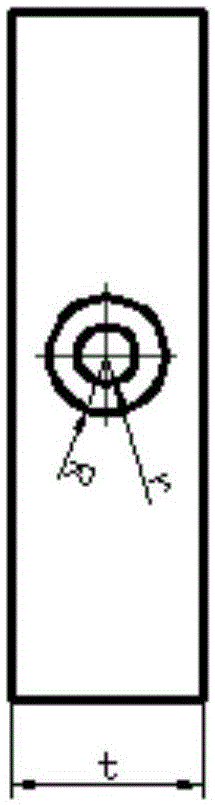

Circular ring type fiber bragg grating (FBG) temperature sensor and encapsulation method

InactiveCN105157873ASmall repeatability errorIncrease the amount of wavelength changeThermometers using physical/chemical changesPhysicsRing type

The invention provides a circular ring type fiber bragg grating (FBG) temperature sensor, which comprises a fiber. A grating is disposed on the fiber. The circular ring type fiber bragg grating temperature sensor further comprises an elastic deformable body. The elastic deformable body is a circular ring, two sides of the circular ring are provided with a through hole and a blind hole, and lower and upper faces are both attached with metal pieces for encapsulation and conduction. The through hole and the blind hole are connected, the through hole is sleeved internally with a capillary metal tube, the capillary metal tube is fixed with an inner wall of the circular ring, the fiber penetrates through the capillary metal tube, the grating on the fiber is located at the axis of the circular ring, and the blind hole is filled with glue for fixing the fiber. The invention has the advantages of high sensor linearity, high sensitivity and excellent repeatability.

Owner:WUHAN UNIV OF TECH

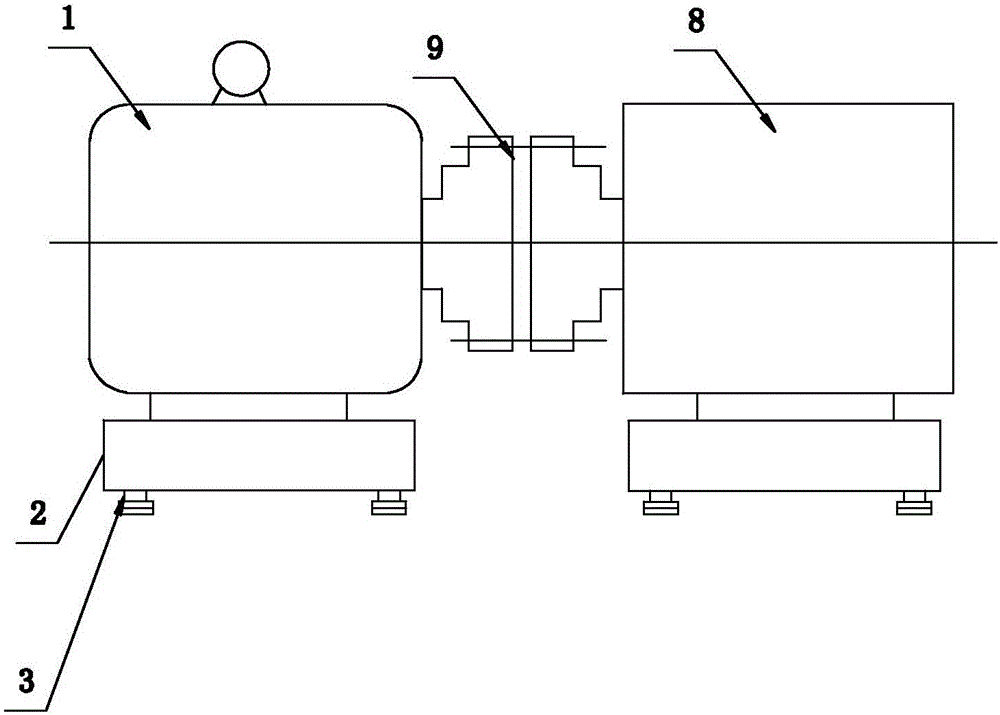

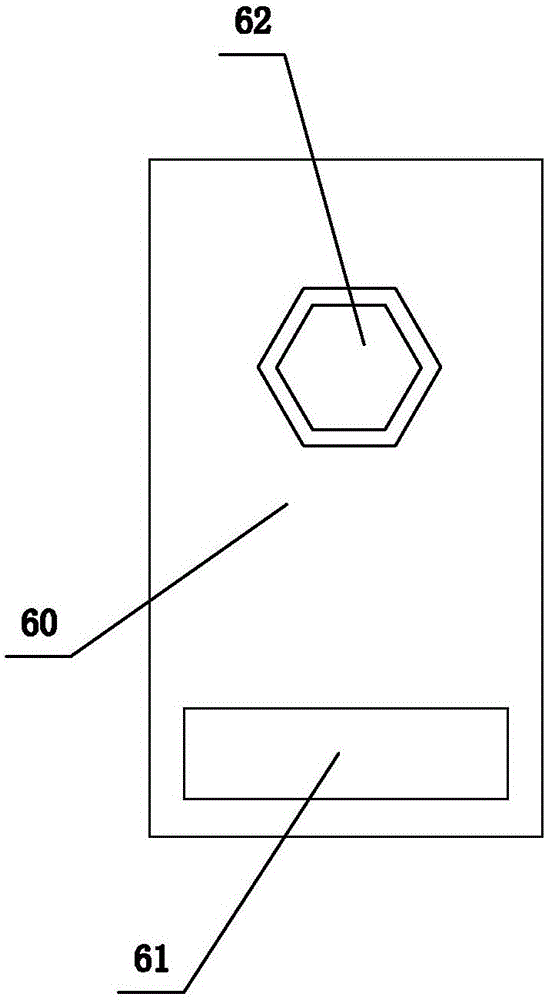

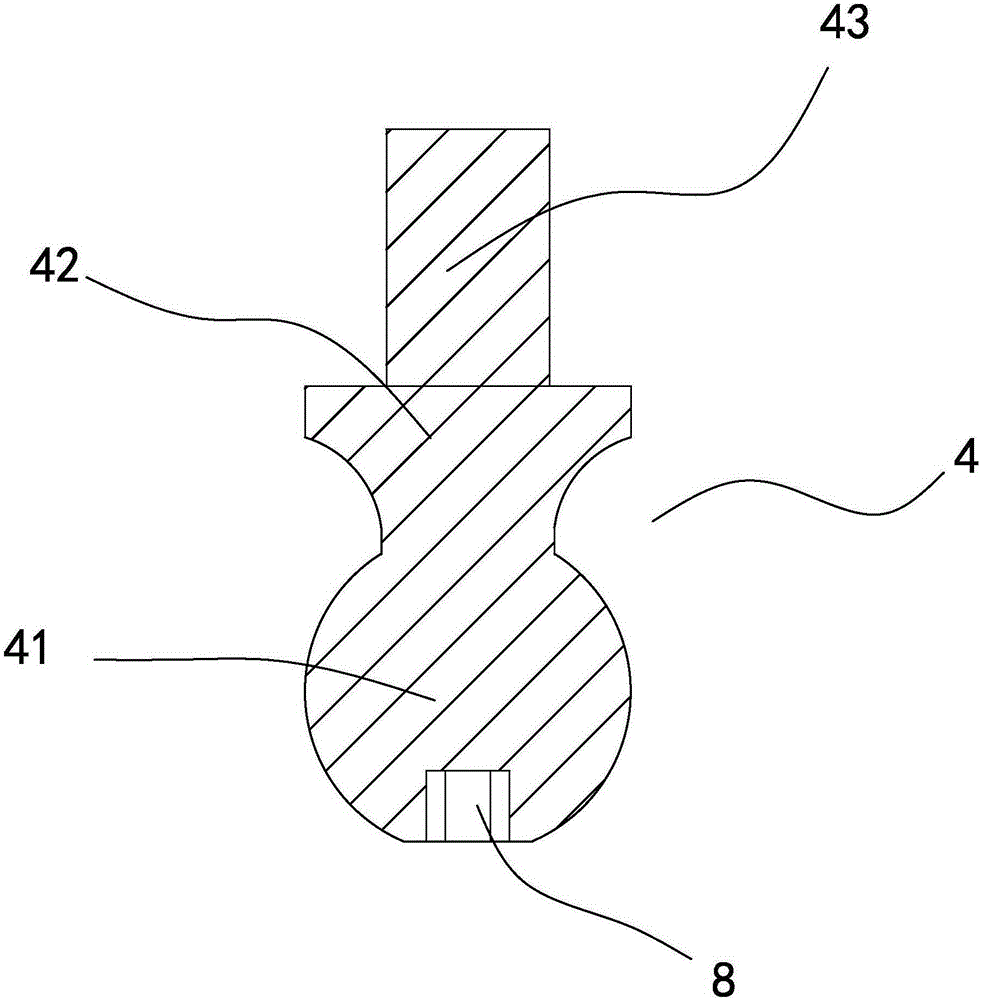

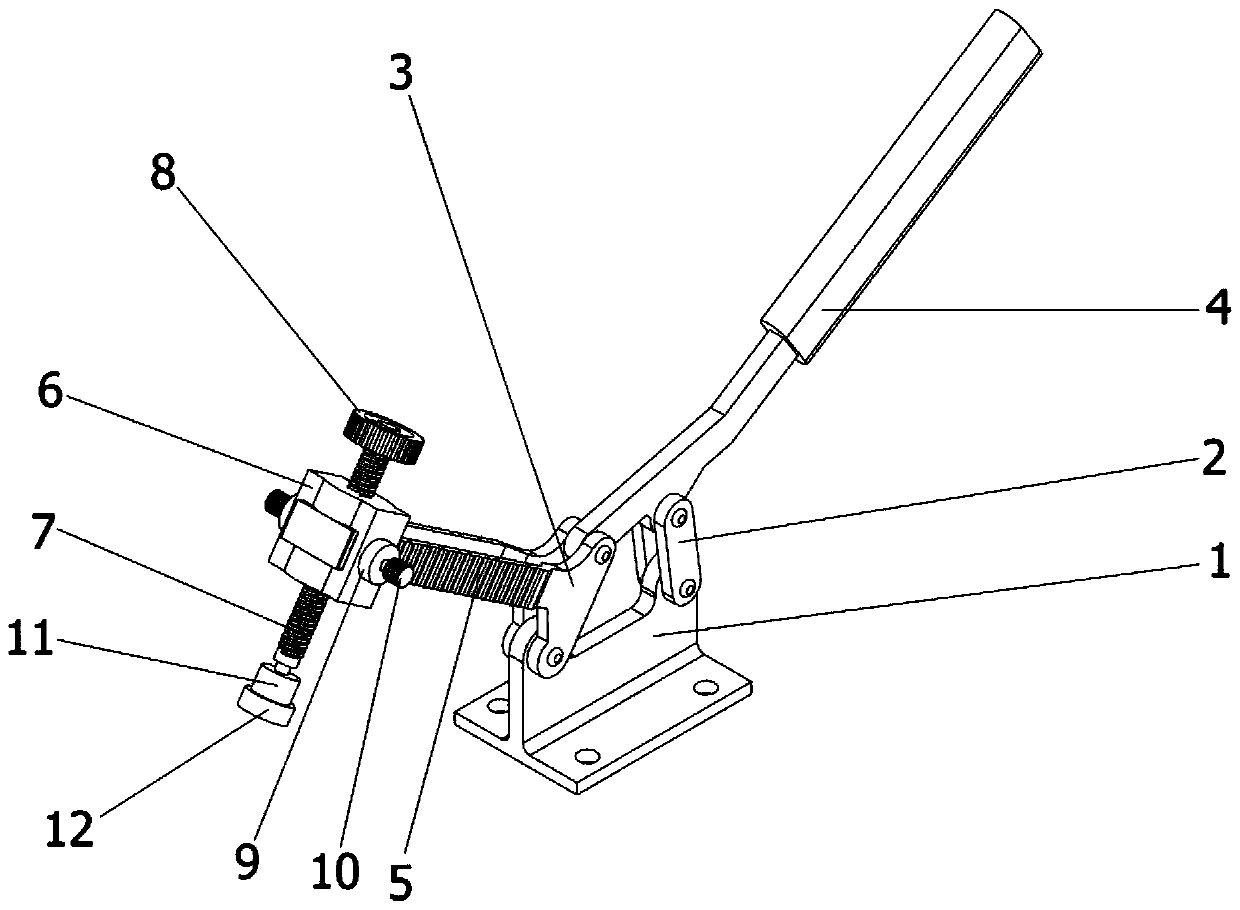

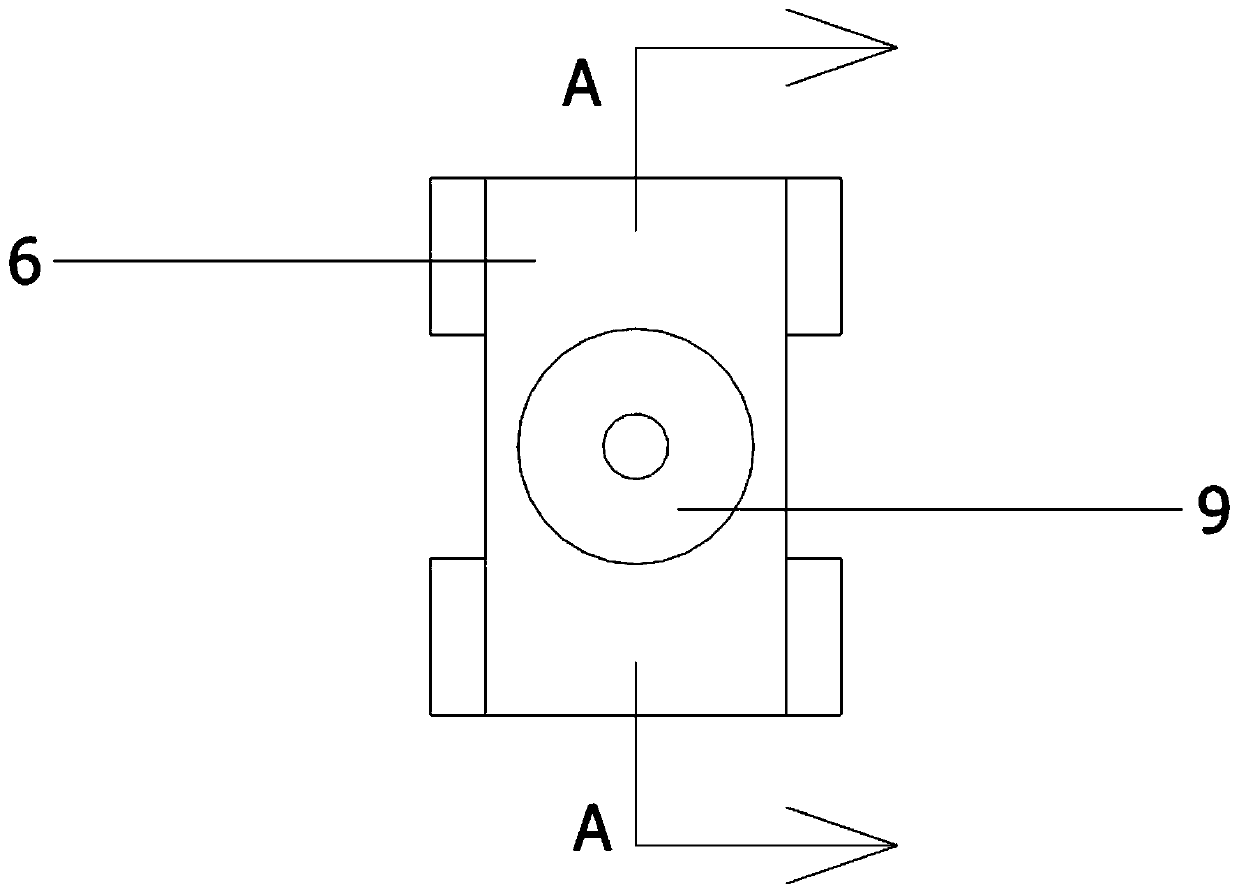

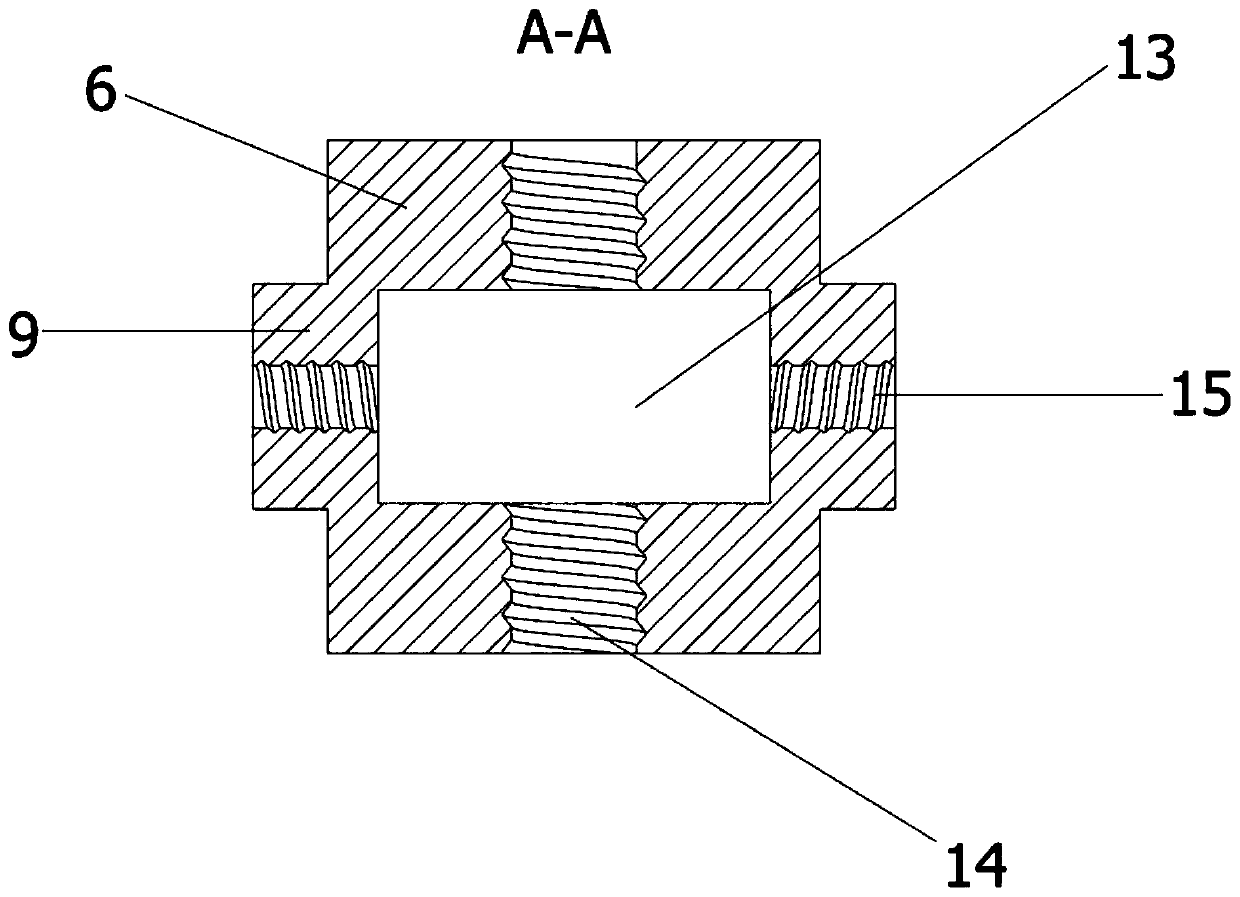

Precise regulating and aligning device of shaft coupler

InactiveCN106041516AReduce labor intensityReduce difficultyMetal working apparatusCouplingEngineering

The invention discloses a precise regulating and aligning device of a shaft coupler. The precise regulating and aligning device comprises at least three regulating units which are separately distributed on at least three corner positions of a base plate of a prime motor, wherein each regulating unit comprises a horizontal regulating assembly, a perpendicular regulating assembly, a locking part and a foundation bolt; a first assembly hole with aperture greater than the diameter of each foundation bolt, is formed in the position, at the mounting position of each regulating unit, of the base plate of the prime motor separately; and one end of each foundation bolt is locked to the ground, and the other end of each foundation bolt sequentially passes through each perpendicular regulating assembly, each horizontal regulating assembly and each first assembly hole, and then is connected to each locking part. The precise regulating and aligning device of the shaft coupler is simple in structure and is high in practicability and takes each foundation bolt as reference datum; each horizontal regulating assembly and each perpendicular regulating assembly precisely regulate a position in the X-axis direction, a position in the Y axis direction and a position in the Z-axis direction of the base plate separately, so that operation is simple and effective, and labor intensity and difficulty of aligning work are reduced, and therefore, mounting quality and mounting efficiency of machine equipment are guaranteed.

Owner:ZHISHENG CHEM

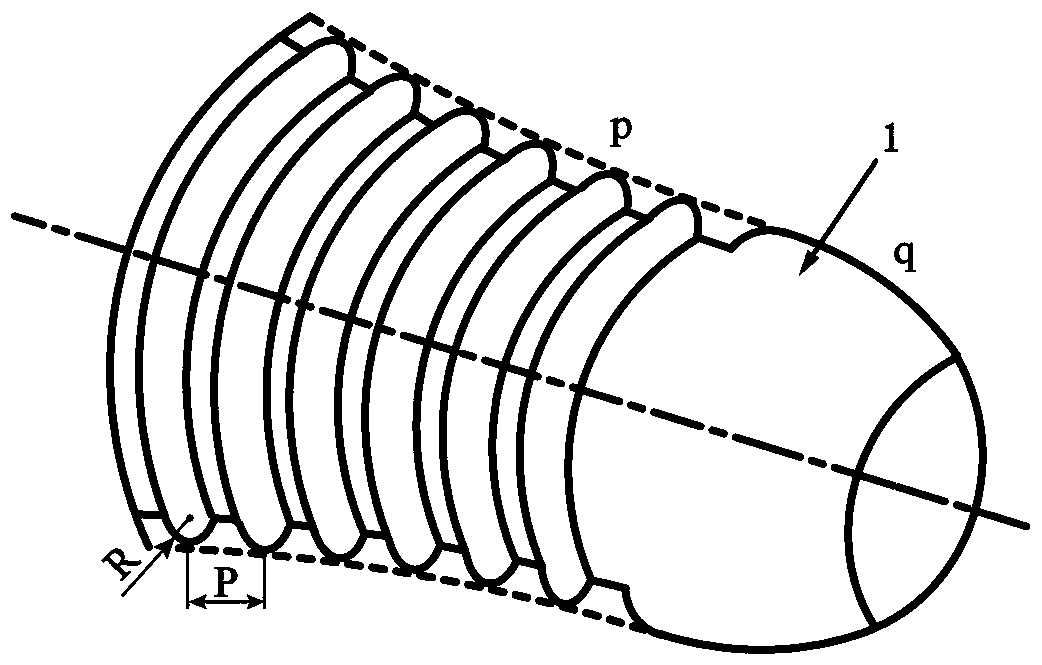

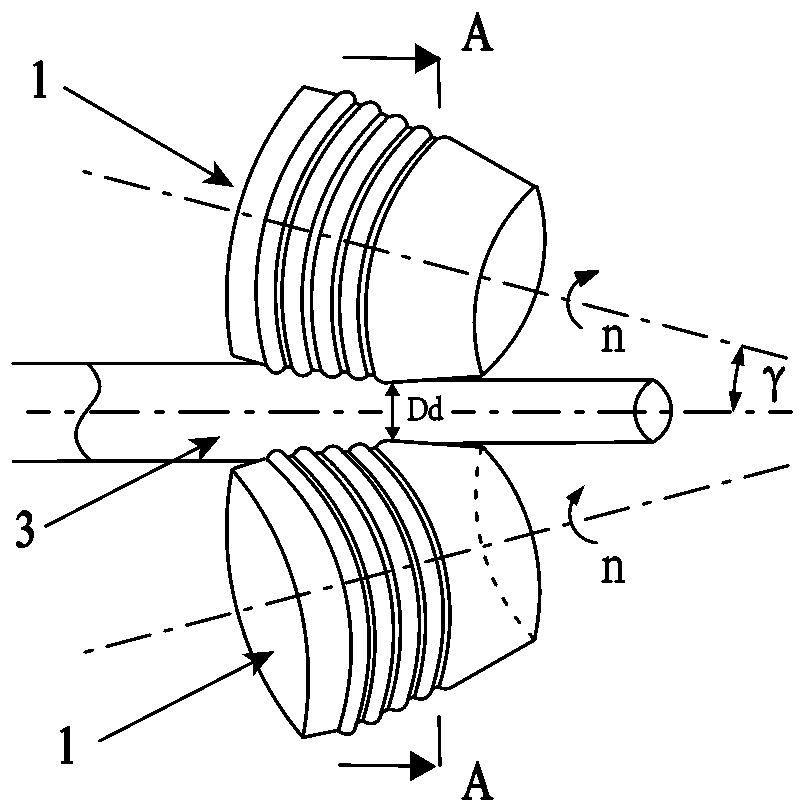

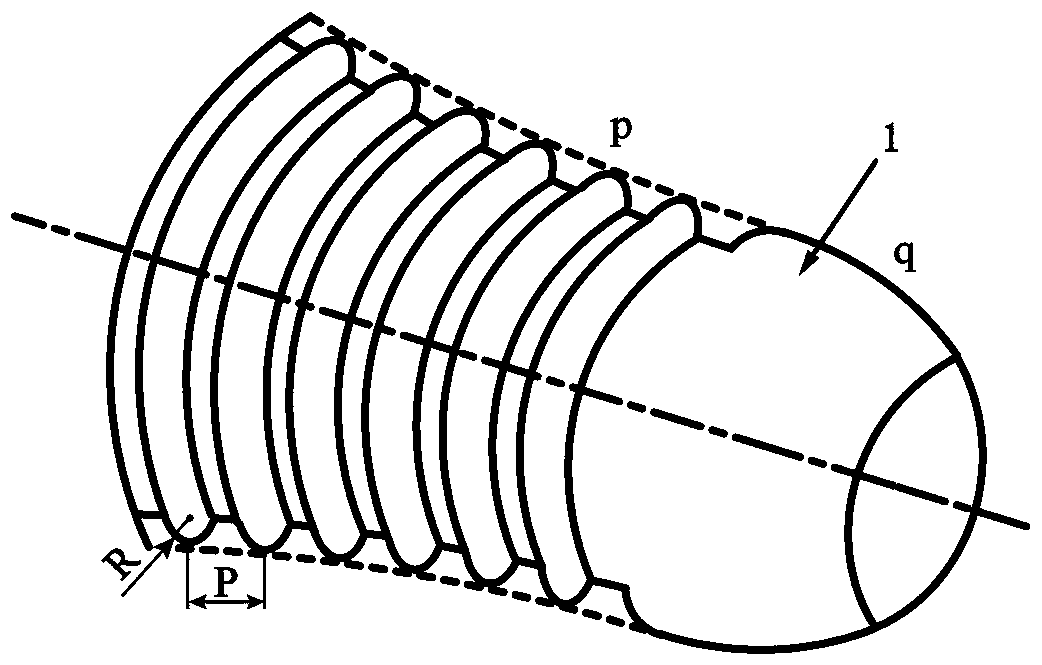

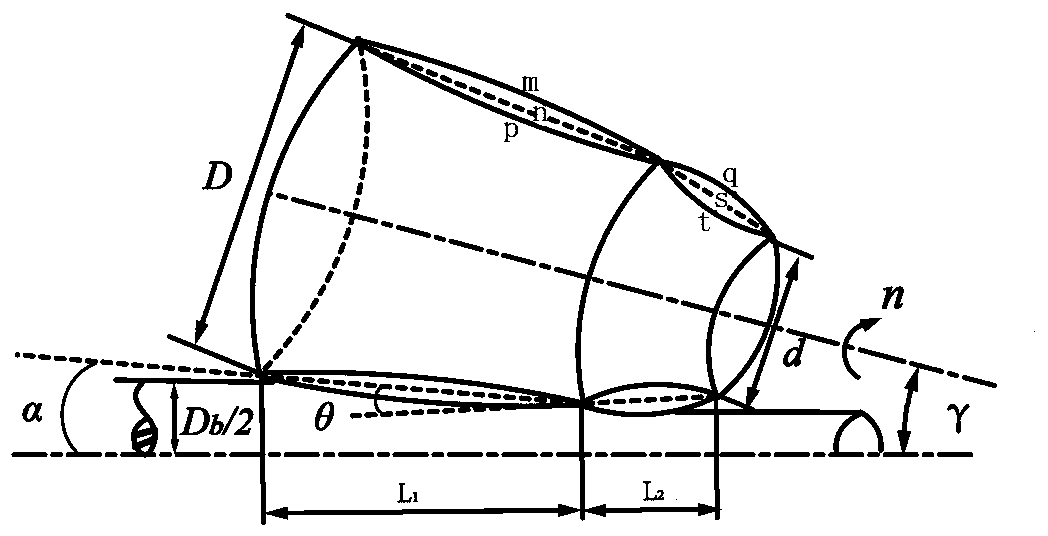

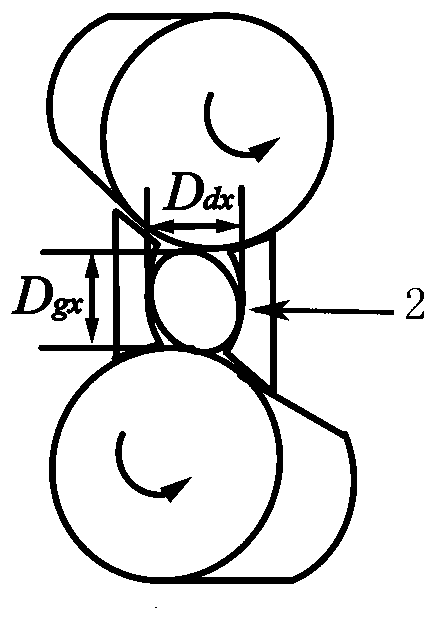

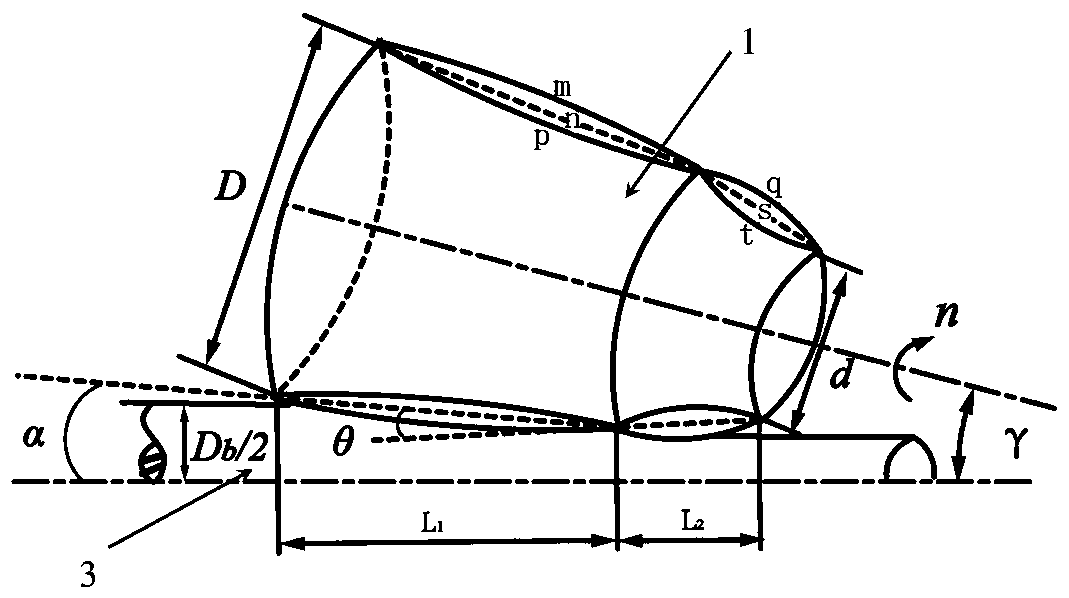

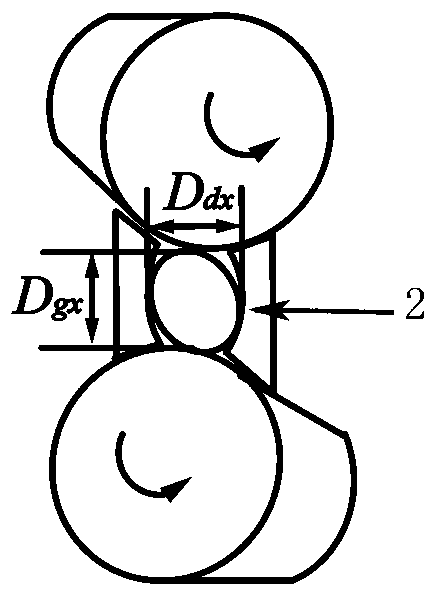

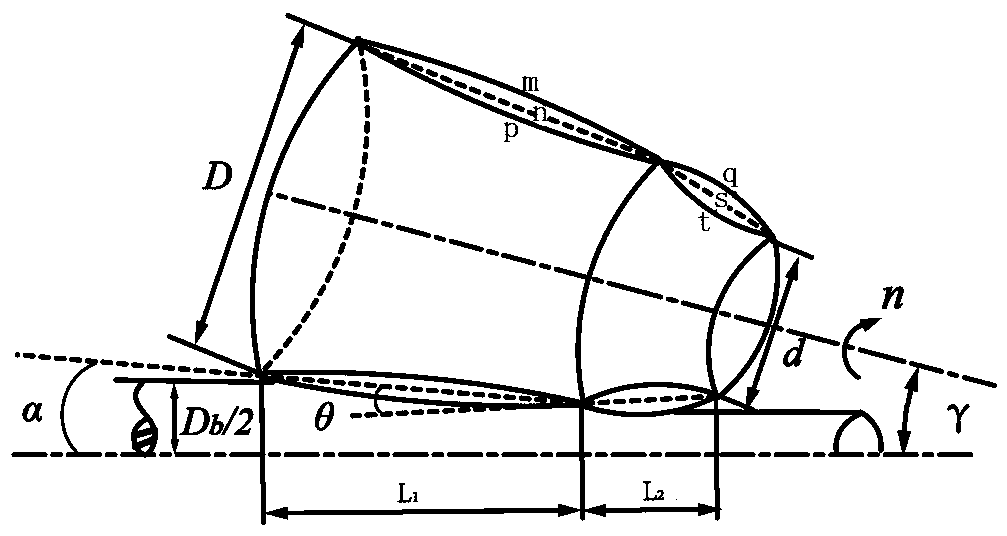

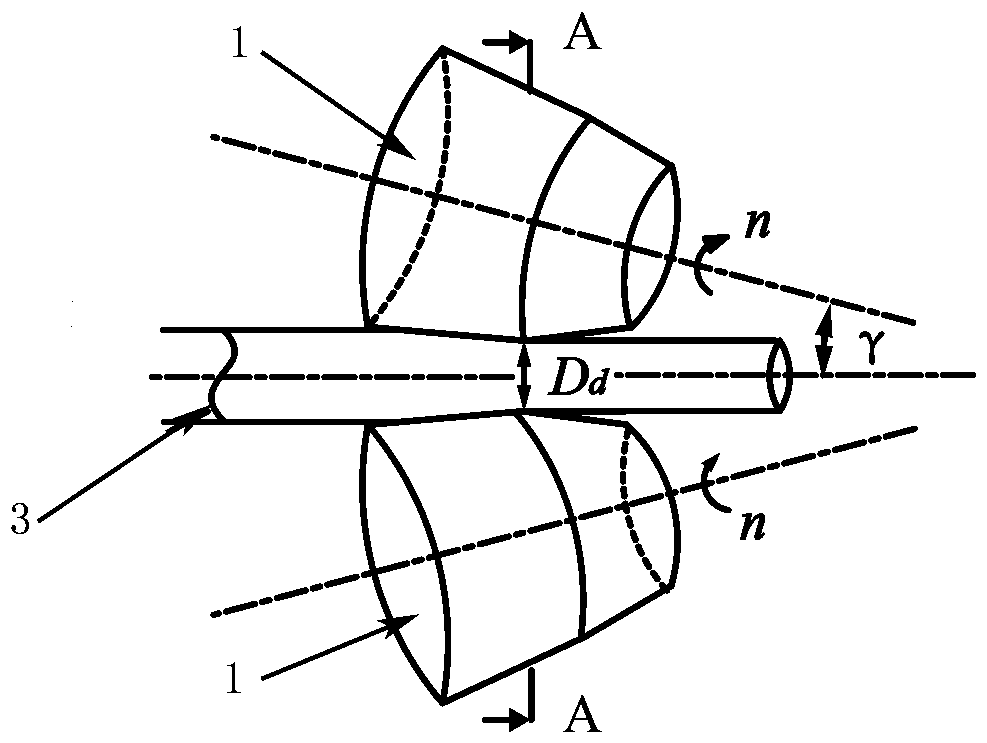

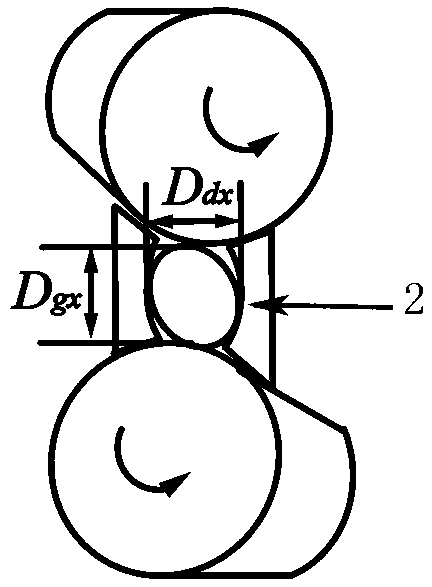

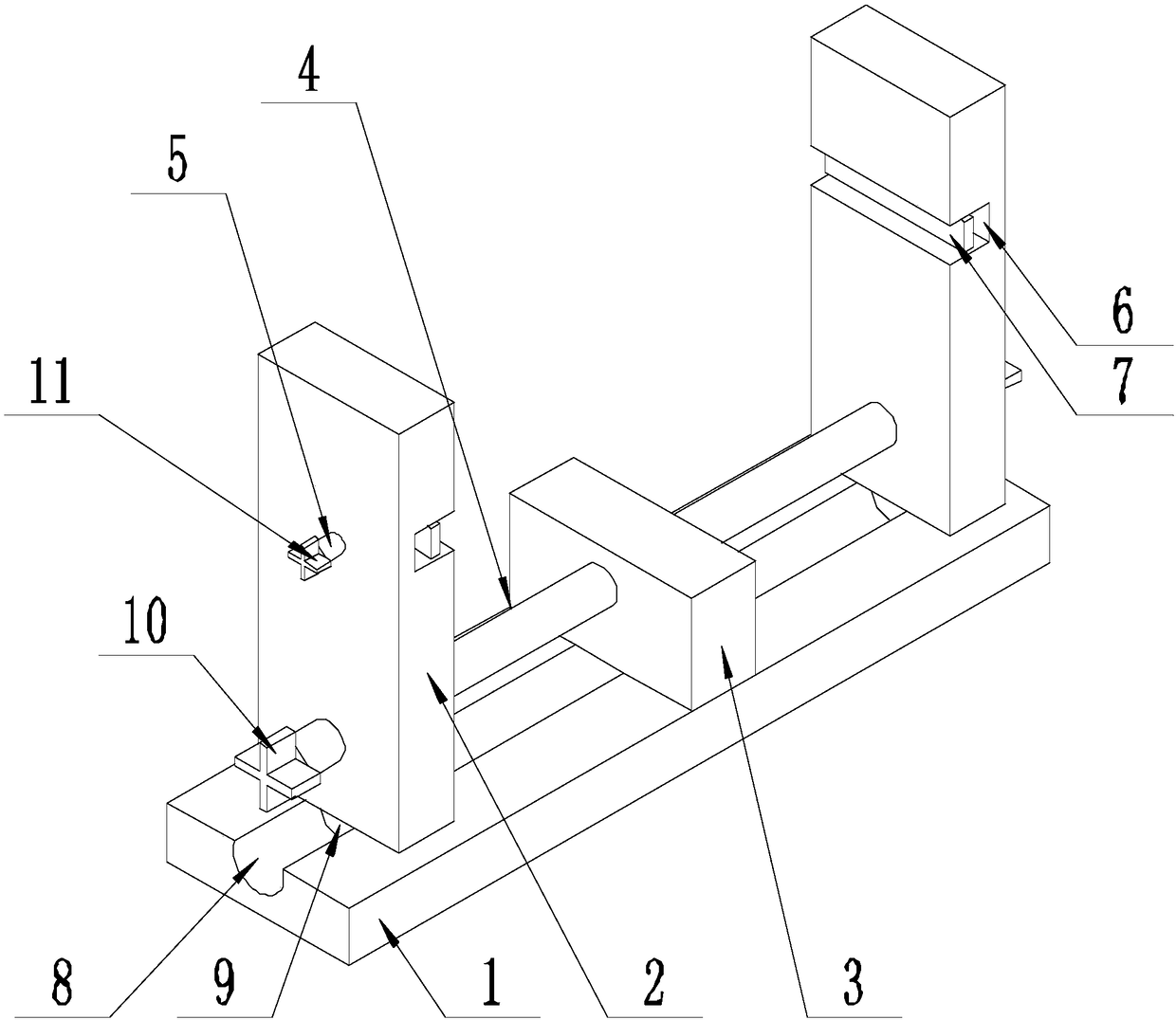

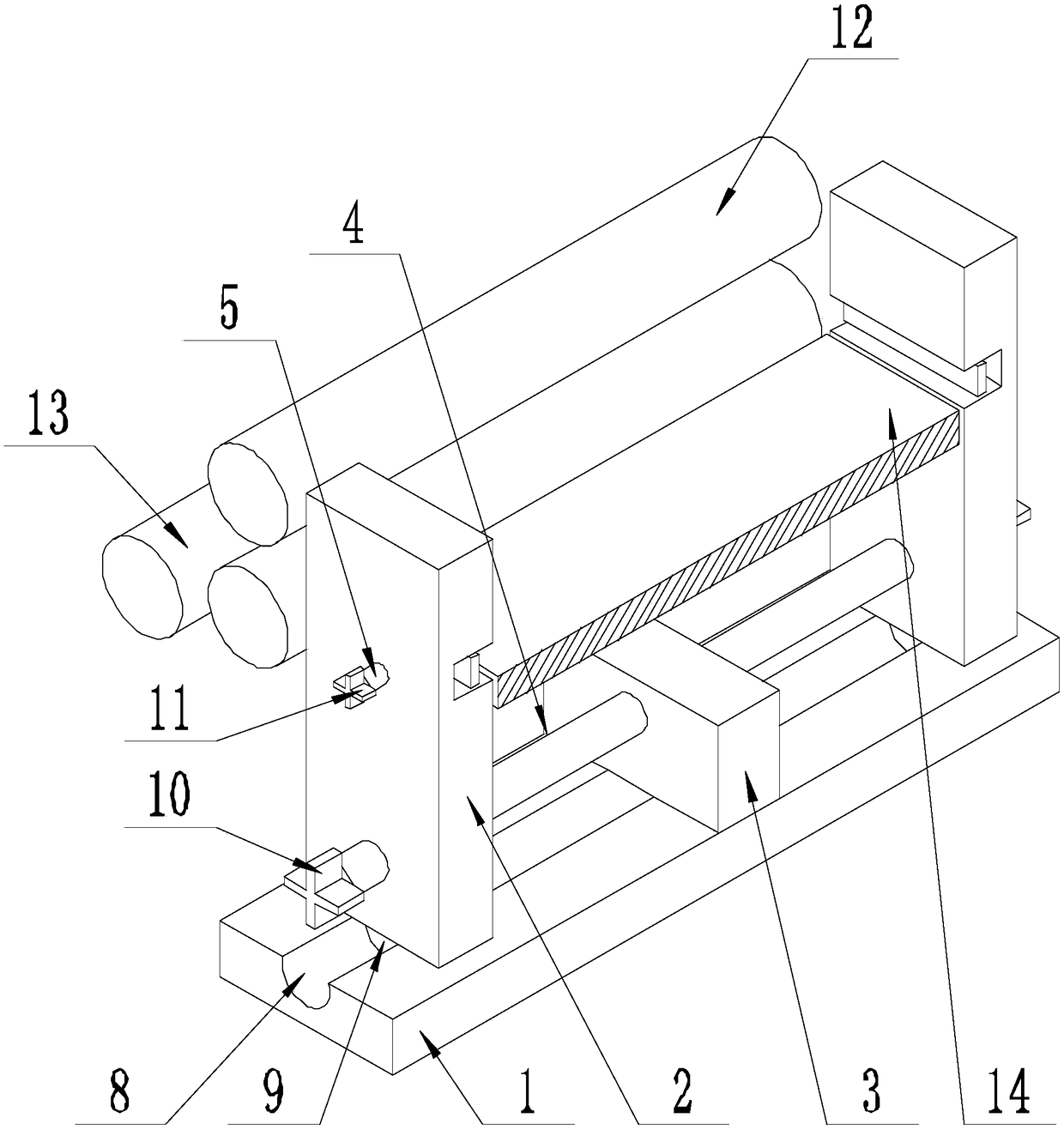

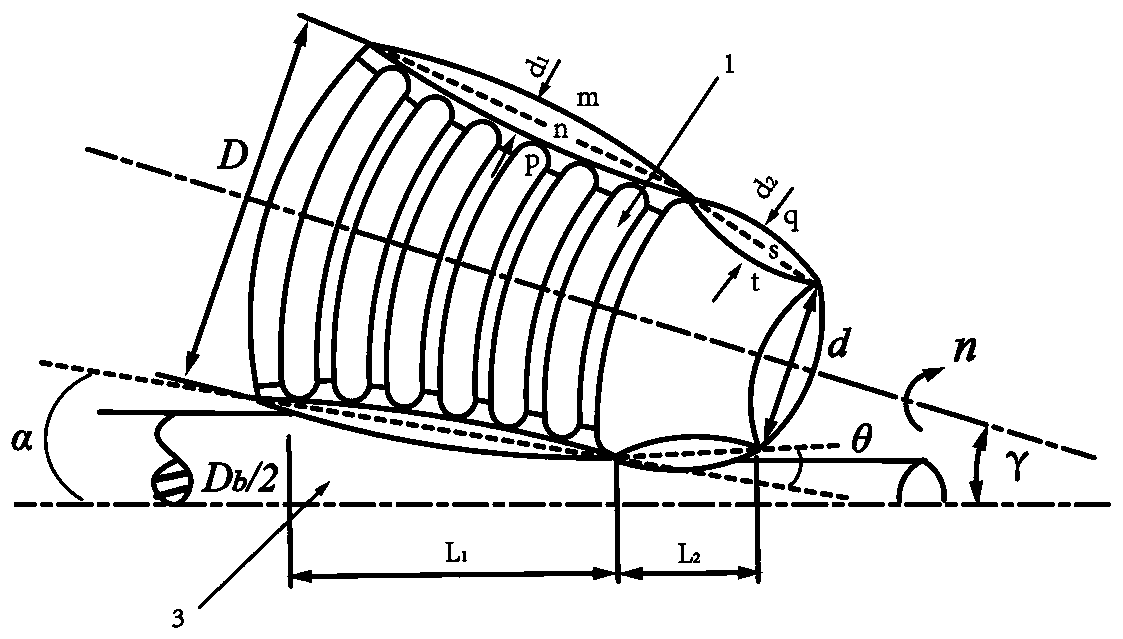

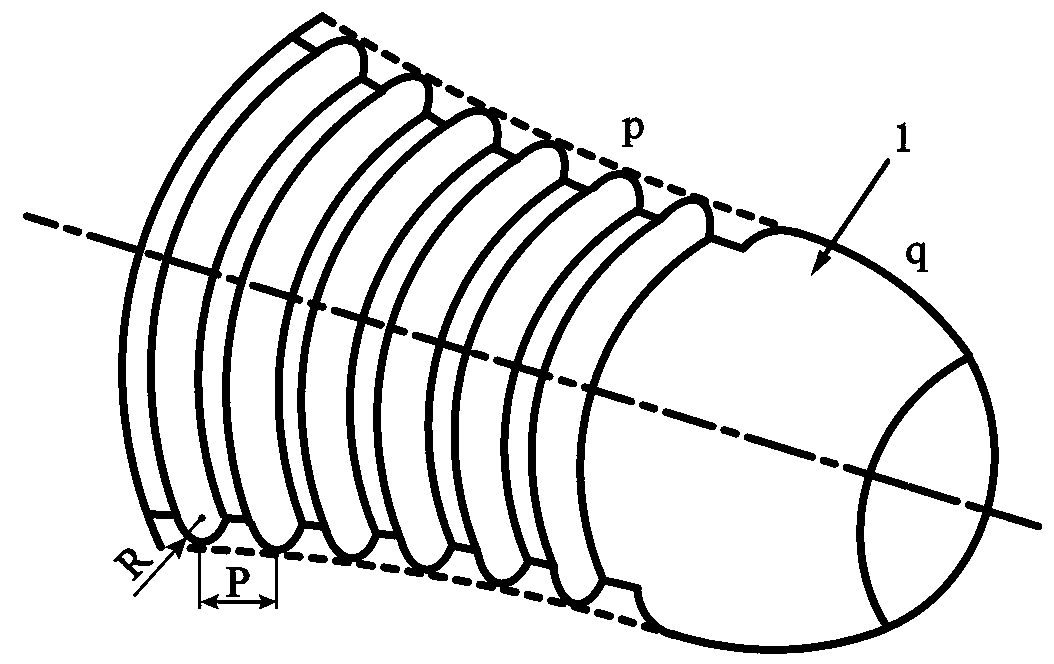

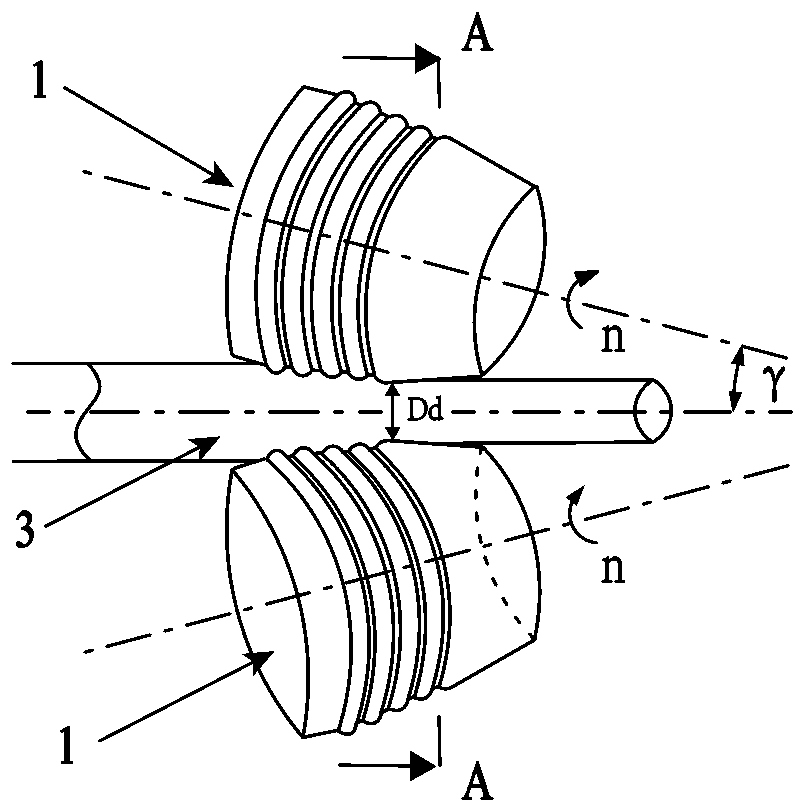

Reversed cone spiral roller ultra-fine grain rolling method of large-sized titanium alloy bar

ActiveCN109909296AReduce the number of repeated rollingReduce tensile stressRollsMetal rolling arrangementsHyperboloidUltra fine

The invention relates to the field of machining, in particular to a reversed cone spiral roller ultra-fine grain rolling method of a large-sized titanium alloy bar. The reversed cone spiral roller ultra-fine grain rolling method of the large-sized titanium alloy bar comprises the following steps that of designing a rolling tool, wherein roller design and guide plate design are involved specifically, and each roller is arranged to be a hyperboloid circular-truncated-cone-like spiral roller; forming a deformation area, wherein the curved faces of the two guide plates are oppositely arranged, thetwo rollers are placed between the two guide plates, and the area defined by the two guide plates and the two rollers is the deformation area; forming a constant-ovality deformation area, wherein theovality in the deformation area is kept constant; and selecting a rolling feeding manner, wherein inverted feeding type rolling manner is adopted. By the adoption of the reversed cone spiral roller ultra-fine grain rolling method of the large-sized titanium alloy bar, by designing the hyperboloid circular-truncated-cone-like spiral rollers and the curved-face guide plates and forming the constant-ovality deformation area, severe plastic deformation can be generated on the premise of remarkably restraining the Mannesmann effect of the core portion.

Owner:安徽东耘智能设备制造有限责任公司

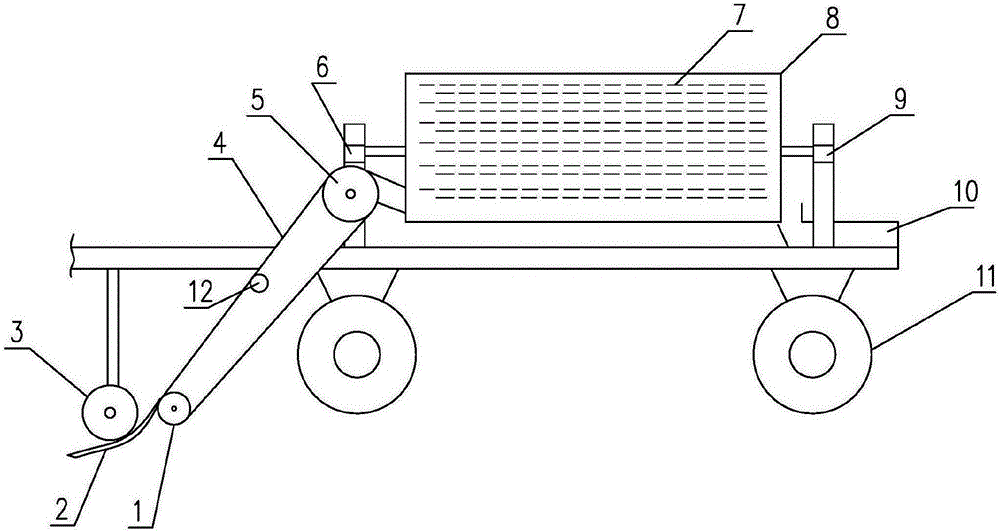

Excavating and screening device for rhizoma corydalis

The invention discloses an excavating and screening device for rhizoma corydalis. The excavating and screening device comprises a main frame, a tunneling shovel, a soil pulverizing roller, a lifting mechanism, a cylinder screen, and a collecting box, wherein a first support and a second support are arranged on the main frame, a cylinder screen shaft is arranged inside the cylinder screen, and the first support and the second support are used for supporting the cylinder screen shaft; the tunneling shovel is arranged at the bottom of the lifting mechanism, the top of the lifting mechanism corresponds to an inlet in the front of the cylinder screen, the soil pulverizing roller is arranged above the tunneling shovel, and the soil pulverizing roller is fixed on the main frame through a third support; the collecting box is arranged on the main frame and is communicated with the outlet of the rear part of the cylinder screen. The excavating and screening device for rhizoma corydalis is capable of improving efficiency of separation of fruits of rhizoma corydalis and soil and has no damage to the fruits of rhizoma corydalis and soil; meanwhile, the manufacturing cost of the device is low, and high net fruit rate and backfilling of the soil are thus achieved.

Owner:山东电立得动力科技有限公司

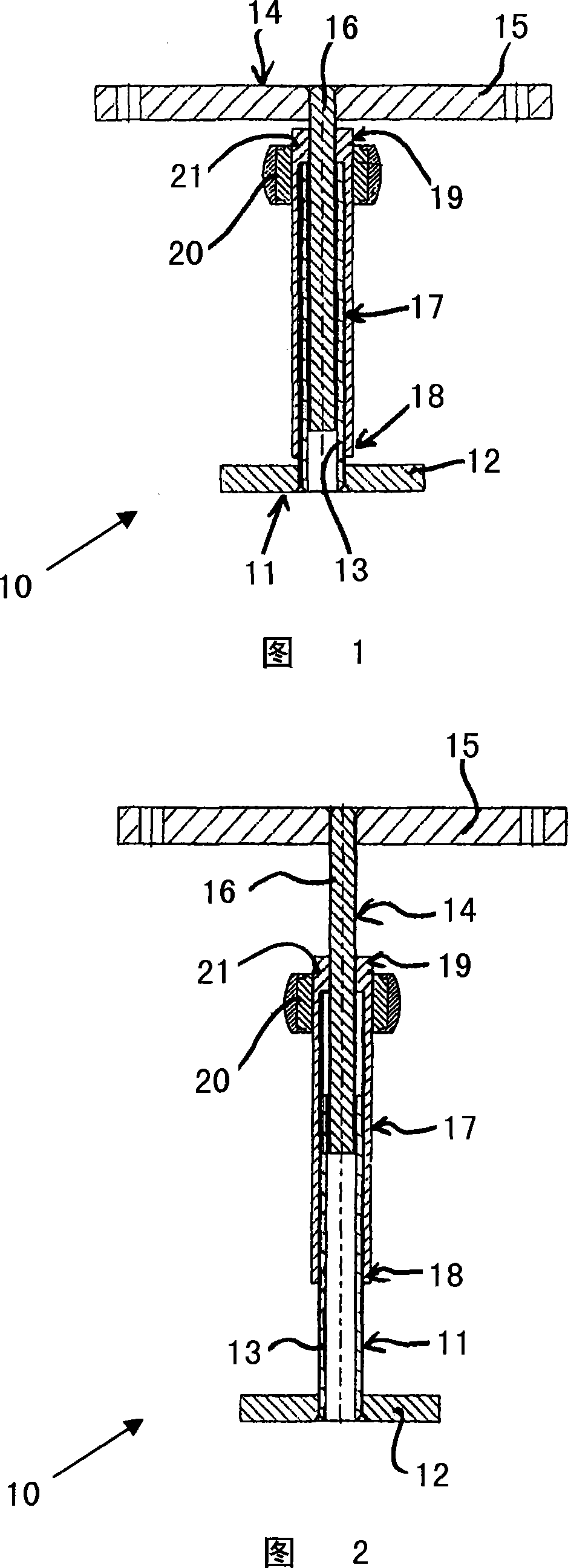

Purchase

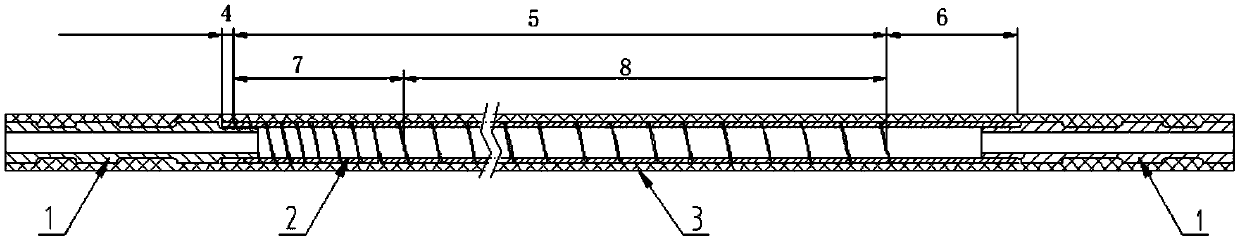

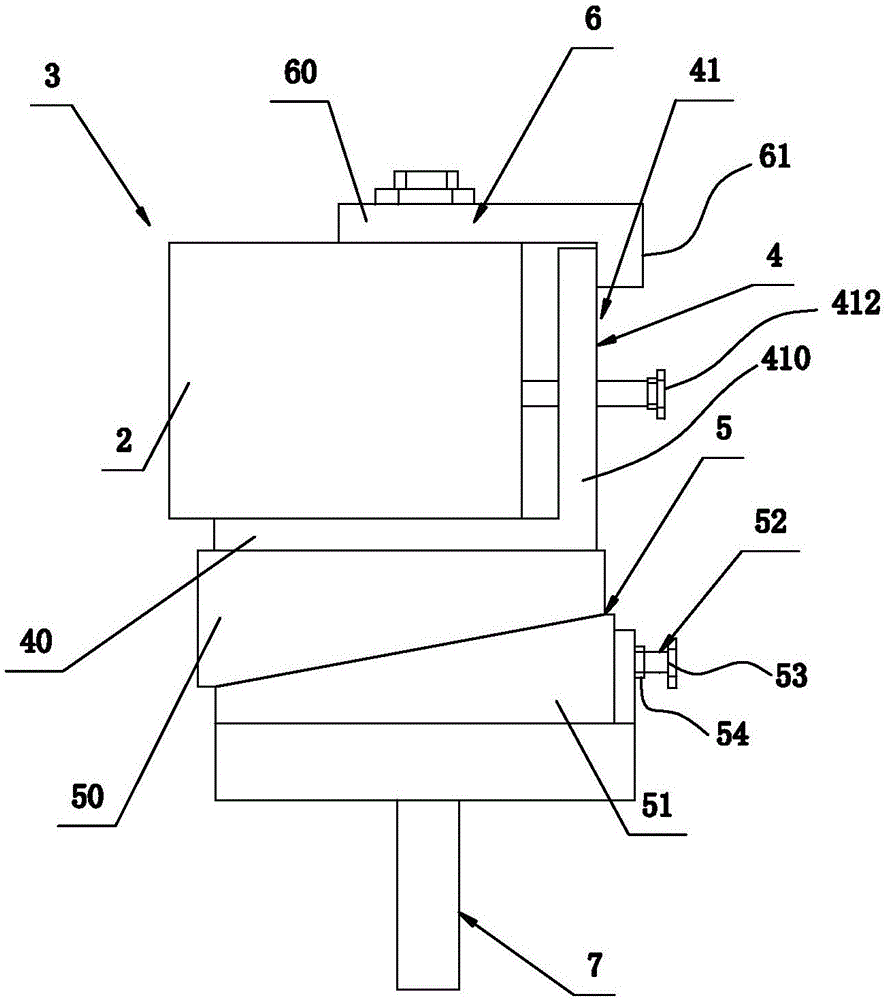

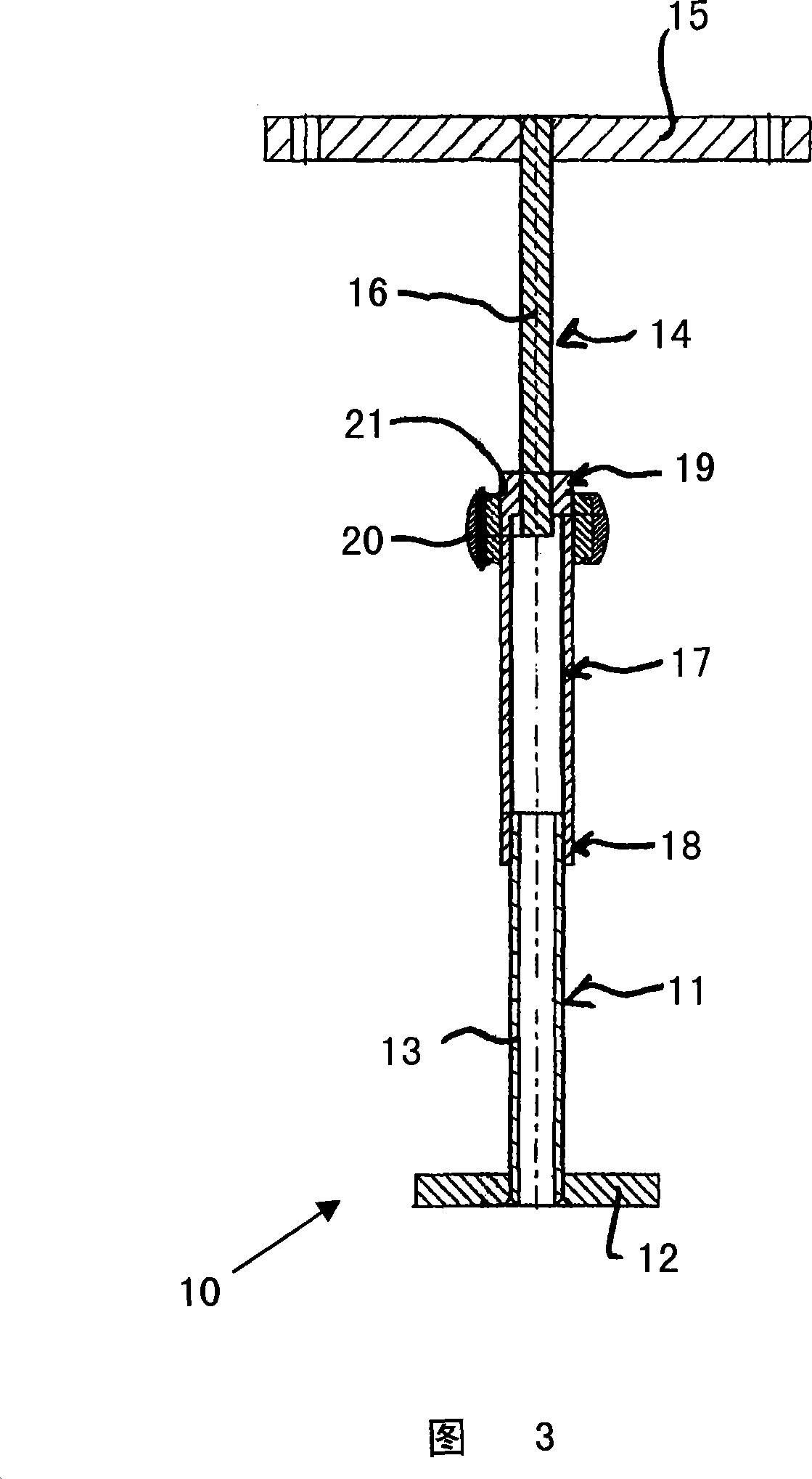

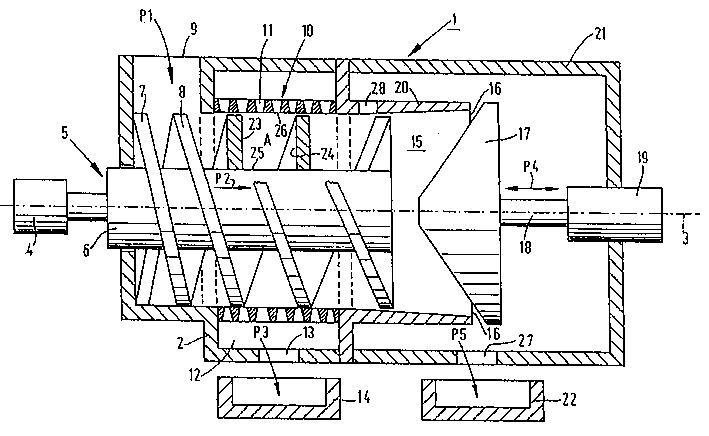

InactiveCN101112965AEasy to operate manuallyBig work scheduleLifting devicesEngineeringInternal combustion engine

The present invention relates to a lifting device, especially a crankshaft bearing lifting device for installing the crankshaft bearing in a internal-combustion engine or disassembling the crankshaft bearing from the internal-combustion engine. The lifting device comprises a first basal body (11) with a first platform (12), a second basal body (14) with a second platform (15) and a cannular middle body (17) which mounts the first basal body (11) to the second basal body (14). The section (13) of the first basal body (11) exserted relative to the first platform locates in a first end part (18) of the cannular middle body (17), the section (16) of the second basal body (14) exserted relative to the second platform locates in a second end part (19), which are guided rotatablely by screw thread separately. Thus by means of the rotatable cannular middle body (17), on the one hand, the middle body (17) can be adjusted relative to the first basal body (11) telescopically, on the other hand, the second basal body (14) can be adjusted relative to the middle body (17) telescopically, that is the first basal body (11) and the second basal body (14) move in the same direction or in the different direction, which is based on the rotary direction of the middle body (17).

Owner:MAN B & W DIESEL AS

Reverse conical spiral roller ultra-fine grain rolling method of large-size 45 steel bar

ActiveCN109807174AReduce the number of repeated rollingReduce tensile stressTemperature control deviceMetal rolling stand detailsRound tableSteel bar

The invention discloses a reverse conical spiral roller ultra-fine grain rolling method of a large-size 45 steel bar, and relates to the field of machining. The method comprises the following steps that a rolling tool is designed, wherein design specifically comprises roller design and guide plate design, and rollers are designed to be dual-curve-face round-table-shaped spiral rollers; a deformingarea is constructed, wherein curve faces of two guide plates are oppositely placed, the two rollers are placed between the guide plates, and the area defined by the guide plates and the rollers is the deforming area; an equal ovality deforming area is constructed, wherein ovality in the deforming area is kept unchangeable; and the inverted feeding manner is selected, wherein the pouring-in type rolling manner is adopted. According to the reverse conical spiral roller ultra-fine grain rolling method of the large-size 45 steel bar, through design of the dual-curve-face round-table-shaped spiralrollers and the curve guide plates, the equal ovality deforming area is constructed, and the violent plastic deforming is generated on the premise of obviously restraining the heart Mannesmann effect.

Owner:安徽东耘智能设备制造有限责任公司

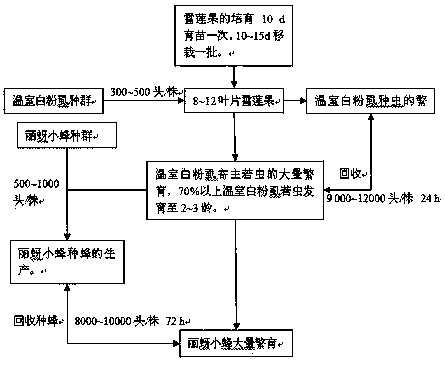

Method for massively breeding Encarsia formosa based on Smallanthus sonchifolius as host plant

InactiveCN107926868AShorten the breeding cycleImprove qualityRoot crop cultivationAnimal husbandryGreenhouseIntermediate host

The invention discloses a method for massively breeding Encarsia formosa based on Smallanthus sonchifolius as a host plant and relates to a novel method for breeding Encarsia formosa. Factory massivebreeding of Encarsia formosa is carried out using Smallanthus sonchifolius as an intermediate host plant and greenhouse whitefly as a host. The method comprises the steps of (1) cultivating healthy plants of Smallanthus sonchifolius; (2) breeding parents of greenhouse whitefly; (3) massively breeding host nymphs of greenhouse whitefly; (4) producing parents of Encarsia formosa; (5) massively breeding Encarsia formosa. The method has the advantages that Encarsia formosa is used as the intermediate host plant to massively breed Encarsia formosa, breeding cycles of greenhouse whitefly and Encarsia formosa are shortened, massive breeding quality of Encarsia formosa is further improved, and the method is significant to the factory breeding of Encarsia formosa.

Owner:JILIN AGRICULTURAL UNIV

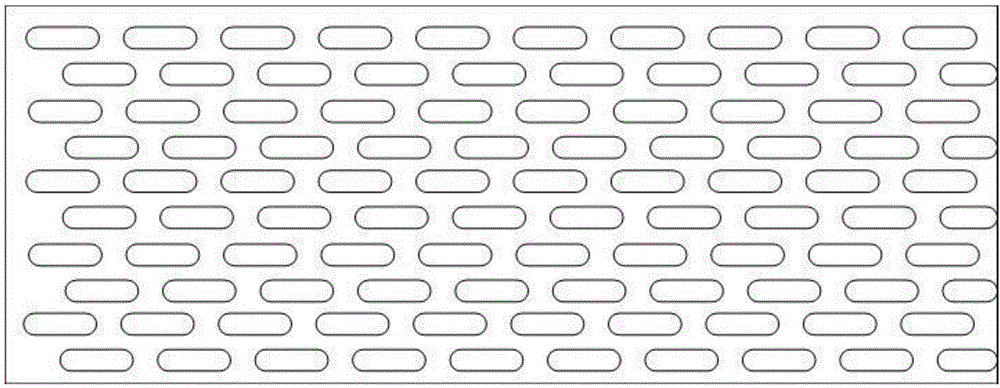

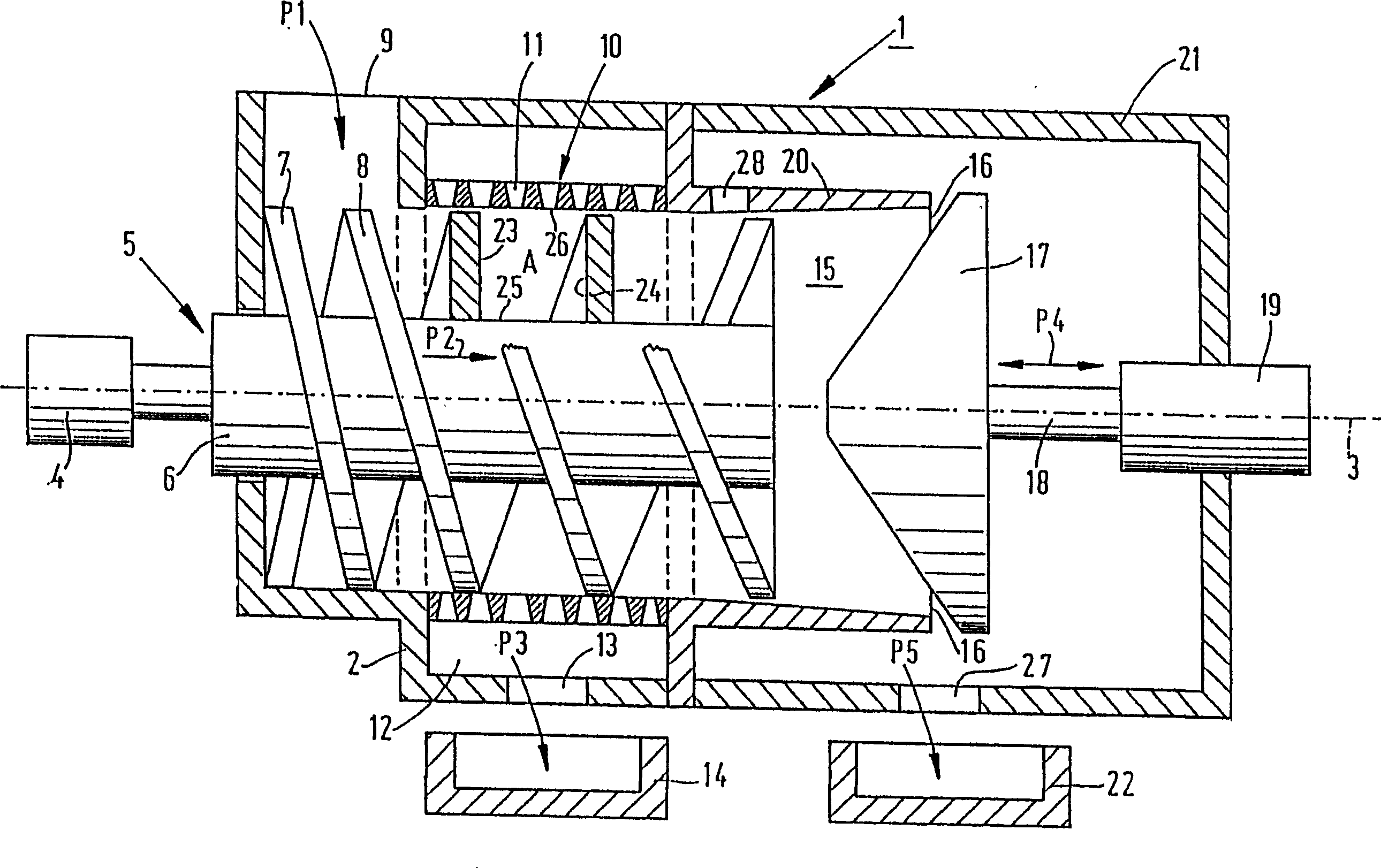

Device for separating substance into two phases

InactiveCN1458878ALarge pitchSmall diameterPressesStationary filtering element filtersRadial planeEngineering

The invention relates to a device (1) for separating a substance into two phases, which device (1) comprises a screw conveyor (5) including a shaft and at least one screw (5) which is mounted on said shaft, which screw conveyor extends between an intake opening (9) for the substance and an outlet opening (16) for one of said two phases, as well as a cylindrical screen (10) provided with screen openings (11), within the screw conveyor (5) is rotatably disposed for conveying the substance in a direction of transport from said intake opening (9) to said outlet opening (16) via flow surfaces lying in a radial plane between said shaft, two successive screw threads in said radial plane and the screen, and for discharging the other one of said two phases via said screen openings (11), wherein the screw length of the screw conveyor (5) is determined by the length of the screen within which the screw extends, and wherein the flow surface area increases along the entire screw lenth, seen in the direction of transport.

Owner:玛希斯·艾外瑞达思·安托尼斯

Automatic packaging machine with convenient feeding function

InactiveCN111634454AEasy to useAdding materials saves effortWrapping material feeding apparatusWrapper twisting/gatheringEngineeringMaterial transport

The invention discloses an automatic packaging machine with a convenient feeding function. The automatic packaging machine specifically comprises a bottom plate, spiral conveyors, a shell and a heat-seal slitting mechanism, wherein universal wheels are installed at the four corners of the bottom end of the bottom plate, the shell is installed in the middle of the top end of the bottom plate, the spiral conveyors are arranged on the two sides of the top end of the bottom plate, the bottom ends of the sides, away from the shell, of the spiral conveyors are provided with feeding ports, the middleof the top end of the shell is fixedly provided with an installation frame, and a heat-seal film installation barrel is arranged at the middle of the top end of the installation frame. According to the automatic packaging machine with the convenient feeding function, the spiral conveyors are arranged, so that raw materials are directly added at the lower position; and the spiral conveyors can convey materials into a material conveying barrel inside the shell, so that the use is quite convenient, the materials have no need being manually lifted and poured into a hopper at the top of the packaging machine, and feeding is more labor-saving.

Owner:DONGGUAN KAILEDI NUMERICAL CONTROL SCI & TECH CO LTD

A method for ultra-fine grain rolling of large size 45 steel bars

ActiveCN109807176BInhibition of the Mannesmann effect in the heartReduce the number of repeated rollingTemperature control deviceMetal rolling stand detailsTectonic deformationMachining

The invention discloses an ultrafine grain rolling method of a large-size 45 steel bar, and relates to the field of machining, particularly to the ultrafine grain rolling method of the large-size 45 steel bar. The ultrafine grain rolling method comprises the following steps of design of rolling tools, specifically comprising design of rollers and design of guide plates: setting the rollers as double-curved surface circular table rollers, specifically, forming generatrices of the rollers through connecting two curves, and setting one surfaces of the guide plates as curved surfaces; constructionof a deformation zone: oppositely placing the curved surfaces of the two guide plates, placing the two rollers between the guide plates, and setting a region refined by the two guide plates and the two rollers as the deformation zone; and selection of rolling feeding manner: selecting reverse feeding rolling manner, and constructing an even-ovality deformation zone. According to the ultrafine grain rolling method of the large-size 45 steel bar provided by the invention, the double-curved surface circular table rollers and the curved surface guide plates are designed, the even-ovality deformation zone is constructed, and severe plastic deformation under the precondition of the Mannesmann effect of a central part can be remarkably inhibited.

Owner:安徽东耘智能设备制造有限责任公司

Trailer arm assembly

The invention provides a trailer arm assembly belonging to the technical field of vehicle dragging devices and solving the problem of poor stability of the existing trailer arm. The trailer arm assembly is characterized by comprising a connecting arm, a supporting arm, a main ball head and an auxiliary ball head, wherein the supporting arm is connected with the connecting arm, and a mounting hole is formed in the supporting arm; the main ball head is provided with a cylindrical extension part inserted to the mounting hole; and the auxiliary ball head is provided with a mounting part which is inserted to the extension part and is in threaded connection with the extension part. The trailer arm assembly has the advantages of simple structure, connection firmness and good stability.

Owner:NINGBO YINZHOU LONGTENG TOOL FACTORY

Automobile side plate welding and pressing tool

InactiveCN110524170AImprove stabilityDecrease productivityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringBilateral symmetry

The invention provides an automobile side plate welding and pressing tool. The automobile side plate welding and pressing tool comprises a support, a T-shaped clamping block and a T-shaped clamping groove, the two second connecting blocks distributed in a bilateral symmetry mode are riveted to the top end of the front side of the support through the rivets, and the two first connecting blocks distributed in a bilateral symmetry mode are riveted to the top end of the rear side of the support through the rivets. The inner circumferential surfaces of the two second threaded through holes are eachconnected with a manual screw through a thread, and the manual screws are mounted at the opposite surface parts of the two circular thickening blocks. The left side face and the right side face of the pressing head are each provided with one circular thickening block, so that the screw pitches of the second threaded through holes are increased, and the stability when the pressing head is fastenedthrough the manual screws is improved. The pressing head is provided with the rectangular through hole, so that the distance of the pressing head can be flexibly adjusted on a pressing arm, the working efficiency of adjusting the distance of the pressing head by the workers is reduced, and the labor consumption of the workers is reduced.

Owner:HUBEI ZANBO INFORMATION TECH CO LTD

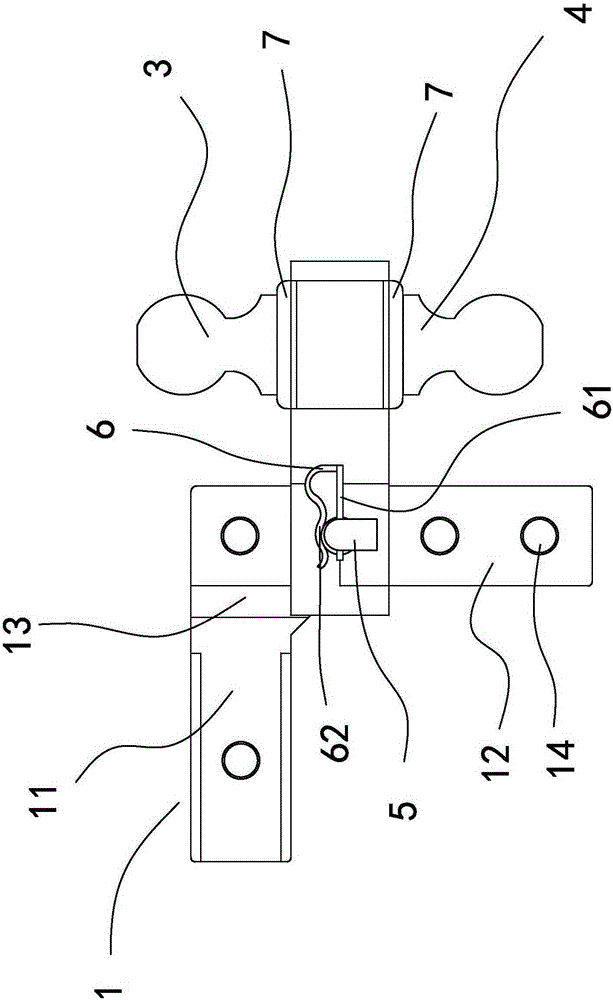

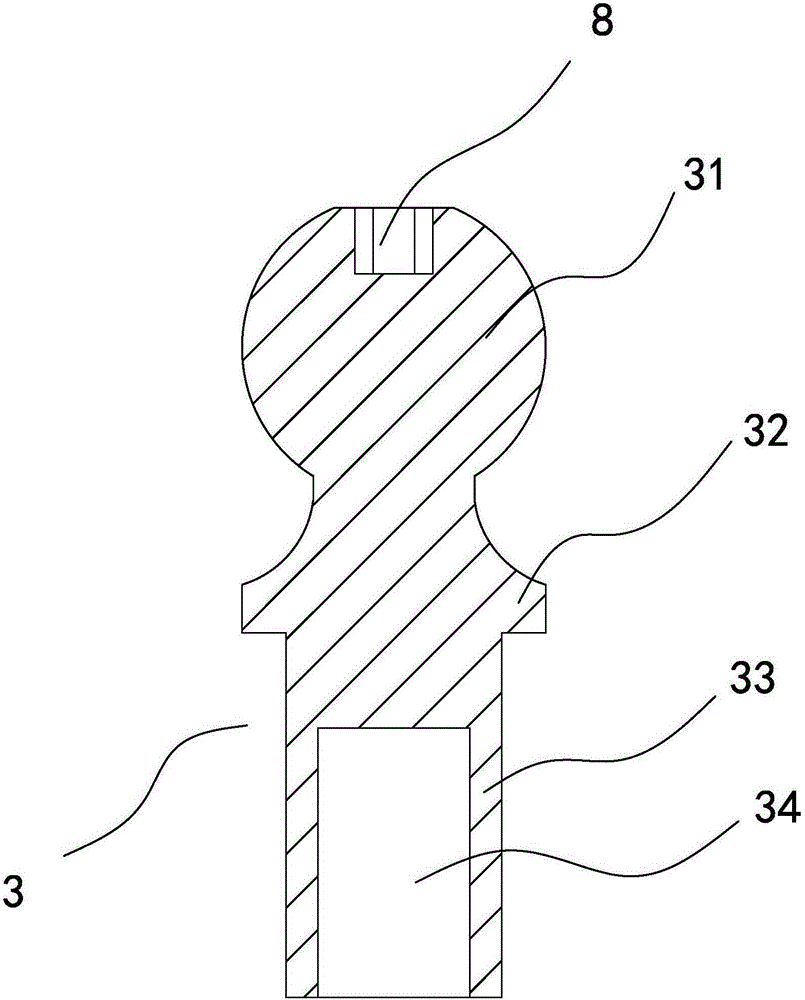

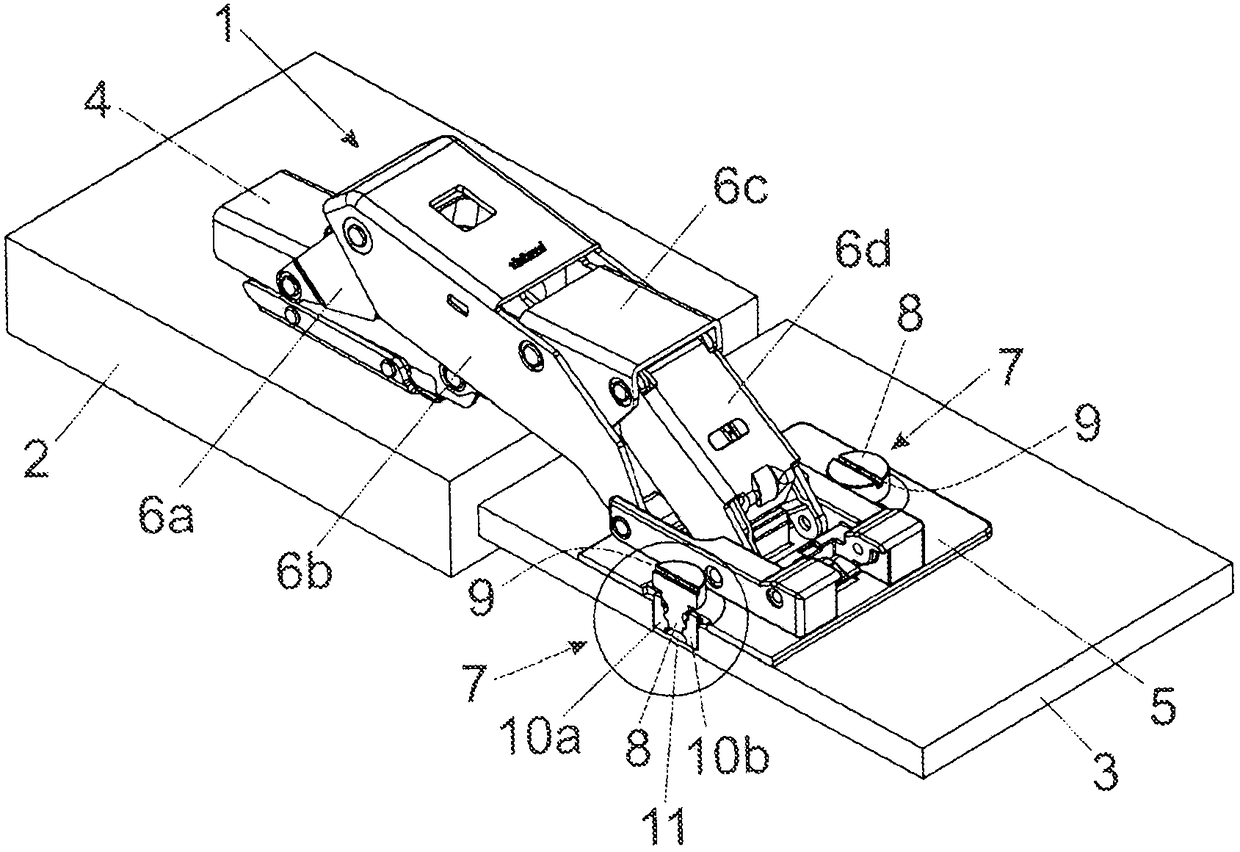

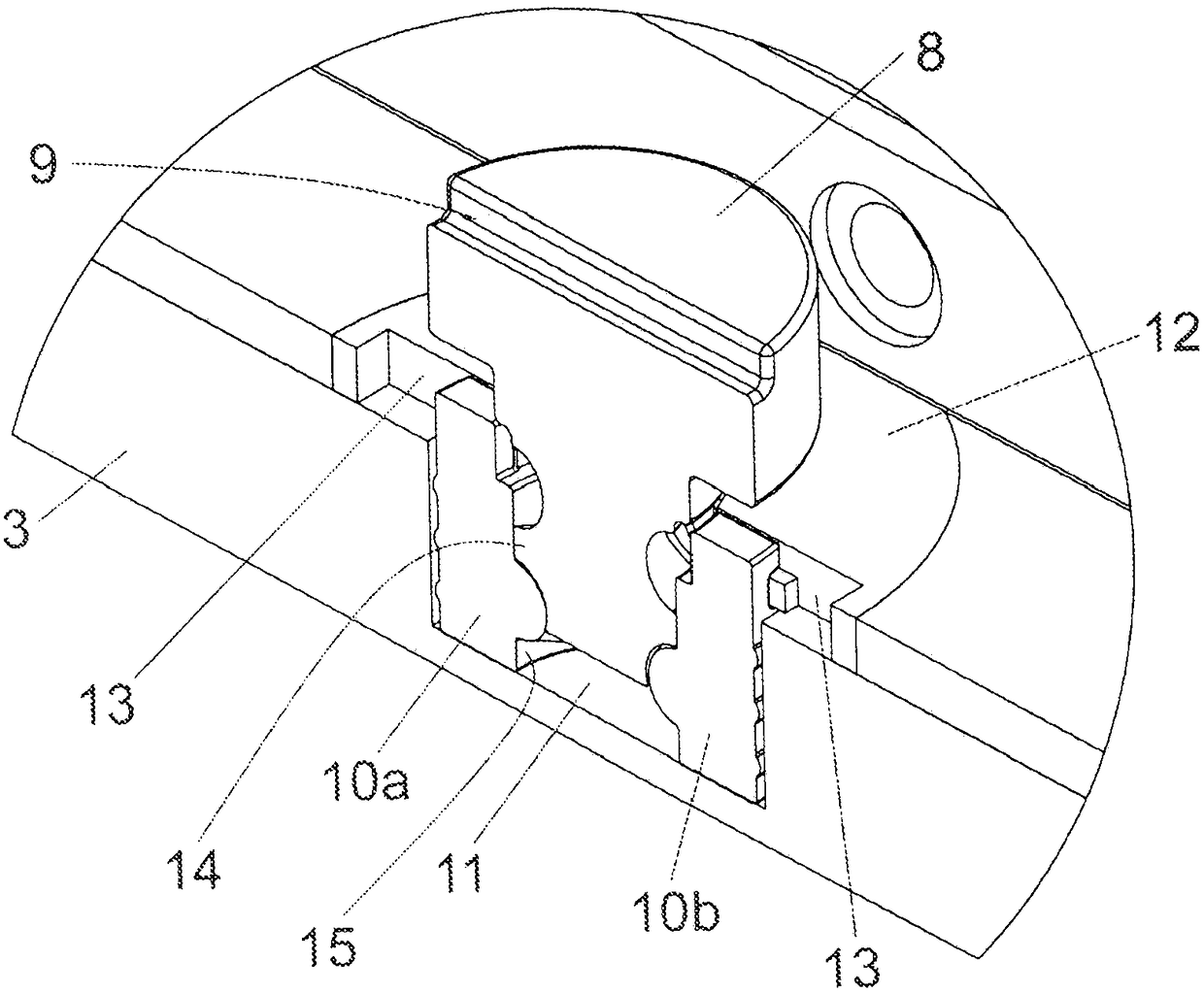

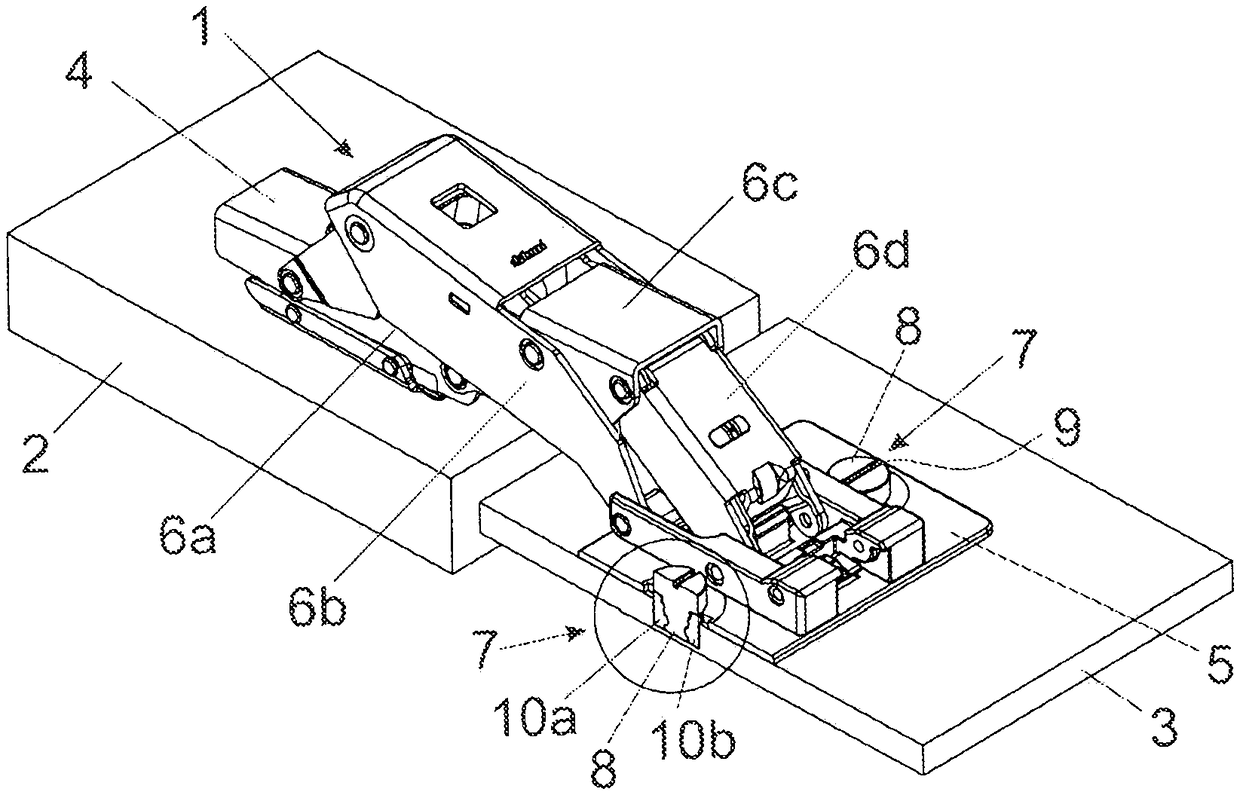

Furniture fitting

The invention relates to a furniture fitting (1) comprising the following: - a flange (12) for contacting a furniture part (3), and - at least one securing device (7) for securing the furniture fitting (1) to the furniture part (3) by means of the flange (12), wherein - the securing device (7) has at least two securing elements (10a, 10b), which can be inserted into an opening (11), in particulara cylindrical bore, of the furniture part (3), and at least one rotatably mounted locking element (8). The at least two securing elements (10a, 10b) can be moved relative to each other and relative tothe flange (12) by rotating the locking element (8) in a first rotational direction starting from a starting position, and the securing elements can thus be pushed into a spreading position in whichthe at least two securing elements (10a, 10b) can be locked in the opening (11) of the furniture part (3). The at least two securing elements (10a, 10b) can be released from the opening (11) by rotating the locking element (8) in a second rotational direction, wherein the at least two securing elements (10a, 10b) are pretensioned in the direction of the starting position by at least one force accumulator (17) such that the at least two securing elements (10a, 10b) can be retracted out of the spreading position into the starting position by rotating the locking element (8) in the second rotational direction.

Owner:JULIUS BLUM GMBH

A method for ultra-fine grain rolling of large-size titanium alloy rods

ActiveCN109807175BInhibition of the Mannesmann effect in the heartReduce the number of repeated rollingTemperature control deviceMetal rolling stand detailsTitanium alloyMachining

The invention discloses an ultra-fine grain rolling method of a large titanium alloy bar and relates to the field of machining, in particular to the ultra-fine grain rolling method of the large titanium alloy bar. The ultra-fine grain rolling method of the large titanium alloy bar comprises the following steps that rolling tools are designed, roller design and guide plate design are included, eachroller is designed into a double-curved face type circular truncated cone roller, and specifically, a bus of each roller is formed by connecting two curves, and one face of each guide plate is designed into a curved face; a deformation zone is configured, wherein the curved faces of the two guide plates are oppositely arranged, the two rollers are arranged between the guide plates, and a regiondefined by the two guide plates and the two rollers is the deformation zone; an equal ovality deformation zone is configured, wherein ovality in the deformation zone is kept unchangeable; and a rolling feeding manner is selected, wherein a backward advancing rolling manner is adopted. According to the ultra-fine grain rolling method of the large titanium alloy bar, by designing the double-curved face type circular truncated cone rollers and the curved face-shaped guide plates and configuring the equal ovality deformation zone, intensive plastic deformation can be generated on the promise of remarkably restraining a Mannesmann effect of the heart.

Owner:安徽东耘智能设备制造有限责任公司

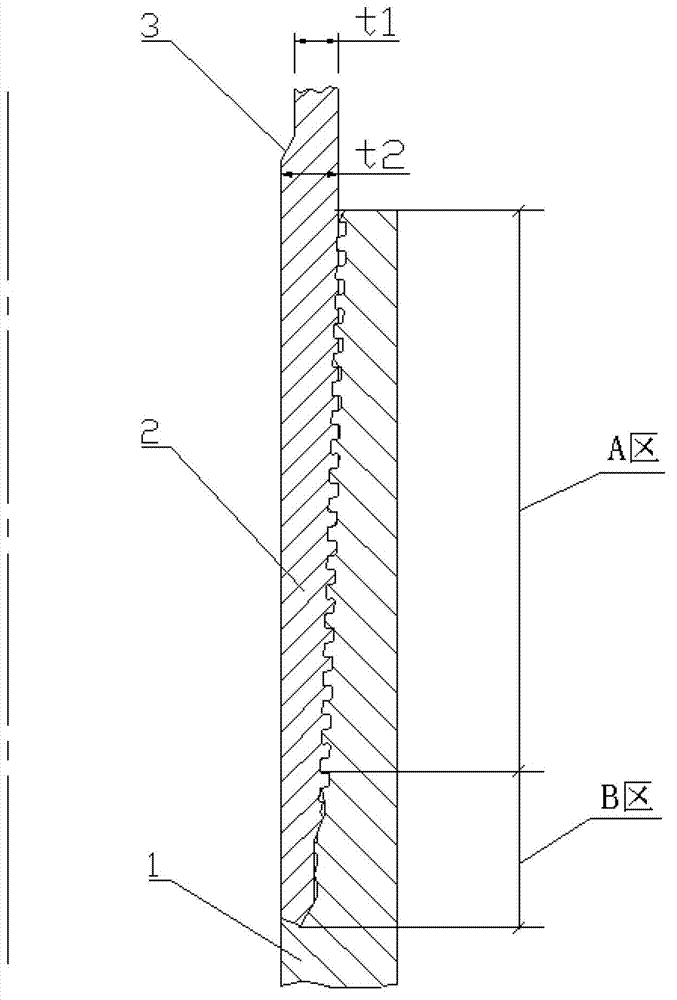

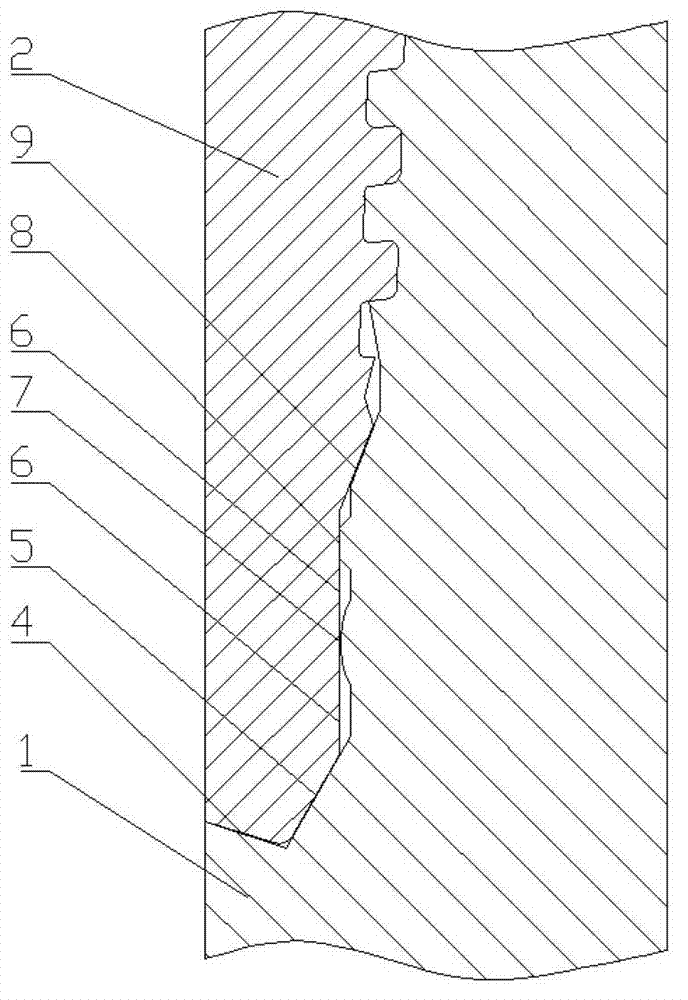

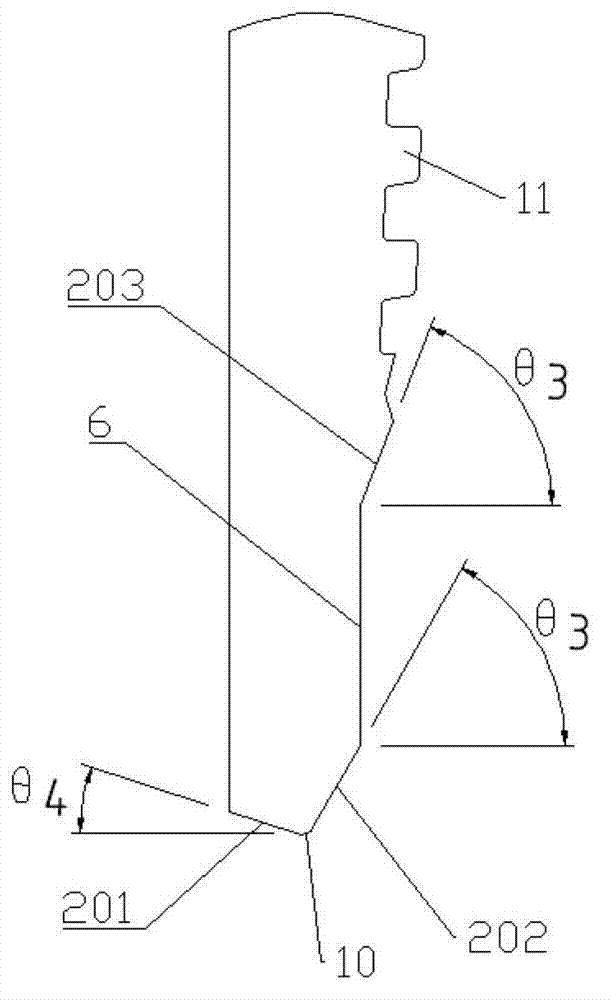

Special screwed joint for gas injection and production of underground gas storage

ActiveCN102829269AImprove safety and reliabilityGuaranteed safety and reliabilityScrew threaded jointsNatural gas storageScrew thread

The invention discloses a special screwed joint for gas injection and production of an underground gas storage, which belongs to the field of natural gas storage and transportation. The special screwed joint comprises an external screwed joint and an internal screwed joint which are assembled together, wherein the assembling parts of the special screwed joint are thread meshing sections and a main sealing section, and the thread meshing section is connected with the main sealing section; the threads of the thread meshing sections of both the external screwed joint and the internal screwed joint are hooked deep toothed threads; and the main sealing section is a multi-seal, and comprises two groups of conical surfaces / conical surface seals, a group of cylindrical surfaces / cylindrical surface seals and a group of cylindrical surfaces / spherical surface seals. With the special screwed joint, the sealing capability of the screwed joint which bears stretching, compressing and bending loads can be improved, and the safety and reliability of the screwed joint during the gas injection and production operations of the underground gas storage are enhanced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Ultrafine grain rolling method of large-size 45 steel bar

ActiveCN109807176AInhibition of the Mannesmann effect in the heartReduce the number of repeated rollingTemperature control deviceMetal rolling stand detailsSteel barLarge size

The invention discloses an ultrafine grain rolling method of a large-size 45 steel bar, and relates to the field of machining, particularly to the ultrafine grain rolling method of the large-size 45 steel bar. The ultrafine grain rolling method comprises the following steps of design of rolling tools, specifically comprising design of rollers and design of guide plates: setting the rollers as double-curved surface circular table rollers, specifically, forming generatrices of the rollers through connecting two curves, and setting one surfaces of the guide plates as curved surfaces; constructionof a deformation zone: oppositely placing the curved surfaces of the two guide plates, placing the two rollers between the guide plates, and setting a region refined by the two guide plates and the two rollers as the deformation zone; and selection of rolling feeding manner: selecting reverse feeding rolling manner, and constructing an even-ovality deformation zone. According to the ultrafine grain rolling method of the large-size 45 steel bar provided by the invention, the double-curved surface circular table rollers and the curved surface guide plates are designed, the even-ovality deformation zone is constructed, and severe plastic deformation under the precondition of the Mannesmann effect of a central part can be remarkably inhibited.

Owner:安徽东耘智能设备制造有限责任公司

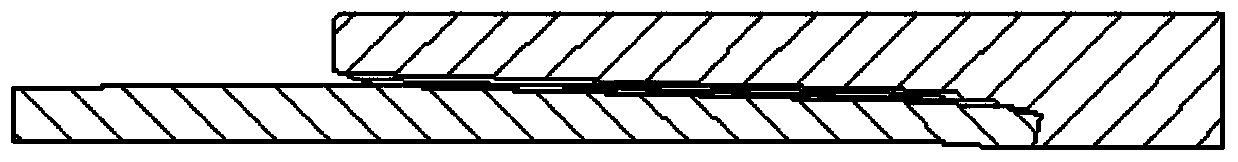

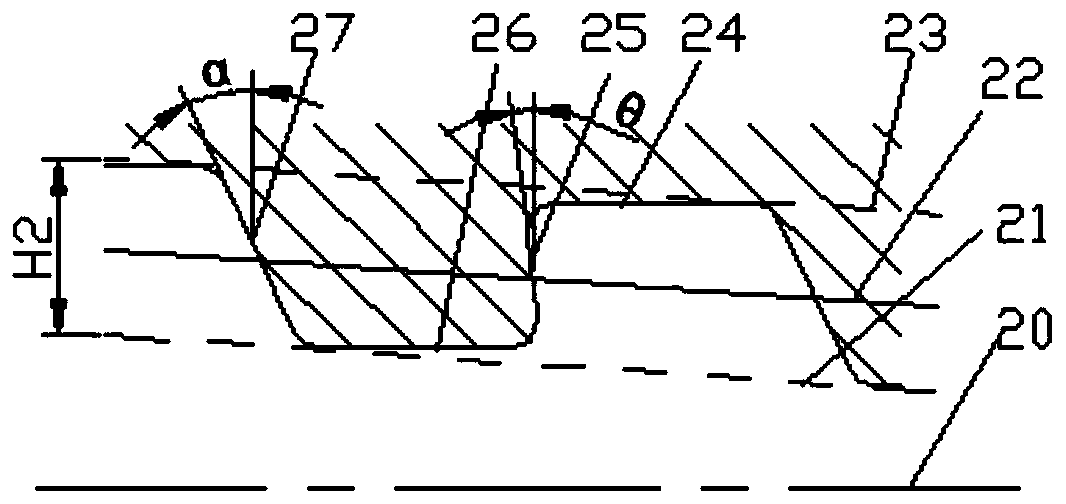

Oil bushing threaded joint

PendingCN110541680AIncrease thread pitchEasy to buckleDrilling rodsDrilling casingsBearing surfacePetroleum engineering

The invention relates to an oil bushing threaded joint which comprises a coupling and a pipe. The oil bushing threaded joint is characterized in that the coupling is provided with an internal taperedthread, an inner sealing tapered surface with a groove and a reverse stopping circular bead; after the end of the pipe is necked down, a necked-down opening is formed, and the pipe is provided with anexternal tapered thread, an external sealing tapered surface and an oblique end face; the internal tapered thread includes an internal tapered thread tooth bottom, an internal tapered thread bearingsurface, an internal tapered thread tooth top and an internal tapered thread guide surface, wherein the internal tapered thread tooth bottom and the internal tapered thread tooth top are both parallelto the coupling axis; and the external tapered thread includes an external tapered thread guide surface, an external tapered thread tooth top, an external tapered thread bearing surface and an external tapered thread tooth bottom, wherein the external tapered thread tooth top and the external tapered thread tooth bottom are both parallel to the pipe axis. The oil bushing threaded joint has the advantages of the good air-sealing performance and the high connection efficiency, and also has the advantages of being strong in anti-twisting ability and less prone to sticking.

Owner:PETROTEX OIL&GAS EQUIP LTD

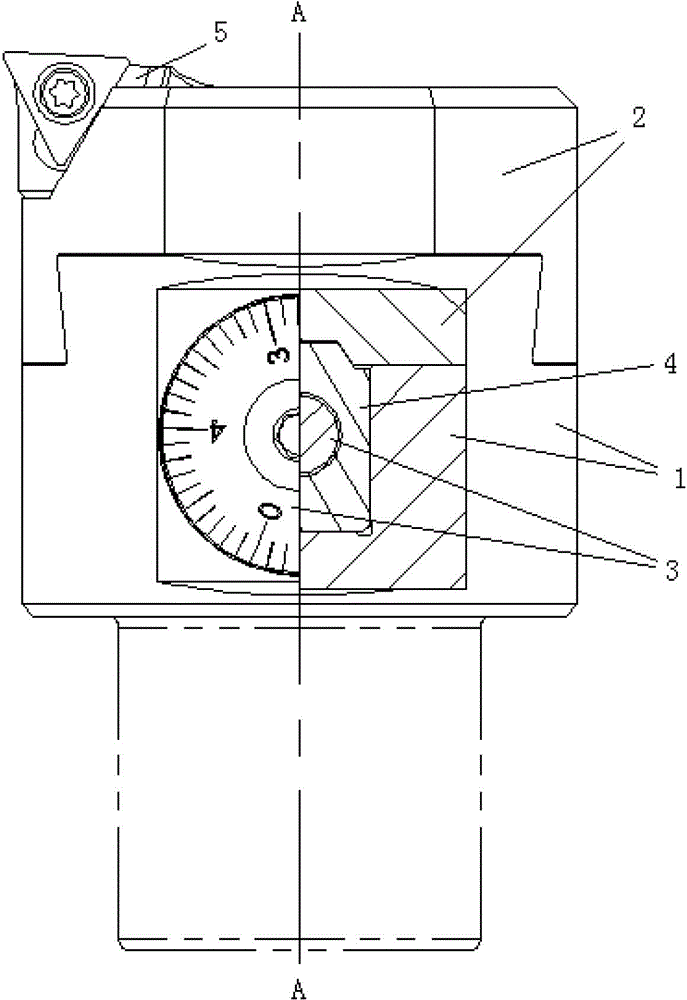

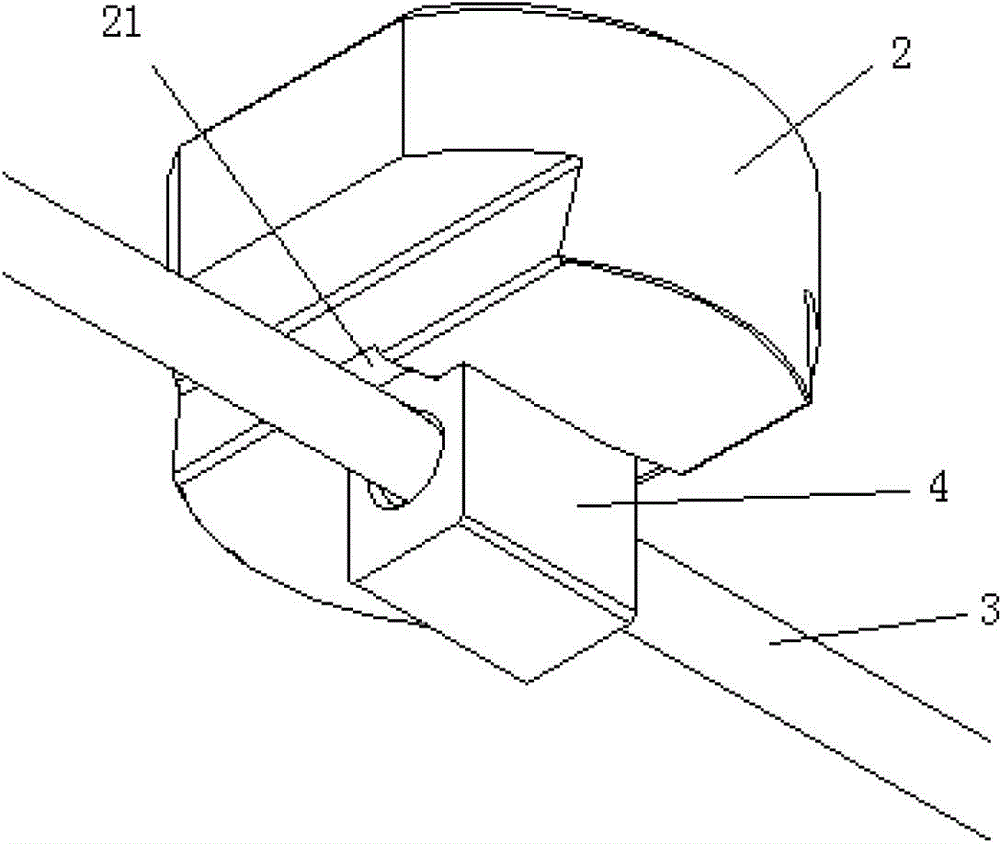

Slant micro-feeding metal cutting tool

The invention provides a slant micro-feeding metal cutting tool, relates to the technical field of metal cutting machining and aims at solving the technical problem of prolonging the service life of a high-precision boring cutter. The cutting tool comprises a tool handle and a tool apron; a slider and a fine adjusting screw are arranged on the tool handle; the slider is mounted on the upper end of the tool handle clamping groove matching and sliding manners, and the sliding axis of the slider is perpendicular to the axis of the tool handle; a fine adjusting groove is formed in the bottom surface of the slider; the fine adjusting groove is a straight groove perpendicular to the axis of the tool handle and inclined to the sliding axis of the slider; the tool apron is mounted on the slider; the fine adjusting screw is rotatably mounted on the tool handle; the rotating axis of the fine adjusting screw is perpendicular to the axis of the handle and perpendicular to the sliding axis of the slider; a fine adjusting nut matched with the threads of the fine adjusting screw sleeves the fine adjusting screw; the top end of the fine adjusting nut is embedded into the fine adjusting groove in the bottom surface of the slider in a clearance fit manner. The cutting tool is high in adjustment precision and long in service life.

Owner:松德刀具(长兴)科技有限公司

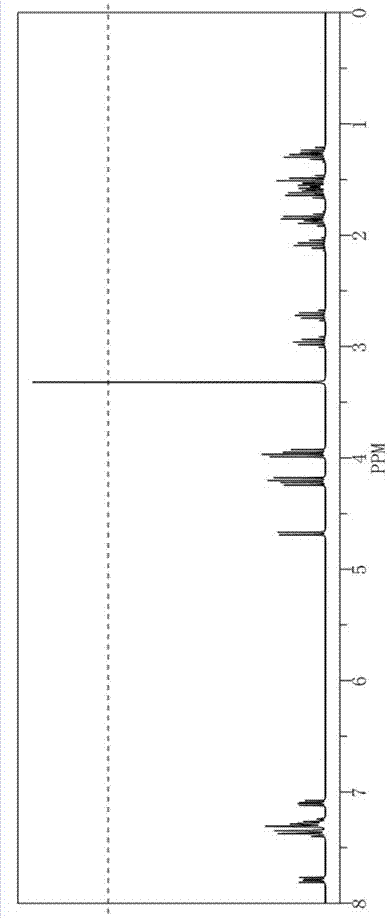

Cyclohexane oxane liquid crystal monomer compound and preparation method thereof

ActiveCN107573948AChange phase transition temperaturePhase transition temperature wideLiquid crystal compositionsOrganic chemistryCrystallographyRotational viscosity

The invention provides a cyclohexane oxane liquid crystal monomer compound and a preparation method of the cyclohexane oxane liquid crystal monomer compound. The structural formula of the compound isshown in the following formula, wherein R is any one of fluorine, chlorine, H, cyano, C1-C5 linear chain alkyl and C1-C5 linear alkoxy. The cyclohexane oxane liquid crystal monomer compound provided by the invention contains sulfonyl laterally and can change the phase transition temperature of molecules, the prepared monomer mixture not only has the advantage of low viscosity, but also has the characteristics of wide phase transition temperature and long screw pitch, and can be taken as raw materials of liquid crystal materials, thereby being beneficial to lowering the rotational viscosity ofthe liquid crystal materials and improving various dielectric coefficients.

Owner:SHAANXI LIGHTE OPTOELECTRONICS MATERIAL CO LTD

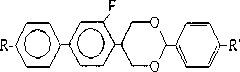

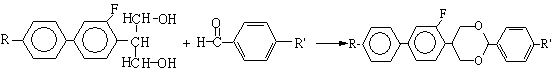

Liquid crystal monomer fluorine dioxane contained compound and synthesis method thereof

ActiveCN102827140AThe synthetic route is simpleLarge pitchOrganic chemistryLiquid-crystal displaySynthesis methods

The invention discloses a liquid crystal monomer fluorine dioxane contained compound and a production method thereof. The structure of the compound is: FORMULA, wherein in the formula, R is one of fluorine, chlorine, H, linear alkyl of C1-C5, and linear alkyl of C1-C5; R' is one of fluorine, chlorine, H, linear alkyl of C1-C5, linear alkyl alkoxy of C1-C5, and cyan; R is the same as R' or different from R'; and the compound can be independently or mixed for liquid crystal display in various display forms. The compound and the method provided by the invention has he characteristics of liquid crystal display, meeting the requirement of 3D (three-dimensional) display technology, reducing the rotary viscosity of liquid crystal material and improving the liquid crystal material.

Owner:山东盛华电子新材料有限公司

Guide device for rolling over the barrel wall of oil barrel

ActiveCN106925685BReduce manufacturing costReduce scrap rateMetal-working feeding devicesPositioning devicesManufacturing cost reductionEngineering

The invention discloses a guide device being convenient to the roll barrel wall of a petrol barrel. The guide device comprises a bottom plate, baffles, a fixing block and screws I, wherein the quantity of the baffles is two, and the baffles are parallel to each other and located on the upper surface of the bottom plate; the fixing block is arranged between the two baffles, and one end of the fixing block is connected, near the bottom plate, with the bottom plate; and the quantity of the screws I is two, one screw I penetrates through one baffle vertically and then is connected with the fixing block in a rotating mode, the other screw I penetrates through the other baffle vertically and then is connected with the fixing block in a rotating mode, all of the screws I can rotate around axes of the screws I, and the screws I can drive the corresponding baffles to move. One side of a steel plate contacts with the plate surface of one baffle in parallel, and the other side of the steel plate contacts with the other baffle in parallel. A rotating screw I makes the baffles to produce a certain top tightening force for both sides of the steel plate, so that the axis of the steel plate parallels to the direction of forward motion, a cylindrical rolling plate which the end surface is not perpendicular to the axis is avoided to be bended out, and the manufacturing costs and the rejection rate are reduced.

Owner:CHENGDU ZHIRONG ZHICHUANG INTPROP MANAGEMENT CO LTD

A method for ultra-fine grain rolling of large-size aluminum alloy rods with reverse-cone helical rolls

ActiveCN109772891BReduce the number of repeated rollingReduce tensile stressRollsMetal rolling arrangementsMachiningFine grain

The invention relates to a reverse cone spiral roller ultra-fine grain rolling method of a large-size aluminum alloy bar, and relates to the field of mechanical processing. The method includes the following steps that a rolling tool is designed, wherein roll design and guide plate design are specifically included, and rollers are arranged to be double curved surface type circular-table-shaped spiral rollers; a deformation zone is constructed, wherein the curved surfaces of two guide plates are oppositely arranged, the two rollers are placed between the guide plates, and an area defined by thetwo guide plates and the two rollers is the deformation zone; an equal-ovality deformation zone is constructed, wherein the ovality in the deformation zone remains unchanged; and a rolling feeding mode is selected, wherein a reverse rolling mode is adopted. According to the reverse cone spiral roller ultra-fine grain rolling method of the large-size aluminum alloy bar, the double curved surface type circular-table-shaped spiral rollers and the curved surface guide plates are designed, the equal-ovality deformation zone is constructed, and acute plastic deformation is generated on the premise that the heart Mannesmann effect is significantly suppressed.

Owner:安徽汉正轴承科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com