Device for separating substance into two phases

A technology of materials and conveyors, applied in the field of devices where materials are separated into two phases, can solve problems such as inapplicability, and achieve the effect of increasing the flow surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

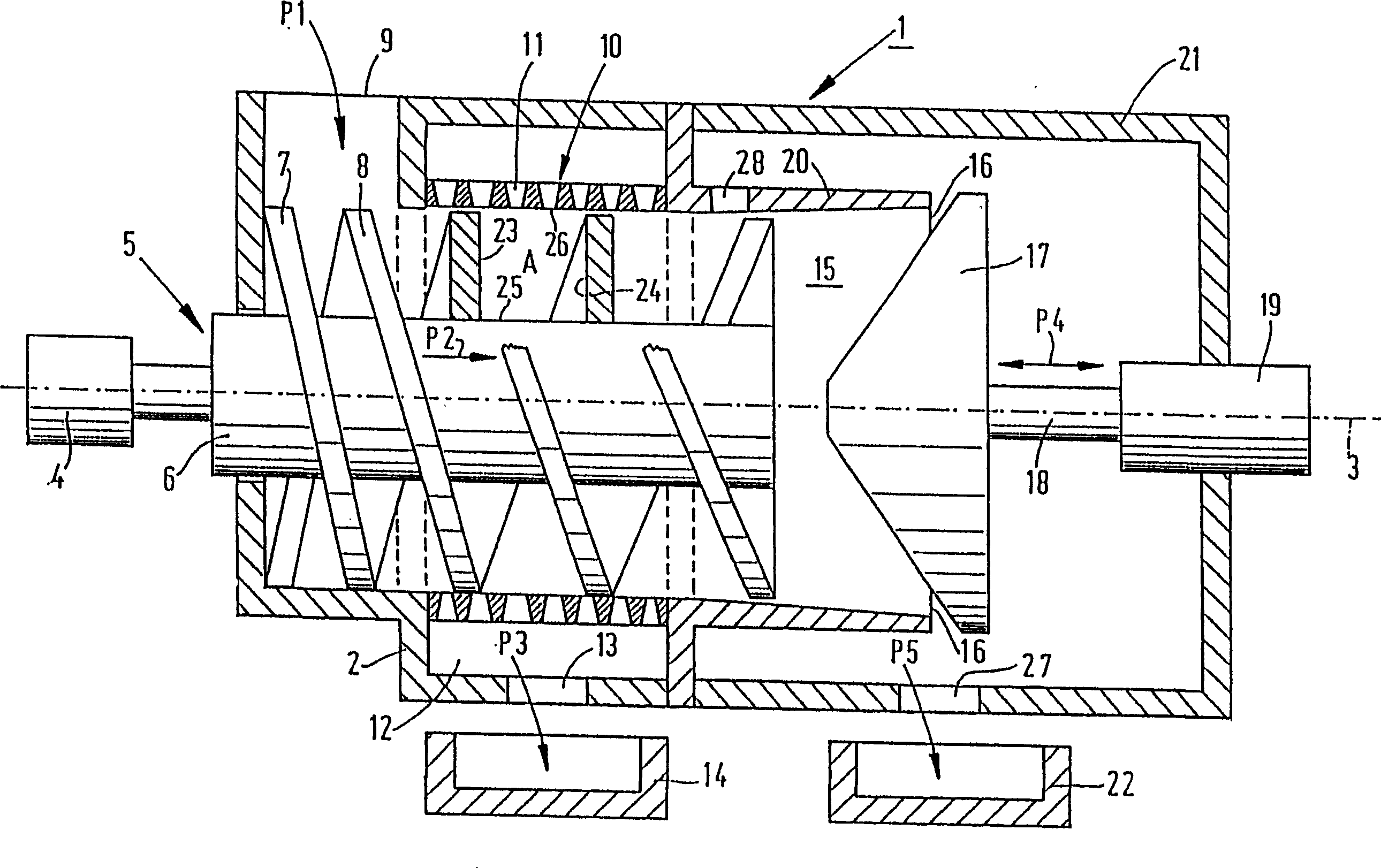

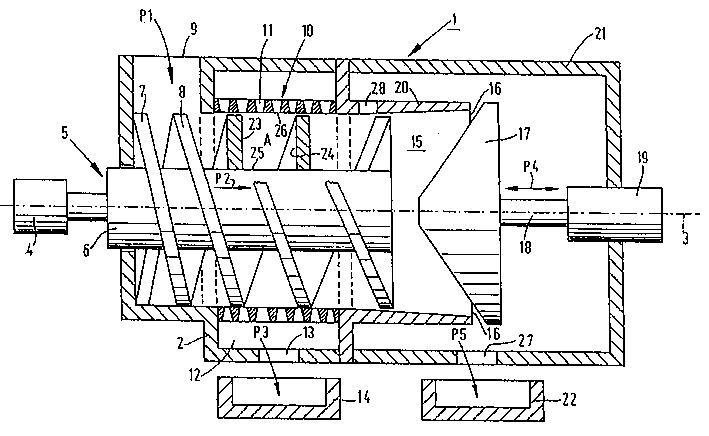

[0023] The separation device 1 according to the invention comprises a chamber 2 . The cavity 2 is shown as a whole in the figure, however in actual application the cavity 2 is composed of many interconnected parts. In the cavity 2 is provided a screw conveyor 5, which can be rotated around the axis 3 by the drive device 4. Aligned helices 7 and 8, the pitch of which increases in the conveying direction P2. On the cavity 2, there is an input port 9 for supplying materials to be separated by the screw conveyor 5 in the direction shown by the arrow P1. The rotation of the screws 7 and 8 will convey the material in the conveying direction P2. The central portion of the screw conveyor 5 in the length direction is surrounded by a cylindrical screen 10 . There are sieve holes in the circumferential direction of the cylindrical sieve 10 for passing the first phase in the material to be separated. In the present invention, the term screw length is used to represent the length of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com