Cyclohexane oxane liquid crystal monomer compound and preparation method thereof

A technology of cyclohexaneoxane and liquid crystal monomer is applied in the field of cyclohexaneoxane liquid crystal monomer compound and its preparation, which can solve the problem that the dielectric anisotropy coefficient cannot independently satisfy the liquid crystal display, etc. Effects of electrical coefficients, pitch length, and phase transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

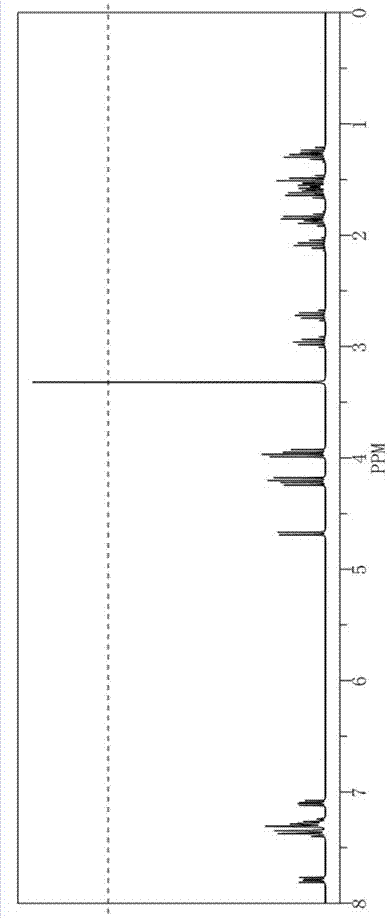

Image

Examples

Embodiment 1

[0042] Preparation of Grignard reagents:

[0043] Weigh 100mL tetrahydrofuran, 24g magnesium powder, 0.3g iodine, 3.9g 2-bromo-4,5-difluoro-benzyl sulfide, stir, let stand at 20-25°C for 30min, then add 0.33g / mL of 2-bromo-4,5-difluoro-benzyl sulfide in tetrahydrofuran 60mL, reflux reaction at 66°C for 1h, the Grignard reagent can be generated, the structural formula is: .

[0044] Wherein, the structural formula of 2-bromo-4,5-difluoro-benzyl sulfide is:

[0045] .

[0046] During the implementation, just weigh tetrahydrofuran, magnesium powder, iodine, 2-bromo-4,5-difluoro-benzyl sulfide, tetrahydrofuran and 2 The volume ratio of bromo-4,5-difluoro-benzyl sulfide in tetrahydrofuran is 5:3, and the Grignard reagent can be prepared by the above method.

Embodiment 2

[0048] 1. a cyclohexane oxane liquid crystal monomer compound, the structural formula of the compound is:

[0049] ,

[0050] Wherein, R is H, and the structural formula of the cyclohexane-based liquid crystal monomer compound is:

[0051] , is compound V1.

[0052] 2. The preparation method of the cyclohexane oxane liquid crystal monomer compound comprises the following steps:

[0053] (1) Weigh 150mL of the Grignard reagent prepared in Example 1 and 50mL of a THF solution of 4-(5-phenyl-1,3-oxanyl-2-yl)cyclohexanone with a concentration of 0.52g / mL , reflux at 66°C for 2 hours to obtain intermediate 1 with a conversion rate of 73.3%, a yield of 57.2%, and a purity of 97% by HPLC;

[0054] (2) Weigh 250mL of dichloroethane, 40g of intermediate 1, 20g of p-toluenesulfonic acid, 20mL of 30% hydrogen peroxide, and react at 75°C for 8 hours to obtain intermediate 2 with a conversion rate of 73.3% and a yield of 62.1 %, purity HPLC=98%;

[0055] (3) Weigh 250mL of dichlor...

Embodiment 3

[0072] 1. a cyclohexane oxane liquid crystal monomer compound, the structural formula of the compound is:

[0073] ,

[0074] Wherein, R is fluorine, and the structural formula of the cyclohexane-based liquid crystal monomer compound is:

[0075] , is compound V3.

[0076] 2. The preparation method of the cyclohexane oxane liquid crystal monomer compound comprises the following steps:

[0077] (1) Weigh 180 mL of the Grignard reagent prepared in Example 1, 50 mL of 4-(5-(4-fluorophenyl)-1,3-oxanyl-2-yl) ring with a concentration of 0.52 g / mL The THF solution of hexanone was refluxed at 60°C for 2 hours to obtain intermediate 1, the purity of which was detected by high performance liquid chromatography was 97%;

[0078] (2) Weigh 240mL of dichloroethane, 40g of intermediate 1, 30g of p-toluenesulfonic acid, 20mL of 30% hydrogen peroxide, and react at 70°C for 8 hours to obtain intermediate 2 with a purity of HPLC=99%;

[0079] (3) Weigh 250mL of dichloroethane, 40g of i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com