Magnetic memory alloy with long function life and preparation method thereof

A memory alloy and high-function technology, applied in the field of shape memory alloys, can solve problems such as hindering the application and promotion of actuators, magneto-strain function decline, actuator function decline, etc., to broaden the scope of industrial applications, excellent mechanical properties, The effect of high functional life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

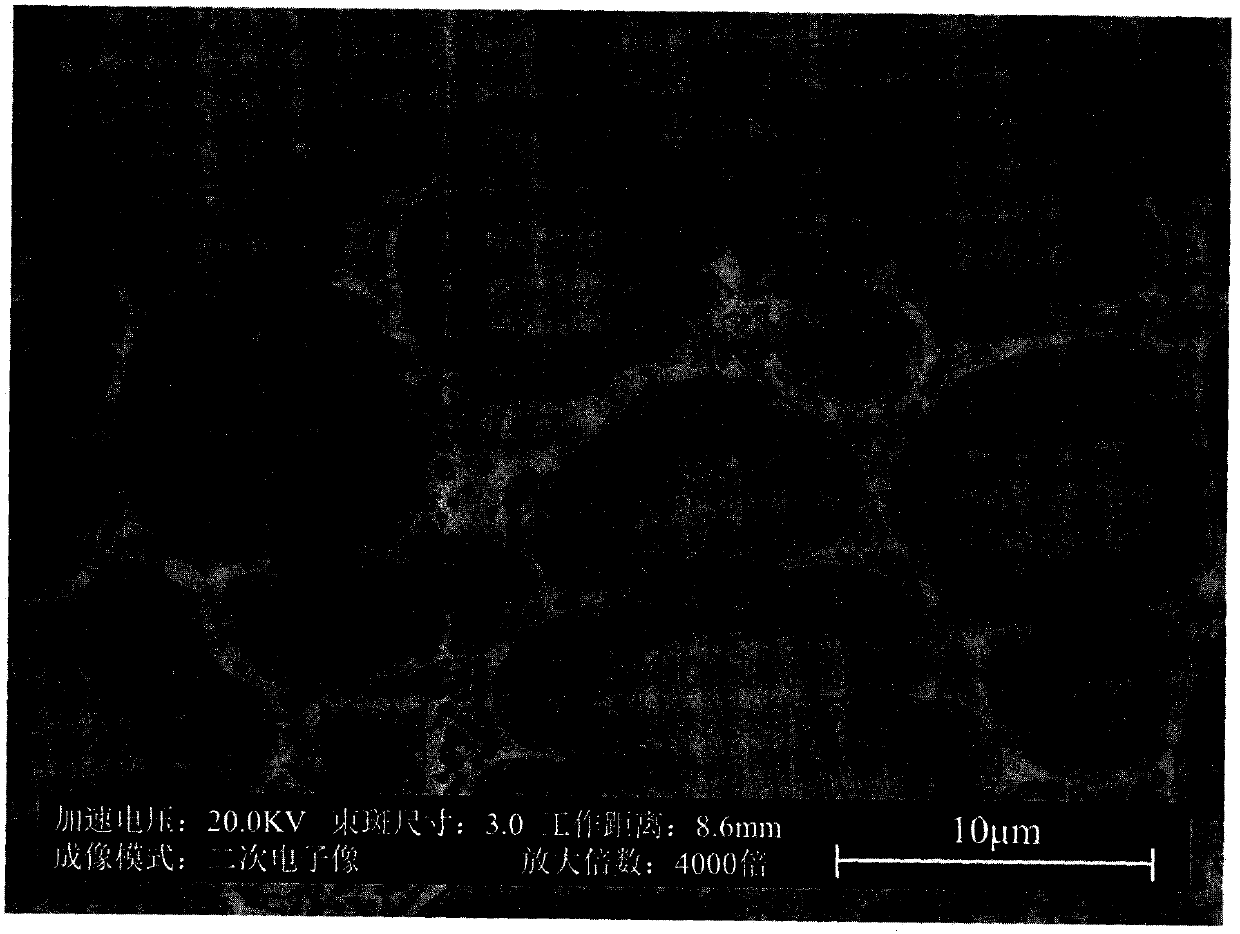

Image

Examples

Embodiment 1

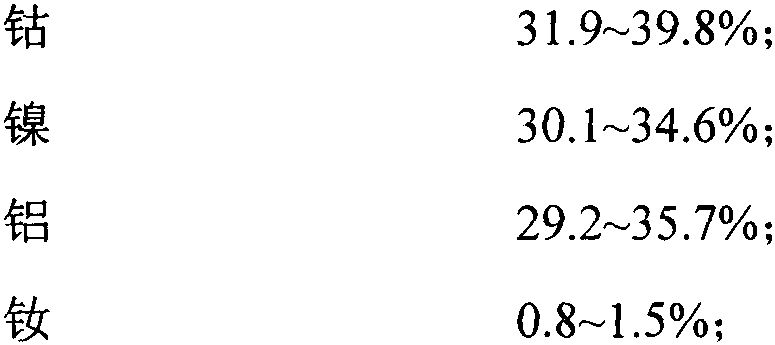

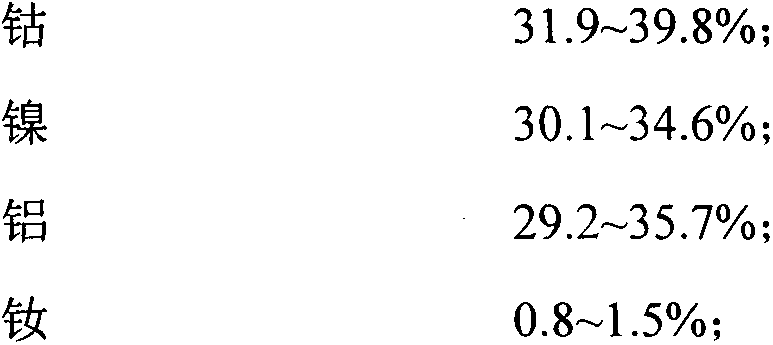

[0026] Prepare 900g composition as Co 35.6 Ni 33.2 al 30.4 Nd 0.8 The low fatigue magnetic memory alloy, its preparation method is as follows:

[0027] S1. Ingredients: Weigh Co, Ni, Al, Nd with a purity of 99.99% respectively;

[0028] S2. Melting: Put the prepared raw materials in a crucible for vacuum melting, the melting conditions are: a.5×10 -2 The low vacuum state of MPa; b. the smelting temperature is 1550 ℃; c. the smelting process adopts magnetic stirring; d. the smelting time is 330s (according to the formula t=K×(M -1 / 2 ) to obtain, where the element coefficient K is 11s g -1 / 2 , M is 900g);

[0029] S3. Magnetic field heat treatment: The alloy ingot obtained by the above vacuum smelting is subjected to vacuum magnetic field heat treatment, the treatment conditions are: temperature 630°C; time: 15 hours; vacuum degree: 5×10 -2 MPa; Applied magnetic field strength: 1×10 5 A·m-1 ; Magnetic field rise rate: 600A·m -1 ·s -1 ;

[0030] S4. Cooling; then cooli...

Embodiment 2

[0033] Prepare 800g composition as Co 39.8 Ni 30.1 Al 29.2 Nd 0.9 The low fatigue magnetic memory alloy, its preparation method is as follows:

[0034] S1. Ingredients: Weigh Co, Ni, Al, Nd with a purity of 99.99% respectively;

[0035] S2. Melting: Put the prepared raw materials in a crucible for vacuum melting, and the melting conditions are: a.6×10 -2 The low vacuum state of MPa; b. the smelting temperature is 1570 ℃; c. the smelting process adopts magnetic stirring; d. the smelting time is 339s (according to the formula t=K×(M -1 / 2 ) to obtain, where the element coefficient K is 12s g -1 / 2 , M is 800g);

[0036] S3. Magnetic field heat treatment: The alloy ingot obtained by the above-mentioned vacuum smelting is subjected to vacuum magnetic field heat treatment, and the treatment conditions are: temperature 640°C; time: 14 hours; vacuum degree: 6×10 -2 MPa; Applied magnetic field strength: 5×10 5 A·m -1 ; Magnetic field rise rate: 600A·m -1 ·s -1 ;

[0037] S4....

Embodiment 3

[0040] Prepare 700g composition as Co 31.9 Ni 31.3 Al 35.7 Nd 1.1 The low fatigue magnetic memory alloy, its preparation method is as follows:

[0041] S1. Ingredients: Weigh Co, Ni, Al, Nd with a purity of 99.99% respectively;

[0042] S2. Melting: Put the prepared raw materials in a crucible for vacuum melting, and the melting conditions are: a.7×10 -2 The low vacuum state of MPa; b. the smelting temperature is 1580 ℃; c. the smelting process adopts magnetic stirring; d. the smelting time is 344s (according to the formula t=K×(M -1 / 2 ) to obtain, where the element coefficient K is 13s g -1 / 2 , M is 700g);

[0043] S3. Magnetic field heat treatment: The alloy ingot obtained by the above-mentioned vacuum smelting is subjected to vacuum magnetic field heat treatment, and the treatment conditions are: temperature 650°C; time: 13 hours; vacuum degree: 7×10 -2 MPa; Applied magnetic field strength: 1×10 6 A·m -1 ; Magnetic field rise rate: 600A·m -1 ·s -1 ;

[0044] S4....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com