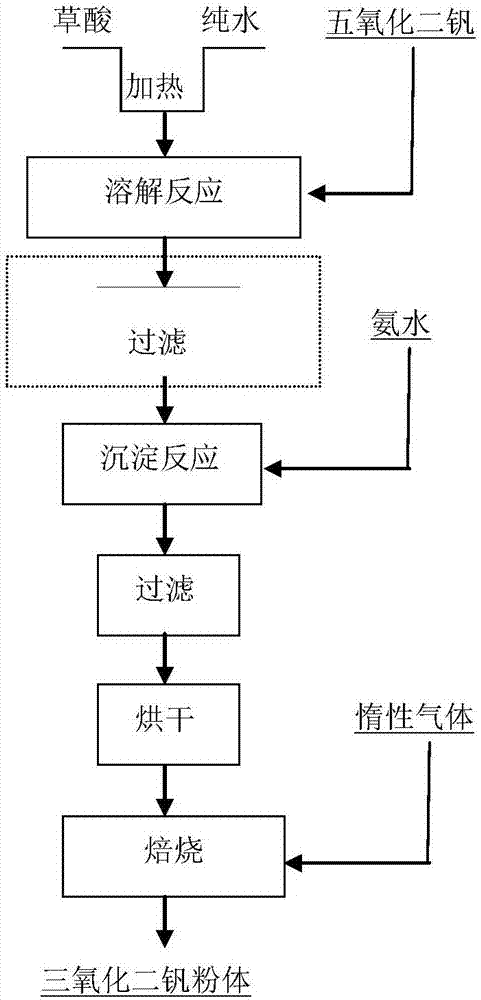

A kind of preparation method of submicron vanadium trioxide powder

A vanadium trioxide, sub-micron technology, applied in the direction of vanadium oxide, etc., can solve the problems of high requirements for reaction equipment and operation control, coarse powder particles, and difficulty in obtaining precursors, etc. The effect of high purity and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

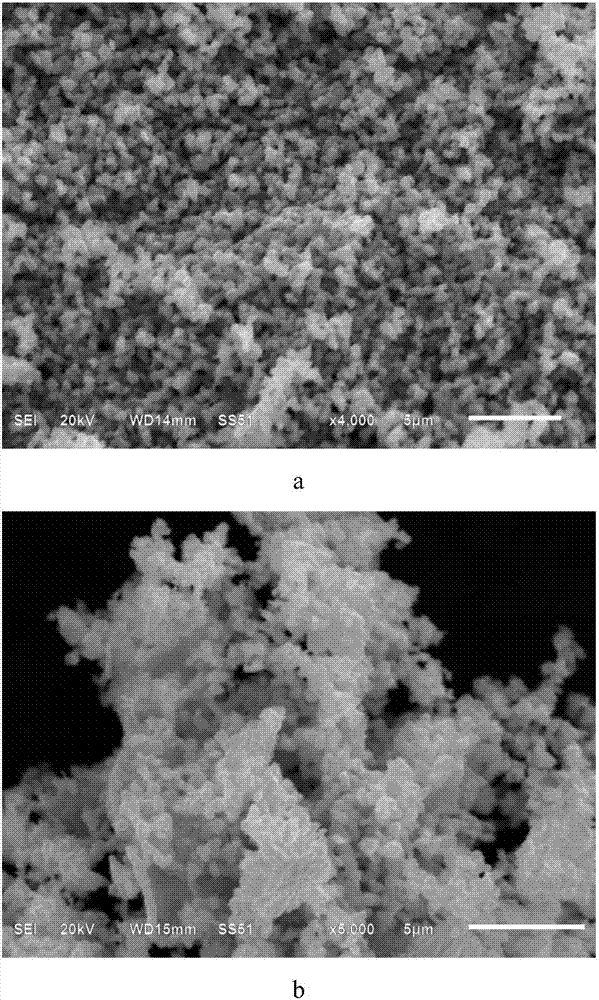

[0029] Use analytically pure oxalic acid and deionized water to prepare 1L of 5mol / L oxalic acid solution, heat it to 70°C, add 100g of vanadium pentoxide powder (purity 4N), stir and react to dissolve it completely; filter the solution after cooling to remove insoluble Impurities; 10wt% ammonia water was added to the filtrate to produce precipitation until pH = 8-9; the precipitate was filtered and dried in an oven at 100°C for 36h, and the obtained highly active precursor was roasted at 800°C for 1h in an argon atmosphere. Cool down to room temperature under an argon atmosphere to obtain a black vanadium trioxide powder product, the particles are spherical, uniform in size, and the particle size is less than 1 μm, at the submicron level. The purity of the product analyzed by ICP-AES was greater than 99.8%.

Embodiment 2

[0031] Use chemically pure oxalic acid and deionized water to prepare 1L of 8mol / L oxalic acid solution, heat it to 80°C, add 200g of vanadium pentoxide powder (purity 4N), stir and react to dissolve it completely; filter the solution after cooling to remove insoluble Impurities; 15wt% ammonia water was added to the filtrate to precipitate to about pH=9; the precipitate was filtered and dried in an oven at 120°C for 48h, and the obtained precursor was roasted at 900°C for 1.5h in an argon atmosphere, Cool down to room temperature to obtain a black vanadium trioxide powder product, the particles are spherical, uniform in size, and the particle size is less than 1 μm, at the submicron level. The purity of the product analyzed by ICP-AES is greater than 99.5%.

Embodiment 3

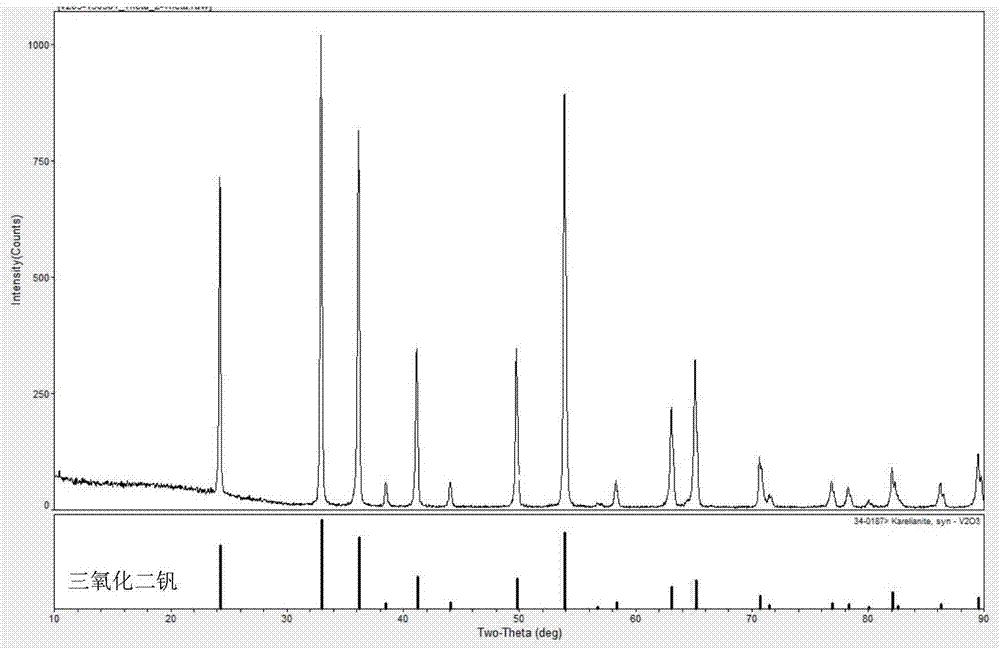

[0033] Prepare 2L of 10mol / L oxalic acid solution with high-grade pure oxalic acid and deionized water, heat to 90°C, add 400g of vanadium pentoxide powder (purity 4N), stir and react to dissolve it completely; filter the solution after cooling, remove Insoluble impurities; 20wt% ammonia water was added to the filtrate to precipitate to about pH=10; the precipitate was filtered and dried in an oven at 120°C for 72h, and the obtained precursor was roasted at 950°C for 2h in an argon atmosphere. Lower the temperature and cool to room temperature to obtain a black vanadium trioxide powder product. The purity of the product analyzed by ICP-AES is greater than 99.9%. The XRD spectrum of the powder is as follows figure 2 As shown, the diffraction peaks are sharp and there are no impurity peaks. The scanning electron microscope photograph of the powder is as image 3 As shown, the particles are spherical, uniform in size, and the particle size is less than 1 μm, at the submicron ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com