Low-fatigue magnetic memory alloy and preparation method thereof

A memory alloy and magnetic technology, applied in the field of shape memory alloy, can solve the problems of short functional life, low frequency of use of industrial drives, etc., and achieve the effects of enhanced fatigue life, long fatigue life, and large magnetically induced strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

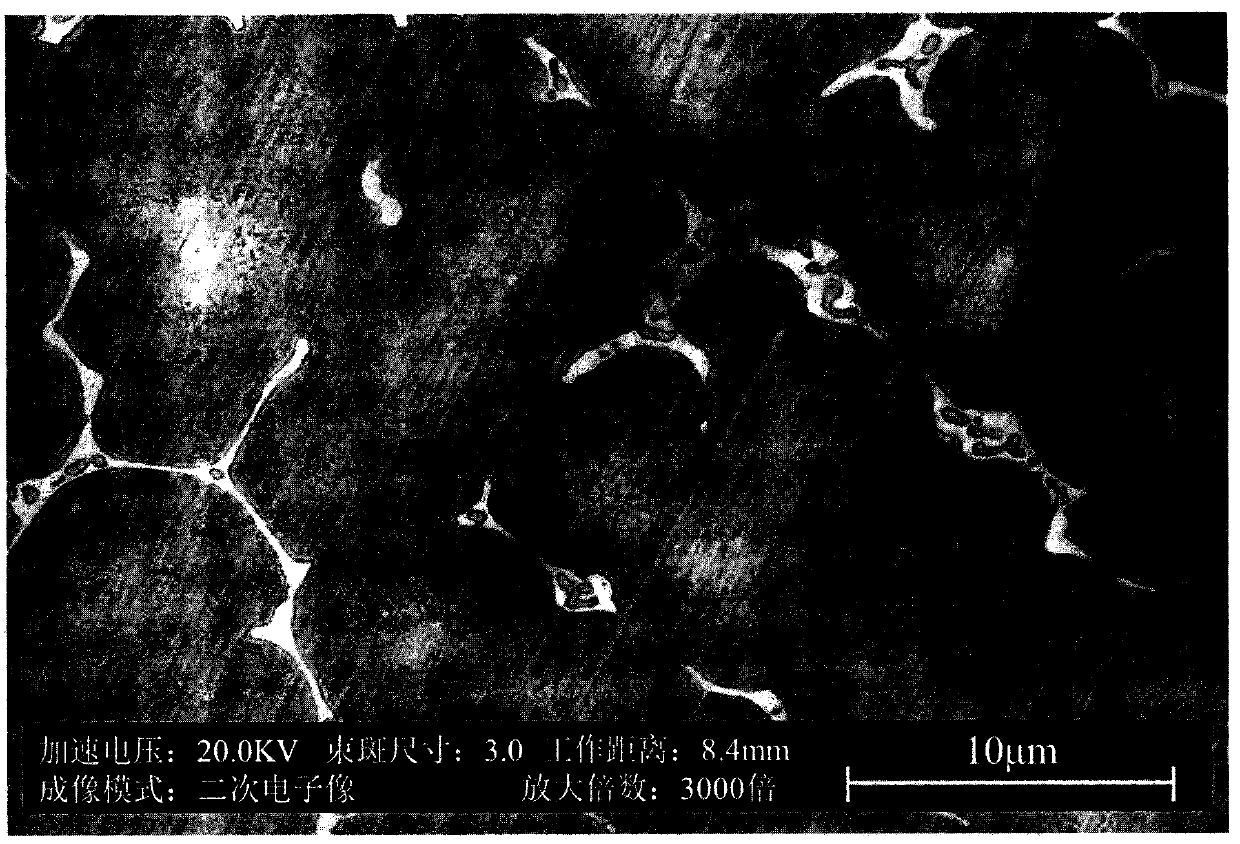

Image

Examples

Embodiment 1

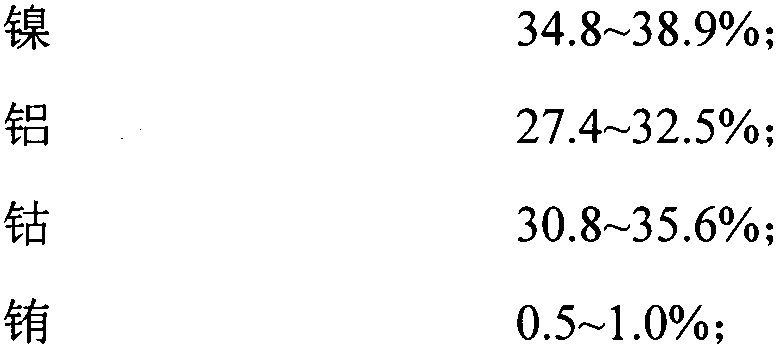

[0027] Prepare 400g composition as Ni 36.2 al 32.1 co 31.2 Eu 0.5 The low fatigue magnetic memory alloy, its preparation method is as follows:

[0028] S1. Ingredients: Weigh Ni, Al, Co, Lu with a purity of 99.99% respectively;

[0029] S2. Melting: Put the prepared raw materials in a crucible for vacuum melting, the melting conditions are: a.1×10 -3 The low vacuum state of MPa; b. melting temperature is 1600 ℃; c. melting process adopts magnetic stirring; d. melting time is 180s (according to formula t=K×(M -1 / 2 ) to obtain, where the element coefficient K is 9s g -1 / 2 , M is 400g);

[0030] S3. Magnetic field heat treatment: The alloy ingot obtained by the above vacuum smelting is subjected to vacuum magnetic field heat treatment, the treatment conditions are: temperature 710°C; time: 12 hours; vacuum degree: 1×10 -3 MPa; Applied magnetic field strength: 5×10 6 A·m-1 ; Magnetic field rise rate: 1000A m -1 ·s -1 ;

[0031] S4. Cooling: followed by furnace cooling, ...

Embodiment 2

[0034] Prepare 500g composition as Ni 38.9 al 27.4 co 33.i Eu 0.6 The low fatigue magnetic memory alloy, its preparation method is as follows:

[0035] S1. Ingredients: Weigh Ni, Al, Co, Lu with a purity of 99.99% respectively;

[0036] S2. Melting: Put the prepared raw materials in a crucible for vacuum melting, the melting conditions are: a.2×10 -3 The low vacuum state of MPa; b. melting temperature is 1610 ℃; c. melting process adopts magnetic stirring; d. melting time is 190s (according to formula t=K×(M -1 / 2 ) to obtain, where the element coefficient K is 8.5s g -1 / 2 , M is 500g);

[0037] S3. Magnetic field heat treatment: The alloy ingot obtained by the above vacuum melting is subjected to vacuum magnetic field heat treatment, and the treatment conditions are: temperature 720°C; time: 11 hours; vacuum degree: 2×10 -3 MPa; Applied magnetic field strength: 8×10 6 A·m -1 ; Magnetic field rise rate: 1000A m -1 ·s -1 ;

[0038] S4. Cooling: followed by furnace co...

Embodiment 3

[0041] Prepare 600g composition as Ni 35.5 al 29.1 co 34.7 Eu 0.7 The low fatigue magnetic memory alloy, its preparation method is as follows:

[0042] S1. Ingredients: Weigh Ni, Al, Co, Lu with a purity of 99.99% respectively;

[0043] S2. Melting: Put the prepared raw materials in a crucible for vacuum melting, and the melting conditions are: a.3×10 -3 The low vacuum state of MPa; b. the smelting temperature is 1620 ℃; c. the smelting process adopts magnetic stirring; d. the smelting time is 195s (according to the formula t=K×(M -1 / 2 ) to obtain, where the element coefficient K is 8s·g -1 / 2 , M is 600g);

[0044] S3. Magnetic field heat treatment: The alloy ingot obtained by the above vacuum smelting is subjected to vacuum magnetic field heat treatment, the treatment conditions are: temperature 730°C; time: 10 hours; vacuum degree: 3×10 -3 MPa; Applied magnetic field strength: 1×10 7 A·m -1 ; Magnetic field rise rate: 1000A m -1 ·s -1 ;

[0045] S4. Cooling: foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com