Spring machine with spring length adjusting device

A technology of length adjustment and adjustment device, applied in the field of spring machines, can solve problems such as waste, affecting production progress, manual screening, etc., and achieve the effects of reducing production costs, improving product accuracy, and improving qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

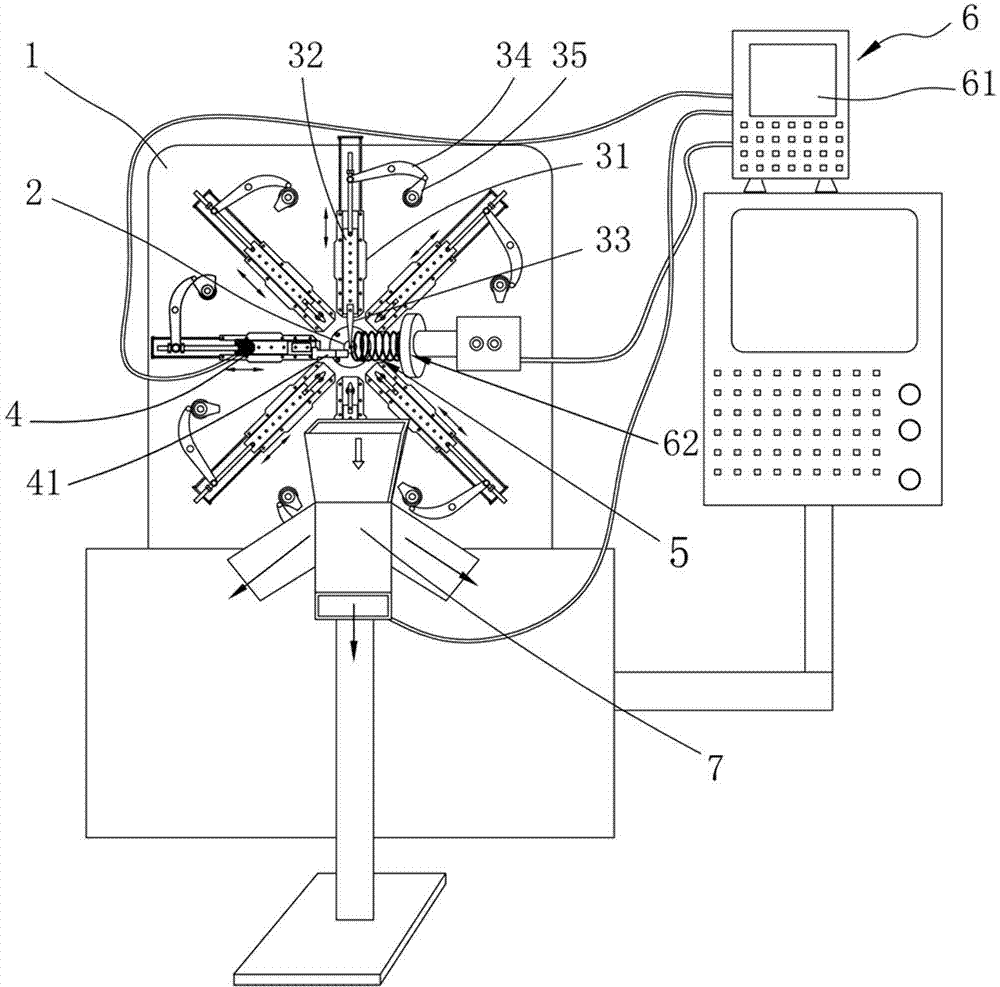

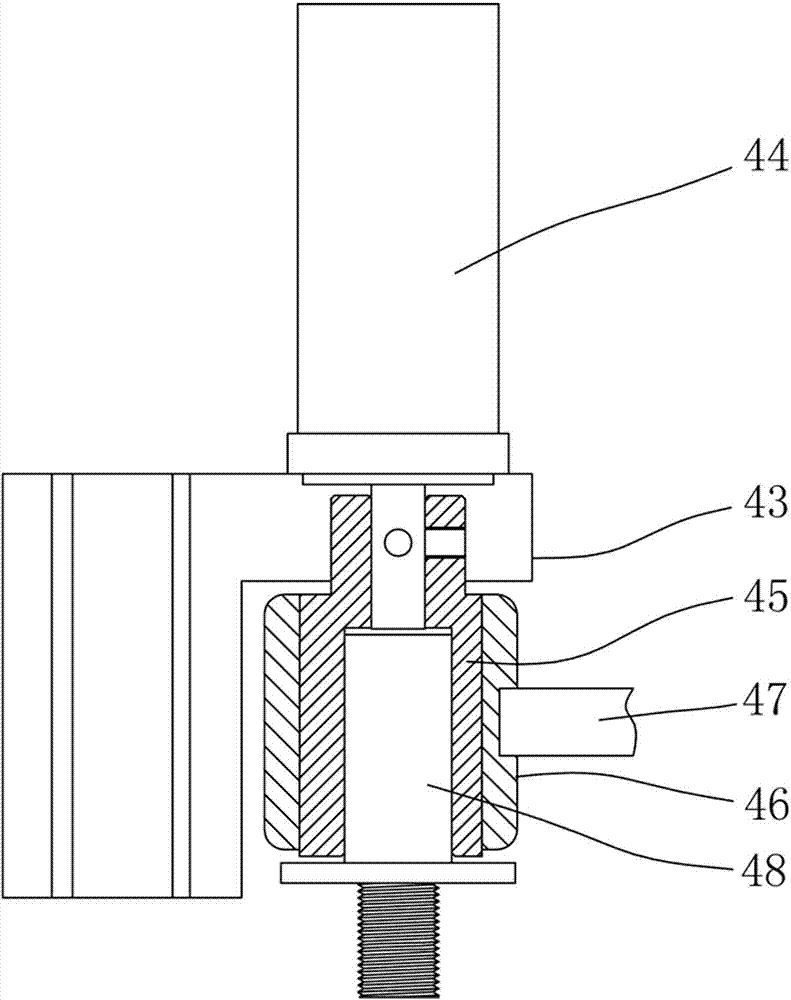

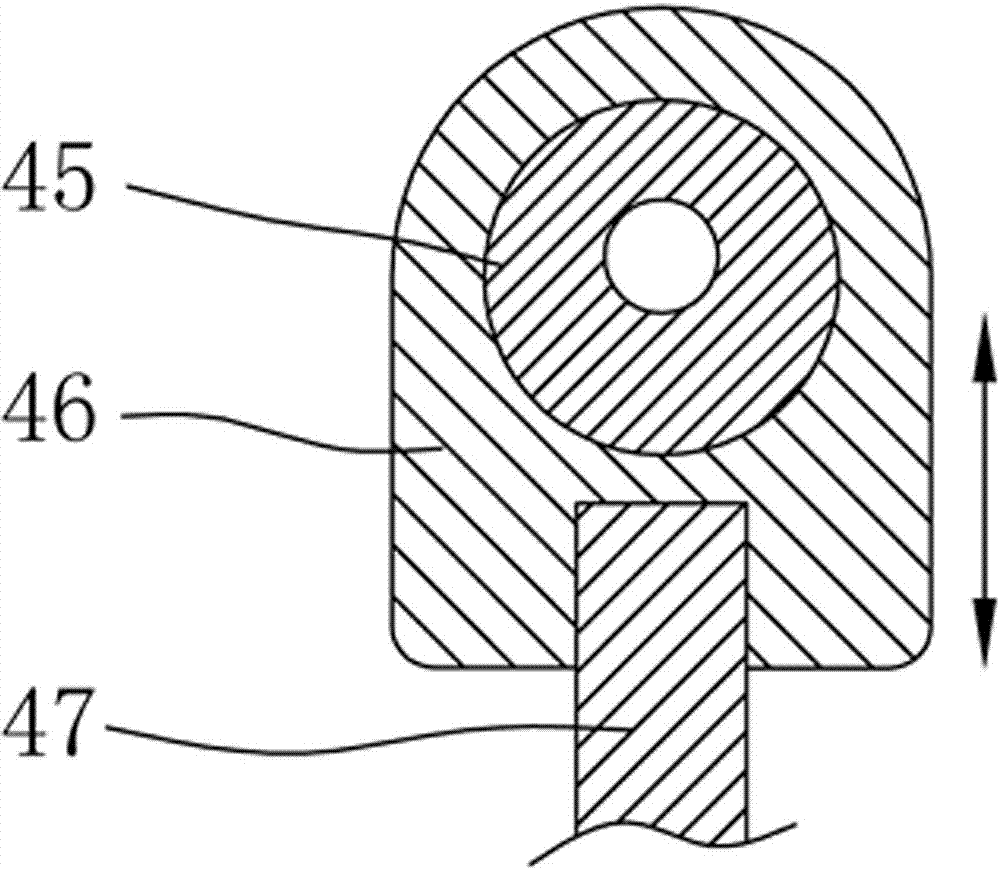

[0015] as attached figure 1 The shown spring machine with a spring length adjustment device includes a frame 1, a discharge port 2 is arranged on the frame 1, and several spring processing arms are installed around the discharge port 2. The spring processing arm includes a sliding seat 31 and a sliding block 32 sliding on the sliding seat 31 , a processing tool 33 is installed on the end of the sliding block 32 near the discharge port 2 , and a crank arm 34 is hinged at the other end. The crank arm 34 is rotatably mounted on the frame 1 in the middle, and a cam 35 is connected to the other end thereof.

[0016] The working process of spring machine is described as follows, cam 35 rotates, drives crank arm 34 to swing around its installation axis with frame 1, and crank arm 34 drives slide block 32 to slide back and forth on slide seat 31. When the slide block 32 slides towards the discharge port 2, the machining tool 33 moves to the top of the discharge port 2. When the spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com