Steel used for non-cold-working connection

A technology of cold working and steel billet, which is applied in the direction of connecting components, threaded fasteners, screws, etc., which can solve the problems of difficult threaded connections, reduced cross-sectional area of turning parts, bottlenecks in the overall performance of rebar, etc., and achieves stable self-locking performance Reliable, small thread pitch, and the effect of avoiding metal fiber breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and examples.

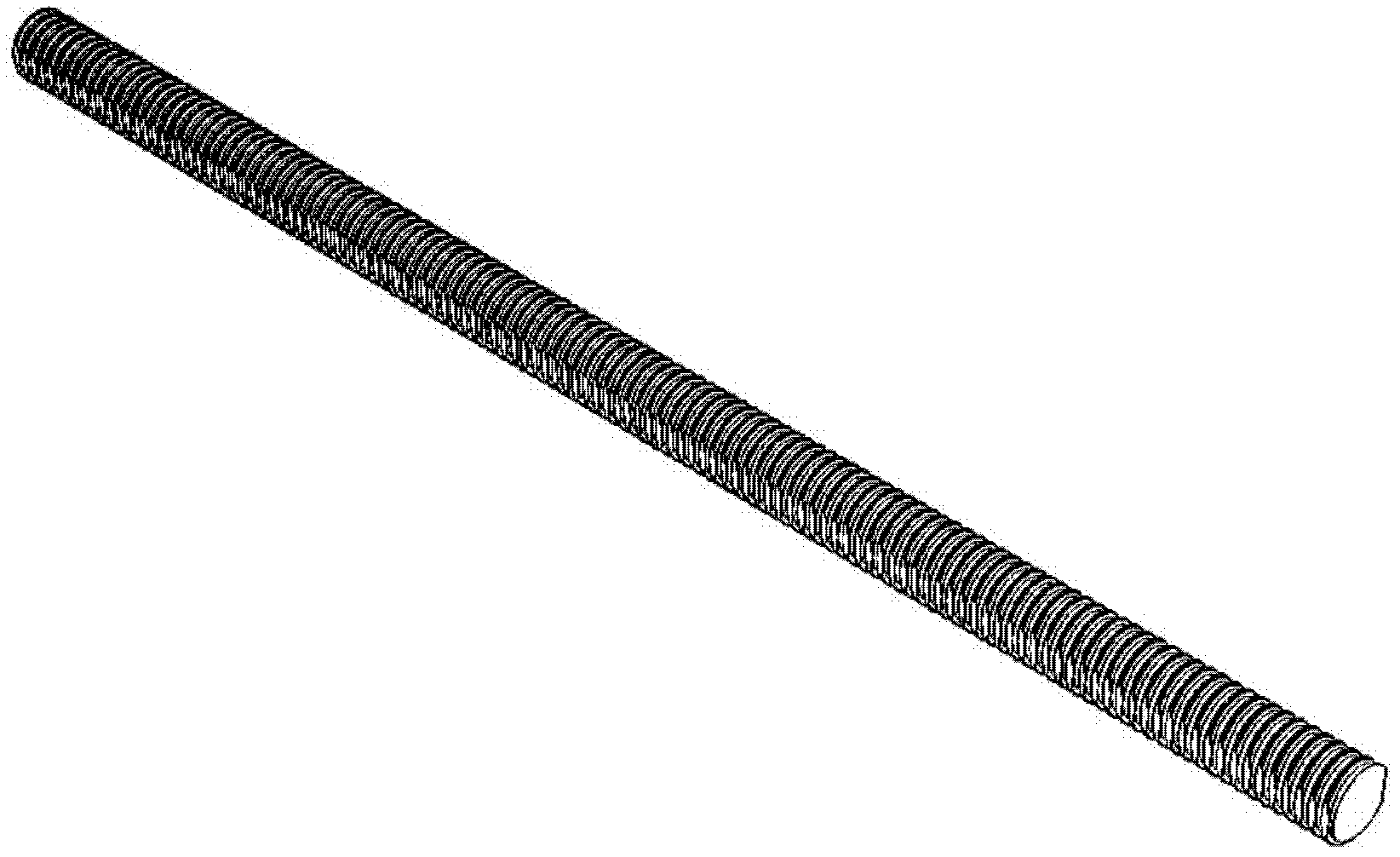

[0025] like figure 1 As shown, the transverse rib on the rod body of the steel cleaning rod for non-cold working connection of the present invention forms a helix on the same helical surface, and any position of the rod body can be screwed with a matching nut without secondary cold working.

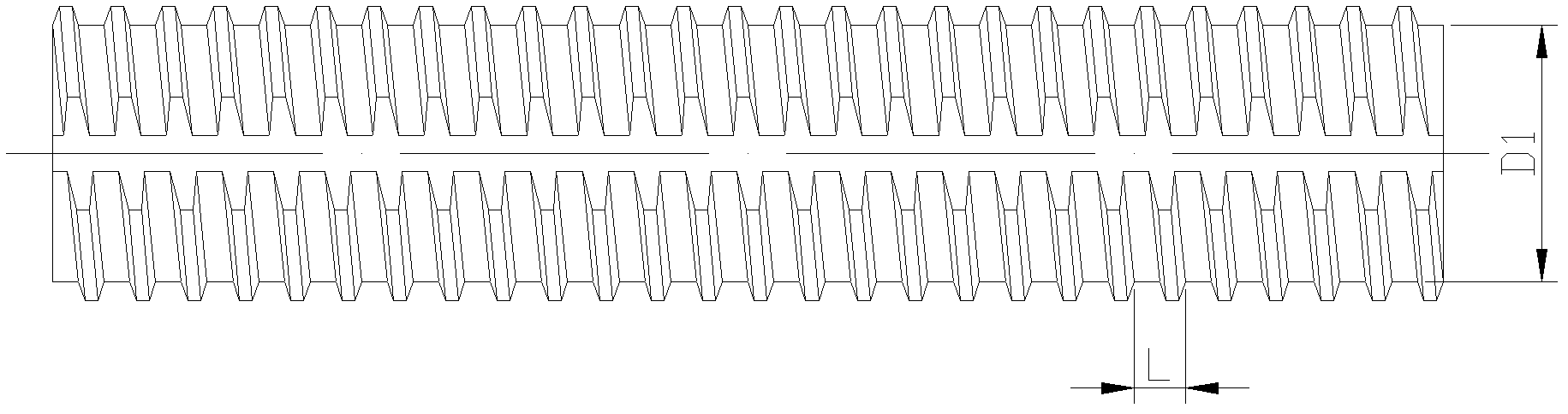

[0026] like figure 2 It shows the thread structure of the steel for non-cold working connection of the present invention, wherein L is the thread pitch, L=4±2mm; preferably, the thread pitch L is 3mm, 4mm, 5mm, 6mm.

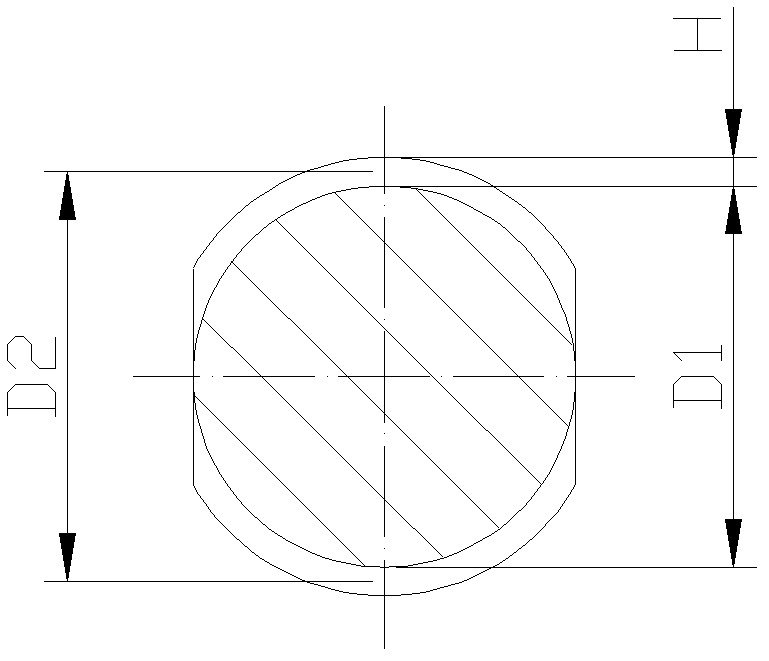

[0027] like image 3 It shows the cross-section of the steel for non-cold working connection of the present invention, wherein H is the thread height, 1.0mm≤H≤1.7mm; preferably, the thread height H is 1.0mm, 1.2mm, 1.4mm, 1.5mm.

[0028] like Figure 4 It shows the longitudinal section of the steel for non-cold working connection of the present inve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com