Combined sleeve spanner

A technology of combining sleeves and sleeves, applied in the directions of wrenches, screwdrivers, manufacturing tools, etc., can solve the problems of carrying tools and inconvenient operation and construction, and achieve the effects of increasing thickness, improving work efficiency, and reducing the angle of rotation and reset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

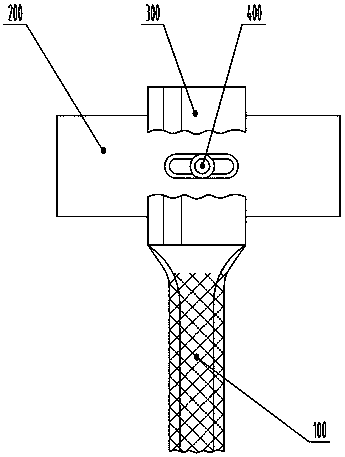

[0036] see figure 1 , in the figure, the combination socket wrench of the present invention includes a handle 100 and a socket assembly 200, which is used to connect the unidirectional torque driver 300 between the end of the handle and the middle part of the outer sleeve surface, and is used for the outer sleeve and each inner sleeve. Sleeve relative sliding and positioning relative sliding and positioning mechanism 400 etc. The outer sleeve and each inner sleeve are assembled together through a relative sliding and positioning mechanism, and the length of the outer sleeve and each inner sleeve is the same.

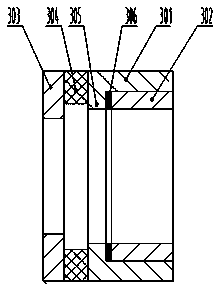

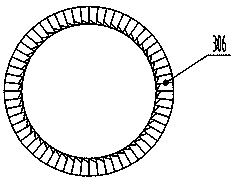

[0037] see Figure 2-3 , in the figure, the one-way torque driver 300 includes an outer ratchet ring 301 and an inner ratchet ring 302 that are matched inside and outside along the axial direction, wherein the inner ratchet ring is fixedly connected with the outer sleeve 201, and one end of the outer ratchet ring is radially And a boss 305 is arranged inwardly, and the...

Embodiment 2

[0041] see Figure 7 , the structure of this embodiment is similar to that of Embodiment 1, and the same numbers in the figure represent the same meaning, and the same parts in the structure of the two will not be repeated here. The sleeve assembly 200 , and the specifications of the sleeve assembly 200 at both ends of the handle 100 are configured in a cross-spaced specification. For example: if a set of combination socket wrench is designed for bolts and nuts of 10mm, 11mm, 12mm, 14mm, 15mm, 17mm, 19mm, 22mm, 24mm, the hexagonal combination socket at one end of the handle can be arranged from the inside to the outside. It is 10mm, 12mm, 14mm, 16mm, 22mm, and the hexagonal combination sleeve at the other end of the handle is arranged from inside to outside in 11mm, 13mm, 15mm, 19mm, 24mm. Arranged in intersecting intervals. Compared with the first embodiment, this embodiment can increase the thickness and mechanical strength of each sleeve in the sleeve assembly, which is b...

Embodiment 3 4

[0044] Present embodiment figure is not drawn. Embodiments 3 and 4 are similar in structure to Embodiments 1 and 2 respectively, and the structurally identical parts will not be repeated here. The difference lies in that the rest of the inner sleeve and Axial slide grooves are correspondingly provided on both sides of the outer sleeve, and the positioning spring is set on the positioning stroke-limiting pin, and together with the positioning stroke-limiting pin, they are sequentially installed in the mounting hole and each axial slide groove on one side.

[0045] In this embodiment, relative to Embodiments 1 and 2, respectively, axial slide grooves are provided on both sides of the other inner sleeves and outer sleeves except the innermost inner sleeve, and the positioning spring sleeve and the positioning travel limit pin can be They are installed in the installation holes and axial chute on one side in turn. Compared with the first and second embodiments, the other inner sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com