Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Improve dusting efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

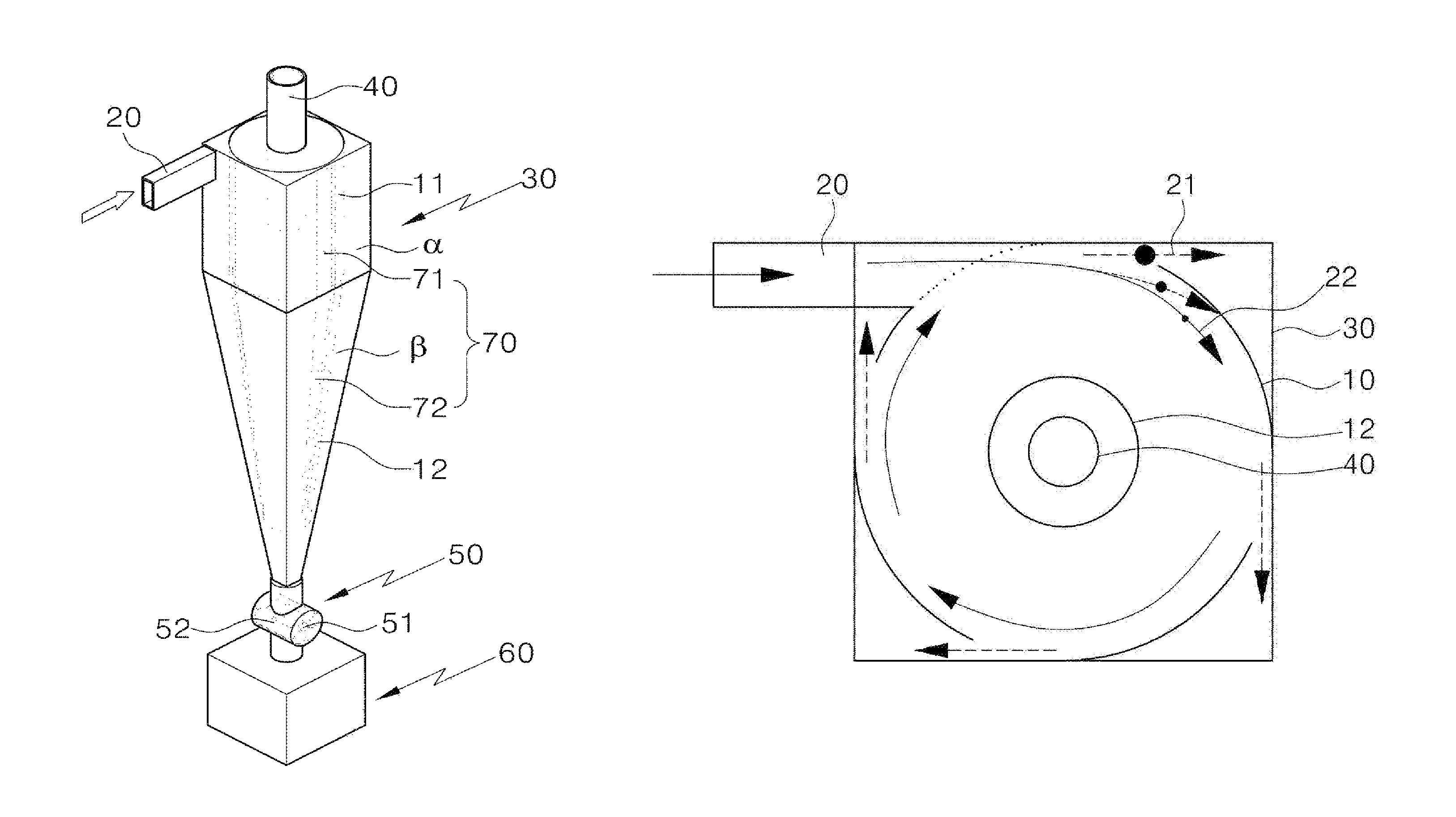

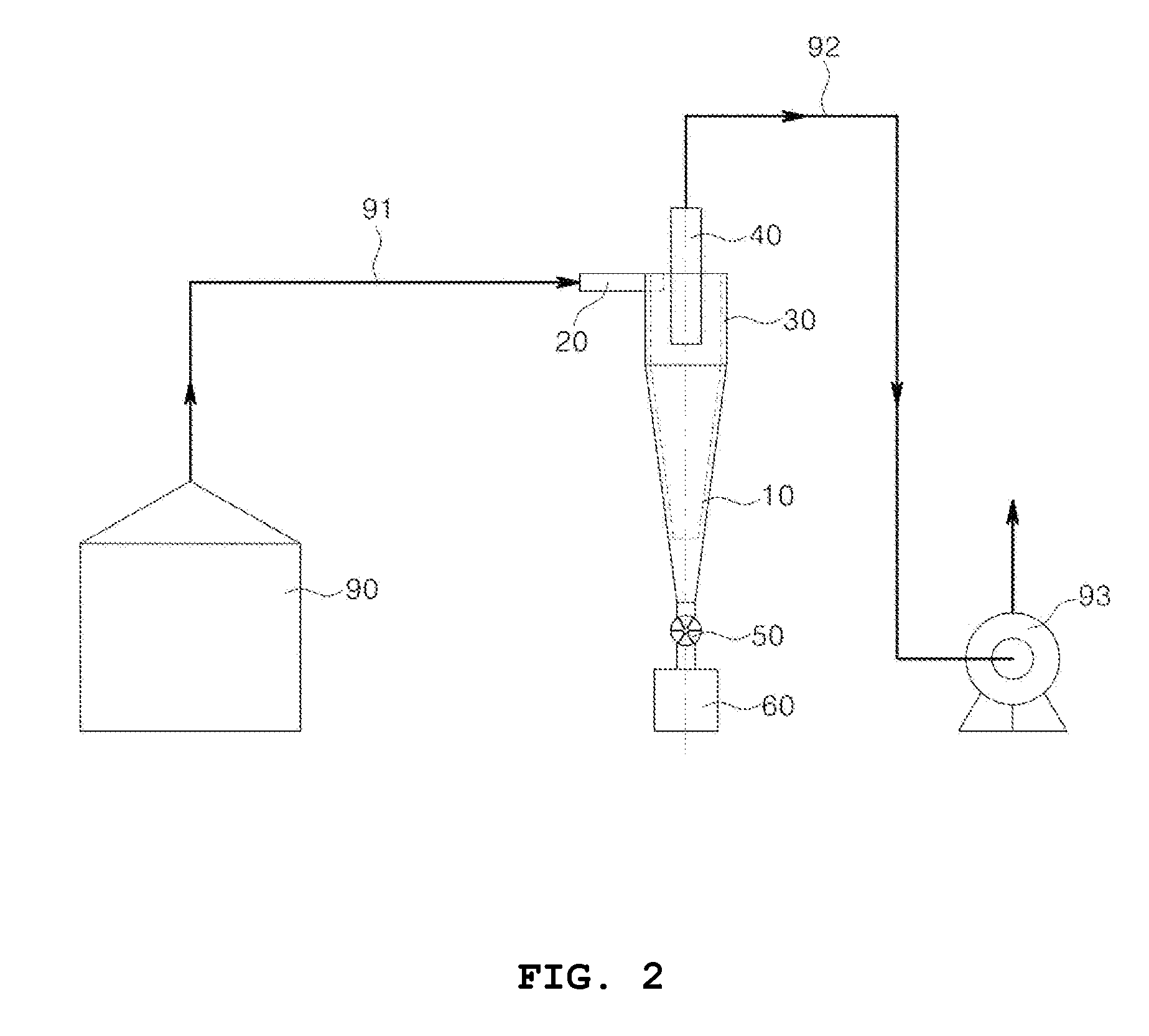

Cyclone dust collector

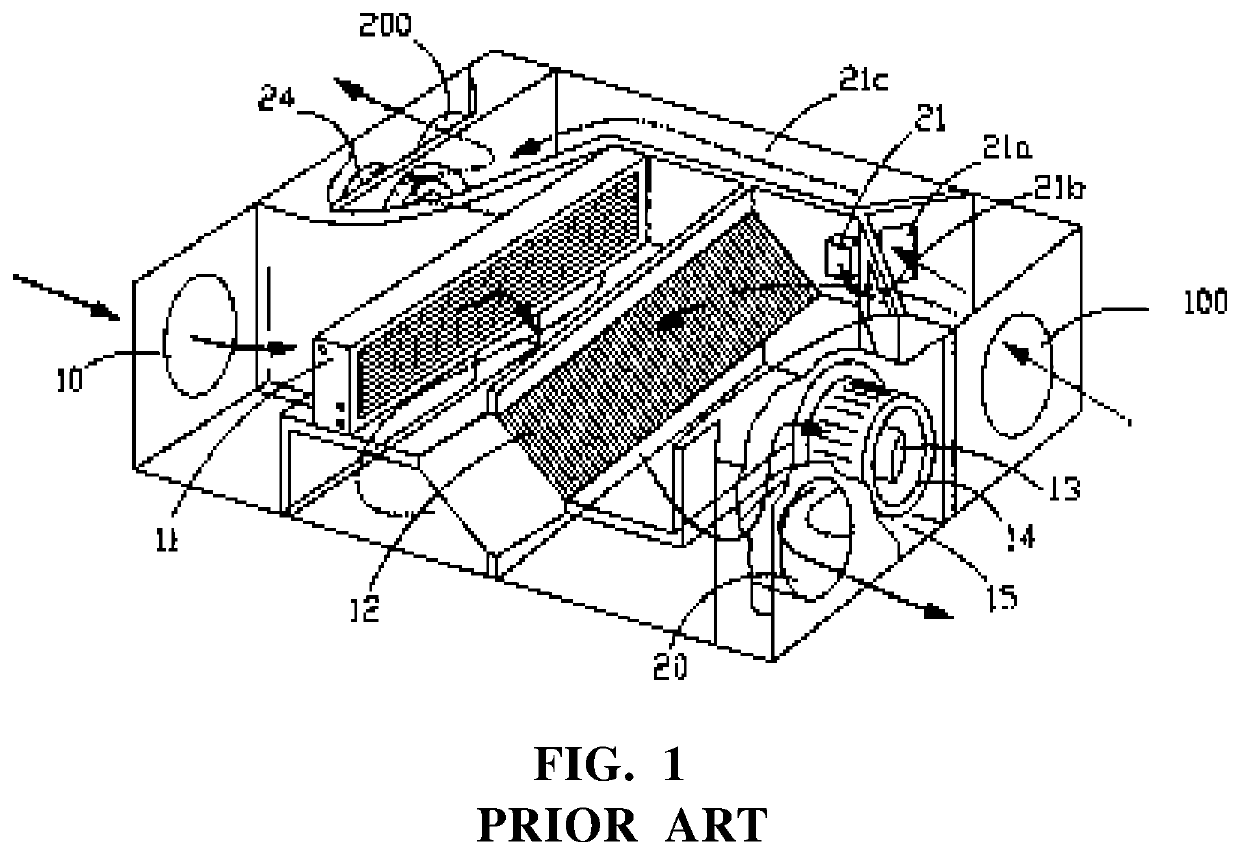

ActiveUS8657910B2Low pressure lossReduce flow rateCombination devicesSuction filtersCycloneCentrifugal force

Owner:KOREA INST OF ENERGY RES

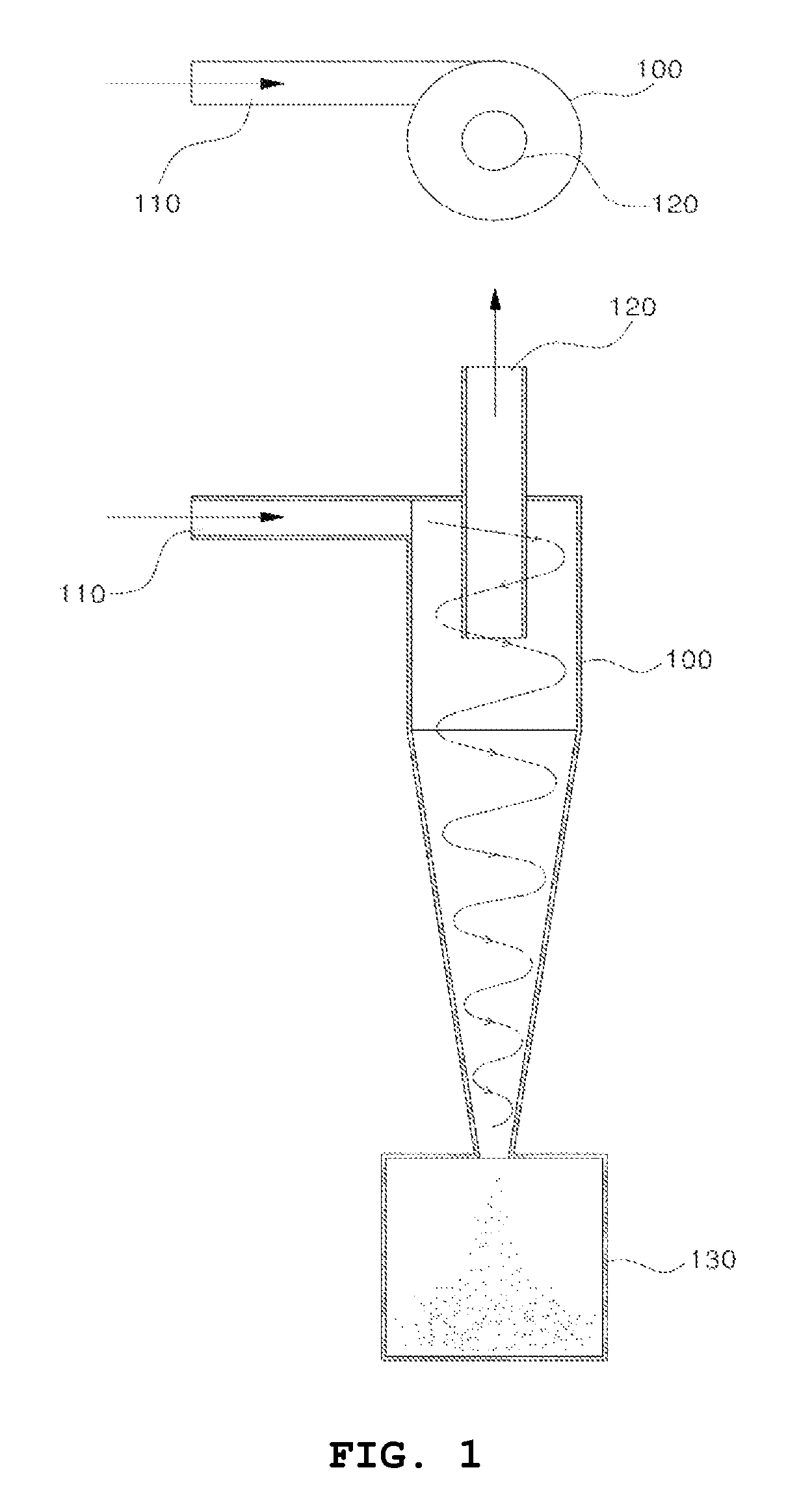

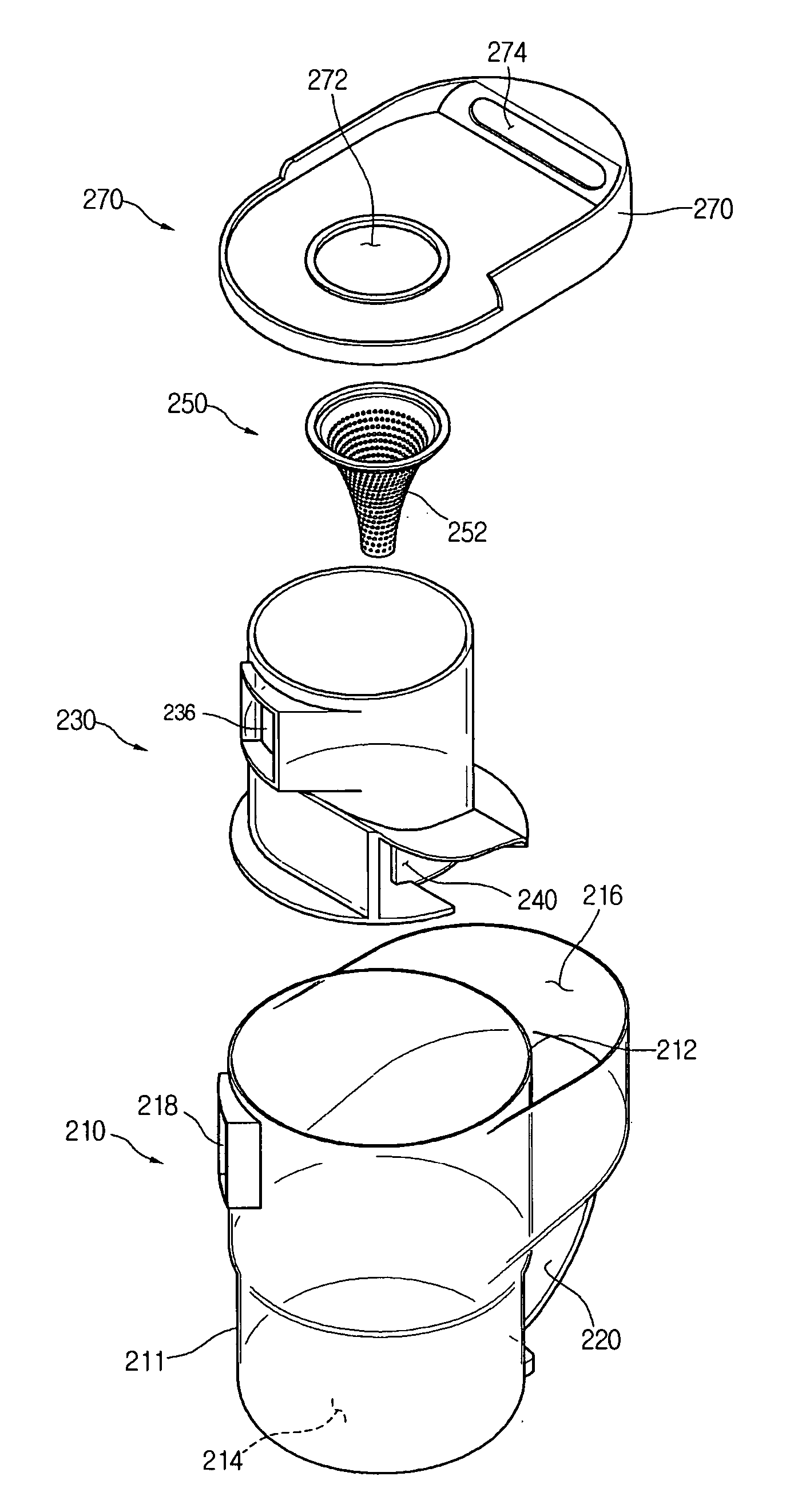

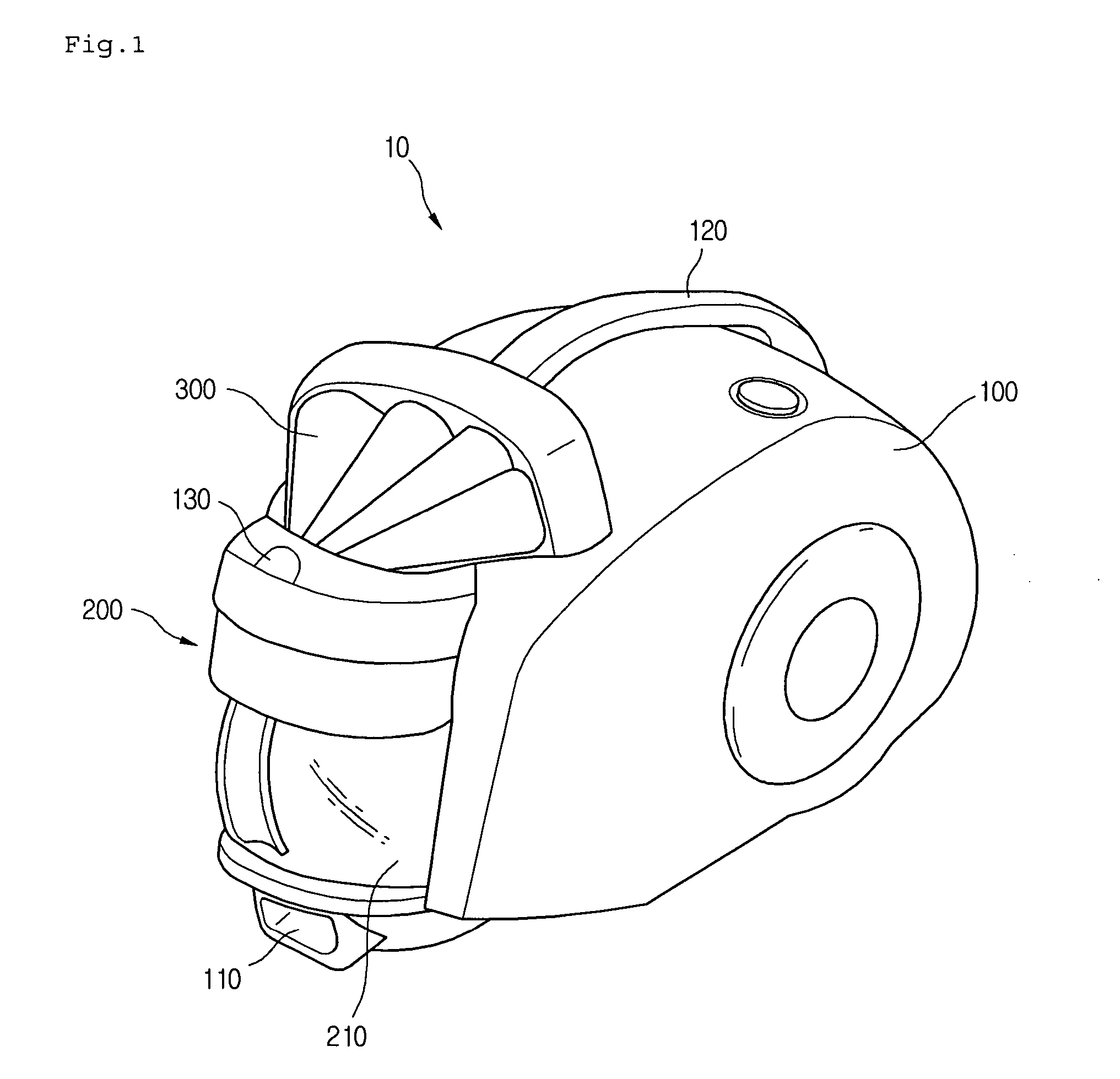

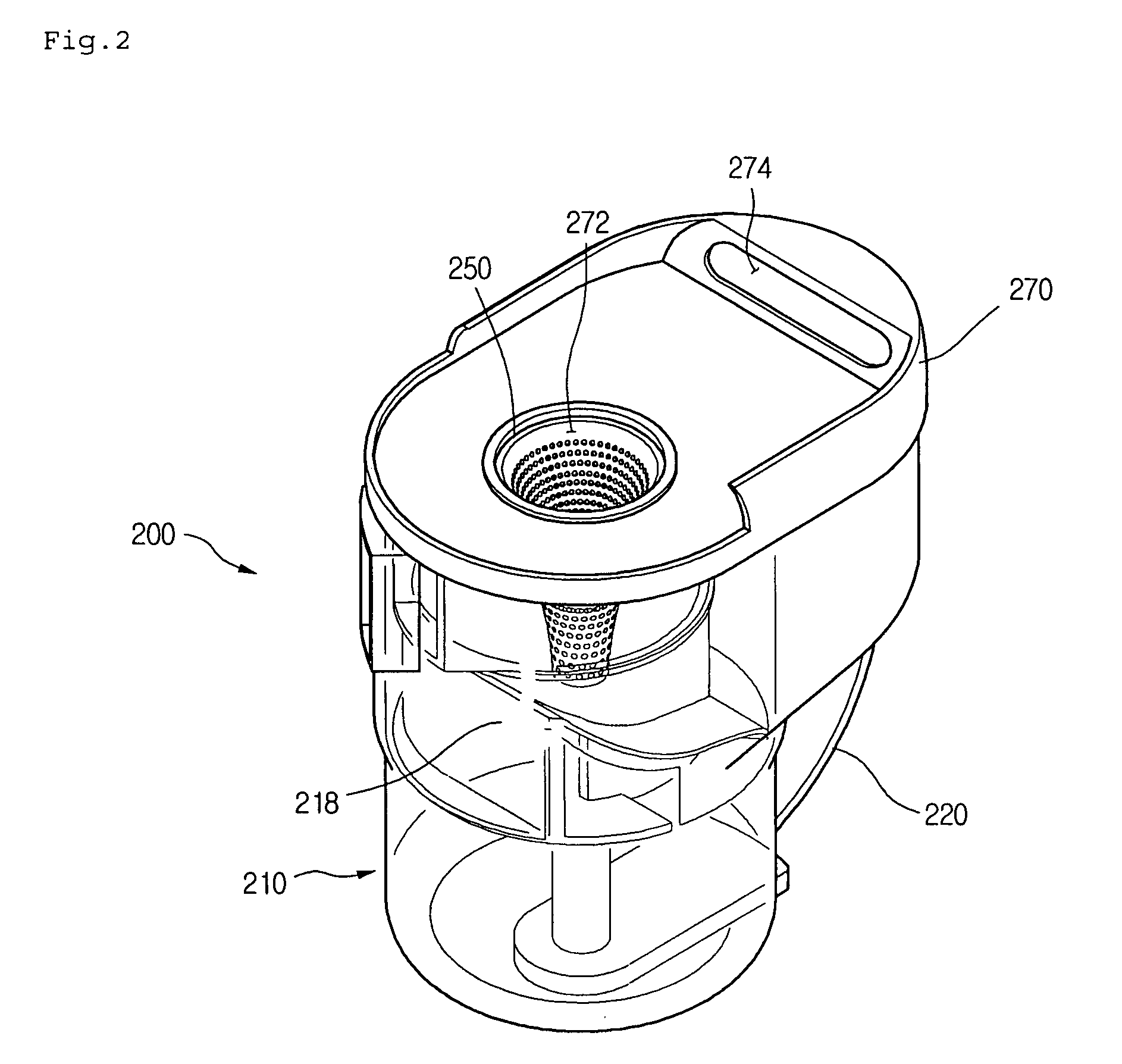

Dust collecting unit of vacuum cleaner

ActiveUS20080010957A1Improve dusting efficiencyImprove efficiencyCombination devicesSuction filtersEngineeringAir separation

Provided is a dust collector of a vacuum cleaner. The dust collector includes a dust separating unit forming a separation space for separating dust from air, a collector body forming a dust storage for storing the dust separated in the dust separating unit, and a dust guide passage connecting the separation space to the dust storage and guiding the separated dust to be discharged from the separation space in a tangential direction.

Owner:LG ELECTRONICS INC

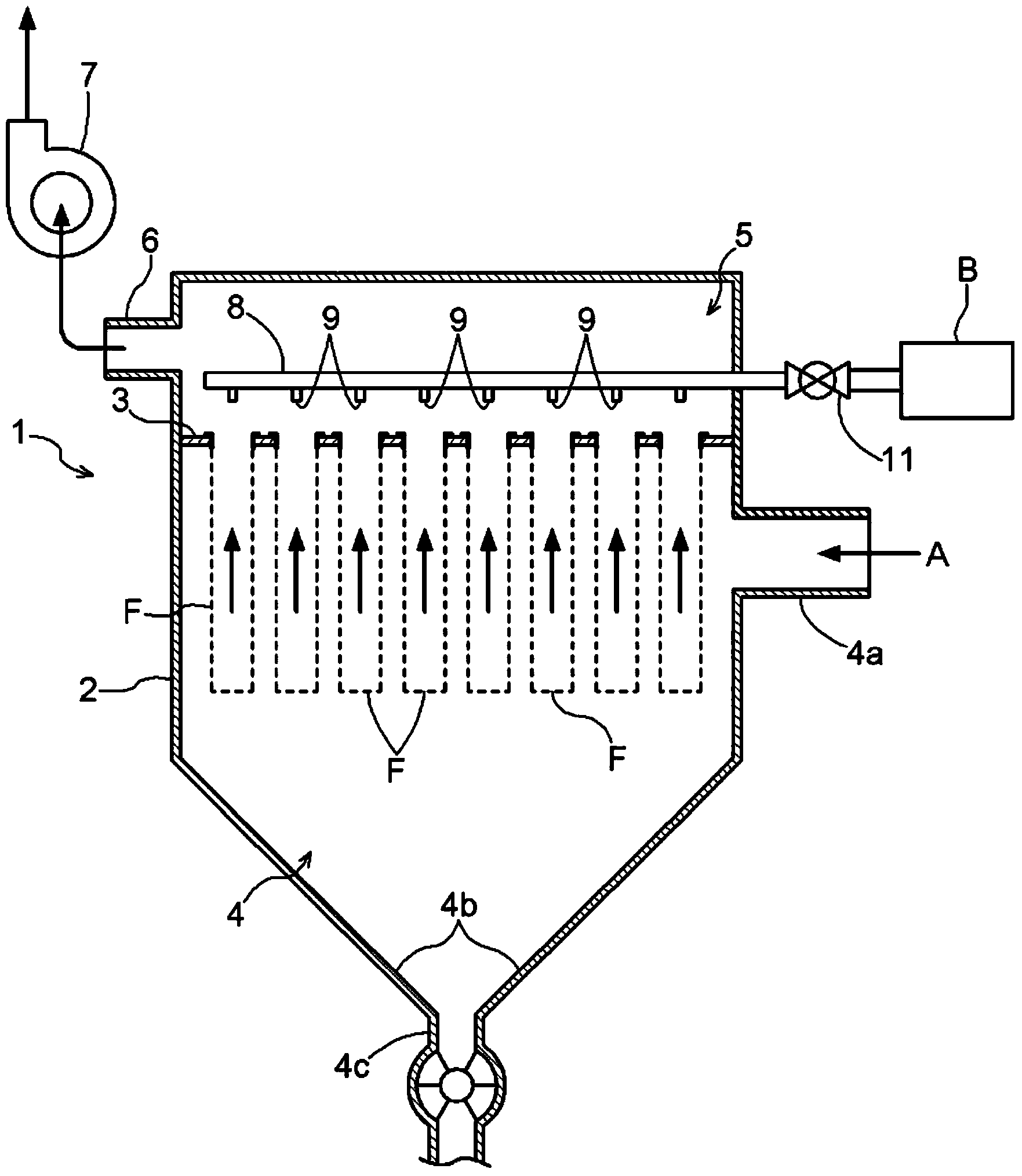

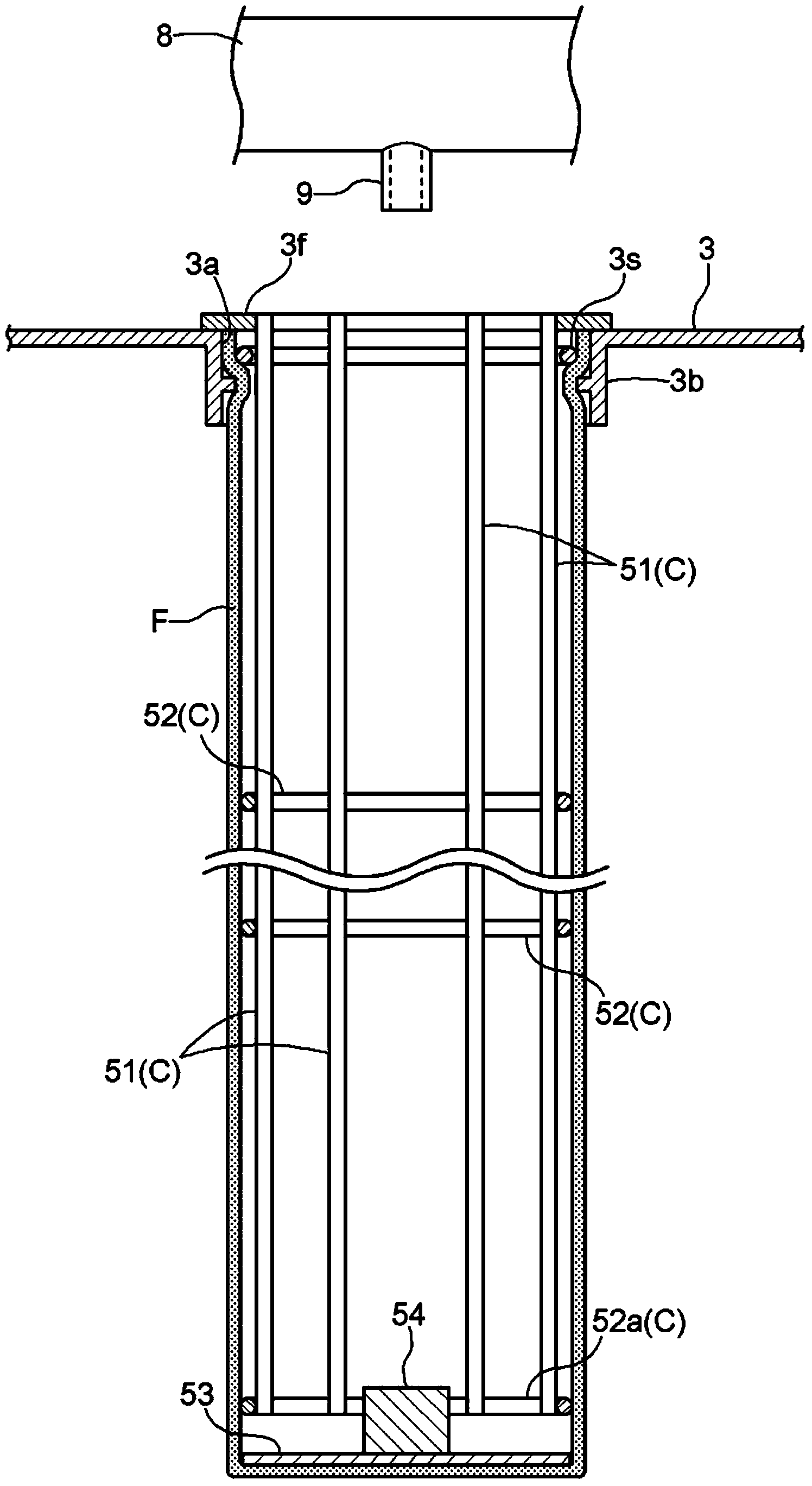

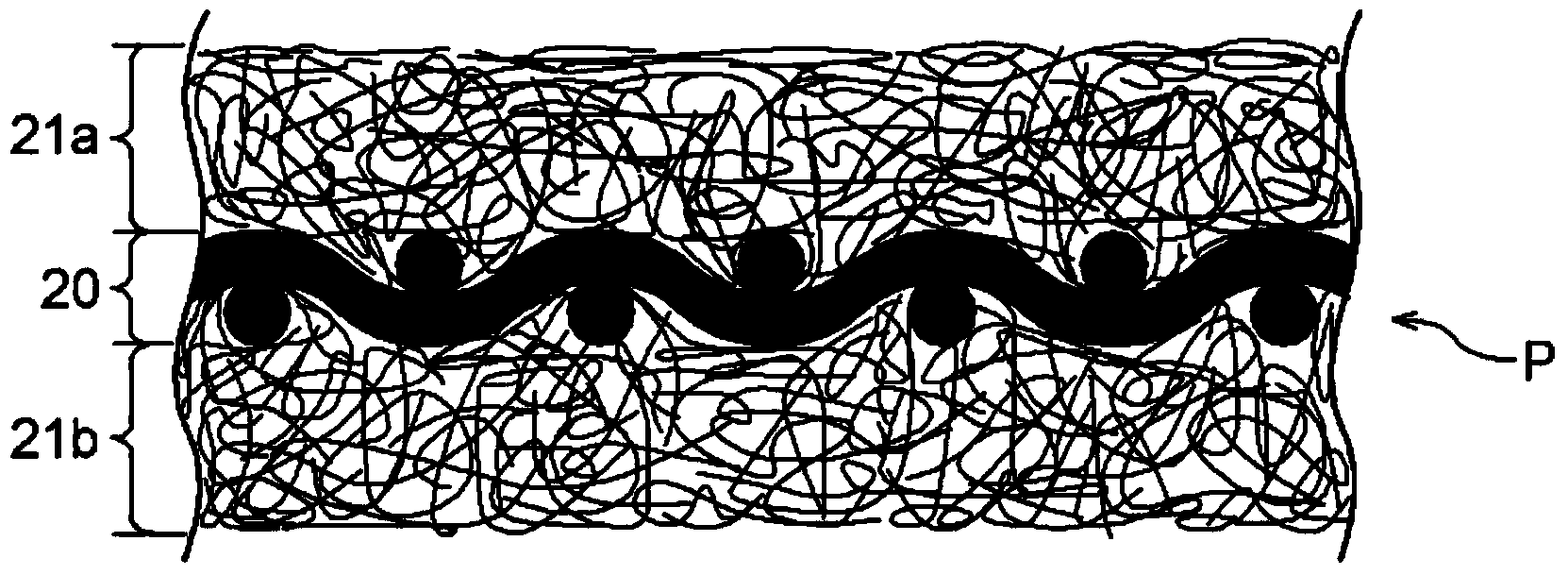

Dust collection filter, dust collection apparatus provided with same, and manufacturing method for dust collection filter

ActiveCN103442781AImprove dusting efficiencyEasy to break awayDispersed particle filtrationTransportation and packagingPower usageCounter current

The present invention provides a dust collection filter capable of reducing power usage by reduction of the average pressure loss of the dust collection filter and extending the filter life by improving efficiency of dust removal at the time of recycling a dust collection filter, and provides also a dust collection apparatus provided with the same. A tubular-shaped filtering fabric (P) has a configuration in which are layered: a base fabric layer (20) comprising a woven fabric; and a filter layer comprising a non-woven fabric combined with at least the filtering front surface side of the base fabric layer (20). A dust collection filter (F) is configured to filter dust containing air by passing the same through the filtering fabric (P) from the filtering front surface side to the filtering rear surface side and to remove the dust captured and collected by passing a counter current of air (H) through the filtering fabric (P) from the filtering rear surface side to the filtering front surface side. In the dust collection filter (F), either warps (20a) or woofs (20b) constituting the woven fabric of the base fabric layer (20) are disposed to be slanted to the tubular circumference direction (Y) of the tubular-shaped filtering fabric (P).

Owner:NIHON SPINDLE MFG CO LTD

Automatic powder spreader

The invention relates to an automatic powder spreader, which comprises a vibration screen, a motor, an eccentric block mounted on a motor shaft, and a motor housing, wherein the vibration screen is respectively connected with a longitudinal support part and a transverse support part through a flexible part and a connecting part; the motor is fixed outside a screen ring of the vibration screen, and the axis of the motor is located at a horizontal position; and an auxiliary screen for sharing the weight of chemical powder, lightening the load of the vibration screen and improving the powder spreading capability is also arranged in the vibration screen. The auxiliary screen is independently suspended on the support parts, the screen bottom of the auxiliary screen consists of a plurality of angle-adjustable vanes, and the angles of the vanes are adjusted to control the gaps of the vanes. The automatic powder spreader has the advantages that the structure is simple, the cost is low, the screen is stable and cannot incline, the vibration strength is high, the service life of the motor is long and the adaptability is wide, and the automatic powder spreader is mainly used for silkworm breeding and can also be used for powder spreading in medical treatment and public health units.

Owner:于大国

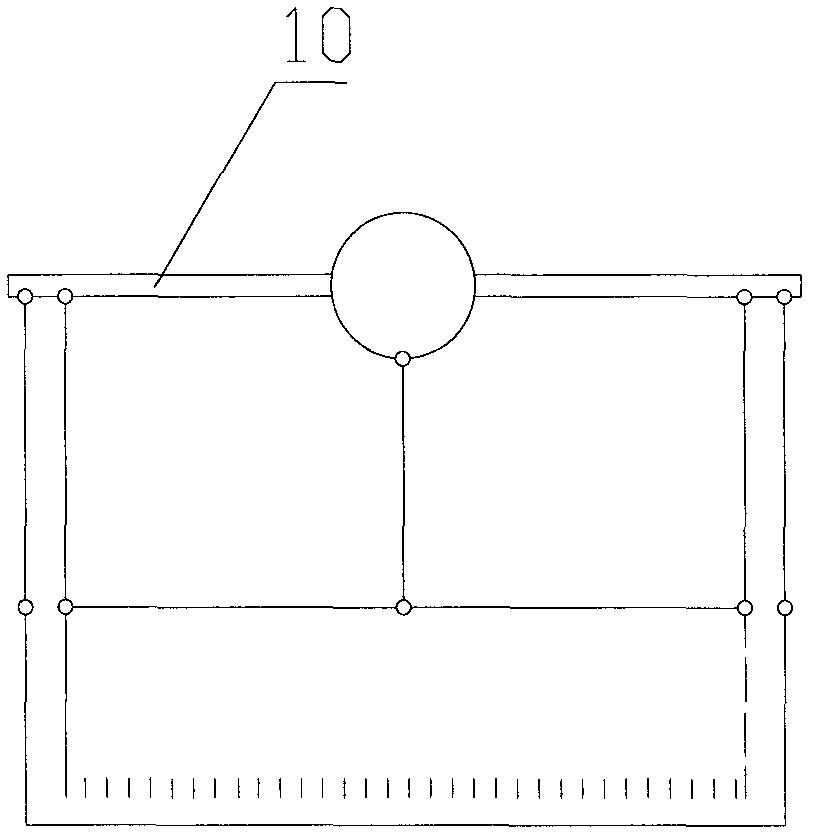

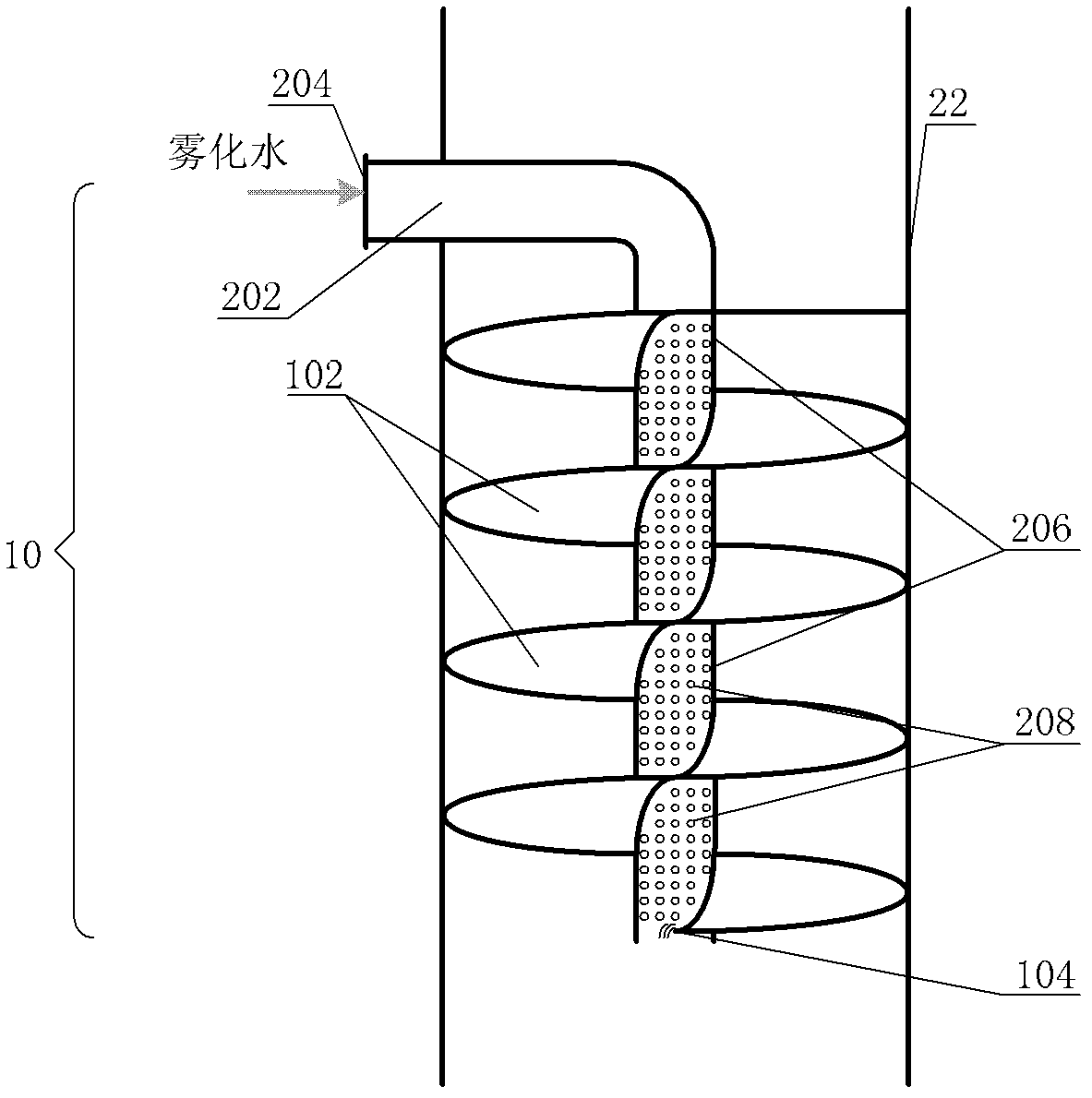

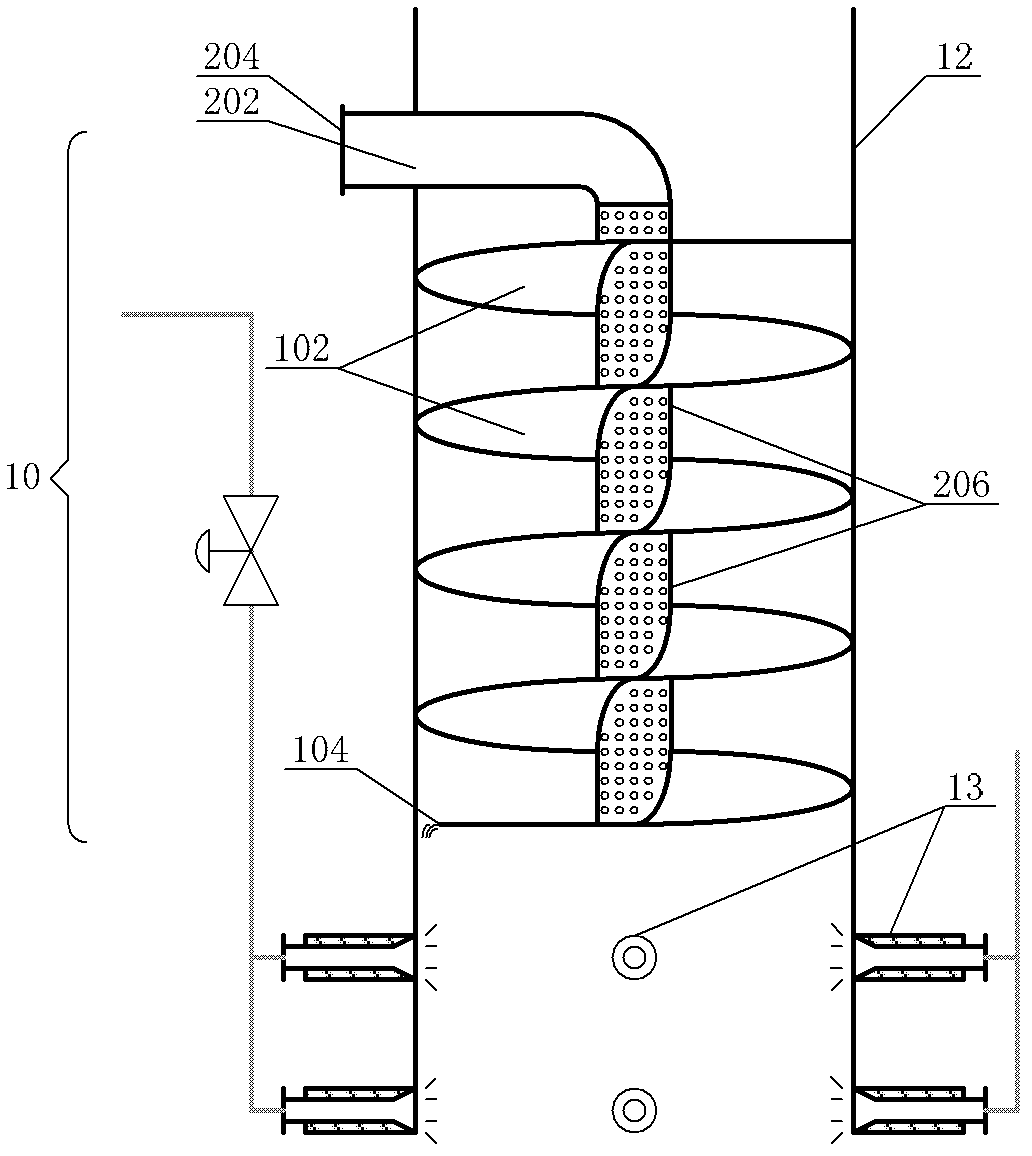

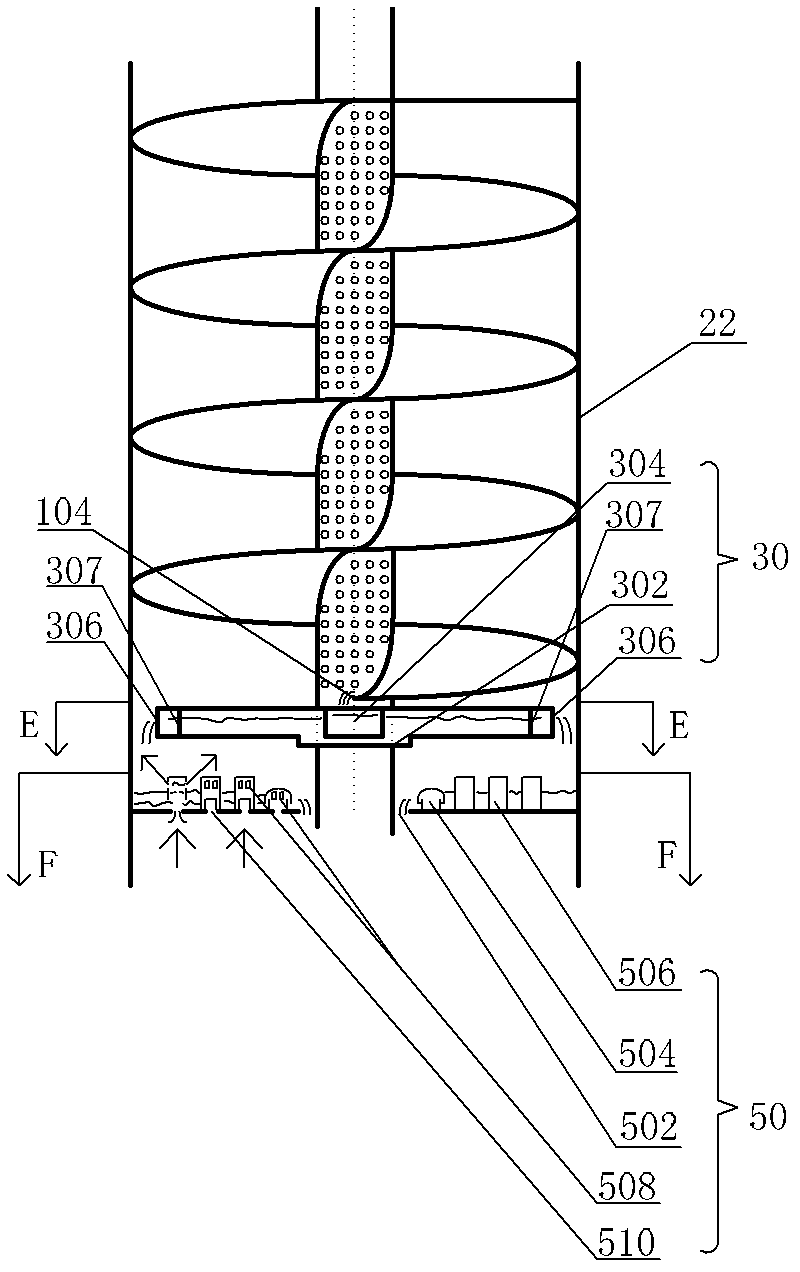

Combined spiral tower tray for gas washing tower, gas cleaning device and application thereof

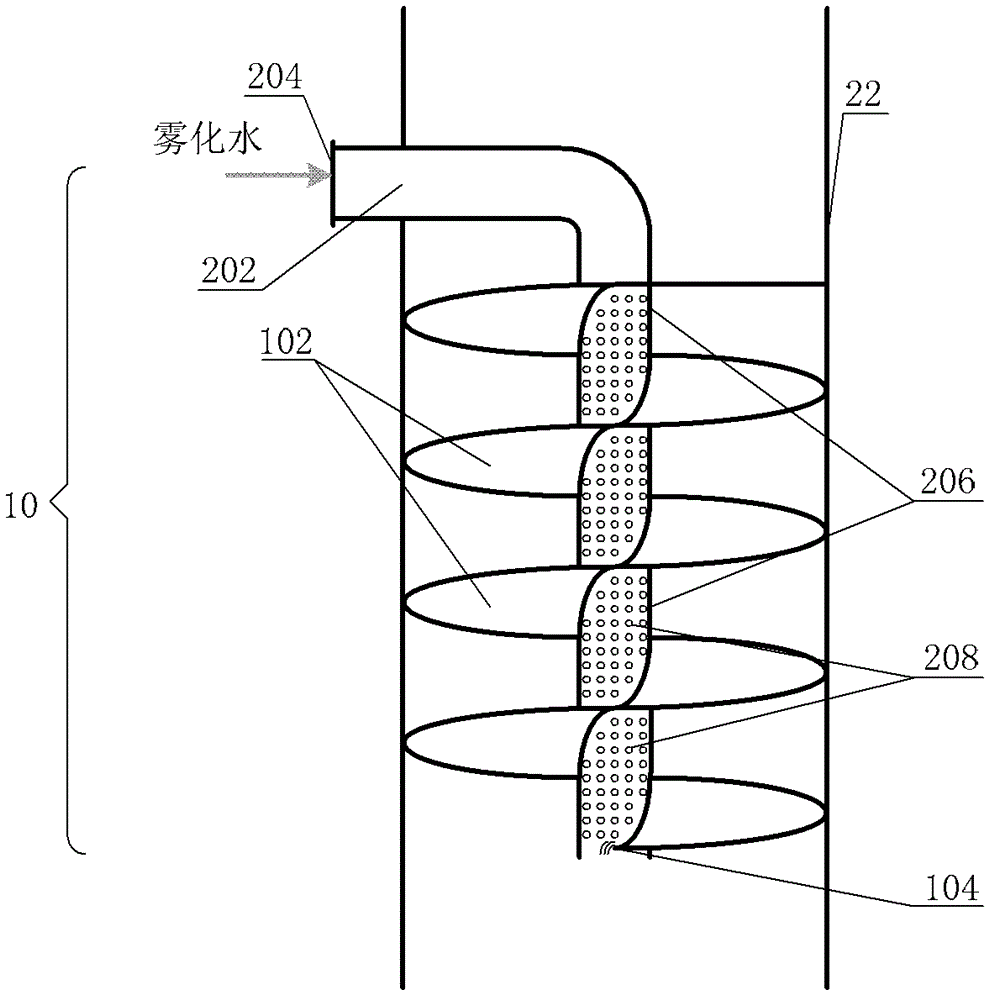

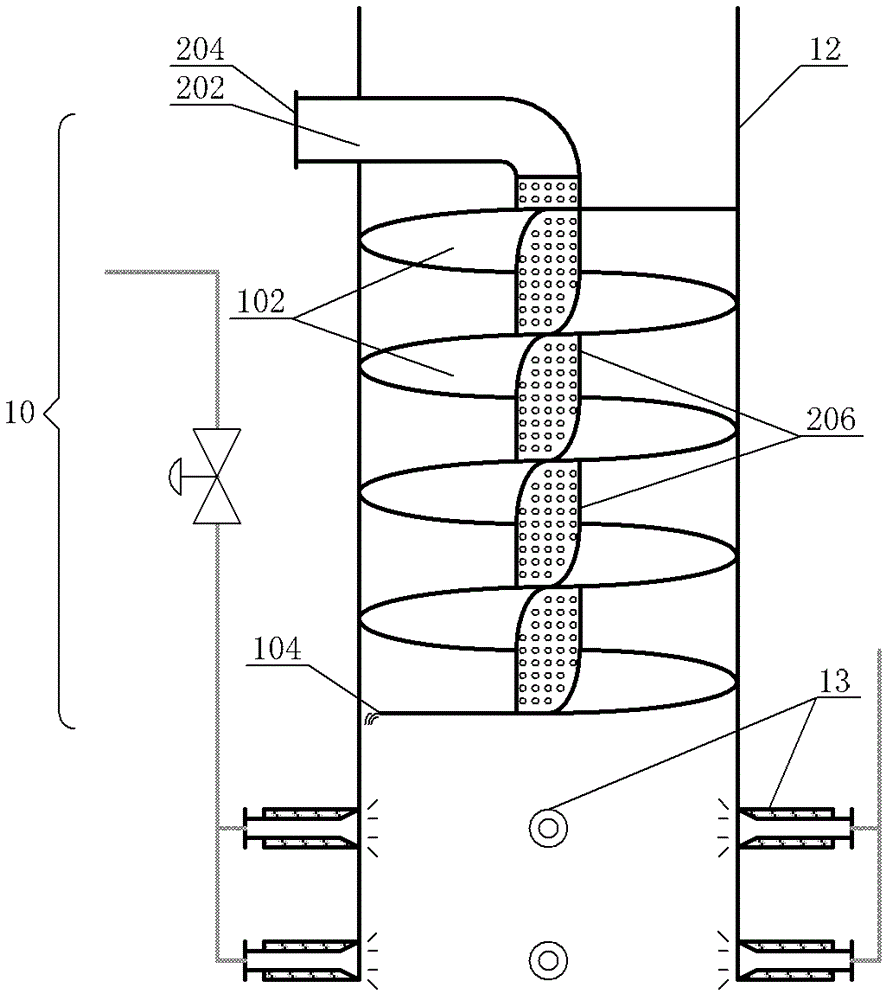

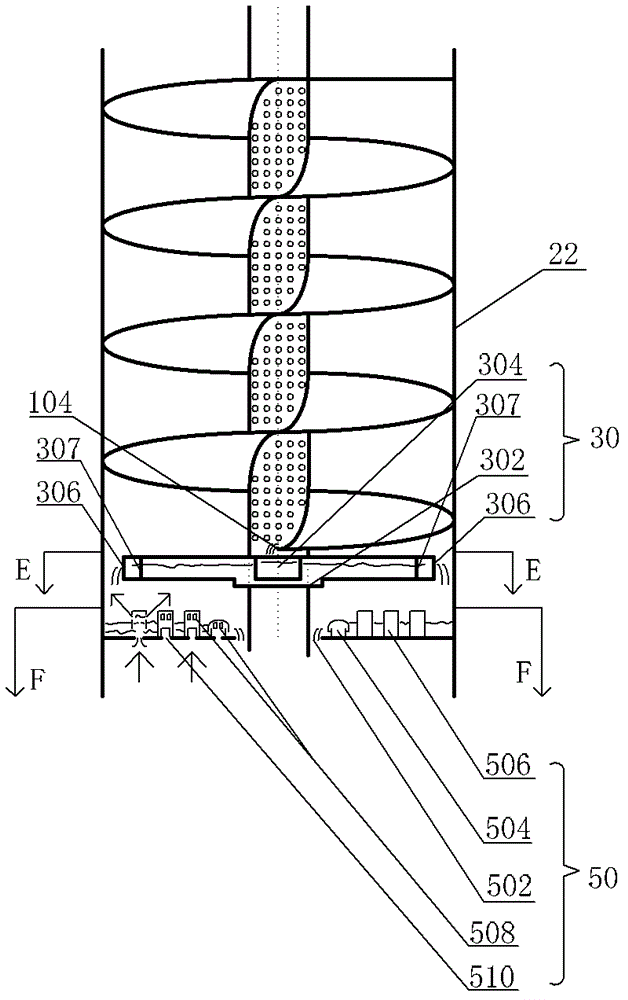

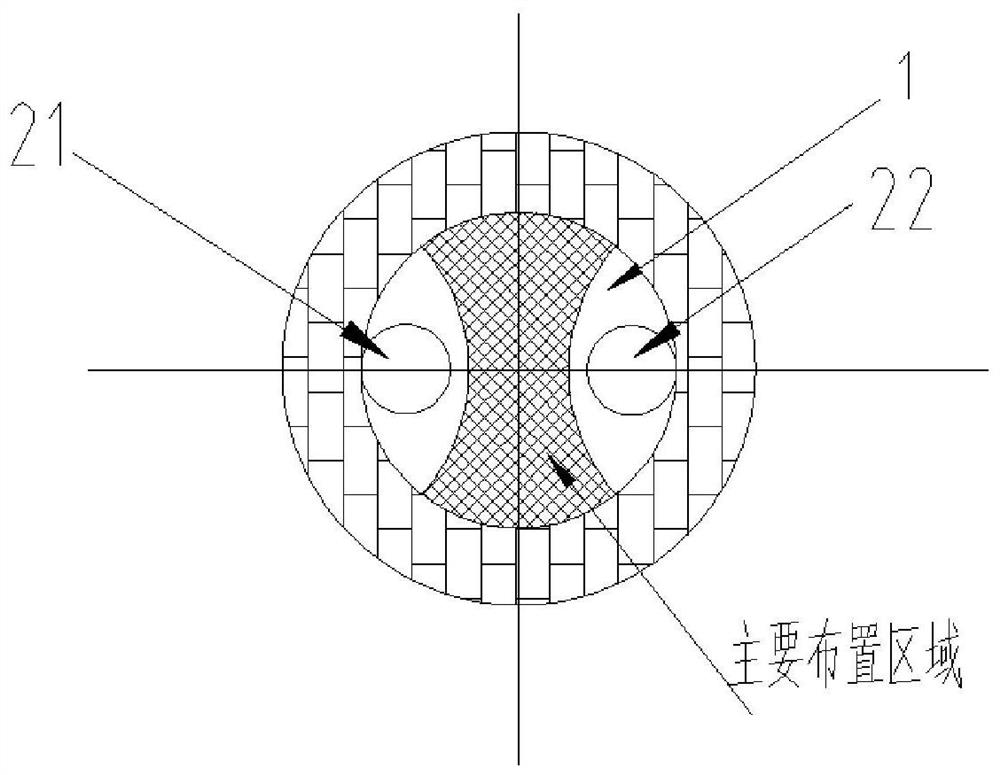

The invention provides a circumferential spiral tower tray for a gas washing tower, a gas cleaning device and application thereof. The circumferential spiral tower tray (10) comprises a spray column inlet pipeline (202), a spray column (206) and a spiral tower tray main body (102), wherein the spray column inlet pipeline (202) is arranged on one side of the upper part of a gas washing tower (1.2) and is basically perpendicular to walls (12 and 22) of the gas washing tower (1.2); the spray column inlet pipeline (202) further comprises an spray column inlet (204) which extends out of the wall of the gas washing tower (1.2); the spray column (206) is connected with the spray column inlet pipeline (202) at the approximate center of the gas washing tower (1.2) in a basically perpendicular mode; the circumference of the spray column (206) is uniformly distributed with a plurality of spray holes (208); the inner side of the spiral tower tray main body (102) is arranged in an upward spiral mode around the outer side of the spray column (206) from the lower end edge (104); and the outer side of the spiral tower tray main body (102) is connected with the inner walls (12 and 22) of the gas washing tower (1.2).

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

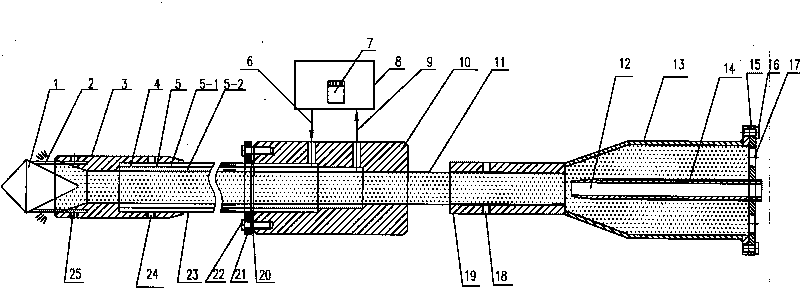

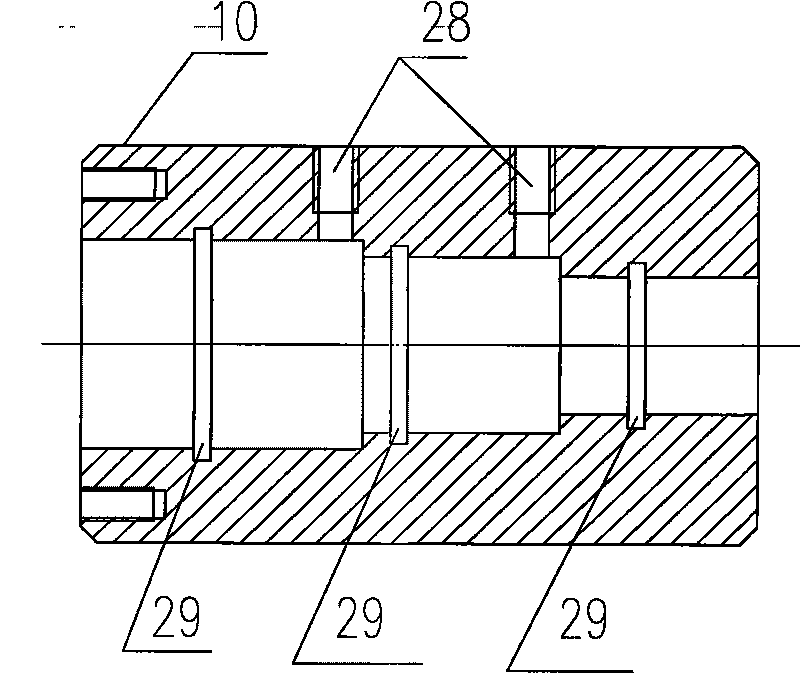

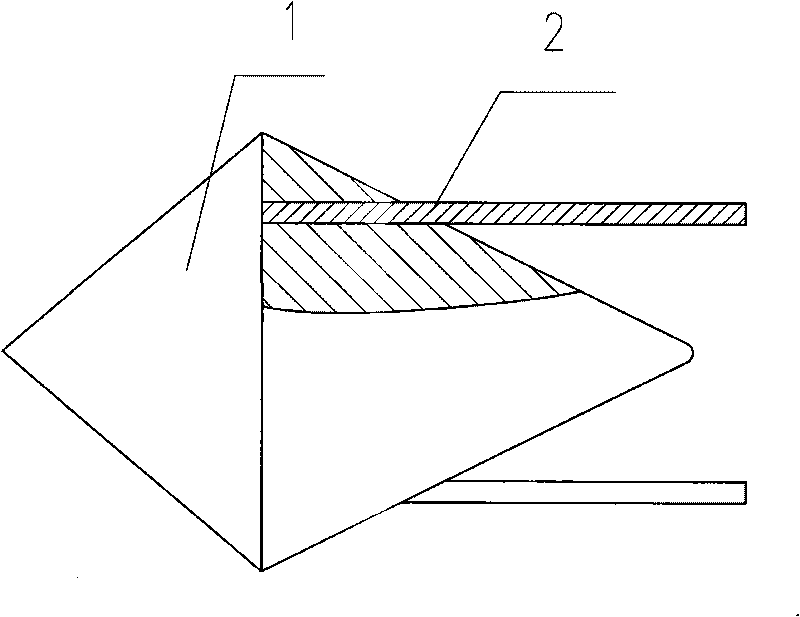

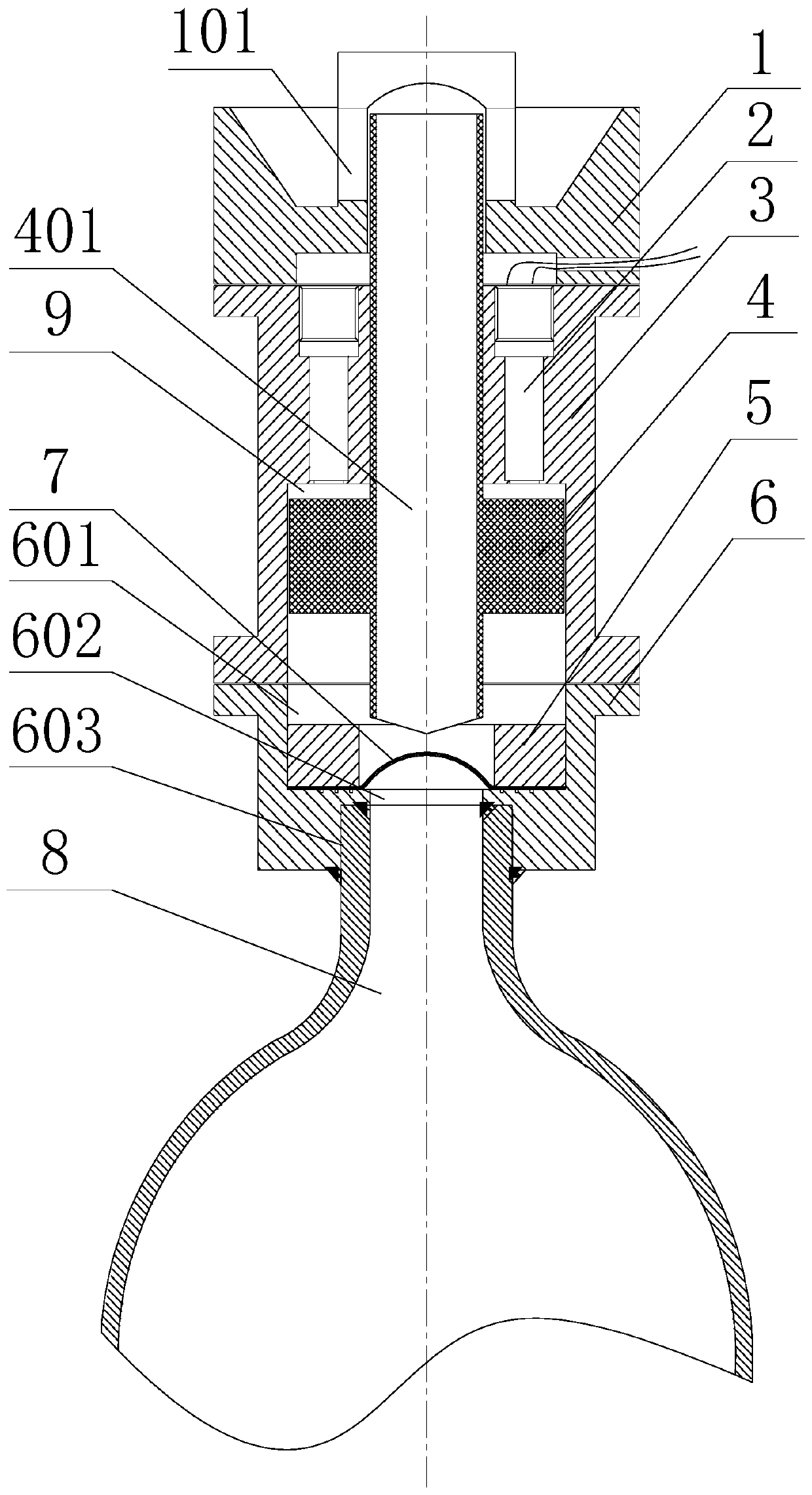

RH vacuum powder spraying refining device and powder spraying method thereof

The invention discloses an RH vacuum powder spraying refining device and a powder spraying method thereof, and belongs to the technical field of molten steel external refining. The RH vacuum refiningpowder spraying device comprises a vacuum molten steel circulating device and a powder spraying device. The vacuum molten steel circulating device comprises a vacuum chamber, a dip pipe, a steel ladleand a lifting gas pipeline. The powder spraying device comprises a powder spraying element, a powder supply pipe, a buffer gas chamber and a quick connecting part. The powder spraying method comprises but is not limited to refining and alloying functions of desulfurization, deoxidation, inclusion removal, alloy addition and the like. The RH vacuum powder spraying refining device and the powder spraying method thereof have the advantages that the bottom of a vacuum tank is improved on the basis of an RH conventional structure, and spray pipe mounting parameters can be adjusted to meet the process requirements of different steel types; and implementation is easy, maintenance is convenient, the production efficiency can be improved, the production cost is saved, and the application prospectsare good.

Owner:CENT IRON & STEEL RES INST

Foldable chair

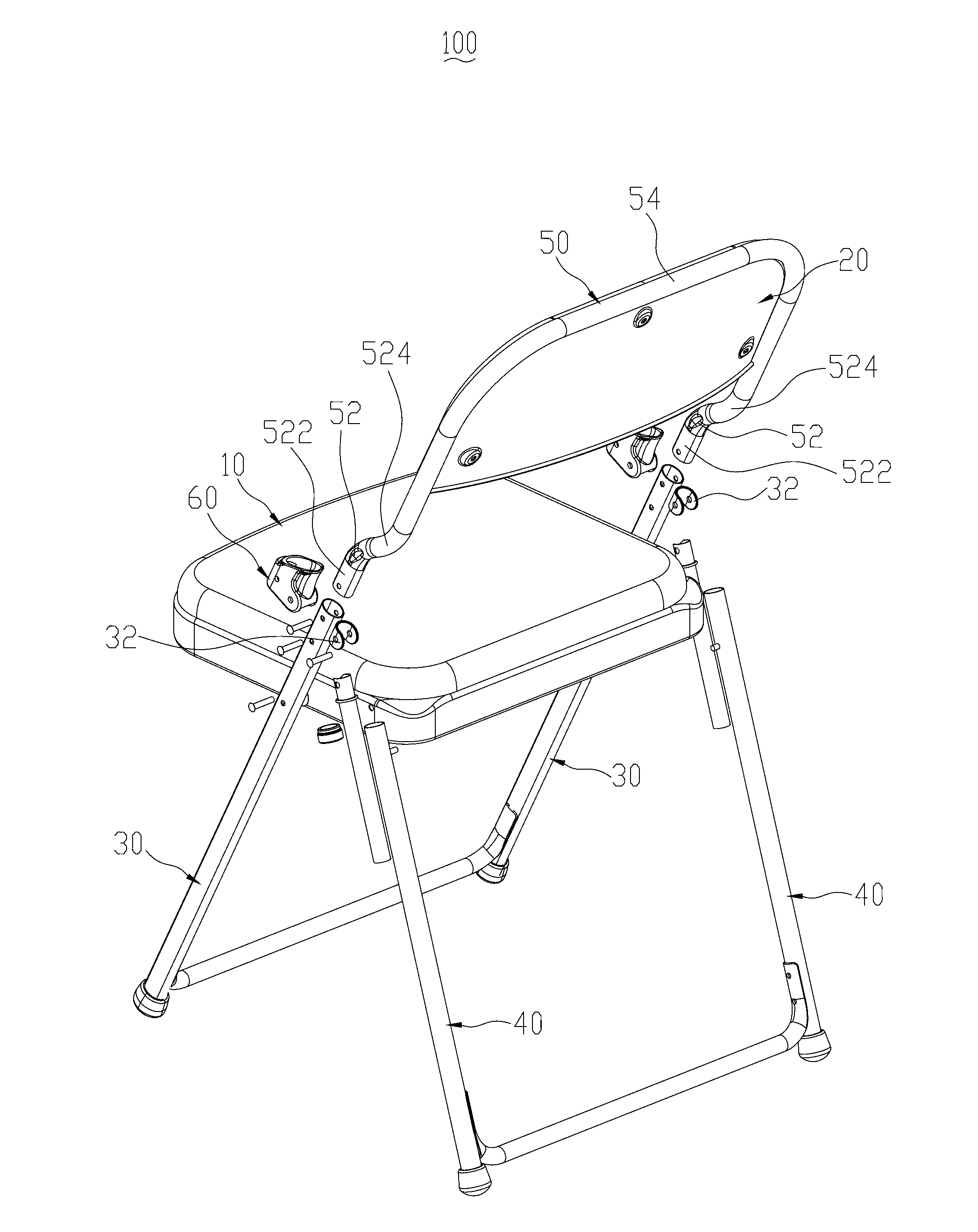

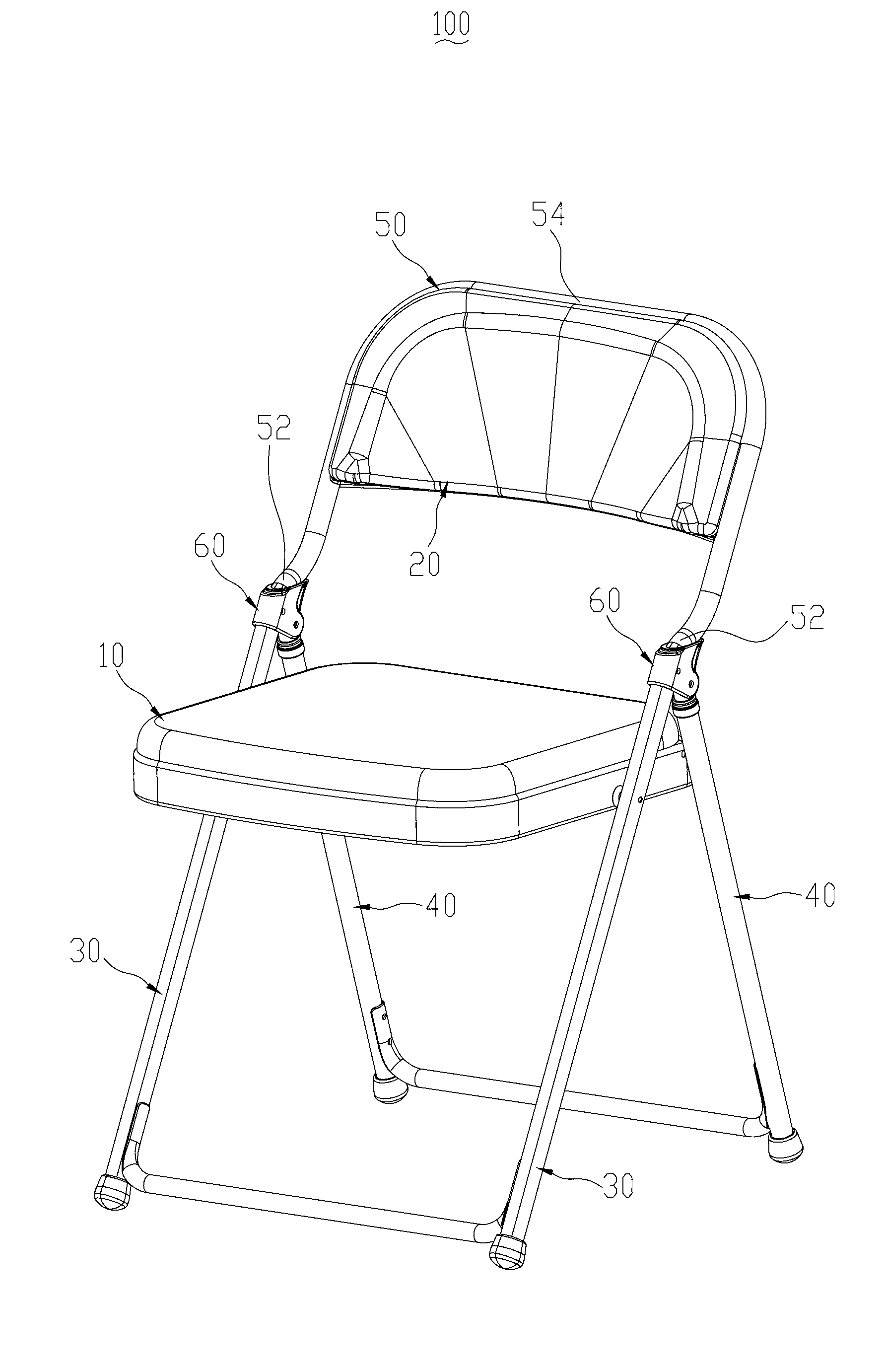

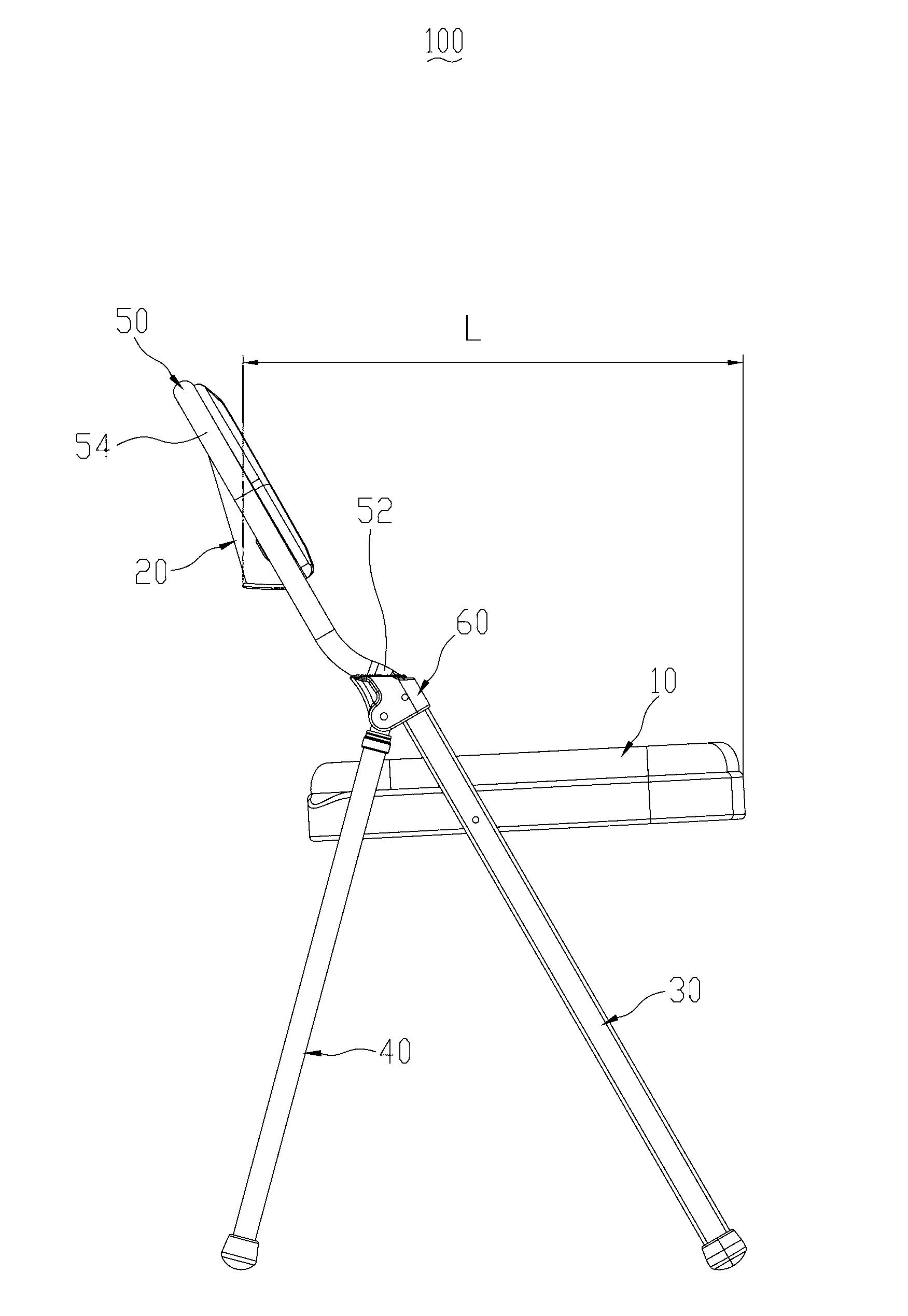

InactiveCN103040263ABigger and deeperImprove comfortDismountable chairsFoldable chairsEngineeringMechanical engineering

The invention discloses a foldable chair which comprises a seat board, a backrest, two front legs and two rear legs, wherein the upper parts of the front and rear legs are respectively connected with the rear parts of the left and right side edges of the seat board; the upper parts of the two front legs are respectively connected with the middle parts of the left and right side edges of the seat board; the upper ends of the rear legs are rotatably pivoted with the upper ends of the front legs; the chair further comprises a U-shaped tube piece; the U-shaped tube piece comprises a U-shaped section for fixing the backrest and fixed sections which are used for being connected with the front legs respectively; the two fixed sections are arranged in a mode of respectively extending and tilting outwards from the opening of the U-shaped section; the U-shaped section and the front legs are not arranged on one same straight line; and the U-shaped section deviates to one sides of the rear legs. As the U-shaped section and the front legs are not arranged on one same straight line, and the U-shaped section deviates to one sides of the rear legs, the distance between the backrest and the front end of the seat board is greatly increased, and the foldable chair has larger sitting depth, so that the human body conformability is greatly improved.

Owner:NEW TEC INTEGRATION (XIAMEN) CO LTD

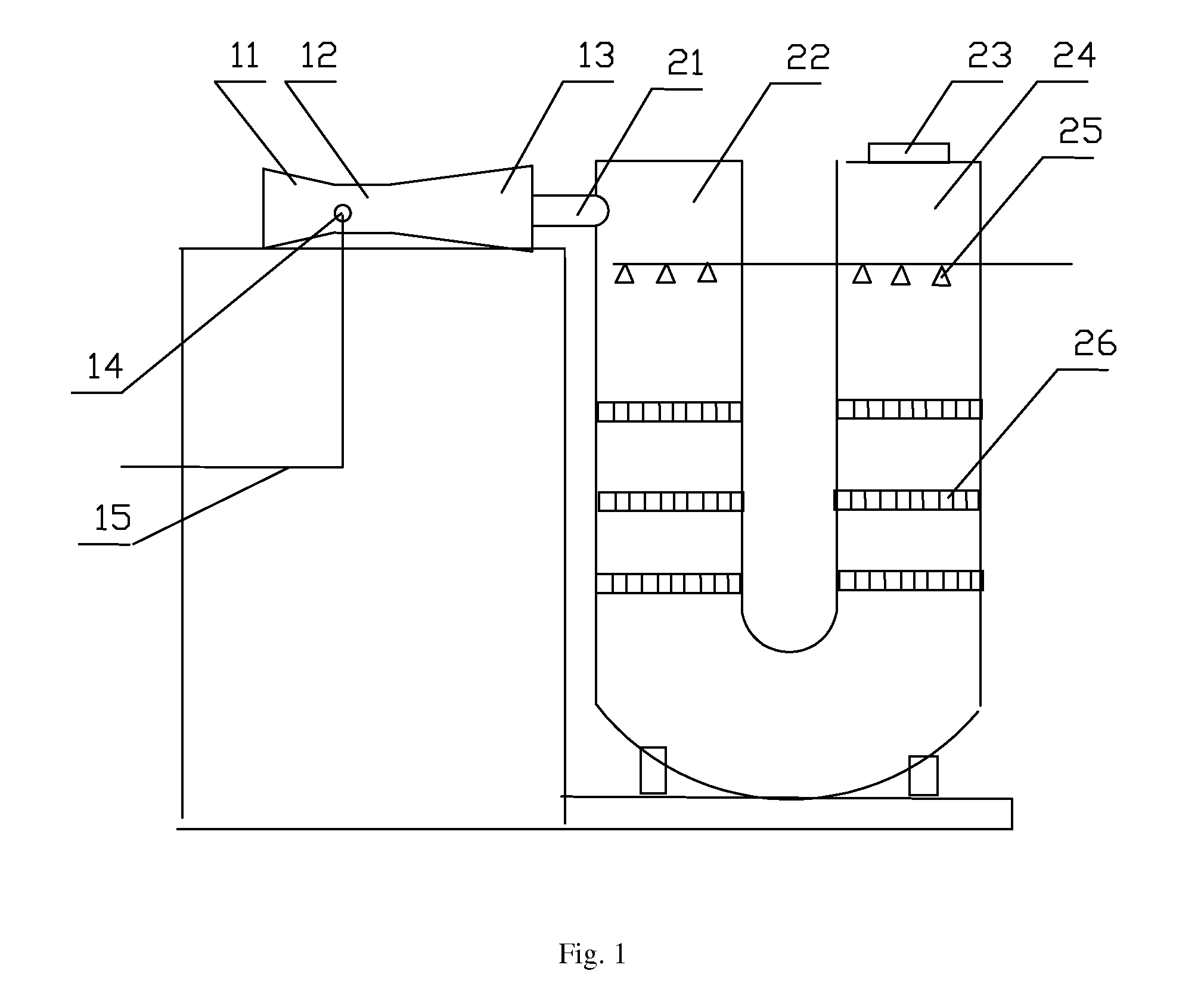

Wet dust remover

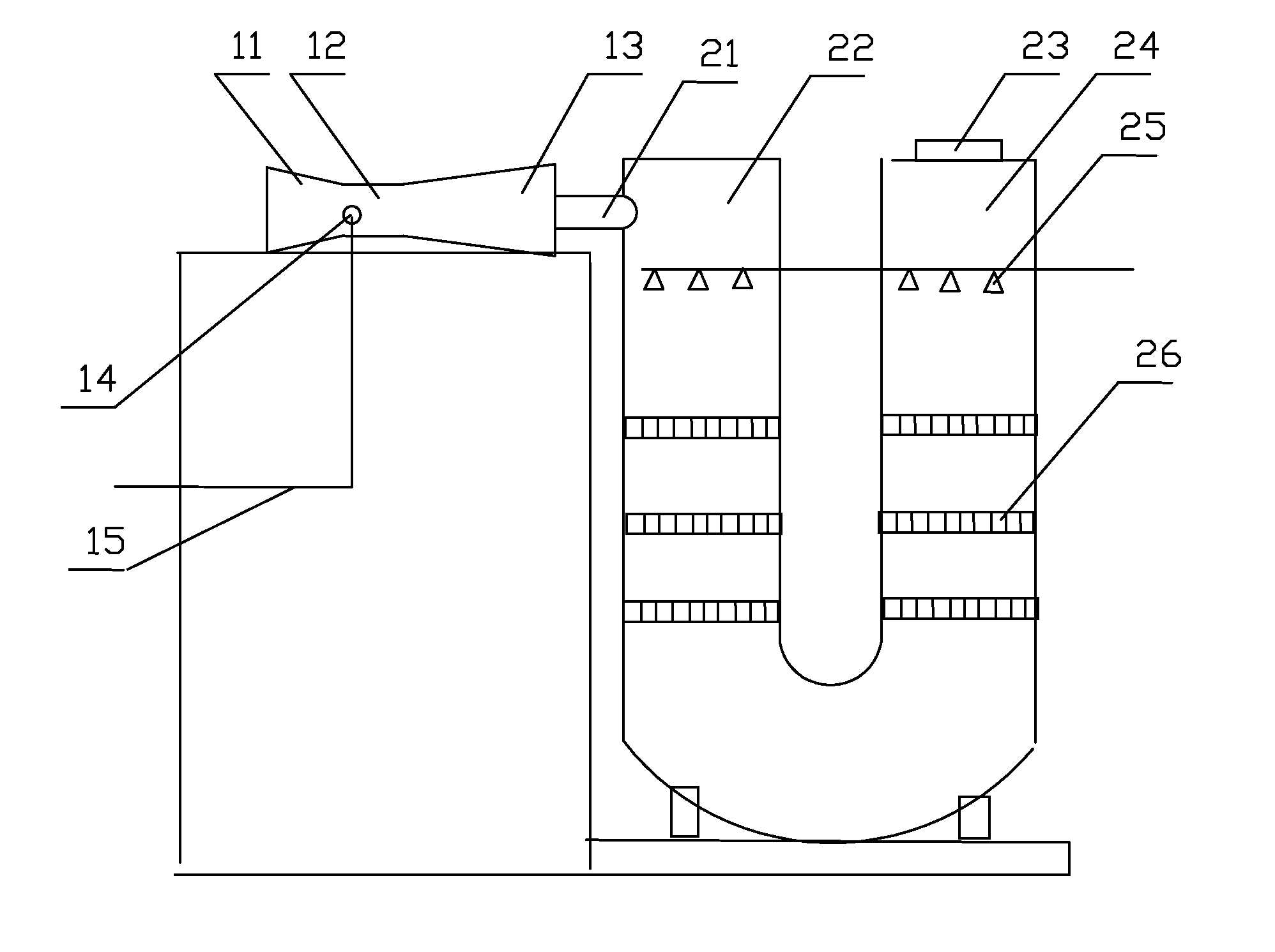

InactiveUS20090165685A1Improve dust removal efficiencyImprove dusting efficiencyUsing liquid separation agentSolid removalHigh concentrationFlue gas

This invention relates A wet dust remover, comprising a Venturi tube and a cylindrical washer, wherein the Venturi tube includes a convergent section, a throat section and a diffusion section, the sidewall of said throat section is provided with one or more through holes, the outer ends of the one or more through holes are connected to a pressure water pipe, the outer end of said diffusion section constitutes the outlet of the Venturi tube, the outer end of said convergent section constitutes the inlet of the Venturi tube, wherein the cylindrical washer includes a plurality of nozzles and a plurality of layers of dehydration wire meshes, the plurality of nozzles and the plurality of layers of dehydration wire meshes are placed in cross sections inside cylindrical washer. This wet dust remover feature less investment, high dust removing efficiency and relative long life, low water consumption and low operation costs and it can be mainly used in dusting applications for industrial dust and high concentration flue gas of all industrial furnaces and kilns.

Owner:HAISIBOTE BEIJING SCIENE & TECH

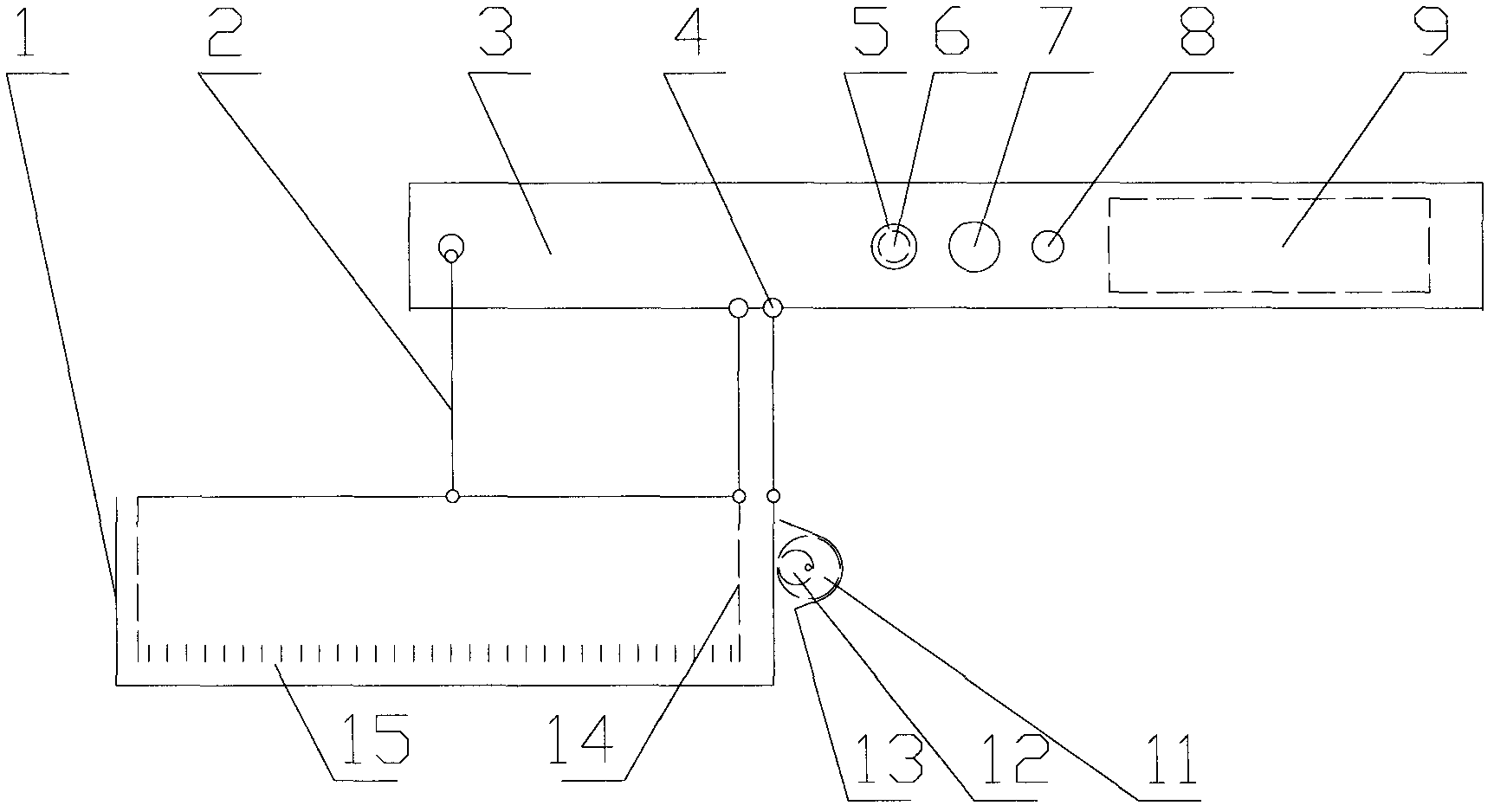

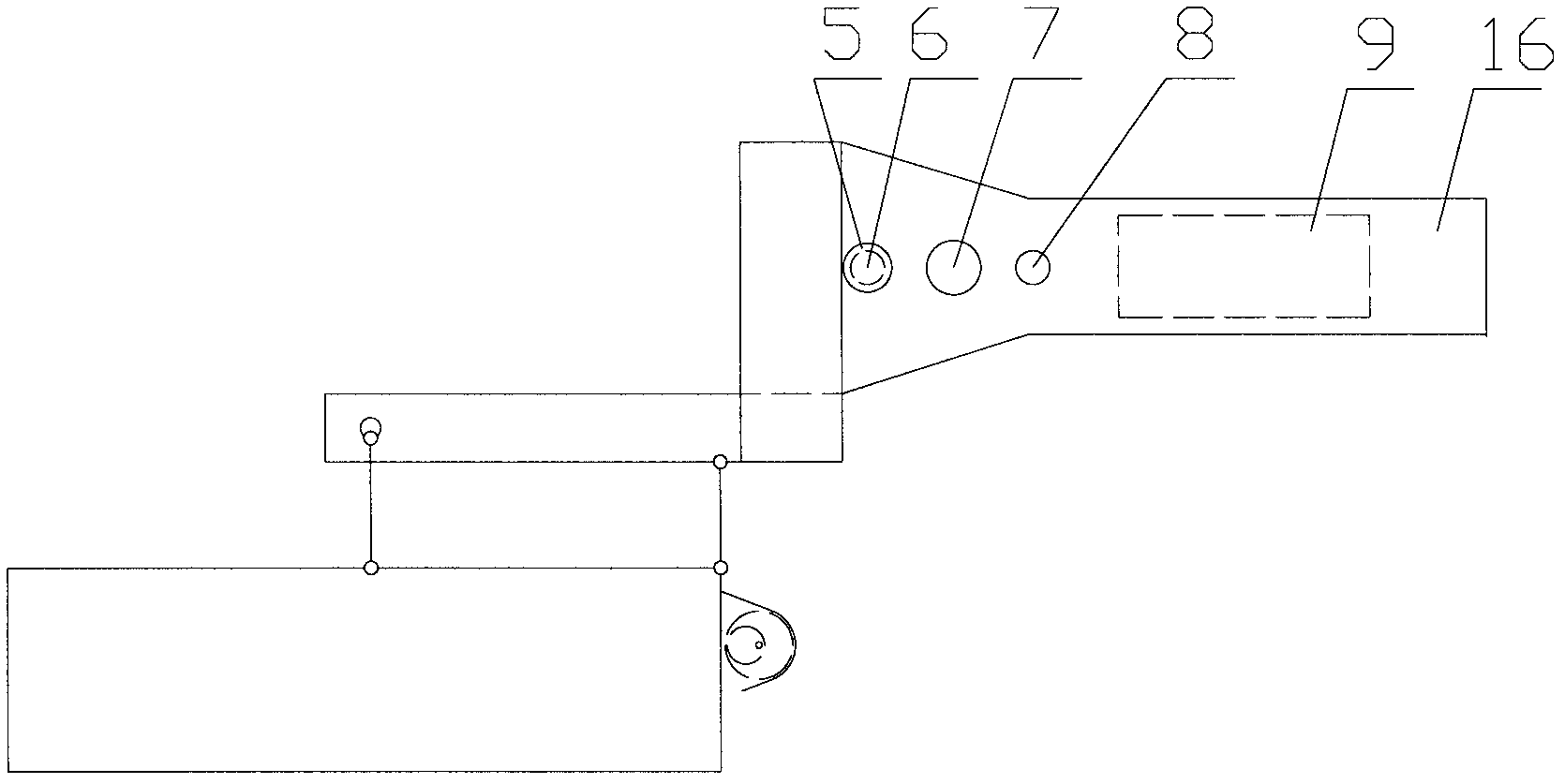

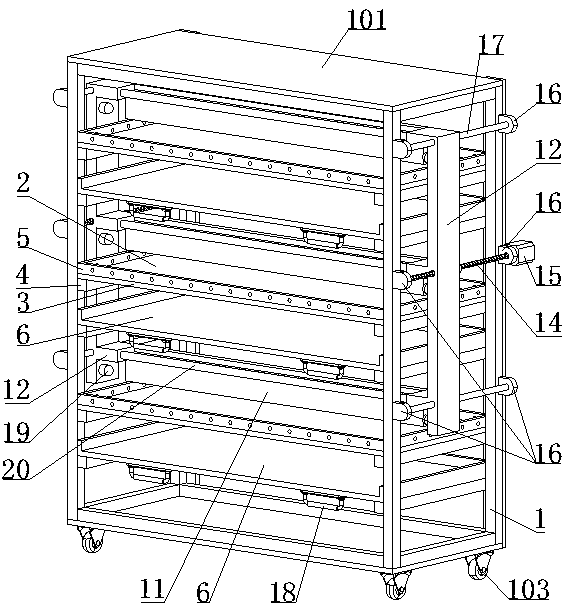

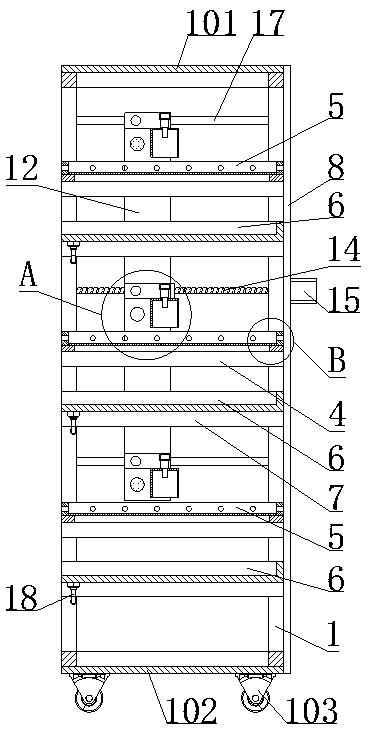

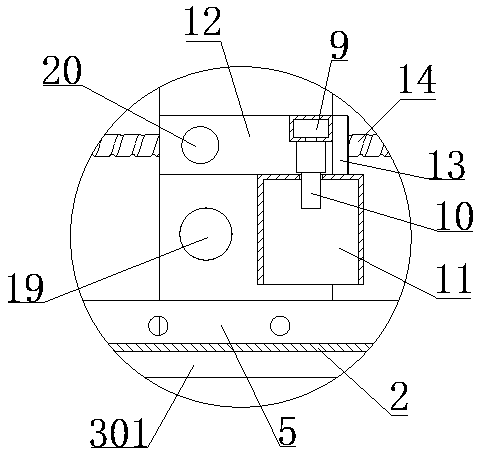

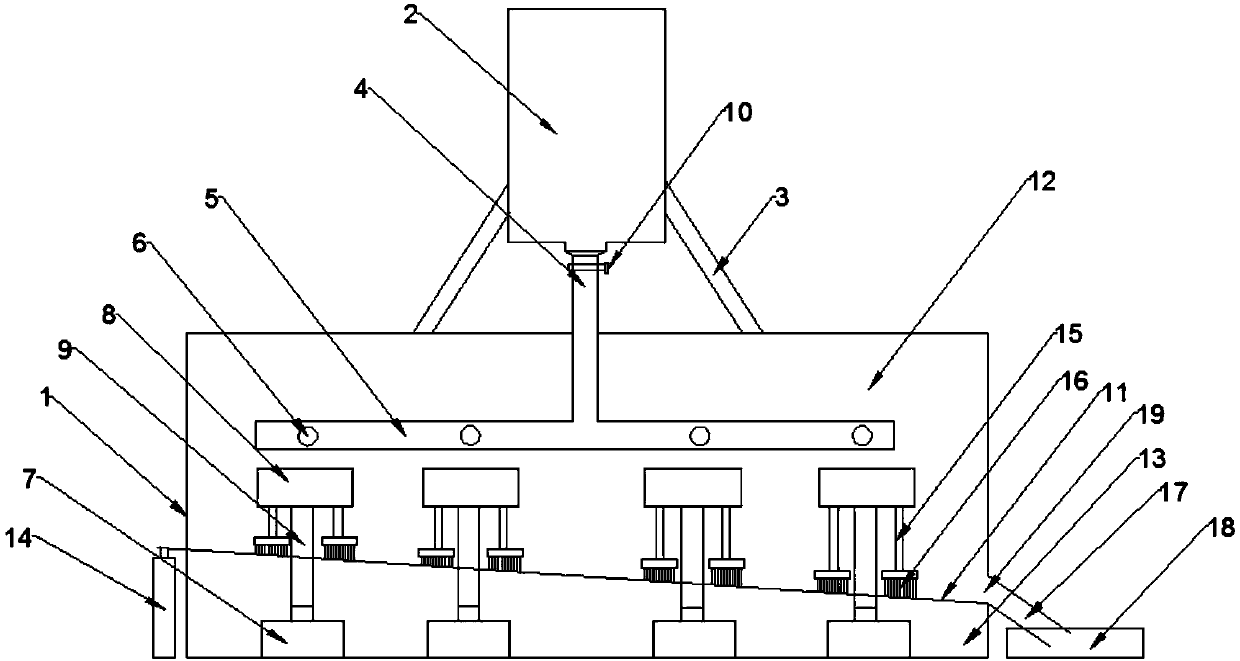

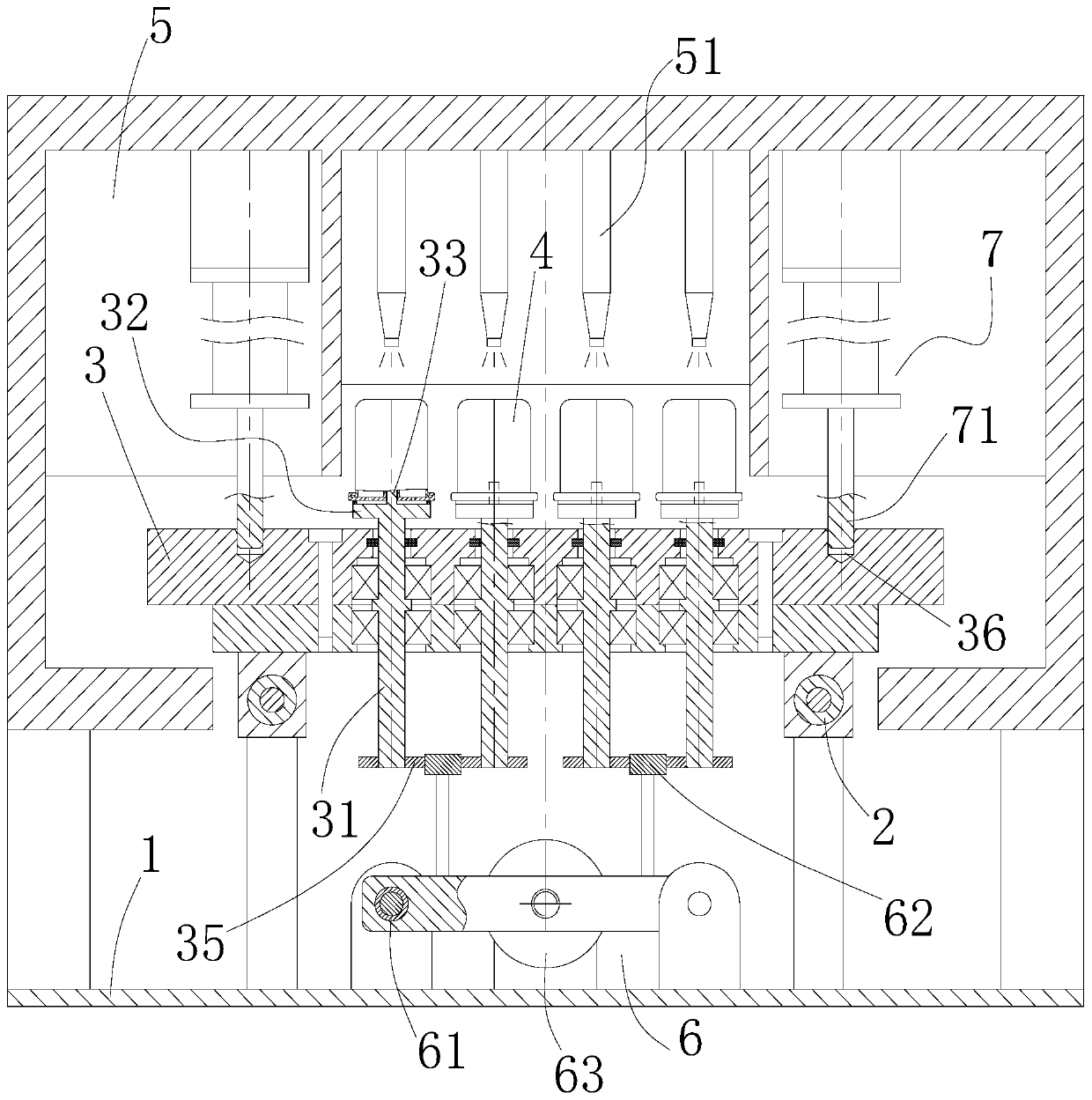

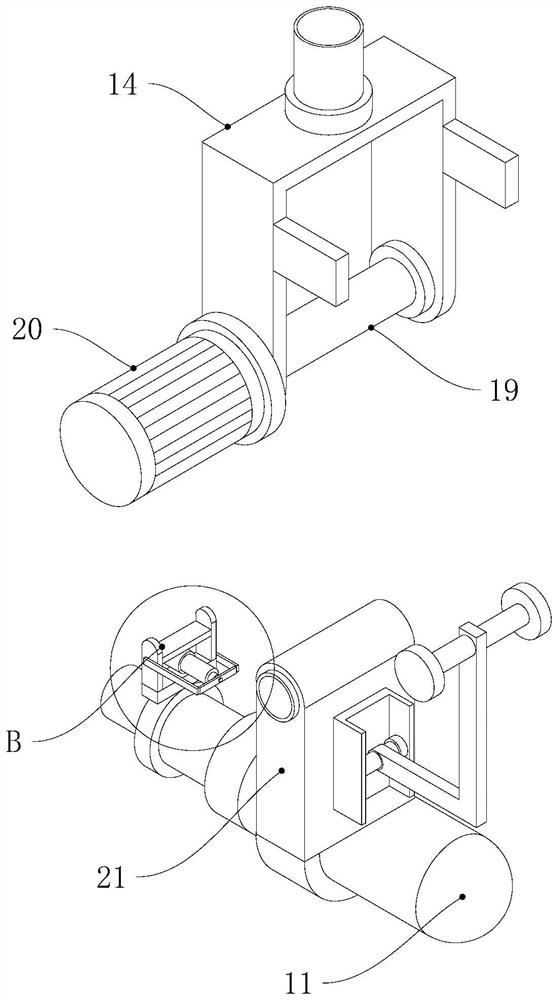

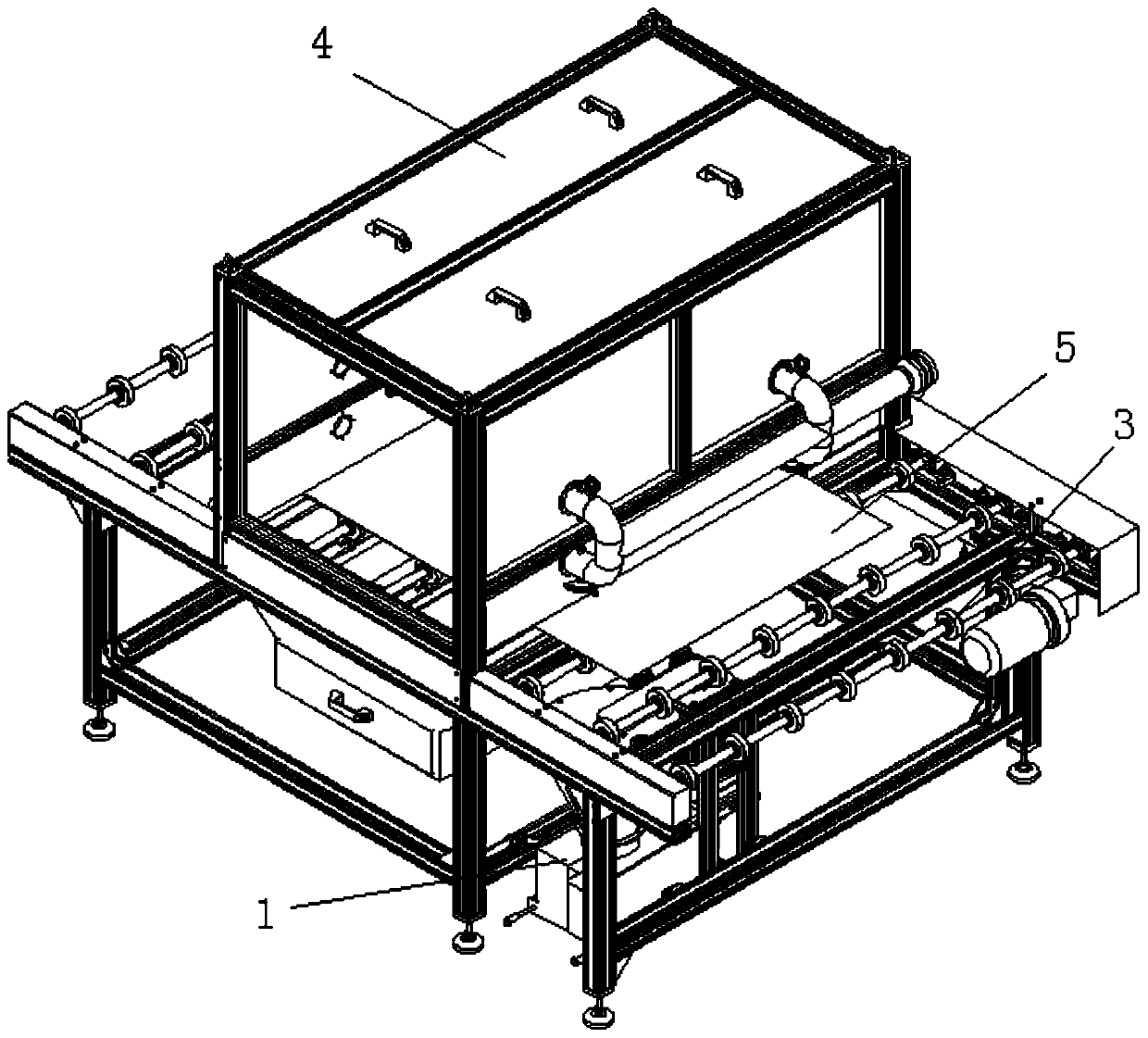

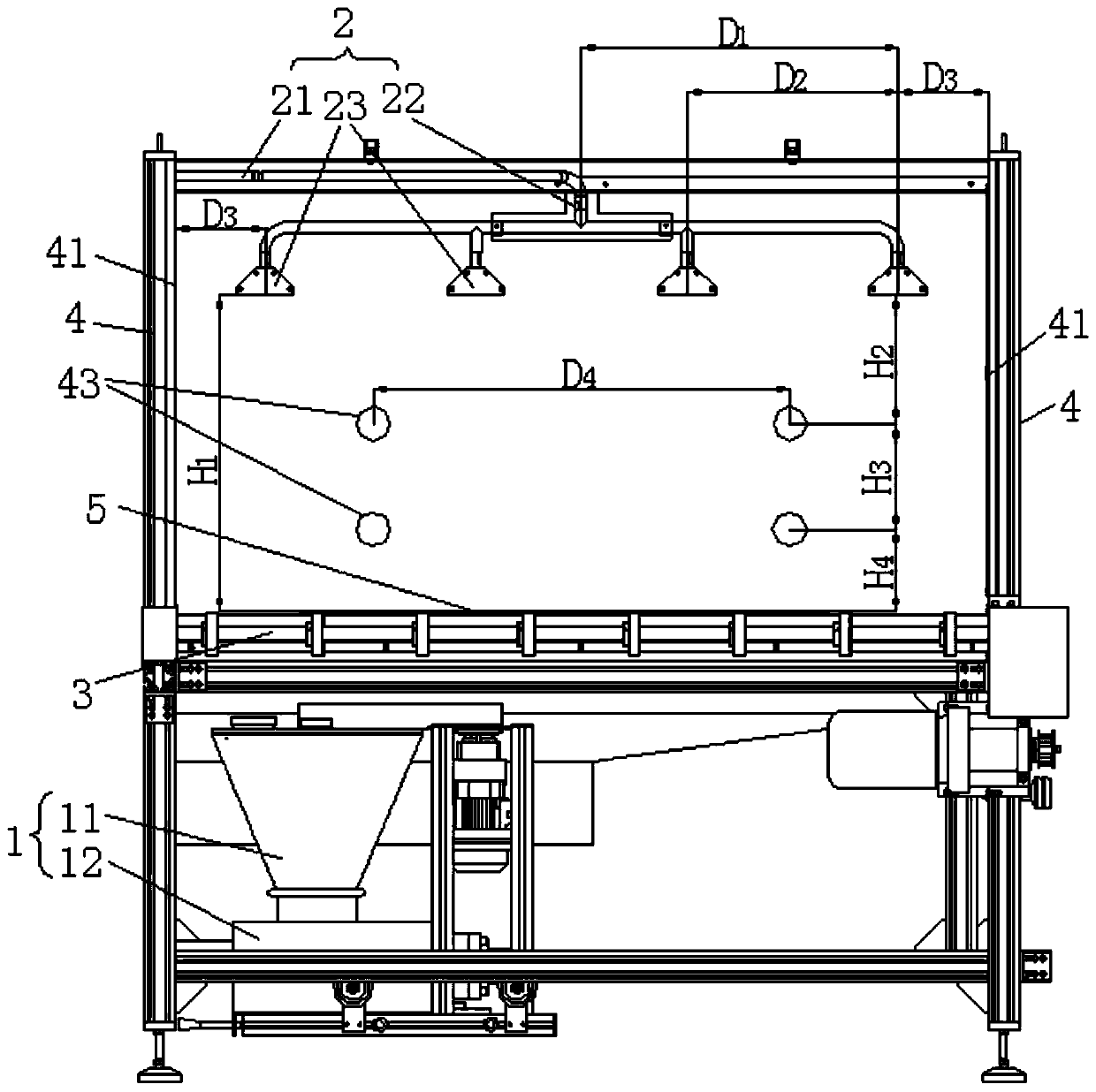

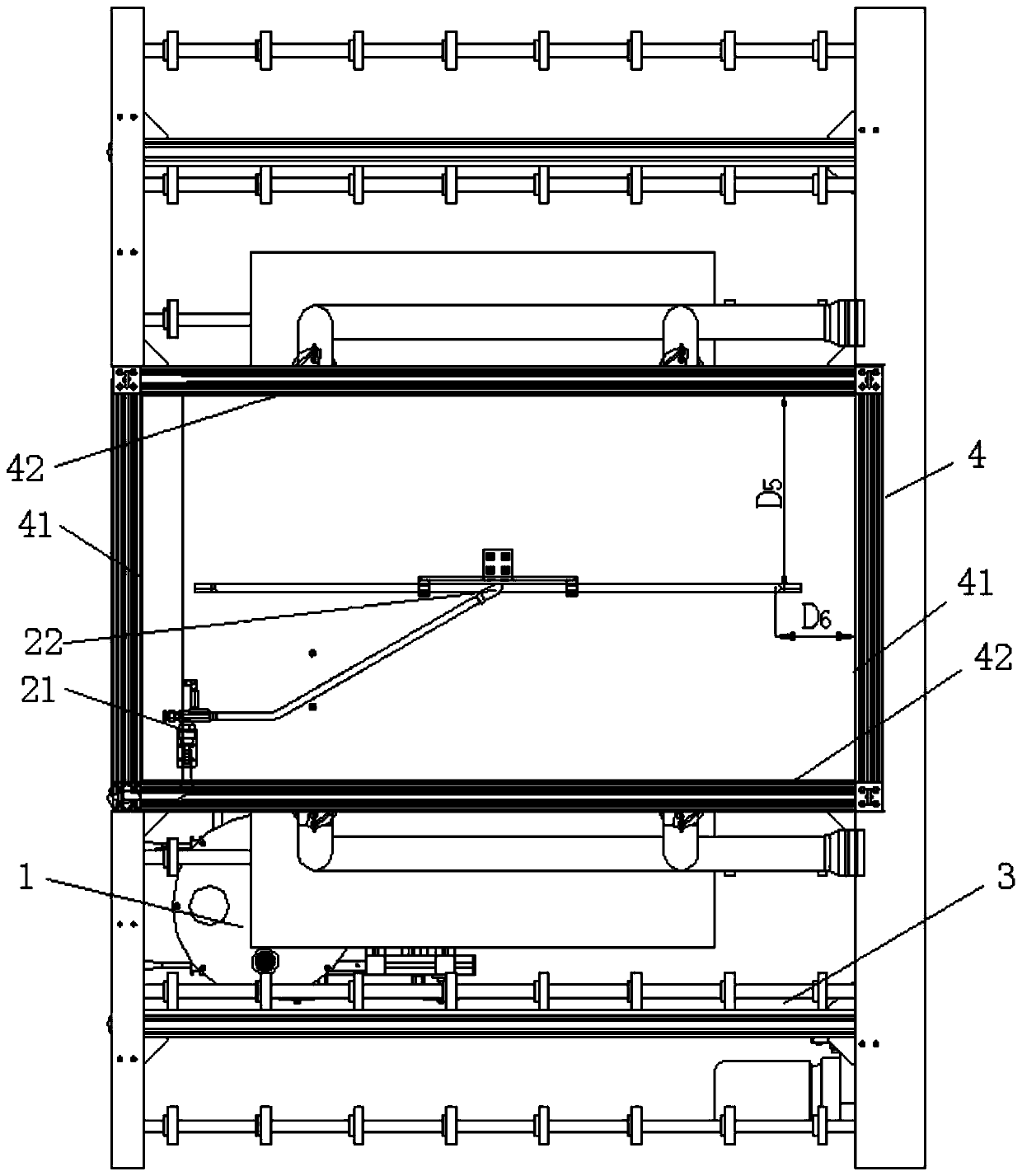

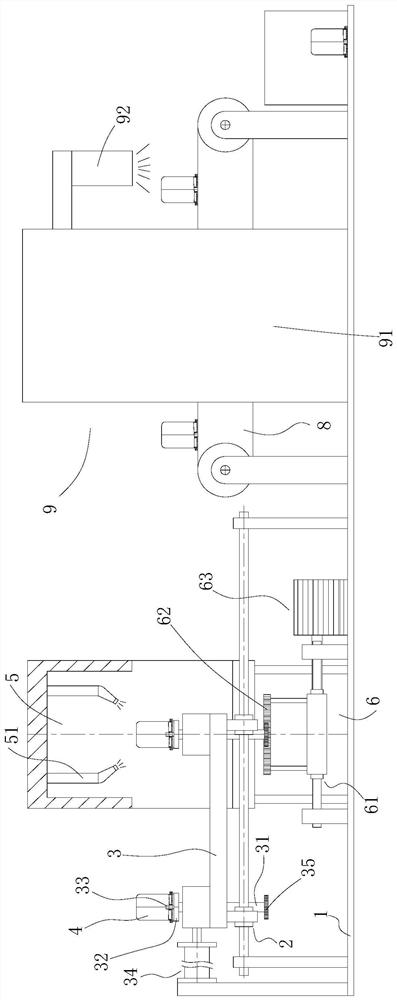

Silkworm rearing and disinfecting powder-spraying equipment based on monitored data

InactiveCN110999876AFully disinfectedImprove dusting efficiencyClosed circuit television systemsFood scienceAnimal scienceMonitoring data

The invention relates to silkworm rearing and disinfecting powder-spraying equipment based on monitored data. The silkworm rearing and disinfecting powder-spraying equipment based on the monitored data comprises a frame, filter screens, supporting frames, powder supply boxes, powder nozzles, mobile frames, a wireless transmission module and a central controller; the filter screens are arranged onthe supporting frames; the supporting frames are arranged on the frame; the powder nozzles are arranged on the bottoms of the powder supply boxes, the powder nozzles are located above the filter screens, and powder spraying directions of the powder nozzles are downward; the powder supply boxes are arranged on the mobile frames; cameras used for collecting images of silkworms and mulberry leaves onthe filter screens are arranged on the mobile frames; driving mechanisms used for driving the mobile frames to move longitudinally to and fro are arranged on the frame; the cameras and the wireless transmission module are in communication connection; the wireless transmission module and the central controller are in communication connection; and the central controller and the powder nozzles are in control connection. The silkworm rearing and disinfecting powder-spraying equipment based on the monitored data can conduct powder spraying disinfection on the silkworms and the mulberry leaves through the mobile powder nozzles according to monitored situations of the silkworms and the mulberry leaves on the filter screens, the powder spraying efficiency is high, and the silkworm rearing and disinfecting powder-spraying equipment based on the monitored data is safer.

Owner:江西修水养蚕人实业有限公司

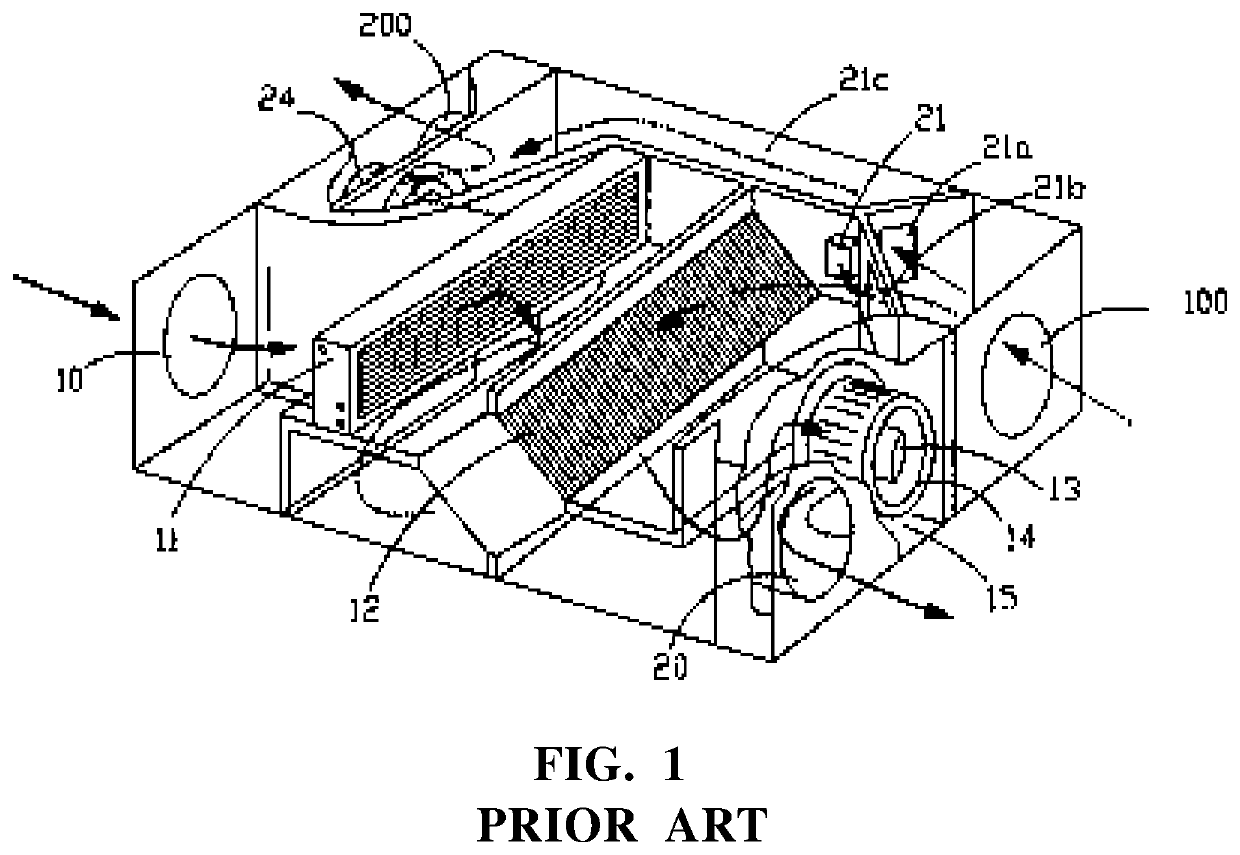

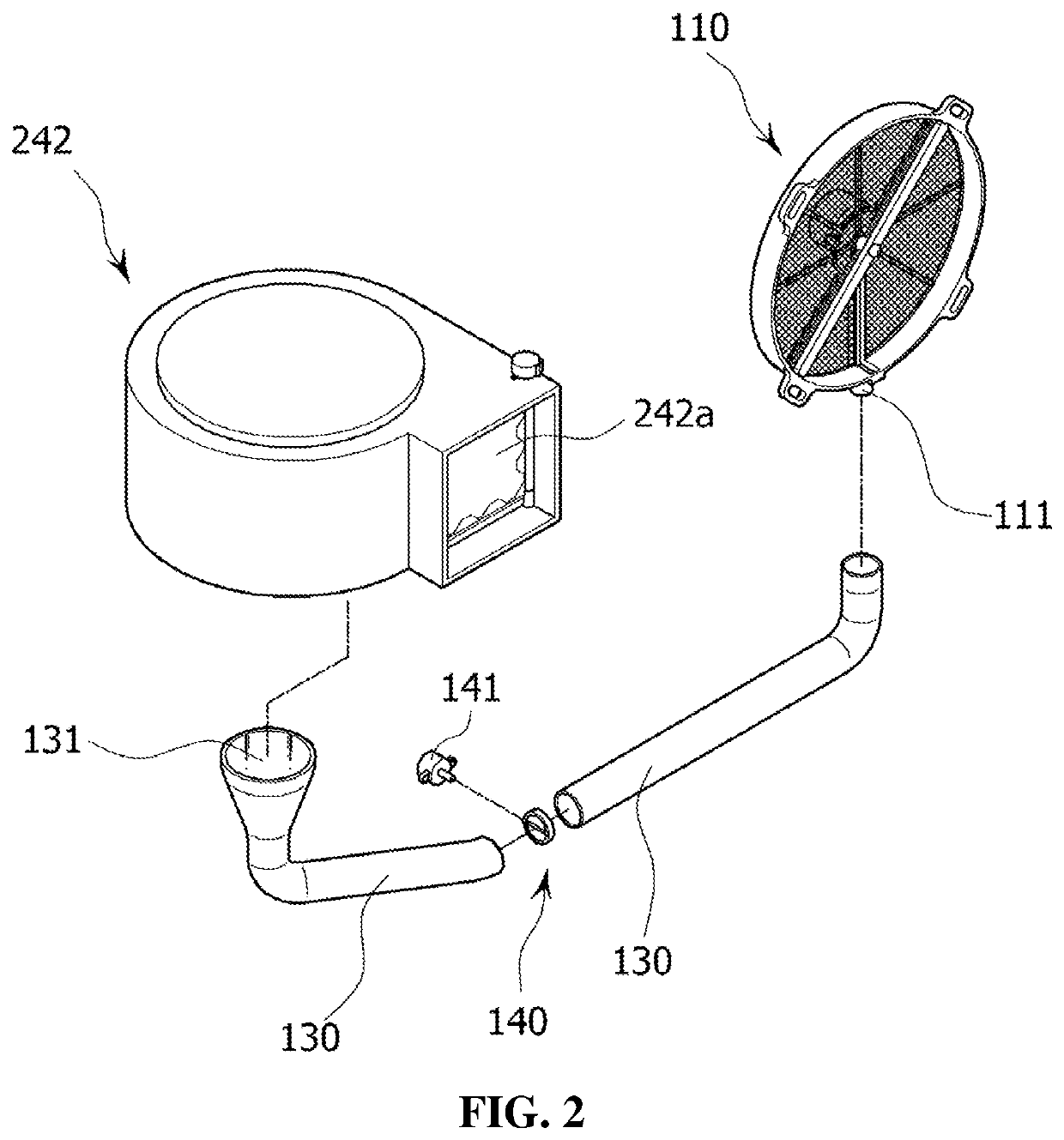

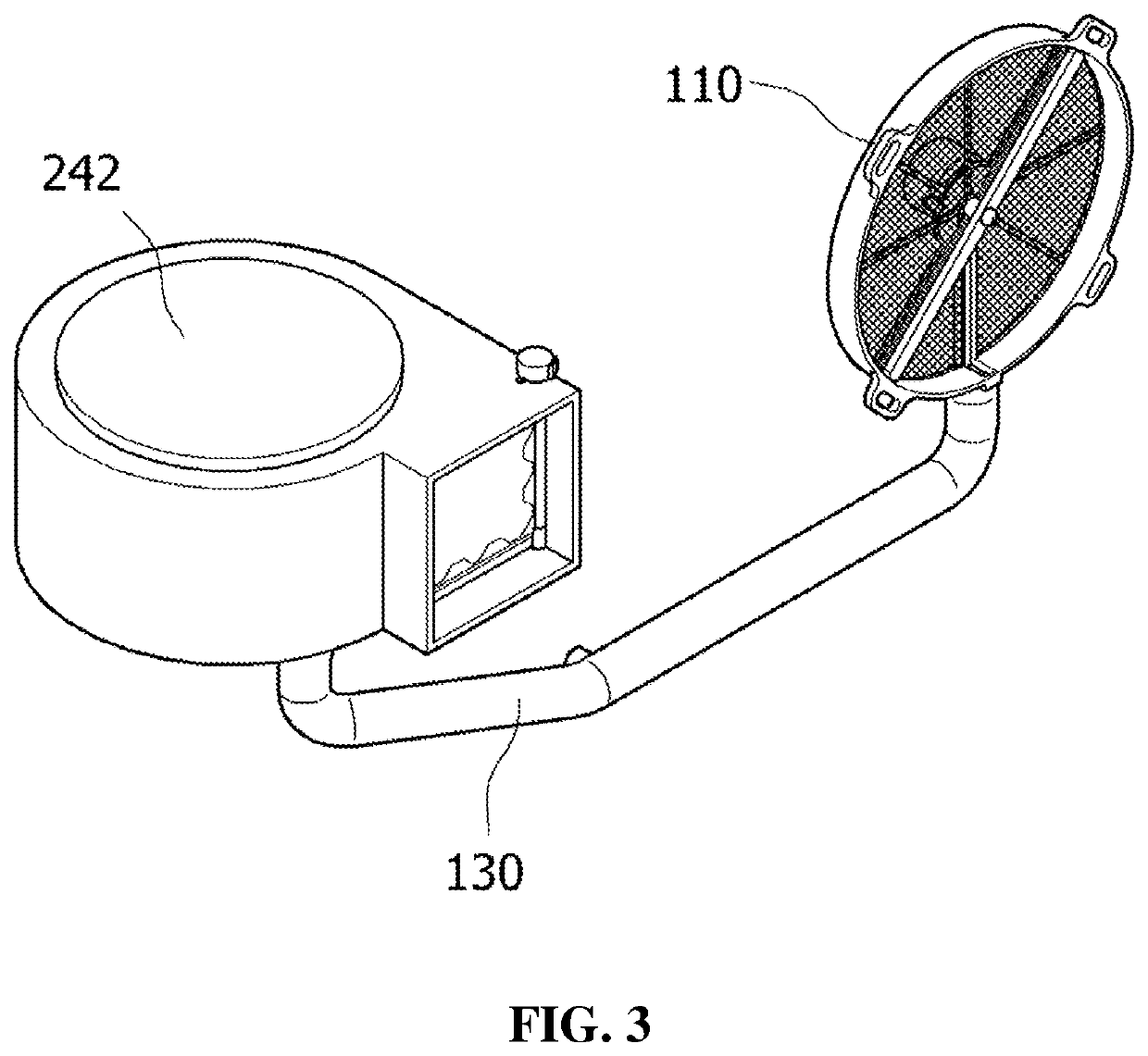

Air-conditioning device having dust removing function

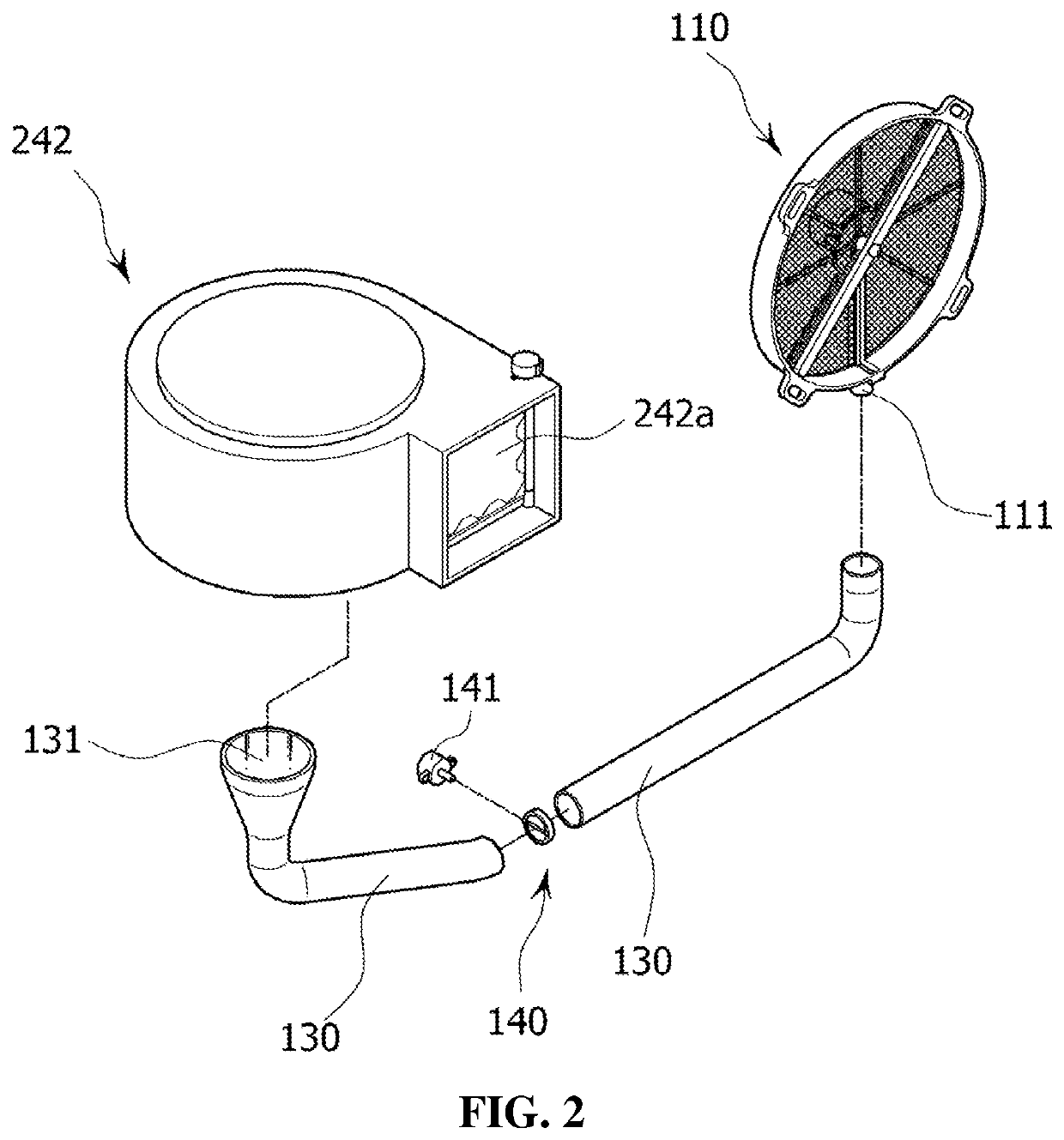

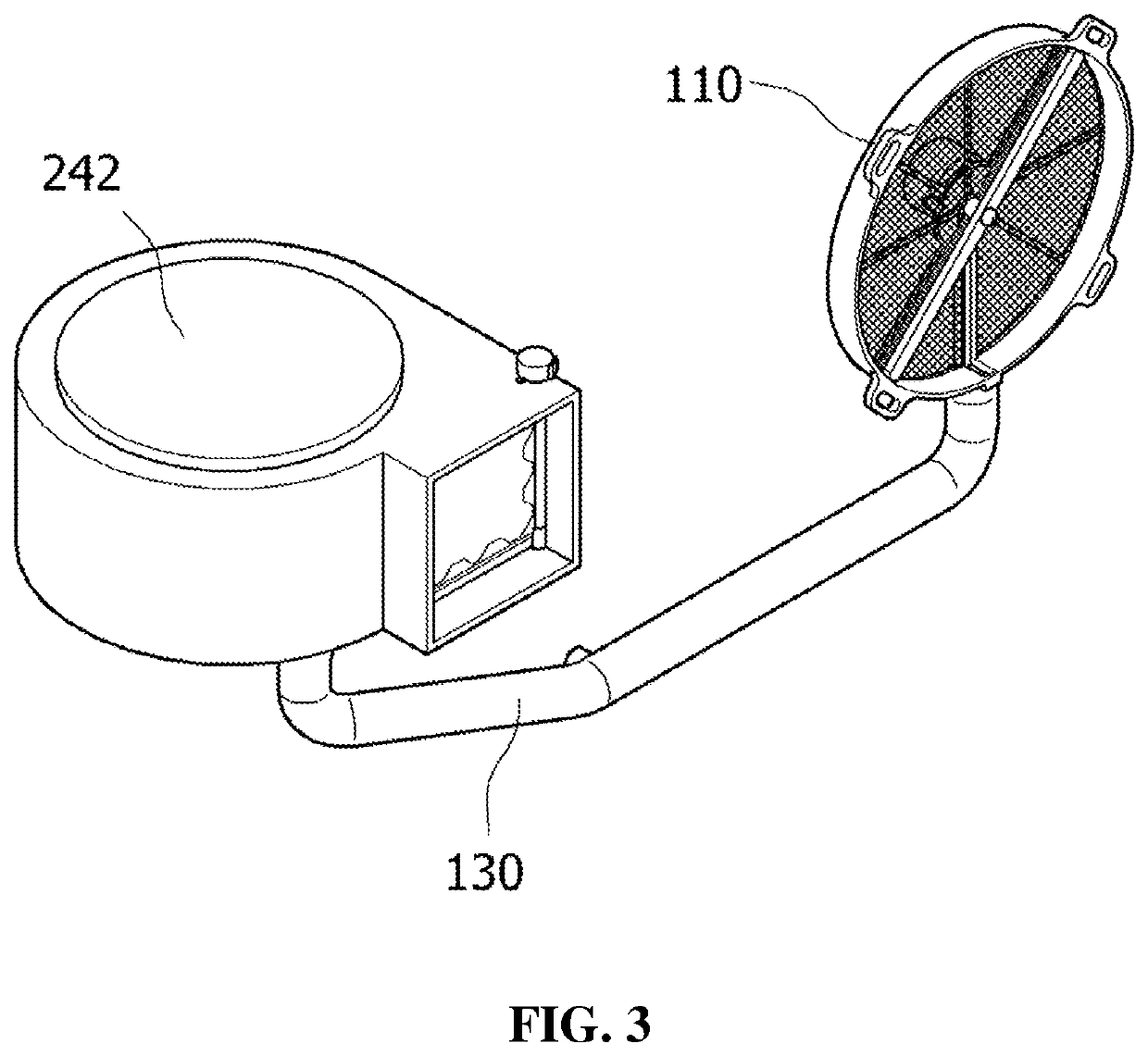

ActiveUS20200155992A1Minimize introductionImprove dust collect efficiencyMechanical apparatusDispersed particle filtrationIndoor airMechanical engineering

An air-conditioning device has a dust removing function, including: an outdoor air introducing portion for introducing outdoor air into a case; an outdoor air discharge portion having a blowing fan for supplying the indoor environment with the outdoor air introduced through the outdoor air introducing portion; an indoor air introducing portion for introducing indoor air; and an indoor air discharge portion having a blowing fan for discharging the indoor air introduced through the indoor air introducing portion into the outdoor environment, wherein the air-conditioning device includes: a filter coupled inside the entrance of the outdoor air introducing portion to be able to collect dust that is introduced together with outdoor air; and an opening formed through the lower end of the edge portion of the filter.

Owner:CENDORI

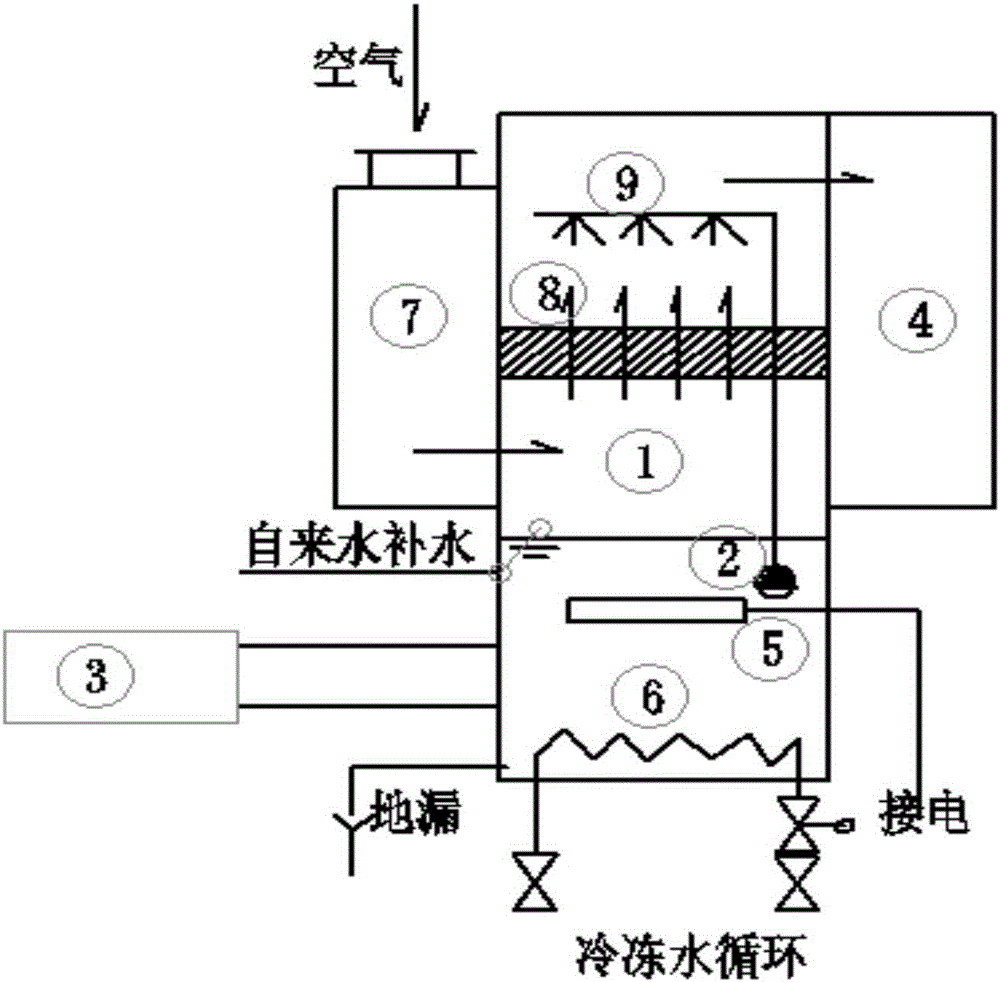

Energy-saving method for forest air conditioner

InactiveCN106524340AEasy to use habitsReduce leakageEnergy recovery in ventilation and heatingMechanical apparatusRecovery methodFresh air

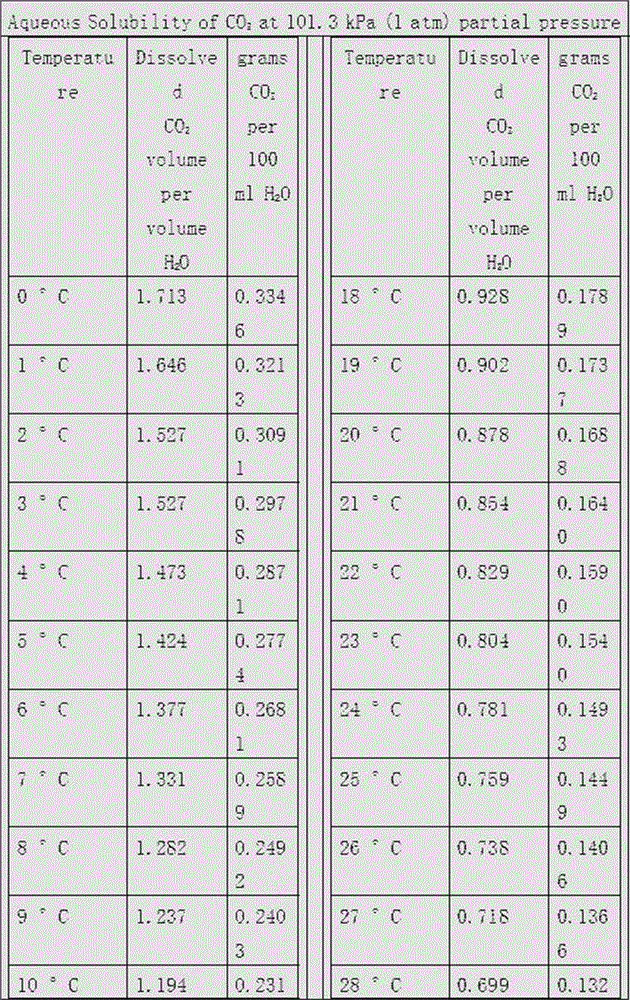

The invention relates to the field of material and energy and the field of environmental protection and discloses a method and process for achieving energy saving based on a manual simulation forest microclimate system under air conditioner application through Carnot cycle. Water is led in to serve as a medium for a conveying and distribution system. through the scheme that a cold water cooling capacity recovery method is adopted, the temperature of a condenser is lowered, secondary latent heat of a refrigerant is used, the temperature condition of an evaporator is raised, heat and cooling capacity output efficiency is improved and fresh air ventilation removal is replaced by a method that indoor carbon dioxide, TVOC, air dust microorganism and other pollutants are removed by washing air, 10%-40% energy is saved in the usage process of the air conditioner.

Owner:周伟文

Air-conditioning device having dust removing function

ActiveUS11433345B2Minimizing introductionAvoid dustMechanical apparatusDispersed particle filtrationEnvironmental engineeringAir blower

An air-conditioning device has a dust removing function, including: an outdoor air introducing portion for introducing outdoor air into a case; an outdoor air discharge portion having a blowing fan for supplying the indoor environment with the outdoor air introduced through the outdoor air introducing portion; an indoor air introducing portion for introducing indoor air; and an indoor air discharge portion having a blowing fan for discharging the indoor air introduced through the indoor air introducing portion into the outdoor environment, wherein the air-conditioning device includes: a filter coupled inside the entrance of the outdoor air introducing portion to be able to collect dust that is introduced together with outdoor air; and an opening formed through the lower end of the edge portion of the filter.

Owner:CENDORI

Powder-coating spraying gun

InactiveCN101712018AImprove dusting efficiencyImprove spraying effectLiquid spraying apparatusEngineeringPowder Spray

The invention discloses a powder-coating spraying gun applied to the preparation of an inner coating of a pipeline and comprising a powder supply pipe, a sprinkle bracket, an adjusting bracket, a powder-merging cavity, a water-cooling sleeve and a water supply system. The sprinkle bracket is arranged at the front end of the powder supply pipe and connected with a sprinkle by the adjusting bracket; the powder-merging cavity is arranged at the rear end of the powder supply pipe; and the water-cooling sleeve is connected with the water supply system by the aid of a matched water-cooling joint seat. The spraying gun structure is also internally provided with an adjustable atomization-adjusting tube and an adjustable conical sprinkle to improve the atomization effect of the powder; the water-cooling sleeve can cool the powder-coating spraying gun in real time, and the powder deposited on the inner wall of the spraying gun can not be caked or melted, thereby improving the powder-spraying effect. The powder-coating spraying gun has good popularization and use values.

Owner:CNPC BOHAI EQUIP MFG +1

Quick-opening valve and prepared explosion suppressor applying quick-opening valve

InactiveCN110440042AImprove dusting efficiencyShort response timeEqualizing valvesSafety valvesSuppressorMechanical engineering

The invention relates to a quick-opening valve and a prepared explosion suppressor applying the quick-opening valve and belongs to the technical field of valves. The quick-opening valve comprises a rupture disk and a valve body and an impact rod and a trigger device which are arranged inside the valve body, wherein one end of the valve body is provided with an inlet passage of an explosion suppressant, the other end of the valve body is provided with a diffusion passage of the explosion suppressant, the rupture disk is arranged on the inlet passage, and the impact rod is provided with an outflow passage of the explosion suppressant, is slidably connected with the valve body and moves to the inlet passage to puncture the rupture disk under the action of the trigger device to make the inletpassage communicate with the outflow passage. According to the quick-opening valve and the prepared explosion suppressor applying the quick-opening valve, by means of the manner that the impact rod ispushed to move to puncture the rupture disk utilizing the trigger device, the problem of poor safety performance existing in existing quick-opening valves is solved.

Owner:CHINA COAL TECH ENG GRP CHONGQING RES INST

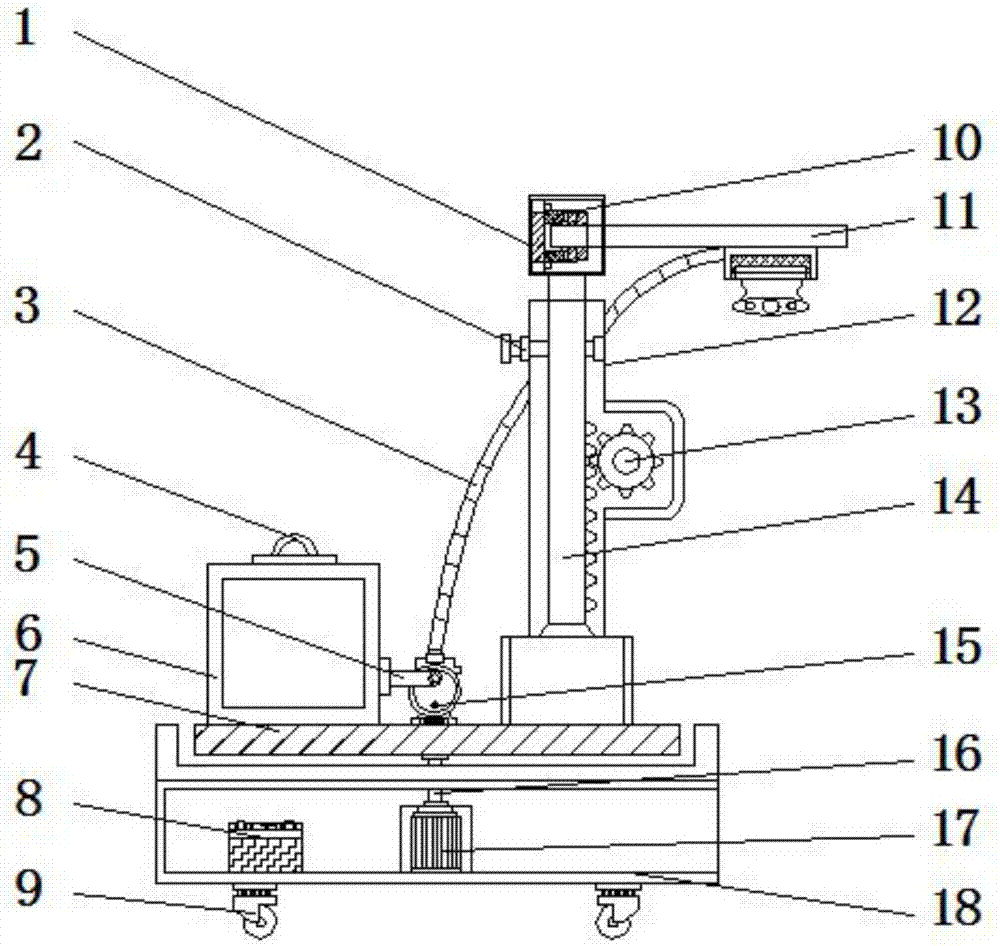

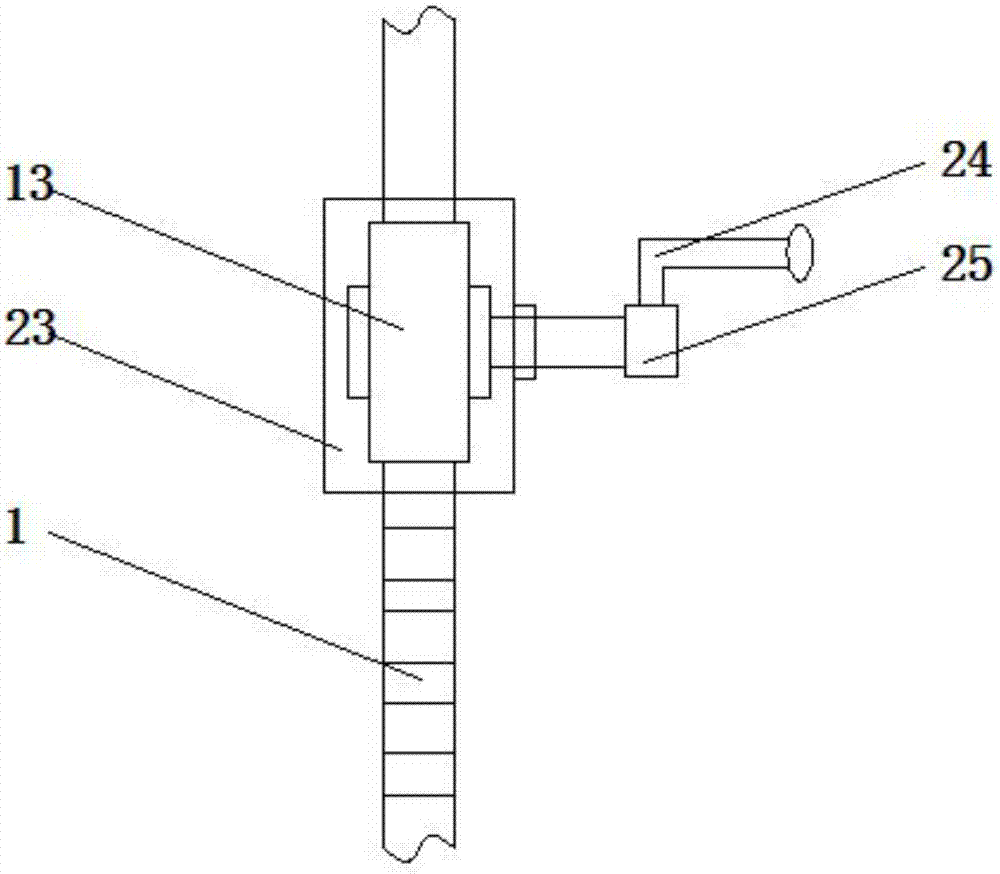

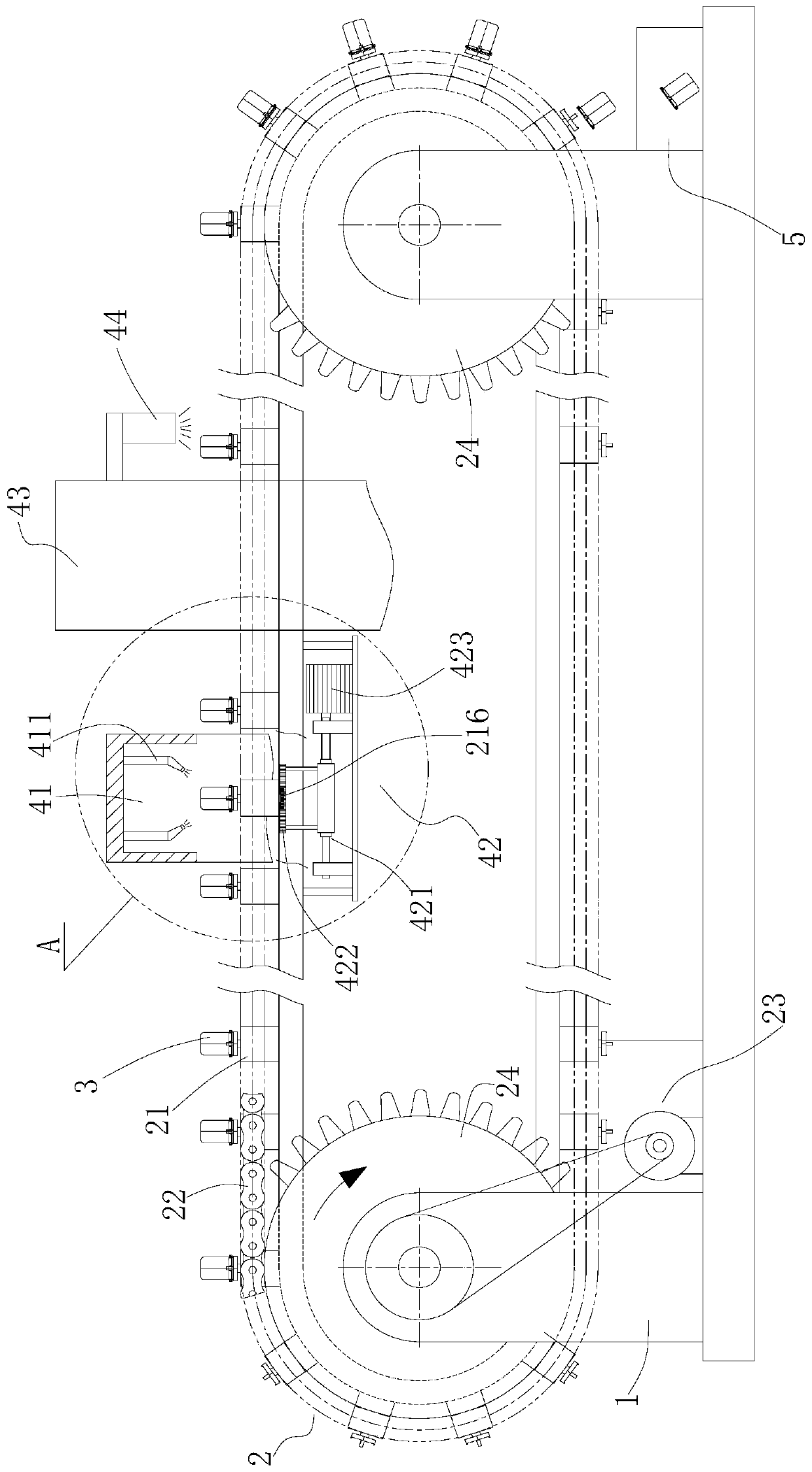

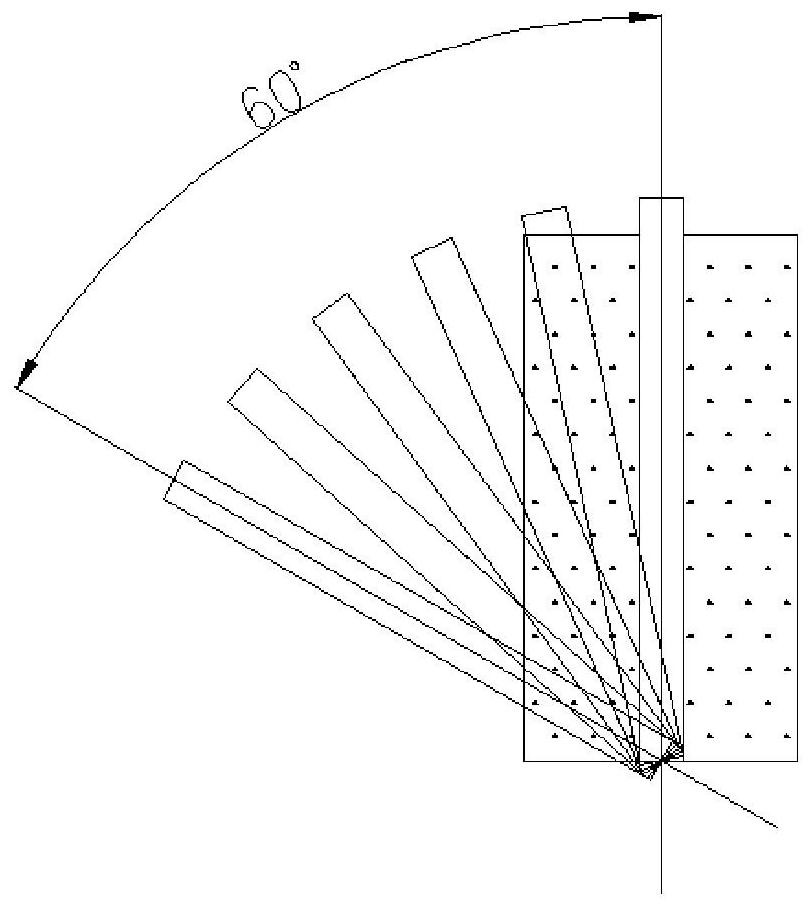

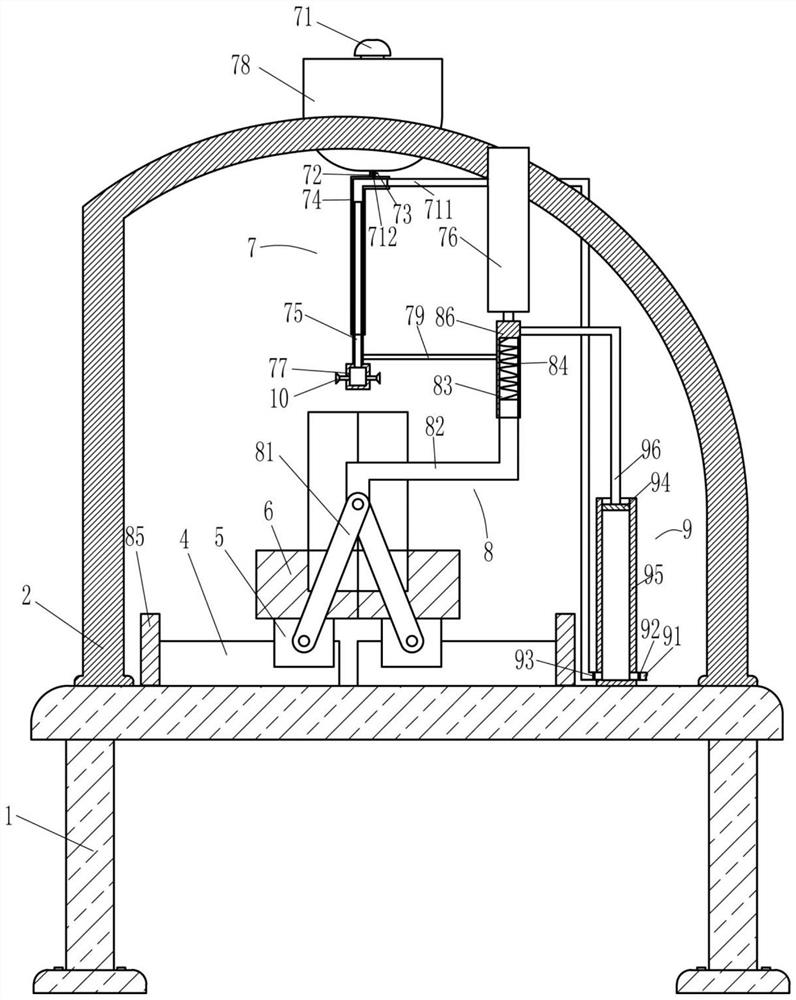

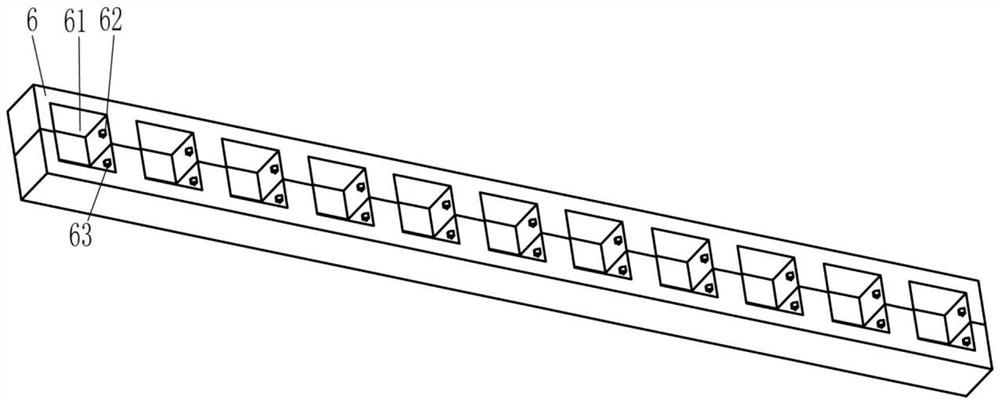

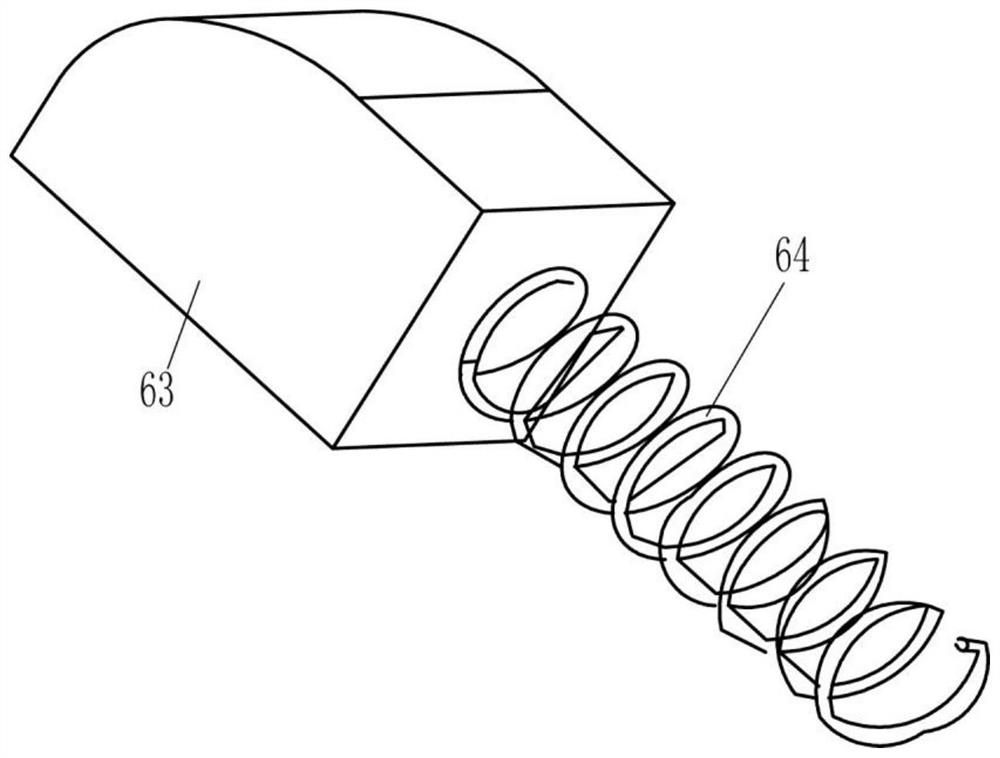

Powder spraying agricultural mechanical equipment for silkworm breeding

InactiveCN107350108ALarge production batchImprove dusting efficiencyLiquid spraying apparatusAnimal husbandryPistonAgricultural engineering

The invention relates to a powder-sprinkling agricultural mechanical equipment for silkworm breeding, which includes a bolt, a turntable, a chain rod and a machine body. A rotating motor is installed at the middle of the inner bottom of the body, and the rotating motor is electrically connected to a storage battery through a wire. One side of the top of the turntable is equipped with a medicine powder storage box, and the other side of the top of the turntable is equipped with a support rod, and a chain rod is installed vertically inside the support rod, and the chain rod is connected with a gear. The present invention is provided with a hydraulic oil cylinder, a piston and a turntable, the hydraulic oil cylinder extends the piston, and the turntable rotates to adjust the angle. With mutual cooperation, the silkworm medicine can be sprinkled on any part of the silkworm tool to sterilize all silkworm bodies, prevent and cure diseases At the same time, the device is equipped with a nozzle and an exhaust fan, and the exhaust fan runs to spray the powder through the nozzle in time, which solves the problem of time-consuming and laborious application of the drug by the user, thereby improving the powder spreading efficiency of the device.

Owner:李小燕

Powder spraying device capable of repeatedly utilizing raw materials for ceramic production

InactiveCN108015888ATo achieve the effect of spraying powderDust evenlyCeramic shaping apparatusMetallurgyPowder Spray

The invention relates to a powder spraying device capable of repeatedly utilizing raw materials for ceramic production. The powder spraying device comprises a shell. The shell is provided with a movable door, an inclined plate is arranged in the shell, one end of the inclined plate stretches out of the shell, a vibration motor is arranged below the end, stretching out of the shell, of the inclinedplate, and the shell is divided by the inclined plate into a powder spraying chamber and an installation chamber in sequence from top to bottom. Multiple rotating motors are arranged in the installation chamber, the rotating motors are connected with placing tables through rotating rods, cleaning devices are symmetrically arranged below the placing tables, the centers of the placing tables are located on the same straight line, the powder spraying assembly comprises a powder barrel, a powder outlet at the bottom of the powder barrel is connected with a first powder supply pipe, the lower endof the first powder supply pipe is connected with a second power supply pipe, multiple powder spray heads capable of spraying powder to the placing tables are arranged in the second powder supply pipe, and the lower end of an inclined plate in the powder spraying chamber is provided with a powder outlet. Powder spraying is comprehensive, the powder spraying efficiency is high, powder can be recycled, and the cost is saved.

Owner:SICHUAN JUHAI FISHERIES TECH CO LTD

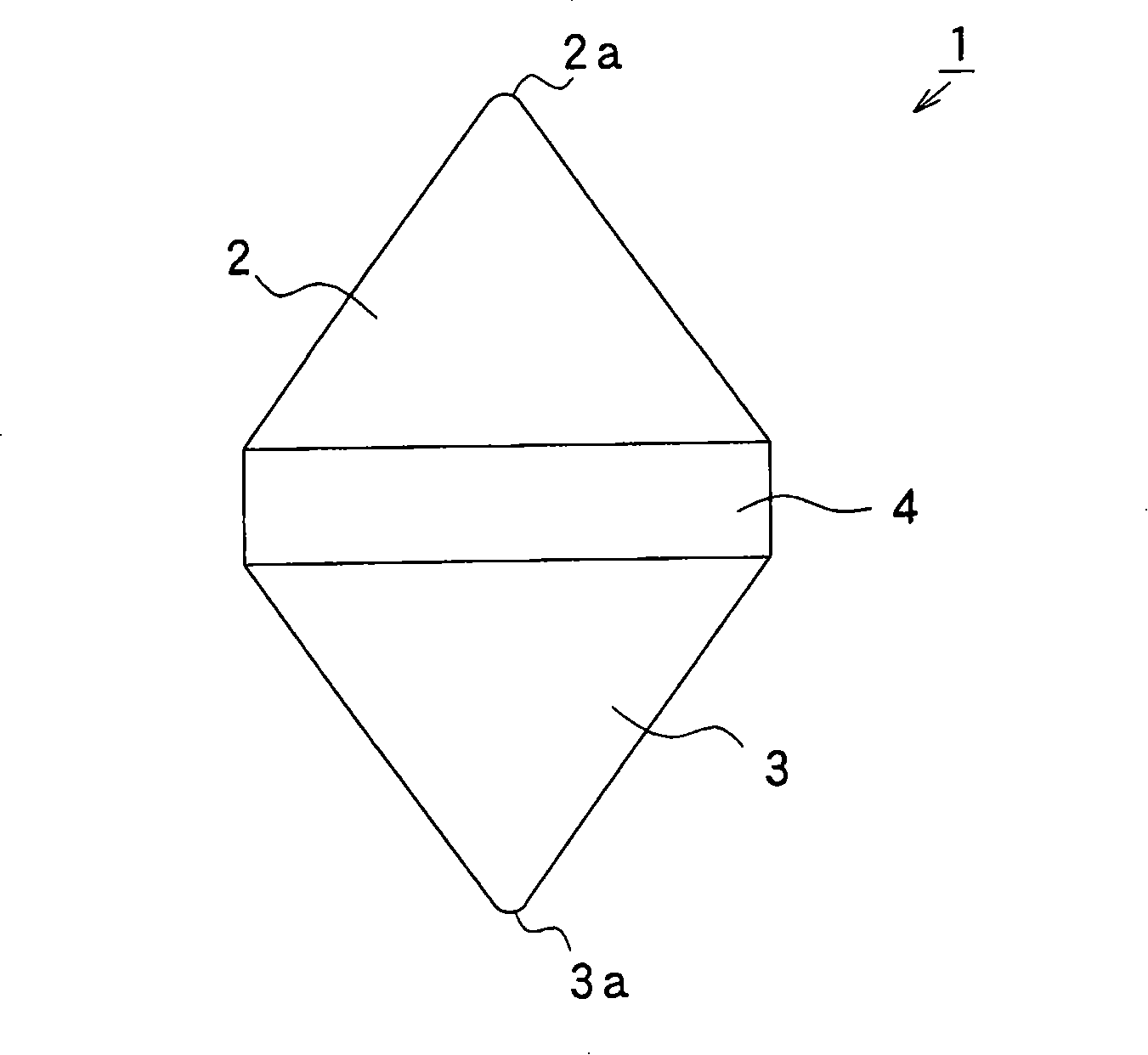

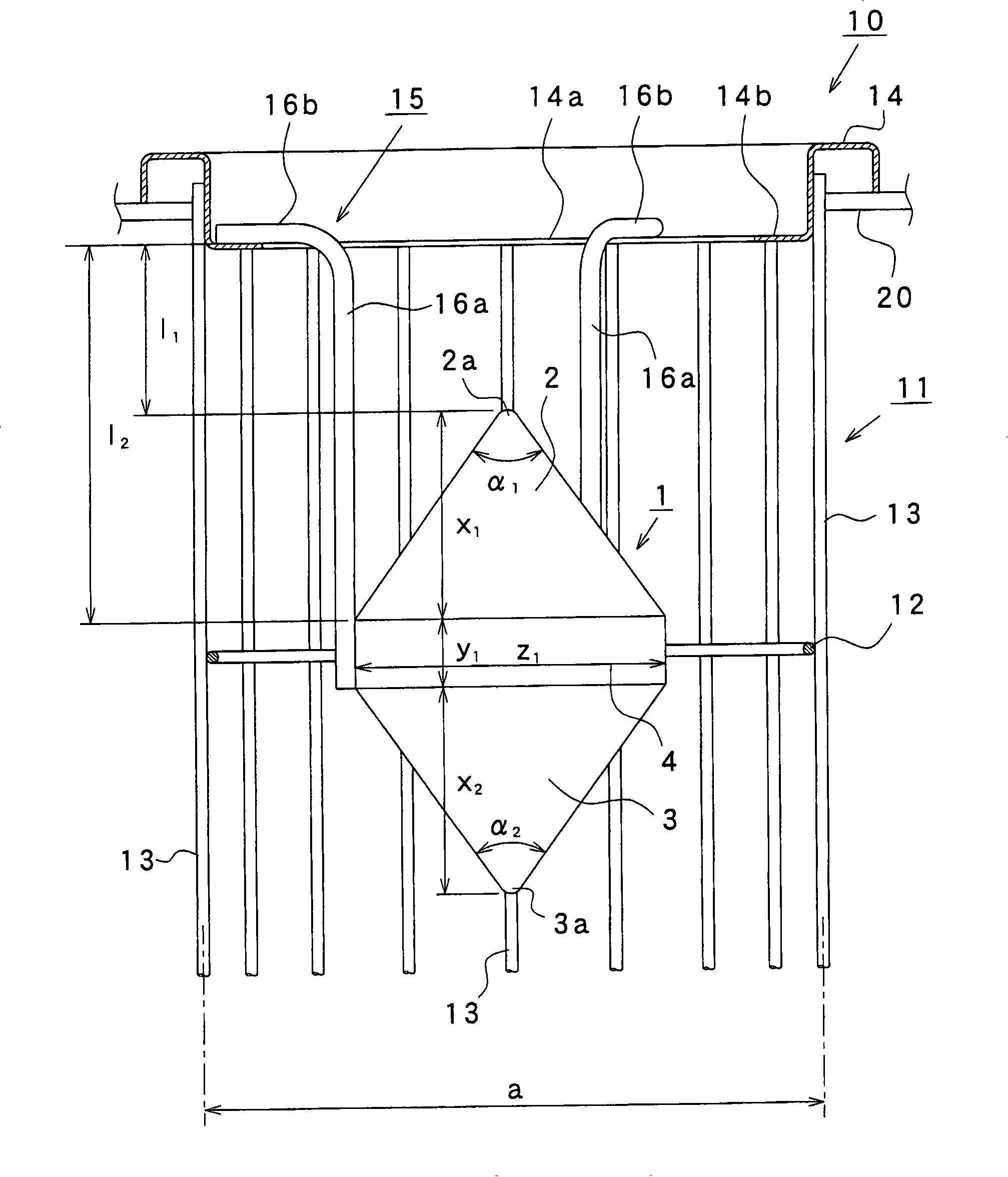

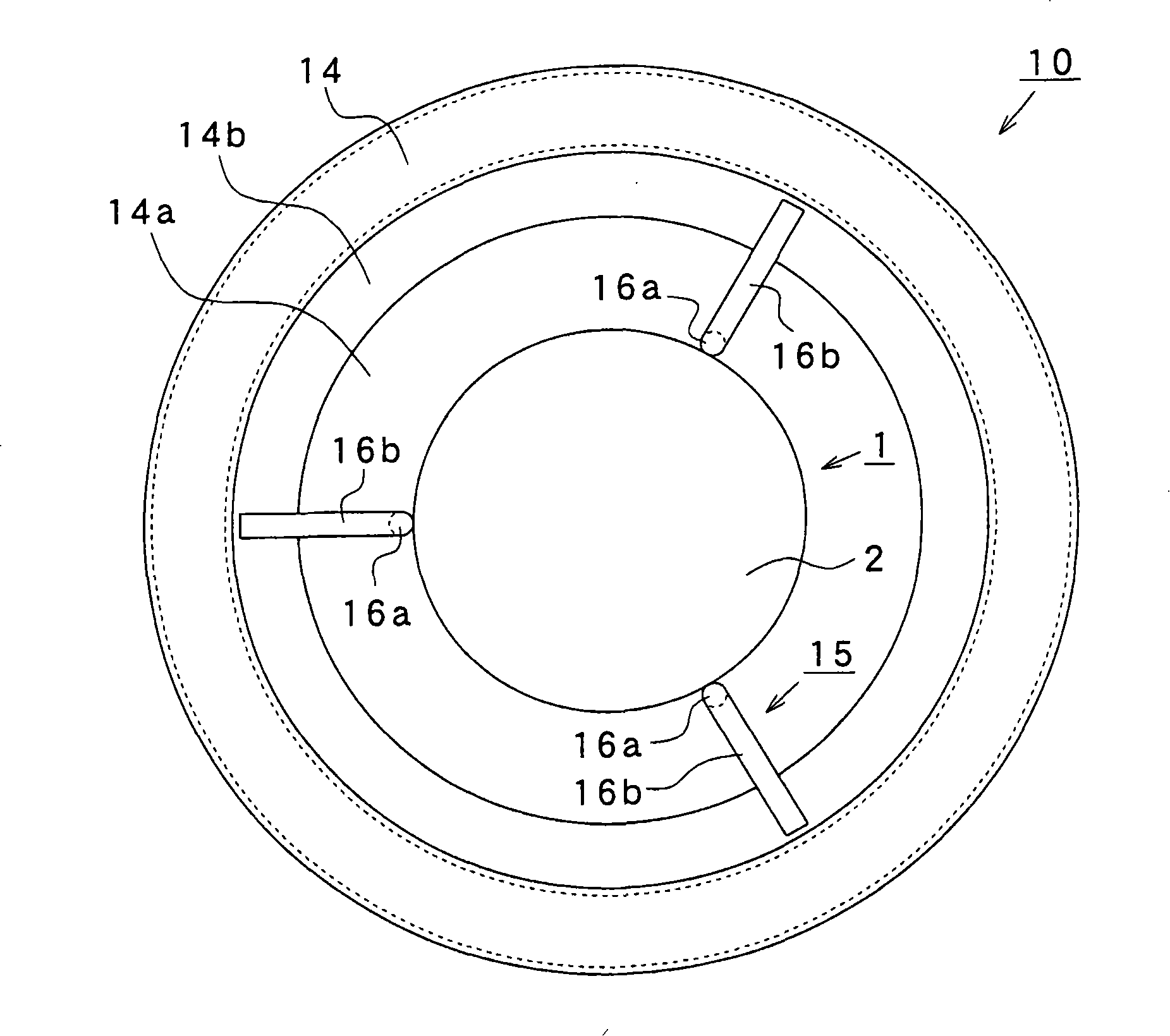

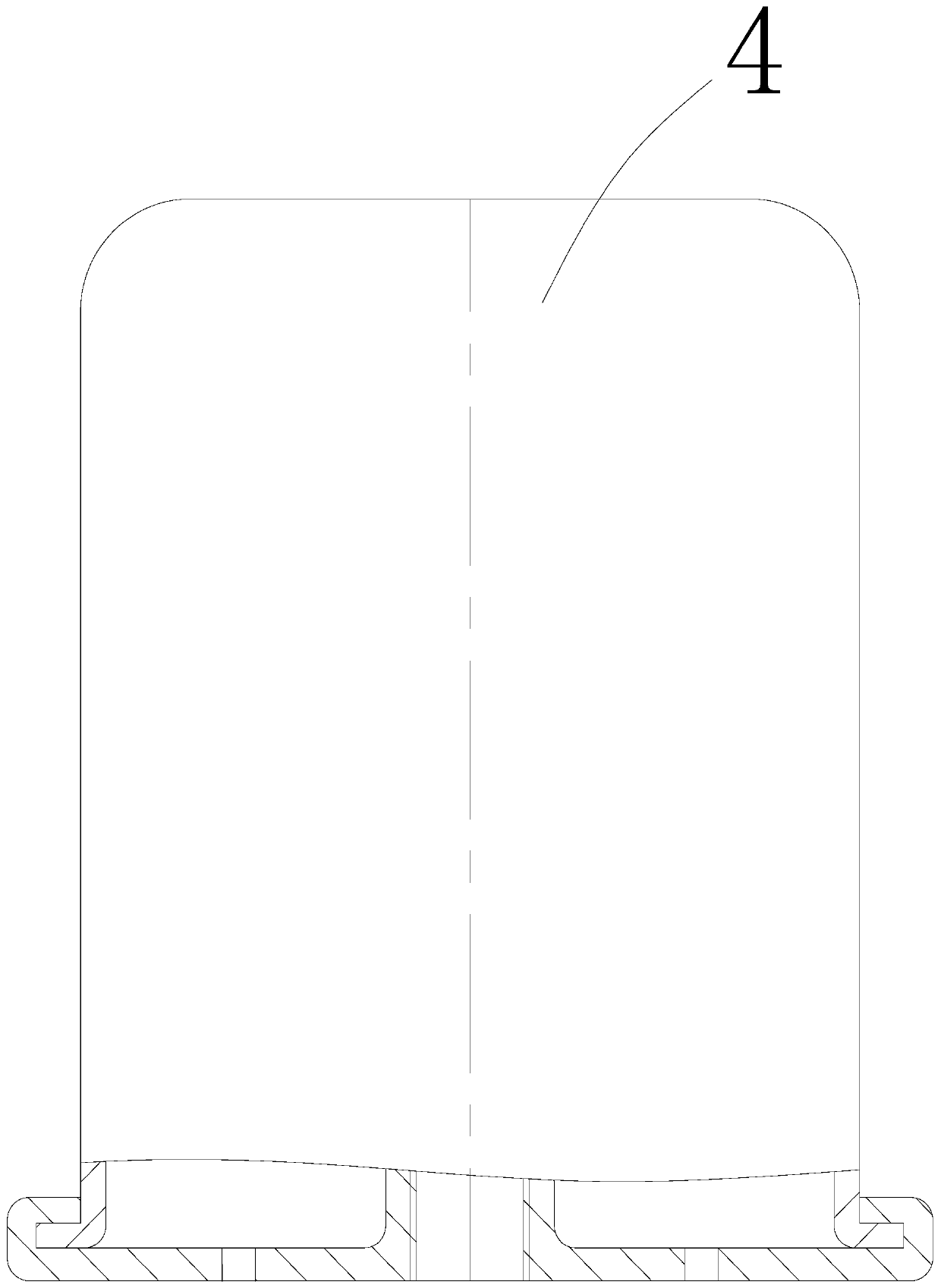

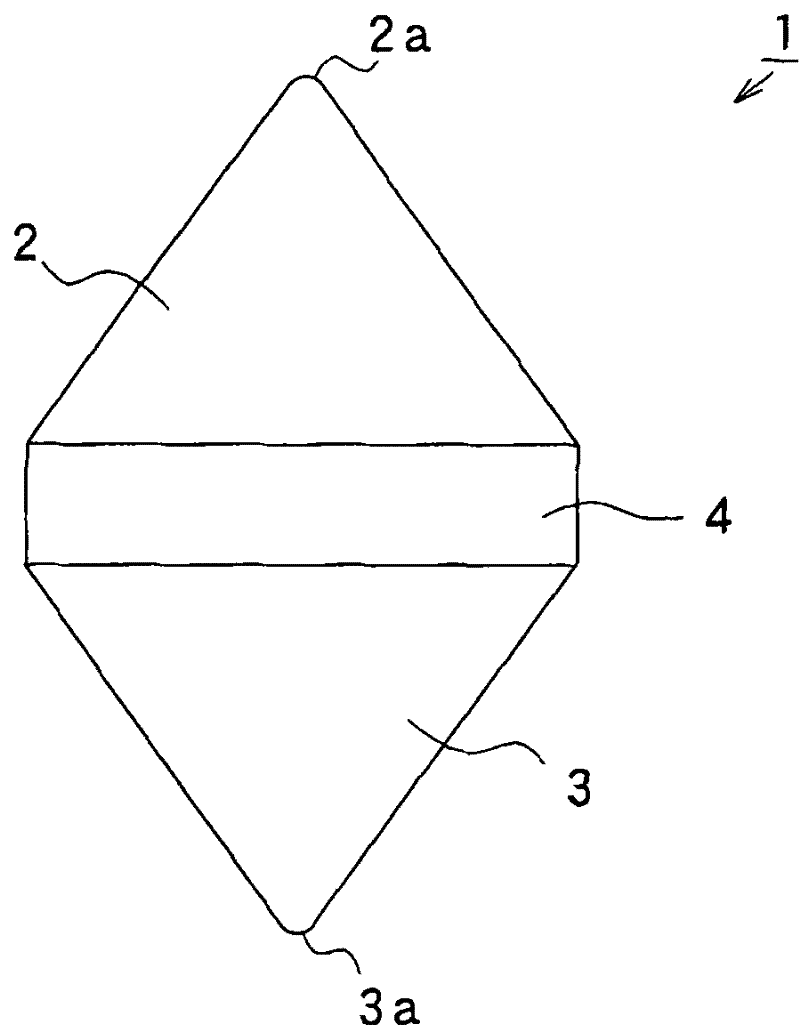

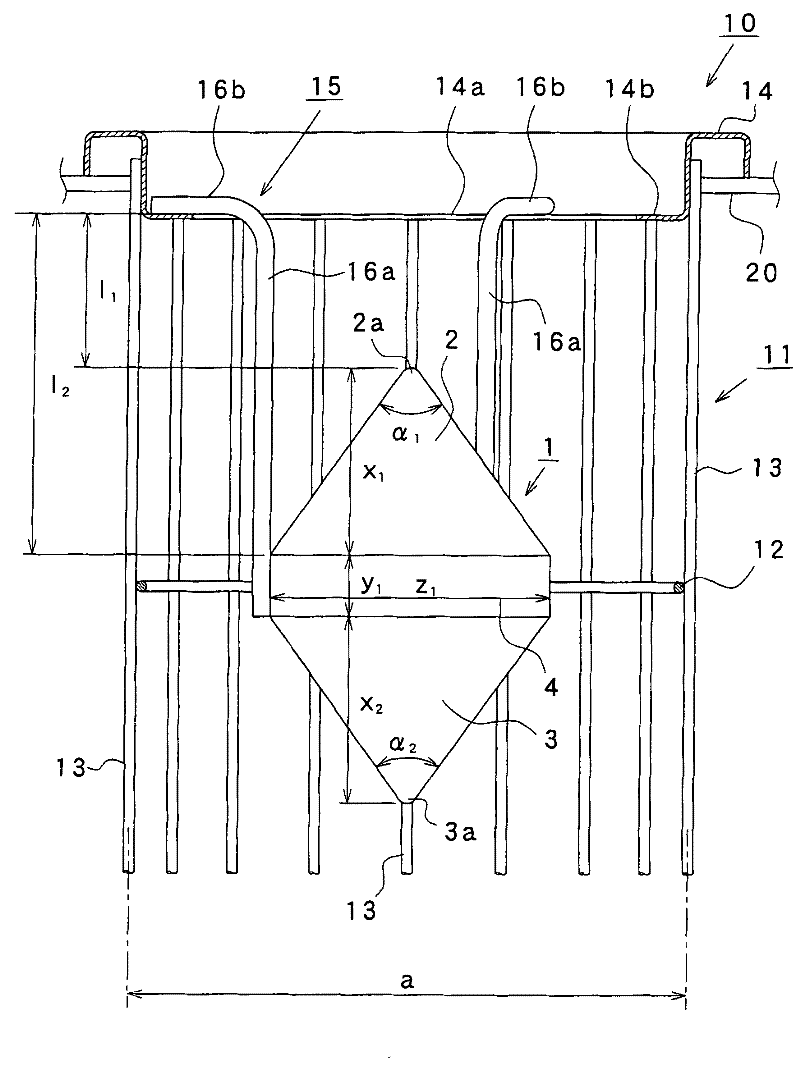

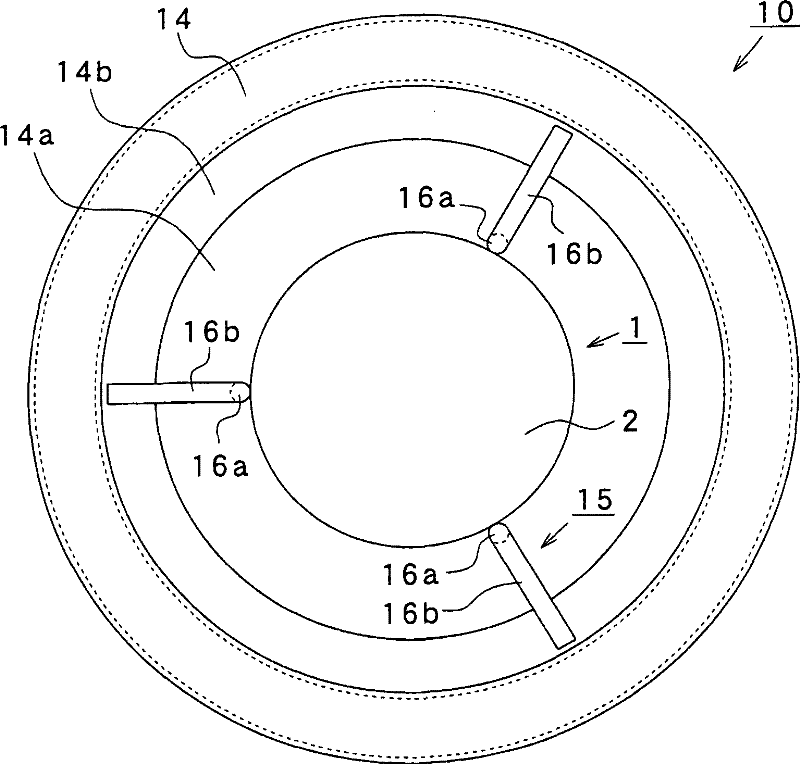

Retainer cone, and bag filter retainer having the same

ActiveCN101213006AAvoid negative pressureImprove reliabilityDispersed particle filtrationTransportation and packagingAir filtrationEngineering

The object of the present invention is to provide a cone for a retainer which is inserted into the center of the upper end of the retainer body which is a negative pressure generating area near the installation position of the conventional Venturi tube, so as to be effective in backwashing. When filtering cloth, a part of the compressed air sprayed from the nozzle on the upper part of the retainer body can be dispersed in the radial direction of the retainer body, preventing negative pressure from being generated on the upper end side of the retainer body, and making the entire area including the upper end side of the retainer body The filter cloth bulges outward, which can reliably dust off the dust attached to the filter cloth. Compared with the existing Venturi type, the cross-sectional area of the flow path at the upper end of the retainer body can be enlarged, and dust collection can be greatly reduced. The load of the blower used for suction. The cone for the holder is inserted in the center of the upper end side of the holder body of the holder for the bag filter, and has an upper-end reduced diameter portion and a lower-end reduced diameter portion, and the upper end reduced-diameter portion faces the upper end at the upper end portion in the longitudinal direction. The reduced diameter is formed; the reduced diameter portion at the lower end is formed by reducing the diameter toward the lower end at the lower end in the longitudinal direction.

Owner:SHINKO IND CO LTD (JP)

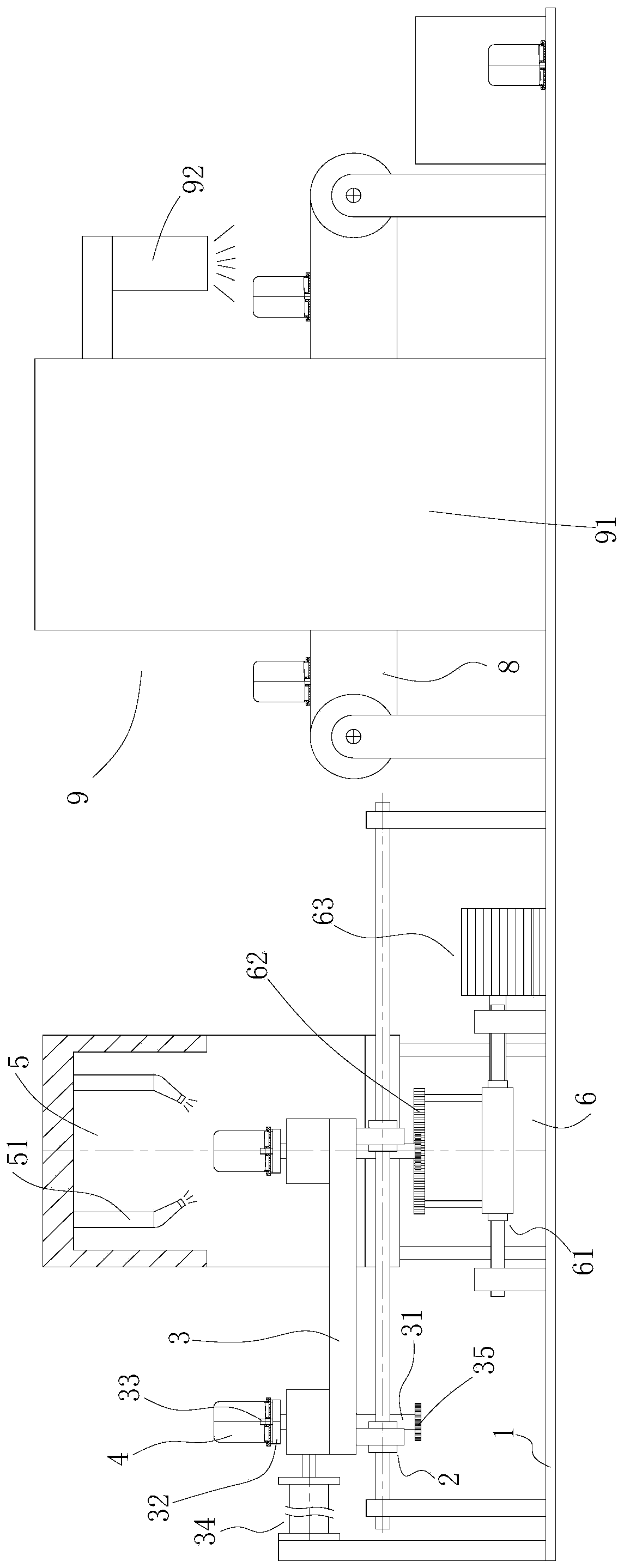

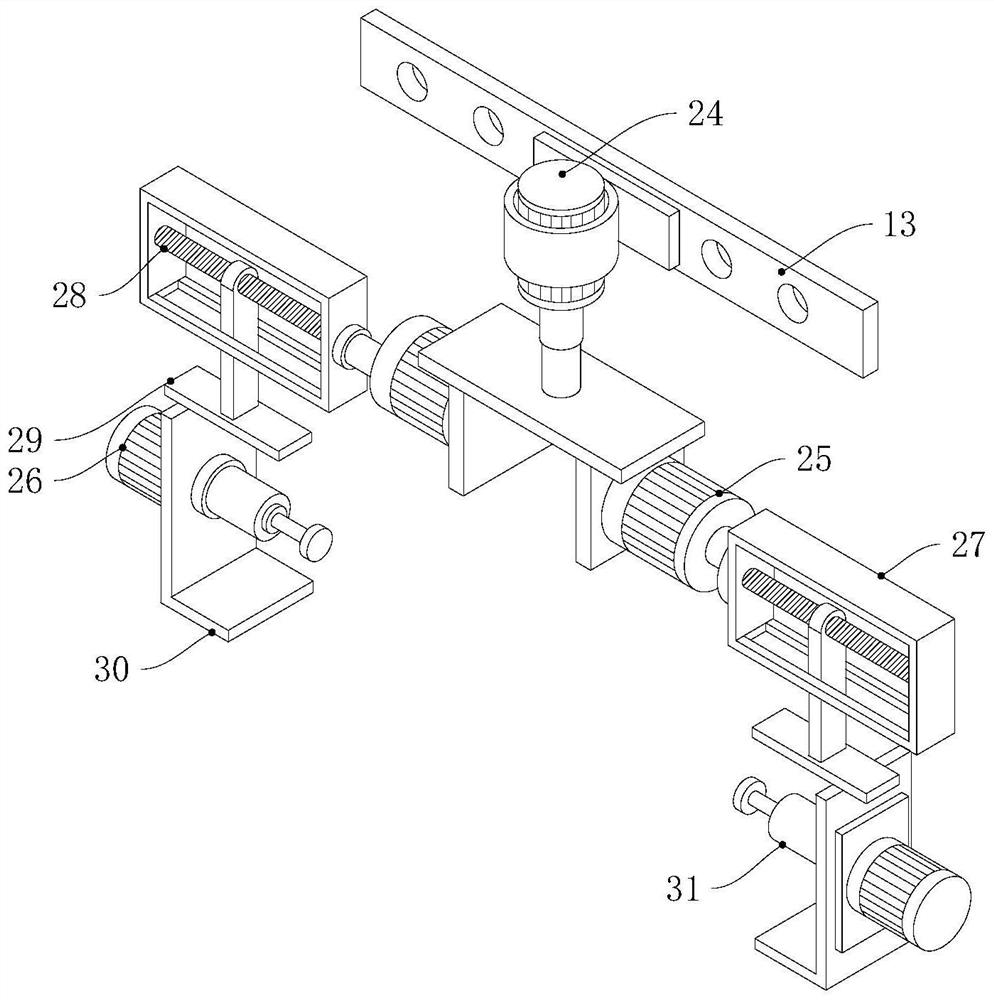

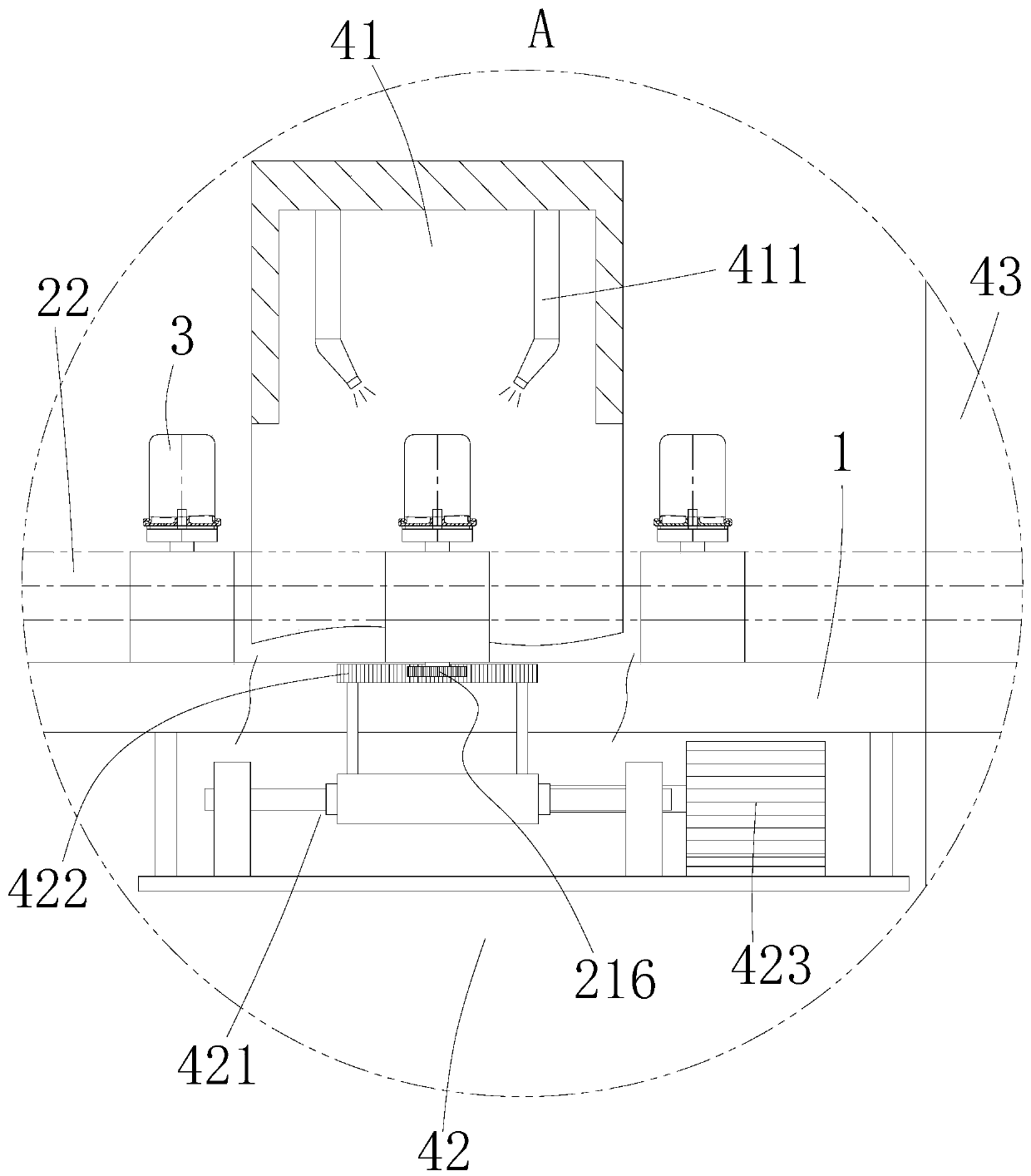

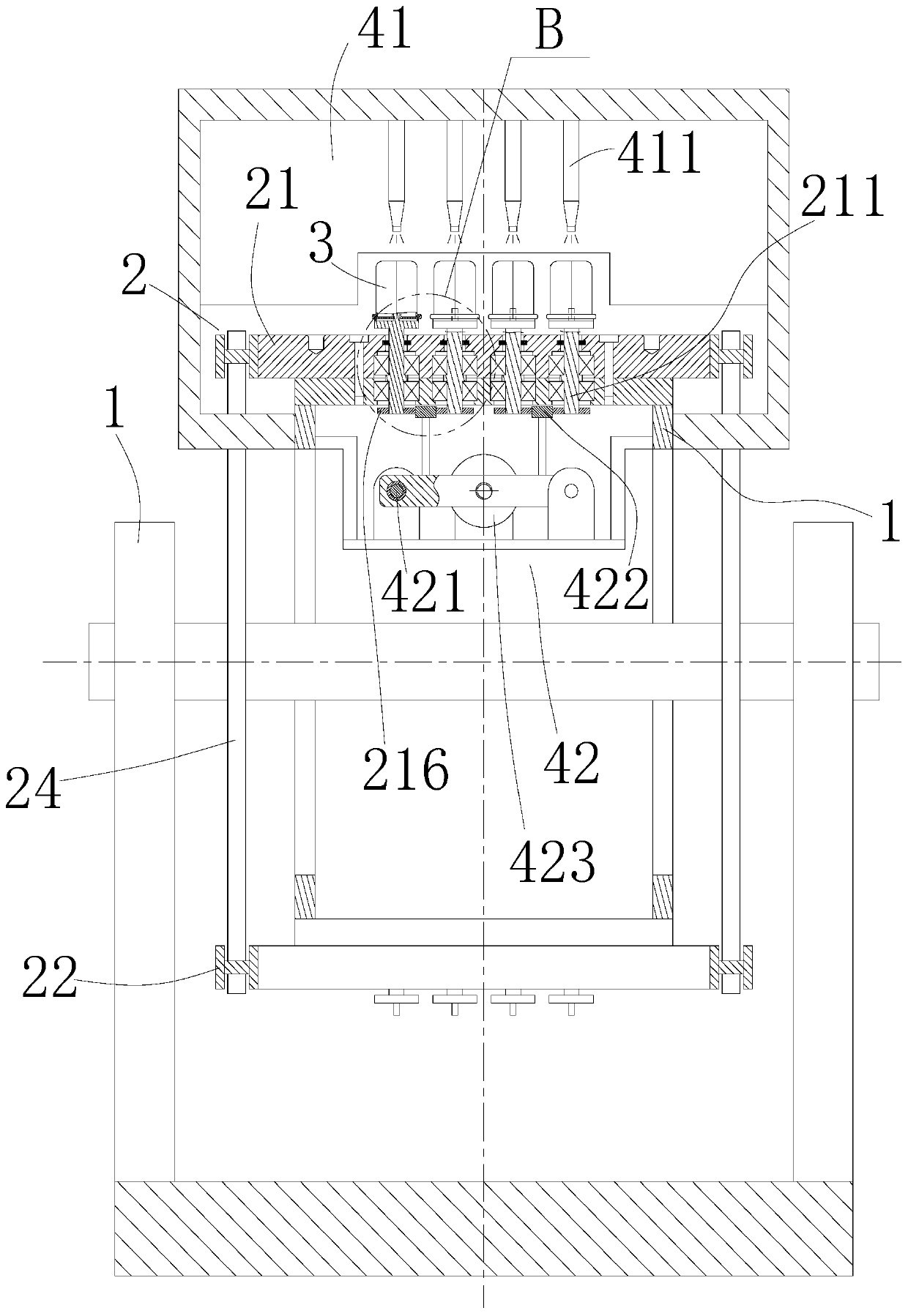

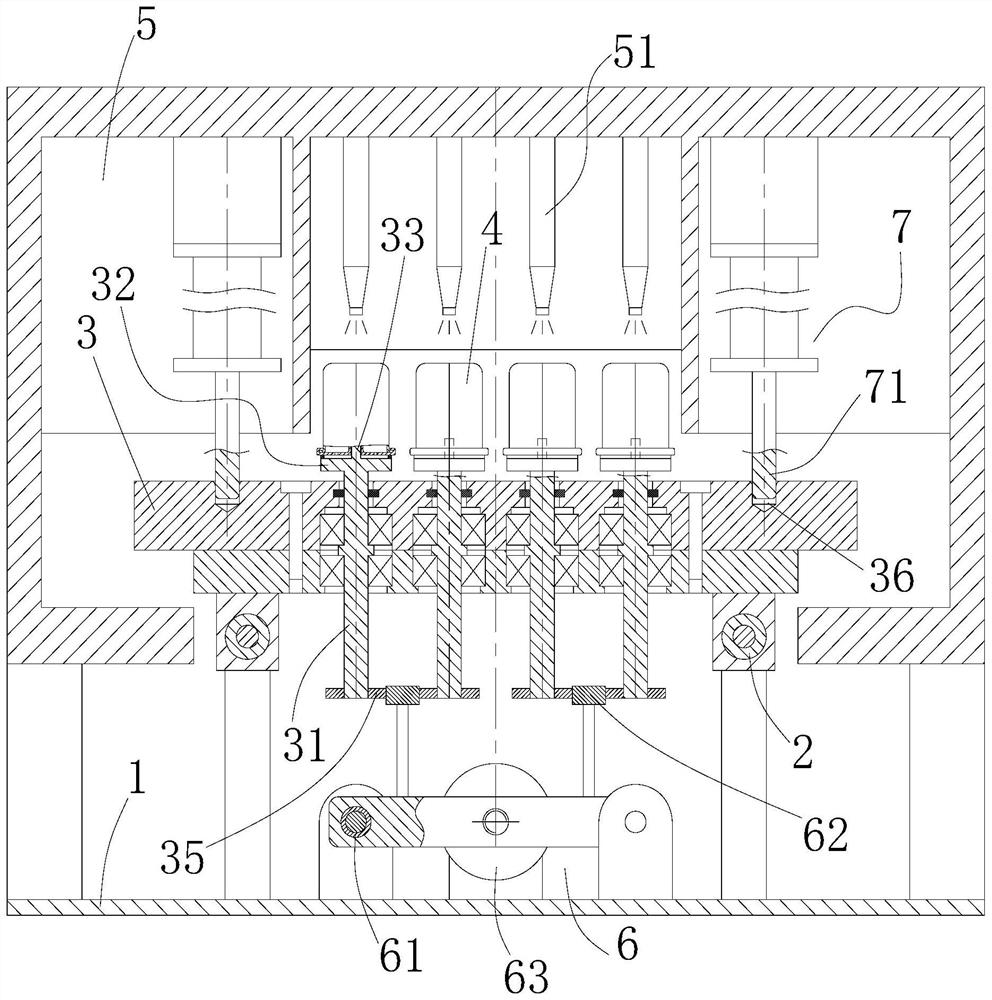

Powder spraying machine for filters

The invention discloses a powder spraying machine for filters. The powder spraying machine comprises a sliding plate mounted on a rack and a sliding plate driving mechanism; at least two groups of rotating shafts are rotationally mounted on the sliding plate; trays are arranged at the top ends of the rotating shafts; positioning columns are arranged on the trays and are sleeved with the filters; the powder spraying machine further comprises a powder spraying chamber; the sliding plate driving mechanism can drive the sliding plate to drive the filters on the different groups of rotating shaftsto enter the powder spraying chamber alternately; a reciprocating driving mechanism is arranged below the filters in the powder spraying chamber and comprises driving strip transversely and glidinglymounted on the rack; the guiding direction of a second guiding mechanism and the driving strips are parallel with the movement direction of the sliding plate; rotating wheels matched with the drivingstrips are arranged at the lower ends of the rotating shafts; a driving strip driving mechanism is further arranged on the rack; part of the sliding plate enters the powder spraying chamber, the rotating wheels are matched with the corresponding driving strips, the driving strips reciprocate in the movement direction of the sliding plate to drive the filters to rotate, and powder spraying heads spray powder to the rotating filters. The powder spraying machine has the advantages that powder is sprayed to the filters relatively uniformly.

Owner:SIXIAN TENGMA AUTO PARTS CO LTD

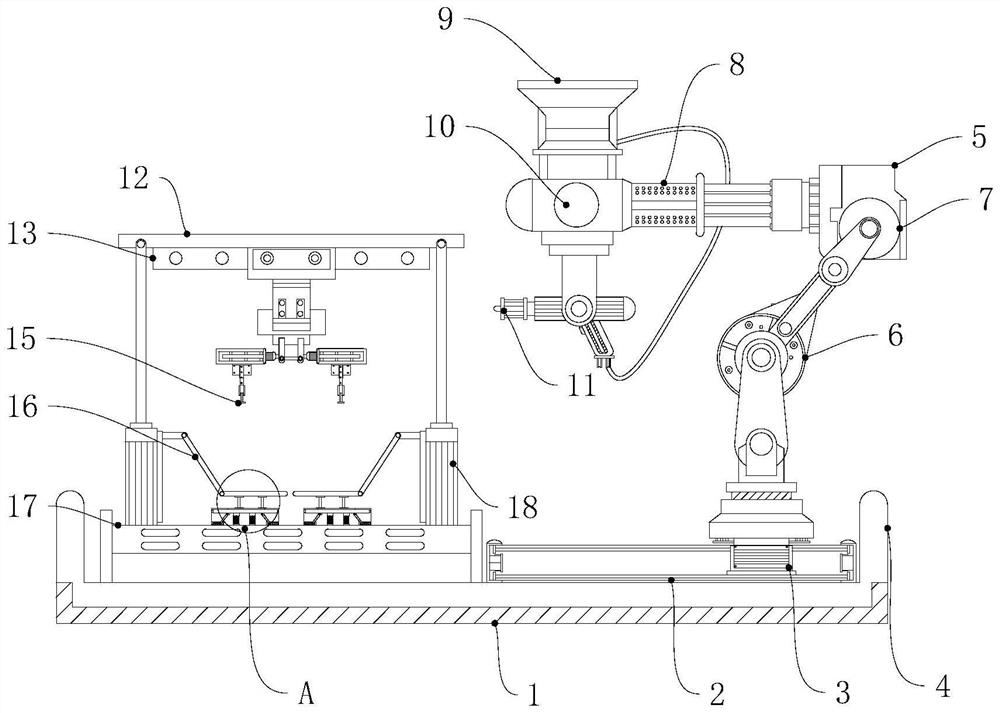

Powder spraying robot for workpiece surface treatment

The powder spraying robot for workpiece surface treatment comprises a base and a robot body, limiting blocks are arranged on the two sides of the top end of the base correspondingly, a guide rail and a clamping mechanism are arranged between the two limiting blocks correspondingly, a movable block is movably arranged in the middle of the guide rail, and the robot body is connected to the top of the movable block; the robot body comprises a first joint and a transmission mechanism for driving the first joint, the top of the first joint is rotationally connected with a second joint through the transmission mechanism, the middle of the second joint is transversely connected with a cross arm through the transmission mechanism, and one end of the cross arm is vertically connected with a third joint through the transmission mechanism; a spray gun body is movably arranged at the bottom of the third joint. The robot and the workpiece clamping area are uniformly arranged on the same bottom plate, and the robot body can transversely move along with the guide rails, so that powder spraying treatment can be conveniently carried out on workpieces in the later period, the working efficiency is improved, and the problems that the workpieces are difficult to clamp and the robot is inconvenient to move are solved.

Owner:SUSONG ANBAO BUSINESS MACHINE

Filter powder spraying device

ActiveCN110721862AImprove dusting efficiencyIncrease productivitySpray boothsControl cellEngineering

The invention relates to the field of filter production, in particular to a filter powder spraying device. The device comprises a rack, a conveying mechanism, filters, a powder spraying chamber, a reciprocating driving mechanism, an oven, a cooling mechanism and a control unit. The filters are conveyed backwards under the action of the conveying mechanism, baked in the oven after powder spraying of the powder spraying chamber and then cooled through the cooling mechanism, so that membranes are formed. The device has the advantages that powder is uniformly sprayed on the surfaces of the filters, and meanwhile, the more the filters subjected to powder spraying every time is, the higher the overall powder spraying and membrane forming efficiency is.

Owner:SIXIAN TENGMA AUTO PARTS CO LTD

Retainer cone, and bag filter retainer having the same

ActiveCN101213006BImprove maintenance effectImprove dust collection efficiencyDispersed particle filtrationTransportation and packagingEngineeringBag filter

Intended is to provide a retainer cone, which is inserted into the center of the upper end portion of a retainer body, which is a negative pressure generating region near the mounting position of a conventional Venturi tube, to disperse a portion of such compressed air radially of the retainer body as is injected from a nozzle at the upper portion of the retainer body at the time of back-washing a filter fabric, so that it can prevent a negative pressure from being generated on the upper end side of the retainer body, which bulges the entire filter fabric containing the upper end side of the retainer body outward so that it can reliably wipe off powder dust having stuck to the filter fabric, and which makes the sectional area of the passage of the retainer body upper end portion larger than that of the conventional Venturi type so that it can drastically reduce the load on a blower to be used for suctions at the dust collecting time. The retainer cone is inserted into and arranged at the central portion on the upper end side of the retainer body for a bug filter retainer, and includes a radially reduced upper end portion so formed at the upper end portion of the longitudinal direction as is radially reduced toward the upper end, and a radially reduced lower end portion so formed at the lower end portion of the longitudinal direction as is radially reduced toward the lower end.

Owner:SHINKO IND CO LTD (JP)

Combined spiral tower tray for gas washing tower, gas cleaning device and application thereof

The invention provides a circumferential spiral tower tray for a gas washing tower, a gas cleaning device and application thereof. The circumferential spiral tower tray (10) comprises a spray column inlet pipeline (202), a spray column (206) and a spiral tower tray main body (102), wherein the spray column inlet pipeline (202) is arranged on one side of the upper part of a gas washing tower (1.2) and is basically perpendicular to walls (12 and 22) of the gas washing tower (1.2); the spray column inlet pipeline (202) further comprises an spray column inlet (204) which extends out of the wall of the gas washing tower (1.2); the spray column (206) is connected with the spray column inlet pipeline (202) at the approximate center of the gas washing tower (1.2) in a basically perpendicular mode; the circumference of the spray column (206) is uniformly distributed with a plurality of spray holes (208); the inner side of the spiral tower tray main body (102) is arranged in an upward spiral mode around the outer side of the spray column (206) from the lower end edge (104); and the outer side of the spiral tower tray main body (102) is connected with the inner walls (12 and 22) of the gas washing tower (1.2).

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

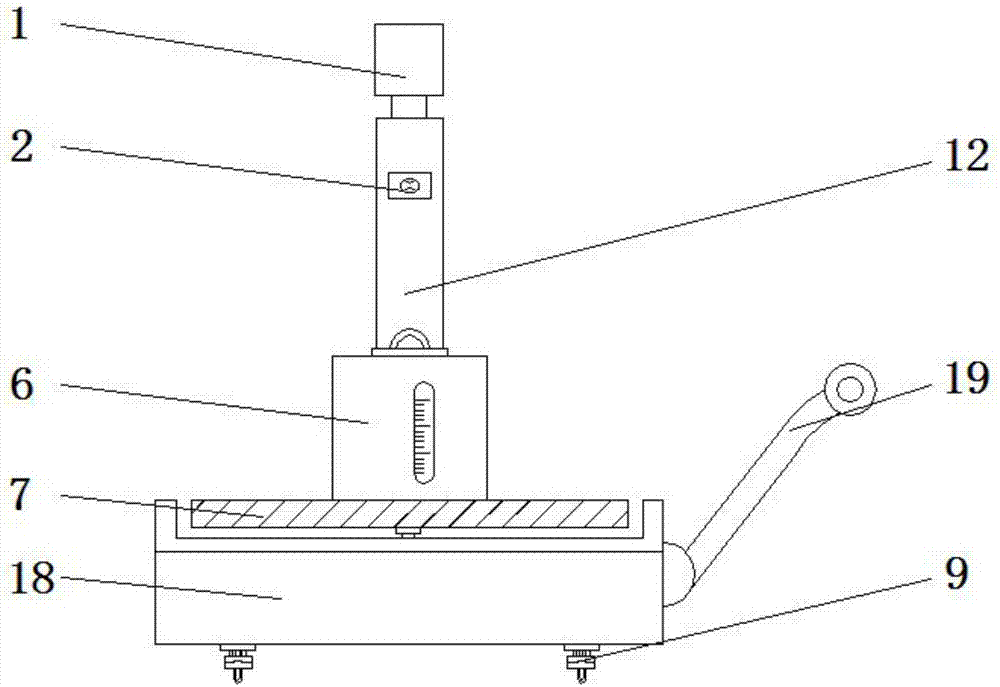

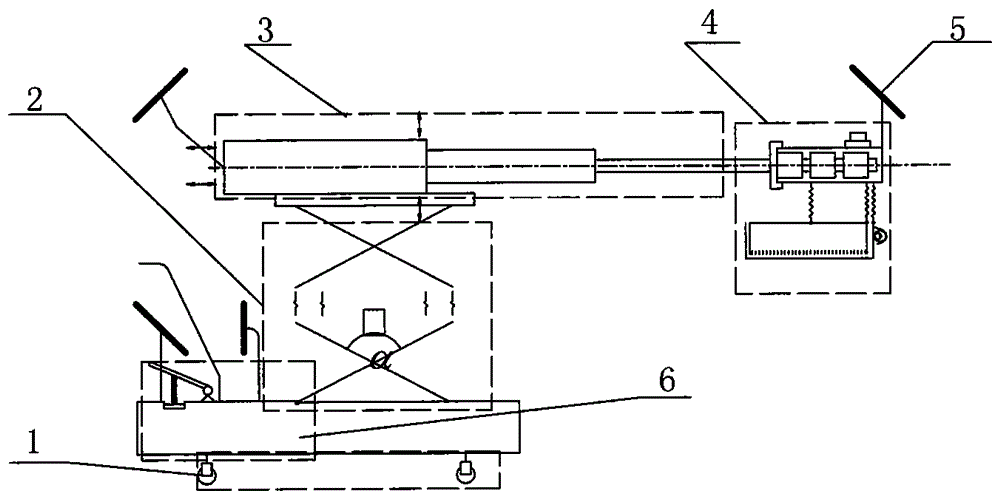

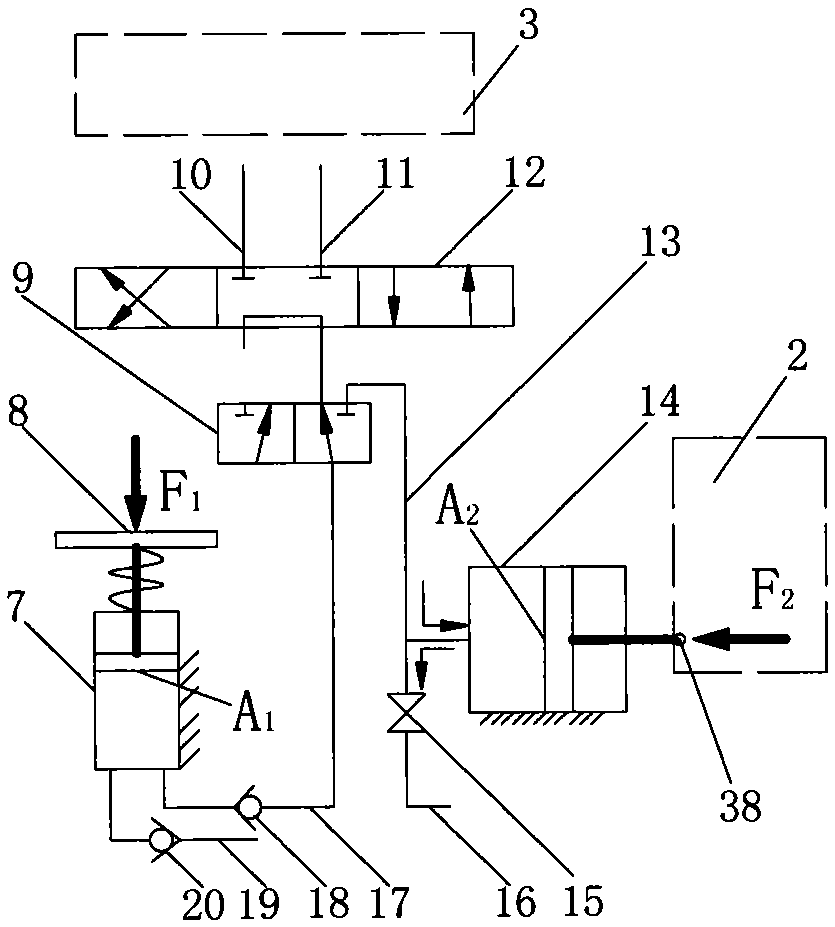

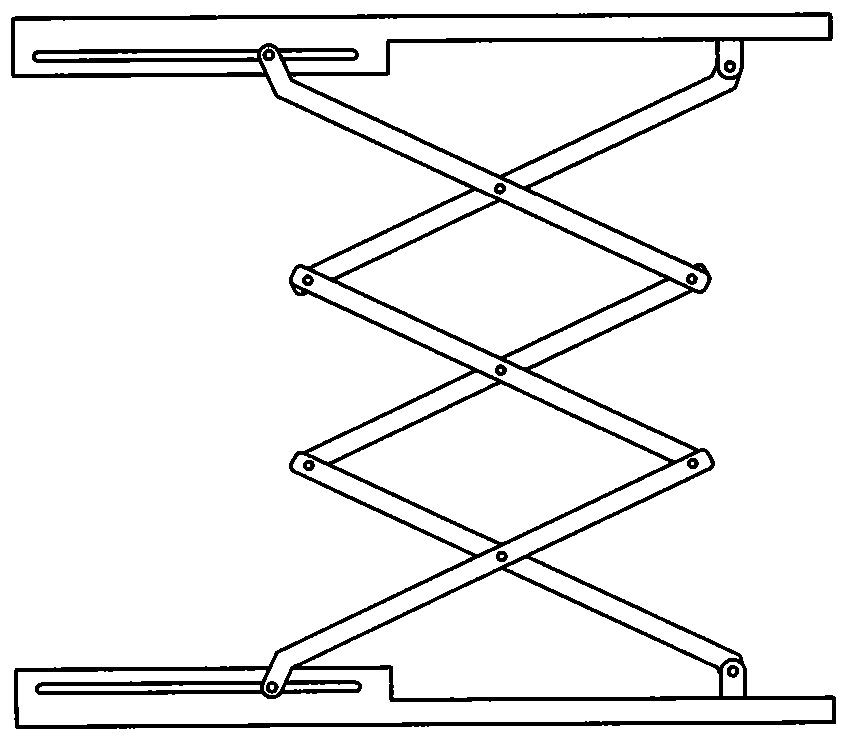

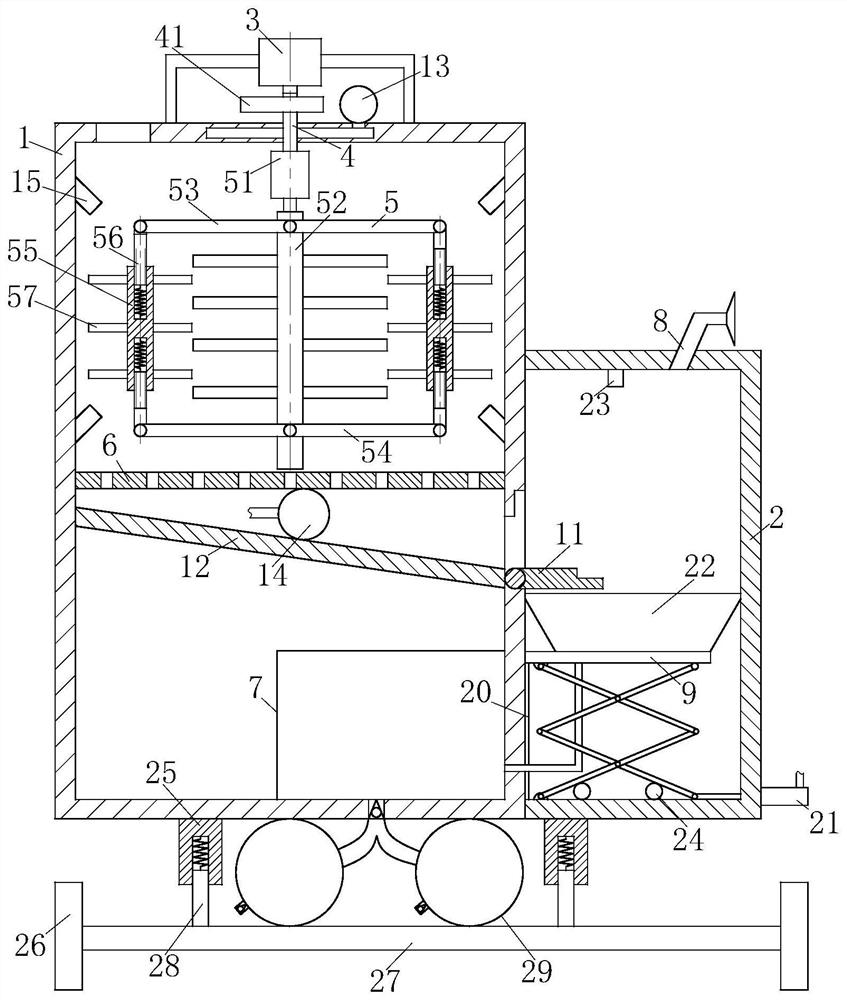

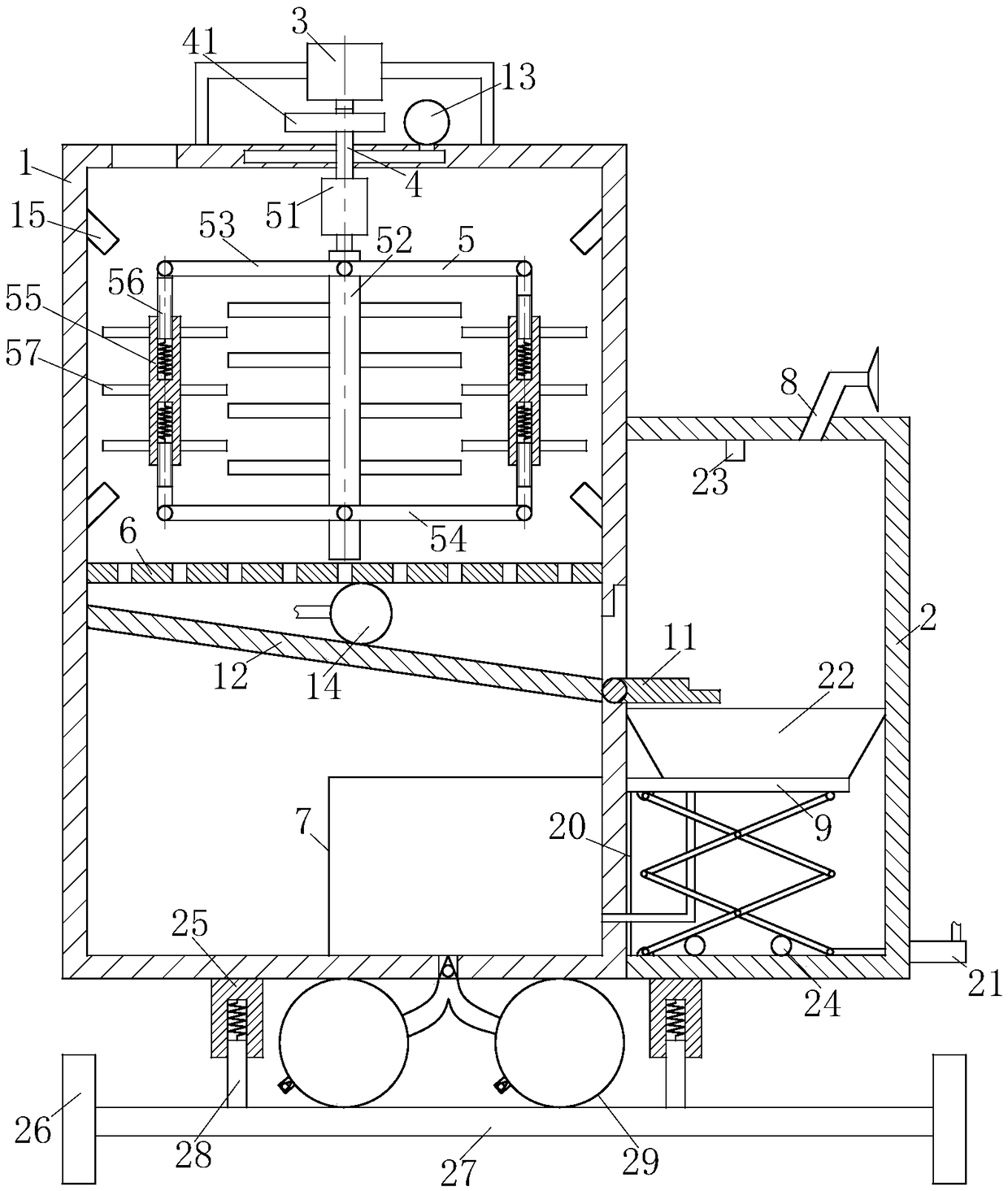

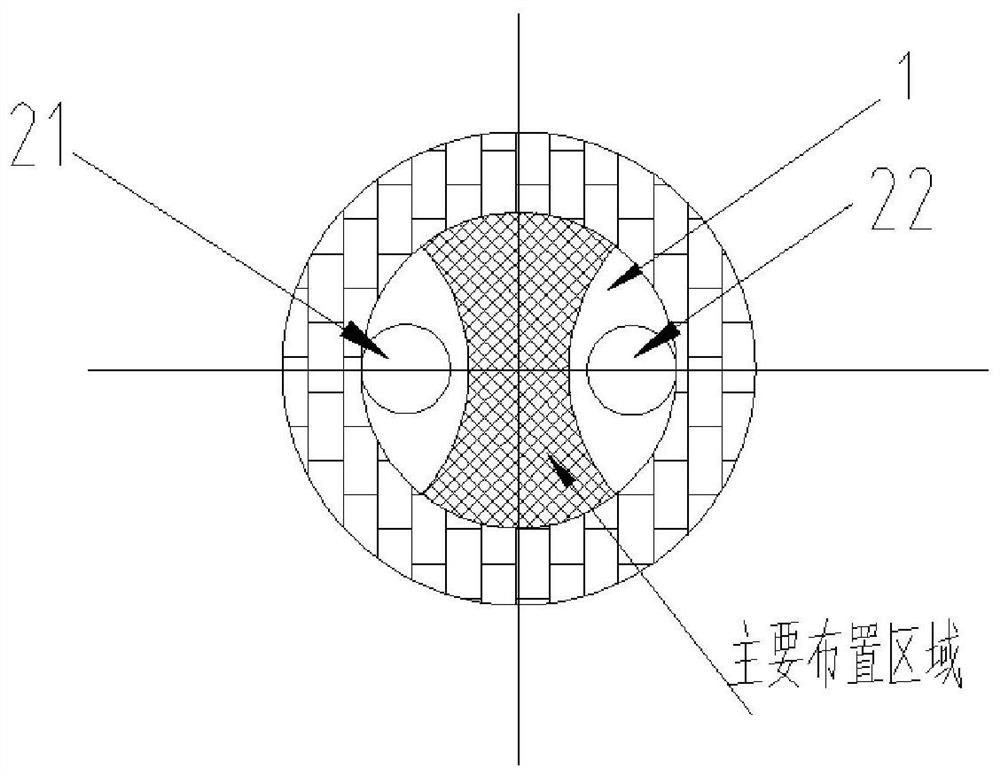

Powder spreading equipment for large-scale silkworm farming

InactiveCN104546215BEasy to adjustEasy to spreadVeterinary instrumentsEngineeringAtmospheric pressure

The invention relates to a dusting tool in agricultural machinery and in particular relates to dusting equipment for large-scale silkworm cultivation. The dusting equipment for large-scale silkworm cultivation mainly solves the mechanical dusting problem in a silkworm rearing room of large-scale silkworm cultivation and comprises six sub-systems; a traveling sub-system comprises universal wheels; a lifting sub-system comprises a shearing type mechanism; a horizontal moving sub-system mainly comprises a multi-stage air cylinder; an execution sub-system adopts the prior art; a reflection mirror sub-system comprises an ordinary reflection mirror and a dual-sided reflection mirror; and pneumatic pressure power sub-system mainly comprises an air cylinder, a direction valve and pipelines. The pneumatic pressure power sub-system provides power to the lifting sub-system and the horizontal moving sub-system, the vertical and horizontal feeding of the equipment can be realized without an external power supply, the energy is saved and the equipment is convenient to move in the silkworm rearing room; and the reflection mirror sub-system is convenient to observe the dusting and the silkworm growth. The dusting equipment for large-scale silkworm cultivation has the beneficial effects of improving dusting automation level, dusting efficiency and quality in the silkworm rearing room of large-scale silkworm cultivation.

Owner:ZHONGBEI UNIV

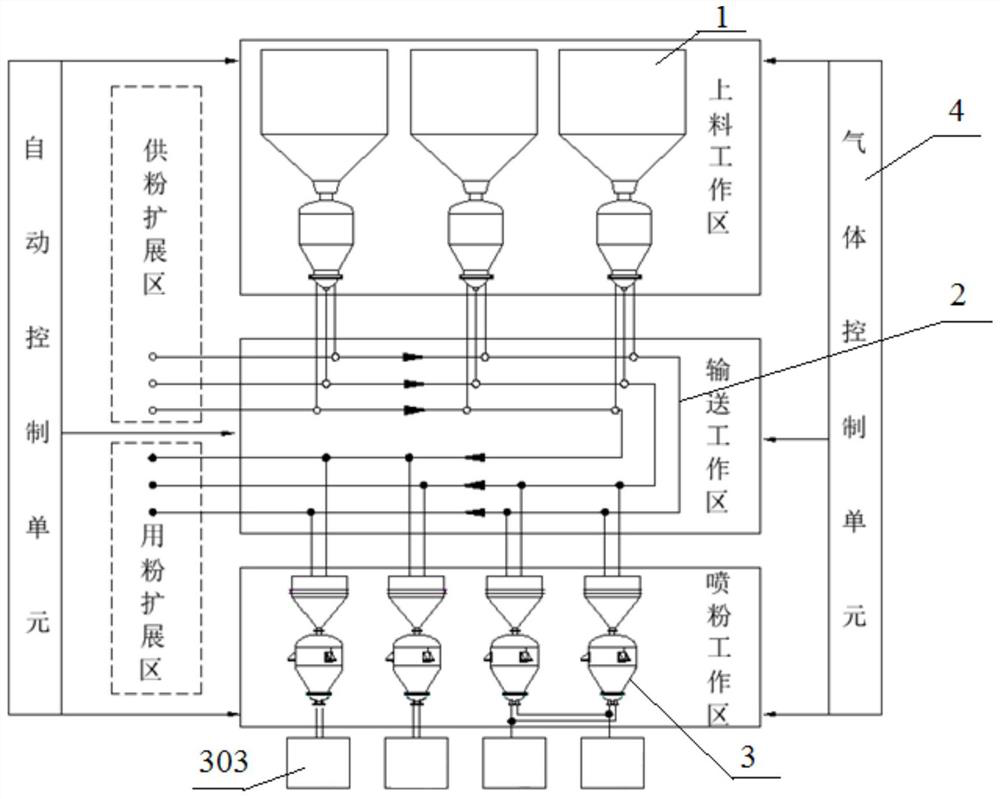

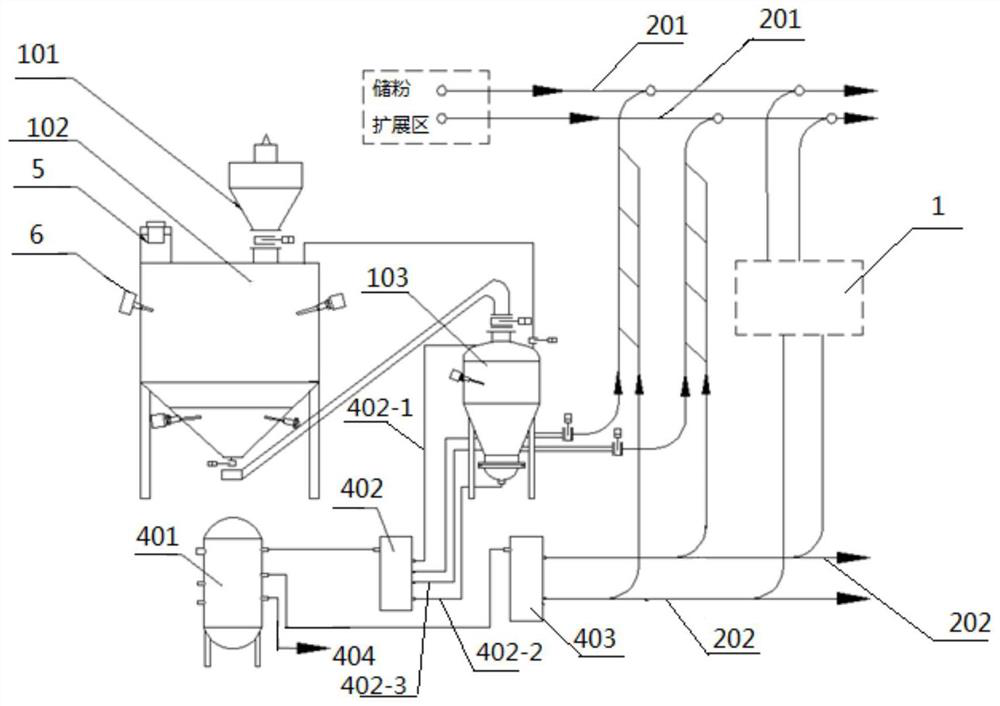

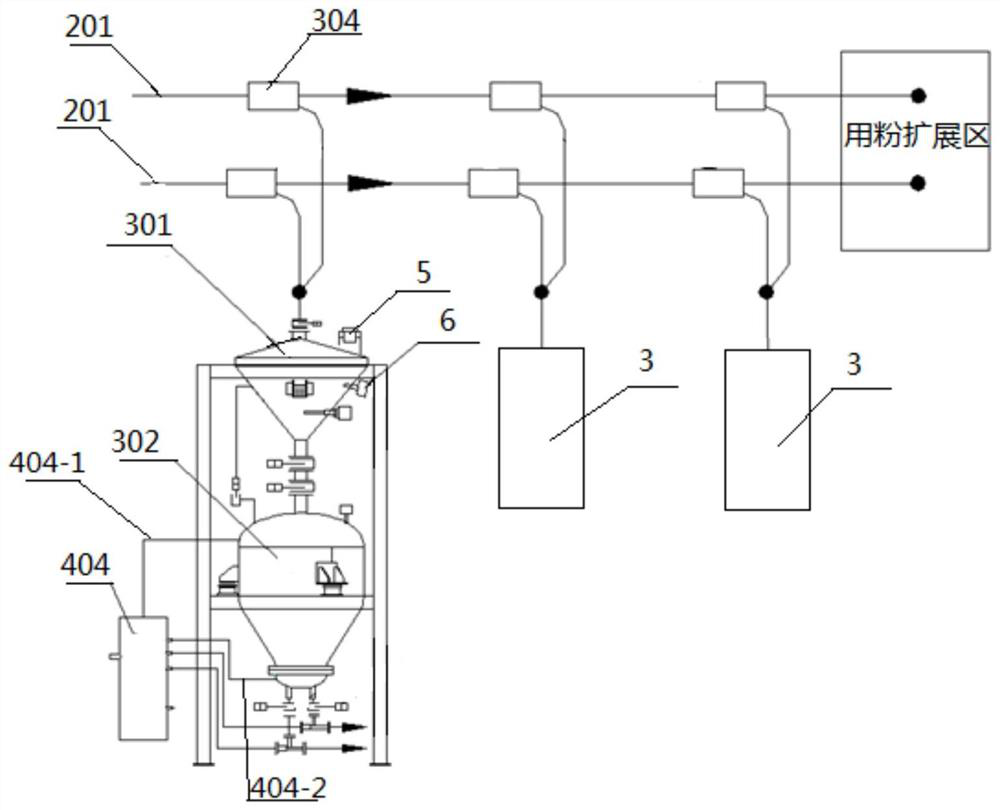

Distributed powder spraying system and method

ActiveCN114410888AFlexible installation areaRealize continuous powder sprayingElectric furnaceProcess efficiency improvementProcess engineeringPowder Spray

The invention relates to a distributed powder spraying system and method, belongs to the technical field of powder spraying metallurgy, and solves the problems that an existing powder spraying system is small in powder storage amount, frequent in powder filling and low in production efficiency. Comprising a feeding working area, a conveying working area, a powder spraying working area and a gas control unit. The feeding working area comprises at least one storage module, the conveying working area comprises at least one conveying module, and the powder spraying working area comprises at least one powder spraying module; the number of the storage module, the conveying module and the powder spraying module is not one. Each material storage module is connected with at least one conveying module, each powder spraying module is connected with at least one conveying module, the gas control unit is communicated with the material storage modules, the conveying modules and the powder spraying modules, and the gas control unit provides gas for conveying powder for the material storage modules, the conveying modules and the powder spraying modules; a valve is arranged between the storage module and the conveying module, and a valve is arranged between the powder spraying module and the conveying module. The powder storage amount is increased, and the production efficiency is improved.

Owner:CENT IRON & STEEL RES INST

A glass dusting system

ActiveCN108970928BWon't condenseImprove dusting efficiencyLiquid surface applicatorsCoatingsSpray nozzlePowder Spray

The invention relates to the technical field of glass processing auxiliary devices, in particular to a glass powder spraying system. The glass powder spraying system comprises a screw powder feeding apparatus installed on a stander, a powder spraying apparatus and a glass conveying apparatus, a closed chamber is arranged above the glass conveying apparatus, the powder spraying apparatus is arranged in the closed chamber, the powder spraying apparatus comprises a venturi powder pump, a powder conveying pipe and spray nozzles which are successively communicated with one another, the screw powderfeeding apparatus comprises a powder storage tank and a shaftless screw powder feeding mechanism, the shaftless screw powder feeding mechanism is used for transporting the isolation powder arranged in the powder storage tank to the venturi powder pump, the isolation powder is sprayed onto the upper surface of glass conveyed on a glass conveying surface of the glass conveying apparatus, and the glass powder spraying system is characterized in that at least two spray nozzles are provided, the two spray nozzles are arranged in parallel along a lateral direction perpendicular to the conveying direction of the glass, a powder outlet of each spray nozzle is in a slit shape, and the length direction of the slit-shaped powder outlet is perpendicular to the glass conveying direction. The glass powder spraying system has the advantages that the powder is uniformly sprayed, the powder spraying efficiency is high, and the powder utilization rate is high.

Owner:FUYAO GROUP FUJIAN MACHINERY MFG

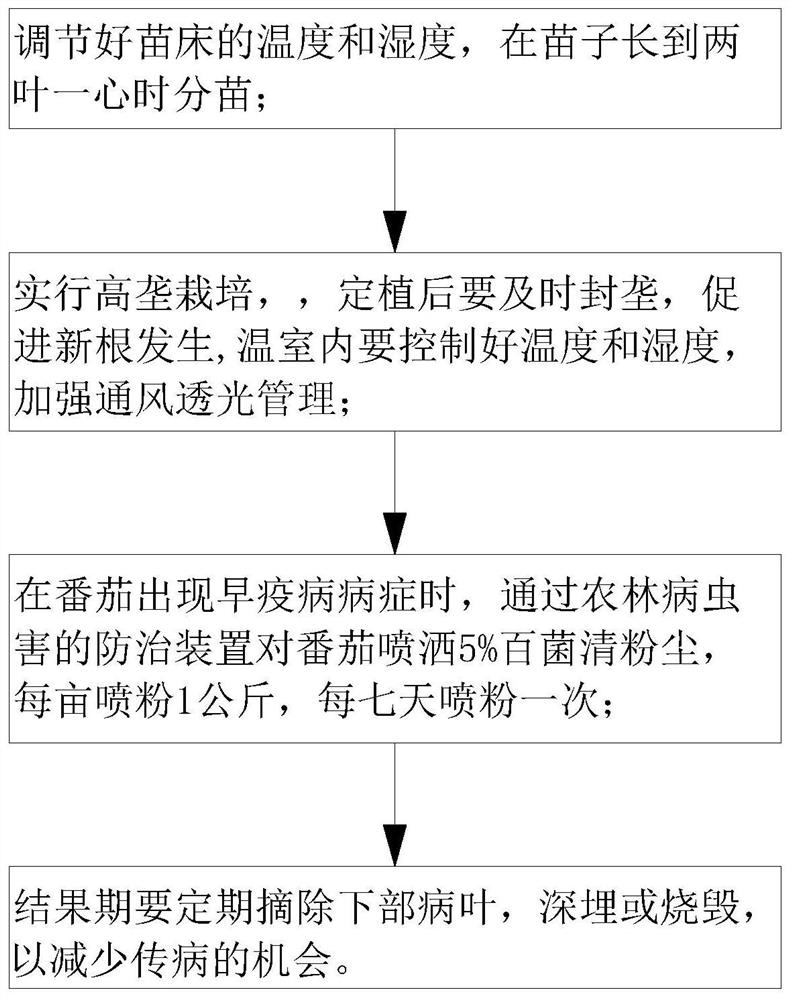

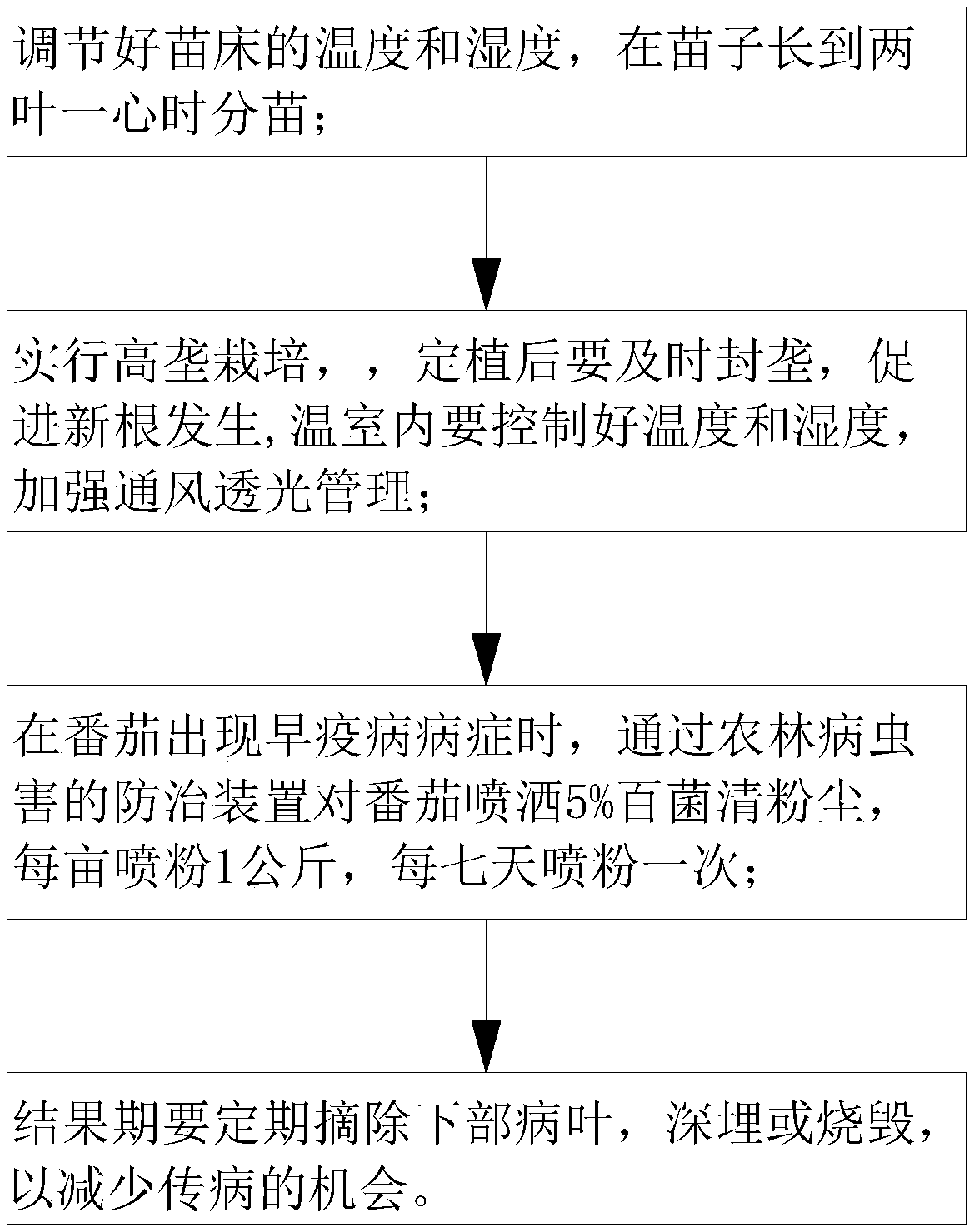

A kind of control method of tomato early blight

ActiveCN109042139BEffective controlEvenly distributedHorticulture methodsFruit crop cultivationPest controlChlorothalonil

Owner:重庆赐康果蔬有限公司

Method for preventing and treating tomato early blight

ActiveCN109042139AEffective controlEvenly distributedHorticulture methodsFruit crop cultivationDiseaseTherapeutic effect

The invention belongs to the technical field of tomato pest and disease prevention and control, and particularly relates to a method for preventing and treating a tomato early blight. The method comprises the following steps of adjusting a temperature and humidity of a seedbed, and separating seedlings when the seedlings grow to a state with two leaves and one heart; performing high ridge cultivation, rationally fertilizing, timely sealing a ridge after field planting and seedling slowing to promote the occurrence of new roots, controlling the temperature and humidity in a greenhouse, strengthening the ventilation and light transmission management, when tomato early blight characteristics occur, spraying tomatoes with 5% chlorothalonil dust through a prevention and control device of agricultural and forestry pests and diseases, spraying a 1 kg of dust per acre, spraying once every seven days, in a fruiting period, regularly removing lower diseased leaves, and burying or burning to reduce the chance of disease transmission; the method is suitable for prevention and treatment of the early blight of large areas of the tomatoes, and has a good prevention and treatment effect.

Owner:重庆赐康果蔬有限公司

A rh vacuum powder spraying refining device and powder spraying method thereof

An RH vacuum powder spraying refining device and a powder spraying method thereof belong to the technical field of molten steel refining outside the furnace. The RH vacuum refining powder spraying device includes a vacuum molten steel circulation device and a powder spraying device. Among them, the vacuum molten steel circulation device includes a vacuum chamber, a dipping pipe, a ladle, and a lifting gas pipeline. The powder spraying device includes a powder spraying element, a powder supply pipe, a buffer air chamber, and quick-connect parts. Powder spraying methods include but are not limited to refining and alloying functions such as desulfurization, deoxidation, removal of inclusions, and addition of alloys. The advantage is that the bottom of the vacuum tank is improved on the basis of the RH conventional structure, and the installation parameters of the nozzle can be adjusted to meet the process needs of different steel types; it is easy to implement and maintain, can improve production efficiency and save production costs, and has great advantages Good application prospects.

Owner:CENT IRON & STEEL RES INST

A filter duster

The invention discloses a filter powder spraying machine, which comprises a slide plate mounted on a frame and a drive mechanism for the slide plate; at least two sets of rotating shafts are mounted on the sliding plate, a tray is arranged at the top of the rotating shaft, a positioning column is arranged on the tray, and a filter cover It is located on the positioning column; it also includes a powder spraying chamber, and the slide plate driving mechanism can drive the slide plate to drive the filters on different groups of rotating shafts into the powder spraying chamber alternately; a reciprocating drive mechanism is set under the filter in the powder spraying chamber, The reciprocating drive mechanism includes a drive bar that is horizontally slidably installed on the frame. The guiding direction of the second guide mechanism and the drive bar are parallel to the moving direction of the slide plate. The lower end of the rotating shaft is provided with a runner that matches the drive bar. Strip drive mechanism, a part of the slide plate enters the powder spraying chamber, the runner cooperates with the corresponding drive bar, the drive bar reciprocates along the moving direction of the slide plate, drives the filter to rotate, and the powder spray head sprays powder to the rotating filter. The present invention has the advantages that: the dust spraying of the filter is comparatively uniform.

Owner:SIXIAN TENGMA AUTO PARTS CO LTD

A self-fastening ring mold powder spraying device

ActiveCN111359804BReduce the effects of waxingAvoid enteringSpraying apparatusFinger-ringsClassical mechanicsStructural engineering

Owner:临沂高新区人才职业培训学校有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com