Wet dust remover

a technology of wet dust removal and vacuuming chamber, which is applied in the direction of combustion treatment, lighting and heating equipment, separation processes, etc., can solve the problems of large floor area, high operation cost, and large investmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

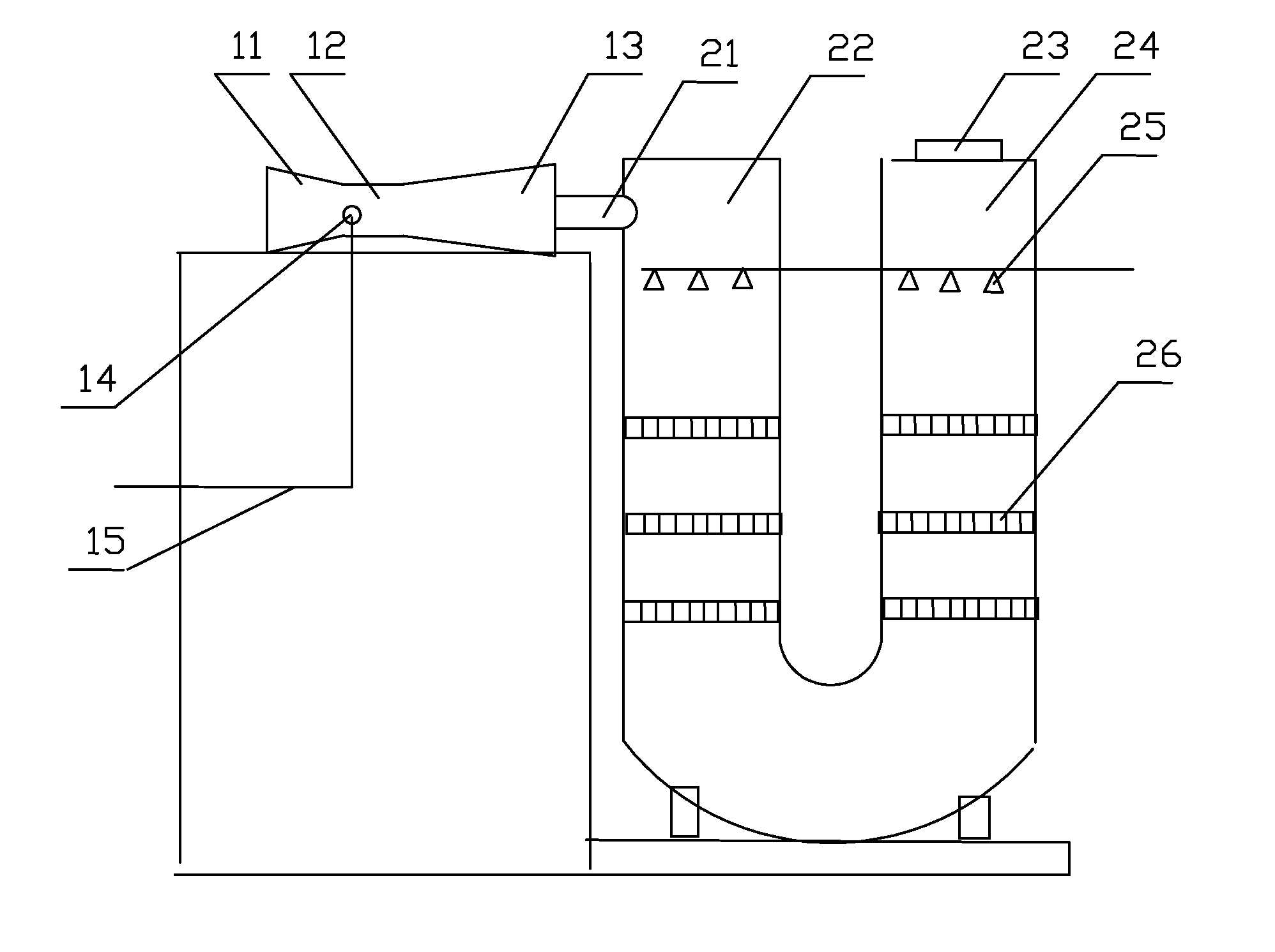

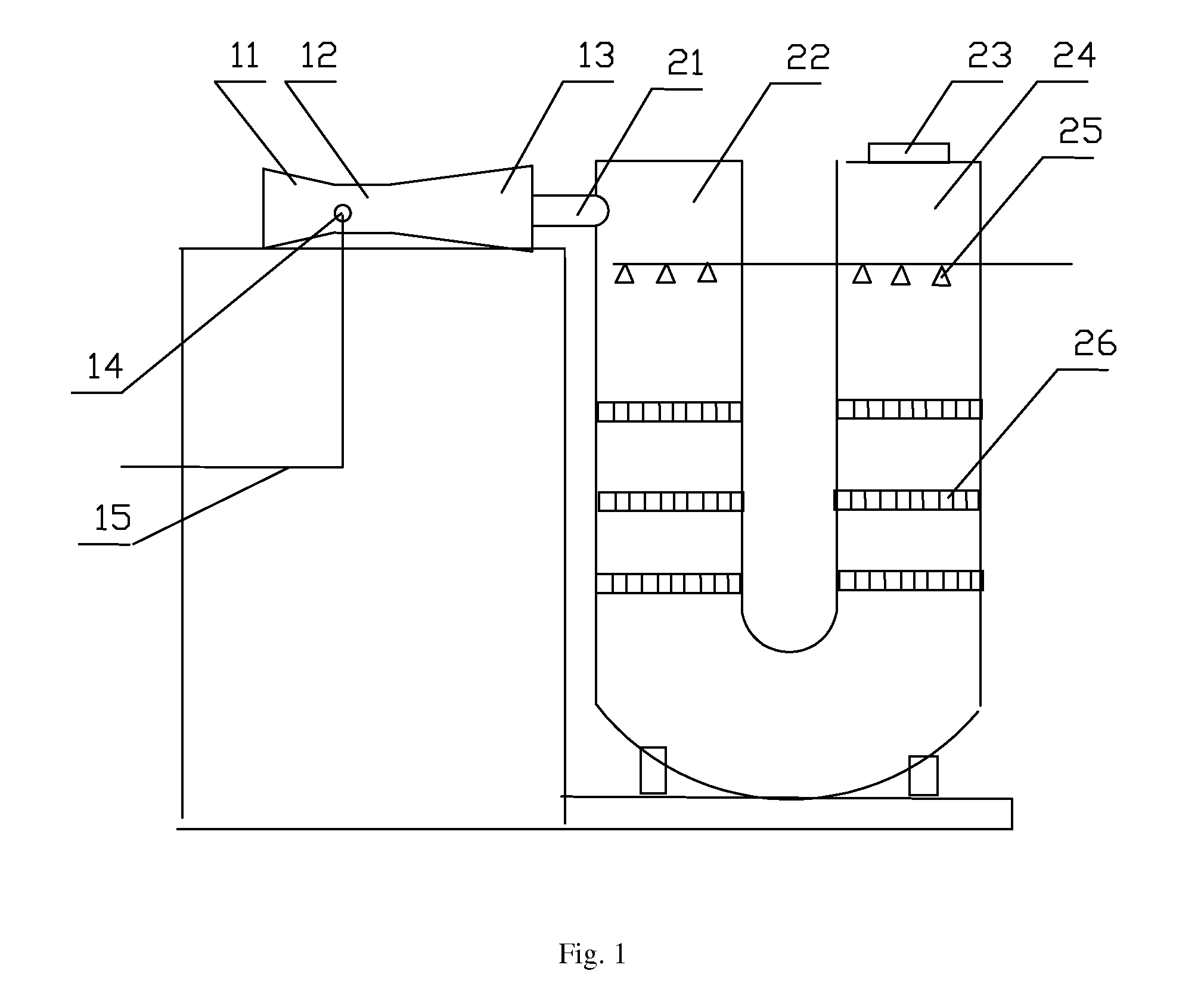

[0017]As shown in FIG. 1, this wet dust remover consists of Venturi tube and cylindrical washer. The air outlet of said Venturi tube is connected with the air inlet of cylindrical washer. The said Venturi tube consists of convergent section 11, throat section 12 and diffusion section 13. There are several through holes 14 on the sidewall of said throat section, the outside of which is connected with pressure water pipe 15. The outer end of said diffusion section composes the outlet of said Venturi tube and the outer end of said convergent section composes the inlet of said Venturi tube. There are several nozzles 25 spreading on the separated cross sections in the said cylindrical washer as well as several layers of dehydration wire meshes 26. The convergent section, throat section and diffusion section of said Venturi tube are integrated together, they can be welded, flange connected or be integral. The said throat section is normally of sizing rectangle tube. The said through holes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shape | aaaaa | aaaaa |

| Efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com