Automatic powder spreader

A powder sprinkler and automatic technology, which is applied in chemical instruments and methods, solid separation, filter and sieve, etc., can solve the problems of too slow spreading, poor heat dissipation of the motor, high temperature, etc., so as to improve the efficiency of powder spreading and save farmers' expenses , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

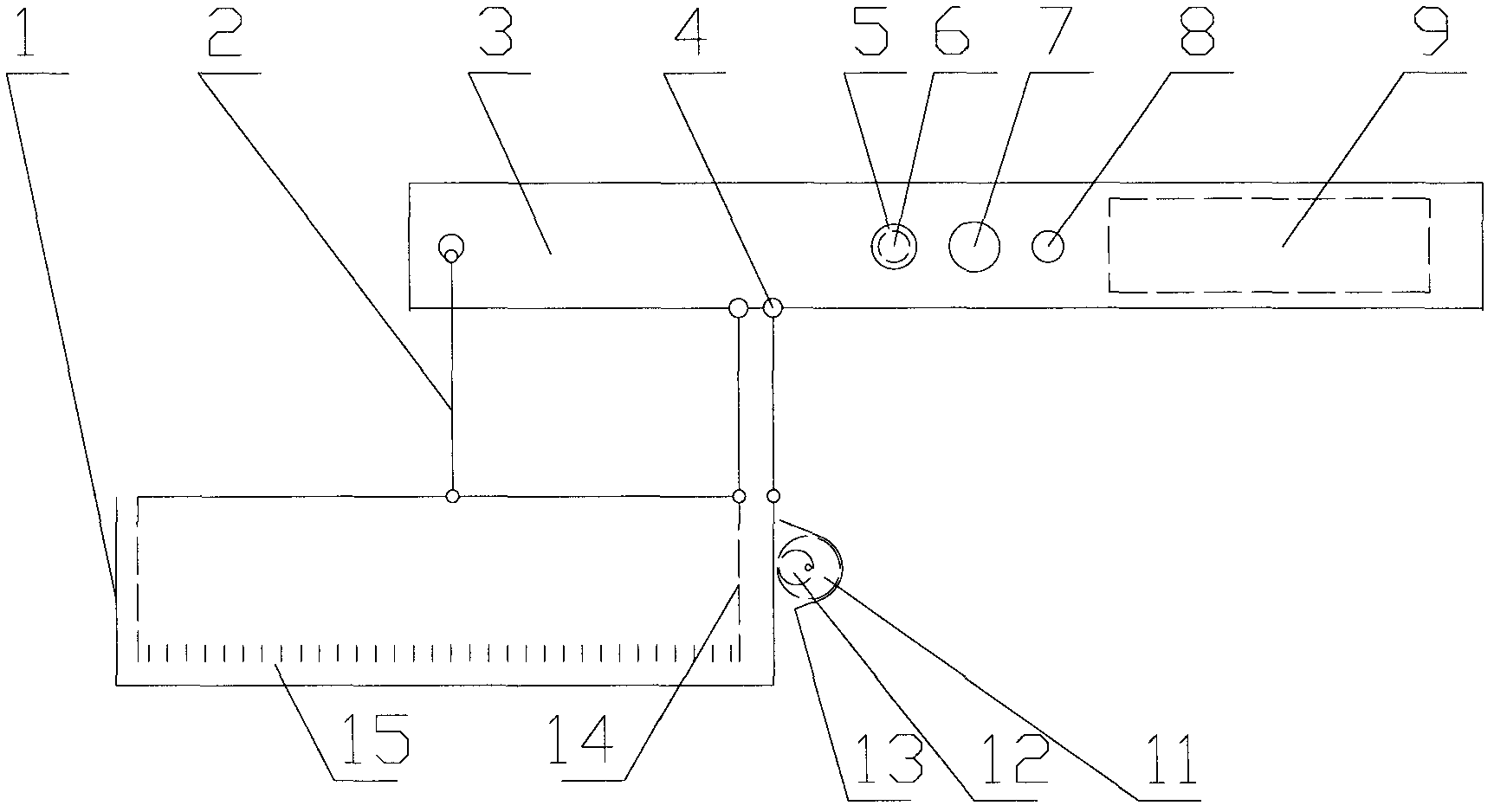

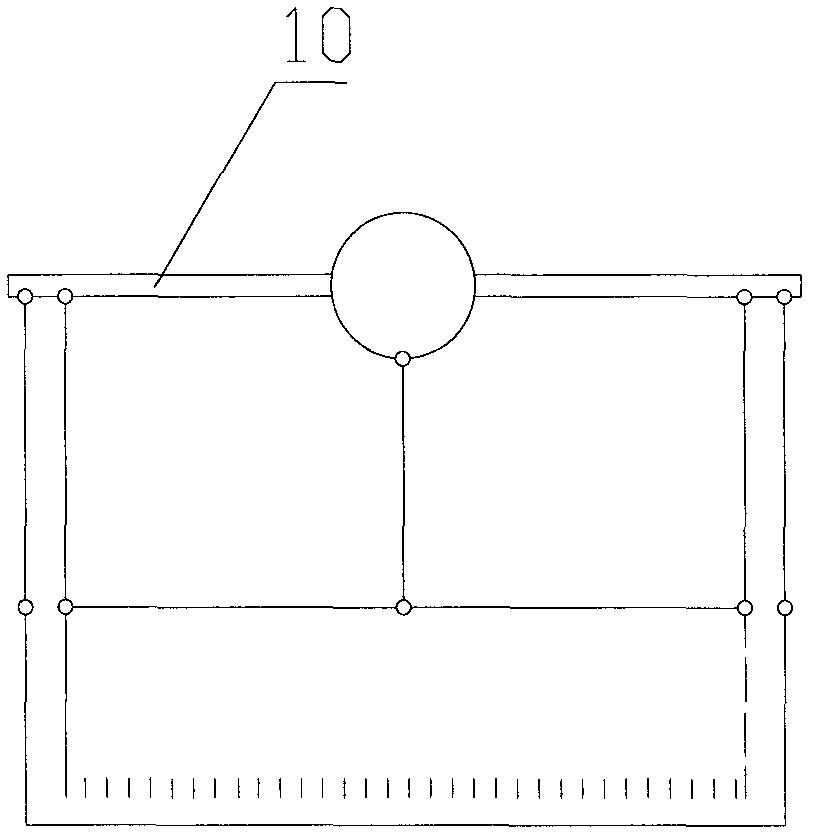

[0030] like figure 1 As shown, an automatic powder spreader includes a vibrating screen 1, a motor 11, an eccentric block 12 installed on the motor shaft, a motor cover 13, a flexible part 2, a connecting part 4 and a supporting part. Described support part is divided into vertical support part 3 and transverse support part 10, and transverse support part is contained on the longitudinal support part, and battery 8 is housed in its longitudinal support part; It is connected with the longitudinal support and the transverse support, and makes the vibrating screen horizontal; the motor 11 and the eccentric block 12 are fixed on the outside of the vibrating screen ring, and are covered by the motor cover 13; the axis of the motor is in a horizontal position Or the included angle with the horizontal plane is less than 45 degrees; the auxiliary sieve 14 for sharing the weight of the medicine powder, reducing the load of the vibrating sieve, and improving the powder spreading ability...

Embodiment 2

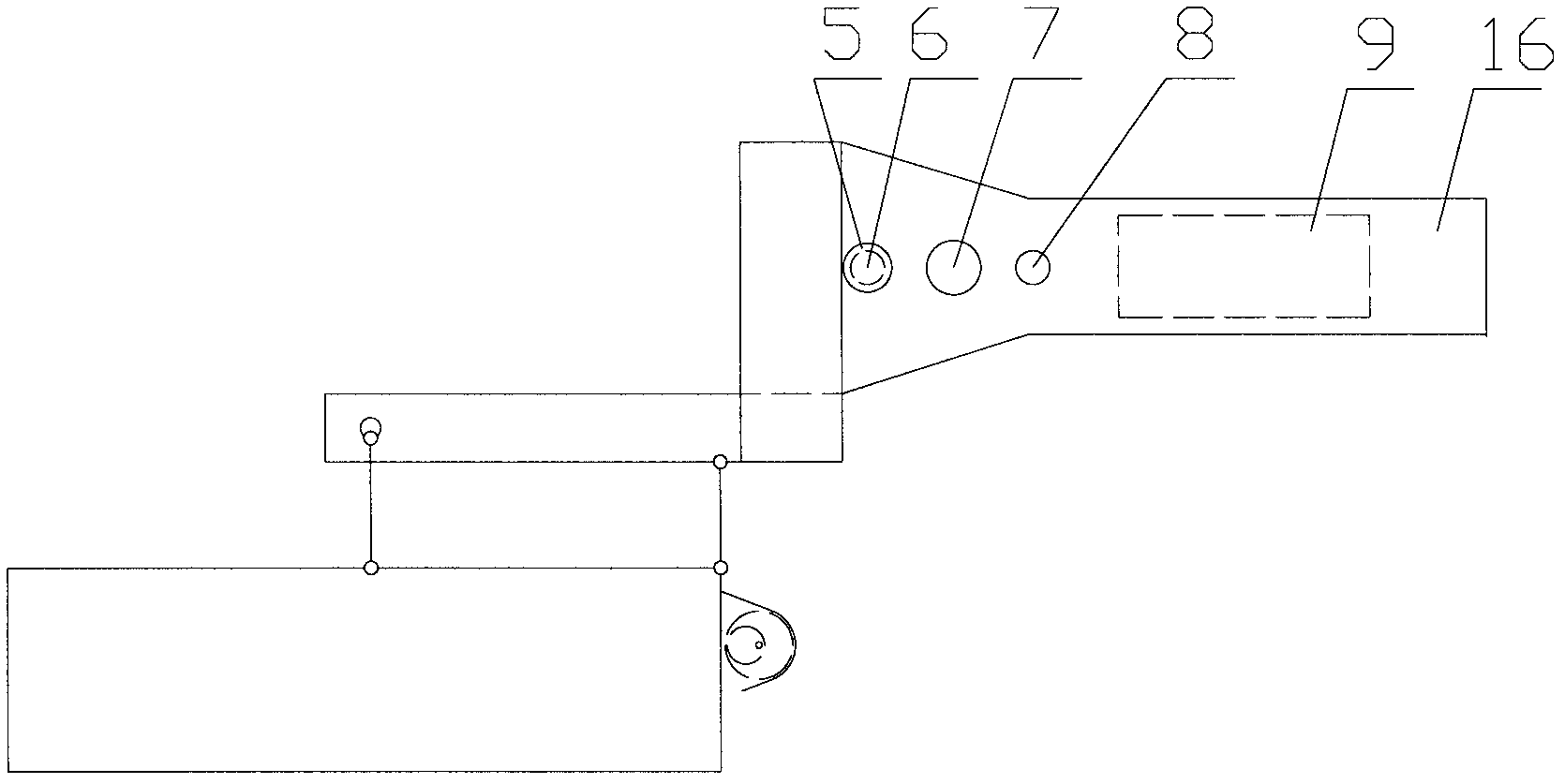

[0044] If the longitudinal support is a combination of a pipe and a flashlight, the pipe can be composed of a fixed pipe and a telescopic pipe, and the telescopic pipe is inserted into the fixed pipe. This can expand the range of spraying. The socket socket 5 that links to each other with battery, the potentiometer 7, the switch 8 that controls motor motion are housed on flashlight 16, and tube and flashlight combination are connected by mechanical means, can disassemble. The screen position is lower than the flashlight, not blocking the light of the lamp. The automatic powder sprinkler of this embodiment has two purposes, that is, it can be used for both lighting and powdering. When not raising silkworms in winter, the plug can be pulled out from the jack, the sieve, the motor, and the motor cover are removed as a whole, the tube is removed from the flashlight, and the flashlight is left for lighting. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com