Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about How to "Good dust effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

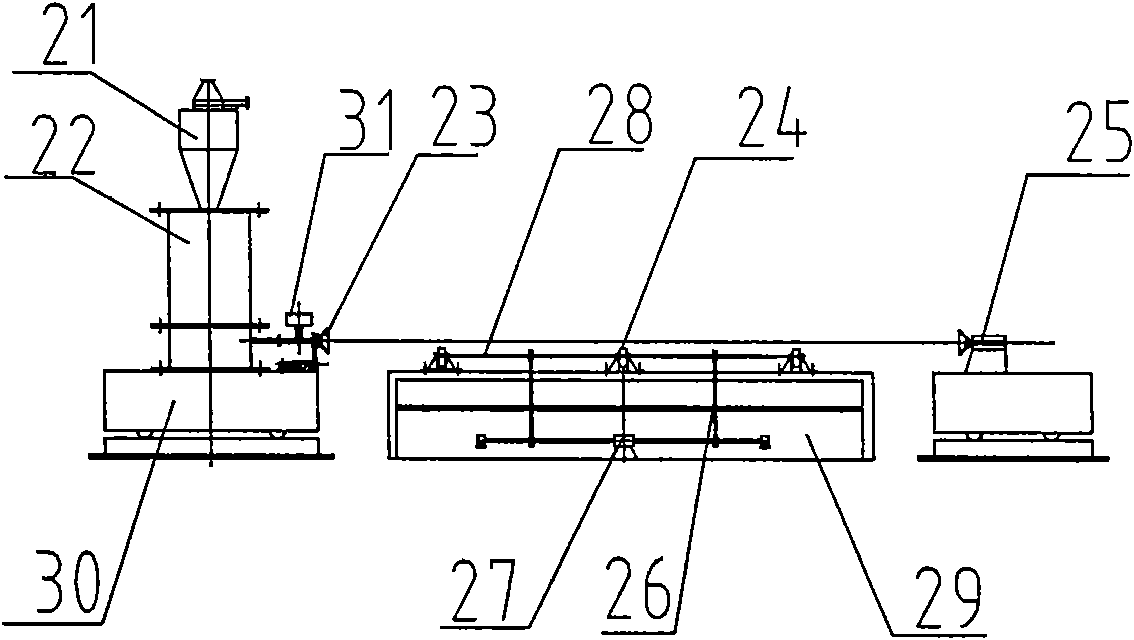

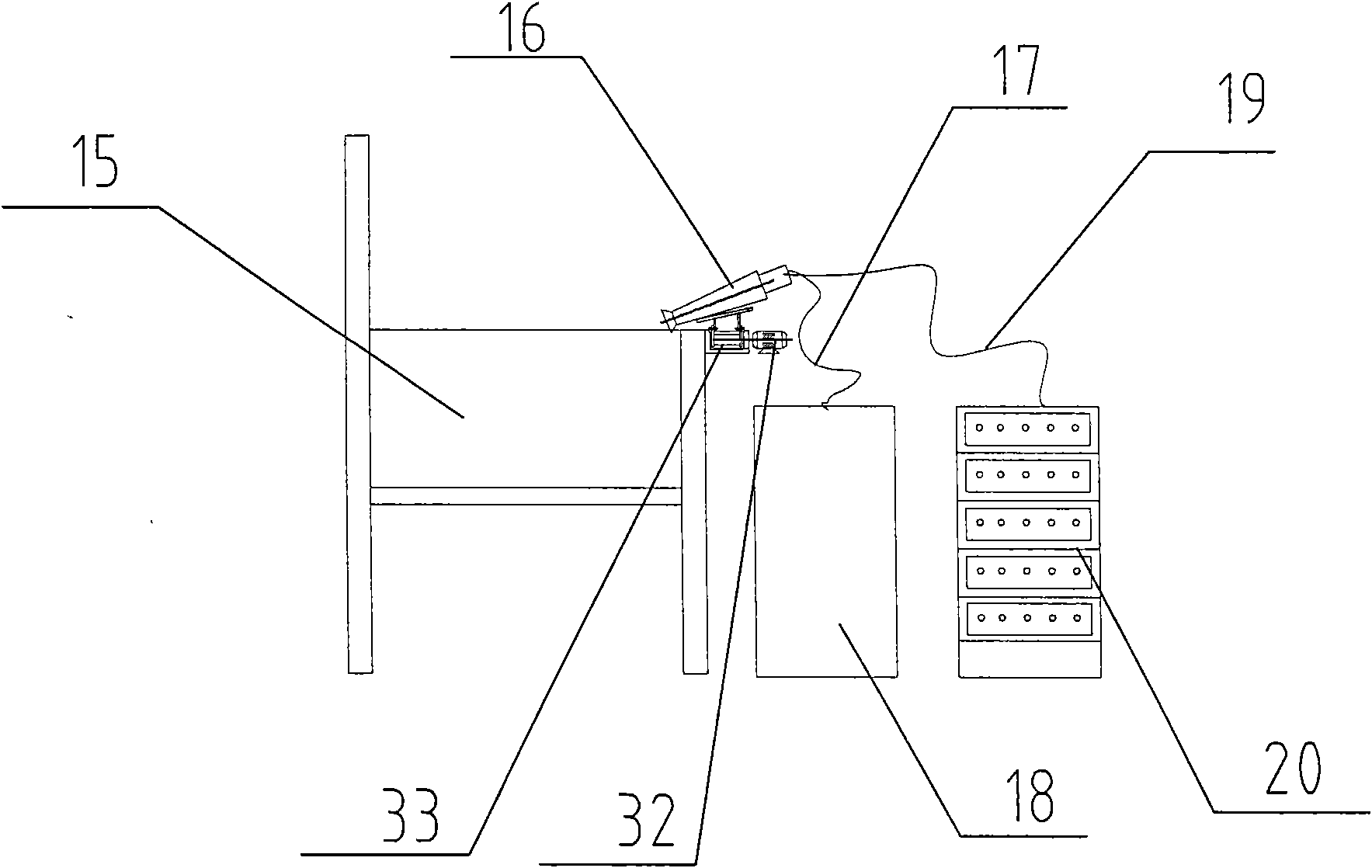

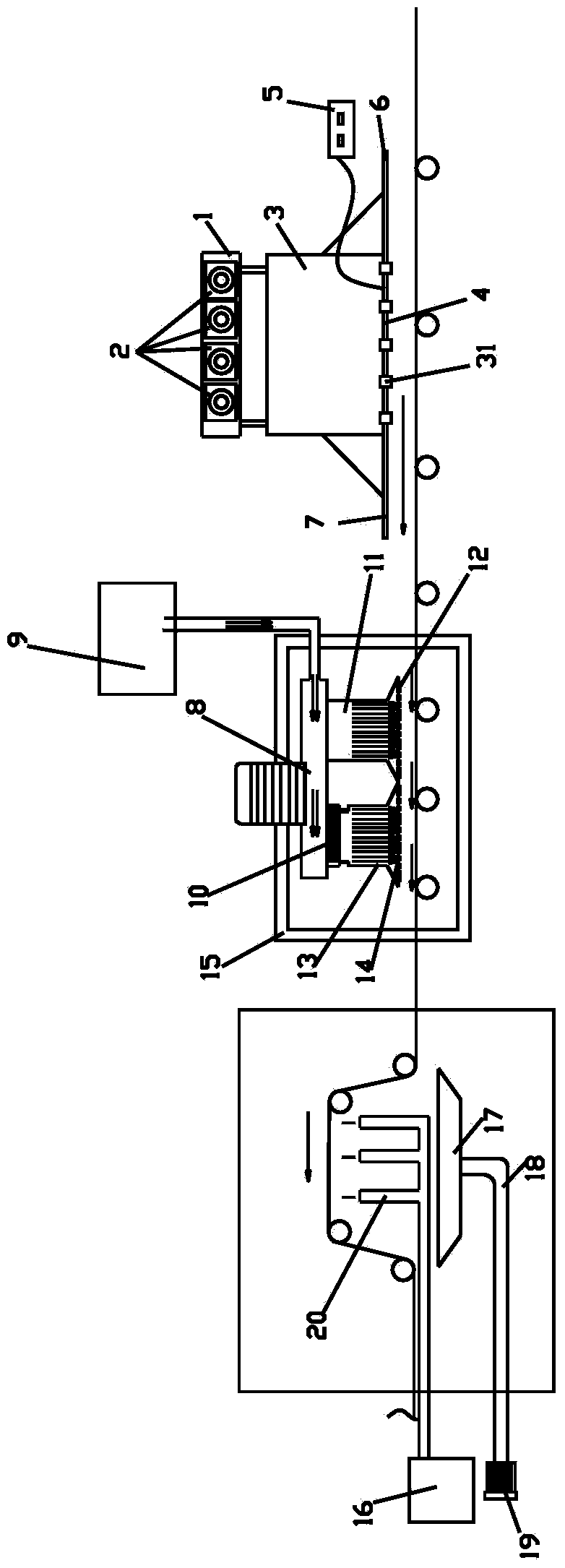

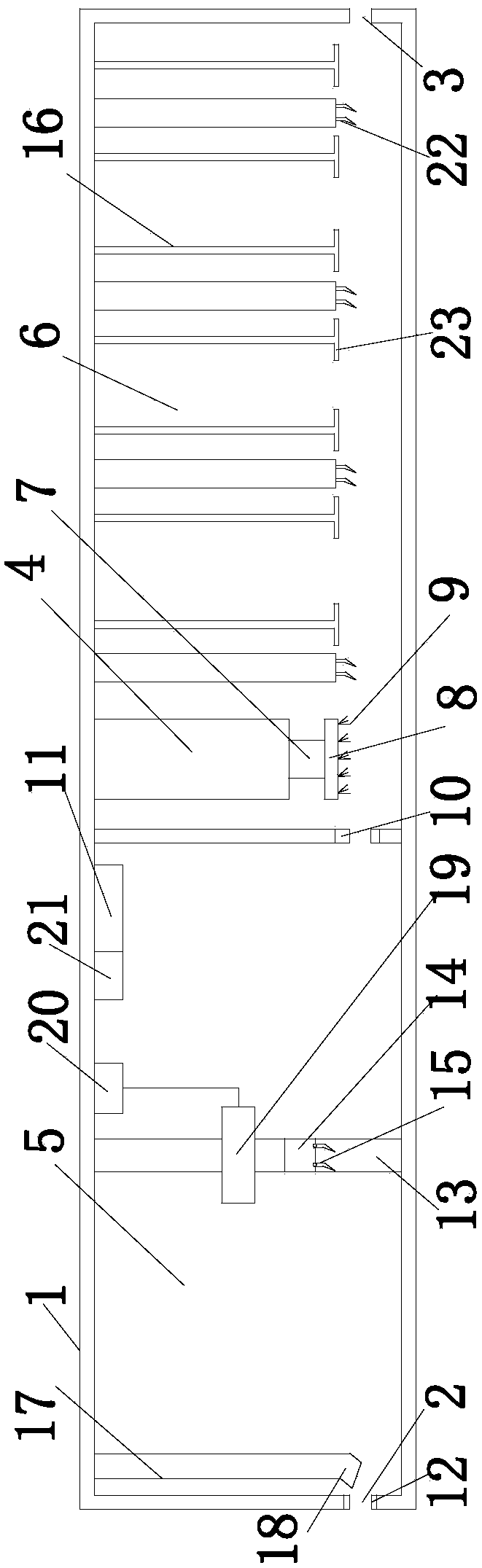

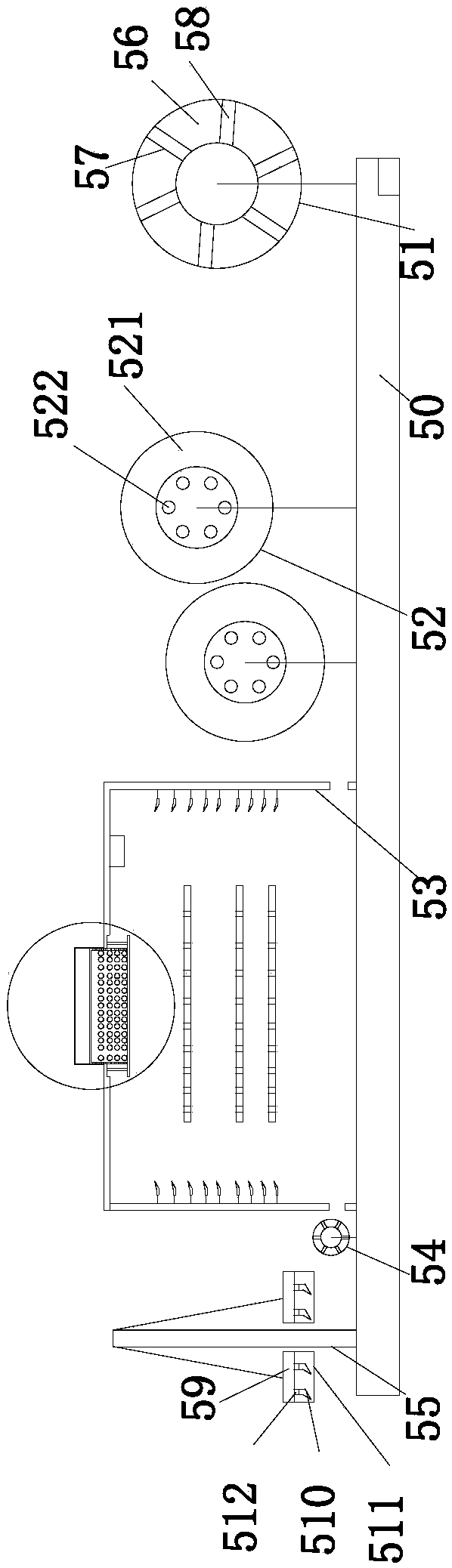

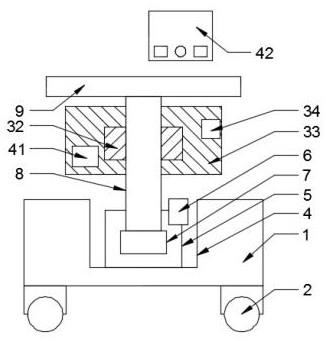

Steel-plastic composite pipe spraying device

InactiveCN101862725AReasonable structureHigh degree of automationLiquid spraying plantsLiquid surface applicatorsEconomic benefitsElectrical control

The invention relates to a steel-plastic composite pipe spraying device, which comprises an electrostatic spraying system for spraying the outer surface of a steel-plastic composite pipe, an inner powder spraying system for spraying the inner wall of the steel-plastic composite pipe, a pre-heating system, a solidifying system, a transportation system and an electric control system for controlling the entire device, wherein the pre-heating system consists of a pre-heating furnace, a pre-heating system fan and a pre-heating system heater, which are connected with the pre-heating furnace; the solidifying system consists of a solidifying furnace, and a solidifying system fan and a solidifying system heater, which are connected with the solidifying furnace; the transportation system consists of a feeding bracket, a discharging bracket, and a pre-heating system transportation track and a solidifying system transportation track, which hare driven by a motor, and a translation bracket for controlling the steel pipe to move among the pre-heating system, the solidifying system, the electrostatic spraying system and the inner powder spraying system, the pre-heating system is arranged behind the feeding bracket, the electrostatic spraying system and the inner powder spraying system are arranged between the pre-heating system and the solidifying system, and the discharging bracket is arranged behind the solidifying system. The steel-plastic composite pipe spraying device has the advantages of reasonable structure, high automation and high efficiency, has good powder spraying effect, can realize the automatic, continuous and stable production, and has good energy conservation and environmental protection as well as good economic benefit.

Owner:鼎顺钢塑管设备材料(杭州)有限公司

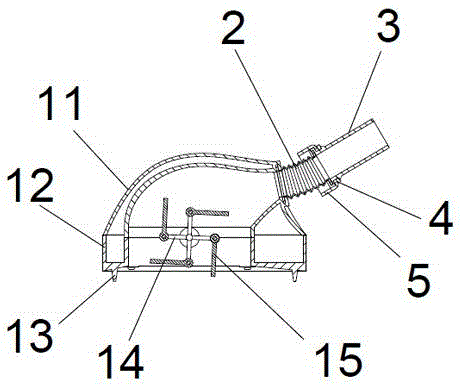

Air purifier with double running modes

InactiveCN103032922AReduce energy consumptionAchieve convectionSpace heating and ventilation safety systemsLighting and heating apparatusAir purifiersEngineering

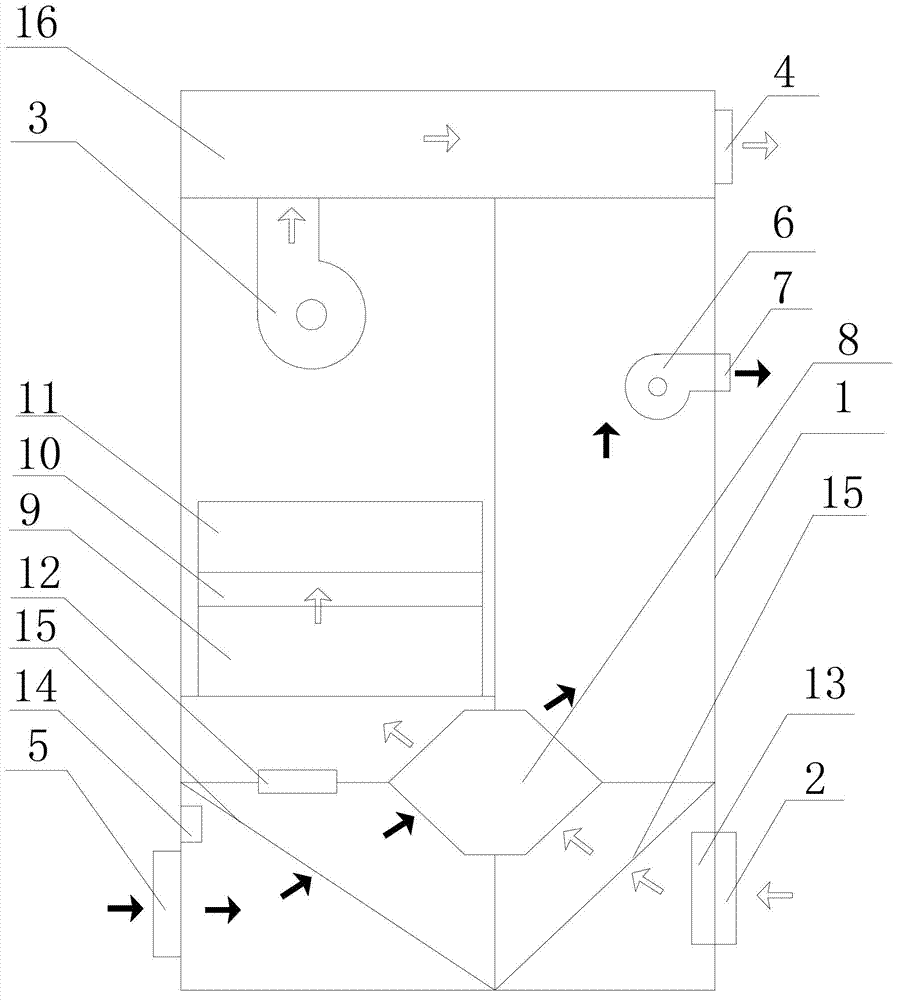

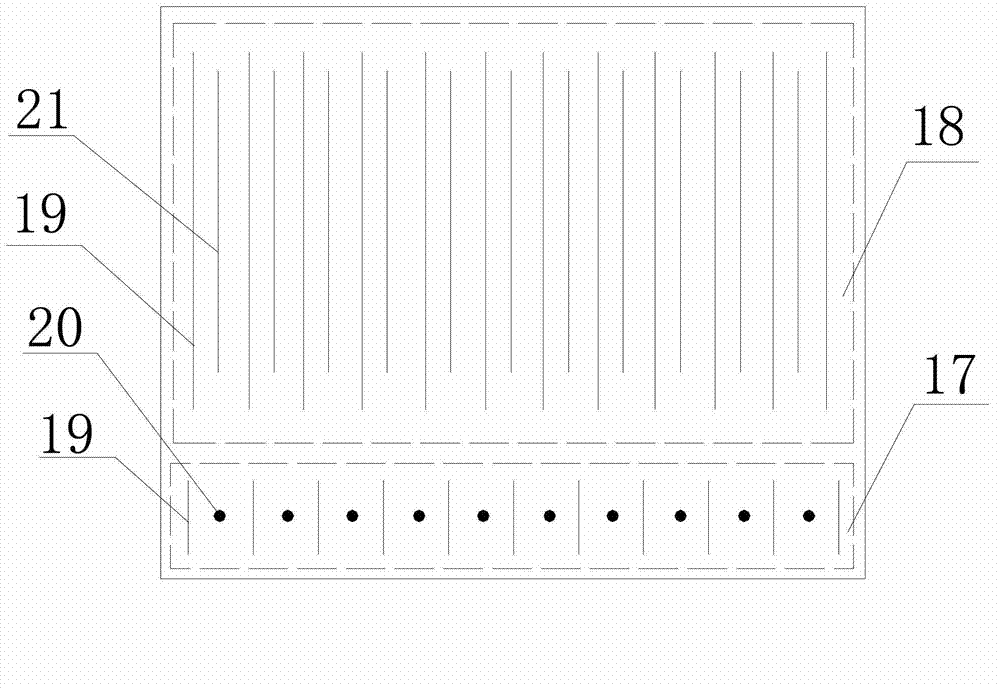

The invention discloses an air purifier with double running modes. The air purifier comprises a shell and a controller, wherein a fresh air channel, an air return channel and a heat exchanger are arranged in the shell; the fresh air channel and the air return channel are connected with the heat exchanger respectively; an electrostatic dust remover is arranged in the fresh air channel; a first electric air valve is connected between the fresh air channel and the air return channel; a second electric air valve is arranged at an air inlet; the controller controls the first electric air valve and the second electric air valve; when the first electric air valve starts, the controller controls to stop an exhaust fan; and when the second electric air valve stars, the controller controls to operate an air feeder and the exhaust fan. The air purifier with double running modes can realize switching of an indoor air circulation purification mode and a fresh air purification mode, achieves a good air purification effect and can reduce the energy consumption of air temperature treatment.

Owner:GUANGZHOU KUAIJING ENVIRONMENTAL PROTECTION TECH CO LTD

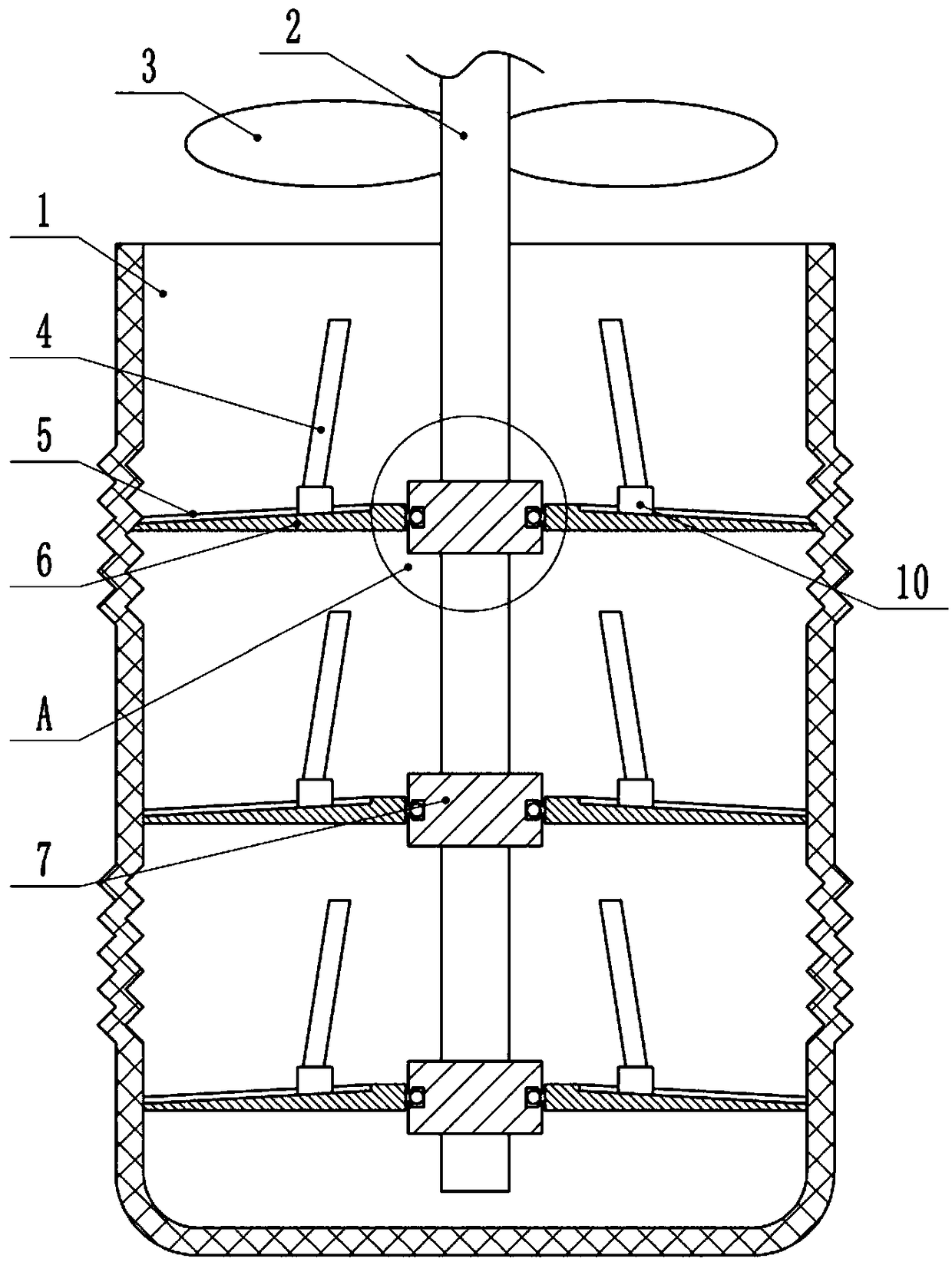

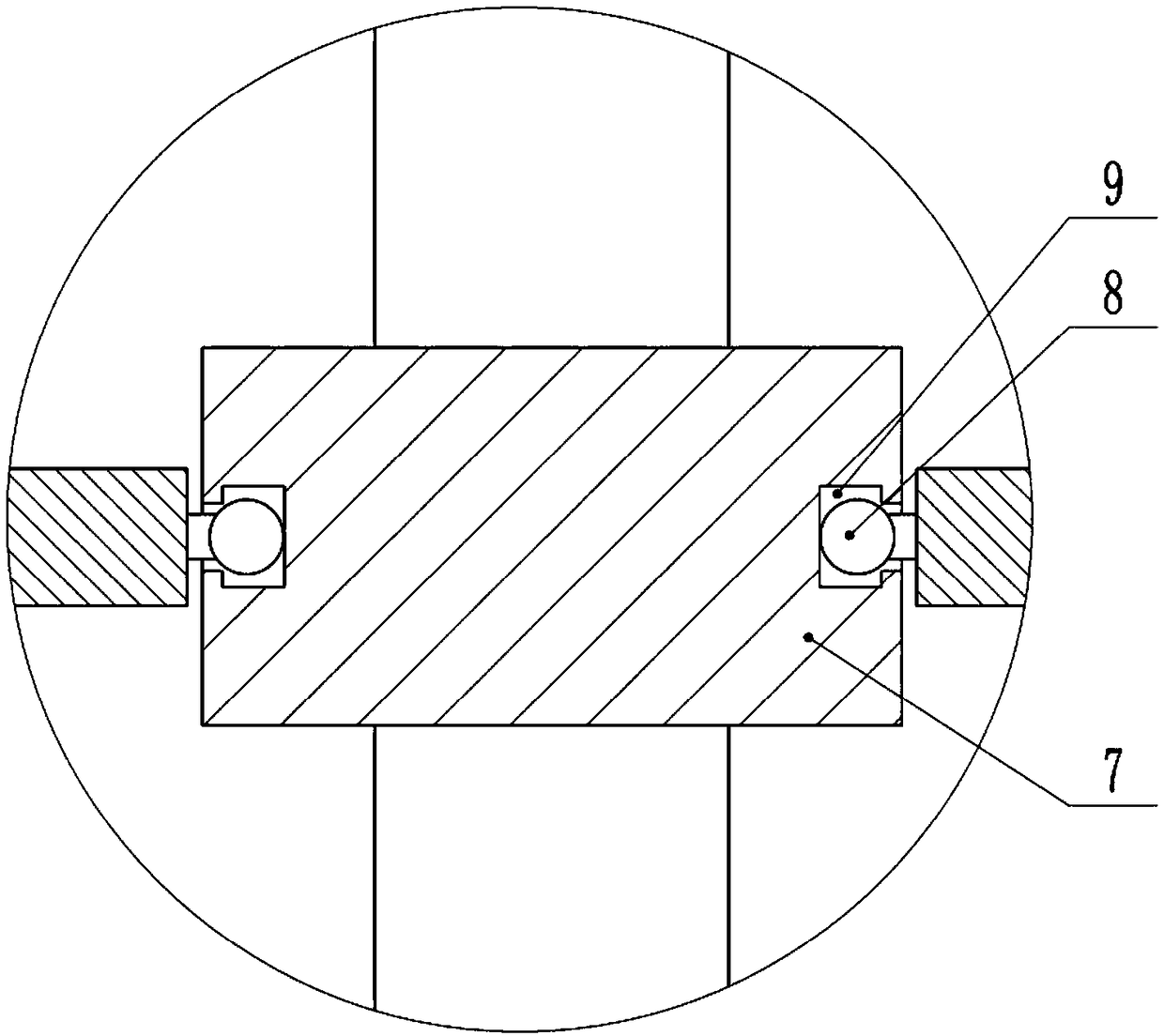

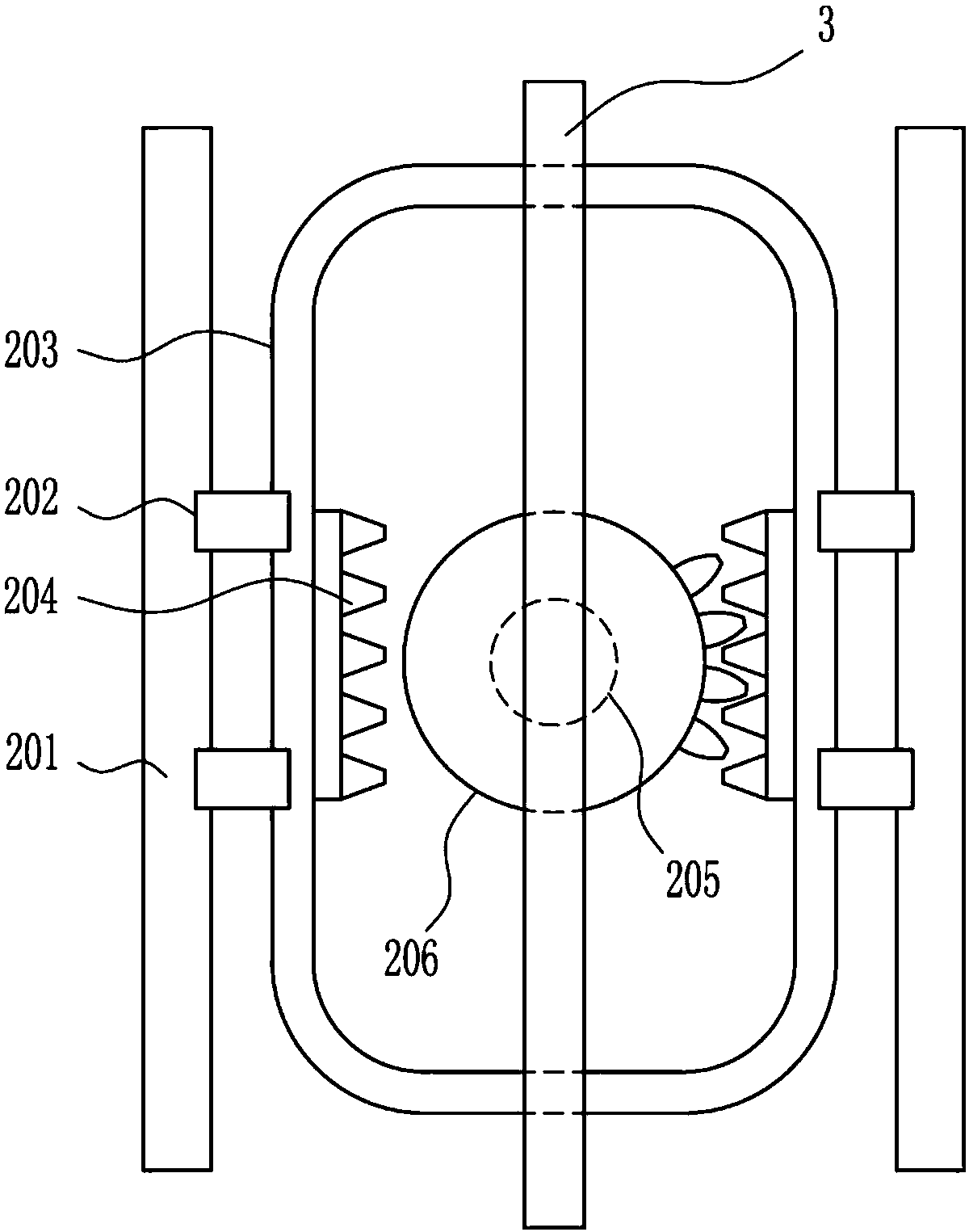

Filter bag device of pulse dust collector

The invention belongs to the technical field of dust collecting equipment, and particularly discloses a filter bag device of a pulse dust collector. The device comprises a filter bag, wherein a rotating shaft is arranged in the filter bag, fan blades are arranged on the rotating shaft, a plurality of cams are arranged on the rotating shaft, bulge parts of two adjacent cams face oppositely, and sliding grooves are formed in curved surfaces of the cams; a plurality of movable rod groups are arranged in the filter bag; each movable rod group comprises two movable rods, one end of each movable rodis clamped in the corresponding sliding groove, the other ends of the two movable rods are fixedly connected with the filter bag, and clappers are glidingly connected to the two movable rods; a firstmagnet and a second magnet are arranged on the bulge part and a cylinder part of each cam respectively, third magnets are arranged on the clappers, the magnetic poles of the sides, close to each other, of the first magnet and the third magnets are identical, and the magnetic poles of the sides, close to each other, of the second magnet and the third magnet are opposite. With the scheme, the filter bag can shake back and forth when being cleaned by a blowing device, and the clappers can also beat the filter bag back and forth, so that the cleaning effect is good.

Owner:GUIZHOU HUANKE ENVIRONMENT ECOLOGICAL RES & DEV CO LTD

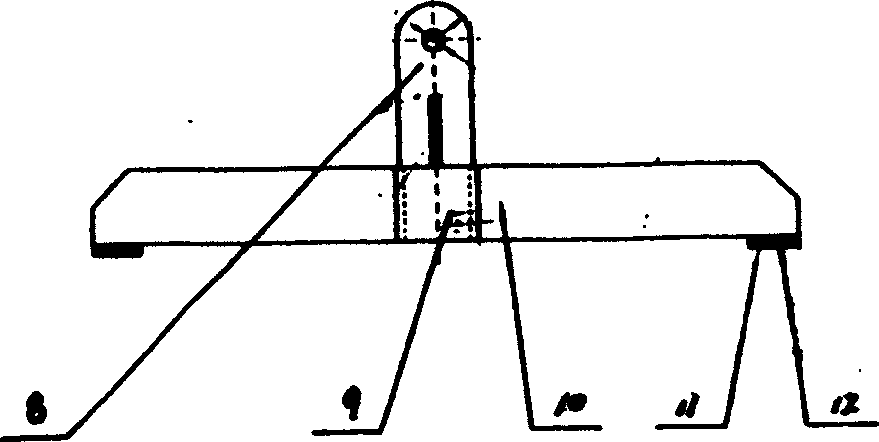

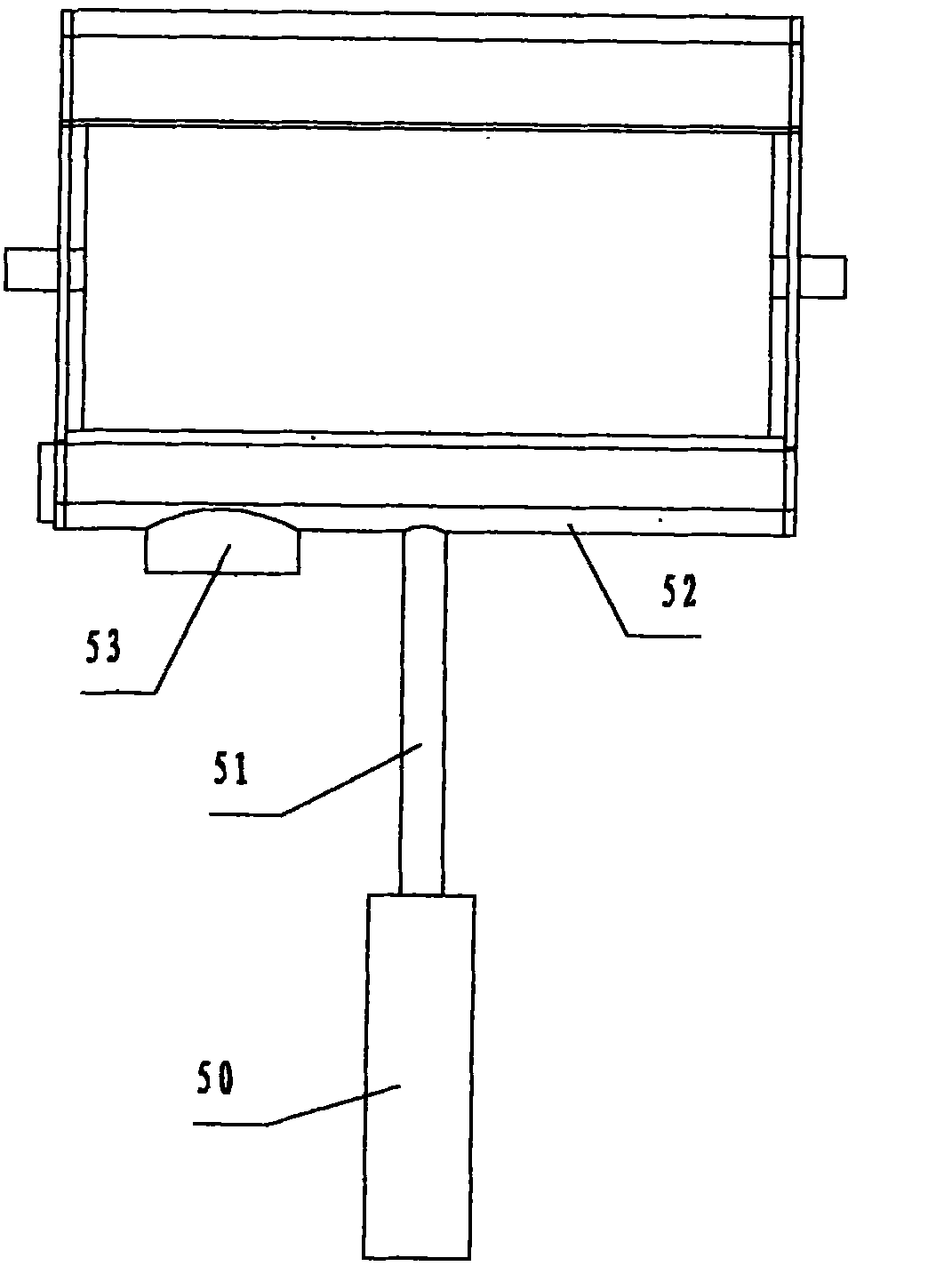

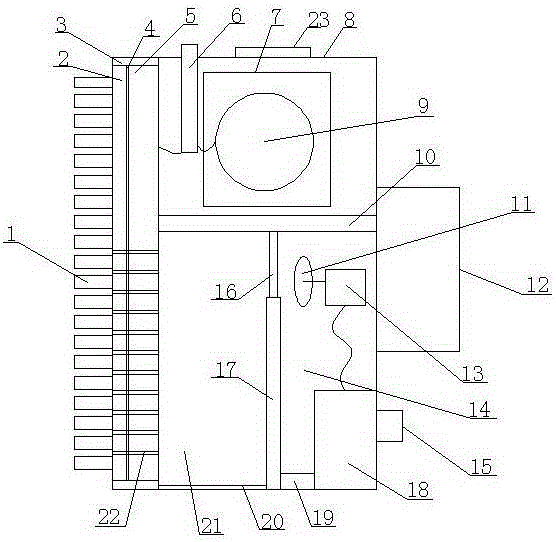

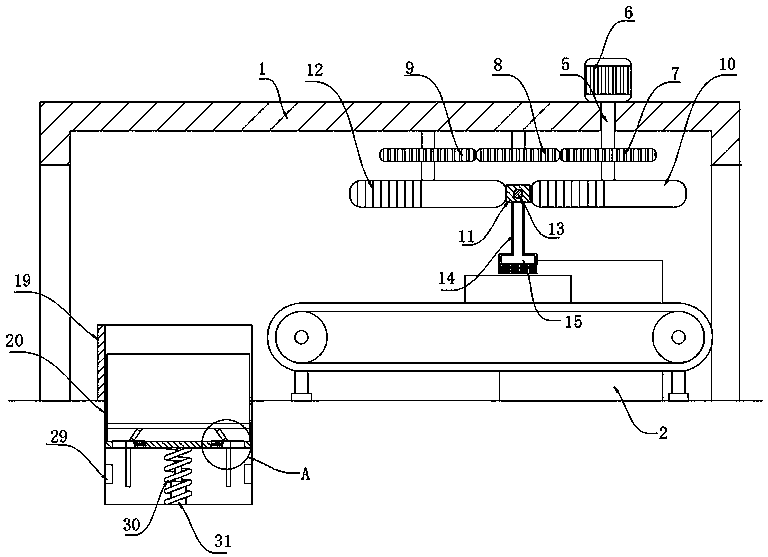

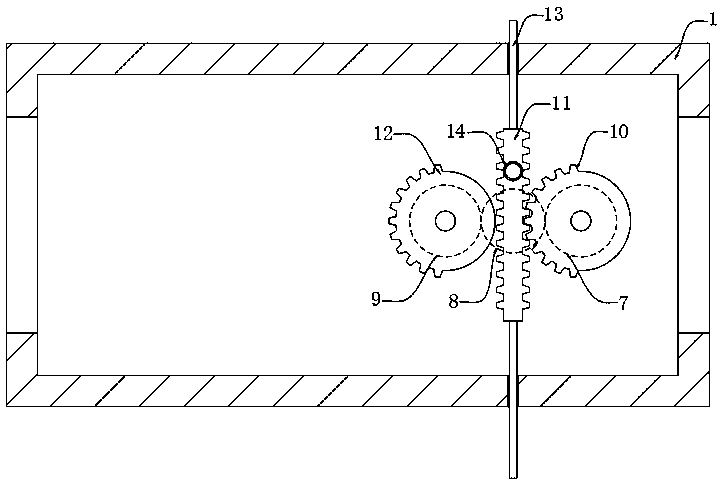

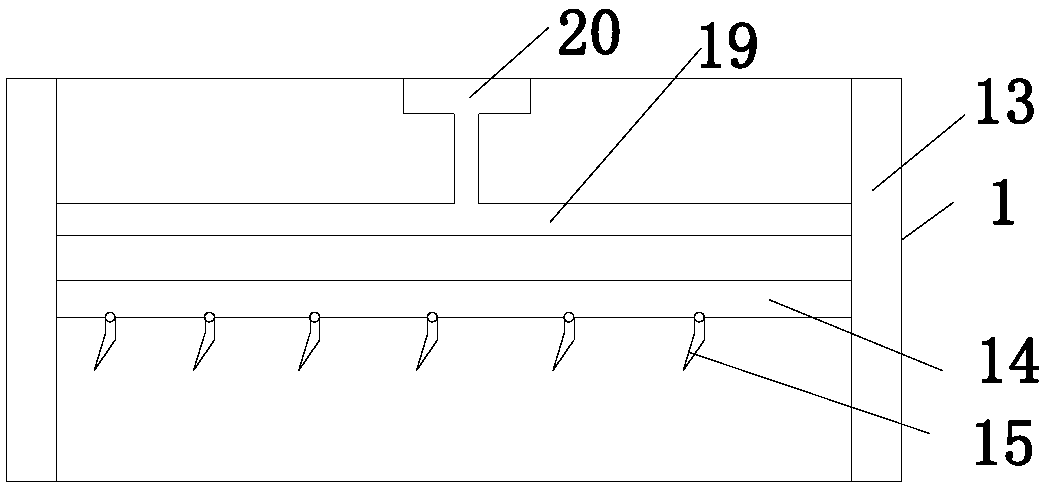

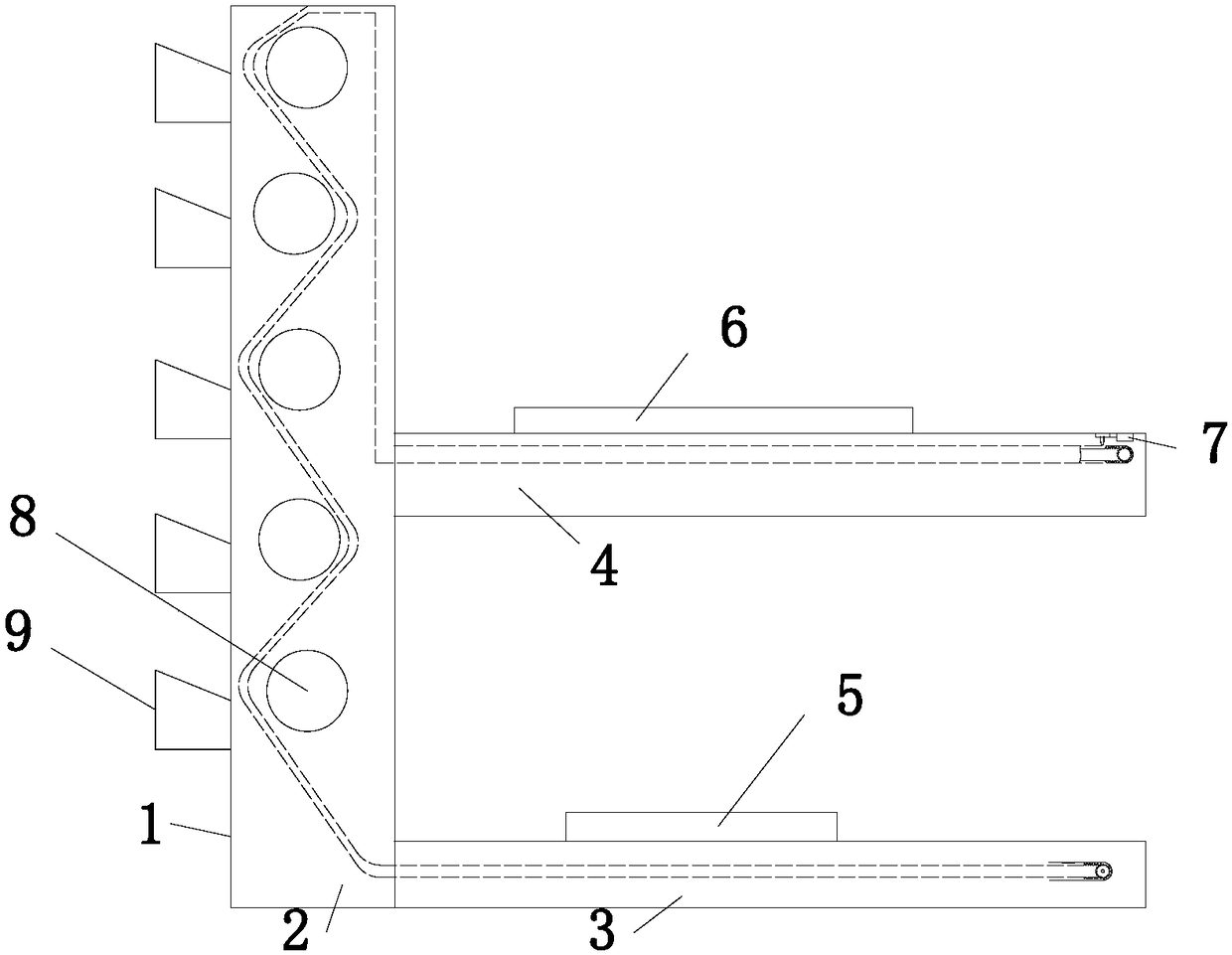

Mechanical flocking plant

InactiveCN103521405AIncrease productivityImprove product qualityLiquid spraying plantsLiquid surface applicatorsProduction lineDrive motor

The invention relates to a mechanical flocking plant and belongs to the technical field of flocking machines. The mechanical flocking plant comprises a supporting frame, a faller, a flocking device, a baking device and a cleaning device. The supporting frame is provided with a circulation conveyor belt, the faller is fixedly arranged on the conveyor belt and simultaneously moves along with the conveyor belt, and the flocking device, the baking device and the cleaning device are arranged on the conveyor belt of the supporting frame in sequence. Drive motors are arranged at the two ends of the conveyor belt respectively and drive the conveyor belt to rotate. The whole processes from electrostatic flocking and drying to fluff removing are operated in a full automation mode, production efficiency and product quality of prints are greatly improved, besides, management of a production line is facilitated, and the purpose of protecting the environment is achieved.

Owner:JIASHAN YIXIN FLOCKING

Shaking and deashing mechanism special for filtering cartridge type dedusting and purifying equipment

InactiveCN1544121AGuaranteed instant reproducibilityExtended service lifeDispersed particle filtrationEngineeringElectric motor

The invention relates to a special rapping dust-cleaning mechanism for filter tube dust-cleaning purification device, composed of positioning pin, link rod, eccentric mechanism, rapping press frame and electric motor, where the eccentric mechanism is driven by the electric motor, one end of the link rod is pinned with the drive plate in the eccentric mechanism and the other one with the positioning pin, and the straight plate in the rapping press frame cooperates with the rapping block in the middle part of the link rod by intermittently colliding. Its advantages: 1, adopting eccentric mechanism as the kernel of rapping dust-cleaning mechanism, so that not only the structure is novel, particular and simple but also the rapping effect completely remarkable, ensuring the instantaneous reappearance of the filter tube; 2, not only having dust-cleaning effect and long service life of the filter tube, but also reducing working noise.

Owner:NANFANG ENVIRONMENT PURIFYING EQUIP HANGZHOU

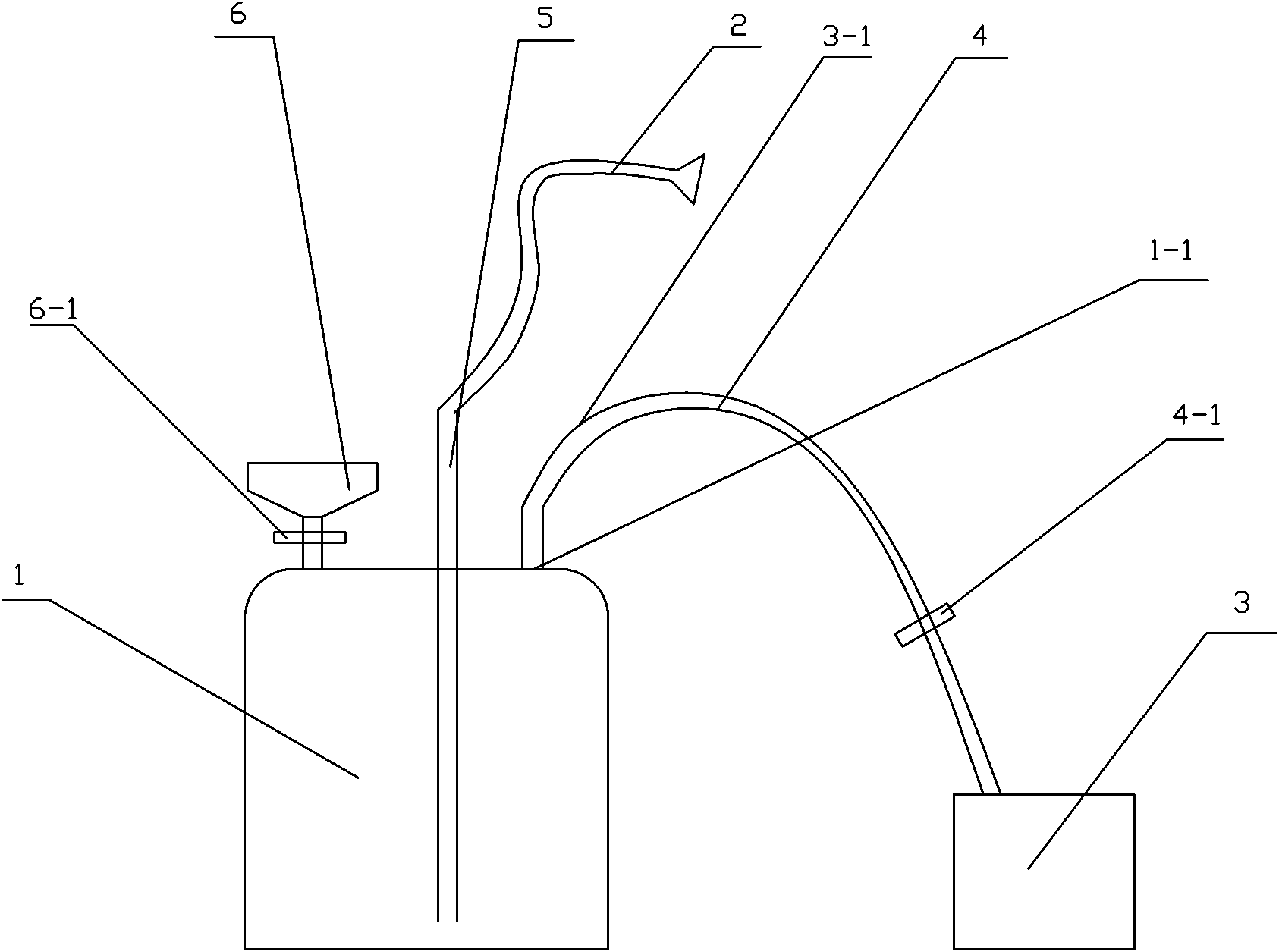

High-pressure powder-spraying device for wet waxes

InactiveCN102728500ASave raw materialsNot easy to condenseCandlesLiquid spraying apparatusWaxMetallurgy

The invention belongs to the field of candle manufacturing, and especially relates to a high-pressure powder-spraying device for wet waxes, which is used for candle manufacturing. The device comprises a wax melting pool and a powder spraying gun; and the device is characterized in that the device mainly comprises a powder spraying pot, the powder spraying gun and a high-pressure air pump, wherein the powder spraying pot is provided with an air inlet, the air inlet is connected with the high-pressure air pump through an air tube, the top of the powder spraying pot is connected with a wax-spraying tube penetrating into the bottom of the powder spraying pot by way of inserting, the wax-spraying tube is connected with the powder spraying gun, and the powder spraying pot is fixedly connected with a feed hopper. The device disclosed by the invention has the advantages that through adding a powder spraying pot, the high-pressure air pump applies a high pressure to the inside of the pot, wax water is sprayed out of the powder spraying gun, particles are less than 0.1 mm, and the low-temperature wax water is not easy to be condensed on a wall, therefore, the powder spraying effect is excellent, and the raw materials of candles are greatly saved.

Owner:TIANJIN HUATAI CANDLE

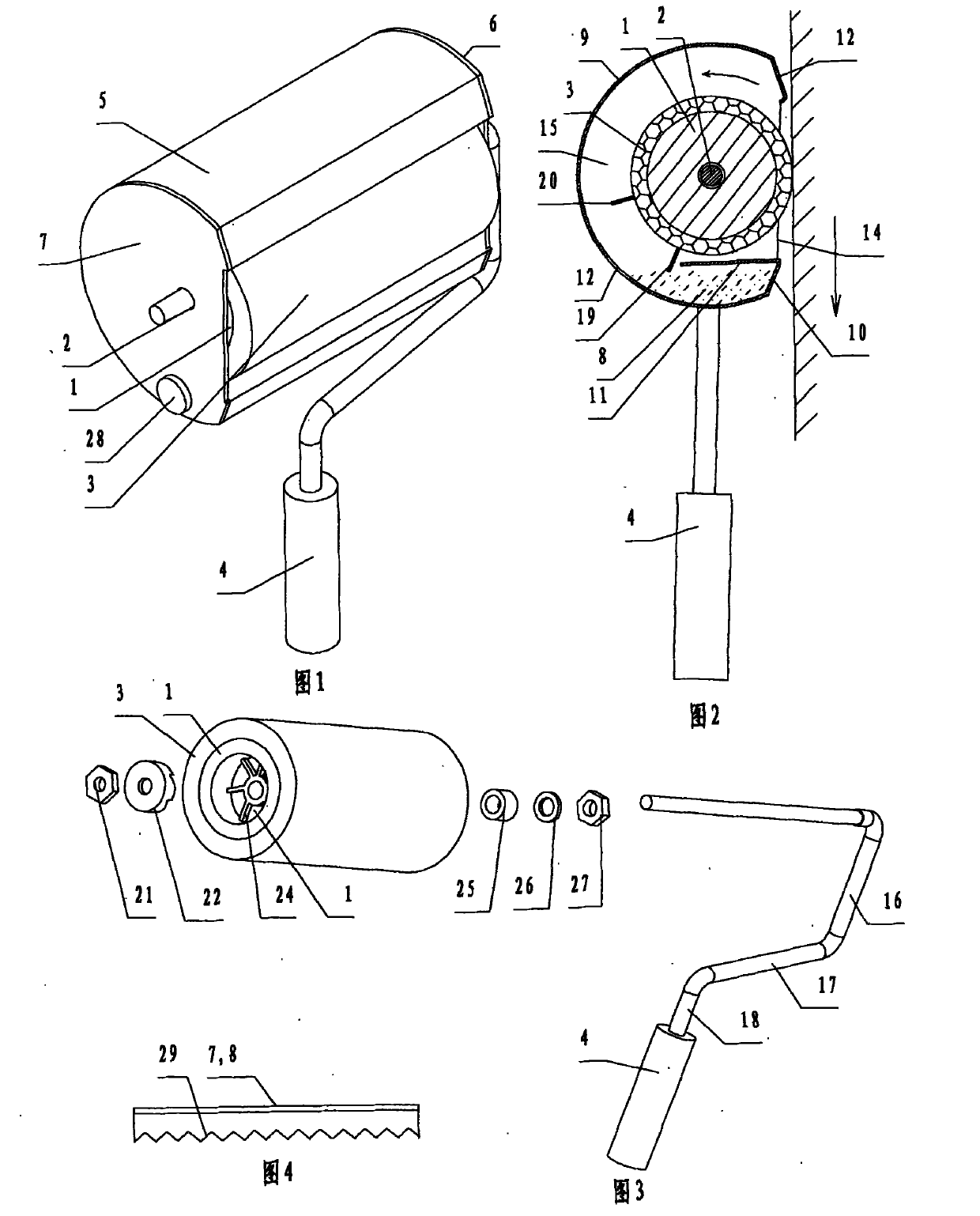

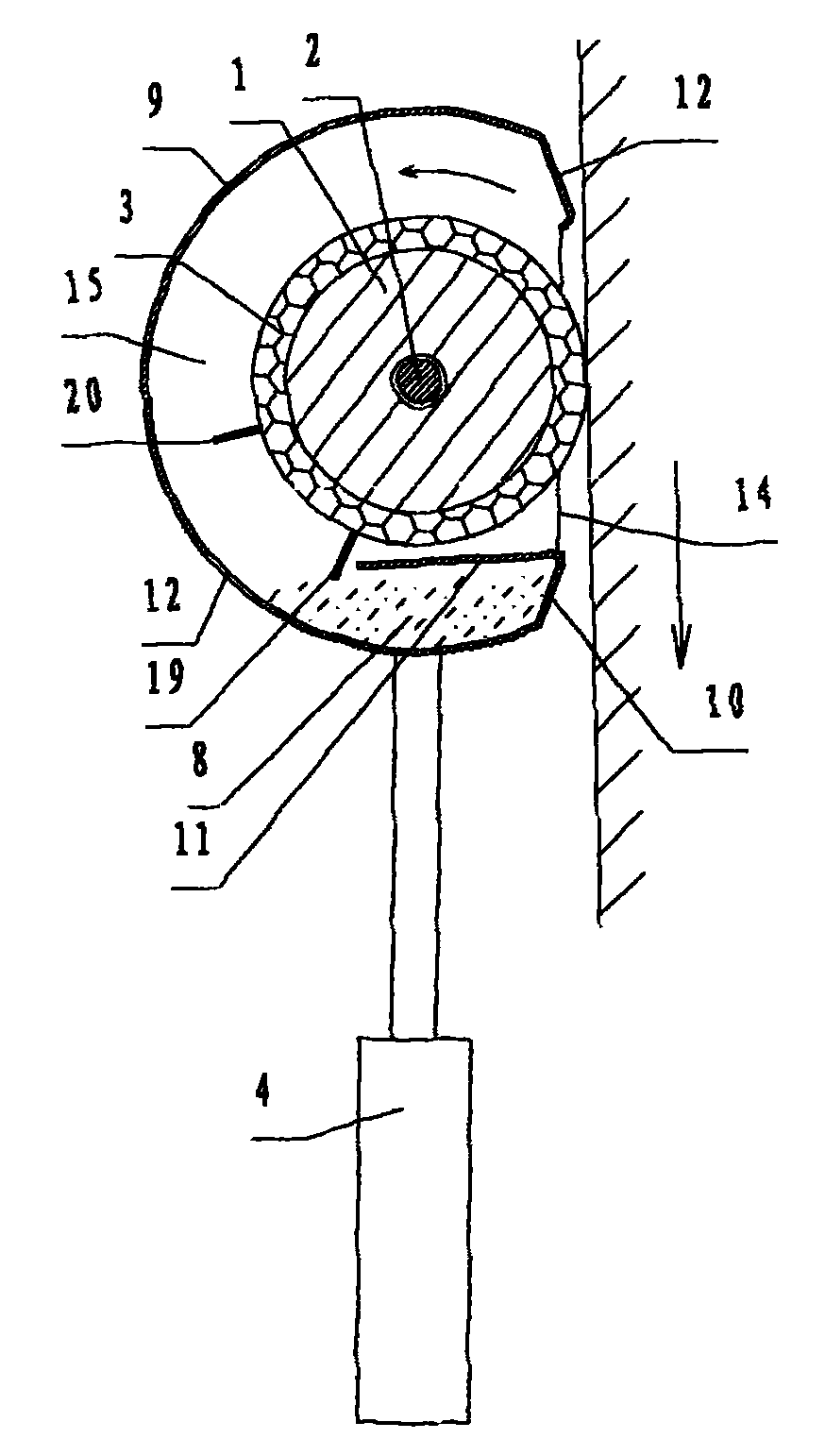

Roller-type dust collection blackboard brush and working method thereof

The invention relates to a roller-type dust collection blackboard brush and a working method thereof. The blackboard brush comprises a roller, a rolling shaft, a flexible brush, a handle, a one-way rotating mechanism, a dust scraping mechanism, a dust outpouring mechanism for pouring chalk dust out of the blackboard brush, and a dust collection cover, wherein the rolling shaft passes through an axle center of the roller; the roller can be rotatably arranged on the rolling shaft; an opening is formed on the left side or the right side of the dust collection cover; the roller and the flexible brush are accommodated in an inner cavity of the dust collection cover; the rolling shaft is supported by two ends of the dust collection cover and is fixed with the dust collection cover; the flexible brush protrudes out of the peak of the opening of the dust collection cover; the dust scraping mechanism is arranged in the inner cavity of the dust collection cover and contacts the flexible brush; the dust outpouring mechanism is arranged close to the bottom of the dust collection cover or at the bottom of the dust collection cover; and the axial line of the handle is vertical to that of the roller. The roller-type dust collection blackboard brush has the advantages that: the blackboard brush moves up and down when used for brushing the chalk dust, the chalk dust stripped from a blackboard can be stuck to the flexible brush or fall on the flexible brush due to gravity action, the dust collection effect is good, the blackboard brush does not raise dust basically when used for brushing the blackboard, and the structure is simple.

Owner:唐一夫

Dust Explosion Experimental Device

The invention discloses a dust explosion experimenting device, and relates to the technical field of manufacturing of experiment teaching aids. The dust explosion experimenting device comprises a tank body with a cover body at a tank opening, and a dust container arranged inside the tank body and communicated with an air pump, wherein a partition board is arranged at the inner bottom of the tank body and at a position close to the tank wall; the partition board and the inner wall of the tank body surround the dust container; a combustion vessel is arranged on one side, with the dust container, of the tank body. Compared with the prior art, the dust explosion experimenting device has the advantage that the explosion experimenting device can solve the problem that the existing dust explosion experiment is low in success rate.

Owner:鹿寨县初级实验中学

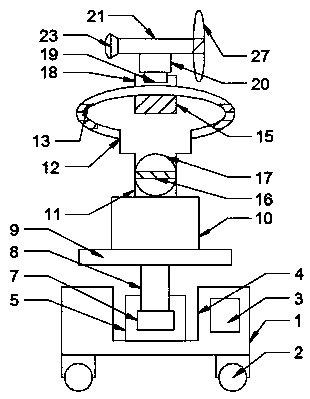

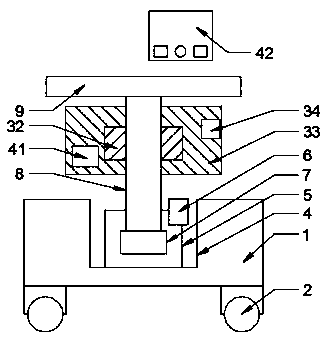

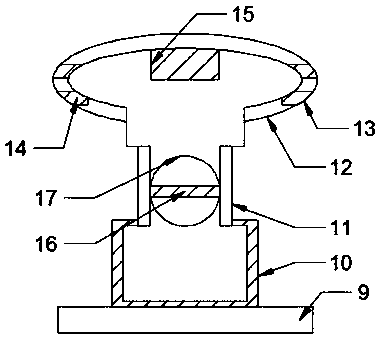

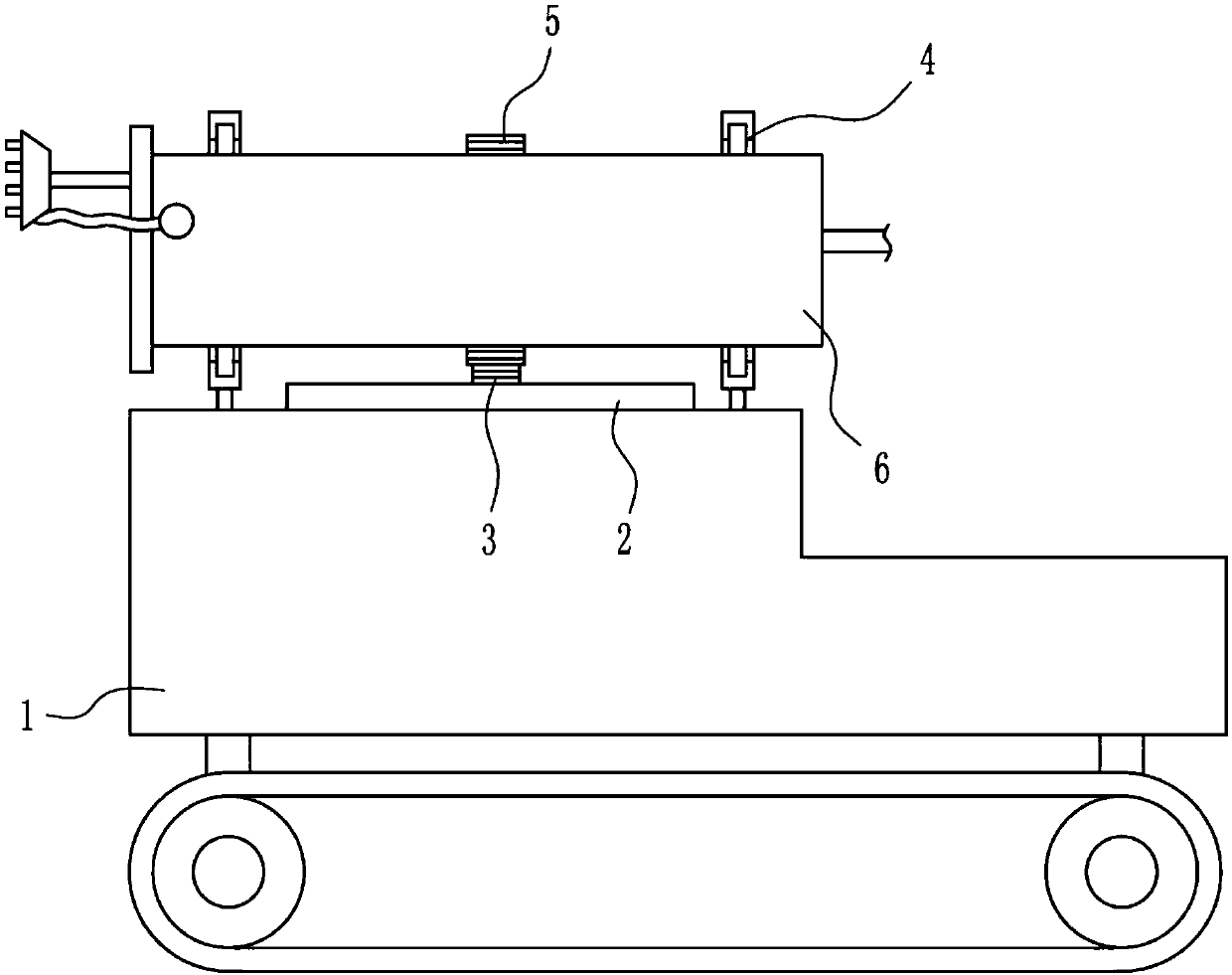

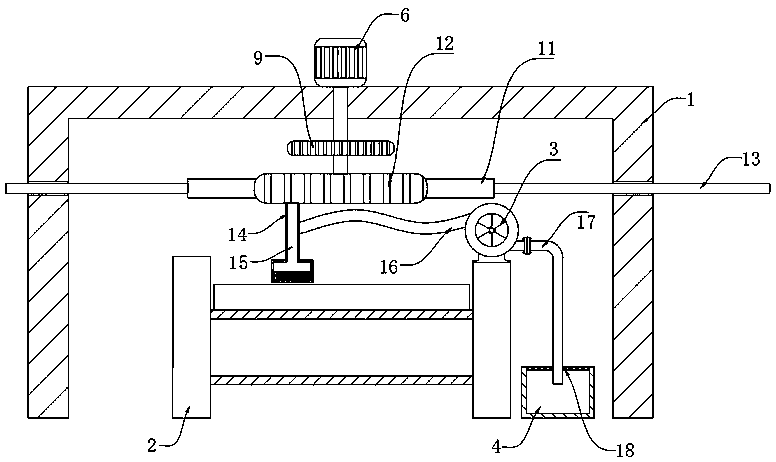

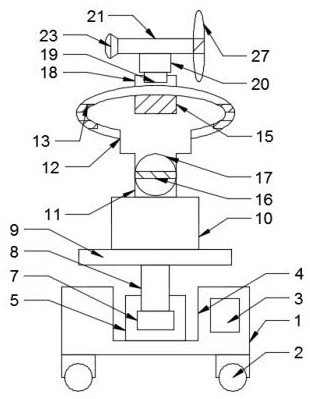

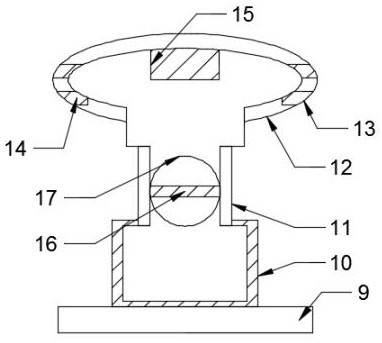

Dust monitoring and treating device for construction site

ActiveCN109999566AAvoid pollutionGood dust effectAnalysing gaseous mixturesDispersed particle separationArchitectural engineeringBuilding construction

The invention discloses a dust monitoring and treating device for a construction site. The dust monitoring and treating device for a construction site comprises a mobile base body, wherein universal wheels are arranged at four corners of the lower part of the mobile base body, the mobile base body is driven to move quickly by the universal wheels, and a height-adjusting mechanism is disposed on the mobile base body; the height-adjusting mechanism is used for adjusting the monitoring height so as to monitor dust of different heights, a dust monitoring and treating mechanism is disposed on the mobile base body, and the dust monitoring and treating mechanism is used for monitoring the content of the dust in the air; a wind-direction wind-speed measuring mechanism is arranged on the mobile base body, and is used for monitoring the wind direction and wind speed, the mobile base body is provided with a sampling mechanism, and the sampling mechanism is used for retaining samples; and a controller is arranged on the mobile base body. The dust monitoring and treating device has the advantages of a simple structure and high practicability.

Owner:山东汇氏环境科技集团有限公司

Road dust suppressant and preparation method thereof

InactiveCN106947432AEasy to getPlay the role of crust and dustOther chemical processesGlycerolEngineering

The invention discloses a road dust suppressant. The road dust suppressant is prepared from, by weight, 5-10% of sodium diethylhexyl sulfosuccinate, 88-93% of glycerol, 0.5-2% of carboxymethylcellulose, 0.1-0.3% of polyacrylamide, and the balance of water for preparation. The road dust suppressant has the advantages of easily obtained components, easiness in preparation, substantial flying dust adsorption effect, and good penetration and moisture retention effects, and the highly-viscose carboxymethylcellulose and polyacrylamide also have an incrustation and dust proofing effects on road surfaces; the road dust suppressant is nontoxic and has no irritation to skins, so the dust suppressant has no threat to the body health of dust suppressant sprinkling workers and passerby; and the dust suppressant has low cost, is suitable for being used in long-distance railway coal transport, road transport, and especially the non-pavement road transport process, and has a substantially better dust suppressing effect than traditional water sprinkling dust suppression and common road dust suppressants.

Owner:江苏赛唯特新材料科技有限公司

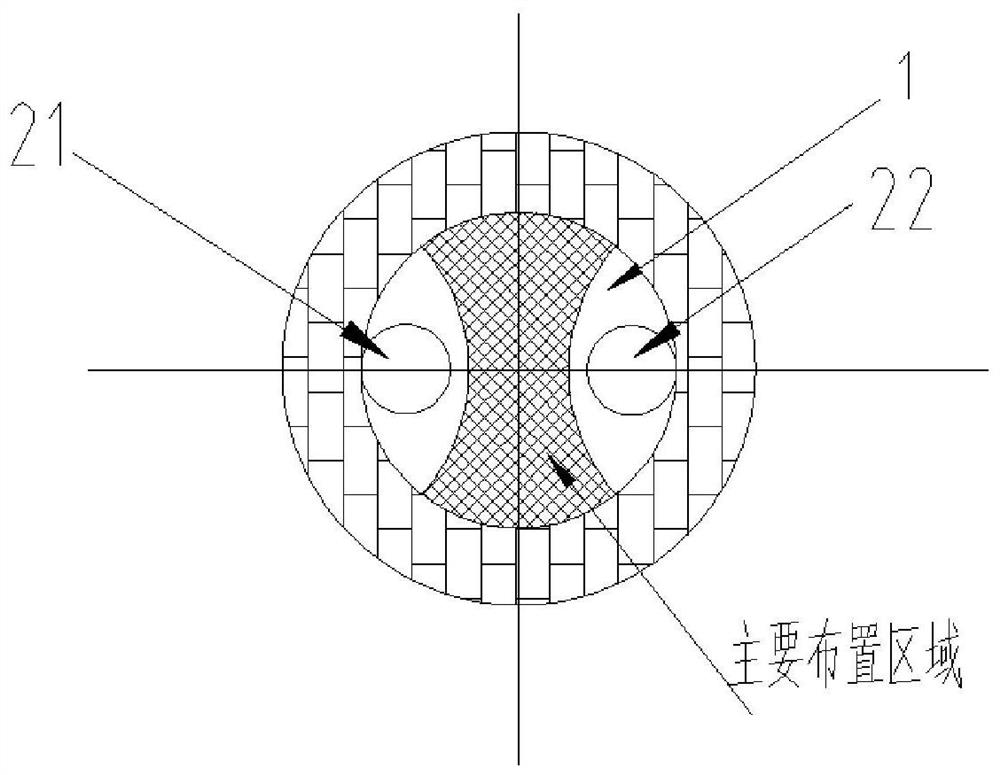

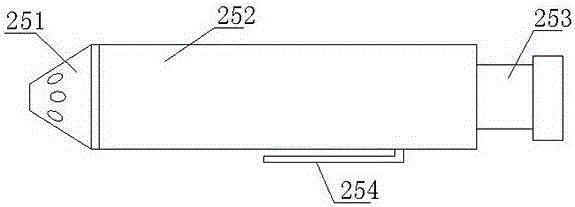

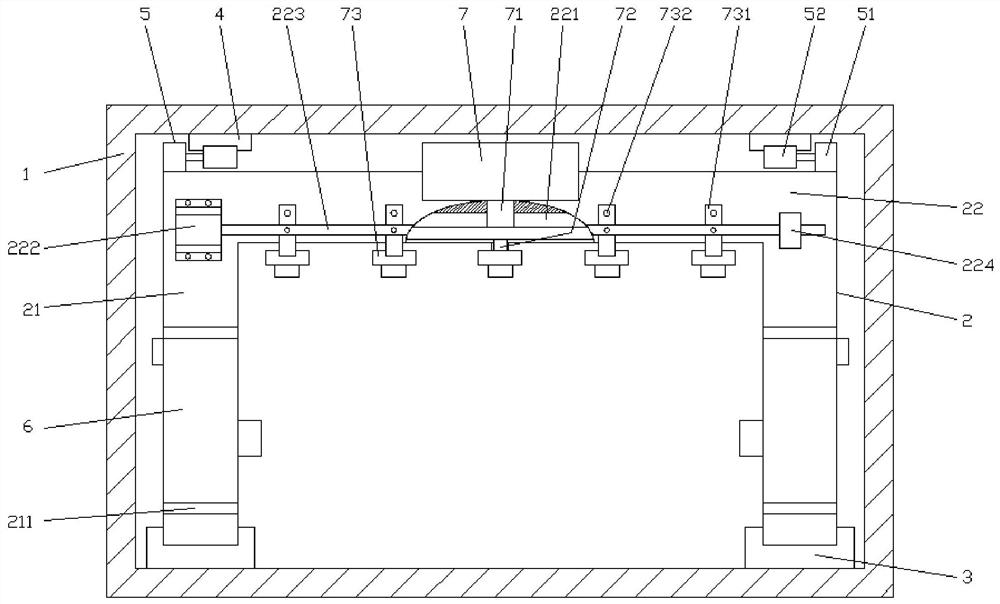

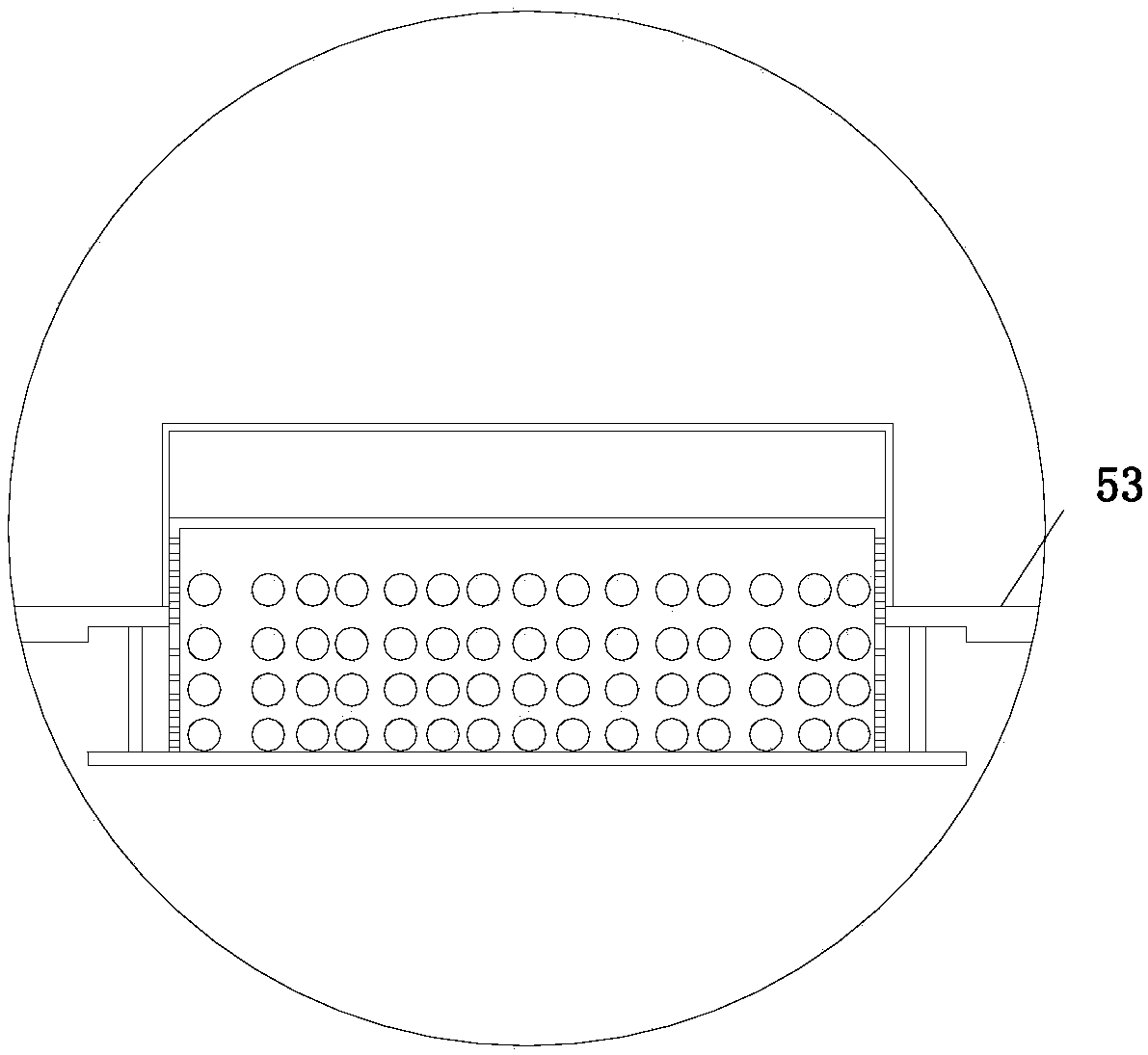

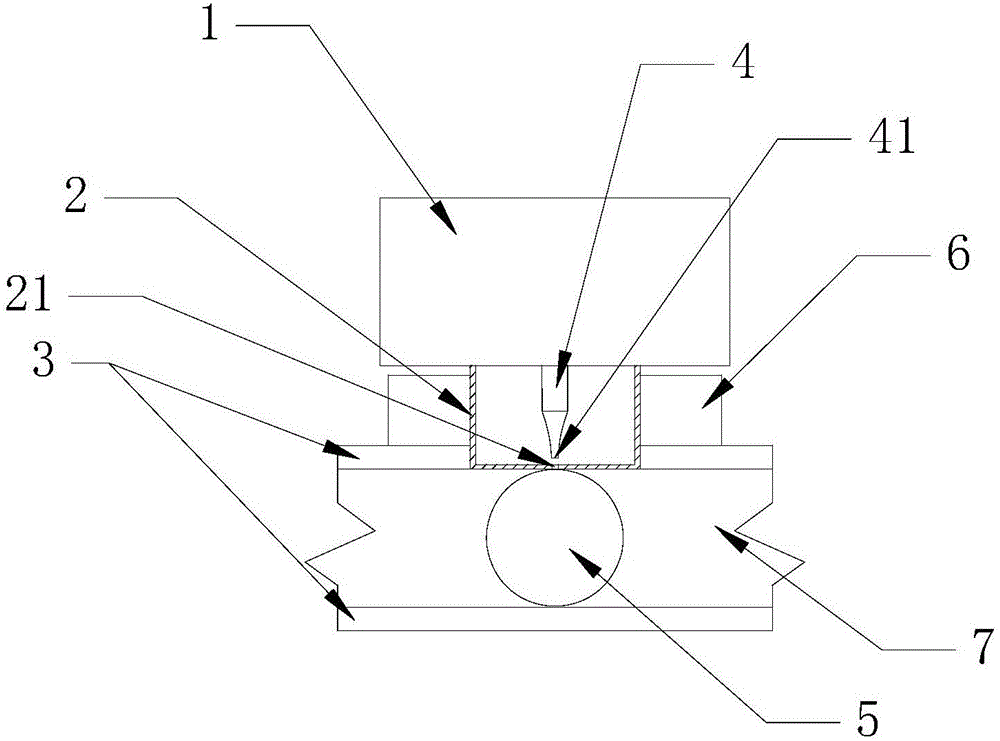

Cable talcum powder spray coating device

InactiveCN106992042AGood dusting effectUniform powderApparatus for feeding conductors/cablesEngineeringMechanical engineering

The invention discloses a cable talc powder spraying device, which relates to the technical field of cable production equipment, and comprises a spraying box, and the middle part of the left and right side walls of the spraying box is respectively provided with a cable core inlet and a cable core outlet, a cable core inlet and a cable wire A spraying channel is formed between the core outlets, and the spraying box includes a spraying mechanism located in the inner cavity. mechanism. The cable wire core of the present invention is sprayed with talc powder in a closed spray box, and the powder spraying effect is good, the powder is even, and the powder will not be wasted during the powder spraying process.

Owner:合肥励仙电力工程有限公司

RH vacuum powder spraying refining device and powder spraying method thereof

The invention discloses an RH vacuum powder spraying refining device and a powder spraying method thereof, and belongs to the technical field of molten steel external refining. The RH vacuum refiningpowder spraying device comprises a vacuum molten steel circulating device and a powder spraying device. The vacuum molten steel circulating device comprises a vacuum chamber, a dip pipe, a steel ladleand a lifting gas pipeline. The powder spraying device comprises a powder spraying element, a powder supply pipe, a buffer gas chamber and a quick connecting part. The powder spraying method comprises but is not limited to refining and alloying functions of desulfurization, deoxidation, inclusion removal, alloy addition and the like. The RH vacuum powder spraying refining device and the powder spraying method thereof have the advantages that the bottom of a vacuum tank is improved on the basis of an RH conventional structure, and spray pipe mounting parameters can be adjusted to meet the process requirements of different steel types; and implementation is easy, maintenance is convenient, the production efficiency can be improved, the production cost is saved, and the application prospectsare good.

Owner:CENT IRON & STEEL RES INST

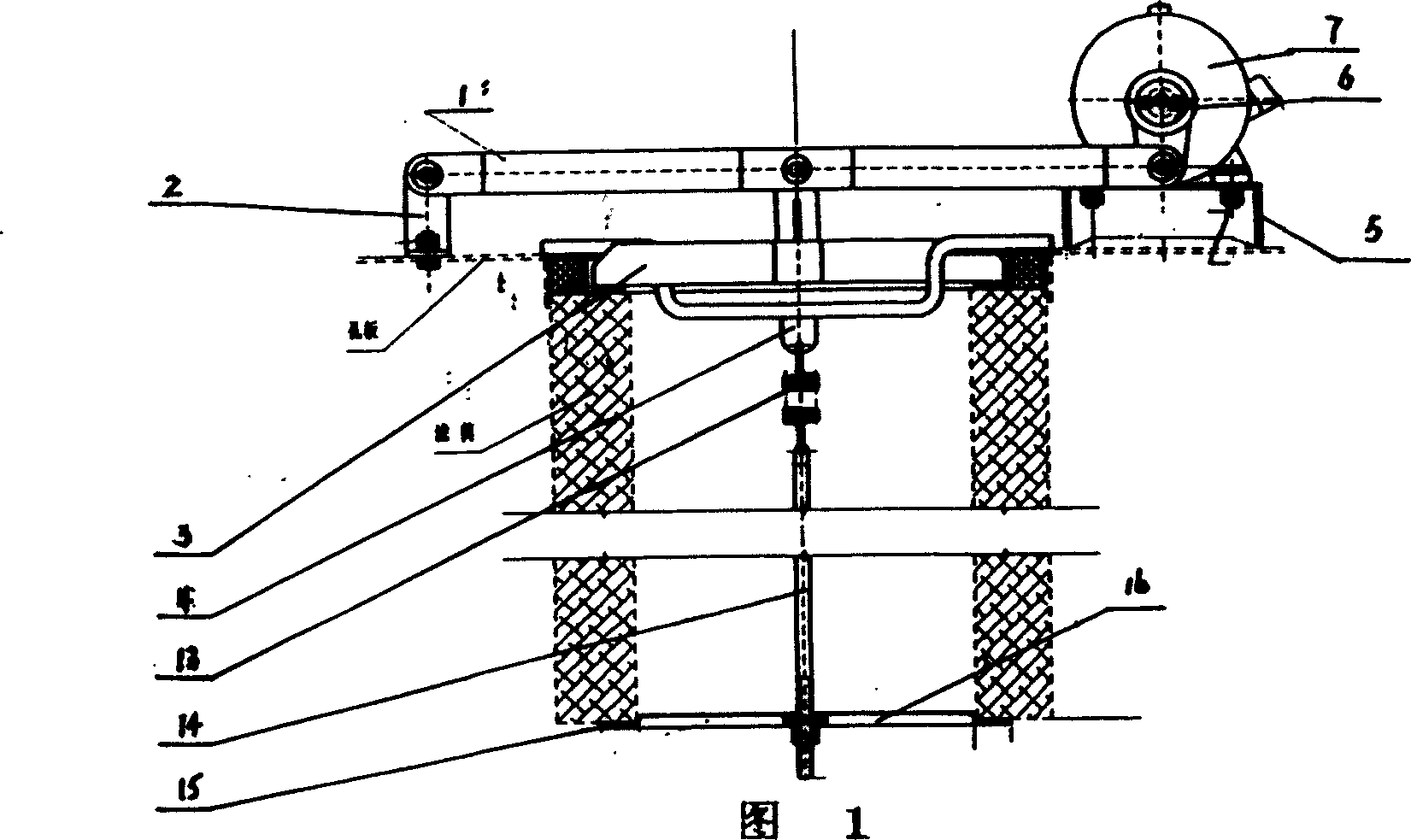

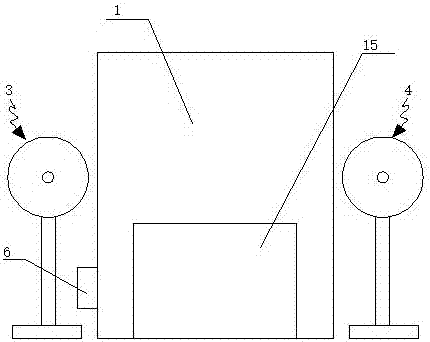

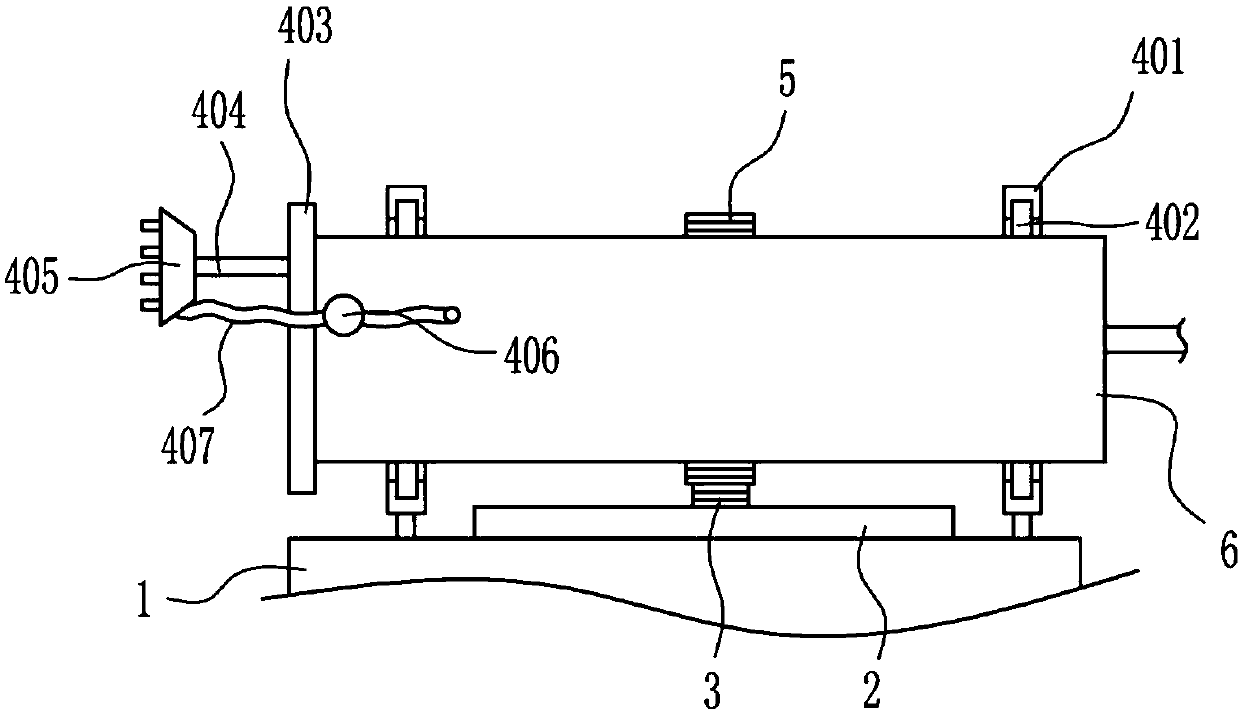

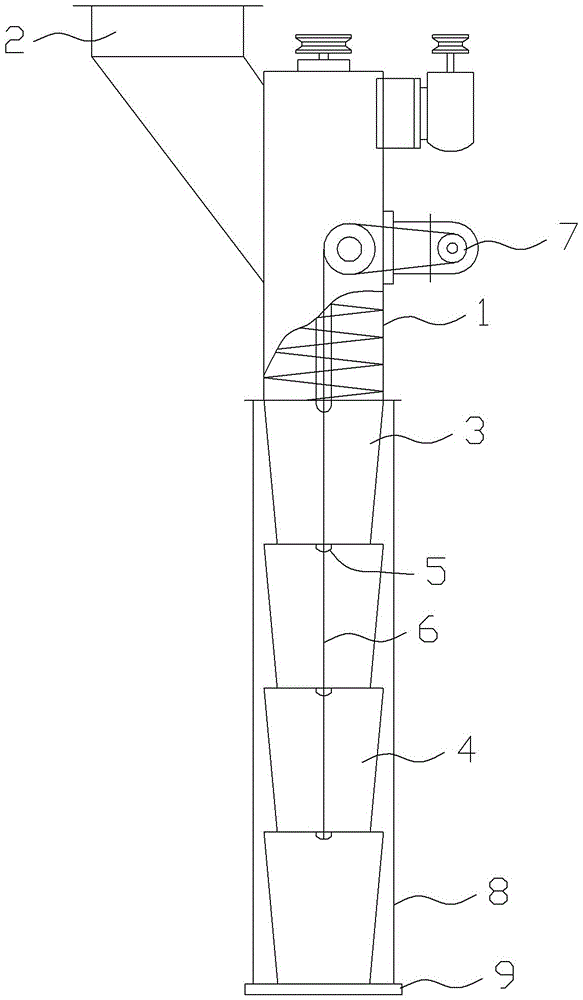

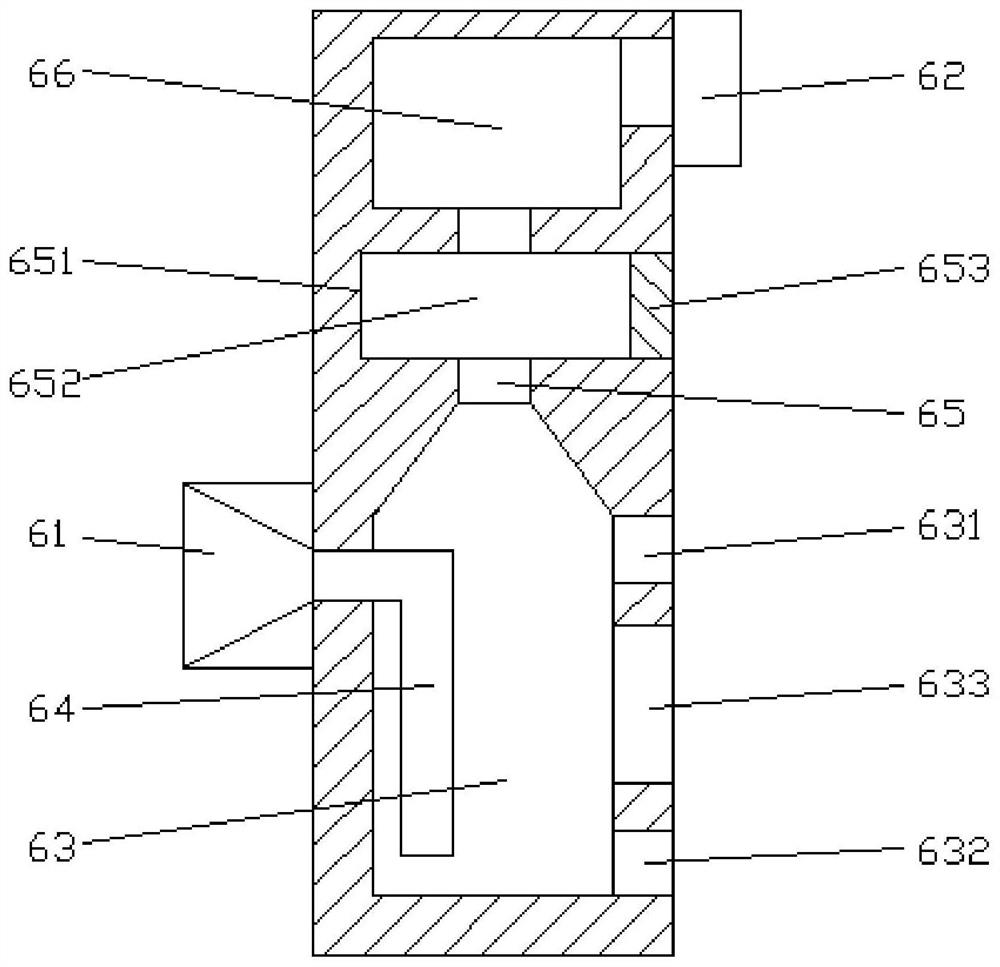

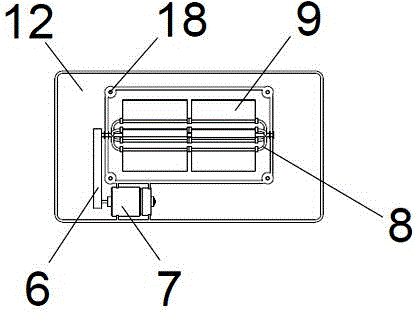

User-friendly printing press

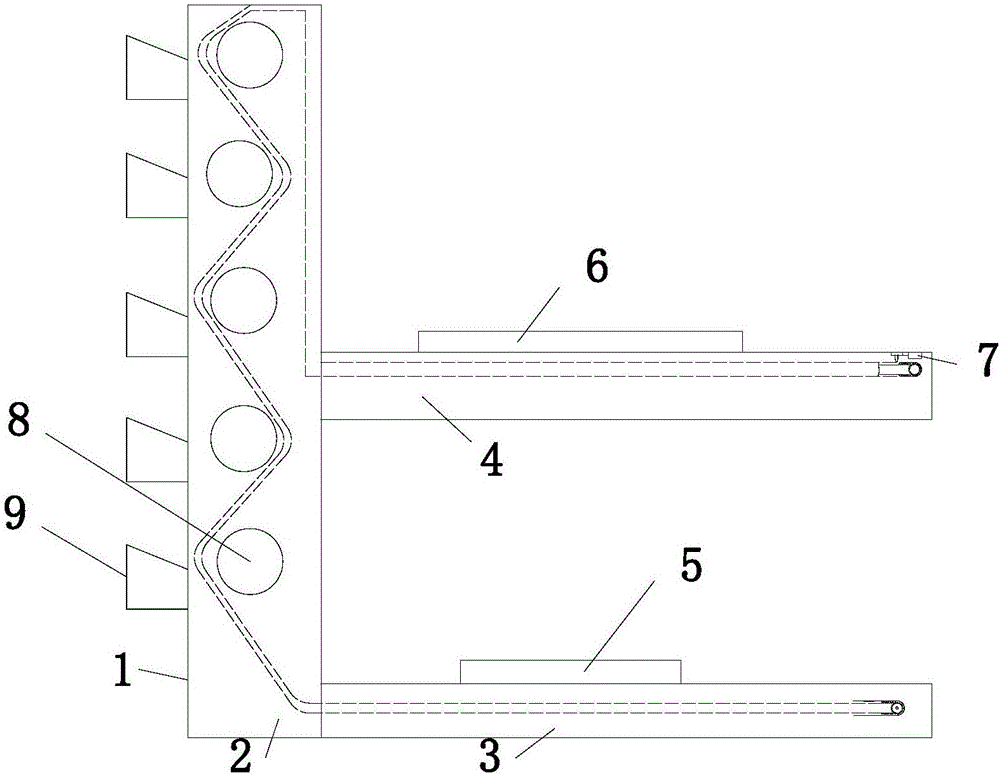

ActiveCN106274050AEasy to handleReduce labor intensityPrinting press partsUser FriendlyPrinting press

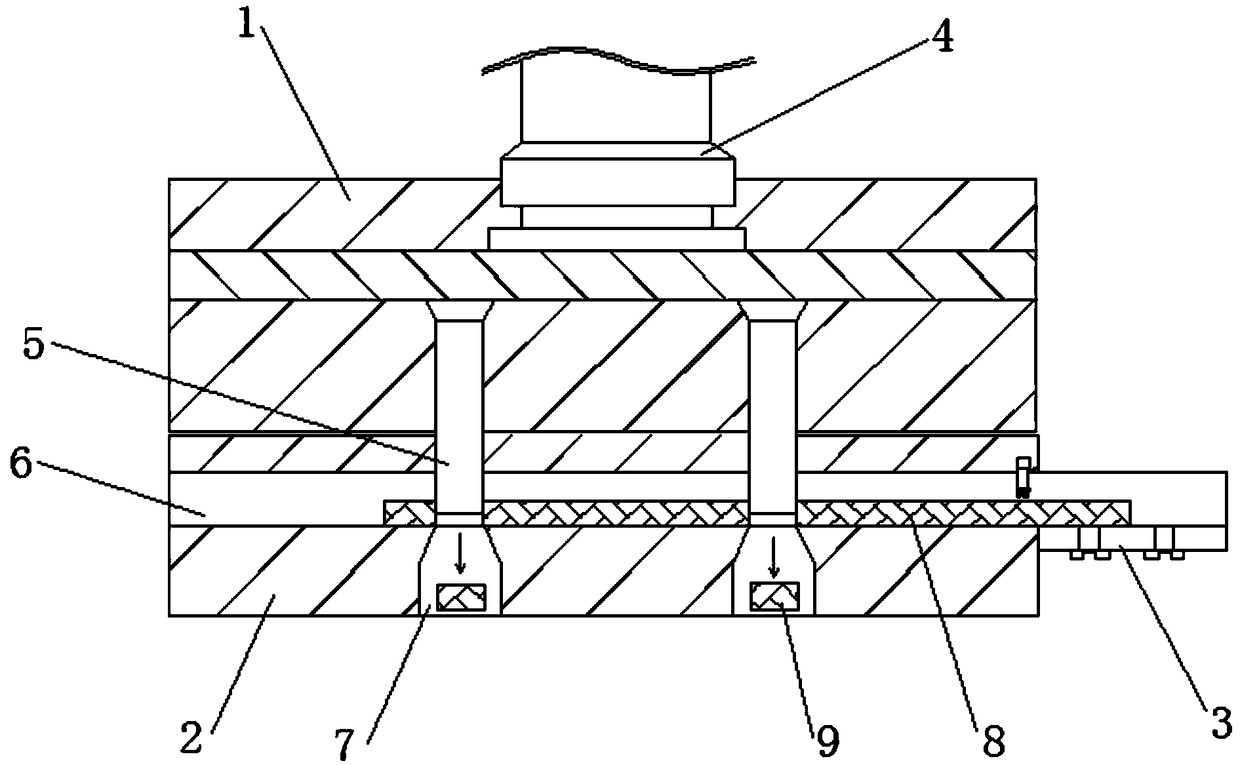

The invention discloses a user-friendly printing press. The printing press comprises a rack (1), wherein the rack (1) comprises a vertical rack (2); a first horizontal rack (3) is arranged at the lower end of the vertical rack (2); a second horizontal rack (4) is arranged at the middle part of the vertical rack (2); a paper processing device (5) is arranged on the first horizontal rack (3); a powder spray device (6) is arranged on the second horizontal rack (4); a printing roll (8) is arranged on the vertical rack (2); a duct device (9) is arranged below the printing roll (8); and the paper processing device (5), the powder spray device (6) and the duct device (9) are connected with a controller (7). The printing press has the characteristics of reducing the labor intensity of workers, improving the printing efficiency, improving the printing quality, facilitating the duct cleaning, preventing the ink from coagulation, adjusting the powder layer thickness in real time, reducing the production cost and adjusting the humidity of printing paper in real time.

Owner:慈溪市黎明彩印有限公司

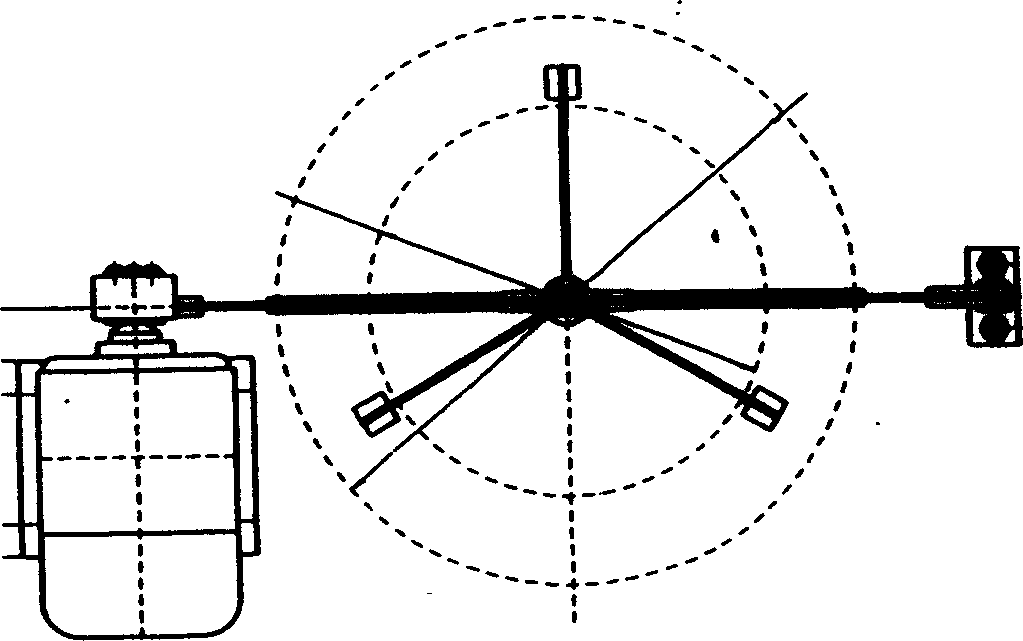

Dust removal device for bridge construction at night

ActiveCN107558527AExpand the spraying areaReduce dustUsing liquid separation agentSoil-shifting machines/dredgersExcavatorWater storage

The invention relates to a construction device, in particular to a dust removal device for bridge construction at night. In order to solve the technical problem that in the prior art, the constructiondust is large, and the illumination of a searchlight can be blocked, the invention provides the dust removal device for bridge construction at night. The dust removal device comprises an excavator and the like; and the top part of the excavator is connected with a moving mechanism, the top part of the moving mechanism is connected with a second rack, the top part of the excavator is connected with a mounting mechanism, a water storage barrel is connected in the mounting mechanism, an outer gear ring is connected to the middle part of the outer wall of the water storage barrel, and the outer gear ring is meshed with the second rack. According to the dust removal device for bridge construction at night, dust generated in the construction process can be effectively reduced, so that definition of an illuminating lamp is improved; and an air cylinder and a second connecting rod are arranged, so that too high and too low dust can be eliminated, and therefore the illumination definition is improved.

Owner:聊城九洲建设集团有限公司

Blackboard eraser good in dust sucking and accumulating effect

ActiveCN105270061APrevent impact on hygieneGood dust effectBoard cleaning devicesEngineeringControl switch

The invention discloses a blackboard eraser good in dust sucking and accumulating effect. The blackboard eraser comprises an insulation box, a water sprayer and a dust accumulating box. A blackboard hairbrush, aluminum foil and a plastic plate are arranged in an installing cavity of the insulation box. The water sprayer comprises a water storage cylinder. An atomizing sprayer and a water outlet button are arranged at the two ends of the water storage cylinder respectively. A buckle is arranged on the circumferential face of the water storage cylinder. The dust accumulating box comprises a dust accumulating box body provided with a positioning step, a mini-type battery and a mini-type fan. The outer end of the mini-type fan is sleeved with a filtering mesh. A ventilation hole is formed in the position, located at the mini-type fan, in the bottom of the dust accumulating box body. Arc ground feet are arranged at the bottom of the dust accumulating box body. A control switch for controlling the on-off state of the mini-type fan is arranged on the side face of the dust accumulating box body. The dust accumulating box and the arc ground feet are all made of electric conduction materials. The insulation box can be placed in the dust accumulating box, and the aluminum foil makes contact with the positioning step. The water sprayer can be used for spraying water, handwriting hard to wipe can be wiped away, and a blackboard is kept clean and cannot be wet.

Owner:林依璇

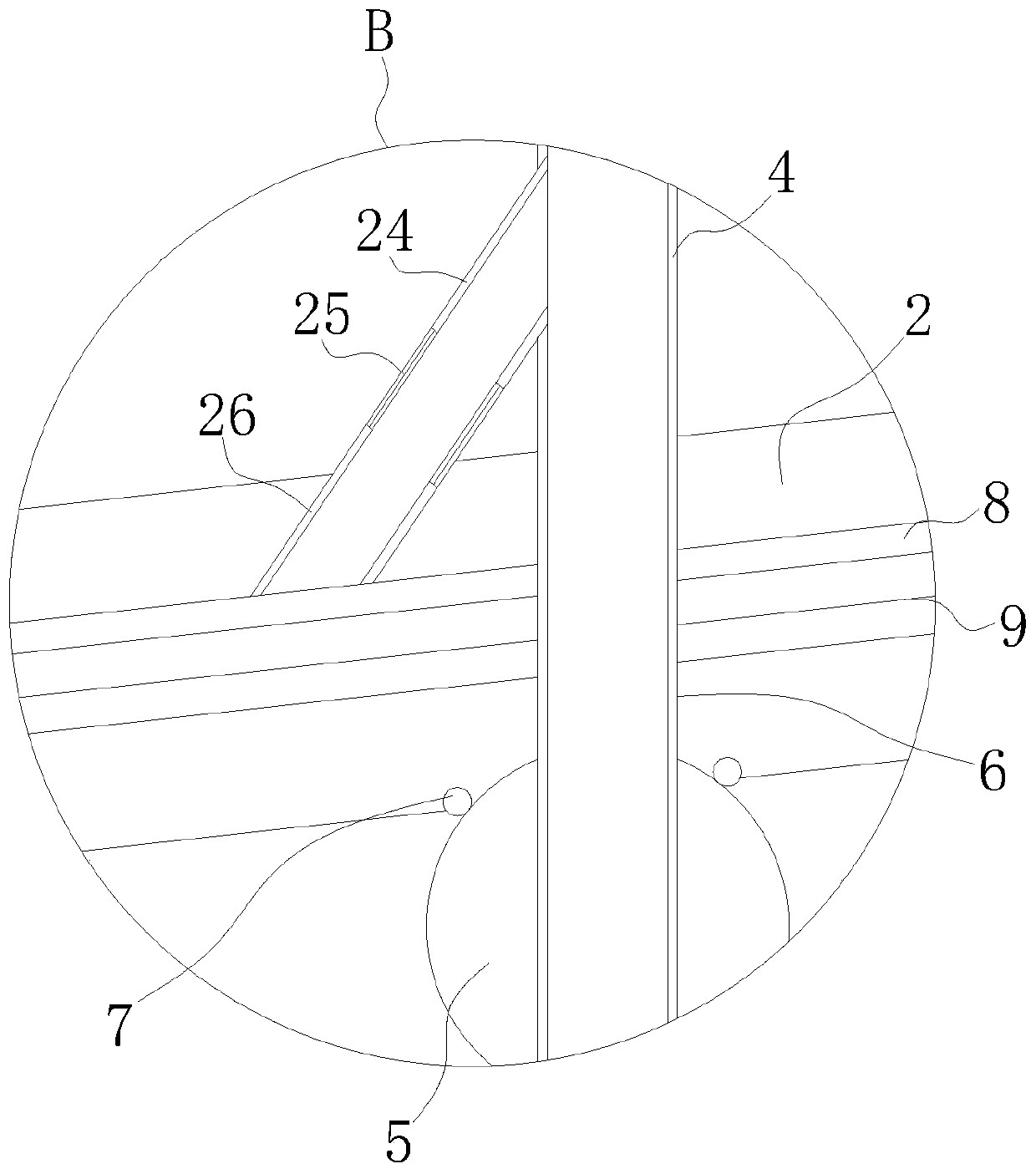

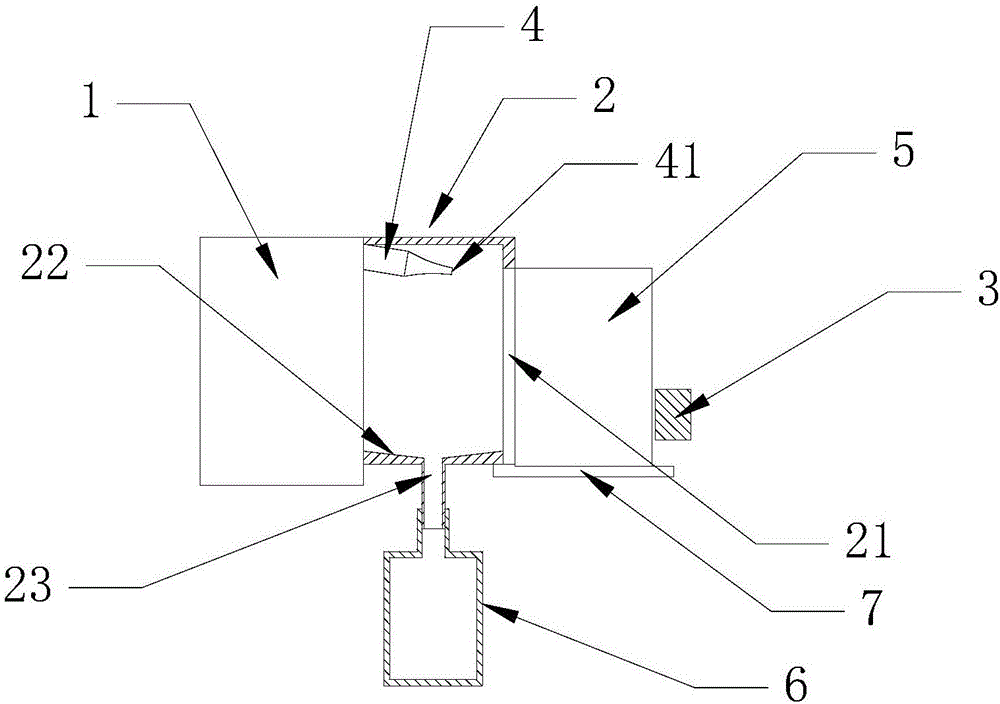

Dust discharging device achieving dust eliminating through telescopic pipe

The invention relates to a dust eliminating device, in particular to a dust discharging device achieving dust eliminating through a telescopic pipe. The dust discharging device comprises a dust discharging control valve (1), a dust inlet (2) of the dust discharging control valve (1) is connected with a dust discharging port of a dust removal device, a dust outlet (3) of the dust discharging control valve (1) is connected with the telescopic pipe which is vertically arranged and composed of multiple segments of casing pipes (4), the lowermost-segment casing pipe (4) is fixedly connected with a sling (6), and the sling (6) is connected with a winch (7) which enables the sling (6) to upwards telescope; the exterior of the telescopic pipe is sleeved with a dustproof bag (8), the upper end of the dustproof bag (8) is fixed to the uppermost-segment casing pipe (4) or the outer wall of the dust discharging control valve (1), the lower end of the dustproof bag (8) is fixed to the lowermost-segment casing pipe (4), and telescoping of the telescopic pipe can be controlled through retracting and releasing of the sling (6). The dust discharging device has the advantages of being simple in structure, low in cost and good in dust raising prevention effect.

Owner:宁安市光明空气净化设备制造有限公司

Wood ash brushing auxiliary equipment used in wood furniture processing

InactiveCN110815481AGood dust effectReduce labor intensityWood working apparatusCleaning using toolsDrive wheelWood ash

The invention discloses wood ash brushing auxiliary equipment used in wood furniture processing. The wood ash brushing auxiliary equipment used in wood furniture processing comprises a supporting frame, wherein openings are symmetrically formed in two sides of the supporting frame, a conveying belt and a collecting box are arranged in the supporting frame, the conveying belt is fixed with the ground through fixing rods, supporting plates are symmetrically arranged on two sides of the conveying belt, a centrifugal fan is welded and fixed on one of the supporting plates, a plurality of rotatingshafts are rotationally connected to the upper wall of the supporting frame through bearings, a power mechanism and a reciprocating mechanism are welded and fixed on the rotating shafts, and a limiting plate is fixedly arranged on one side, far away from the supporting plate, of the supporting frame. A motor drives a driving wheel and a first half gear to rotate, the driving wheel drives a drivenwheel and a second half gear to rotate through a linking wheel, the first half gear and the second half gear drive a double-sided rack to reciprocate, so that the double-sided rack drives a brush plate to reciprocate to brush ash on the surface of a wood plate, the ash brushing effect is good, the labor intensity is reduced, and the efficiency is improved.

Owner:杨晓曼

Mine coal dust suppressant

InactiveCN106634848AEasy to getEasy to manufactureOther chemical processesPreservativePhysical well being

The invention discloses a mine coal dust suppressant, which is characterized by being prepared from the following ingredients in percentage by weight: 30 to 80 percent of sodium diethylhexyl sulfosuccinate, 3 to 8 percent of glycerinum, 1 to 3 percent of preservative and the other ingredient of water for preparation. The mine coal dust suppressant has the advantages that the flying dust adsorption effect is obvious; no influence is caused on the coal quality; no toxicity exists; no stimulation is generated on the skin, so that the threat on the body health of mine field workers is avoided; the cost is low; the mine coal dust suppressant is suitable for being used in large-scale coal mining, piling and transportation processes; the dust suppression effect is obviously improved through being compared with that of a traditional coal dust suppressant.

Owner:江苏赛唯特新材料科技有限公司

Coarse food grain tea bubble preparing equipment based on heat conduction

The invention provides coarse food grain tea bubble preparing equipment based on heat conduction. The coarse food grain tea bubble preparing equipment comprises supporting legs, coarse food grain teabubbles and a plurality of powder rolling trays, wherein a powder rolling tank is fixedly connected to the surfaces of supporting legs; supporting hollow steel pipes are fixedly connected to the innerwall of the powder rolling tank; a plurality of disk rolling balls are fixedly connected to the surfaces of the supporting hollow steel pipes; penetrating holes are formed in the surface of each powder rolling tray; a plurality of disk rolling balls are embedded in the inner wall of each penetrating hole. The invention relates to the field of coarse food grain tea bubbles. According to the coarsefood grain tea bubble preparing equipment based on heat conduction disclosed by the invention, through circular wind sucking and wind blowing of a sucking and blowing fan, the recycling of tea powderis convenient; gravity is utilized to enable the whole rolling device to be in continuous circulating operation, so that energy is saved, and the working efficiency is improved; the working temperature in the powder rolling tank is in thermostatic control through heat condition, so that the problems that when powder rolling is performed by conventional coarse food grain tea bubble preparing equipment, the situation that the powder rolling is not uniform is easy to generate, the working efficiency is low, and during continuous working, the energy consumption of the equipment is high are effectively solved.

Owner:广东玺瑞健康产业科技有限公司

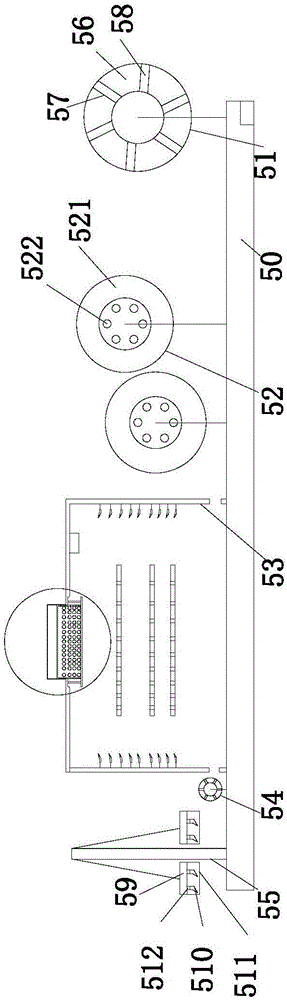

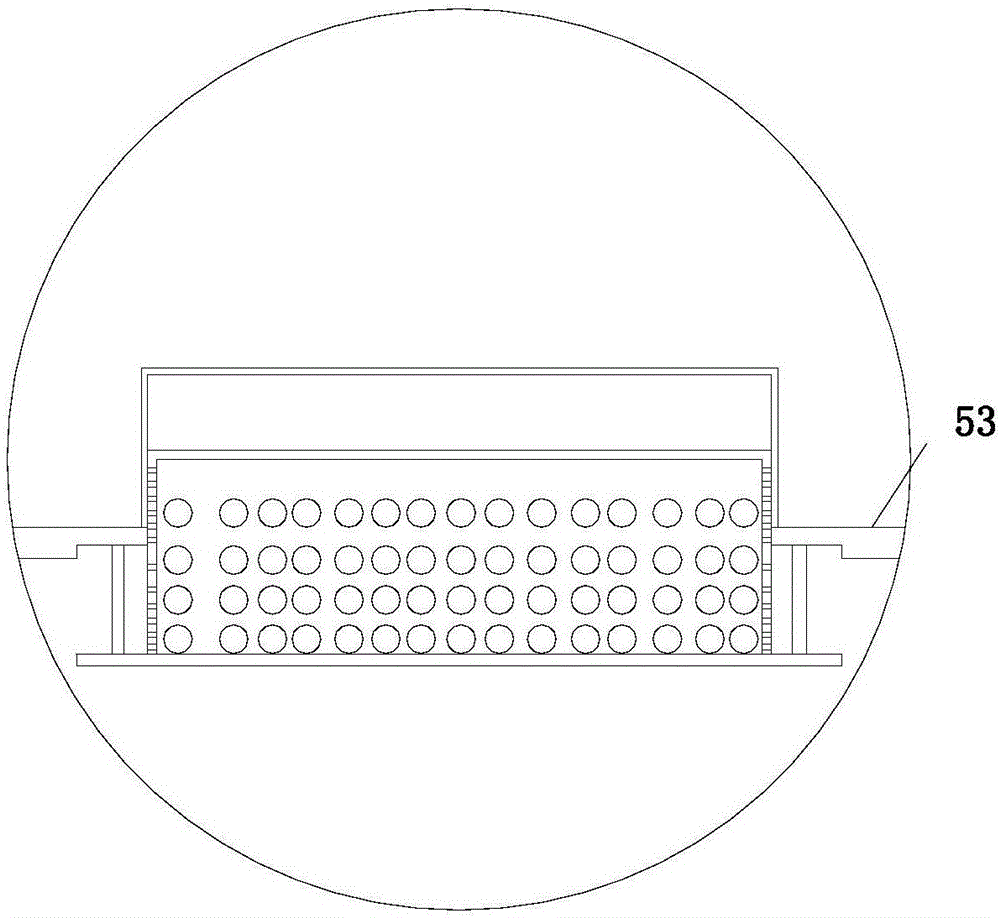

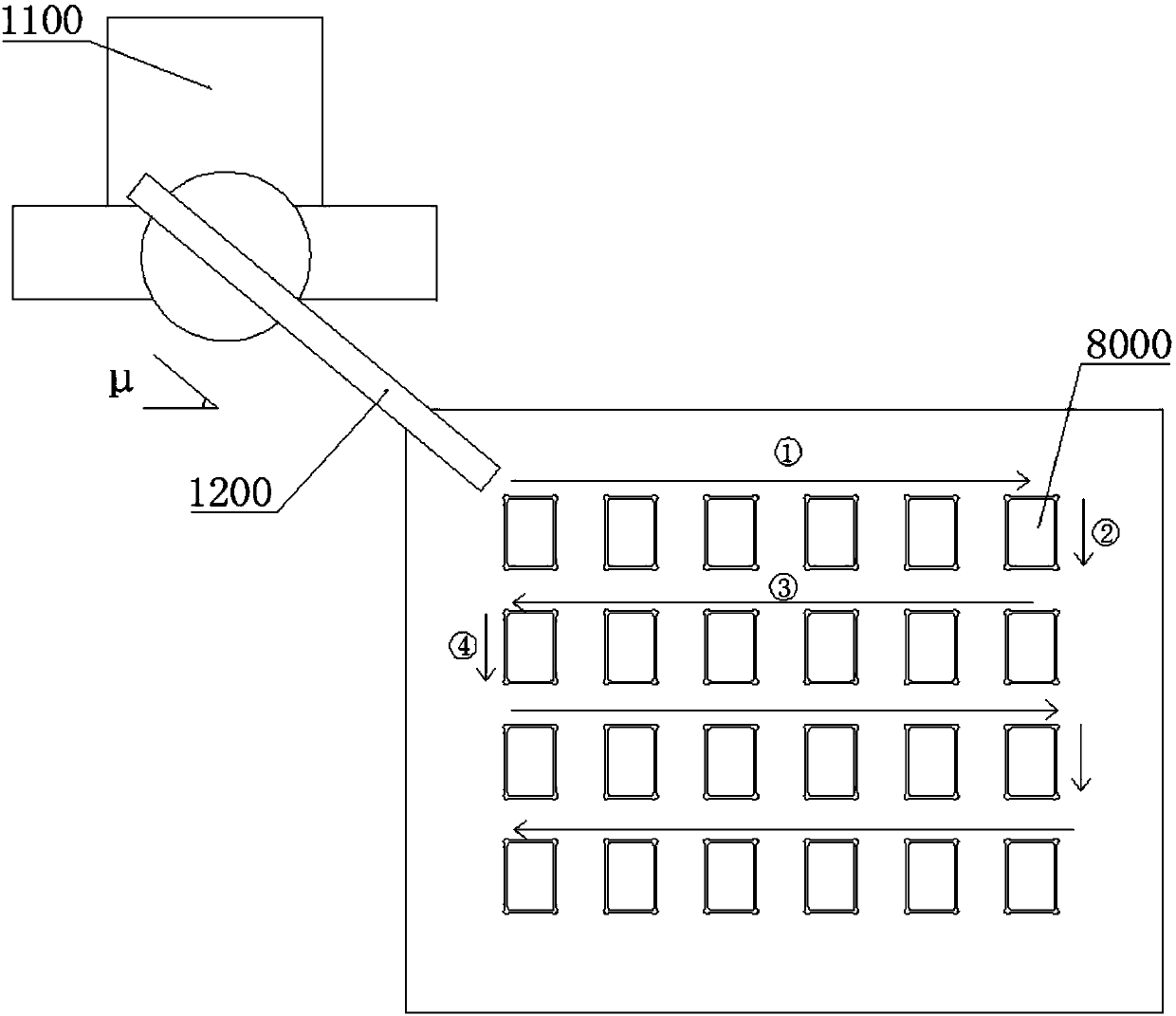

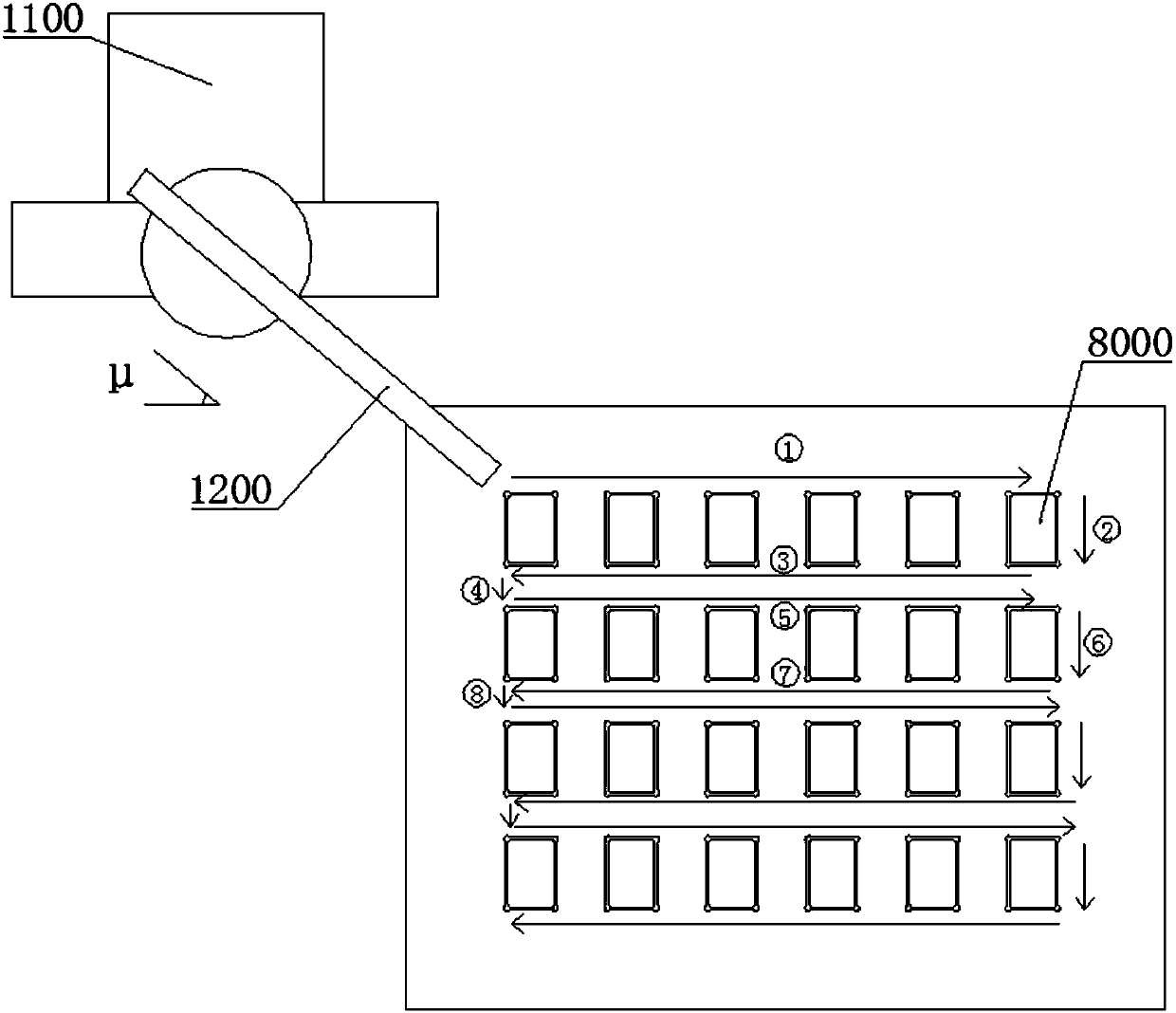

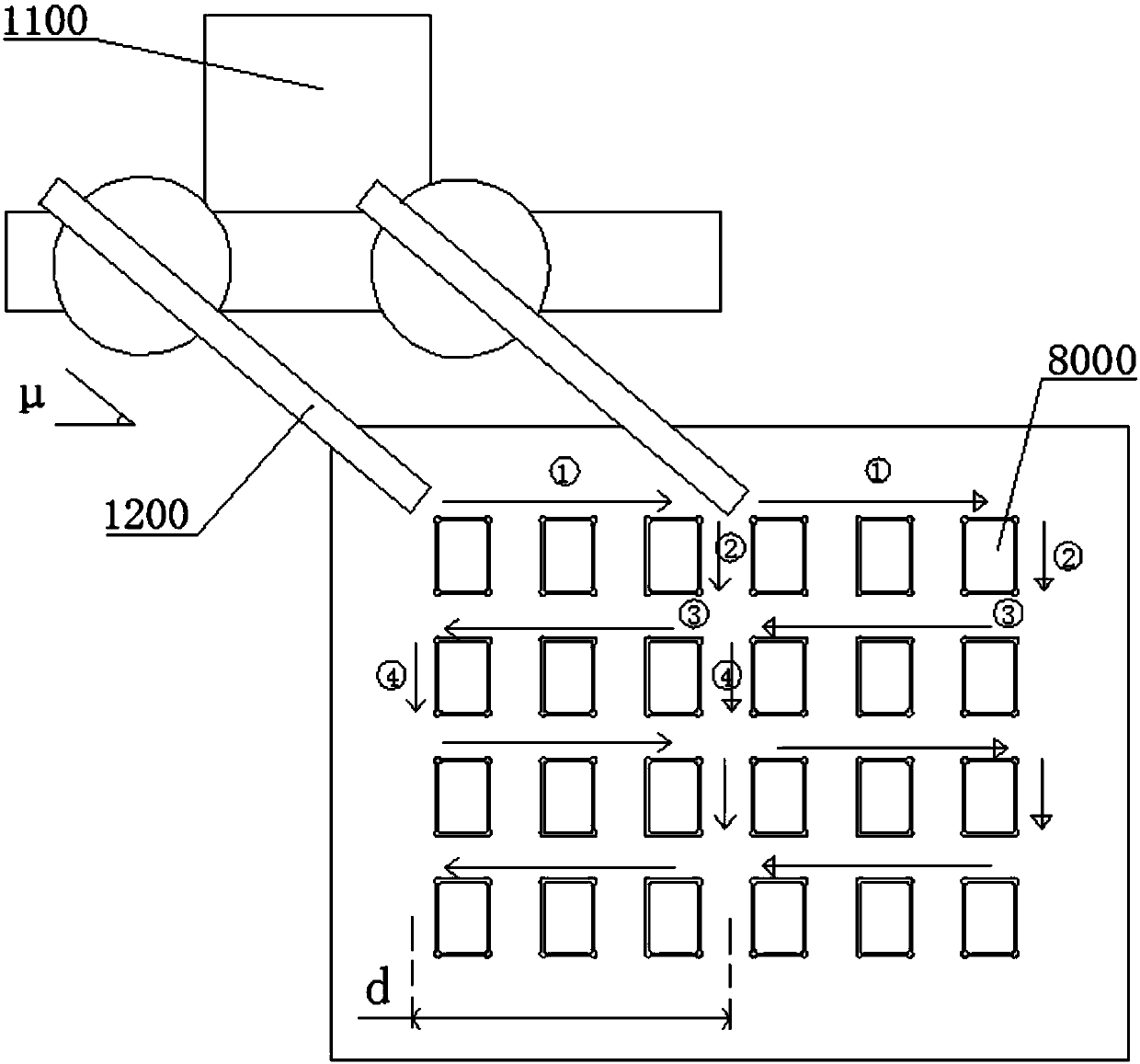

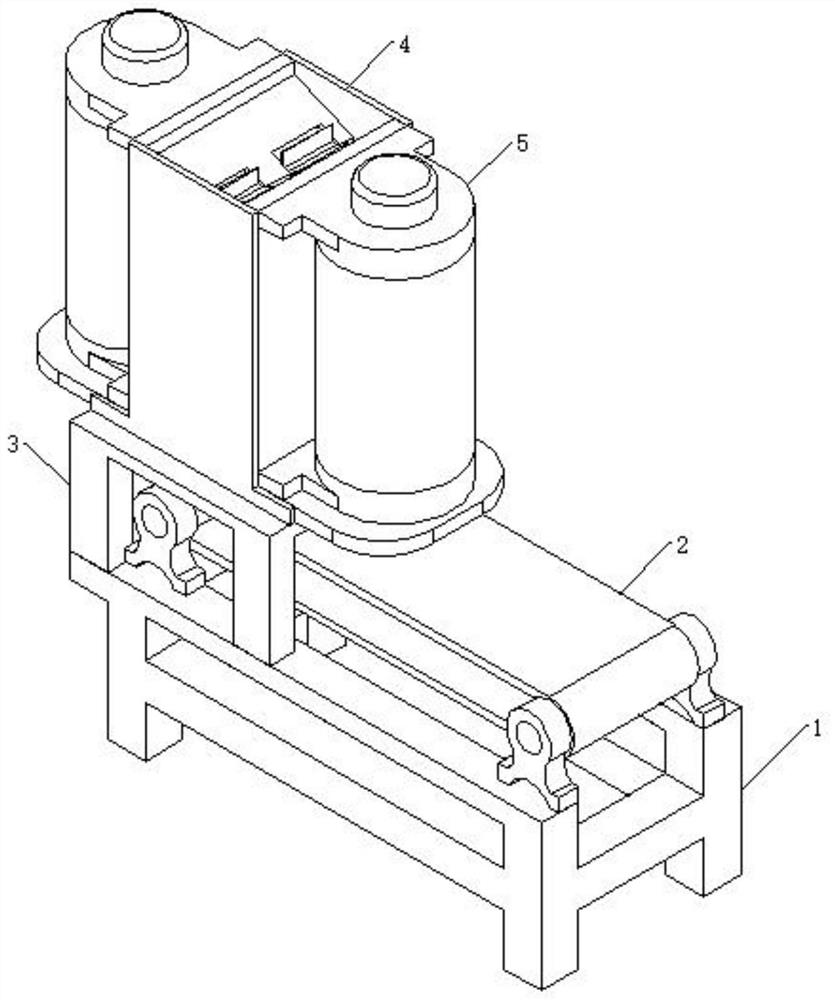

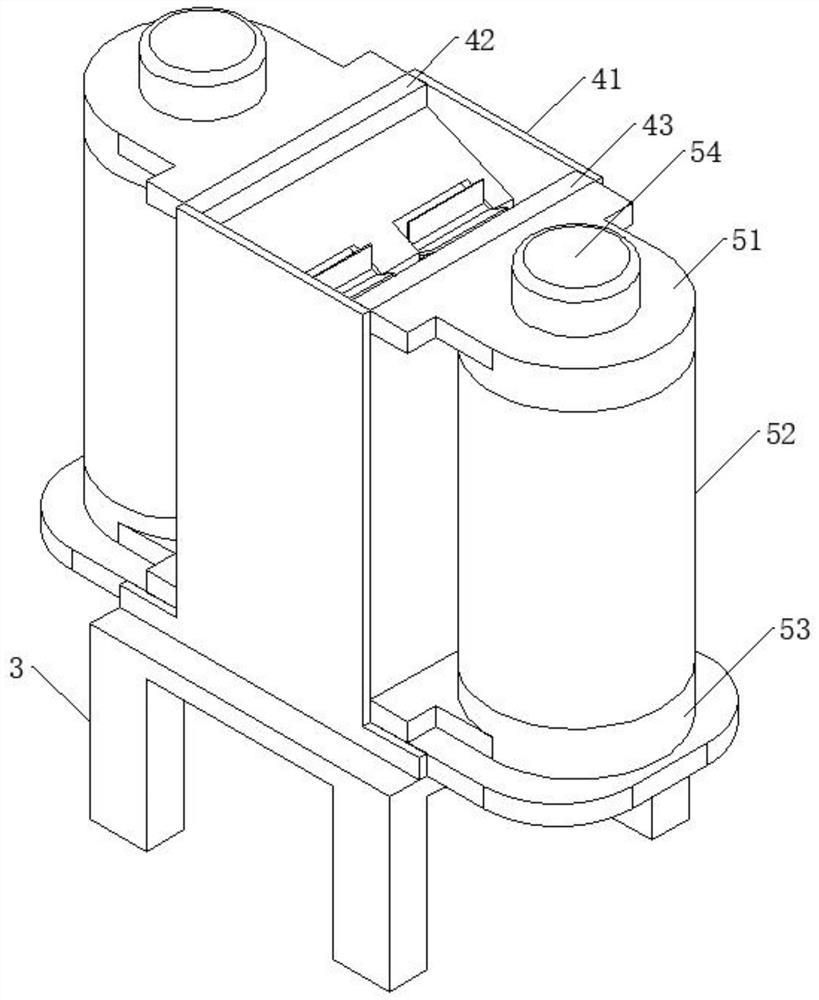

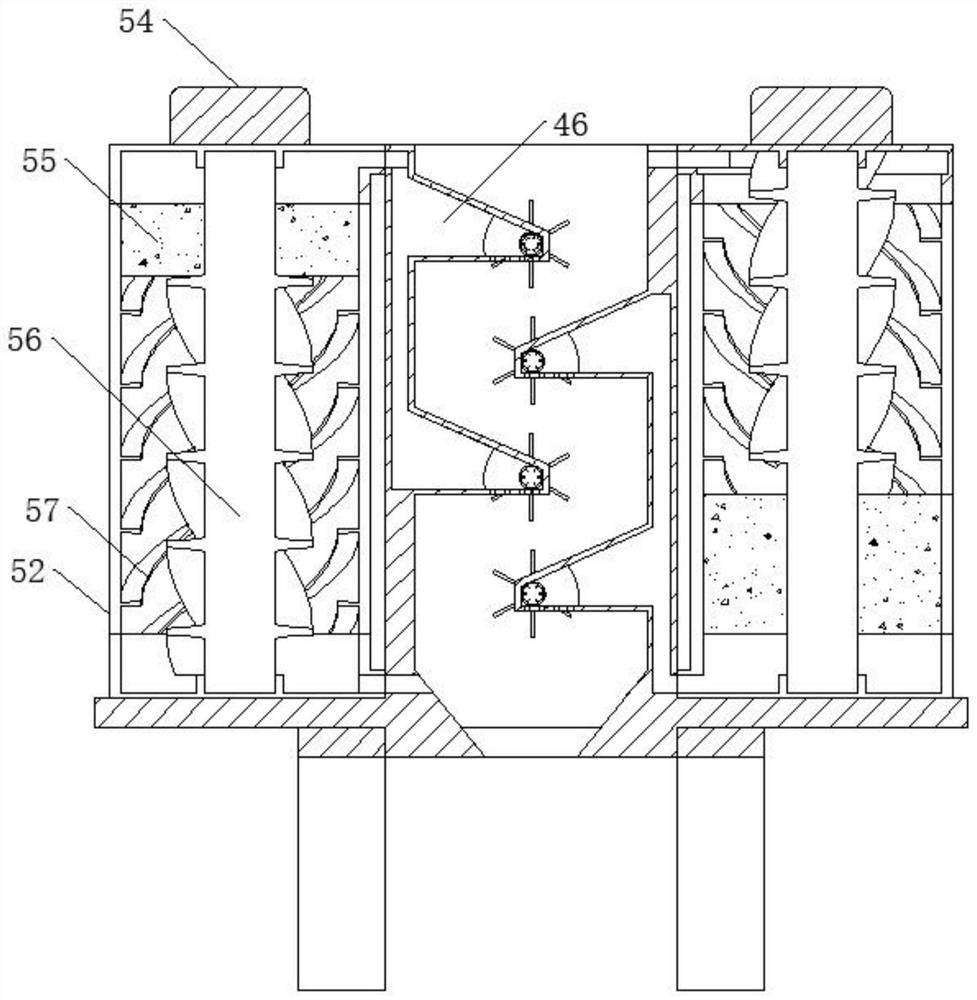

Dry ice cleaning system and method applied to electronic module assembly process

ActiveCN107671077AReduce complexityImprove cleaning efficiencyCleaning processes and apparatusSpray nozzleDry ice

The invention discloses a dry ice cleaning system and method applied to the electronic module assembly process. The cleaning system comprises an ice breaking mechanism, an injection pipeline, a mechanical arm, a cleaning base and a nozzle. Multiple electronic modules are arranged in a parallelogram array manner and fastened to the cleaning base, and a heating structure for heating the electronic modules is arranged on the cleaning base. The ice breaking mechanism provides dry ice particles for the nozzle through the injection pipeline. The nozzle is arranged on the mechanical arm, and the nozzle is located above the cleaning base and can be aligned at the electronic modules for cleaning. The nozzle and the mechanical arm are rotationally connected so as to adjust the included angles between the nozzle and the surfaces of the electronic modules. The mechanical arm drives the nozzle to clean the surfaces and the sides of the electronic modules according to a snakelike reciprocating path.The advancing direction of the snakelike reciprocating path is parallel to the line direction of the parallelogram array. The snakelike reciprocating cleaning path is short in route, the speed is high, the dry ice cleaning system and method adapt to cleaning of the electronic modules in the parallelogram array form, and the automation degree is high.

Owner:HUANWEI ELECTRONICS SHANGHAI CO LTD

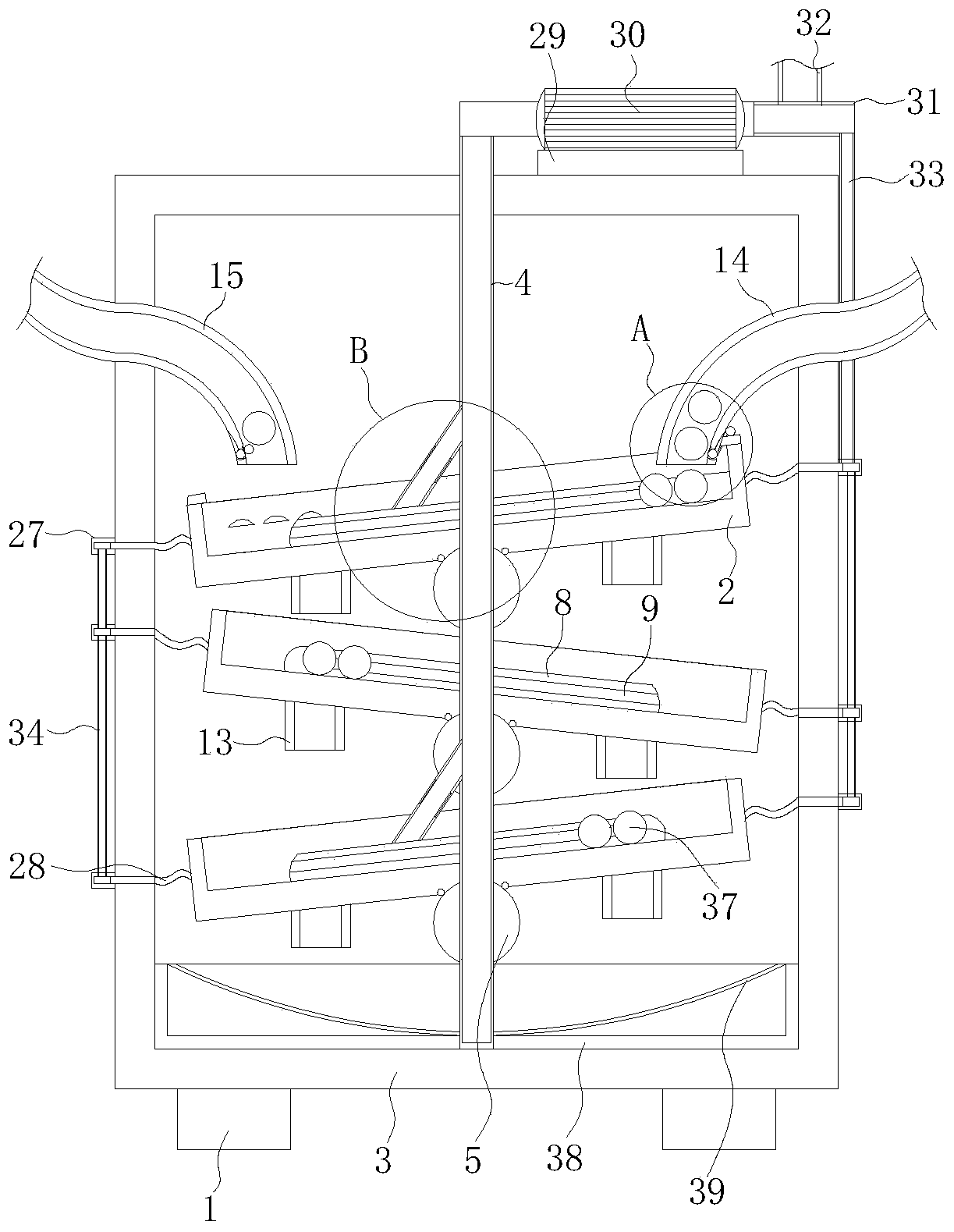

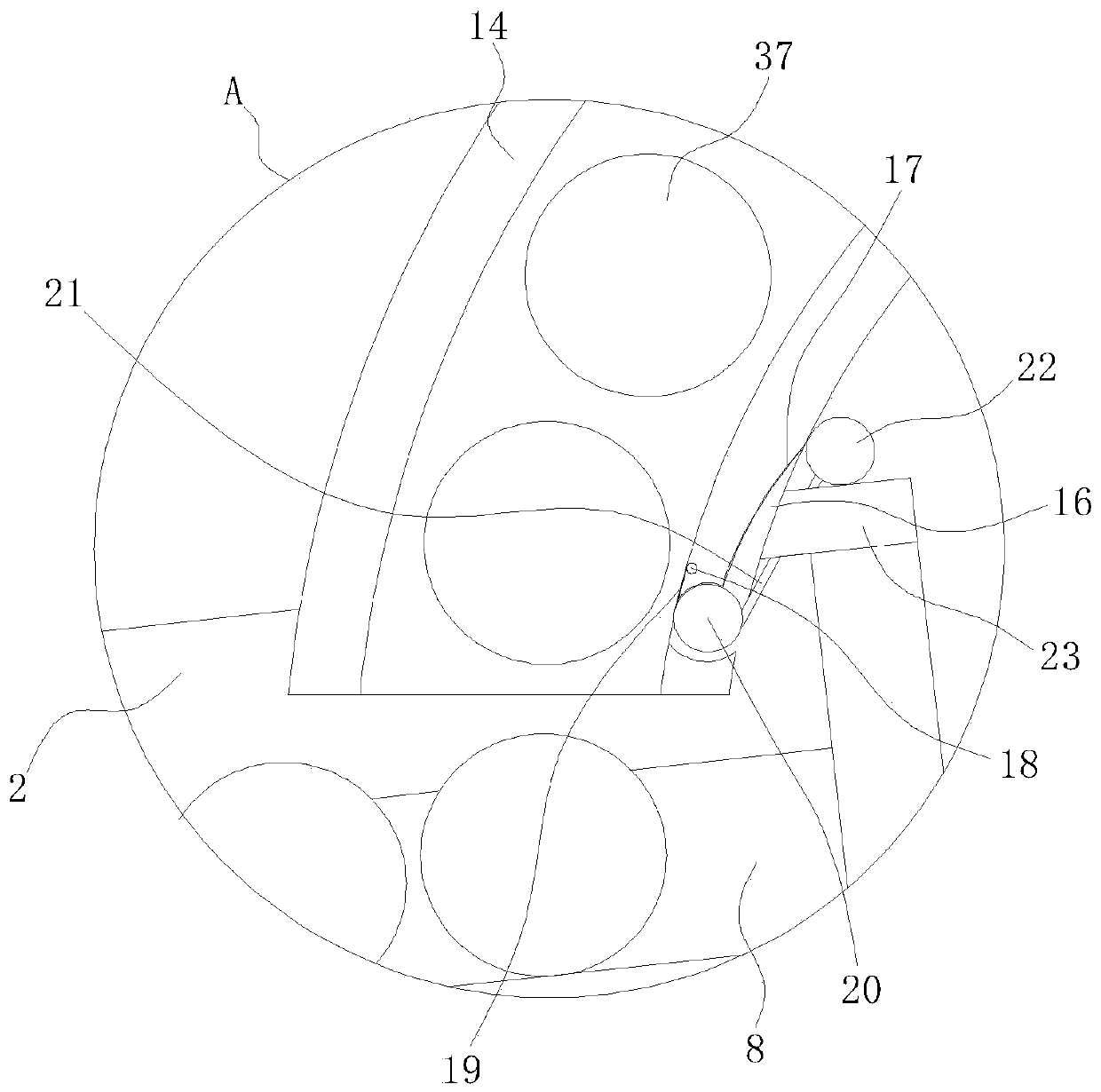

Warp knitting workshop dust removal equipment

ActiveCN111889454AImprove work performanceGood dust effectCombination devicesDispersed particle filtrationDust controlWorking environment

The invention discloses warp knitting workshop dust removal equipment. The equipment comprises a workshop main body and is characterized by further comprising a movable support, a first sliding rail,a second sliding rail, a driving mechanism, a dust remover and an air blower; and compared with the prior art, the dust removal equipment is simple in structure, reasonable in design and capable of effectively removing batting and dust in a warp knitting workshop, a good working environment is provided for personnel and equipment in the workshop, so that the product quality and the operation comfort of the personnel in the workshop are improved.

Owner:海盐荣华经编有限公司

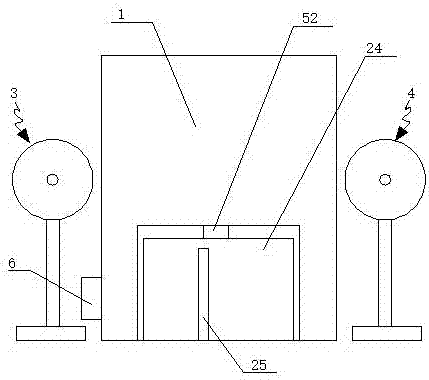

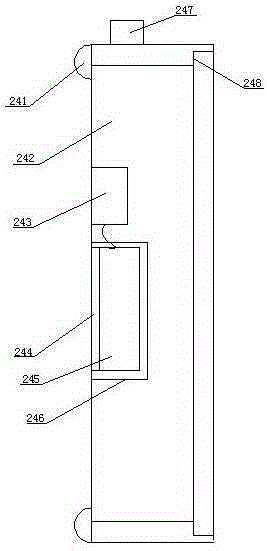

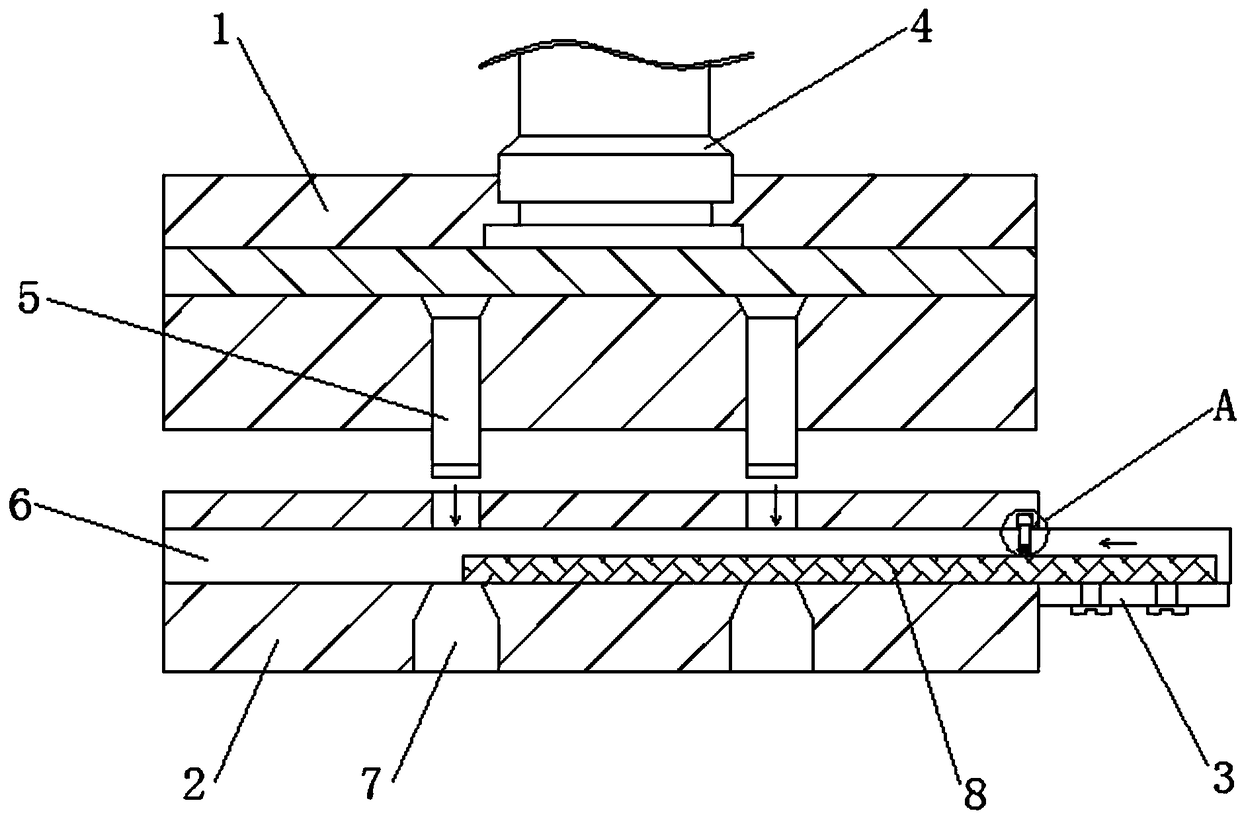

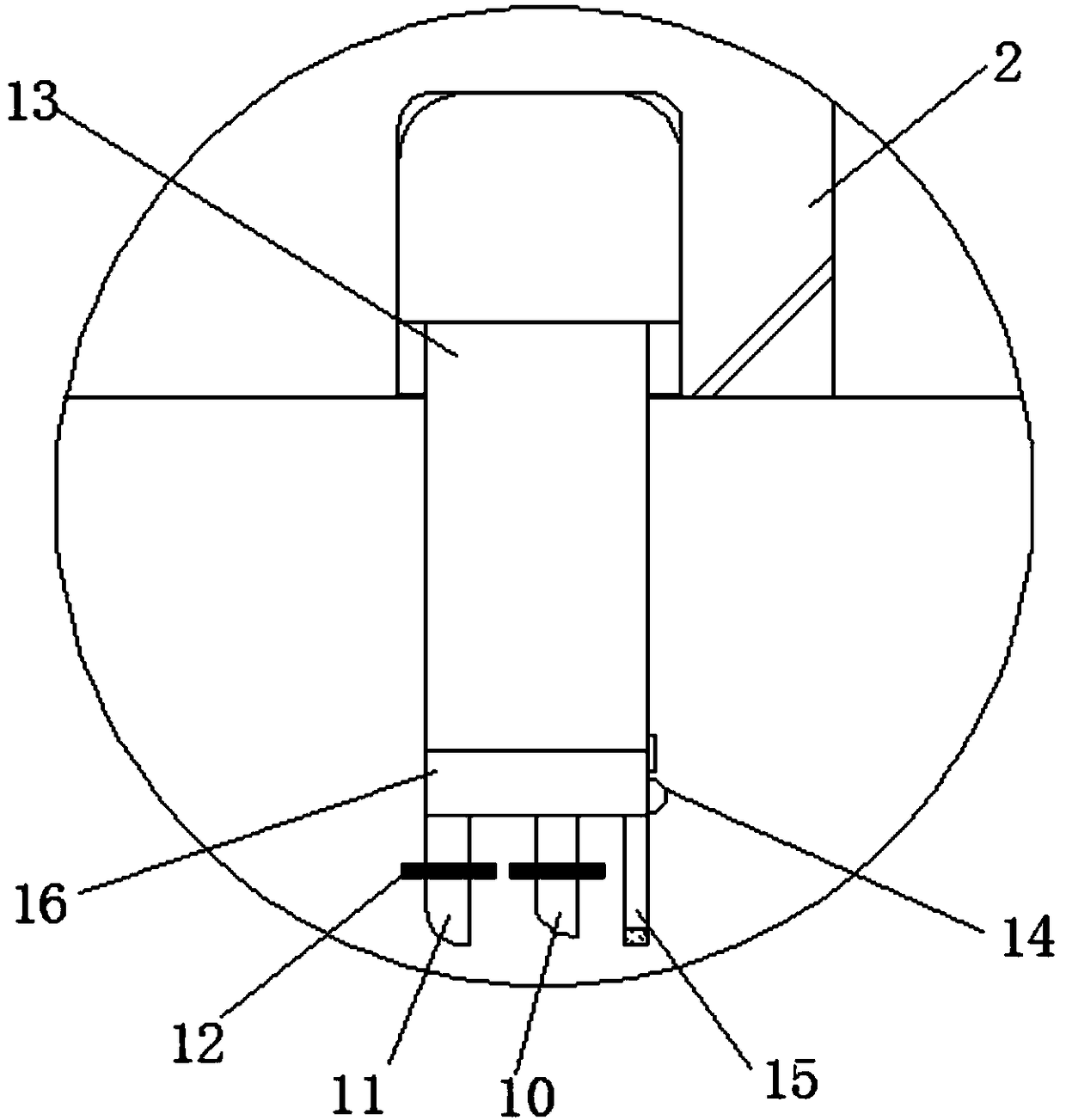

A powder spraying device for a printing machine

InactiveCN106079878BPrinting effect is not affectedSpeed up coolingPrinting press partsPhysical healthSpray nozzle

The invention discloses a powder spraying device of a printing machine. The powder spraying device of the printing machine comprises a shell (1), wherein a baffle plate (4) is arranged in the shell (1); one side of the baffle plate (4) is provided with a powder spraying chamber (5); the other side of the baffle plate (4) is provided with a dust removing chamber (6); one side, which approaches the baffle plate (4), of the powder spraying chamber (5) is provided with a thickness sensor (10); the thickness sensor (10) is connected with a controller (11), a sliding track (13) is arranged in the powder spraying chamber (5); the sliding track (13) is provided with a powder conveying pipe (14); the lower part of the powder conveying pipe (14) is provided with spraying nozzles (15); the spraying nozzles (15) are connected with the controller (11). The powder spraying device of the printing machine has the characteristics that the thickness of a powder layer can be regulated in real time in a powder spraying process; the powder spraying effect is improved; the pollution to an environment is reduced; the influence on the physical health of a worker is decreased; the production cost is decreased.

Owner:湖南天成印务有限公司

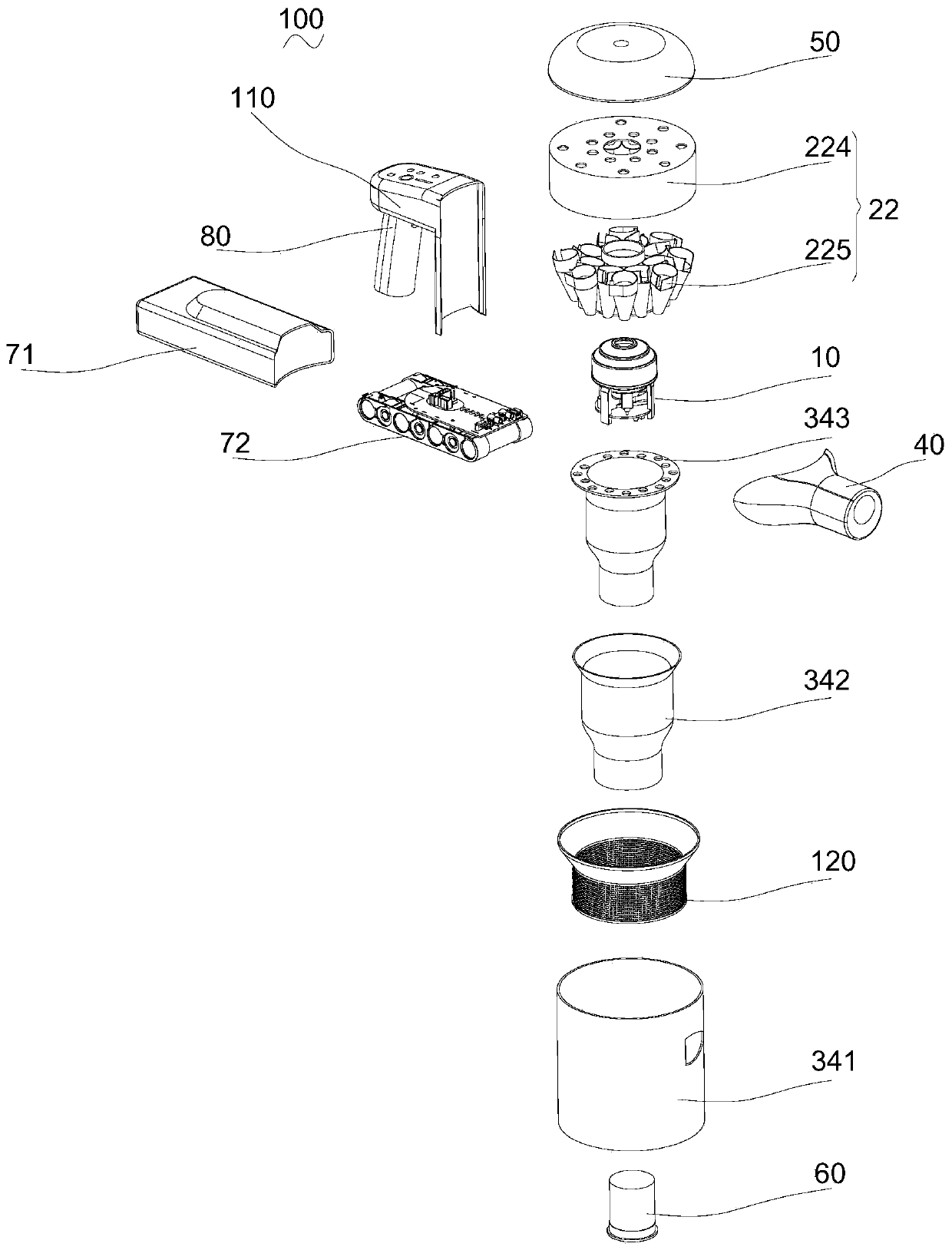

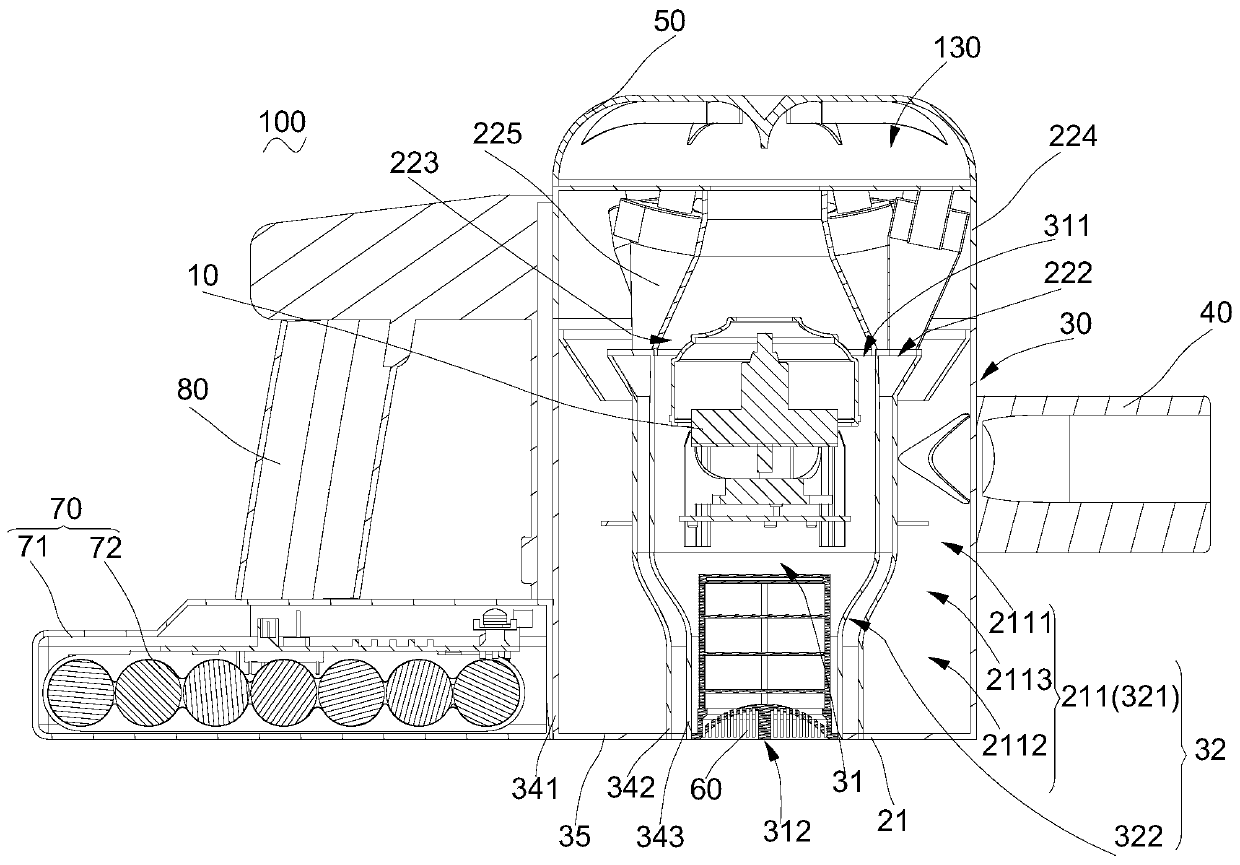

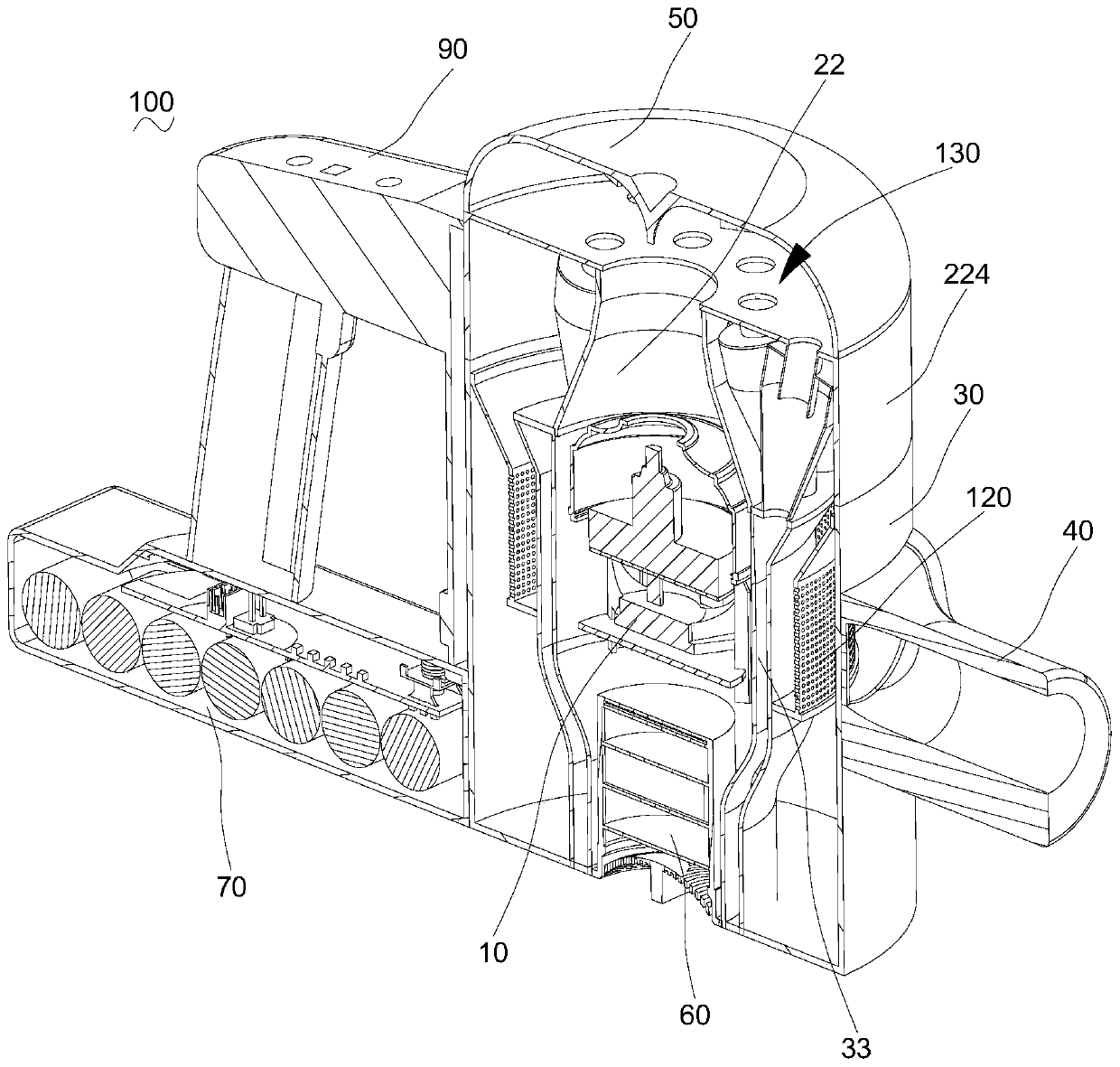

Dust collector

PendingCN110720858AGood dust effectReduce noiseSuction filtersExhaust-air diffusionEngineeringMechanical engineering

The invention relates to a dust collector which comprises a dust collection mechanism, a gas-dust separation mechanism and a gas generation mechanism, wherein the interior of the dust collection mechanism is hollow and is provided with a gas flow cavity with a gas suction hole and a gas exhaust hole; the interior of the dust collection mechanism is further provided with a dust collection cavity formed outside the gas flow cavity in a surrounding manner; the gas-dust separation mechanism is used for separating gas and dust, the dust formed after separation is deposited in the dust collection cavity, and the gas formed after separation flows to the gas suction hole; the gas generation mechanism is at least partially assembled in the gas flow cavity and is used for providing power for the gasto flow in the dust collector; the dust collection cavity and the gas flow cavity have a common wall; and the gas generation mechanism abuts against the common wall to transmit vibration to the common wall. When the gas generation mechanism works, the vibration of the gas generation mechanism is transmitted to the common wall, and the common wall vibrates together with the gas generation mechanism; and due to the fact that the common wall is used as the cavity wall of the dust collection cavity, the dust deposited on the wall surface of the dust collection cavity is separated from the wall surface to be deposited at the bottom of the dust collection cavity under the vibration action, and the relatively good dust falling effect is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

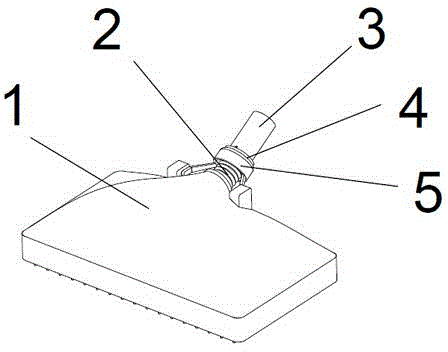

Dust-collection head applicable to textile fabrics

ActiveCN104905733AOvercome the defect of poor dust disturbance effectTo achieve the purpose of raising dustSuction nozzlesEngineeringMechanical engineering

The invention discloses a dust-collection head applicable to textile fabrics. A support is installed in a shell body, two ends of the support are movably fixed on the shell body, wherein one end is connected with a motor, and the motor is installed in the shell body. The parallel direction, along the rotating shaft, of the support is divided into multiple fulcrum shafts, each fulcrum shaft is sleeved with a flapping plate, and the two ends, on one flapping plate of each fulcrum shaft are fixed with limiting blocks. The dust-collection head applicable to the textile fabrics is powered by the motor which is internally arranged in the dust-collection head, the flapping plates are driven to continuously flap the textile fabrics through the rotation of the support, and thus the purpose of dust rising is achieved. The dust-collection head applicable to the textile fabrics overcomes the defect that a common dust-collection head is not good in dust raising effect just by a brush when cleaning the surface of the textile fabrics, and effectively improves the dust raising effect.

Owner:湖州优研知识产权服务有限公司

An easy-to-use printing press

Owner:慈溪市黎明彩印有限公司

Circulating air dust removal device applied to intelligent storage of grains

InactiveCN113894040AAchieve dust removalIncrease the feeding distanceCombination devicesGas current separationSuction forceEnvironmental engineering

The invention discloses a circulating air dust removal device applied to intelligent storage of grains, and relates to the technical field of crop processing. The circulating air dust removal device comprises a base, a conveying belt is fixedly mounted on the base, and a mounting frame is fixedly mounted at the feeding end of the conveying belt; a feeding part is fixedly mounted on the mounting frame, and dust removal parts communicating with the interior of the feeding part are mounted on the two opposite sides of the feeding part; and the discharging end of the feeding part is located at the feeding end of the conveying belt. Feeding is achieved through the arranged feeding part, grains fall down layer by layer after passing through the feeding part, dust contained in the grains flies, air mixed with the dust is sucked into the dust removal part through suction force generated by the dust removal part communicating with the interior of the feeding part for dust removal work, and dust removal of the grains is achieved easily.

Owner:李享懋

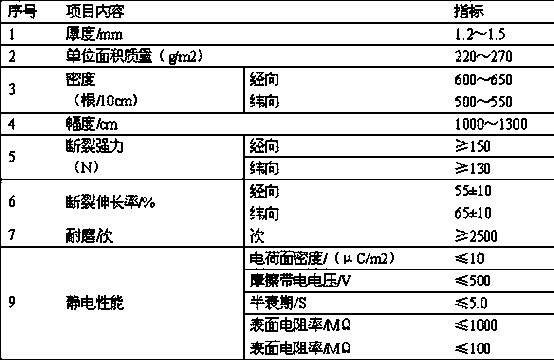

Wiping cloth for tin plate surface black ash and manufacturing process thereof

PendingCN111005109AOleophobic propertiesWith dust absorption performanceWeft knittingTwo or more solvent application treatmentTinningWool fibre

The invention discloses a wiping cloth for tin plate surface black ash and a manufacturing process thereof. The wiping cloth for the tin plate surface black ash is blended with cotton, wool and chemical fiber, wherein the content of cotton is 60% to 80%, the content of wool fiber is 0 to 10%, and the content of chemical fiber is 10 to 40%; after the cotton, wool and chemical fiber are blended, a conventional ring spinning machine is used for obtaining a spindle, and then a circular weft knitting machine is used for weaving the gray fabric; after singeing and mercerizing the gray fabric, an overflow machine is used for performing softening treatment; the gray fabric is dipped twice and rolled twice in a far-infrared finishing liquid, and dried after rolling; and after the wiping cloth is softened, the edges are sizing for 1 to 5 mm to fix. The wiping cloth for the tin plate surface black ash disclosed by the invention has softness, oil repellency and certain ash absorption, and can absorb the black ash wiped off when wiping the surface of the tin plate; meanwhile, the wiping cloth for the tin plate surface black ash also has a certain elasticity, which meets the requirements of a ash wiping device to automatically transport the wiping cloth; and the wiping effect of the wiping cloth is good, and at the same time, the oil film on the surface of the tin plate cannot be damaged during the wiping process, and the scratches cannot be generated.

Owner:SHANGHAI WUBAO ELECTROMECHANICAL TECH

Can body spraying system fixed to side face of one guide rail

InactiveCN106076718AEnable recyclingGood dust effectLiquid surface applicatorsSpray nozzlesSpray nozzleWeld seam

The invention provides a can body spraying system fixed to the side face of one guide rail. The can body spraying system comprises a spraying device fixed to a rack, a conveyor belt and guide rails. The spraying device is fixed to the side face of one guide rail and comprises a spray nozzle facing the conveyor belt. A spray box is arranged between the spraying device and the corresponding guide rail. The spray nozzle extends into the spray box. The height of the spray box is greater than or equal to that of a can body. The side, close to the corresponding guide rail, of the spray box is provided with an opening identical to a weld seam outside the can body in length. The lowermost end of the opening is flush with the upper surface of the conveyor belt. The spray nozzle directly faces the opening. The can body spraying system can be used for well realizing the powder spraying process for the weld seam outside the can body, and is good in powder spraying effect and high in efficiency.

Owner:天津万事达印铁包装容器有限公司

A dust monitoring and processing device for construction sites

ActiveCN109999566BAvoid pollutionGood dust effectAnalysing gaseous mixturesDispersed particle separationEngineeringAtmospheric sciences

The invention discloses a dust monitoring and processing device for a construction site, which includes a mobile base body, universal wheels are arranged at the lower four corners of the mobile base body, and the mobile base body is driven by the universal wheels to move rapidly, so The body of the mobile base is provided with a height adjustment mechanism, and the height during monitoring can be adjusted through the height adjustment mechanism, so as to monitor different heights of dust, the body of the mobile base is provided with a dust monitoring and processing mechanism, and the dust monitoring and processing mechanism To monitor the dust content in the air, the mobile base body is provided with a wind direction and wind speed measuring mechanism, and the wind direction and wind speed is monitored by the wind direction and wind speed measuring mechanism, and the moving base body is provided with a sampling mechanism, and the sample is retained by the sampling mechanism , the body of the mobile base is provided with a controller. The invention has the advantages of simple structure and strong practicability.

Owner:山东汇氏环境科技集团有限公司

Separation process for metal stamping part

ActiveCN109433900AGuaranteed smoothnessQuality improvementCleaning using toolsMetal working apparatusEngineeringMetal

The invention discloses a separation process for a metal stamping part, and belongs to the field of metal stamping. The separation process for the metal stamping part comprises a sheet metal part anda separating device, and the separating device is connected with a monitoring mechanism and a slicking mechanism; the separation process comprises the first step of material placing, the second step of material pushing, the third step of detecting, the fourth step of slicking, wherein the slicking mechanism is used for slicking the upper surface of the sheet metal part, the fifth step of materialstopping, the sixth step of material pressing, wherein the separating device starts to press the sheet metal part at a fixed point, and a falling piece is pressed out from the sheet metal part; the seventh step of material falling, wherein the falling piece pressed from the upper portion falls off from the separating device, the falling piece is collected, and the separating process is completed.By means of the scheme, before the sheet metal part enters a feeding channel, the sheet metal part is electronically detected, debris adhered on the upper surface of the sheet metal part can be automatically removed in time, the smoothness of the upper surface of the sheet metal part is ensured, and the quality of the falling piece obtained after blanking is greatly improved.

Owner:深圳市新锐标牌科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com