User-friendly printing press

A printing machine, a convenient technology, applied in the direction of printing machines, printing, general parts of printing machinery, etc., can solve problems such as increased cost, too thick powder layer, easy ink adhesion, etc., to reduce labor intensity, reduce usage, Guaranteed drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and examples, but not as a basis for limiting the present invention.

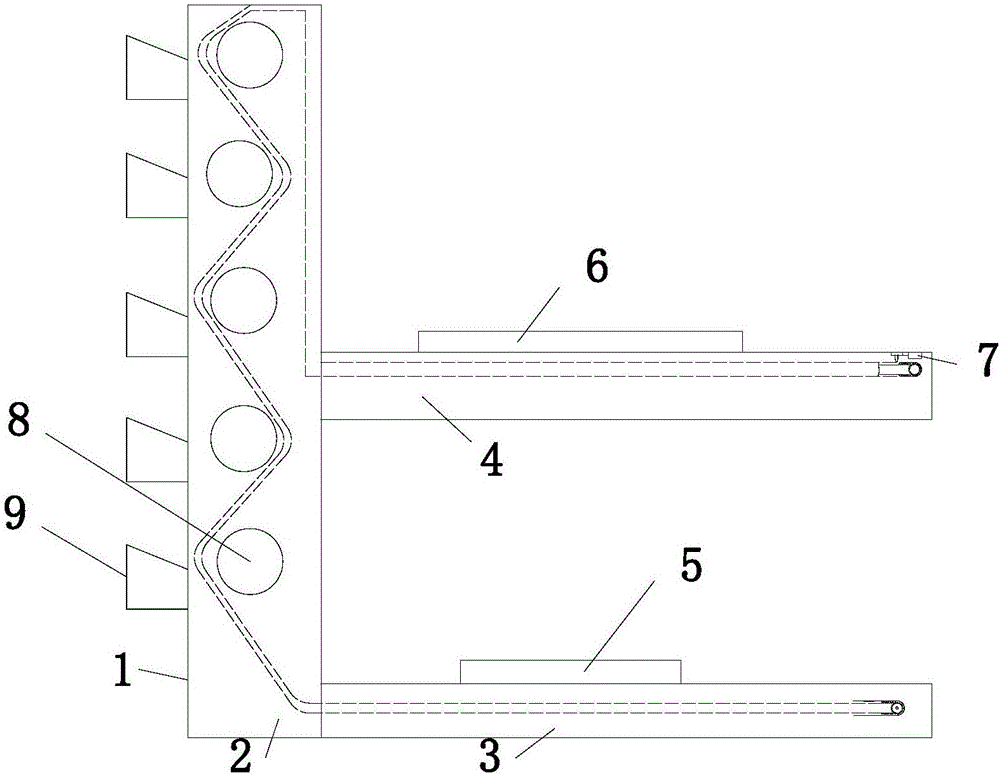

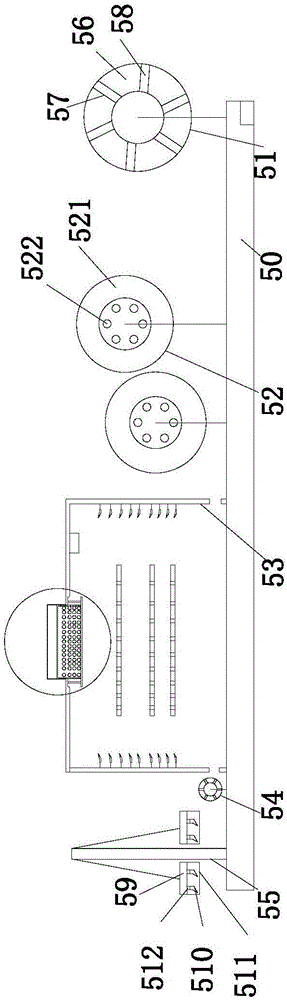

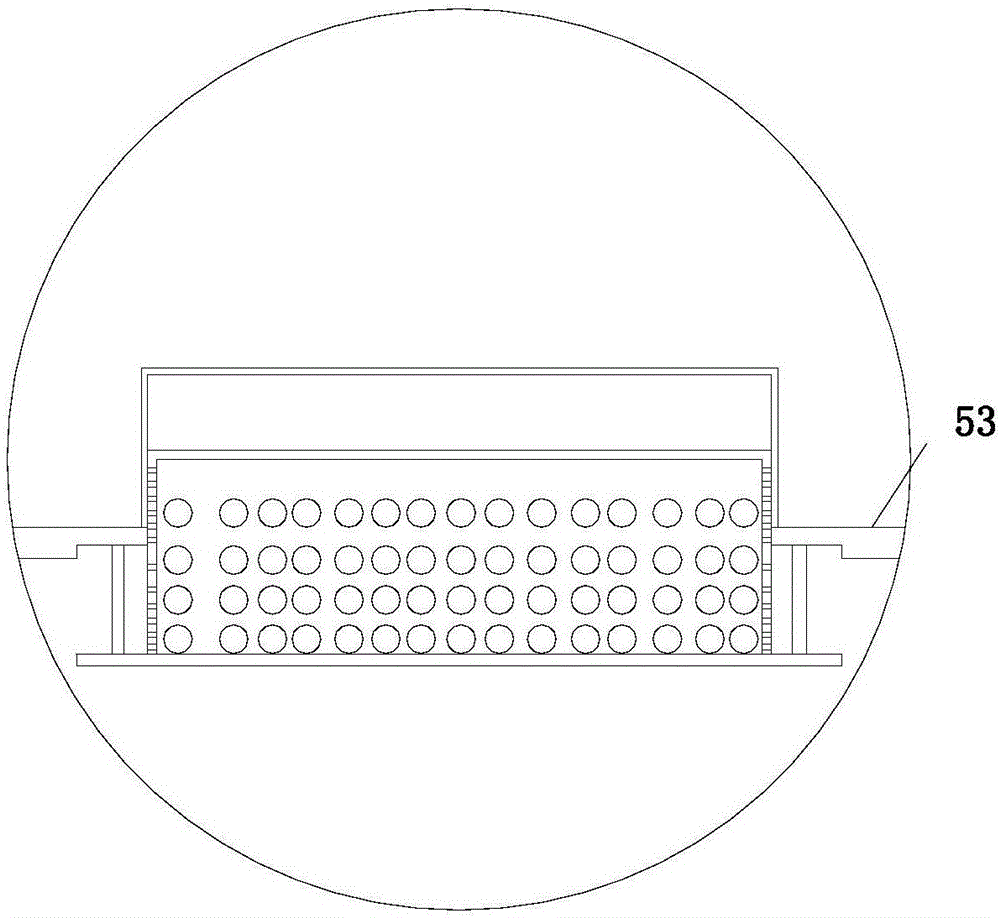

[0025] Example. A convenient printing machine, constituted as Figure 1 to Figure 8 Shown, comprise frame 1, and frame 1 comprises vertical section frame 2, and vertical section frame 2 lower end is provided with first horizontal section frame 3, and the middle part of vertical section frame 2 is provided with second horizontal section machine Frame 4, the first horizontal section frame 3 is provided with a paper processing device 5, the top of the second horizontal section frame 4 is provided with a powder spraying device 6, and the vertical section frame 2 is provided with multiple sets of printing rollers 8, the printing rollers 8 below is provided with ink fountain device 9 correspondingly; Described paper processing device 5, powder spraying device 6 and ink fountain device 9 are all connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com