Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Guaranteed packaging efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

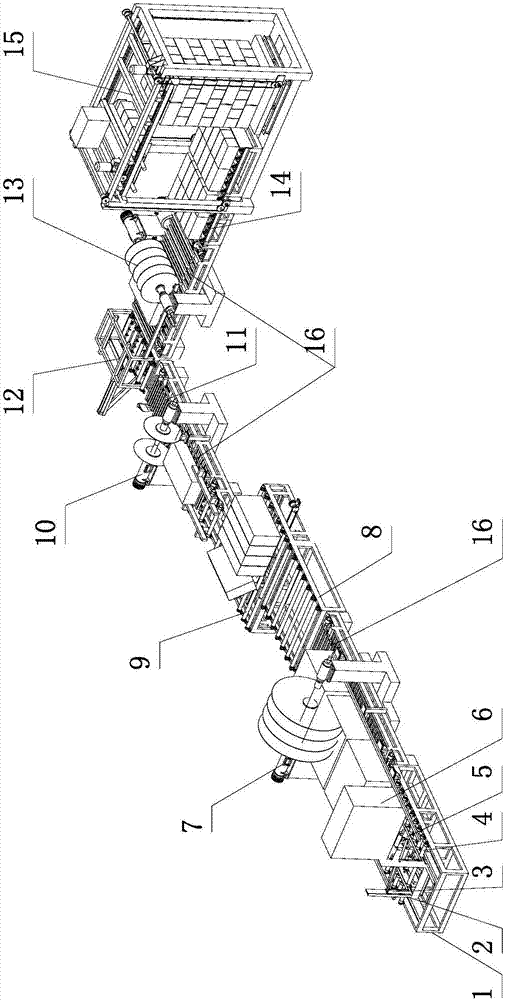

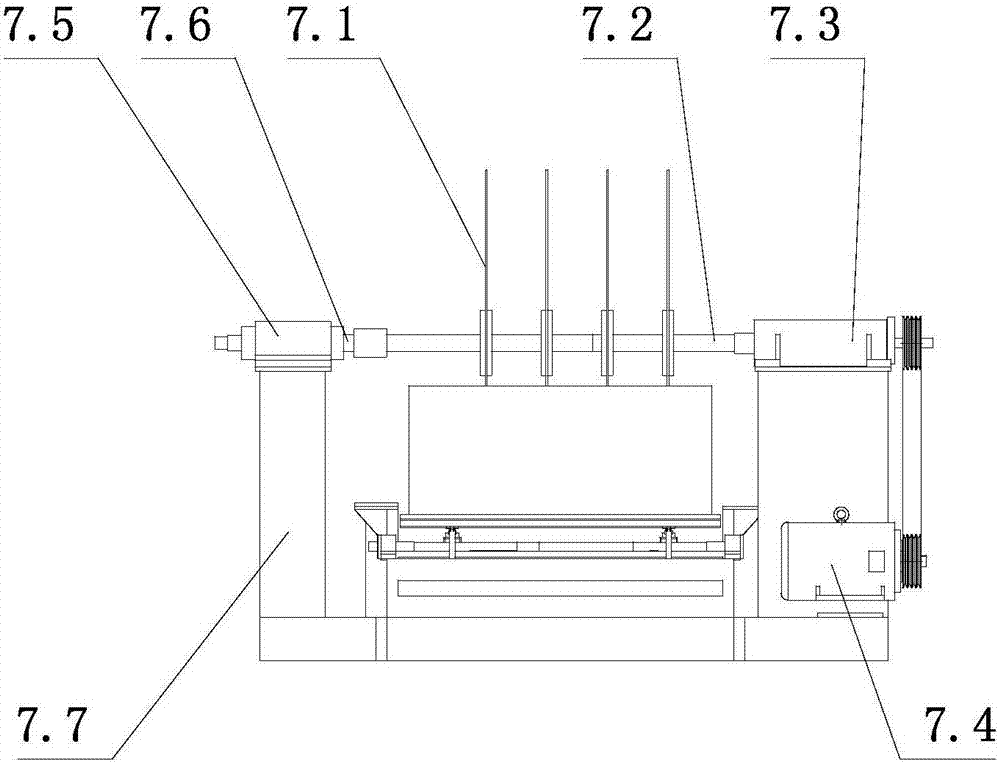

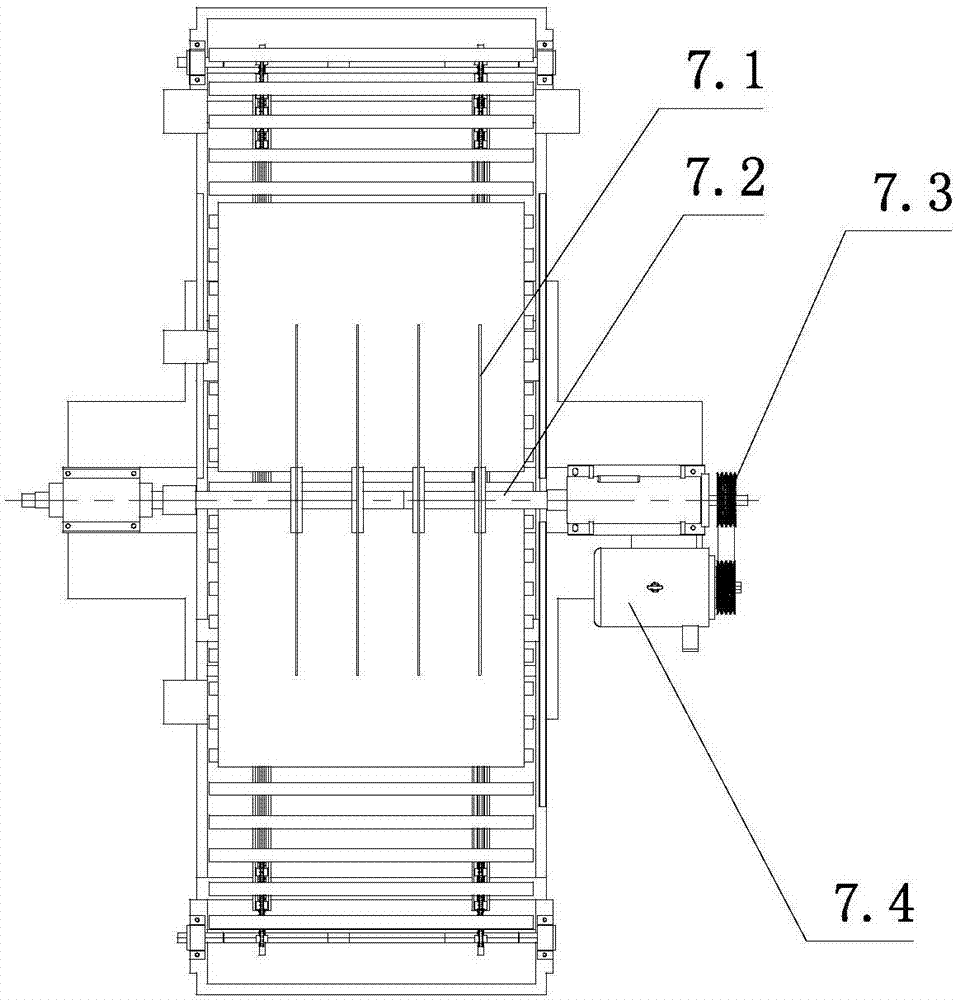

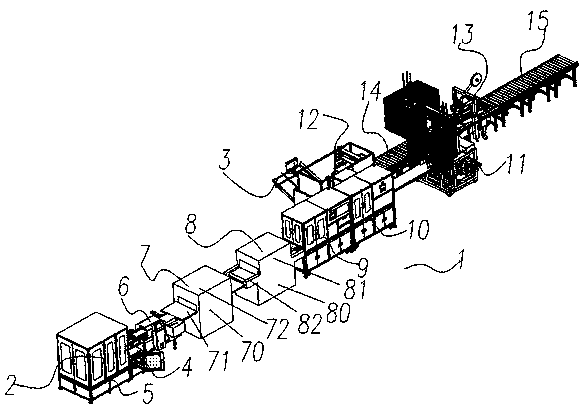

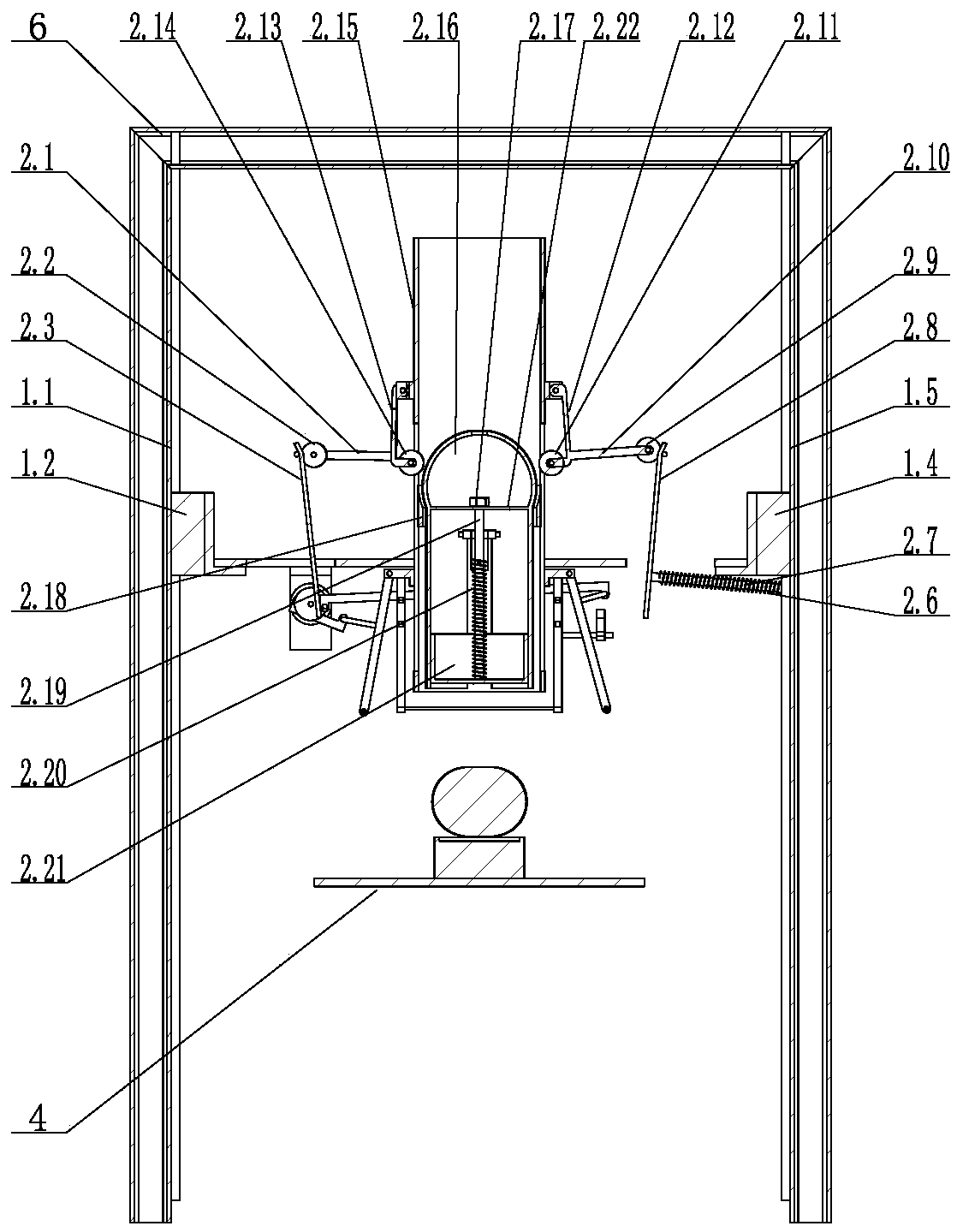

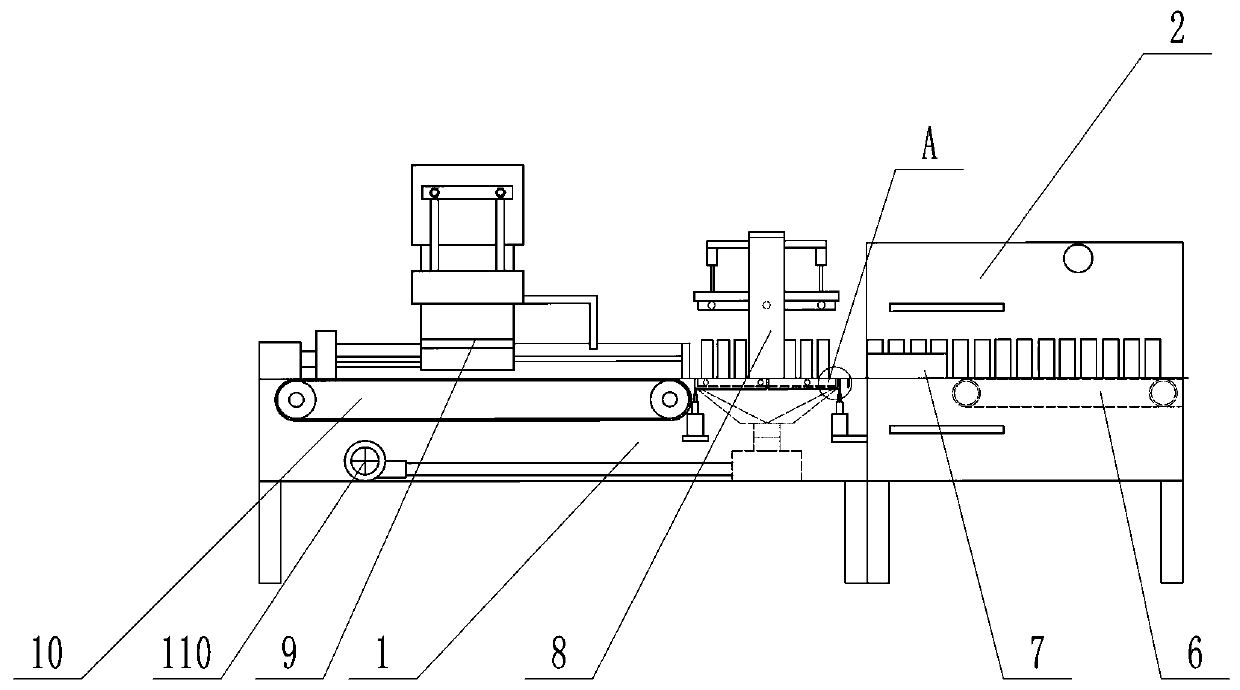

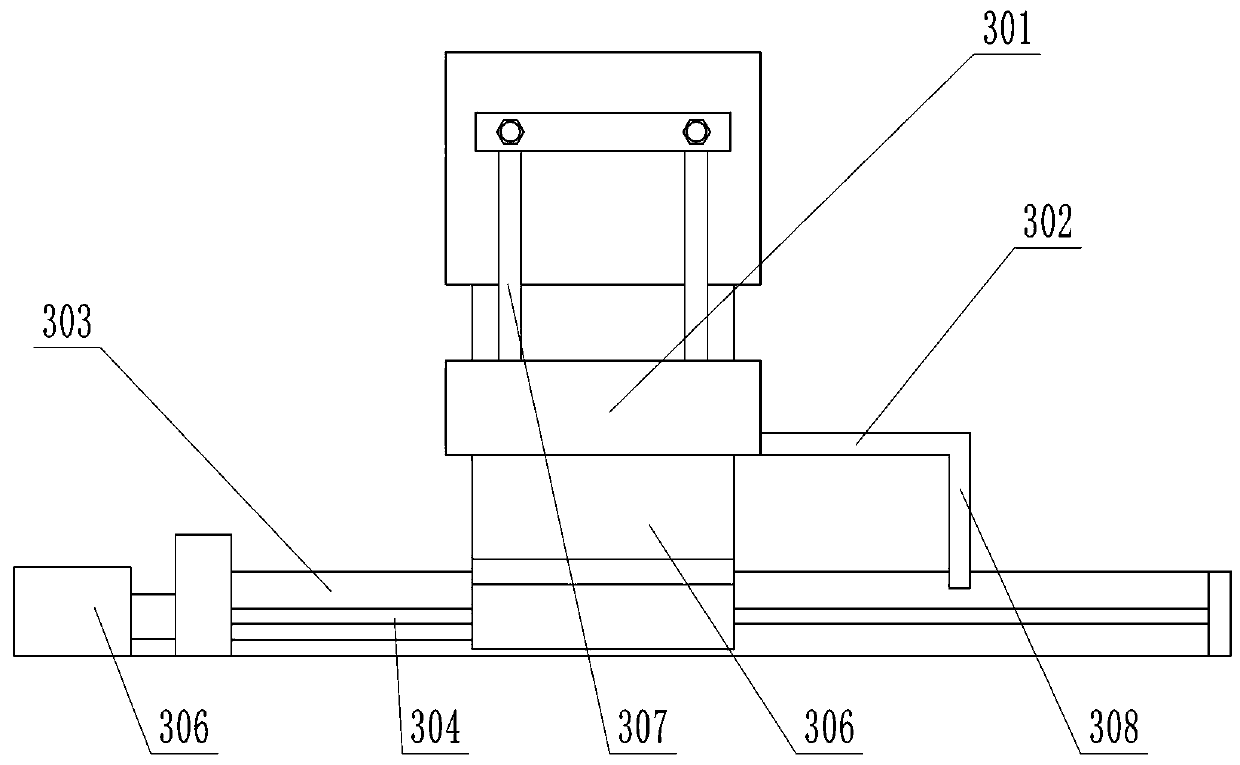

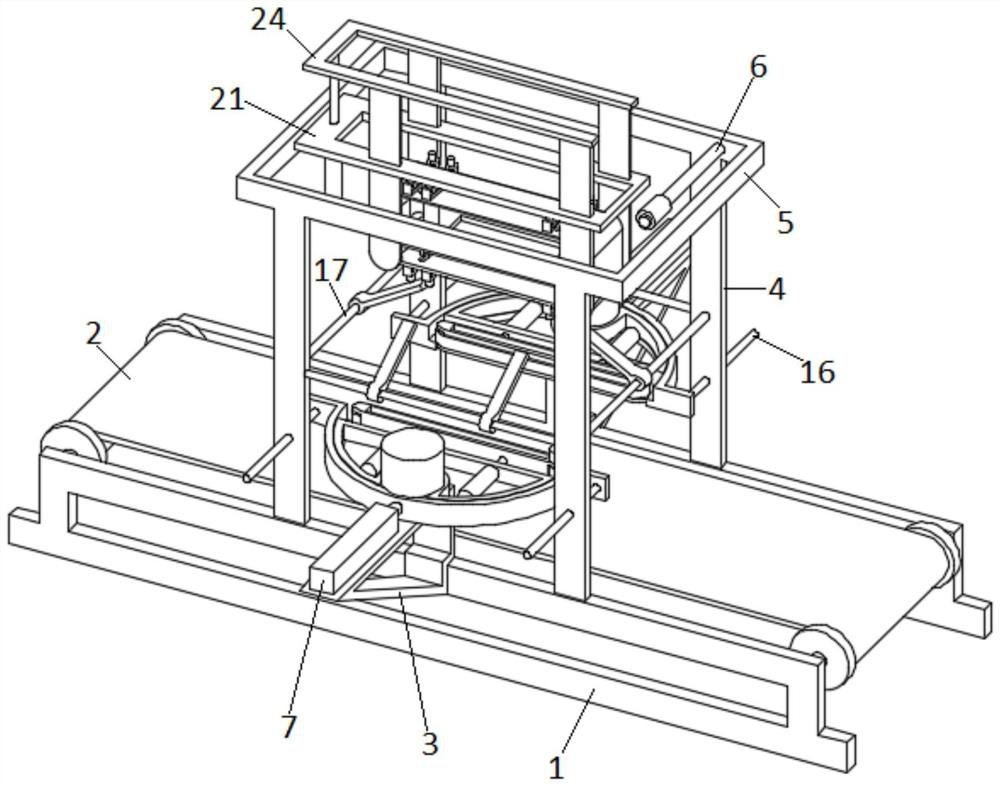

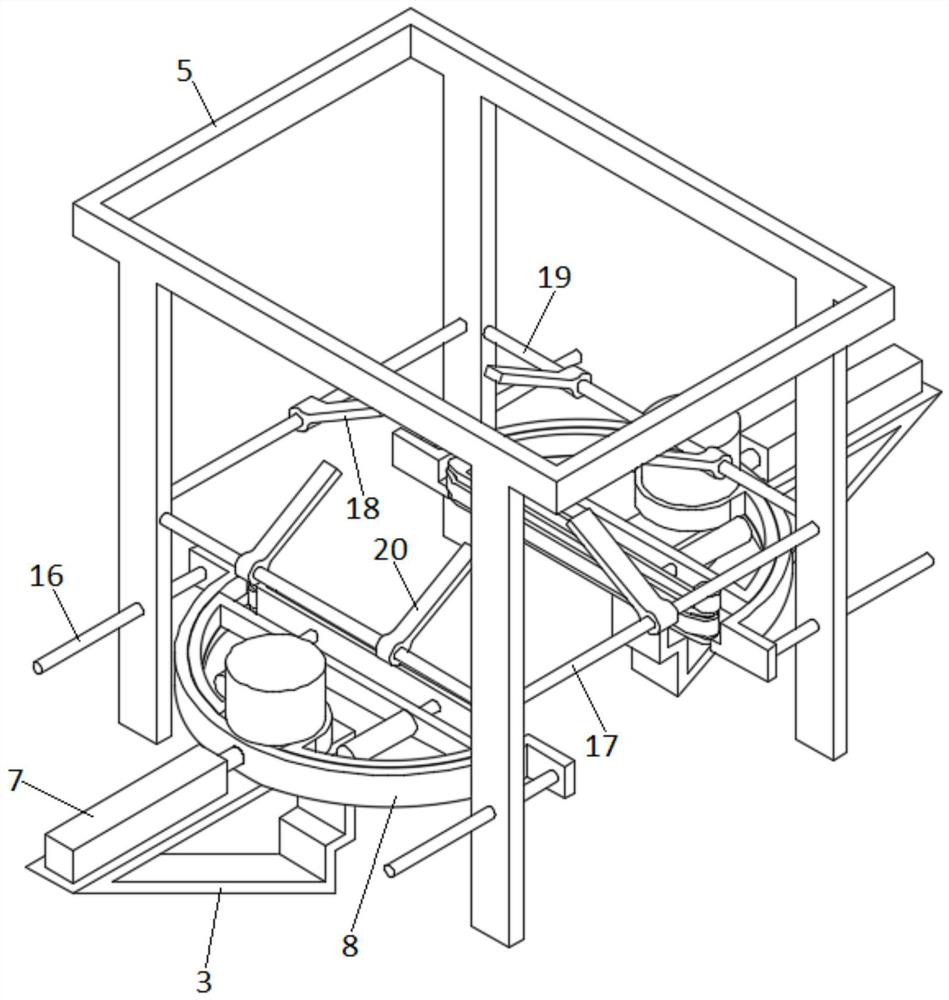

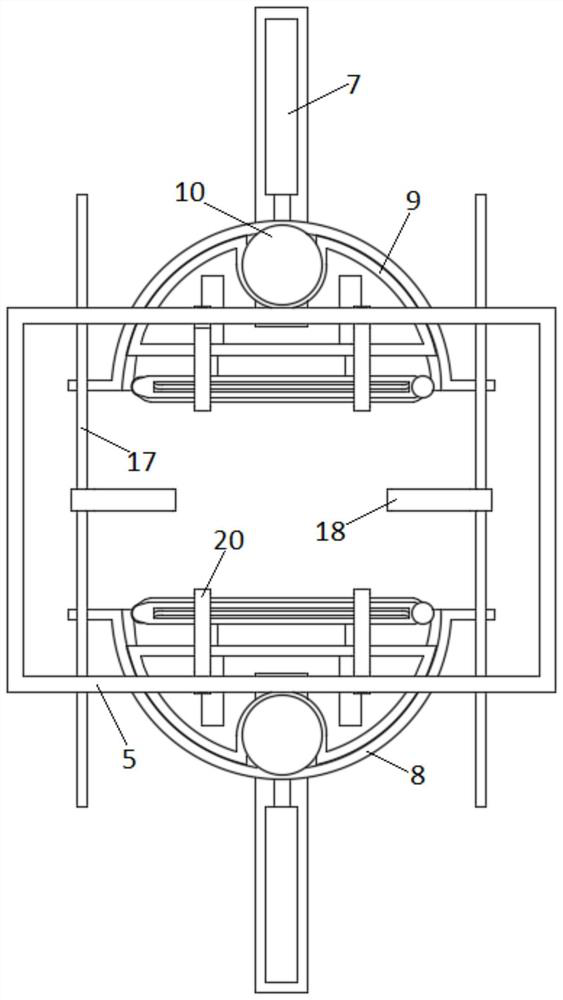

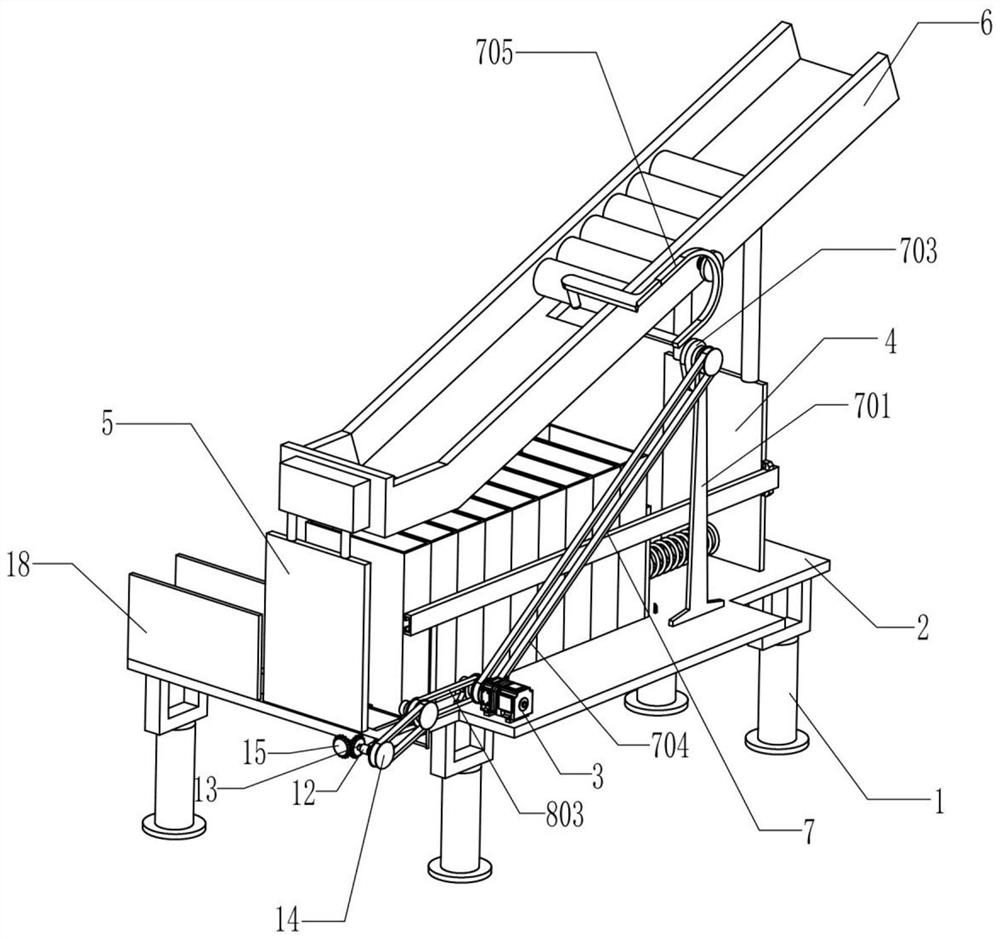

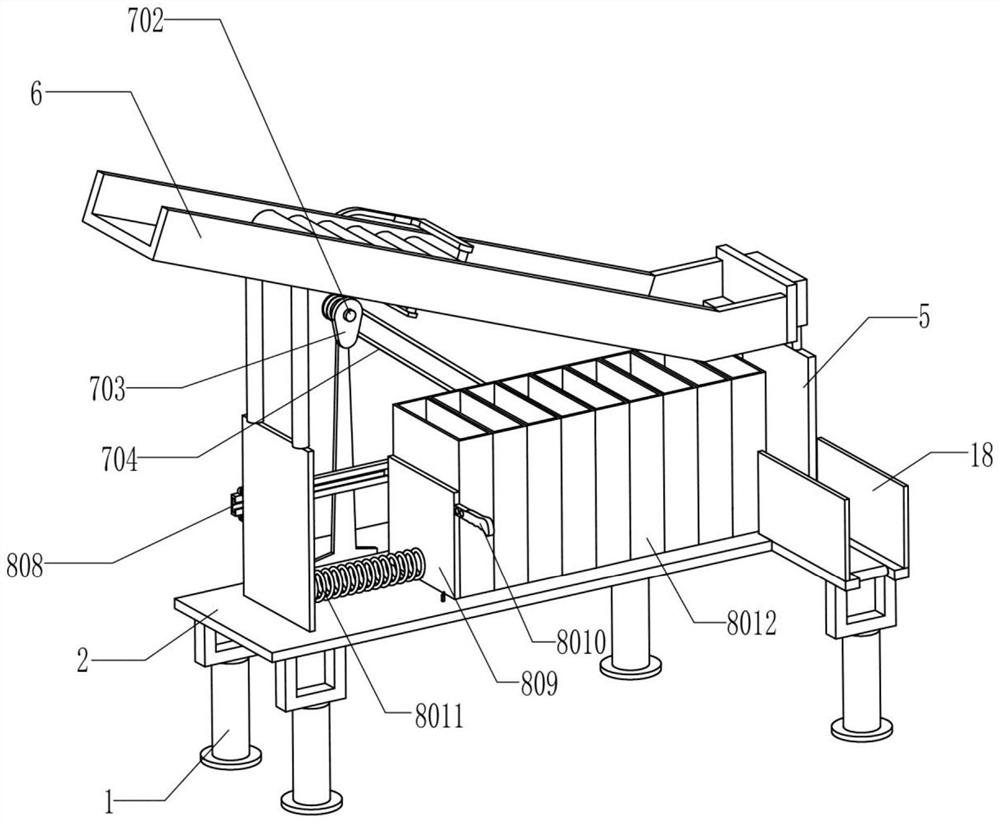

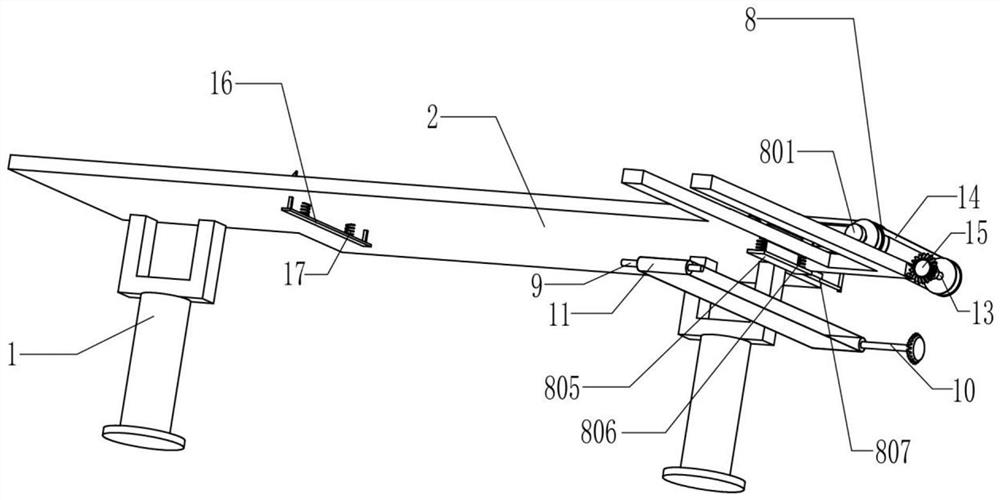

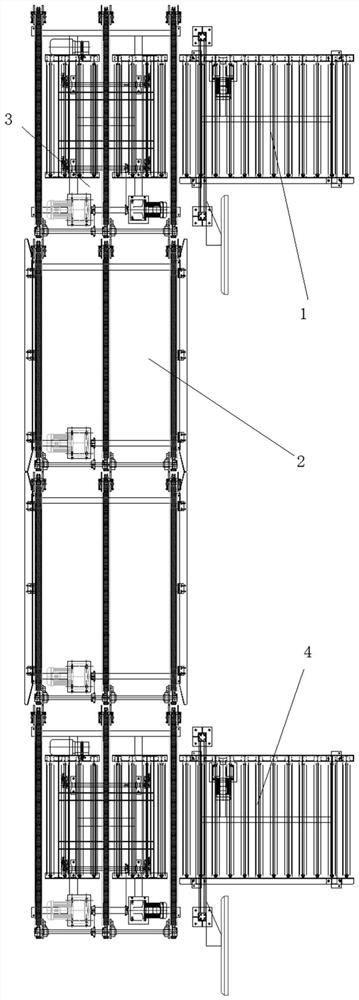

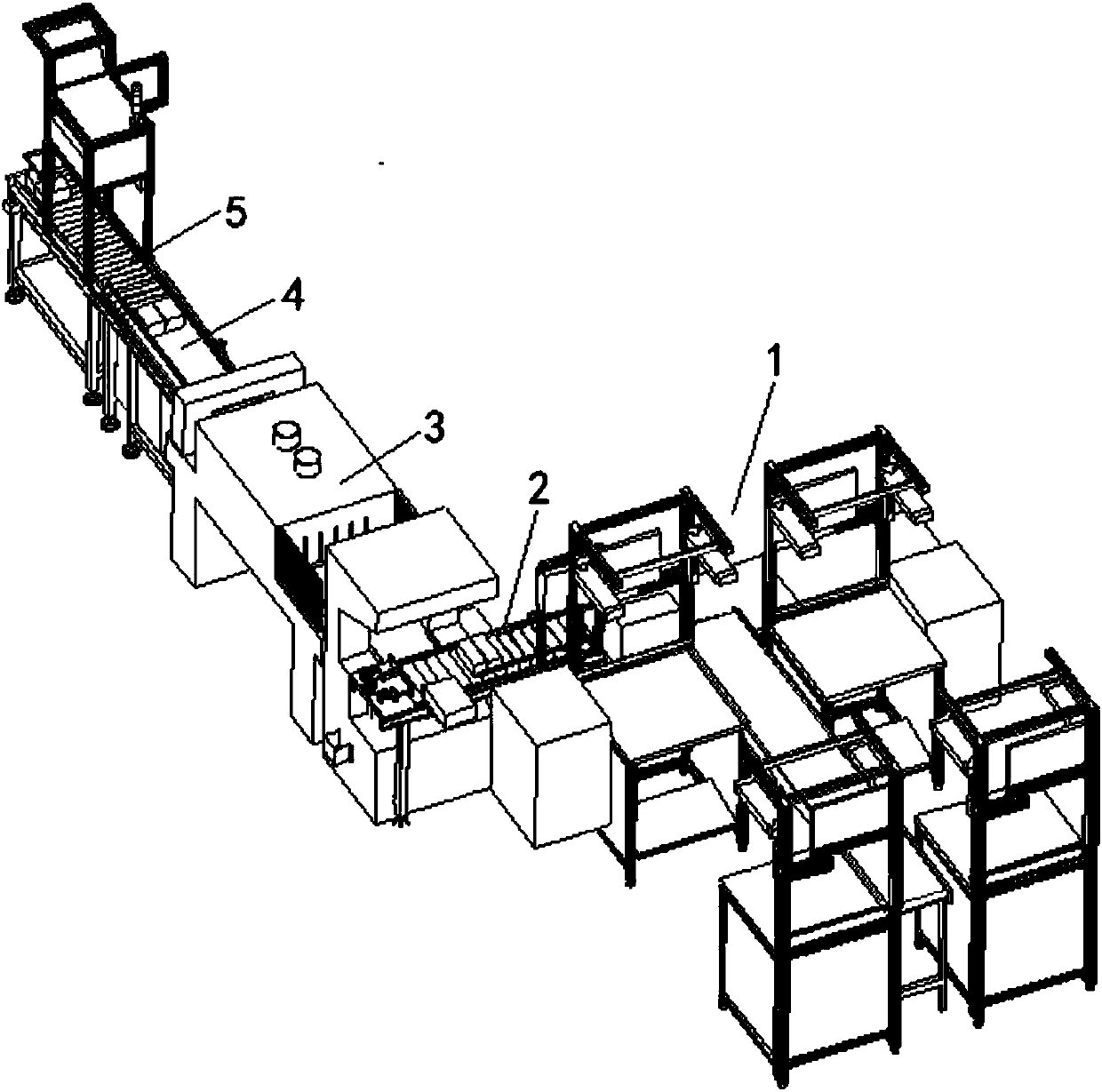

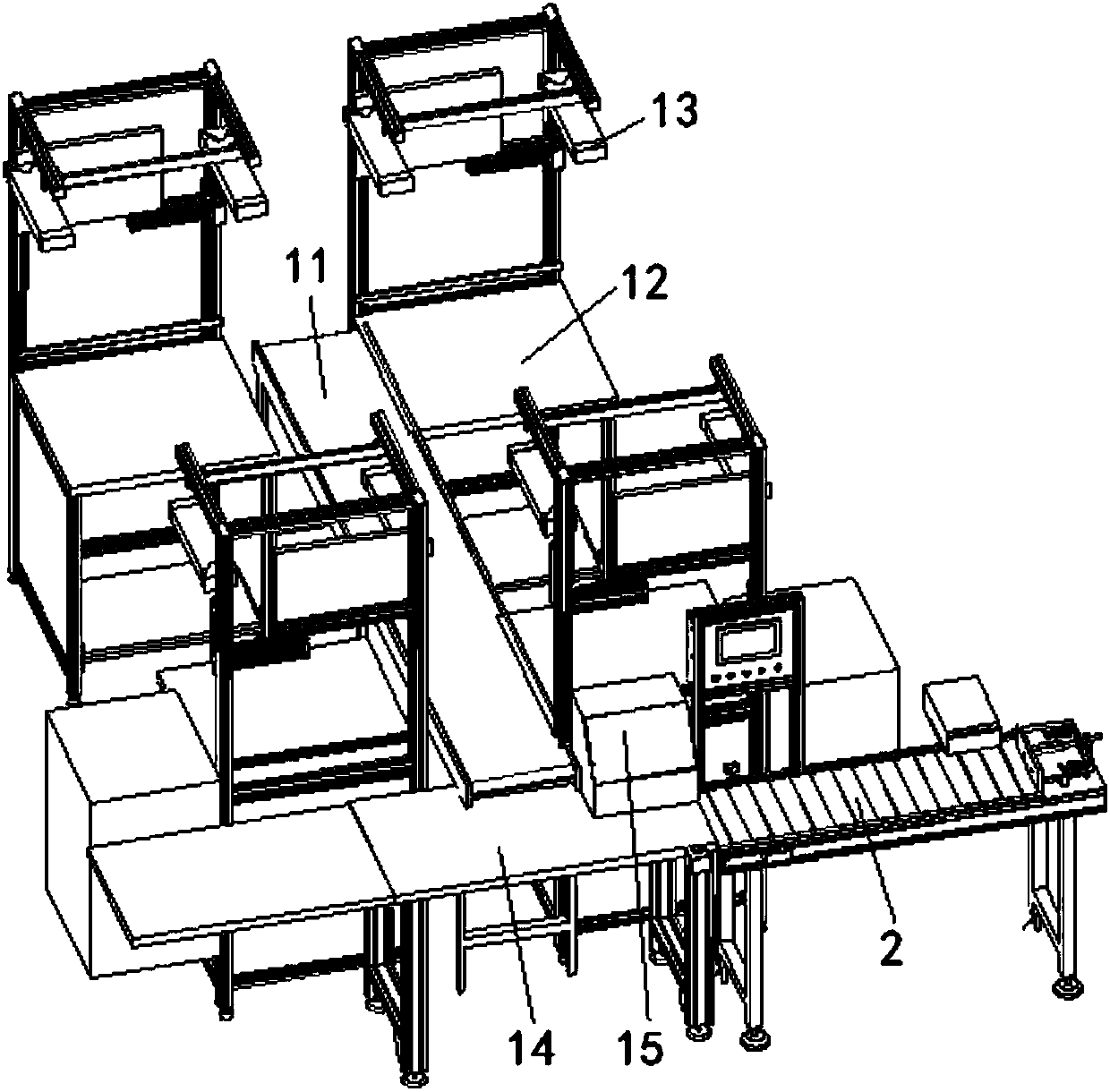

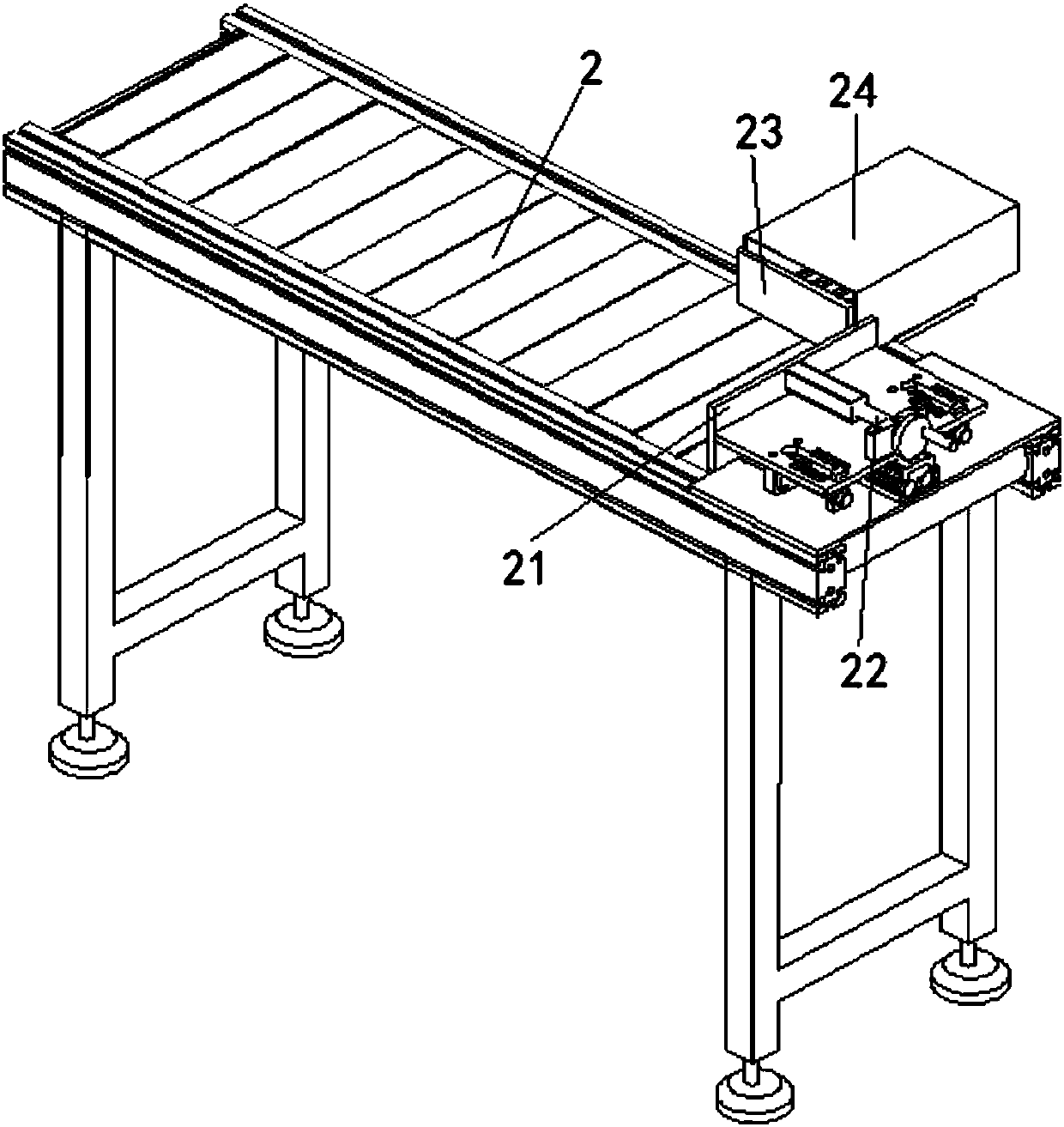

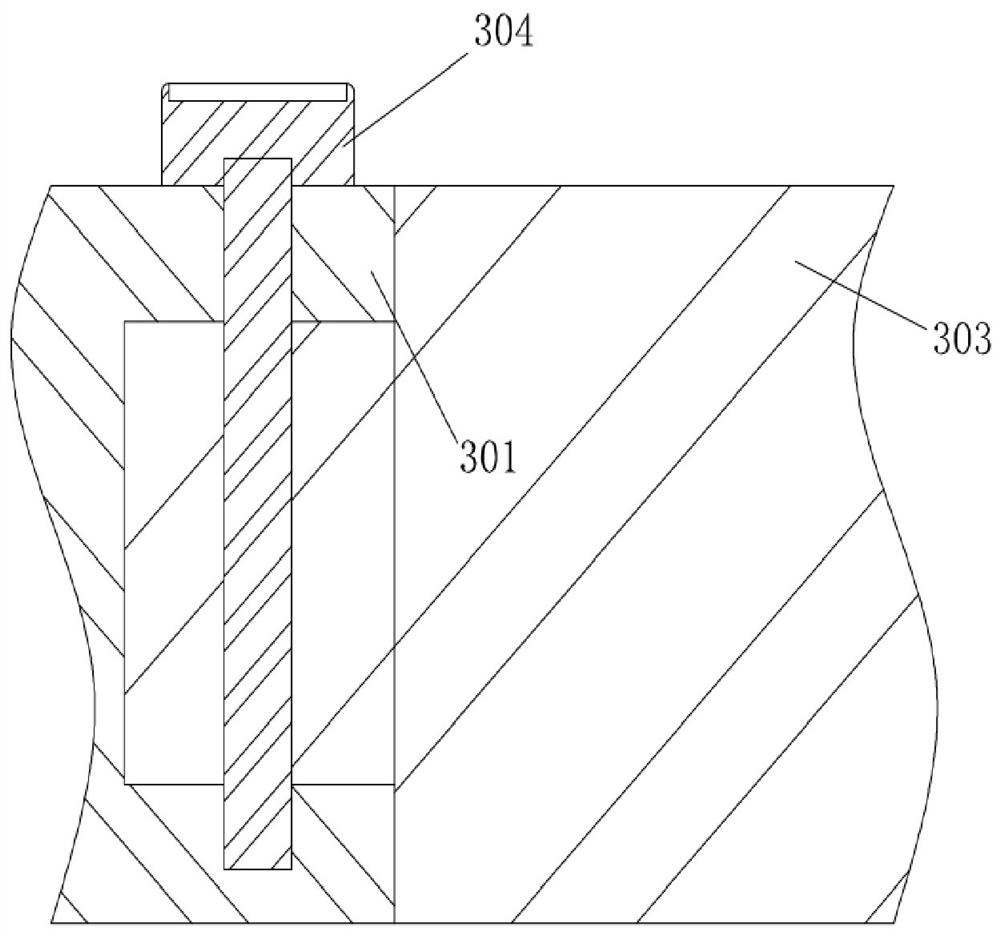

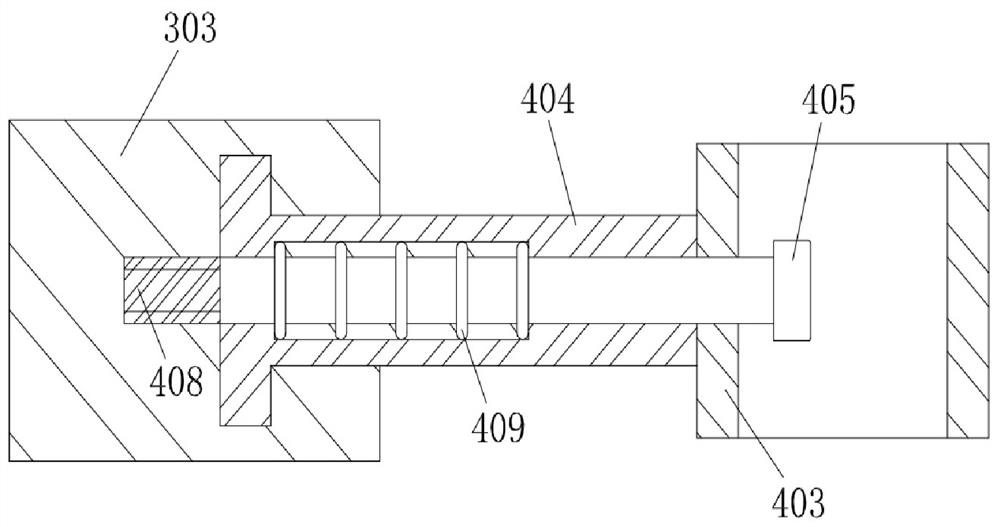

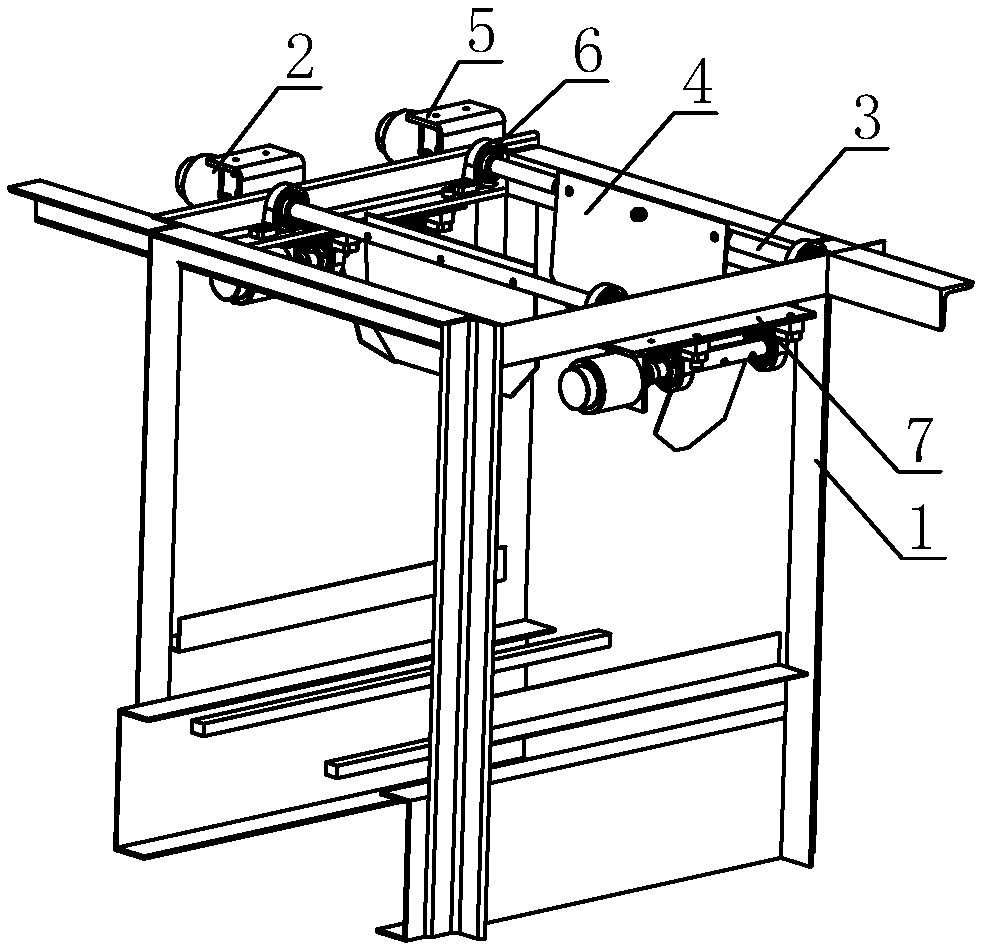

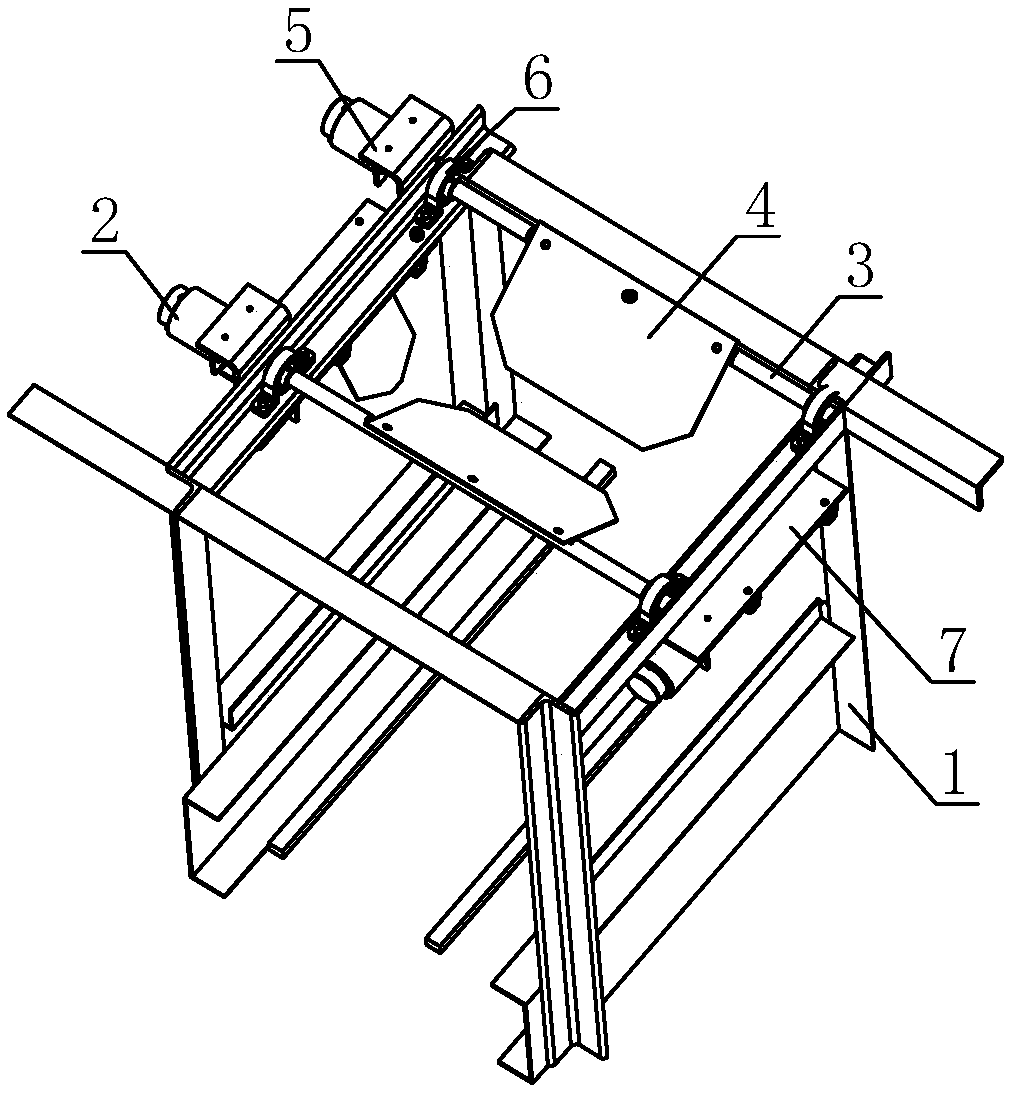

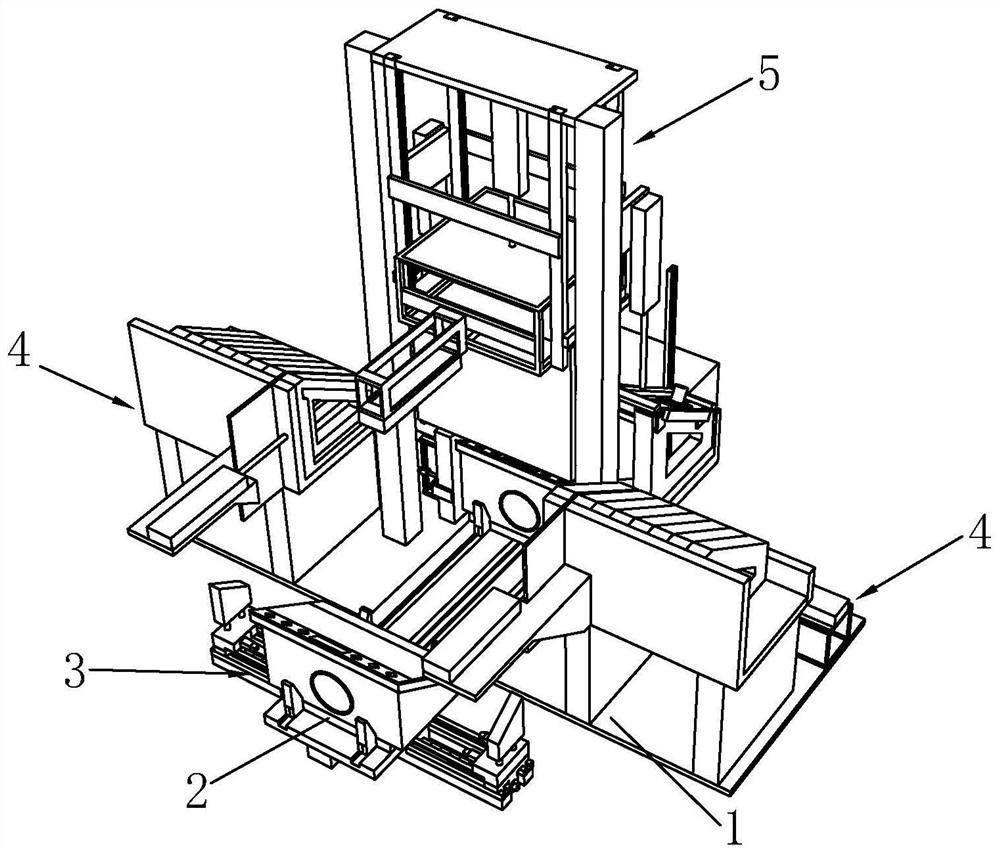

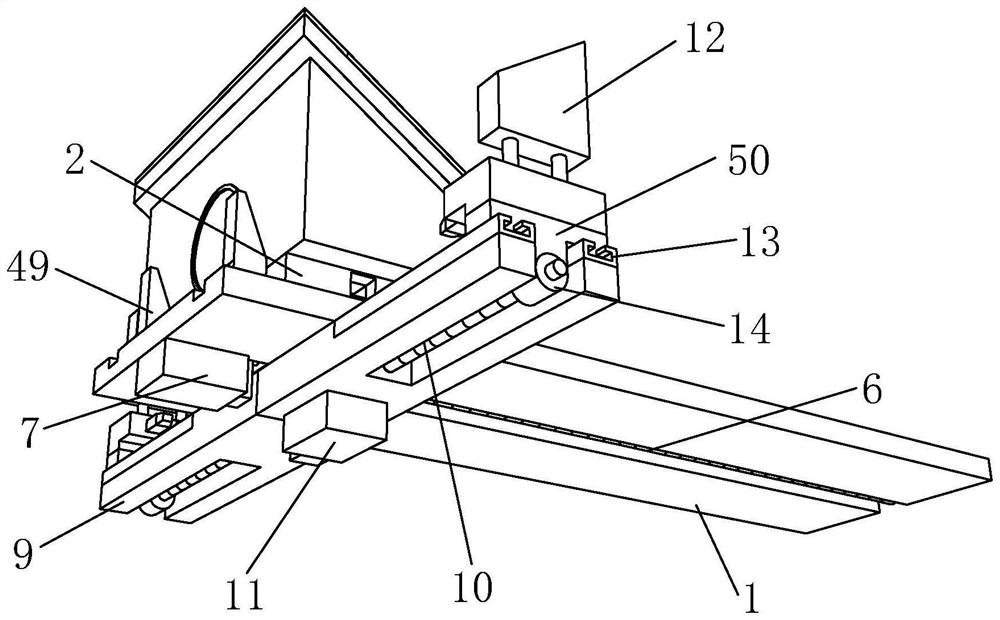

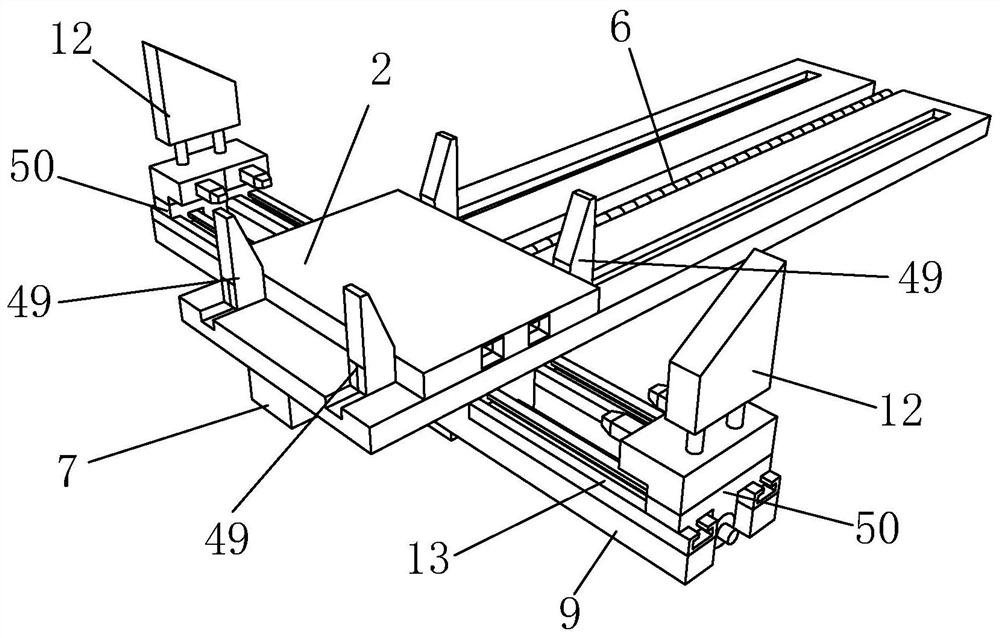

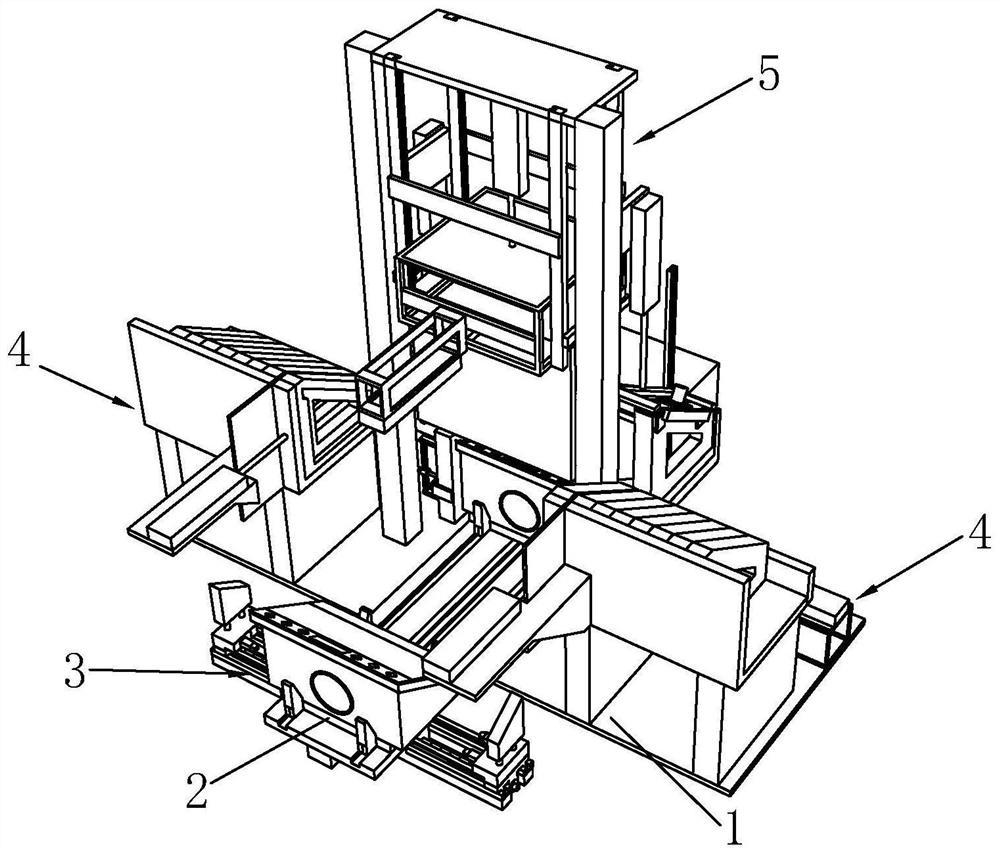

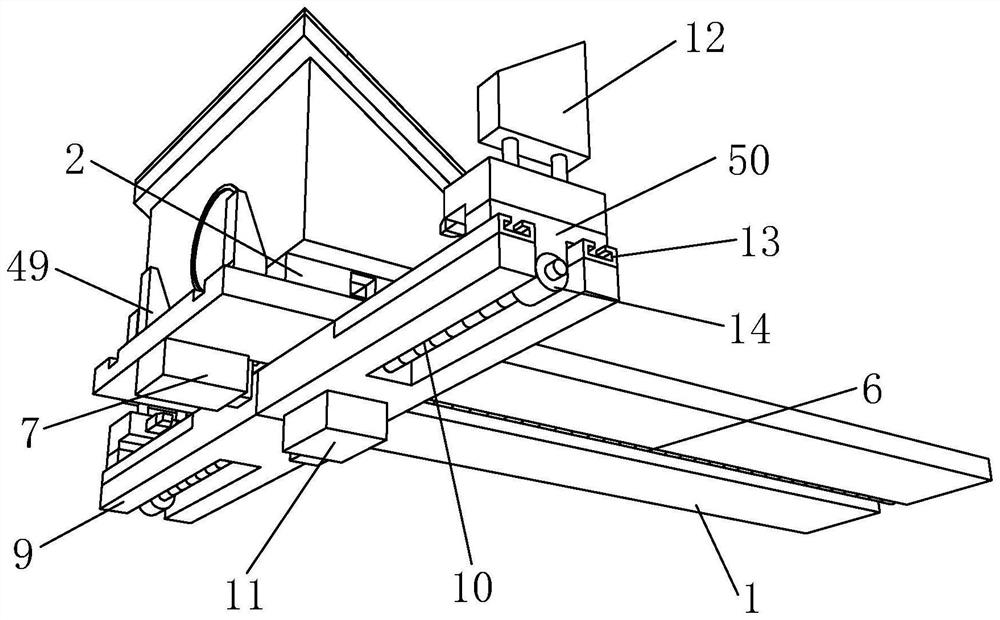

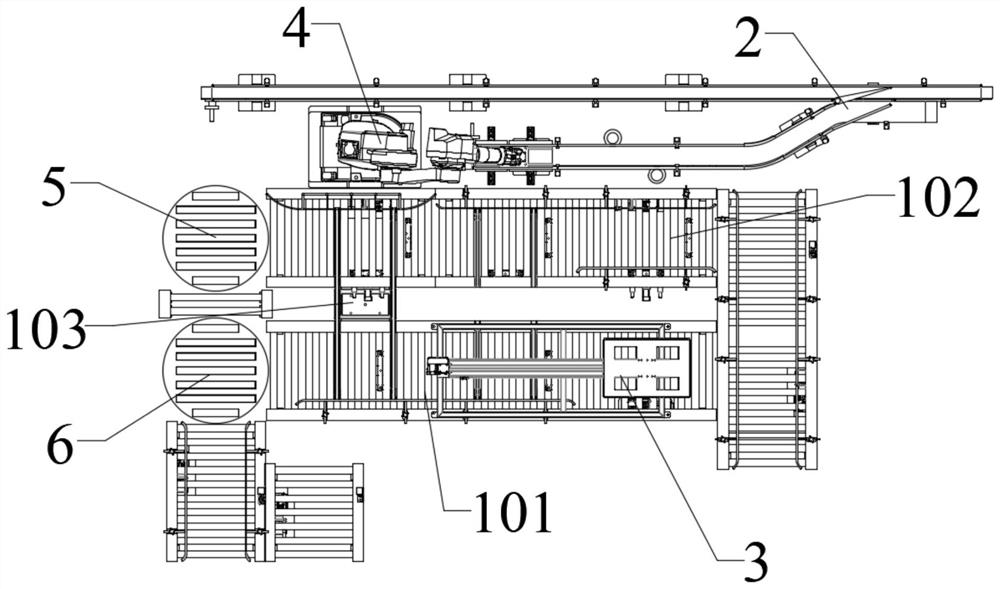

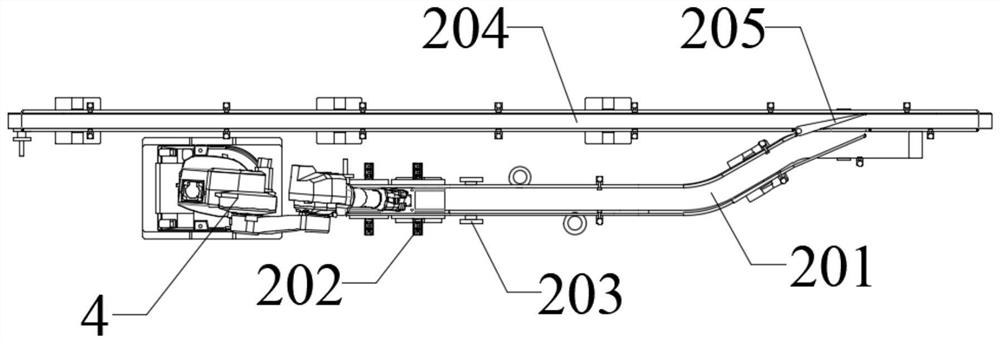

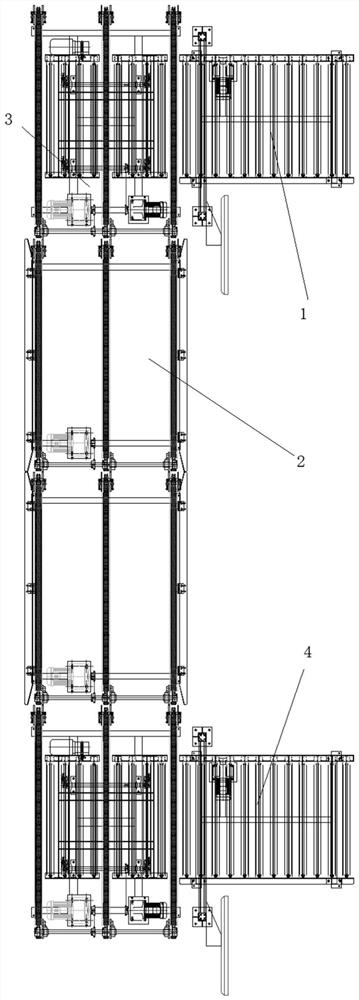

Cutting production line for building blocks

InactiveCN107053443AImprove cutting efficiencyGood quality finished productAuxillary shaping apparatusConveyor partsArchitectural engineeringProduction line

The invention belongs to the field of cutting equipment for building blocks and particularly relates to a cutting production line for the building blocks. The production line comprises a rack and main conveying device arranged on the rack; a No.1 cutting machine, a No.2 cutting machine and a No.3 cutting machine are sequentially arranged on the rack; a transverse distributing and turning mechanism for turning the building blocks by 90 degrees is arranged between the No.1 cutting machine and the No.2 cutting machine; and a reversing mechanism for reversing the building blocks is arranged between the No.2 cutting machine and the No.3 cutting machine. The production line is applicable to cutting of concrete building blocks and building block foam bricks, can perform six-surface cutting on the building blocks automatically, has the high production efficiency and guarantees the appearance quality and the size accuracy of finished products.

Owner:BINZHOU XINTONGDA MACHINE CASTING CO LTD

Three-dimensional container stuffing method based on combination heuristics

ActiveCN109761066AImprove packing rateGuaranteed packaging efficiencyControl devices for conveyorsLoading/unloadingRecognition heuristicSimulation

The invention discloses a three-dimensional container stuffing method based on combination heuristics. The method comprises the steps that a three-dimensional coordinate system is established on the basis of a container body of a three-dimensional container; then the placement rule of goods in the container is made; the encasement process of the goods is simulated repeatedly according to the different encasement requirements of the goods; and finally, the total volumes of the goods which are put into the three-dimensional container in the repeated simulated encasement processes are calculatedin a statistics mode, the values of the total volumes are compared, placement starting points of the goods in the simulated encasement process with the maximum total volume of the goods which are putinto the three-dimensional container are outputted, the corresponding goods are put into the container according to the placement starting points, and therefore the container stuffing is achieved. Themethod has the advantages that the goods encasement scheme with the highest three-dimensional container stuffing rate can be given out in the short time period according to the goods with the different encasement requirements, and the stuffing rate is high on the basis that the stuffing efficiency is guaranteed.

Owner:辽宁沿港物流有限公司

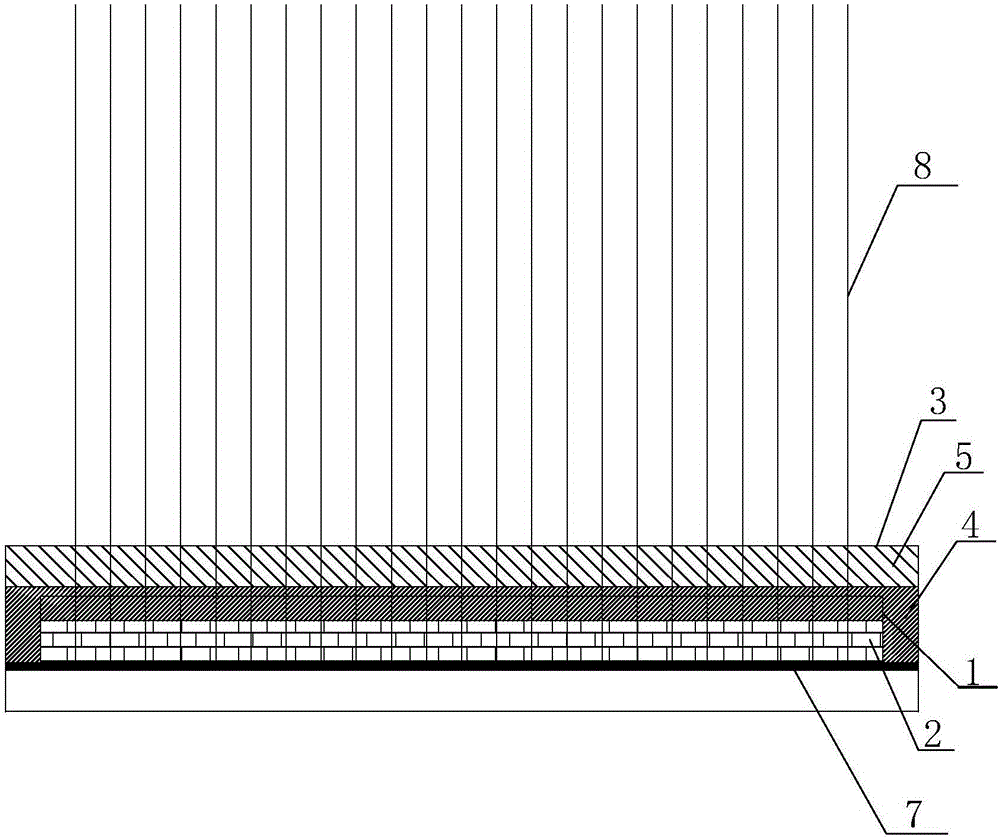

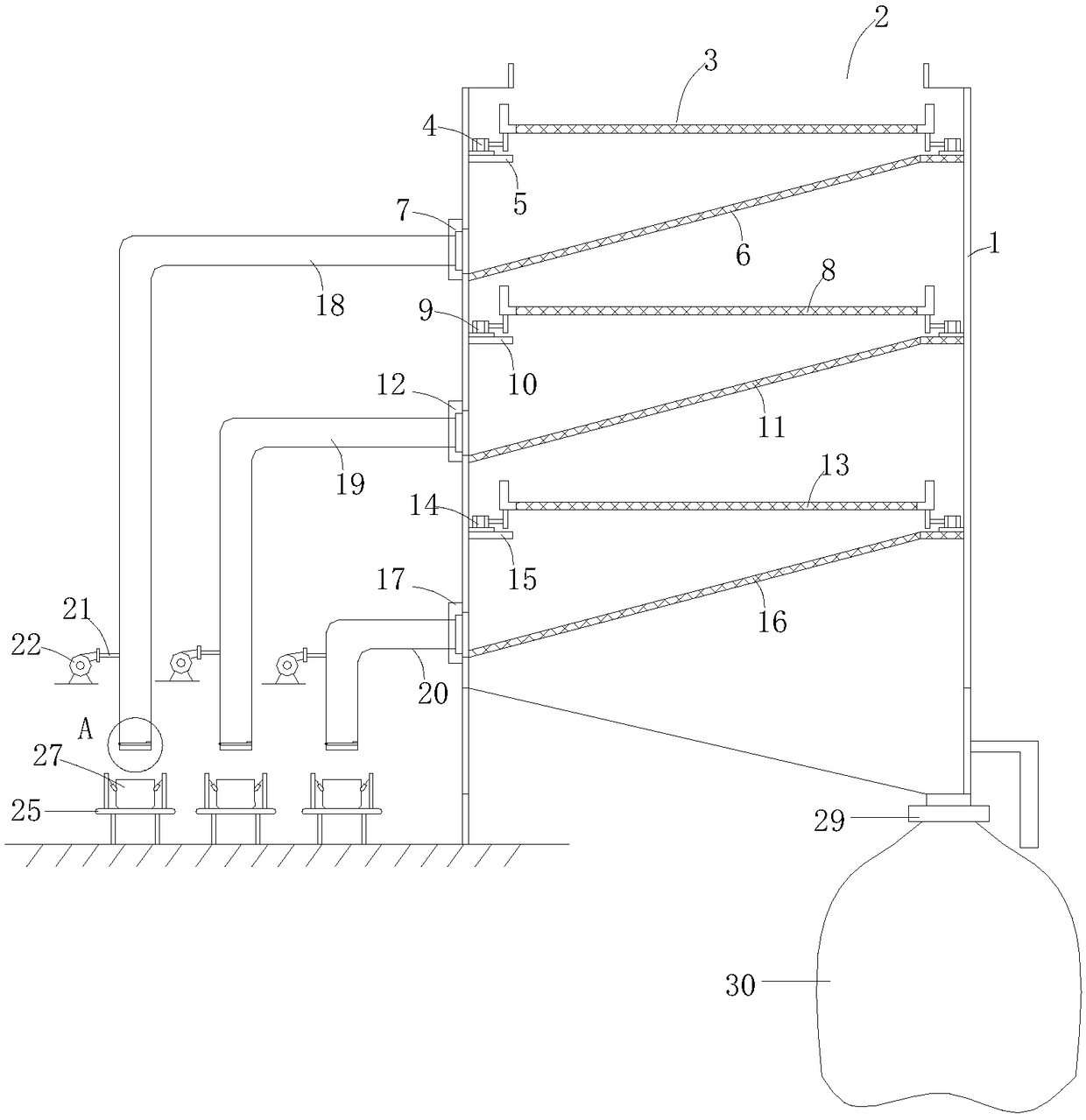

Flaky curtain type membrane packaging and leaking stoppage process

ActiveCN106178958AGuaranteed packaging efficiencySolve the leakage problemSemi-permeable membranesEngineeringWater pipe

The invention relates to the technical field of membrane separation and particularly relates to and discloses a flaky curtain type membrane packaging and leaking stoppage process. The flaky curtain type membrane packaging and leaking stoppage process includes the following steps of pre-packaging, wherein the lower ends of membrane filaments are cut to be flat, holes are blocked, the membrane filaments are vertically arranged in an open packaging box, first glue layer liquid is poured, and standing for curing is carried out; secondary packaging, wherein the membrane filament holes in the end face of the packaging box are cut open, the packaging box is inserted into a step inside a water collecting pipe and is sealed and bound, second glue layer liquid is poured on a first glue layer, and standing for curing is carried out; forming of a protective layer, wherein third glue layer liquid continues to be poured, and standing for curing is carried out; leaking stoppage, wherein gas leakage detection is carried out, cutting off is carried out at a leaking point, pyrocondensation materials are sleeved with the two ends, heating is carried out, leakage detection is carried out again till no abnormality exists, and a finished flaky curtain type membrane is prepared. According to the flaky curtain type membrane packaging and leaking stoppage process, through three times of glue layer pouring, packaging efficiency is guaranteed, the problem of leaking points caused by root filament breakage is effectively solved, packaging quality is guaranteed, packaging is attractive and free of flaws and knotting, cost is low, efficiency is high, and the process is suitable for volume production.

Owner:HANGZHOU CREFLUX MEMBRANE TECH

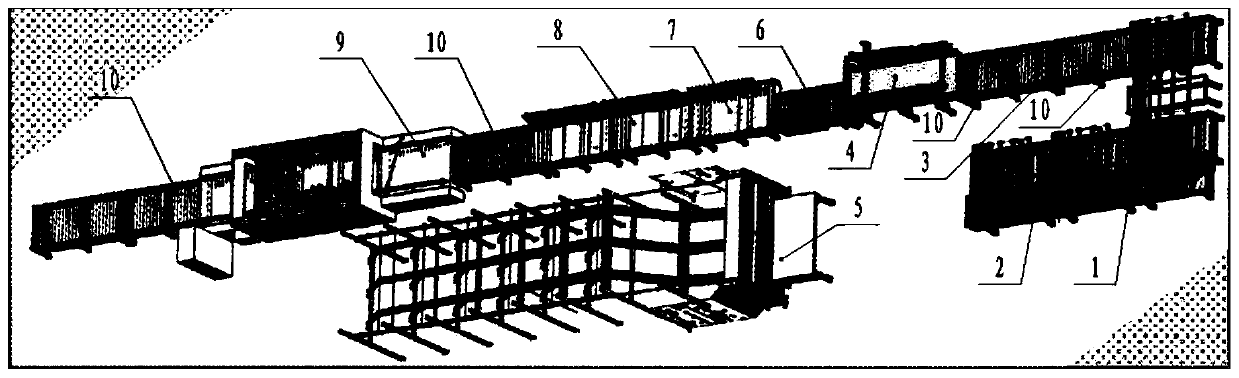

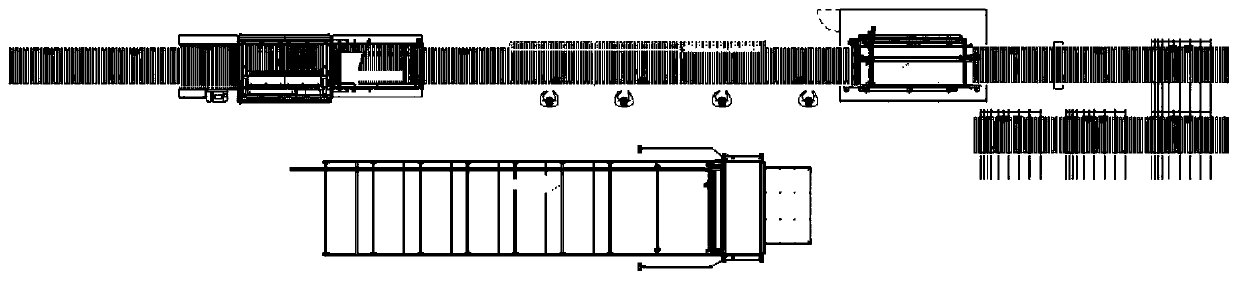

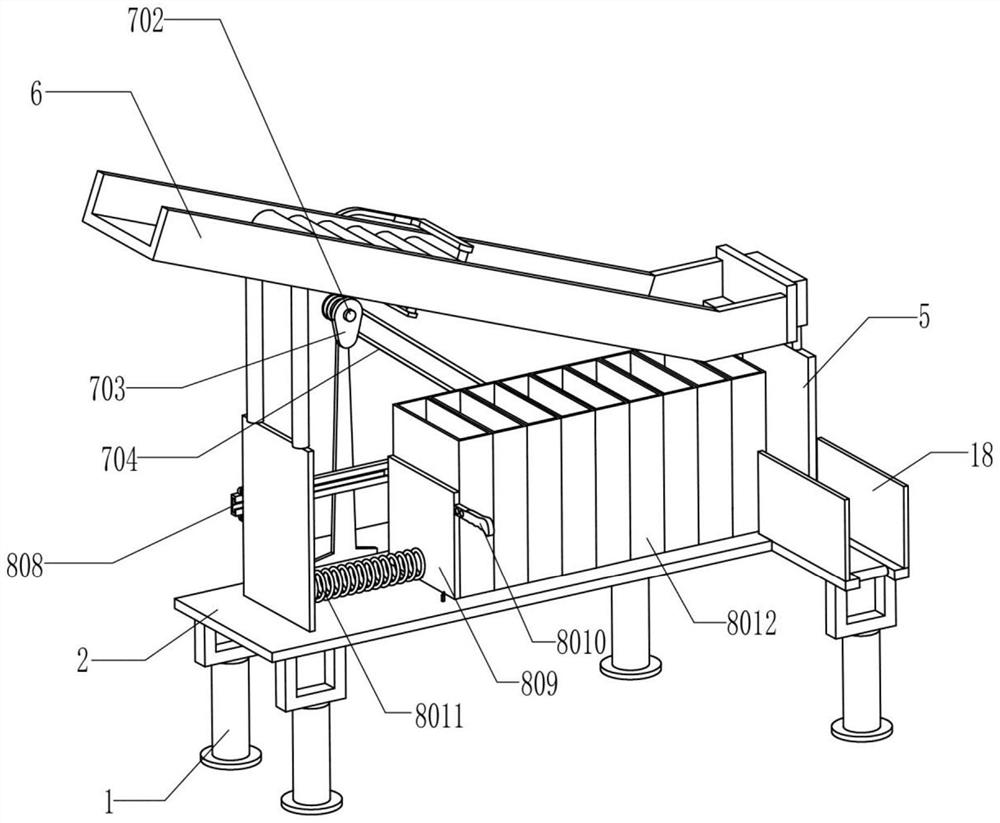

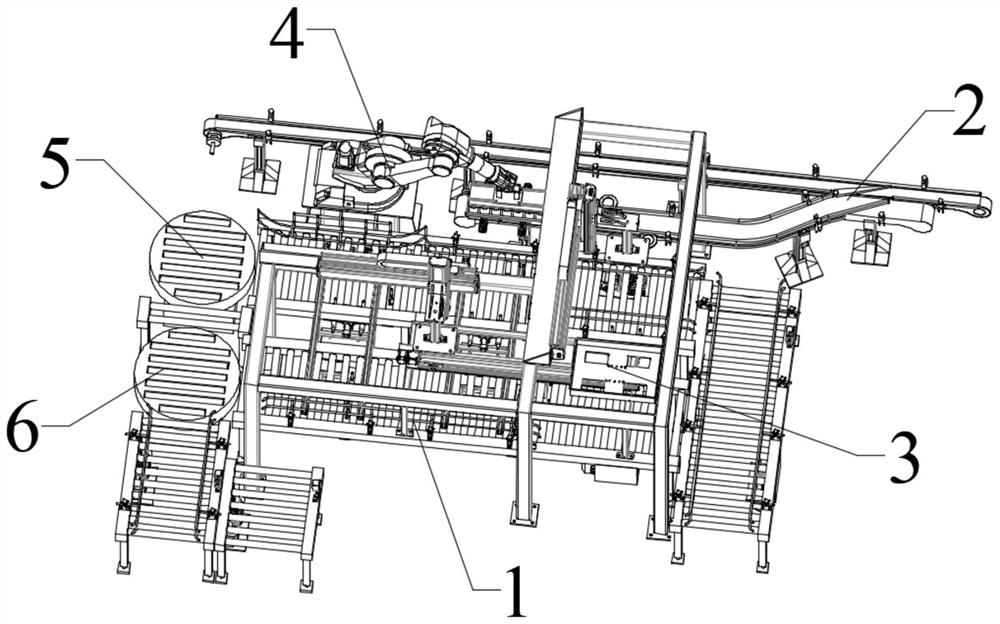

Full-automatic detection and packaging system for circular dinner plate and detection and packaging method

PendingCN110861811AImprove securityImprove efficiencyPackaging automatic controlPackaging machinesProcess engineeringManufacturing line

The invention discloses a full-automatic detection and packaging system for a circular dinner plate. The full-automatic detection and packaging system comprises a circular dinner plate full-automaticdetection packaging production line and a boxing packaging production line, wherein the circular dinner plate full-automatic detection packaging production line comprises a control box, a circular dinner plate splitting and feeding device, a weighing device, a dust removal device, a disinfection device, a visual detection device, an automatic stacking device and a packaging bag automatic packing device. The invention further discloses a detection and packaging method. According to the full-automatic detection and packaging system, the procedures of automatic sorting separation feeding, weighing detection, dust removal treatment, disinfection treatment, appearance detection, unqualified and qualified product sorting and qualified product automatic bagging packaging and boxing are integrated, the detection packaging efficiency and the product detection qualification rate are improved, the labor intensity of workers is reduced, the hygiene standards of products is improved, and the follow-up use of the products can be ensured; and the system can be used for detecting and packaging of the products with various specifications, the applicability is high, and the requirements of existingautomation and high-precision detection and packaging can be met.

Owner:GUANGDONG INTELLIGENT ROBOTICS INST +1

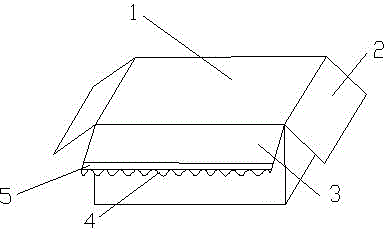

Packaging carton and packaging method thereof

PendingCN105083686APackage structure is simpleEasy to operateWrapper twisting/gatheringRigid containersCartonEngineering

The invention discloses a packaging carton and a packaging method thereof, and belongs to the technical field of packaging materials. The packaging carton comprises a box body of a cuboid structure. The top and the bottom of the box body are each provided with two long edges and two short edges. Adhesive sticker tape is pasted on the side faces of the long edges. The length of the adhesive sticker tape is at least 2 / 3 of the length of the long edges. The lower half portions of stickers on the adhesive sticker tape are attached to base hands. The upper half portions of the stickers are each of a corrugated structure. The short edges of the box body are folded, the long edges are then folded, the stickers of the adhesive sticker tape are each arranged into a vertical structure, and the long edges and the short edges of the box body are bonded through the adhesive sticker tape. On one hand, the carton is prevented from being damaged when packaged or detached, and the carton can be recycled; and on the other hand, the length of the adhesive sticker tape of the packaging carton can be changed according to requirements of different objects, the application range of the packaging carton is widened, quite high flexibility is achieved, and cost is saved.

Owner:KUNSHAN JIAMEI XINGYE ELECTRONICS MATERIALS

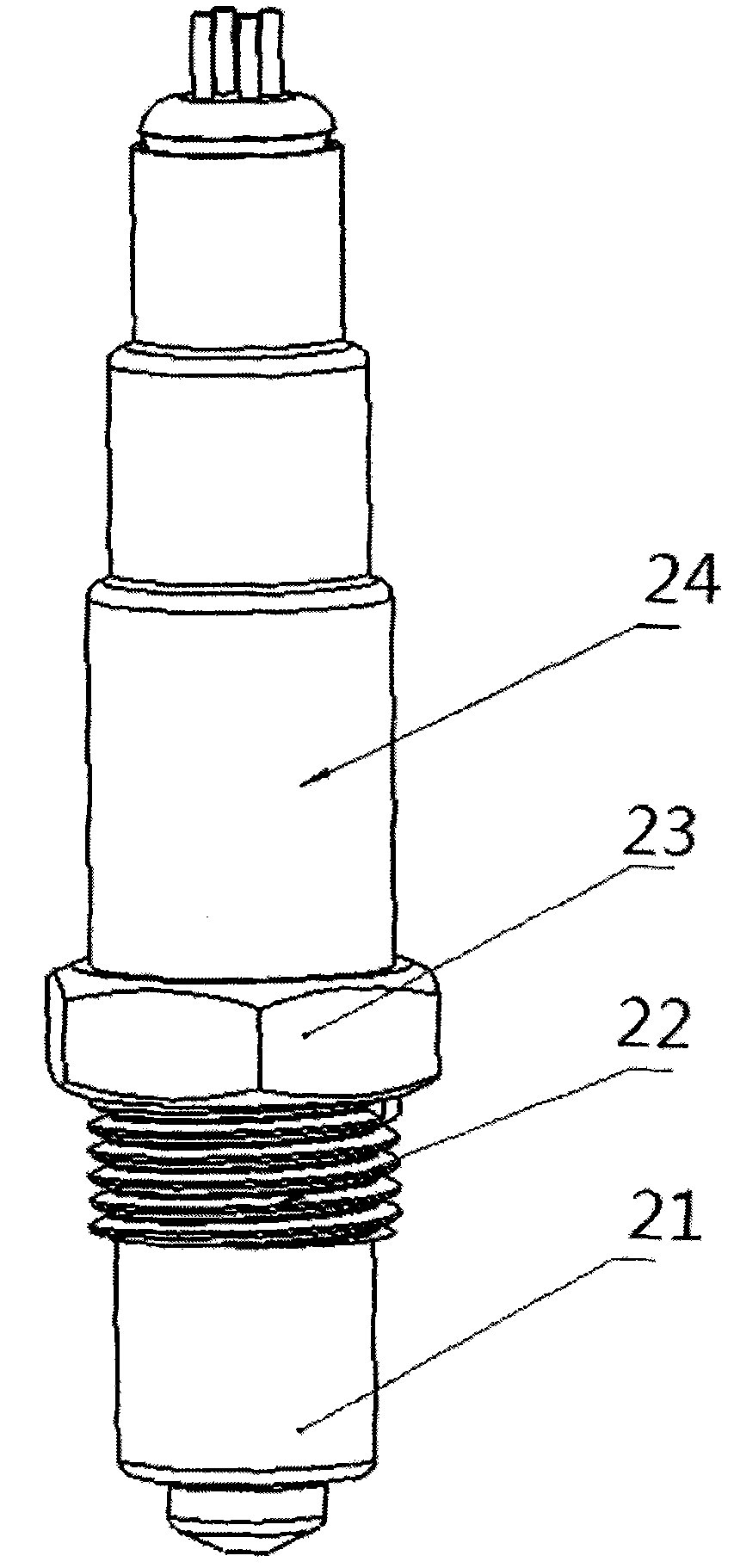

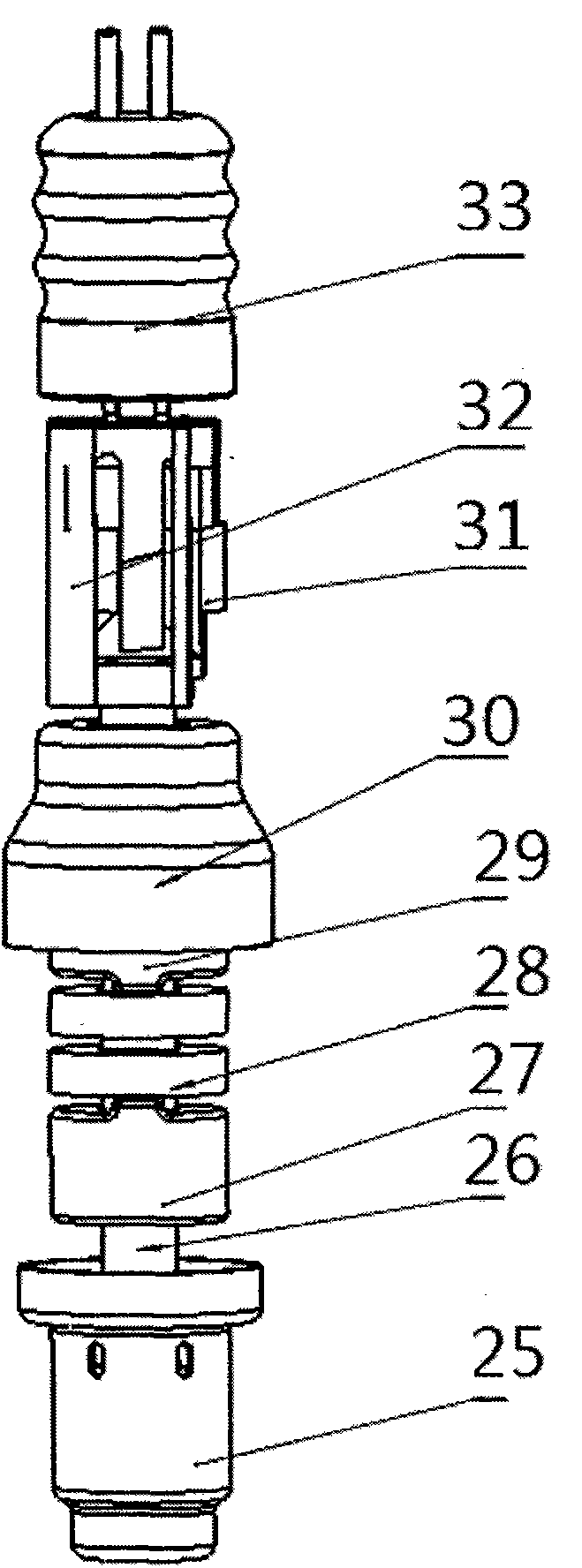

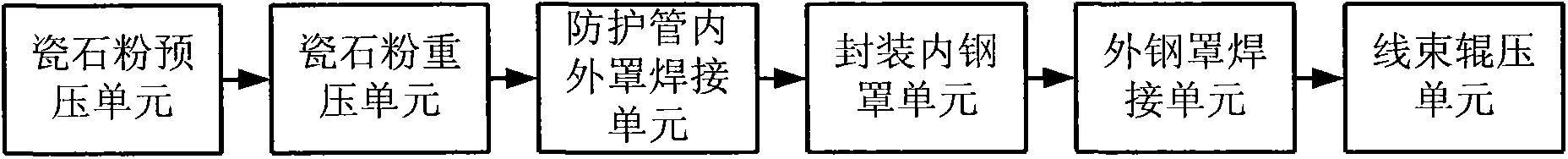

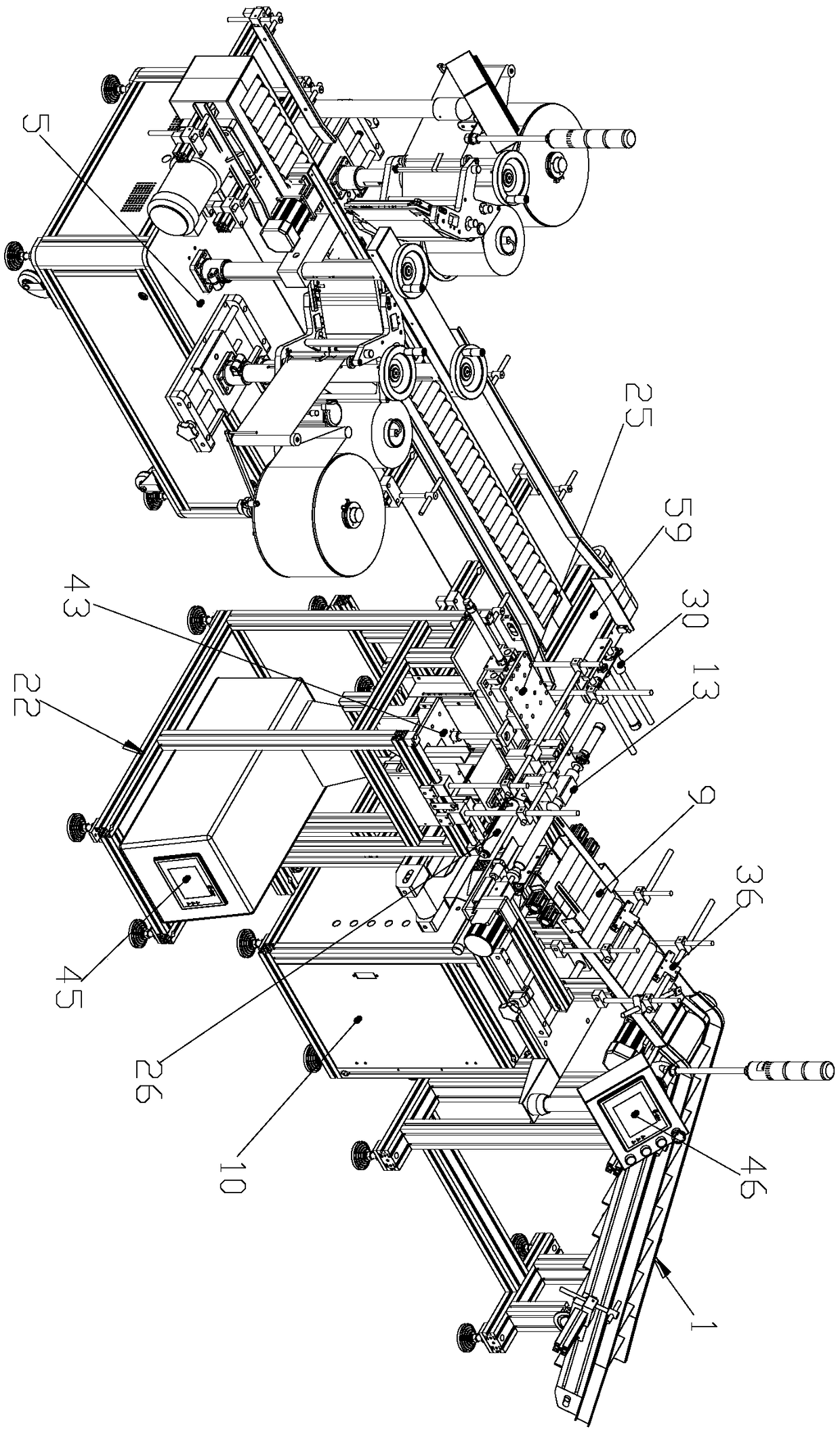

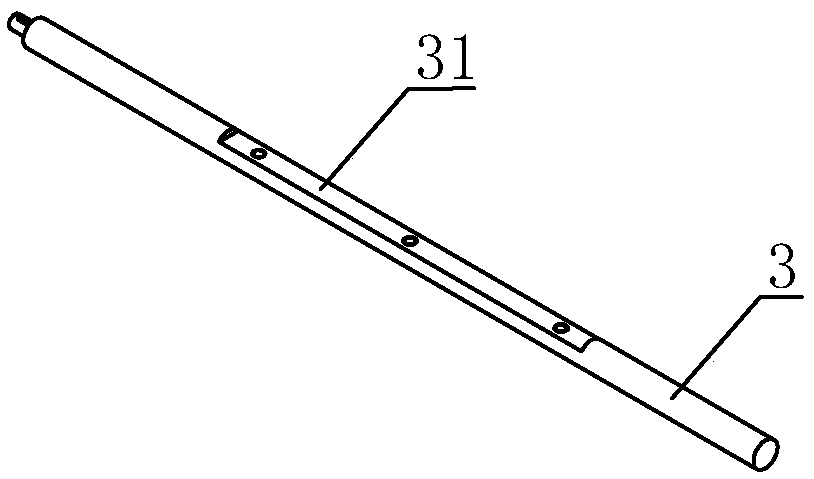

Automatic production line device for packaging oxygen sensor

ActiveCN103949891ARealize the assemblyIn line with the status quo of production technologyOther manufacturing equipments/toolsProduction lineOxygen sensor

The invention provides an automatic production line device for packaging an oxygen sensor. The automatic production line device comprises a China stone powder pre-pressing unit, a China stone powder repressing unit, a protective inner and outer cover welding unit, an inner steel cover packaging unit, an outer steel cover welding unit and a wire harness rolling unit, wherein the structures of the protective inner and outer cover welding unit and outer steel cover welding unit are the same, a laser beam is used for welding a protective pipe inner cover, a protective pipe outer cover and an outer steel cover with a hexagonal base together so as to protect an interior sensor chip. According to the automatic production line device, the units are sequentially connected according to the assembling technology of the oxygen sensor, and semi-automatic and full-automatic assembling of the oxygen sensor product is realized, so that the product quality can be stabilized and improved, the working conditions are improved, the occupied area for production is reduced, the production cost is reduced, and the production cycle is shortened.

Owner:WENZHOU UNIVERSITY

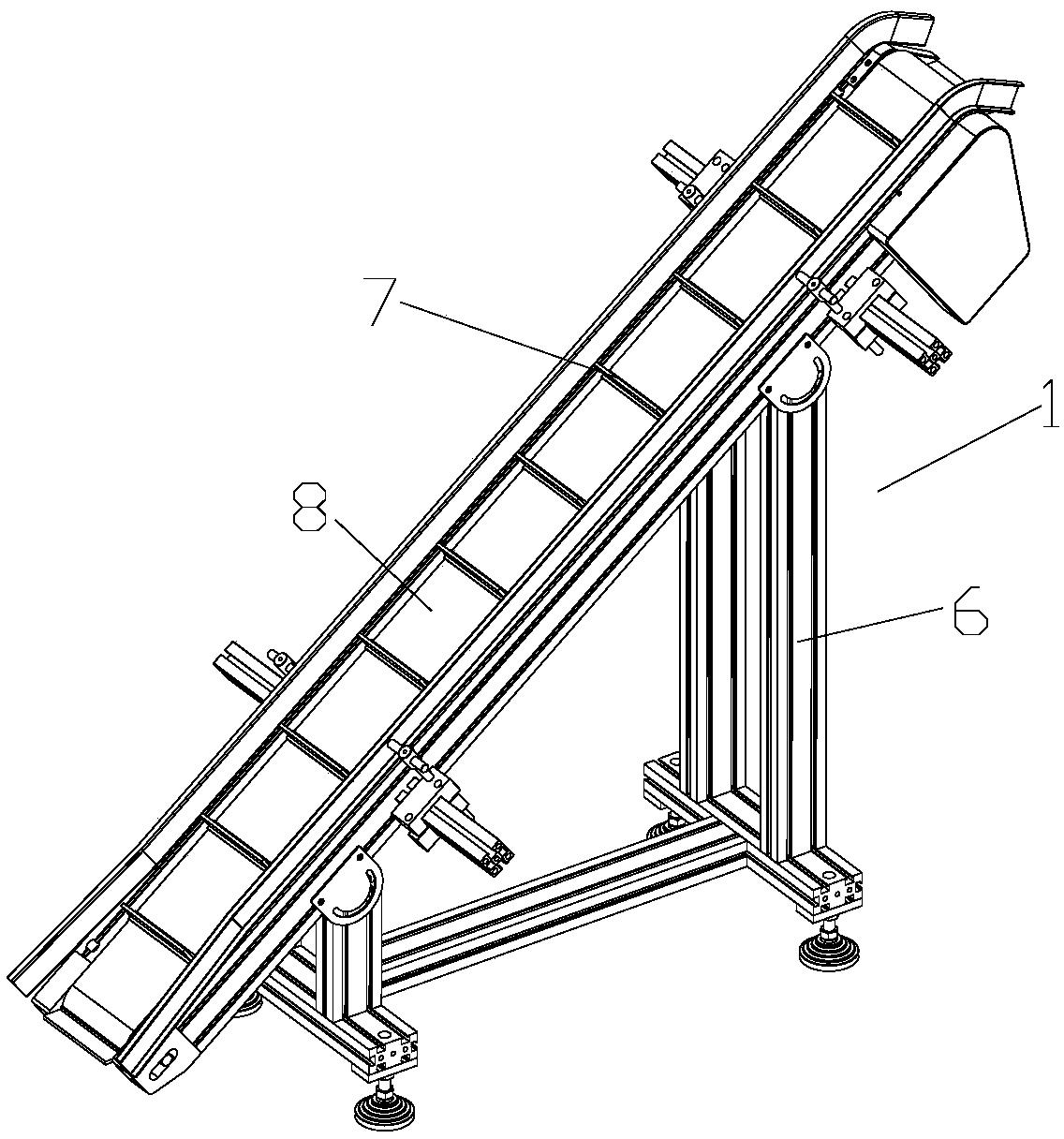

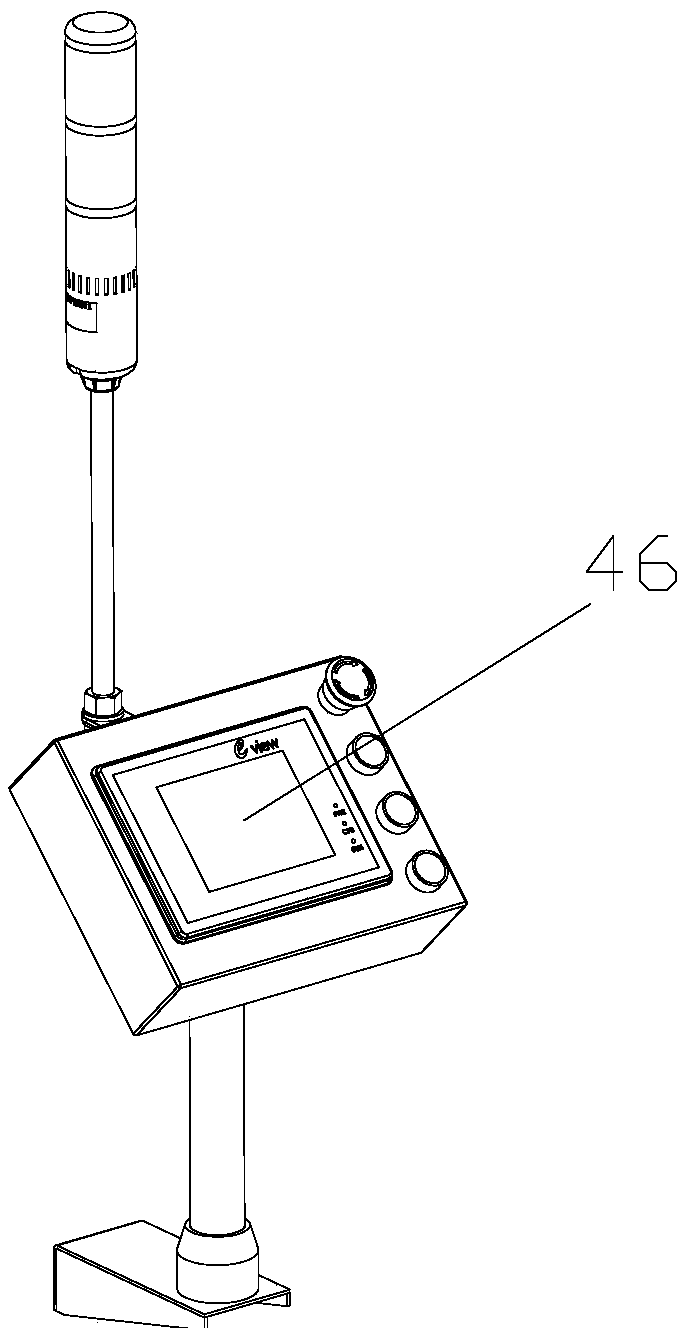

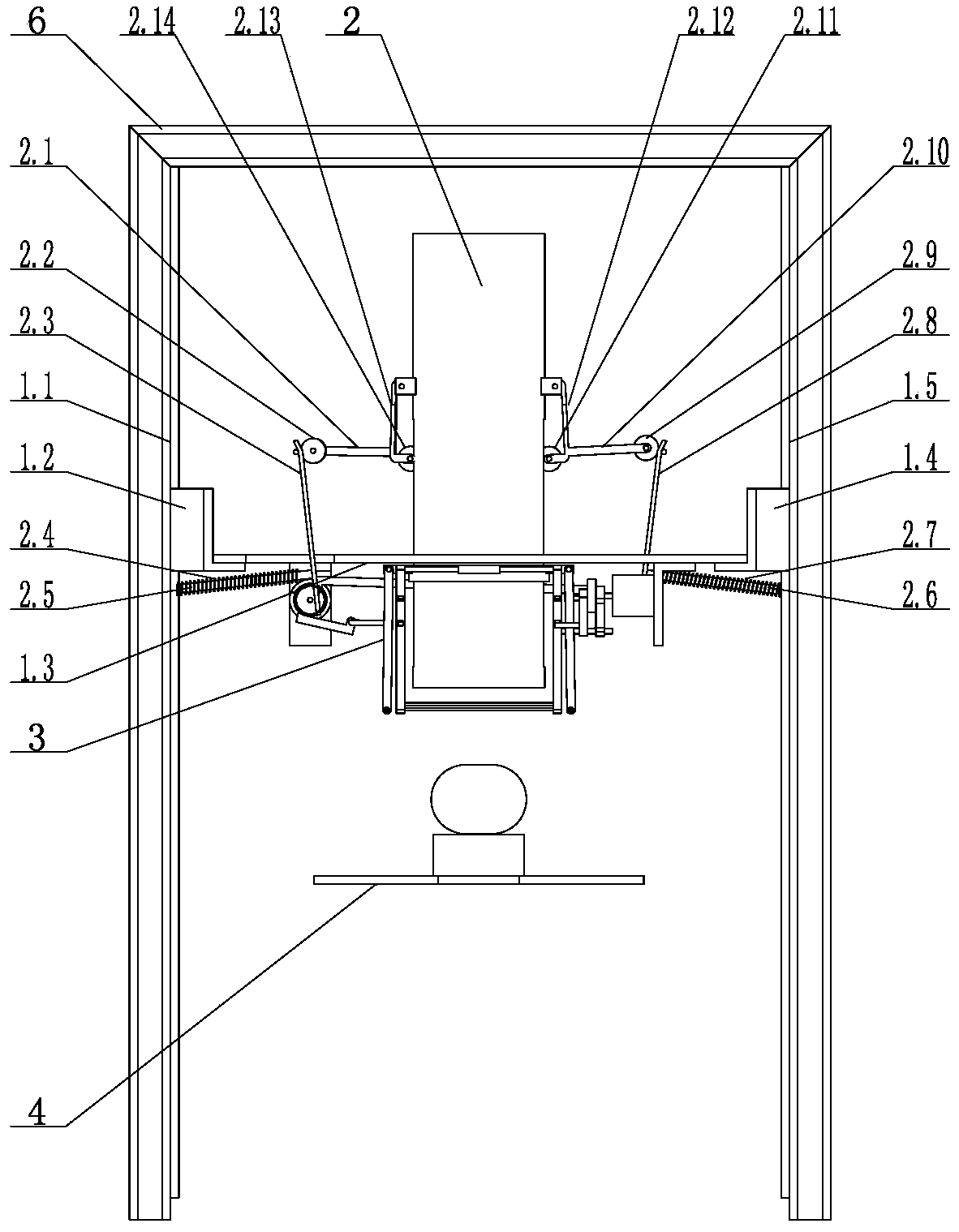

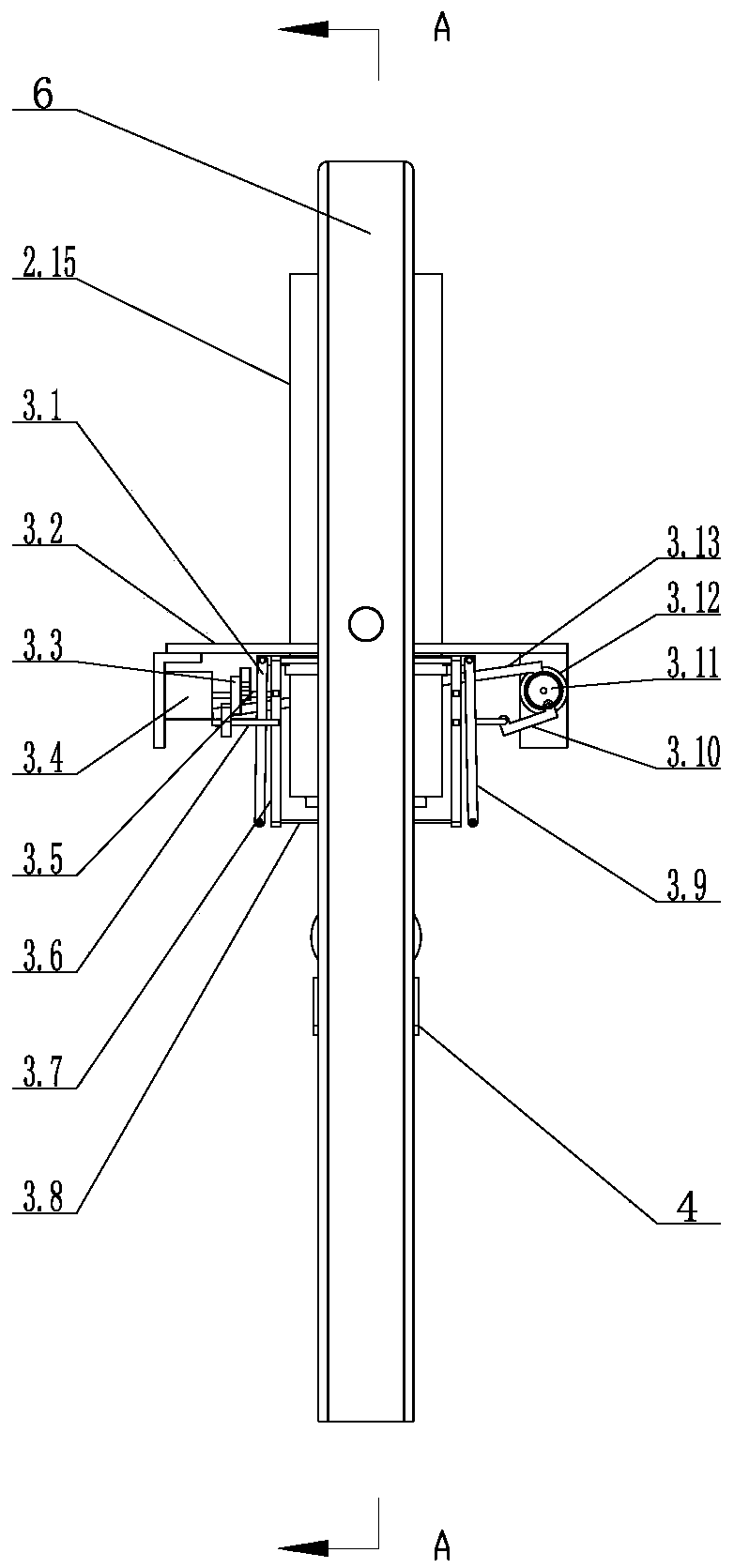

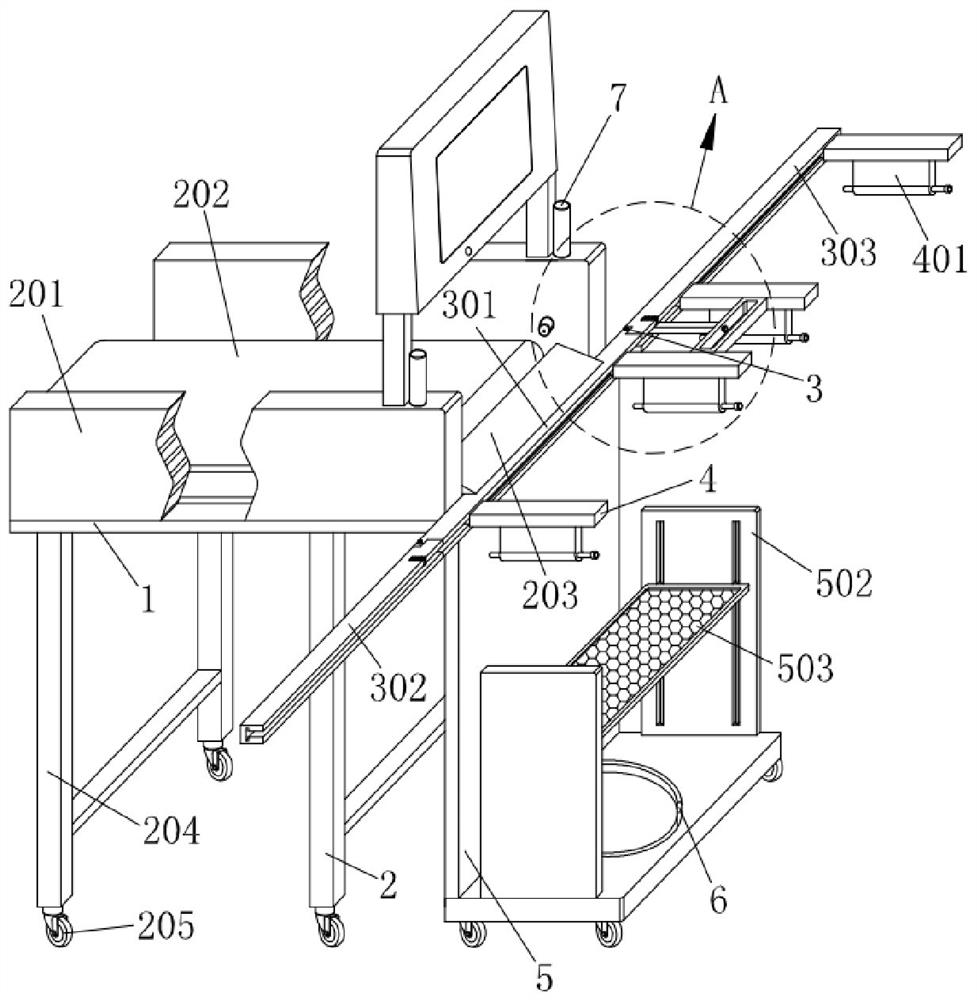

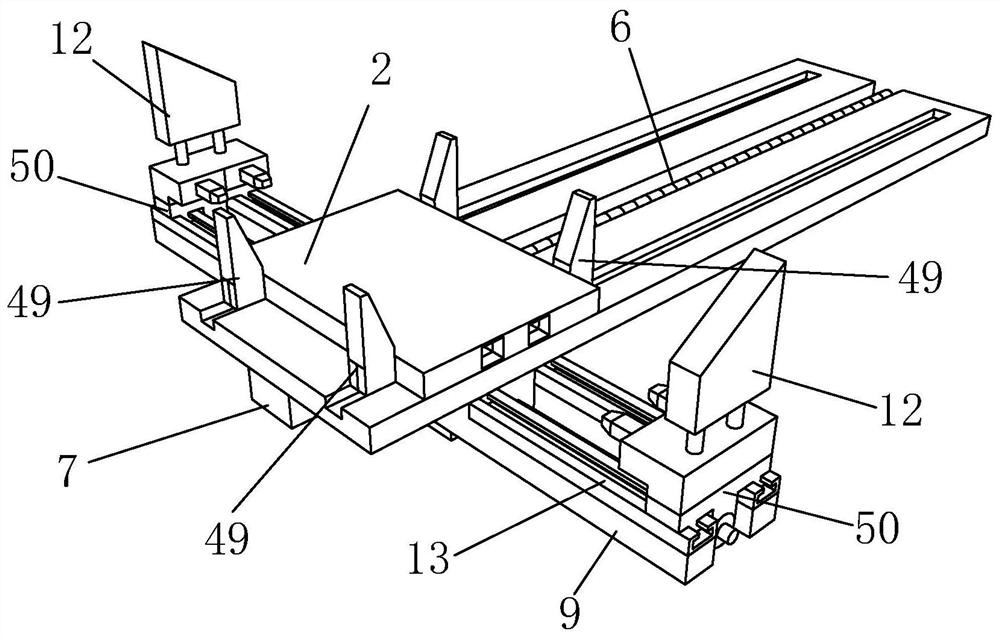

Packaging production line and packaging method for freshness protection packages

PendingCN109279126AImprove packaging efficiencyFully automatedLabelling machinesProduction lineEngineering

The invention discloses a packaging production line and a packaging method for freshness protection packages. The packaging production line comprises a conveying device, a discharging positioning device, a curved face labeling device, a transition conveying device and a side face labeling device. Unpackaged rolled freshness protection packages at the bottom end are sequentially conveyed to the topend. The discharging positioning device is in butt connection with the top end of the conveying device and conveys single rolled freshness protection packages to the label rolling position in sequence, and the rolled freshness protection packages at the label rolling position are clamped and rotated. The curved face labeling device is arranged at the downstream position of the discharging positioning device, and in the rotating process of the rolled freshness protection packages, labels are conveyed to the label rolling position to enable the labels to be stuck to the rolled freshness protection packages along with rotation of the rolled fresh protection packages. The transition conveying device is arranged at the labeling position and conveys the rolled freshness protection packages. Theside face labeling device is arranged at the downstream position of the curved face labeling device and carries out side face labeling on the curved-face-labeled rolled freshness protection packages.According to the packaging production line, automatic packaging of the freshness protection packages from feeding to positioning to labeling is achieved, the packaging efficiency is improved, and thelabor cost is reduced.

Owner:中山市信华智能自动化设备有限公司

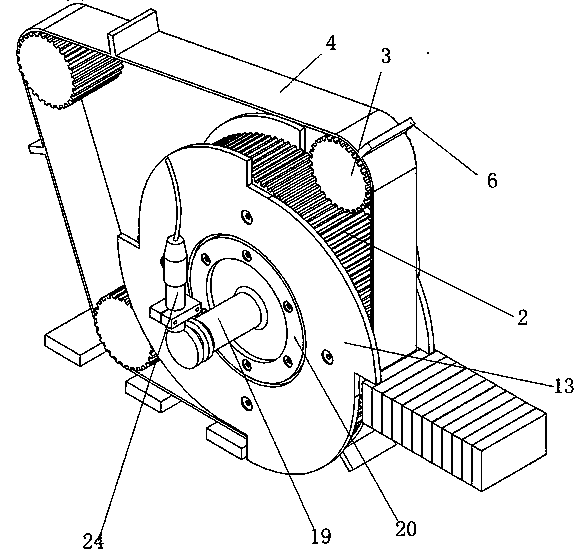

Fully automatic fruit foaming mesh belt packaging machine

InactiveCN109941493ARealize automatic supplyRealize automatic packaging and conveyingPackaging fruits/vegetablesEngineeringFully automatic

The invention discloses a fully automatic fruit foaming mesh belt packaging machine, and belongs to the field of fruit packaging equipment. The machine is characterized by comprising a rack and a transmission device, the transmission device comprises a conveying chain, the middle of the rack is provided with a fruit packaging position, and the conveying chain penetrates through the fruit packagingposition; a fixing holding chain plate is installed on the conveying chain; an upper sleeve mesh mechanism is arranged on the upper portion of the rack, and the upper sleeve net mechanism is arrangedabove the conveying chain; the upper sleeve net mechanism is driven by the sleeve net power mechanism to move up and down. According to the machine, a mechanical principal ingeniously utilized to utilize energy consumption power driving devices as less as possible, various functions of the conveying, clamping, tightening, cutting, bag dragging and the like of the foaming mesh belt are achieved, and the automatic supplying and automatic packaging conveying of the mesh belt are completely achieved. The machine has the advantages that the automation level is high, and the packaging efficiency and quality can be ensured.

Owner:成壮之

Automated moxa cone packaging machine

PendingCN110683119AGuaranteed efficiencyGuaranteed tightnessWrappers shrinkageWrapping material feeding apparatusEngineeringHot blast

The invention discloses an automated moxa cone packaging machine. The automated moxa cone packaging machine comprises a rack. A loading belt conveyor, a film feeding mechanism, a material placing mechanism, a material transferring mechanism, a hot plastic sealing mechanism and a feeding belt conveyor are arranged on the rack. The hot plastic sealing mechanism comprises a lower heating assembly andan upper heating assembly which are arranged on the rack. The lower heating assembly comprises a lower heating plate support arranged on the rack. A lower heating plate is arranged on the lower heating plate support. The upper heating assembly comprises an upper heating support, a first telescopic cylinder and an upper heating plate. The upper heating support is arranged in the position, corresponding to the position right above the lower heating plate, in the rack. The first telescopic cylinder is arranged on the upper heating support downwards. The lower heating plate is arranged at the telescopic end of the first telescopic cylinder. A hot wind output assembly is arranged on the rack. An annular air outlet is formed in the rack. A tapered type air bin is arranged in the position, corresponding to the position right under the annular air outlet, in the rack in a covering manner. An air inlet is formed in the bottom of the air bin. The air inlet is connected with a hot wind blower through a pipeline. The automated moxa cone packaging machine has the integrated function of automatic loading, tray placing, packaging and feeding and the advantage of being high in production efficiency.

Owner:南阳顺天祥艾业有限公司

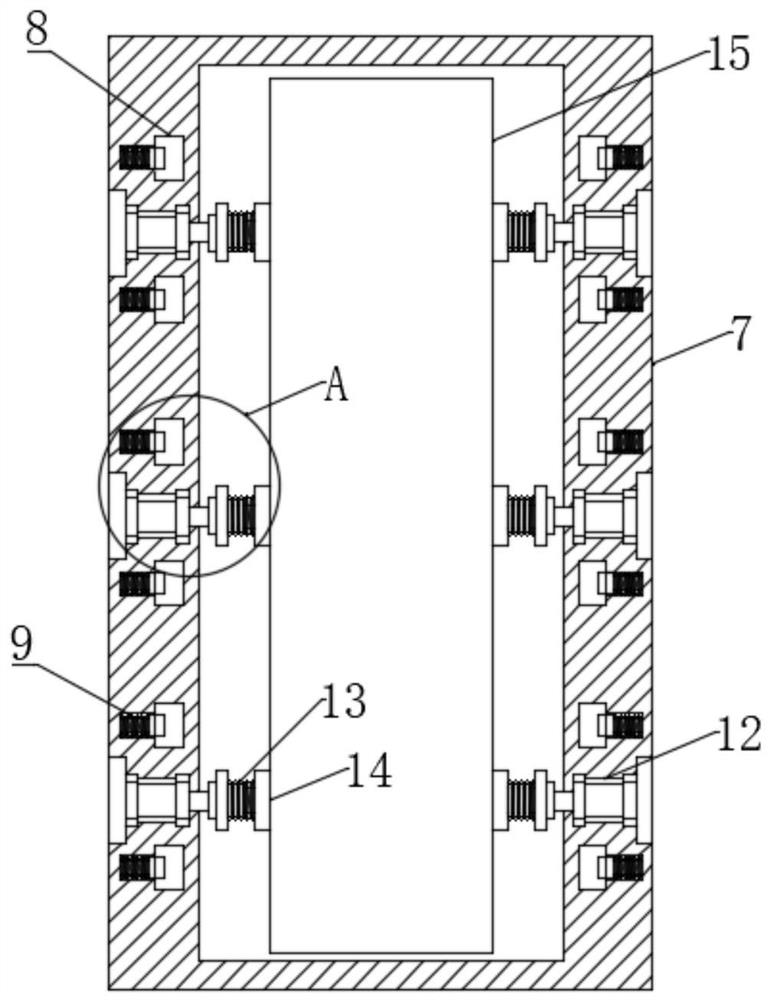

Box sealing and packaging platform based on intelligent automation

InactiveCN112278438AGuaranteed packaging efficiencyGuaranteed packaging effectWrapper twisting/gatheringAdhesive beltStructural engineering

The invention discloses a box sealing and packaging platform based on intelligent automation, and relates to the technical field of intelligent equipment. The box sealing and packaging platform comprises supporting seats; a power transmission belt is arranged between the two supporting seats; bearing frames are arranged on the two opposite sides of the power transmission belt; the two bearing frames are correspondingly fixed at the upper parts of the two supporting seats; a rotary clamping assembly is arranged between the two bearing frames; the rotary clamping assembly is used for adjusting the position of a packaging box; a pressing assembly is arranged above the rotary clamping assembly; the pressing assembly is used for pressing an upper cover plate of the packaging box; supporting columns are vertically fixed to the two opposite sides of the two bearing frames; the upper ends of the four supporting columns are connected through a fixing frame; an adhesive tape mounting rod and a gluing assembly are arranged on the inner side of the fixing frame; and the gluing assembly is used for adhering an adhesive tape to the packaging box. The box sealing and packaging platform is reasonable in structural design and convenient to use, the box sealing and packaging efficiency and effect are effectively guaranteed, and the high market application value is achieved.

Owner:马鞍山昌亚智能科技有限公司

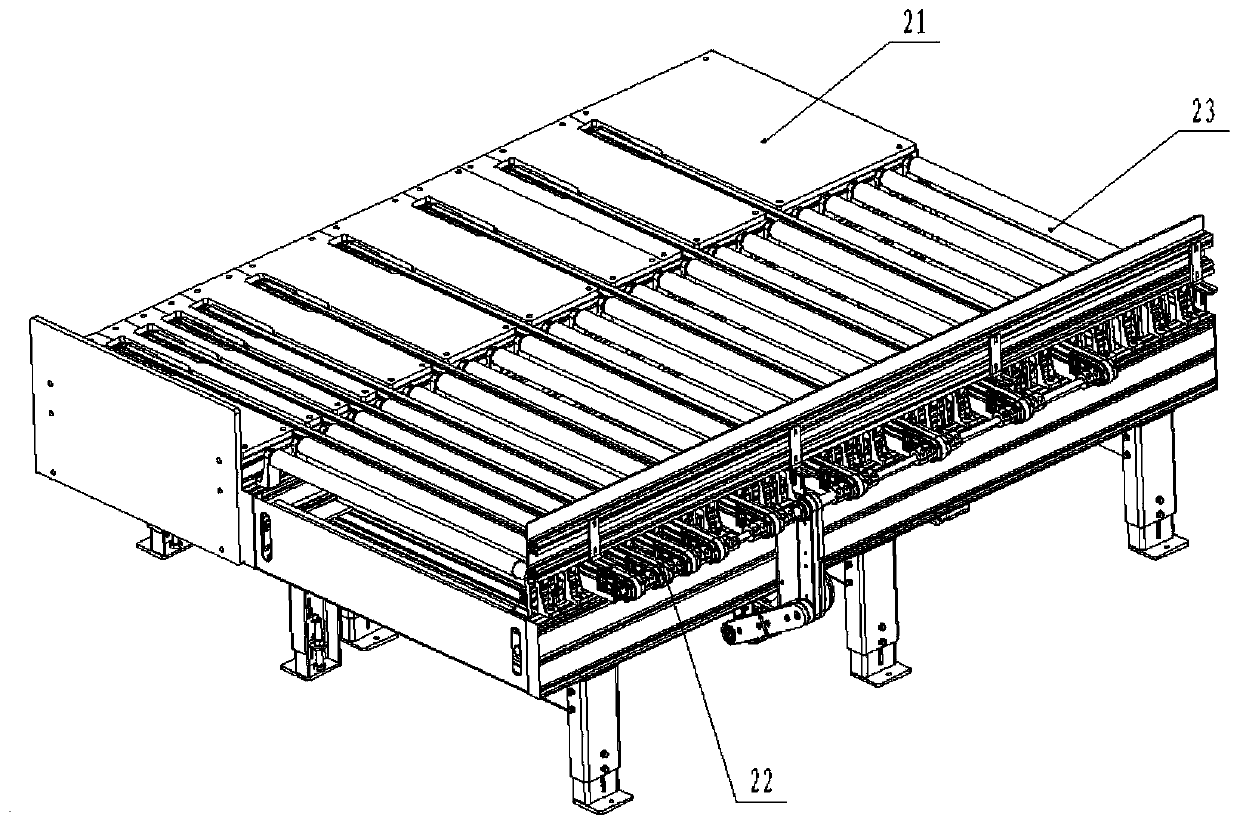

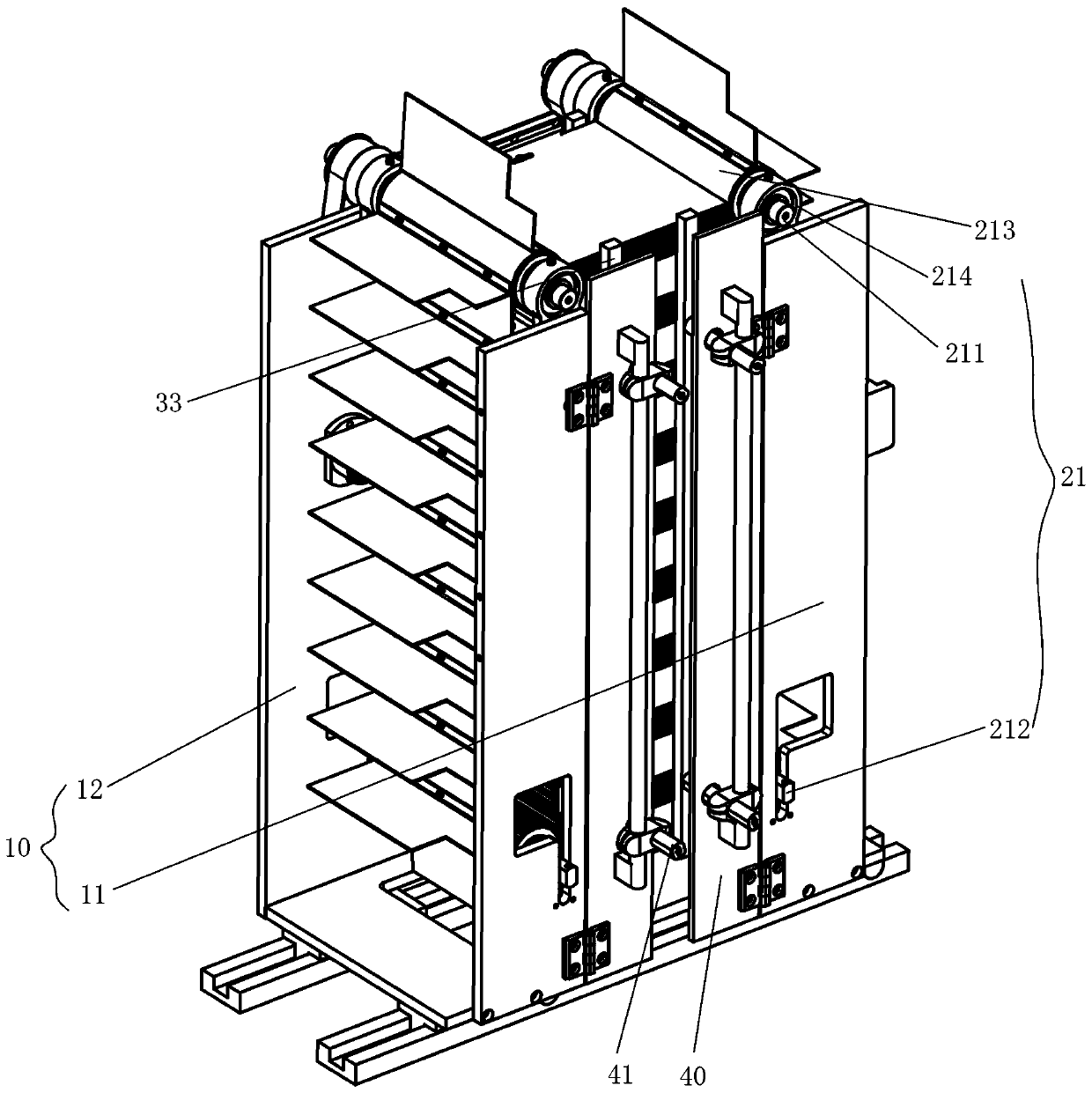

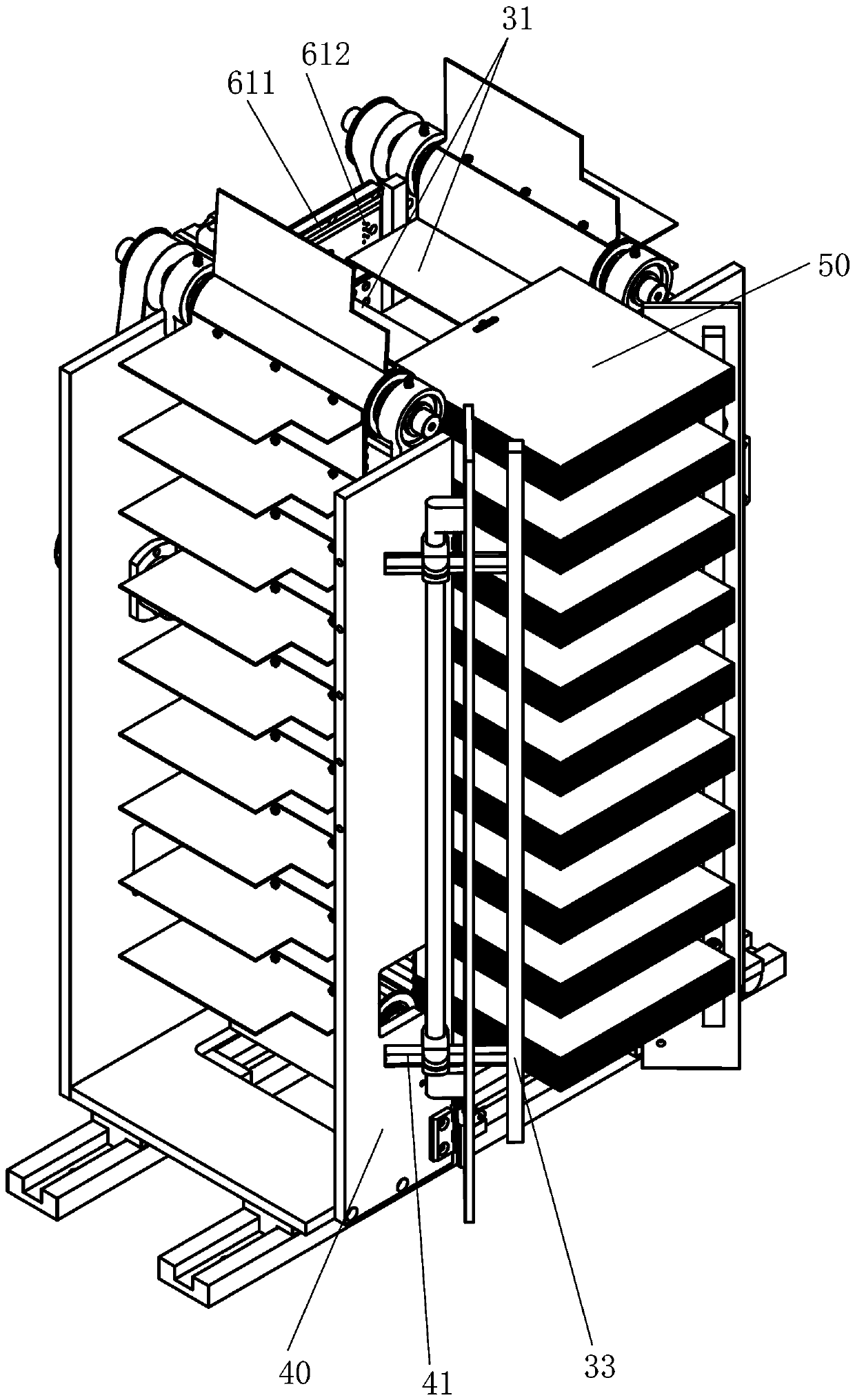

Intelligent automatic packaging line and method for customized furniture

InactiveCN111003267AQuality improvementGuaranteed packaging efficiencyPackaging automatic controlHot meltTransfer line

The invention discloses an intelligent automatic packaging line for customized furniture production, and relates to the technical field of furniture packaging and transportation. The intelligent automatic packaging line comprises a roller conveying line, and an intelligent bag folding table, an automatic pre-measuring machine, an intelligent squaring measuring machine, a full-automatic corrugatedpaper cutting machine, a box conveying machine, a cover turning machine, a pre-folding machine and a full-automatic hot melt adhesive box sealing machine which are sequentially arranged in the conveying direction. The packaging line has an automatic operation function, so that the labor cost is saved, the labor intensity of workers is greatly reduced, and the line also has the advantage of savingspace.

Owner:宁玢菲

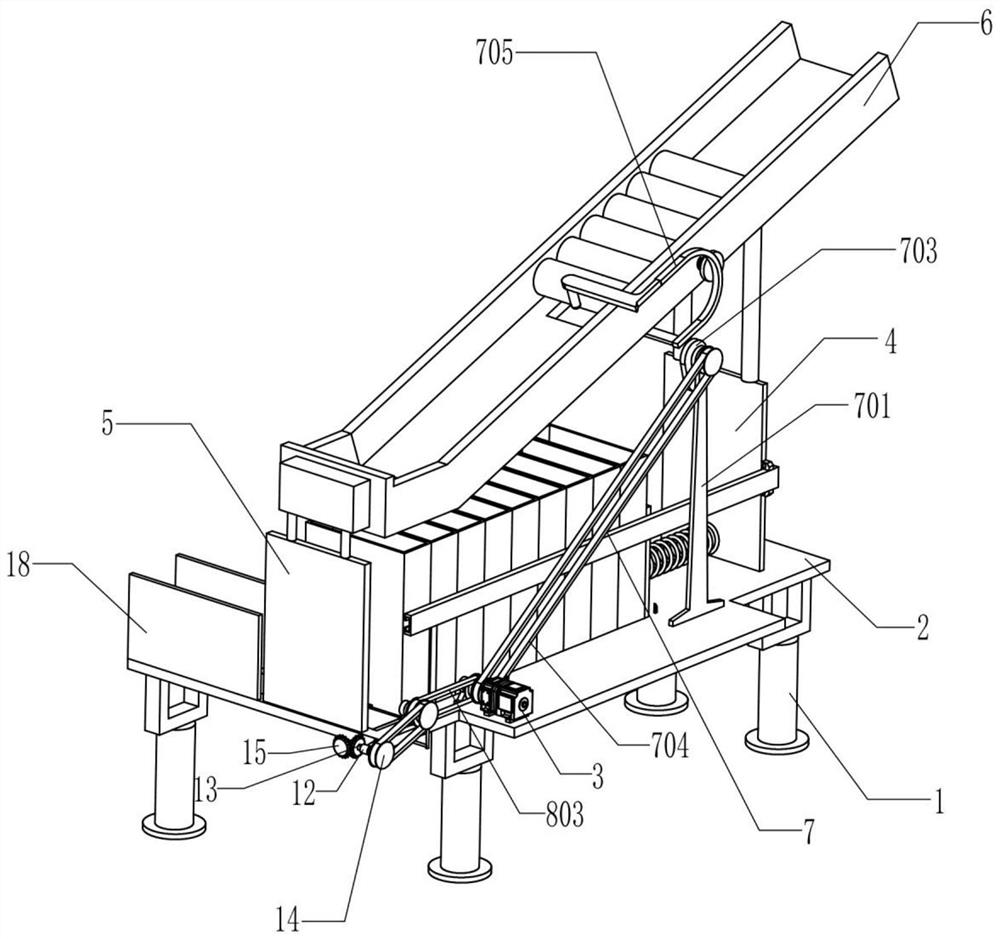

Intermittent subpackaging equipment for ternary lithium batteries

ActiveCN111674625AIntegrity guaranteedGuaranteed aestheticsPackagingPhysical chemistryElectrical and Electronics engineering

The invention relates to the technical field of lithium battery processing, in particular to intermittent subpackaging equipment for ternary lithium batteries. The invention aims to provide the intermittent subpackaging equipment for the ternary lithium batteries which can perform intermittent subpackaging operation on the ternary lithium batteries, reduce adverse effects caused by collision extrusion and impact force, ensure the integrity and the attractiveness of the ternary lithium batteries and maintains a rapid and continuous subpackaging function. The technical scheme is as follows thatthe intermittent subpackaging device for the ternary lithium batteries comprises a base, a mounting plate, a servo motor, a first supporting plate and the like; the mounting plate is fixedly arrangedat one end of the base; the servo motor is fixedly arranged on one side surface of the mounting plate; and the first supporting plate is fixedly arranged on one side face of the mounting plate. According to the intermittent subpackaging equipment for the ternary lithium batteries in the invention, a conveying frame and a lithium battery clearance falling device work in cooperation, so that intermittent subpackaging operation can be performed on the ternary lithium batteries, the damage to the ternary lithium batteries can be reduced, and the surface integrity of the ternary lithium batteries is ensured.

Owner:深圳市豫尚电子科技有限责任公司

Intelligent transportation packaging line

ActiveCN112977985AMeet the transmissionGuaranteed packaging efficiencyConveyor partsPackaging machinesElectric machineryEngineering

The invention discloses an intelligent transportation packaging line. A front conveying belt is arranged to convey workpieces to be packaged to a packaging position, a rear conveying motor provides power to convey the packaged workpieces in the front conveying belt to a packaging module, data transmitted by a visual detector are received and analyzed, the initial conveying speed of a front conveying motor and the initial conveying speed of the rear conveying motor are determined according to the determined packaging reference value of the workpieces to be packaged, when two or more packaged workpieces exist, a central control module compares the distance between the packaging position and the first packaged workpiece and the distance between the first packaged workpiece and the second packaged workpiece with a distance error, judges the packaging speed of the packaging position, and initially adjusts the speed of the front conveying belt, the central control module conducts secondary adjustment on the conveying speed of the front conveying belt according to the number of the packaged workpieces on a rear conveying belt, and therefore the conveying speed of the front conveying belt can better meet the requirement for conveying of the intelligent packaging line.

Owner:北京中都星徽物流有限公司

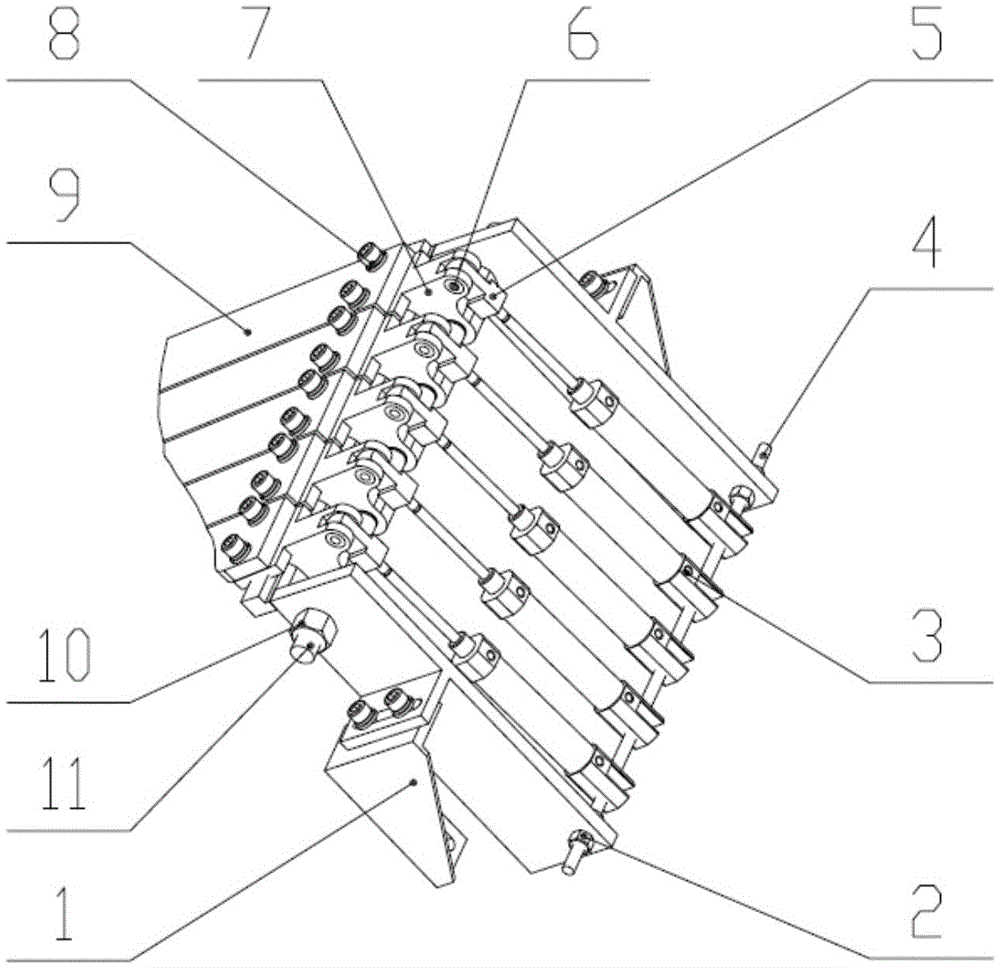

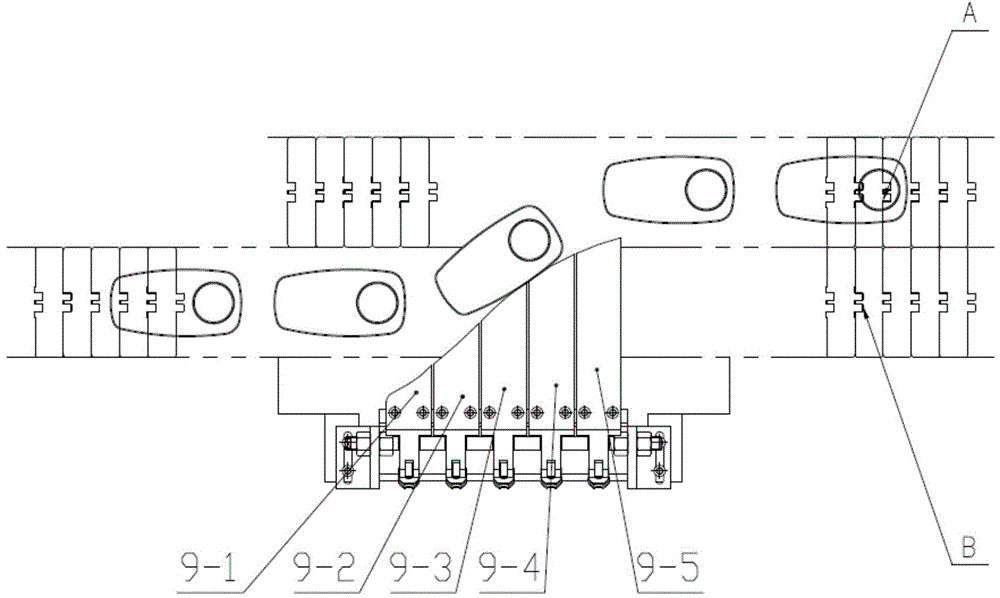

Multi-cylinder dynamic rejecting mechanism

InactiveCN104588333AGuaranteed packaging efficiencyGuaranteed speedSortingEngineeringMechanical engineering

Owner:BEIJING AREOSTANARD NEW TECH +2

Rice sorting and bag packaging mechanism

InactiveCN109317397AGuarantee quality and efficiencyGuaranteed packaging efficiencySievingGas current separationEngineering

Owner:浙江中兴粮油有限公司

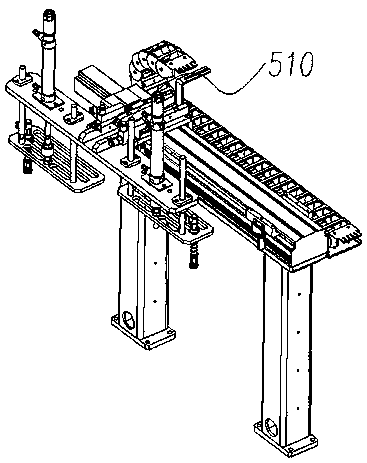

Bag stack conveying device and packaging machine

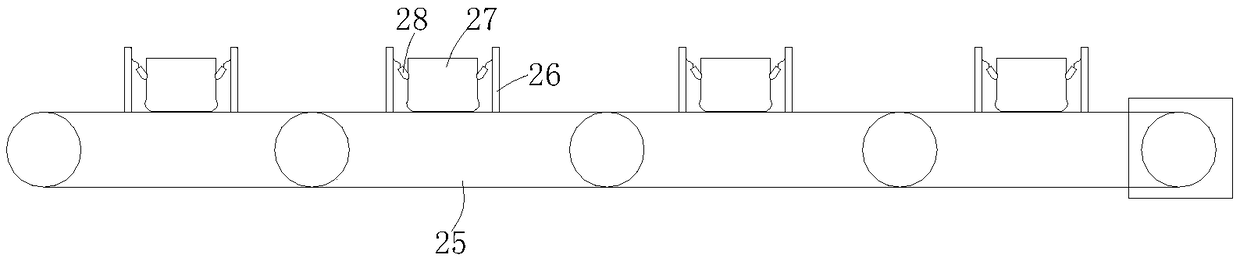

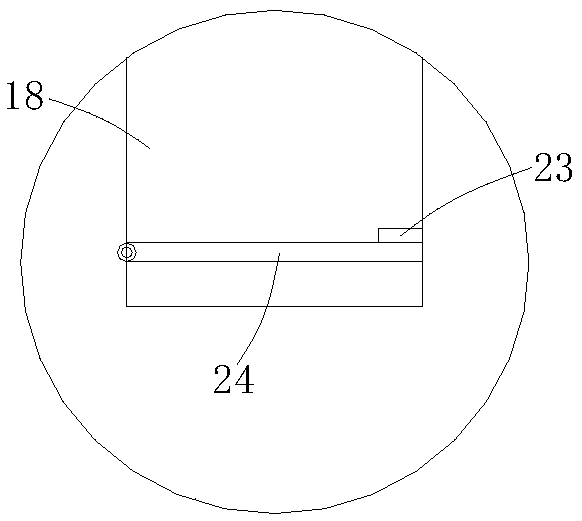

PendingCN108033066AImprove general performanceEasy to arrange and useConveyorsPackagingVertical planeEngineering

The invention provides a bag stack conveying device and a packaging machine. The bag stack conveying device comprises support seats which are symmetrically arranged left and right, a plurality of bagbins for containing bag stacks and a driving mechanism for driving each bag bin to circularly move to a bag taking position, the plurality of bag bins are aligned at the same vertical plane, and thedriving mechanism comprises two belt wheel assemblies which are arranged on the two supports in a one-to-one correspondence mode and a rotation driving device which is connected with the two belt wheel assemblies; a plurality of supporting plates are arranged on each of the two belt wheel assemblies, wherein the two supporting plates on the same horizontal plane form a bag-placing supporting plate, and a front protecting plate and a rear protecting plate are arranged between the two supports and are located outsides the supporting plates; and the front protecting plate, the rear protecting plate, the two belt wheel assemblies and the bag-placing supporting plates form the bag bins, the rear protecting plate is arranged on an opening and closing baffle plate, and the opening and closing baffle plate is hinged to the supports. According to the bag stack conveying device, a plurality of stations can be further arranged, so that packaging efficiency of the packaging machine is guaranteed,and occupied land space is saved.

Owner:XIAMEN GACHN TECH

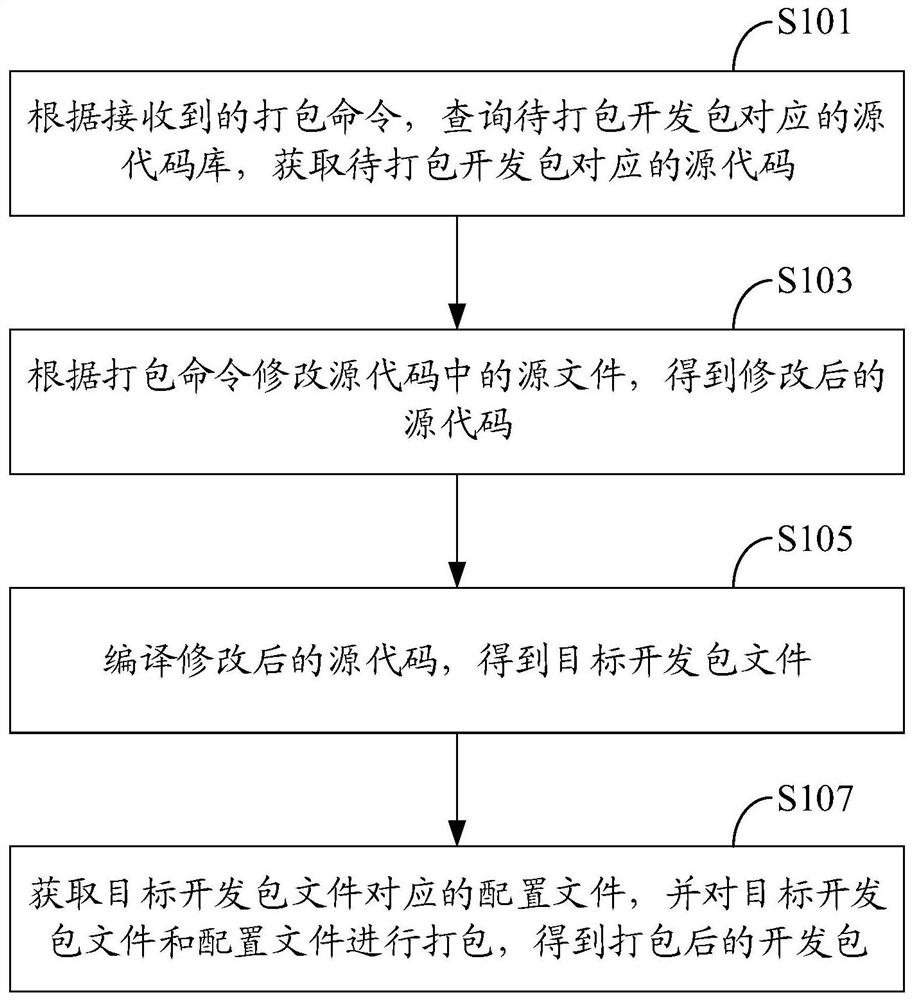

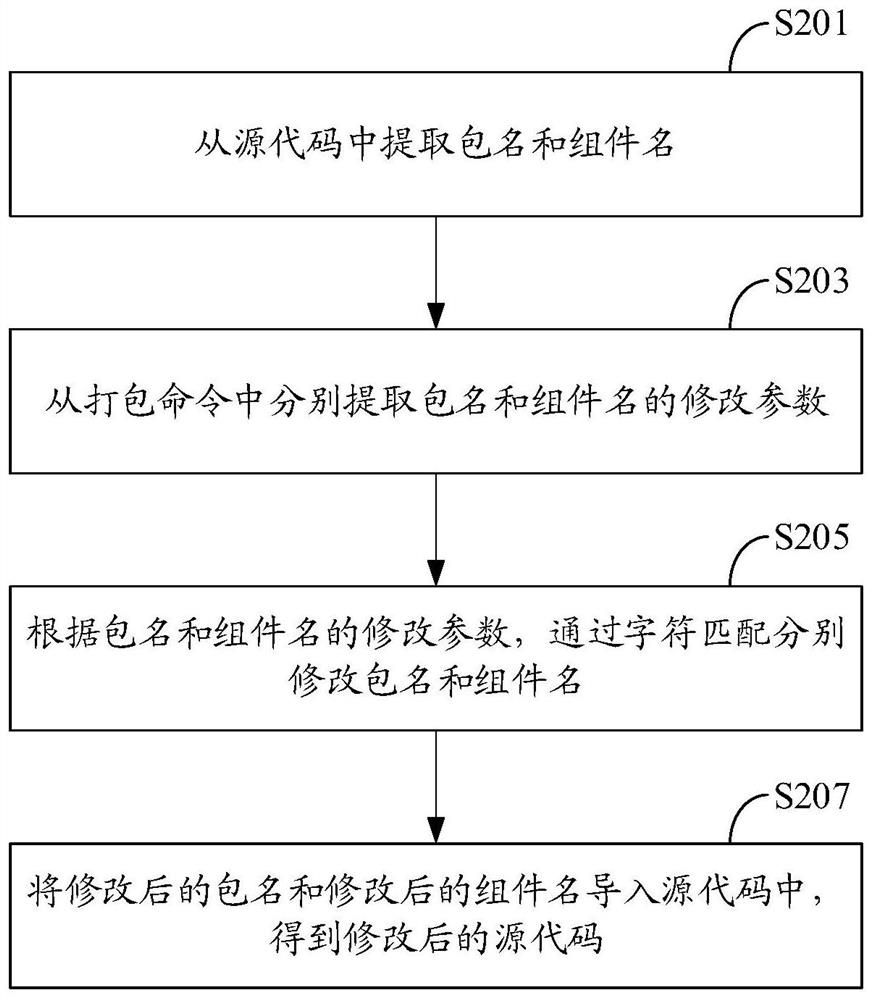

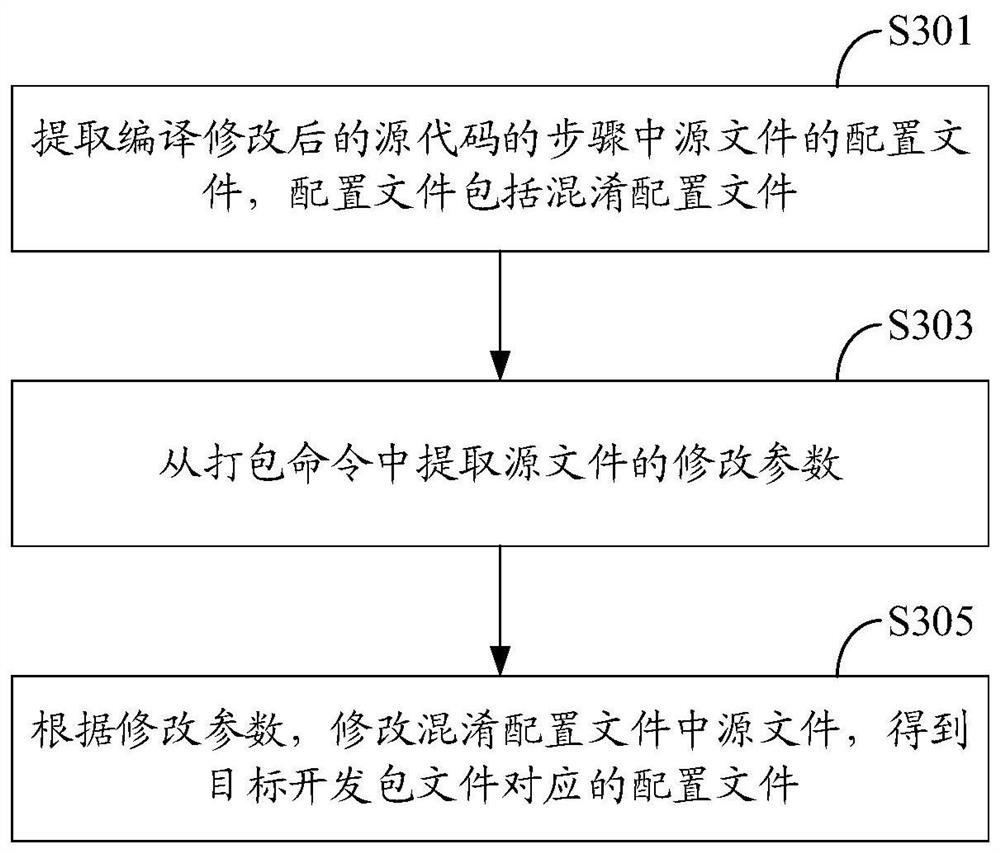

Development kit packaging method, system, readable storage medium and computer equipment

ActiveCN108037927BGuaranteed packaging efficiencySoftware deploymentCode compilationSoftware engineeringSource code

The invention relates to a development kit packaging method and system, a readable storage medium and computer equipment. The method comprises the steps that a source code library corresponding to a to-be-packed development kit is inquired according to a received packaging command, and a corresponding source code is obtained; a source file in the source code is modified according to the packagingcommand, and the modified source code is obtained; the modified source code is compiled, and a target development kit file is obtained; a configuration file corresponding to the target development kitfile is obtained, and the target development kit file and the configuration file are packaged to obtain a packaged development kit. According to the scheme, in the packaging process of the development kit, the source file in the source code is modified according to the packaging command, then the modified source code is compiled, finally, packaging is carried out according to the compiled targetdevelopment kit file and the corresponding configuration file, the development kit does not need to be unpacked, configuration of modifying the development kit in the packaging process is achieved, and the packaging efficiency of the development kit is ensured.

Owner:GUANGZHOU YOUMI INFORMATION TECH

Heat-shrinkable packaging assembly line

PendingCN107934094AGuaranteed packaging efficiencyMissingPackaging automatic controlPackaging machinesAssembly lineTransfer line

The invention relates to a heat-shrinkable packaging assembly line. The heat-shrinkable packaging assembly line comprises a box body detection device, a heat-shrinkable film packaging machine, a feeding conveying line and a discharging conveying line, wherein the feeding conveying line is arranged between the box body detection device and a feeding port of the heat-shrinkable film packaging machine, and the discharging conveying line is arranged at a discharging port of the heat-shrinkable film packaging machine; and the box body detection device comprises a material loading conveying line arranged at the feeding end of the feeding conveying line and a plurality of detection frames which are arranged at intervals on the two sides of the material loading conveying line. According to the heat-shrinkable packaging assembly line, the plurality of detection frames can be used for rapidly detecting whether short shipment, over shipment and damage of products exist or not in the box body, andtherefore the packaging efficiency can be guaranteed, and short shipment, over shipment and damage of the products can be prevented.

Owner:苏州麦克韦尔自动化设备有限公司

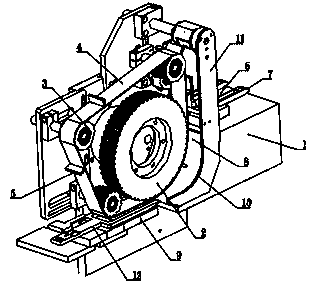

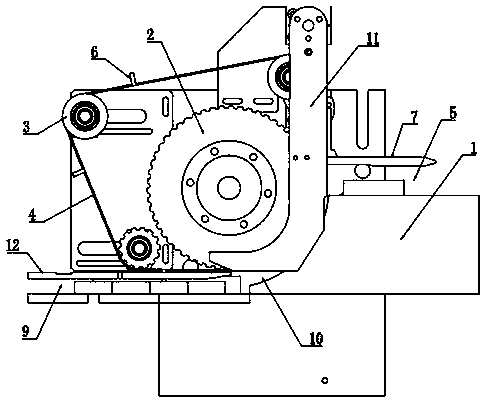

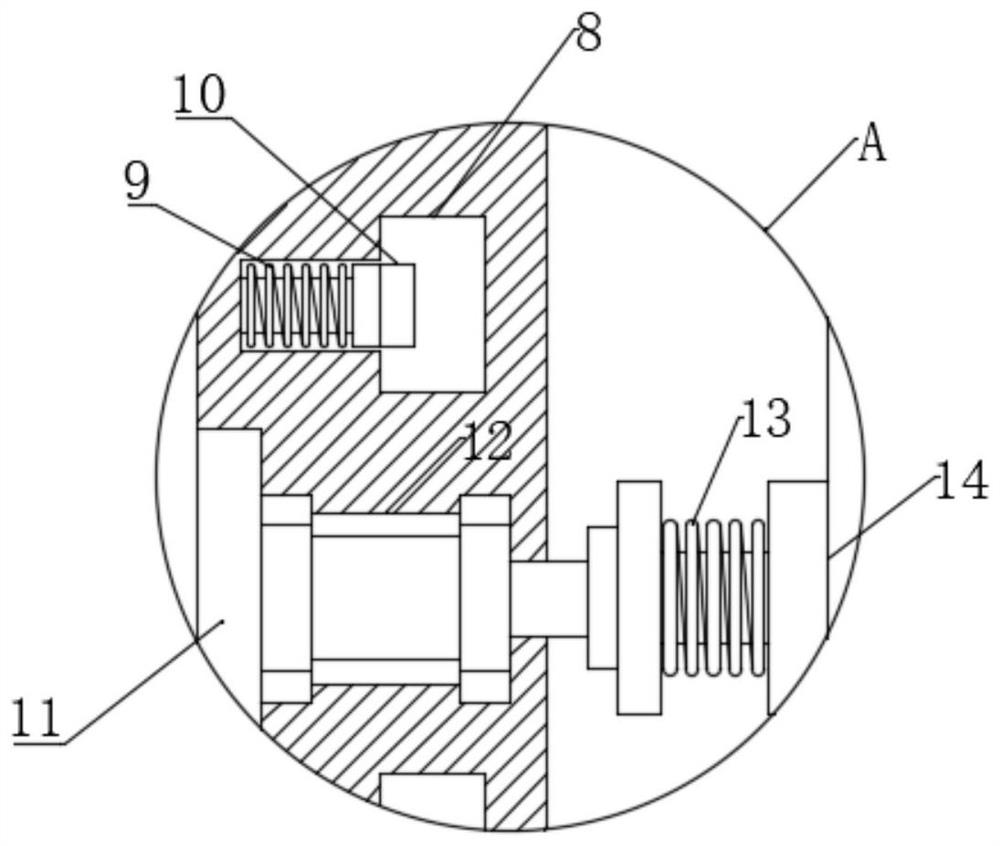

A kind of focke401 packaging machine cigarette package separation steering device

ActiveCN110040290BGuaranteed packaging efficiencyStop in timePackagingConveyor partsDrive wheelStructural engineering

The invention provides a tobacco bale separating steering device of a FOCKE401 packaging machine, and belongs to the technical field of tobacco machinery. The tobacco bale separating steering device of the FOCKE401 packaging machine comprises a rack, a main belt wheel, a driven wheel, a tooth-shaped belt and an overload clutch device. Through the tooth-shaped belt and a star wheel plate, tobacco bales which are mounted on the side, and are arranged side by side and next to each other are separated, lying-down tobacco bales are formed, the tobacco bales are rapidly fed into the downstream portion, packaging efficiency is ensured, the overload clutch device ensures that when the device is blocked by the tobacco bales, the device is shut down in time, device damage is prevented, and after shut down, the device is recovered to be normal and is portable.

Owner:HONGTA TOBACCO GRP

A ternary lithium battery intermittent packaging equipment

ActiveCN111674625BIntegrity guaranteedGuaranteed aestheticsPackagingEngineeringMechanical engineering

The invention relates to the technical field of lithium battery processing, in particular to intermittent packaging equipment for ternary lithium batteries. The purpose of the present invention is to provide a kind of intermittent packaging operation for ternary lithium batteries, reduce the adverse effects caused by collision extrusion and impact force, ensure the integrity and aesthetics of ternary lithium batteries, and have rapid and continuous Intermittent dispensing equipment for ternary lithium batteries with dispensing function. The technical solution is: a ternary lithium battery intermittent packaging equipment, including a base, a mounting plate, a servo motor and a first support plate, etc.; the mounting plate is fixed on one end of the base, and the servo motor is fixed on the One side of the installation board, the first support board is fixedly installed on one side of the installation board. In the present invention, through the cooperation of the conveying frame and the lithium battery gap drop device, the ternary lithium battery can be intermittently packed, which can reduce the damage to the ternary lithium battery and ensure the integrity of the surface of the ternary lithium battery.

Owner:深圳市豫尚电子科技有限责任公司

A packaging device for garlic processing

ActiveCN113716134BAvoid taking up packaging timeGuaranteed packaging efficiencyCleaningPackaging machinesAgricultural engineeringStructural engineering

The present invention relates to the technical field of garlic processing, in particular to a packaging device for garlic processing, comprising a mounting plate, a transmission mechanism is arranged on the mounting plate, a fixing mechanism is arranged on the mounting plate, and a There is a bag-hanging mechanism, a receiving mechanism is provided on the placement plate, a shaking mechanism is provided in the receiving mechanism, and a cleaning mechanism is provided on the transmission mechanism; the fixing mechanism is set on the placement plate, and the bag-hanging mechanism is set on the On the fixing mechanism, through the cooperation of the bag hanging mechanism and the fixing mechanism, it is convenient to use two sets of different hanging racks to realize the hanging of the packaging bag for the next group of garlic in advance during the operation of the equipment, avoiding excessive occupation of packaging time , to ensure the packaging efficiency; the receiving mechanism is set on the placement plate, which is convenient for buffering and protecting the garlic during packaging, preventing the garlic from falling from a higher place at the beginning, thereby avoiding more garlic at the bottom of the bag Crushed cloves ensure the packaging effect and subsequent sales of garlic.

Owner:邳州东泰食品有限公司

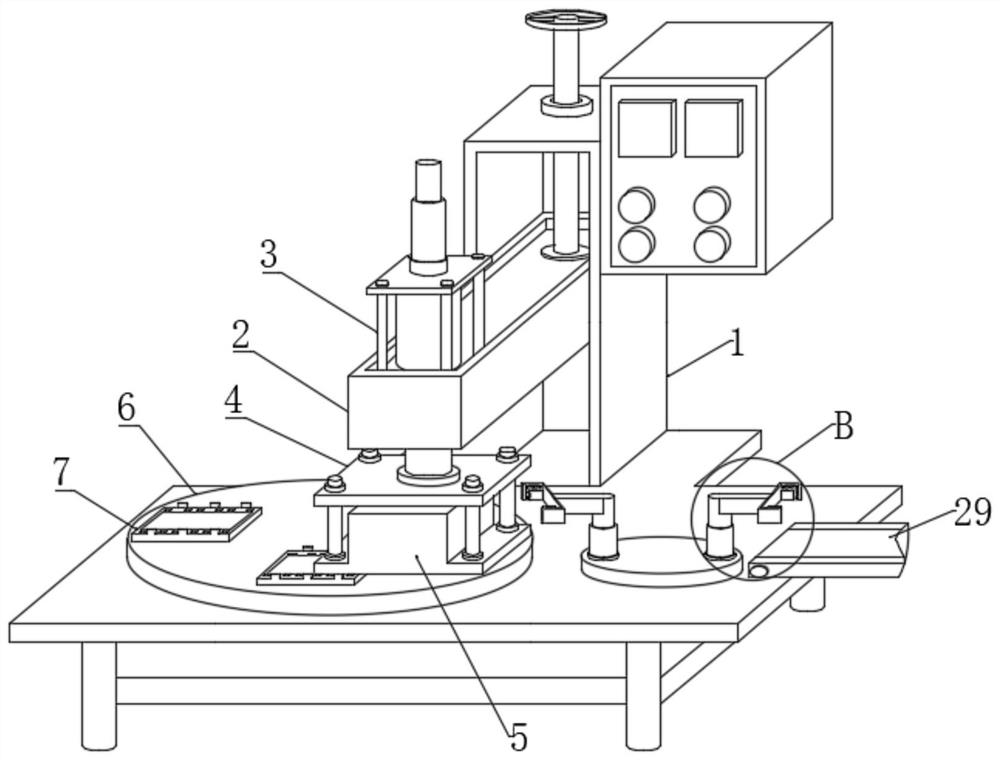

Pressing machine for carton packaging

The invention relates to a pressing machine for carton packaging. The pressing machine comprises a machine frame, wherein pressing mechanisms are arranged in the four directions of the machine frame,each pressing mechanism comprises a pressing plate, a turnover roller and a driving mechanism, the pressing plates are arranged on the turnover rollers, and the driving mechanisms are arranged at oneends of the turnover rollers and drive the turnover rollers to rotate. According to the pressing machine for carton packaging, the structure is simple and ingenious; and the pressing mechanisms are arranged on the machine frame, and when products are not put into a carton, the pressing plates in the pressing mechanisms press a paper box cover; and when the products are placed in the carton, the driving mechanisms in the pressing mechanisms drives the turnover rollers to drive the pressing plates to turn over, so that the labor intensity of operators can be effectively reduced, the packaging efficiency of the products is guaranteed, and the production and development of enterprises are facilitated.

Owner:平湖市福运包装股份有限公司

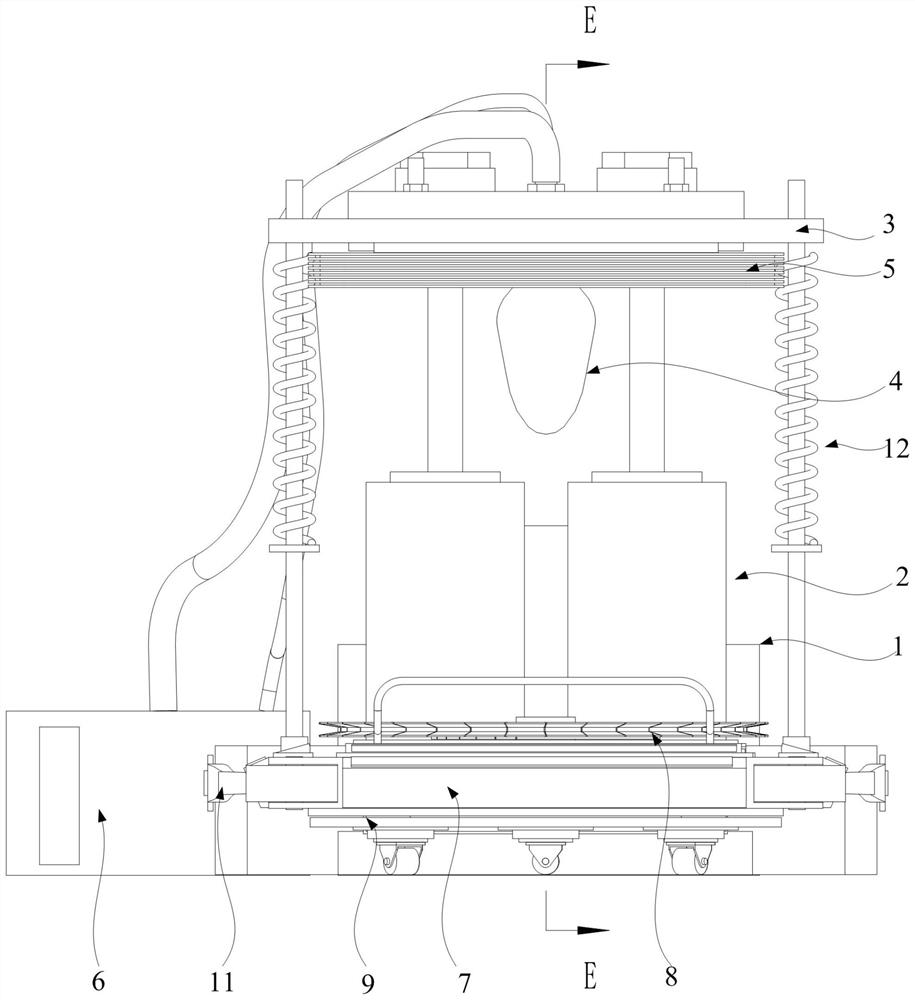

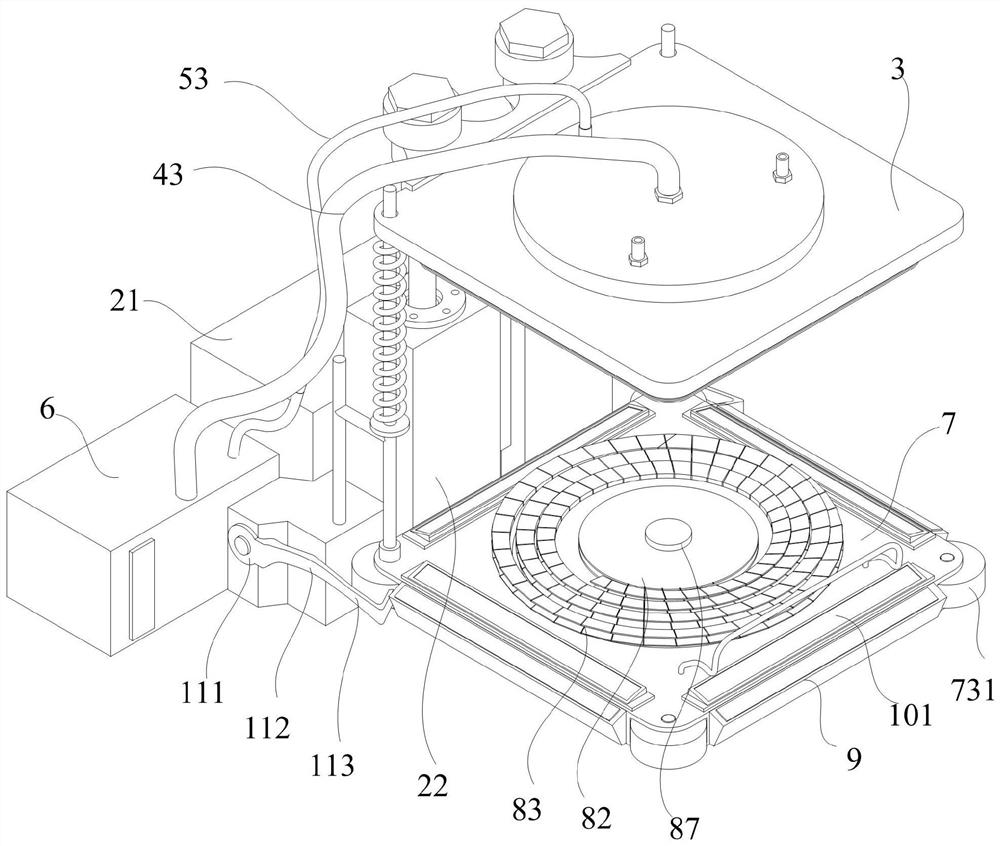

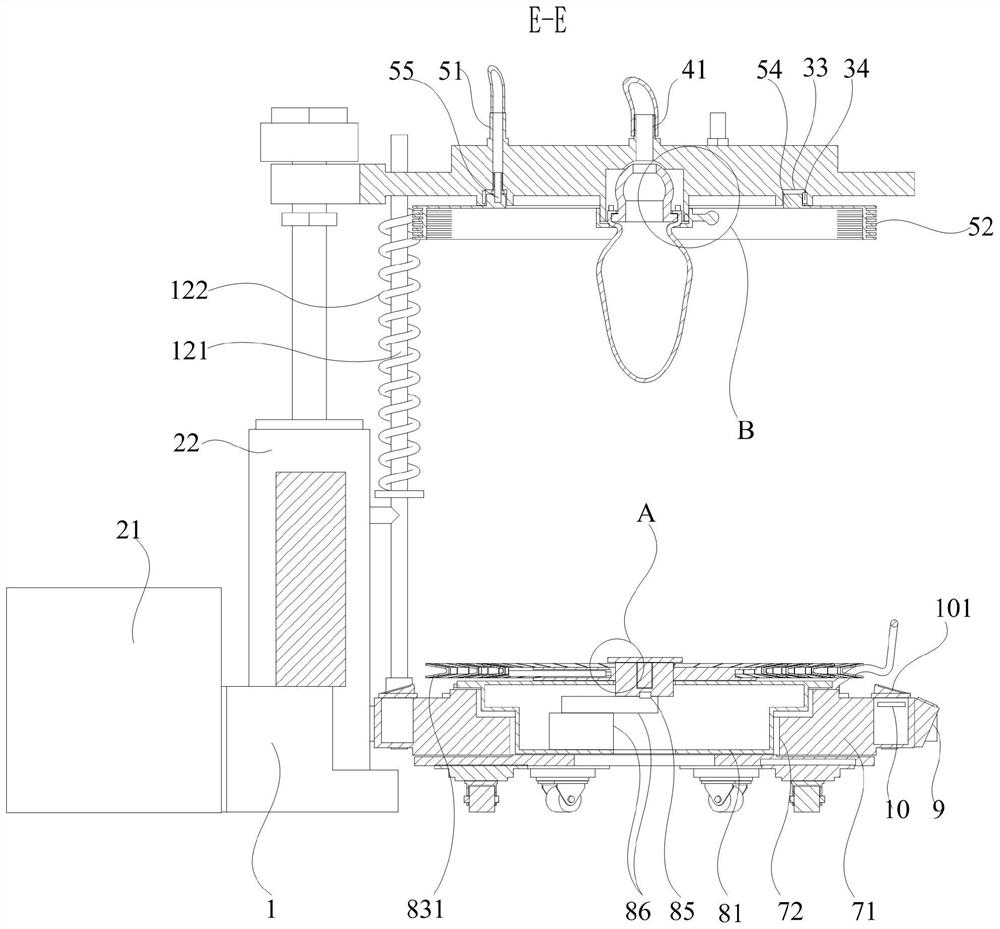

Intelligent hydraulic packing machine

ActiveCN113479369AImprove waterproof and moisture-proof performanceImprove stabilityPackaging automatic controlBundling machine detailsIn vehicleStructural engineering

The invention provides an intelligent hydraulic packaging machine. The intelligent hydraulic packing machine comprises a machine frame, a hydraulic mechanism is arranged on the machine frame, a linear moving seat is arranged at the movable end of the hydraulic mechanism, an inner-layer pneumatic packing assembly and an outer-layer pneumatic packing assembly are arranged on the linear moving seat, the inner-layer pneumatic packing assembly comprises an inner air nozzle, an inner packing balloon and a first hose, the outer-layer pneumatic packing assembly comprises an outer air nozzle, an outer packing air bag and a second hose, the input end of the first hose and the input end of the second hose are both arranged on an air pressure station, an article carrying vehicle is arranged below the linear moving seat, a horizontal stretchable bearing mechanism, an image recognition mechanism, an artificial intelligence plate and a display screen are arranged on the article carrying vehicle, the display screen is in a long strip shape and is obliquely arranged on the periphery of the top face of a saddle, anti-collision pieces are arranged at the corners of the side face of the saddle, and a pair of limiting pieces movably matched with the anti-collision pieces are arranged on the two sides of the machine frame. The intelligent hydraulic packing machine is high in packaging capacity, beneficial for reducing cost and improving the waterproof and moisture-proof performance of packaging, suitable for packaging mixed articles and suitable for large-scale popularization.

Owner:泰安隆泰金属制品有限公司

Range hood packaging device and packaging method thereof

ActiveCN112550818AAchieve recumbencyDoes not impede movementPackaging automatic controlElectric machinerySlide plate

Owner:浙江欧帝智能厨电有限公司

Range hood packaging device and packaging method thereof

ActiveCN112550818BGuaranteed installationGuaranteed accuracyPackaging automatic controlElectric machineSlide plate

The invention discloses a range hood packaging device and a packaging method thereof. The device comprises a frame, a slide plate, a positioning mechanism, a foam support installation mechanism and a push packaging mechanism, and the positioning mechanism, the foam installation mechanism and the push packaging mechanism are all arranged on the frame , the slide plate is set on the frame, the slide plate is slidingly connected with the frame, the frame is equipped with a conveying screw and a conveying motor, the conveying screw is connected with the frame in rotation, the conveying motor is connected with the conveying screw, and the conveying motor drives the conveying screw to rotate , the slide plate is provided with a transport nut, and the transport nut is set on the transport screw rod and threadedly connected with the screw rod; the method adopts a, range hood positioning; b, foam bracket fixing; c, push box packing; d, packing box inspection and packaging , a total of four steps. The invention can improve packaging efficiency and packaging quality, save labor costs, ensure the packaging quality and packaging efficiency of the range hood, facilitate the packaging of the range hood, and reduce the labor intensity of packaging personnel.

Owner:浙江欧帝智能厨电有限公司

Film shortage reminding device

InactiveCN106005612ATimely supplementRemind in timePackaging automatic controlAgricultural engineeringEconomic shortage

Owner:昆山沃优自动化设备科技有限公司

High-tank boxing device and boxing method

PendingCN114261574AImprove packing efficiencyLabor savingPackagingMaterial transferStructural engineering

The invention discloses a high-tank boxing device and method, and belongs to the technical field of boxing. The high-tank boxing device comprises a box feeding assembly, a tank feeding assembly, a cover plate transferring assembly and a mechanical arm; the box feeding assembly comprises a first conveying mechanism and a second conveying mechanism which are arranged side by side. The box body entering from the feeding end of the first conveying mechanism comprises a first box body and a second box body; the cover plate transferring assembly is arranged above the two conveying mechanisms and used for taking and placing cover plates. A first material transferring mechanism is further arranged between the first conveying mechanism and the second conveying mechanism and used for conveying the box bodies with the cover plates removed to the second conveying mechanism for partition plate placement and tank body placement work. According to the high-tank boxing device, automatic transportation of box bodies, automatic taking and placing of cover plates, automatic placing of partition plates and automatic boxing of tank bodies are achieved, full automation of tank body boxing is achieved, automatic correction of the box bodies, transfer of the tank bodies and the like are achieved, the intelligent degree is high, and the efficiency is good.

Owner:武汉船舶通信研究所

A kind of computer digital tube packaging equipment

ActiveCN111211207BAchieve sealingSimple structureIdentification meansSemiconductor devicesConveyor beltNixie tube

The present invention relates to the technical field related to packaging equipment, specifically a computer digital tube packaging equipment, including a packaging frame, a first cylinder is slidingly connected to the inside of the adjustment frame, a connecting frame is screwed on the surface of the first cylinder, and the digital tube frame is screwed. Connected to the surface of the sealing frame, the inner wall of the packaging frame is screwed with the third cylinder, the surface of the fourth cylinder is welded with the clamping frame, the surface of the clamping frame is screwed with the fifth cylinder, and the surface of the packaging frame is screwed with the conveyor belt. The beneficial effect is: when a group of digital tubes is packaged, another group of square boxes is fixed in another group of fixed frames, and after the package of a group of digital tubes is completed, the fourth cylinder and the fifth cylinder are adjusted by rotating the rotating disk. The transfer of the packaged digital tubes is realized, and the structure is simple. At the same time, the packaging plate is rotated to move another group of square boxes to the lower end of the packaging rack. At this time, another group of digital tubes can be packaged. The packaging efficiency is high and it is suitable for promotion.

Owner:佛山市德林电子科技有限公司

An intelligent transport packaging line

ActiveCN112977985BMeet the transmissionGuaranteed packaging efficiencyConveyor partsPackaging machinesControl engineeringElectric machinery

The invention relates to an intelligent transportation and packaging line that transmits the workpieces to be packaged to the packaging position by setting the front conveyor belt, and transmits the packaged workpieces in the front transmission section to the packaging module through the power provided by the rear transmission motor, and transmits them through the receiving visual detector According to the determined packaging reference value of the workpiece to be packaged, the initial transmission speeds of the front transmission motor and the rear transmission motor are determined, and when there are two or more packaged workpieces, the central control module compares the packaging position with the Compare the distance between the first packaged workpiece and the distance between the first packaged workpiece and the second packaged workpiece with the distance error to determine the packaging speed of the packaging position, and compare the front conveyor belt The speed is adjusted for the first time, and the central control module makes secondary adjustments to the transmission speed of the front conveyor belt according to the number of packaged workpieces on the rear conveyor belt, so that the transmission speed of the front conveyor belt can better meet the transmission of intelligent packaging lines.

Owner:北京中都星徽物流有限公司

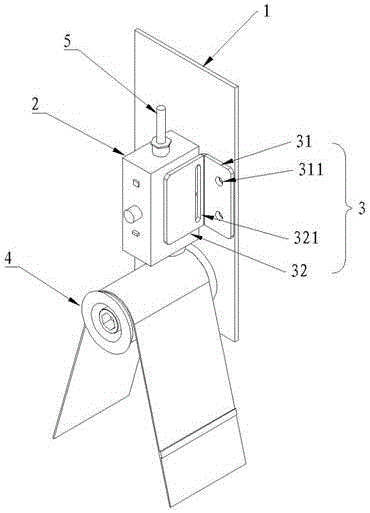

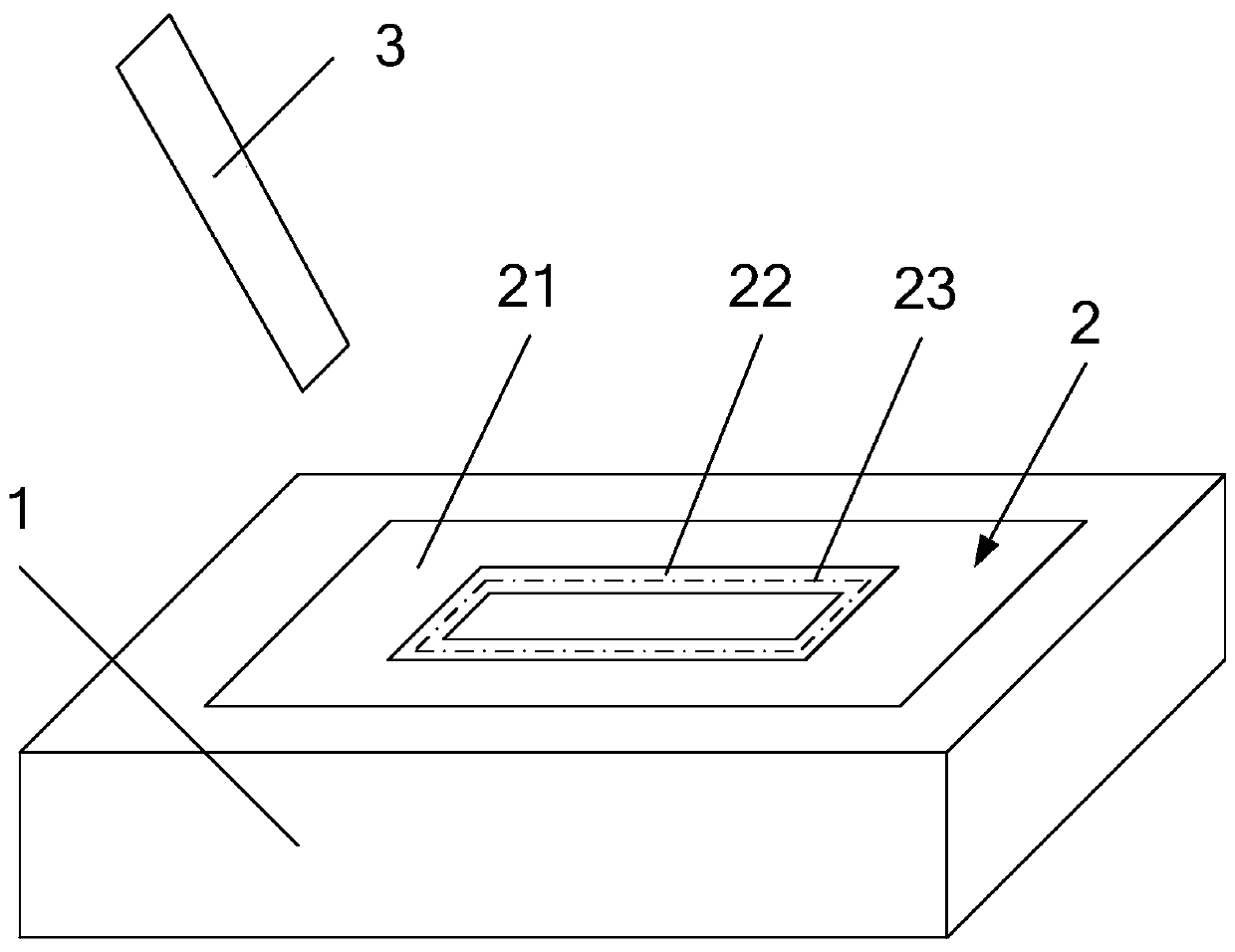

Laser packaging method and laser packaging equipment

ActiveCN107121850BEliminate manual debugging processGuaranteed packaging efficiencyNon-linear opticsAdhesiveOptoelectronics

Owner:BOE TECH GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com