Heat-shrinkable packaging assembly line

A packaging line and heat shrinking technology, applied in the field of packaging, can solve the problems of easy omission, large amount of engineering, influence on corporate reputation, etc., and achieve the effect of ensuring packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

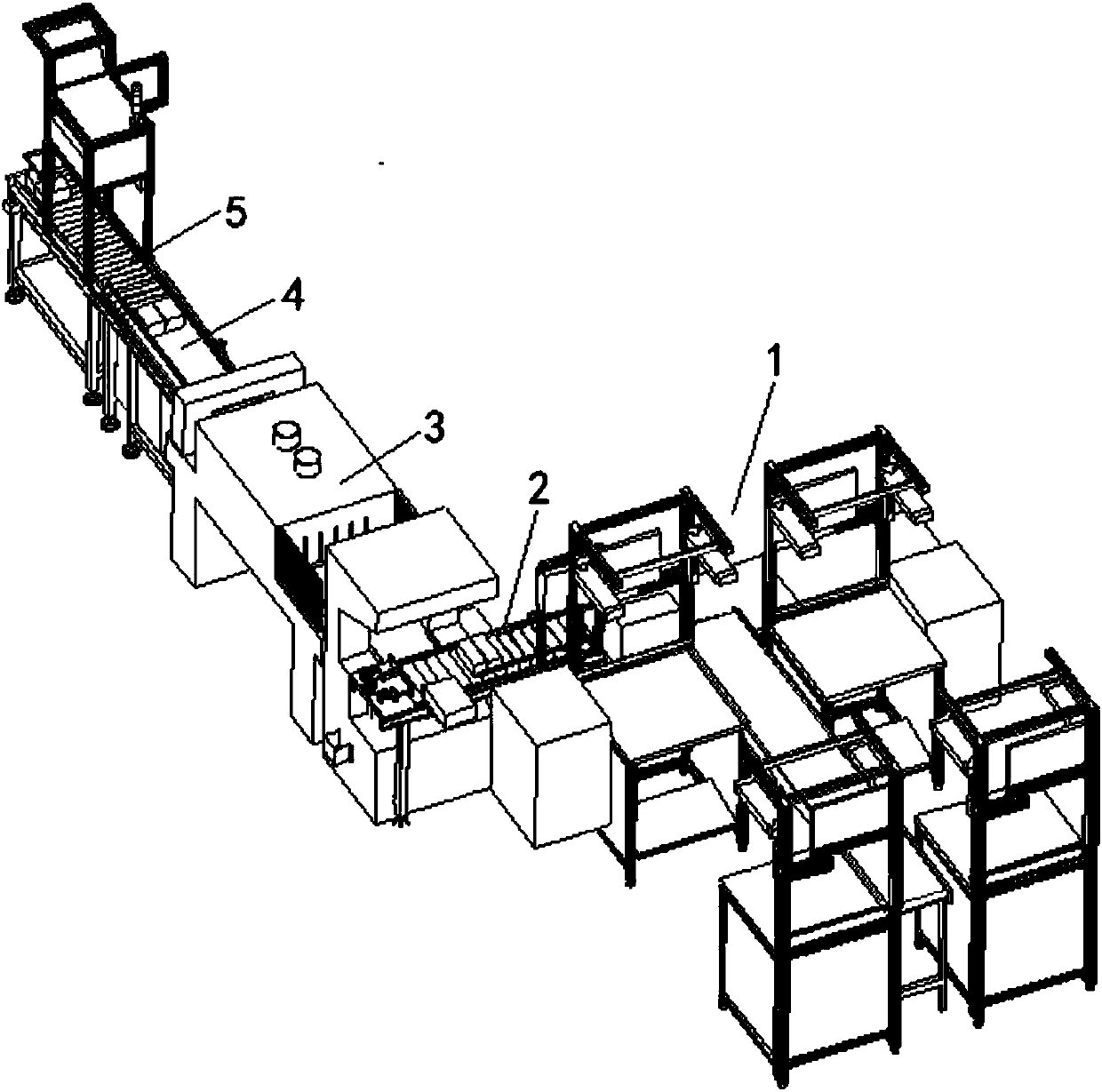

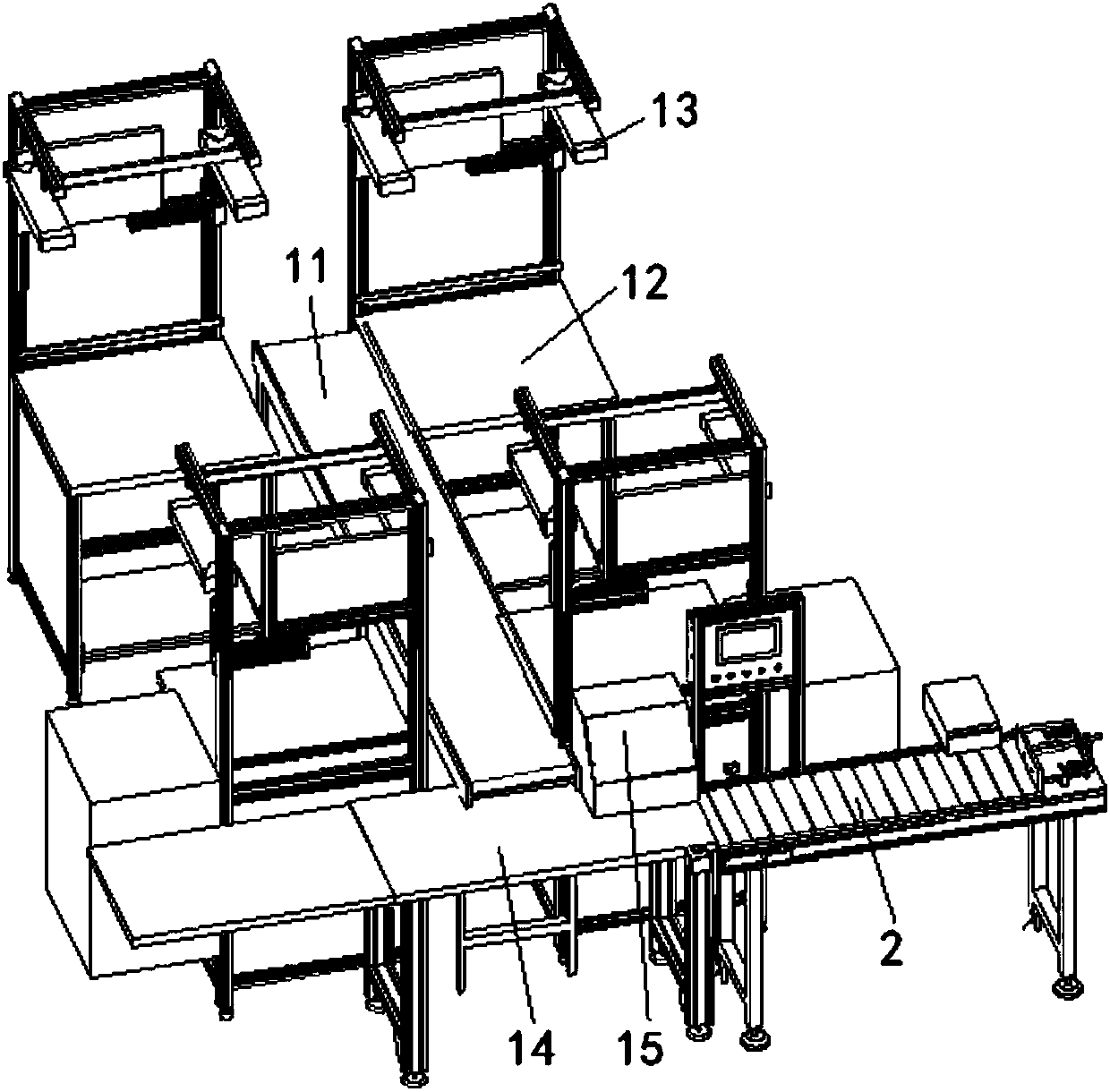

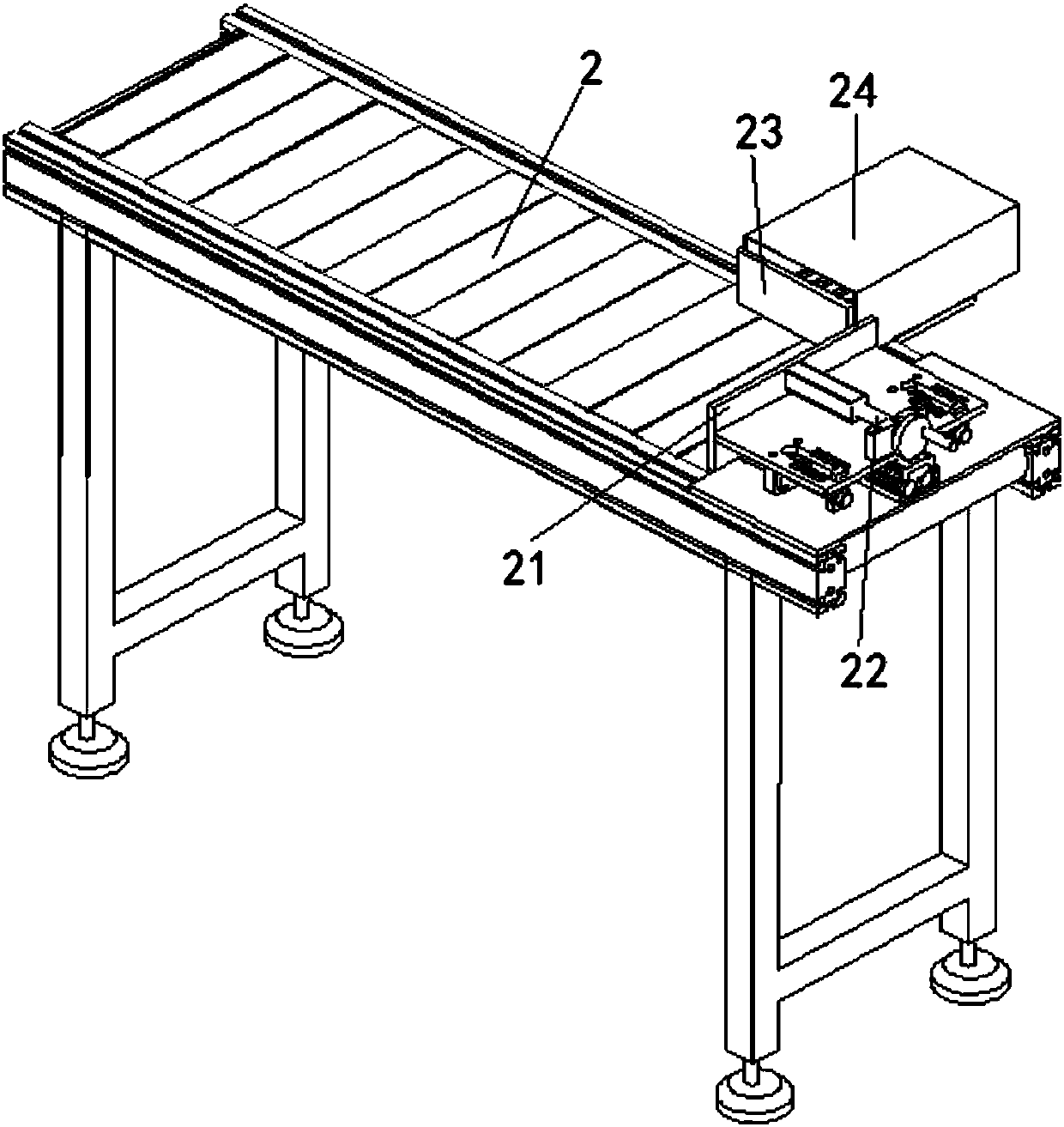

[0018] attached Figure 1-3 It is the heat shrink packaging assembly line according to the present invention, including a box body detection device 1, a heat shrink film packaging machine 3, and a feeding conveying line 2 arranged between the box body detection device 1 and the feed port of the heat shrink film packaging machine 3. 2. The unloading conveying line 4 arranged at the discharge port of the heat shrinkable film packaging machine 3; 11. There are multiple inspection racks 12 on both sides of the box to detect whether there are missing, multi-packed and damaged products in the box. In work, each inspection rack 12 is equipped with a staff, and the staff is observed by human eyes or equipment detection. Whether the products in the box are missing, multi-packing or damaged, etc., if there is no problem, put them on the feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com