Full-automatic detection and packaging system for circular dinner plate and detection and packaging method

A packaging system, fully automatic technology, used in packaging, packaging machines, packaging protection, etc., can solve problems such as plate cracking, low applicability, missed or wrong detection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The following descriptions are only preferred embodiments of the present invention, and do not therefore limit the protection scope of the entity's novelty.

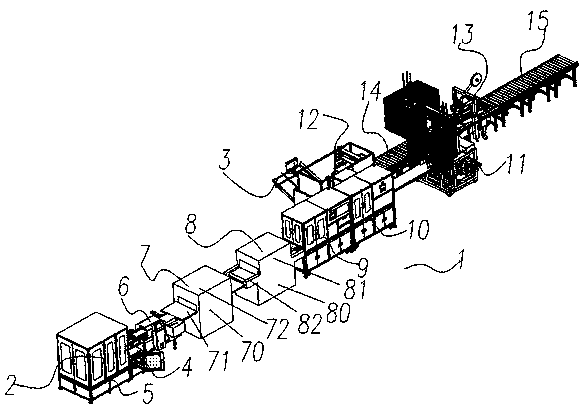

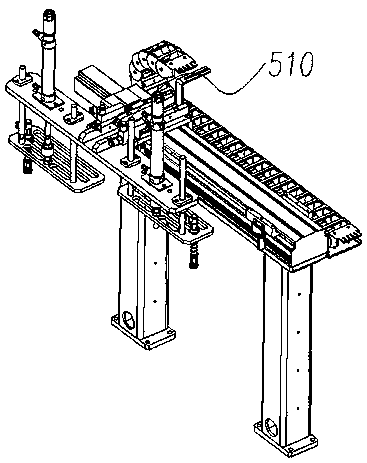

[0055] Examples, see attached Figure 1~Figure 20 , a circular dinner plate automatic detection and packaging system 1 includes a circular dinner plate automatic detection and packaging production line 2 and a packing and packaging production line 3, and the circular dinner plate automatic detection and packaging production line 2 includes a control box 4, a circular Plate disassembly feeding device 5, weighing device 6, dust removal device 7, disinfection device 8, visual inspection device 9, automatic palletizing device 10 and automatic packaging bag packaging device 11, the packing and packaging production line 3 includes automatic folding box Device 12 and box sealing device 13.

[0056] The full-automatic inspection and packaging production line 2 for round dinner plates is arranged in front of the boxing an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com