Flaky curtain type membrane packaging and leaking stoppage process

A curtain-type membrane and sheet-like technology, applied in the field of membrane separation, can solve the problems of poor packaging quality of hollow fiber membranes, unguaranteed leakage points, ugly appearance, etc., and achieve low cost, control packaging quality, and ensure packaging efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

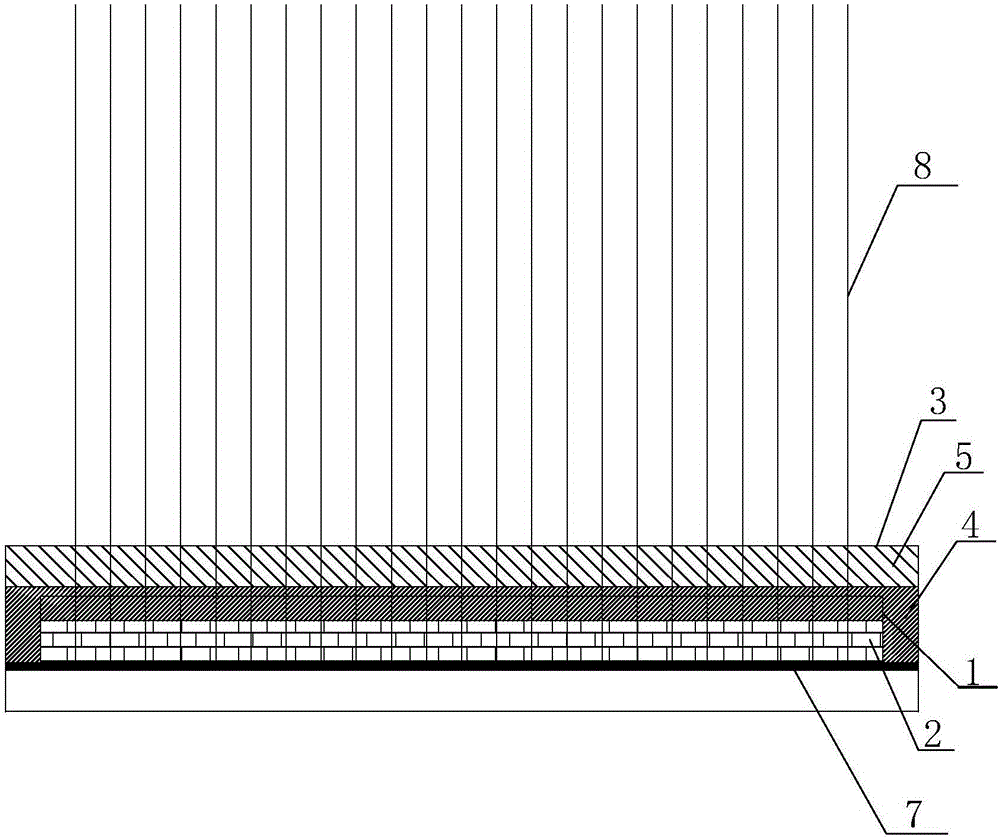

[0021] Combine below Figure 1-2 The present invention will be further described with specific embodiments.

[0022] A sheet curtain membrane encapsulation and leak plugging process such as figure 1 , 2 shown, including the following steps:

[0023] 1) Pre-encapsulation: 180 hollow fiber membrane filaments 8 with a specification of 1.0m in length, 1.1mm in outer diameter, and 0.55mm in inner diameter are formed into membrane filament bundles, and 10 bundles are taken, and the upper end is used for conventional packaging and fixing. Cut the lower ends of the membrane filaments 8 evenly, plug the membrane filament holes with a conventional plugging process, clamp them with a clamp, hang the fixed ends of the 8 bundles of membrane filaments vertically on the packaging table, insert the lower ends vertically into the open packaging box 1, and pour the first The glue layer 2 is liquid epoxy resin with a height of 3 cm and a hardness of shoreD40, so that the outside of the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com