Multi-cylinder dynamic rejecting mechanism

A rejection mechanism, multi-cylinder technology, applied in sorting and other directions, can solve the problems of difficulty in removing various types of packaging, difficult and efficient continuous rejection, lack of versatility, etc., to achieve efficient dynamic rejection, rapid action, structure reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

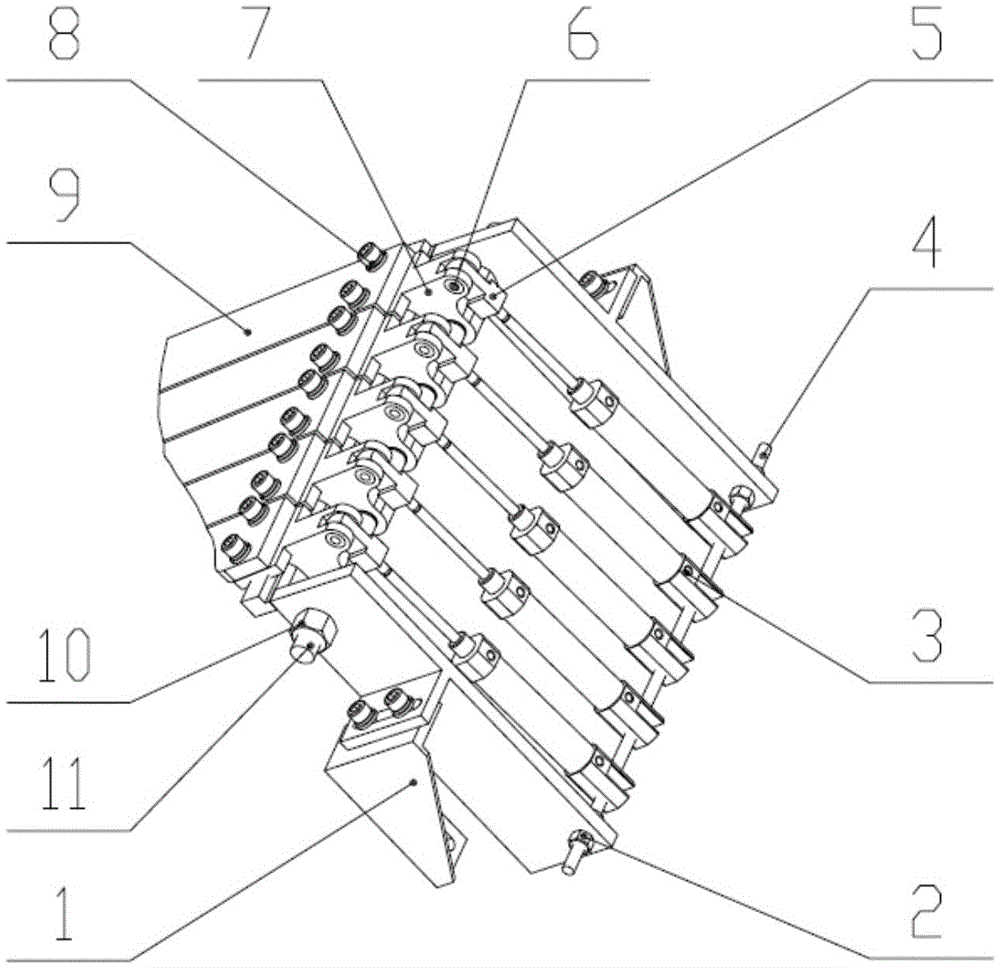

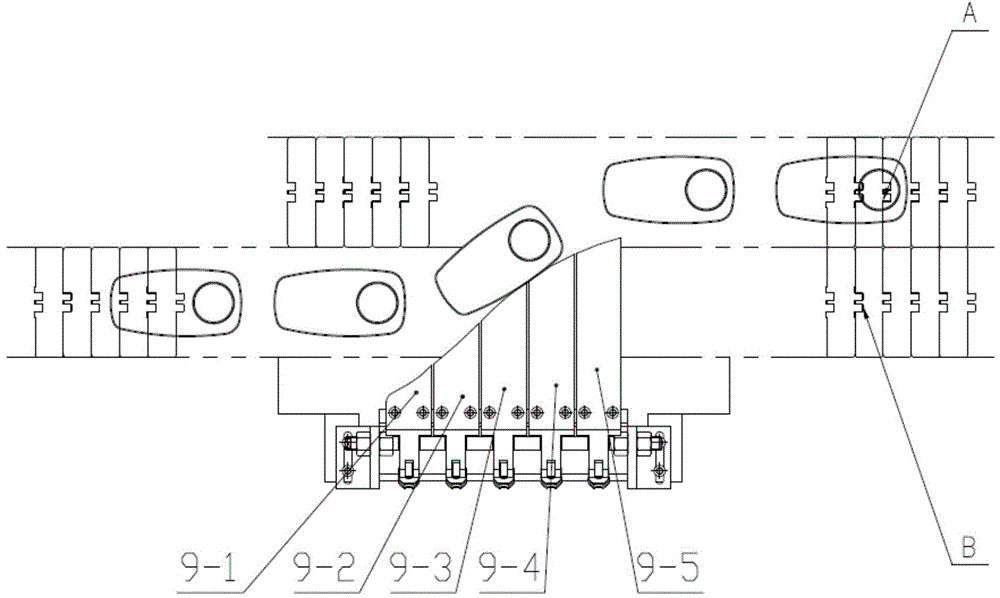

[0017] Taking the dynamic rejecting mechanism of five cylinders as an example, the patent of the present invention will be further described in detail in conjunction with the accompanying drawings and embodiments.

[0018] Such as figure 1 As shown, the multi-cylinder dynamic rejecting mechanism of the present embodiment has a groove-shaped connecting frame 1, including a back plate and two side plates, the bottom of the side plates has a through hole, and the middle of the outer sides of the two side plates is respectively provided with An ear piece 12 is respectively connected with a reinforcing rib; the cylinder fixed rod 4 passes through the through hole at the bottom of the two side plates of the connecting frame 1, and the two ends of the cylinder fixed rod 4 are threaded on the outer parts of the connecting frame 1 two side plates, A small hex nut 2 is installed on the threaded part of the fixed rod 4 to realize axial positioning and avoid loosening. Pass through five ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com