Intelligent automatic packaging line and method for customized furniture

An automatic packaging and intelligent technology, which is applied in the field of furniture packaging and transportation, can solve the problems of insufficient manual packaging efficiency, poor appearance, and high labor intensity of workers, so as to reduce the difficulty of manual operation, reduce the intensity of manual labor, and save labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

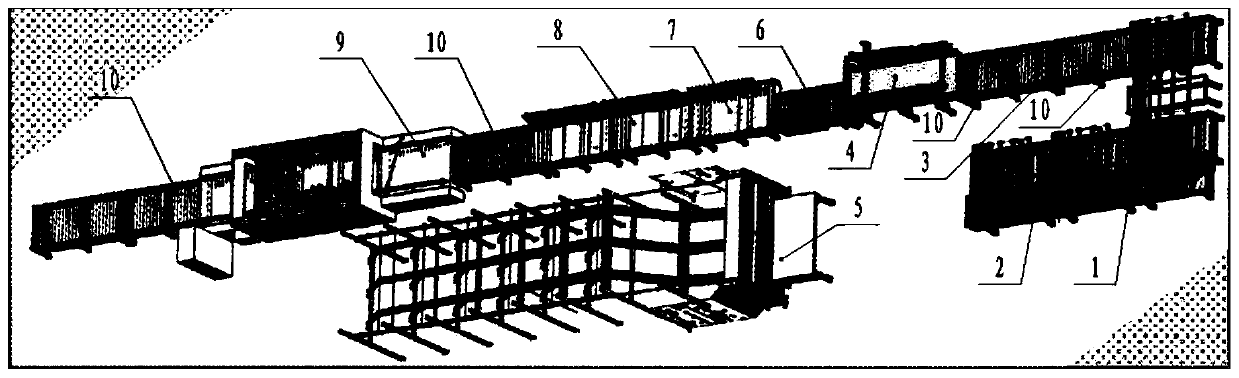

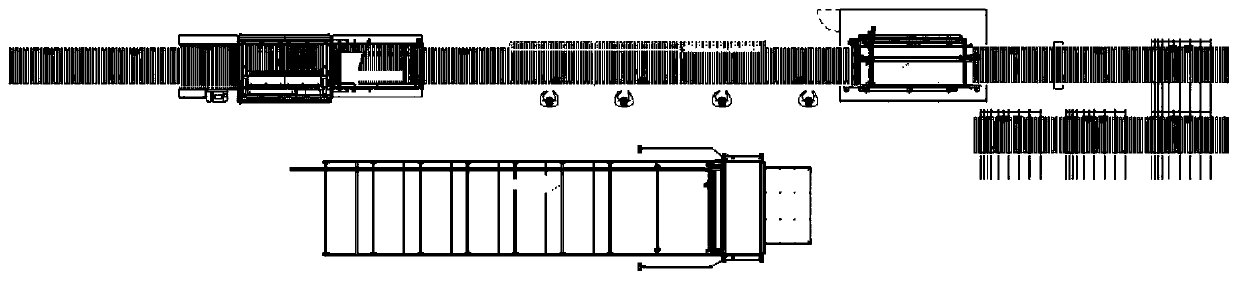

[0034] An intelligent automatic packaging line for custom-made furniture provided in this embodiment, the overall structure is as follows Figure 1-2 As shown, it includes a roller conveying line 10, and along the conveying direction, there are intelligent stacking table 2, automatic pre-measuring machine 3, intelligent square measuring machine 4, fully automatic corrugated paper cutting machine 5, box feeding machine 6, and cover turning machine 7 , Pre-folding machine 8, automatic hot melt adhesive sealing machine 9.

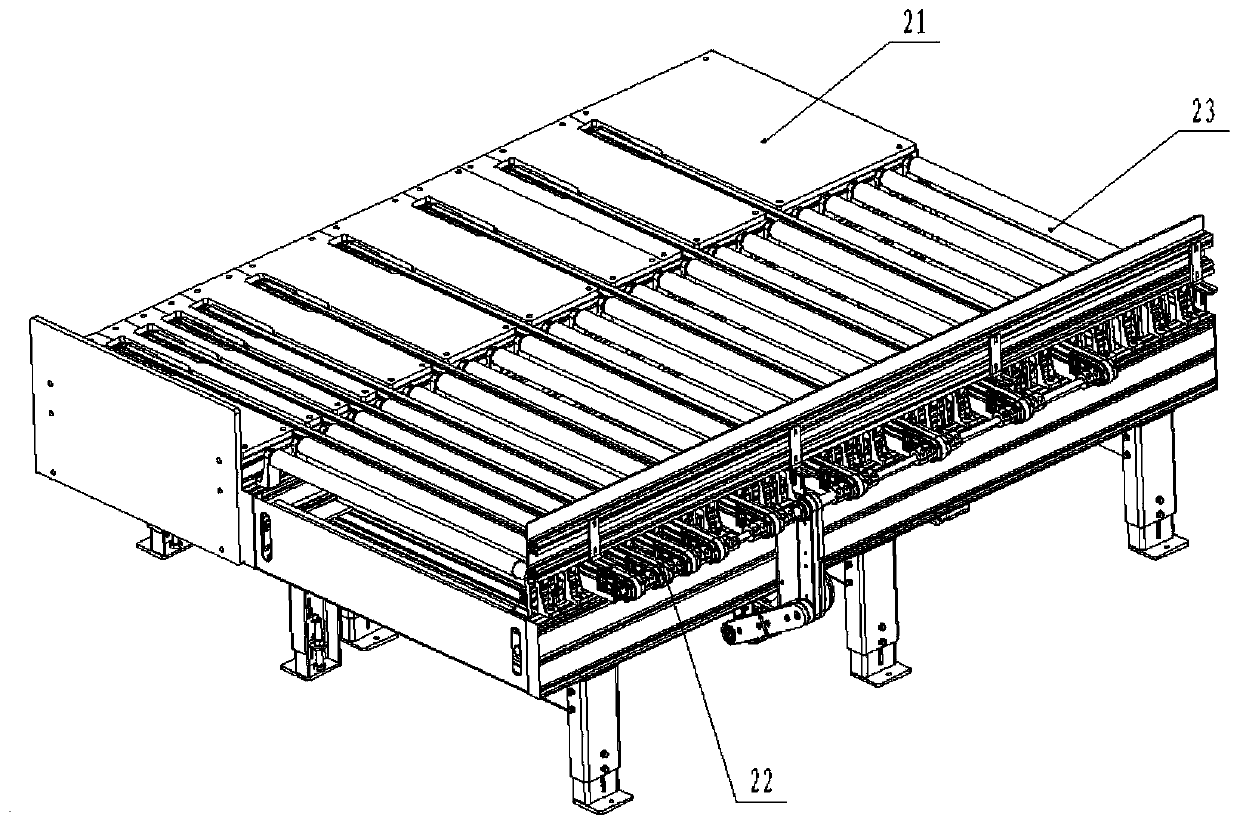

[0035] Such as image 3 As shown, the intelligent stacking platform 2 performs artificial intelligence scanning codes on the boards, guides the stacking and confirms whether there are missing boards, including the stacking platform 21, the lifting and translation belt assembly 22, and the roller conveying assembly 1 23. The stacking platform 21 is for manual labor. Sweep and stack the boards, the roller conveying assembly 23 is set on one side of the stacking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com