Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Guaranteed neutral" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

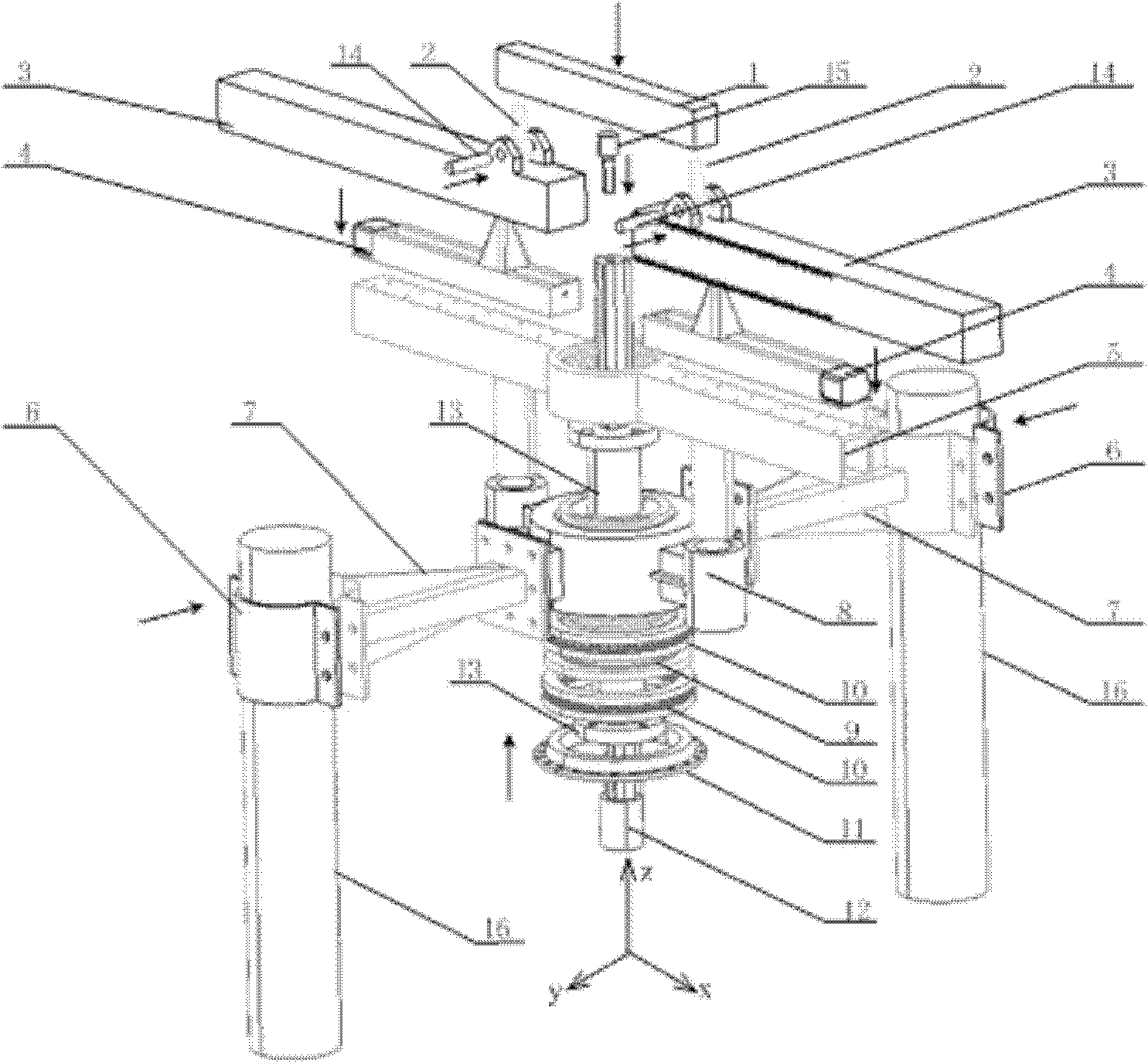

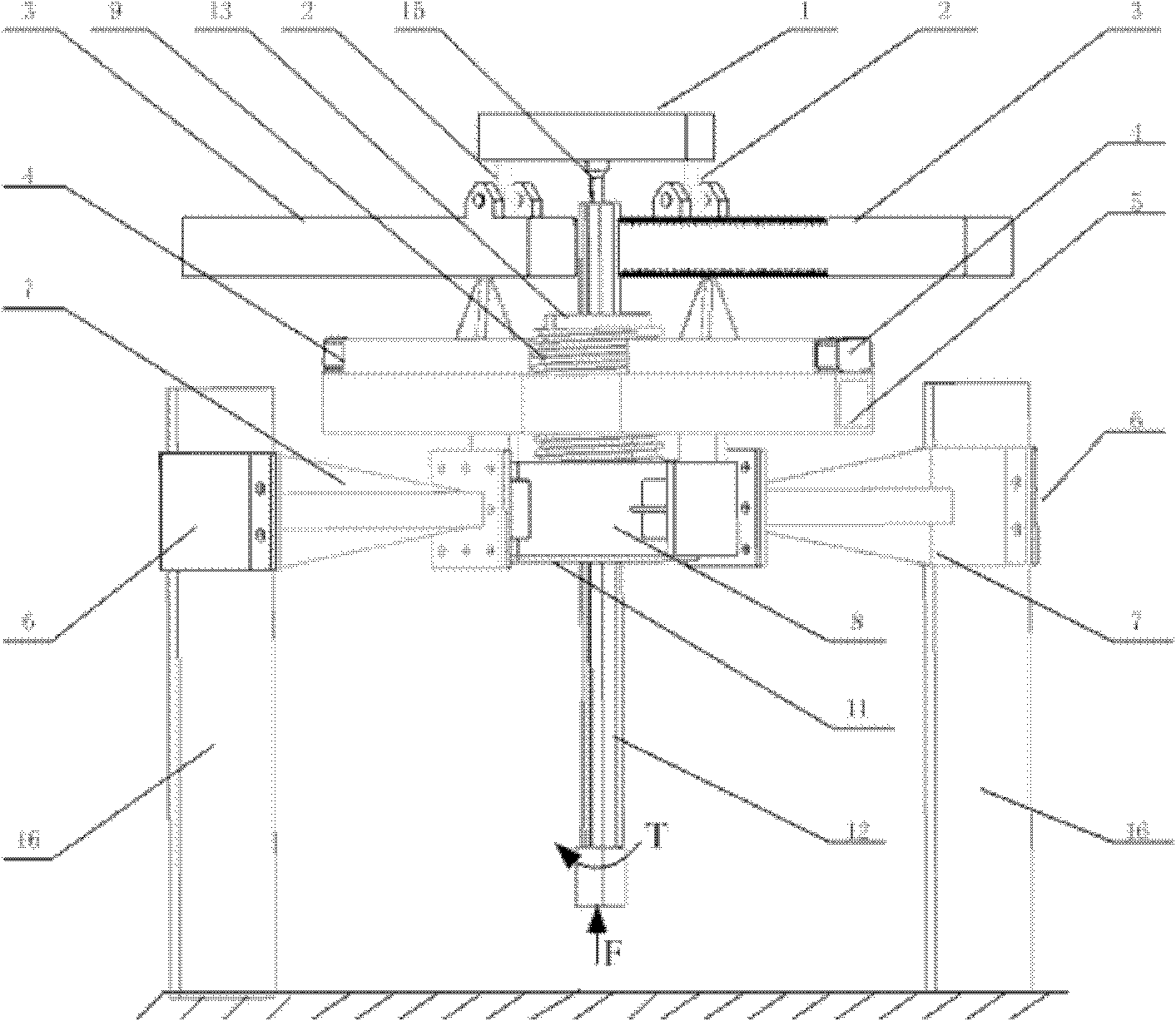

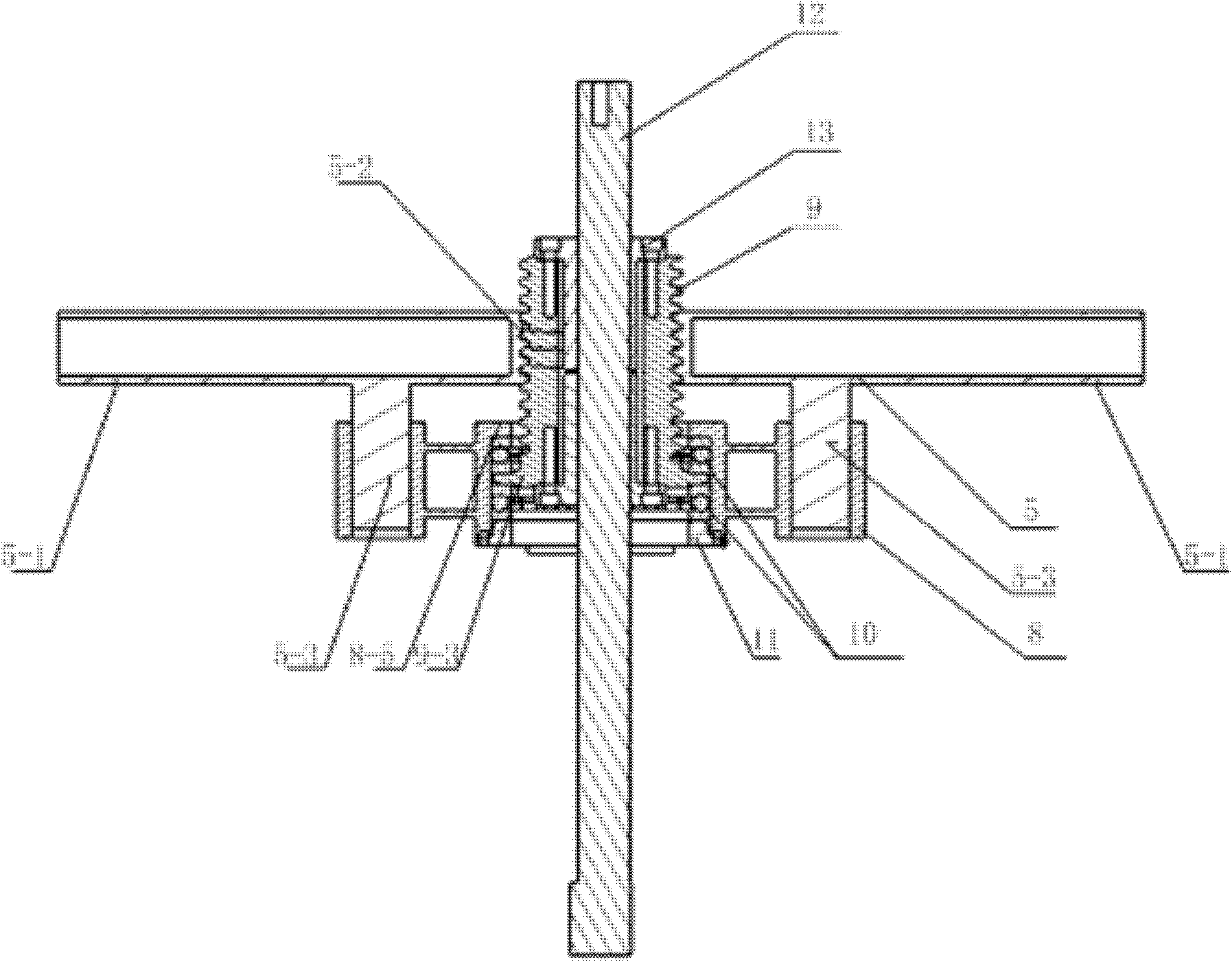

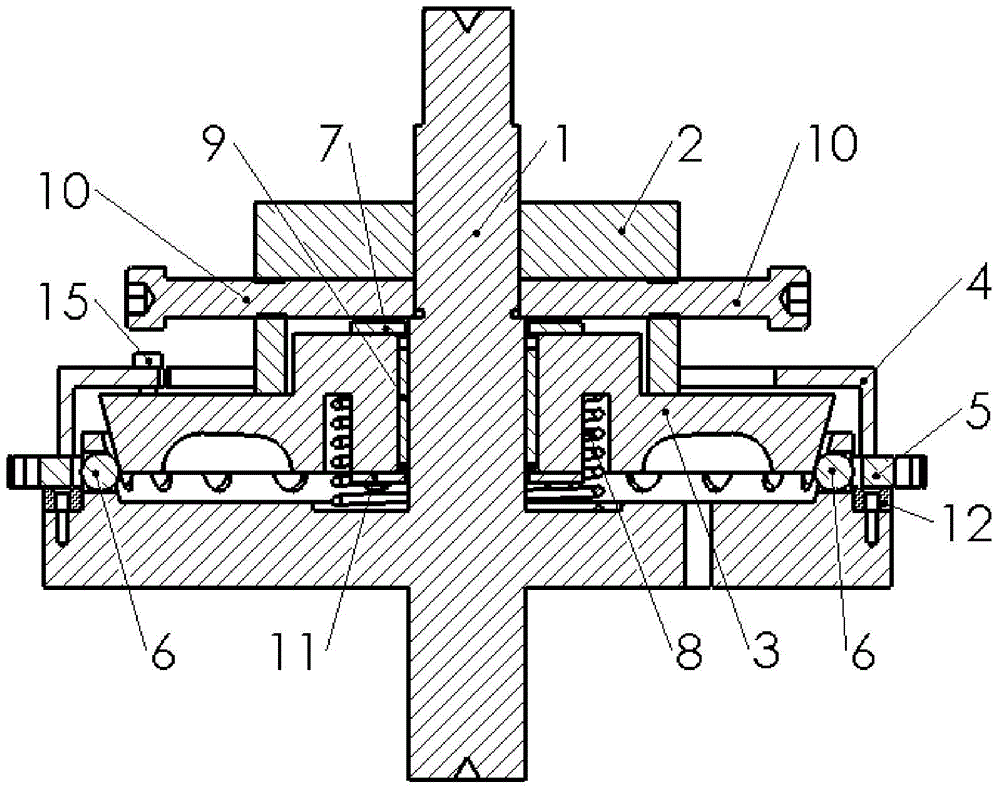

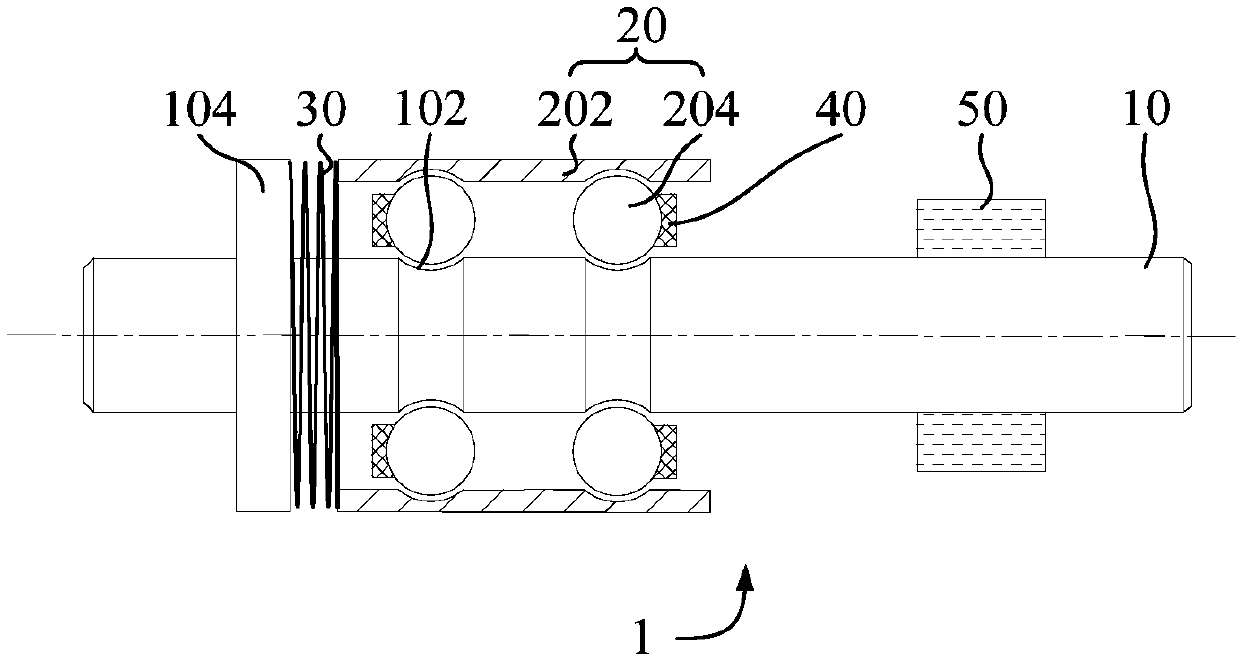

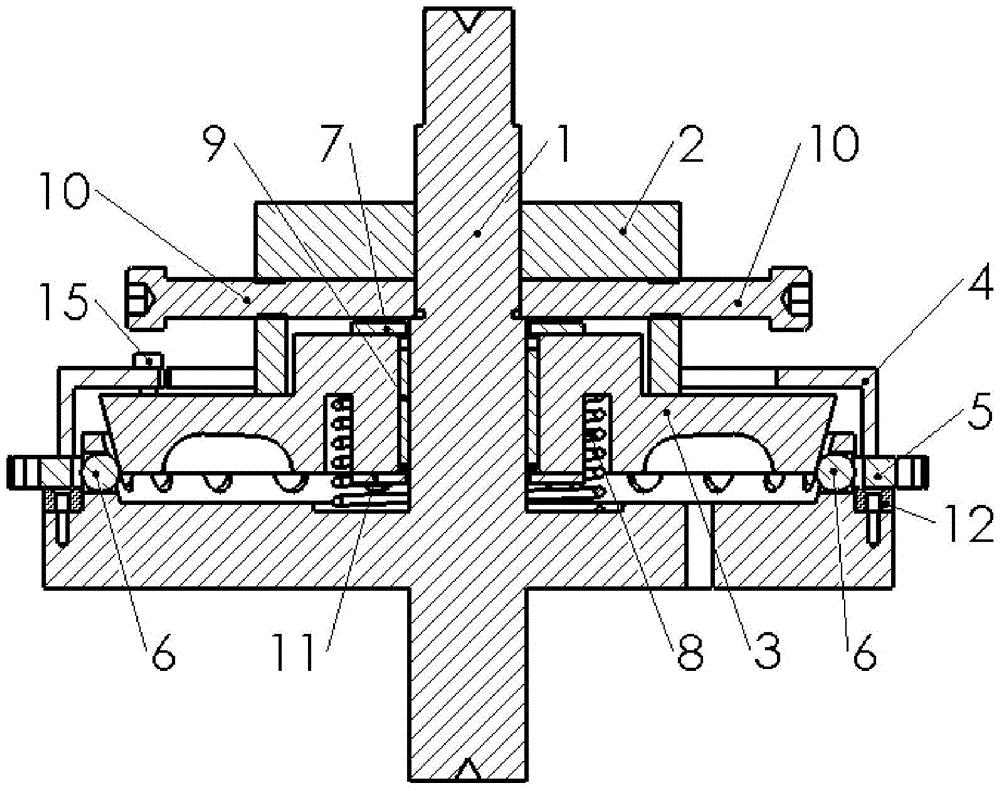

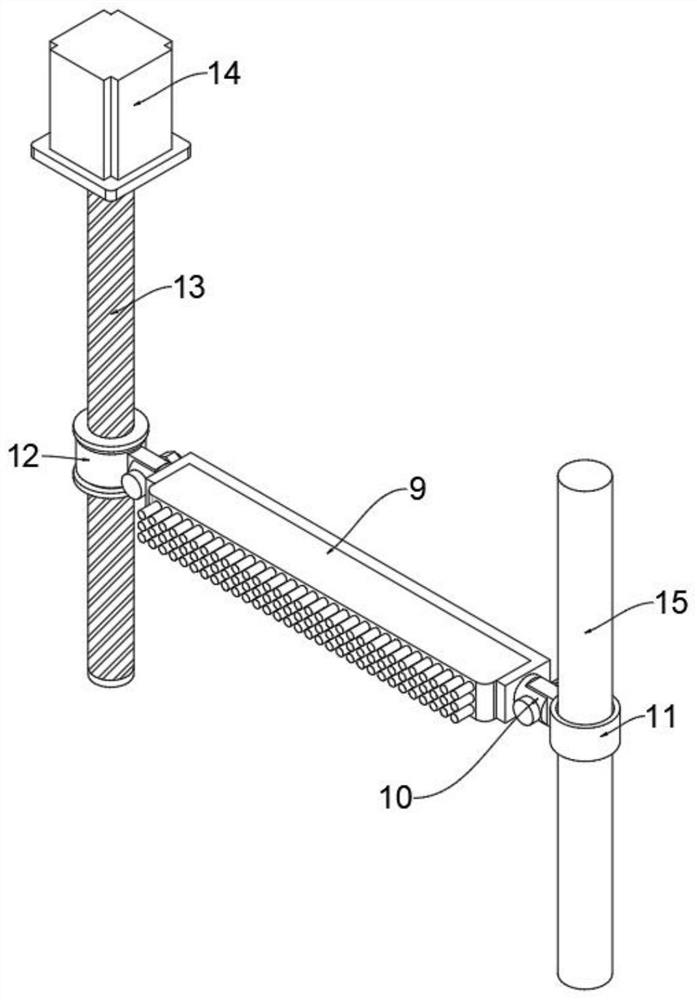

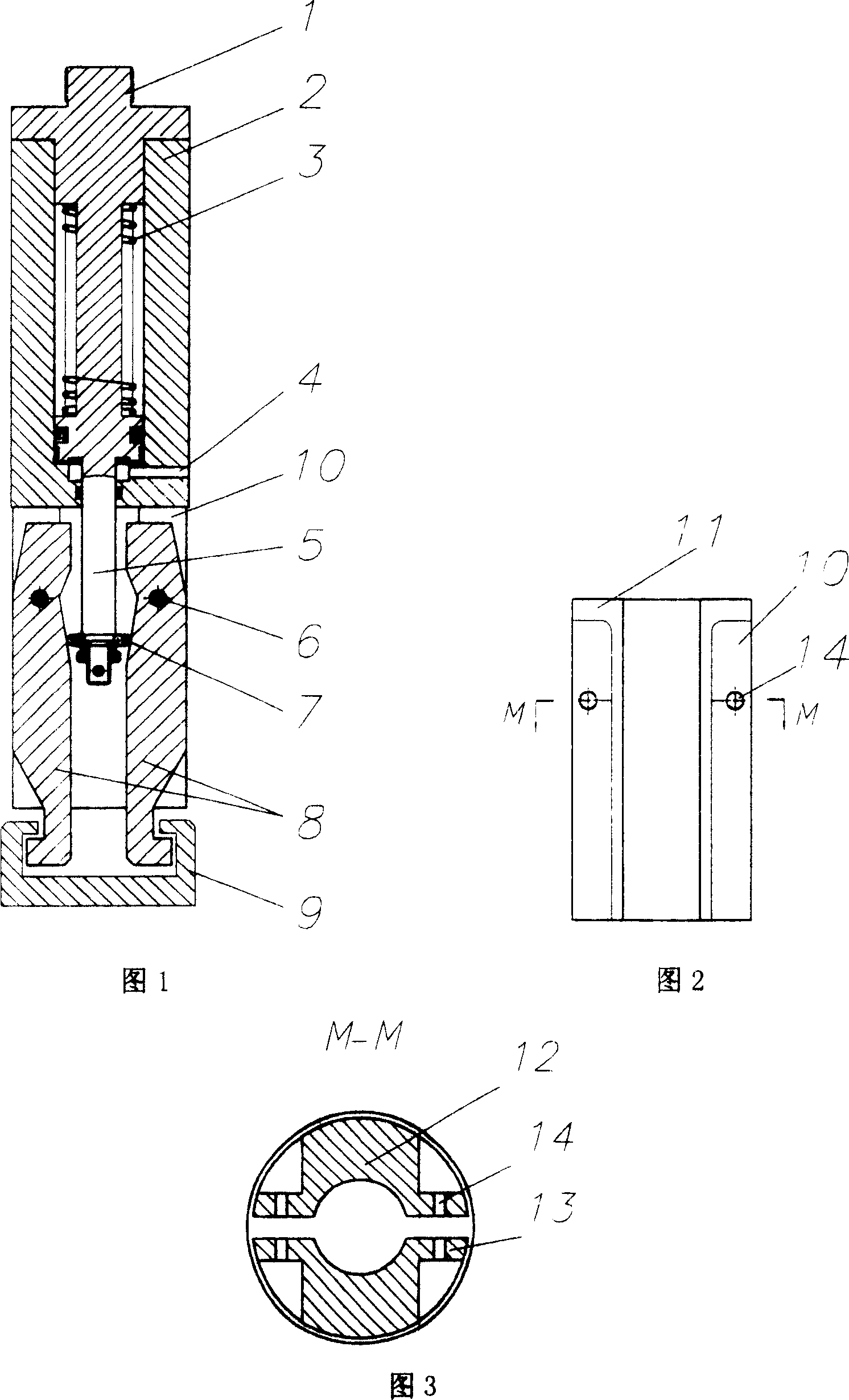

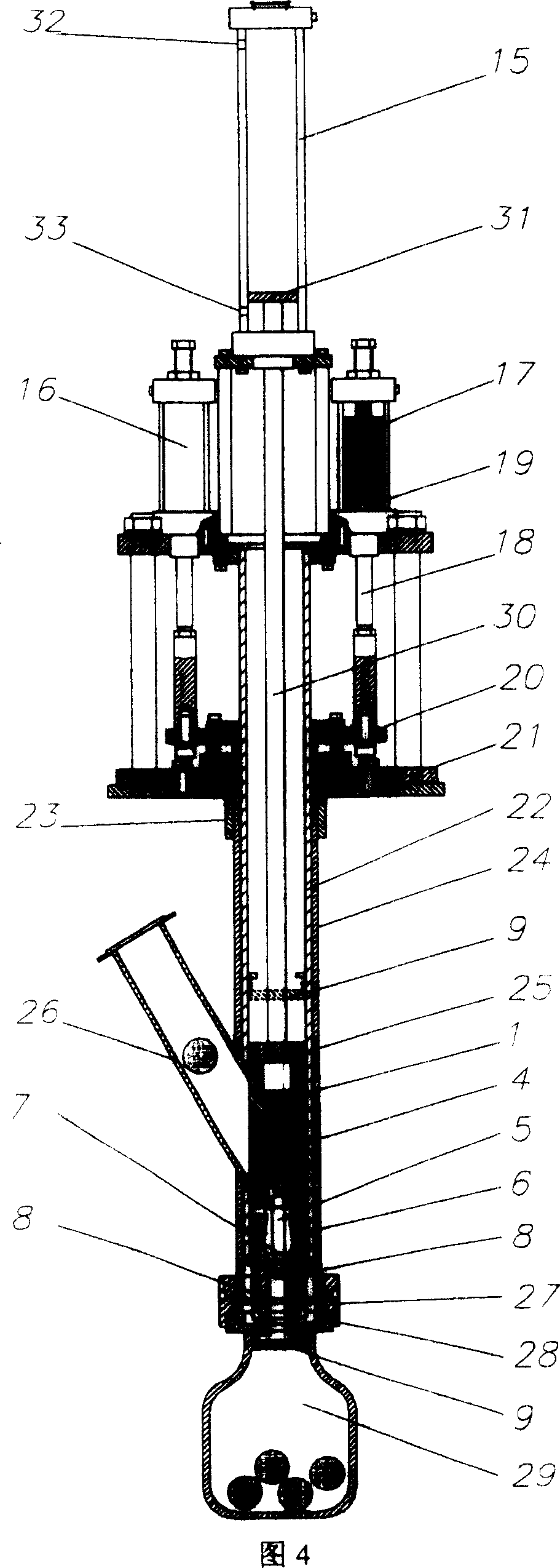

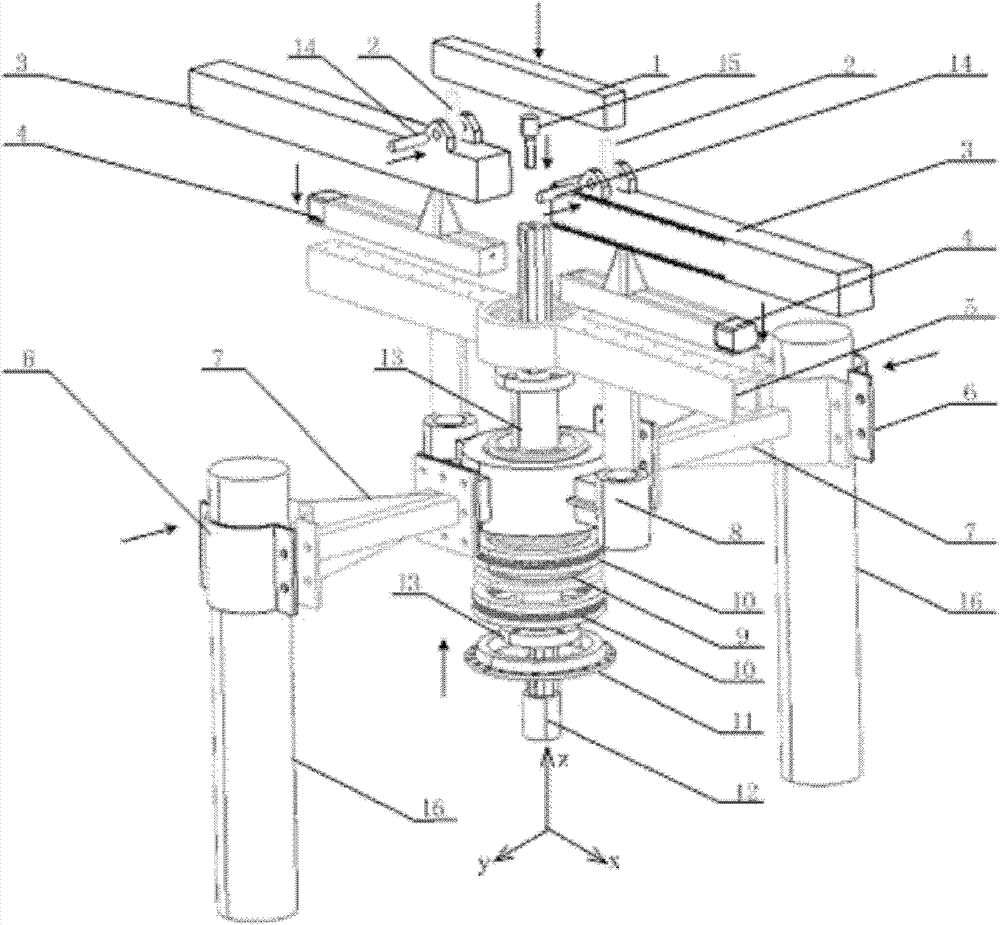

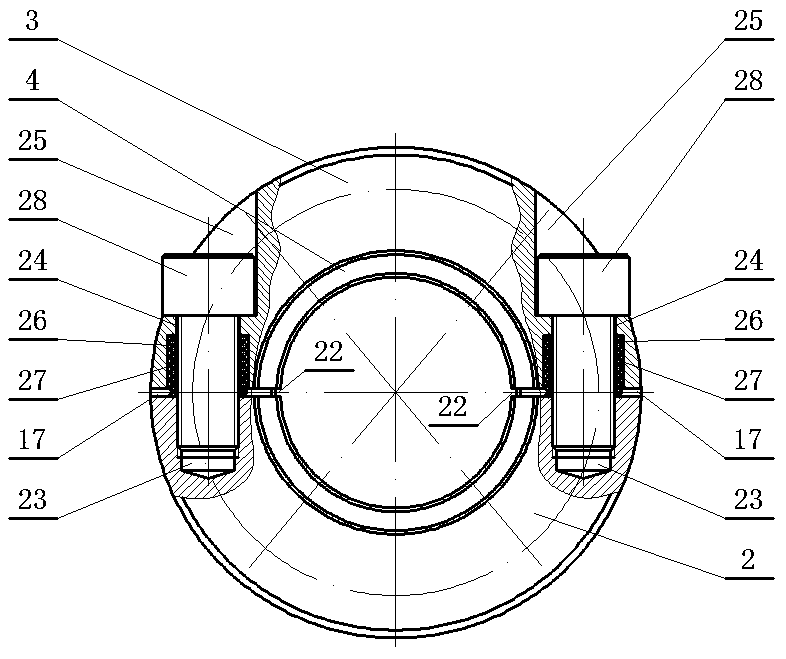

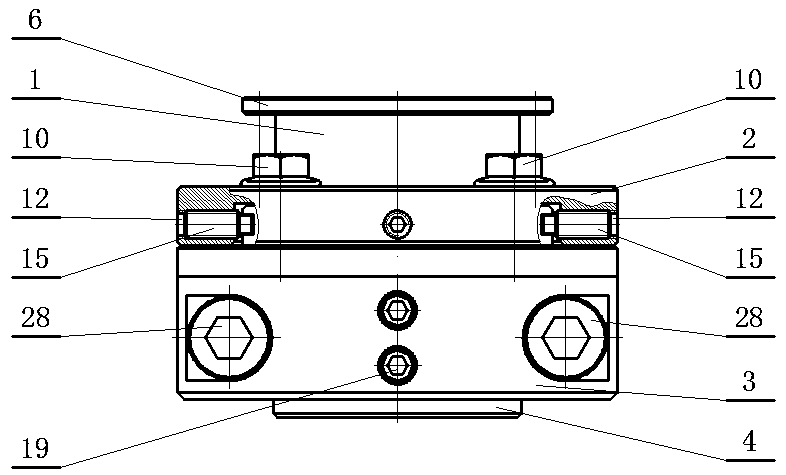

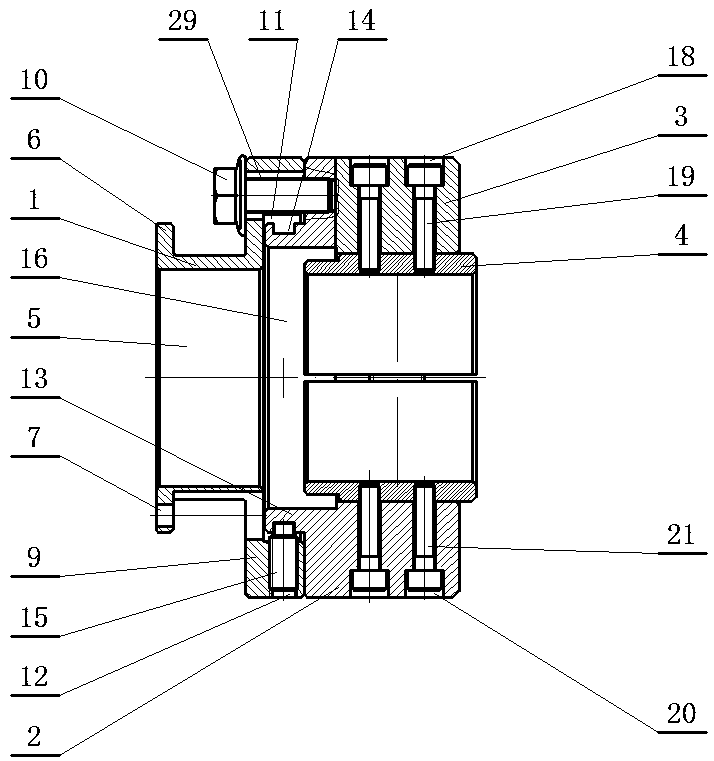

Impact loading mechanism

InactiveCN102156081AImprove applicabilityGuaranteed continuous gradientMaterial strength using repeated/pulsating forcesBall bearingThrust bearing

The invention relates to an impact loading mechanism comprising two sets of bracket arms, two bracket arm splints, an installation barrel, a seal cover, two sets of thrust force bearings, two sets of movable loading cones, a threaded sleeve, a spline shaft, two flange splines, two loading arms, two rod end joint ball bearings, two support columns, two impact loading rods and a joint ball bearing.The impact loading mechanism can convert the torque of the load input end of the spline shaft into the thrust force of the movable loading cones and apply the thrust force of the movable loading cones to the impact loading rods, and the impact loading mechanism can directly apply the thrust force or pull force of the load input end of the spline shaft to the impact loading rods through the first loading arm. Because mobile blocks on the movable loading cones can be movable or static, the distance between two loading points on a single impact loading rod can change along with time or keep unchanged. Thus, the dynamic synchronous multi-point movement simulation impact loading of the impact loading rods can be realized, and random dynamic or static shearing force and torque can be obtained at the roots of the impact loading rods.

Owner:BEIHANG UNIV

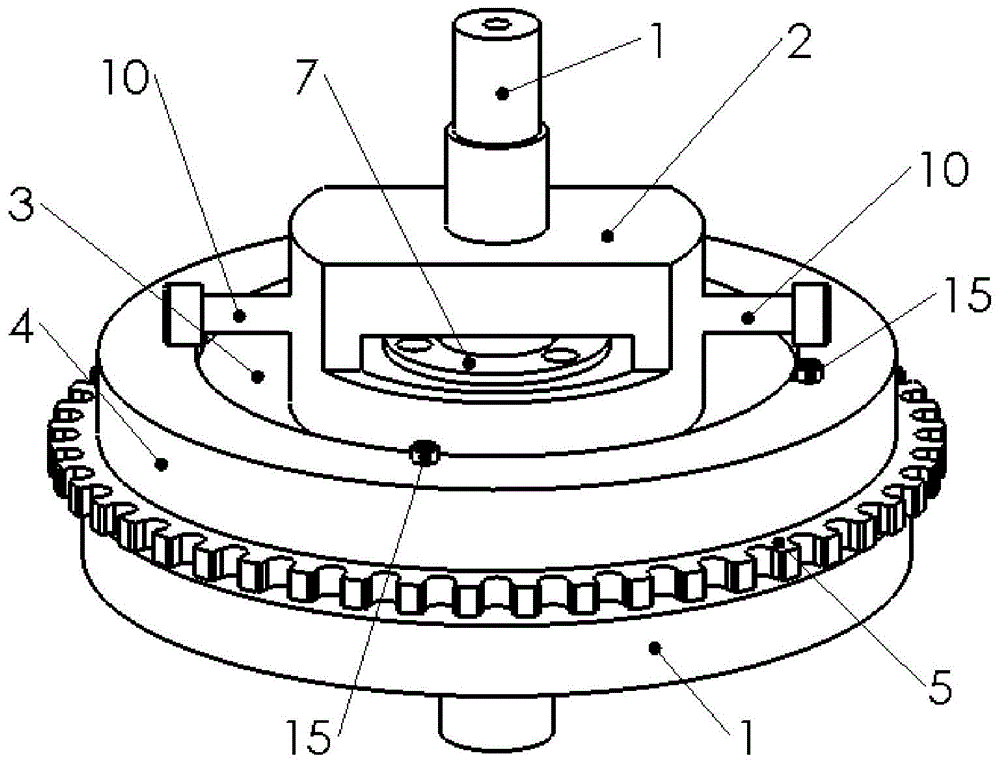

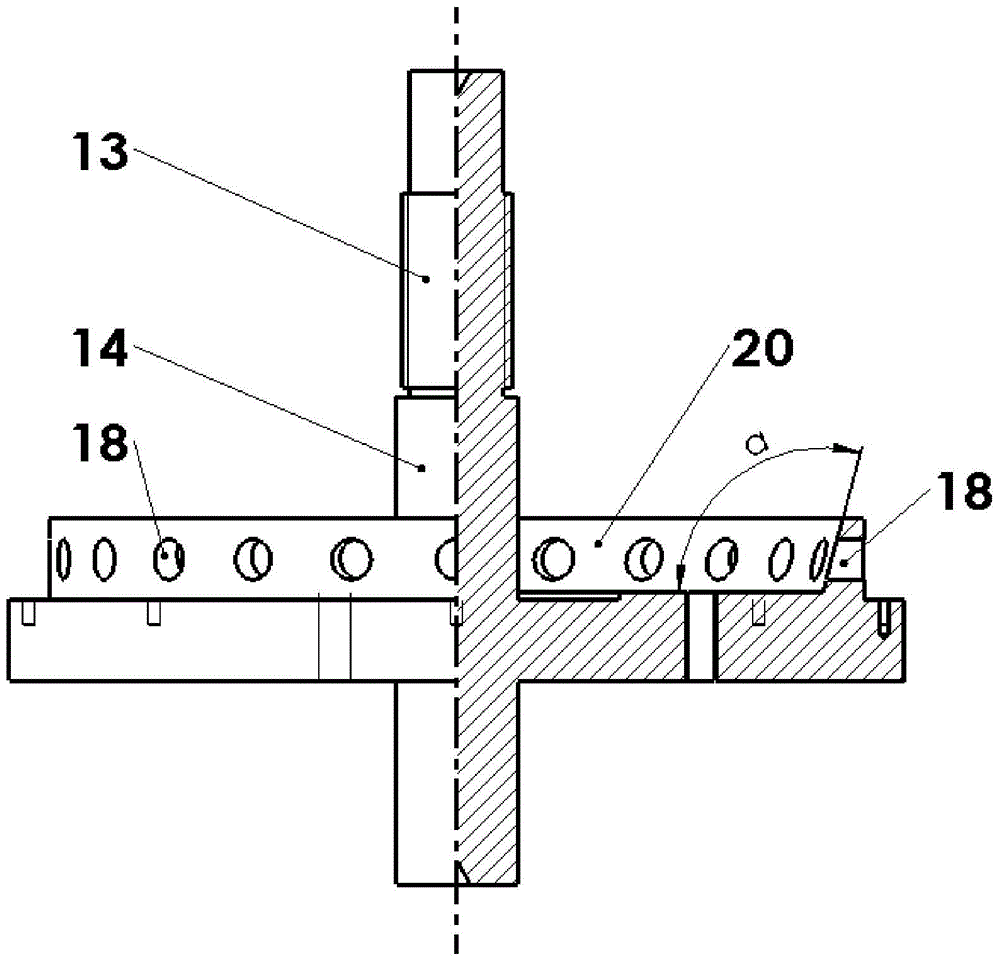

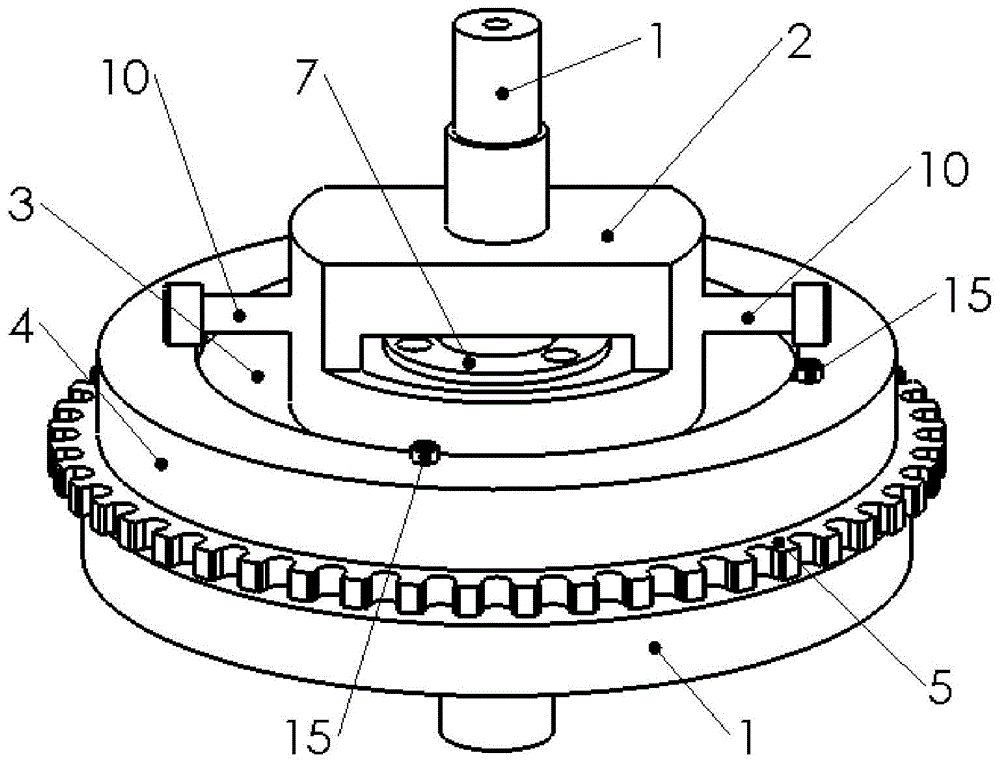

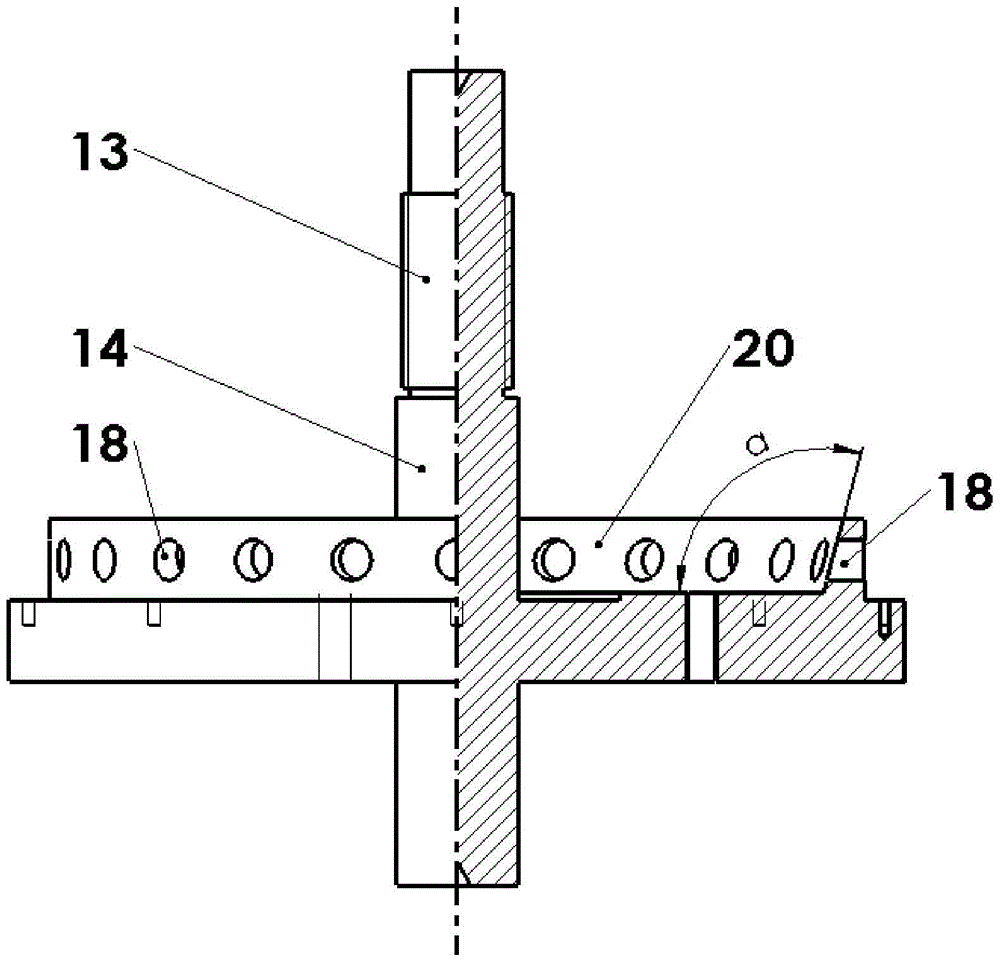

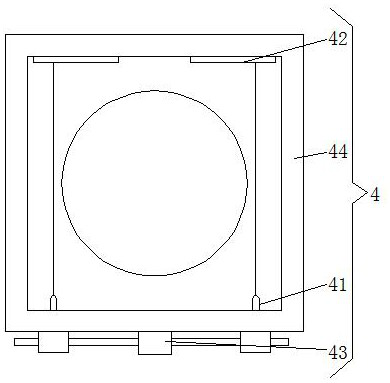

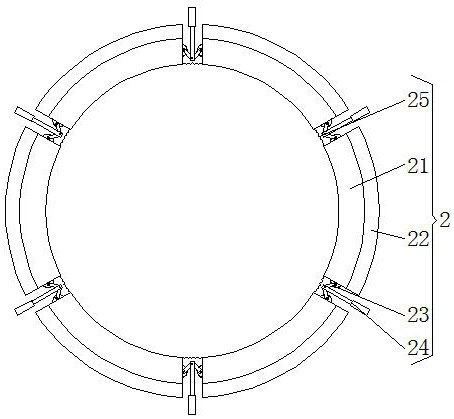

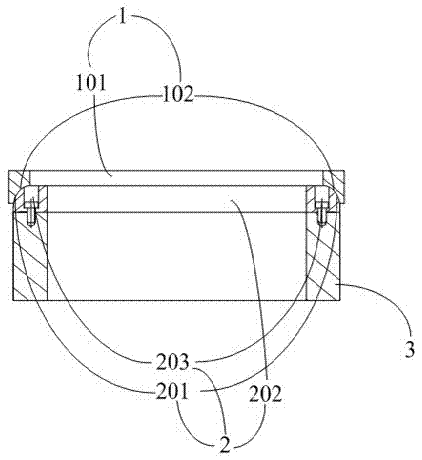

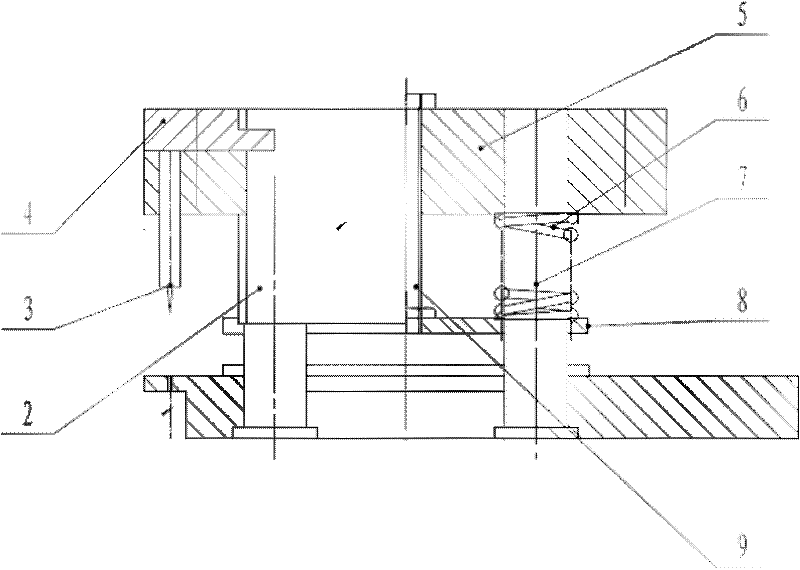

Thin-wall gear ring self-centering tensioning installation fixture

InactiveCN104589230AAvoid deformationReduce distortionMachine gearing/transmission testingWork holdersEngineeringSteel ball

Owner:XI AN JIAOTONG UNIV

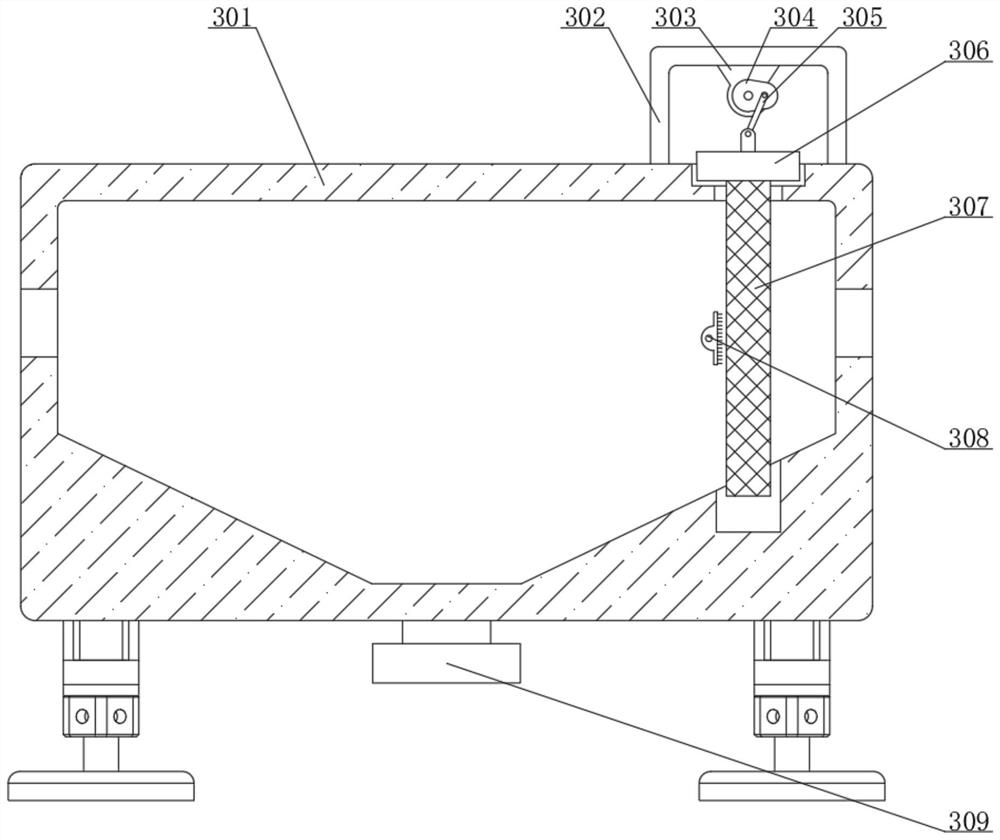

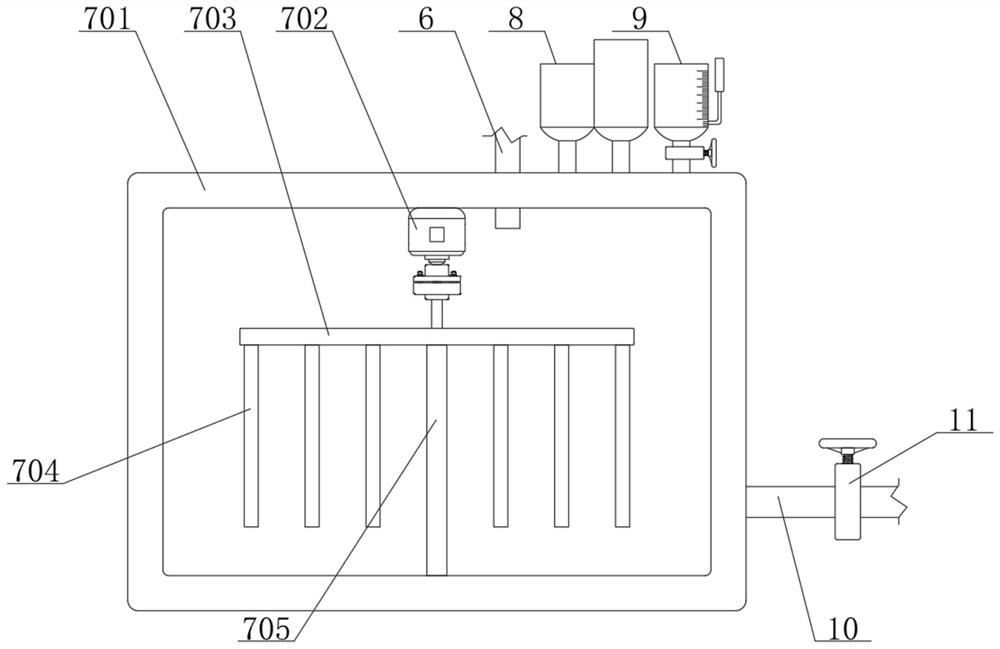

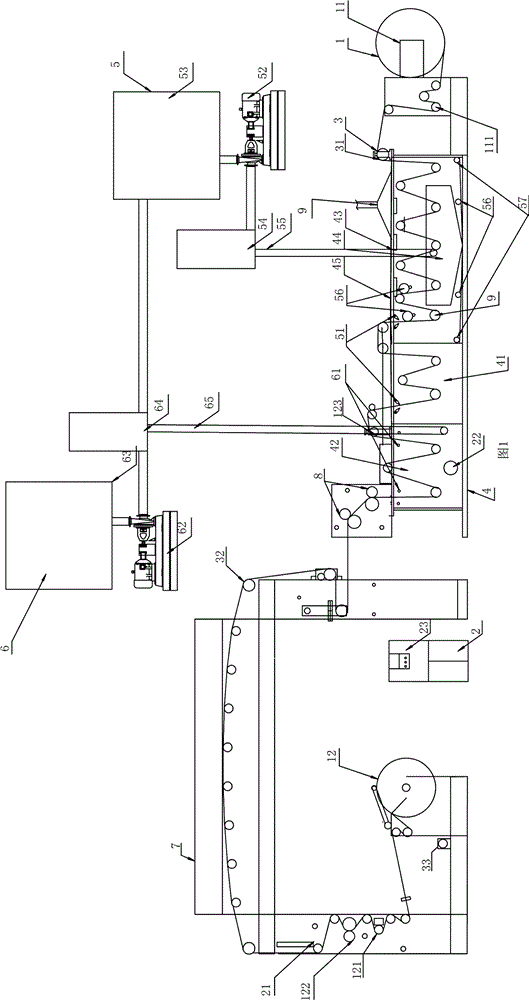

Method and device for removing aluminum of base membrane

ActiveCN103990620AImprove utilization efficiencyReduce usageDirt cleaningCleaning using toolsSuspended matterChemistry

The invention discloses a method for removing aluminum of a base membrane. The method is characterized by including the following steps: (1) feeding the base membrane with the surface containing an aluminum coated layer into a cleaning solution to carry out aluminum removing, (2) feeding the base membrane into clear water to carry out cleaning, and (3) drying the base membrane. A device for removing the aluminum of the base membrane is adopted in the method for removing the aluminum of the base membrane and comprises a cleaning groove, a base membrane reeling-unreeling mechanism and a drying oven. The cleaning groove is divided by a partition plate into a cleaning solution groove and a clear water groove, the drying oven is located behind the cleaning groove, and the base membrane reeling-unreeling mechanism sequentially passes through the cleaning groove and the drying oven. The device for removing the aluminum of the base membrane is characterized by further comprising a cleaning solution circulation filtering mechanism. According to the method and device, the cleaning solution circulation filtering mechanism is additionally arranged in an aqueous alkali circulation system, the cleaning solution located at the top is overflowed from the cleaning solution groove to the cleaning solution circulation filtering mechanism, suspended matter in the cleaning solution is filtered out, the filtered cleaning solution returns to the interior of the cleaning solution groove again through circulation to be continuously used, and the use efficiency of the cleaning solution is improved.

Owner:GUANGDONG ZHUANGLI COLOR PRINTING

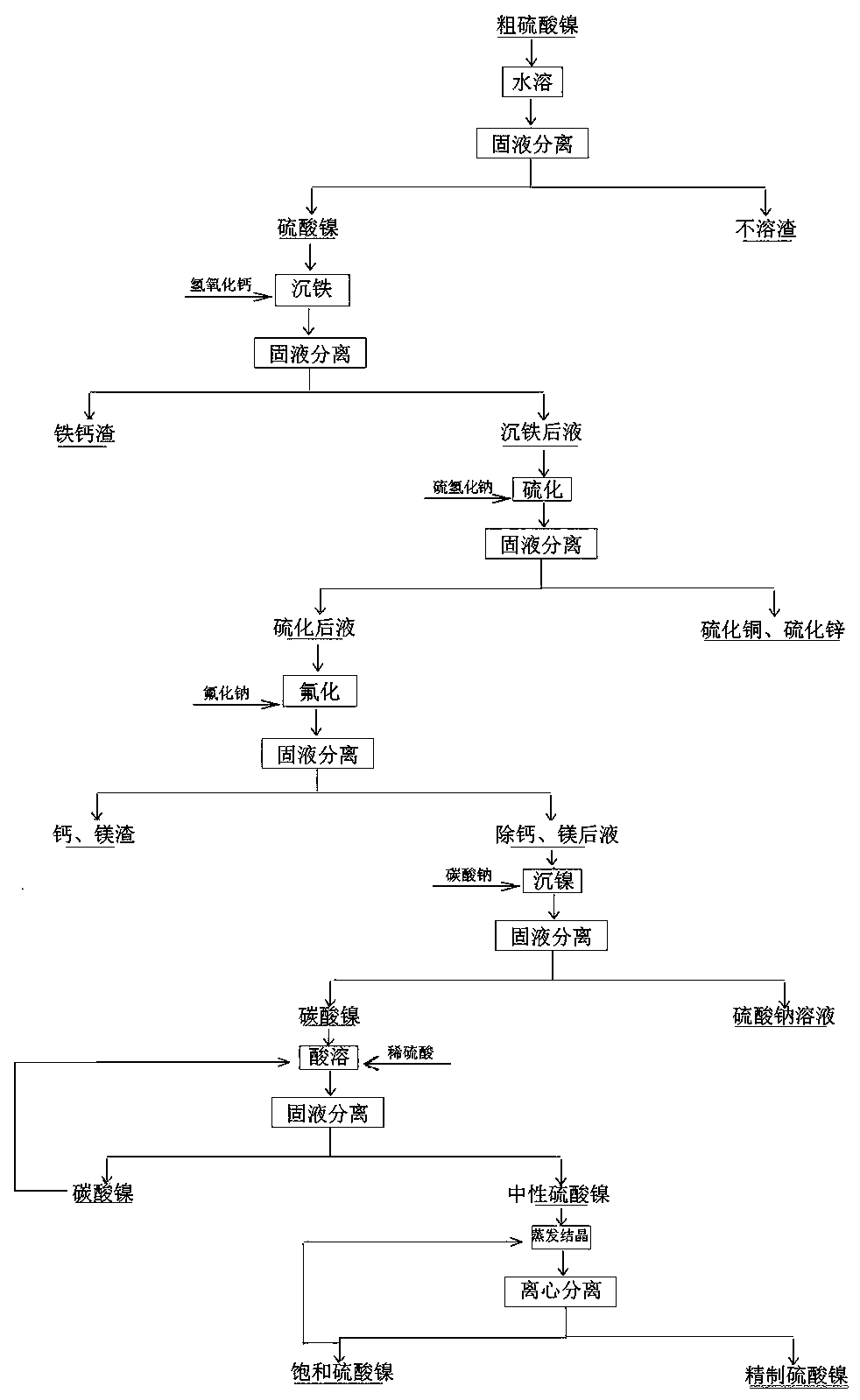

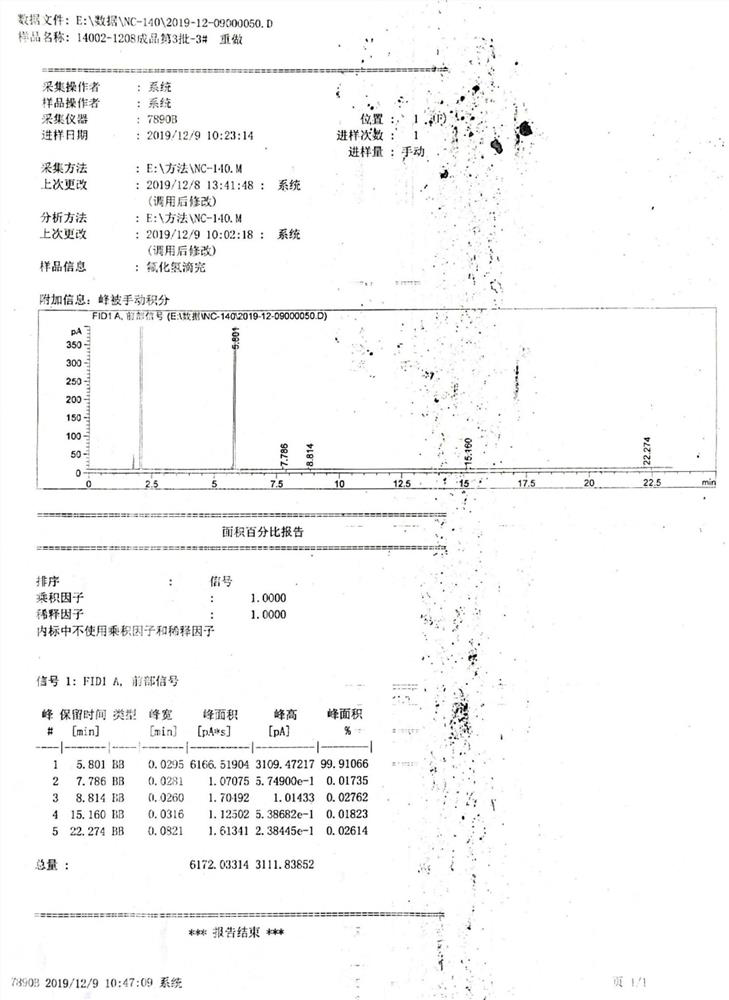

Process for refining battery-grade nickel sulfate from crude nickel sulfate

PendingCN111170378AImprove filtering effectLow impact on purificationNickel sulfatesFerric hydroxideSodium hydrosulfide

The invention provides a process for refining battery-grade nickel sulfate from crude nickel sulfate. The process comprises the following steps: dissolving crude nickel sulfate with high-temperature water according to a certain ratio, carrying out solid-liquid separation to remove a part of calcium and magnesium impurities in crude nickel sulfate in a precipitation form, adjusting the pH value ofa solution obtained after water dissolution to a proper value by using calcium hydroxide, allowing iron to form an iron hydroxide precipitate and allowing calcium to form a calcium sulfate precipitate; according to different precipitation coefficients of sulfides of arsenic, copper, zinc and nickel, adding a certain amount of sodium hydrosulfide to enable copper sulfide, arsenic sulfide and zinc sulfide precipitates to be formed in the solution so as to remove impurity elements including copper, arsenic and zinc; adding sodium fluoride with a certain excess coefficient into a sulfurized solution to form calcium fluoride and magnesium fluoride precipitates and a fluorinated solution; adding sodium carbonate into the fluorinated solution to adjust a pH value, thereby forming a nickel carbonate precipitate and wastewater; adding dilute sulfuric acid with a certain concentration into nickel carbonate to partially dissolve the nickel carbonate so as to form a pure nickel sulfate solution and undissolved nickel carbonate, wherein the nickel sulfate solution is neutral, the undissolved nickel carbonate returns to a dissolving procedure, and subjecting the nickel sulfate solution to high-temperature evaporation crystallization to obtain battery-grade nickel sulfate meeting national standards in China.

Owner:DONGYING FANGYUAN NONFERROUS METALS +2

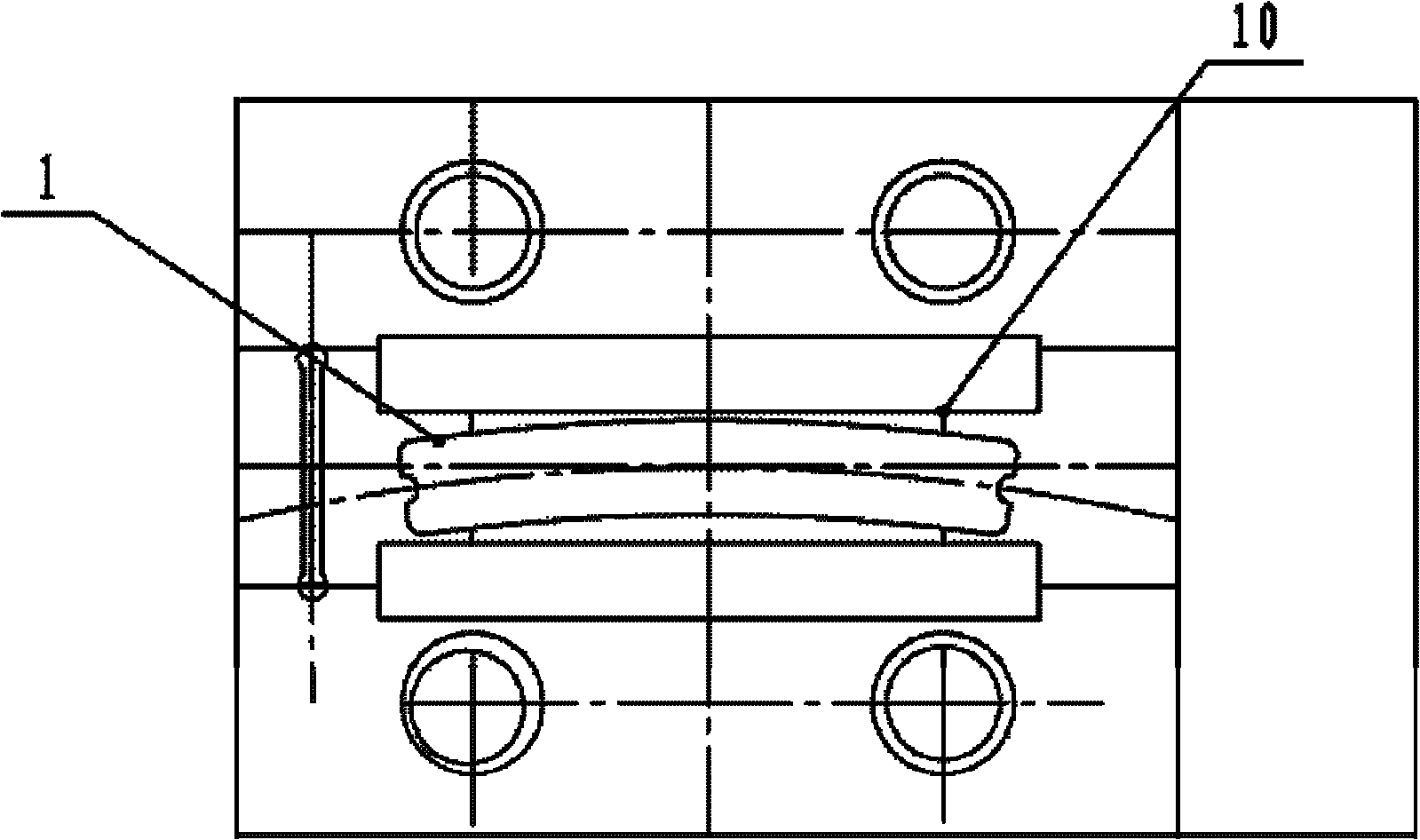

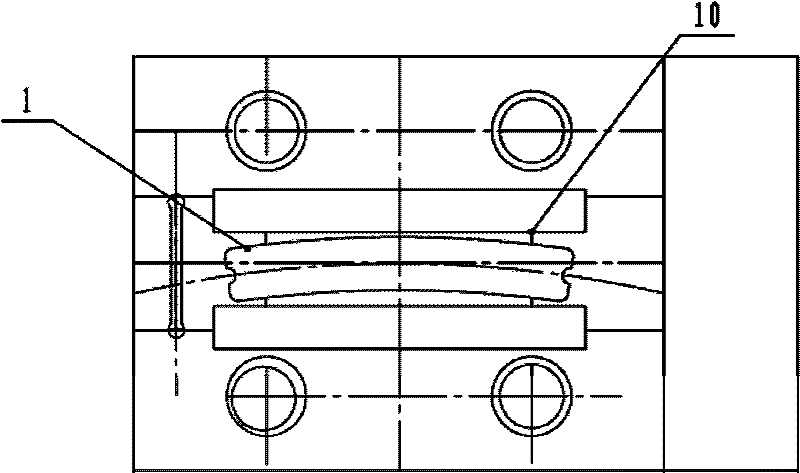

Fan strip label shaping and shearing device

InactiveCN101898304AGuaranteed continuous moldingHigh degree of automationOther manufacturing equipments/toolsEngineeringMechanical engineering

The invention relates to a fan strip label shaping and shearing device, which has the advantages of simple structure, convenient use, one-step shaping and the like. The device comprises a female die and a male die, wherein contours of the two dies are consistent with the peripheral shape of a shaped label; a fit clearance is reserved between the two dies; the male die is connected with a datum plate; the shearing device is arranged on the datum plate; the datum plate is arranged on a guiding device; the male die is matched with a discharging plate; the discharging plate is connected with the datum plate; and a resetting device is arranged between the discharging plate and the datum plate.

Owner:SHANDONG UNIV +1

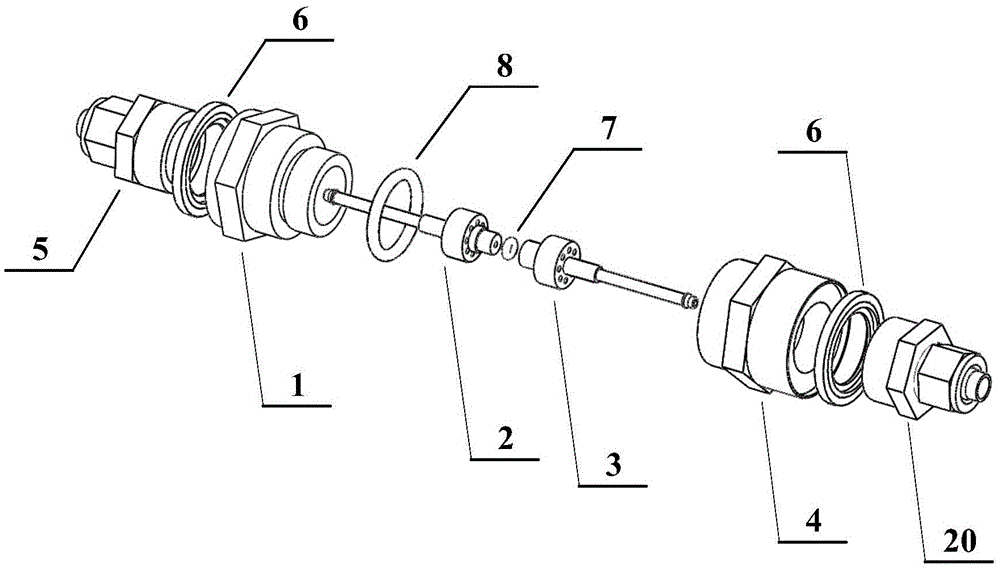

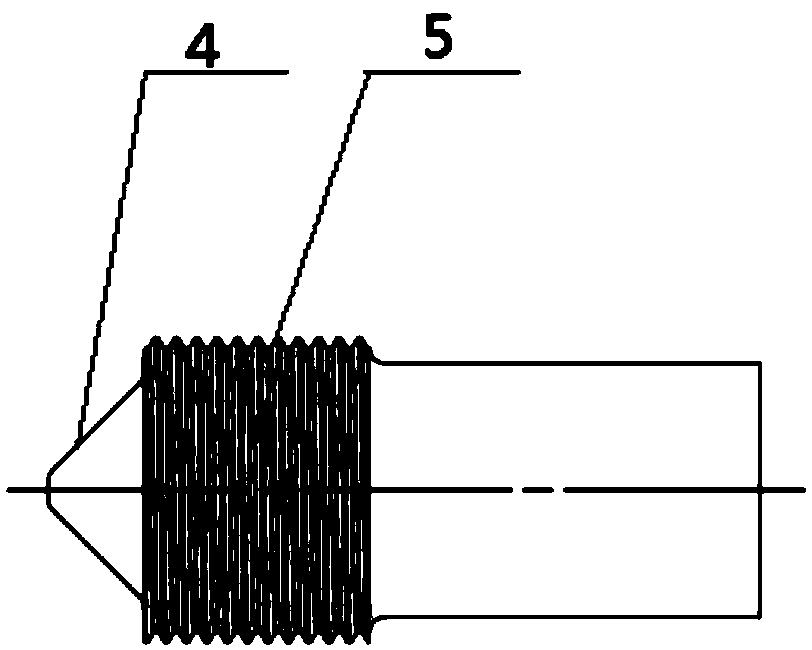

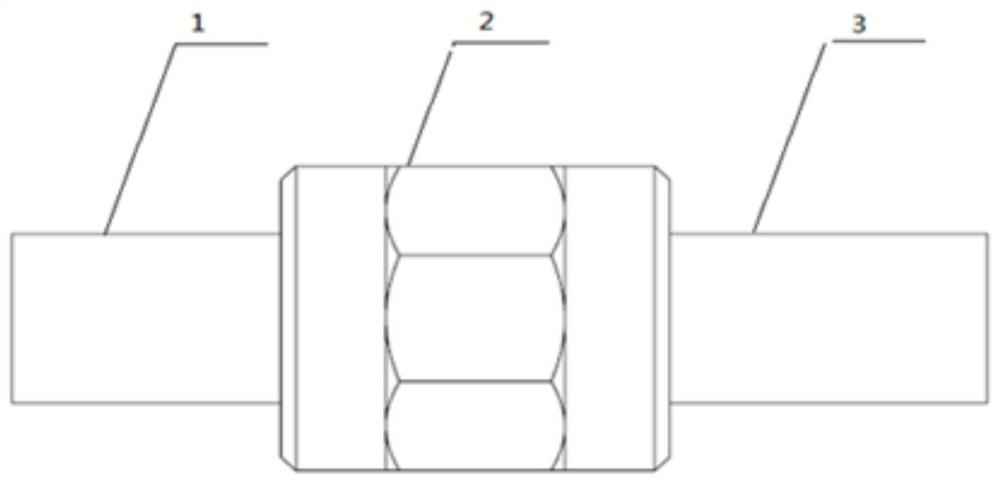

Connecting device for inner and outer pipes of MQL (Minimal Quantity Lubrication) system

InactiveCN105522438AGuaranteed normal transmissionQuick connectionMaintainance and safety accessoriesRandom combinationMaterial consumption

The invention discloses a connecting device for inner and outer pipes of an MQL (Minimal Quantity Lubrication) system and belongs to the field of machining. The connecting device for the inner and outer pipes of the MQL system comprises a connecting housing A, a connecting housing B, a connecting inner core A, a connecting inner core B, a quick female adapter A, a quick female adapter B, a connecting inner core O-type sealing ring, a connecting inner core O-type sealing ring and a copper washer. The connecting housing A and the connecting housing B are in threaded connection with each other to ensure the alignment of the pipes and the stability and efficiency of connection. The connecting device can be in direct plug-in connection with the inner and outer pipes, the connecting housings and the connecting inner cores can be used in random combination during mounting, the connection is quick and stable, and the sealing is tight and reliable. Lubrication media have good transport flowability in the connecting device, and the connecting device cannot be blocked easily and has no leakage loss. Meanwhile, the connecting device can well isolate the lubrication media transported in the inner and outer pipes, avoids the phenomenon of mixing of the inner and outer lubrication media. The connecting device is small in size, light in weight, low in material consumption and cost and suitable for batch production.

Owner:袁松梅

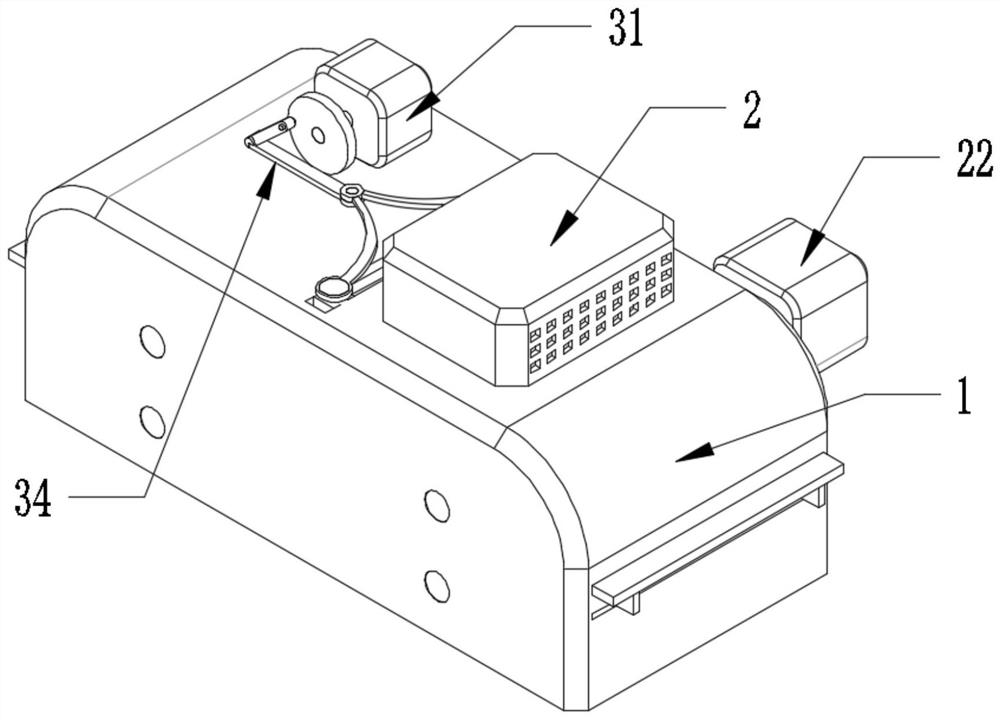

Plastic film detection device

The invention relates to the technical field of plastic film detection, and discloses a plastic film detection device which comprises a detection box, a controller is arranged outside the detection box, the controller is connected with the detection box, an adjusting motor is further arranged on the outer side of the detection box, the adjusting motor is connected with the detection box, the output end of the adjusting motor is provided with an adjusting disc, the adjusting disc is connected with the output end of the adjusting motor, the outer side of the adjusting disc is provided with an adjusting rod, the adjusting rod is connected with the adjusting disc, and one end of the adjusting rod is provided with a push rod. The plastic film detection device provided by the invention can be used for conveniently detecting a plastic film, and compared with a common detection device, the detection device provided by the invention can assist in film transmission, avoid film stretching and detect defects of the film, and the position of the detection sensor can be conveniently adjusted.

Owner:浙江兴士烨新材料科技有限公司

Integrated method for high organic silt high-efficiency dehydration and nutrient soil preparation

InactiveCN106866258ALarge poresIncrease fatnessCalcareous fertilisersBioloigcal waste fertilisersFlocculationPhosphate

Belonging to the technical field of environmental geotechnical engineering, the invention discloses an integrated method for high organic silt high-efficiency dehydration and nutrient soil preparation. The method includes: adding 8%-10% by mass of ground phosphate rock into silt subjected to flocculating setting, and performing stirring to obtain a first silt mixture; adding 6%-8% by mass of dried crushed straw and 2%-4% of dried furfural residue into the first silt mixture, and performing stirring to obtain a second silt mixture; adding 1%-3% by mass of quick lime into the second silt mixture, and performing stirring to obtain a third silt mixture; subjecting the third silt mixture to dehydration treatment so as to obtain a mud cake; and mixing the mud cake with humus and kitchen garbage, and then performing crushing. The method provided by the invention synthesizes the integrated processing steps of high organic silt high-efficiency dehydration and nutrient soil preparation enhances the dehydration efficiency and is based on organic silt nutrient soil fertility, and the obtained nutrient soil has nutrient content close to the national organic fertilizer standard.

Owner:JIANGSU ZHONGYI ECOLOGICAL SOIL INST +1

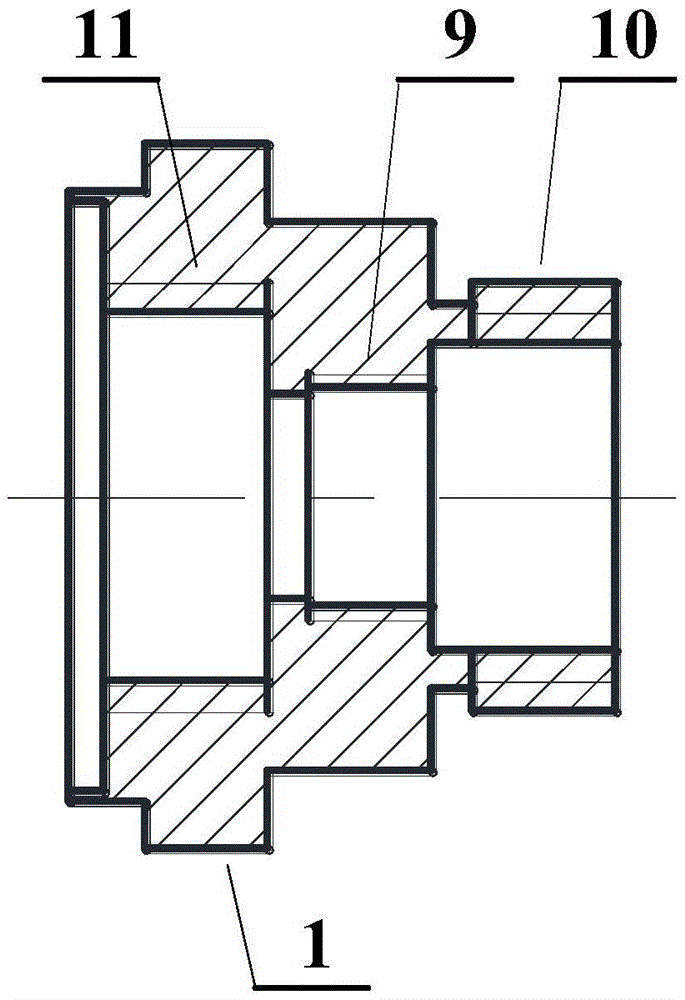

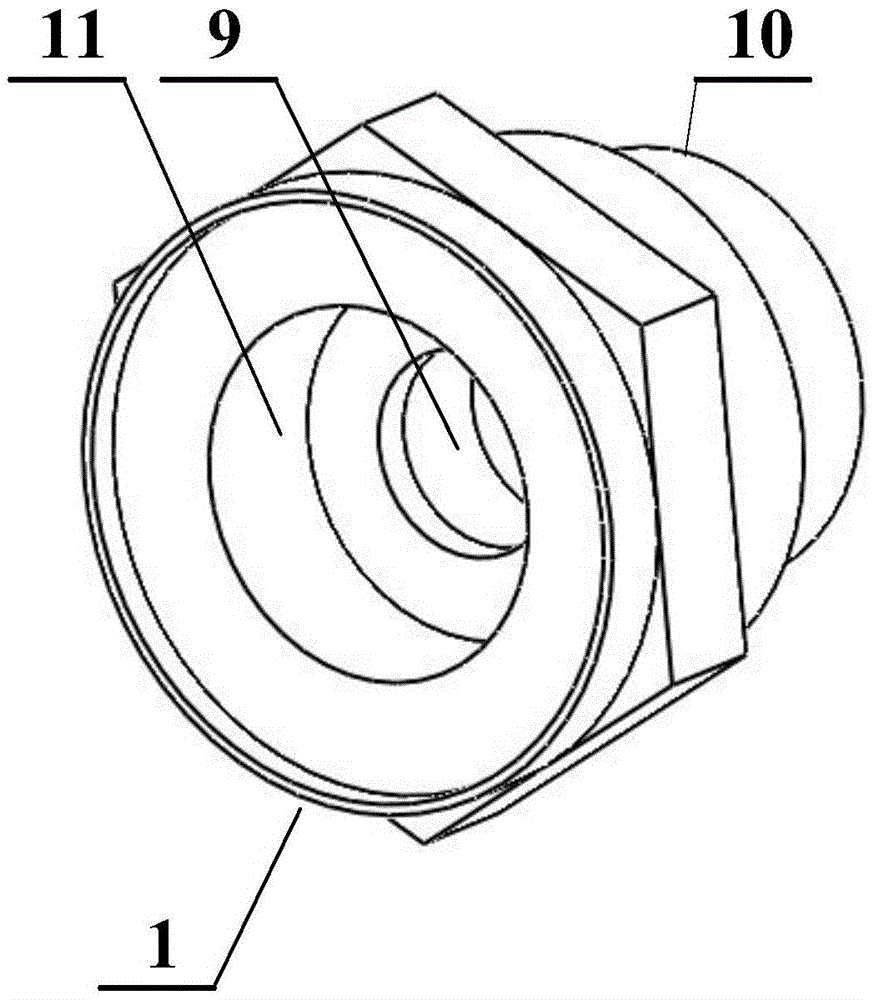

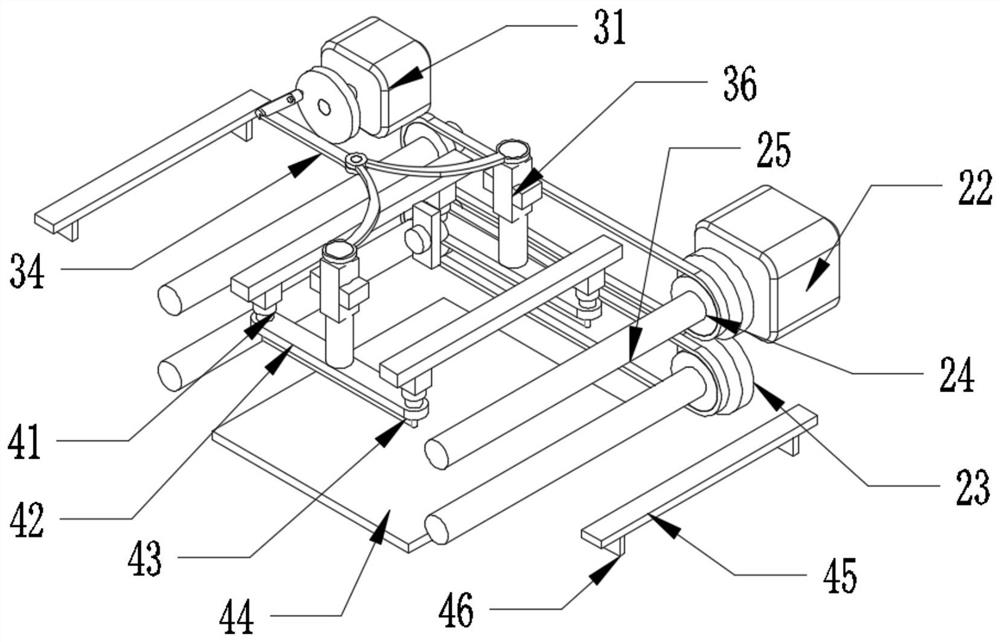

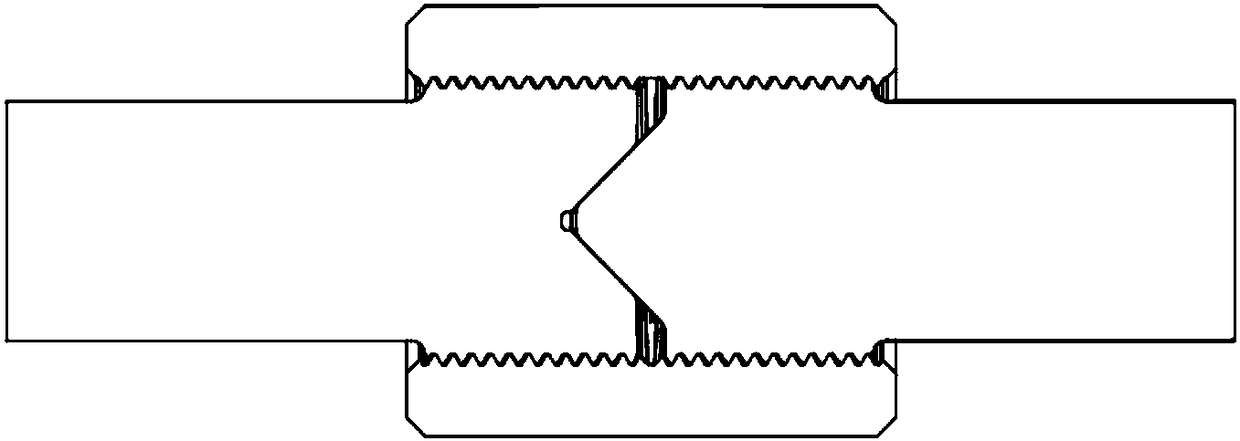

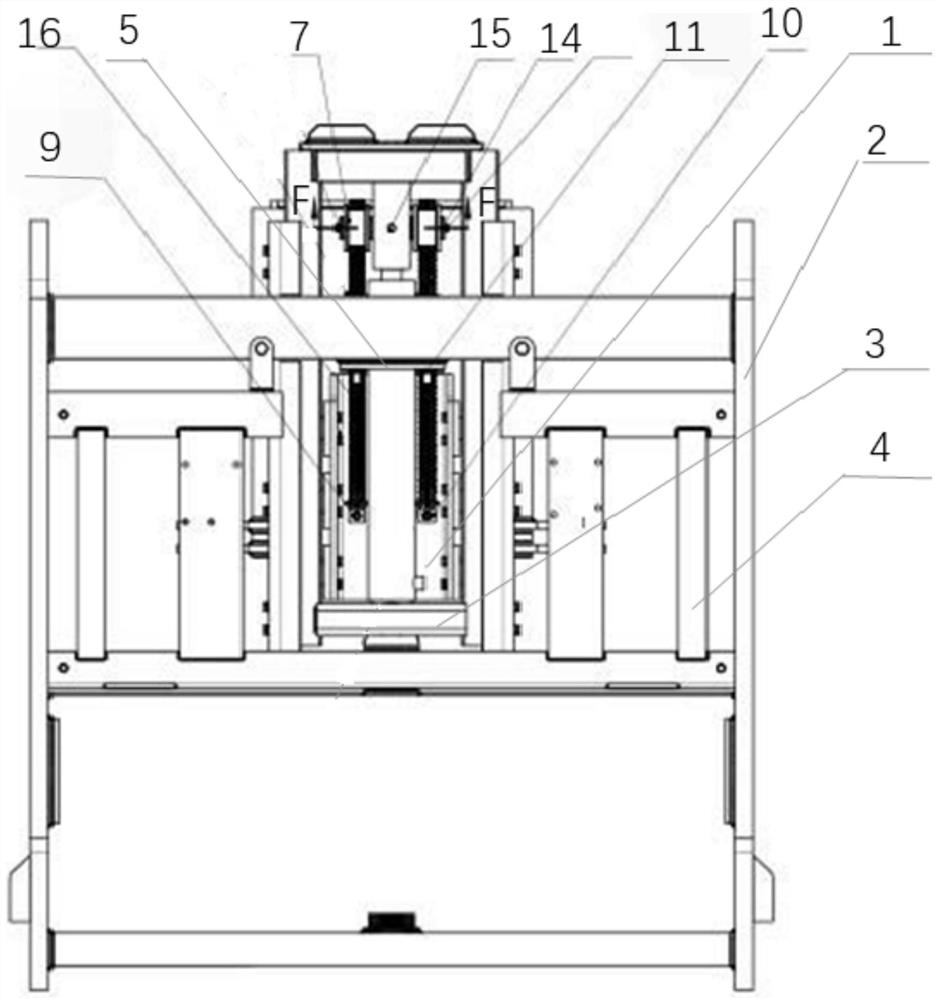

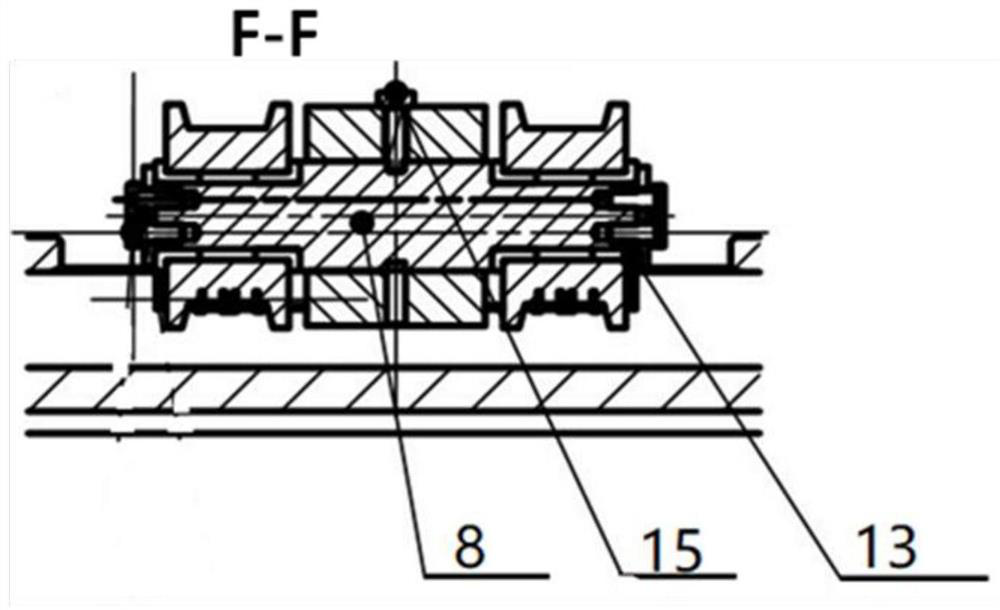

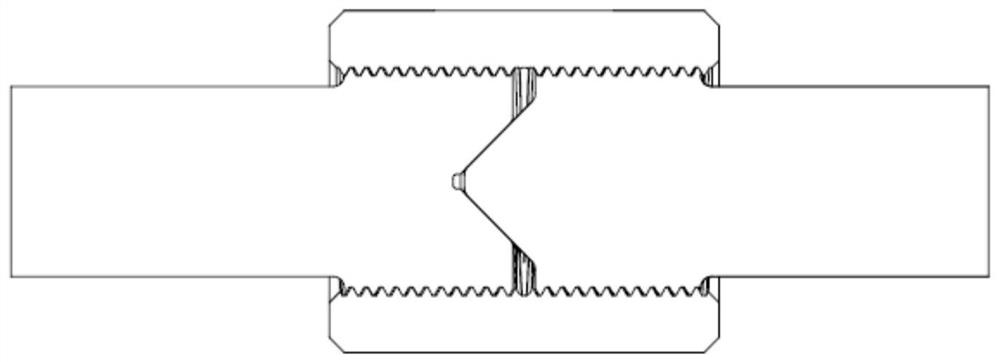

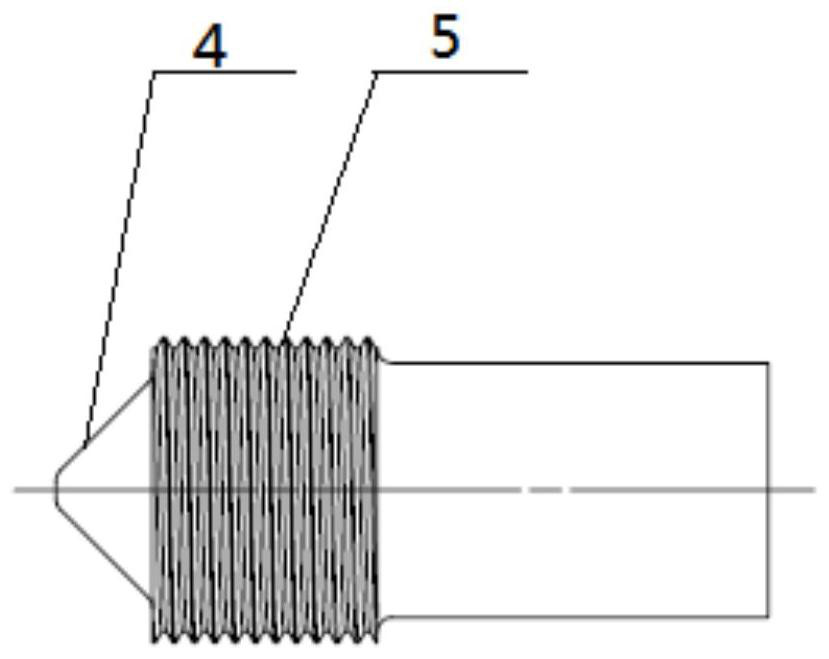

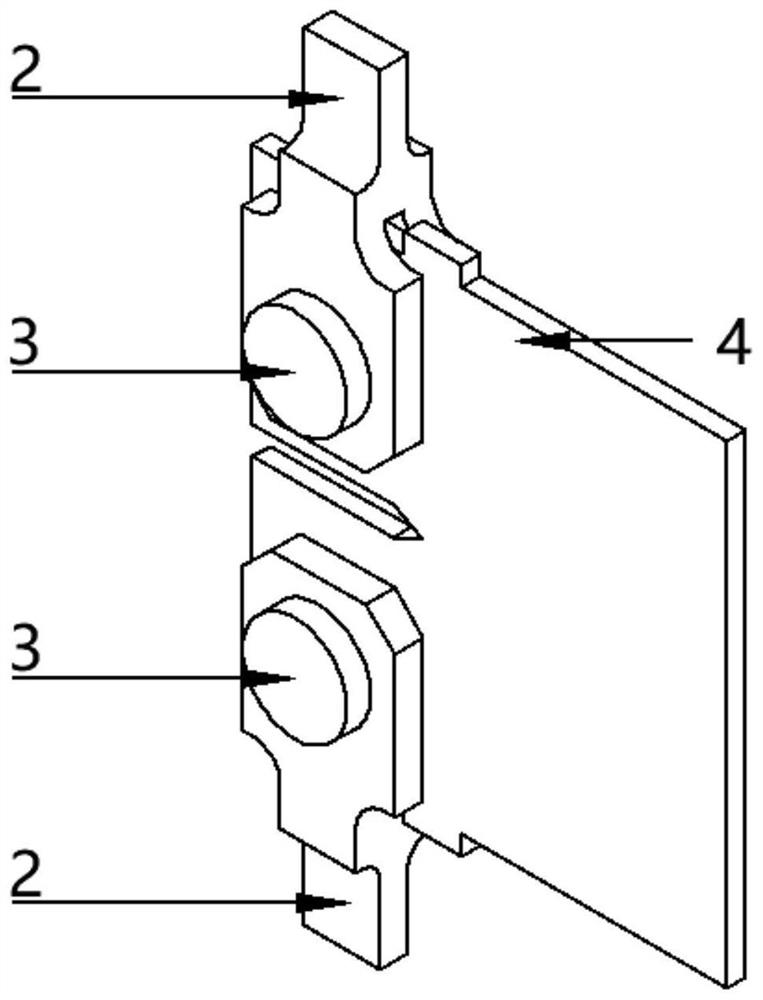

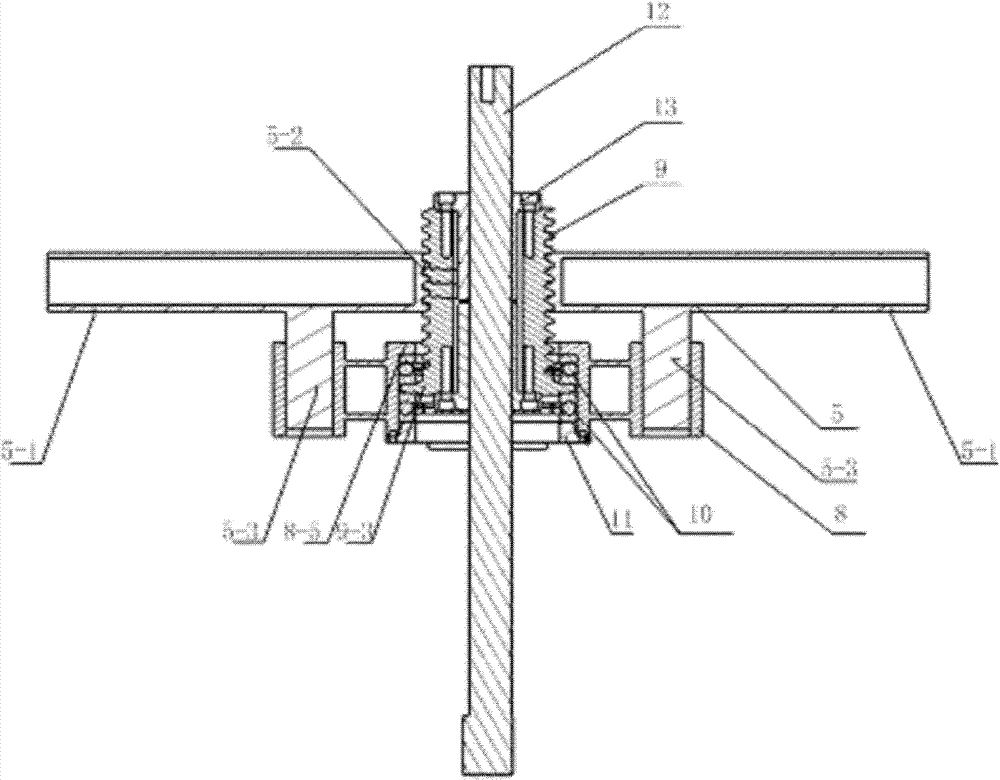

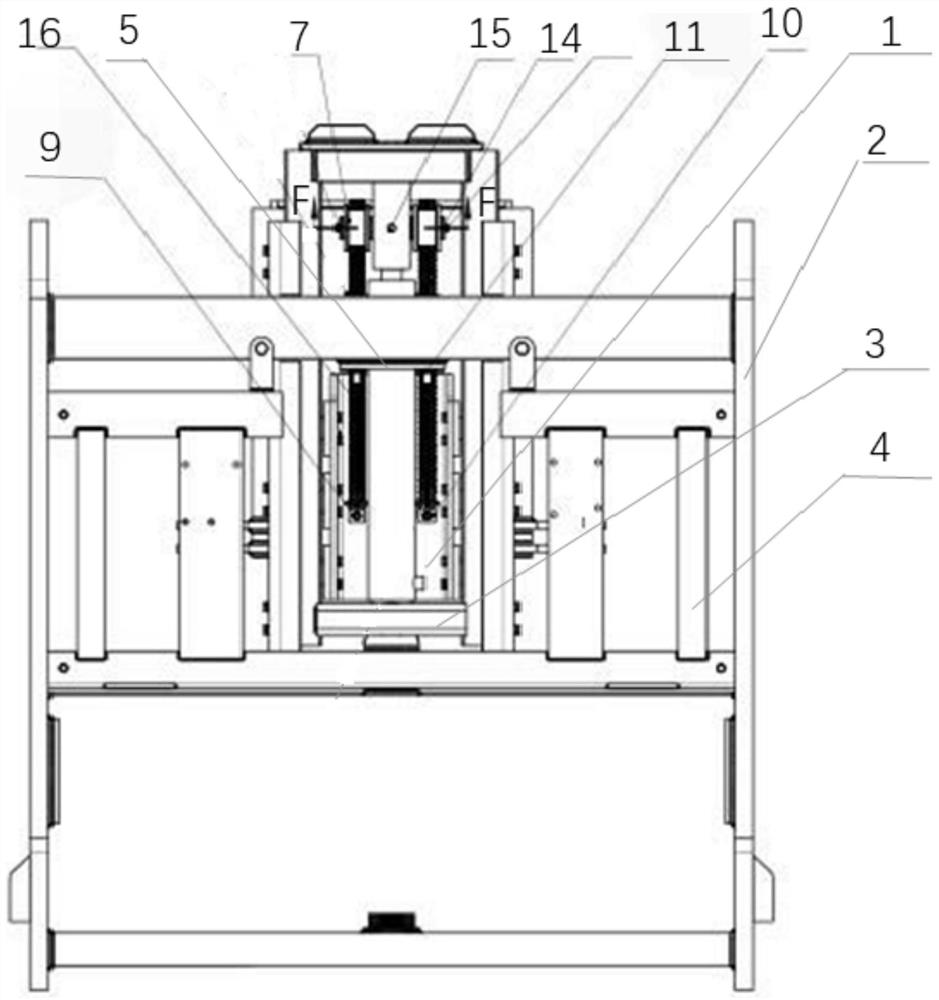

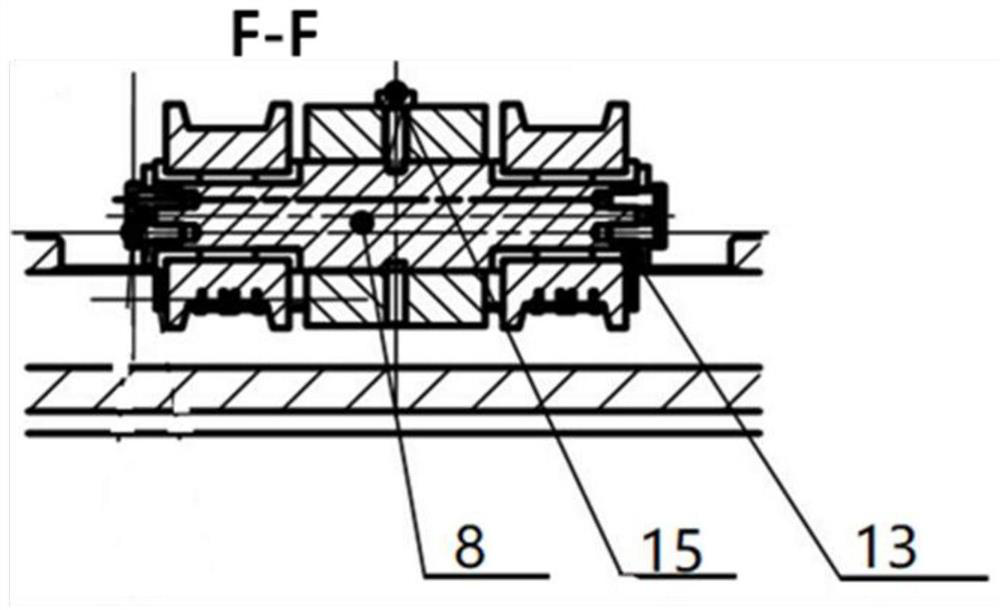

High-centering precision clamp connecting device for mechanical testing machine

ActiveCN108287109AGuaranteed neutralGuaranteed accuracyStrength propertiesFlangeElectrical and Electronics engineering

The invention discloses a high-centering precision clamp connecting device for a mechanical testing machine. The high-centering precision clamp connecting device for the mechanical testing machine comprises a clamping part, a fixing part and a connecting part, wherein a positioning convex conical surface is arranged on the end surface of one end, connected with the connecting part, of the clampingpart; a positive-tooth external thread is close to the positioning convex conical surface, and is used for connecting and locking the connecting part in a matching manner; a positioning concave conical surface is arranged on the end surface of the other end, connected with the fixing part, of the connecting part; a reverse-tooth external thread is close to the positioning concave conical surface,and is used for connecting and locking the connecting part in a matching manner; the connecting part is a connecting thread sleeve with a positive-tooth external thread and a reverse-tooth external thread at the two ends respectively. The high-centering precision clamp connecting device for the mechanical testing machine is compact in structure, light, convenient, low in production cost and easyto operate; meanwhile, extremely high centering precision of a clamp and a pull rod of the testing machine can be guaranteed during an experiment, and connection is steady; compared with the conventional flange plant connection, the connection way adopted by the invention can have the advantage that the axial position of the clamp is continuously adjustable.

Owner:BEIHANG UNIV

Motor

PendingCN111293817AReduce vibration and noiseGuaranteed neutralitySupports/enclosures/casingsElectric machineFriction loss

The invention provides a motor. The motor comprises a rotating shaft, a rolling piece and an elastic piece; the rotating shaft is provided with a positioning part and a limiting part; the rotating shaft is sleeved with the rolling piece; the rolling piece is provided with a barrel and a rolling body; the rolling body is arranged between the barrel and the positioning part in a rolling mode; and the rotating shaft is sleeved with the elastic piece; and the two ends of the elastic piece abut against the limiting part and the rolling piece correspondingly. According to the motor of the invention,the assembling structure of the rotating shaft and the rolling piece is reasonably arranged, so that centering performance of the assembly of the rolling body relative to the rotating shaft is ensured, and therefore, the friction loss of the rolling piece during the operation of the motor is reduced, the service life of the rolling piece is prolonged, and the vibration noise of the motor is reduced, the operation stability and reliability of a product are improved; the initial pre-pressure of the motor in a start-stop stage is guaranteed through the assembly structure of the elastic piece, sothat the rolling body is prevented from being in an irregular free sliding state, and therefore, abnormal noise generated by the rolling piece during the start and shutdown of the motor is effectively avoided.

Owner:WELLING WUHU MOTOR MFG +1

A self-centering tensioning installation fixture for thin-walled ring gear

InactiveCN104589230BAvoid deformationReduce distortionMachine gearing/transmission testingWork holdersSteel ballMechanical engineering

Owner:XI AN JIAOTONG UNIV

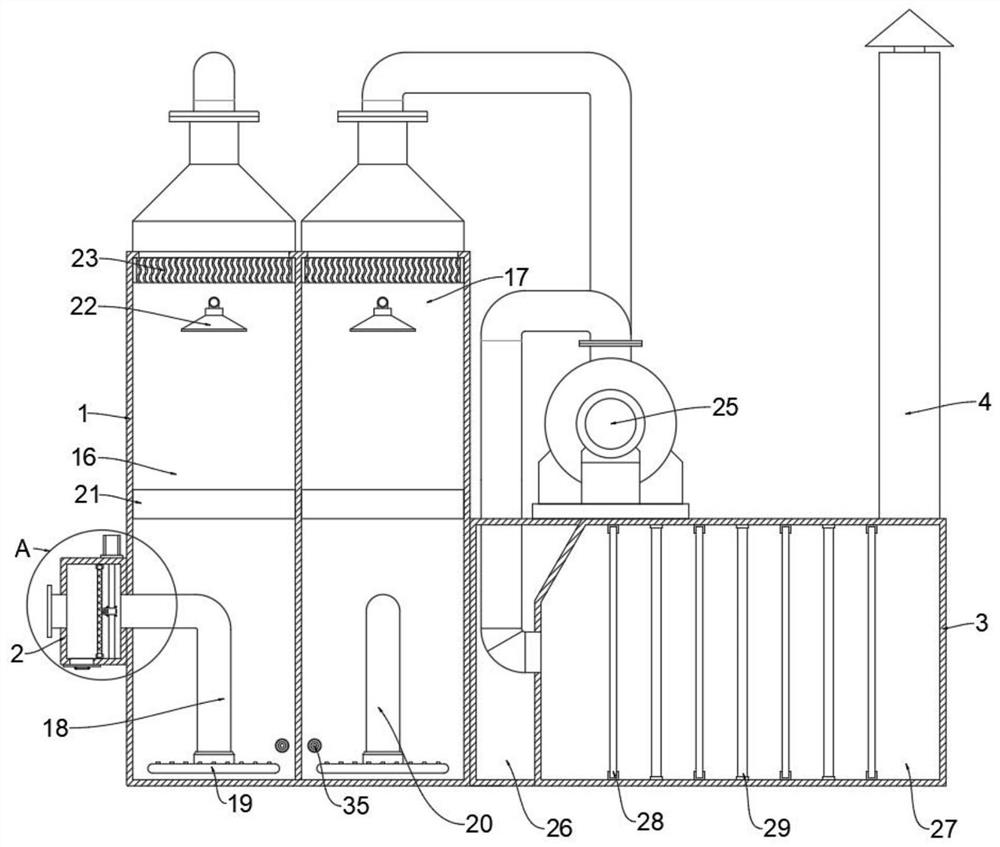

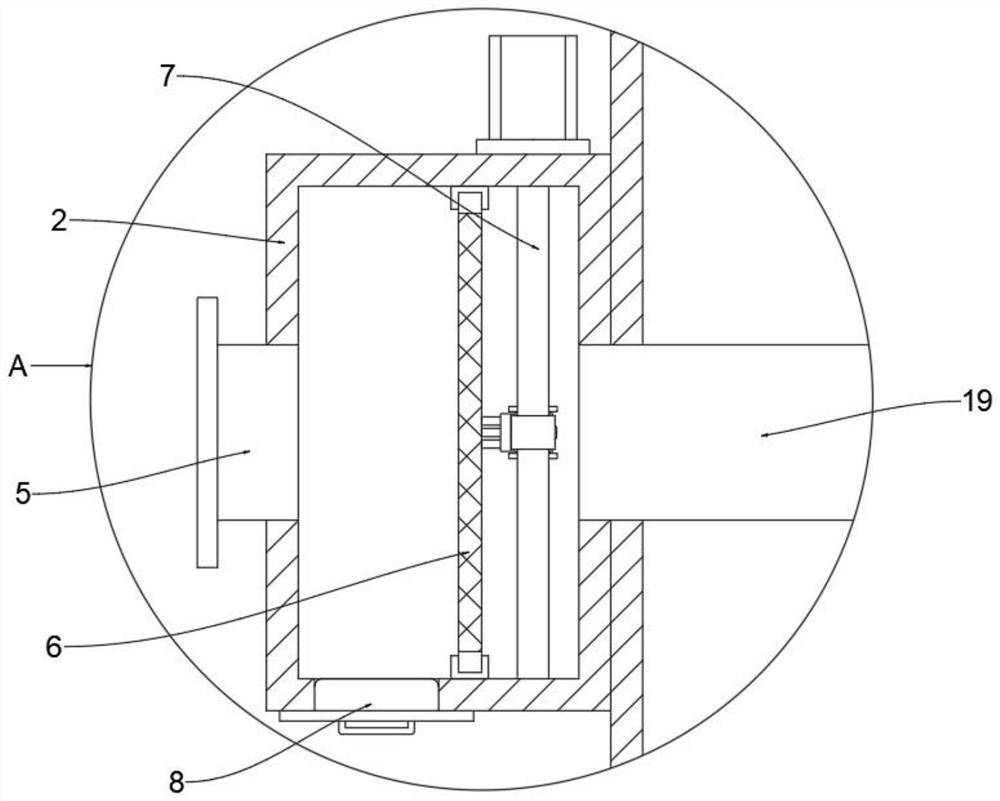

Odor treatment device for garbage power generation equipment and use method of odor treatment device

InactiveCN112843892AIncrease diversityImprove processing efficiencyGas treatmentDispersed particle filtrationPhotocatalysisEnvironmental geology

The invention discloses an odor treatment device for garbage power generation equipment and a use method of the odor treatment device. The odor treatment device comprises a washing box, and an acid washing chamber and an alkali washing chamber which are arranged in the washing box. The odor treatment device also comprises a filter box, a scraping mechanism, a manhole, a photolysis box and a discharge chimney. The filter box is arranged on one side of the washing box, an air inlet is formed in the end, away from the washing box, of the filter box, and a filter screen is installed in the filter box; the scraping mechanism is arranged on one side, far away from the air inlet, of the filter screen; the manhole is formed in the bottom of the filter box; the photolysis box is arranged on the other side of the washing box, a containing chamber and a photolysis chamber are arranged in the photolysis box, photocatalyst carriers are installed in the containing chamber, and UV lamps are installed between the adjacent photocatalyst carriers; and the discharge chimney is arranged above one end, far away from the washing box, of the photolysis box. According to the odor treatment device, the diversity of treatment modes of the odor treatment device is realized, and a very good treatment effect can also be achieved when odor with relatively high concentration is treated.

Owner:赵峰

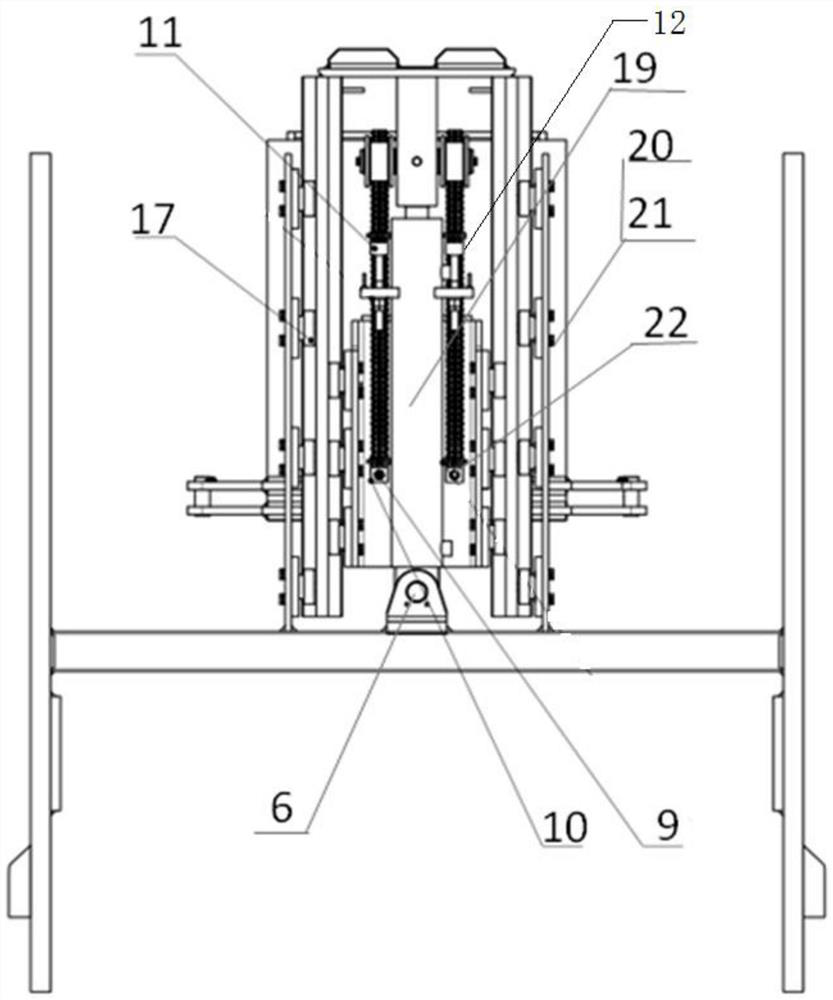

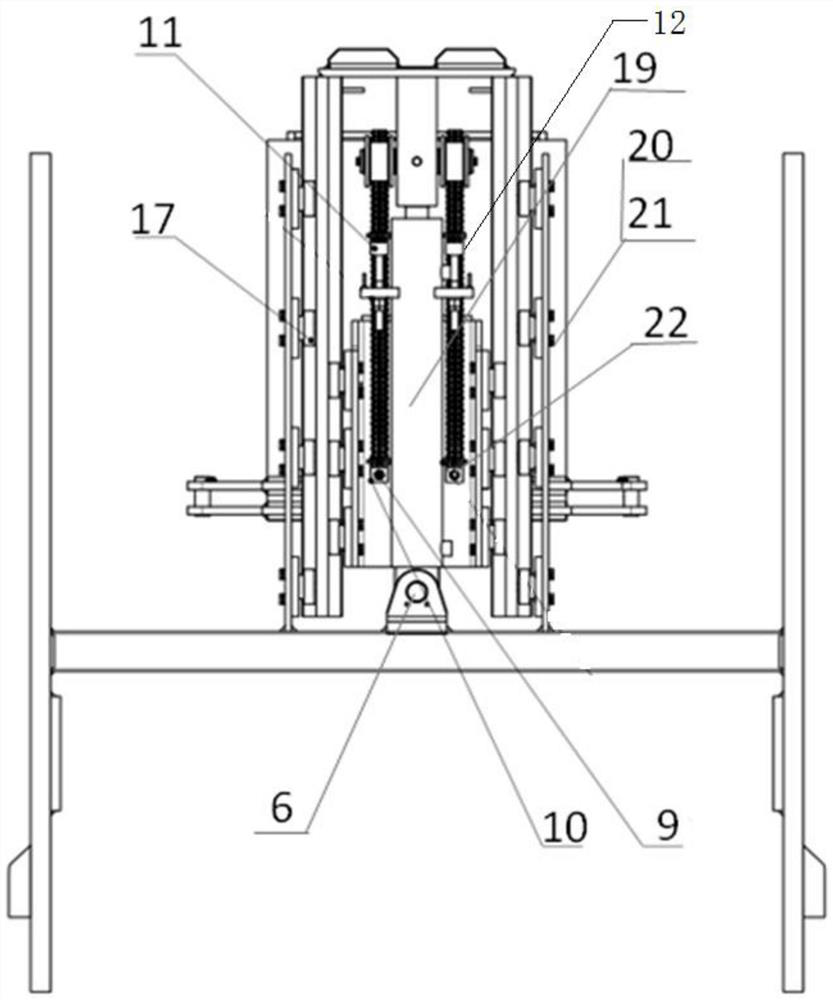

A kind of iron diamond rotation clamp lift mechanism

ActiveCN112081542BIncrease flexibilityImprove fluencyDrilling rodsDrilling casingsClassical mechanicsMachine

The invention discloses a lifting mechanism for an iron driller's turnbuckle pliers, which comprises a support frame assembly, and composite roller bearing groups are installed on the left and right sides of the support frame assembly; the support frame assembly moves up and down in the guide body assembly; Composite roller bearings are installed on the left and right sides of the body assembly, and the guide body assembly moves up and down in the frame body assembly; the upper end of the guide body assembly is connected with the support cylinder; the lower end of the support cylinder is hinged with the frame body assembly through a pin shaft ; The connecting seat is connected with the frame body assembly by bolts; one end of the hoisting chain is fixed on the lock a through the connecting shaft a, the other end of the lifting chain is fixed on the lock b through the connecting shaft b, and the lock b passes through The bolt is fixed on the connecting seat; the sheave is installed on the sheave shaft through the self-lubricating bearing; the extension or retraction of the support cylinder realizes the up and down movement of the support frame assembly and the guide body assembly, so as to realize the up and down movement of the turnbuckle machine move. The invention has simple structure, convenient disassembly and assembly and maintenance.

Owner:中油国家油气钻井装备工程技术研究中心有限公司 +2

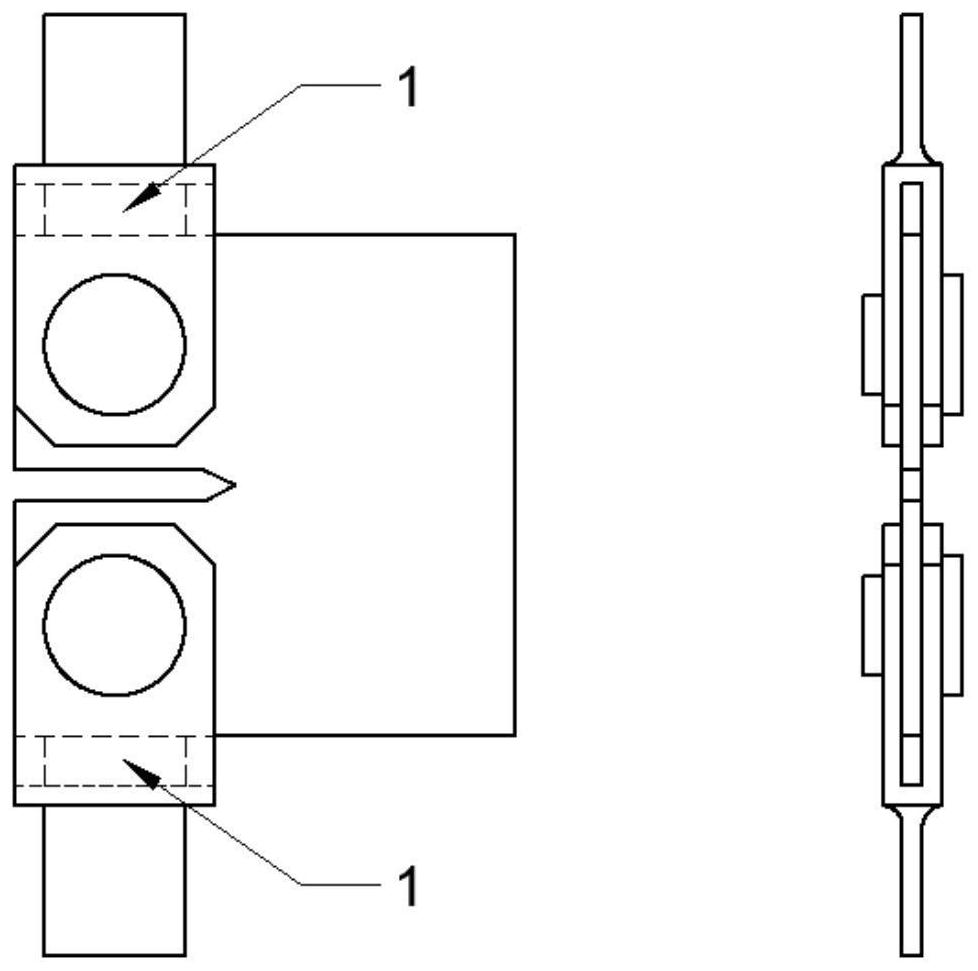

High centering precision fixture connection device for mechanical testing machine

The invention discloses a high-centering precision clamp connecting device for a mechanical testing machine. The high-centering precision clamp connecting device for the mechanical testing machine comprises a clamping part, a fixing part and a connecting part, wherein a positioning convex conical surface is arranged on the end surface of one end, connected with the connecting part, of the clampingpart; a positive-tooth external thread is close to the positioning convex conical surface, and is used for connecting and locking the connecting part in a matching manner; a positioning concave conical surface is arranged on the end surface of the other end, connected with the fixing part, of the connecting part; a reverse-tooth external thread is close to the positioning concave conical surface,and is used for connecting and locking the connecting part in a matching manner; the connecting part is a connecting thread sleeve with a positive-tooth external thread and a reverse-tooth external thread at the two ends respectively. The high-centering precision clamp connecting device for the mechanical testing machine is compact in structure, light, convenient, low in production cost and easyto operate; meanwhile, extremely high centering precision of a clamp and a pull rod of the testing machine can be guaranteed during an experiment, and connection is steady; compared with the conventional flange plant connection, the connection way adopted by the invention can have the advantage that the axial position of the clamp is continuously adjustable.

Owner:BEIHANG UNIV

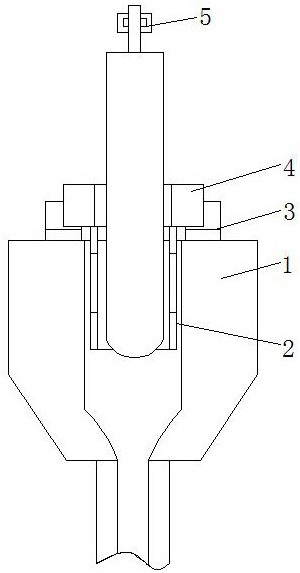

Cap pneumatic picker of var fuel pot of ball bed high-temperature reactor air cooled

ActiveCN1331159CAvoid harmGuaranteed neutralityNuclear energy generationReactor fuel elementsMechanical engineeringPiston cylinder

A stopper pneumatic grab of exhausted fuel pot on ball - bed high temperature GCR is prepared by setting piston in piston cylinder, joining the fixing piece top relatively with piston cylinder, and its bottom with jack catch, setting piston rod at piston head and elongating it into fixing piece, forming T shaped channel between jack catches to let pressing wheel set at piston rod head slide up and down along T shaped channel.

Owner:TSINGHUA UNIV

Heating furnace for keeping centering of optical fiber preform rod and use method of heating furnace

The invention relates to the technical field of optical fiber manufacturing equipment, and discloses a heating furnace for keeping centering of an optical fiber preform, the heating furnace comprises a furnace body, a heating piece and a rotating table, the rotating table is arranged above the furnace body, the upper end of the furnace body is connected with a detection piece through the rotating table, and the rotating table comprises a rotating ring and a base. According to the heating furnace for keeping centering of the optical fiber preform and the use method thereof, the eccentricity condition of the preform is measured through the detection piece, then the preform is directly adjusted in place through the movable clamp, starting and stopping in the centering process are reduced, centering errors are reduced, early warning is conducted when the preform is about to collide with the furnace wall, the preform is prevented from colliding with the furnace wall, meanwhile, the operation of secondary delivery is reduced, and the inner diameter of the heating piece is synchronously adjusted after the detection piece detects the outer diameters of different axial positions, so that the gap between the heating piece and the preform rod is always kept at the optimal distance, the heating uniformity is improved, and the wire drawing quality is improved.

Owner:郎庆岩

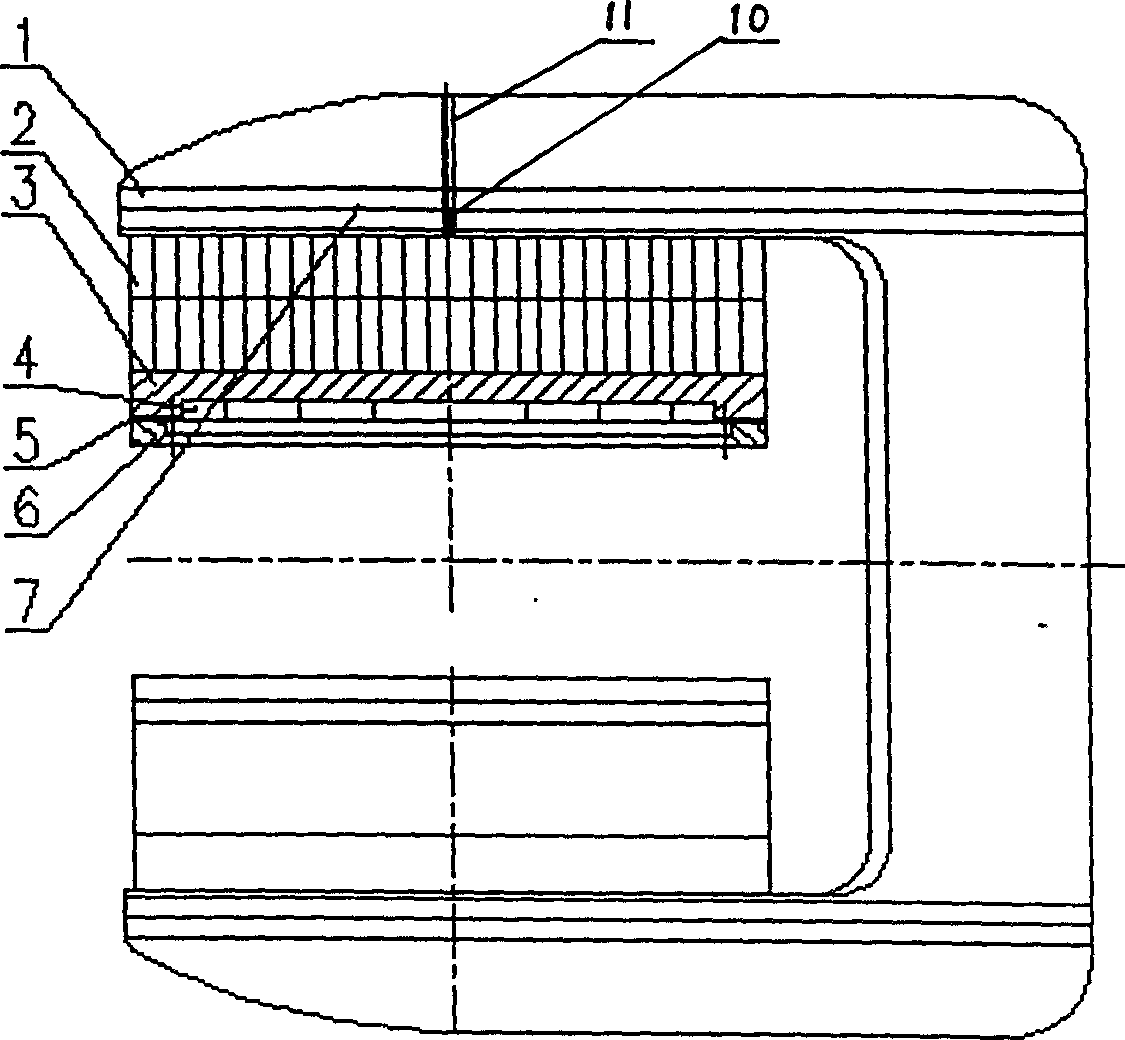

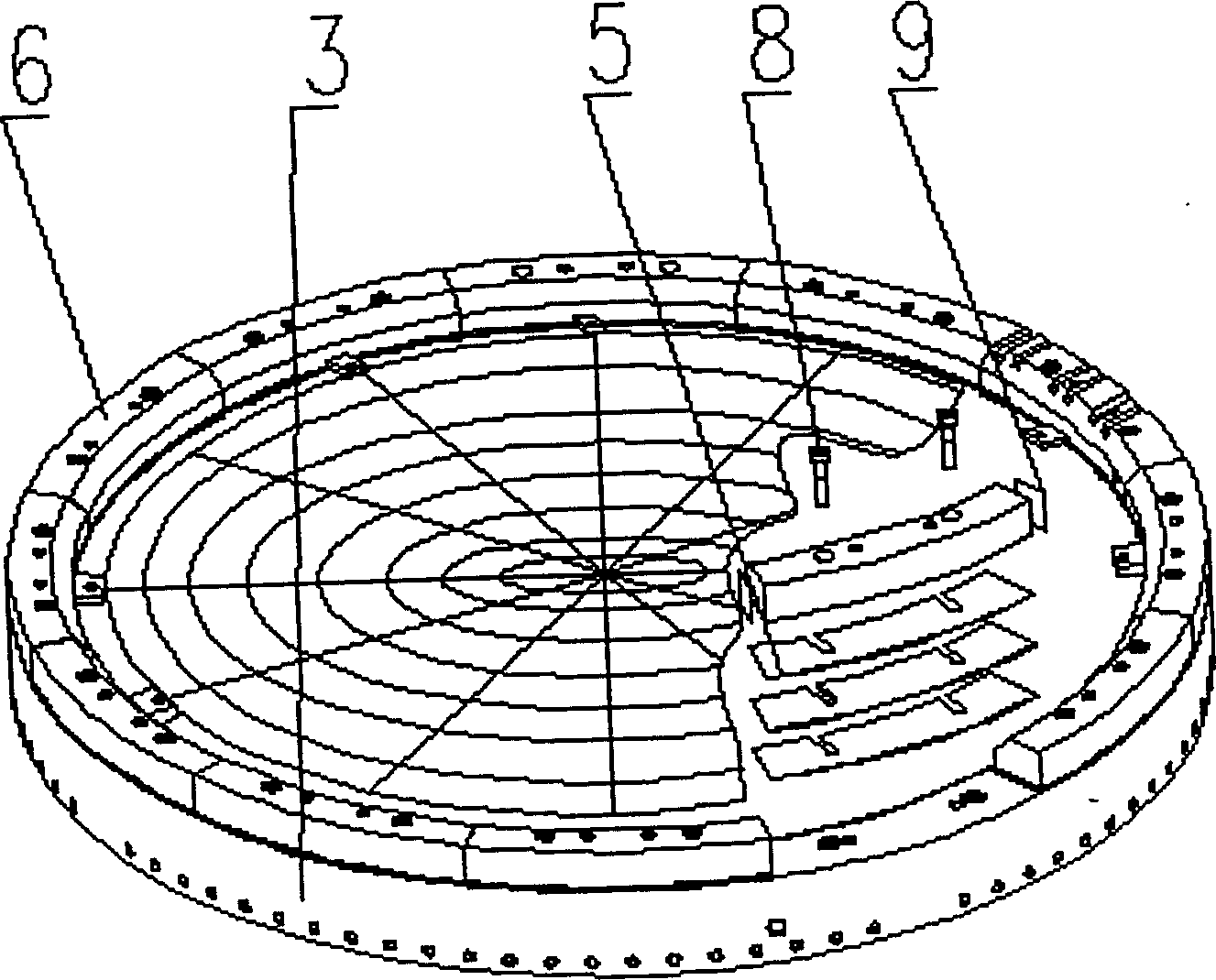

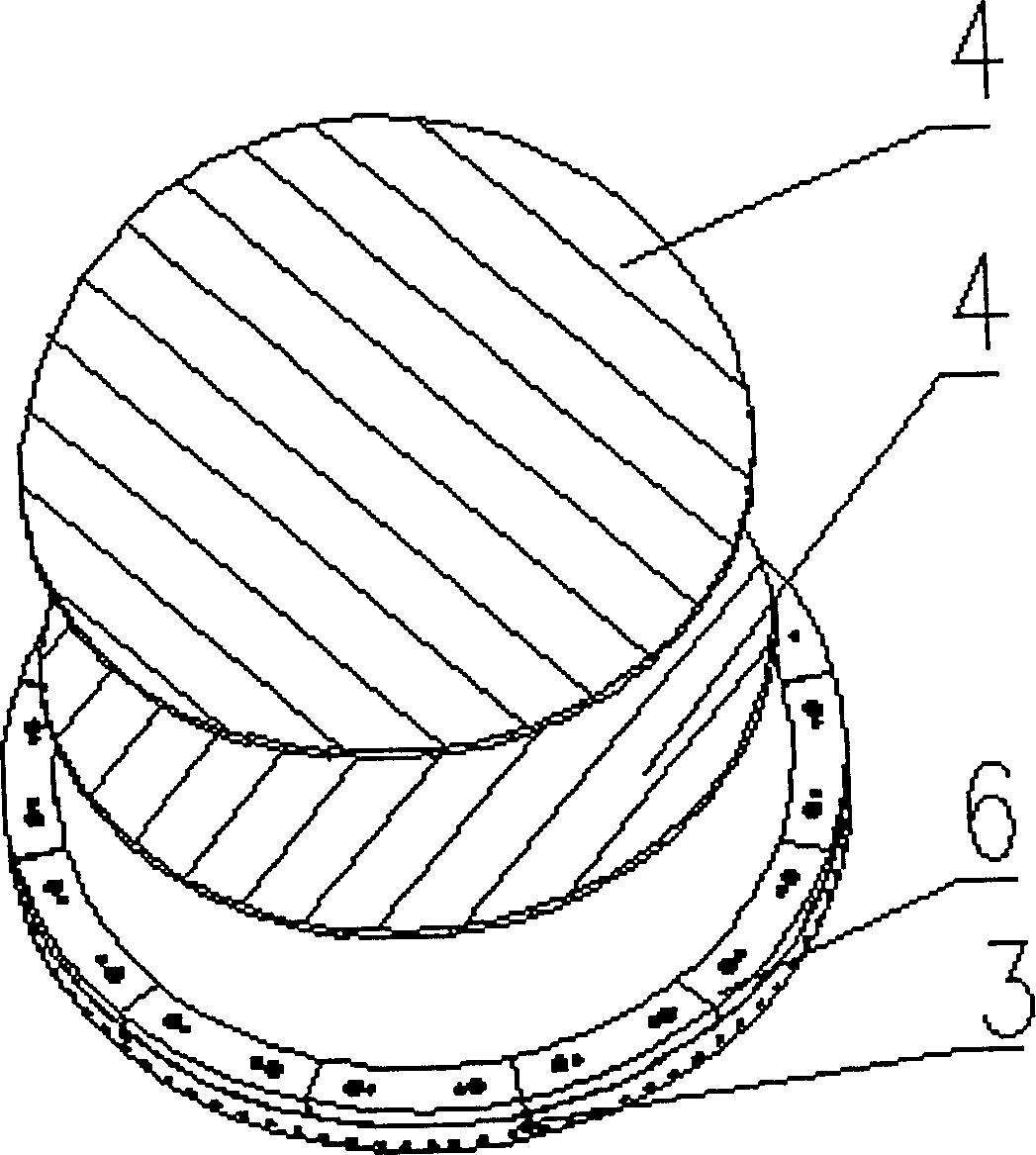

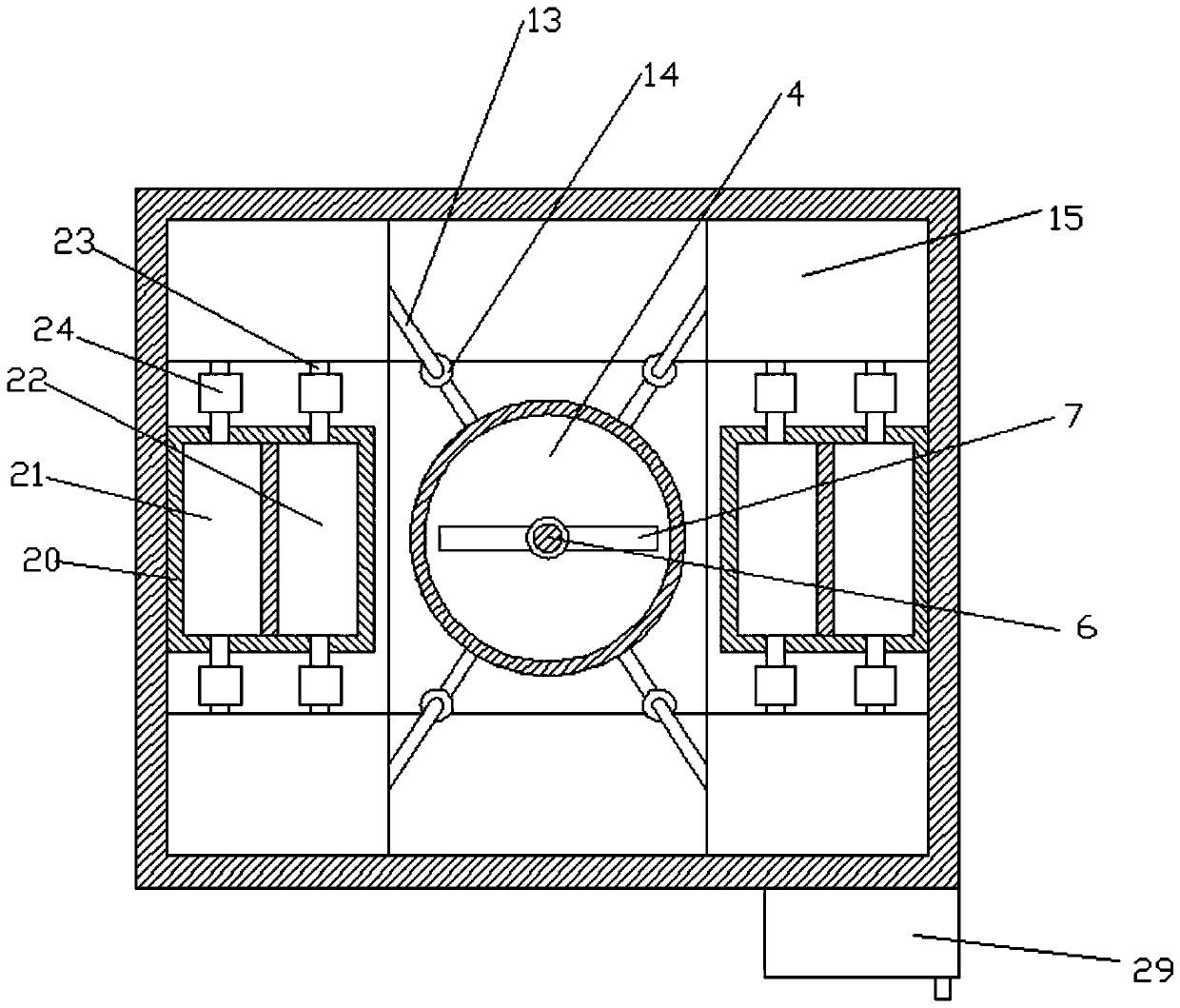

Magnet for head and limb magnetic resonance imaging device

InactiveCN1261075CGuaranteed neutralReduce mistakesMagnetic measurementsPermanent magnetsWhole body mriEngineering

The invention relates to a magnetic body for head- limb magnetic resonant imaging device, which comprises an open C type rack with two upright columns, a magnetic steel material, a cartridge, an anti-spinning disk, a shimming ring adjustment sheet, a shimming ring, low-temperature heating cables and a temperature probe, wherein the anti-spinning disk employs double layer alternating de-spinning disk, the top and bottom surfaces the cartridge element are provided with the shimming ring with inclination angle and shimming ring adjustment sheet of the corresponding number.

Owner:沈阳东软波谱磁共振技术有限公司

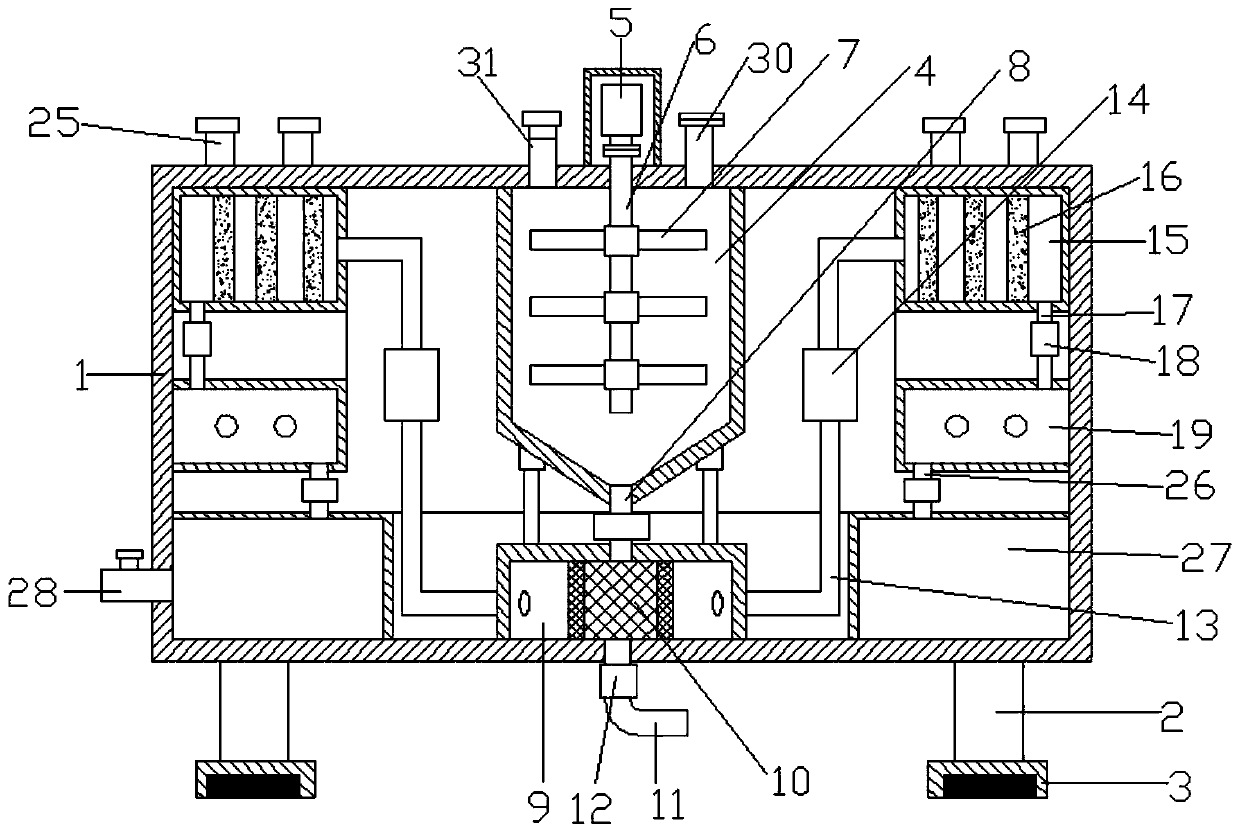

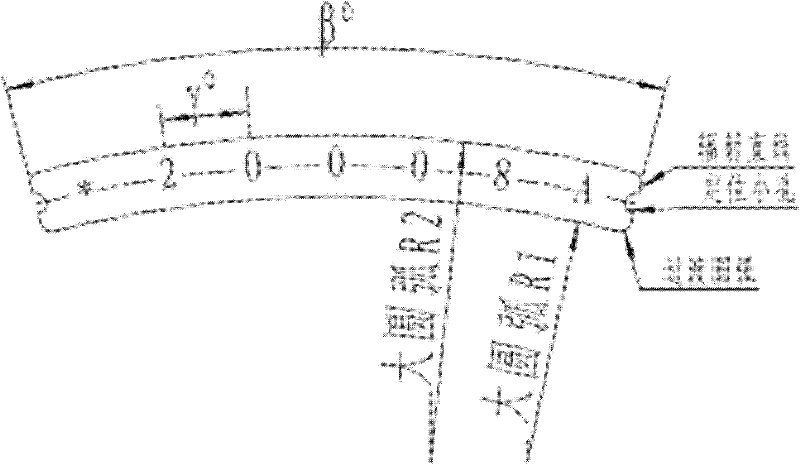

Double-PZT symmetrical integrated large-strain loading device

InactiveCN101776699BReduce displacementGuaranteed neutralityScanning probe techniquesMicro nanoBiochemical engineering

The invention relates to the mechanics measurement and the experimental mechanics of the micro-nano structure, in particular to a double-PZT symmetrical integrated large-strain loading device. The double-PZT symmetrical integrated large-strain loading device adopts the following technical scheme that: the double-PZT symmetrical integrated large-strain loading device comprises a pair of piezoelectric ceramics PZT with the identical technical indexes, a pressure sensor, a quasi-static charge amplifier and a computer, wherein the piezoelectric ceramics PZT are arranged on both sides of a test piece for pushing a clamp to generate micrometric displacement and realize simultaneous loading on the both sides of the test piece; the pressure sensor is connected with the computer through the quasi-static charge amplifier; and the pressure sensor is a piezoelectric type force sensor. The double-PZT symmetrical integrated large-strain loading device is mainly used on the occasion where researchesare carried out on the performance of the thin film loaded with heavy load.

Owner:TIANJIN UNIV

Clamp capable of applying pulling/pressing cyclic load to CT test piece

ActiveCN113804537AIncrease profitOptimize the fixture structure formMaterial strength using tensile/compressive forcesWork unitStructural engineering

The invention relates to a clamp capable of applying a pulling / pressing cyclic load to a CT test piece. The clamp is composed of a working unit and a pin unit. The clamp is connected with the testing machine through the clamping part of the working unit, and in order to prevent the clamp from sliding during loading, the roughness of the clamping surface needs to be increased; the CT test piece is placed in the groove of the working unit, when the clamp is used for providing a pressing-pressing cyclic load, the upper surface and the lower surface of the groove are directly in plane contact with the top end and the bottom end of the CT test piece, and when the clamp is used for providing a pulling-pulling cyclic load, the pin unit needs to be used for transmitting the load. Two different types of loads can be applied to the CT test piece, and the utilization rate of the clamp is increased; meanwhile, the structural form of the clamp is optimized, a pin unit does not need to be placed during compression loading, and the clamping time of the CT test piece is saved; and the anti-skid table is additionally arranged on the CT test piece, so that the CT test piece is prevented from moving left and right when the clamp performs plane compression loading, and the load centering property is ensured.

Owner:BEIHANG UNIV

Impact loading mechanism

InactiveCN102156081BImprove applicabilityGuaranteed continuous gradientMaterial strength using repeated/pulsating forcesBall bearingPull force

Owner:BEIHANG UNIV

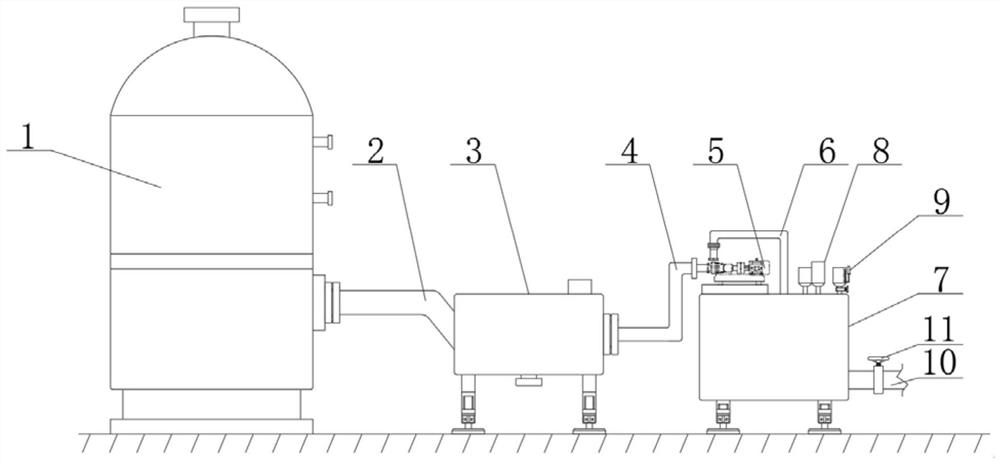

A sewage treatment process and device for instant food processing and extraction

ActiveCN111348774BPrecise neutralization ratioGuaranteed neutralSpecific water treatment objectivesTreatment involving filtrationElectric machinerySewage

The invention relates to the technical field of sewage treatment, in particular to a sewage treatment process and device for instant food processing and extraction, including a tank body and a delivery pipe, the right end surface of the tank body is fixedly connected with a delivery pipe, and the right end surface of the delivery pipe is fixedly connected There is a filtering device, the right end of the filtering device is fixedly connected with an input pipe, the right side of the filtering device is provided with a stirring device, the left side of the upper end of the stirring device is fixedly connected with a water pump, and the input end of the water pump is fixedly connected with the input pipe , the output end of the water pump is fixedly connected with an output pipe, and the other end of the output pipe is fixedly connected with the stirring device; in the present invention, through the provided filter box, rotating motor, eccentric wheel, fixed plate, filter screen and cleaning brush, After the hot concentration process, the residue in the coffee is discharged along with the sewage, and then pre-filtered through the filter to filter out the residue to ensure the normal progress of the next process and avoid direct discharge of sewage.

Owner:昆明弘承食品科技有限公司

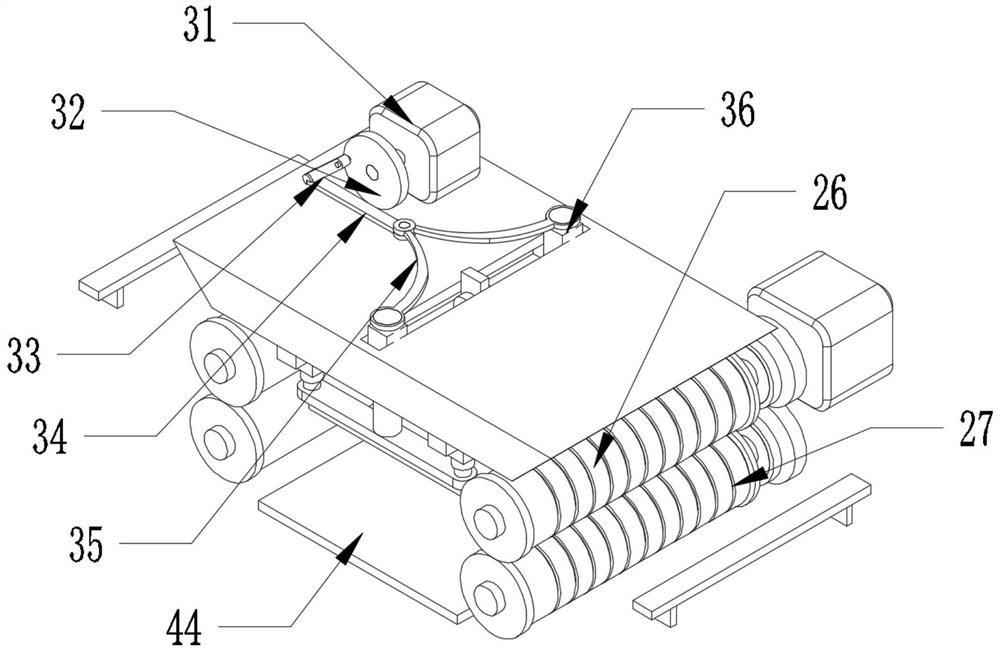

Iron roughneck spinning wrench lifting mechanism

ActiveCN112081542AIncrease flexibilityImprove fluencyDrilling rodsDrilling casingsIndustrial engineeringWrench

The invention discloses an iron roughneck spinning wrench lifting mechanism which comprises a supporting frame assembly. Composite roller bearing sets are installed at the left side and the right sideof the supporting frame assembly; the supporting frame assembly moves up and down in a guide body assembly; composite roller bearings are mounted at the left side and the right side of a frame body assembly, and the guide body assembly moves up and down in the frame body assembly; the upper end of the guide body assembly is connected with a supporting oil cylinder; the lower end of the supportingoil cylinder is hinged with the frame body assembly through a pin shaft; a connecting seat is connected with the frame body assembly through a bolt; one end of a hoisting loop chain is fixed on a lock catch a through a connecting shaft a, the other end of the hoisting loop chain is fixed on a lock catch b through a connecting shaft b, and the lock catch b is fixed on the connecting seat through abolt; a grooved wheel is mounted on a grooved wheel shaft through a self-lubricating bearing; and the supporting oil cylinder stretches out or retracts back to achieve vertical movement of the supporting frame assembly and the guide body assembly, and therefore vertical movement of a whole spinning wrench is achieved. The iron roughneck spinning wrench lifting mechanism is simple in structure andconvenient to disassemble, assemble and maintain.

Owner:中油国家油气钻井装备工程技术研究中心有限公司 +2

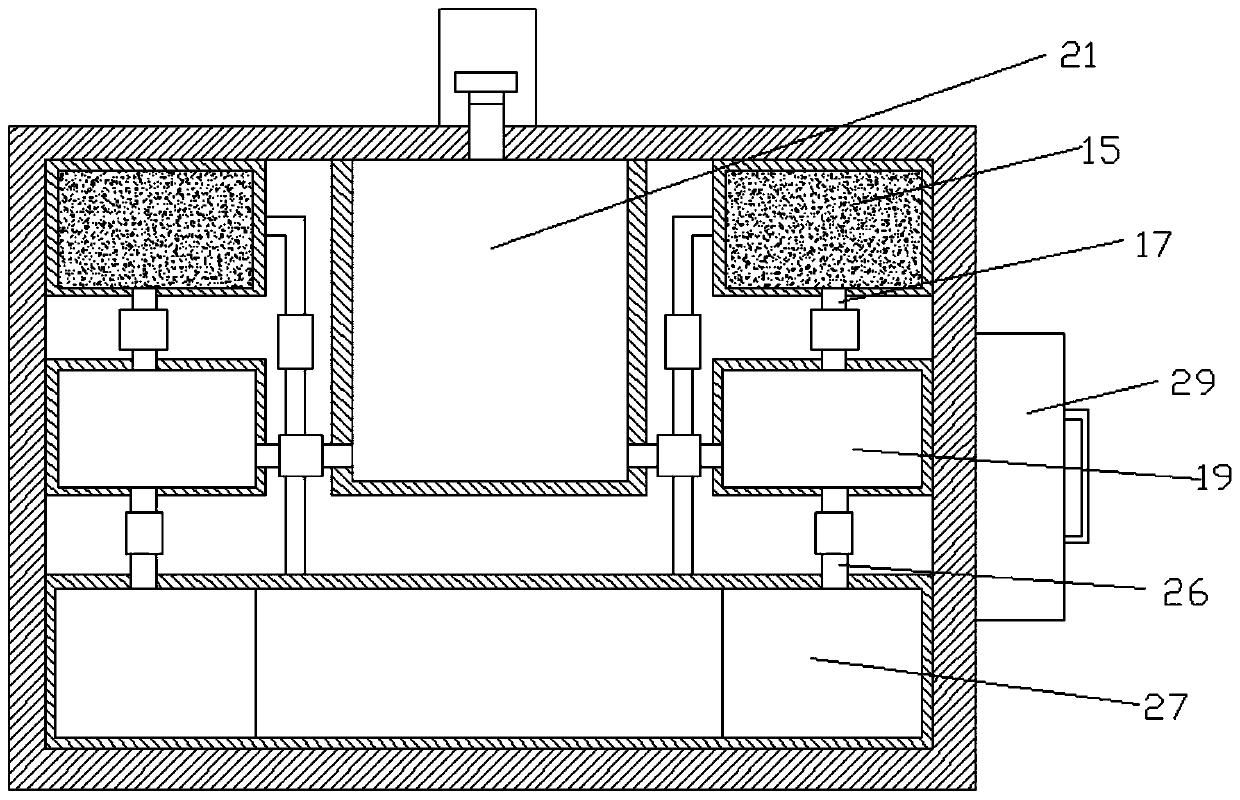

A small industrial wastewater treatment equipment

ActiveCN107555672BEffective filteringEasy to handleWater contaminantsMultistage water/sewage treatmentFiltrationSludge

Small-size industrial wastewater treatment equipment is disclosed. The equipment includes a tank body. The front right side of the tank body is provided with an electric control cabinet. The upper endof the middle of the tank body is provided with a stirring cavity. A motor is disposed on the stirring cavity. A feeding port is disposed on the left of the motor. A liquid adding pipe is disposed atthe right of the motor. The lower part of the motor is provided with a rotating shaft. Two sides of the rotating shaft are provided with stirring bars. The lower part of the stirring cavity is provided with a liquid discharging pipe. A filtration cavity is disposed below the liquid discharging pipe. The middle of the filtration cavity is provided with a filter shield. The lower part of the filtration cavity is provided with a sludge discharging pipe. Four corners of the filtration cavity are provided with water suction pipes. Processing cavities are disposed outside the upper ends of water suction pumps. First connecting pipes are disposed outside the lower parts of the processing cavities. The first connecting pipes are provided with acid-alkali detectors. Acid-alkali neutralizing cavities are disposed below the first connecting pipes. The lower parts of the acid-alkali neutralizing cavities are provided with third connecting pipes. A water storage cavity is disposed below the thirdconnecting pipes. The left side of the water storage cavity is provided with a water discharging pipe. Industrial wastewater can be treated effectively by the equipment, thus effectively protecting the environment and saving the water resource.

Owner:中关村科技租赁股份有限公司

A method and equipment for dealumination of base film

ActiveCN103990620BImprove utilization efficiencyReduce usageDirt cleaningCleaning using toolsSuspended matterChemistry

A method for dealuminating a base film, which is characterized in that it includes the following steps: a. Send the base film containing an aluminum-plated layer on the surface into a cleaning solution to wash the aluminum; b. Send the above-mentioned base film into clean water for cleaning; c. , dry the above base film. The base film dealumination equipment used in the above-mentioned base film dealumination method includes a cleaning tank, a base film rewinding and unwinding mechanism, and an oven. The cleaning tank is divided into a cleaning liquid tank and a clean water tank by partitions. The oven is located in the cleaning area. Behind the tank, the base film rewinding and unwinding mechanism passes through the cleaning tank and the oven in sequence, and is characterized in that: the base film dealumination equipment also includes a cleaning solution circulation filtering mechanism. The present invention adds a cleaning solution circulation filtering mechanism to the alkali solution circulation system, so that the cleaning solution at the top overflows from the cleaning liquid tank into the cleaning solution circulation filtering mechanism, the suspended matter therein is filtered, and the filtered cleaning solution passes through the circulation Return to the cleaning solution tank again to continue use, which improves the utilization efficiency of the cleaning solution.

Owner:GUANGDONG ZHUANGLI COLOR PRINTING

Chuck used for die head threading machine clamping without damages

PendingCN110052672AGuaranteed accuracyGuarantee the quality of processing threadThread cutting toolsThread cutting machinesOut degreeEngineering

The invention relates to a chuck used for die head threading machine clamping without damages. The chuck comprises a mounting disc and a clamping sleeve mounted on the end part of the mounting disc, and further comprises an inner barrel for clamping a steel tube, wherein the mounting disc is provided with a coaxial through hole A; the clamping sleeve is cylindrical, and is provided with a coaxialthrough hole B; a notch is formed in the cylindrical wall of the right end of the clamping sleeve, and a clamping block is arranged in the notch; the clamping block and the clamping sleeve define a complete cylinder; a seam A is formed between the clamping sleeve and the clamping block, a spring is arranged between the clamping sleeve and the clamping block, and the clamping sleeve and the clamping block are connected through a bolt E; the inner barrel comprises an upper half barrel and a lower half barrel, and a seam B is formed between the upper half barrel and the lower half barrel; the upper half barrel is mounted on the clamping block through a bolt C; and the lower half barrel is mounted on the inner wall of the clamping sleeve through a bolt D. The chuck has the beneficial effects of not generating clamping damages on the steel tube, being capable of regulating circular run-out degree after once clamping, and guaranteeing clamping precision.

Owner:CEC JINJIANG INFO IND

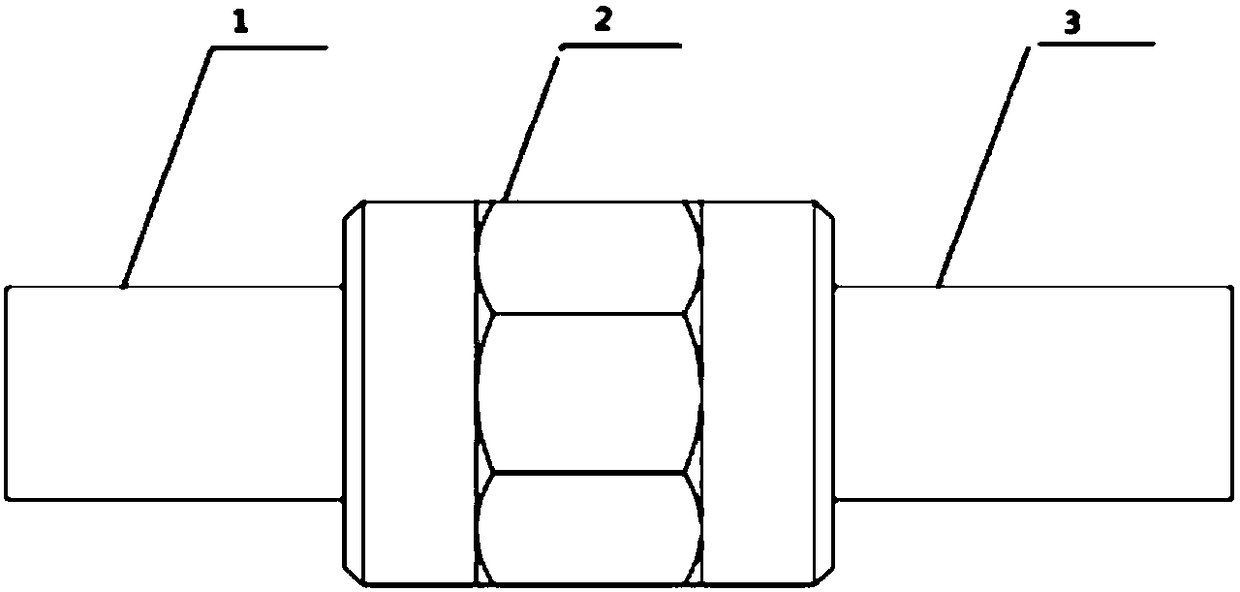

Spherical washer

InactiveCN106931072AEasy to installGuaranteed neutralityWashersRopes and cables for vehicles/pulleyEngineering

The present invention proposes a spherical washer, which includes a concave ball washer and a convex ball washer that are used in pairs. The concave ball washer is a hollow cylinder with a through-hole of the concave ball washer inside and communicated with the concave ball washer. A concave spherical surface with the holes connected to and concave toward the through hole of the concave ball pad; the convex ball pad is a truncated hollow spherical body, and its side surface is a convex spherical surface that protrudes outwards; wherein, the concave spherical surface and the convex spherical surface are The spherical surfaces have the same spherical radius; the concave spherical surface is matched with the convex spherical surface, so that the concave spherical pad and the convex spherical pad are inlaid into one body. When the outer working surface is inclined or uneven, the concave ball pad and the convex ball pad of the spherical washer of the present invention can contact and adjust the alignment by themselves, so as to ensure the neutrality and contact area of the carrier used by the outside world, thereby ensuring the smooth operation of the anchor cable sensor. The installation improves the installation efficiency, and has the characteristics of simple structure, low cost, easy installation and convenient use.

Owner:SHANGHAI KNP CHEM +2

Fan strip label shaping and shearing device

InactiveCN101898304BStable positionGuaranteed neutralityOther manufacturing equipments/toolsEngineeringMechanical engineering

The invention relates to a fan strip label shaping and shearing device, which has the advantages of simple structure, convenient use, one-step shaping and the like. The device comprises a female die and a male die, wherein contours of the two dies are consistent with the peripheral shape of a shaped label; a fit clearance is reserved between the two dies; the male die is connected with a datum plate; the shearing device is arranged on the datum plate; the datum plate is arranged on a guiding device; the male die is matched with a discharging plate; the discharging plate is connected with the datum plate; and a resetting device is arranged between the discharging plate and the datum plate.

Owner:SHANDONG UNIV +1

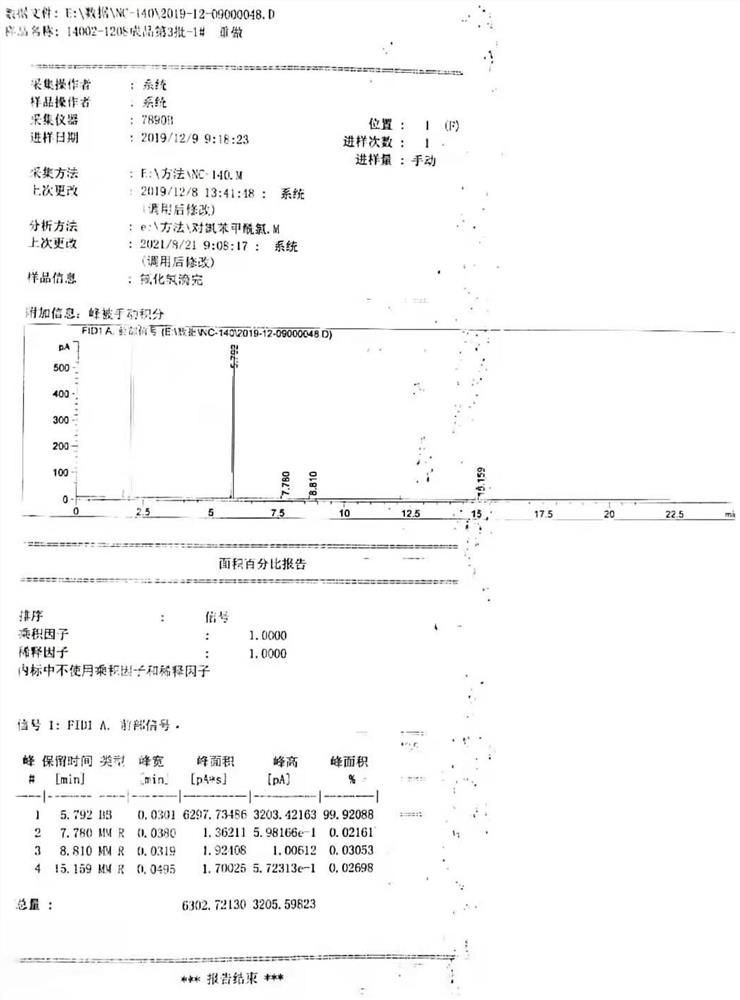

Preparation method of difluorobenzodioxole

The invention relates to a preparation method of difluorobenzodioxole, which comprises the following steps: step 1, introducing chlorine and phosphorus trichloride at 0-80 DEG C according to a molar ratio of 1: (3-9) to react to prepare phosphorus pentachloride, and after the phosphorus pentachloride is prepared, refluxing for 1-4 hours to enable the chlorine and the phosphorus trichloride to react completely so as to prevent the phosphorus pentachloride from adhering to the wall; 2, benzodioxole is dropwise added into phosphorus pentachloride for 1-24 h, and the molar ratio of benzodioxole to phosphorus pentachloride in phosphorus pentachloride is 1: (0.5-1.5); after dropwise adding, refluxing for 1-24 hours at the temperature of 50-100 DEG C; removing the phosphorus trichloride solvent to obtain dichlorobenzodioxole; and 3, reacting dichlorobenzodioxole with hydrogen fluoride according to the molar ratio of (1.8-8): 1, dropwise adding hydrogen fluoride into dichlorobenzodioxole for 0.5-24 hours, reacting at the reaction temperature of 5-40 DEG C for 0.5-24 hours after dropwise adding, adjusting the pH value to 7-14, and distilling with water vapor to obtain dichlorobenzodioxole. The method is simple and easy to implement, the difluorobenzodioxole is obtained with high yield and high purity, the cost is low, the reaction conditions are mild, and the method is suitable for industrial mass production.

Owner:山东福尔有限公司

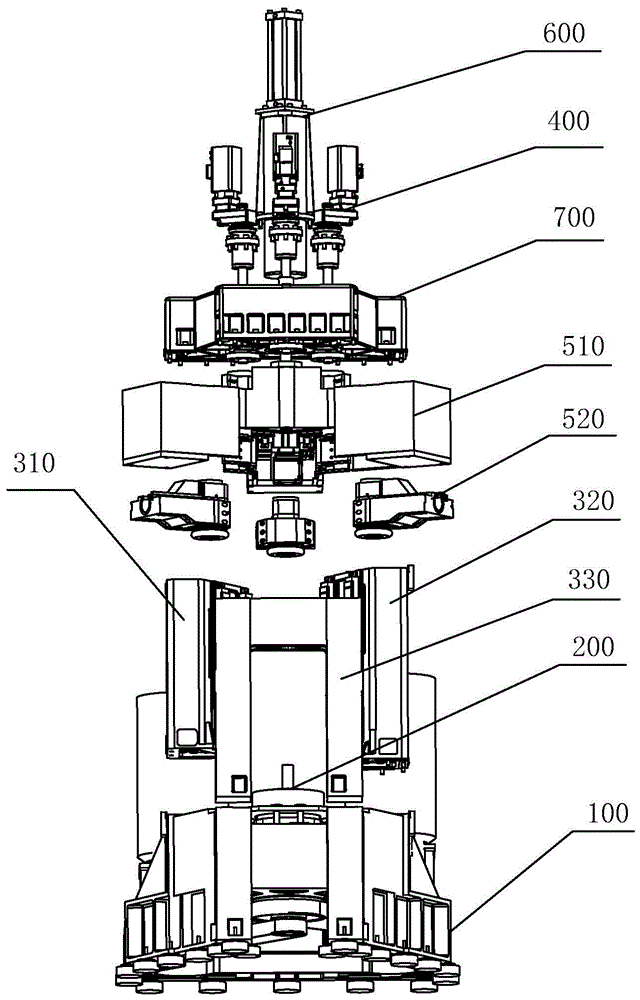

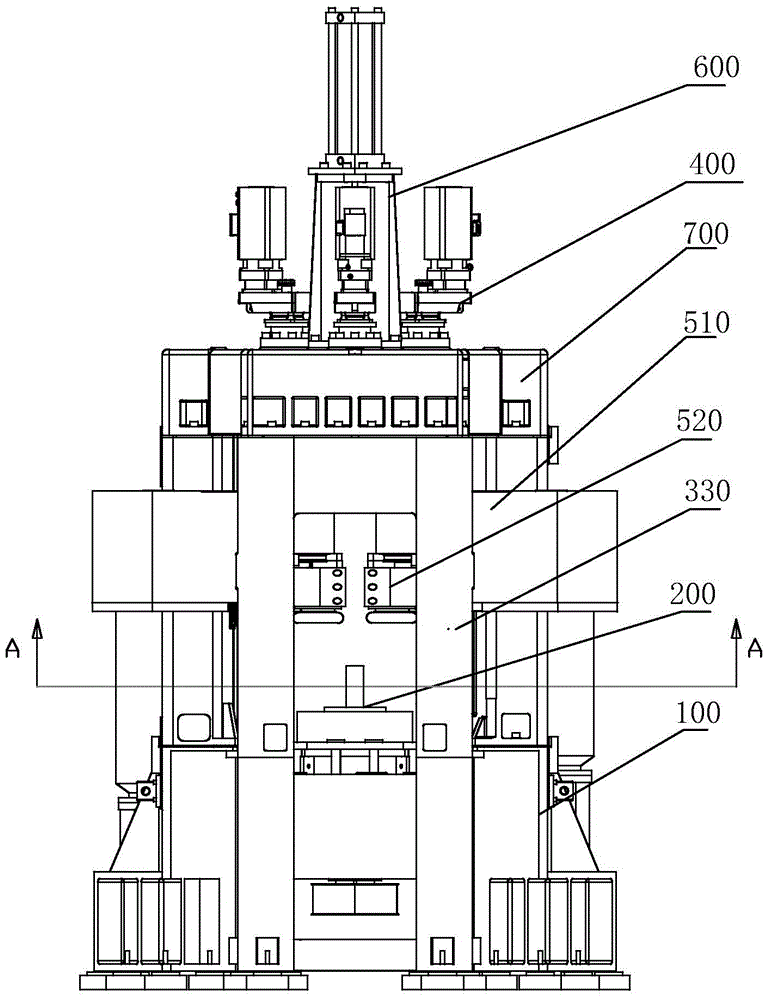

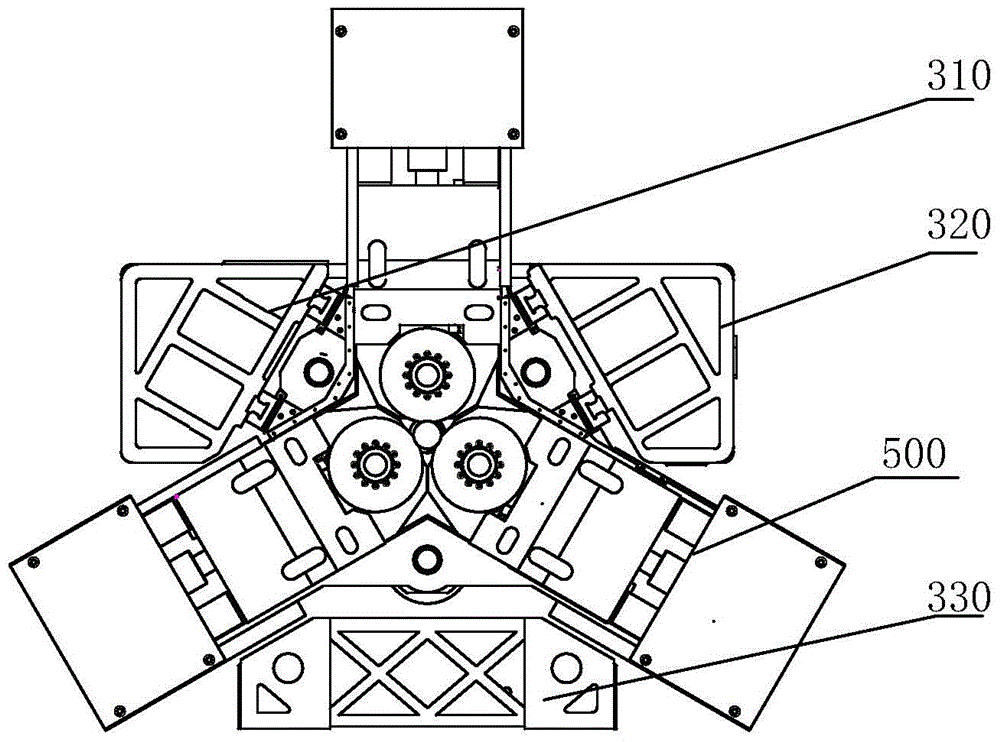

Vertical spinning machine

ActiveCN104668329BEasy to liftEasy to transportShaping safety devicesEngineeringMechanical engineering

The invention discloses a vertical spinning machine comprising a machine body, a spindle device, three posts, a sliding frame device and a tail ejecting device. The spindle device is installed on the machine body, and the top of the spindle device is provided with a joint platform accommodating a workpiece; the posts are distributed on the periphery of the spindle device and are provided with a longitudinal transmission device; the sliding frame device is connected to the longitudinal transmission device and comprises a frame body, a machining unit and a transverse transmission device, the frame body is in an integral triangular structure, and the transverse transmission device drives the machining unit to move on the frame body transversely; the tail ejecting device is arranged above the sliding frame device and corresponds to the spindle device in position. The spindle is not subject to partial load, the rigidity is high, the accurate cylindrical part spinning and forming are guaranteed, the centering performance of the machining unit during radial feeding is guaranteed, and difficulty in assembling and debugging is lowered.

Owner:SUZHOU PRESSLER ADVANCED FORMING TECHNOLOGIES CO LTD

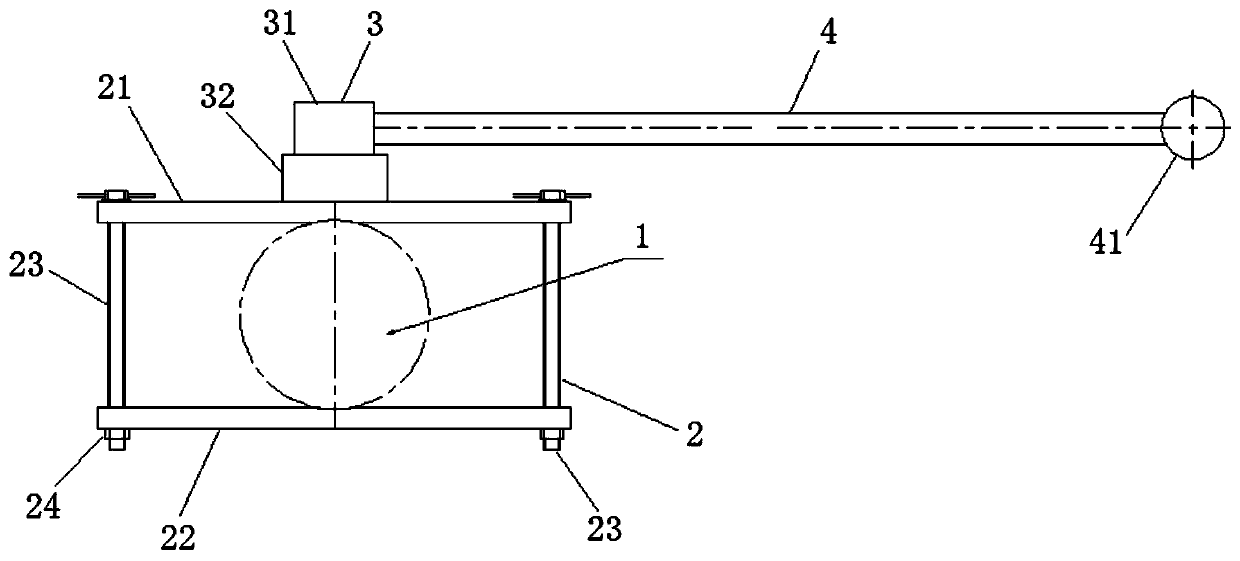

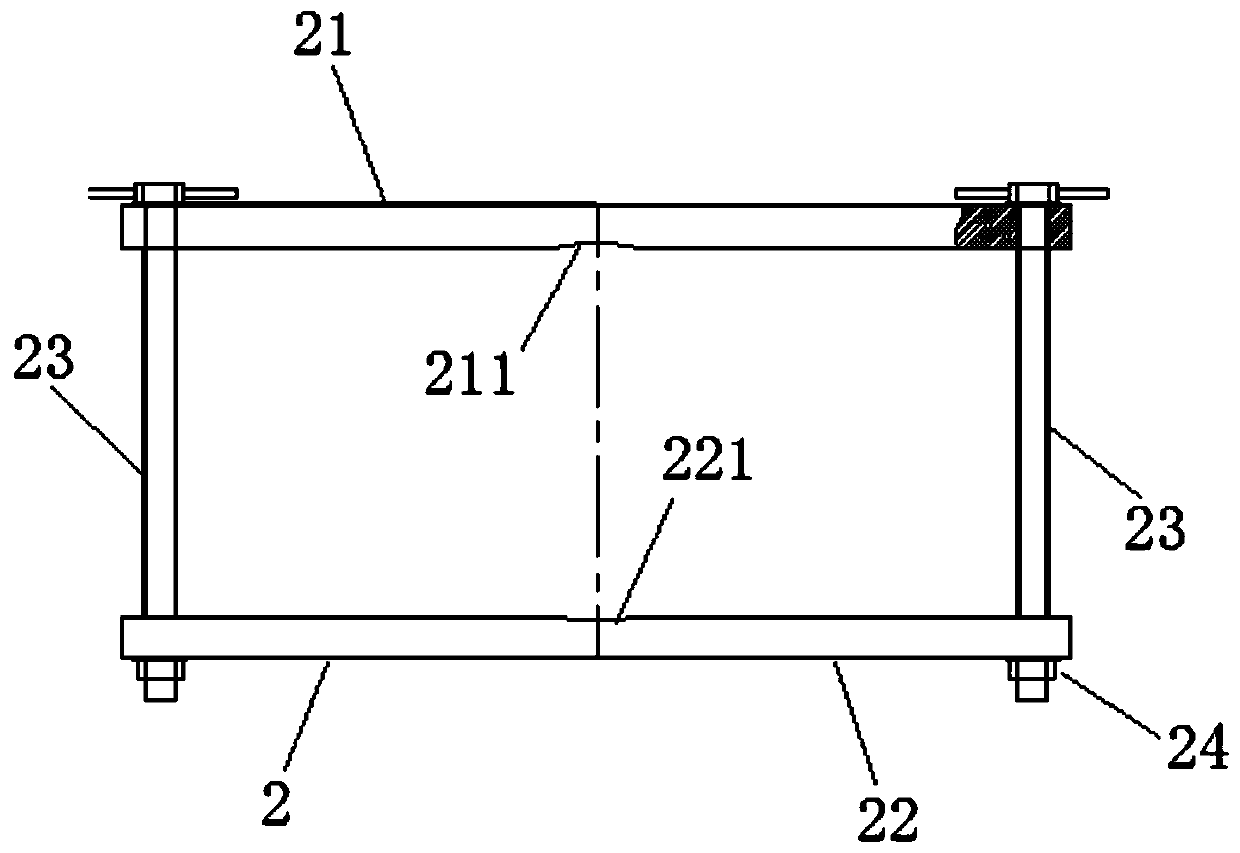

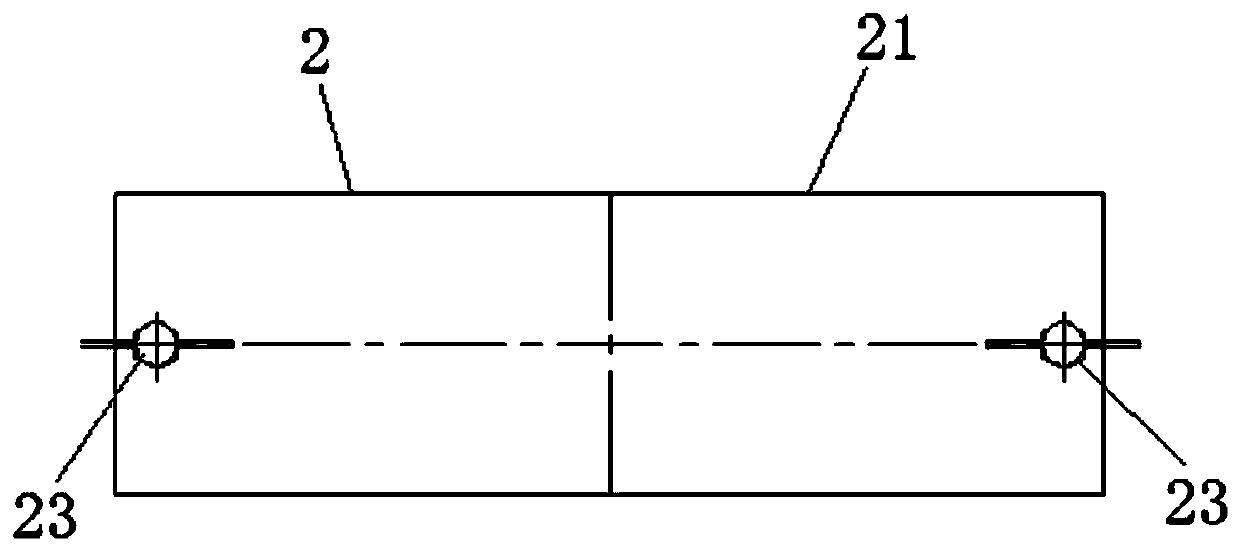

Roller measuring device and using method thereof

InactiveCN111595278AGuaranteed neutralImprove measurement efficiencyMeasurement devicesWork holdersMagnetic tension forceStructural engineering

Owner:MCC BAOSTEEL TECH SERVICE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com