Vertical spinning machine

A spinning machine and vertical technology, which is applied in the field of automobile parts manufacturing, can solve the problems of reduced dimensional accuracy of machined parts, inability to meet technical requirements in strength, and inability to meet high-precision fields, so as to reduce transmission links, save manpower, and reduce The effect of assembly and debugging difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that all the drawings of the present invention are in simplified form and use inaccurate scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

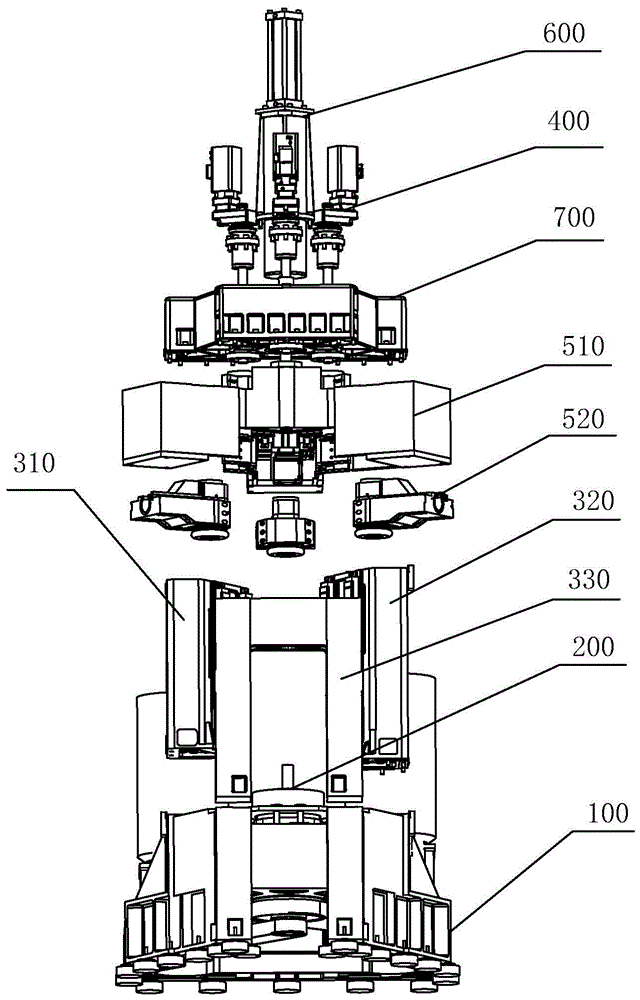

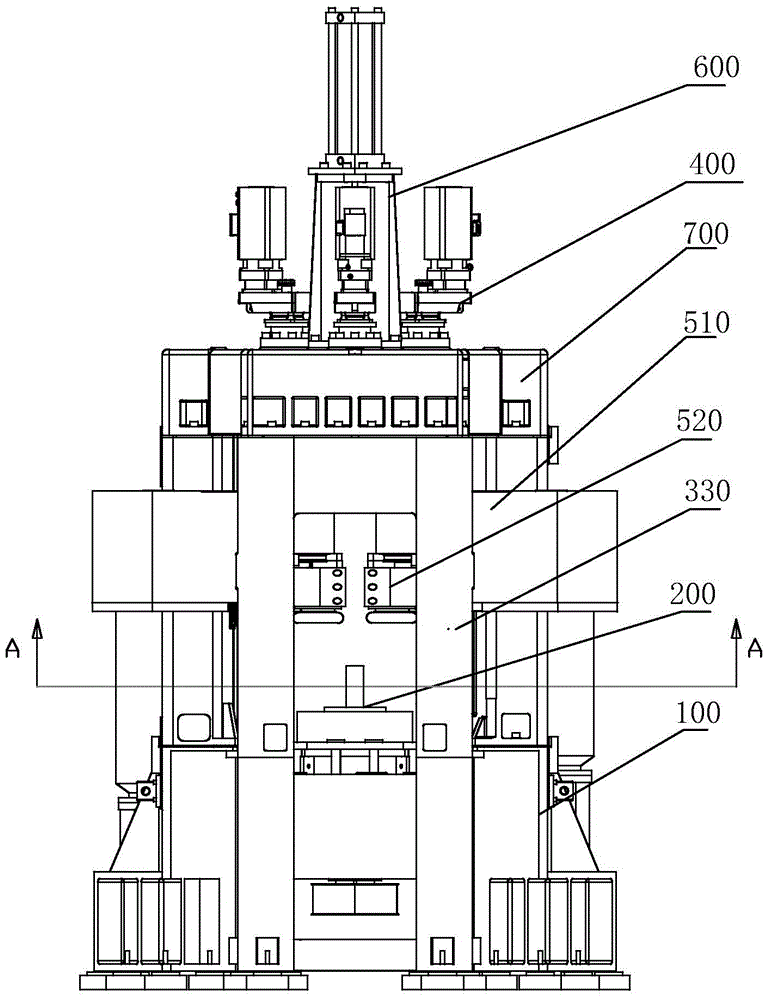

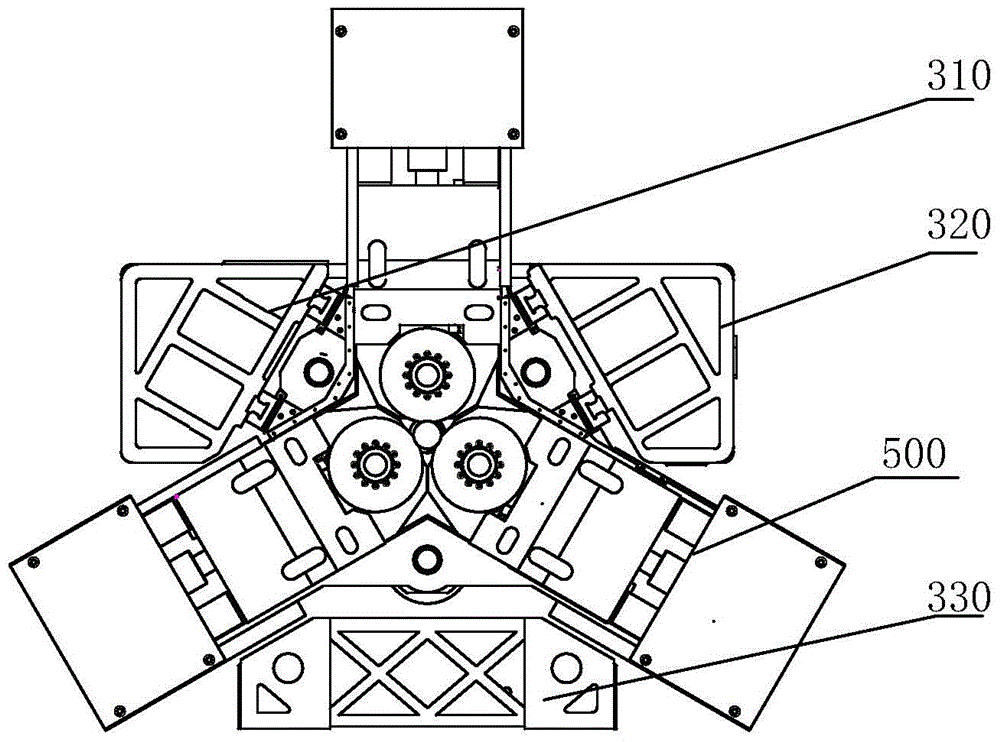

[0051] like Figure 1 to Figure 5As shown, the vertical spinning machine of the present invention includes: a bed 100 , a spindle device 200 , a column, a longitudinal transmission device 400 , a carriage device 500 , a tail top device 600 and a beam 700 . The main shaft device 200 is installed on the bed 100, and there are three upright columns, which are evenly distributed around the main shaft device 200. The longitudinal transmission device 400 is installed on the upright column and connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com