Spherical washer

A technology of spherical washers and ball pads, which is applied in the direction of washers, transmission elements or ropes or cables for pulleys, textile cables, etc., can solve the problems of low installation efficiency and the inability to adjust the anchor cable sensor in time, so as to improve installation efficiency and ensure correct Neutrality and contact area to ensure smooth installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

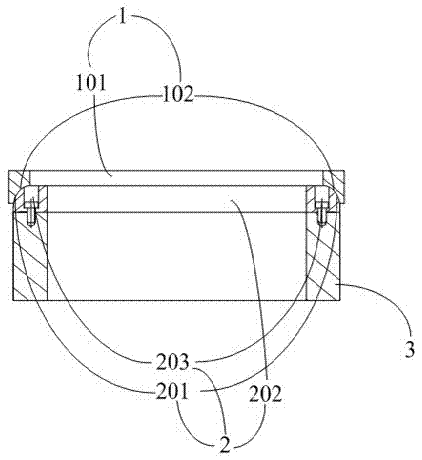

[0012] see figure 1 , the present invention provides a spherical gasket, including a concave ball pad 1 and a convex ball pad 2 used in pairs, the concave ball pad 1 is a hollow cylinder, in this embodiment, the concave ball pad 1 is a hollow cylinder, Its inside is provided with concave ball pad through hole 101 and with concave ball pad through hole 101 and the concave spherical surface 102 that is sunken toward concave ball pad through hole 101; The convex spherical surface 201 is raised; wherein, the concave spherical surface 102 and the convex spherical surface 201 have the same spherical radius;

[0013] In the present invention, the convex ball pad 2 is provided with a convex ball pad through hole 202 vertically penetrating therethrough, and the diameter of the convex ball pad through hole 202 is smaller than the concave spherical sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com