Fan strip label shaping and shearing device

A cutting device and label technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problem of inability to form fan strip labels, and achieve the effect of simple structure, continuous forming, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

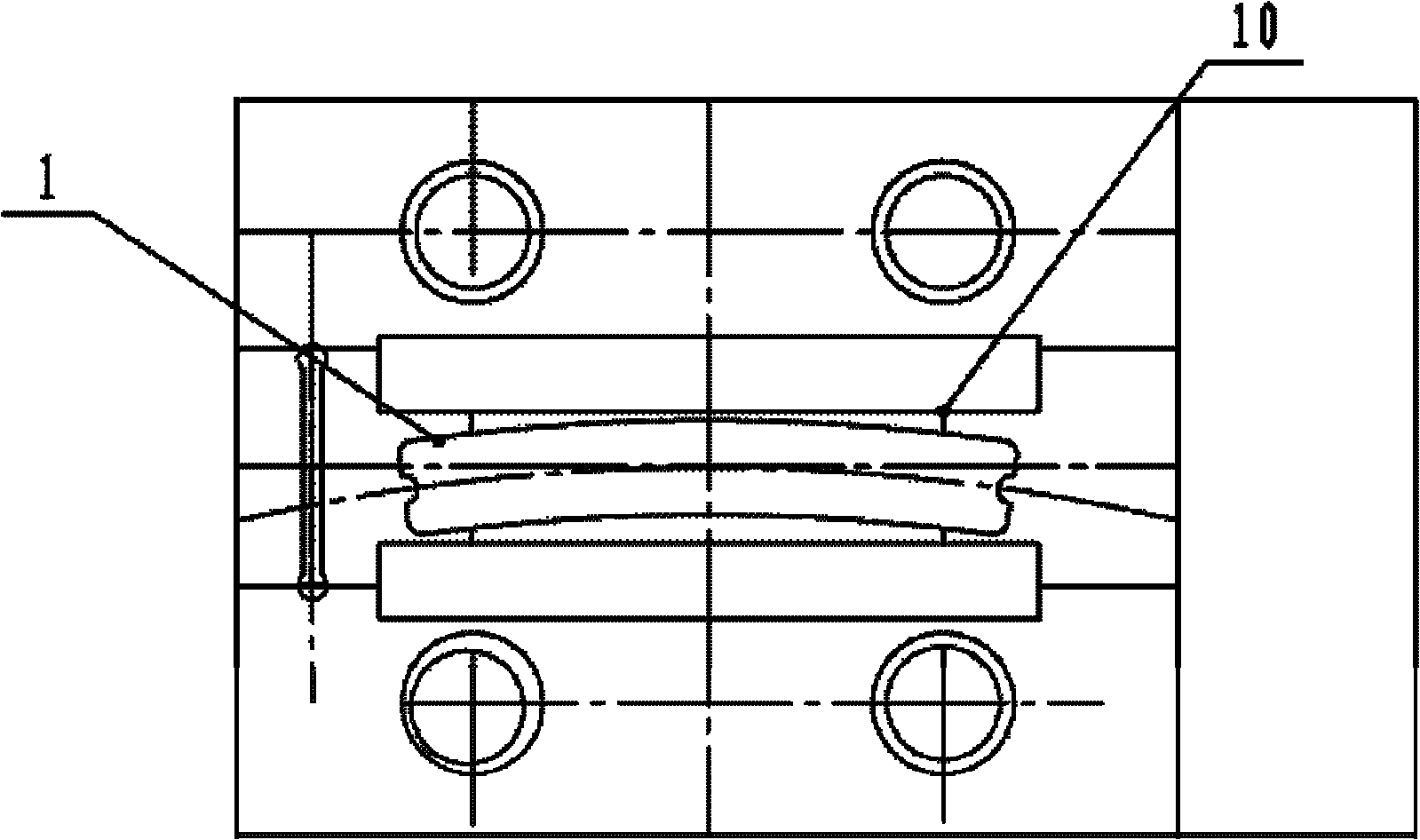

[0020] figure 2 , image 3 Among them, the label forming is completed by the concave mold 1 and the convex mold 2 with the same profile, and the installation reference hole of the convex mold 2 is consistent with the concave mold 1 to ensure the centering of the convex and concave molds. The movement of the punch 2 is positioned by 4 guide columns to ensure the correct moving position; the centering of the strip above the die 1 is guaranteed by two guide plates 10; Complete, and the waste material shearing has special shearing knife 3 to complete.

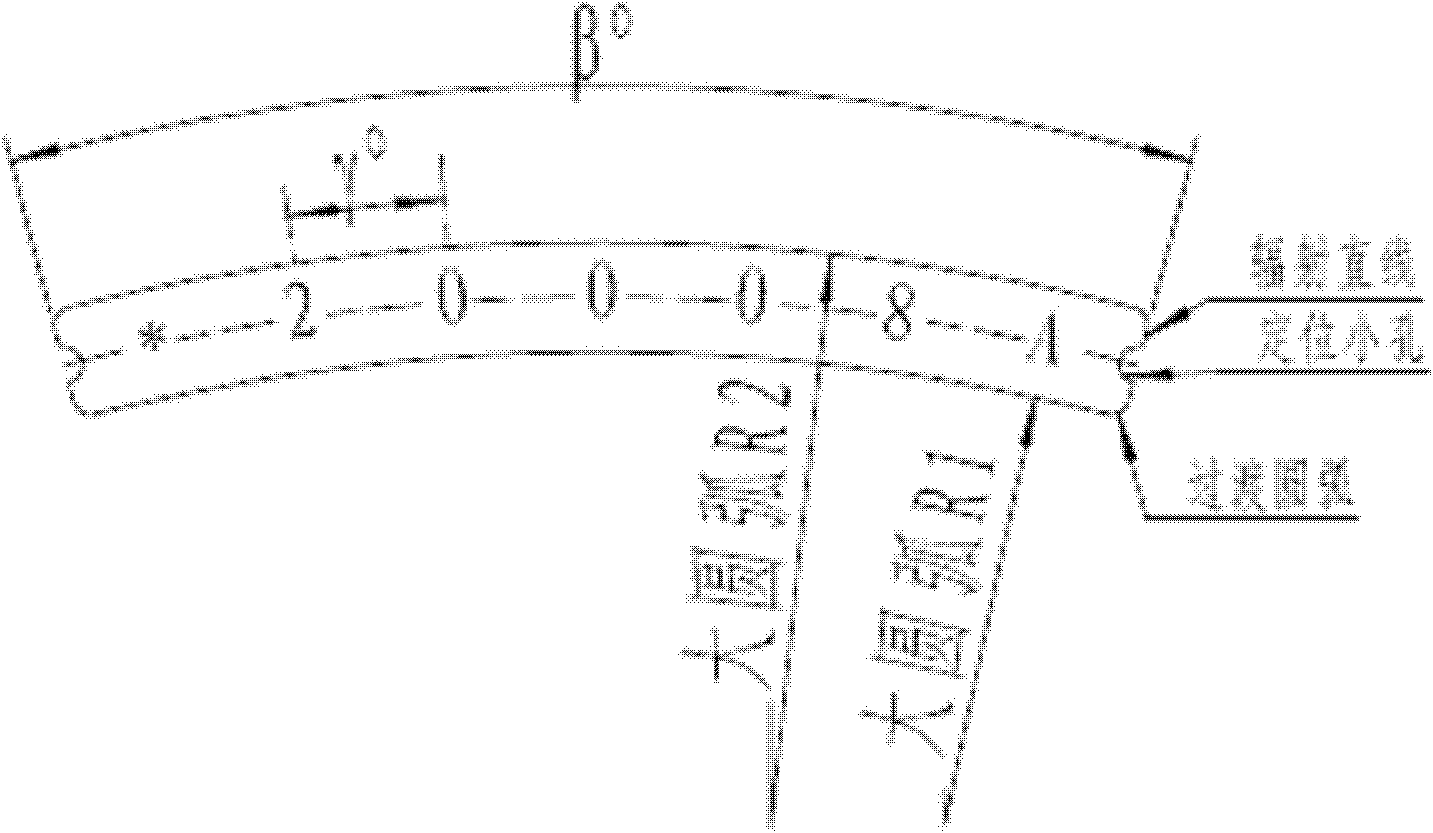

[0021] The die 1 and the punch 2 are both closed profiles consistent with the label to be cut, with parallel arcs on both sides and radial lines with a certain angle at both ends. The arcs and radial lines have arc transitions. There is a concave semicircle in the middle of the radial lines at both ends....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com