Small hole square head chamfer end label shearing device and method

A shearing device and chamfered end technology are applied in the field of label shearing devices for small hole square head chamfered ends, which can solve the problems of not giving the end shape and structure realization method and technology, and achieve simple structure and molding accuracy. High and process saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

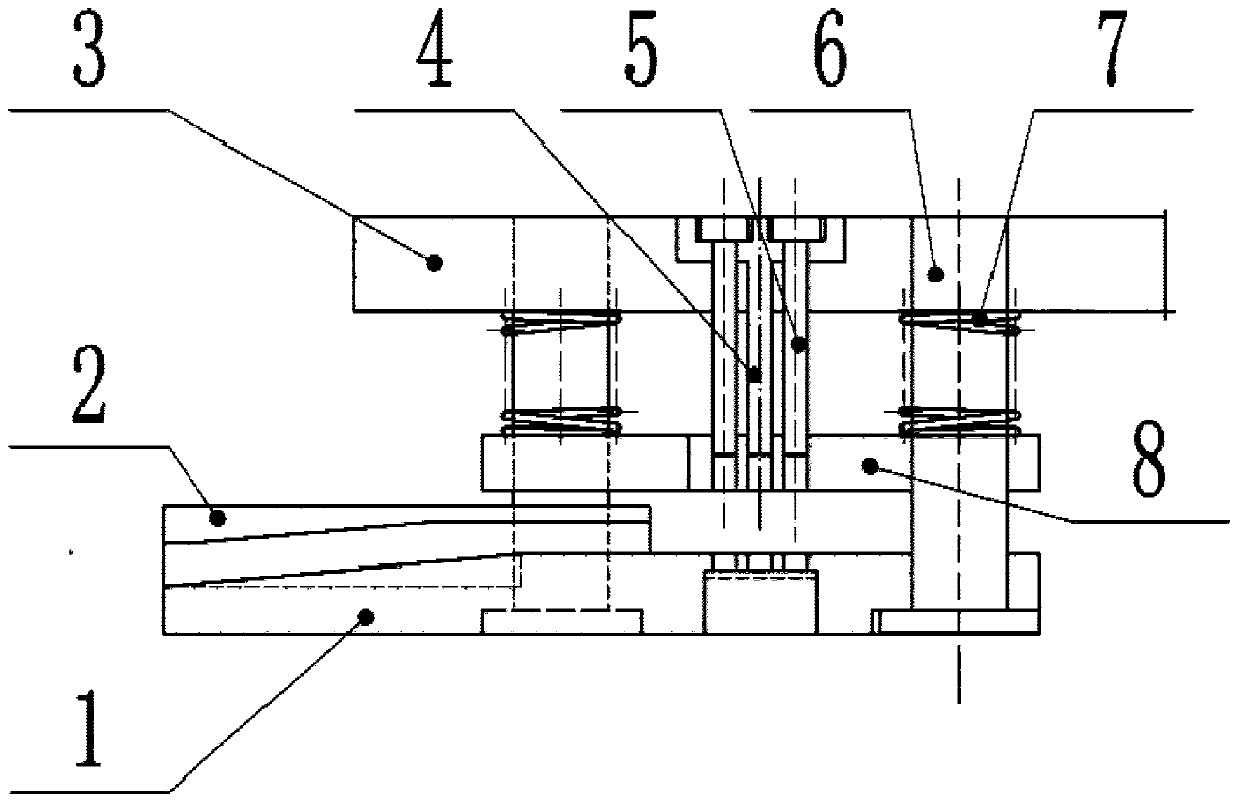

[0037] This embodiment discloses a small hole square head chamfer end label shearing device, including a die 1, a guide groove, a reference plate 3, a punch 4, a small hole punch, a guide post 5, a spring 6, a press The discharge plate 7, the small hole punching needle and the punch 4 are connected to the reference plate 3, and the reference plate 3 is connected to the guide column 5; the die 1 is installed on the base, the punch 4, the small hole punching needle and the guide column 5 are all worn Overpressure material unloading plate 7, punch 4, small hole punching pin guide post 5 and pressing material unloading plate 7 are matched in clearance to ensure relative movement, and spring 6 is sleeved on guide post 5.

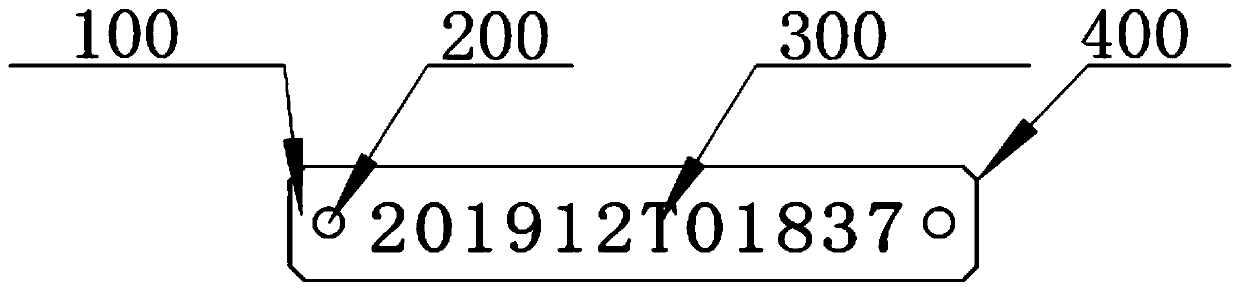

[0038] This embodiment is aimed at making the small hole square chamfer of the strip metal label, so it is necessary to introduce the specific shape of the square chamfer. The square chamfer is a chamfer that is removed from the four corners of the rectangular lab...

Embodiment 2

[0052] Embodiment 2 discloses a method for cutting a label at the end of a small hole with a square head chamfer, using the device for cutting a label at the end of a small hole with a square head chamfer disclosed in Embodiment 1, comprising the following steps:

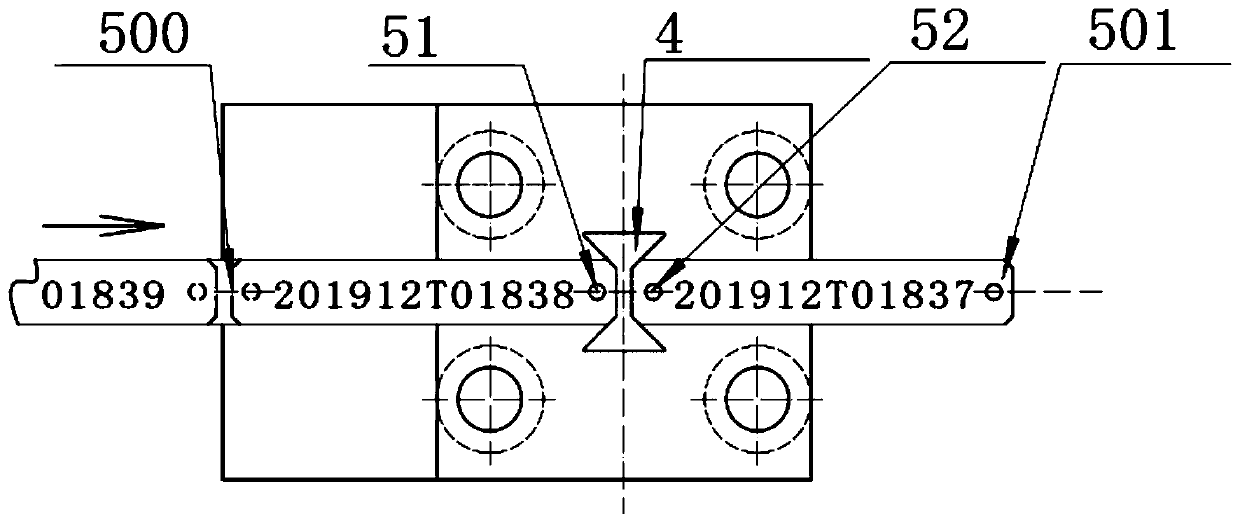

[0053] 1) Import the label to be cut into the chute;

[0054] 2) The label to be cut advances gradually with the drive of the power source;

[0055] 3) Every fixed time t1, or every time the label to be cut moves a certain distance s1, the reciprocating power source starts forward, driving the reference plate 3 to descend in the vertical direction, and the pressing and unloading plate 7 Press the label to be cut first, the end face of the punch 4 cuts the label to be cut, the small hole punching needle punches the label to be cut, after the cutting and punching are completed, the reciprocating power source starts in reverse , driving the reference plate 3 to reset, and the pressing and unloading plate 7 pushes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com