High-centering precision clamp connecting device for mechanical testing machine

A technology of mechanical testing machine and connecting device, which is applied in the direction of measuring devices, scientific instruments, strength characteristics, etc., can solve the problems of sample torsion, affecting test results, occupying space, etc., and achieves the effect of ensuring accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

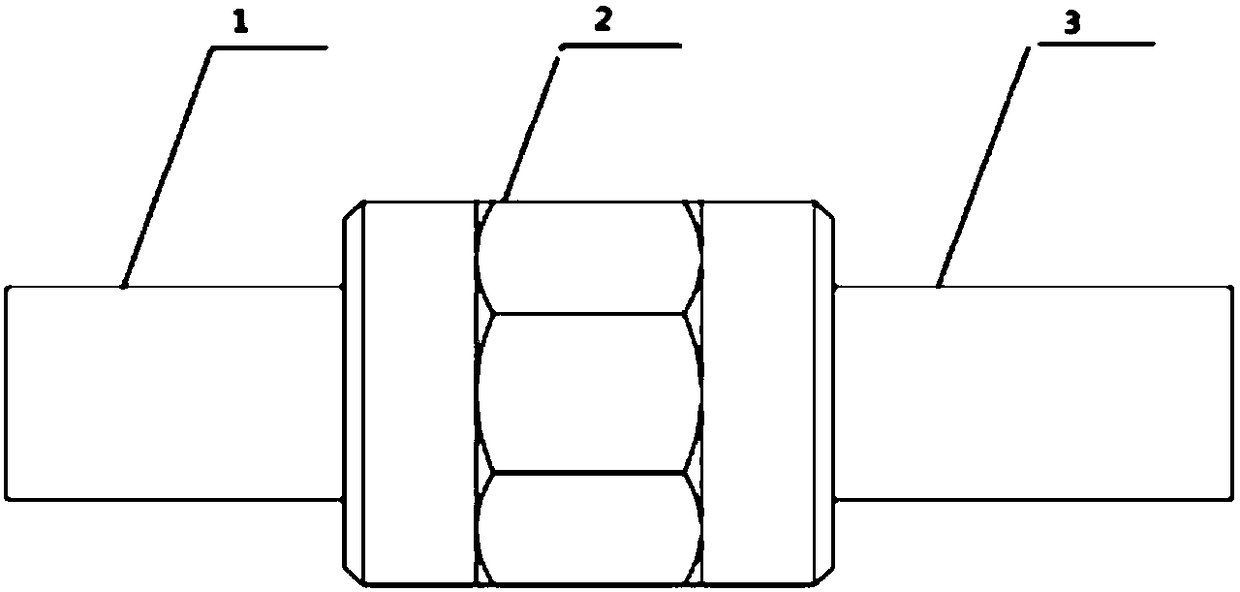

[0022] Please refer to Figure 1 to Figure 6 , The high centering precision jig connection device for testing machine of the present invention includes a fixing part 1 , a connecting part 2 and a clamping part 3 .

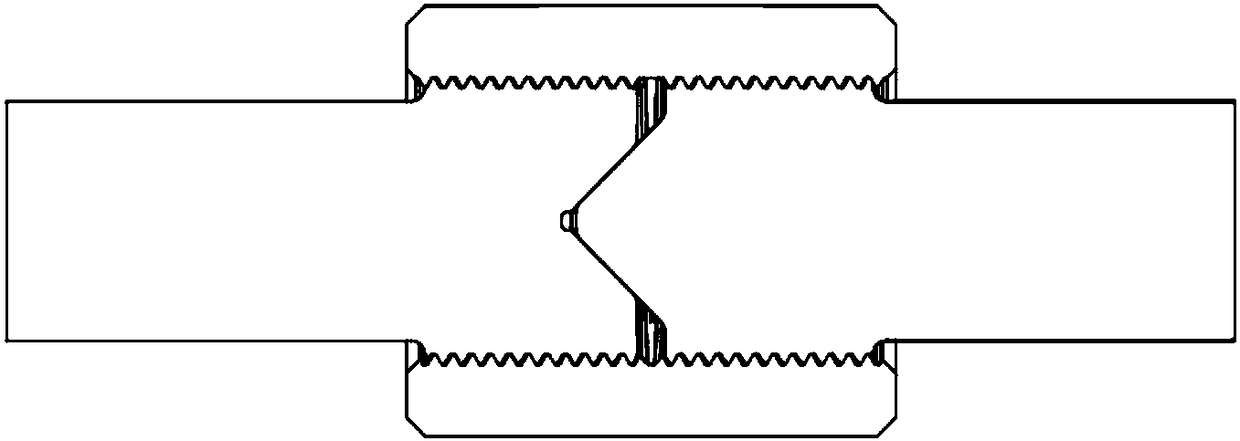

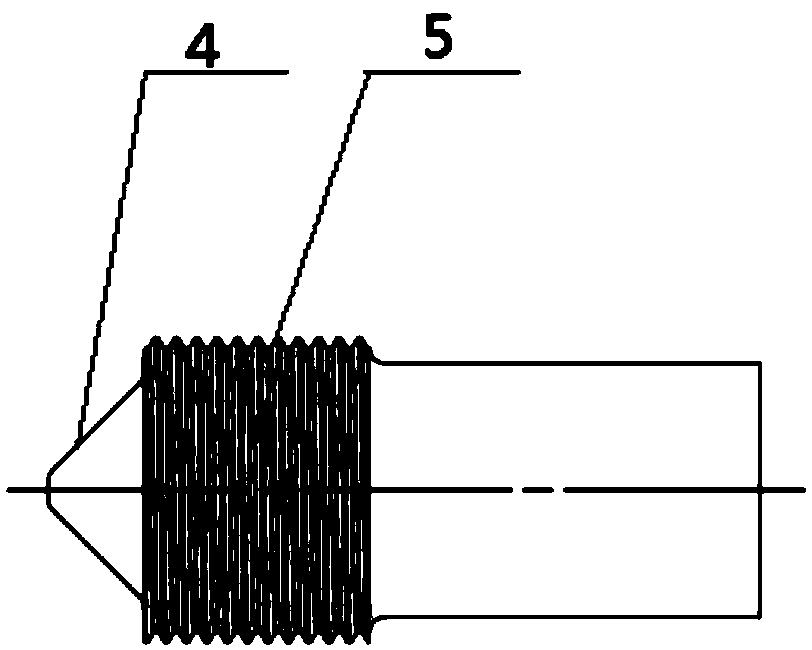

[0023] The fixed part 1 includes a structure with a positioning concave tapered surface 6 on the end surface and a reverse tooth external thread 7 adjacent to the positioning concave cone surface. One end of anti-tooth internal thread 8 links to each other. The clamping part 3 includes a positioning convex tapered surface 4 on the end surface and a positive thread 5 adjacent to the positioning convex tapered surface. One end of the internal thread 9 is connected, and the cone surface area of the positioning convex tapered surface 4 accounts for 60% of the total cylinder area during processing, and the axial displacement of the clamping part can be adjusted by rotating the clamping part 3 . The coupling part 2 includes a reverse tooth internal thread 8 and a pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com