Preparation method of difluorobenzodioxole

A technology of difluoropiperone and dichloropiperone, applied in the direction of organic chemistry and the like, can solve the problems of consuming hydrogen fluoride environment, high equipment requirements, complicated operation, etc., and achieves the effects of low equipment requirements, high yield, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

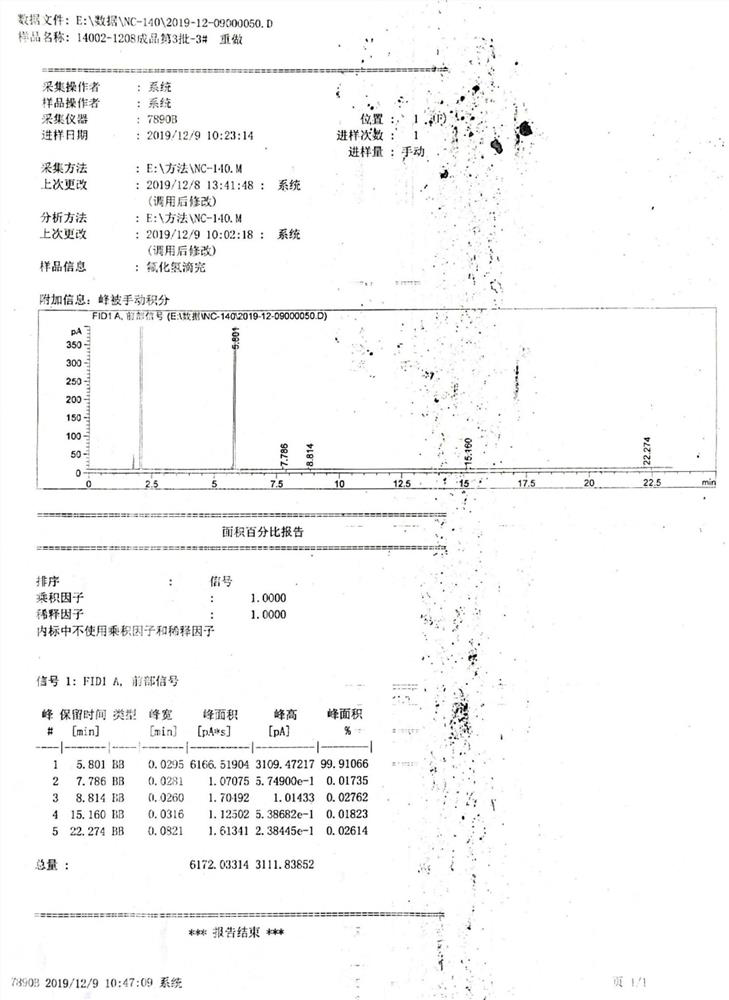

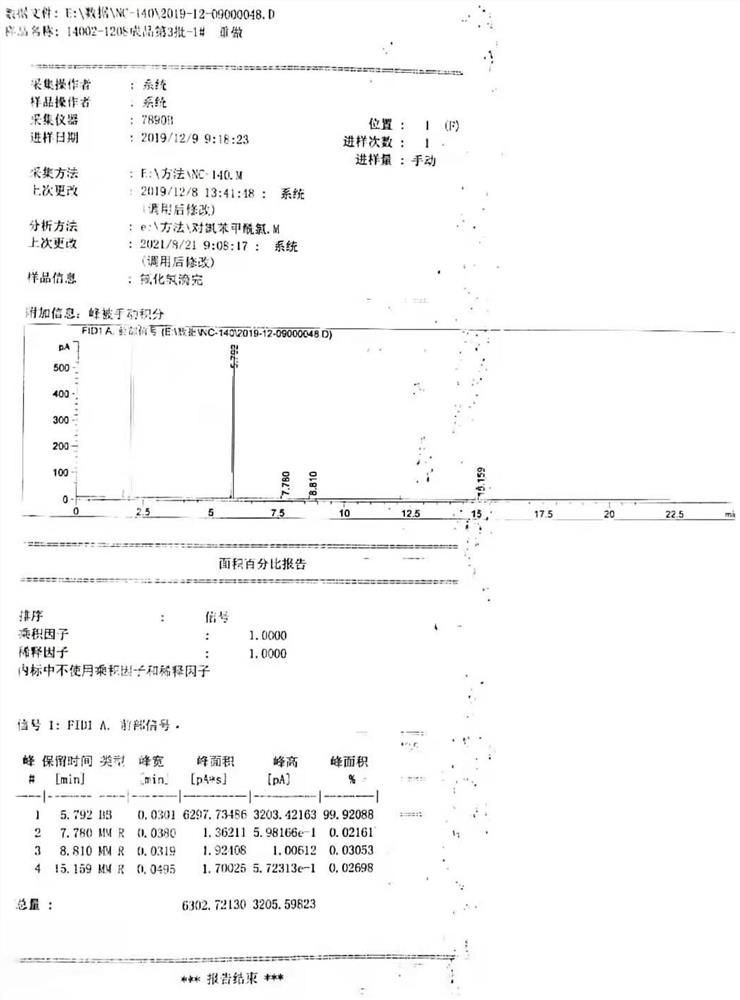

Examples

Embodiment 1

[0041] Check the 5000L chlorination kettle and its ancillary equipment to confirm that it is dry and clean, and the valve is closed. (There should be no accumulation of liquid in the kettle, phosphorus trichloride will release a lot of heat when it encounters water, and it may spray material). Open the vacuum valve of the chlorination kettle to evacuate to -0.08MPa, open the nitrogen valve and fill with nitrogen to replace the air in the chlorination kettle and the pipeline of the ancillary facilities, and replace it until the system pressure is normal pressure, and repeat this twice. Open the chlorination kettle vent valve, open the phosphorus trichloride feeding valve, and use a diaphragm pump to add 4332Kg of phosphorus trichloride into the reaction kettle chlorination kettle. Turn on the cooling oil of the jacket of the chlorination kettle in advance, the temperature of the kettle has dropped to 10-15°C, and the control temperature is less than 40°C, and 760Kg of chlorine ...

Embodiment 2

[0043] Check the 5000L chlorination kettle and its ancillary equipment to confirm that it is dry and clean, and the valve is closed. (There should be no accumulation of liquid in the kettle, phosphorus trichloride will release a lot of heat when it encounters water, and it may spray material). Open the vacuum valve of the chlorination kettle to evacuate to -0.08MPa, open the nitrogen valve and fill with nitrogen to replace the air in the chlorination kettle and the pipeline of the ancillary facilities, and replace it until the system pressure is normal pressure, and repeat this twice. Open the chlorination kettle vent valve, open the phosphorus trichloride feeding valve, and use a diaphragm pump to add 4332Kg of phosphorus trichloride into the reaction kettle chlorination kettle. Turn on the cooling oil of the jacket of the chlorination kettle in advance, the temperature of the kettle has dropped to 10-15°C, and the control temperature is less than 40°C, and 760Kg of chlorine ...

Embodiment 3

[0045] Check the 5000L chlorination kettle and its ancillary equipment to confirm that it is dry and clean, and the valve is closed. (There should be no accumulation of liquid in the kettle, phosphorus trichloride will release a lot of heat when it encounters water, and it may spray material). Open the vacuum valve of the chlorination kettle to evacuate to -0.08MPa, open the nitrogen valve and fill with nitrogen to replace the air in the chlorination kettle and the pipeline of the ancillary facilities, and replace it until the system pressure is normal pressure, and repeat this twice. Open the chlorination kettle vent valve, open the phosphorus trichloride feeding valve, and use a diaphragm pump to add 4332Kg of phosphorus trichloride into the reaction kettle chlorination kettle. Open the chlorination kettle jacket cooling oil in advance, the kettle temperature has dropped to 10-15℃, the control temperature is less than 60-70℃, 760Kg of chlorine gas is introduced, and the maxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com