Clamp capable of applying pulling/pressing cyclic load to CT test piece

A cyclic load and test piece technology, applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, measuring devices, etc., can solve the problems of load neutrality variation, pin hole micro cracks, small aluminum block movement, etc. Achieve the effect of improving utilization rate, improving clamping efficiency and ensuring load neutrality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

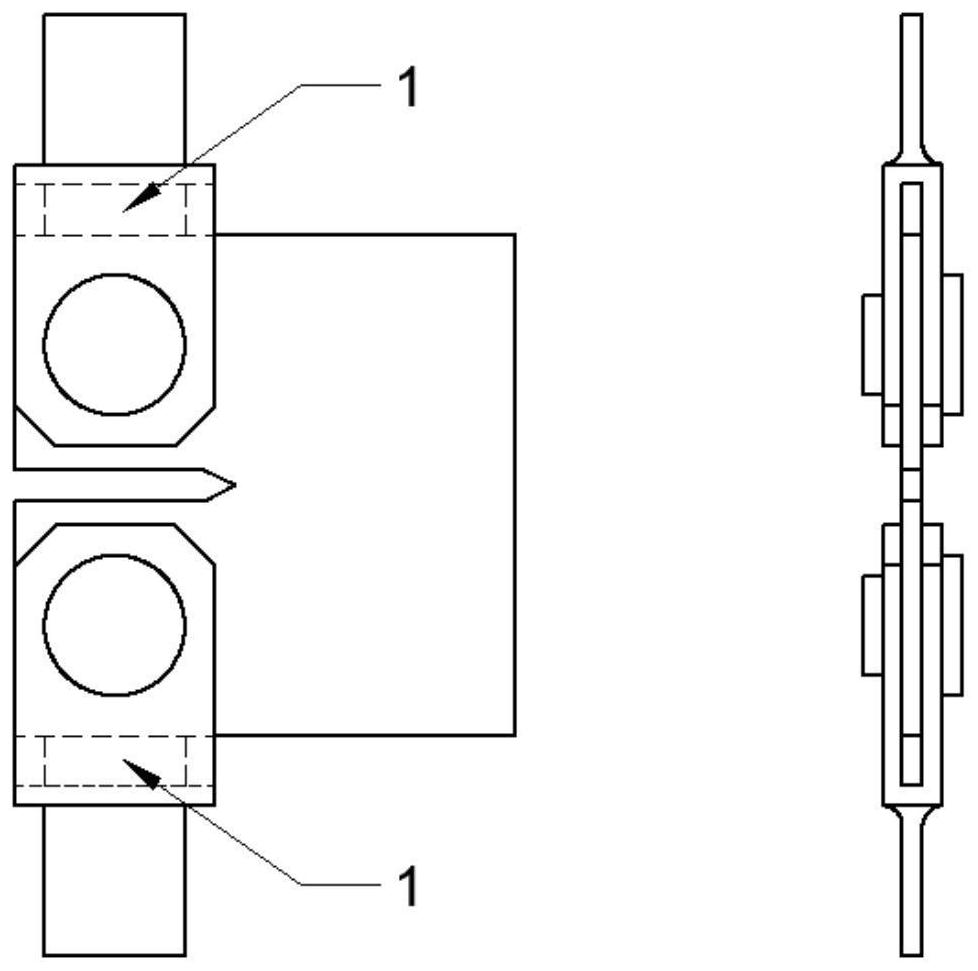

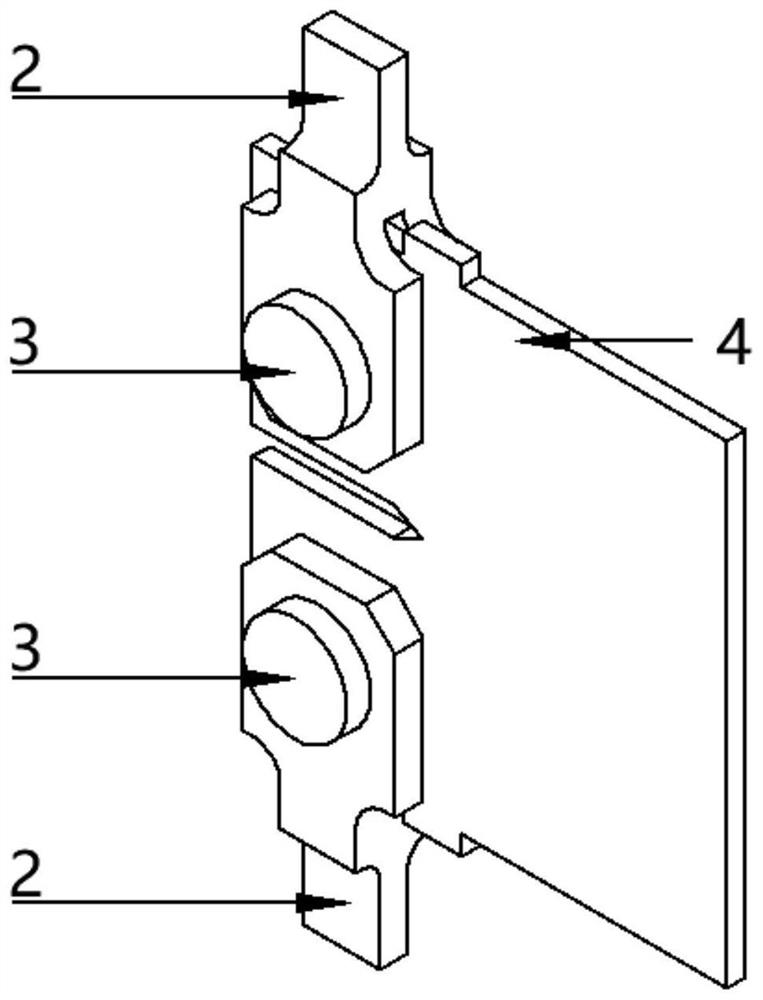

[0027] By the following Figure 1-9 And implementation step further illustrates the technical solutions of the present invention.

[0028] 1, CT test piece 4 uses 7075 aluminum alloy manufacturing, this test will use small CT test pieces, the detailed structure size of the test piece can be referred to the ASTM-E647 standard, then design fixture according to the CT test piece 4 size;

[0029] 2, press-pressure circulating load prefabricated cracks. The test was carried out on the MTS-880 fatigue test machine. First, the clamping portion of the clamping unit 2 is fixed with the upper and lower clamps of the test machine to ensure that the upper and lower clamp work unit 2 is sufficient while maintaining neutral. The space is placed in the CT test piece 4, and then the CT test piece 4 is mounted in the groove of the clamp operating unit 2, and the working unit 2 is placed between the two anti-slide 5, and then gradually reduces the upper chuck, so that the CT test The top end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com