Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Fast and accurate calibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

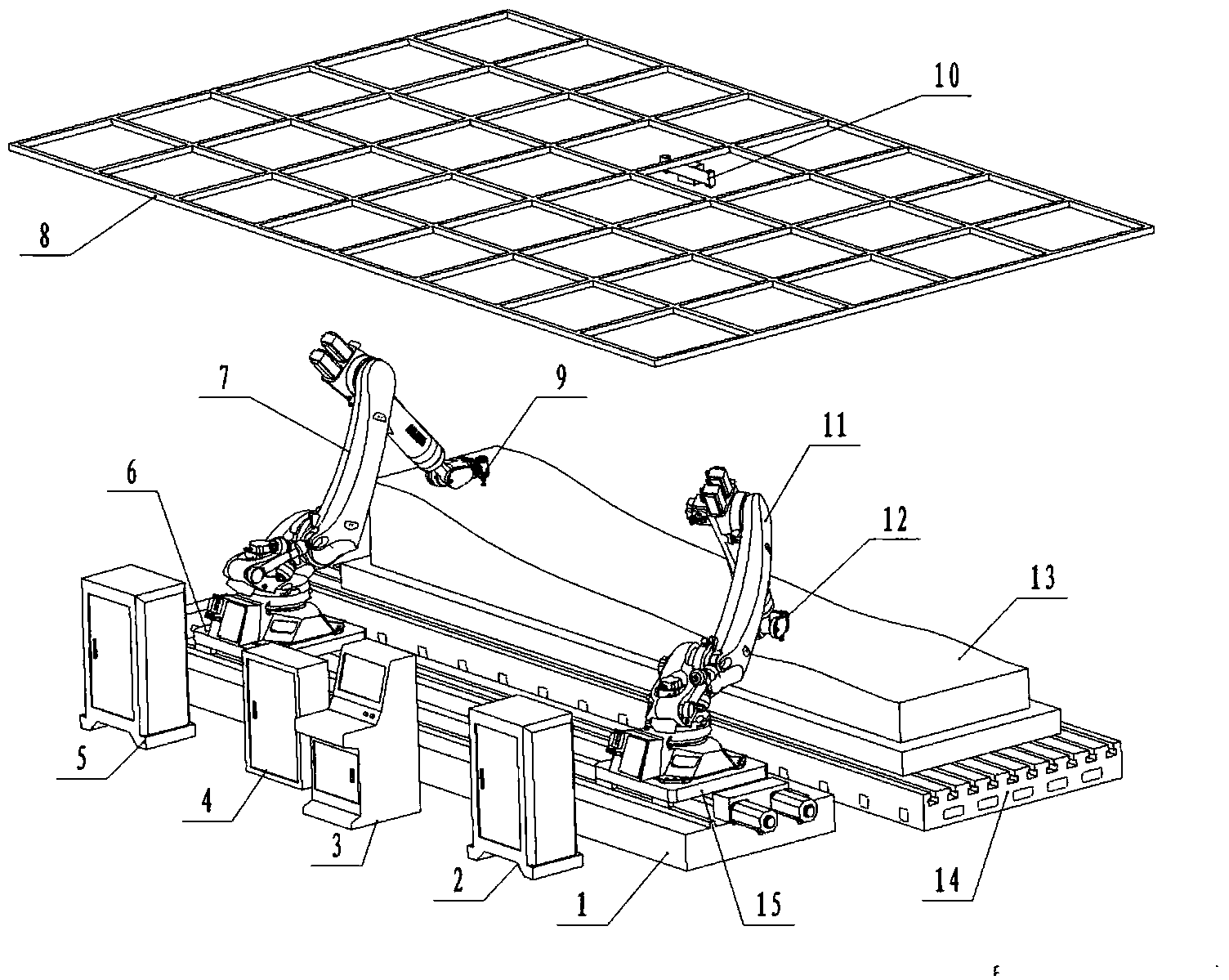

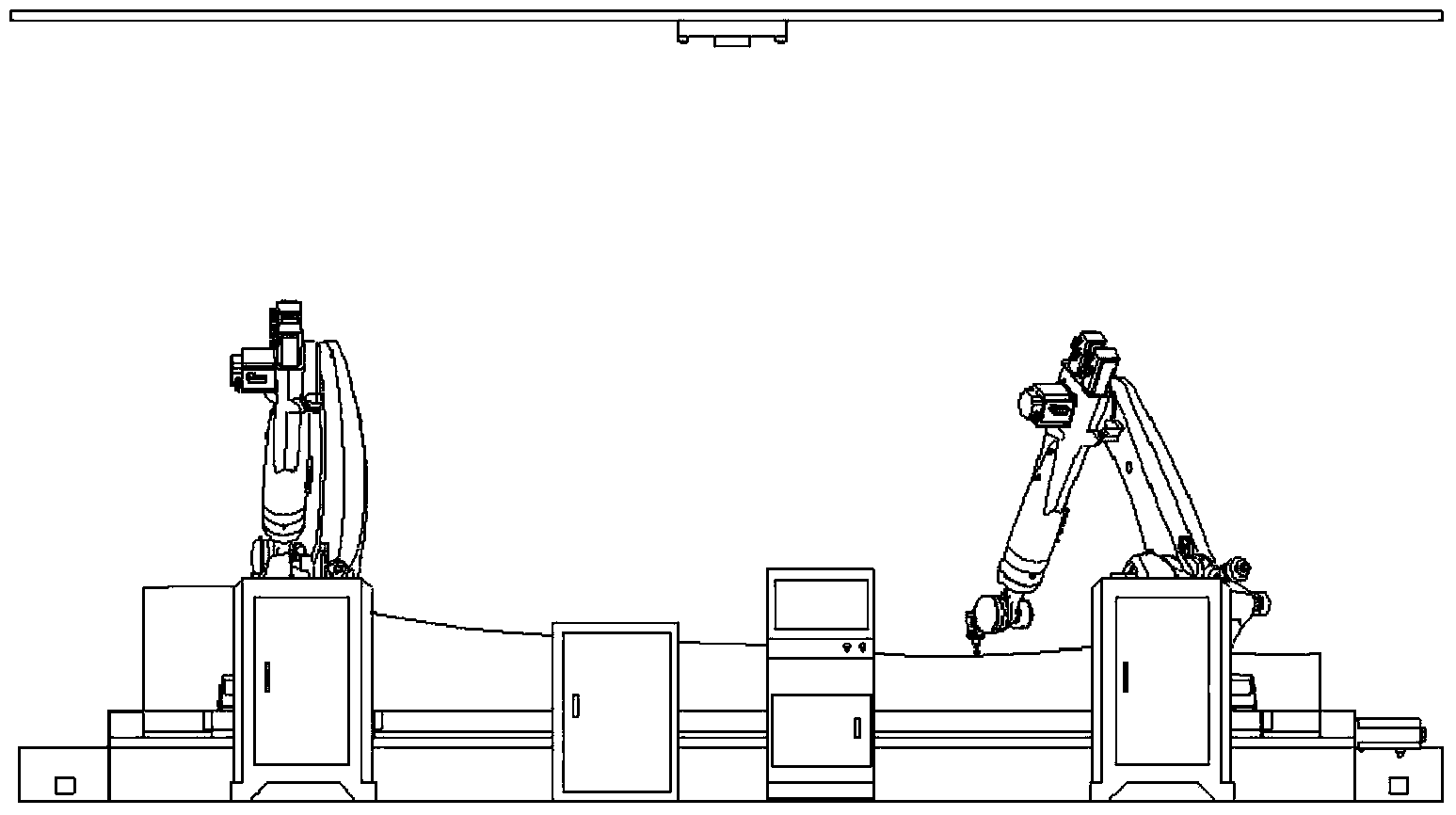

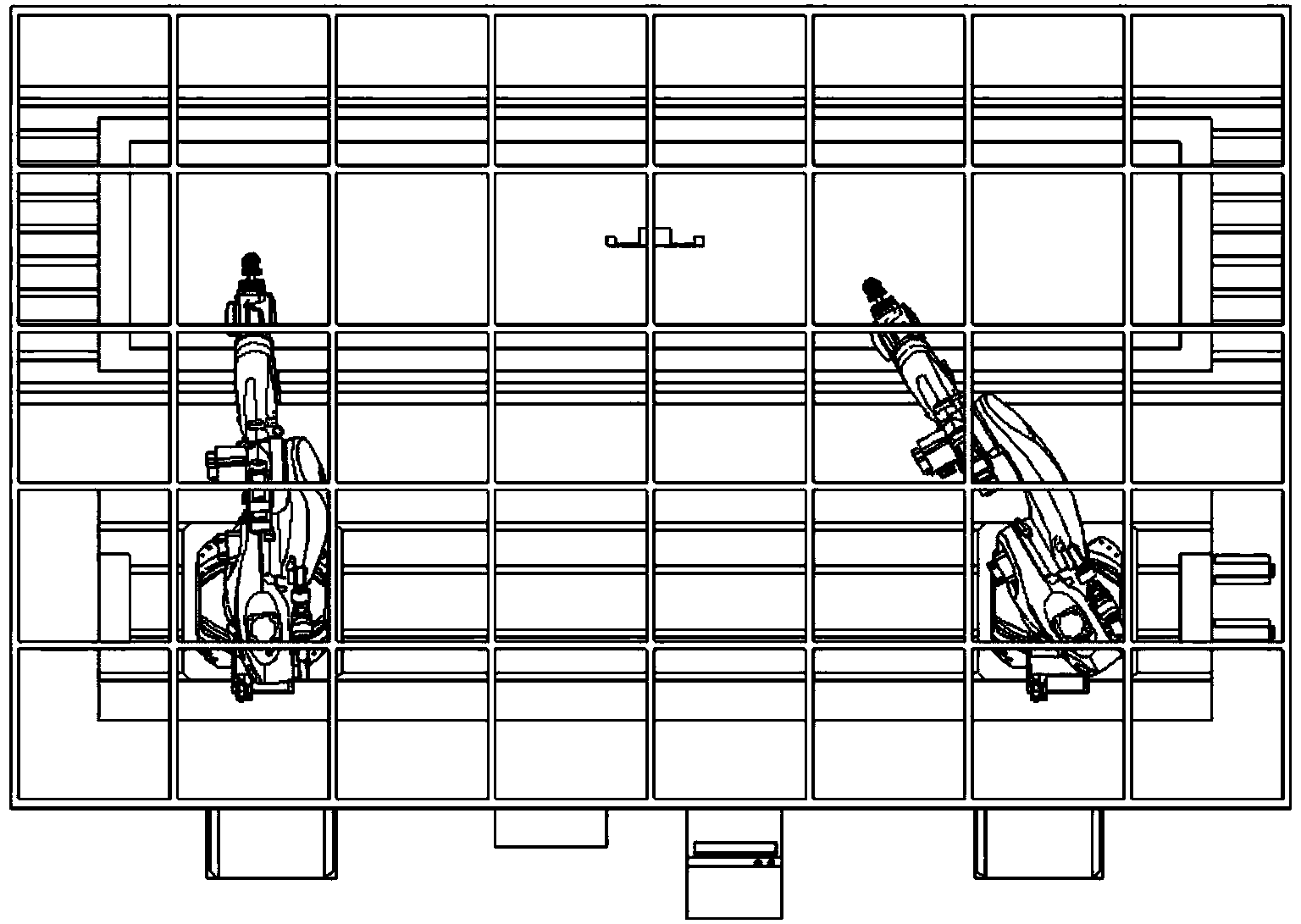

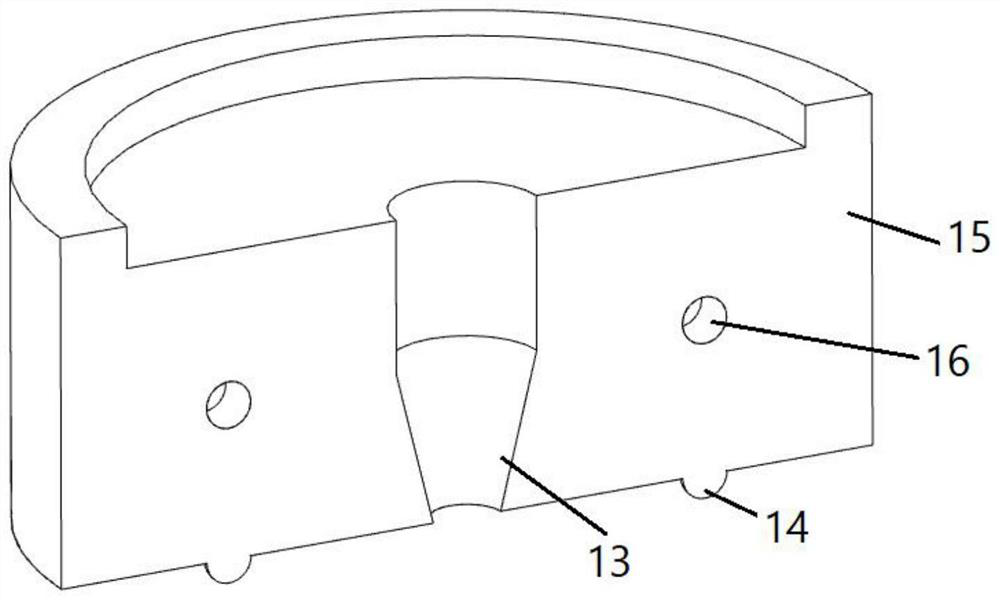

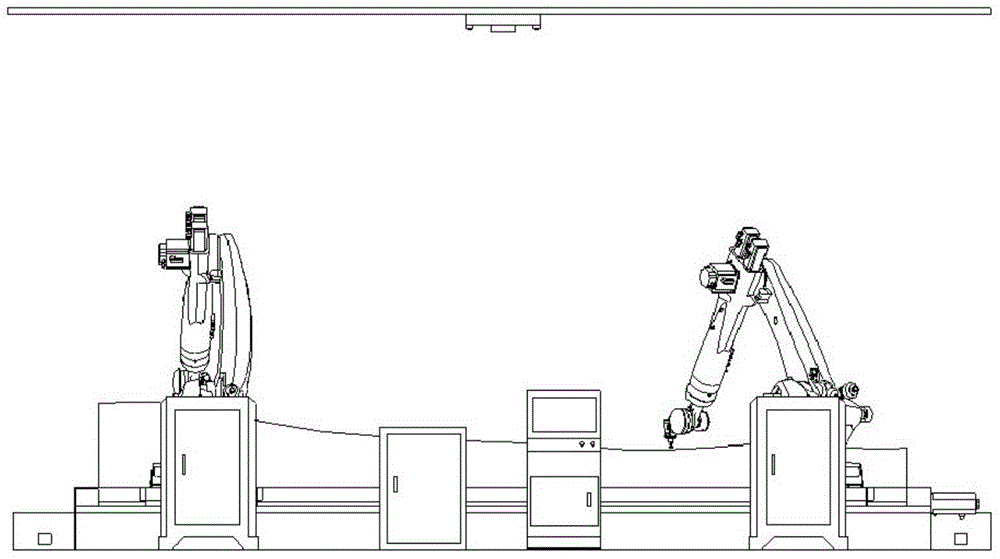

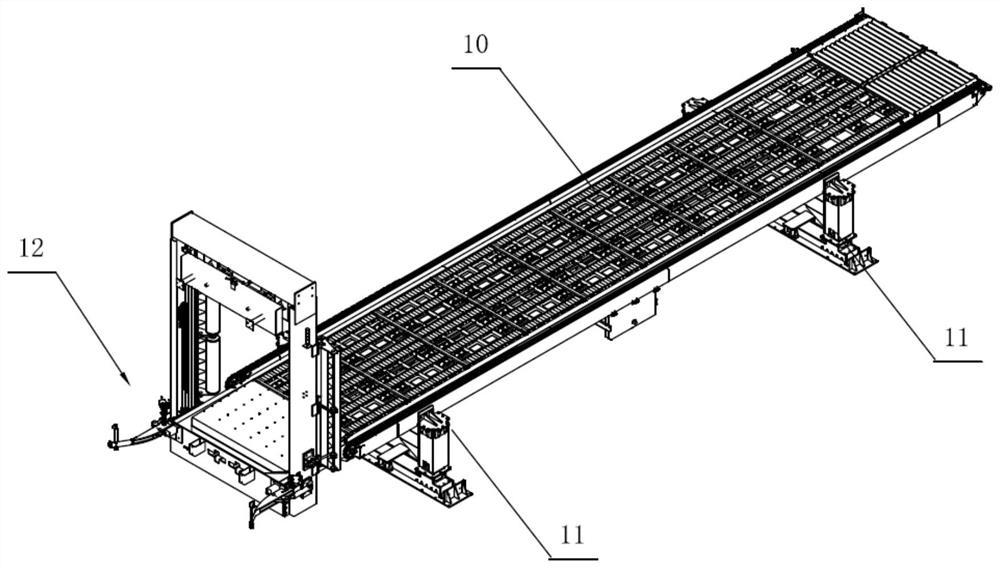

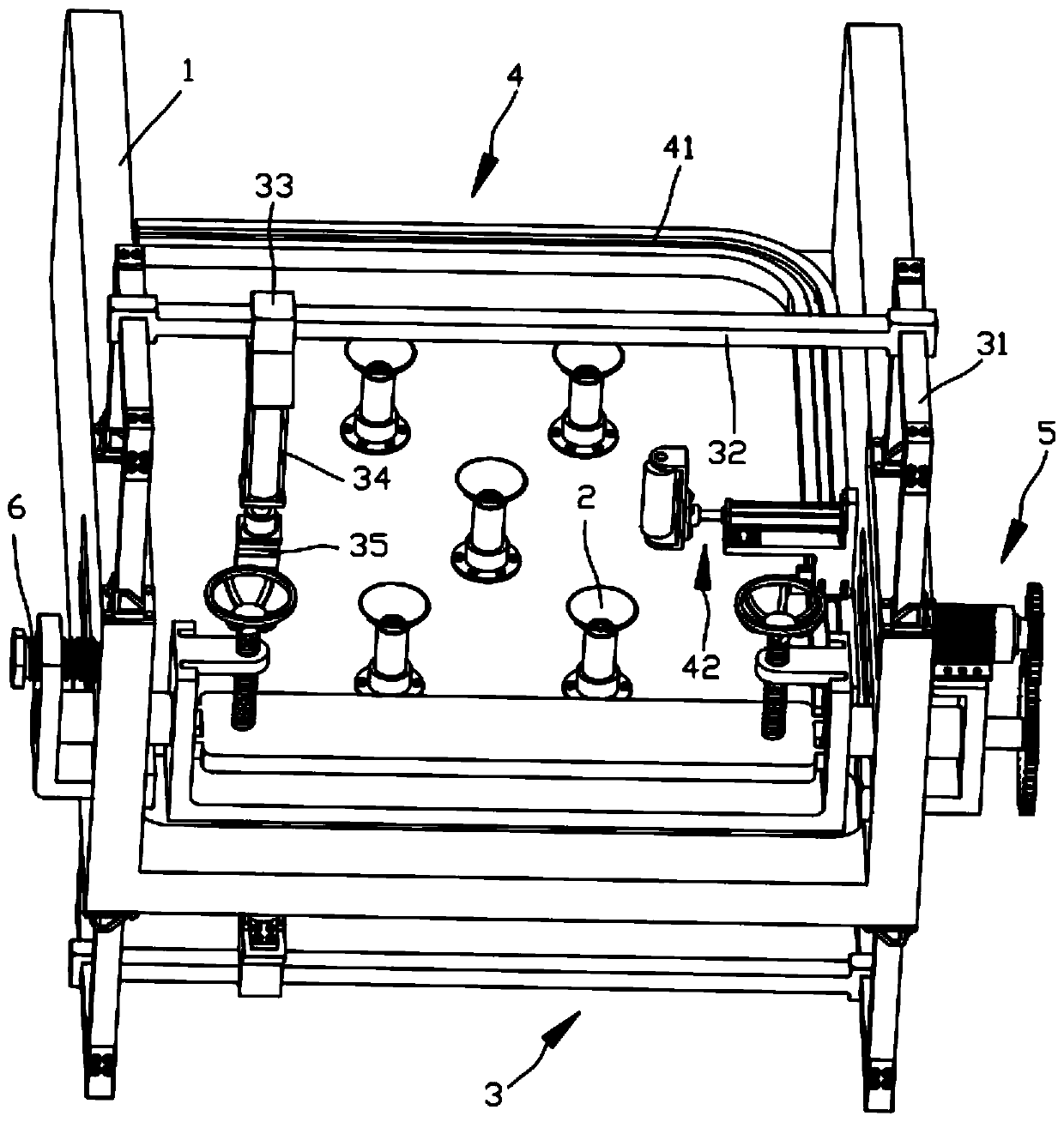

Robot parallel polishing system

ActiveCN103862340APressure controllableGuaranteed grinding removalEdge grinding machinesGrinding drivesSimulationSelf positioning

The invention discloses a robot parallel polishing system which comprises a coarse polishing system, a refined polishing system, a base component, a system control cabinet, a pneumatic control cabinet, a robot vision self-positioning system, workpieces and a working table. The workpieces with large free curved faces can be coarsely and finely polished through the polishing systems at the same time, simultaneous polishing on the two same workpieces can be achieved, the polishing accuracy can be effectively guaranteed, and the polishing efficiency is improved. Before the robot parallel polishing system works, the polishing areas are divided by path generative software according to three-dimensional models of the workpieces, the polishing paths are generated, standards of the workpieces are rapidly and accurately demarcated through the robot vision self-positioning system, two industrial robots drive a pneumatic polishing head to conduct coarse polishing and refined polishing on the polishing areas according to the planed paths, the pneumatic mild force control technology, the normal polishing force control technology and the path real-time calibration compensation technology are adopted in the polishing process, and the polishing accuracy and the coincidence of the polishing quality are effectively guaranteed.

Owner:中科君胜(深圳)智能数据科技发展有限公司

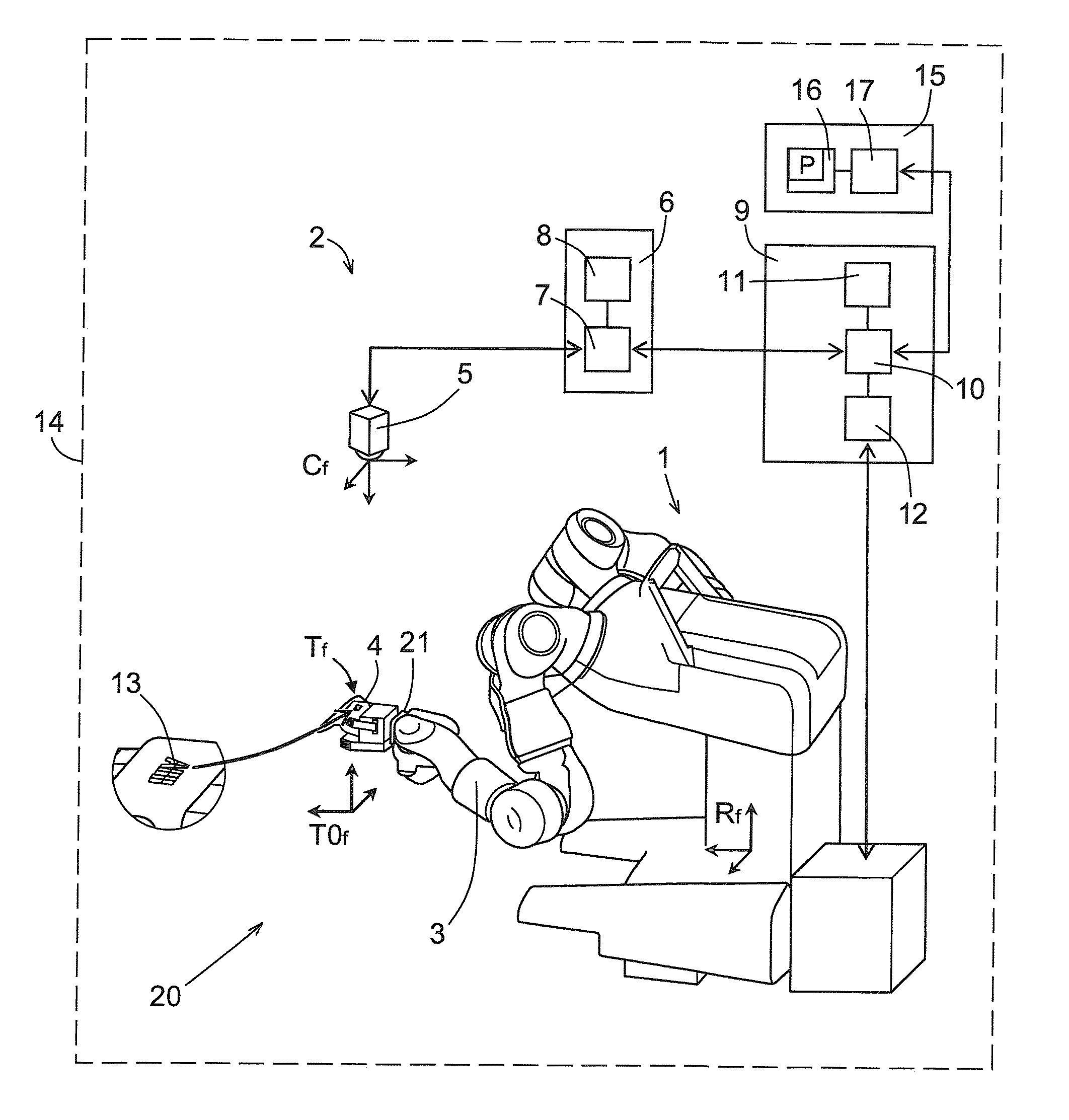

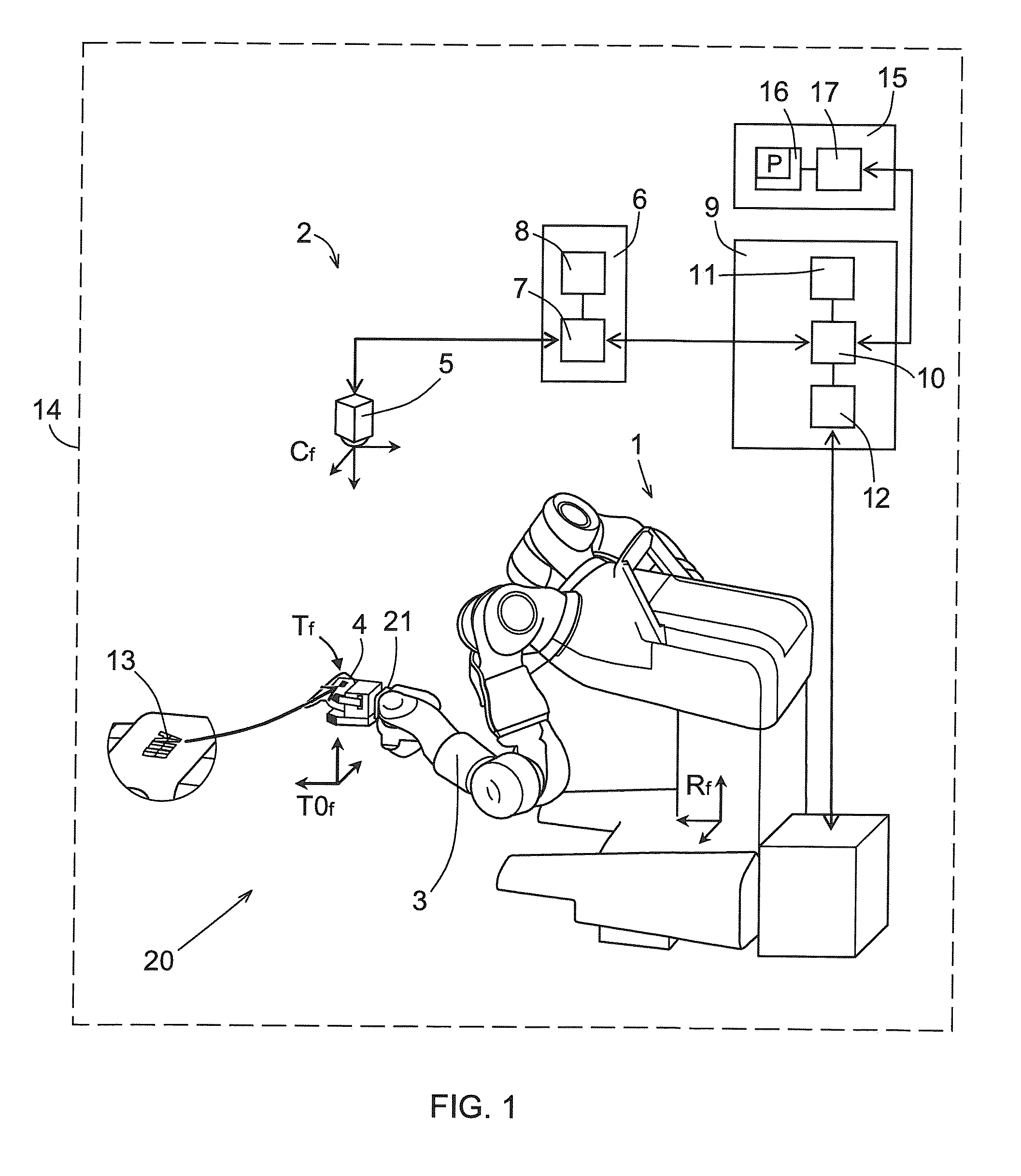

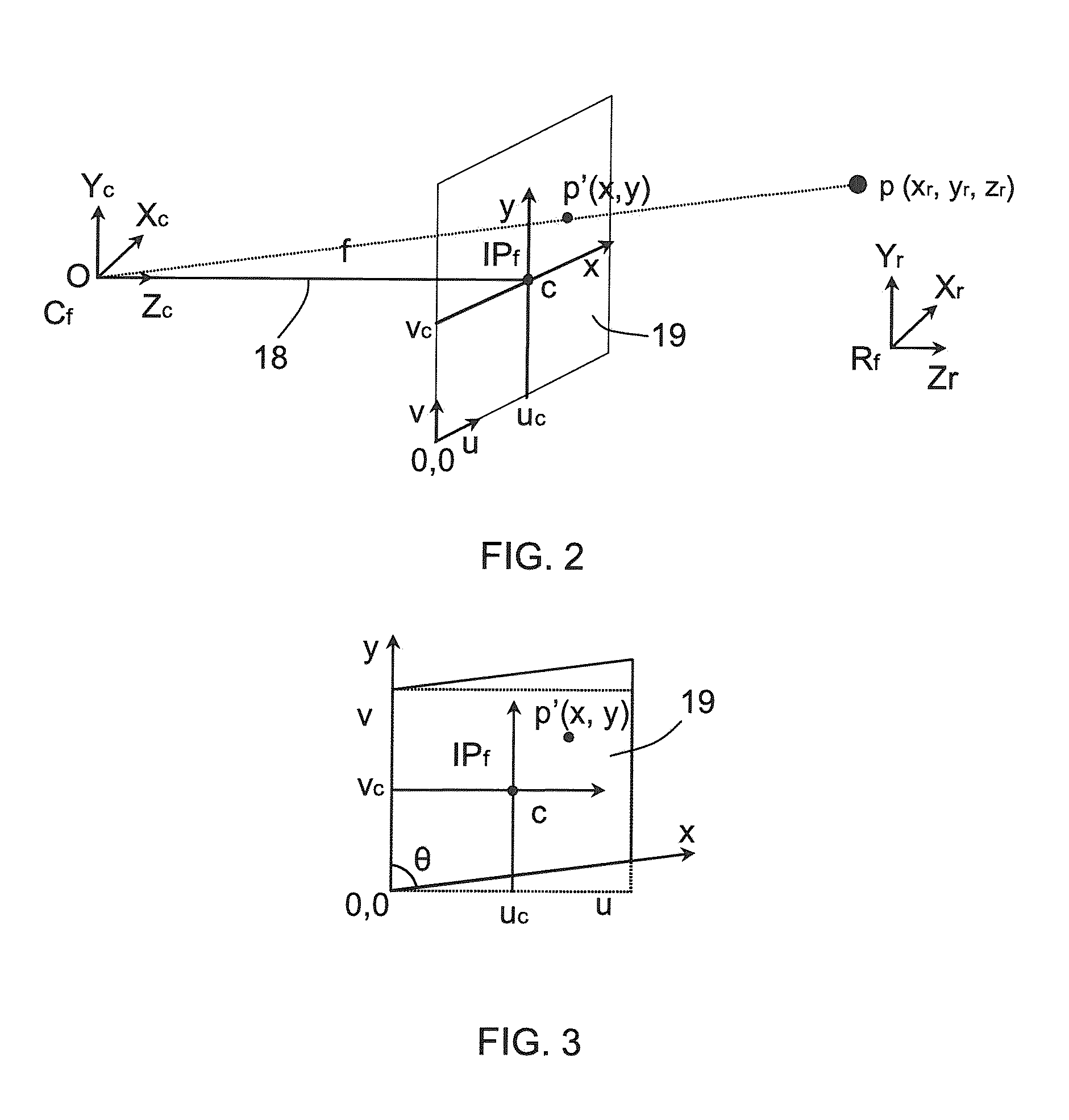

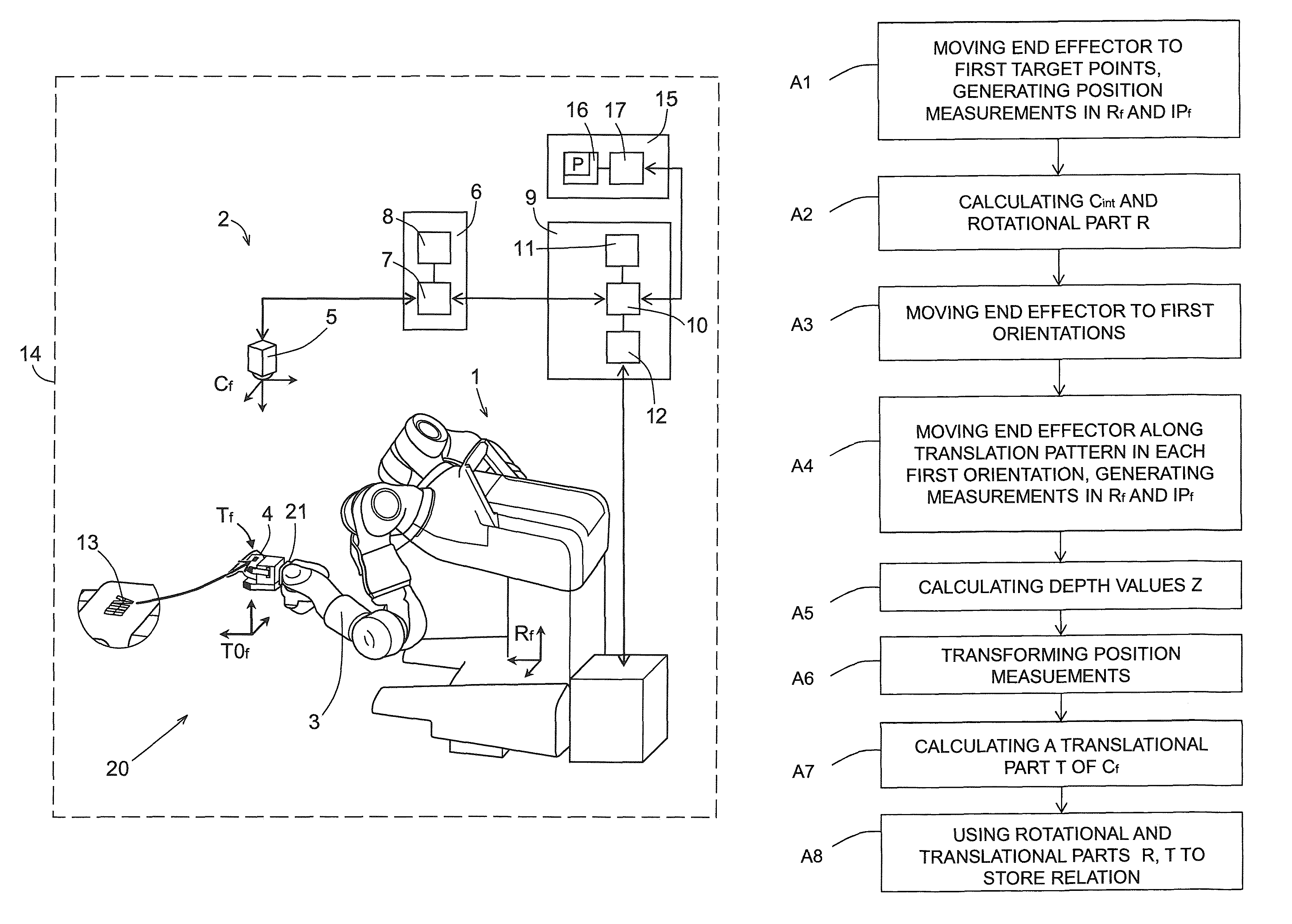

Robot System And Method For Calibration

ActiveUS20160039094A1Fast and Accurate CalibrationAccurately doneProgramme-controlled manipulatorComputer controlRobotic systemsEngineering

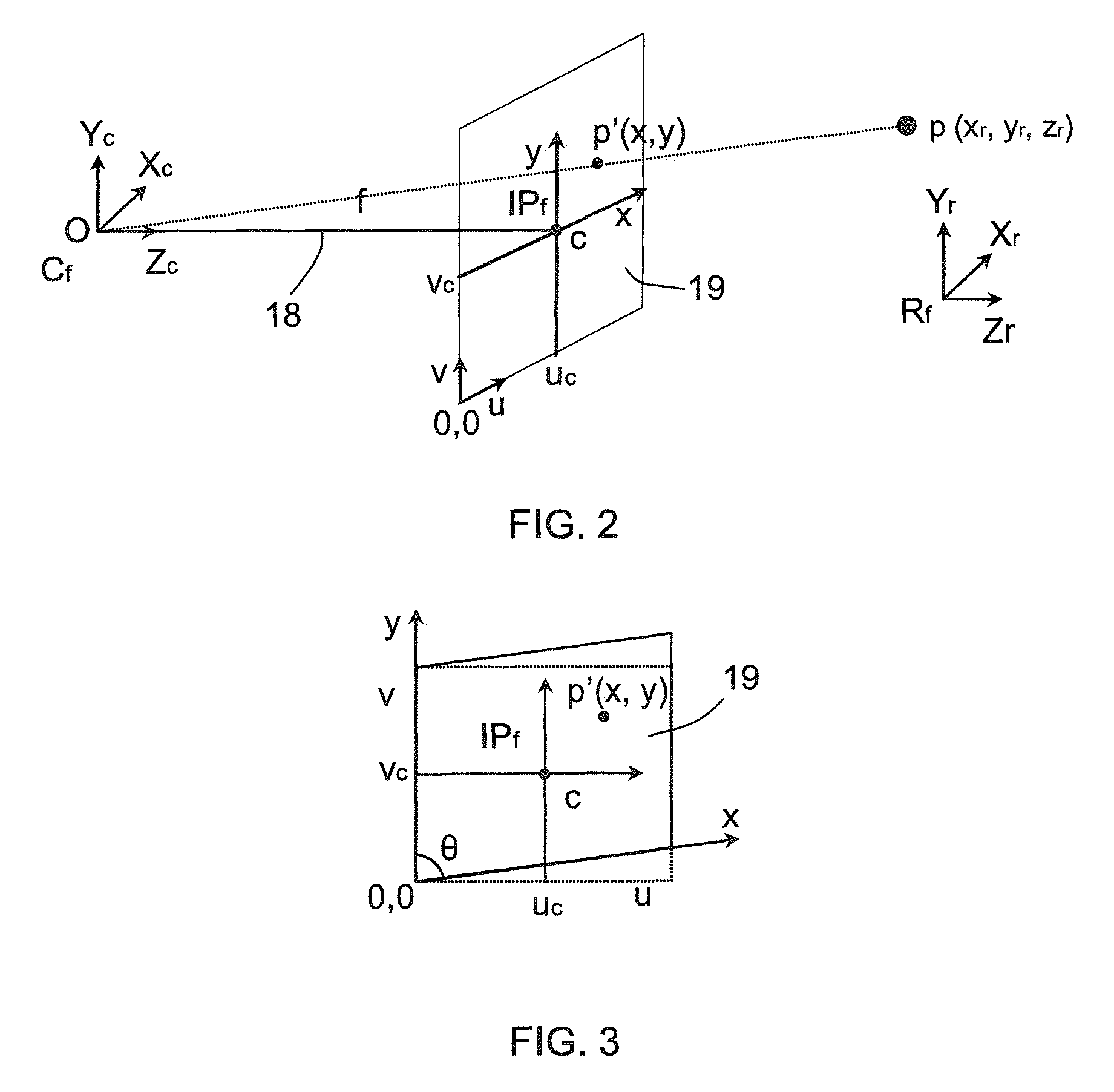

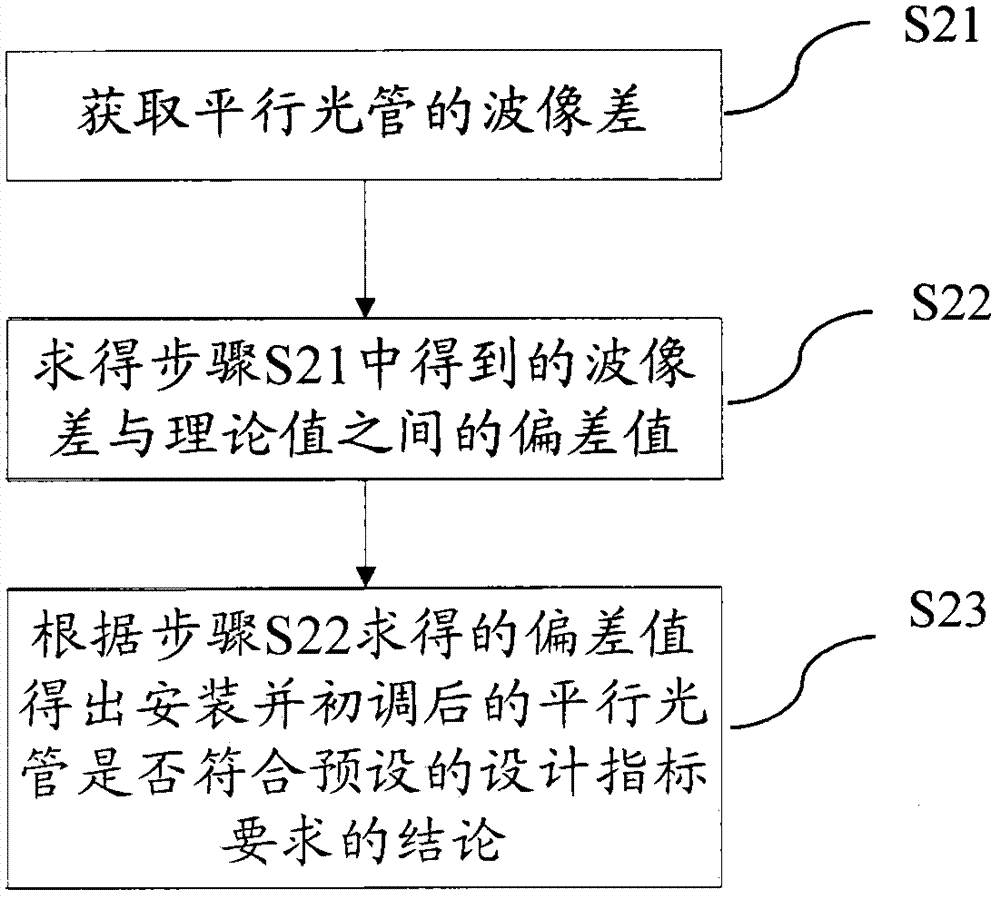

A method and a system for calibrating a first coordinate system Rf of a robot unit with a second coordinate system Cf of an object identification unit, wherein the robot unit includes a robot arm with an end effector and the object identification unit includes a camera unit. The calibration is performed using a calibration marker on the end effector. The method determines the intrinsic and the extrinsic parameters of the camera unit in two steps, a first step where the intrinsic parameters and a rotational part of the extrinsic parameters are determined, and a second step where a translational part of the extrinsic parameters are determined.

Owner:ABB (SCHWEIZ) AG

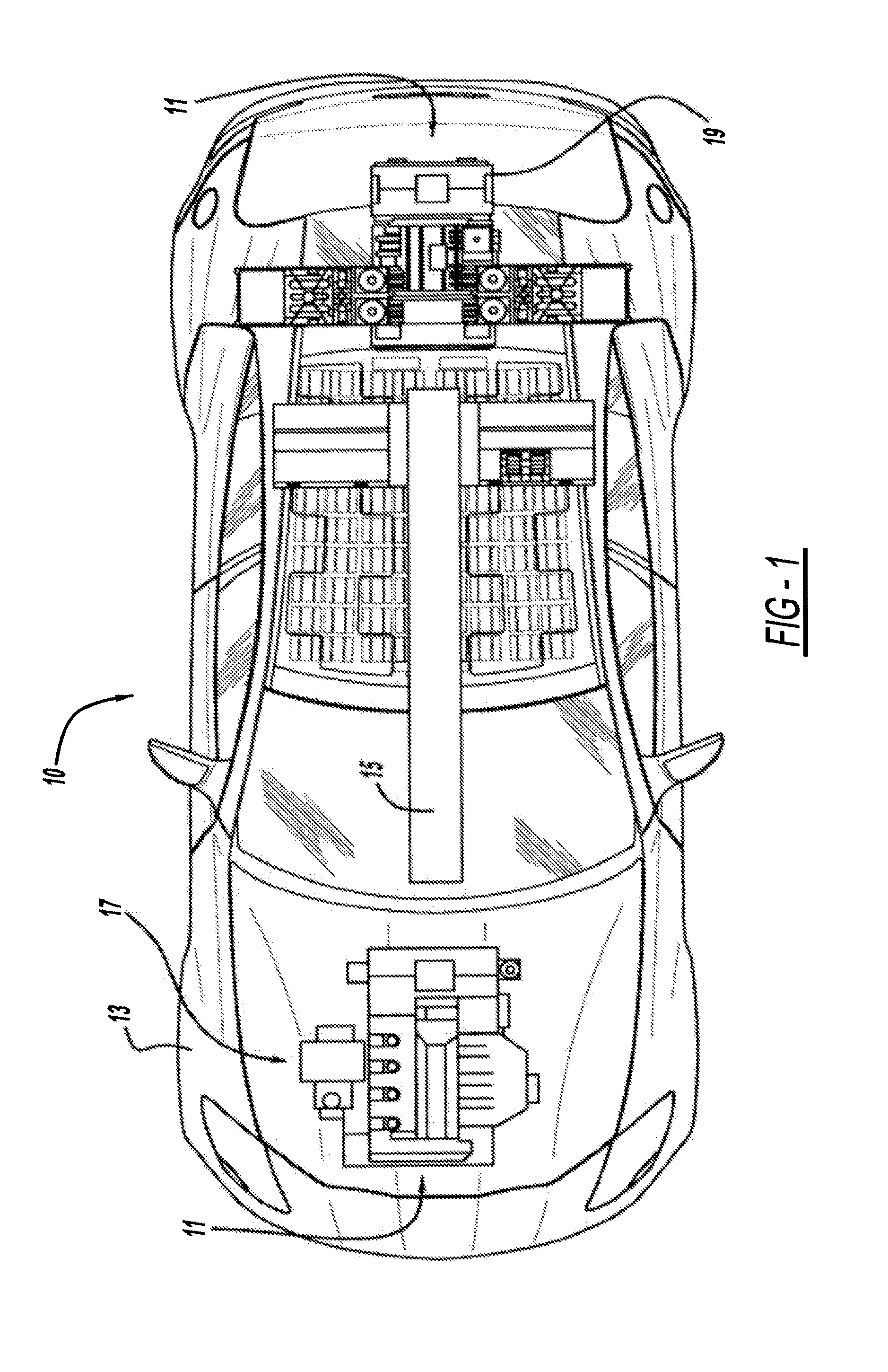

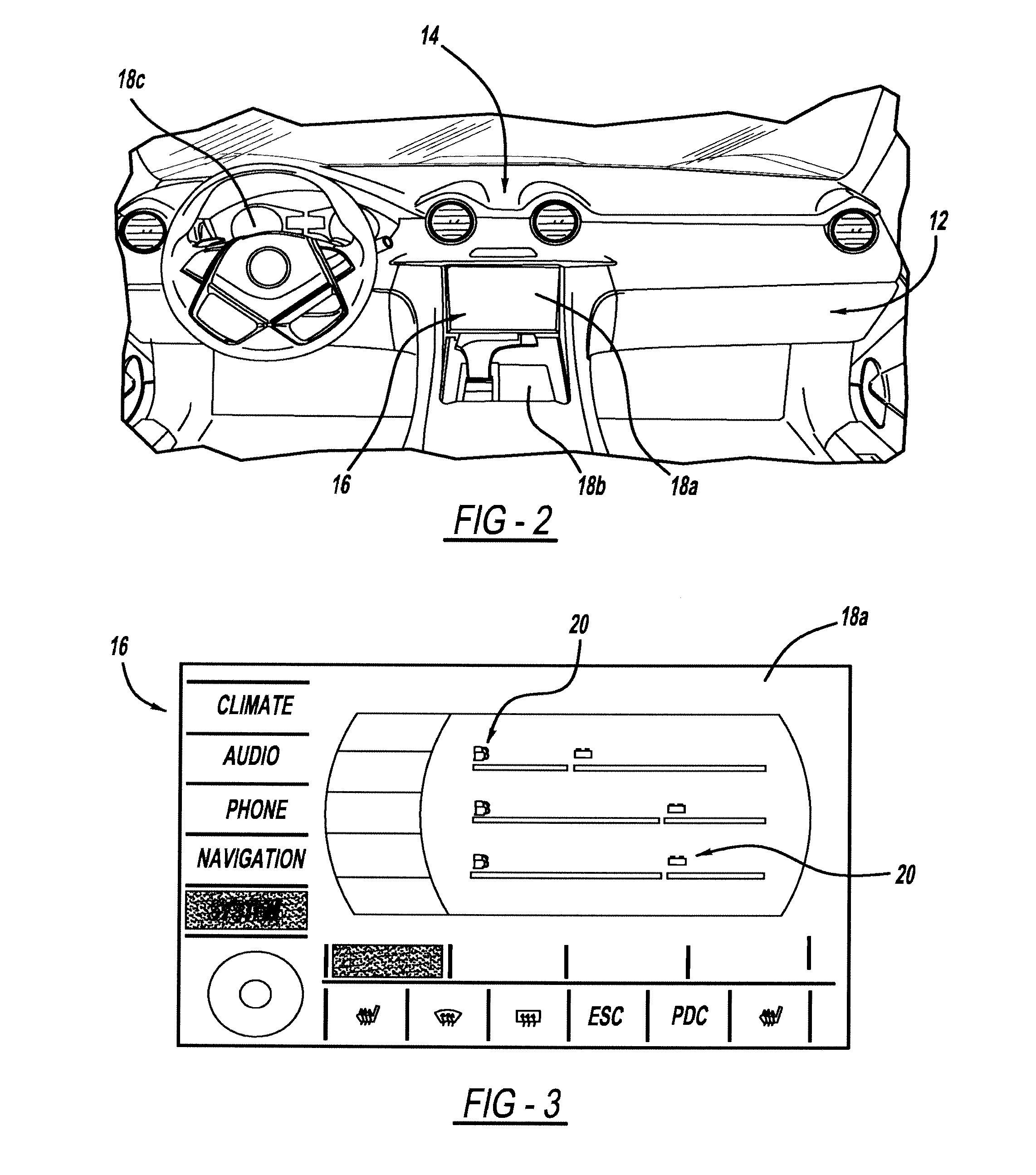

System and method for range calculation in vehicles

InactiveUS20140121956A1Improve prediction accuracyQuick and accurate calibrationHybrid vehiclesAnalogue computers for vehiclesIn vehicleDriver/operator

Owner:FISKER AUTOMOTIVE & TECH GRP

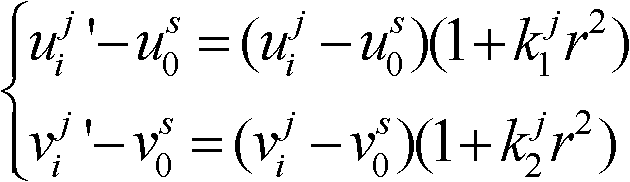

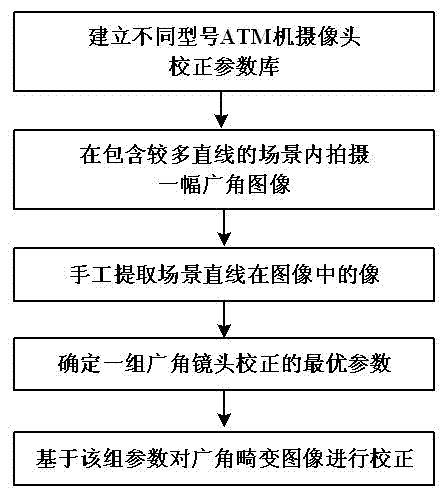

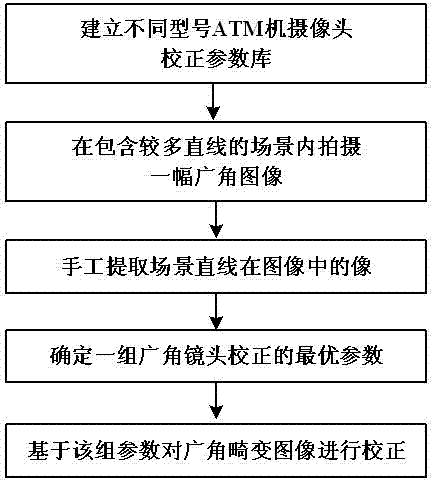

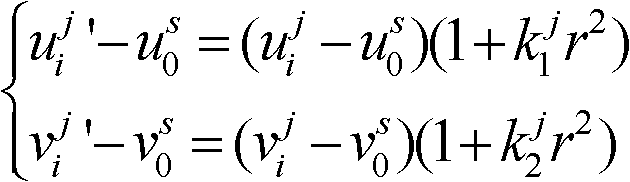

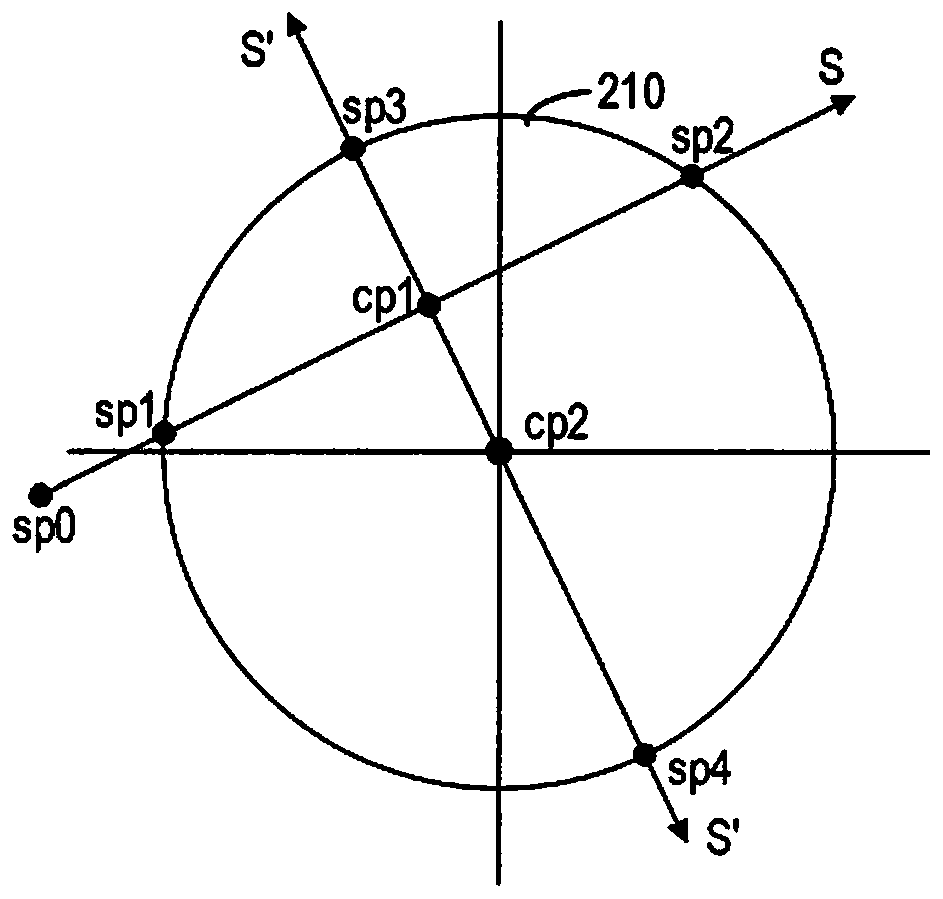

Method for correcting wide-angle camera lens distortion of automatic teller machine (ATM)

InactiveCN102075785AEffective correctionFast and accurate calibrationImage analysisTelevision systemsCamera lensImaging processing

The invention relates to the technical field of image processing, in particular relating to a method for correcting wide-angle camera lens distortion of an automatic teller machine (ATM). The method comprises the following steps: establishing a database in accordance with correction parameters for the wide-angle camera lens distortions of ATMs of different types from different manufacturers; shooting a wide-angle image in a scene containing a plurality of straight lines; manually extracting curves in the image; determining a group of optimal correction parameters for the wide-angle camera lens of the ATM; and correcting the wide-angle image in accordance with the optimal parameters. By utilizing the method provided by the invention, the optimal correction parameters can be acquired fast and accurately, and the wide-angle lens images can be accurately corrected based on the optimal parameters.

Owner:WUHAN UNIV

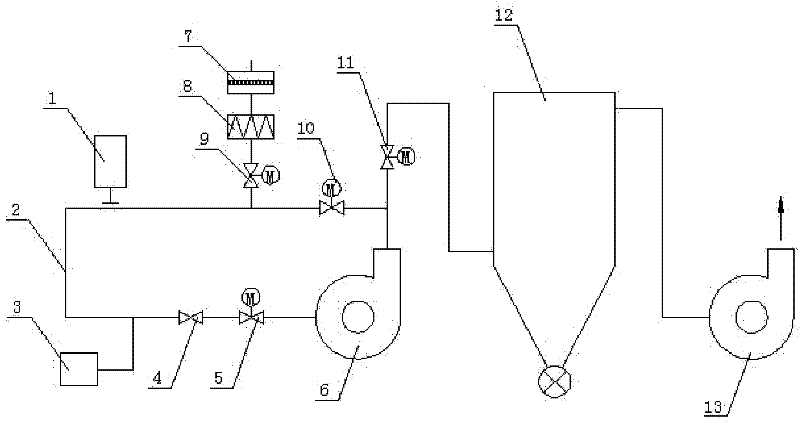

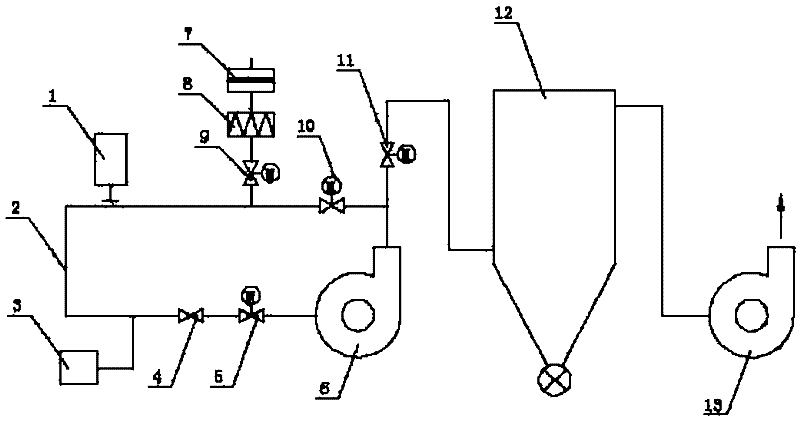

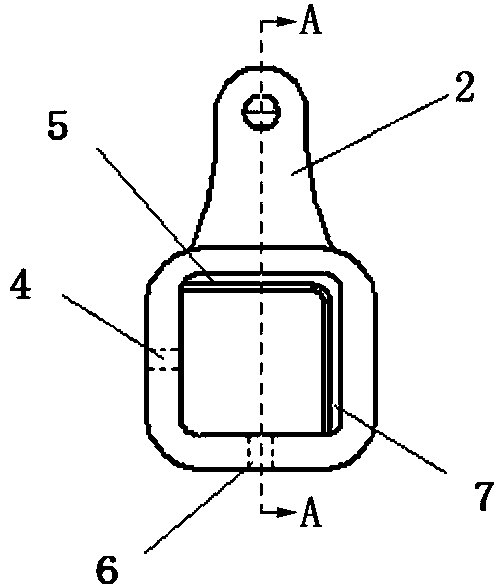

Method and equipment for calibrating dust-measuring instrument

InactiveCN102590447AFast and Accurate CalibrationThe measurement data is reliableMaterial analysisMeasurement deviceAir filter

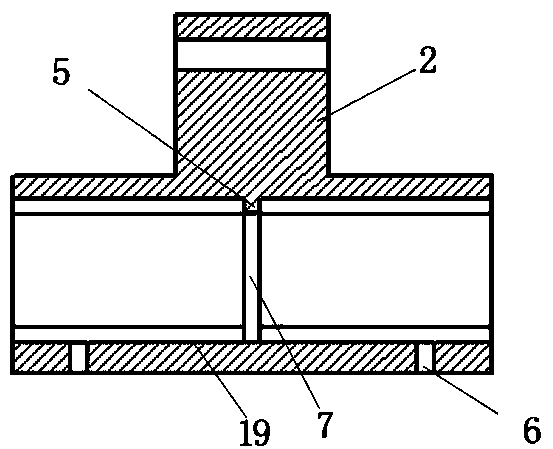

The invention relates to a method and equipment for calibrating a dust-measuring instrument. Weighed test dust is dispersed and then fed into a self-circulation system with stable gas flow, so that flowing standard dust-containing gas with stable concentration is prepared; and standard dust-containing gas with different concentrations can be prepared just by changing the quantity of the fed dust, and the dust-measuring instrument to be calibrated can be rapidly and correctly calibrated. The equipment comprises the dust-measuring instrument (1), a self-circulation pipeline (2), a dust generating device (3), a flow measuring device (4), a flow velocity and pressure adjusting valve (5), a circulating fan (6), an air filter (7), an air heater (8), a switch valve, a dust collector (12), an exhaust fan (13), connecting pipelines between all devices, and the like. Compared with the prior art, the method and the equipment can rapidly and correctly calibrate the dust-measuring instrument, thereby greatly reducing the error of the dust-measuring instrument and enabling the measurement data of the dust-measuring instrument to be more real and reliable.

Owner:上海信孚环保技术工程有限公司

Robot system and method for calibration

ActiveUS9457470B2Fast and Accurate CalibrationAccurately doneProgramme controlProgramme-controlled manipulatorRobotic systemsEngineering

A method and a system for calibrating a first coordinate system Rf of a robot unit with a second coordinate system Cf of an object identification unit, wherein the robot unit includes a robot arm with an end effector and the object identification unit includes a camera unit. The calibration is performed using a calibration marker on the end effector. The method determines the intrinsic and the extrinsic parameters of the camera unit in two steps, a first step where the intrinsic parameters and a rotational part of the extrinsic parameters are determined, and a second step where a translational part of the extrinsic parameters are determined.

Owner:ABB (SCHWEIZ) AG

Assembly and rectification method for collimator

InactiveCN104501831AFast and accurate calibrationImprove the accuracy of installation and calibrationTesting optical propertiesComputer scienceCollimator

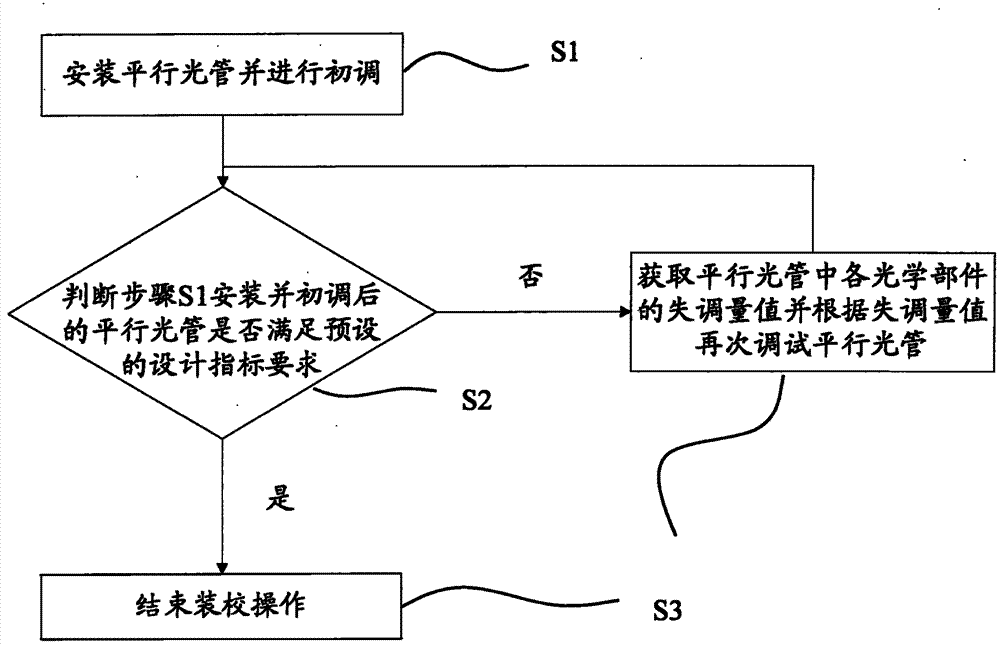

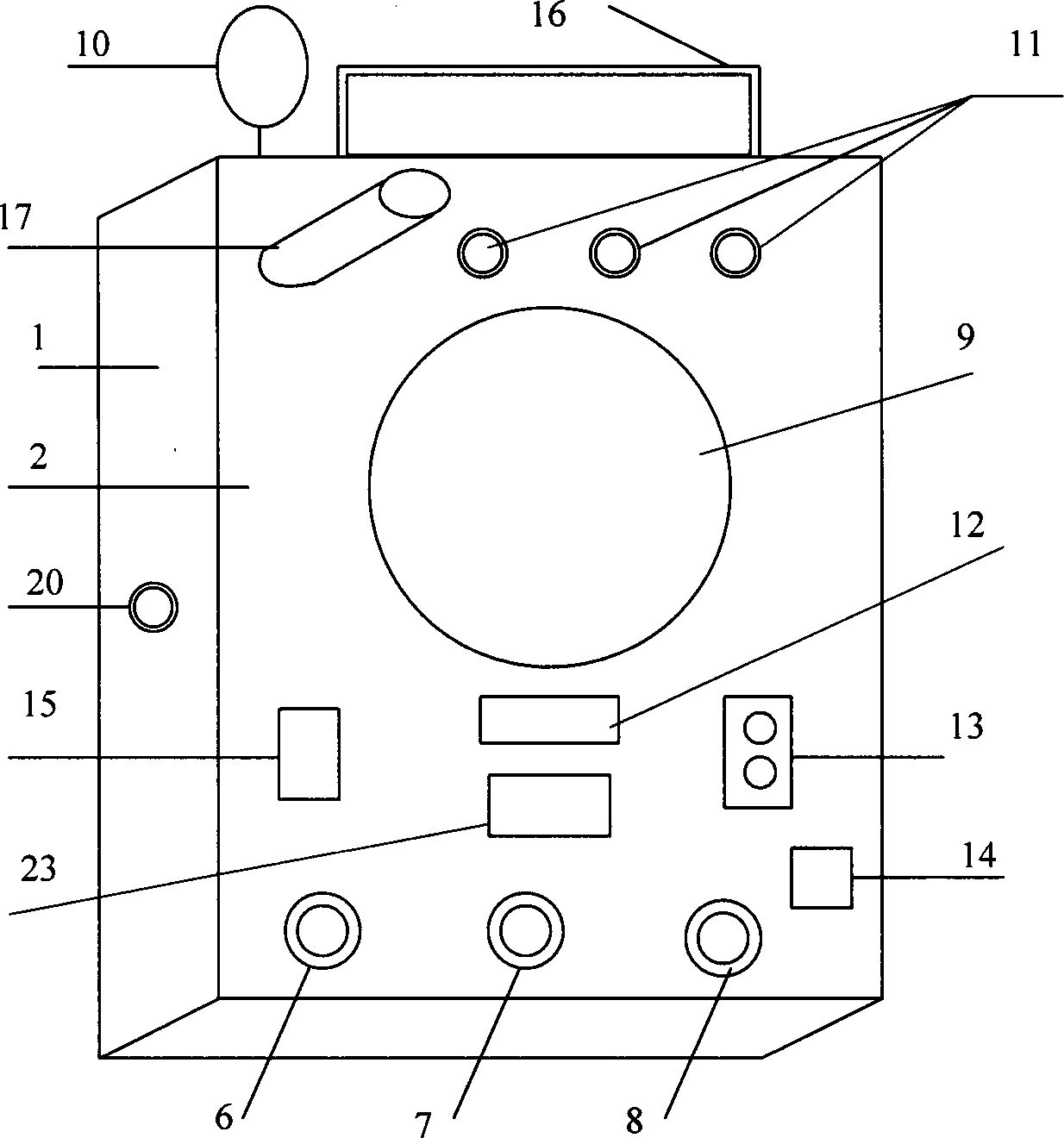

The invention provides an assembly and rectification method for a collimator. The method comprises the following steps: S1, installing the collimator and performing primary adjustment on the collimator; S2, judging whether the collimator installed and subjected to primary adjustment in the step S1 meets preset design index requirements; and S3, if the collimator does not meet the preset design index requirements according to the judging result of the step S2, obtaining an imbalance quantity value of each optical component of the collimator and re-adjusting the collimator according to the imbalance quantity value, and if the collimator meets the preset design index requirements, finishing the assembly and rectification operation. The assembly and rectification method can be used for realizing the fast and accurate assembly and rectification of the collimator, the defects that the traditional assembly and rectification method is strong in randomness, long in assembly and rectification period and the like are overcome, the precision of the assembly and rectification of the collimator is markedly improved, and the nonparallelism of the collimated light beam is decreased.

Owner:BEIJING ZHENXING METROLOGY & TEST INST

Portable pressure instrument calibrator

The invention discloses a portable pressure instrument calibrator, and belongs to the field of automation instrument calibration instruments. The calibrator is characterized by comprising a box body and a panel, wherein the panel is provided with a pressure regulation valve, an inspection valve, a micrometering valve, a first pressure gauge, an output pressure connector, a digital display meter, an output current connector, a power control, a power connector, a resistor network and a pressure transmitter support. The upper portion of the box body is provided with a handle and a second pressure gauge. A check valve, a high-pressure air cylinder, an air filtering pressure reducer, a storage battery, a support, a high-pressure air pipe and an output pipeline are installed in the box body. An air source connector is arranged on the side of the box body. The portable pressure instrument calibrator has the advantages of being compact in structure, convenient to carry, easy to operate and quick and precise in calibration.

Owner:NANJING COLLEGE OF CHEM TECH

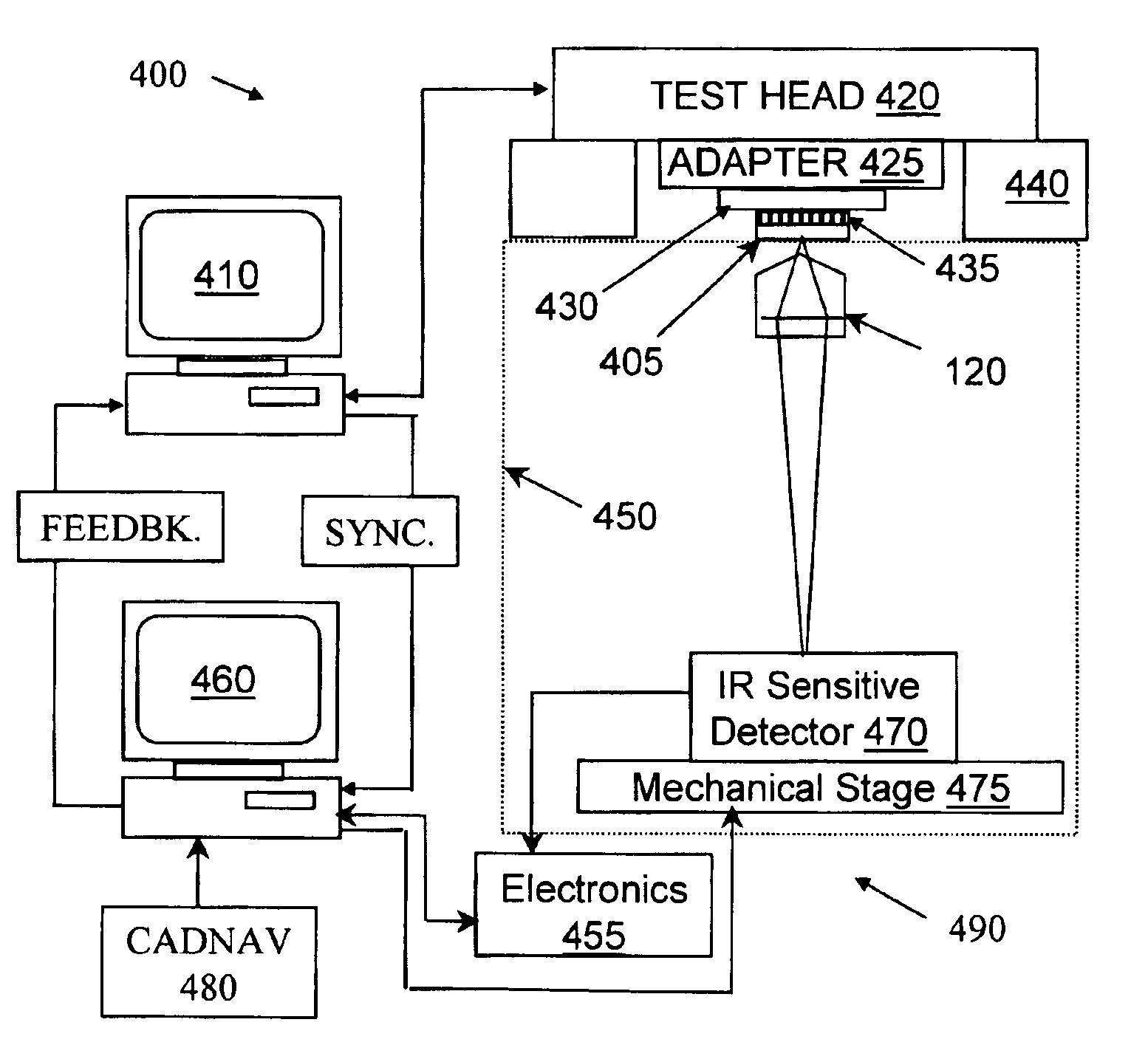

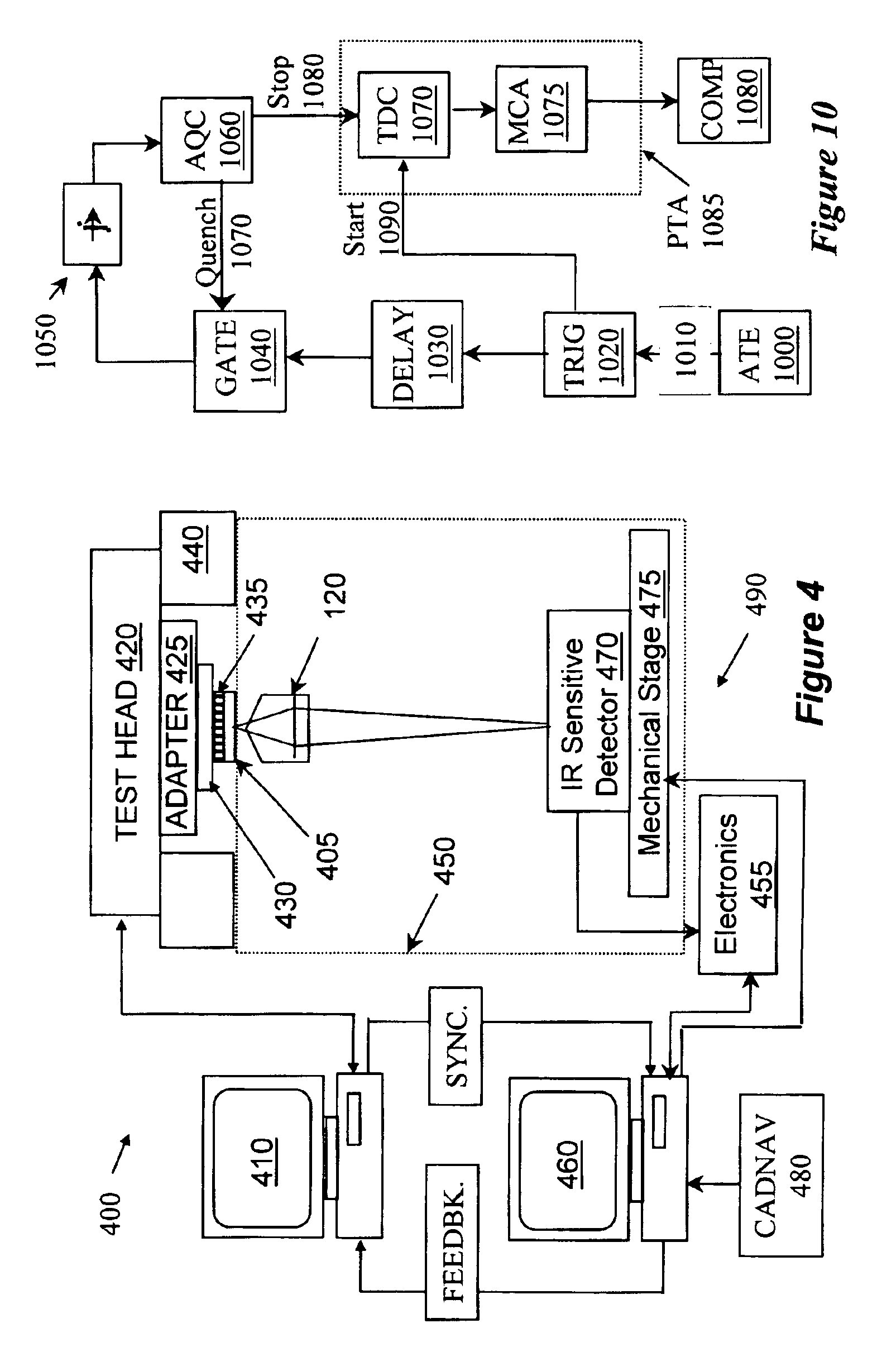

System and method for calibration of testing equipment using device photoemission

InactiveUS6956365B2Accurate characterizationAccurate characterization and correctionDigital circuit testingIndividual semiconductor device testingTesting equipmentTester device

A system and method for calibration of a commercial semiconductor test system (tester). The system receives a synchronization signal from the tester and detects light emission from a device under test (DUT). The system then compares the timing and characteristics of the light emission to the synchronization signal to obtain a delay timing and signal change caused by intermediate elements of the tester. The delay timing and signal change are used to calibrate the various channels of the tester. Also described are various designs for DUT's to obtained enhanced accuracy of the delay timing. Further, a system and method are described for reconstruction of a test signal and study of the effects of intermediate elements of the tester on the shape of the test signal.

Owner:DCG SYST

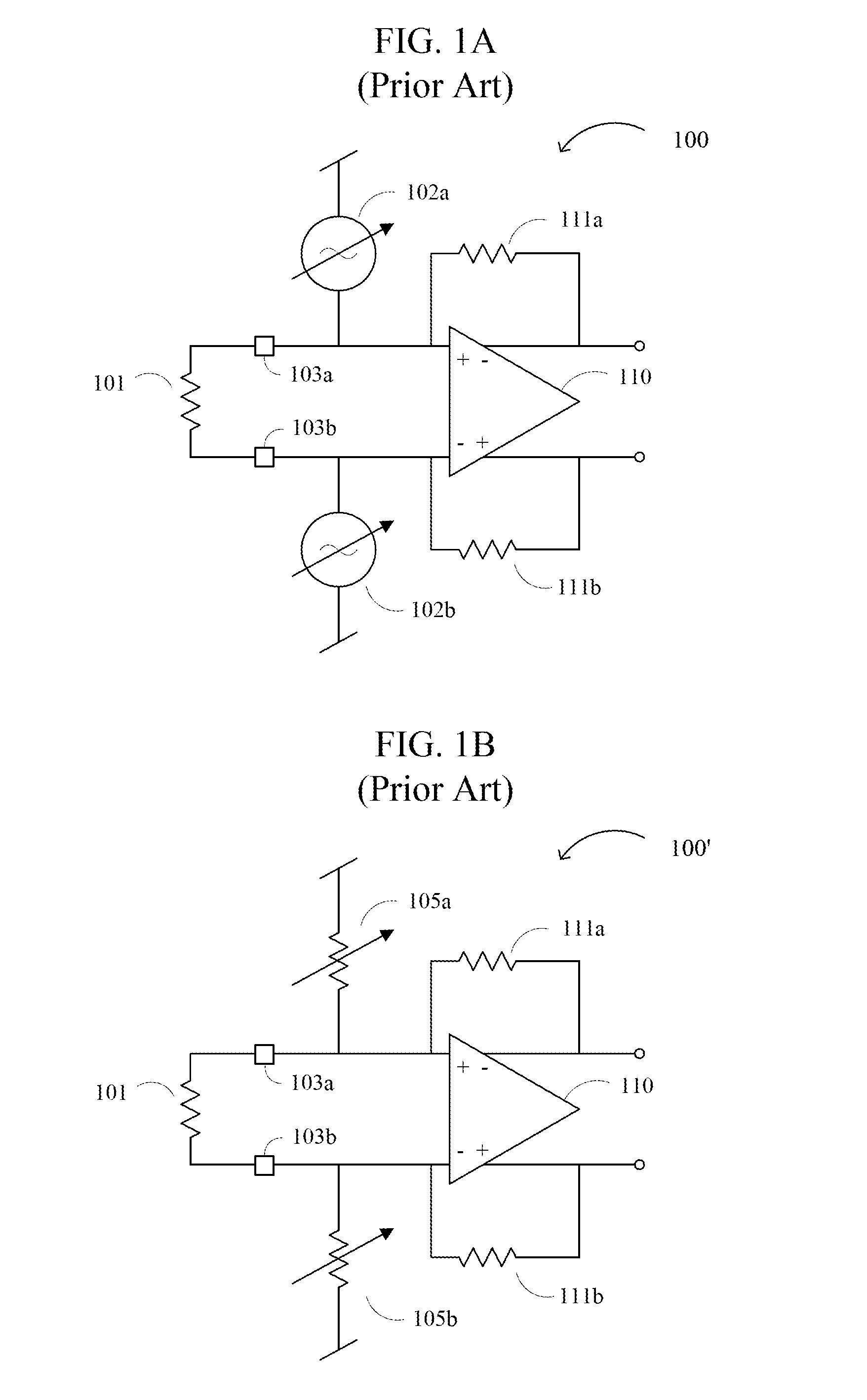

Circuits, systems, and methods for calibration of bias across a magneto-resistive sensor

ActiveUS7751139B1Fast and Accurate CalibrationReadily apparentMagnetic-field-controlled resistorsSolid-state devicesResistive sensorsAudio power amplifier

Circuits, systems, and methods for generating and calibrating bias for a magneto-resistive (MR) sensor. The circuit relates to a preamplifier circuit in a magnetic storage system, including an amplifier having an input coupled to a first MR sensor node, a first feedback path comprising a feedback resistor, the path configured to receive an amplifier output from the amplifier and to provide a feedback output to the first MR sensor node, a charging circuit configured to generate a current, apply the current to the first MR sensor node, and sample a voltage between the first MR sensor node and a second MR sensor node to produce a sampled voltage, the charging circuit operating when the feedback path is activated, and a bias circuit configured to apply a bias voltage across the first and second MR sensor nodes and to adjust the bias voltage to match the sampled voltage, the bias circuit operating when the feedback path is deactivated. The present invention advantageously provides for fast and accurate calibration of bias across an MR sensor that compensates for bias error introduced by the feedback path.

Owner:MARVELL ASIA PTE LTD

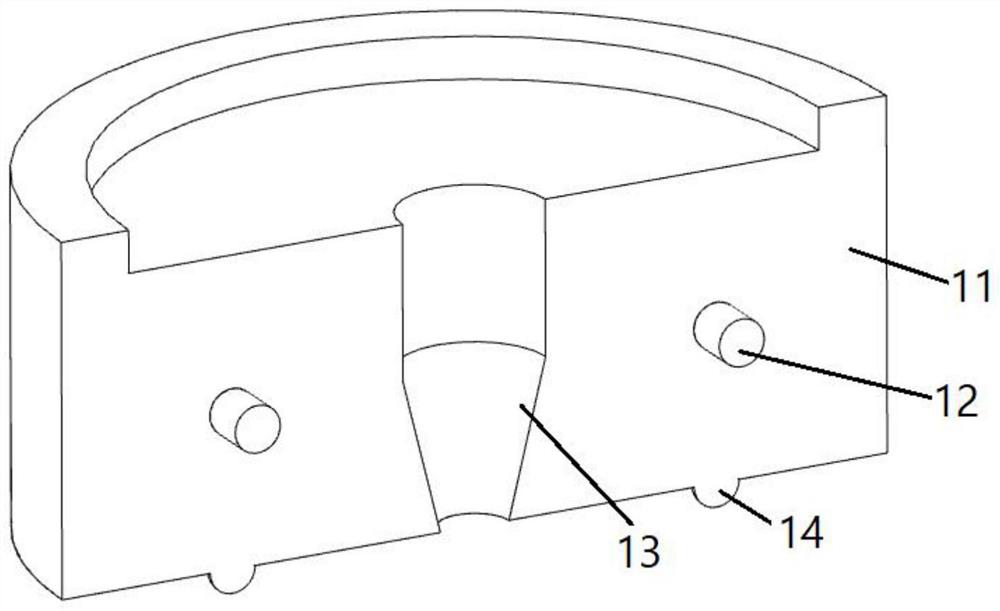

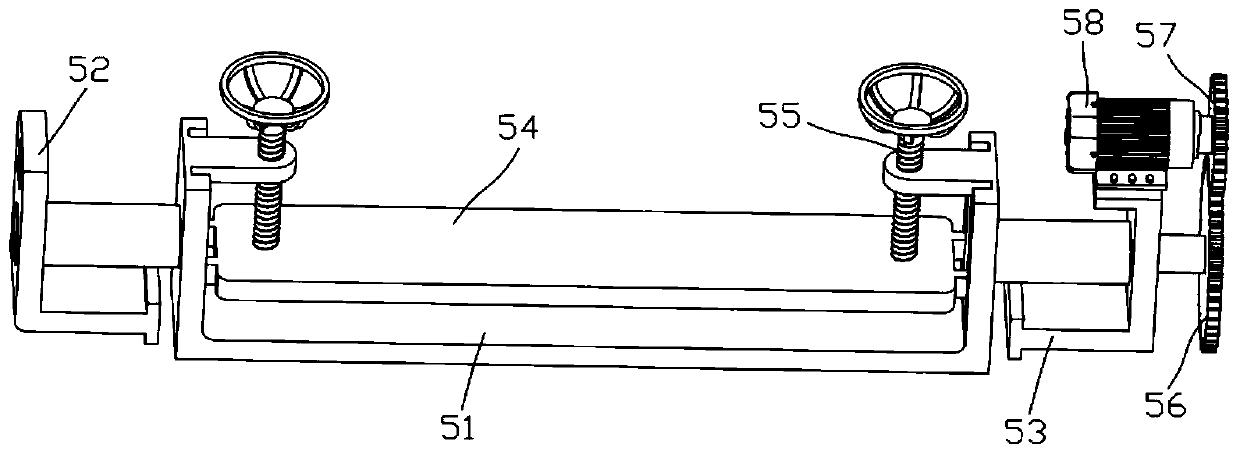

Firearm laser calibrator, method for demarcating firearm laser calibrator, method for calibrating firearm and method for determining target point of bore axis

The invention discloses a firearm laser calibrator, a method for demarcating the firearm laser calibrator, a method for calibrating a firearm, and a method for determining the target point of the boreaxis. The firearm laser calibrator comprises an inserted rod, a laser fixing frame and a laser generator, wherein the inserted rod is in a straight-handle rod shape, the diameter of the inserted rodis slightly less than the sunny side inner diameter of a gun barrel inner rotation line of a calibrated firearm, so that the inserted rod is smoothly inserted and connected into a gun barrel from a gun muzzle; the laser fixing frame includes a positioning cylinder for fixing the laser generator and an inserted rod positioning piece arranged on the upper side of the positioning cylinder, and the front end of the inserted rod is fixedly connected to the inserted rod positioning piece; and the laser generator is arranged in the positioning cylinder of the laser fixing frame. By means of the firearm laser calibrator, the purpose of calibrating the firearm can be achieved, and the accurate positioning of the extension line on the bore axis can also be achieved, the firearm laser calibrator is simple in structure, and convenient to use, the calibration work of the general light weapons such as rifles without live firing can be achieved, the calibration process is fast and accurate, and the firearm laser calibrator is very suitable for the use of the gun application unit of a basic level which lacks the special gun calibrator equipment.

Owner:ARMY ENG UNIV OF PLA

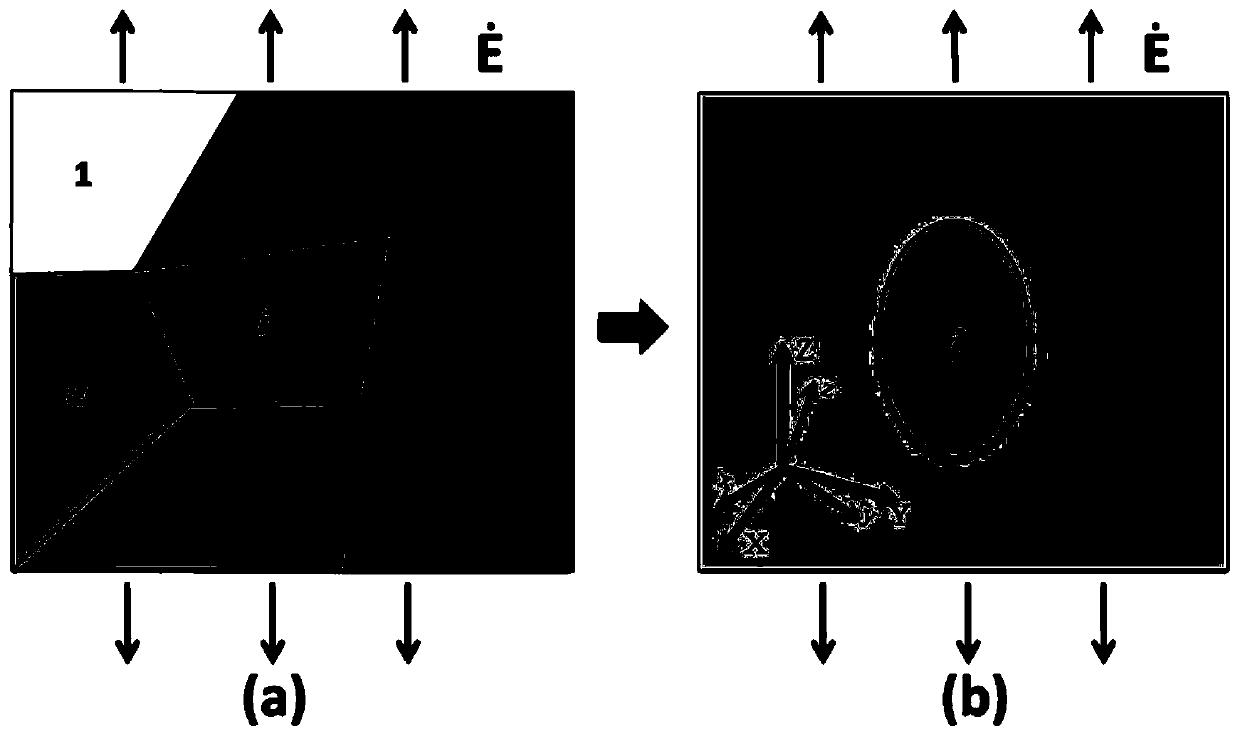

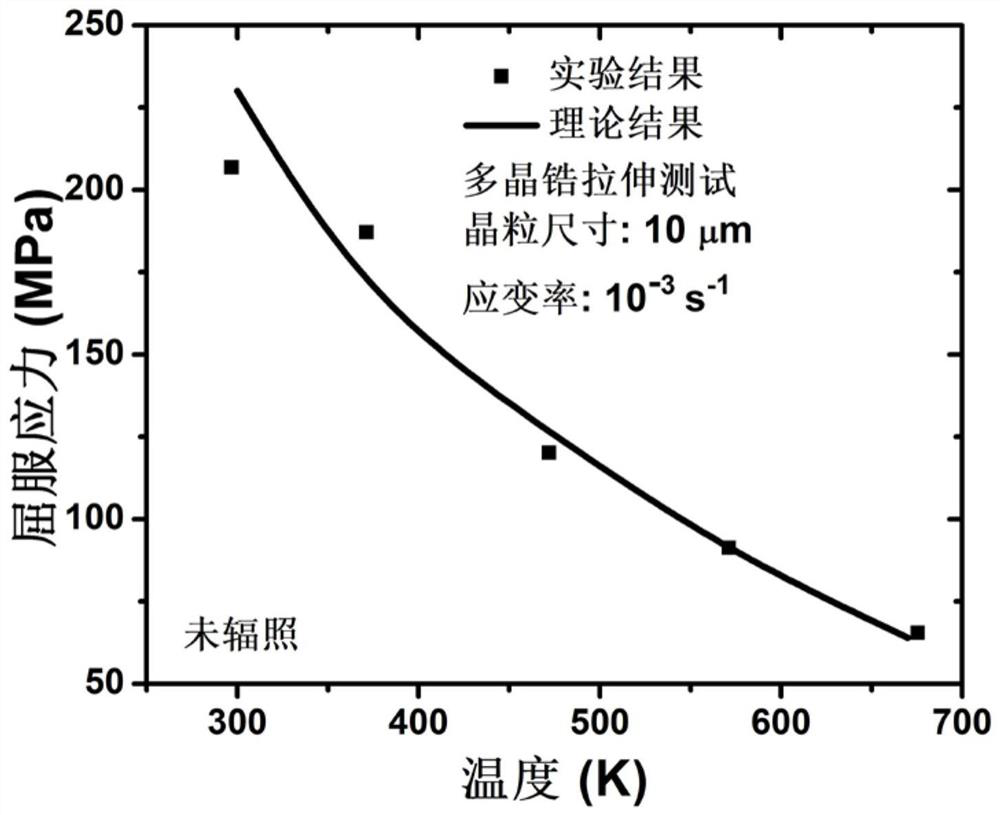

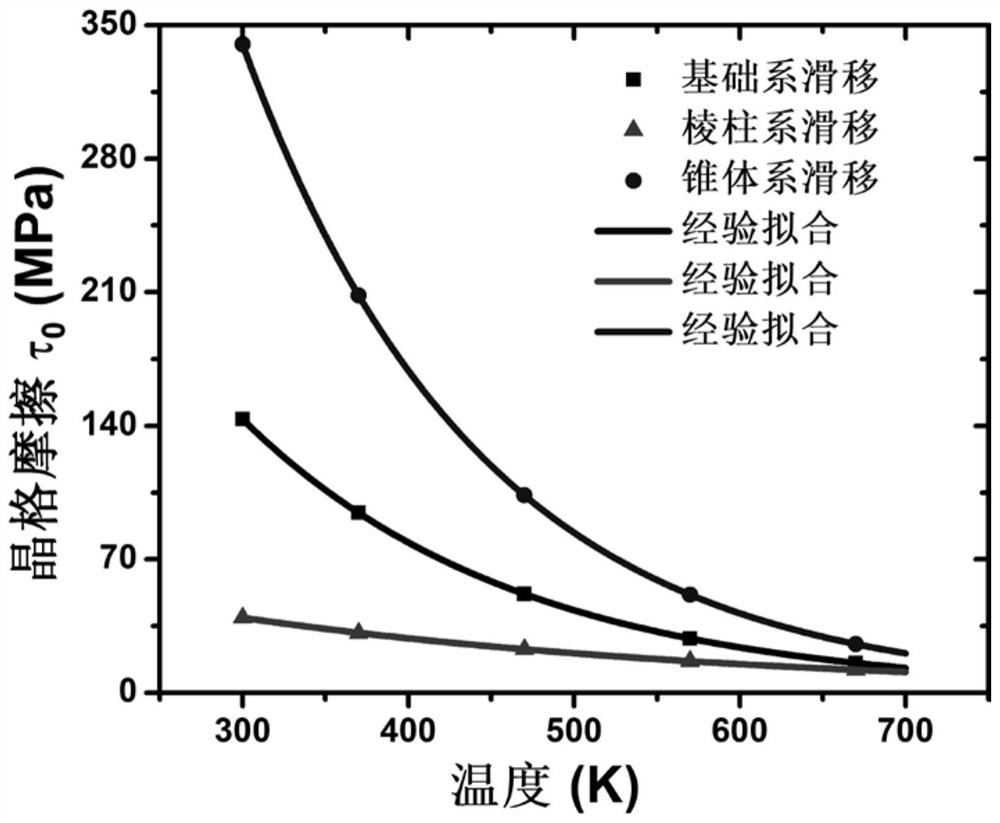

Method for constructing zirconium alloy thermal coupling constitutive relation under neutron irradiation condition

ActiveCN110543744AEasy CalibrationFast and accurate calibrationSpecial data processing applicationsZirconium alloySelf consistent

The invention discloses a method for constructing a zirconium alloy thermal coupling constitutive relation under a neutron irradiation condition. According to the method, the elastic-viscous-plastic self-consistent theory is combined, a cross-scale theoretical system from single crystals to polycrystals is established, model parameters can be simply, rapidly and accurately calibrated through an adopted Matlab calculation program, and meanwhile the numerical result of the model can be well matched with experimental data under different external load conditions. The theoretical model framework has wide applicability and expansibility, and can provide a reliable theoretical basis for macromechanics behavior research of nuclear materials.

Owner:CENT SOUTH UNIV

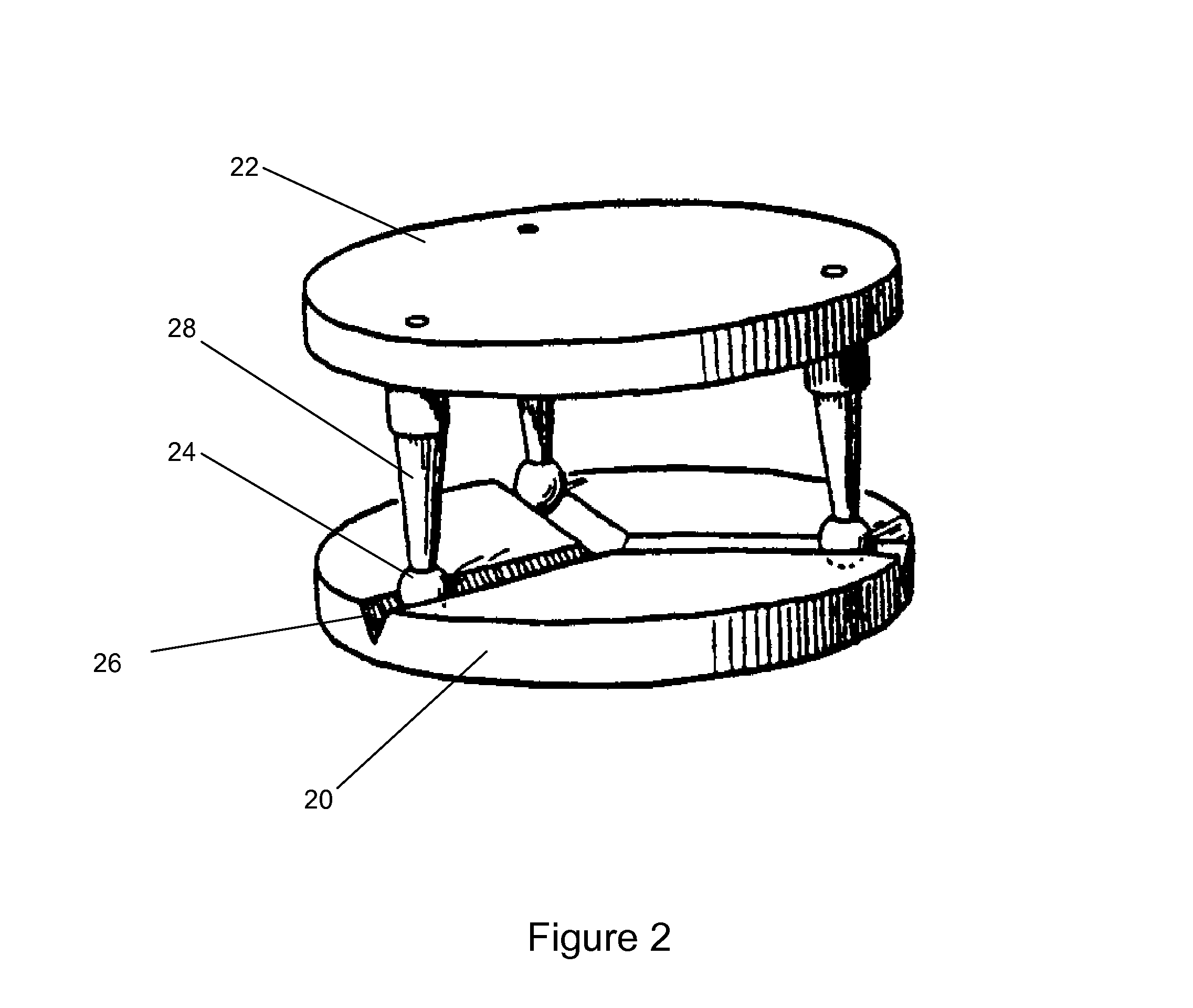

Calibration of a base coordinate system for an industrial robot

ActiveUS8467901B2Fast and Accurate CalibrationQuick calibrationProgramme-controlled manipulatorComputer controlControl modeEngineering

A method for calibration of a base coordinate system of an industrial robot in relation to a work area includes:mounting a first part of a kinematic coupling which is constrained in the same number of degrees of freedom as the robot, on the robot wrist interface of the robot,mounting a second part of the kinematic coupling in the work area,moving the robot including the base portion to the work area,set the robot in compliant control mode,move the first part of the kinematic coupling to mate with the second part,storing axis positions of the robot during mating of the kinematic coupling,determining the position and orientation of the base portion based on the stored axis positions and a kinematic model of the robot, and on basis thereon calibrating the base coordinate system of the robot.

Owner:ABB (SCHWEIZ) AG

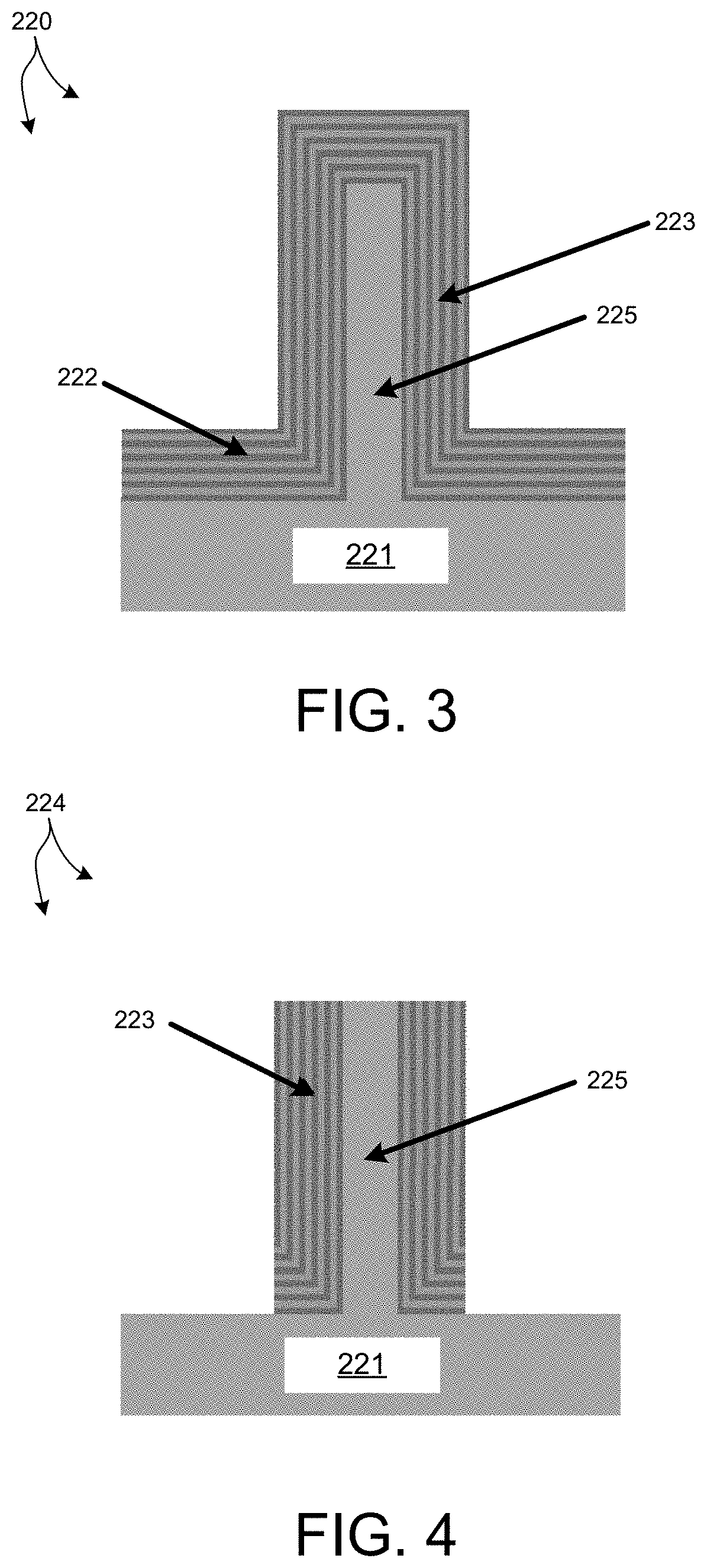

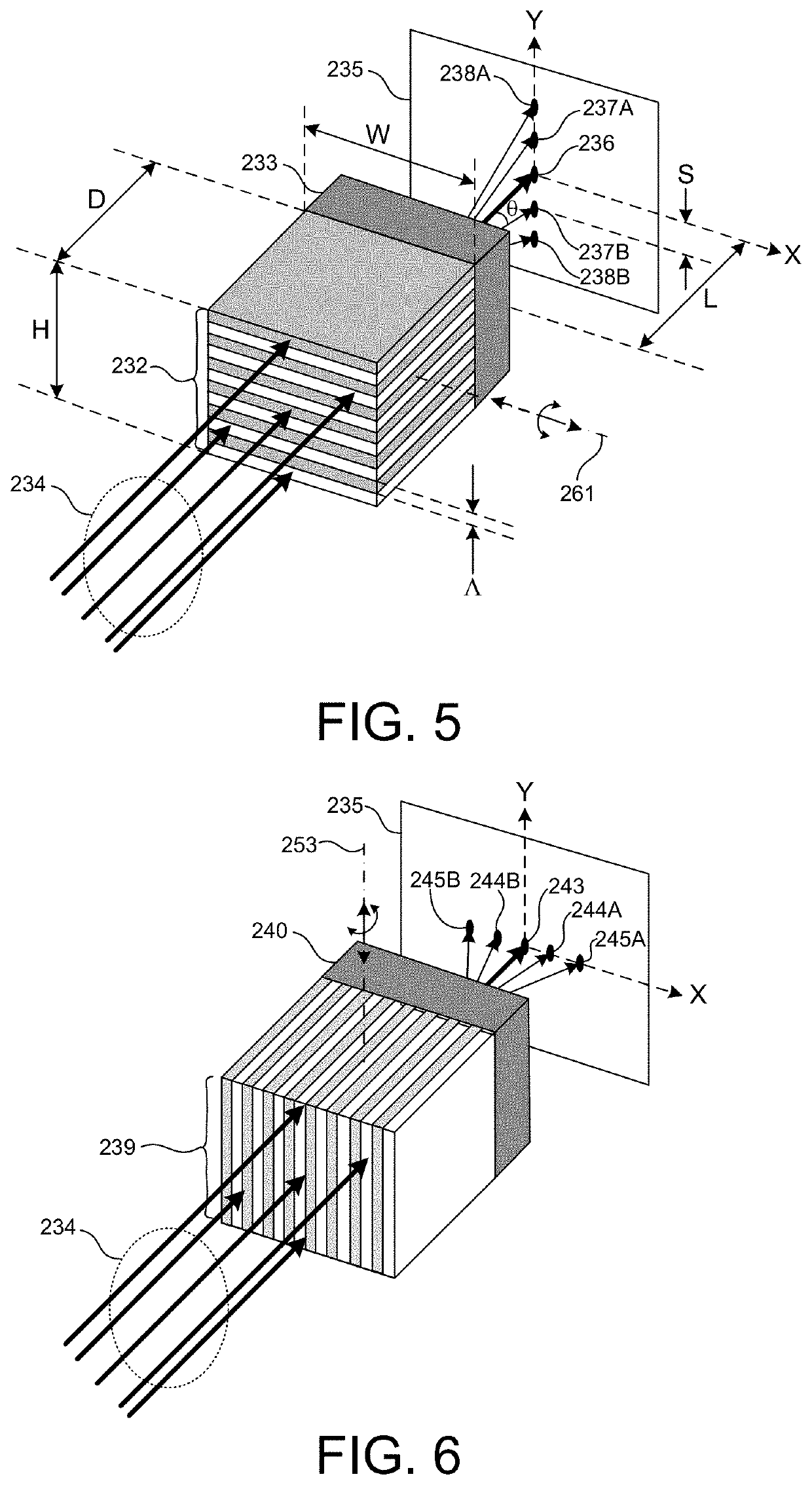

Multilayer targets for calibration and alignment of X-ray based measurement systems

ActiveUS10816486B2Fast and Accurate CalibrationHigh diffraction efficiencyMaterial analysis using wave/particle radiationSemiconductor/solid-state device manufacturingAbsolute calibrationRay

Owner:KLA CORP

Glass cutting device

ActiveCN108545921AGood cutting effectFast and Accurate CalibrationGlass severing apparatusEngineeringCutting glass

The invention provides a glass cutting device. The glass cutting device comprises a stander, a plurality of suction discs, two cutting mechanisms, a correction mechanism, a side separating mechanism and a fastening bolt, wherein the suction discs are fixedly mounted on the stander, the two cutting mechanisms are oppositely mounted at the upper and lower ends of the stander, the correction mechanism comprises an L-shaped guiding slot and a driving mechanism, the L-shaped guiding slot is fixedly formed in the stander, the driving mechanism is movably mounted in the L-shaped guiding slot, and theside separating mechanism is movably mounted on the stander. The two surfaces of glass are cut by virtue of oppositely mounted cutting mechanisms, so that the relatively cutting effect is achieved when relatively thick glass is cut; the position of the glass is corrected by virtue of the correction mechanism, so that the complex manual correction process is avoided; and the cut glass is processedby virtue of the side separating mechanism, so that the cut glass is completely separated from a master batch and does not need to be manually processed in the subsequent process.

Owner:ANHUI FENGYANG COUNTY QIANLI GLASSWORK CO LTD

Calibrating a magnetic transmitter

ActiveCN110058187ACalibration process is simpleAccelerated Calibration and TestingElectric/magnetic position measurementsElectrodynamic magnetometersMechanical engineeringTransmitter

A calibration device comprising: a plurality of magnetic sensors positioned at the calibration device, the plurality of magnetic sensors defining a space; a controller configured to be positioned in the space defined by the plurality of magnetic sensors, wherein the controller includes a magnetic transmitter; and one or more processors configured to: cause the magnetic transmitter to generate magnetic fields; receive signals from the plurality of magnetic sensors that are based on characteristics of the magnetic fields received at the plurality of magnetic sensors; calculate, based on the signals received from the plurality of magnetic sensors, positions and orientations of the plurality of magnetic sensors relative to a position and orientation of the magnetic transmitter; and determine whether the calculated positions and orientations of the plurality of magnetic sensors are within one or more threshold limits of known positions and orientations of the plurality of magnetic sensors.

Owner:ASCENSION TECH

Nano hard alloy micro-drill bar production system

The invention discloses a nano hard alloy micro-drill bar production system, and relates to the technical field of mold machining. An oil cylinder is arranged at the upper end of a top bracket, and a punching head is fixed on an output shaft at the lower end of the oil cylinder; supporting columns are arranged on the periphery of the lower side of the top support, and a clamping plate is fixed to the lower ends of the supporting columns; a first die plate is arranged on the lower side of the clamping plate, a second die plate is fixed on the lower side of the first die plate, and a storage device is arranged on the lower side of the second die plate; a material accommodating cavity and a mold cavity which are communicated with each other are formed in the first die plate and the second die plate respectively; the first die plate is provided with a left die and a right die, and the cross sections of the left die and the right die are semicircular; a heating device is arranged outside the lower end of the material accommodating cavity, and a cooling device is arranged outside the cavity; and the storage device is provided with a base, a supporting plate is arranged on the upper side of the base, and a placing groove is formed in the middle of the upper side of the base. The die plates can be prevented from being blocked, meanwhile, disassembly and cleaning are convenient, the forming effect of the die is guaranteed, and the product quality is improved.

Owner:蓬莱市超硬复合材料有限公司

A robot parallel grinding system

ActiveCN103862340BPressure controllableGuaranteed grinding removalEdge grinding machinesGrinding drivesSimulationSelf positioning

The invention discloses a robot parallel polishing system which comprises a coarse polishing system, a refined polishing system, a base component, a system control cabinet, a pneumatic control cabinet, a robot vision self-positioning system, workpieces and a working table. The workpieces with large free curved faces can be coarsely and finely polished through the polishing systems at the same time, simultaneous polishing on the two same workpieces can be achieved, the polishing accuracy can be effectively guaranteed, and the polishing efficiency is improved. Before the robot parallel polishing system works, the polishing areas are divided by path generative software according to three-dimensional models of the workpieces, the polishing paths are generated, standards of the workpieces are rapidly and accurately demarcated through the robot vision self-positioning system, two industrial robots drive a pneumatic polishing head to conduct coarse polishing and refined polishing on the polishing areas according to the planed paths, the pneumatic mild force control technology, the normal polishing force control technology and the path real-time calibration compensation technology are adopted in the polishing process, and the polishing accuracy and the coincidence of the polishing quality are effectively guaranteed.

Owner:中科君胜(深圳)智能数据科技发展有限公司

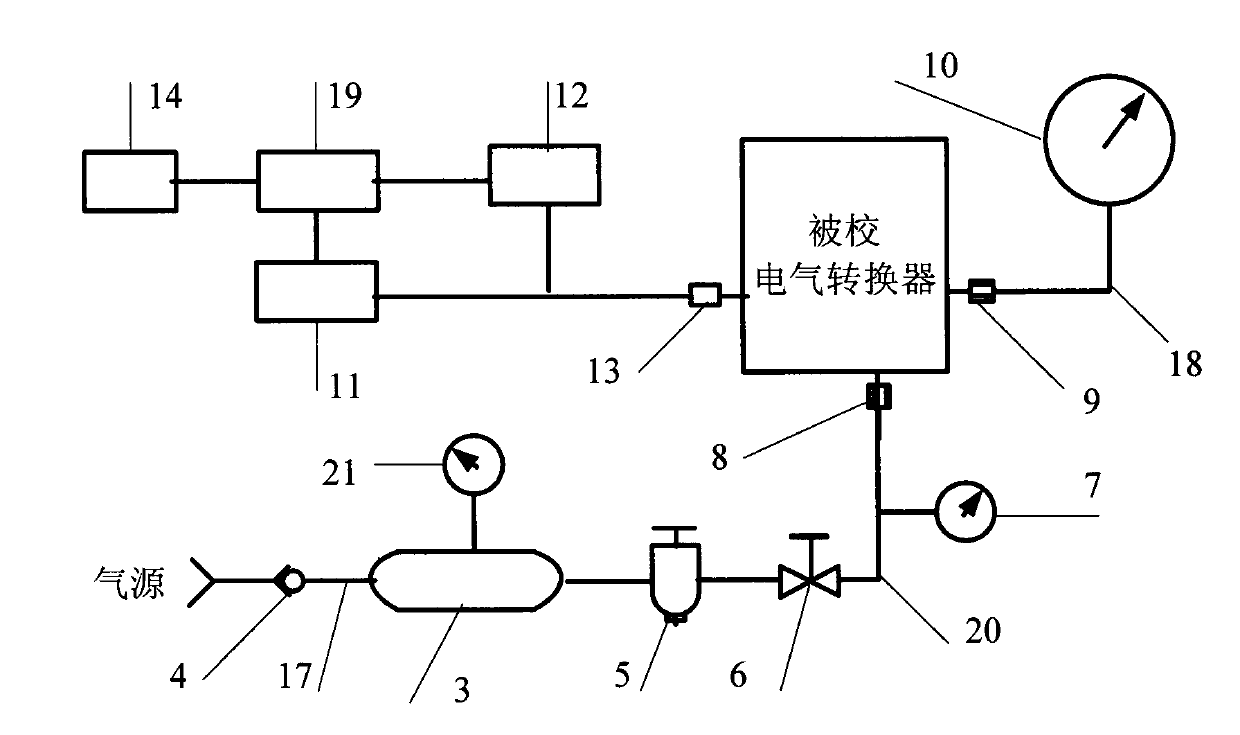

Portable calibration instrument for electrical/pneumatic convertor

The invention discloses a portable calibration instrument for an electrical / pneumatic convertor and belongs to the field of automatic instrument testers. The portable calibration instrument for the electrical / pneumatic convertor is characterized by comprising a case body and a panel, wherein the panel is provided with a pneumatic valuator, an air source connector, an output air pressure connector, a precision pressure gauge, an electric valuator, a digital display meter, a current signal connector and a power supply controller; a high-pressure air bottle, a check valve, an air filtration pressure reducer, a support, a high-pressure air tube, an output line, a storage battery and an airtight line are arranged in the case body; the upper part of the case body is provided with a lifting handle; and the left side part of the case body is provided with a first pressure gauge and a second pressure gauge. The portable calibration instrument for the electrical / pneumatic convertor disclosed by the invention has the characteristics that the structure is compact, carrying is convenient, the operation is simple, and calibration is rapid and accurate.

Owner:NANJING COLLEGE OF CHEM TECH

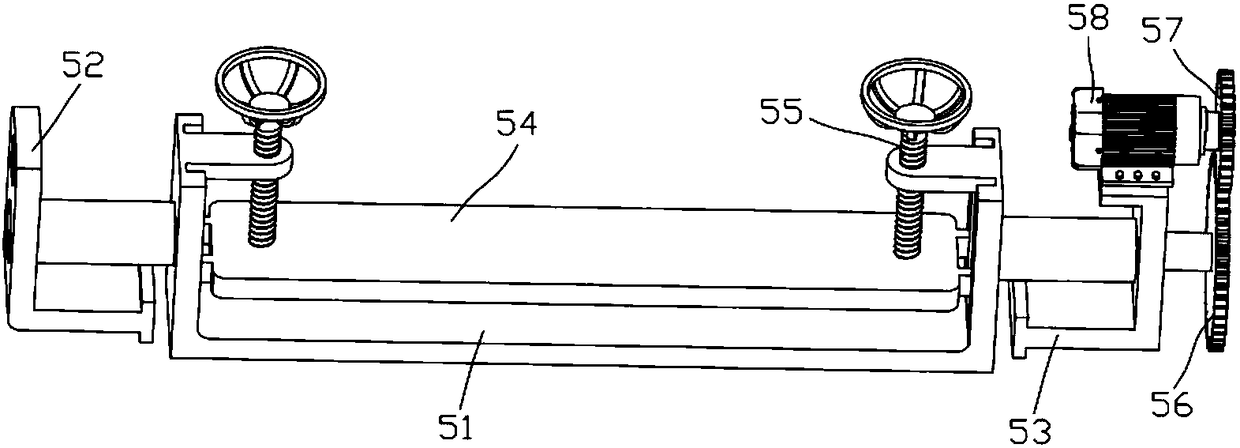

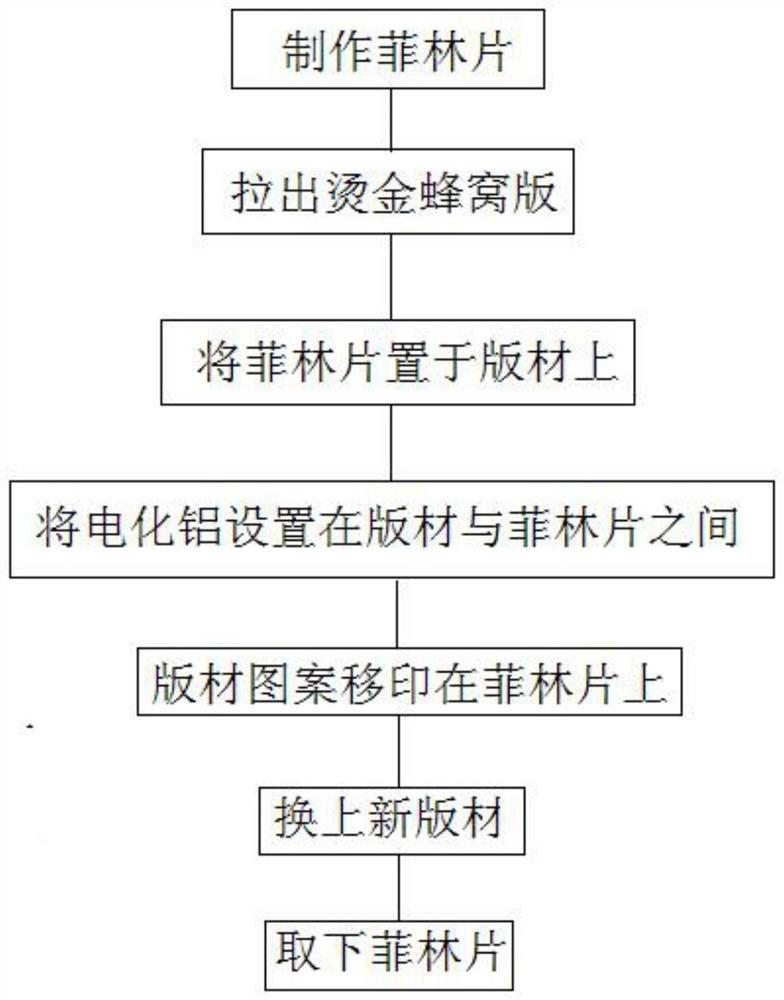

A method for rapid plate change of bronzing plates

ActiveCN109484022BFast and accurate calibrationReduce generationPrinting press partsWaste productProcess engineering

Owner:长春吉星印务有限责任公司

Calibrating a magnetic sensor

PendingCN110058186ACalibration process is simpleSpeed up calibration and testingDiagnosticsMagnetic field offset compensationCalibration algorithmNuclear magnetic resonance

A calibration system comprising: a Helmholtz device comprising thee pairs of coils defining an inner volume, wherein each of the three pairs of coils is configured to generate a magnetic field that isuniform throughout the inner volume; a mount configured to accept a device that includes a magnetic sensor, wherein at least a portion of the mount is positioned within the inner volume such that themagnetic sensor is positioned at or near a center of the inner volume when the device is positioned on the mount; and a computer system configured to communicate with the Helmholtz device and the magnetic sensor, wherein the computer system is configured to: provide instructions to cause each of the three pairs of coils to generate a magnetic field; receive signals from the magnetic sensor that are based on characteristics of the magnetic fields received at the magnetic sensor; measure, based on the signals received from the magnetic sensor, one or more characteristics of the magnetic sensor;and determine, using a calibration algorithm, one or more calibration correction factors for the magnetic sensor based on the one or more characteristics of the magnetic sensor and the provided instructions.

Owner:ASCENSION TECH

A Construction Method of Thermal-Mechanical Coupling Constitutive Relationship of Zirconium Alloy Under Neutron Irradiation

ActiveCN110543744BEasy CalibrationFast and accurate calibrationDesign optimisation/simulationNeutron irradiationSingle crystal

The invention discloses a method for constructing the thermal-mechanical coupling constitutive relationship of zirconium alloys under neutron irradiation conditions. The method of the invention combines the elasto-viscoplastic self-consistent theory to establish a cross-scale theoretical system from single crystal to polycrystal. The Matlab calculation program can easily, quickly and accurately calibrate the model parameters, and the numerical results of the model can be in good agreement with the experimental data under different external load conditions. The theoretical model framework has wide applicability and scalability, and can provide a reliable theoretical basis for the study of the macroscopic mechanical behavior of nuclear materials.

Owner:CENT SOUTH UNIV

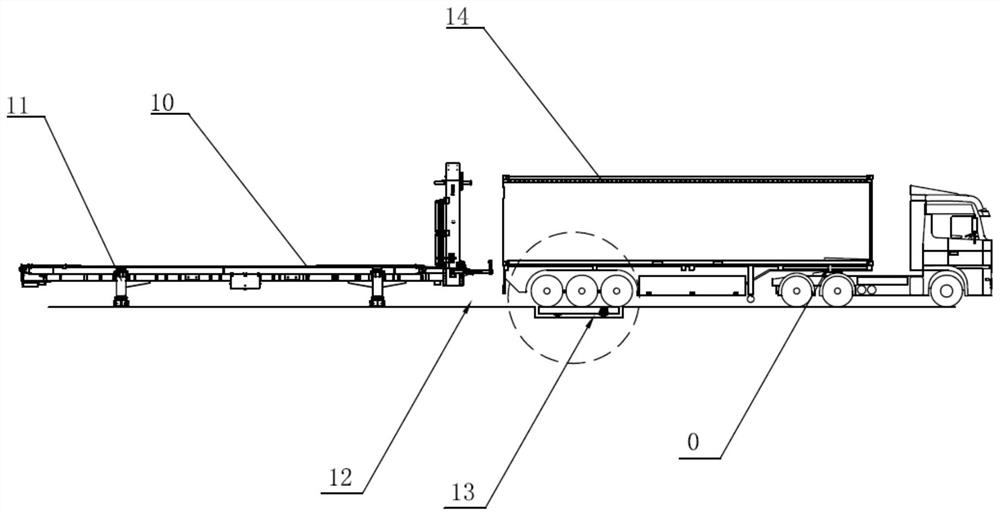

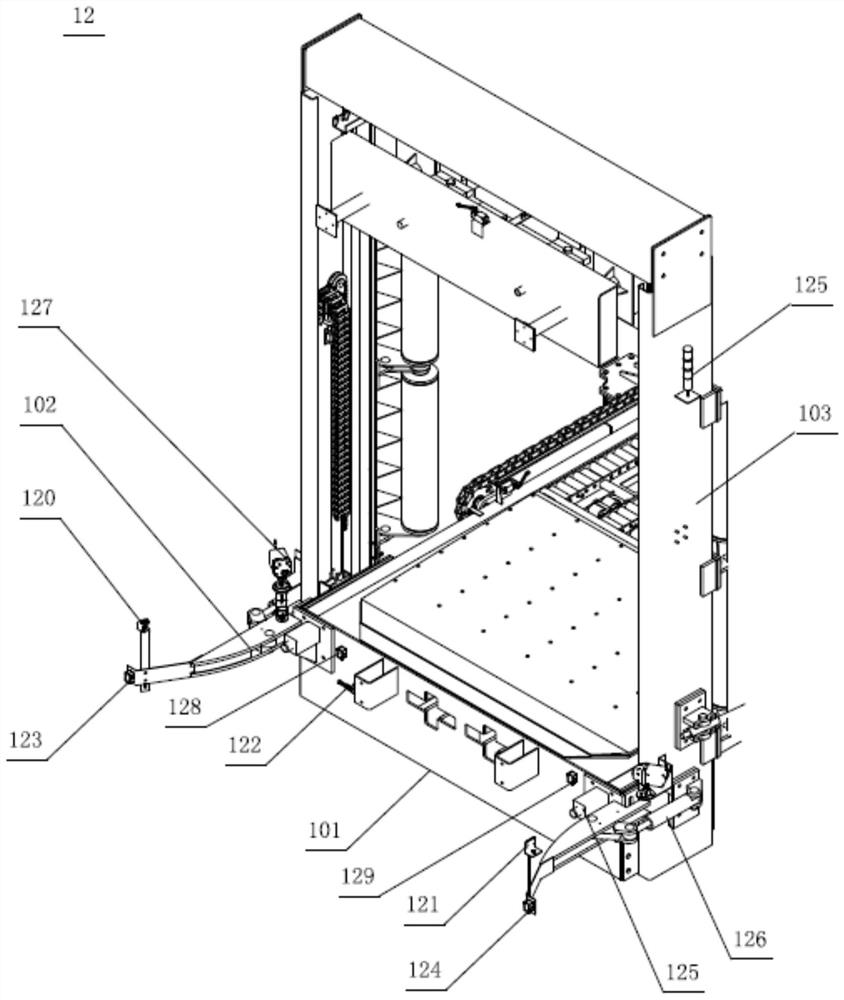

Angle-adjustable loading alignment device for container extreme speed loading and its control method

ActiveCN111170034BFast loadingFast and Accurate CalibrationConveyorsControl devices for conveyorsStructural engineeringControl theory

The invention provides an angle-adjustable loading alignment device for extremely fast loading of containers and a control method thereof. The angle-adjustable loading alignment device for extremely fast loading of containers includes a detection unit and an arc-shaped swing platform; the arc-angle swing platform is embedded in the ground and is spaced apart from the tail of the cargo transmission unit for The tail wheel of the truck is carried, and the arc angle swing platform can be fine-tuned and swung with the rotating shaft of the truck compartment as the center of the circle; the detection unit is used to detect whether the tail of the truck is facing the cargo transmission unit. When the included angle between the truck compartment and the cargo transmission unit is greater than a first threshold, the arc-shaped angle swing platform is controlled to perform fine-tuning swing with the rotation axis of the truck compartment as the center of a circle.

Owner:LONGHE INTELLIGENT EQUIP MFG CO LTD

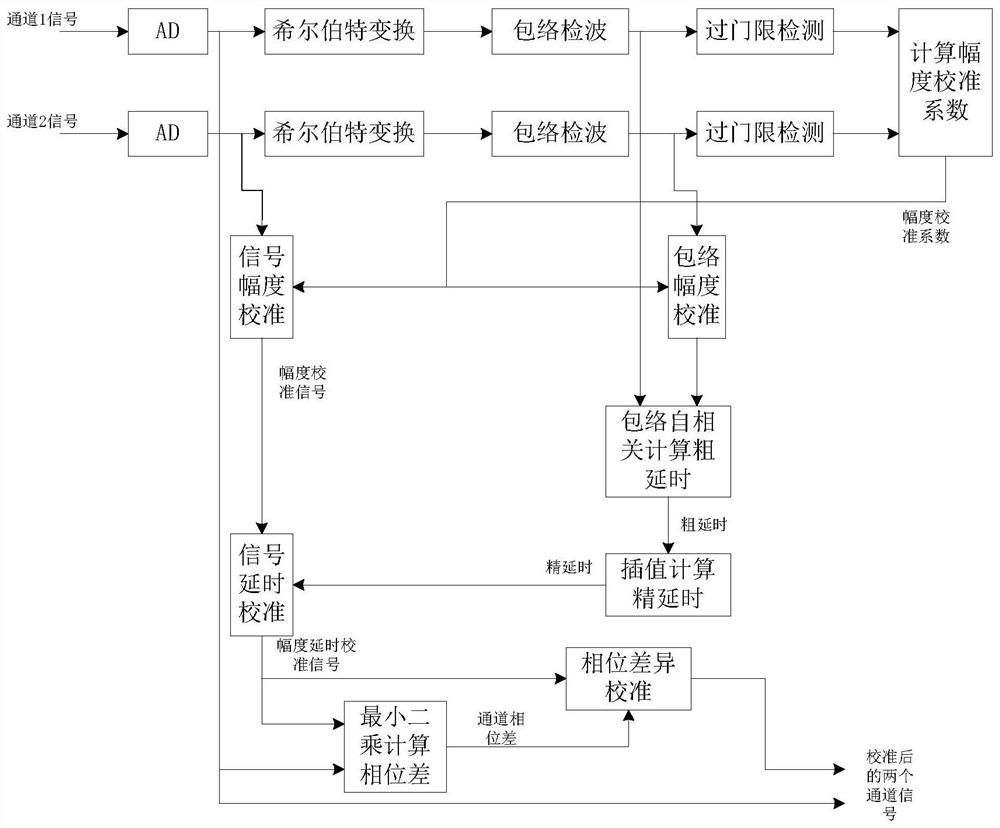

A signal channel calibration method and device based on correlation and least squares

ActiveCN111289950BAchieve consistencyReduce dependenceWave based measurement systemsAlgorithmEngineering

The invention discloses a signal channel calibration method and device based on correlation and least squares, which includes determining the transmission delay between the channel to be calibrated and a pre-selected reference channel, and completing the calibration process according to the obtained transmission delay. Channel signal delay calibration; the least square method is used to calculate the initial phase of each channel, and determine the phase difference between the channel to be calibrated and the reference channel; according to the obtained phase difference, complete the signal phase difference calibration of the channel to be calibrated. The present invention adopts a method based on correlation least squares, and designs a signal multi-channel amplitude-phase characteristic analysis calculation and calibration method. The method is based on the signal acquisition data of the same signal in each channel, and the signal amplitude is calculated by using the envelope correlation method. Delay information, the phase information of each channel signal is obtained through least square calculation, and the calibration of the amplitude and phase characteristics of each signal channel is automatically completed according to the measurement information, so as to achieve the consistency of the amplitude and phase characteristics of each signal channel.

Owner:NANJING CHANGFENG AEROSPACE ELECTRONICS SCI & TECH

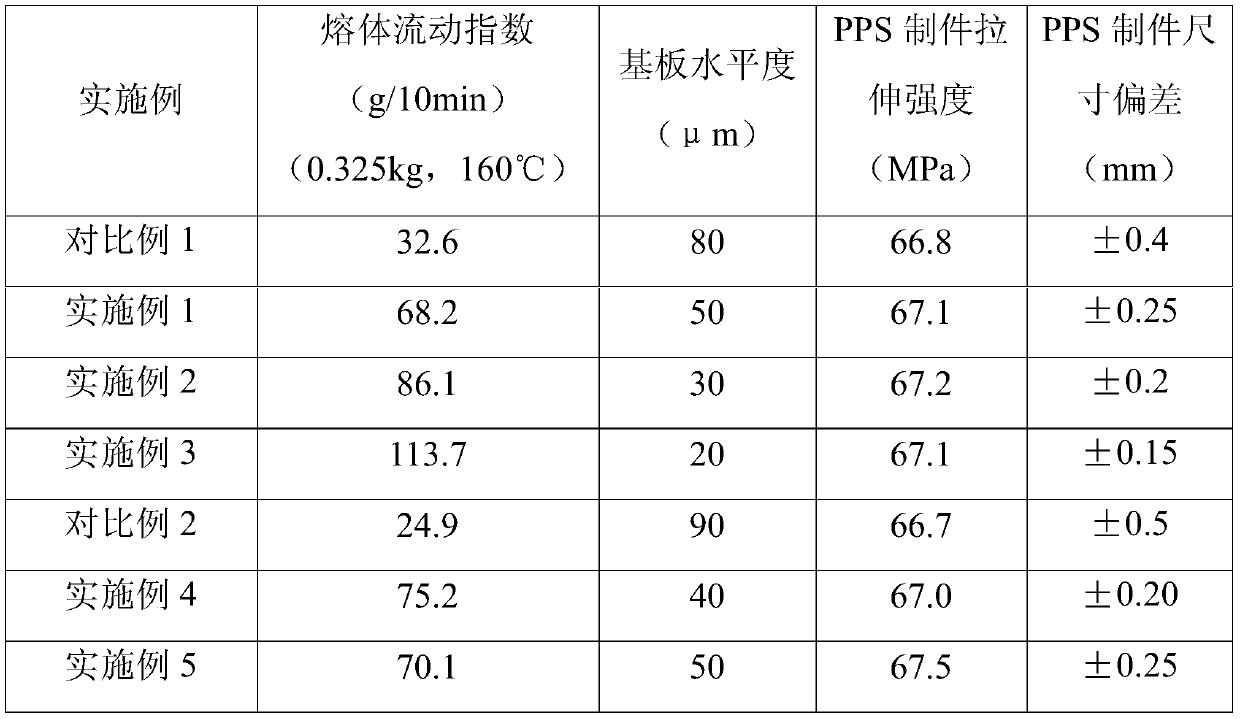

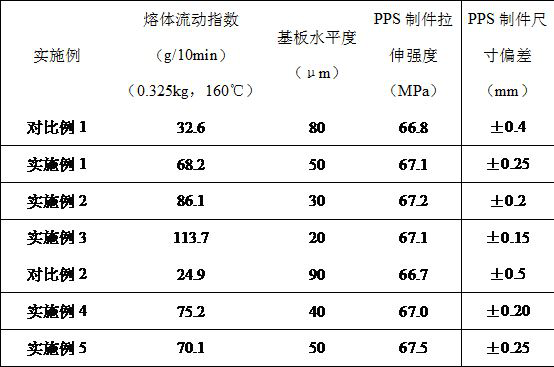

High molecular polymer powder material

ActiveCN109852231AImprove melt fluidityStrong adhesionPowdery paintsPolyamide coatingsPolymer sciencePolymer substrate

A high molecular polymer powder material is characterized by comprising the following components in percentage by mass: 80-99.8 percent of high molecular polymer substrate, 0.1-5 percent of adhesion promoting resin and 0.1-15 percent of melt flow assistant. A mechanical mix process or an extrusion blending repulverizing process is adopted to uniformly mix the high molecular polymer substrate, theadhesion promoting resin and the melt flow assistant to obtain the high molecular polymer powder material; wherein the high molecular polymer powder material has excellent melt flow, and the melt flowrate thereof is at least 20% higher than the same polymer substrate without the addition of melt flow assistant, as measured according to ASTM 1238 (2015) at 160 DEG C under a load of 0.325 kg. The invention makes use of the self-leveling property of the melted high molecular polymer powder material with good melt fluidity, realizes accurate and rapid leveling of the substrate, improves the production efficiency, reduces the cost, and improves the accuracy and surface quality of the sintered workpiece.

Owner:HUNAN FARSOON HIGH TECH CO LTD

Method for correcting wide-angle camera lens distortion of automatic teller machine (ATM)

InactiveCN102075785BEffective correctionFast and accurate calibrationImage analysisTelevision systemsCamera lensImaging processing

Owner:WUHAN UNIV

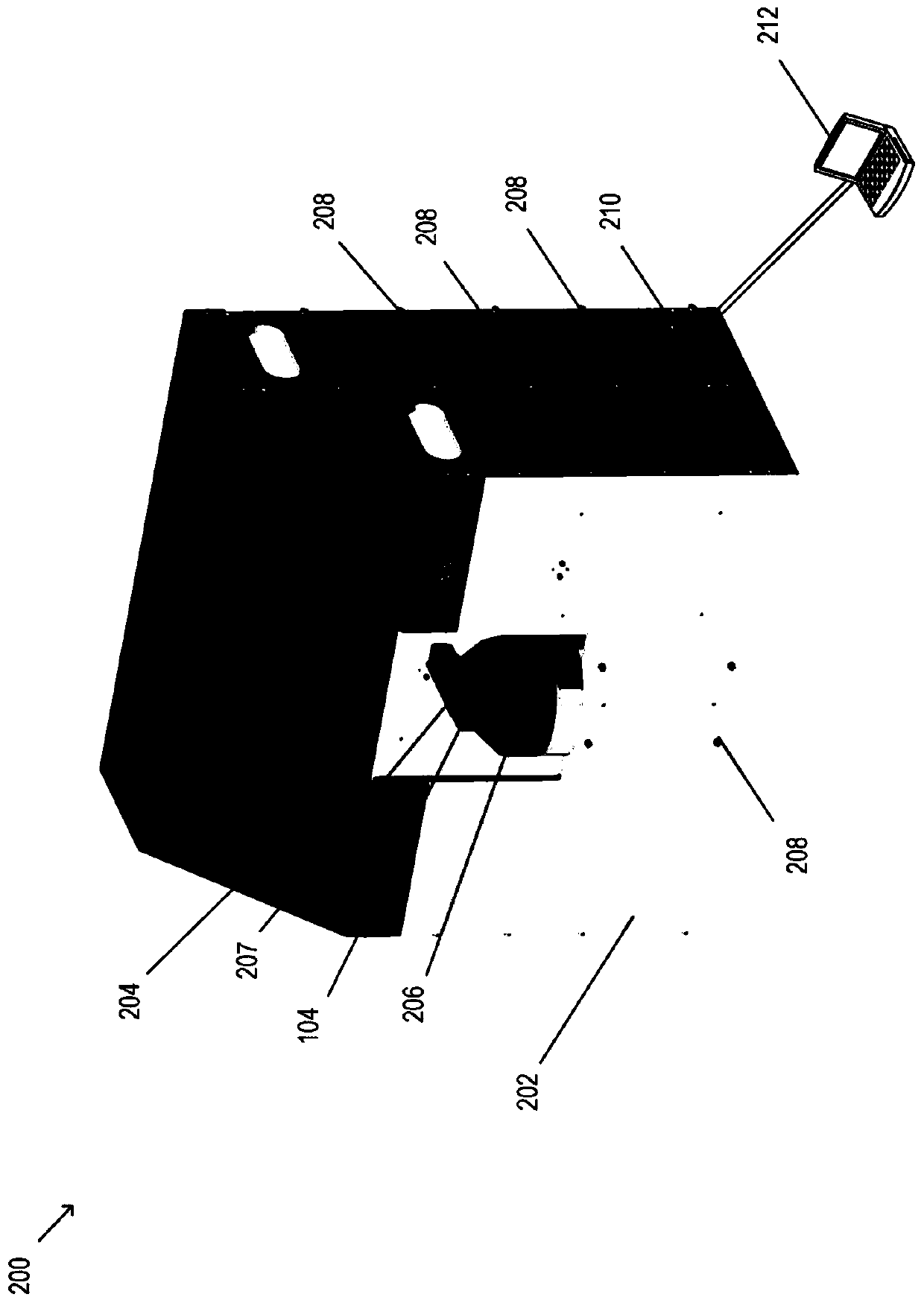

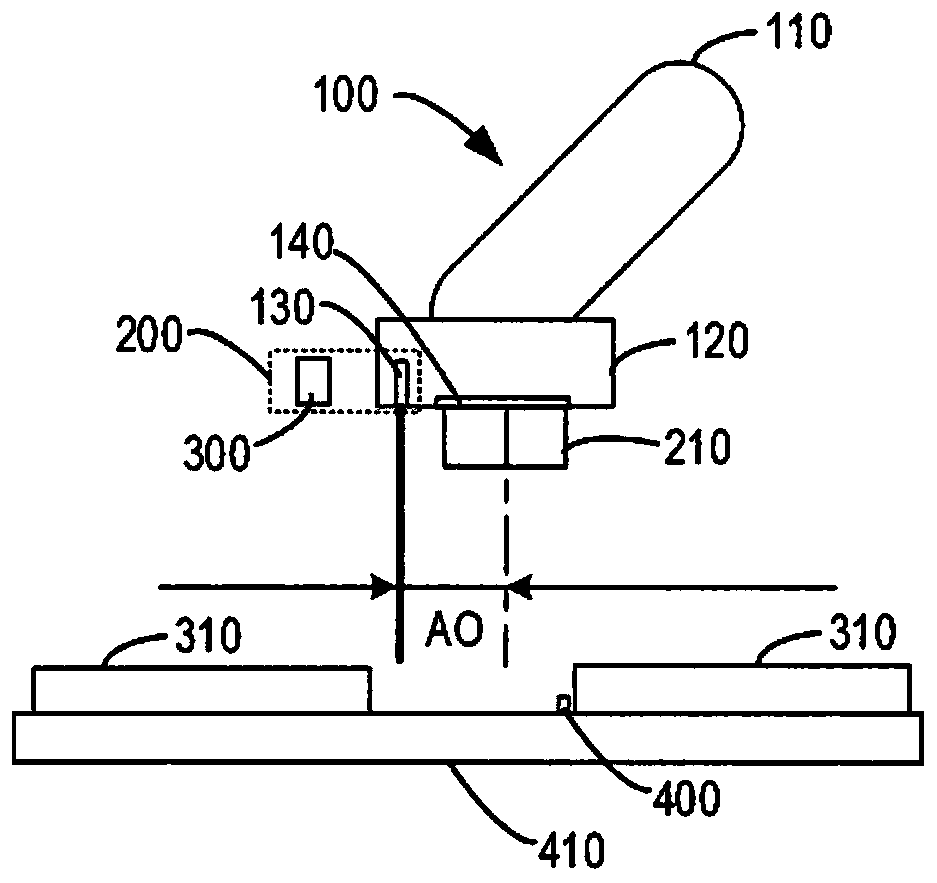

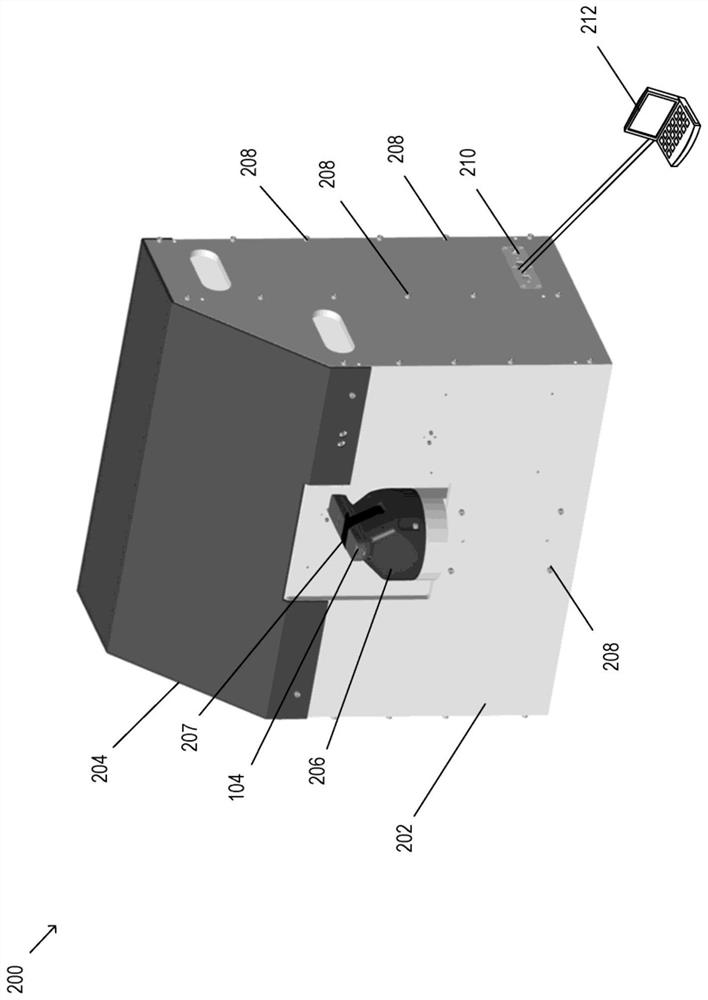

Apparatus and method for use with robot

ActiveCN111344119AFast and Accurate CalibrationFast and accurate teachingProgramme controlProgramme-controlled manipulatorEngineeringComputer vision

An apparatus (200) for use with a robot (100) is disclosed. The apparatus (200) comprises a reflective photoelectric sensor (130) arranged on a gripper (120) of the robot (100) and a controller (300).The controller (300) is configured to: cause the reflective photoelectric sensor (130) to scan over a target object (210, 210'); monitor changes in an output signal from the reflective photoelectricsensor (130); for each detected change exceeding a threshold, determine a coordinate of a gripping component (140) on the gripper (120) in a robot coordinate system, to obtain a set of coordinates; determine a position of the target object (210,210') in the robot coordinate system based on the set of coordinates and a predefined offset value (PO) between the reflective photoelectric sensor (130) and the gripping component (140); and store the position of target object (210, 210') for future use in assembling objects. A method, a robot and a computer program product are also disclosed. The apparatus (200) and the method provide a new solution for calibrating or teaching the robot.

Owner:ABB (SCHWEIZ) AG

Calibrate Magnetic Transmitters

ActiveCN110058187BFast and Accurate CalibrationQuick and accurate determinationElectric/magnetic position measurementsElectrical measurementsEngineeringMechanical engineering

The present invention relates to calibrating magnetic transducers. A calibration device includes: a plurality of magnetic sensors positioned at the calibration device, the plurality of magnetic sensors defining a space; a controller configured to be positioned in the space defined by the plurality of magnetic sensors, wherein the controller includes a magnetic transmitter; and one or more processors configured to: cause the magnetic transmitter to generate a magnetic field; receive from the plurality of magnetic sensors based on calculating the position and orientation of the plurality of magnetic sensors relative to the position and orientation of the magnetic transducer based on the signals received from the plurality of magnetic sensors; and determining the calculated plurality of magnetic sensors Whether the positions and orientations of the magnetic sensors are within one or more threshold limits of known positions and orientations of the plurality of magnetic sensors.

Owner:ASCENSION TECH

A kind of polymer powder material

ActiveCN109852231BImprove melt fluidityStrong adhesionPowdery paintsPolyamide coatingsPolymer sciencePolymer substrate

A high molecular polymer powder material, characterized in that it includes the following components in mass percentage: high molecular polymer substrate 80-99.8%, adhesion promoting resin 0.1-5%, melt flow aid 0.1- 15%: The high molecular polymer powder material is prepared by uniformly mixing the above high molecular polymer base material, adhesion promoting resin and melt flow aid by mechanical mixing process or extrusion blending re-pulverization process; wherein, The high molecular polymer powder material has excellent melt flowability, and its melt flow rate, measured at 160° C. under a load of 0.325 kg according to ASTM1238 (2015), is higher than that of the same polymer base without adding melt flow aids. The material is increased by at least 20%. The invention utilizes the self-leveling properties of the melted polymer powder material with good melt fluidity to realize accurate and rapid leveling of the substrate, improve production efficiency, reduce costs, and improve the precision and surface quality of sintered workpieces.

Owner:HUNAN FARSOON HIGH TECH CO LTD

A glass cutting device

ActiveCN108545921BEasy to cutFast and Accurate CalibrationGlass severing apparatusCutting glassEngineering

Owner:ANHUI FENGYANG COUNTY QIANLI GLASSWORK CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com