Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

279results about "Electrodynamic magnetometers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

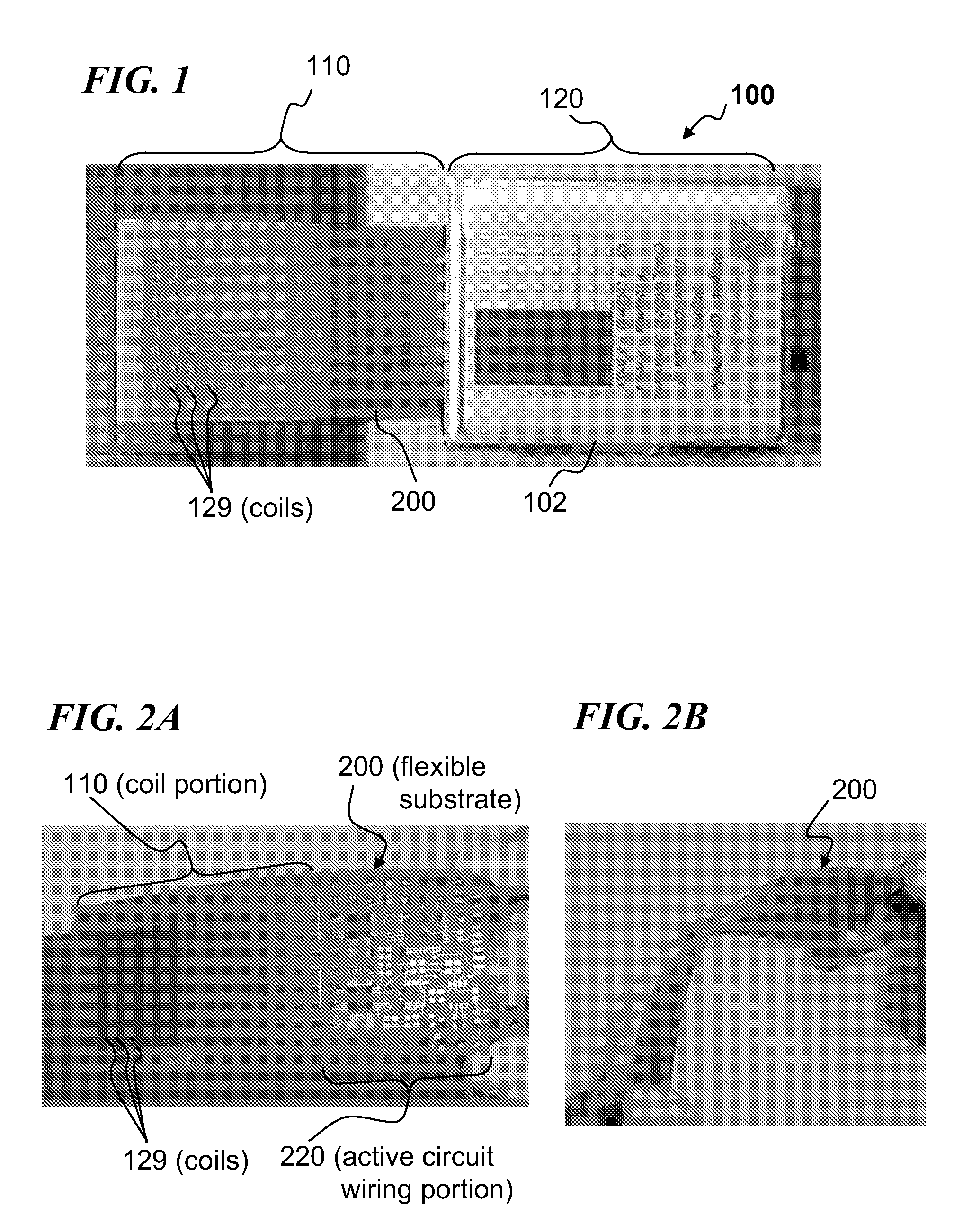

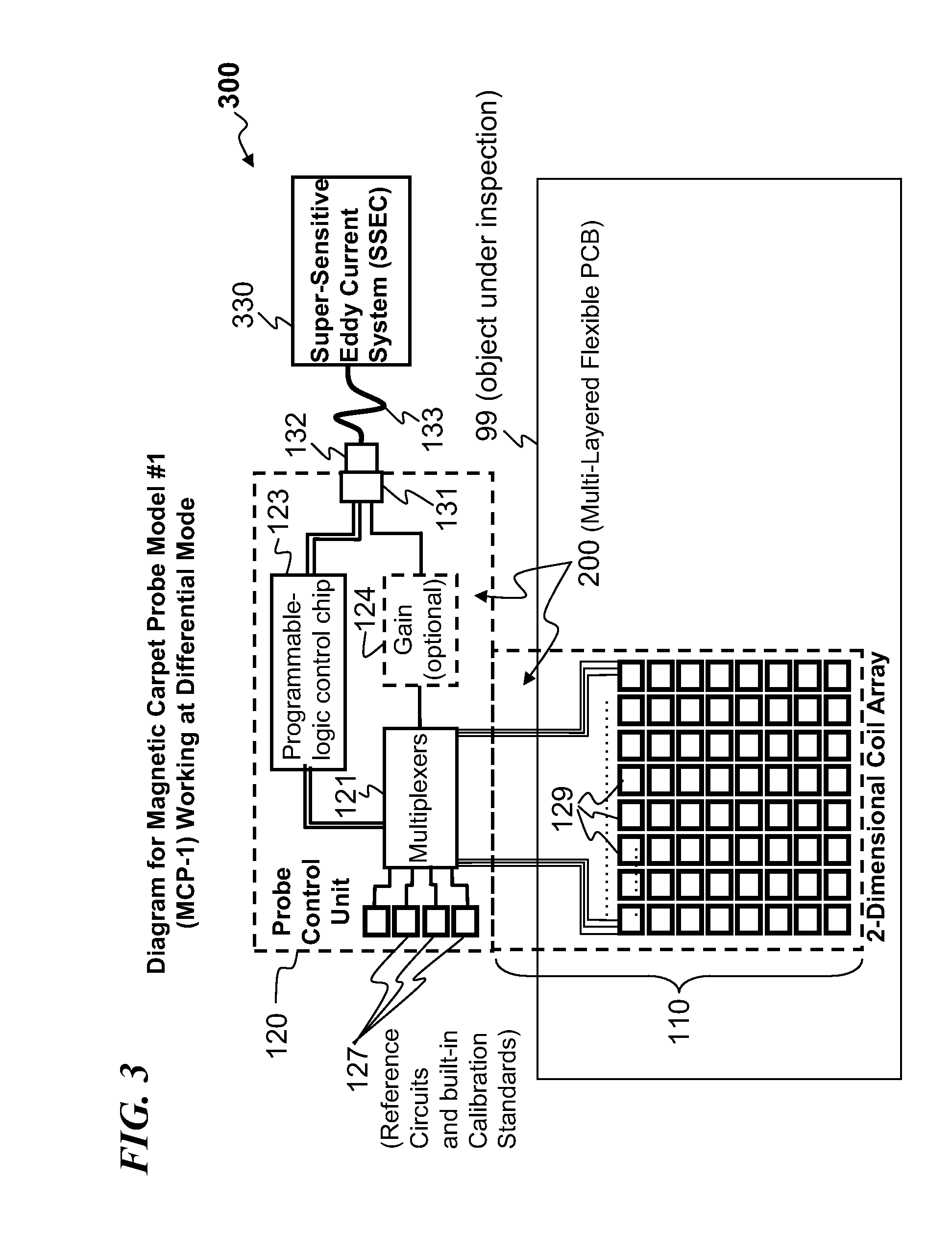

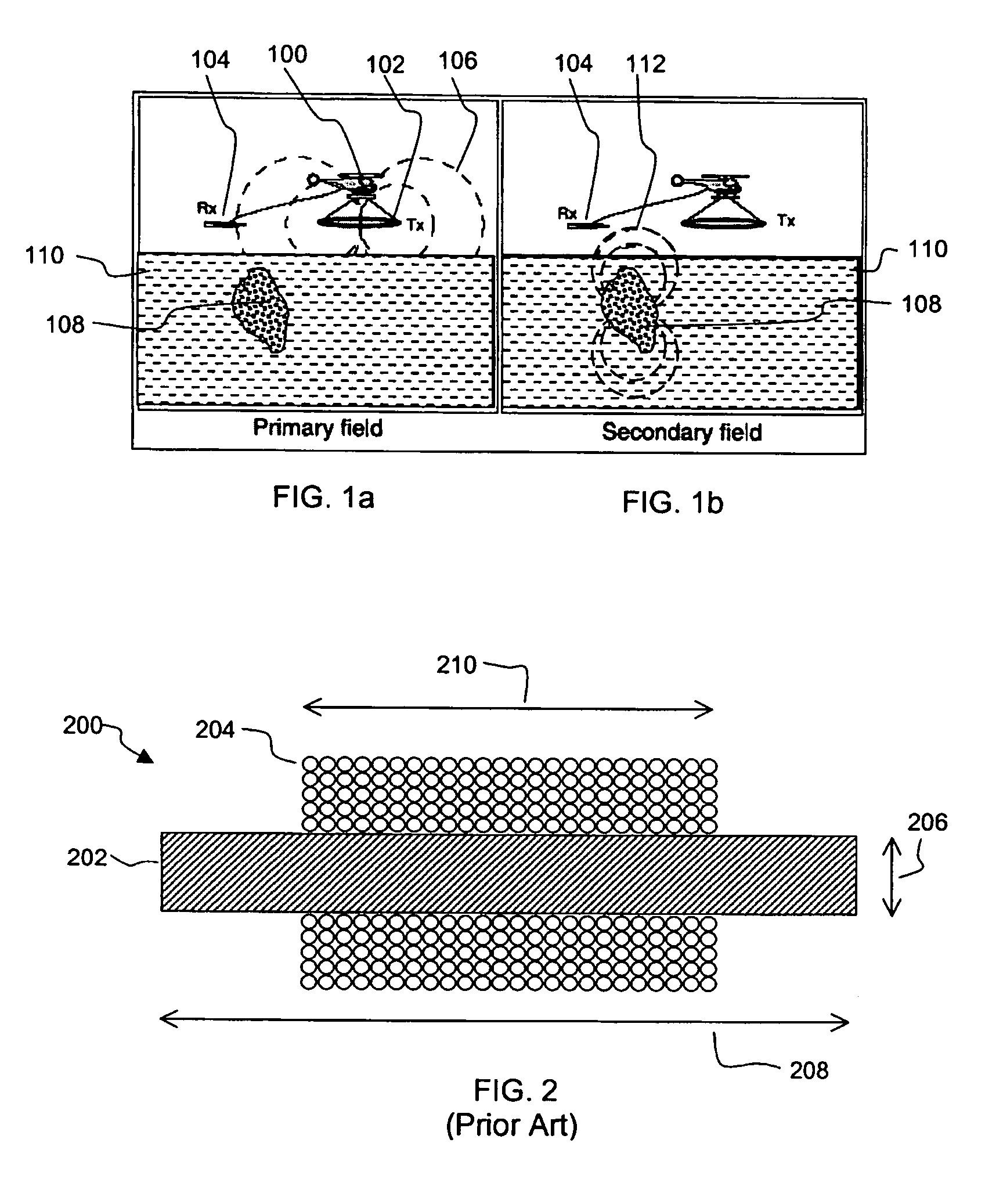

Apparatus and method for eddy-current scanning of a surface to detect cracks and other defects

ActiveUS7560920B1Reduce changesCancel noiseMagnetic field measurement using flux-gate principleMagnetic property measurementsFlexible circuitsMultiplexer

An apparatus having a plurality of coils (e.g., numerous thin-film coils formed in an array on a flex circuit), each coil acting as an excitation unit that generates an alternating excitation magnetic signal; and as a sensor configured to detect an eddy-current signal's phase and amplitude changes relative to the excitation magnetic signal. In some embodiments, the apparatus electronically scans a surface (e.g., of a metal plate) by successively switching to individual ones of the plurality of excitation / sensing coils (using, e.g., an analog multiplexer) without physical movement in order to detect anomalous signal changes in a manner that reduces signal changes due to probe lift-off relative to the surface. In some embodiments, the coils are placed across a large area of interest, for inspection of a large surface area in a few seconds without moving the apparatus. This can provide high-sensitivity detection and an accurate indication of flaw locations.

Owner:INNOVATIVE MATERIALS TESTING TECH

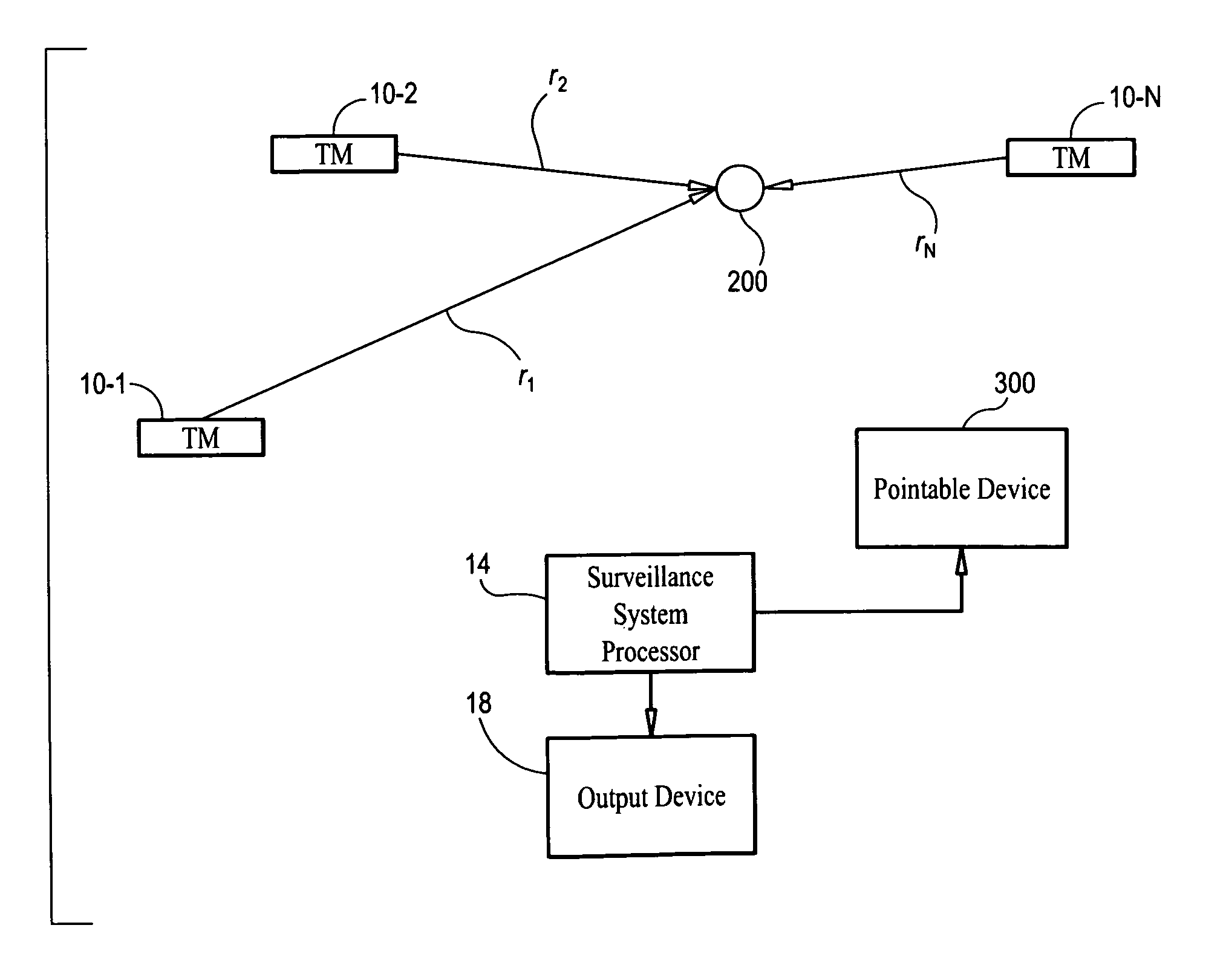

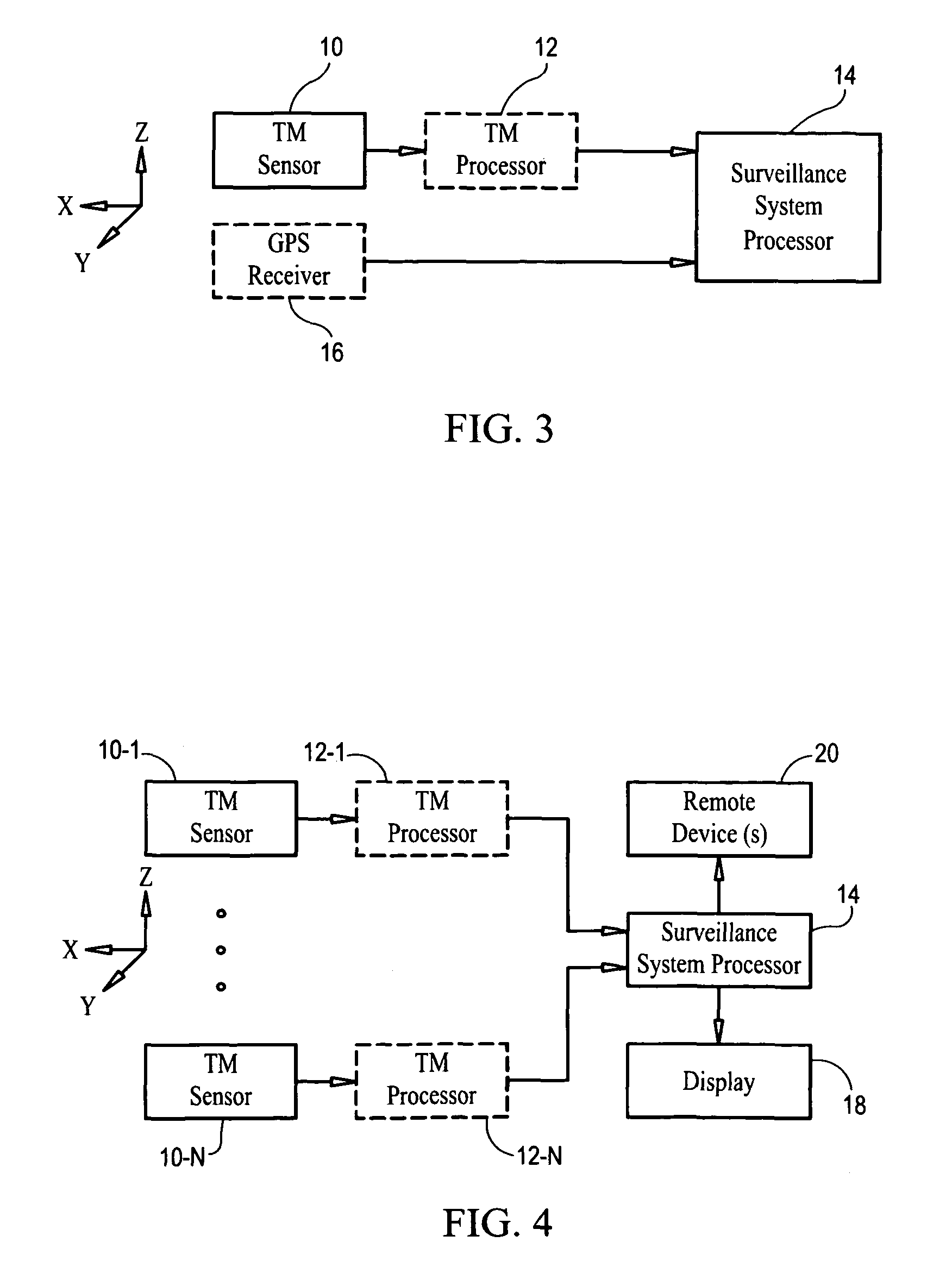

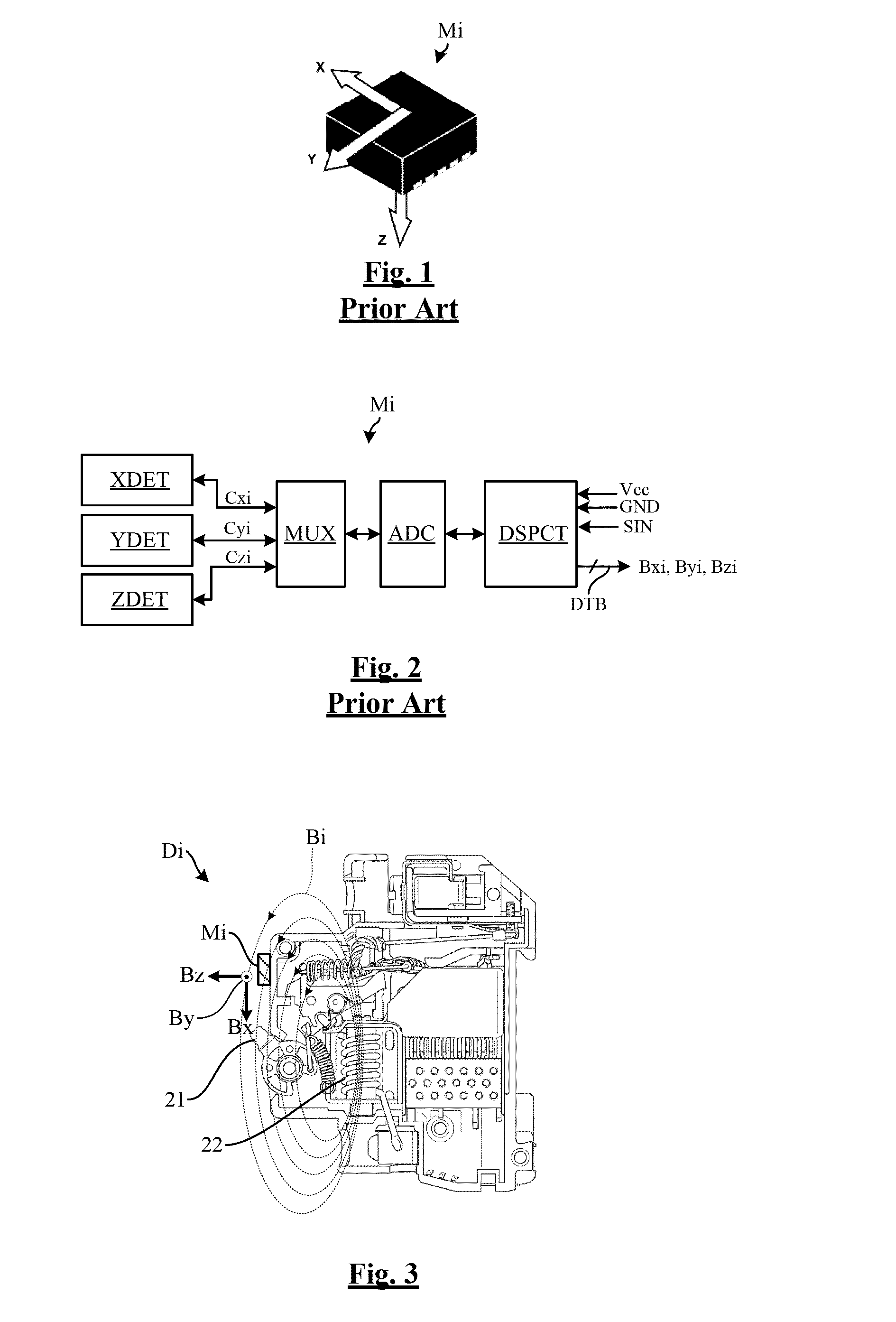

Magnetic anomaly surveillance system using spherical trilateration

InactiveUS8575929B1Digital computer detailsSpeed measurement using gyroscopic effectsOutput deviceMagnetic anomaly

A magnetic anomaly surveillance system includes triaxial magnetometer (TM) sensors arranged at known locations in an array. A processor coupled to the TM sensors generates a scalar magnitude of a magnetic anomaly field measured at each of the TM sensors. The scalar magnitude is indicative of a spherical radius centered at the known location associated with a corresponding one of the TM sensors. The processor also generates a comparison between each scalar magnitude and a threshold value. The processor then determines at least one magnetic anomaly location in the coordinate system via a spherical trilateration process that uses each spherical radius and each scalar magnitude associated with selected ones of the TM sensors for which the threshold value is exceeded. One or more output devices coupled to the processor output data indicative of the one or more magnetic anomaly locations.

Owner:USA REPRESENTED BY THE SEC OF THE NAVY

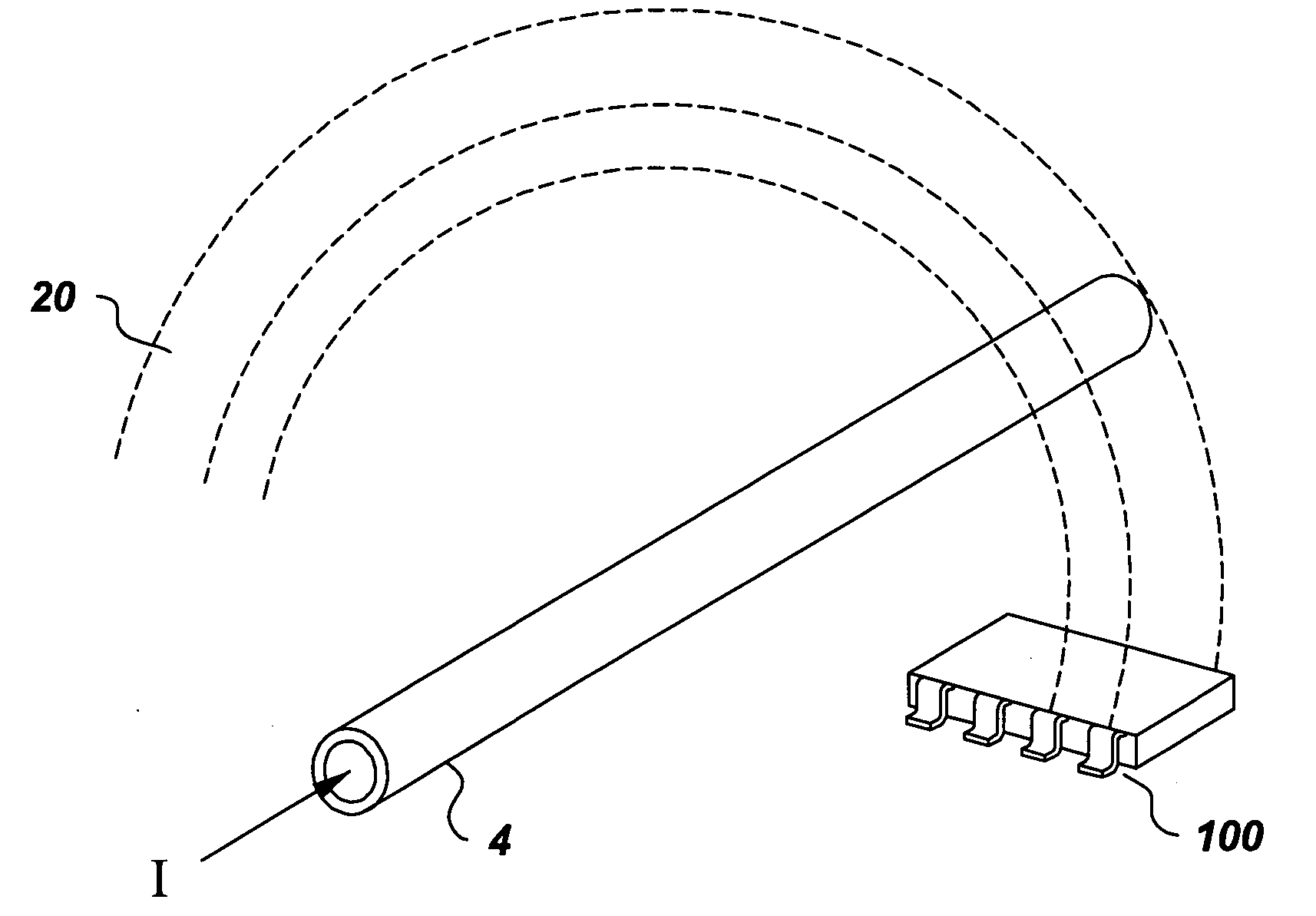

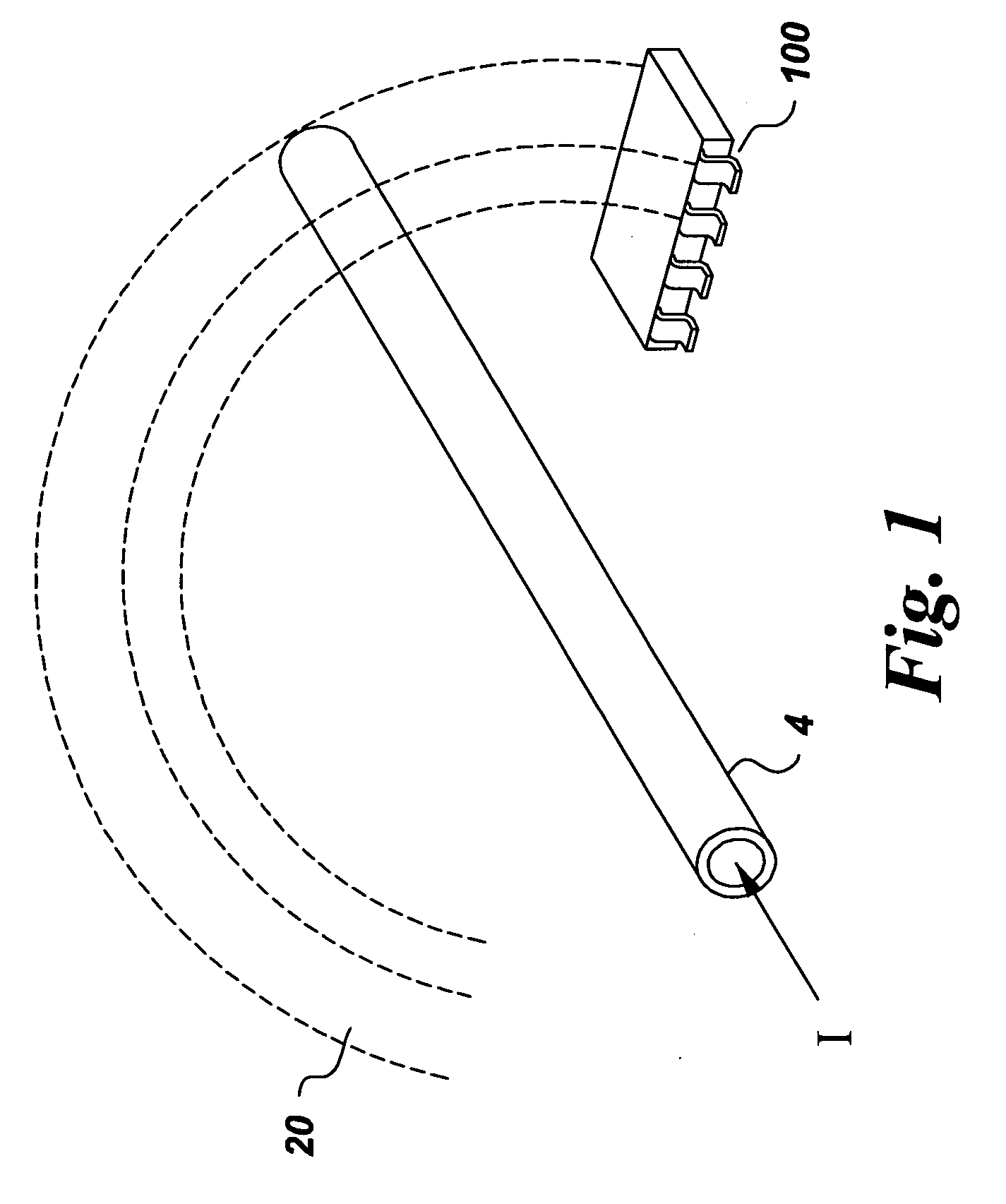

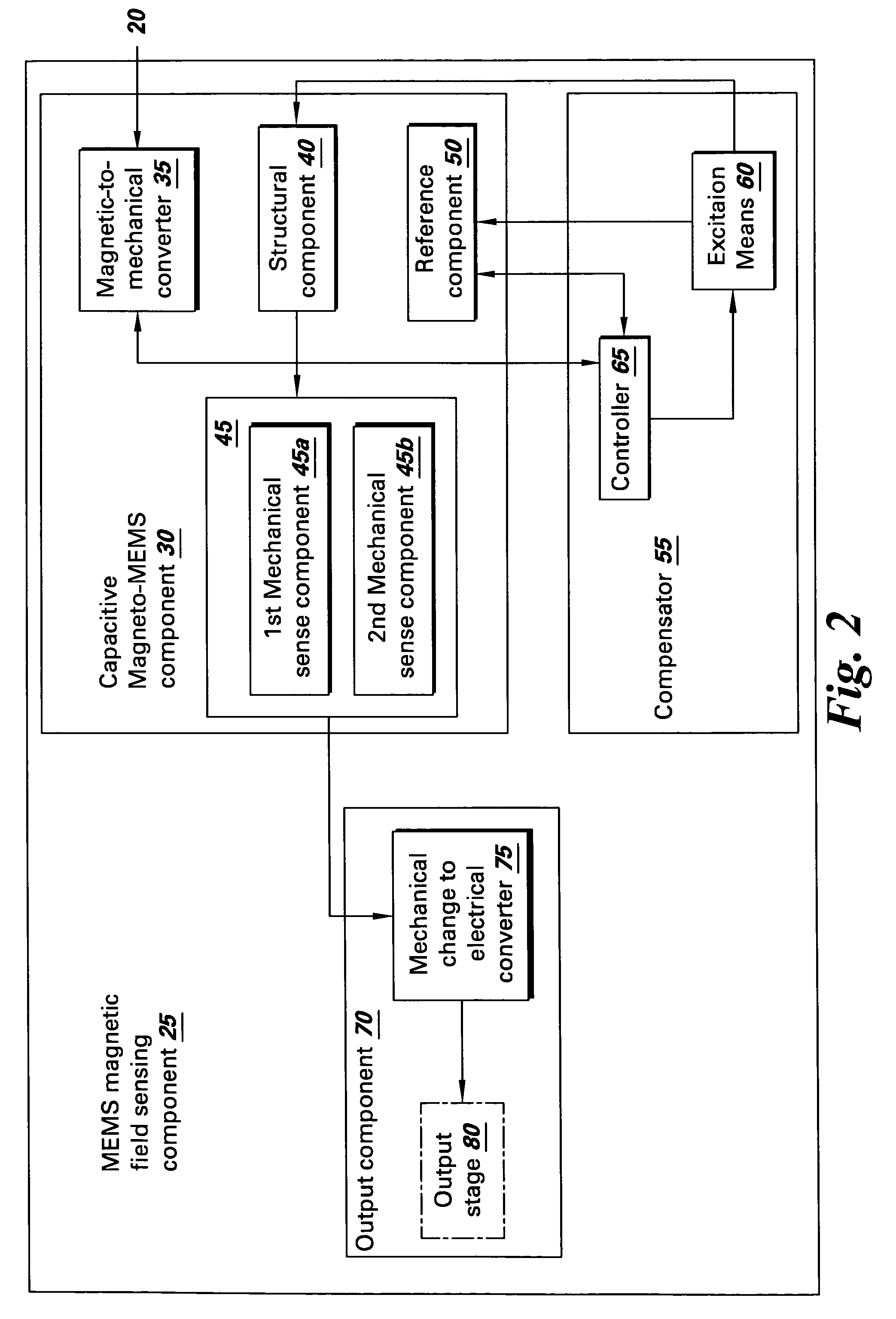

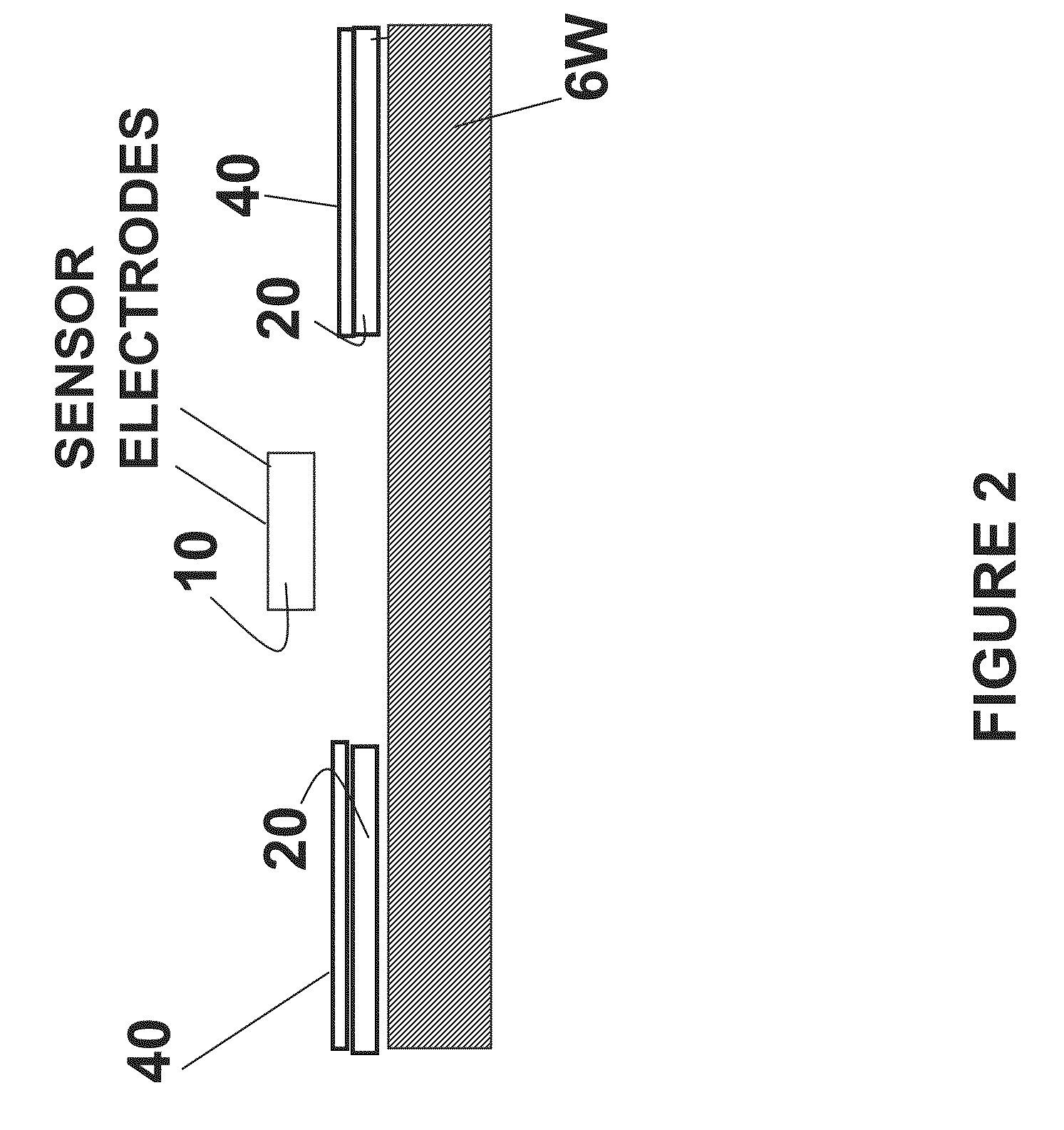

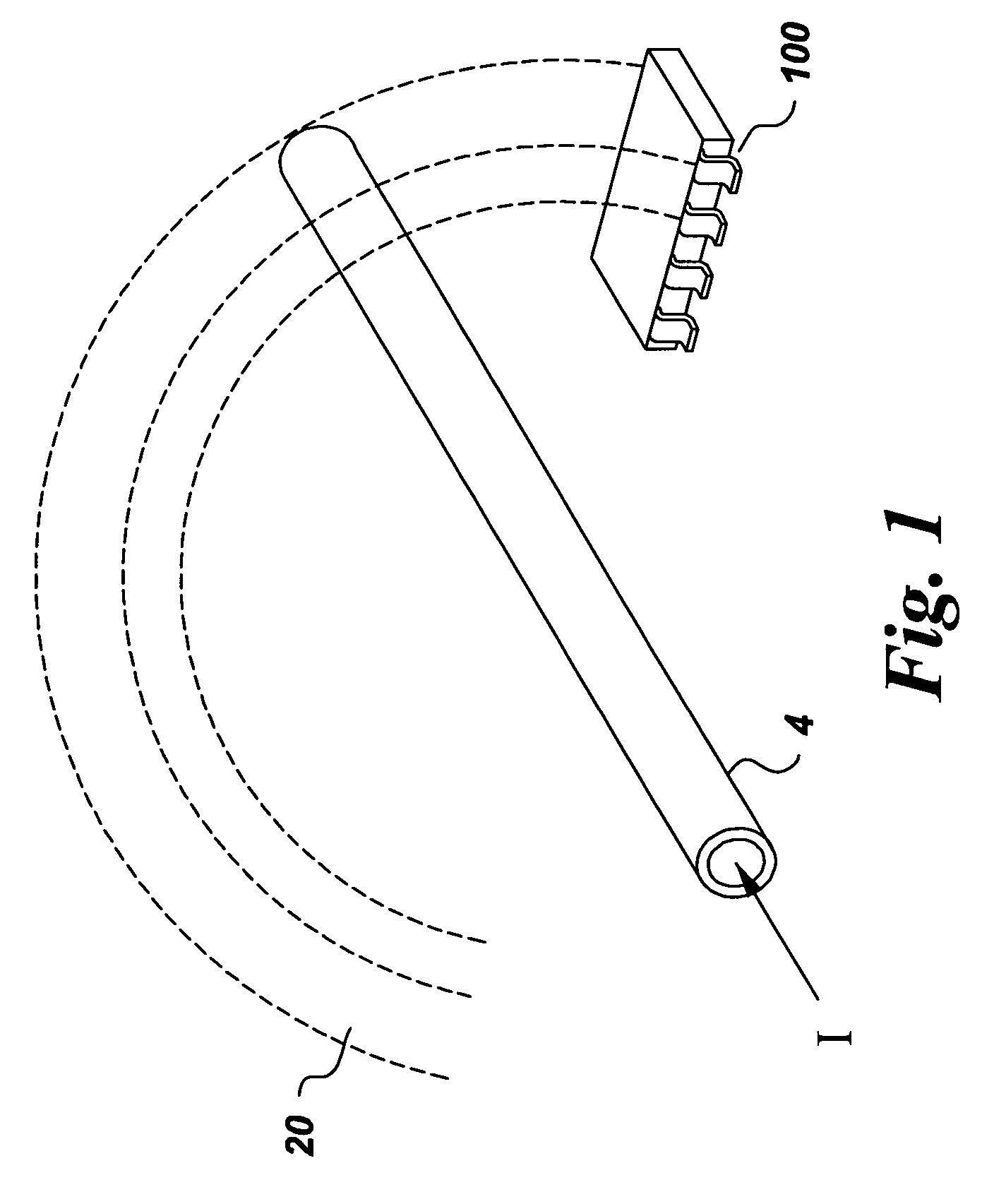

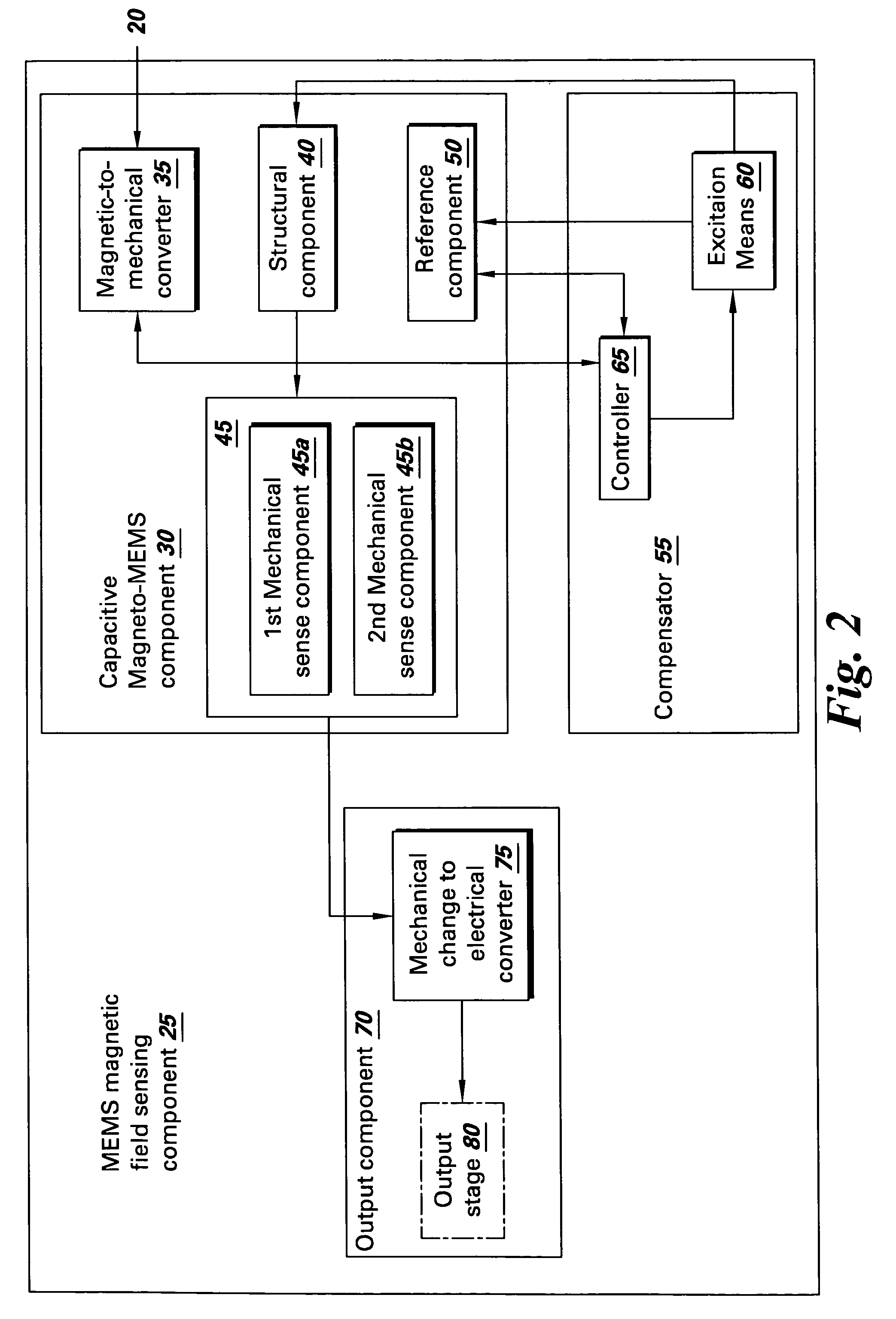

Micro-electromechanical system (MEMS) based current & magnetic field sensor having capacitive sense components

A micro-electromechanical system (MEMS) based current & magnetic field sensor includes a MEMS-based magnetic field sensing component having a capacitive magneto-MEMS component, a compensator and an output component for sensing magnetic fields and for providing, in response thereto, an indication of the current present in a respective conductor to be measured. In one embodiment, first and second mechanical sense components are electrically conductive and operate to sense a change in a capacitance between the mechanical sense components in response to a mechanical indicator from a magnetic-to-mechanical converter.

Owner:ABB SPA

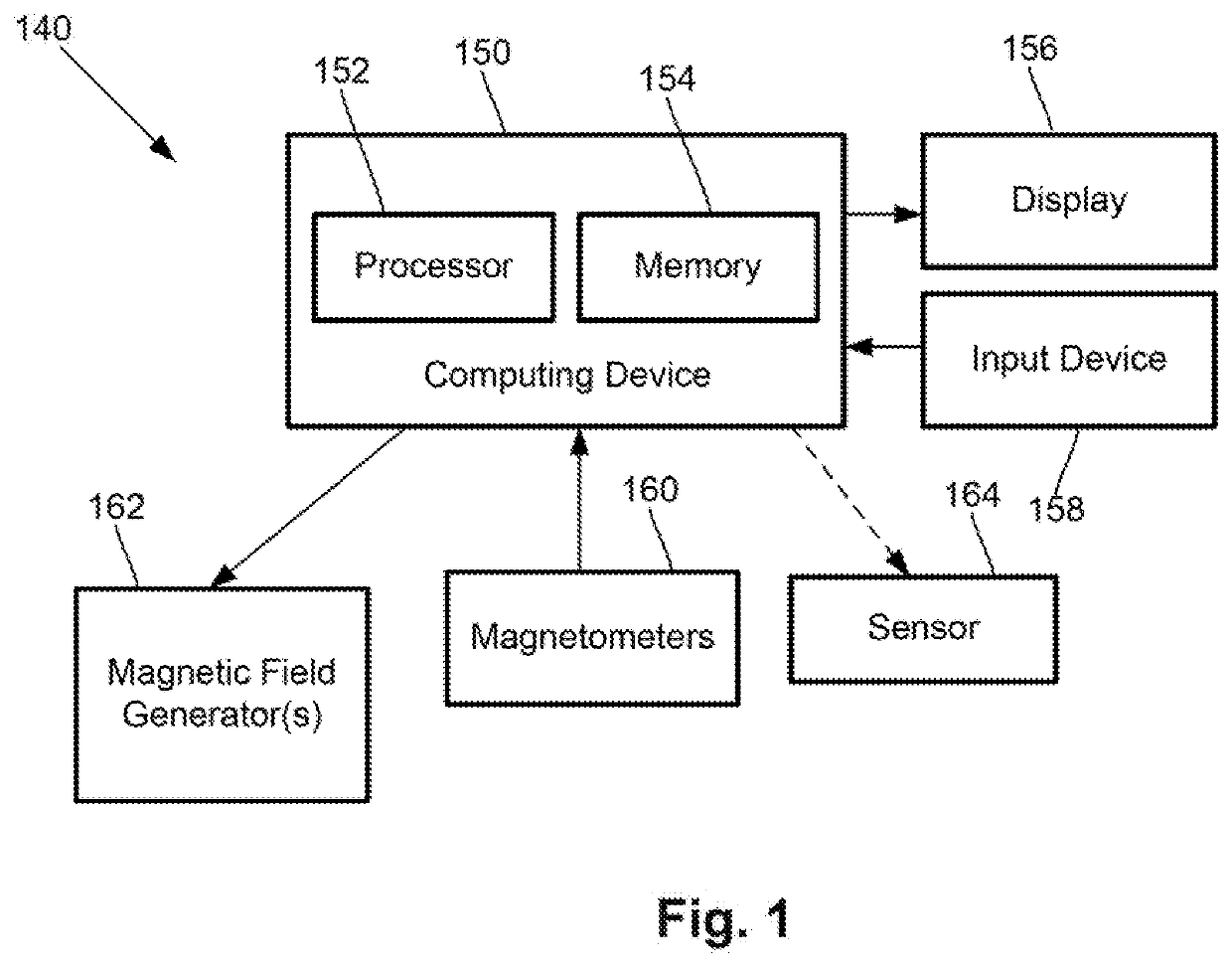

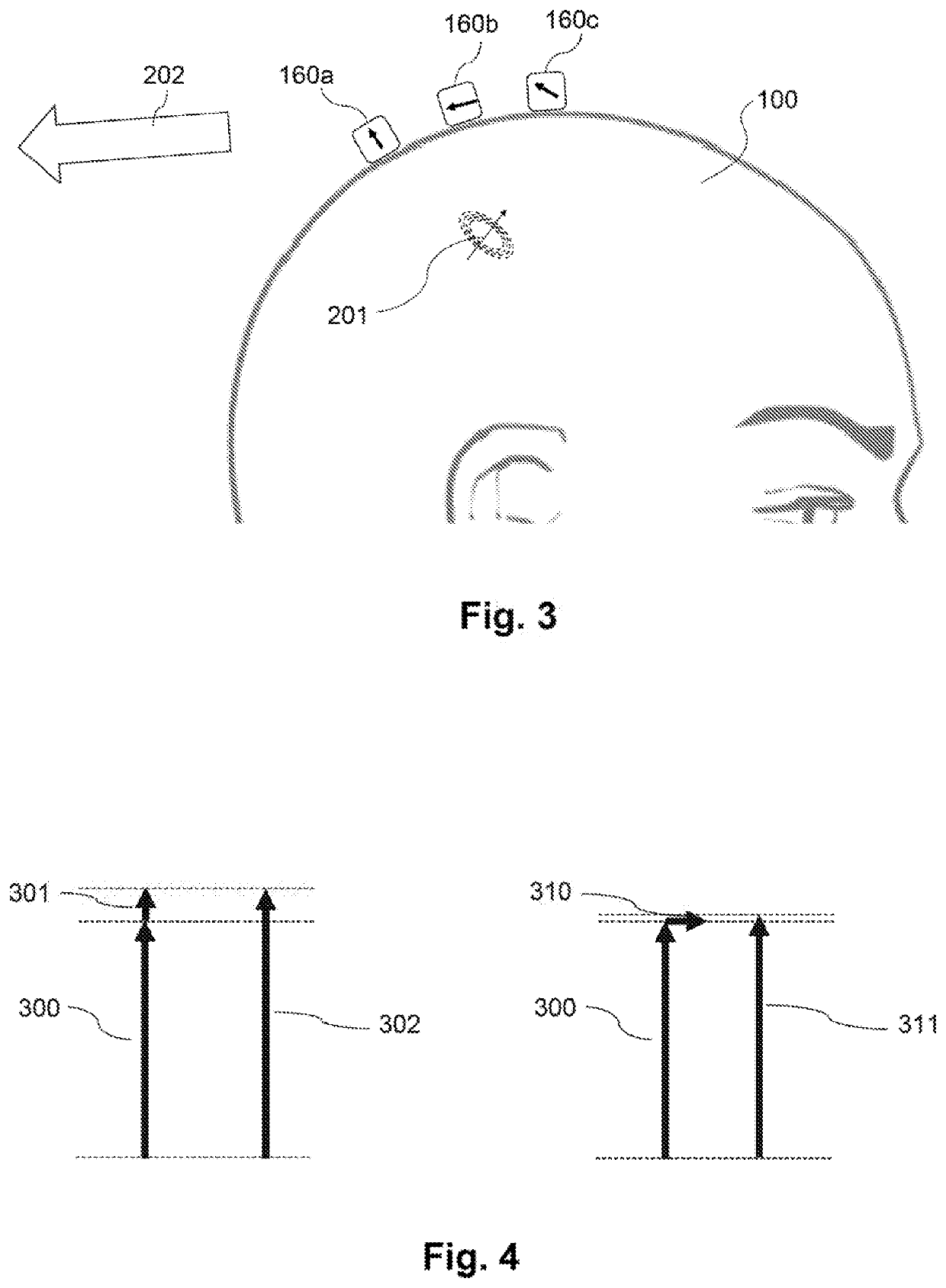

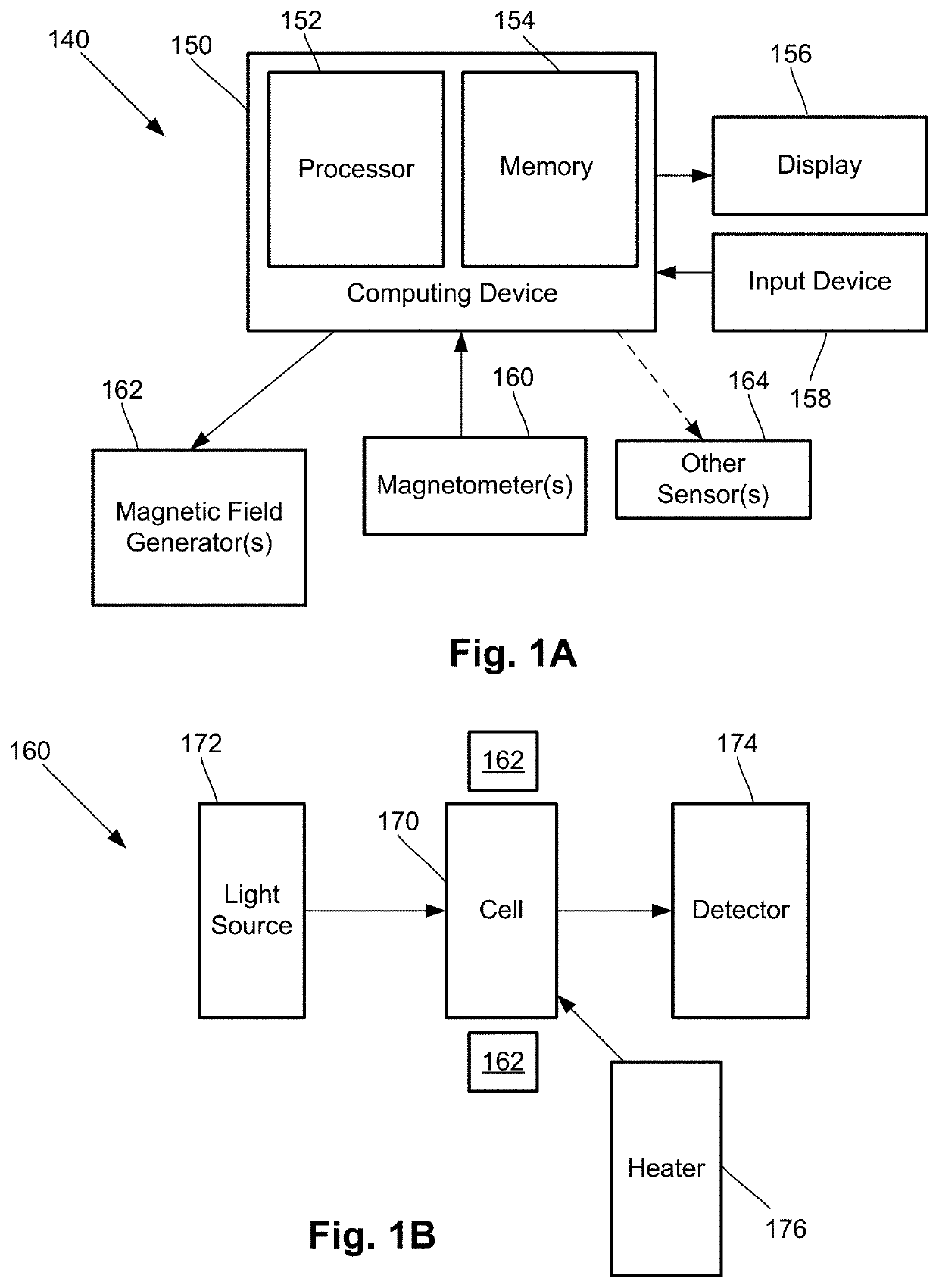

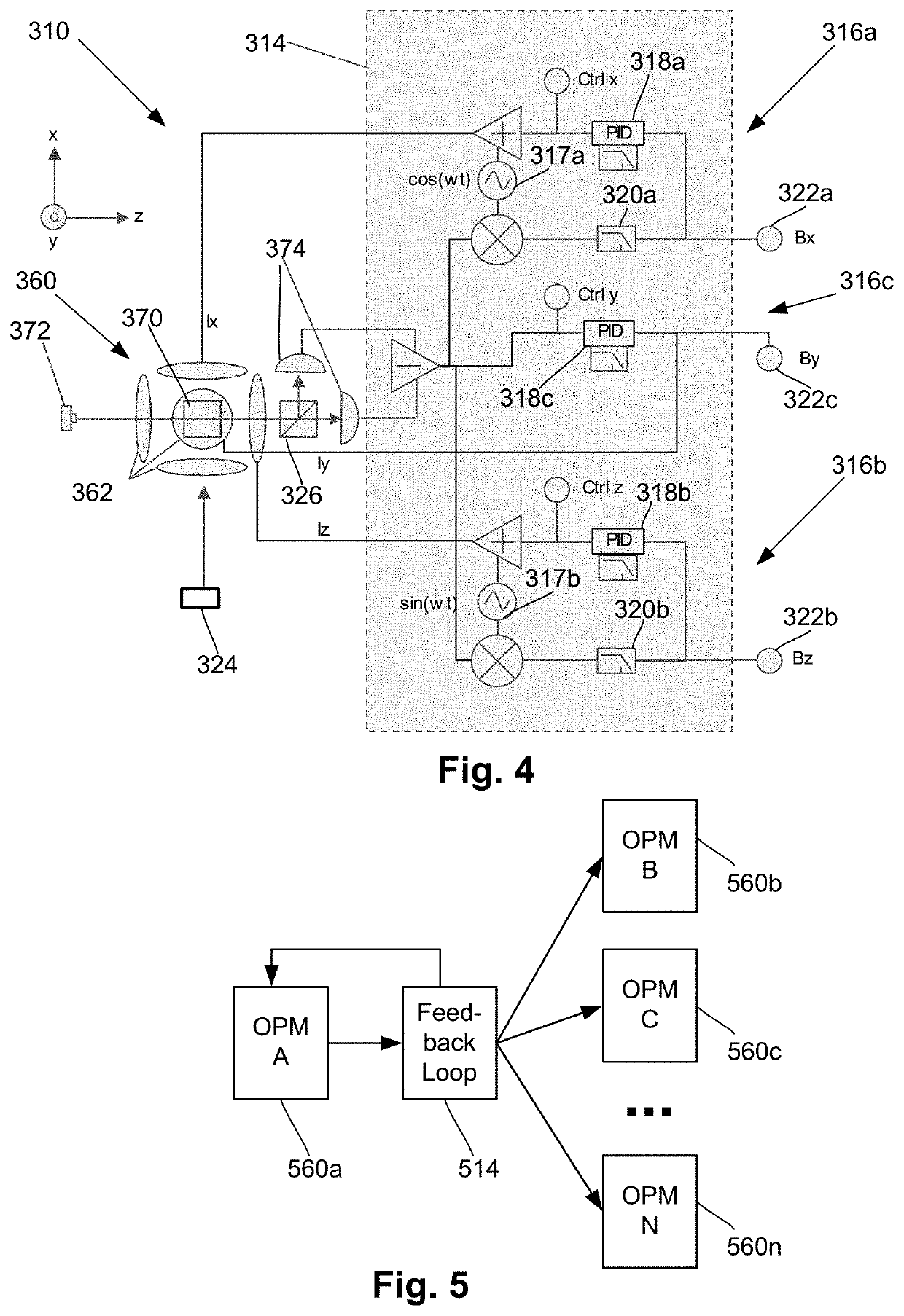

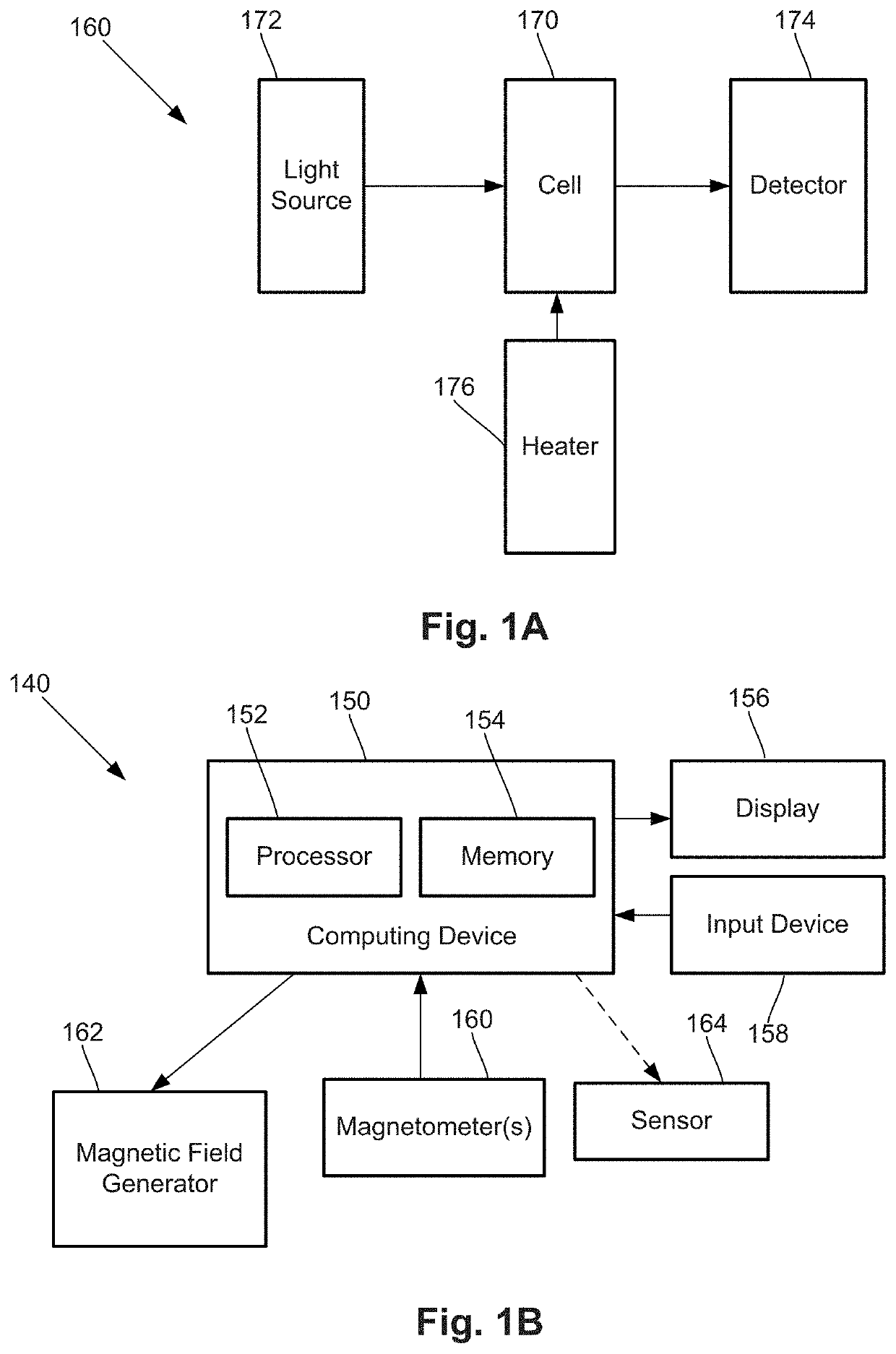

Magnetic field measurement systems and methods of making and using

InactiveUS20190391213A1Magnetic field offset compensationMagnetic field measurement using flux-gate principleMagnetic tension forceCondensed matter physics

A magnetic field measurement system includes an array of magnetometers; at least one magnetic field generator with each of the at least one magnetic field generator configured to generate a first magnetic field at one or more of the magnetometers, wherein the generated first magnetic field combines with the ambient magnetic field to produce a directional magnetic field at the one or more of the magnetometers, where a magnitude and direction of the directional magnetic field is selectable using the at least one magnetic field generator; and a controller coupled to the magnetometers and the at least one magnetic field generator, the controller including a processor configured for receiving signals from the magnetometers, observing or measuring a magnetic field from the received signals, and controlling the at least one magnetic field generator to generate the first magnetic field and select the direction of the directional magnetic field.

Owner:HI LLC

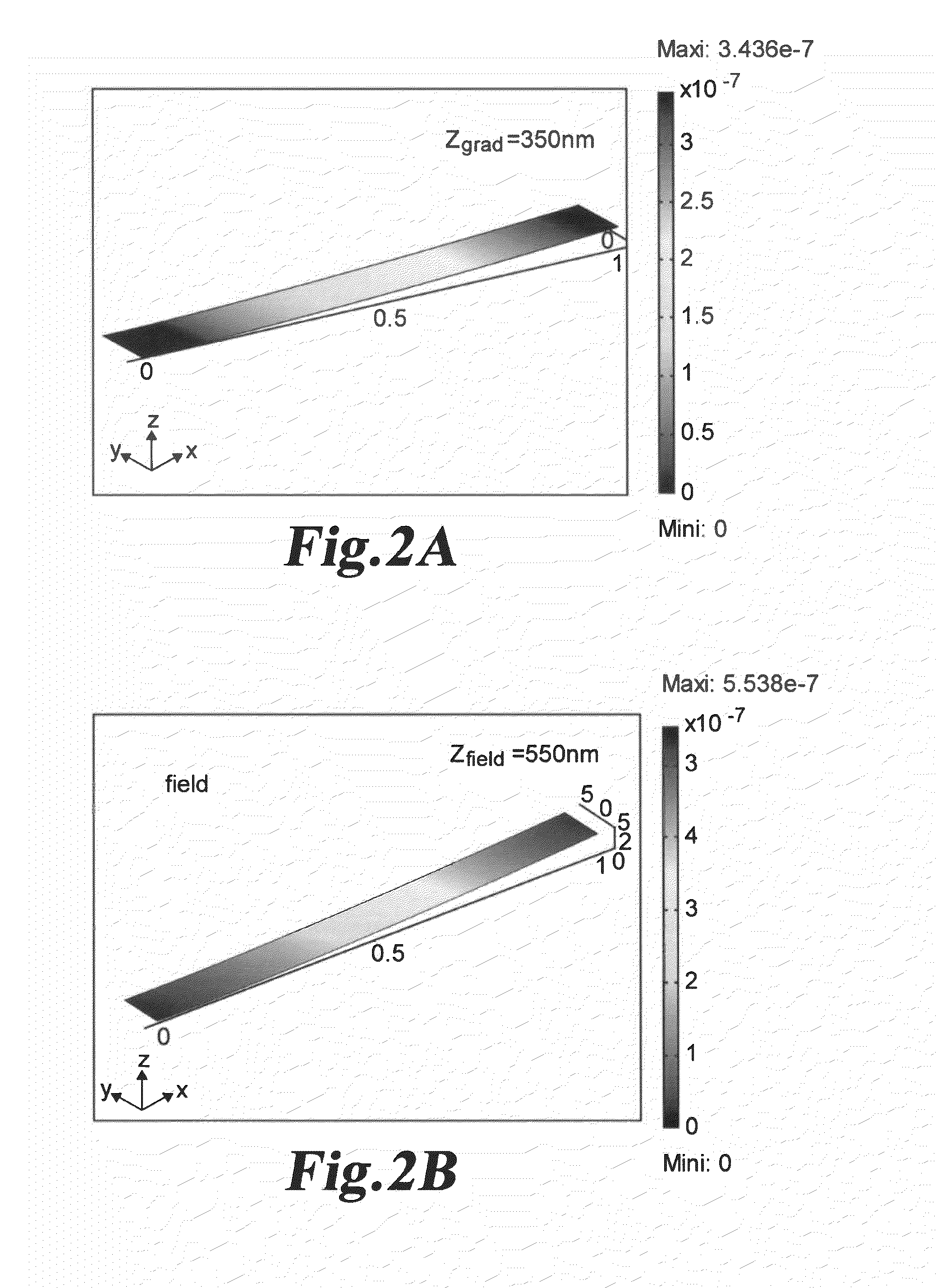

PZT MEMS resonant Lorentz force magnetometer

InactiveUS7642692B1Small sizeSmall weightElectrodynamic magnetometersElectrostatic generators/motorsEngineeringConductive materials

A MEMS magnetometer comprises a deflectable resonator comprising a base layer; a Lorentz force (LF) drive conductor attached to the base layer; and a piezoelectric sensor attached to the base layer and electrically isolated from the LF drive conductor. The LF drive conductor comprises conductive material configured for receiving a current at a mechanical resonant frequency of the device capable of causing mechanical deformation of the deflectable resonator, wherein the current causes formation of Lorentz forces in a presence of a magnetic field, and wherein the deflectable resonator is mechanically deformed as a result of the formation of the Lorentz forces. The mechanical deformation of the deflectable resonator generates a detectable piezoelectric electrical signal that is proportional to the magnitude of the magnetic field.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

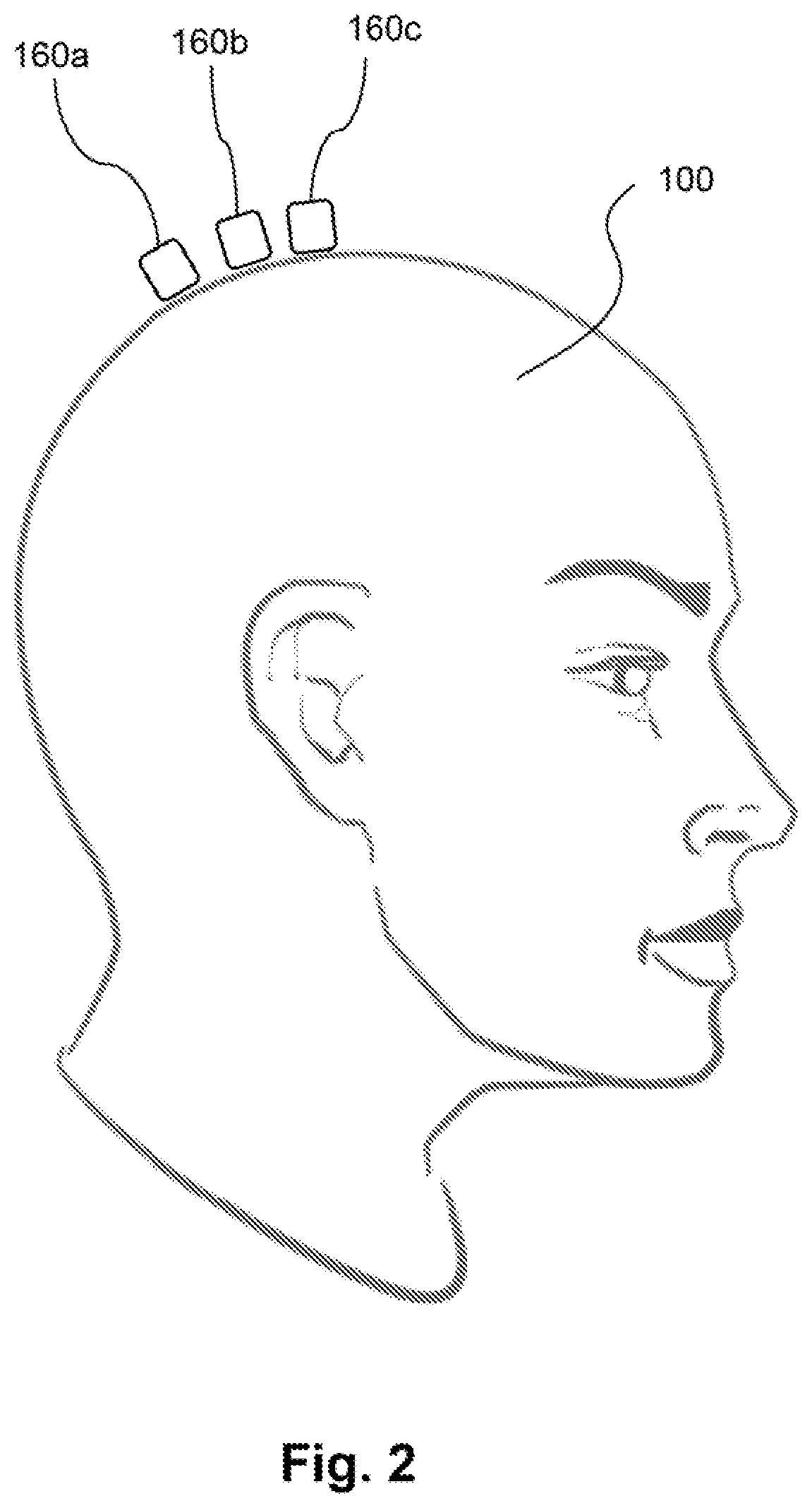

Neural feedback loop filters for enhanced dynamic range magnetoencephalography (MEG) systems and methods

ActiveUS20200256929A1Analysis using optical pumpingDiagnostic recording/measuringLow-pass filterSoftware engineering

One embodiment is a magnetic field measurement system that includes at least one magnetometer having a vapor cell, a light source to direct light through the vapor cell, and a detector to receive light directed through the vapor cell; at least one magnetic field generator disposed adjacent the vapor cell; and a feedback circuit coupled to the at least one magnetic field generator and the detector of the at least one magnetometer. The feedback circuit includes at least one feedback loop that includes a first low pass filter with a first cutoff frequency. The feedback circuit is configured to compensate for magnetic field variations having a frequency lower than the first cutoff frequency. The first low pass filter rejects magnetic field variations having a frequency higher than the first cutoff frequency and provides the rejected magnetic field variations for measurement as an output of the feedback circuit.

Owner:HI LLC

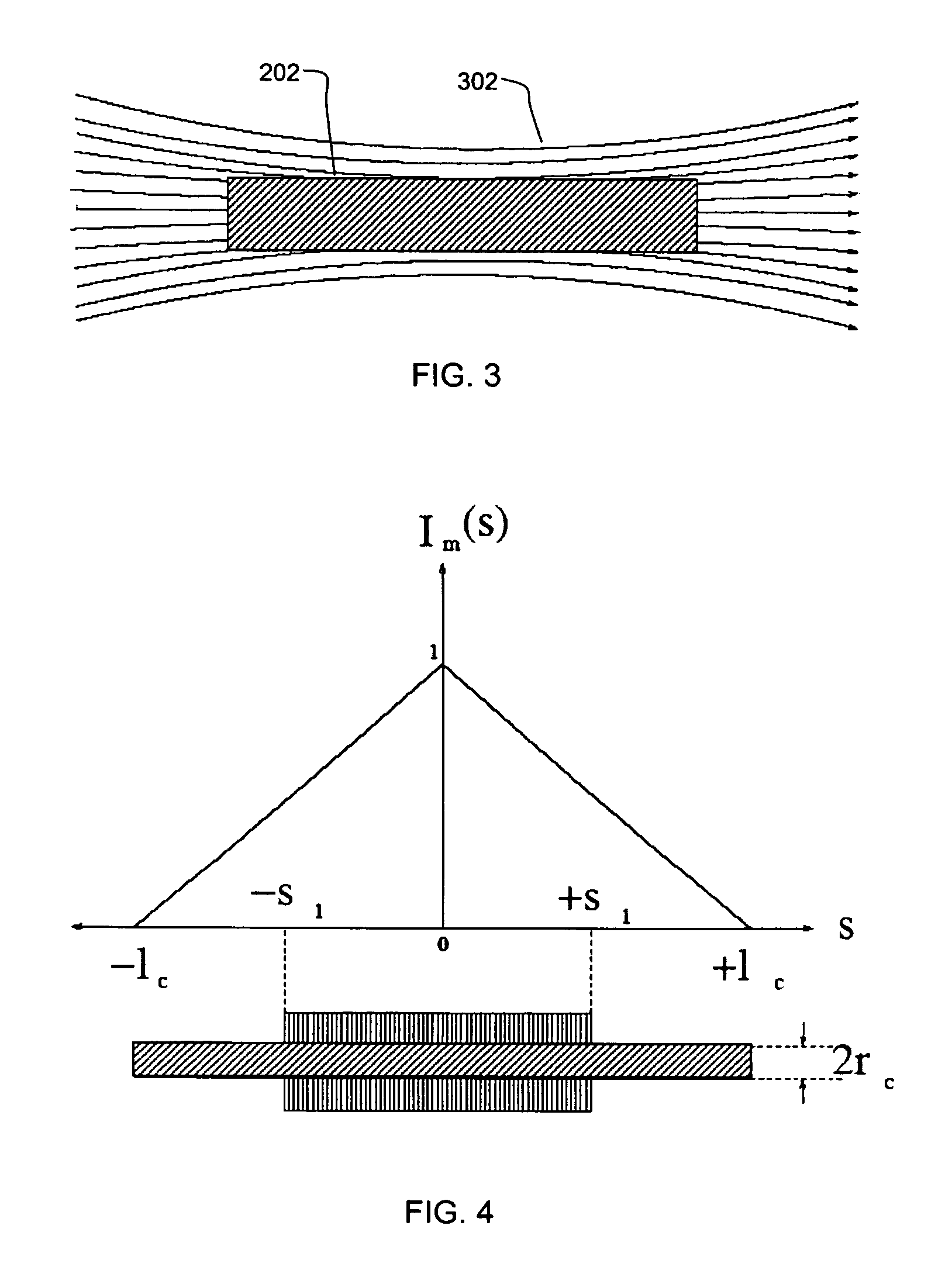

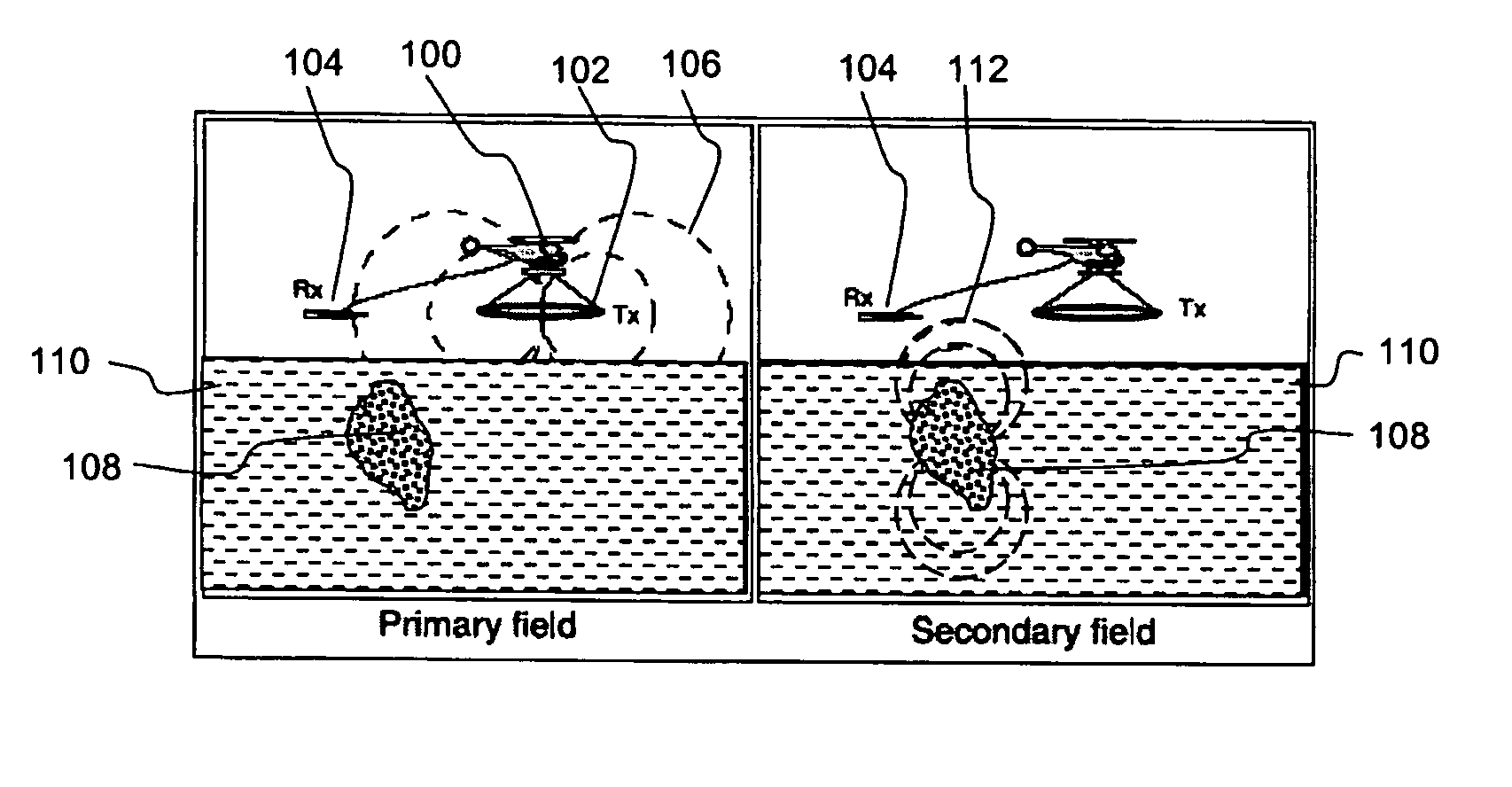

Induction magnetometer

InactiveUS7375529B2Convenient ArrangementHigh aspect ratioElectrodynamic magnetometersAcoustic wave reradiationSelf resonanceUltimate tensile strength

An array of induction magnetometers for use in airborne transient electromagnetic (ATEM) geophysical exploration is disclosed, having similar weight and external dimensions of prior art induction magnetometers but with improved signal strength, signal-to-noise ratio, higher frequency, self-resonance and bandwidth, and providing accurate and well monitored calibration.

Owner:UNIVERSITY OF NEW BRUNSWICK

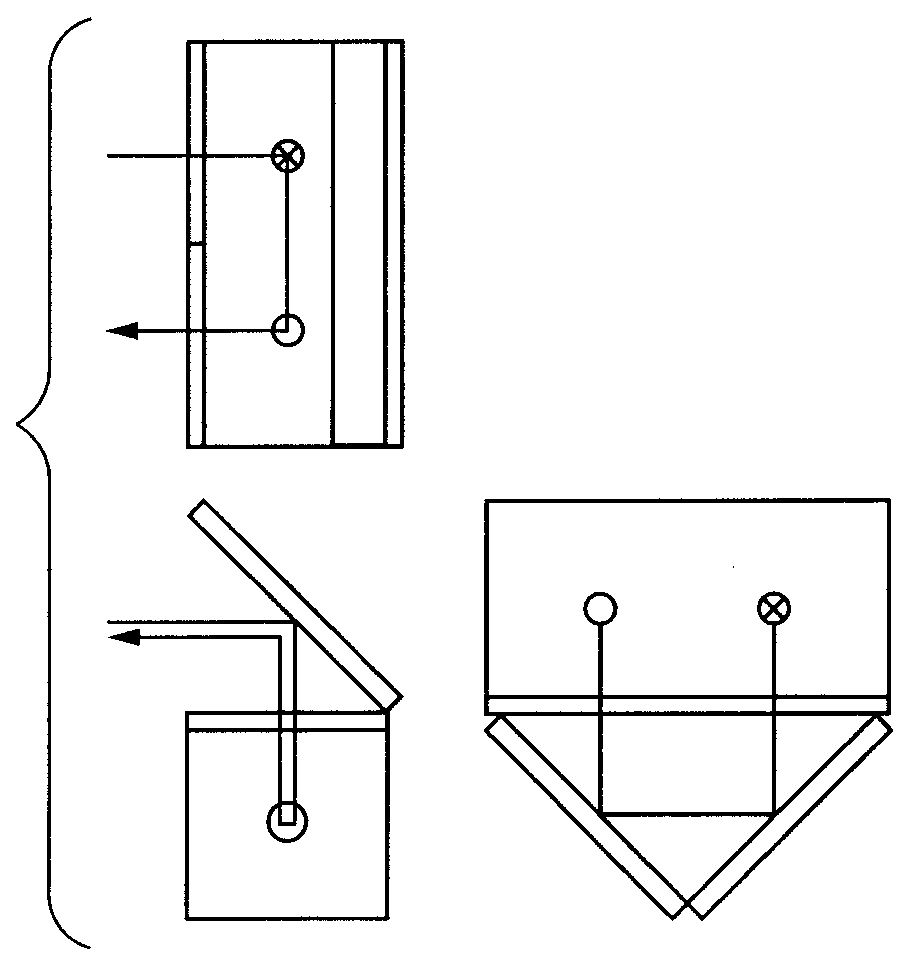

Magnetic gradiometer and magnetic sensing method

ActiveUS9383419B2Magnetic field measurement using flux-gate principleMagnetic field measurement using galvano-magnetic devicesLight beamSignal source

A gradiometer in which a probe beam for reading sequentially passes through two magnetic field measurement regions to obtain signals according to magnetic flux densities of the respective regions is formed using an optically pumped magnetometer. In particular, in a gradiometer using a high sensitivity optically pumped magnetometer, a geometric arrangement enabling obtainment of a large signal from a dipole moment as a signal source is defined.

Owner:CANON KK

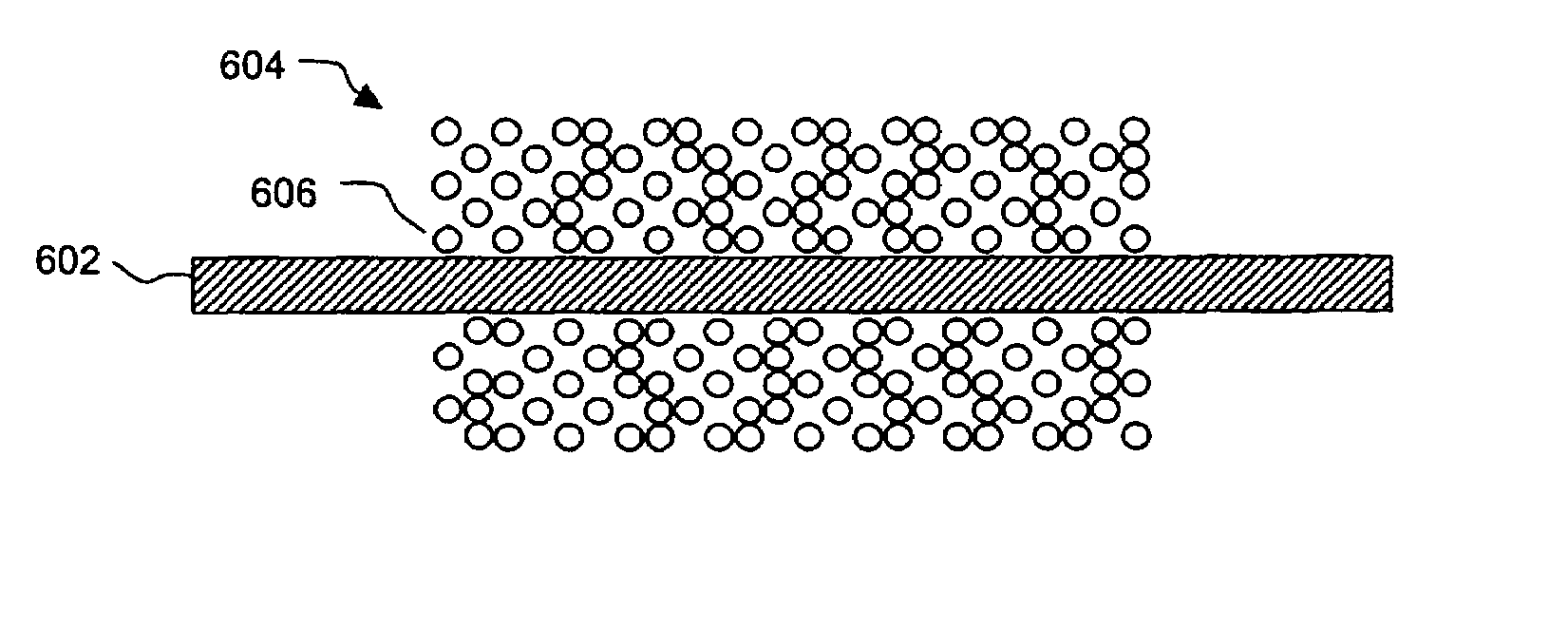

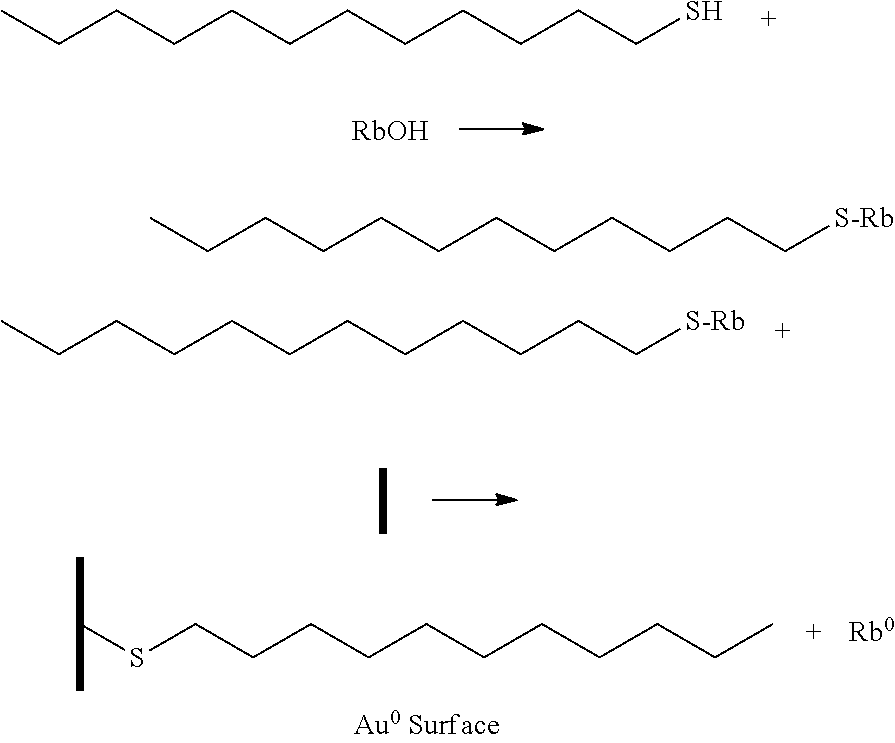

Dispensing of alkali metals mediated by zero oxidation state gold surfaces

ActiveUS20200056263A1Electrodynamic magnetometersMagnetic field measurement using magneto-optic devicesSulfurPhysical chemistry

A method for generating alkali metal in a zero oxidation state includes reacting an alkali metal compound having a —S-M substituent, where M is an alkali metal and S is sulfur, with gold in a zero oxidation state to release the alkali metal in the zero oxidation state. For example, an alkali metal alkylthiolate can be reacted with a gold in a zero oxidation state to release the alkali metal in the zero oxidation state. As another example, an alkali metal sulfide can be reacted with gold in a zero oxidation state to release the alkali metal in the zero oxidation state. The alkali metal may be used in various applications including vapor cells, magnetometers, and magnetic field measurement systems.

Owner:HI LLC

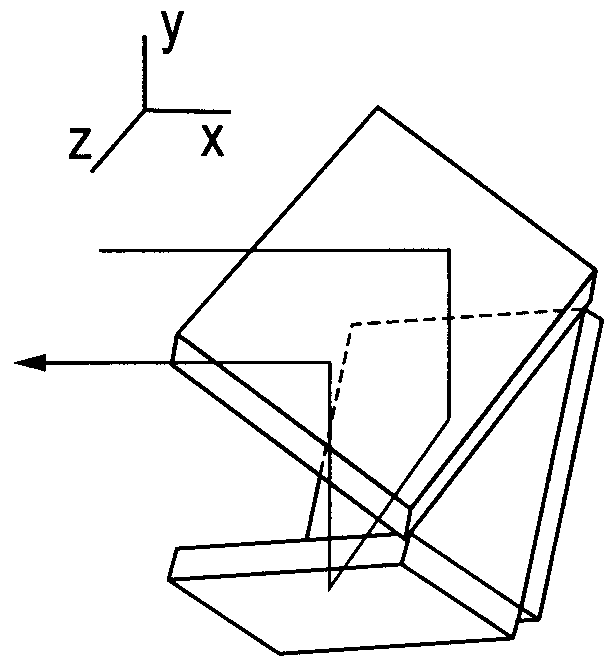

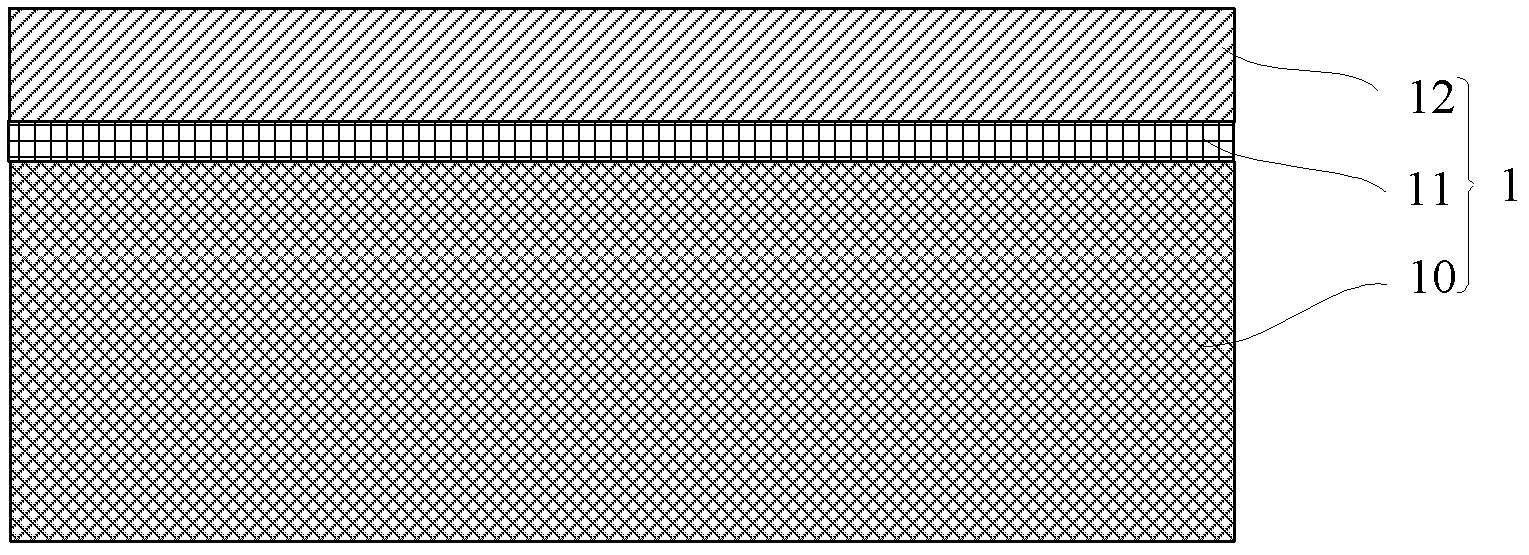

Triaxial magnetic field sensor

ActiveUS20140247042A1Easy to integrateReduce magnetic noiseMagnetic sensor geometrical arrangementsElectrodynamic magnetometersThermal stabilitySingle chip

The present invention discloses a triaxial magnetoresistive sensor. It comprises a substrate integrated with a biaxial magnetic field sensor, a Z-axis sensor that has a sensing direction along Z-axis perpendicular to the two axes of the biaxial magnetic field sensor, and an ASIC. The biaxial magnetic field sensor comprises an X-axis bridge sensor and a Y-axis bridge sensor. The Z-axis sensor and the two-axis sensor are electrically interconnected with the ASIC. A single-chip implementation of the triaxial magnetic field sensor comprises a substrate, onto which a triaxial magnetic field sensor and an ASIC are stacked. The triaxial magnetic field sensor comprises an X-axis bridge sensor, a Y-axis bridge sensor, and a Z-axis bridge sensor. The above design provides a highly integrated sensor with high sensitivity, low power consumption, good linearity, wide dynamic range, excellent thermal stability, and low magnetic noise.

Owner:MULTIDIMENSION TECH CO LTD

System and method for magnetometer calibration and compensation

A system comprises an inertial measurement unit comprising one or more gyroscopes configured to measure angular velocity about a respective one of three independent axes and one or more accelerometers configured to measure specific force along a respective one of the three independent axes; a magnetometer configured to measure strength of a local magnetic field along each of the three independent axes; and a processing device coupled to the inertial measurement unit and the magnetometer; the processing device configured to compute kinematic state data for the system based on measurements received from the magnetometer and the inertial measurement unit. The processing device is further configured to calculate magnetometer measurement calibration parameters using a first technique when position data is unavailable and to calculate magnetometer measurement calibration parameters using a second technique when position data is available.

Owner:HONEYWELL INT INC

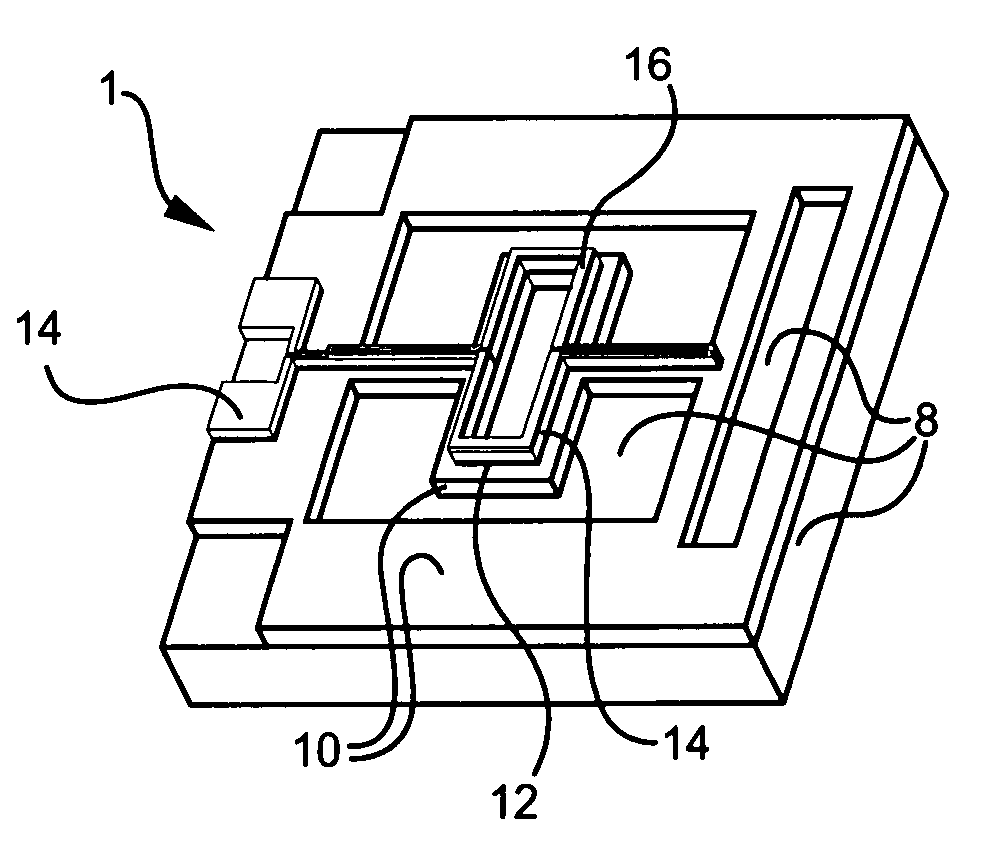

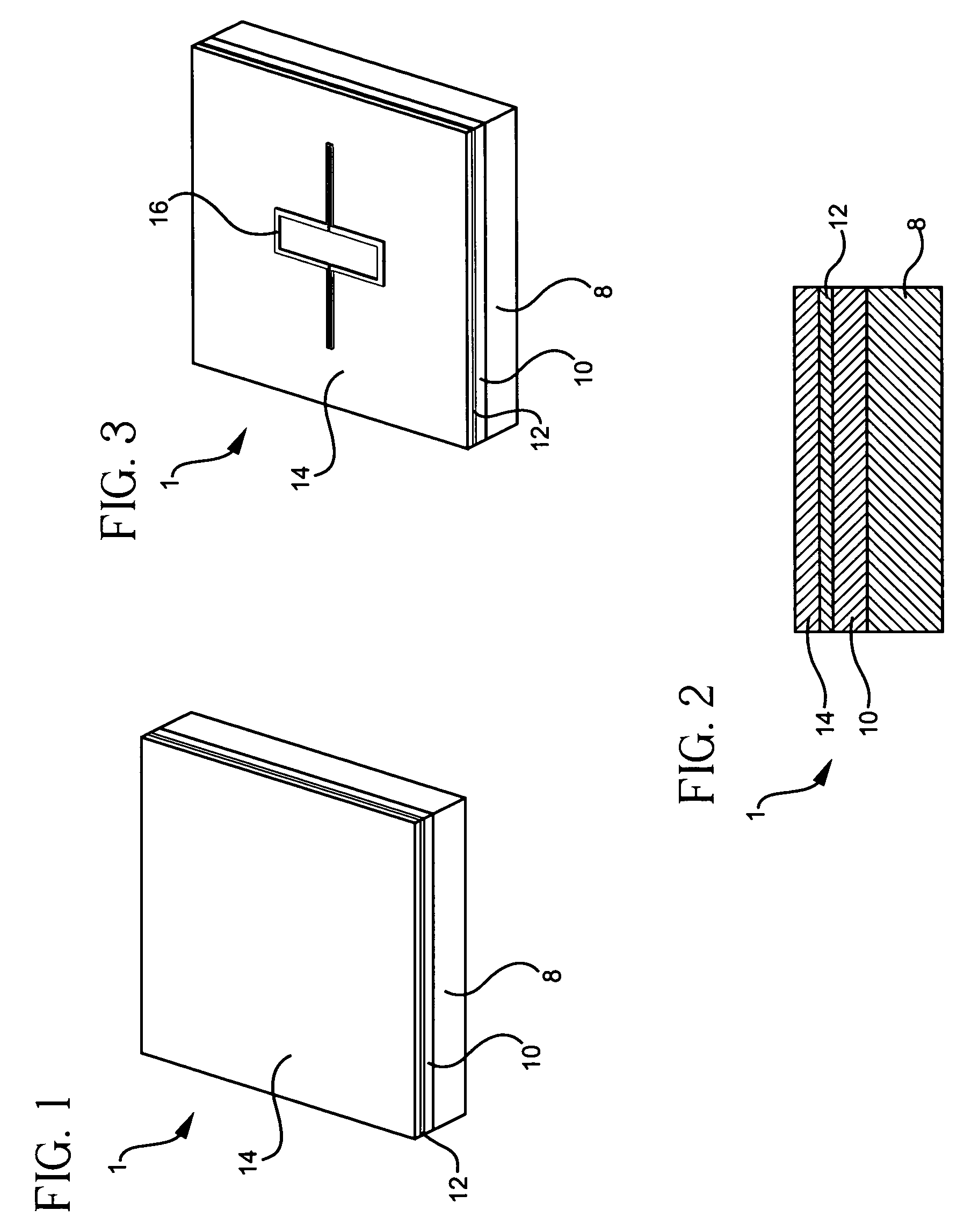

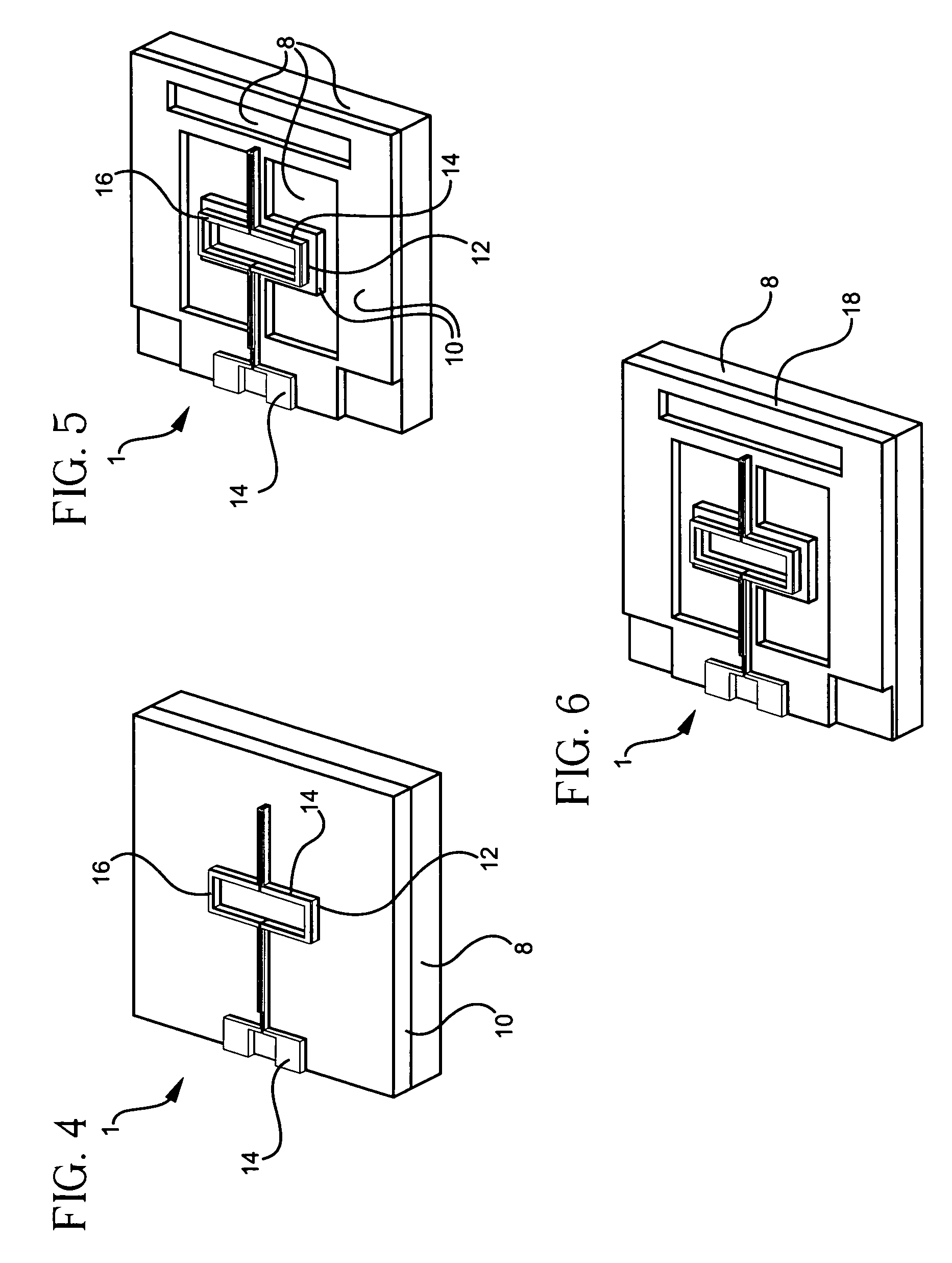

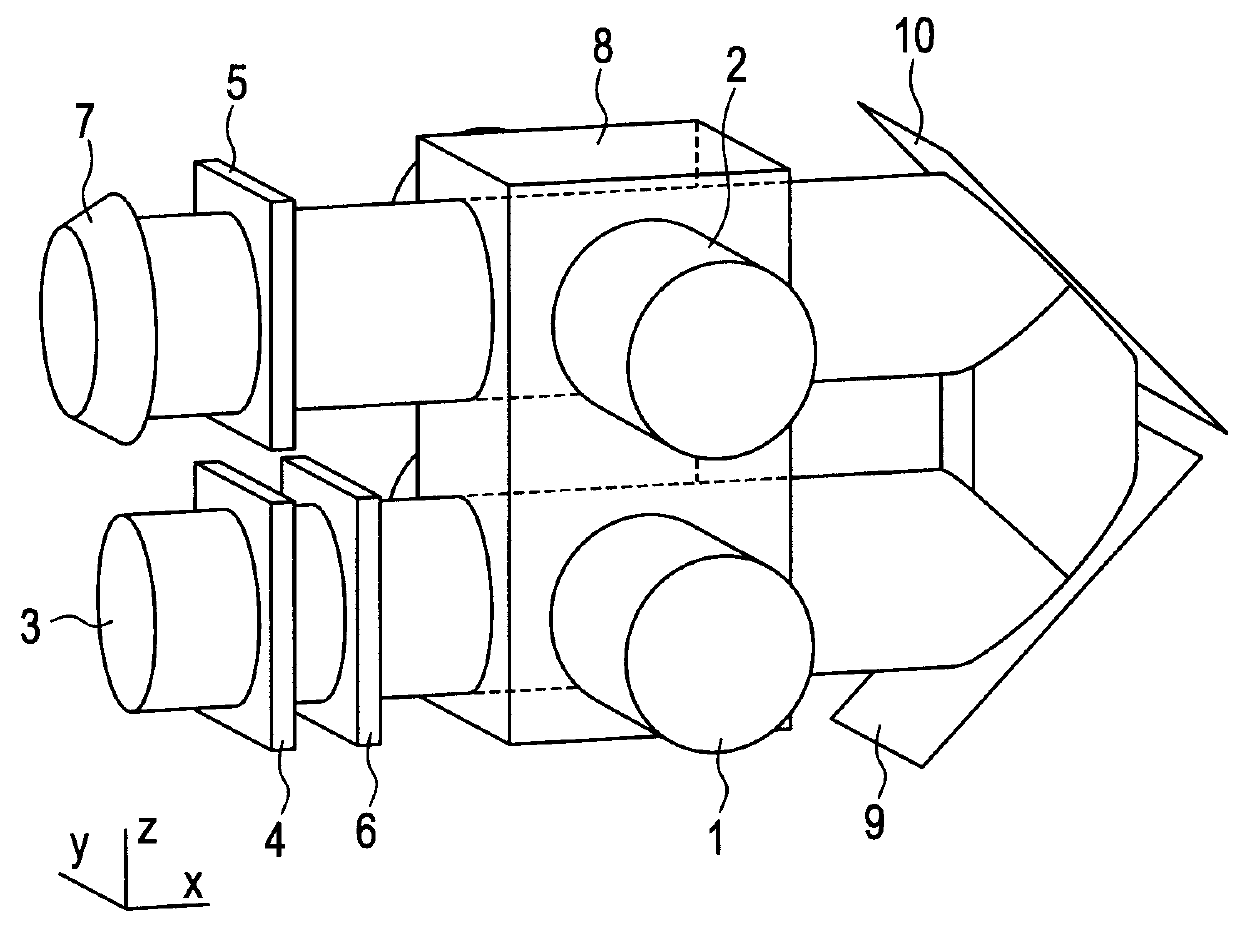

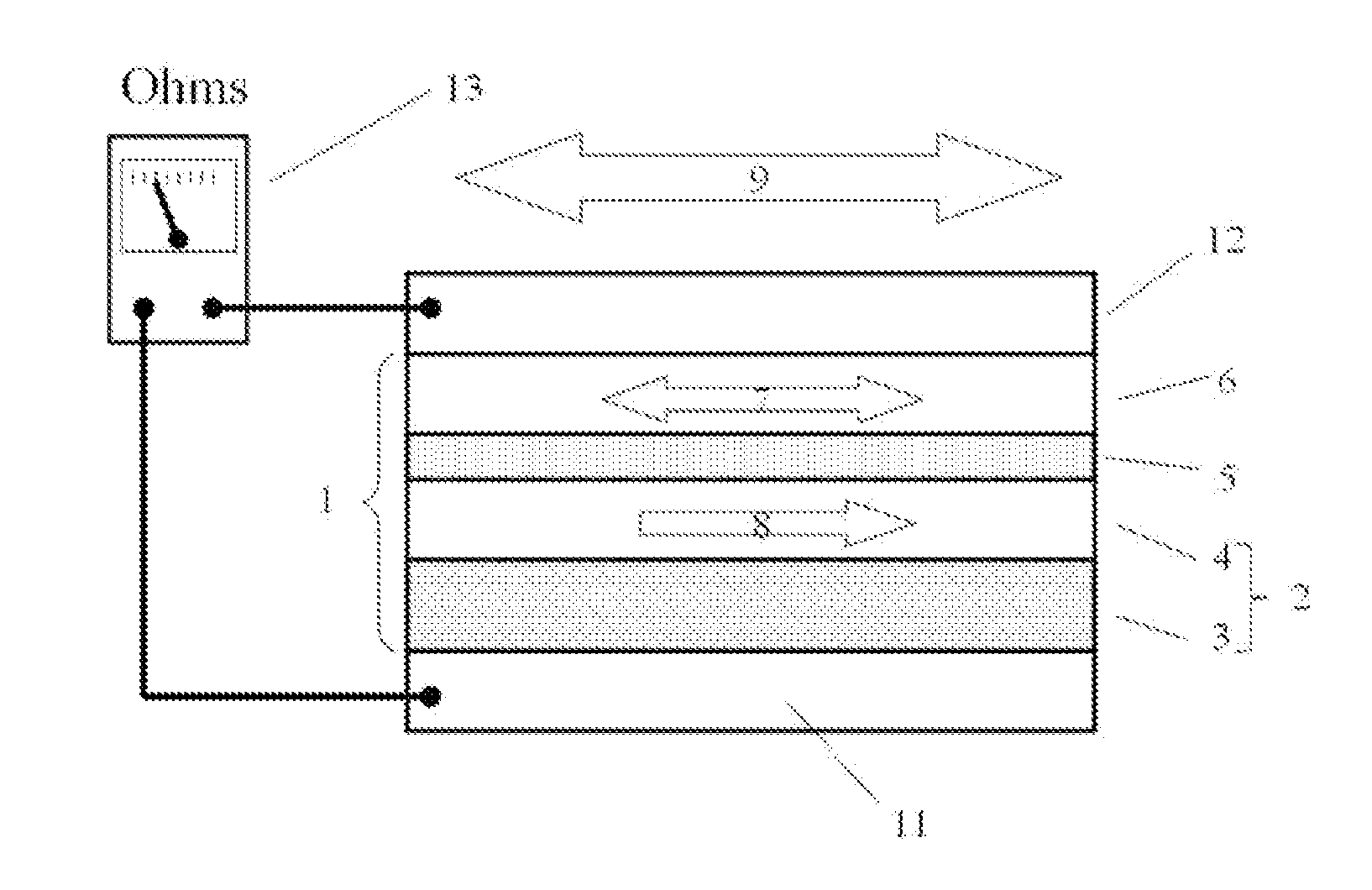

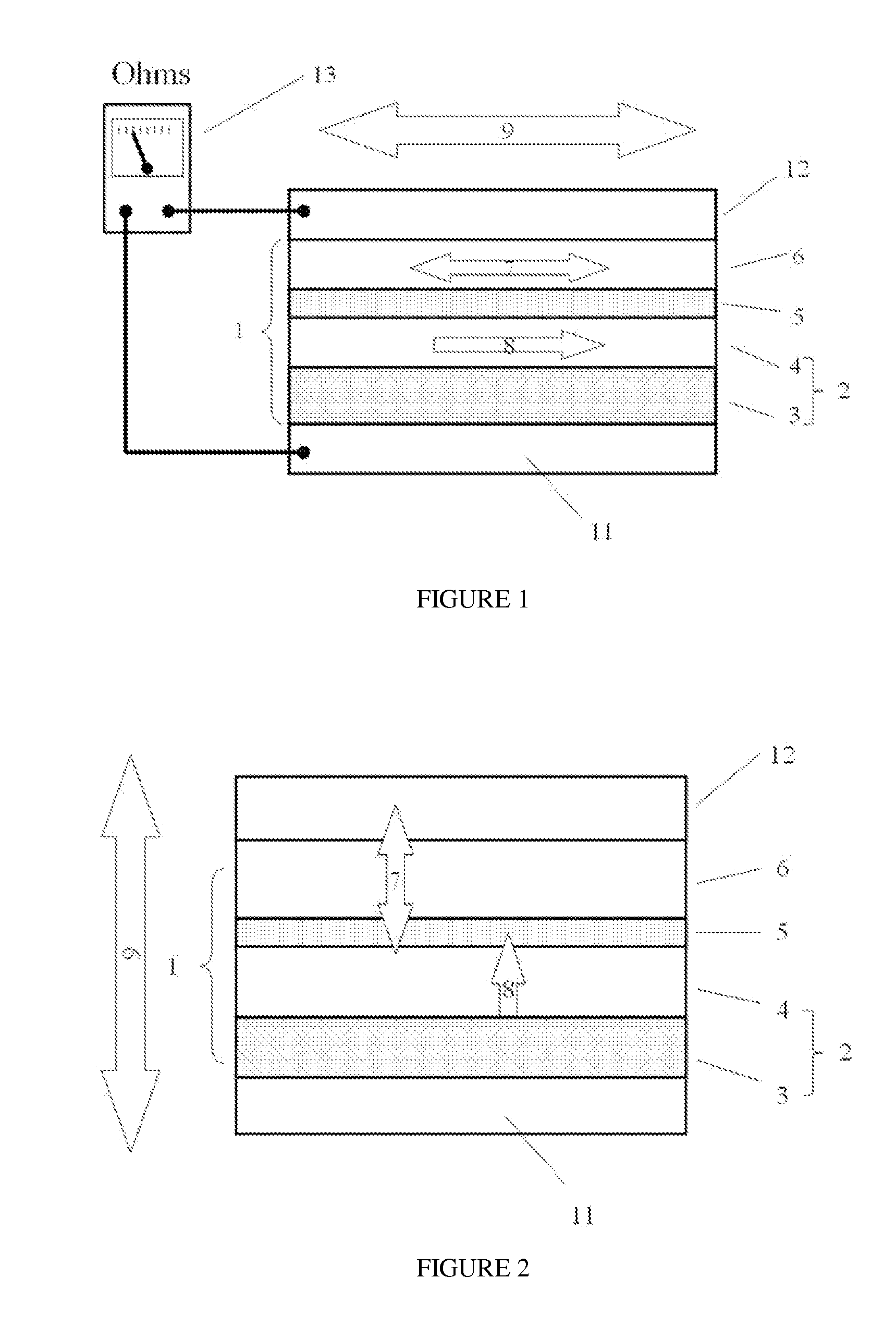

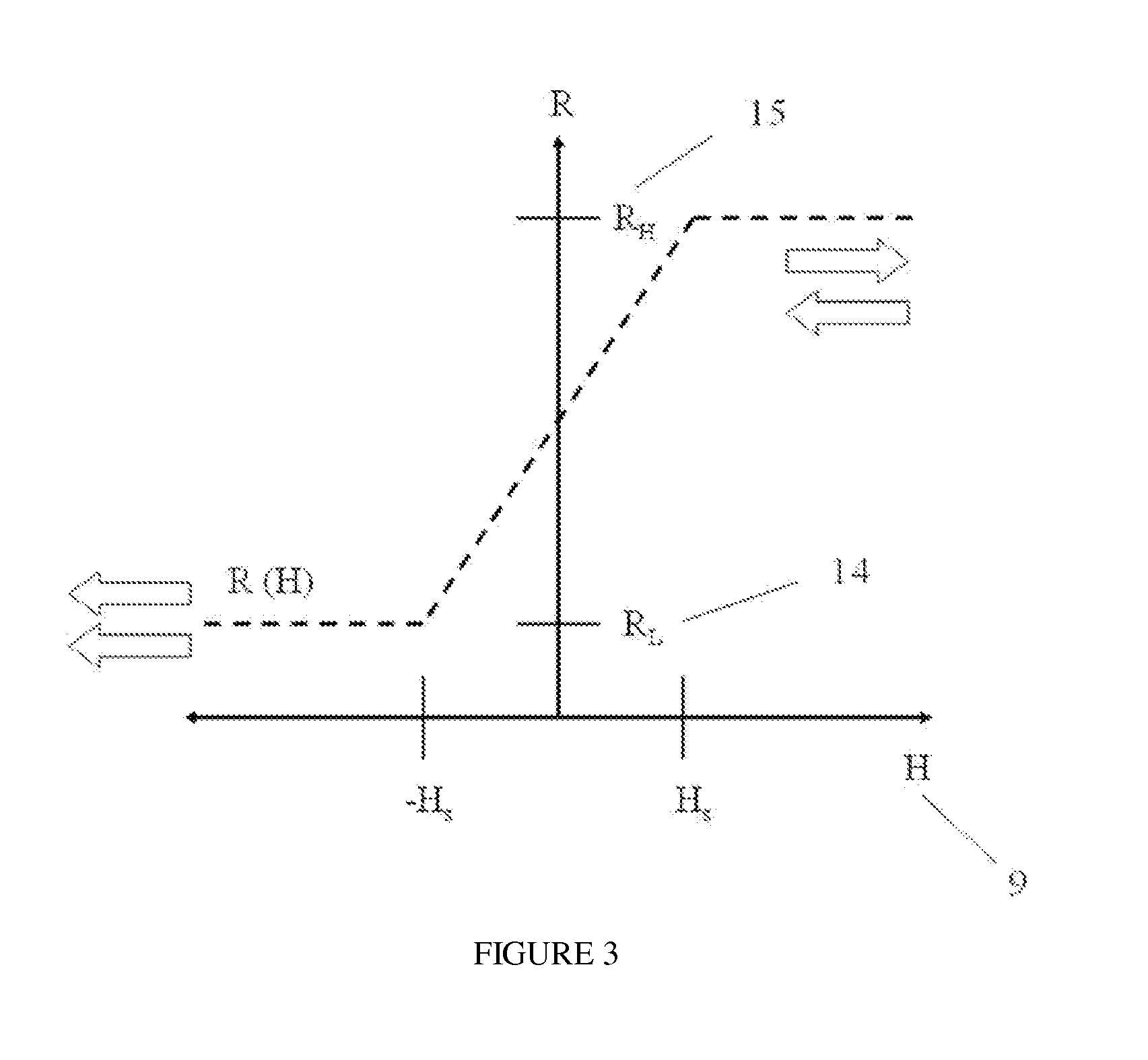

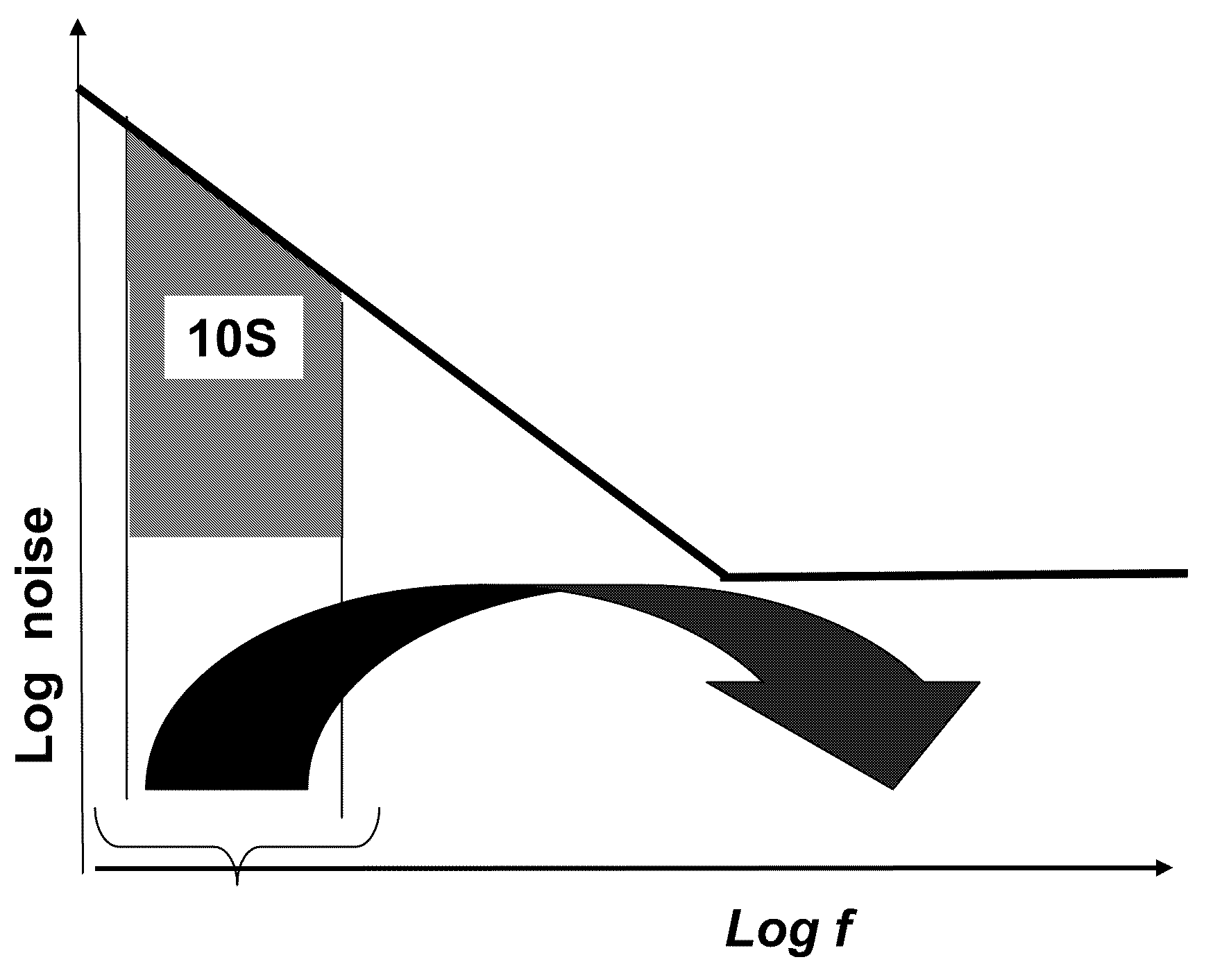

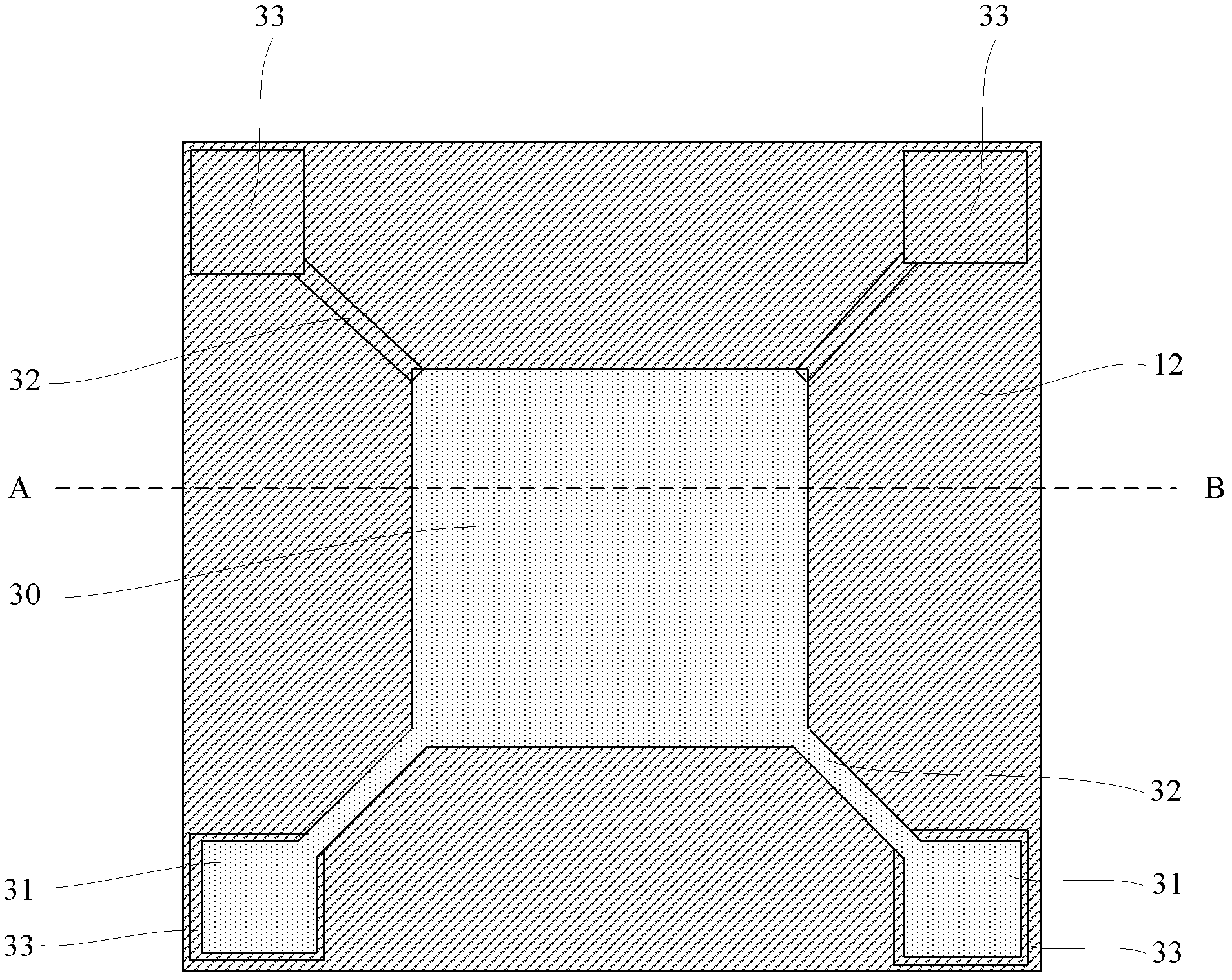

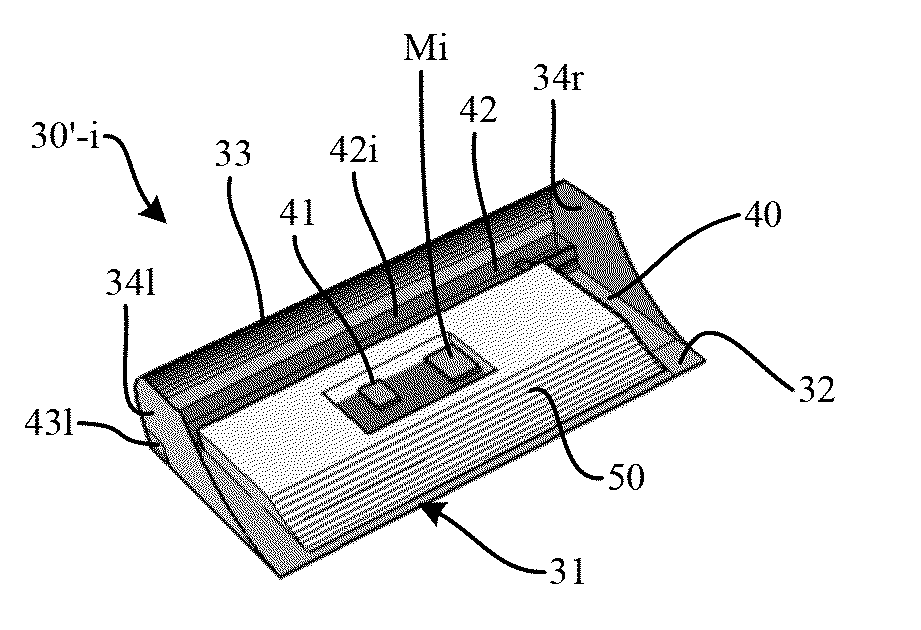

MEMS device with tandem flux concentrators and method of modulating flux

InactiveUS20100039106A1Minimize noiseIncreased magnetic sensitivityMagnetic field measurement using flux-gate principleElectrodynamic magnetometersMagnetic transducersHigh flux

A microelectromechanical modulating magnetic sensor comprising a base; a magnetic transducer associated with the base that provides an output in response to a magnetic field; a pair of movable flux concentrators positioned to move relative to the magnetic transducer; the pair of movable flux concentrators having a region of high flux concentration between the pair of movable flux concentrators; the pair of flux concentrators moving together in tandem with the distance between the pair remaining substantially constant during movement; support structure for supporting the pair of movable flux concentrators; a power source for causing the movable flux concentrators to move at a frequency within a predetermined frequency range; whereby when the pair of movable flux concentrators is in a first position the region of high flux concentration is in a first location, and when the pair of movable flux concentrators is in a second position, the region of high flux concentration is in a second position; such that as the flux concentrators move from the first position to the second position the intensity of the flux sensed by the transducer is modulated as the region of high flux concentration approaches and recedes from the location of the transducer.

Owner:ARMY US SEC THE THE

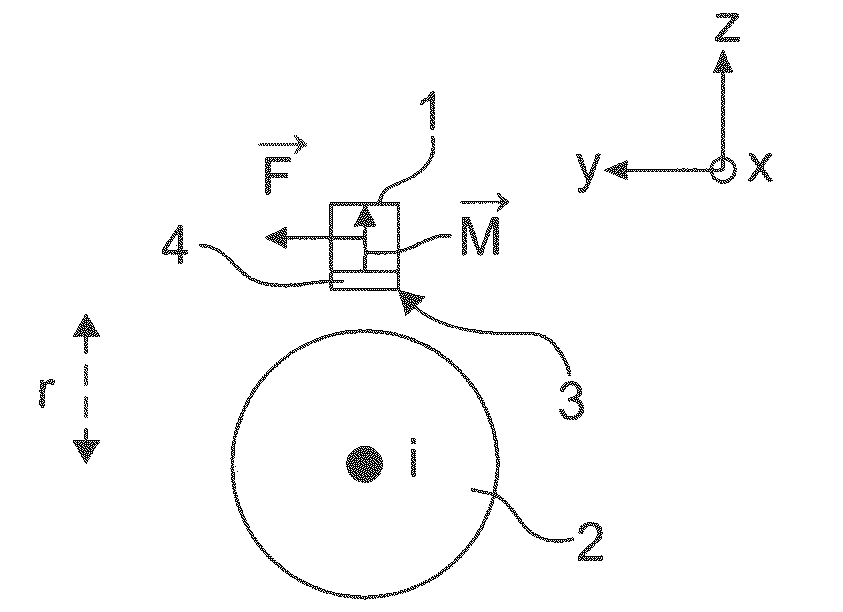

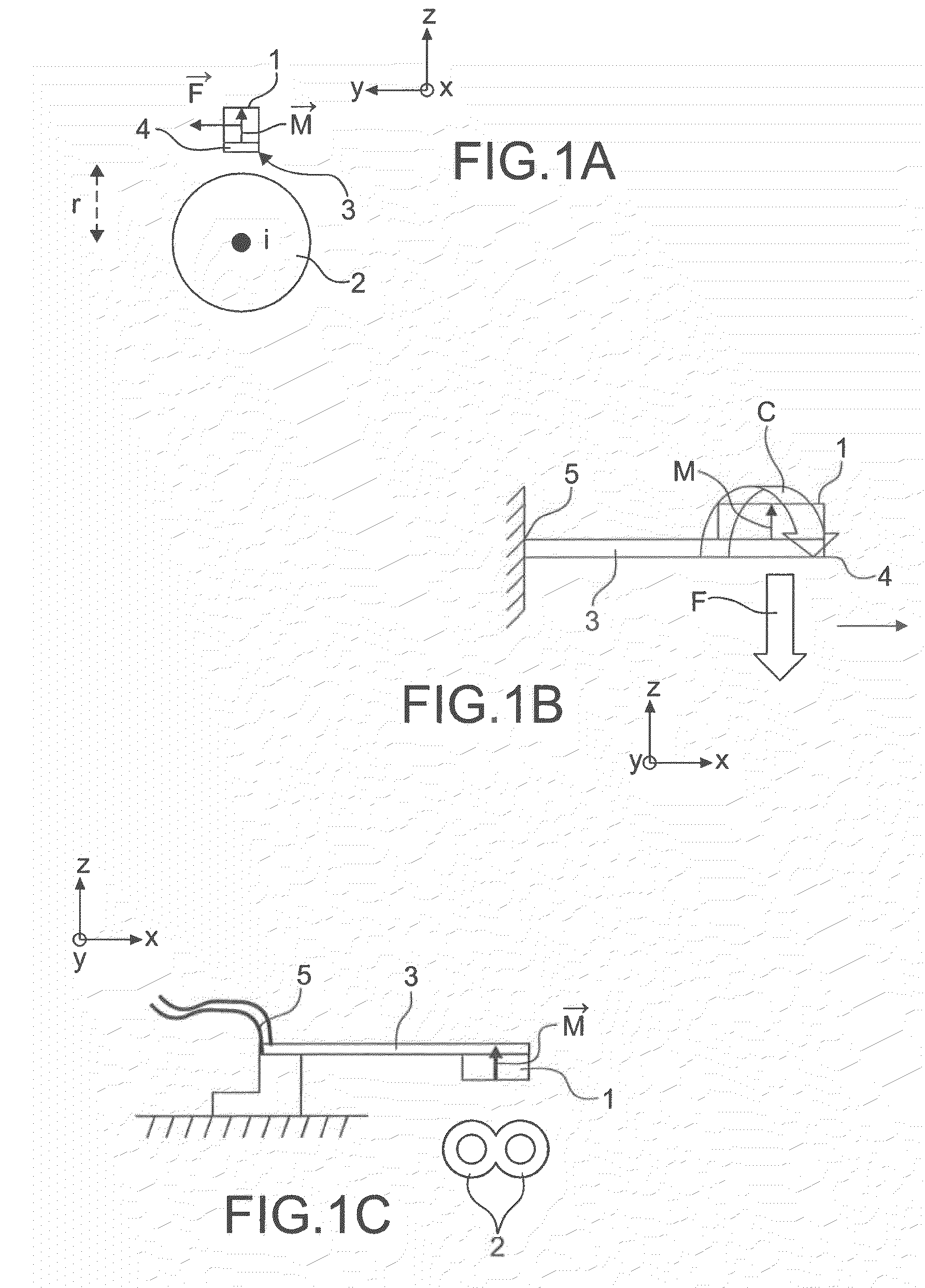

Gradient sensor of a component of a magnetic field with permanent magnet

InactiveUS20100295546A1Easy to distinguishSemiconductor/solid-state device manufacturingElectrodynamic magnetometersClassical mechanicsMagnetization

A gradient sensor of a component of a magnetic field comprising at least one elementary sensor comprising a deformable mass (31) equipped with a permanent magnet (32) having a magnetization direction substantially colinear to the direction of the gradient of the component of the magnetic field to be acquired by the sensor. The deformable mass (31) is able to deform under the effect of a force exerted on the magnet by the gradient, the effect of this force being to shift it, by dragging the deformable mass (31), in a direction substantially colinear to the component of the magnetic field for which the sensor has to acquire the gradient. The deformable mass (31) is anchored to a fixed support device (33) in at least two anchoring points (36) substantially opposite relative to the mass (31). The elementary sensor also comprises measuring means (35, 35.1, 35.2, 35.3) of at least one electric variable translating deformation or stress of the deformable mass (31) engendered by the gradient.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

Sensor element

InactiveUS6462566B1Using electrical meansElectrodynamic magnetometersElectrical conductorClassical mechanics

A sensor element, in particular for determining an angle of rotation, has a detection medium whose position varies as a function of a change in a parameter to be measured, where the change in the position of the detection medium leads to a change in an analyzable signal of the sensor element which is influenced by the detection medium. The detection medium has at least one conductor loop carrying current which is exposed to an external magnetic field; the detection medium is rotationally movably mounted so that a rotational motion of the sensor element about an angle of rotation in the plane of the magnetic field is converted into a deflection of the detection medium perpendicular to the magnetic field.

Owner:ROBERT BOSCH GMBH

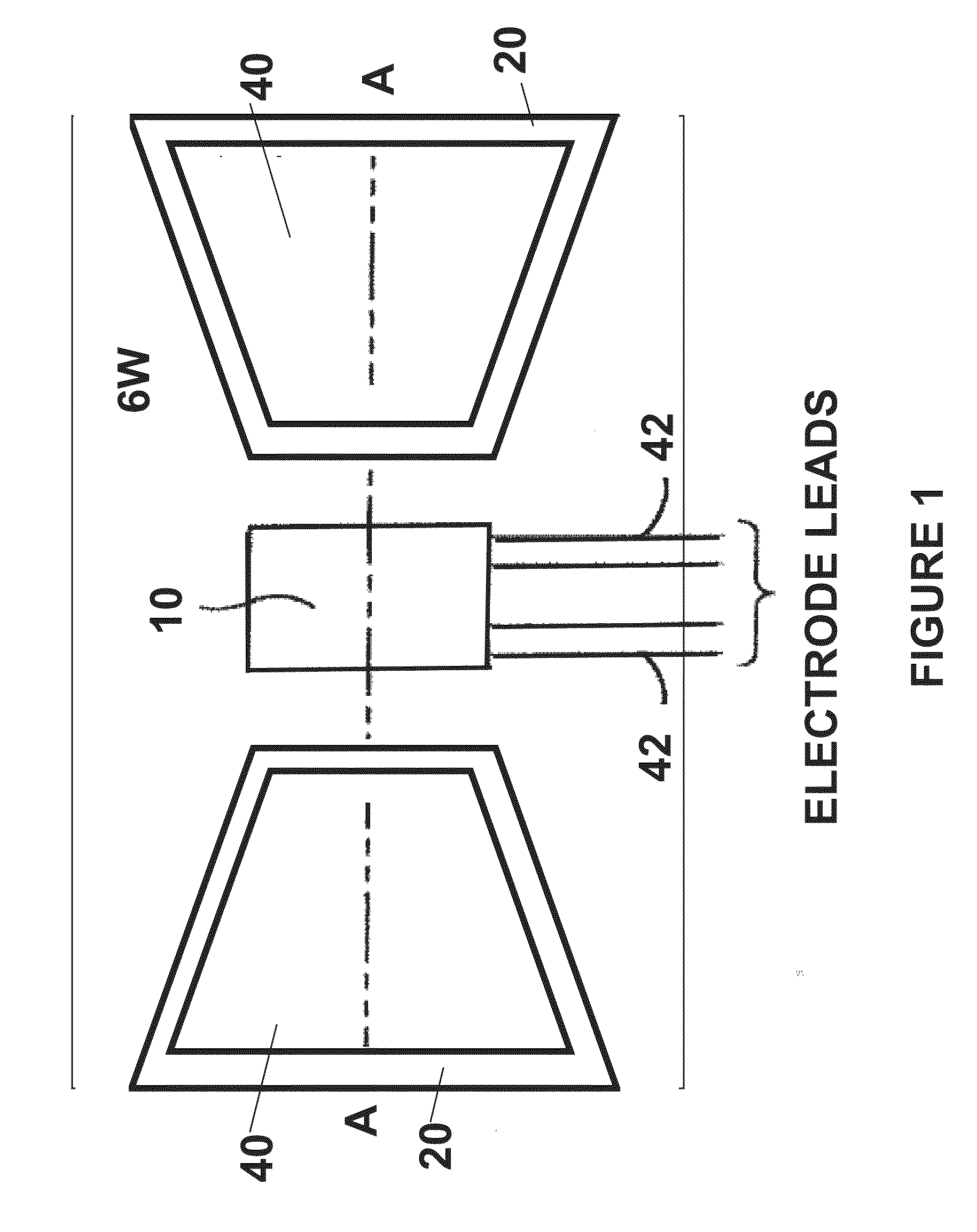

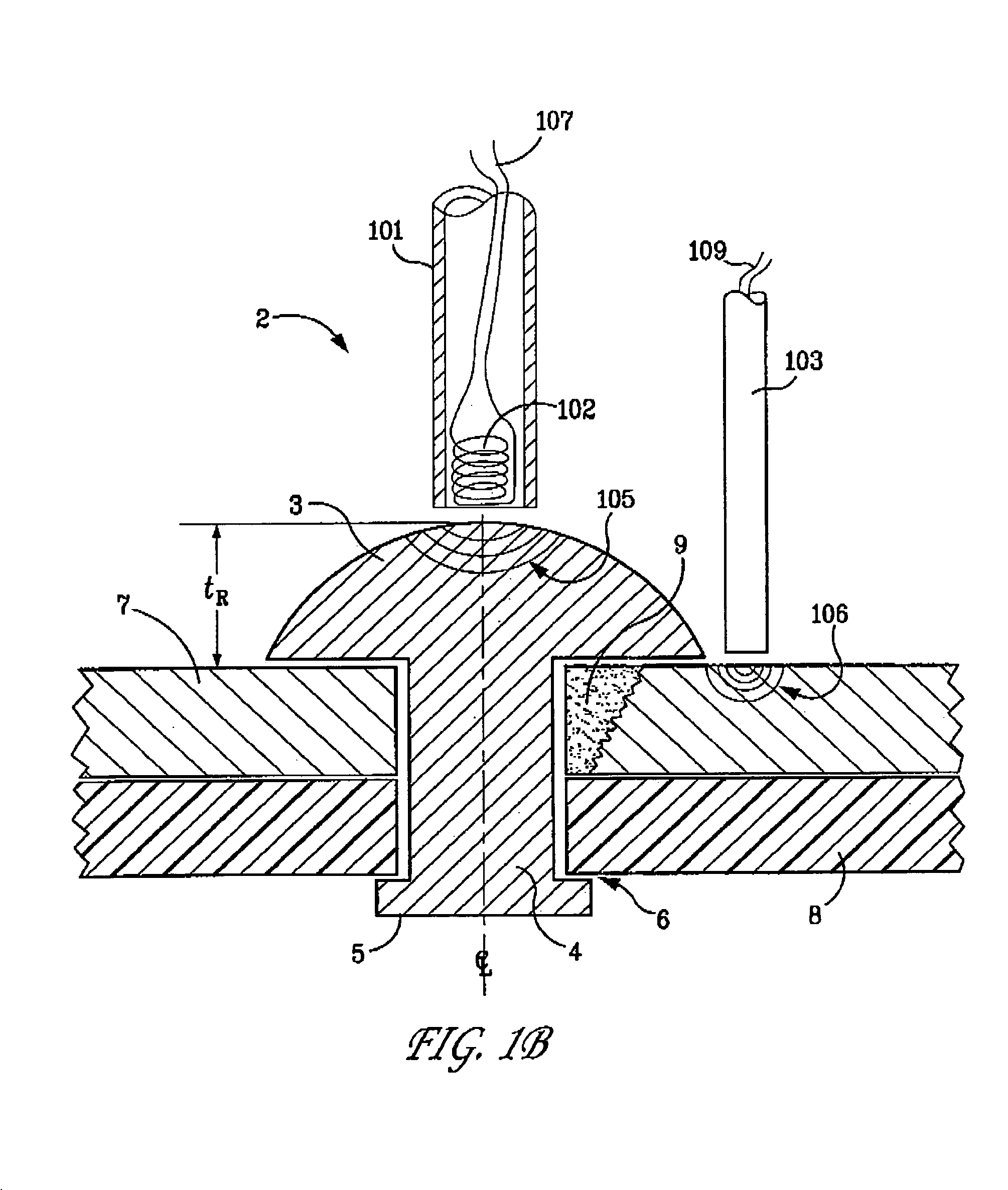

Rotating concave eddy current probe

ActiveUS7352176B1Overcomes inspection impedimentEasy alignmentMagnetic property measurementsElectrodynamic magnetometersEngineeringEddy current

A rotating concave eddy current probe for detecting fatigue cracks hidden from view underneath the head of a raised head fastener, such as a buttonhead-type rivet, used to join together structural skins, such as aluminum aircraft skins. The probe has a recessed concave dimple in its bottom surface that closely conforms to the shape of the raised head. The concave dimple holds the probe in good alignment on top of the rivet while the probe is rotated around the rivet's centerline. One or more magnetic coils are rigidly embedded within the probe's cylindrical body, which is made of a non-conducting material. This design overcomes the inspection impediment associated with widely varying conductivity in fastened joints.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Induction magnetometer

InactiveUS20050156601A1Convenient ArrangementIncreased apparent permeabilityMagnetic field measurement using flux-gate principleElectrodynamic magnetometersSelf resonanceUltimate tensile strength

An array of induction magnetometers for use in airborne transient electromagnetic (ATEM) geophysical exploration is disclosed, having similar weight and external dimensions of prior art induction magnetometers but with improved signal strength, signal-to-noise ratio, higher frequency, self-resonance and bandwidth, and providing accurate and well monitored calibration.

Owner:UNIVERSITY OF NEW BRUNSWICK

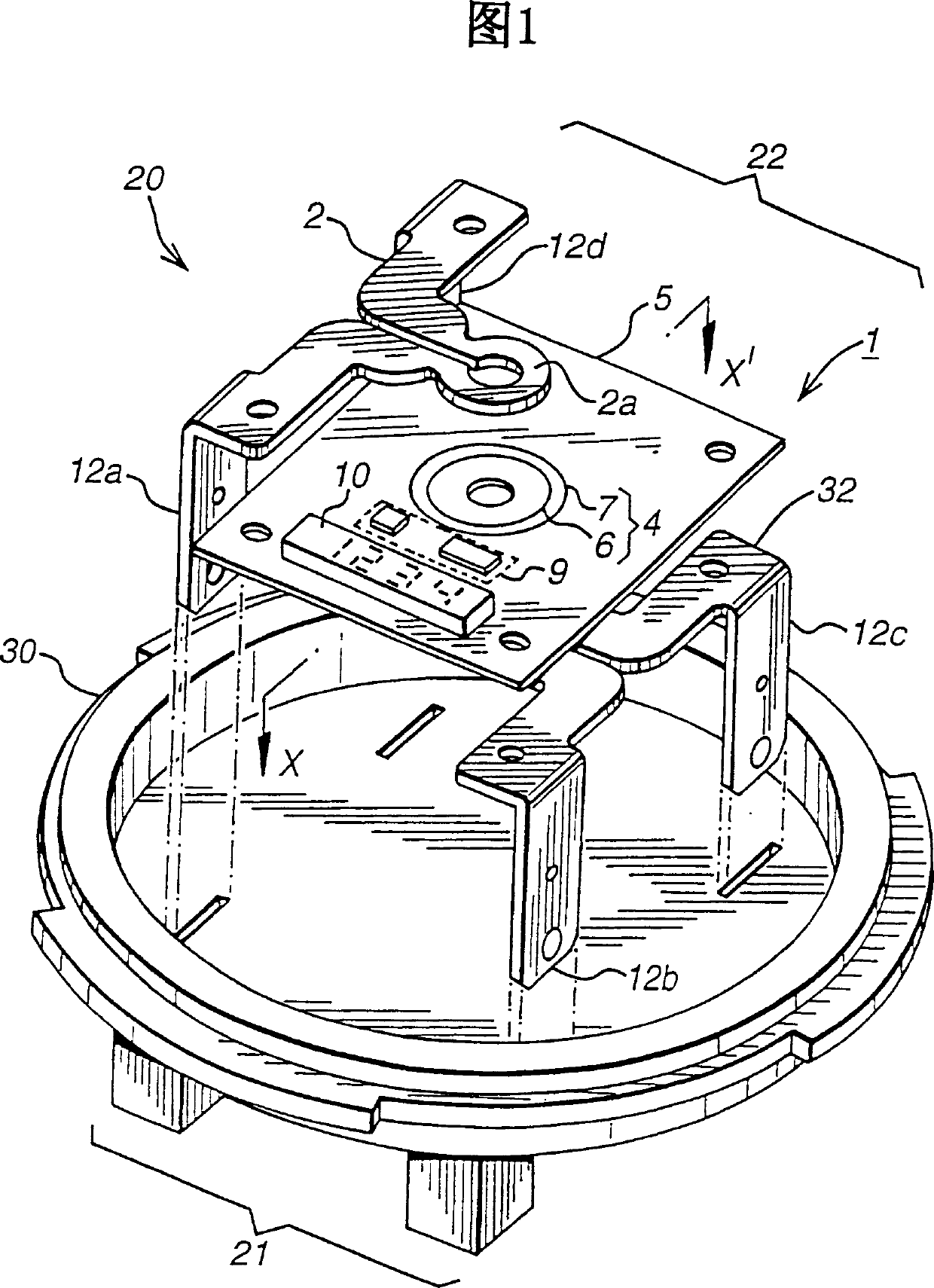

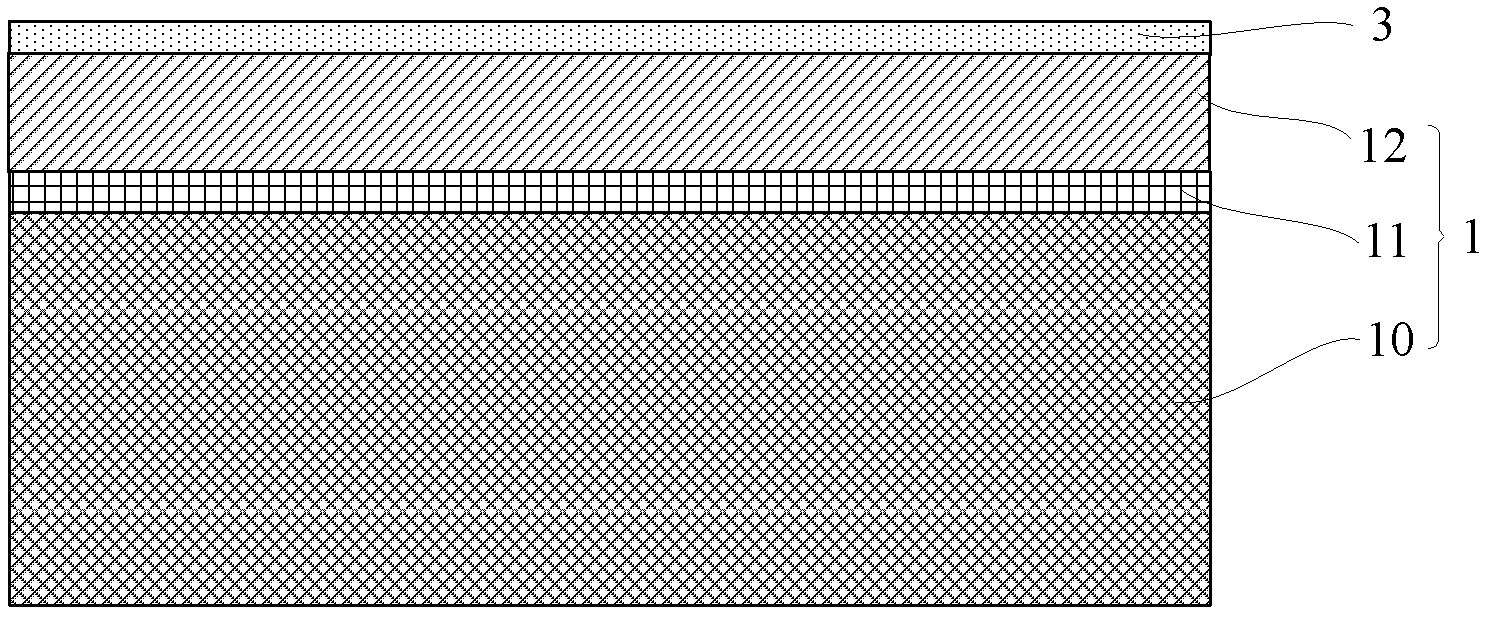

Micro machinery magnetic field sensor and preparation method thereof

ActiveCN102645565AReduce power consumptionHigh strengthDecorative surface effectsManufacture of electrical instrumentsMicroelectromechanical systemsElectromotive force

The invention provides a micro machinery magnetic field sensor and a preparation method thereof, which belong to the field of a micro electro mechanical system. A sacrifice layer with a contact hole is deposited on a structural layer of a device, a metal coil is prepared on the sacrifice layer, then the sacrifice layer is corroded, and finally dry etching is used to manufacture a device structure, and the device structure is released to form a resonance oscillator so as to form the metal coil to hang on the micro machinery magnetic field sensor above the resonance oscillator. The resonance oscillator of the micro machinery magnetic field sensor works in an extension module, so that induced electromotive force produced by each small section of metal cutting magnetic induction lines on the metal coil can be overlapped, strength of output signals is strengthened, and contact surface between the metal coil and the resonance oscillator is reduced to solve the problem of signal crosstalk in high frequency. In addition, the micro machinery magnetic field sensor has the advantages of being low in power consumption, simple in driving-detection circuit, small in temperature influence, simple in process and the like.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Pulsed free induction decay nonlinear magneto-optical rotation apparatus

ActiveUS8421455B1Electrodynamic magnetometersElectric/magnetic detectionOptoelectronicsSignal processing

A magnetometer and concomitant magnetometry method comprising emitting light from a light source, via a pulse generator pulsing light from the light source, directing the pulsed light to an atomic chamber, employing a field sensor in the atomic chamber, and via a signal processing module receiving a signal from the field sensor.

Owner:SOUTHWEST SCI +1

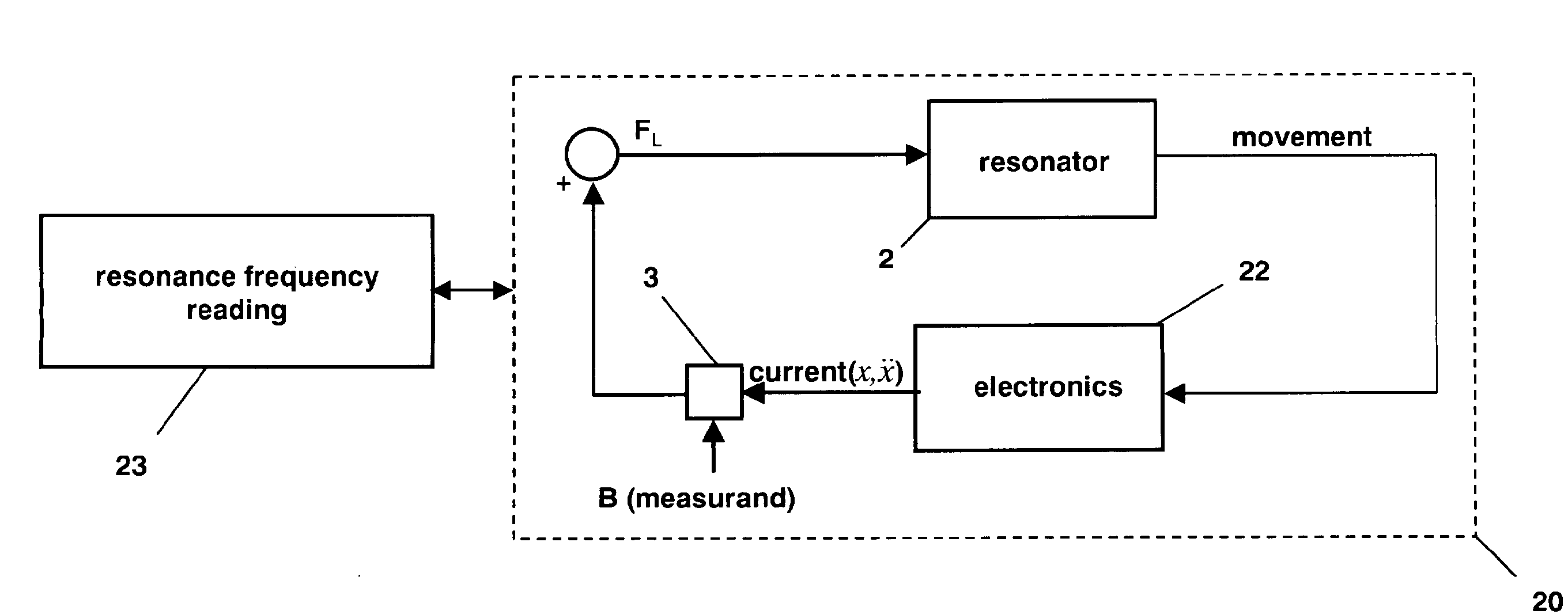

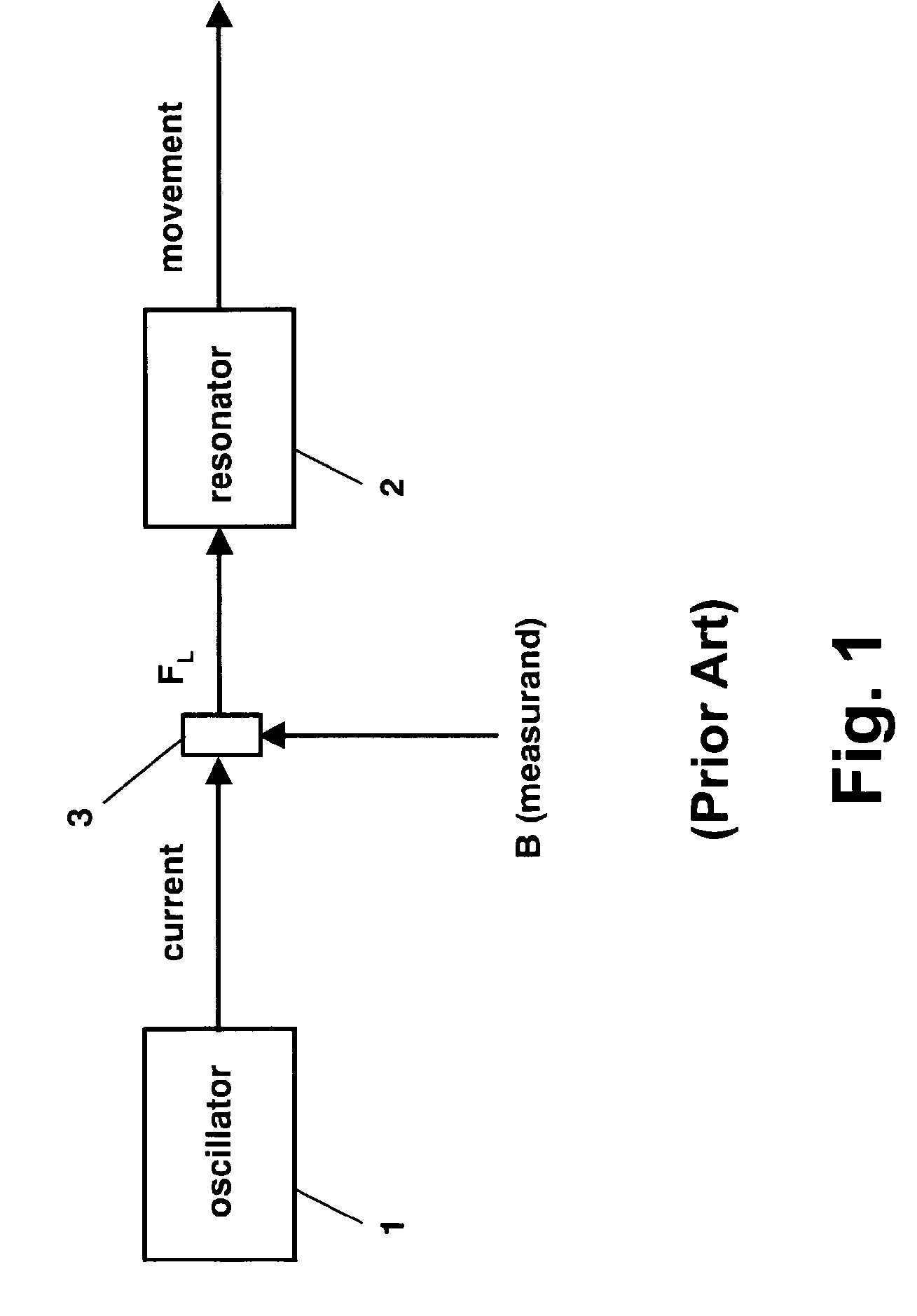

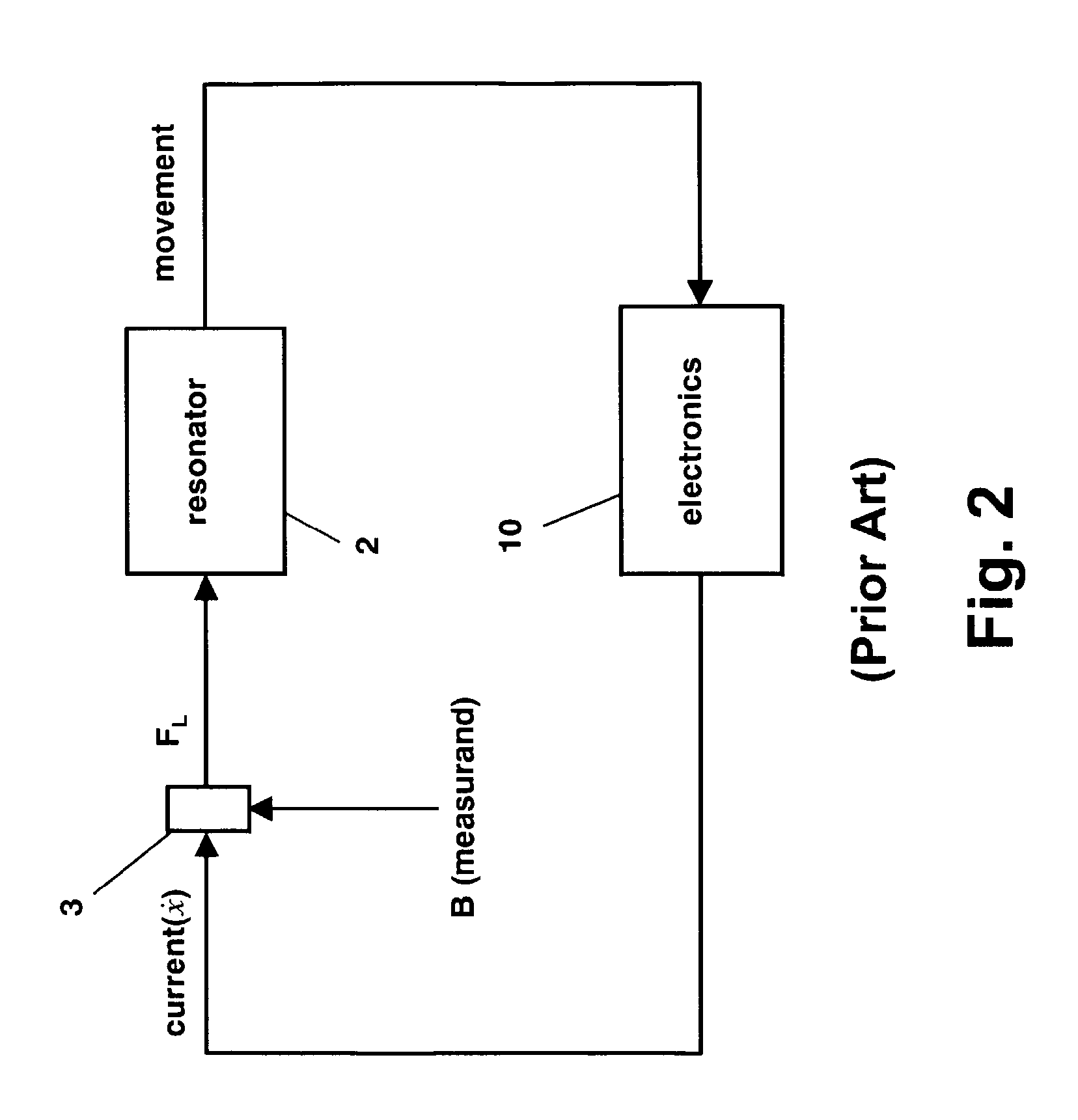

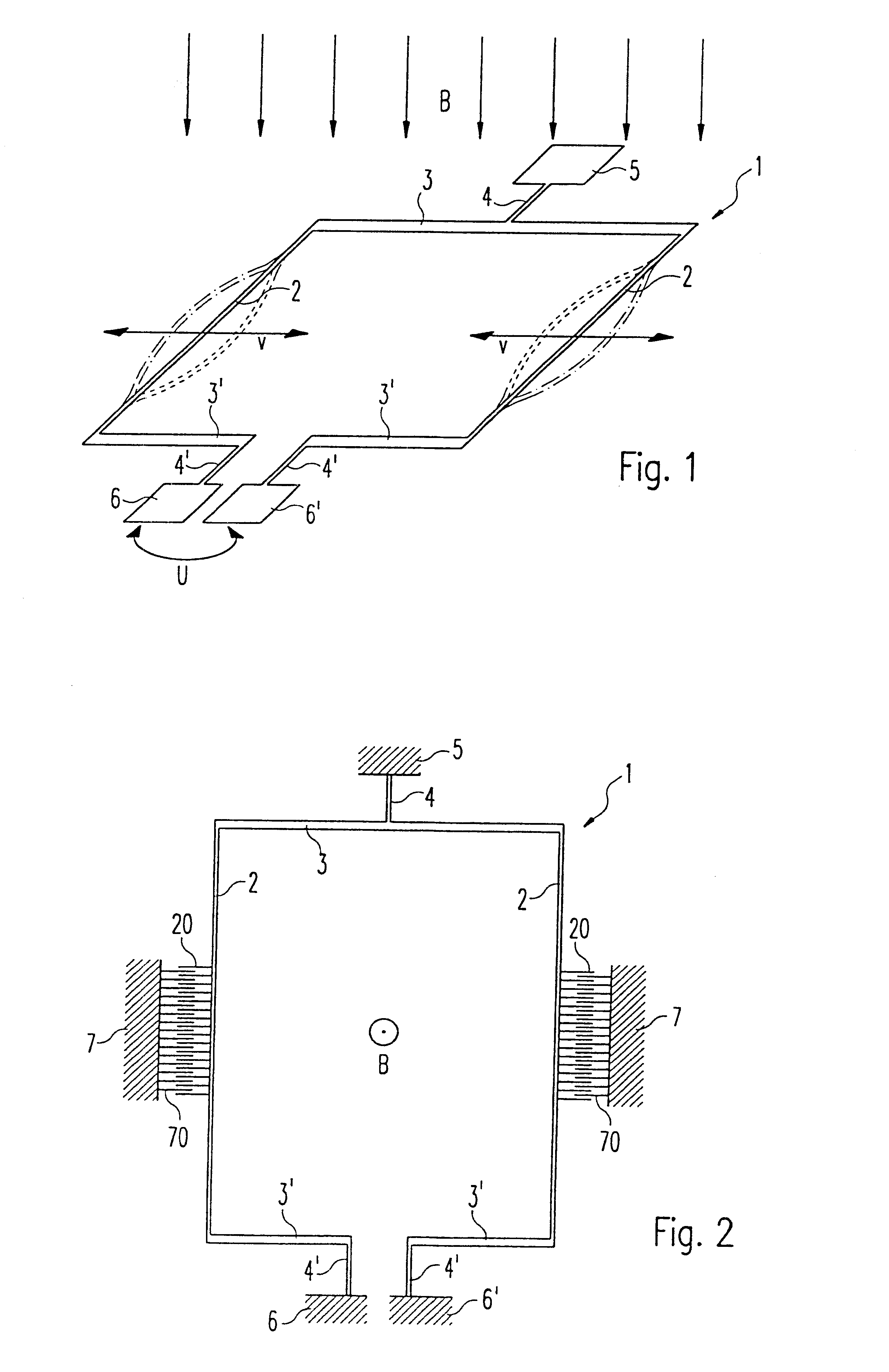

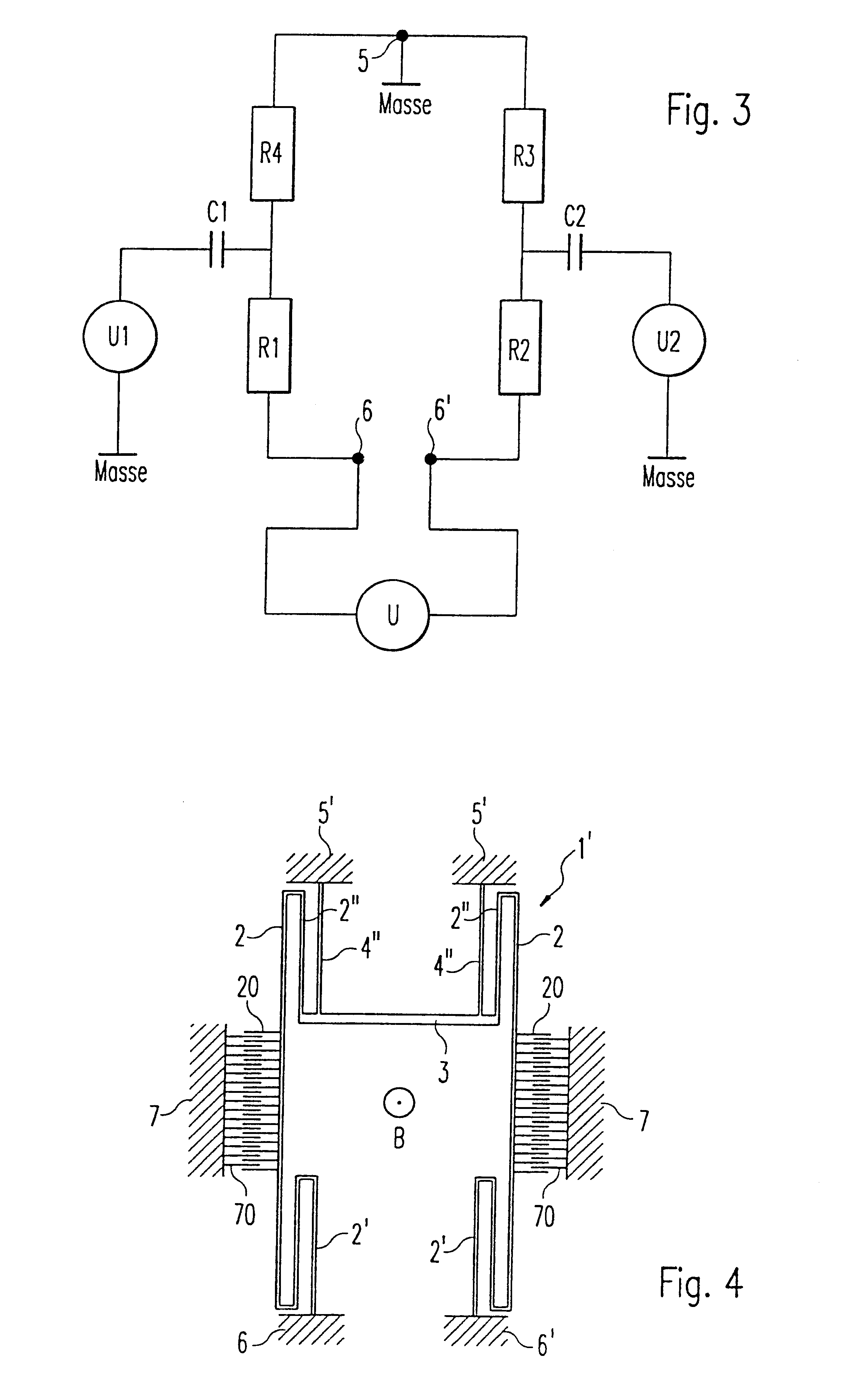

Resonator-based magnetic field sensor

The resonator-based magnetic field sensor system has an oscillatory member as resonator, means for driving an electrical current through said resonator such that its resonance frequency is altered by an external magnetic field to be measured (measurand), and means for detecting or measuring said altered resonance frequency. A secondary excitation of the resonator is effected to determine the said altered resonance frequency from which the measurand can be deduced. In the preferred embodiment, the secondary excitation is included in a closed loop, thus creating an oscillator vibrating at the altered resonance frequency. Though it is known to use the oscillation amplitude of a suitable resonator for this purpose, the novel sensor system identifies and / or measures the frequency (not the amplitude) of the oscillation, which is a function of the magnetic field to be measured.

Owner:SENSIRION AG

Current sensor

InactiveCN1379860AElectrodynamic magnetometersVoltage/current isolationElectrical conductorCurrent sensor

A fiscal electricity meter is described for measuring the energy supplied to a load. The load current flows through the primary winding of a transformer and induces an EMF indicative of the current flowing in the secondary winding. The secondary winding comprises a sense coil, arranged to couple more strongly to the primary, and a cancellation coil which have equal and opposite turns area products so as to provide a null response to extraneous magnetic fields. The coils are arranged so that their magnetic axis are co-located and aligned together so that they also provide a null response to extraneous magnetic fields having a field gradient.

Owner:SENTEC SA

Micro-mechanical magnetic field sensor and preparation method thereof

ActiveCN102680917AHigh strengthReduce power consumptionDecorative surface effectsSolid-state devicesMEMS magnetic field sensorElectromotive force

The invention provides a micro-mechanical magnetic field sensor and a preparation method thereof and belongs to the field of micro-electro-mechanical systems. The method comprises the following steps of: manufacturing metal coils and a pad on a device structure layer; manufacturing a device structure by dry etching; and releasing the device structure to form a harmonic oscillator. The harmonic oscillator of the micro-mechanical magnetic field sensor provided by the invention operates in an extension mode, so induced electromotive force which is generated by each section of metal cutting magnetic induction line on each metal coil can be superposed, and the intensity of an output signal is improved. Moreover, the micro-mechanical magnetic field sensor has the advantages of low power consumption, simple driving / detection circuit, simple process, high industrial value and the like and is slightly influenced by temperature.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

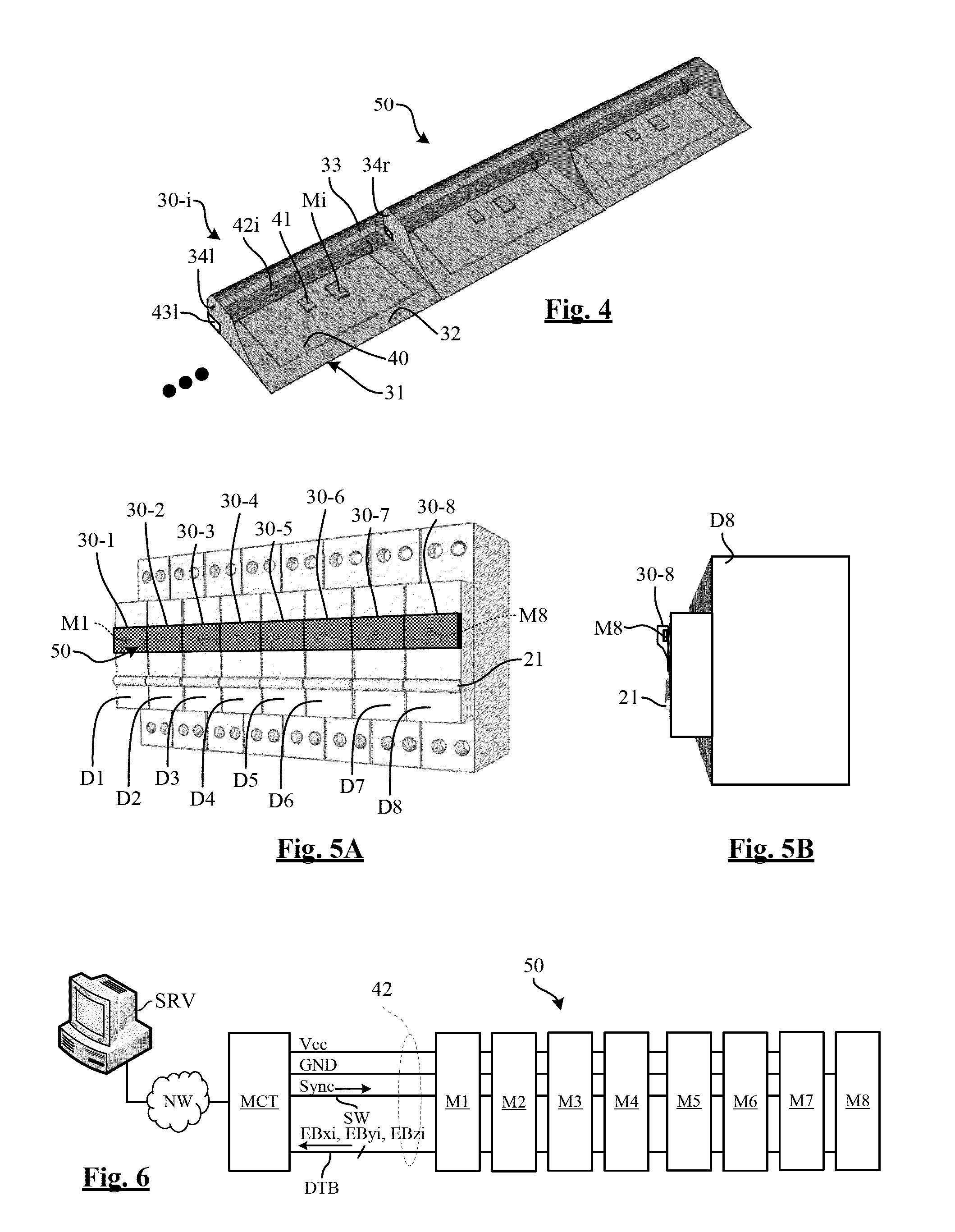

Method for measuring current in an electric network

ActiveUS20130229173A1Inhibition effectMagnetic field offset compensationElectrodynamic magnetometersElectric lightSemiconductor chip

A method for measuring current in an electric network comprising at least one first electric line. The method includes fitting the first line with a circuit breaker having a protection coil and having a wall traversed by a magnetic field emitted by the protection coil; arranging on the wall of the circuit breaker a synchronous three-axis digital magnetometer on a semiconductor chip; by way of the digital magnetometer, measuring at least one component of a magnetic field emitted by the coil; and determining the value of a current traversing the electric line from the measured component.

Owner:SMARTFUTURE

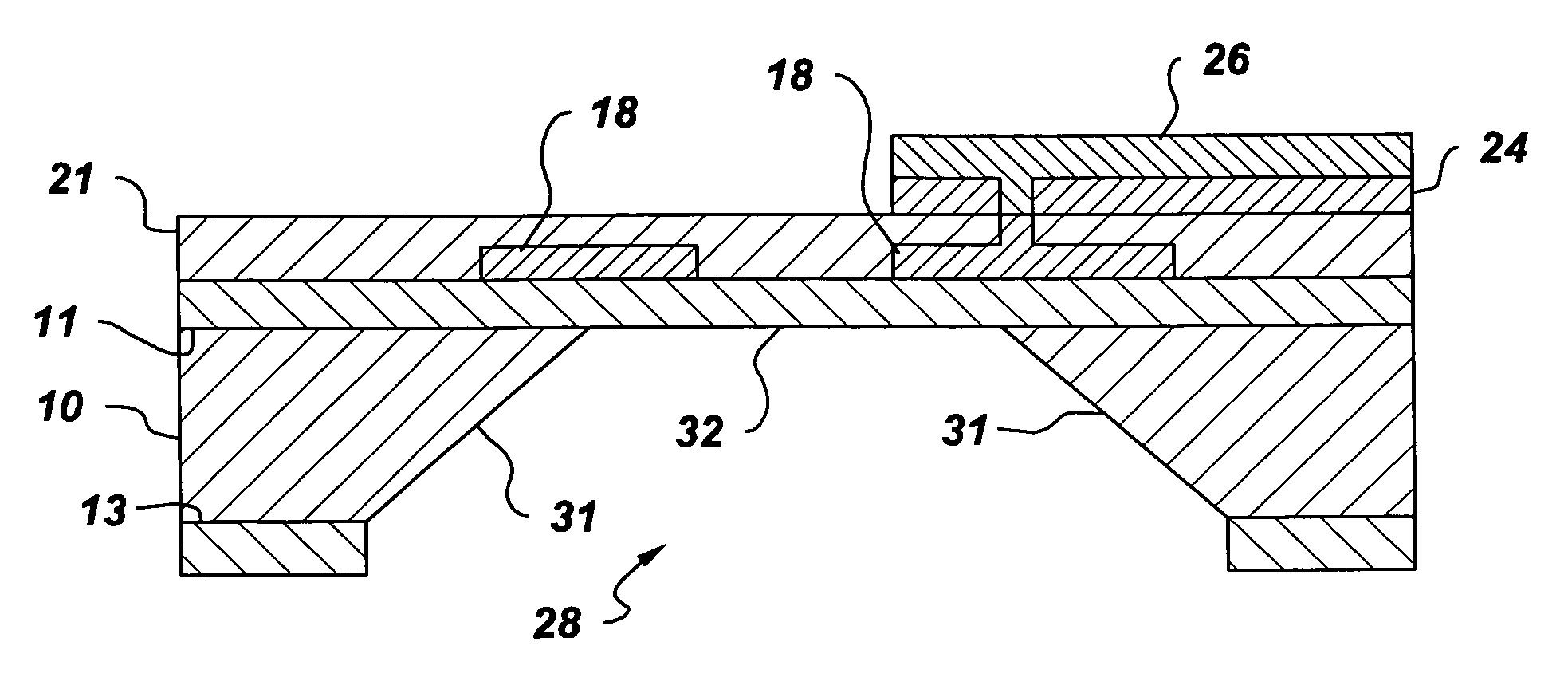

Micro-electromechanical system (MEMS) based current and magnetic field sensor having capacitive sense components

ActiveUS7315161B2Measurement using dc-ac conversionBase element modificationsCapacitanceElectrical conductor

A micro-electromechanical system (MEMS) based current & magnetic field sensor includes a MEMS-based magnetic field sensing component having a capacitive magneto-MEMS component, a compensator and an output component for sensing magnetic fields and for providing, in response thereto, an indication of the current present in a respective conductor to be measured. In one embodiment, first and second mechanical sense components are electrically conductive and operate to sense a change in a capacitance between the mechanical sense components in response to a mechanical indicator from a magnetic-to-mechanical converter.

Owner:ABB SPA

Detecting device, detecting system, power transmitting device, noncontact power transmission system, and detecting method

ActiveCN103176217AImprove accuracyDielectric property measurementsBatteries circuit arrangementsElectricityTransport system

A detecting device includes a reading coil configured to read a magnetic flux generated by a detecting coil for detecting a magnetic field of an electromagnetic wave output from an exciting coil according to the magnetic field. The detecting device further includes a Q-value measuring section configured to measure a Q-value of the detecting coil on a basis of a temporal transition of oscillation of a voltage obtained in the reading coil according to the magnetic flux generated by the detecting coil.

Owner:SONY CORP

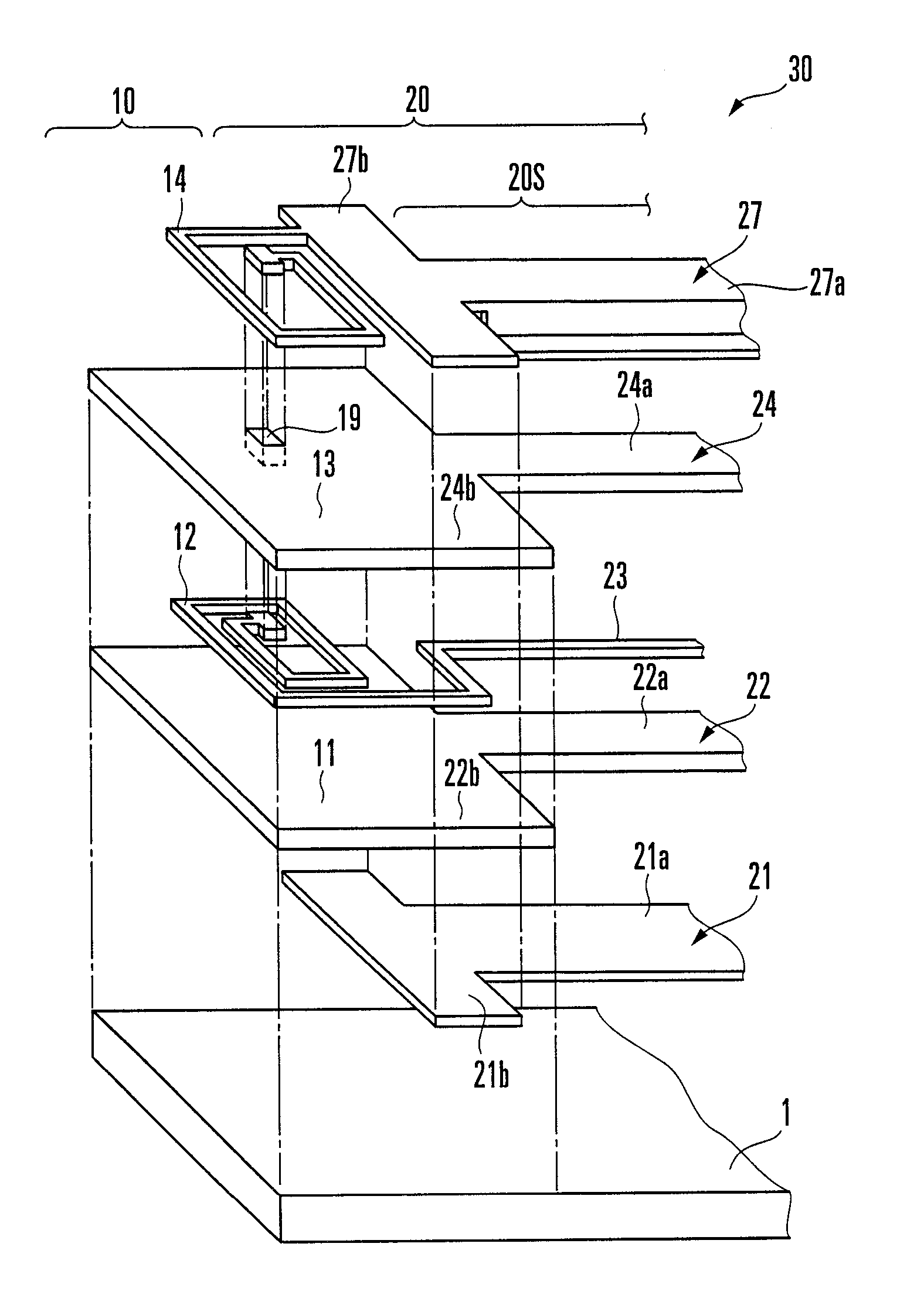

Magnetic Field Sensor

InactiveUS20070216408A1Simple designLarge electromotive forceElectrically conductive connectionsElectrodynamic magnetometersContact formationElectrical conductor

Two coil forming elements (12, 14) formed of conductor layers and a contact means (19), which is formed in an interlayer dielectric film (13) interposed between the conductor layers and brings the upper and lower coil forming elements into contact with each other through a via hole form a stacked coil (10). One end of the stacked coil is connected to an upper grounding layer (27) of a strip line (20), and the other end of the stacked coil is connected to a strip conductor (23) of the strip line. The number of turns of the stacked coil is larger than 1. A magnetic flux penetrating through the stacked coil increases to be able to induce a relatively large electromotive force. Thus, a high spatial resolution can be obtained easily.

Owner:NEC CORP

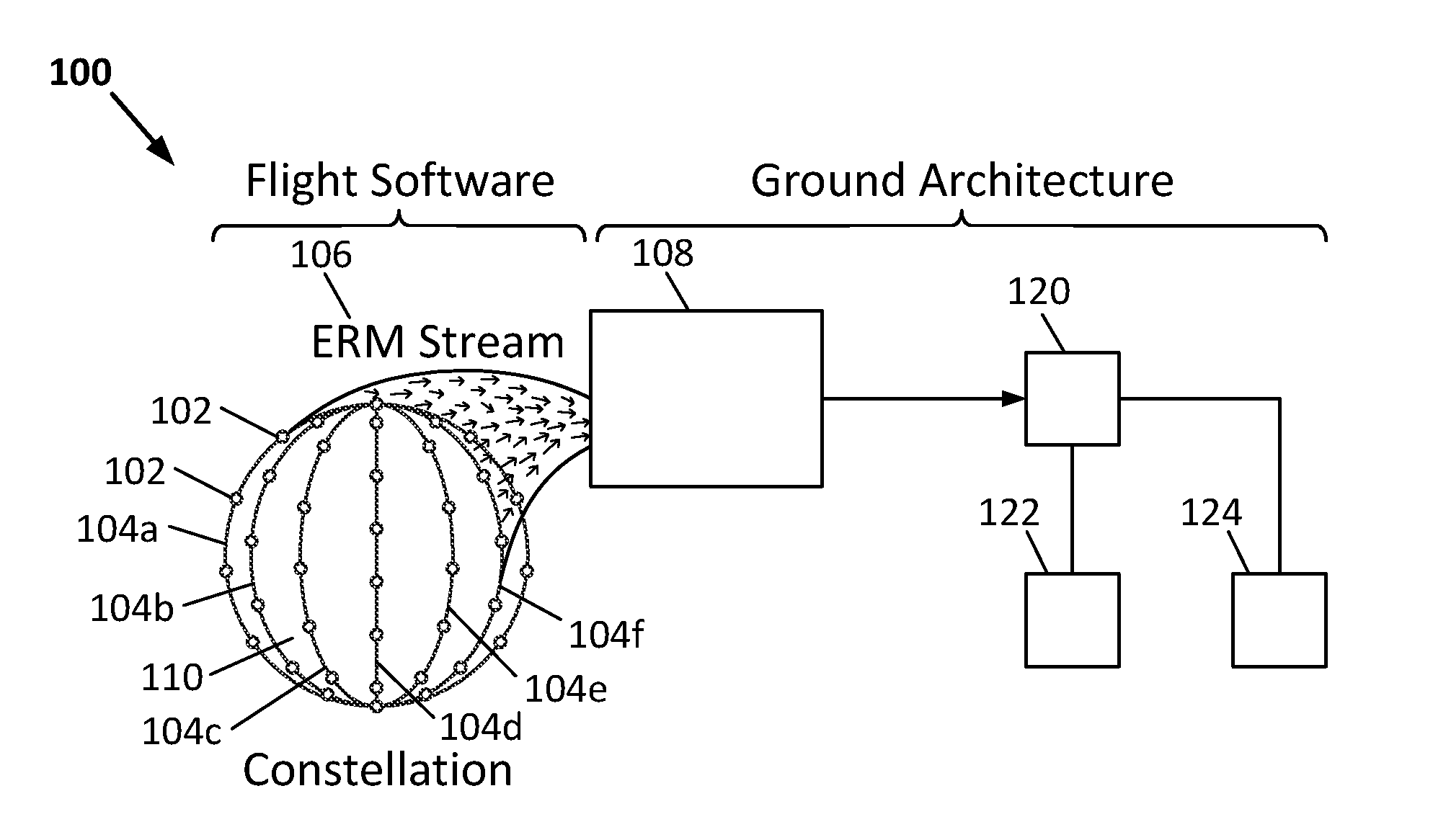

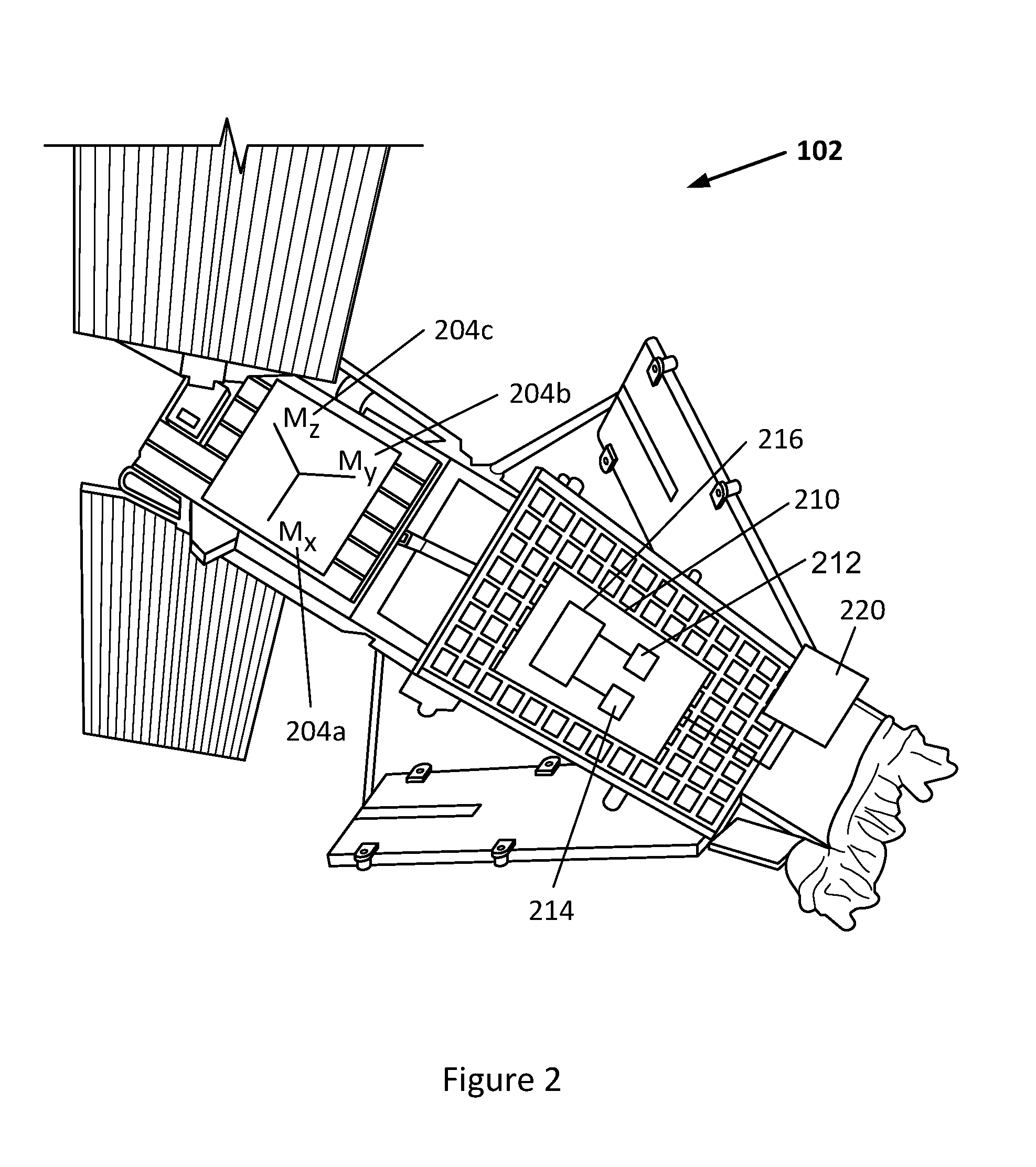

Automated Pre-Processing of Body-Mounted Magnetometer Data from Constellations of Low Earth Orbit Satellites for Derivation of Birkeland Current Signatures

A system, method and computer-readable medium for mapping magnetic activity for a current linking a planet's space environment to an ionosphere of the planet are disclosed. Magnetic field measurements of the current are obtained from a plurality of satellites orbiting the planet. A residual magnetic field is determined from the obtained magnetic field measurements. The determined residual magnetic field is arranged to create a time series for a selected location of a planet-centered coordinate system. The magnetic activity is mapped using the created time series for the selected location.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

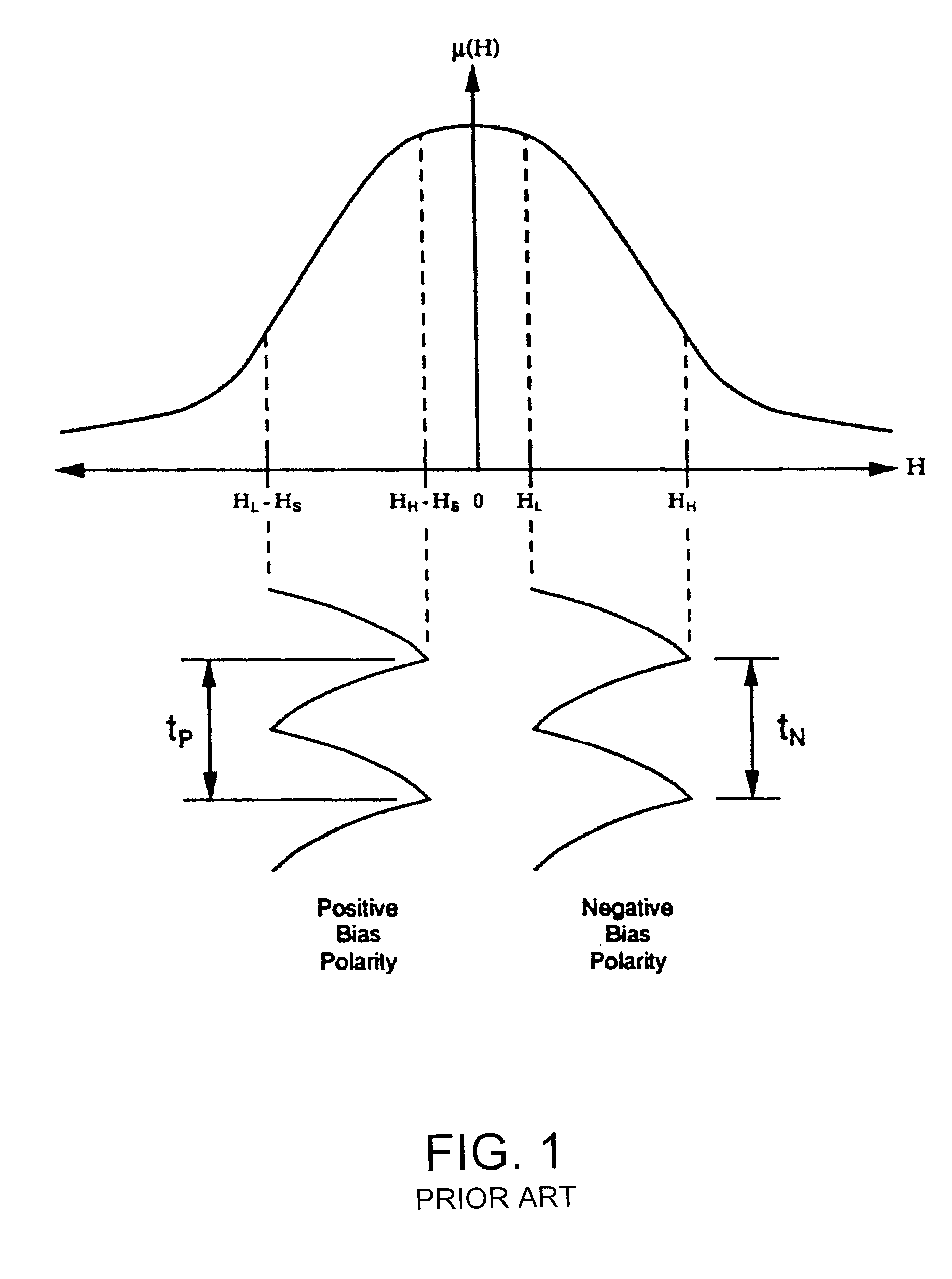

Magnetometer having a dynamically adjustable bias setting and electronic vehicle compass incorporating the same

InactiveUS7053608B2Small levelMagnetic field measurement using flux-gate principleElectrodynamic magnetometersEngineeringSignal characteristic

According to some embodiments of the present invention, a magnetometer includes at least one sensor for sensing a magnetic field component, a biasing circuit, and a processor. The sensor generates an output signal having a signal characteristic that varies in response to the sensed magnetic field component and in response to an applied bias. The biasing circuit dynamically biases the sensor in response to a bias setting signal. The processor is coupled to receive the output signal from the sensor and coupled to the biasing circuit. The processor is operable to generate the bias setting signal and thereby control the biasing circuit to dynamically bias the sensor such that the signal characteristic of the output signal is maintained in a target range. The processor determines the magnetic field component sensed by the sensor as a function of the bias setting applied to the sensor.

Owner:GENTEX CORP

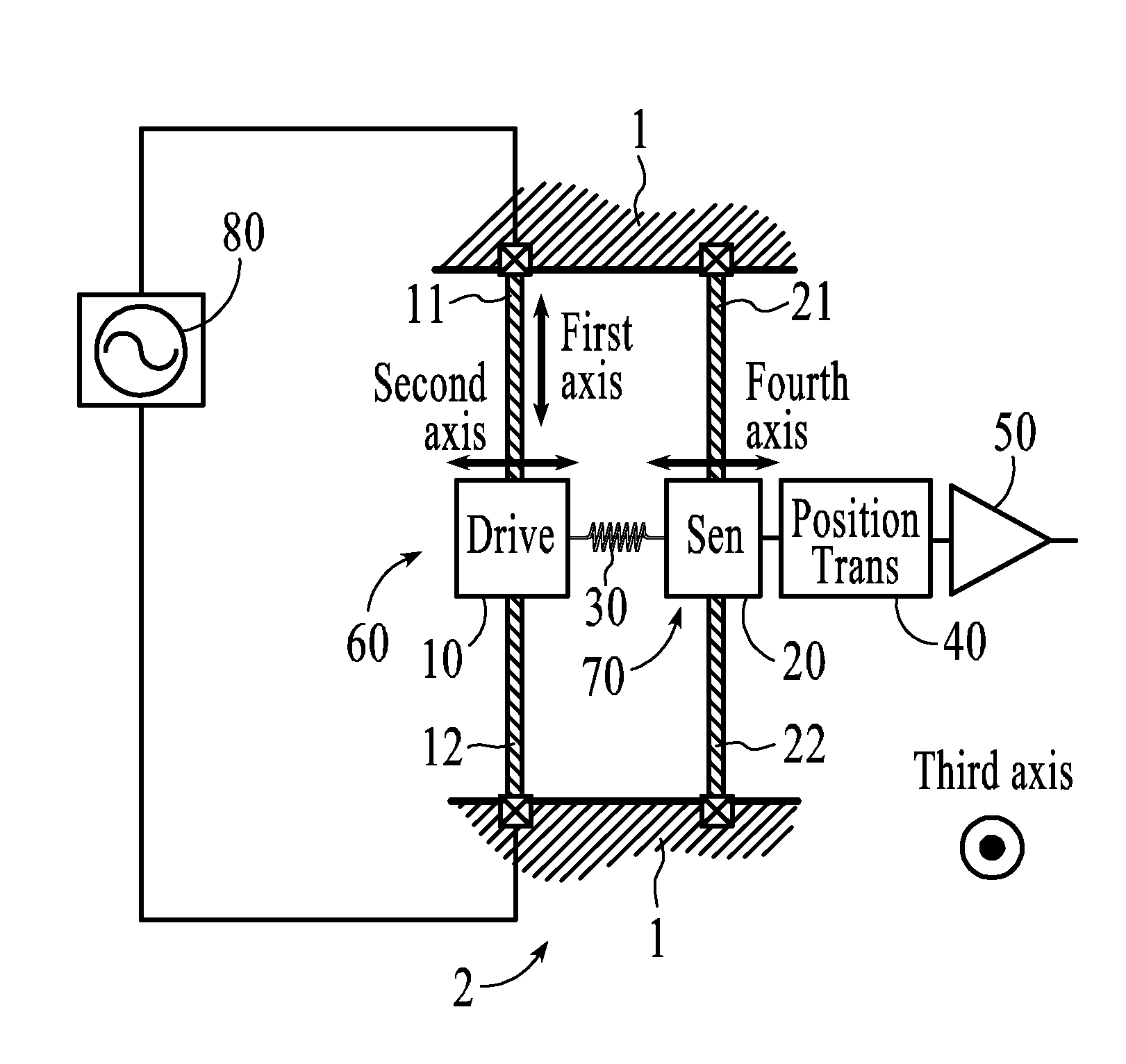

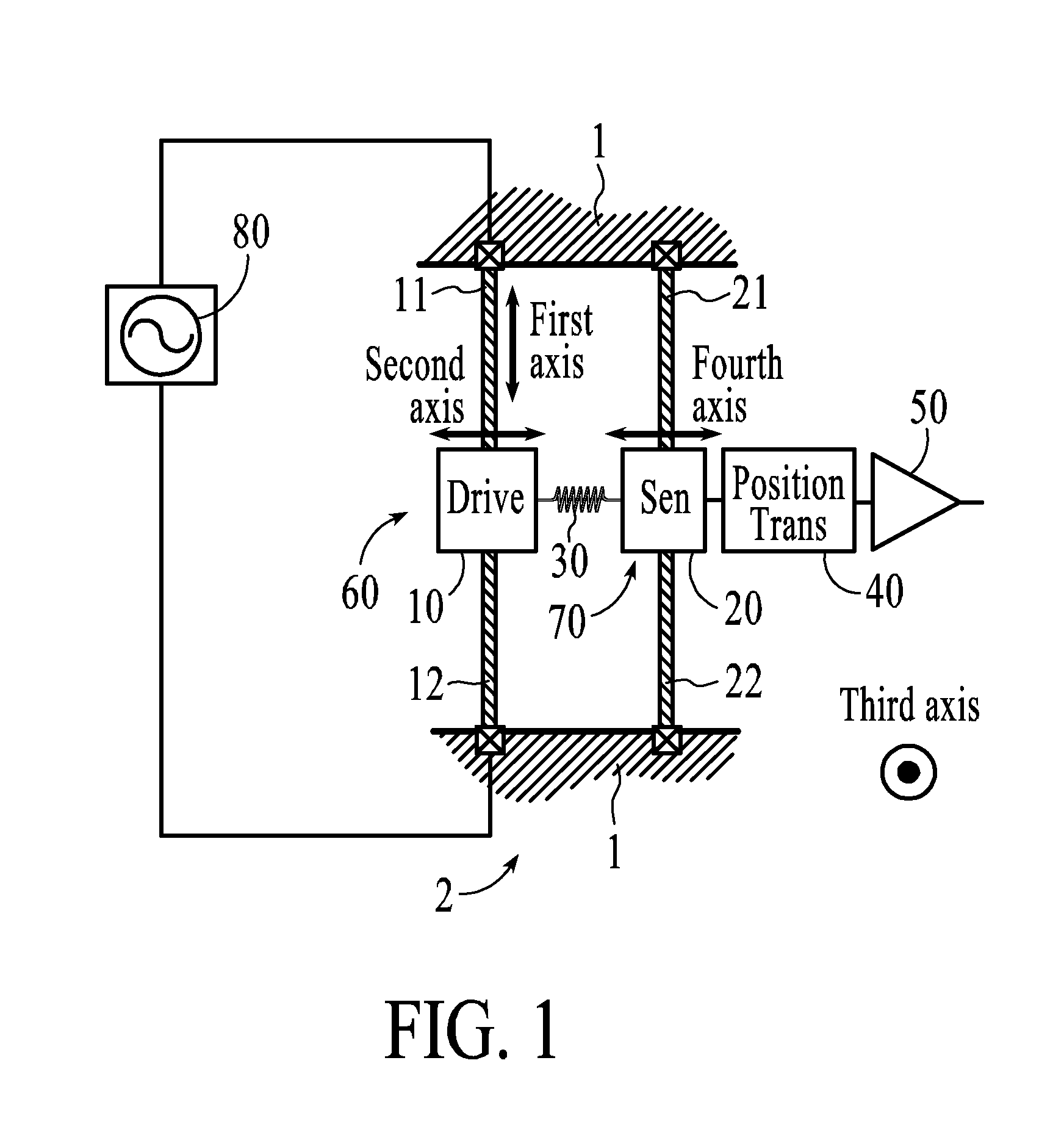

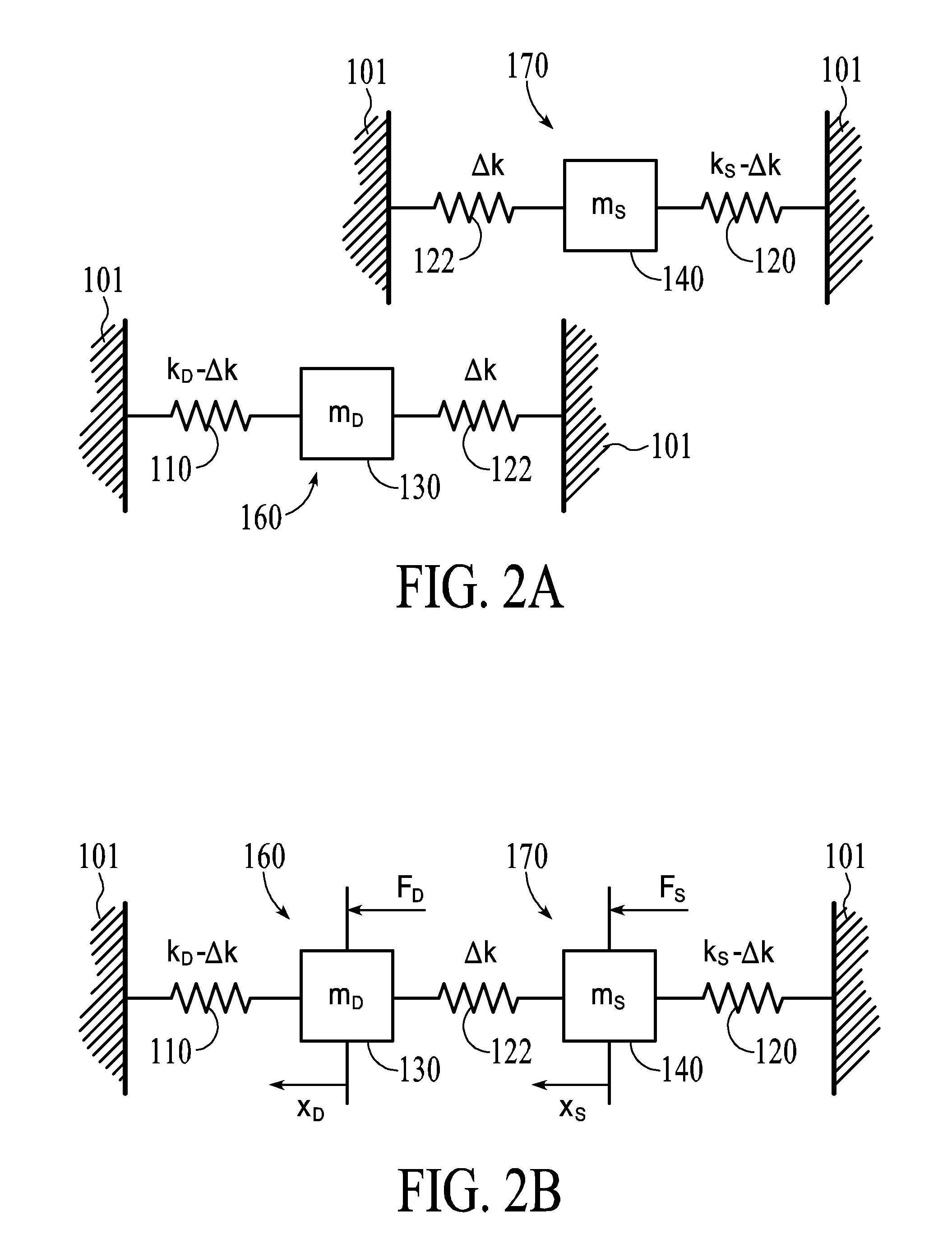

Micromachined resonant magnetic field sensors

ActiveUS20120176128A1High sensitivityLow costMagnetic field measurement using permanent magnetsElectrodynamic magnetometersPower flowCoupling

A micromachined magnetic field sensor comprising is disclosed. The micromachined magnetic field comprises a substrate; a drive subsystem, the drive subsystem comprises a plurality of beams, and at least one anchor connected to the substrate; a mechanism for providing an electrical current through the drive subsystem along a first axis; and Lorentz force acting on the drive subsystem along a second axis in response to a magnetic field along a third axis. The micromachined magnetic field sensor also includes a sense subsystem, the sense subsystem comprises a plurality of beams, and at least one anchor connected to the substrate; wherein a portion of the sense subsystem moves along a fourth axis; a coupling spring between the drive subsystem and the sense subsystem which causes motion of the sense subsystem in response to the magnetic field; and a position transducer to detect the motion of the sense subsystem.

Owner:INVENSENSE

Magnetic field sensor having deformable conductor loop segment

InactiveUS6486665B1Change areaSignificant changeMagnetic property measurementsUsing electrical meansElectrical conductorVoltage sensing

A magnetic field sensor that can be manufactured using the technology of surface micromechanics, having a conductor loop that has at least one deformable segment; a deformation device for deforming the deformable segment of the conductor loop with a predeterminable time dependence; a voltage sensing device for sensing the voltage induced at the ends of the conductor loop upon deformation in the presence of a magnetic field; and a magnetic field determining device for determining the present static and / or dynamic magnetic field in consideration of at least the time dependence of the deformation.

Owner:ROBERT BOSCH GMBH

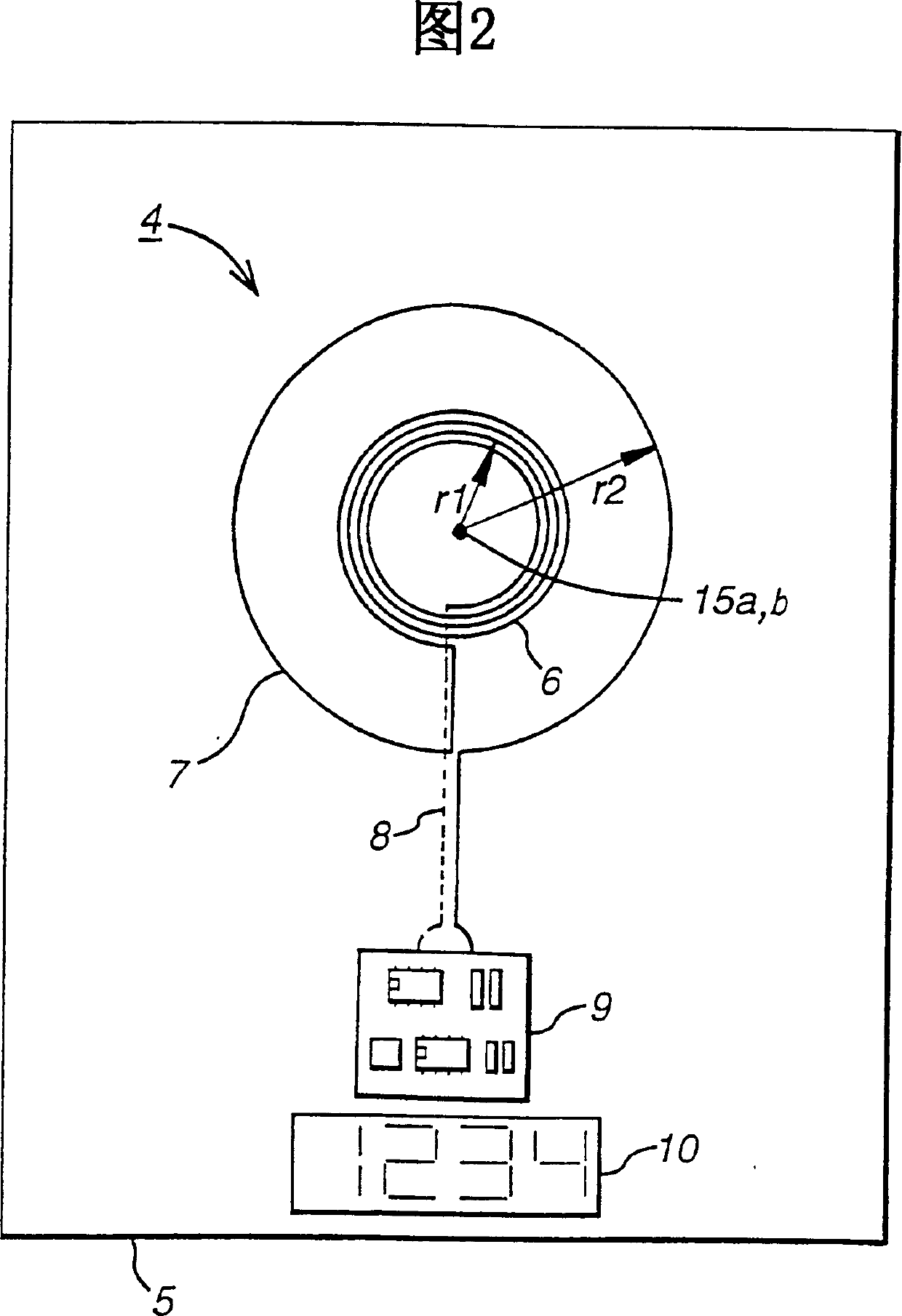

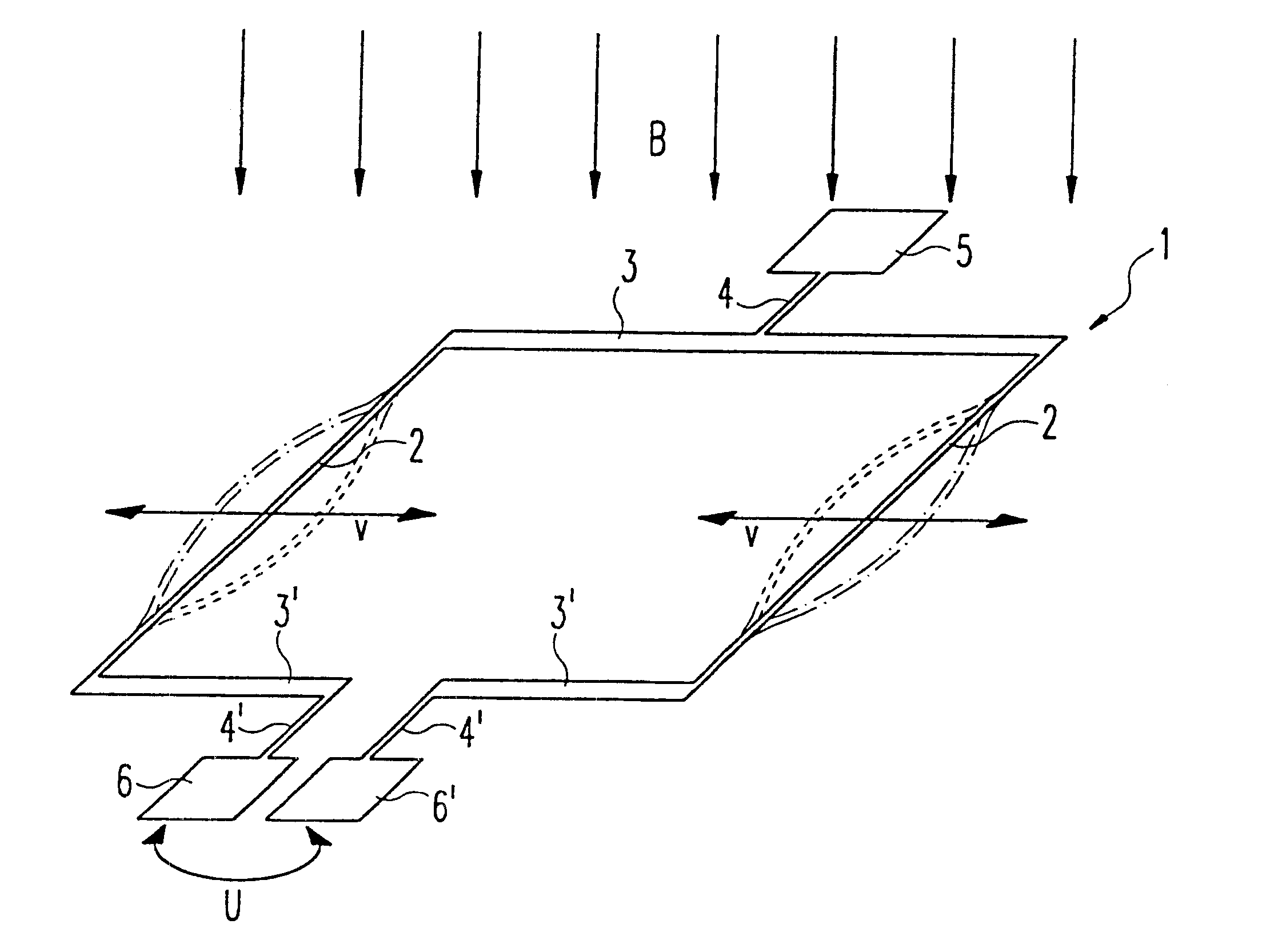

Micromechanical magnetic field sensor and application thereof

ActiveCN102914749AEliminate capacitively coupled signalsSimple magnetic field output signal detectionElectrodynamic magnetometersCapacitive couplingDifferential signaling

The invention provides a micromechanical magnetic field sensor and application thereof. The micromechanical magnetic field sensor at least comprises a resonant vibrator pair and insulating layers and metal coils, which are formed on the surface of the resonant vibrator pair in sequence. The micromechanical magnetic field sensor has the following beneficial effects: the micromechanical magnetic field sensor utilizes differential capacitor excitation and electromagnetic induction to measure the size of a magnetic field, wherein two resonant vibrator structures forming the resonant vibrator pair work in an inverse phase mode, the winding directions of the metal coils on the resonant vibrator structures are opposite, and the induced electromotive forces generated by the metal coils on the two resonant vibrator structures are connected with each other in parallel; as driving signals are differential signals, capacitive coupling signals in output signals are eliminated to obtain simple magnetic field output signals; meanwhile, the two resonant vibrator structures are coupled by a coupling structure so that the two resonant vibrator structures are connected and move as a whole; and furthermore, the micromechanical magnetic field sensor has simple structure, large output signals, high sensitivity and high detection accuracy, is slightly affected by temperature and is suitable for high working frequency.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com