Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Eliminate the effects of flatness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

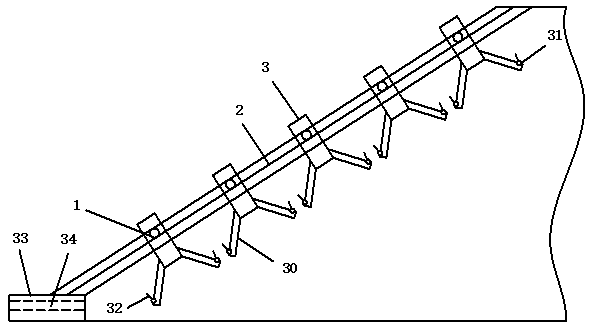

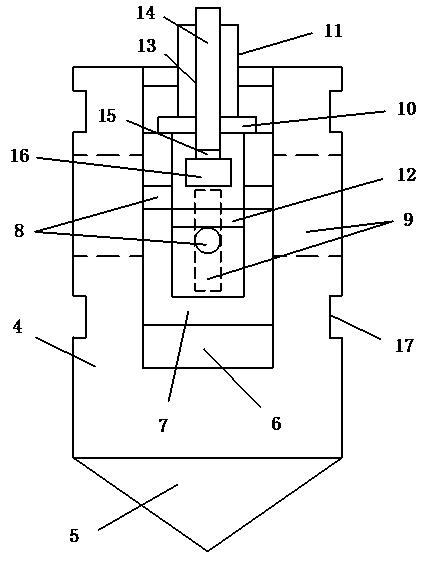

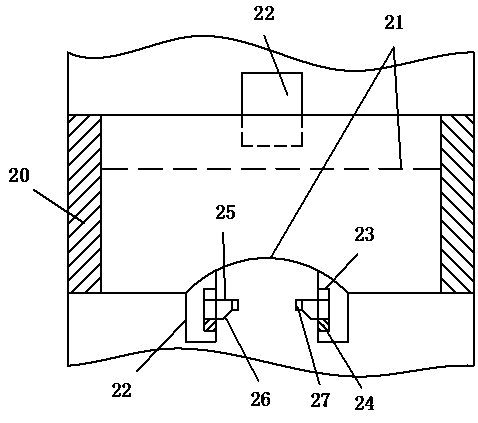

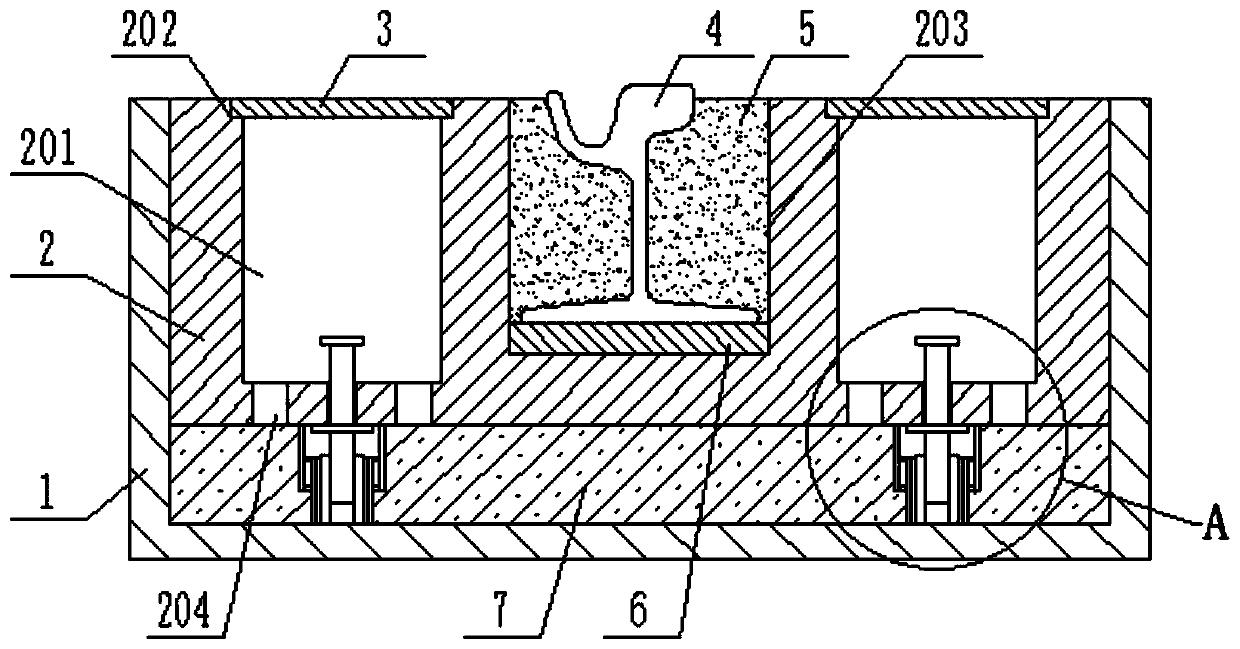

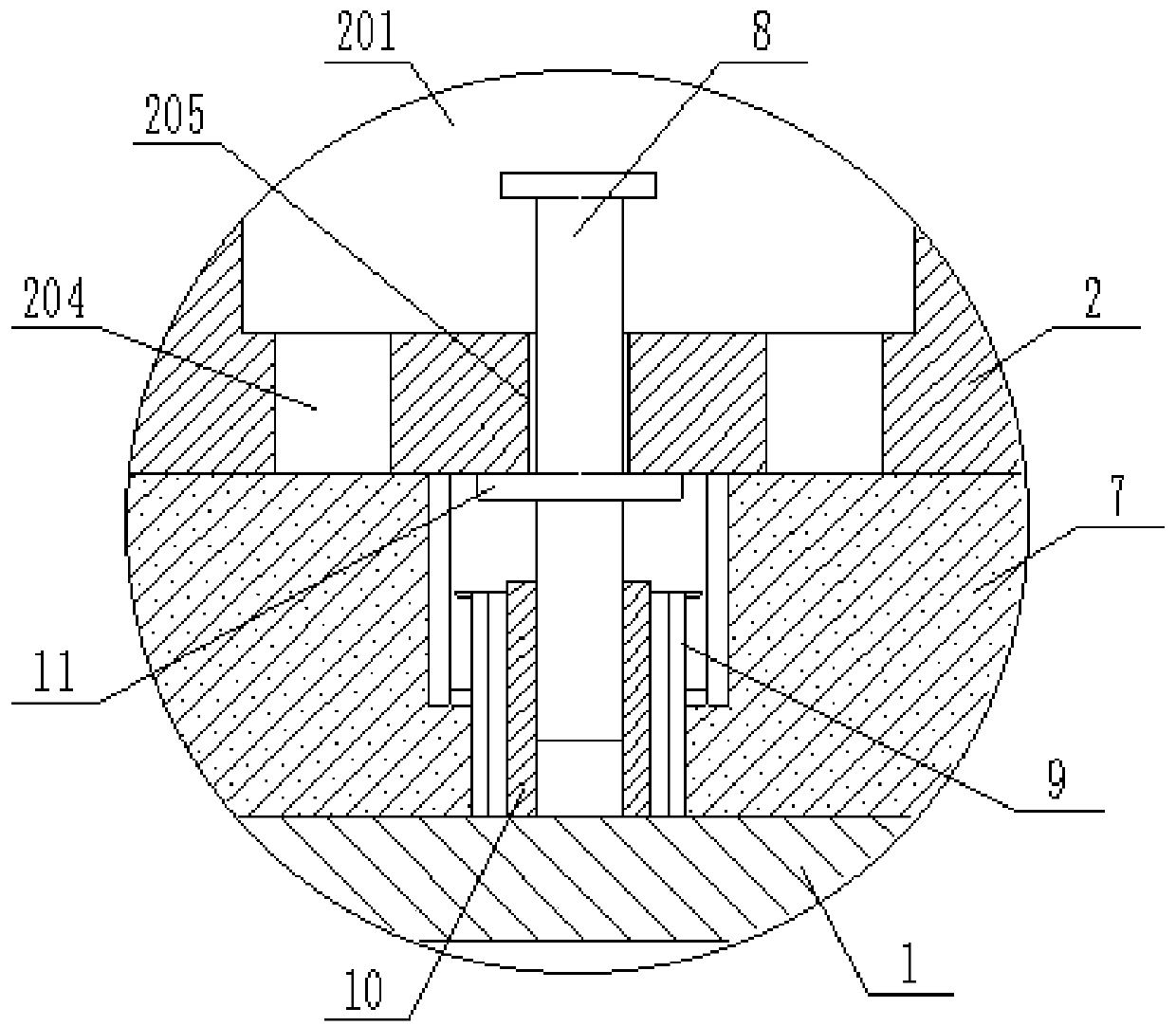

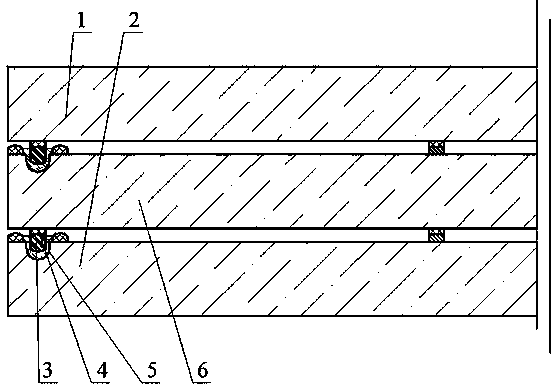

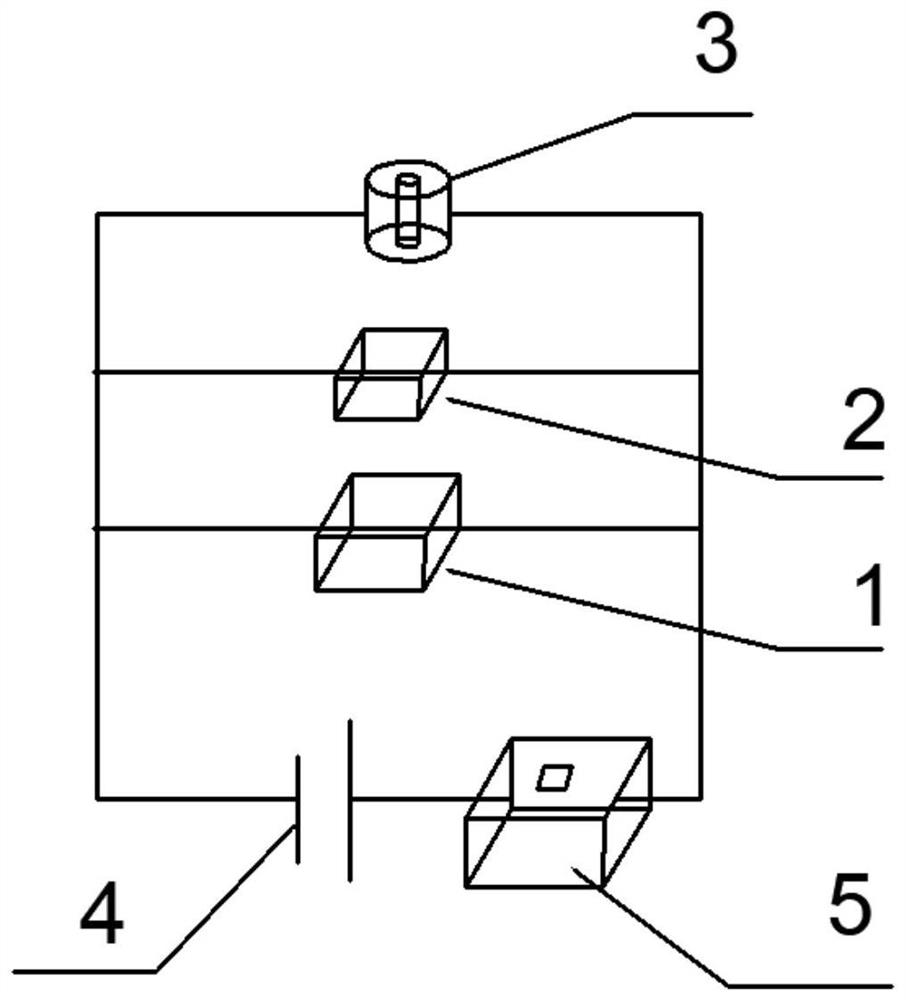

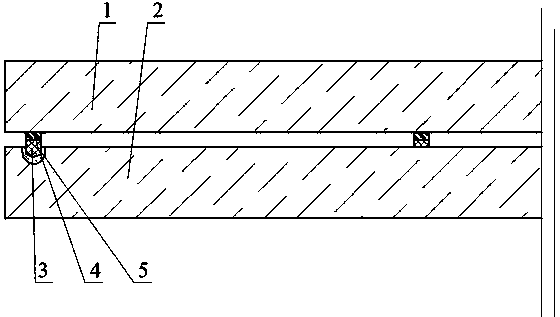

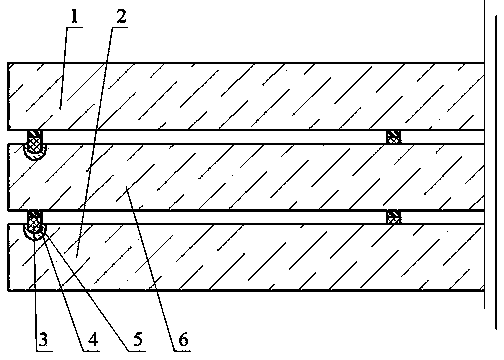

Supporting device of high-water-content side slope and construction method of supporting device

ActiveCN109056756AReduce misalignmentRealize all-round clamping and fixingExcavationsBulkheads/pilesEcological environmentHigh water content

The invention discloses a supporting device of a high-water-content side slope. The supporting device comprises multiple transverse steel bars and longitudinal steel bars which are arranged in a net shape. Anchor columns are arranged at the lap-joint positions of the transverse steel bars and the longitudinal steel bars. Each anchor column comprises a column body. An anchor head is fixed to the bottom of each column body. A blind hole is formed in each column body. An inner sleeve is movably connected in each blind hole in an inserted manner. Two perpendicular through holes are formed in eachinner sleeve. Two through grooves cooperating with the corresponding through holes are arranged on the surface of each column body. A cushion block is arranged in each inner sleeve. The top of each inner sleeve is in shaft joint with a first adjusting rod through a first bearing. A through threaded hole is formed in each first adjusting rod and the corresponding inner sleeve. A second adjusting rod is in threaded connection in each threaded hole. The bottom of each second adjusting rod is in shaft joint with a press block through a second bearing. The press blocks are in pressure joint to thetransverse steel bars. A protection net is connected between the transverse steel bars and the longitudinal steel bars in a hanging manner. According to the supporting device, the defects in the priorart can be overcome, the protection effect to the side slope is improved, water and soil losses of the side slope are reduced, and the ecological environment is protected.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

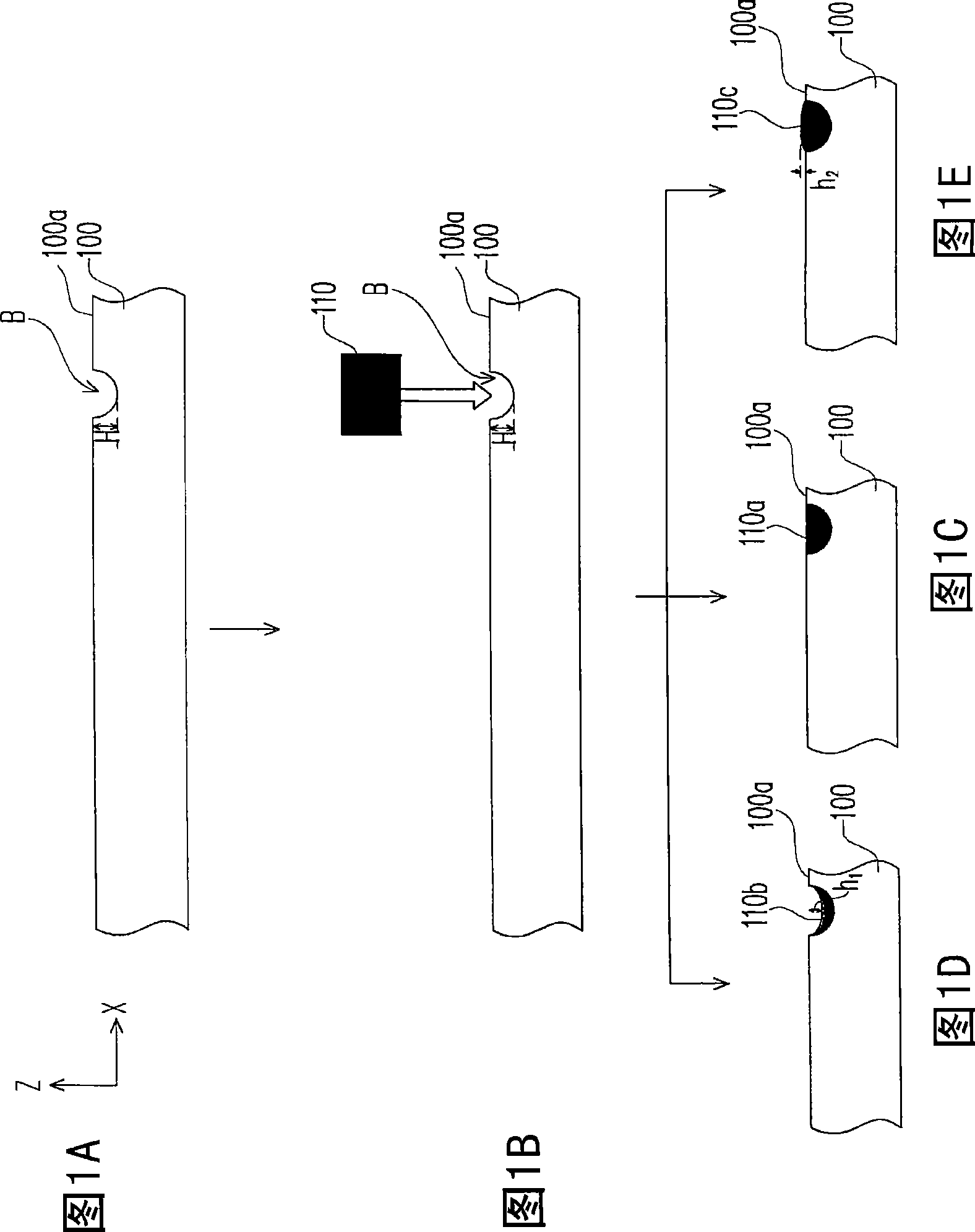

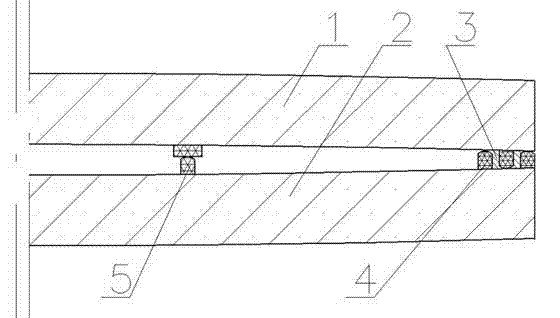

Mending method and production method of colorful filtering substrate

ActiveCN101477257AImprove production pass rateEliminate the effects of flatnessNon-linear opticsRepair materialFilling-in

The invention relates to a repairing method and a method for manufacturing a color filter substrate. The repairing method is suitable for repairing bubble defect on the surface of a glass substrate; the repairing method comprises the following steps: firstly, the sunken depth caused by the bubble defect is reckoned; and secondly, a repairing material is filled in the bubble defect so as to reduce the influence of the bubble defect on the surface planeness. The method for manufacturing the color filter substrate comprises that: the glass substrate is provided; whether the bubble defect is on the surface of the glass substrate is judged; the sunken depth caused by the bubble defect is reckoned; the repairing material is filled in the bubble defect so as to reduce the influence of the bubble defect on the surface planeness; a color filter layer is formed on the glass substrate; and a common electrode is formed on the color filter layer. The repairing method can be applied to a process of the color filter substrate so as to increase the manufacturing qualification rate of the color filter substrate.

Owner:AU OPTRONICS CORP

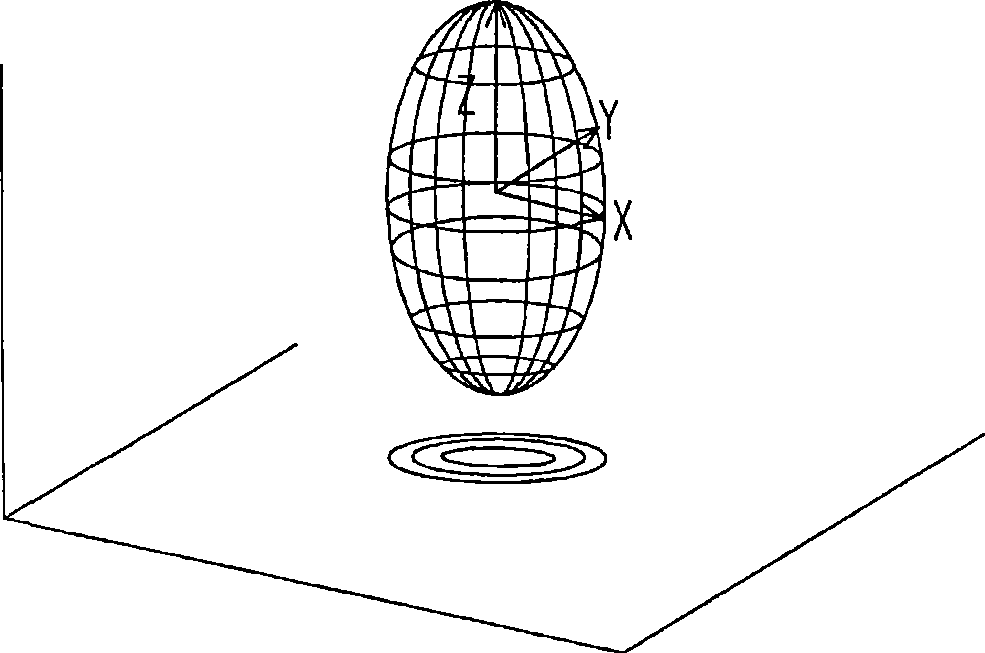

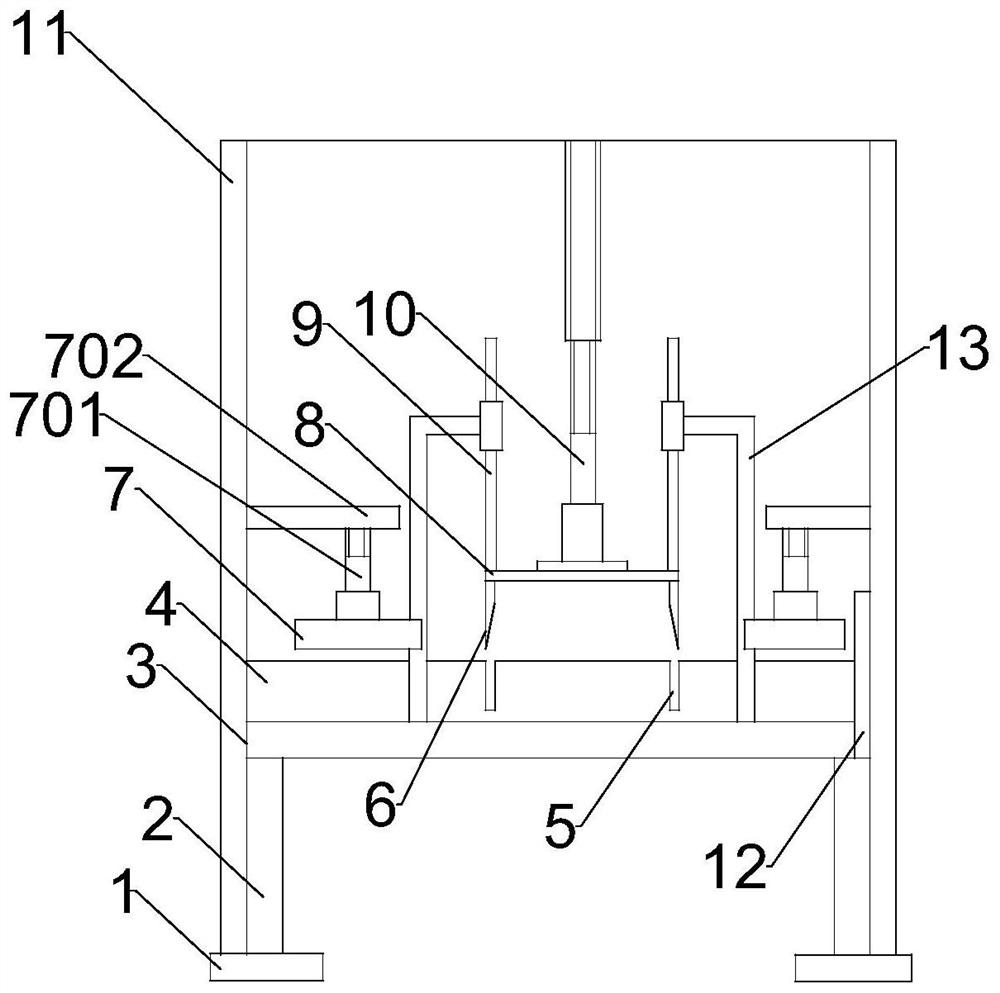

Vehicle-mounted ice surface repairing device based on dry ice refrigeration for short-track speed skating

The invention discloses a vehicle-mounted ice surface repairing device based on dry ice refrigeration for short-track speed skating. The device comprises a supporting top plate; walking side plates are fixedly connected to the left and right sides of the top of the supporting top plate; a transmission sleeve rod is fixedly connected to the left side of the top of the supporting top plate; a transmission screw rod penetrates through the transmission sleeve rod and is in threaded connection with the transmission sleeve rod; the bottom end, located below the supporting top plate, of the transmission screw rod is fixedly connected with a limiting repairing mechanism; an ice layer pretreatment mechanism is fixedly connected to the middle position of the top of the limiting repairing mechanism;a filling and leveling scraping plate is fixedly connected to the bottom of the supporting top plate and located on the back face of the walking wheel; limiting inner rails are fixedly connected to the inner sides of the back faces of the walking side plates; and ice scraping knives are slidably connected into the limiting inner rails. According to the vehicle-mounted ice surface repairing devicebased on dry ice refrigeration for short-path speed skating, which relates to the technical field of short-track speed skating ice tracks, the firmness of a repaired ice layer is improved, rapid ice surface repairing is achieved, and consumption of ice surface repairing is reduced.

Owner:杨健

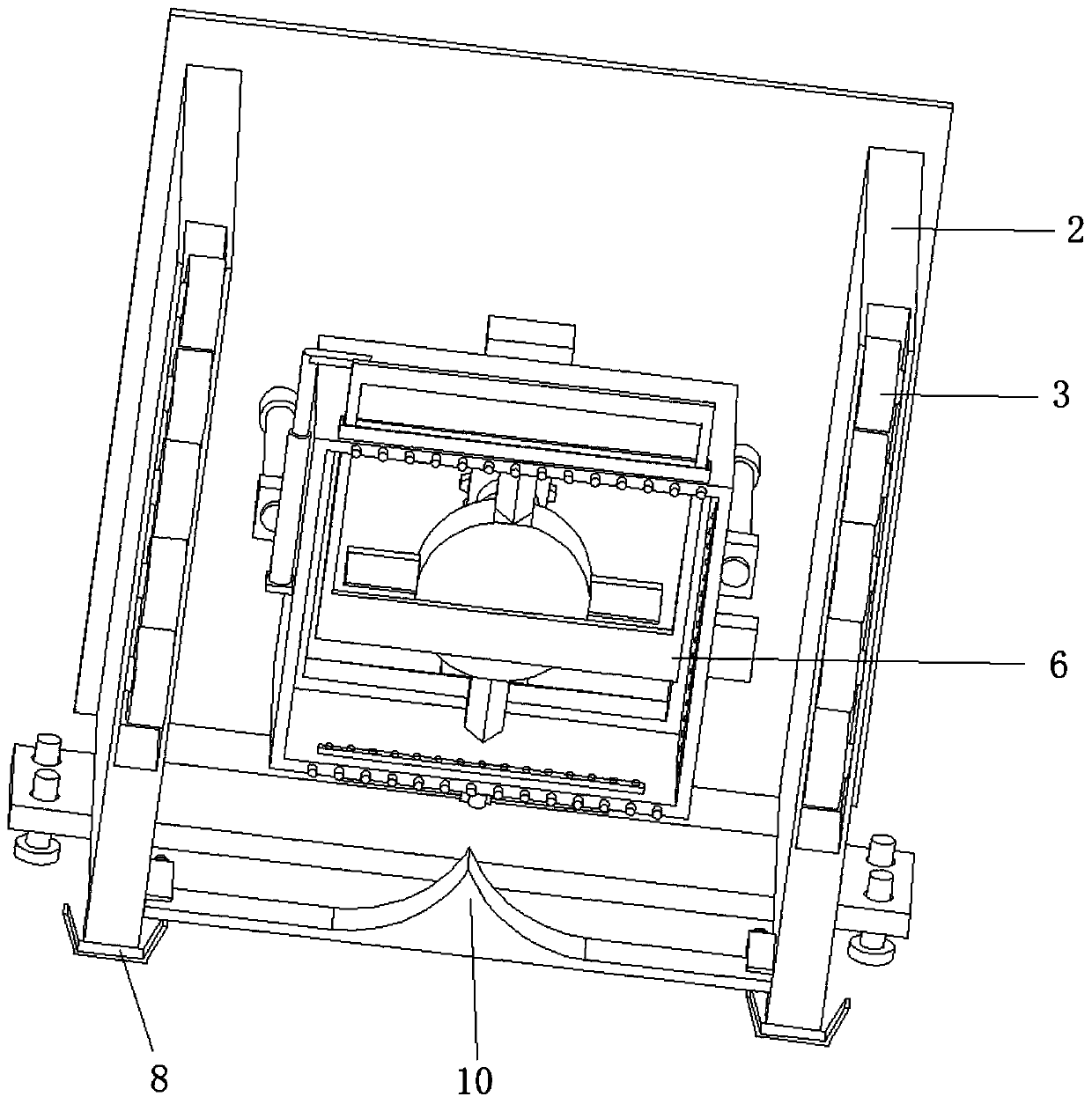

Buttress type ecological retaining wall structure

PendingCN106759472AEliminate the effects of flatnessSolve the inability to carry out greeningArtificial islandsUnderwater structuresButtressLand resources

The invention relates to a buttress type ecological retaining wall structure which comprises a buttress vertical plate. A buttress bottom plate is arranged at the lower end of the buttress vertical plate. The shore side of the buttress vertical plate and the buttress bottom plate are connected and strengthened through a buttress rib plate. An ecological building block is arranged on the water side of the buttress vertical plate and comprises a planting soil material which is tightly attached to the water side of the buttress vertical plate, and multiple building block bodies arranged above the planting soil material. The multiple building block bodies are spliced in a staggered manner, plants are planted on the multiple building block bodies, the ecological building block and the buttress vertical plate are connected through connecting ribs, and the ecological building block and the buttress vertical plate are sequentially fixed. Water and soil connecting round hole channels are transversely arranged in the buttress vertical plate so that the shore side of the buttress vertical plate can communicate with the water side of the buttress vertical plate. The buttress type ecological retaining wall structure has the functions of being convenient to construct, ecological, attractive, economical and the like and is suitable for places where geological conditions are good, land resources are relatively in shortage and other structures exist nearby and suitable for river channels with high river channel water flowing speed and high requirements for the shore anti-erosion capability for shore protection, and the application prospect is wide.

Owner:CCCC THIRD HARBOR CONSULTANTS

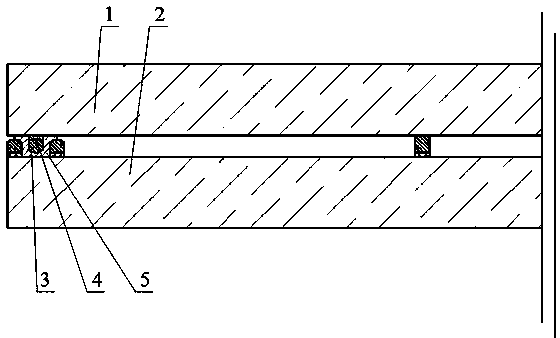

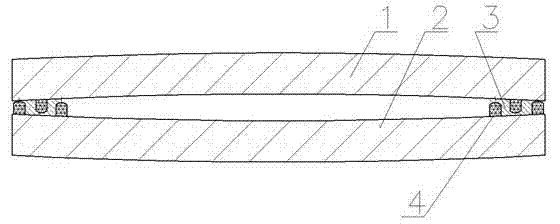

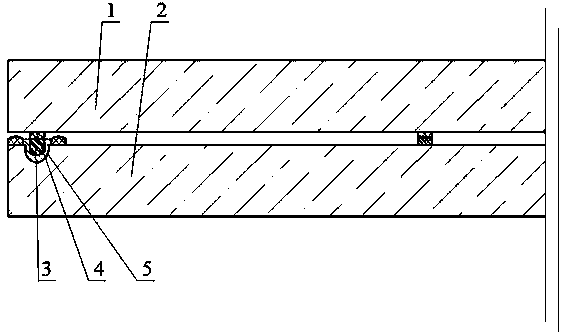

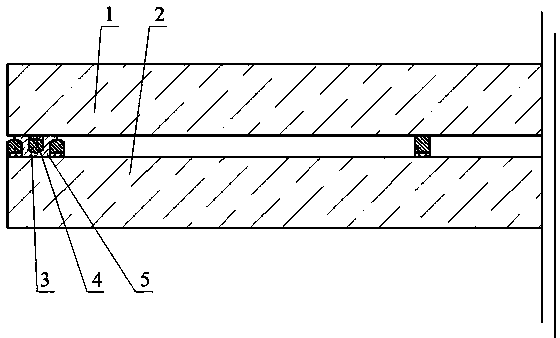

Glass-solder microwave-welded planar tempered vacuum glass edge-sealed by using bar frames

InactiveCN104291597AReduce stressReduce the breakage rate of glassGlass reforming apparatusGlass productionElastomerMicrowave

The invention relates to glass-solder microwave-welded planar tempered vacuum glass edge-sealed by using bar frames. The glass is characterized in that upper glass and lower glass are common tempered glass or plated tempered glass. Edge-sealing bar frames are provided at the peripheries of the upper glass and lower glass. The peripheries of the upper and lower glass are welded together with microwaves by using a glass solder. A sealed vacuum layer is formed between the upper glass and lower glass. One or two layers of supporters are provided in the vacuum layer. The edge-sealing bar frames and the supporters are composed of tempered glass ink and a high-polymer. The high-polymer is first prepared into a pre-polymer. When the glass is tempered, the pre-polymer is prepared on the glass or on the tempered glass ink. The pre-polymer is cured into elastomer under room temperature or high temperature. The pre-polymer or elastomer can be automatically adapt to the changes in the height of the vacuum layer. Volatile gases in the elastomer can be eliminated under high temperature and high vacuum. The method provided by the invention is suitable for mechanized and automated productions. With the method, mass productions of high-performance and low-cost tempered vacuum glass can be realized.

Owner:戴长虹

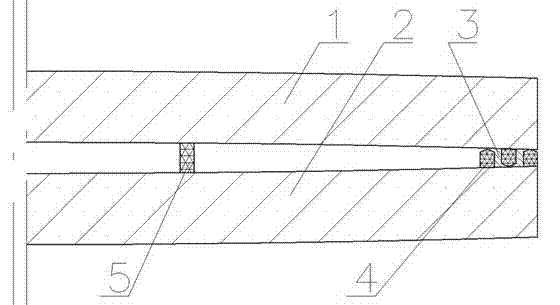

Metal solder-microwave welded and strip frame-edge-sealed convex low vacuum glass and manufacturing method thereof

InactiveCN102951818AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionMicrowave ovenMetallurgy

The invention relates to low vacuum glass. The low vacuum glass is characterized in that each of upper glass and lower glass is convex glass, edge sealing strip frames are arranged on the welded peripheries of the upper glass and the lower glass, and the upper glass and the lower glass are welded together by utilizing metal or alloy solder in a microwave oven; and the manufacturing of the low vacuum glass is simpler and more convenient, and the matching of the upper and the lower edge sealing strip frames can ensure a good sealing effect. The method has the advantages of simpleness in manufacturing process, low cost, high production efficiency, reliability in sealing and connecting and good sealing effect; the one-step large-batch preparation of the low vacuum glass can be realized by utilizing the technology, and the manufactured low vacuum glass is strong in resistance to wind pressure and good in heat insulation and sound insulation; and the method can be used for manufacturing the ordinary low vacuum glass and is particularly suitable for manufacturing tempered low vacuum glass.

Owner:戴长虹

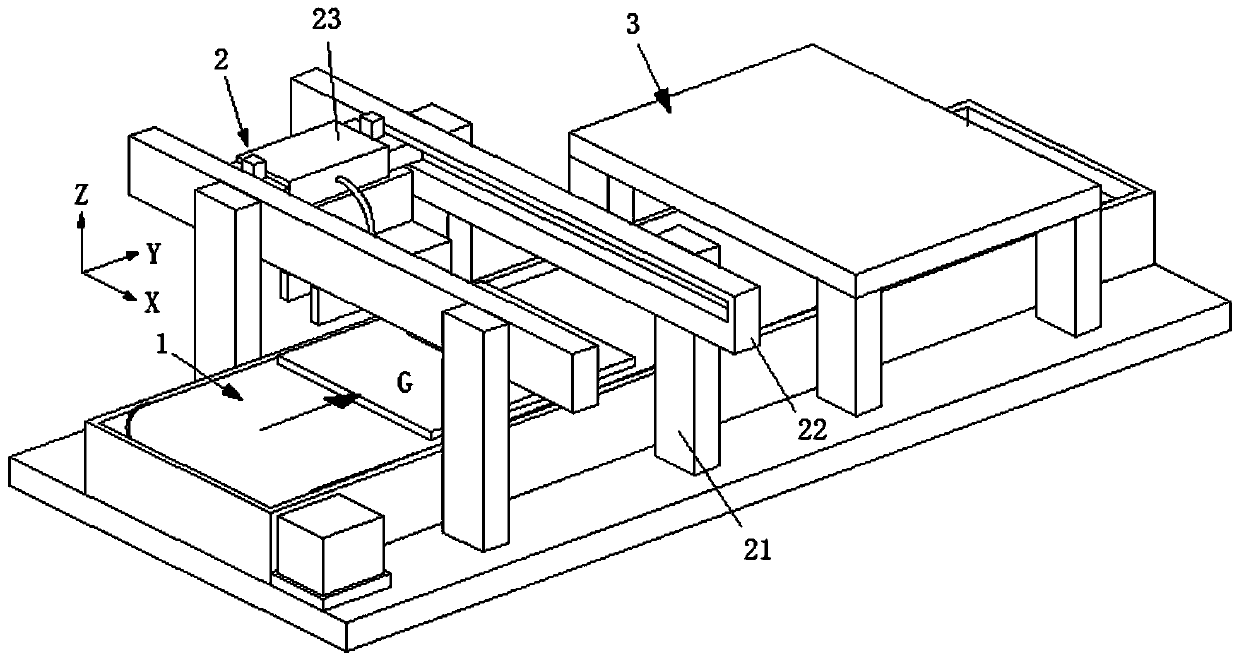

Polishing device and polishing method for improving flatness of float glass

ActiveCN110281137AImprove work efficiencyAvoid wear marksPolishing machinesGrinding feedersEngineeringConveyor belt

The invention belongs to the technical field of float glass polishing, and discloses a polishing device and a polishing method for improving the flatness of float glass. The polishing device comprises a feeding mechanism, a polishing mechanism and a flushing mechanism, wherein the feeding mechanism comprises a shell and a conveyor belt device; a cleaning chamber and an installation chamber are arranged in the shell; the conveyor belt device is fixed into the installation chamber; the top surface of the conveyor belt device is higher than the top surface of the shell; a conveyor belt in the conveyor belt device adopts a fine mesh-shaped structure; a U-shaped plate, a guiding roller group and a cleaning fluid guiding box are further arrange din the installation chamber; and a belt guiding roller group is further arranged in the cleaning chamber. According to the polishing device and the polishing method for improving the flatness of the float glass provided by the invention, the processes of automatic feeding, automatic positioning, automatic polishing, automatic cleaning and drying and the like are combined, so that the working efficiency of the whole polishing device can be greatly improved; and the guiding roller group is contained in an automatic feeding structure, so that the separation between a polishing area and a cleaning area is effectively realized, and the polishing quality is ensured.

Owner:望美实业集团有限公司

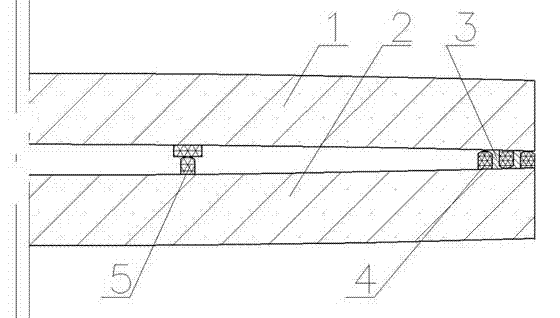

Convex low-altitude glass welded by glass solders in microwave manner and subjected to edge sealing by strip frames, and manufacturing method of glass

InactiveCN102951804AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionMicrowave ovenMetallurgy

The invention discloses low-altitude glass. The low-altitude glass is characterized in that upper glass and lower glass are convex; the peripheries of the upper and lower glass are provided with edge sealing strip frames; and the upper and lower glass are welded together by low-temperature glass solders in a microwave oven, so that the low-altitude glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the upper and lower edge sealing strip frames. A manufacturing method of the low-altitude glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing low-altitude glass in mass by virtue of a one-step method, and can be used for manufacturing not only common low-altitude glass but also tempered low-altitude glass.

Owner:戴长虹

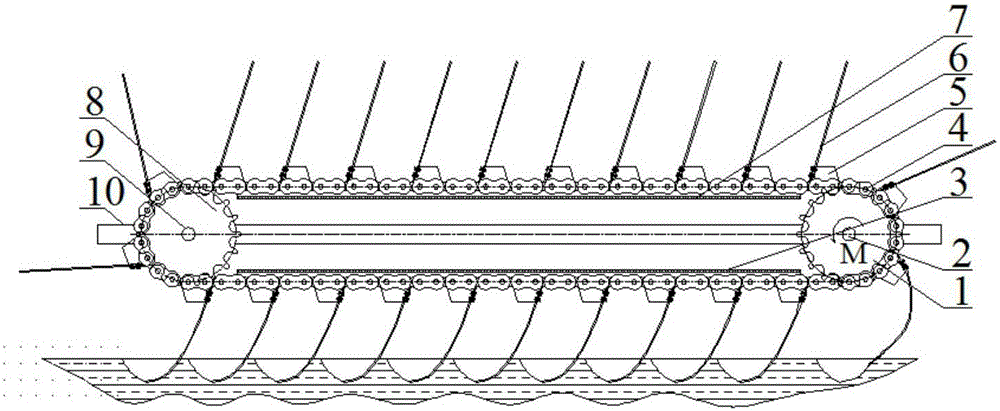

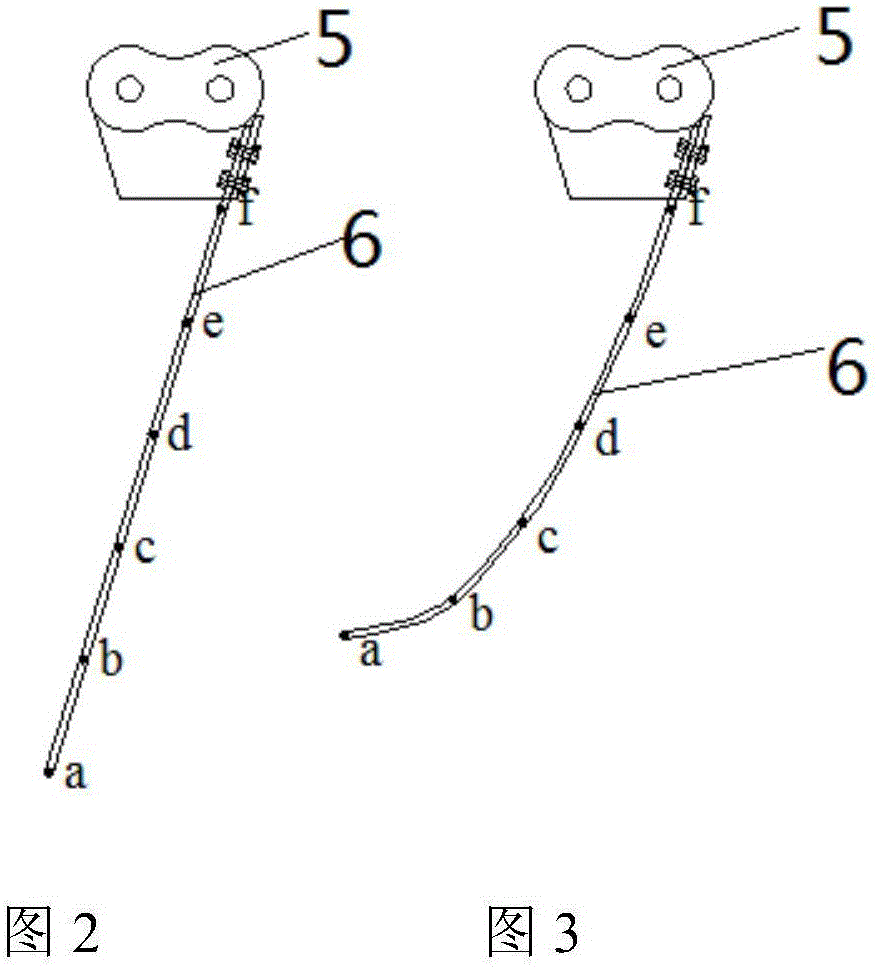

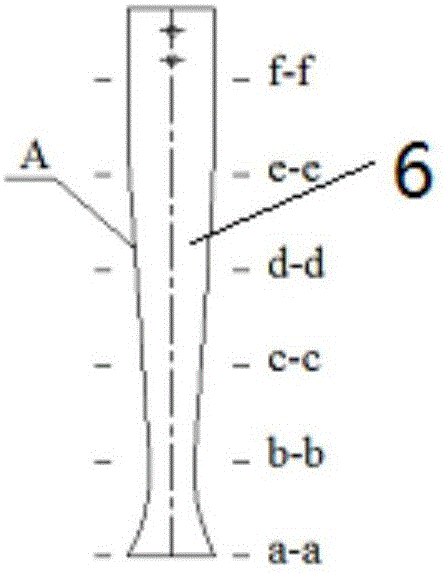

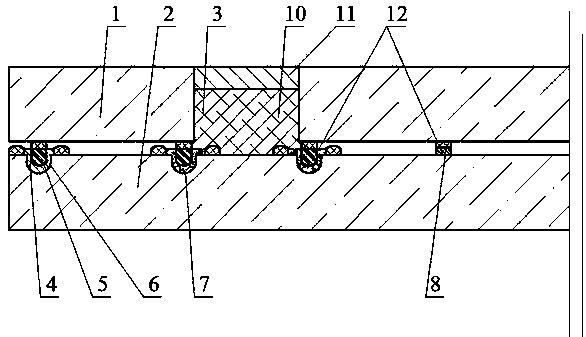

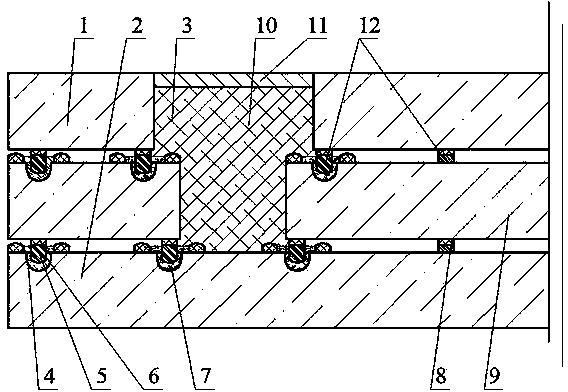

Multipoint contact elastic piece type paddy filed travelling mechanism

InactiveCN105947000AEliminate the effects of flatnessReduce subsidenceAmphibious vehiclesEndless track vehiclesDrive wheelEngineering

The invention relates to a multipoint contact elastic piece type paddy filed travelling mechanism. A driving wheel bearing and a driven wheel bearing are mounted on a rack. A driving wheel and a driven wheel are mounted on the driving wheel bearing and the driven wheel bearing correspondingly. A supporting track is chained with the rack. A chain is engaged with the driving wheel and the driven wheel. The lower half part of the chain makes contact with the supporting track. The upper half part makes contact with a chain towing track. Each elastic piece is connected with one link of the chain through a chain sheet connector, and the elastic pieces are arranged at equal intervals. The multiple elastic pieces are adopted for bearing load jointly, each elastic piece is deformed after making contact with soil and makes fully contact with the soil after being deformed, bearing capacity is distributed on all bearing points, stress on each bearing point is small, and settlement is small; and the influence on the flatness of a water field is reduced, the deformed parts, making contact with the soil, of the elastic pieces generate tangential relative speed when the elastic pieces leave the soil, and desliming is facilitated. The mechanism is simple in structure, convenient to mount, low in cost, capable of carrying various large agricultural machines to go to the water field and quite wide in application.

Owner:HUBEI UNIV OF TECH

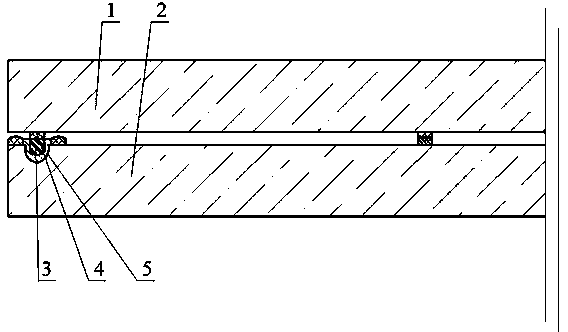

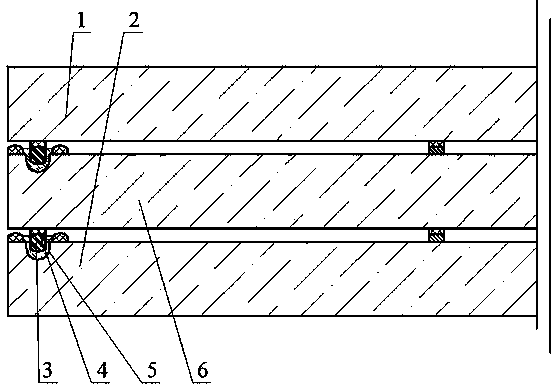

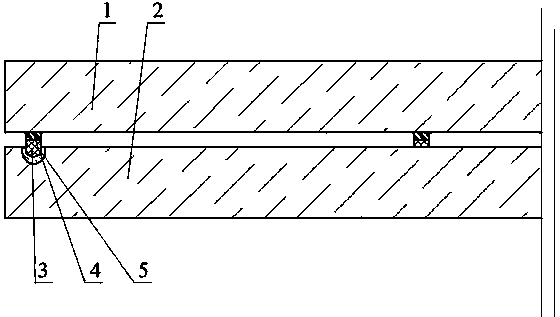

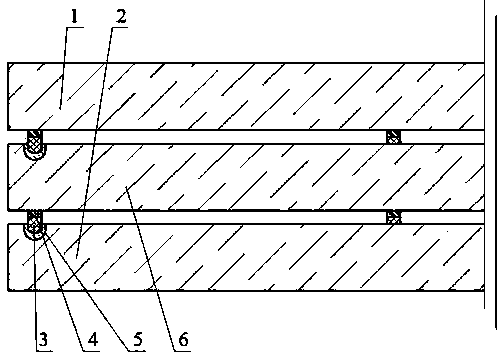

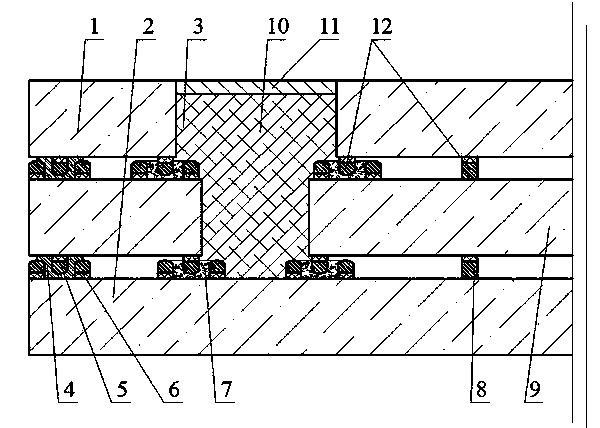

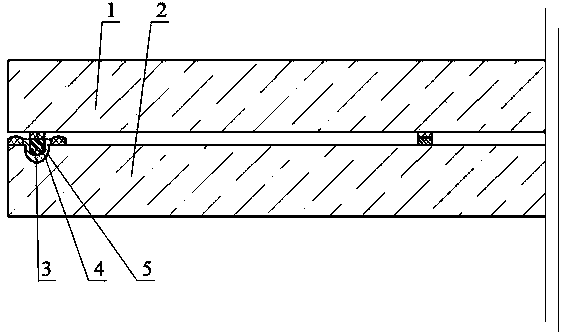

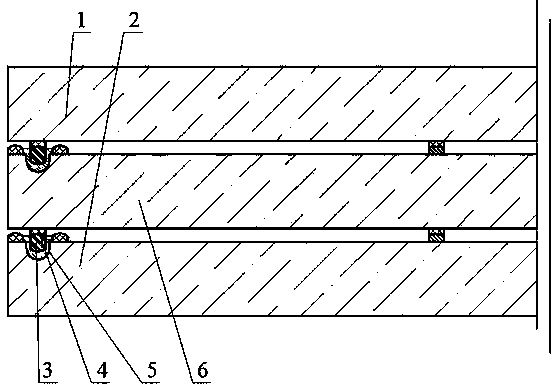

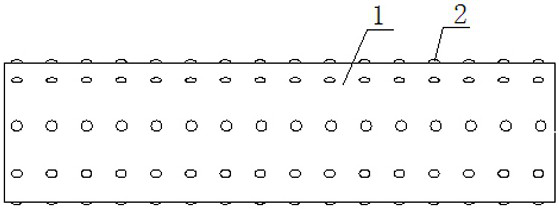

Embedded traffic rail assembly

The invention discloses an embedded traffic rail assembly. The embedded traffic rail assembly comprises an outer positioning shell and a rail board, a placing groove is formed in the surface of the rail board, a damping cushion is arranged at the inner bottom of the placing groove, steel rails are arranged on the surface of the damping cushion, and the portion between the steel rails and the placing groove is filled with a high-molecular pouring material; adjusting cavities are formed in the four corners of the surface of the rail board, through holes and pouring holes run through the inner bottom faces of the adjusting cavities, adjusting bolts penetrate through the through holes, and adjusting boards are fixedly installed on the outer sides of the adjusting bolts; fixing sleeves are installed on the inner bottom face of the outer positioning shell, and a pouring supporting layer is arranged between the outer positioning shell and the rail board. The embedded traffic rail assembly hasthe advantages that laying of the device is completed, adjustment of the height of the rail board can be achieved through the adjusting bolts and the adjusting boards, and therefore adjustment of theheight of the steel rails is achieved; the influence of settling after the embedded traffic rail assembly is used for a long time on the flush performance between the steel rails can be eliminated, the flush performance between the steel rails is guaranteed, and the train driving safety is guaranteed.

Owner:ZHENGZHOU RAILWAY VOCATIONAL & TECH COLLEGE

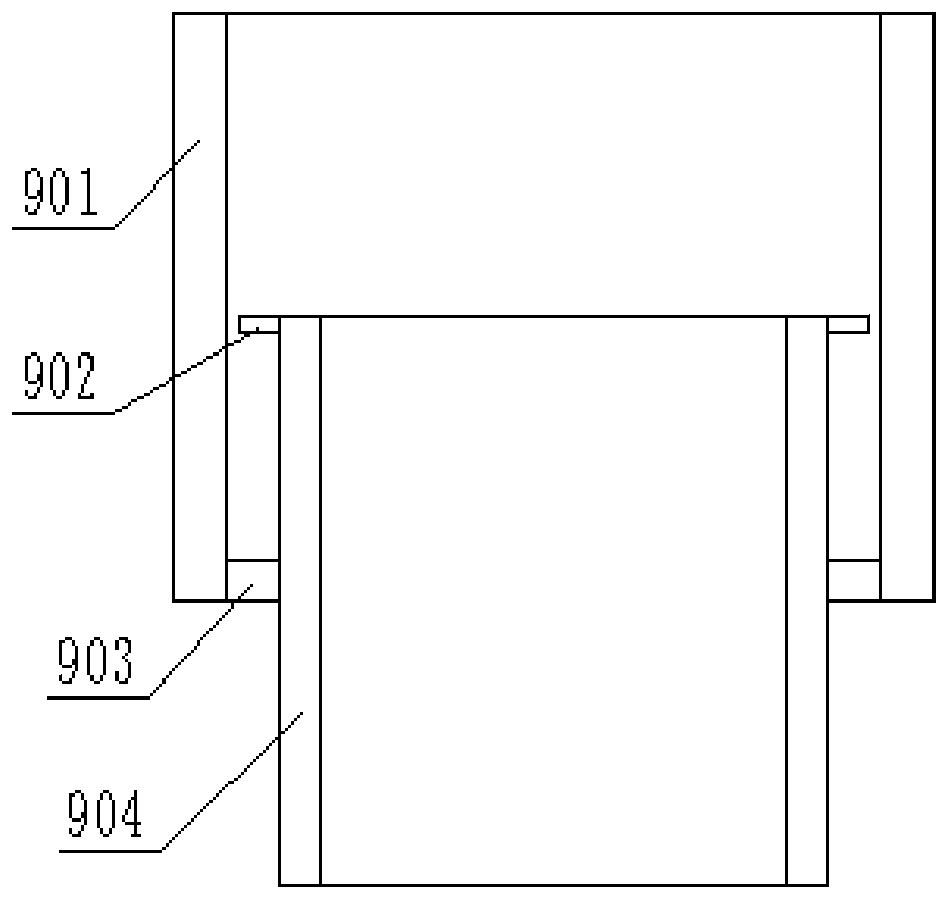

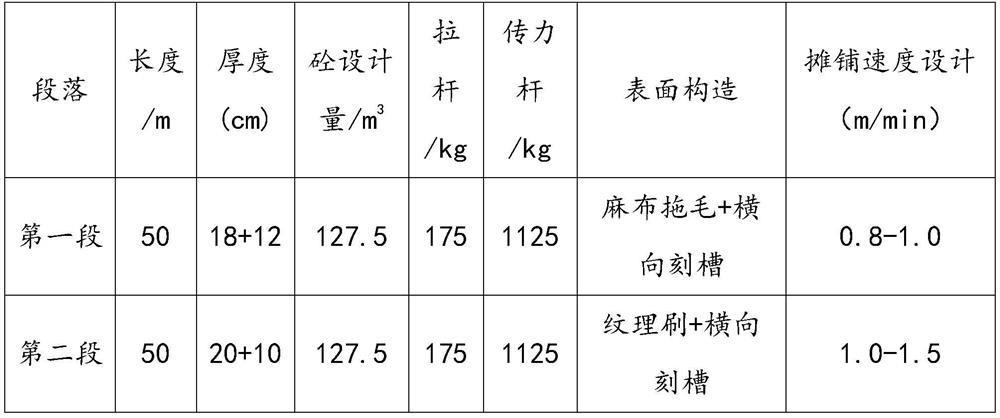

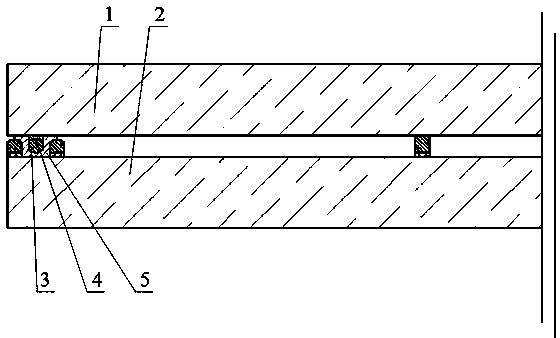

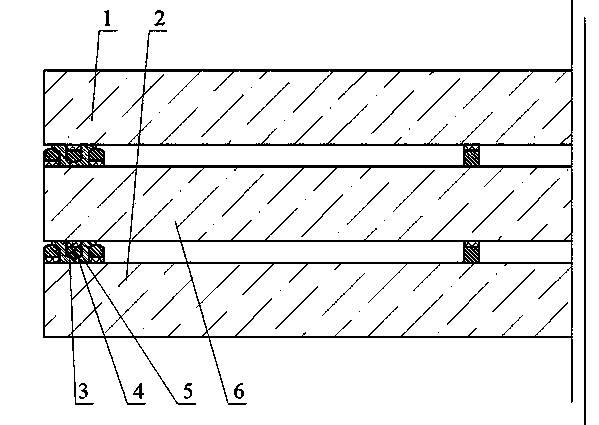

Double-machine double-layer continuous slip-form concrete paving construction application

InactiveCN114045723AHigh pass rate of flatnessGuaranteed flatnessRoads maintainenceArchitectural engineeringDowel

The invention discloses double-machine double-layer continuous slip-form concrete paving construction application, which specifically comprises the following steps: adopting two slip-form pavers to carry out double-machine double-layer echelon combined slip-form paving construction operation. The method comprises the following steps that: (1), a front slip-form paver with an IDBI device performs slip-form paving construction on a first bottom layer in front; the forming width is the sum of the width of the main lane and the width of the curb strip, the forming thickness is 2 / 3 of the design thickness, a dowel bar is automatically implanted, and the embedding depth is equal to 2 / 3 of the design thickness minus 1 / 2 of the design thickness; (2), a rear slip-form paver is close to the front slip-form paver for paving a second upper layer, the paving width is consistent with that of the first bottom layer, and the thickness is 1 / 3 of the designed thickness; and (3), the distance between the foremost side of a front crawler belt of the rear paver and the rearmost side of a rear crawler belt of the front paver to be 8 meters, and synchronization is performed during paving. The application has the effect that the flatness qualification rate of the concrete on the forming surface is high, and the defect of the concrete above the dowel bar caused when the dowel bar is placed is overcome.

Owner:GUANGDONG PROVINCIAL CHANGDA HIGHWAY ENG

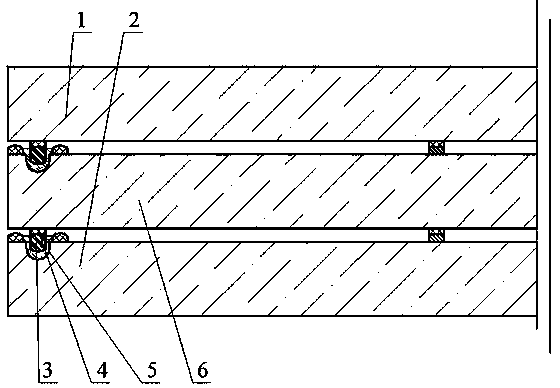

Metal-solder-welded planar toughened vacuum glass with edges being sealed by strip borders

The invention discloses metal-solder-welded planar toughened vacuum glass with edges being sealed by strip borders. The metal-solder-welded planar toughened vacuum glass is characterized in that upper glass and lower glass are planar ordinary toughened glass or coated toughened steel; the peripheries of the welding surfaces of the upper glass and the lower glass are provided with edge-sealing strip borders; the peripheries of the upper glass and the lower glass are welded together through a metal solder; an enclosed vacuum layer is formed between the upper glass and the lower glass; one or two layers of support objects are arranged in the vacuum layer; the edge-sealing strip borders and the support objects consist of toughened glass ink and a high polymer; the high polymer is prepared into a prepolymer firstly; after toughening of the glass, the prepolymer is prepared on the glass or the toughened glass ink; the prepolymer is cured into an elastomer at a room temperature or a high temperature; the prepolymer or the elastomer can automatically adapt to the height change of the vacuum layer; and the elastomer exhausts contained volatile gas at a high temperature and in high vacuum. Through adoption of the method disclosed by the invention, mechanical and automatic production can be implemented easily, and high-performance and low-cost toughened vacuum glass can be manufactured on a large scale.

Owner:戴长虹

Planar tempered vacuum glass microwave-welded by using metal solder and edge-sealed by using bar frames and groove

The invention relates to a planar tempered vacuum glass which is microwave-welded by using a metal solder and which is edge-sealed by using bar frames and a groove. The glass is characterized in that upper glass and lower glass are planar tempered glass. An edge-sealing bar frame is provided on the periphery of the upper glass; an edge-sealing bar frame and an edge-sealing groove are provided on the periphery of the lower glass; the peripheries of the upper glass and the lower glass are welded together by using a metal solder, such that a sealed vacuum layer is formed. One or two layers of supporters are provided in the vacuum layer. The edge-sealing bar frames and the supporters are composed of tempered glass ink and a high-polymer. The high-polymer is first prepared into a pre-polymer; when the glass is tempered, the pre-polymer is prepared on the tempered glass ink; and the pre-polymer is cured into elastomer under room temperature or high temperature. The pre-polymer or the elastomer can be automatically adapted to the changes of vacuum layer height. Volatile gases in the elastomer can be eliminated under high temperature and high vacuum. The method provided by the invention is suitable for mechanized and automated productions. With the method, mass production of tempered vacuum glass with high performance and low cost can be realized.

Owner:戴长虹

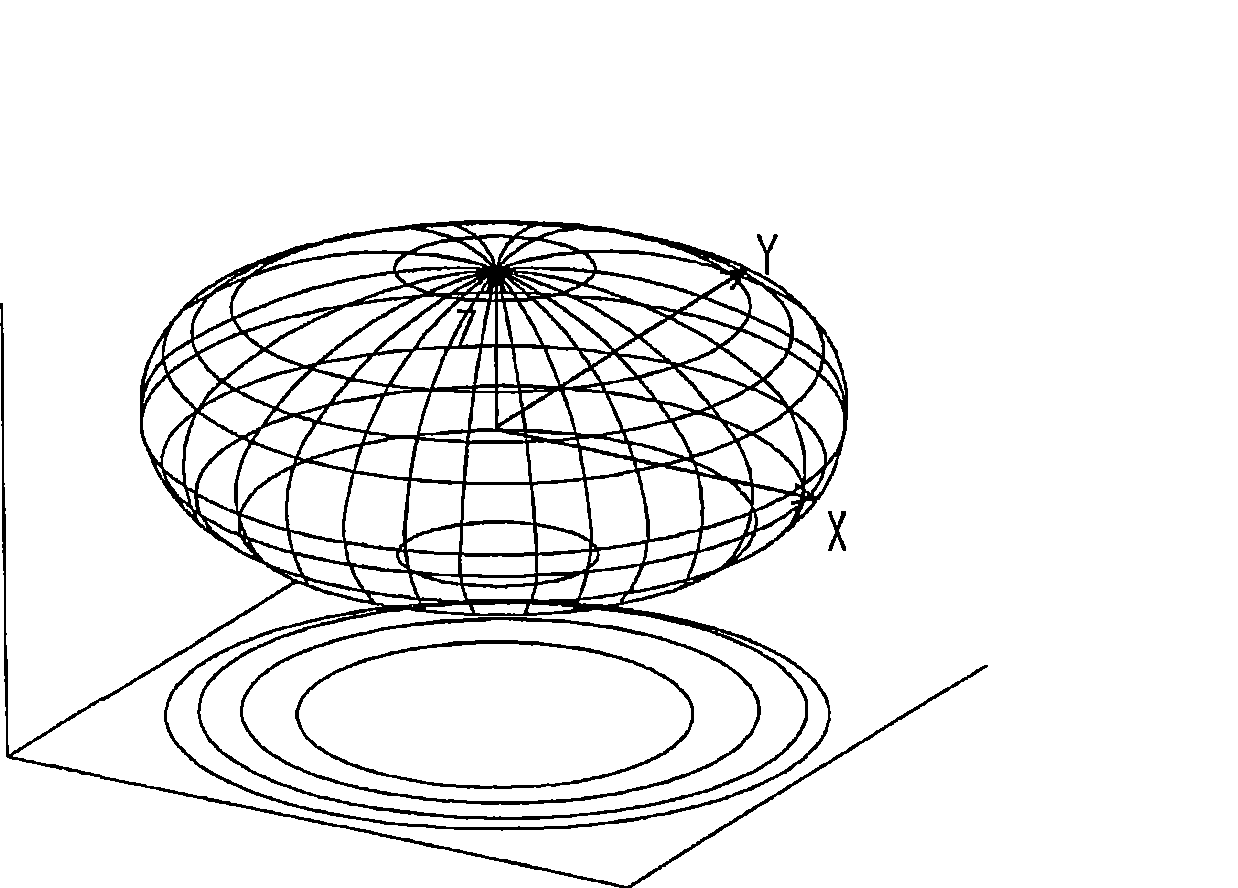

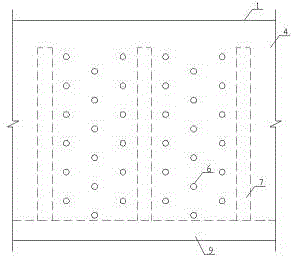

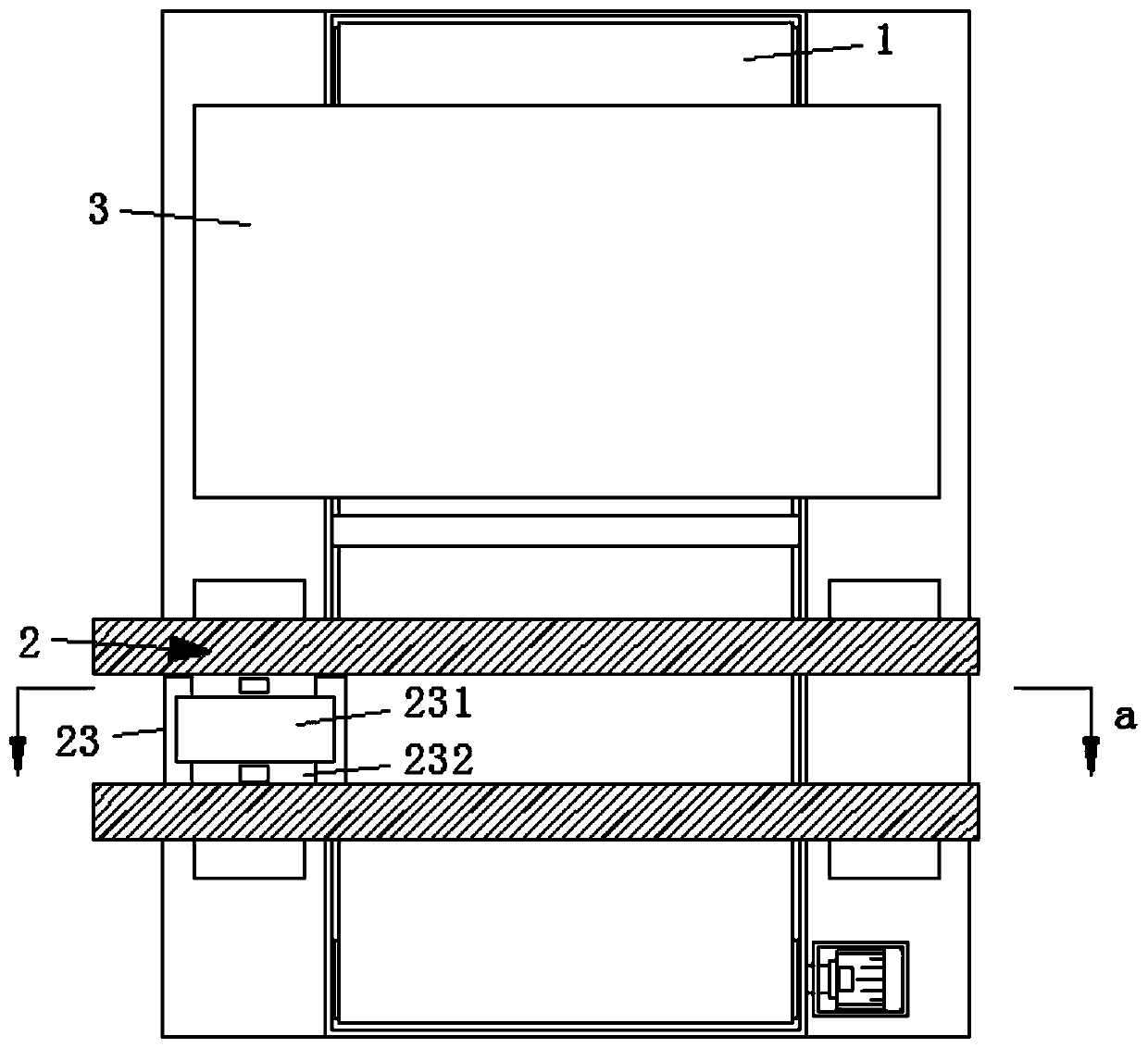

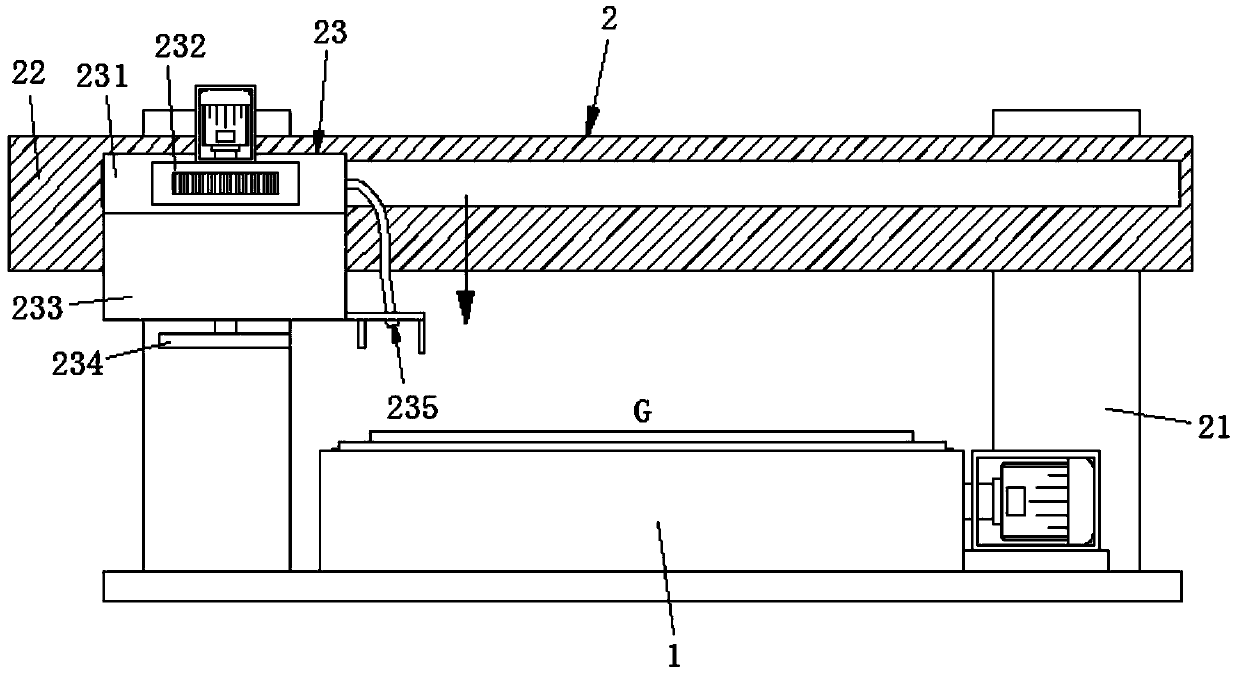

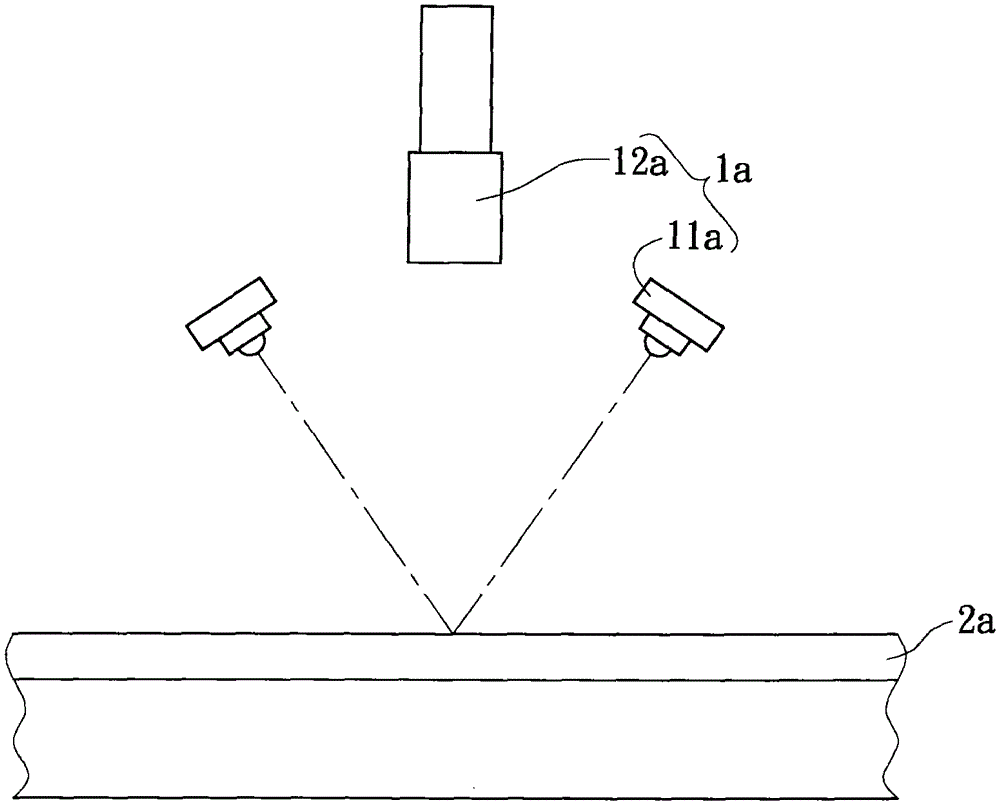

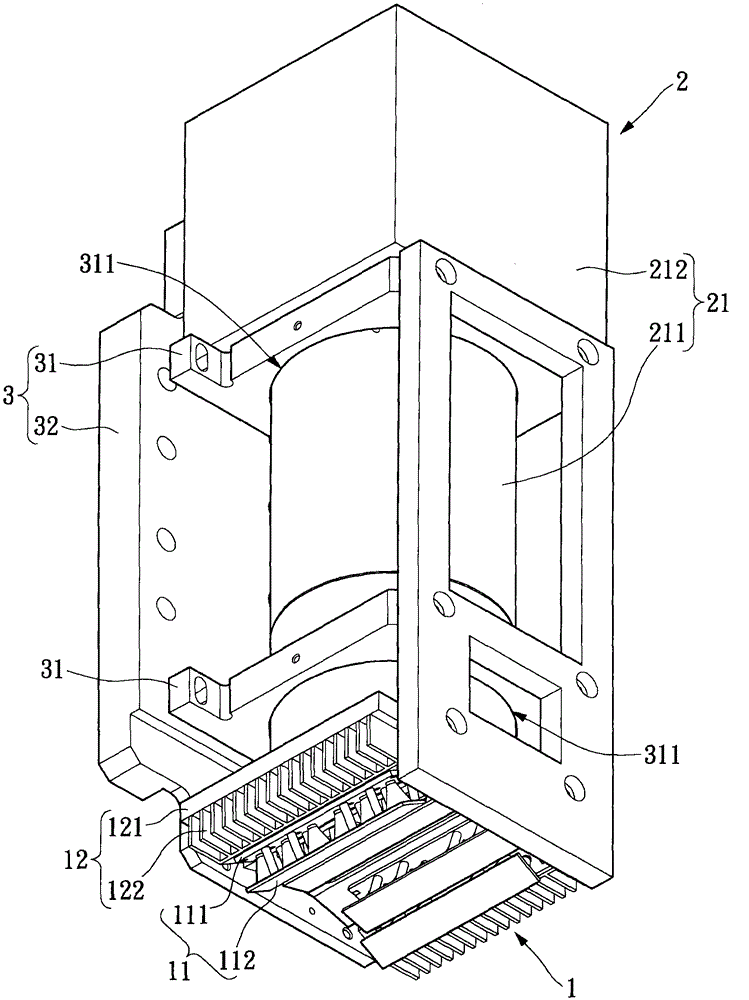

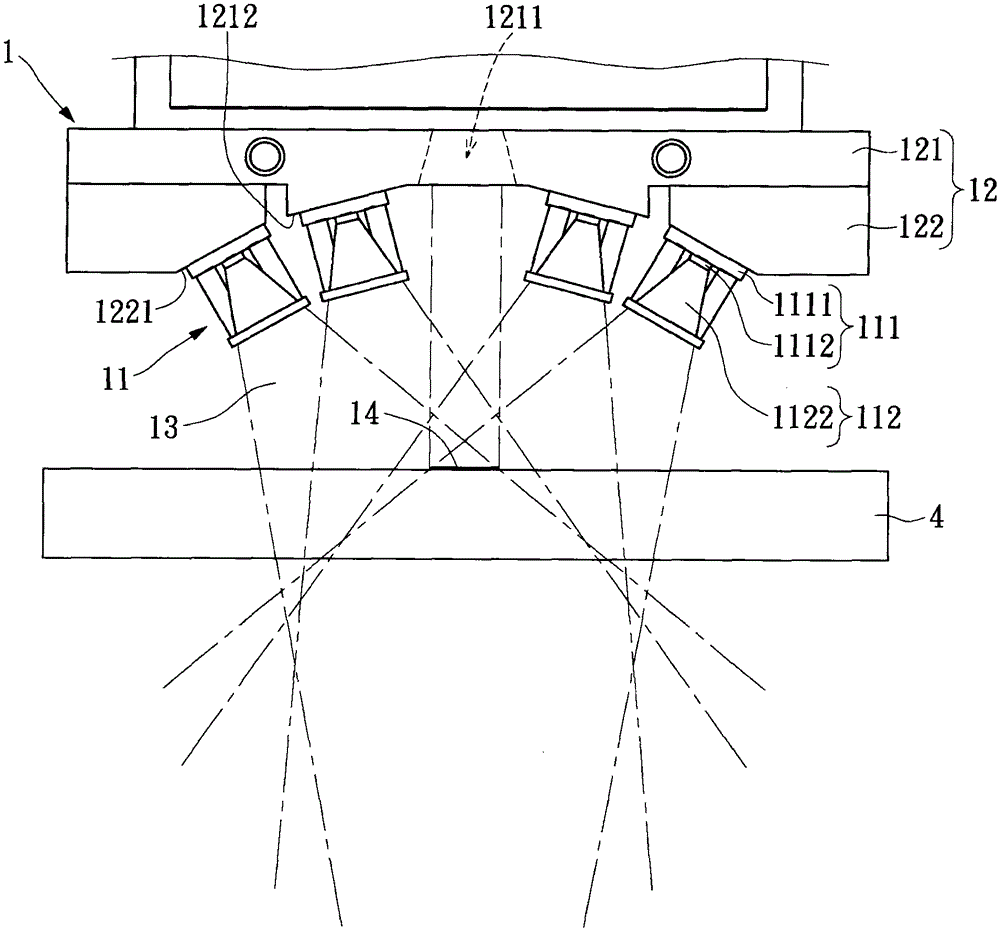

Surface scanning unit and optical detection device with surface scanning unit

ActiveCN103220449BEliminate the effects of flatnessPictoral communicationPattern recognitionOptical surface

The invention discloses a facial shape scanning unit and an optic detecting device with the facial shape scanning unit. The facial shape scanning unit and the optic detecting device are used for scanning a facial shape and capturing an image of an object to be detected. The optic detecting device comprises the facial shape scanning unit and an image capturing unit. The facial scanning unit comprises a plurality of light source modules which are respectively used for sending a facial shape light ray, the facial shape light rays sent by the plurality of light source modules irradiate the object to be detected respectively from different projecting angles, and the facial shape light rays sent by the plurality of the light source modules form a facial shape scanning block on the surface of the object to be detected in an overlapping mode. The image capturing unit comprises an image pickup module which is used for receiving the light rays reflected by the part, corresponding to the facial scanning block, of the surface of the object to be detected. Therefore, the optic detecting device with the facial shape scanning unit reduces influence of the surface evenness of the object to be detected.

Owner:YAYATECH

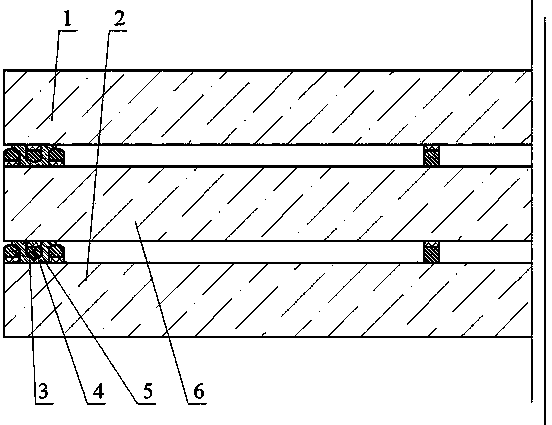

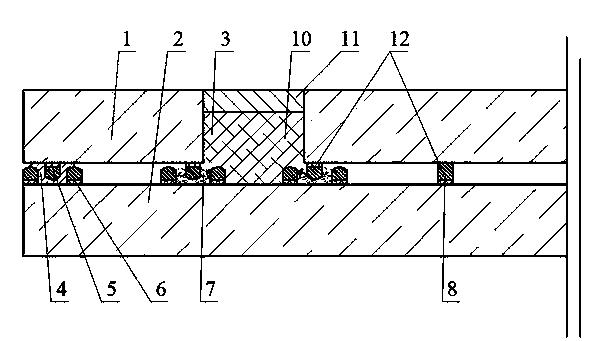

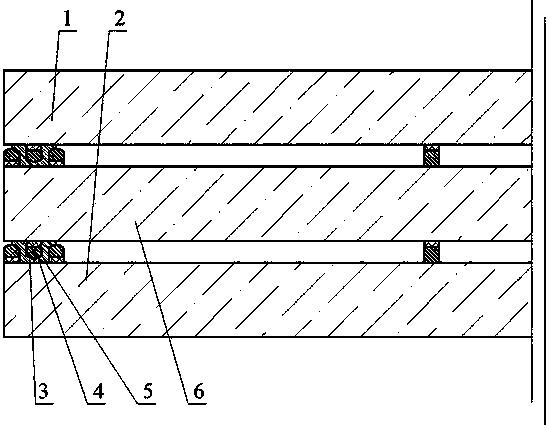

Planar toughened vacuum glass welded by using glass solder with edges being sealed by strip borders and groove

InactiveCN104291582AReduce stressReduce breakage rateGlass reforming apparatusGlass productionElastomerRoom temperature

The invention discloses planar toughened vacuum glass welded by using a glass solder with edges being sealed by strip borders and a groove. The planar toughened vacuum glass is characterized in that upper glass and lower glass are planar ordinary toughened glass or coated toughened glass; the periphery of the upper glass is provided with an edge-sealing strip border; the periphery of the lower glass is provided with an edge-sealing strip border and an edge-sealing groove; the peripheries of the upper glass and the lower glass are welded together through a glass solder, thereby forming an enclosed vacuum layer; one or two layers of support objects are arranged in the vacuum layer; the edge-sealing strip borders and the support objects consist of toughened glass ink and a high polymer; the high polymer is prepared into a prepolymer firstly; after toughening of the glass, the prepolymer is prepared on the toughened glass ink; the prepolymer is cured into an elastomer at a room temperature or a high temperature; the prepolymer or the elastomer can automatically adapt to the height change of the vacuum layer; and the elastomer exhausts contained volatile gas at a high temperature and in high vacuum. Through adoption of the method disclosed by the invention, mechanical and automatic production can be implemented easily, and high-performance and low-cost toughened vacuum glass can be manufactured on a large scale.

Owner:戴长虹

Planar toughened vacuum glass welded through metal solder by means of microwaves with edges being sealed by grooves

The invention discloses planar toughened vacuum glass welded through a metal solder by means of microwaves with edges being sealed by grooves. The planar toughened vacuum glass consists of upper glass and lower glass, and is characterized in that the periphery of the upper glass is provided with an edge-sealing strip border; the periphery of the lower glass is welded with an edge-sealing groove; the peripheries of the upper glass and the lower glass are welded together through the metal solder by means of microwaves; an enclosed vacuum layer is formed between the upper glass and the lower glass; one or two layers of support objects are arranged in the vacuum layer; the edge-sealing strip border and the support objects are made by compounding toughened glass ink and / or a high polymer; the high polymer is prepared into a prepolymer firstly; after toughening of the glass, the prepolymer is prepared on the glass or the toughened glass ink; the prepolymer is cured into an elastomer at a room temperature or a high temperature at last; the prepolymer or the elastomer can automatically adapt to the height change of the vacuum layer; and the elastomer exhausts own contained volatile gas at a high temperature and in high vacuum. Through adoption of a method disclosed by the invention, mechanical and automatic production can be implemented easily, and high-performance and low-cost toughened vacuum glass can be manufactured on a large scale.

Owner:戴长虹

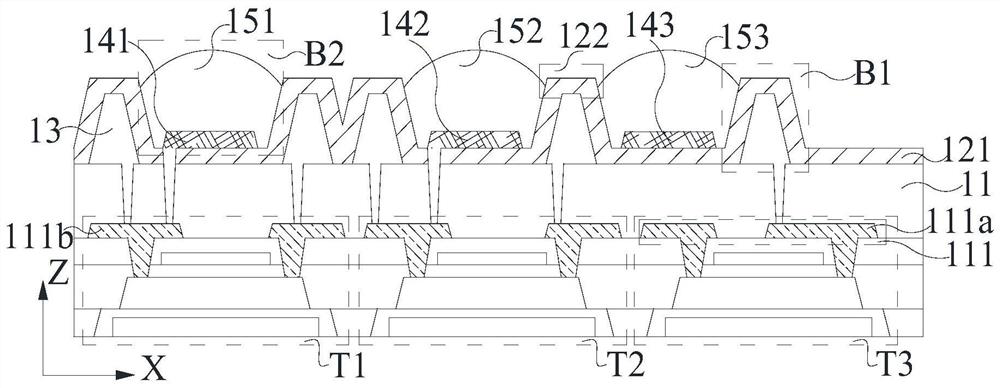

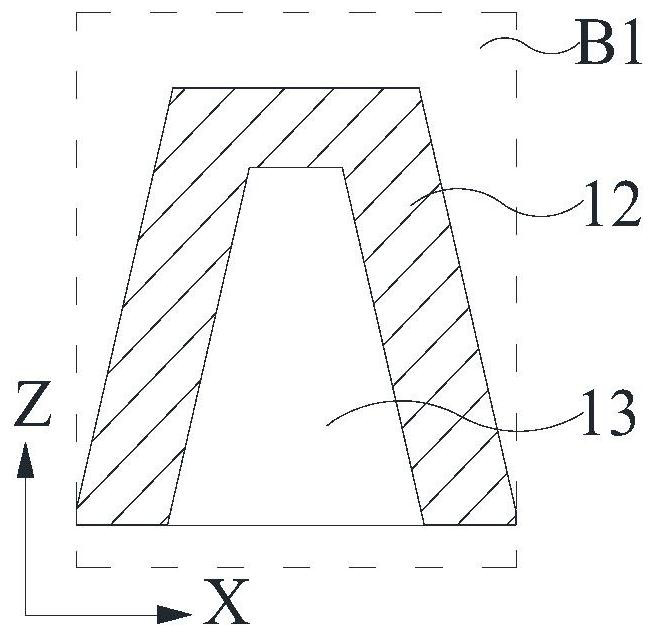

Display panel and display device

ActiveCN113053969AImprove display uniformityReduce the effect of flatnessSolid-state devicesSemiconductor devicesDisplay deviceMaterials science

The embodiment of the invention discloses a display panel and a display device. The display panel comprises a pixel definition layer which comprises a first metal layer provided with a plurality of openings at intervals, and a light-emitting layer which comprises a plurality of light-emitting units, wherein each light-emitting unit is located in the corresponding opening. The first metal layer is arranged in the pixel definition layer so that the influence on the flatness of the surface of the array substrate due to the fact that the first metal layer is arranged in the array substrate can be reduced, and the display uniformity of the display panel is improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

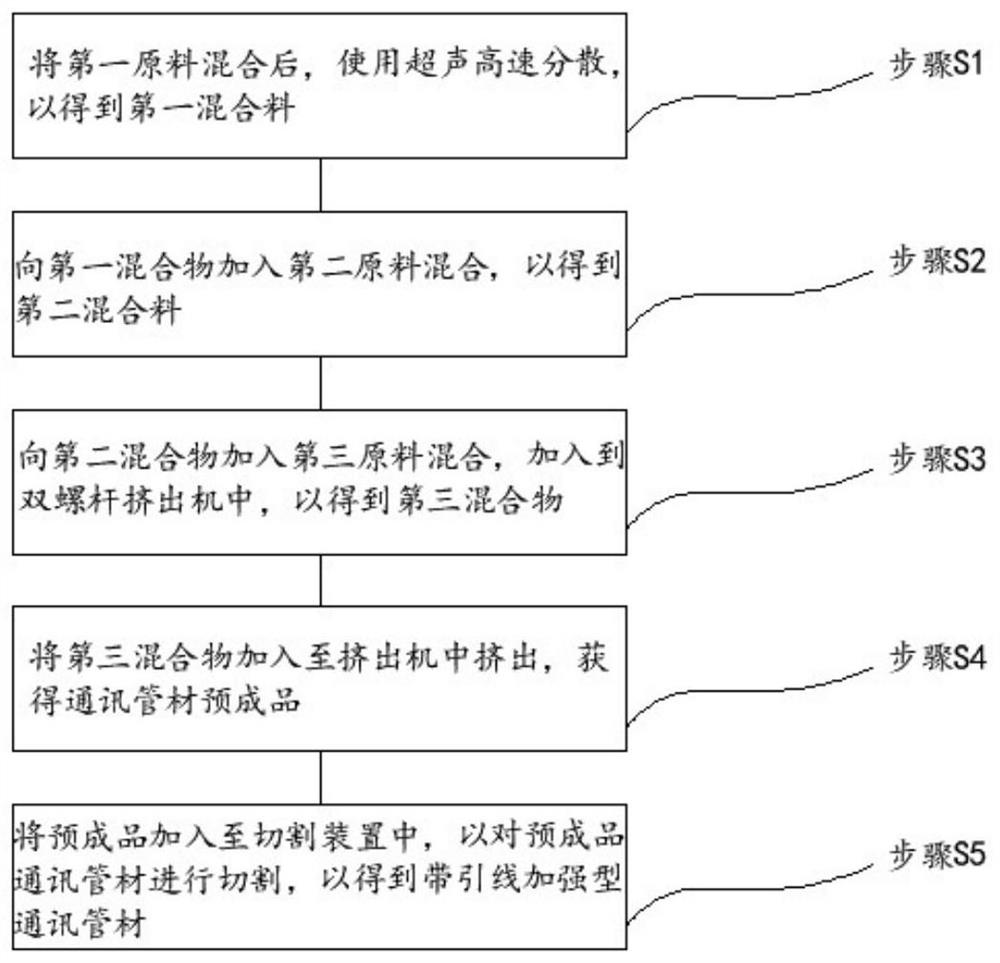

Preparation process of reinforced communication pipe with lead

ActiveCN114683508AQuality improvementReduce speedTubular articlesProcess engineeringIndustrial engineering

The invention relates to a preparation process of a reinforced communication pipe with a lead, which comprises the following steps: S1, mixing a first raw material, and carrying out ultrasonic high-speed dispersion to obtain a first mixture; s2, adding a second raw material into the first mixture, mixing, and performing ultrasonic high-speed dispersion to obtain a second mixture; s3, adding a third raw material into the second mixture, mixing, carrying out ultrasonic high-speed dispersion, and after the dispersion is completed, adding into a double-screw extruder, and carrying out melt mixing, so as to obtain a third mixture; s4, the third mixture is added into an extruder for extrusion, and a communication pipe pre-finished product is obtained; and S5, the pre-finished product is added into a cutting device, the pre-finished product communication pipe is cut, and the reinforced communication pipe with the lead is obtained. According to the communication pipe cutting device, the cutting process can be mastered in real time in the pipe preparation process, the quality of communication pipes is improved, and the cutting speed is effectively increased.

Owner:杭州中祥通讯器材有限公司

Metal-solder-welded planar toughened vacuum glass with edges being sealed by strip borders and groove

The invention discloses metal-solder-welded planar toughened vacuum glass with edges being sealed by strip borders and groove. The planar toughened vacuum glass is characterized in that upper glass and lower glass are planar ordinary toughened glass or coated toughened glass; the periphery of the upper glass is provided with an edge-sealing strip border; the periphery of the lower glass is provided with an edge-sealing strip border and an edge-sealing groove; the peripheries of the upper glass and the lower glass are welded together through a metal solder, thereby forming an enclosed vacuum layer; one or two layers of support objects are arranged in the vacuum layer; the sealing strip borders and the support objects consist of toughened glass ink and a high polymer; the high polymer is prepared into a prepolymer firstly; after toughening of the glass, the prepolymer is prepared on the toughened glass ink; the prepolymer is cured into an elastomer at a room temperature or a high temperature; the prepolymer or the elastomer can automatically adapt to the height change of the vacuum layer; and the elastomer exhausts contained volatile gas at a high temperature and in high vacuum. Through adoption of a method disclosed by the invention, mechanical and automatic production can be implemented easily, and high-performance and low-cost toughened vacuum glass can be manufactured on a large scale.

Owner:戴长虹

A method for arranging sample powder when the sample tablet for xrfs analysis is pressed

ActiveCN111289548BSimple structureEasy to manufactureMaterial analysis using wave/particle radiationPaper towelStructural engineering

The invention relates to a method for arranging sample powders when a sample tablet for XRFS analysis is pressed. The technical scheme is as follows: the square steel plates with a thickness of 2.0mm and 1.0mm are opened with the same corner holes and large round holes, and the large round holes of the square steel plate with a thickness of 2.0mm are provided with countersunk holes; The corner holes of a square steel plate are flexibly connected, the side with the countersunk hole is facing up, and a single layer of tissue sheets is laid flat between the two square steel plates to obtain a paper bottom sample tray. Place 1.5-2.0 g of boric acid on the lower pressure head in the silo of the tablet press, fill the paper bottom sample tray with the powder to be pressed and scrape it flat, and put the paper towel sample tray together with the powder sample to be pressed. Put it into the loading bin of the tablet press, and press the sample powder to be pressed and the paper bottom of the paper bottom loading tray to the loading bin of the tablet press from the upper plane of the paper towel loading tray with the pressing rod, that is, the sample powder is completed. arrangement. The invention has the characteristics of simple structure of the paper bottom sample loading tray, fast sample loading speed, small fluctuation of sample quality and high sample strength.

Owner:WUHAN UNIV OF SCI & TECH +3

Flat tempered vacuum glass edge-sealed with sealing bar and having vacuumizing hole and manufacturing method thereof

InactiveCN104291660AExtend your lifeImprove productivityGlass reforming apparatusGlass productionElastomerRoom temperature

A flat tempered vacuum glass edge-sealed with sealing bars and having a vacuumizing hole is characterized in that an upper glass and a lower glass are flat tempered glass. A vacuumizing hole is formed in the upper glass. Peripheries of the upper glass and the vacuumizing hole are provided with the sealing bars and the periphery of the lower glass and positions corresponding to the vacuumizing hole are provided with the sealing bars. The peripheries of the upper glass and the lower glass are welded to each other in an edge-sealing oven at a normal pressure through a low-temperature glass solder. The vacuumizing hole is automatically sealed in a vacuum oven through a metal solder. A sealed vacuum layer, with a dot-array-arranged support object therein, is formed between the upper glass and the lower glass. The edge-sealing bar and / or the support object are composed of tempered glass printing ink and / or a high polymer. The high polymer is firstly prepared into a pre-polymer. The pre-polymer, after the glass being tempered, is manufactured on the glass or the tempered glass printing ink. Finally the pre-polymer is solidified to form an elastomer at room temperature or a high temperature. The pre-polymer or the elastomer can automatically adapt with change of height of the vacuum layer. Volatile gas in the elastomer is exhausted from the elastomer at a high temperature and a high vacuum degree.

Owner:戴长虹

Glass-solder microwave-welded planar tempered vacuum glass with edge sealed by using bar frames and groove

InactiveCN104291601AReduce stressReduce the breakage rate of glassGlass reforming apparatusGlass productionElastomerMicrowave

The invention relates to glass-solder microwave-welded planar tempered vacuum glass with the edge sealed by using bar frames and a groove. The glass is characterized in that upper glass and lower glass are planar tempered glass. An edge-sealing bar frame is provided on the periphery of the upper glass. An edge-sealing bar frame and an edge-sealing groove are provided on the periphery of the lower glass. The peripheries of the upper glass and the lower glass are welded together with a glass solder by using microwave, such that a sealed vacuum layer is formed. One or two layers of supporters are provided in the vacuum layer. The edge-sealing bar frames and the supporters are composed of tempered glass ink and a high-polymer. The high-polymer is first prepared into a pre-polymer. When the glass is tempered, the pre-polymer is prepared on the tempered glass ink. the pre-polymer is cured into elastomer under room temperature or high temperature. The pre-polymer or elastomer can be automatically adapted to the changes of the height of the vacuum layer. Volatile gases in the elastomer can be eliminated under high temperature and high vacuum. The method provided by the invention is suitable for mechanized and automated productions. With the method, mass productions of high-performance and low-cost tempered vacuum glass can be realized.

Owner:戴长虹

Anti-deformation jointing die for board book

InactiveCN111873658AIncrease elasticity and flexibilityImprove performance and service lifeBookbinding adhesiveAdhesive glueStructural engineering

The invention discloses an anti-deformation jointing die for a board book. The die comprises a carrier, a layer of rubber covers a gluing working surface of the carrier, bulges with closed outer contours are uniformly distributed on the rubber, and the distribution density of the bulges is set by taking the gluing area required for laminated board book inner pages as a standard. According to the die, the elasticity and flexibility of the working surface of the carrier are increased through the rubber, glue marks after gluing form relatively independent closed bodies one by one through the bulges, with closed outer contours, arranged on the rubber, stress is relatively closed, concentrated and uniform, and the phenomenon of mutual stress concentration among the glue marks when glue is driedand contracted is avoided; and the manufactured laminated board book is stable in quality and high in flatness, is not limited by the size of the board book, and cannot deform and wrinkle after beingused for a long time.

Owner:赵晓旭

Mending method and production method of colorful filtering substrate

ActiveCN101477257BEliminate the effects of flatnessImprove production pass rateNon-linear opticsRepair materialRepair method

The invention relates to a repairing method and a method for manufacturing a color filter substrate. The repairing method is suitable for repairing bubble defect on the surface of a glass substrate; the repairing method comprises the following steps: firstly, the sunken depth caused by the bubble defect is reckoned; and secondly, a repairing material is filled in the bubble defect so as to reducethe influence of the bubble defect on the surface planeness. The method for manufacturing the color filter substrate comprises that: the glass substrate is provided; whether the bubble defect is on the surface of the glass substrate is judged; the sunken depth caused by the bubble defect is reckoned; the repairing material is filled in the bubble defect so as to reduce the influence of the bubbledefect on the surface planeness; a color filter layer is formed on the glass substrate; and a common electrode is formed on the color filter layer. The repairing method can be applied to a process ofthe color filter substrate so as to increase the manufacturing qualification rate of the color filter substrate.

Owner:AU OPTRONICS CORP

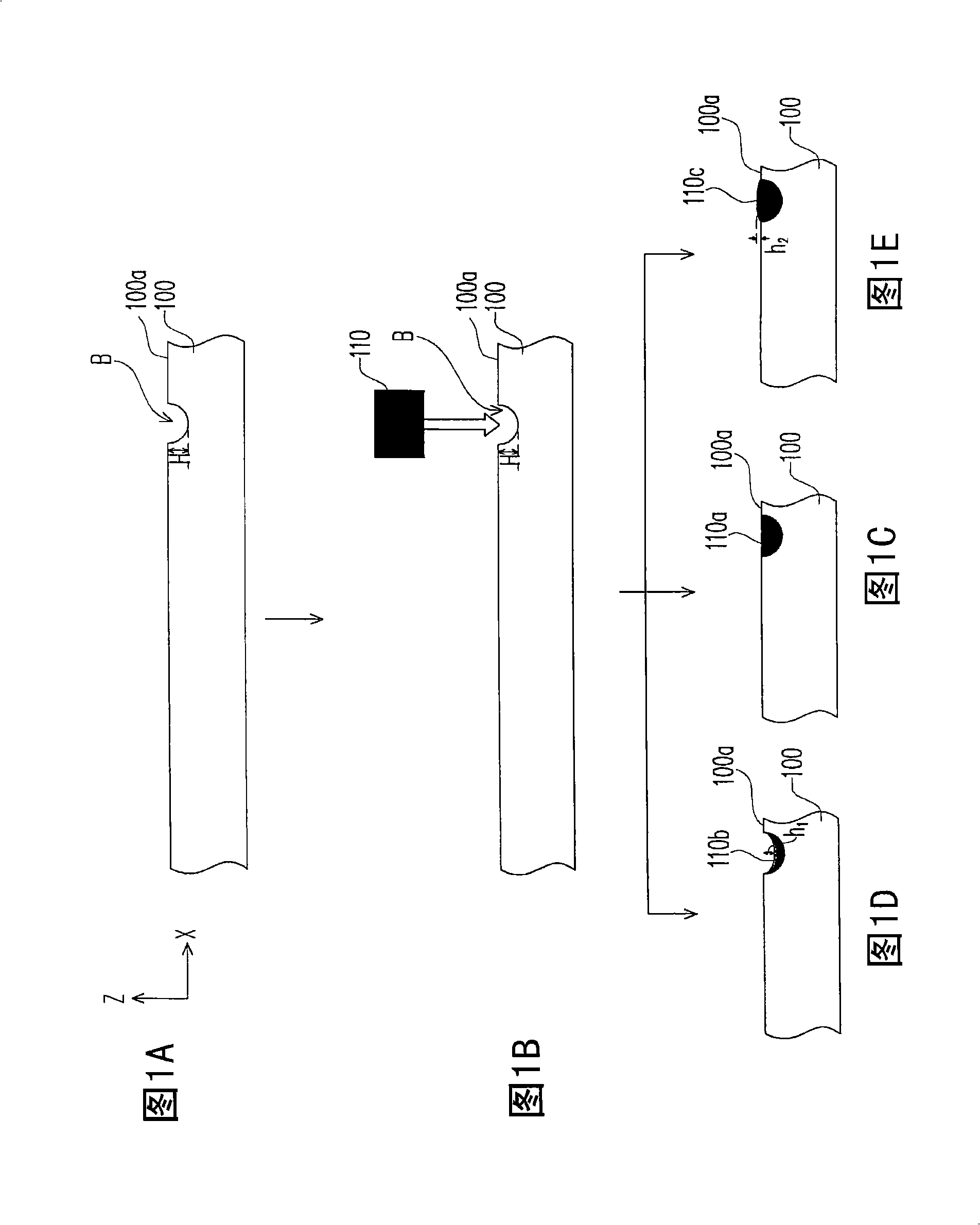

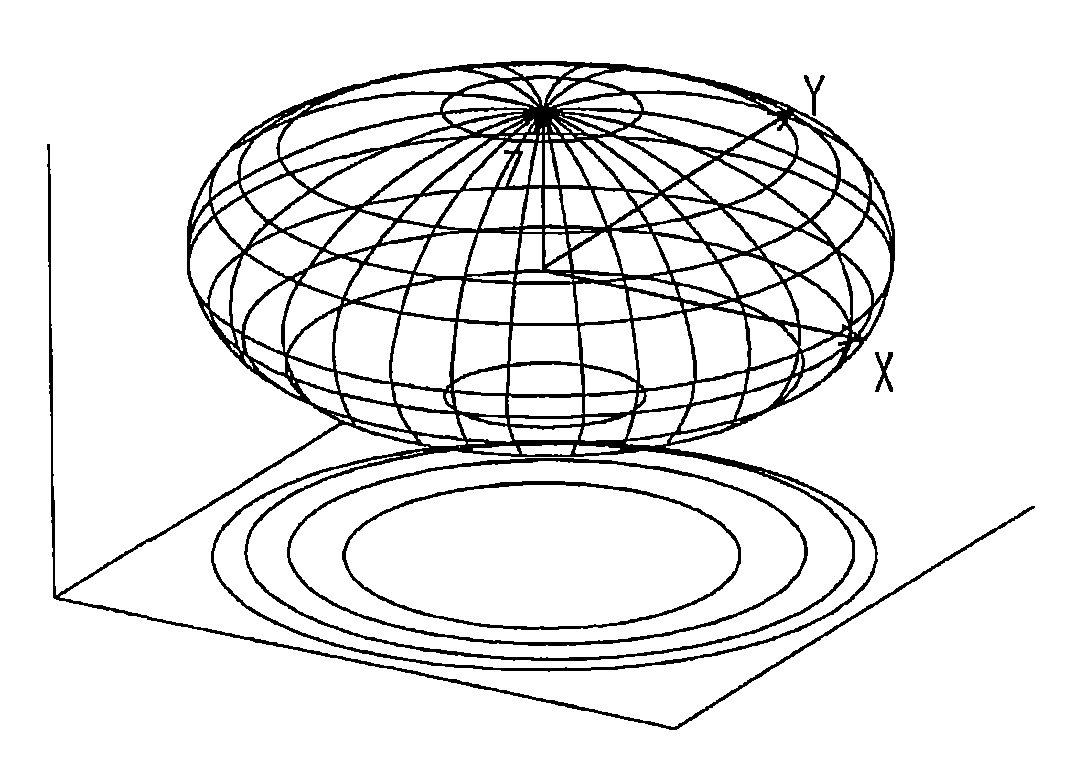

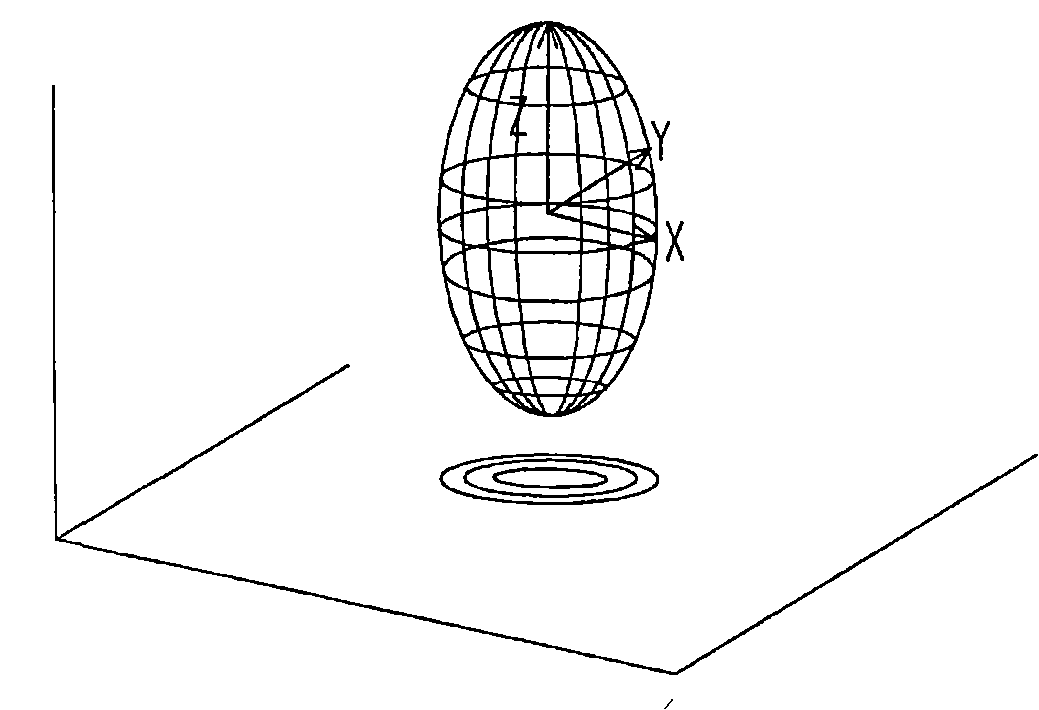

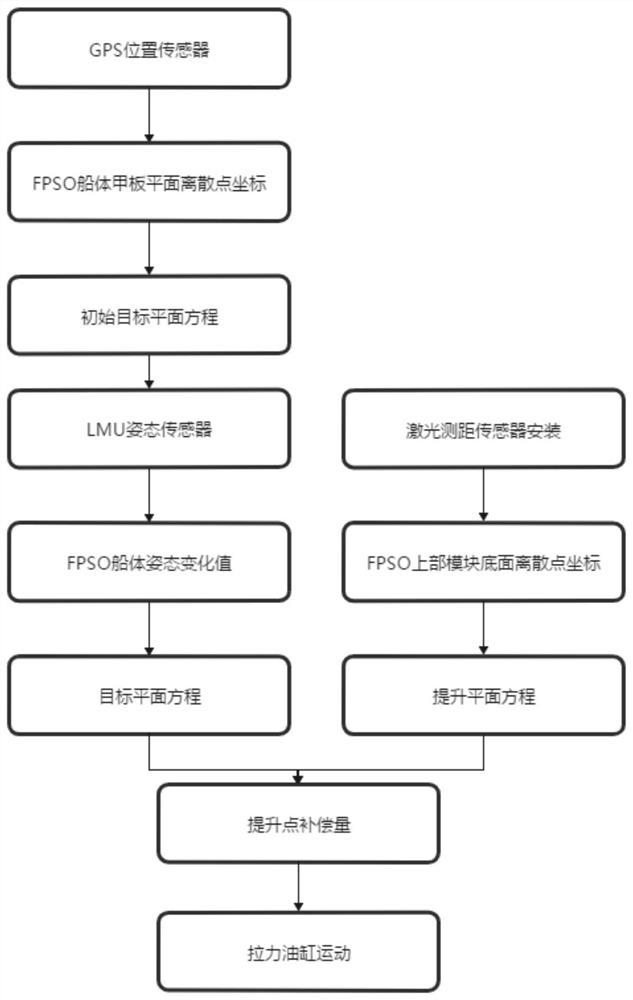

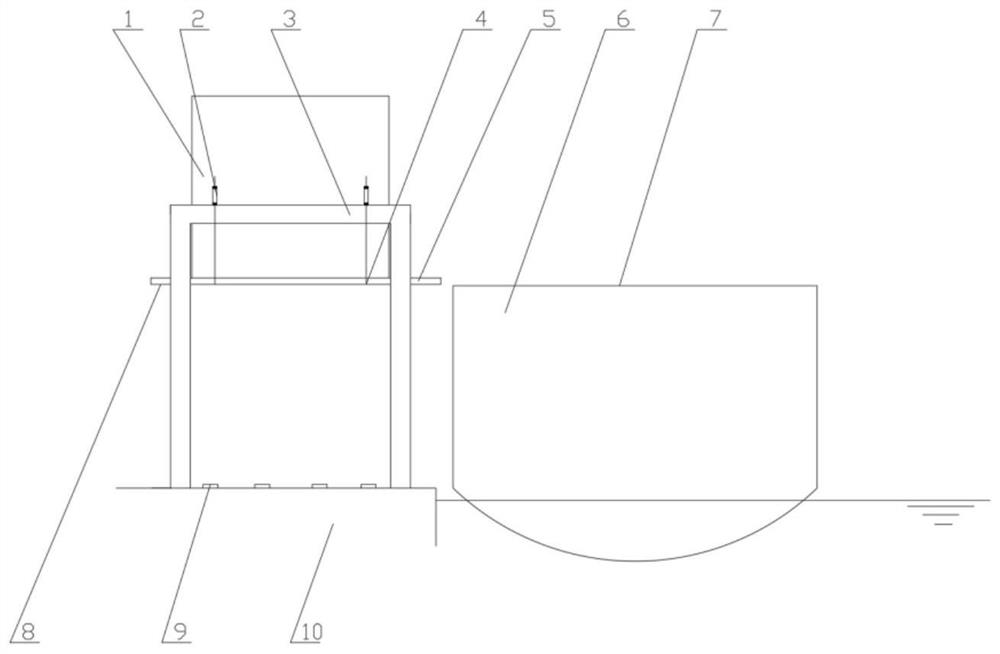

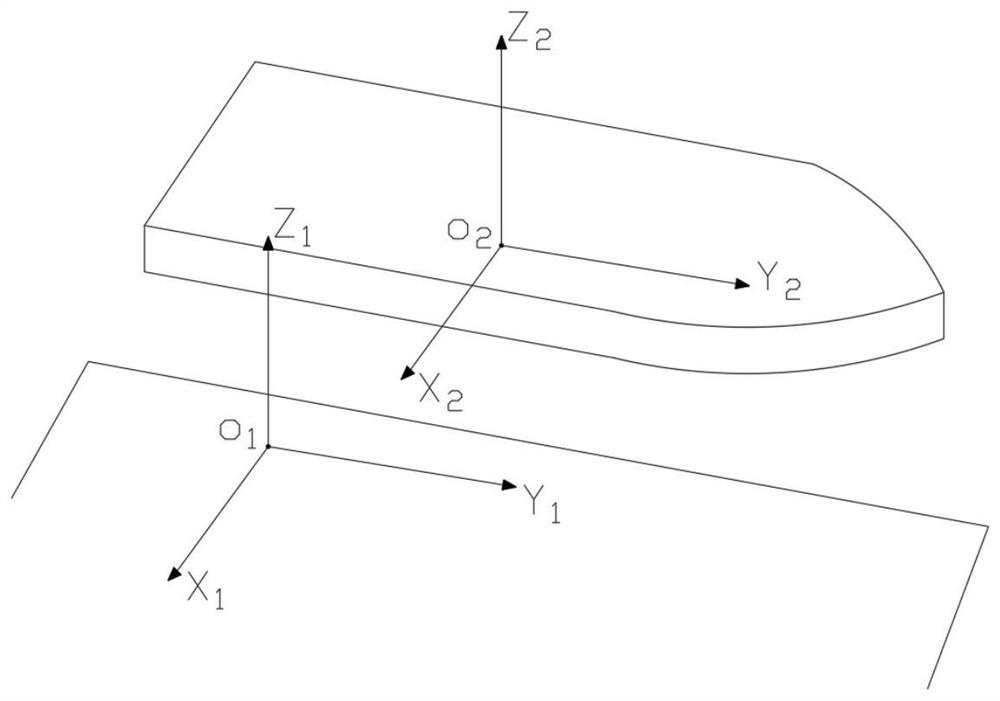

Motion compensation method suitable for FPSO upper module lifting and installing process

PendingCN113942622AGuaranteed accuracySolve the fast change of poseWaterborne vesselsLoad-engaging elementsLaser rangingControl theory

The invention discloses a motion compensation method suitable for the lifting and installing process of an FPSO upper module. The method comprises the steps of establishing a global coordinate system and a ship body coordinate system; calculating an initial target plane equation in the FPSO upper module installation process by using a GPS position sensor; calculating an FPSO upper module installation process target plane equation by using an RMU pose sensor; calculating a lifting plane equation of the FPSO upper module installation process through a laser distance measuring sensor; calculating the compensation amount of each lifting point in the installation process of the FPSO upper module; synchronously increading lifting heights of all the tension oil cylinders in a lifting installation system which is set in the computer, and gradually lifting the FPSO upper module to the position coplanar with the FPSO ship deck plane. According to the method, the butt joint precision is greatly guaranteed, the safety of the installation process is guaranteed, the change of the marine environment on a wharf can be efficiently dealt with, and the problems that in the FPSO upper module lifting installation process, the FPSO ship body pose change is fast, and the butt joint precision is poor can be effectively solved.

Owner:BOMESC OFFSHORE ENG CO LTD

Planar toughened vacuum glass welded by using metal solder by means of microwave welding with edges being sealed by strip borders

The invention discloses planar toughened vacuum glass welded by using a metal solder by means of microwave welding with edges being sealed by strip borders. The planar toughened vacuum glass is characterized in that upper glass and lower glass are planar ordinary toughened glass or coated toughened glass; the peripheries of the upper glass and the lower glass provided with edge-sealing strip borders; the peripheries of the upper glass and the lower glass are welded together through the glass solder by means of microwave welding; an enclosed vacuum layer is formed between the upper glass and the lower glass; one or two layers of support objects are arranged in the vacuum layer; the edge-sealing strip borders and the support objects consist of toughened glass ink and a high polymer; the high polymer is prepared into a prepolymer firstly; after toughening of the glass, the prepolymer is prepared on the toughened glass ink; the prepolymer is cured into an elastomer at a room temperature or a high temperature; the prepolymer or the elastomer can automatically adapt to the height change of the vacuum layer; and the elastomer exhausts contained volatile gas at a high temperature and in high vacuum. Through adoption of the method disclosed by the invention, mechanical and automatic production can be implemented easily, and high-performance and low-cost toughened vacuum glass can be manufactured on a large scale.

Owner:戴长虹

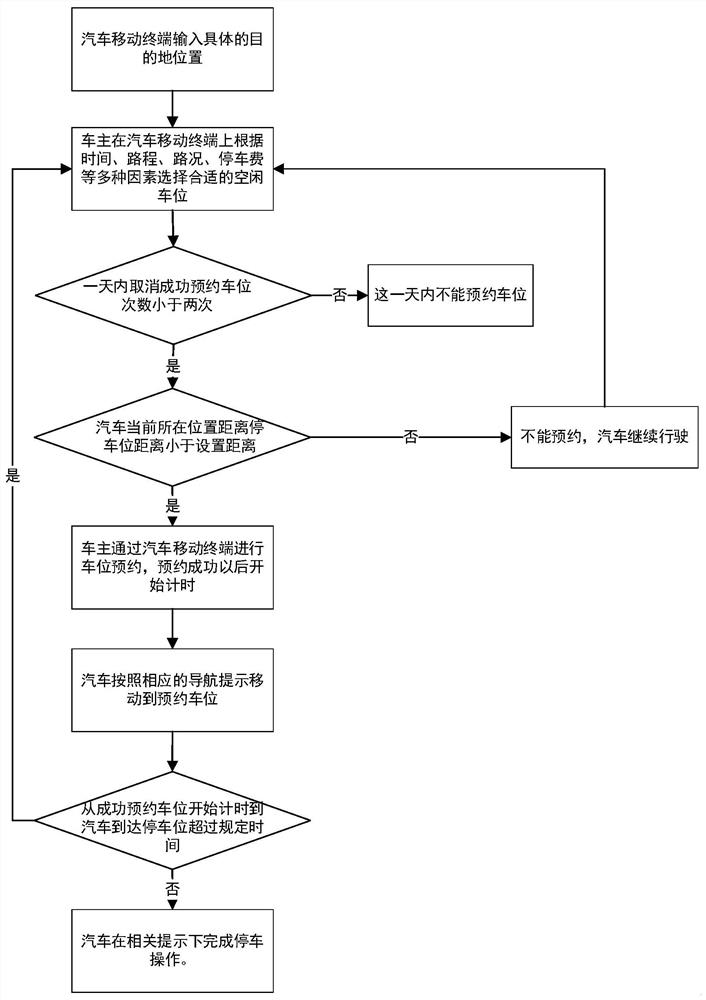

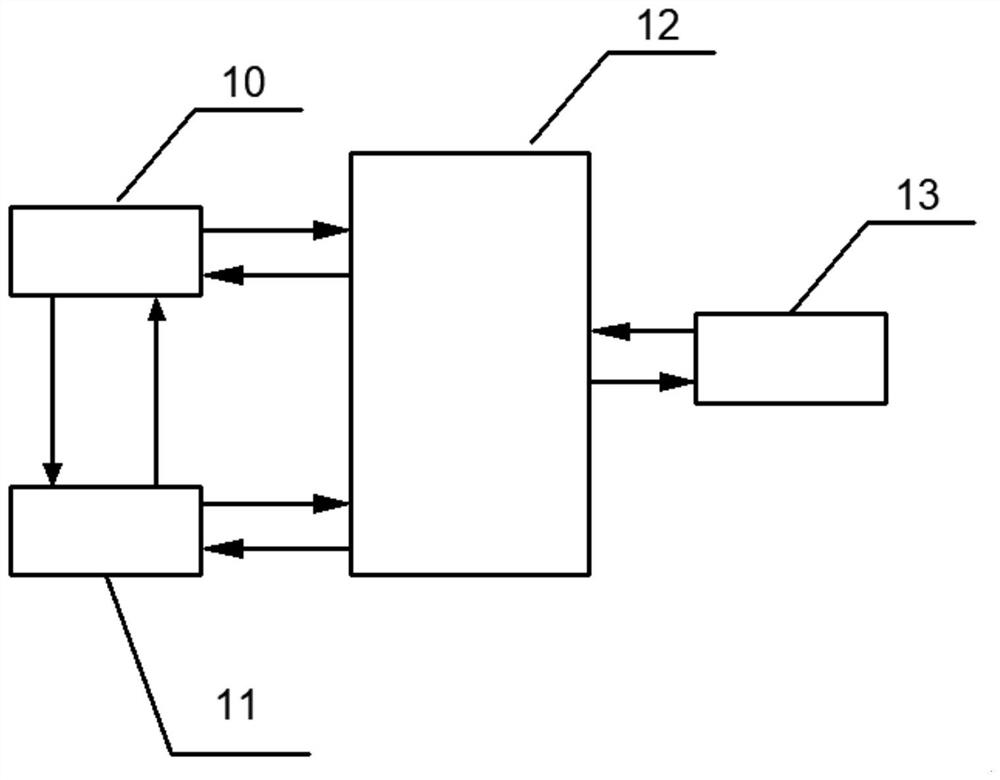

An intelligent parking and illegal parking detection system and its application method

ActiveCN109584614BIncrease profitReduce parking timeIndication of parksing free spacesInformation transmissionComputer science

The invention provides an intelligent parkingand illegal parking detection system and a using method thereof. The intelligent parkingand illegal parking detection system includes a parking detection device (10), a car mobile terminal (11), a data center processor (12) and a manager terminal (13), and wireless information transmission is carried out among the parking detection device (10), the carmobile terminal (11), the data center processor (12) and the manager terminal (13). When the intelligent parkingand illegal parking detection system is in use and a car owner inputs a specific destination location through the car mobile terminal (11), the car mobile terminal (11) searches for parking information near the destination and provides the location of a free parking space to the car owner, the car owner selects the appropriate free parking space at the car mobile terminal ( 11) according to various factors such as time, distance, road condition and parking fee, the owner makes a parking space reservation through the car mobile terminal (11), and after the reservation is successful, a car moves to the reserved parking space according to the corresponding navigation prompt. The intelligent parking and illegal parking detection system and the using method thereof can timely inform the car owner who need to park the car of parking space information in a region, the parking time of the owner is greatly saved, and the utilization of the parking space in the entire region is improved.

Owner:CHONGQING UNIV

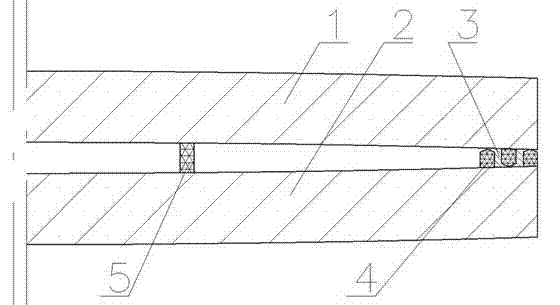

Flat tempered vacuum glass welded by metal solder and edge-sealed with groove

A flat tempered vacuum glass welded by a glass solder and edge-sealed through a groove is composed of an upper glass and a lower glass and is characterized in that a periphery of the upper glass is provided with an edge-sealing bar frame and the periphery of the lower glass is provided with an edge-sealing groove. The peripheries of the upper glass and the lower glass are welded to each other through the metal solder. A sealed vacuum layer, with a supporting object therein, is formed between the upper glass and the lower glass, wherein the supporting object includes one layer or two layers. The edge-sealing bar frame and the supporting object are manufactured from tempered glass printing ink and a high polymer in a composite manner. The high polymer is firstly prepared into a pre-polymer. The pre-polymer, after the glass being tempered, is manufactured on the glass or the tempered glass printing ink. Finally the pre-polymer is solidified to form an elastomer at room temperature or a high temperature. The pre-polymer or the elastomer can automatically adapt with change of height of the vacuum layer. Volatile gas in the elastomer is exhausted from the elastomer at a high temperature and a high vacuum degree. The method is easy to mechanize and automate and can be used for manufacturing the tempered vacuum glass with high performance and low cost in large scale.

Owner:戴长虹

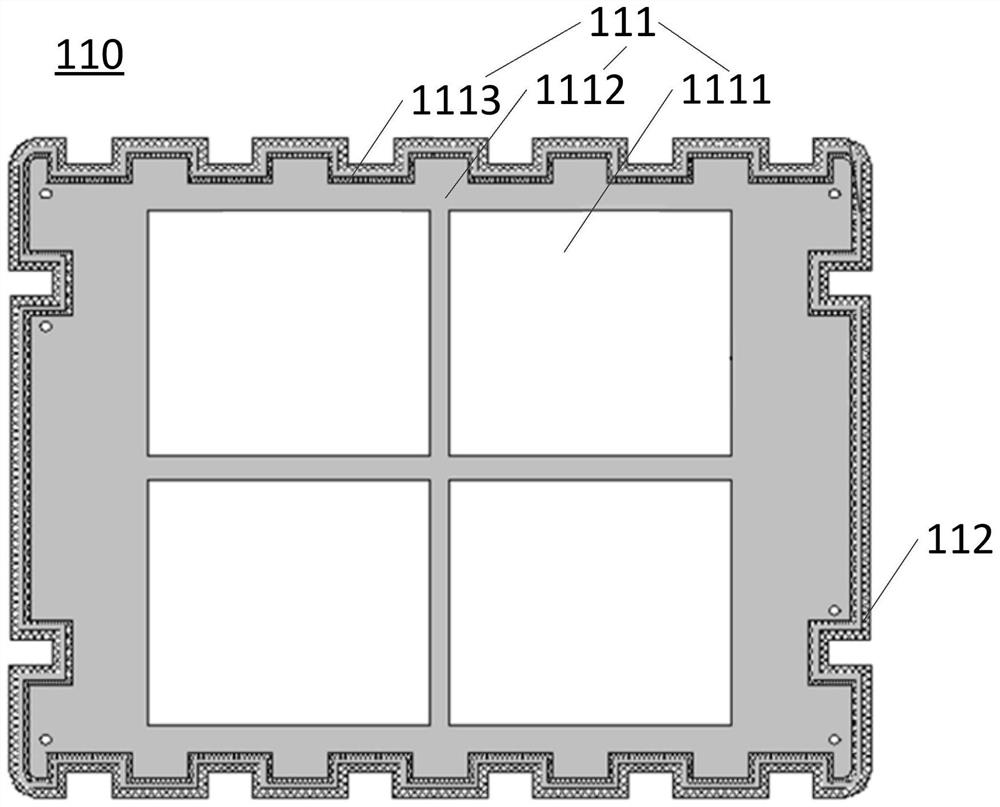

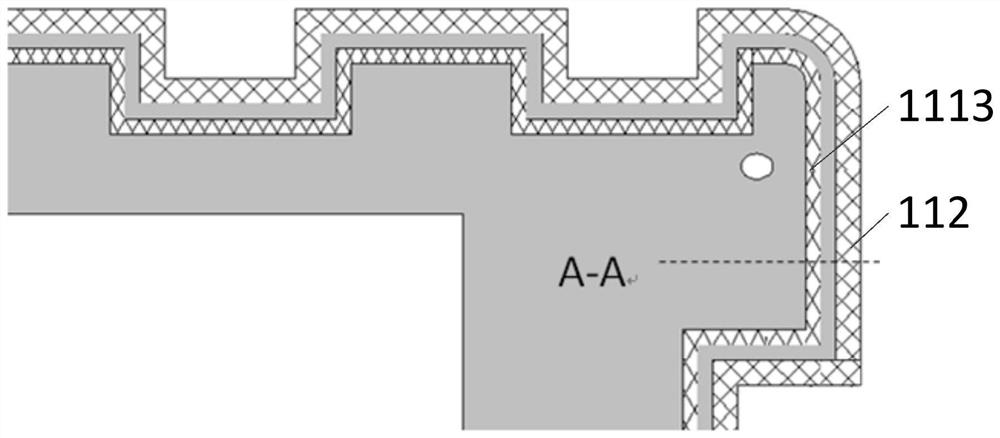

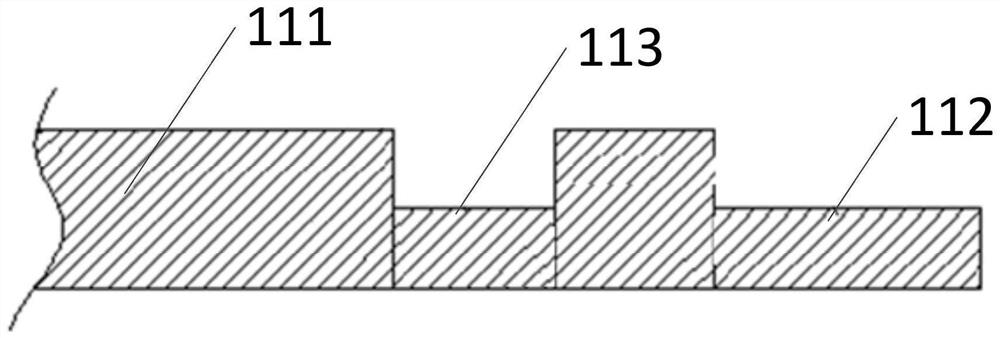

Supporting plate, mask plate and preparation method of mask plate

PendingCN113604777ASimplify the netting processSave operating timeVacuum evaporation coatingSolid-state devicesPhysicsEngineering

The embodiment of the invention discloses a supporting plate, a mask plate and a preparation method of the mask plate. In one specific implementation mode, the supporting plate for the mask plate comprises a plate body, wherein the plate body comprises a first surface, a second surface and a side wall connected with the first surface and the second surface; and the plate body further comprises at least one hollow area penetrating through the first surface and the second surface. The supporting plate further comprises a protruding part formed by protruding outwards from the side wall of the plate body, and the protruding part is used for being fixedly connected with a frame of the mask plate; and the thickness of the protruding part is less than that of the plate body. The supporting plate is directly connected and fixed with the frame of the mask plate by arranging the protruding part, a traditional stretching assembly process for a single metal mask layer is replaced, a net stretching process is greatly simplified, and therefore the bad conditions that the metal mask layer is prone to deformation, wrinkles or damage and the like in the stretching process in the prior art are prevented.

Owner:BOE TECH GRP CO LTD

Planar toughened vacuum glass provided with extraction opening with edges being sealed by sealing strips and sealing grooves and manufacturing method thereof

InactiveCN104291624AGuaranteed tightnessExtend your lifeGlass reforming apparatusGlass productionElastomerRoom temperature

The invention discloses planar toughened vacuum glass provided with an extraction opening with edges being sealed by sealing strips and sealing grooves. The planar toughened vacuum glass is characterized in that upper glass and lower glass are planar toughened glass; the upper glass is provided with the extraction opening; the sealing strips are arranged on the peripheries of the upper glass and the extraction opening, and the sealing strips and the sealing grooves are arranged on the periphery of the lower glass and corresponding positions of the extraction opening; the peripheries of the upper glass and the lower glass are welded together in an edge-sealing furnace under a normal pressure through a glass solder; the extraction opening is automatically enclosed in a vacuum furnace by using a metal solder; an enclosed vacuum layer is formed between the upper glass and the lower glass; one or two layers of support objects are arranged in the vacuum layer; the sealing strips and / or the support objects consist of toughened glass ink and a high polymer; the high polymer is prepared into a prepolymer firstly; after toughening of the glass, the prepolymer is prepared on the glass or the toughened glass ink; the prepolymer is cured into an elastomer at a room temperature or a high temperature; the prepolymer or the elastomer can automatically adapt to the height change of the vacuum layer; and the elastomer exhausts contained volatile gas at a high temperature and in high vacuum.

Owner:戴长虹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com